Page 1

TM

USM2.5 Status Monitoring Module

with Acterna Embedded Transponder

Technical Manual

Effective: September, 2003

Alpha T echnologies

®

Page 2

Alpha Technologies

Power

®

2

018-041-C0-003 Rev. C

Page 3

™

USM2.5 Status Monitoring Module

with Acterna Embedded T ransponder

T echnical Manual

018-041-C0-003 Rev. C — © 2003 by Alpha Technologies, Inc.

Effective: September 2003

Statement of Intended Usage

Alpha denies responsibility for any damage or injury involving its enclosures, power

supplies, generators, batteries, or other hardware when used for an unintended

purpose, installed or operated in an unapproved manner , or improperly maintained.

Information on CE Compliance

Alpha T echnologies Communications Module, model USM 2.5, has been qualified as an

EMC Class B product, when configured in an Alpha Uninterruptible Power Supply (UPS)

product. When an (optional) Acterna Embedded T ransponder Assembly is configured in

an Alpha UPS with model USM 2.5 Communications Module, the result ant UPS product

configuration complies only to Class A requirements, in accordance with the EMC

Directive and applicable T echnical S tandards.

Contacting Alpha Technologies:

For general product information and customer service

1-800-863-3930

(7:00 AM to 5:00 PM Pacific Time )

For complete technical support

1-800-863-3364

(7:00 AM to 5:00 PM Pacific Time, or 24/7 emergency support)

018-041-C0-003 Rev. C

3

Page 4

Table of Contents

Safety.................................................................................................5

1. Installation .....................................................................................9

1.1 Installation in an XM Series 2 Power Supply..........................................9

1.2 Transponder Inputs and Outputs.......................................................... 11

1.3 Battery Monitor Connections ............................................................... 12

1.4 Generator Connection .........................................................................19

1.5 Generator Ignition Battery Connection ................................................. 20

1.6 COMM and RF Connections................................................................21

2. Specifications..............................................................................22

2.1 Channel Parameters............................................................................ 22

3. Troubleshooting ..........................................................................23

3.1 Important Troubleshooting Notes .........................................................23

3.2 T roubleshooting Specifics and T esting .................................................25

4. Part Numbers..............................................................................26

4.1 Cable Kit Options ................................................................................ 26

List of Tab les and Figures

Figure 1-1 Transponder Installation.......................................................................................10

Figure 1-2 Input / Output Connections .................................................................................. 11

Figure 1-3 Battery Monitor Connections for three 48Vdc battery packs ................................12

Figure 1-4 Battery Monitor Connections for two 48Vdc battery packs...................................13

Figure 1-5 Battery Monitor Connections for one 48Vdc battery pack ....................................14

Figure 1-6 Battery Monitor Connections for one 36Vdc battery pack ....................................15

Figure 1-7 Battery Monitor Connections for two 36Vdc battery packs...................................16

Figure 1-8 Battery Monitor Connections for three 36Vdc battery packs ................................17

Figure 1-9 Battery Monitor Connections for four 36Vdc battery packs ..................................18

Figure 1-10 Generator Monitor Connections ...........................................................................19

Figure 1-11 Generator Ignition Battery Connection .................................................................20

Figure 1-12 COMM / RF Connections ....................................................................................21

Figure 3-1 Battery String Example........................................................................................24

T ab le 2-1 Channel Parameters............................................................................................22

Table 4-1 Cable kit part numbers ........................................................................................26

4

018-041-C0-003 Rev. C

Page 5

Safety

Safety Notes

This symbol identifies conditions and actions that pose a hazard to the user.

This symbol cautions the user of conditions and actions that may damage the

powersupply or associated equipment.

This symbol identifies a condition that may be corrosive to equipment and parts,

or damaging to skin.

This symbol identifies a condition in which it is required to recycle discarded

materials.

This symbol identifies a situation in which static-sensitive components are present.

Warnings

WARNING: This power supply and its associated hardware (enclosure, batteries,

cabling) may contain equipment, batteries or parts which have accessible

hazardous voltage or currents.

T o av oid injury

:

• This power supply and its associated hardware must be serviced by authorized

personnel only .

• The enclosure which contains the power supply and associated equipment must remain

locked at all times, except when authorized service personnel are present.

• Remove watch and/or jewelry prior to servicing equipment, parts, connectors, wiring, or

batteries.

• Read and follow all installation, equipment grounding, usage, and service instructions

included in this manual.

• Use proper lifting techniques whenever handling equipment, parts, or batteries.

• Batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service and replacement must be performed by authorized

personnel only .

• Never use uninsulated tools or other conductive materials when installing, maintaining,

servicing or replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly

connected battery cable or an unconnected battery cable can result in arcing, a fire, or

possible explosion.

• A battery that shows signs of cracking, leaking or swelling must be replaced immediately

by authorized personnel using a battery of identical type and rating.

018-041-C0-003 Rev. C

5

Page 6

Safety

Warnings,

continued

• Avoid any contact with gelled or liquid emissions from a valve-regulated lead-acid

(VRLA) battery . Emissions contain dilute sulfuric acid which is harmful to the skin and

eyes. Emissions are electrolytic, which are electrically conductive and are corrosive.

Follow the Chemical Hazards notes if contact occurs.

• Do not smoke or introduce sparks in the vicinity of a battery .

• Under certain overcharging conditions, lead-acid batteries can vent a mixture of

hydrogen gas which is explosive. Proper venting of the enclosure is required.

• Follow the battery manufacturer’s approved transportation and storage instructions.

Cautions

NOTE: Equipment or parts may be damaged or cause damage if used or

installed improperly .

T o a void damage

:

• Prior to installation, verify that the AC input voltage to the enclosure and its equipment

match with respect to voltage and frequency .

• Prior to installation, verify that the output voltage from the enclosure or its equipment

match the voltage requirements of the connected equipment (load).

• Prior to installation, verify that the enclosure’s utility service panel is equipped with a

properly rated circuit breaker for use with the equipment inside. Refer to manufacturer’s

recommendations.

• Review and upgrade utility service panel circuit breaker requirements whenever the

equipment within the enclosure is changed.

• Prior to installation, contact local utilities, local building maintenance departments, and

cable/piping locator services to ensure that installation does not interfere with existing

utility or building cables/piping.

• Do not exceed the output rating of equipment. V erify load requirements prior and during

connection process.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static

charge that may hav e dev eloped in your body.

The circuit board contains static-sensitive components. Please follow all appropriate

ESD (Electro Static Discharge) handling practices. As an extr a precaution, handle the

USM2.5 with Acterna Embedded Transponder Module b y the edges and keep fingers awa y

from card edge connectors.

6

018-041-C0-003 Rev. C

Page 7

Battery Safety

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service and replacement must be performed by authorized personnel

only.

Any gelled or liquid emissions from a V alve-Regulated lead-acid (VRLA) battery

contain dilute sulfuric acid, which is harmful to the skin and eyes. Emissions are

electrolytic, which are electrically conductive and corrosive.

Chemical Hazards

T o avoid injury:

Safety

• Wear protective clothing (insulated gloves, eye protection, etc) whenever installing,

maintaining, servicing, or replacing batteries.

• If any battery emission contacts the skin, wash immediately and thoroughly with water .

Follow your company’s approved chemical exposure procedures.

• If any battery emission contacts the eye, wash immediately and thoroughly with water for

10 minutes with pure water or a special neutralizing eye wash solution and seek

immediate medical attention. Follow your company’s approved chemical exposure

procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved

spill kit or with a solution of 1 lb. bicarbonate of soda to 1 gal of water. Report chemical

spill using your company’s spill reporting structure and seek medical attention if

necessary.

• Always replace batteries with those of an identical type and rating. Never install old or

untested batteries.

• Do not charge batteries in a sealed container . Each individual battery should have at least

0.5 inches of space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of

potentially dangerous gas.

018-041-C0-003 Rev. C

7

Page 8

Safety

Maintenance Guidelines

The battery maintenance instructions listed below are for reference only . Battery manufacturer’s

instructions for transportation, installation, storage or maintenance take precedence over these

instructions.

• T o prevent damage inspect batteries every 3 months for:

-Signs of battery cracking, leaking or swelling. The battery should be replaced

immediately by authorized personnel using a battery of the identical type and rating.

-Signs of battery cable damage. Battery cable should be replaced immediately by

Authorized Personnel using replacement parts specified by vendor .

-Loose battery connection hardware. Refer to battery manufacturer’s documentation

for the correct torque and connection hardware for the application.

• Apply battery manufacturer’s specified antioxidant compound on all exposed connections.

• Verify battery terminals and/or exposed connection hardware has not shif ted within 2

inches of a conductive surface. Reposition batteries as necessary to maintain adequate

clearance.

• Clean up any electrolyte (battery emission) in accordance with all federal, state, and local

regulations or codes.

Recycling and Disposal Instructions

Spent or damaged batteries are considered environment ally unsafe. Always recycle used

batteries or dispose of the batteries in accordance with all federal, state and local

regulations.

8

018-041-C0-003 Rev. C

Page 9

1.1 Installation in an XM Series 2 Power Supply

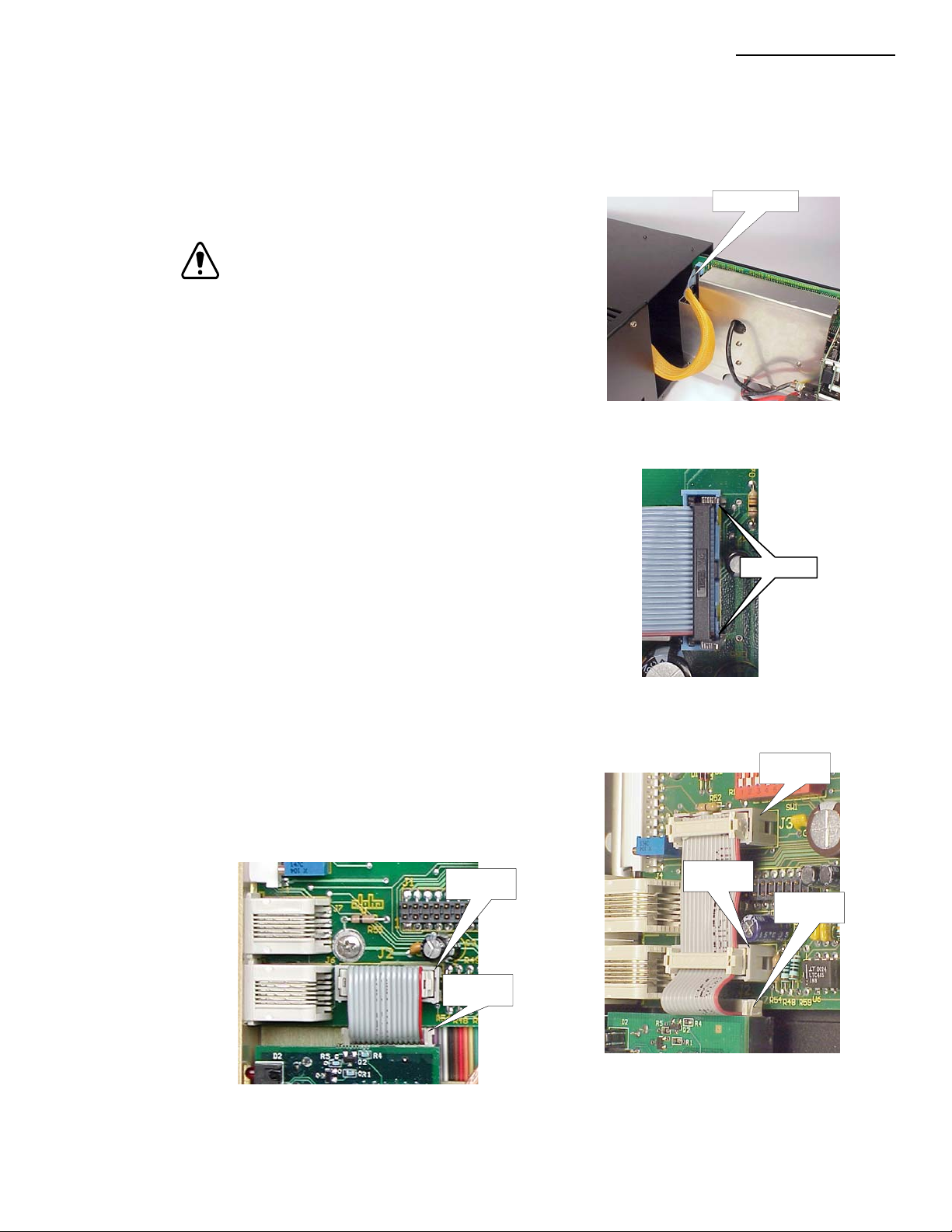

1. Record the transponder address (located on the sheet

metal of the front panel).

2. Open the power supply enclosure.

NOTE: Backup power will not be available while

batteries are disconnected.

3. Set the battery breaker on the front of the power

supply to the OFF position.

4. Unplug all connectors on the front of the power

supply inverter module.

5. Loosen the thumb screws holding the inverter

module into the power supply.

6. Slide the inverter module out far enough to unplug

the ribbon cable at the back of the inverter module

(fig A). Disengage the tw o latches holding the plug

into the socket (fig. B), and remove the plug.

1. Installation

Disconnect here

Fig. A

7. Slide the inverter module all of the way out of the

power supply .

8. Remove the blanking plate and USM2 (if installed)

from the inverter module.

9. Install the USM2.5 (refer to USM2.5 Operator's and

T echnical manual. P/N: 704-683-B0-xxx).

10(a).

For a USM2.5 with single ribbon cable socket (J2):

Attach one end of the 2-position ribbon cable to the

connector (JP2) at the top of the transponder , and

the other end to the connector on the USM2.5 (J2).

(fig. C)

J2

JP2

Unlatch

Fig. B

J3

J2

JP2

018-041-C0-003 Rev. C

Fig. D; Three-Position Ribbon Cable

Connection

Fig. C; T wo-P osition Ribbon Cable Connection

9

Page 10

1. Installation

1.1 Installation in an XM Series 2 Power Supply,

10(b).

For a USM2.5 with two ribbon cable sockets (J2, J3):

Attach one end of the 3-position ribbon cable to the connector (JP2) at the top of the

transponder, and the other tw o connectors to the USM2.5 (J2, J3). (fig. D)

8 Position DIP

Switch

Captive

screw

10 Position

Jumper

Captive

screw

continued

Figure 1-1 Transponder Installed

11. Using the two captive screws just behind the face plate, secure the transponder

to the inverter module.

12. Verify that the 10-position jumper on the transponder is set to the correct

battery pack voltage.

13. Verify that the 8-position DIP Switch on the USM2.5 is set correctly. Ref er to the USM2.5

operators manual (Alpha p/n 704-683-B0).

14. Set the inverter module onto the guides, and slide it 1 or 2 inches into the power supply.

15. Reconnect the ribbon cable to the inverter module, and latch the two retaining

clips over the ribbon cable plug.

16. Slide the inverter module fully into the power supply , and tighten the thumb

screws. Set the BATTERY BREAKER to the ON position.

17. Verify after 10-30 seconds, the Smart Display on the power supply reads

'OPERA TION NORMAL'.

18. Download Alarm Profile from CheetahNet to initiate appropriate mode of operation.

10

19. Verify that, after approx. 1 minute , the 'CPU' LED on the front of the transponder

is blinking, if not, press the RESET button behind the hole next to the LEDs

(see fig. 1-2).

018-041-C0-003 Rev. C

Page 11

1. Installation

1.2 Transponder Inputs and Outputs

The following section describes the input and output connections on the transponder. Refer to

the sections indicated below for a brief description and pin-out of the connector .

CPU LED Flashing: Normal operation, P-Code running.

Solid: Initial start-up, R-Code running.

RX LE D Data is being received from the HEC (Head End Controller).

TX LED Data is being sent to the HEC.

CPU

RESET

CPU / Seria l P ort

Activity

Section 1.3

Battery A/B Monitor

Section 1.3

Battery C/D Monitor

Section 1.6

Craft Port

A/B

C/D

COM

RX TX

1

1

G/BATT

TEMP

GEN

1

1

Section 1.4

Generator

Section 1.5

Generator Battery

Section 1.6

RF

Communication

018-041-C0-003 Rev. C

Figure 1-2 Input / Output Connections

11

Page 12

1. Installation

1.3 Battery Monitor Connections

WARNING: V erify that the 10 P osition jumper on the tr ansponder is set to

NOTE: A maximum of 12 batteries can be monitored by the transponder .

Connector Pin # String Reference Wire Label CheetahNet Display (48V)

A/B 1 1A - (0Vdc) A/B[C/D] NEG

C/ D 1 1C - (0Vdc) A/B[C/D] NEG

Refer to section 4 for wire kit part numbers.

the proper battery voltage prior to connecting the battery monitor

wire kit.

2 1A + (+12Vdc) Vbatt 1A [C] 12V Battery #4 Vdc

3 2A + (+24Vdc) Vbatt 2A [C] 24V Battery #3 Vdc

4 3A + (+36Vdc) Vbatt 3A [C] 36V Battery #2 Vdc

5 1B + (+12Vdc) Vbatt 1B [D] 12V Battery #8 Vdc

6 2B + (+24Vdc) Vbatt 2B [D] 24V Battery #7 Vdc

7 3B + (+36Vdc) Vbatt 3B [D] 36V Battery #6 Vdc

4A + (+48Vdc) Battery #1 Vdc

8 4B + (+48Vdc) Vbatt A/B [C/D] 48V Battery #5 Vdc

2 1C + (+12Vdc) Vbatt 1A [C] 12V Battery #11 Vdc

3 2C + (+24Vdc) Vbatt 2A [C] 24V Battery #10 Vdc

4 3C + (+36Vdc) Vbatt 3A [C] 36V Battery #9 Vdc

5

6

7

8 4C + (+48Vdc) Vbatt A/B [C/D] 48V Battery #12 Vdc

NOTE: Only TW O 48V strings can be monitored when using a generator .

DO NOT connect to the BATT C/D connector if using the generator option.

Battery Monitored

Via Pin 8

12V

24V

36V

48V

Battery String A

A/B

8

4

7

3

6

2

1

5

1A

12V

2A

24V

3A

36V

4A

48V

To Power Supply

Battery String B

12V

1B

24V

2B

36V

3B

48V

4B

Battery String C

C/D

1C

2C

3C

4C

4

8

3

7

6

2

1

5

12

Figure 1-3 Battery Monitor Connections for three 48Vdc battery packs

018-041-C0-003 Rev. C

Page 13

1. Installation

1.3 Battery Monitor Connections

, continued

Connector Pin # String Reference Wire Label CheetahNet Display (48V)

A/B 1 1A - (0Vdc) A/B[C/D] NEG

2 1A + (+12Vdc) Vbatt 1A [C] 12V Battery #4 Vdc

3 2A + (+24Vdc) Vbatt 2A [C] 24V Battery #3 Vdc

4 3A + (+36Vdc) Vbatt 3A [C] 36V Battery #2 Vdc

5 1B + (+12Vdc) Vbatt 1B [D] 12V Battery #8 Vdc

6 2B + (+24Vdc) Vbatt 2B [D] 24V Battery #7 Vdc

7 3B + (+36Vdc) Vbatt 3B [D] 36V Battery #6 Vdc

4A + (+48Vdc) Battery #1 Vdc

8 4B + (+48Vdc) Vbatt A/B [C/D] 48V Battery #5 Vdc

Battery Monitored

Via Pin 8

12V

24V

36V

48V

Battery String A

A/B

8

4

7

3

6

2

1

5

1A

12V

2A

24V

3A

36V

4A

48V

To Power Supply

Battery String B

1B

2B

3B

4B

C/D

4

8

3

7

6

2

1

5

Not used in this configuration

018-041-C0-003 Rev. C

Figure 1-4 Battery Monitor Connections for two 48Vdc battery packs

13

Page 14

1. Installation

1.3 Battery Monitor Connections

, continued

Connector Pin # String Reference Wire Label CheetahNet Display (48V)

A/B 1 1A - (0Vdc) A/B[C/D] NEG

2 1A + (+12Vdc) Vbatt 1A [C] 12V Battery #4 Vdc

3 2A + (+24Vdc) Vbatt 2A [C] 24V Battery #3 Vdc

4 3A + (+36Vdc) Vbatt 3A [C] 36V Battery #2 Vdc

5

6

7

8 4A + (+48Vdc) Vbatt A/B [C/D] 48V Battery #1 Vdc

A/B

C/D

12V

24V

36V

48V

Battery String A

3487

2

6

5

1

1A

2A

3A

4A

To Power Supply

Not used in this configuration

3487

2

1

6

5

Figure 1-5 Battery Monitor Connections for one 48Vdc battery pack

14

018-041-C0-003 Rev. C

Page 15

1. Installation

1.3 Battery Monitor Connections, continued

Connector Pin # String Reference Wire Label CheetahNet Display (36V)

A/B 1 1A - (0Vdc) A/B[C/D] NEG

2 1A + (+12Vdc) Vbatt 1A [C] 12V Battery #3 Vdc

3 2A + (+24Vdc) Vbatt 2A [C] 24V Battery #2 Vdc

4 3A + (+36Vdc) Vbatt 3A [C] 36V Battery #1 Vdc

5

6

7

8

12

V

24

V

36

V

Battery String A

A/B

3487

2

6

1

5

1A

2A

3A

To Power Supply

C/D

3487

2

6

1

5

Not used in this configuration

018-041-C0-003 Rev. C

Figure 1-6 Battery Monitor Connections for one 36Vdc battery pack.

15

Page 16

1. Installation

1.3 Battery Monitor Connections

, continued

Connector Pin # String Reference Wire Label CheetahNet Display (36V)

A/B 1 1A - (0Vdc) A/B[C/D] NEG

2 1A + (+12Vdc) Vbatt 1A [C] 12V Battery #3 Vdc

3 2A + (+24Vdc) Vbatt 2A [C] 24V Battery #2 Vdc

4 3A + (+36Vdc) Vbatt 3A [C] 36V Battery #1 Vdc

5 1B + (+12Vdc) Vbatt 1B [D] 12V Battery #6 Vdc

6 2B + (+24Vdc) Vbatt 2B [D] 24V Battery #5 Vdc

7 3B + (+36Vdc) Vbatt 3B [D] 36V Battery #4 Vdc

8

A/B

4

8

3

7

6

2

1

5

12V

1A

24V

2A

36V

3A

Battery String A Battery String B

To Power Supply

12V

24V

36V

1B

2B

3B

C/D

4

8

3

7

6

2

1

5

Not used in this configuration

16

Figure 1-7 Battery Monitor Connections for two 36Vdc battery packs

018-041-C0-003 Rev. C

Page 17

1. Installation

1.3 Battery Monitor Connections

, continued

Connector Pin # String Reference Wire Label CheetahNet Display (36V)

A/B 1 1A - (0Vdc) A/B[C/D] NEG

2 1A + (+12Vdc) Vbatt 1A [C] 12V Battery #3 Vdc

3 2A + (+24Vdc) Vbatt 2A [C] 24V Battery #2 Vdc

4 3A + (+36Vdc) Vbatt 3A [C] 36V Battery #1 Vdc

5 1B + (+12Vdc) Vbatt 1B [D] 12V Battery #6 Vdc

6 2B + (+24Vdc) Vbatt 2B [D] 24V Battery #5 Vdc

7 3B + (+36Vdc) Vbatt 3B [D] 36V Battery #4 Vdc

8

C/ D 1 1C - (0Vdc) A/B[C/D] NEG

2 1C + (+12Vdc) Vbatt 1A [C] 12V Battery #9 Vdc

3 2C + (+24Vdc) Vbatt 2A [C] 24V Battery #8 Vdc

4 3C + (+36Vdc) Vbatt 3A [C] 36V Battery #7 Vdc

5

6

7

8

A/B

C/D

4

8

3

7

6

2

1

5

12V

24V

36V

Batte ry S trin g A

1A

2A

3A

To Power Supply

12V

24V

36V

Batte ry S trin g B

1B

2B

3B

12V

24V

36V

Batte ry S trin g C

1C

2C

3C

Figure 1-8 Battery Monitor Connections for three 36Vdc battery packs

4

8

3

7

6

2

1

5

018-041-C0-003 Rev. C

17

Page 18

1. Installation

1.3 Battery Monitor Connections

, continued

Connector Pin # String Reference Wire Label CheetahNet Display (36V)

A/B 1 1A - (0Vdc) A/B[C/D] NEG

2 1A + (+12Vdc) Vbatt 1A [C] 12V Battery #3 Vdc

3 2A + (+24Vdc) Vbatt 2A [C] 24V Battery #2 Vdc

4 3A + (+36Vdc) Vbatt 3A [C] 36V Battery #1 Vdc

5 1B + (+12Vdc) Vbatt 1B [D] 12V Battery #6 Vdc

6 2B + (+24Vdc) Vbatt 2B [D] 24V Battery #5 Vdc

7 3B + (+36Vdc) Vbatt 3B [D] 36V Battery #4 Vdc

8

C/ D 1 1C - (0Vdc) A/B[C/D] NEG

2 1C + (+12Vdc) Vbatt 1A [C] 12V Battery #9 Vdc

3 2C + (+24Vdc) Vbatt 2A [C] 24V Battery #8 Vdc

4 3C + (+36Vdc) Vbatt 3A [C] 36V Battery #7 Vdc

5 1D + (+12Vdc) Vbatt 1A [D] 12V Battery #12 Vdc

6 1D + (+12Vdc) Vbatt 2A [D] 24V Battery #11 Vdc

7 1D + (+12Vdc) Vbatt 3A [D] 12V Battery #10 Vdc

8

NOTE: Only THREE 36V strings can be monitored when

using a generator. DO NO T connect a f ourth string

to the BATT C/D connector if using the generator option.

12V

24V

36V

Battery String A

1A

2A

3A

To Power Supply

A/B

4

8

3

7

6

2

1

5

12V

24V

36V

Battery String B

1B

2B

3B

12V

24V

36V

Battery String C Battery String D

1C

2C

3C

C/D

8

4

7

3

6

2

1

5

Figure 1-9 Battery Monitor Connections for four 36Vdc battery packs

12V

24V

36V

1D

2D

3D

18

018-041-C0-003 Rev. C

Page 19

1. Installation

1.4 Generator Connection

The Generator Connector provides the Transponder with alarms and status signals. Control

signals can also be sent to the generator for test and Run / Stop. Refer to the ECM operation

and maintenance manual for further information on the generator connections.

PIN # Generator connection

1 APU Fail / Major Alarm

2 APU Minor Alarm

3 Engine Alarm

4 Gas Hazard Alarm

5 APU T est Fail Alarm

6 APU Enclosure Alarm

7 Engine Status

8 APU Enclosure Tamper

9 APU Signal Return / ground

1 0 APU Run / Test Command

11 Run / T est Command Return

12 No Connection

Battery

Breaker

Battery

Output 1LRI

Input

Temp

Probe

Figure 1-10 Generator monitor connections

Wire Entry

View

612

511

410

39

28

17

Alpha P/N 874-975-20

Wire Entry

View

159

2610

3711

4812

To Generator

Compartment

018-041-C0-003 Rev. C

19

Page 20

1. Installation

1.5 Generator Ignition Battery Connection

The Generator Battery Connector provides the transponder with voltage information on the

Ignition Battery and optional ambient temperature probe.

PIN # Generator Connection

1 Ignition Battery Negative / Chassis Ground

2 Ignition Battery Positive

3 External T emperature Probe

4 Ignition Battery Negative / Chassis Ground

Battery

Breaker

Battery

Output 1LRI

Input

Temp

Probe

Optional External

Temp Probe

Figure 1-11 Generator Ignition battery connection

Wire Entry

View

2

4

1

3

Alpha P/N 874-976-20

Wire Entry

To Generator

Compartment

View

External T emp Probe

2

Chassis Gro u nd

1

Alpha P/N 745-178-20

Wire Entry

View

2

1

Ignition Pos.

Ignition Neg.

20

018-041-C0-003 Rev. C

Page 21

1. Installation

1.6 COMM and RF Connections

The COMM connector allows the technician to bypass the RF modulator and communicate

with the transponder through a PC's RS-232 serial port.

The RF connector is the primary I/O port to the head-end modem.

RF Cable

To Headend

COMM (RJ-11)

Output 1LRI

Battery

Breaker

User Provided

Ground Block

Battery

Input

Temp

Probe

User Prov ided

RF

Acterna

Provided Cable

(RJ-11 to DB9)

Acterna P/N 3200-00-4002

Laptop With

Test2Way Software

018-041-C0-003 Rev. C

See note below

Figure 1-12 COMM / RF connections

NO TE : Wire from the ground block MUST be connected to the enclosure's

grounding lug, or ground bar. Ensure that all connections are

clean and bare. Coax MUST share the same ground as the

power supply .

21

Page 22

2. Specifications

2.1 Channel Parameters

Channel

Description

Analog Inputs Internal Temperature (C) 0 10 50 60

Analog Inputs

Analog Inputs AC Output Curre nt 1 (AMPS) 0.5 2 25 25.5

Analog Inputs AC Output Curre nt 2 (AMPS) 0.5 2 25 25.5

Analog Inputs Battery Voltage #1 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #2 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #3 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #4 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #5 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #6 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #7 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #8 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #9 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #10 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #11 (VDC) 10 11 14.4 14.8

Analog Inputs Battery Voltage #12 (VDC) 10 11 14.4 14.8

Analog Inputs Generator Battery (VDC) 10 11 14.4 14.8

Analog Inputs AC Output Voltage (VAC) 50 55 95 98

Analog Inputs AC Input Voltage (VAC) 95 100 125 128 2

Analog Inputs AC Input Voltage (VAC) 200 210 245 255 4

Digital input Standby Mode Normal Standby

Digital input Tamper Switch Open Closed

Digital input Output Fail Alarm Normal Alarm

Digital input General Alarm Normal Alarm 1

Digital input APU Test Fail Alarm Normal 1

Digital input Engine Status OFF ON 1

Digital input APU Fail / ECM Alarm Normal 1

Digital input APU Response Alarm Normal 1

Digital input Gas Hazard Alarm Alarm Normal 1

Digital input APU Engine Alarm Alarm Normal 1

Digital input Generator Enclosure Open Closed 1

Digital input Generator Tamper Closed Open 1

Digital output Standby ON / OFF OFF ON

Digital output Equalize ON / OFF OFF ON

Digital output Engine ON / OFF OFF ON

Note 1 - Generator

Note 2 - AC Input 120 VAC Models

Note 3 - External Temperature

Note 4 - AC Input 240 VAC Models

Paramete r na me Units Maj Low Min Low Min Hi Maj Hi Note

External

Temperature

(C) 0 10 50 60 3

Hi State Lo State

22

T ab le 2-1 Channel Parameters

018-041-C0-003 Rev. C

Page 23

3. Troubleshooting

3.1 Important Troubleshooting Notes

Always troubleshoot communication problems before working on battery-related and/or generatorrelated problems. The embedded transponder runs off of the power supply’s USM2.5 logic voltages,

and does not require the sensing cables (from the batteries or the generator) to communicate.

1.

USM2.5 Switch Set-up: The 8 position “DIP” switch on the USM2.5 board must be set correctly .

See the complete chart in the USM2.5 Status Monitor Operator’s and T echnical Manual P/N

704-683-B0-xxx. Note that SW1-4 (the fourth switch from the front) must be turned ON when

using an internal Acterna transponder .

USM2.5 Switch Settings for Embedded Acterna T ransponders

XM2 Models

all XM2 -610 & -615; all XM2-910 &

-915; XM2-1350 @ 75VAC or 90VAC

XM2-1350 @ 60VAC

XM2-1350-48 @ 75VAC or 90VAC

XM2-1350-48 @ 60VAC; all XM2-922

SW1SW2SW3SW4SW5SW6SW

ON ON

ON ON ON

off off off off off off

off off off off off

off off off off

ON ON

off off off

ON ON

ON ON

ON ON

ON

SW

8

7

2. Transponder Address: The transponder address is the five (5) digit number printed on the sticker

on the FRONT of the Embedded T ransponder Assembly , above the “F” connector . The address

is not the printed circuit board serial number (typically in the format of 1B followed by six

numbers) from the sticker on the PCB itself. The address can be verified from the SOC (Sys-

tems Operation Center).

3. Transponder Driver: The correct Acterna device driver must be downloaded from the HEC to the

transponder. The following is Acterna’ s list of device drivers for embedded (internal) transponders

in Alpha T echnologies XM2 power supplies, as of 17 October 2002.

Acterna Battery Input / Utility Power

Driver # Voltage Battery Monitoring Voltage Generator Supply

8028 36VDC 4 battery strings max 120VAC none single

8029 36VDC 3 battery strings max 120VAC w ith generator single

8030 48VDC 3 battery strings max 120VAC none single

8031 48VDC 2 battery strings max 120VAC w ith generator single

8033 36VDC 4 battery strings max 240VAC none single

8034 36VDC 3 battery strings max 240VAC w ith generator single

8035 48VDC 3 battery strings max 240VAC none single

8036 48VDC 2 battery strings max 240VAC w ith generator single

8037 48VDC 1 battery strings max 240VAC w ith generator dual

018-041-C0-003 Rev. C

For technical support for cable products, contact Tollgrade at:

T ollgrade Communications, Inc.

7020 Professional Parkway

Sarasota FL 34240

T AC Phone: 941-373-6850 / 1-888-486-3510

T AC FAX: 941-373-6885

Email: cheetahsupport@tollgrade.com

23

Page 24

3. Troubleshooting

V

V

V

V

3. 1 Impor tant Troubleshooting Notes,

If there are two power supplies in the same enclosure, make sure that the interface cable from

the generator ECM is connected to the correct embedded transponder.

4. Battery Voltage Jumper: Verify that the battery voltage jumper block is in the correct position:

continued

• The jumper will be installed in the bottom position for 36VDC battery systems (shorting the

bottom two rows of pins, and with the top row of pins exposed)

• The jumper will be installed in the top position for 48VDC battery systems (shorting the top

two rows of pins, and with the bottom row of pins exposed).

Use extreme care when removing the jumper – lift the jumper only , don’t pry the pin assembly

off the PC board.

5. Battery Voltage Sensing: Verify the battery sensing cables are connected correctly – battery

polarity is critical. The battery numbering / labeling conforms to the requirements of the SCTE

HMS standard. (Refer to section 1.3, Battery Monitor Connections.) The battery numbering

shown in Acterna’ s CheetahNet display will be as listed in the manual.

• Each string is labeled A, B, C, or D, shown as “x” below. Not all battery sensing wires will

be present in all harnesses. For example, in a 2 string system, there may only be one

NEG wire - connect to either string’s battery # 1 negative post.

Black (neg) wire

to power supply

Red (pos) wire to

power supply

Battery

1x

Battery

Battery

3x

Battery

4x

-

+

-

+

-

+

-

+

NEG

batt 1x +12V

batt 2x +24V

batt 3x +36V

batt 4x +48V

Figure 3-1 Battery String Example

24

018-041-C0-003 Rev. C

Page 25

3. Troubleshooting

3.2 Troubleshooting Specifics and Testing

Troubleshooting

Problem: Missing parts or shipping damage.

Solution: Contact Alpha T echnologies at:

Alpha T echnologies, Inc.

3767 Alpha Wa y

Bellingham, W A. 98226

360-647-2360

Problem: Unable to communicate with transponder .

Solution: Check port assignments, cables, and RPS name / port.

Problem: Incorrect device type selected when adding unit.

Solution: Check the device type in the Device Configuration screen (CheetahNet).

Problem: Incorrect address.

Solution: Verify that address in the De vice Configuration screen (CheetahNet)

matches address on front panel. If they do not match, contact network

operations center technician.

Problem: Incorrect controller frequencies.

Solution Verify that frequencies on the HEC port configuration screen match

address on front panel. If they do not match, contact network

operations center technician.

Problem: Incorrect signal level.

Solution: Verify forward and return signals are within Acterna specifications.

Padding ma y have to be added or remov ed.

Problem: Unable to communicate with CheetahNet.

Solution: Verify that the transponder is not in 'R' mode. Use laptop computer

running 'T est2Wa y' to verify what code is running.

If the CPU LED is on steady, unit is in 'R-code', if the LED is flashing, unit

is in 'P-code' (normal operation).

Testing

018-041-C0-003 Rev. C

All testing shall be performed via Acterna's CheetahNet and Test2wa y software. Ref er to

software manufacturer's instructions.

25

Page 26

4. Part Numbers

4.1 Cable Kit Options

Combination Kits

Part Number Description

745-181-20 Combo Batt Sense Kit, 1x36V , w/ Gen Interface

745-197-23 Combo Batt Sense Kit, 2x36V, w/ 35' Ext.

745-197-22 Combo Batt Sense Kit, 3x36V , w/ 2x35' Ext.

745-198-21 Combo Batt Sense Kit, 3x36V , 1 @ 6', 2 @ 9'

745-180-20 Combo Batt Sense Kit, 4x36V , w/ 2x35' Ext.

745-182-20 Combo Batt Sense Kit, 4x36V , 2 @ 6', 2 @ 9'

745-246-20 Combo Batt Sense Kit, 1x48V , w/ Gen Interface

745-197-20 Combo Batt Sense Kit, 2x48V, w/ 35' Ext.

745-197-21 Combo Batt Sense Kit, 3x48V , w/ 2x35' Ext.

745-198-20 Combo Batt Sense Kit, 3x48V , 2 @ 6', 1 @ 9'

745-245-20 Combo Generator Xpdr Wire Kit

Individual Kits

Part Number Description

874-842-21 Wire Kit, Battery Sense, 1x36V , 6'

874-842-20 Wire Kit, Battery Sense, 2x36V , 6'

874-842-27 Wire Kit, Battery Sense, 1x36V , 9'

874-842-28 Wire Kit, Battery Sense, 2x36V , 9'

874-841-21 Wire Kit, Battery Sense, 1x48V , 6'

874-841-20 Wire Kit, Battery Sense, 2x48V , 6'

874-841-25 Wire Kit, Battery Sense, 1x48V , 9'

874-841-24 Wire Kit, Battery Sense, 2x48V , 9'

874-841-23 Extension Wire Kit, Battery Sense, 6'

874-841-22 Extension Wire Kit, Battery Sense, 35'

874-975-20 Emb. Transponder Gener ator Interface Wire Kit

874-976-20 Emb. Tr ansponder Ignition Battery Wire Kit

Ribbon Cable Kits (for spare parts or replacement)

Part Number Description

874-992-20 Wire Assy, Ribbon Cable, 14p, Int/Ext, USM2.5

875-045-20 Wire Assy, Ribbon Cable, 14p, 3 Skt, Int/Ext, USM2.5

Dual Power Supply Monitor Conversion Kit

26

Part Number Description

745-238-20 Kit, 1Xpndr , 2Pwr Sply , Interconn, XMS2

Table 4-1 Cable kit part numbers

018-041-C0-003 Rev. C

Page 27

Page 28

Page 29

Page 30

Alpha Technologies

Power

®

Corporate

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: (360) 647-2360

Fax: (360) 671-4936

Web: www.alpha.com

Alpha Technologies Lt d.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: (604) 430-1476

Fax: (604) 430-8908

Alpha Technologies

Europe Ltd.

Cartel Business Estate

Edinburgh Way

Harlow, Essex CM20 2TT

UNITED KINGDOM

Tel: +44-1279-4221 10

Fax: +44-1279-423355

Alpha Technologies

Hansastrasse 8

D-91126 Schwabach

GERMANY

Tel: +49-9122-79889-0

Fax: +49-9122-79889-21

Alphatec

339 St. Andrews Street

Suite 101

Andrea Chambers

Limassol, Cyprus

CYPRUS

Tel: +357-25-375675

Fax: +357-25-359595

Alpha Technologies

Unit R5-R7 Regents Park

Estate

Corner Park Rd and Prince’s

Rd East

Regents Park, NSW 2143

AUSTRALIA

Tel: +61-2-9722-3320

Fax: +61-2-9722-3321

Copyright © 2003 by Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 018-041-C0-003 Rev. C.

Due to continuing product improvements, Alpha reserves the right to change specifications without notice.

Loading...

Loading...