Page 1

USM2.5 S tatus Monitor

Operator’s and Technical Manual

USM2.5 St atus Monitor

Effective: April, 2006

Page 2

Alpha Technologies

Power

®

Page 3

™

USM2.5 Staus Monitoring Module

Operator’s and Technical Manual

704-683-B0-004 Rev. D— © 2006 by Alpha Technologies, Inc.

Effective: April, 2006

Statement of Intended Usage

Alpha denies responsibility for any damage or injury involving its enclosures, power

supplies, generators, batteries, or other hardware when used for an unintended

purpose, installed or operated in an unapproved manner, or improperly maintained.

Information on CE Compliance

Alpha T echnologies Communications Module, model USM 2.5, has been qualified as an

EMC Class B product, when configured in an Alpha Uninterruptible Power Supply (UPS)

product. When an (optional) Acterna Embedded T ransponder Assembly is configured in

an Alpha UPS with model USM 2.5 Communications Module, the result ant UPS product

configuration complies only to Class A requirements, in accordance with the EMC

Directive and applicable T echnical S tandards.

Contacting Alpha Technologies:

For general product information and customer service

1-800-863-3930

(7:00 AM to 5:00 PM Pacific Time )

For complete technical support

1-800-863-3364

(7:00 AM to 5:00 PM Pacific Time, or 24/7 emergency support)

3

Page 4

Table of Contents

Safety ................................................................................................................... 5

1. Introduction ...................................................................................................... 7

1.1 USM2.5 Introduction.............................................................................. 7

1.2 Identification of USM2.5 ........................................................................ 7

2. Installation........................................................................................................ 8

2.1 Inverter Module Removal and Installation, XM Series 2 .......................... 8

2.2 USM2.5 Installation, XM Series 2.......................................................... 9

3. Configuration................................................................................................... 11

3.1 USM2.5 Configuration (V Models)....................................................... 10

3..2 USM2.5 Configuration......................................................................... 11

4. Signal Definitions........................................................................................... 15

4.1 USM2.5 Signal Definition.................................................................... 15

5. Operation ...................................................................................................... 21

5.1 USM2.5 Operations ............................................................................ 21

6. Troubleshooting ............................................................................................. 22

6.1 Troubleshooting the Communications Link .......................................... 22

7. Parts.............................................................................................................. 23

8. Reference...................................................................................................... 24

8.1 USM2.5 Signals, Quick Reference...................................................... 24

8.2 T esting and Troubleshooting, Quick Reference .................................... 25

List of Figures and Tables

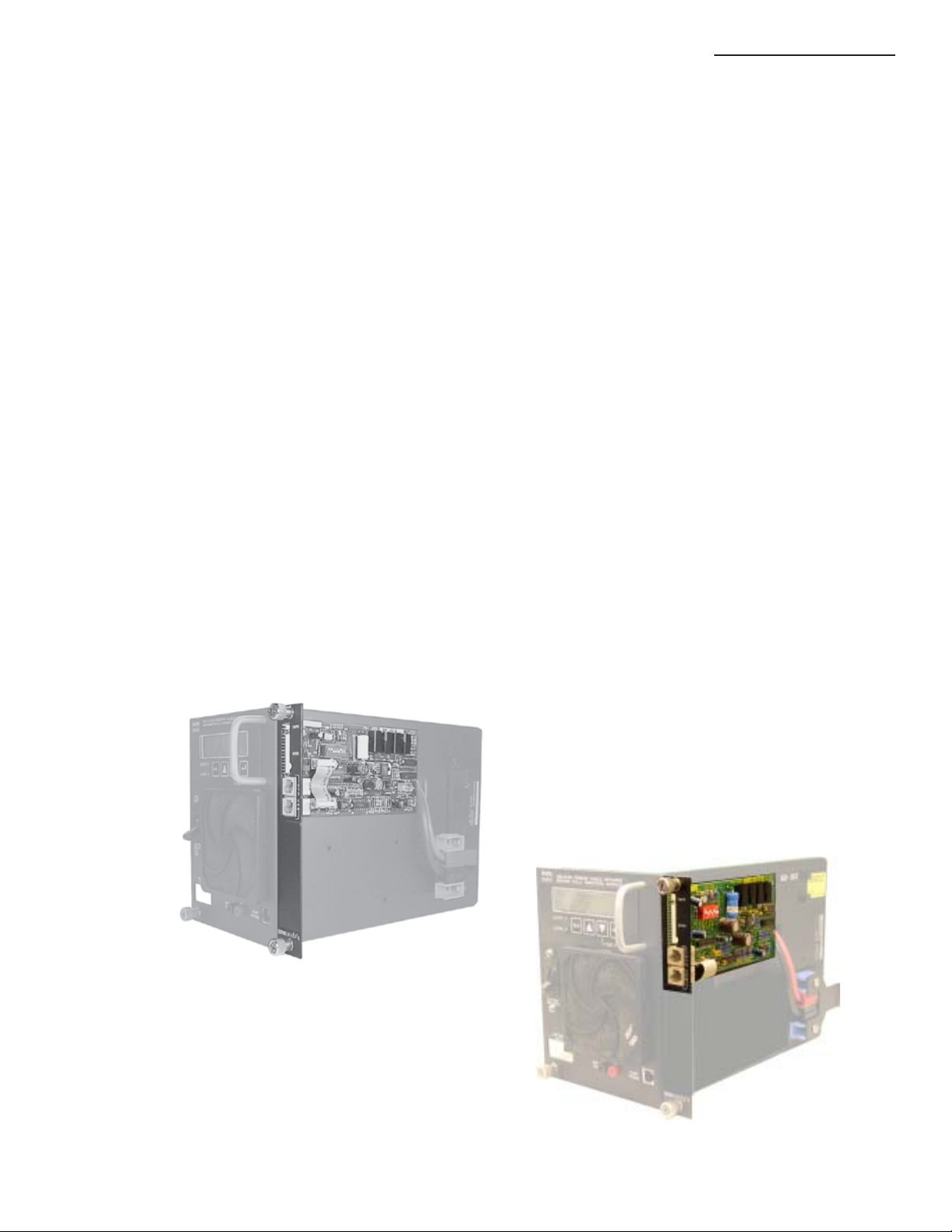

Figure 1-1, Old Version of USM2.5 ....................................................................... 7

Figure 1-2, New Version of USM2.5...................................................................... 7

Figure 2-1, Inverter Module ribbon cable ............................................................... 8

Figure 2-2, Optional Blanking Plate ..................................................................... 10

Figure 2-3, 2X9 Pin Strip Connector ................................................................... 10

Figure 2-4, Previous Version USM2.5 Front Panel and PCBA ............................ 10

Figure 2-5, Current Version USM2.5 Front Panel and PCBA............................... 10

Figure 3-1, USM2.5 Switch Location(Older Version ............................................ 13

Figure 3-2, USM2.5 Switch Location (New Version ) ........................................... 13

Figure 4-1, USM2.5 Signal Connections ............................................................. 16

T able 3-1, USM2.5 DIP Switch Setup ................................................................ 12

T able 3-2, USM2.5 Transponder Output V oltages .............................................. 12

T able 4-1, USM2.5 Output Scaling Samples ...................................................... 15

4

704-683-B0-004, Rev. D

Page 5

Safety

Safety Notes

This symbol identifies conditions and actions that pose a hazard to the user.

This symbol cautions the user of conditions and actions that may damage the

powersupply or associated equipment.

This symbol identifies a condition that may be corrosive to equipment and parts,

or damaging to skin.

This symbol identifies a condition in which it is required to recycle discarded

materials.

This symbol identifies a situation in which static-sensitive components are present.

Warnings

WARNING: This power supply and its associated hardware (enclosure, batteries,

cabling) may contain equipment, batteries or parts which have

accessible hazardous voltage or currents.

To avoid injury

:

• The USM2.5 must be serviced by authorized personnel only.

• The enclosure which contains the USM2.5 and associated equipment must remain

locked at all times, except when authorized service personnel are present.

• Remove watch and/or jewelry prior to servicing equipment, parts, connectors, or wiring.

• Read and follow all installation, equipment grounding, usage, and service instructions

included in this manual.

• Use proper lifting techniques whenever handling equipment, or parts.

704-683-B0-004, Rev. D

5

Page 6

Safety

Cautions

NOTE: Equipment or parts may be damaged or cause damage if used or

installed improperly.

To avoid damage

:

• Prior to installation, verify that the AC input voltage to the enclosure and its equipment

match with respect to voltage and frequency.

• Prior to installation, verify that the output voltage from the enclosure or its equipment

match the voltage requirements of the connected equipment (load).

• Prior to installation, verify that the enclosure’s utility service panel is equipped with a

properly rated circuit breaker for use with the equipment inside. Refer to manufacturer’s

recommendations.

• Review and upgrade utility service panel circuit breaker requirements whenever the

equipment within the enclosure is changed.

• Prior to installation, contact local utilities, local building maintenance departments, and

cable/piping locator services to ensure that installation does not interfere with existing

utility or building cables/piping.

• Do not exceed the output rating of equipment. Verify load requirements prior and during

connection process.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static

charge that may have developed in your body.

6

704-683-B0-004, Rev. D

Page 7

1.1 USM2.5 Introduction

This Operator’s and Technical Manual will cover the installation, signal definition, operation,

and basic troubleshooting for the USM2.5 when used with the Alpha XM Series 2 Power

Supply.

The USM2.5 card is a logic controller PCB which may be used to upgrade any XM Series 2

Power Supply for the purpose of remote status monitoring. As part of the Communications

Module upgrade, the USM2.5 connects directly to the XM2’s Inverter Module via an 18 pin

jumper. No recalibration of the power supply is required at the time of installation.

System Concept

The USM2.5 remote status monitoring system is comprised of the following basic building

blocks:

• An Alpha XM Series 2 Uninterruptible Power Supply.

• An approved transponder.

• The USM2.5 status monitoring card.

Operating through a transponder and status monitoring system, the operator may issue

commands to the USM2.5 to control the operating mode of the power supply; evaluate

potential fault conditions reported by the software; or run routine checks on the power supply.

1. Introduction

For example, the operator may issue a command that initiates a “Self-Test” mode to check

the inverter circuitry, status of the batteries, or obtain values for battery voltages. This kind

of information allows for a more accurate assessment of the operating condition, and ability

to supply uninterrupted performance of each power supply. More importantly, proper USM2.5

operations allow for preventive maintenance on an “as required” basis. This has obvious

advantages over a scheduled maintenance program, since service personnel can be

dispatched when required with the appropriate parts and tools.

1.2 Identification of USM2.5

Figure 1-2,

New Version of USM2.5

Figure 1-1,

Old Version of USM2.5

704-683-B0-004, Rev. D

7

Page 8

2. Installation

2.1 Inverter Module Removal and Installation

The XM Series 2 Power Supply comes with a field-replaceable Inverter Module, containing

the inverter, battery charger and control logic circuitry. The Inverter Module is designed to

accept USM2.5 plug-in logic upgrades to facilitate remote status monitoring. The Inverter

Module can be removed while the power supply is running on line power. With the Inverter

Module removed, the power supply will continue to operate in a non-standby mode.

Remove the Inverter Module prior to adding the optional USM2.5 circuit board. Follow the

first procedure below precisely.

CAUTION: ALWAYS switch the battery breaker OFF prior to removing the Inverter Module.

XM Series 2 Inverter Module Removal Procedure:

1. Switch OFF the battery breaker. Disconnect the battery input, and the temp

probe cables.

2. Disconnect all remaining cables as needed from the Inverter Module.

3. Loosen the thumbscrews on the Inverter Module.

4. To remove the Inverter Module: grasp ONLY the handle of the Inverter Module,

pull firmly to release the module from the connector. Slide the module

assembly straight out.

5. Disconnect the Ribbon cable attaching the inverter module to the power

distribution board before sliding the inverter module all of the way out. (Refer

to Figure 2-1.)

XM Series 2 Inverter Module Installation Procedure:

1. Attach the ribbon cable to the inverter module.

2. To reseat the Inverter Module: align the metal shield in the upper and lower

card-guides. Using ONLY the Inverter Module’s handle (

pressure of any kind to the front panel

) firmly drive the module back into the

absolutely apply no

connectors. The connectors are designed to be made with reasonable force.

The thumbscrews are not intended to aid in making these connections, but

to secure the Inverter Module to the chassis.

3. If the Inverter Module is correctly seated the front panel Smart Display will

start-up, and the “Inverter Disconnected Alarm” will NOT be active.

4. Retighten thumbscrews. It is recommended that screws be tightened by

hand ONLY. Avoid using tools to tighten thumbscrews.

5. Reconnect all the cables (TMPR, XPDR, and SYS COM) as needed to the

Communications Module.

6. Verify that the battery breaker is OFF, reconnect the battery input and the

temp probe cables, verify battery polarity, and then finally switch ON the

battery breaker.

Disconnect here

Disconnect here

Unlatch

Figure 2-1, Inverter Module ribbon cable

8

704-683-B0-004, Rev. D

Page 9

2.2 USM2.5 Installation

The optional USM2.5 status monitoring upgrade plugs into the XM Series 2 Inverter Module.

The USM2.5 can be configured for various status monitoring interfaces by setting the DIP

switch. Status monitoring interfaces are listed according to their manufacturer, along with

the associated parts in Section 3.1. The USM2.5 also accommodates a tamper switch

assembly to indicate unauthorized enclosure entries.

CAUTION: The USM2.5 PCB contains static sensitive components that could be easily

damaged if not handled properly.

When installing the USM2.5 use the following procedure:

USM2.5 Installation Procedure:

1. Refer to Section 2.1 for Inverter Module removal.

2. Install the USM2.5 assembly on the Inverter Module:

Tools Required: #2 Phillips head screwdriver.

2. Installation

a) The 2 x 9 pin Strip Connector (Fig. 2-3), must be installed onto the

Inverter Module. A properly installed strip connector will be fully

seated and firmly in place.

b) A new USM2.5 will come with a snap-on support. Position the

USM2.5 over the strip connector and the rear hole for the support

and carefully push into place. Verify the position of the strip connector,

and that the support is fully seated into the Inverter Module mounting

shield.

c) When replacing a USM2.5 the support may already be installed. If

so, align the USM2.5 over the supports and gently rock onto the

strip connector. verify the position of the strip connector, and that

the support is fully seated into the Inverter Module mounting shield.

d) Secure the top of the USM2.5 card to the Inverter Module with the

captive screw fastener. The lower portion is covered by an optional

blanking plate (Fig. 2-2) or an Internal Transponder. Use 2 #6 screws

to secure the blanking plate, or the two captive screw fasteners

with the Internal Transponder.

3. Setup the USM2.5 for proper operation (see Section 3, Configuration):

a) Before reinstalling the Inverter Module, set the DIP switch, SW1 to

the proper configuration settings for the status monitoring interface,

as per Table 3-1 (page 12). Always verify USM2.5 configuration

especially after upgrading or modifying the XM Series 2 Power

Supply.

4. Carefully reinstall the Inverter Module. Refer to section 2.1.

704-683-B0-004, Rev. D

9

Page 10

2. Installation

2.2 USM2.5 Installation

Figure 2-2; Optional Blanking Plate

Part Number 745-419-20

Tamper

Switch

, continued

PEM

Fastener

Figure 2-3; 2X9 Pin Strip Connector

Part Number 540-581-10

External

Transponder

System

Communication

Configuration

Switch SW1

VOUT Scaled DC

Adjust Pot.

Pin 1

Indicator

Figure 2-4; Old Version USM2.5 Front Panel & PCB

Tamper

Switch

External

Transponder

(PEM

Fastener)

Configuration

Switch SW1

VOUT Scaled DC

Adjust Pot.

10

System

Communication

Pin 1

Indicator

Figure 2-5; New Version USM2.5 Front Panel & PCB

704-683-B0-004, Rev. D

Page 11

3. Configuration

3.1 USM2.5 Configuration (V Models)

The following information affects the use of the USM2.5 module on all V5 and VP versions of

the XM2 Power supply. It should be referenced in place of the information contained in the

relevant sections of this manual.

AC Output Current Monitoring On V5 And VP Models

• The AC current from output 1 of the Power supply is present on Pin 13 of

the USM2.5 transponder connector J3.

• The AC current from output 2 of the Power supply is present on Pin 8 of the

USM2.5 transponder connector J3.

This information overrides the following sections of this manual:

• 4.1 USM2.5 Signal Definition – Figure 4-1 USM2.5 Signal Connections (page

16)

• 4.3 USM2.5 Signal Definition – Name: Output Current #1 (page 18)

• 4.3 USM2.5 Signal Definition – Name: Output Current #2 (page 20)

• 5.1 USM2.5 Operations – USM2 Start Up and Test Procedure 3 (page 21)

Note: The output current pins are swapped on the V5 and VP models in relation to the basic

XM2 models. AC Outputs 3 and 4 are not monitored by the USM2.5 module or V5 and

VP Power Supplies.

AC Output Current Scaling on V5 and VP Models

When monitoring the AC Current of Output 1 and Output 2 on the USM2.5 module position 3

of the Function Switch (SW1) should be set to the ON position in order to gain the correct

output current scaling of 0.4VDC/AAC. This is the case for all V5 and VP models independent

of the issue of USM2.5 module used or the rating of the power supply.

This information overrides the following sections of this manual:

• 3.2 USM2.5 Configuration – Table 3-1 USM2.5 DIP Switch Set-up (page 12)

• 3.2 USM2.5 Configuration – SW1 (3): Output Current Scaling (page 13)

704-683-B0-004, Rev. D

11

Page 12

3. Configuration

3.2 USM2.5 Configuration

Refer to the following chart to determine your USM2.5 model

USM2-5 Model: XM2 Model:

USM2.5 XM2-615; XM2-915

USM2.5 22 XM2-1350 @ 60 VAC Output

USM2.5 48 XM2-1350-48

USM2.5 4822 XM2-922

Transpon d er Manuf acturer Alpha Part Number Battery Voltage Output Current

Acterna

Form er l y S EG / Cheetah

AM Communications

Tollgra de

Internal Acterna

Proprietary Transponder

<22A<48US M2-5 (default )

22A<48USM2-5 22

<22A48USM2-5 48

22A48USM2- 5 48 22

<22AN/AUSM2-5 TG

22AN/AUSM2-5 TG22

<22A<48USM2-5 INT-ACTP

22A<48USM2-5 INT-ACTP22

<22A48USM2-5 INT-ACTP48

22A48USM2-5 INT-ACTP4822

Table 3-1; USM2.5 DIP Switch Setup

NOTE: Switch 1-3 should always be ON for units equipped with the ONU option.

Transpon d er Manuf acturer Alpha Part Number Battery Voltage Output Current

Acterna

Form er l y S EG / Cheetah

AM Communications

Tollgra de

Internal Acterna

Proprietary Transponder

<22A<48US M2-5 (default )

22A<48USM2-5 22

<22A48USM2-5 48

22A48USM2- 5 48 22

<22A<48USM2-5 AM

22A<48USM2-5 AM22

<22A48USM2-5 AM48

22A48USM2- 5 AM4822

<22AN/AUSM2-5 TG

22AN/AUSM2-5 TG22

<22A<48USM2-5 INT-ACTP

22A<48USM2-5 INT-ACTP22

<22A48USM2-5 INT-ACTP48

22A48USM2-5 INT-ACTP4822

1 2 3 4 5 6 7 8

ON ON

ON ON ON

OFF OFF OFF OFF OFF

ON ON

ON ON ON

OFF

ON

OFF

ON ON

OFF OFF OFF OFF

OFF OFF

ON ON

ON ON ON

OFF OFF OFF

OFF

OFF OFF

Batt

Scale

volts/volt

.5VDC

.1VDC

.5VDC

.3 VDC

.1VDC

.5VDC

.1VDC

Voltage

(+)5VDC

(+)15VDC

(+)5VDC

(+)24VDC

Switch SW1

OFF OFF OFF

OFF OFF

OFF OFF

ON ON

ON

OFF OFF OFF

OFF OFF

OFF OFF OFF

OFF OFF

ON

OFF

ON

OFF

ON ON

Xpndr

ON

OFF

ON

OFF

ON ON

OFF

ON

Out V

Scale

volts/volt

.5VAC

.15VDC

.5VAC

ON

ON

ON

ON

ON

ON

ON

ON

OFF

OFF

ON

ON

ON

Tamper

Non inverting

Inverting

Non inverting

OFF OFF

OFF OFF

OFF OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

OFF OFF

OFF OFF

OFF OFF

OFF OFF

OFFOFF OFF

ON<22A<48USM2-5 AM

ON22A<48USM2-5 AM22

ON<22A48USM2-5 AM48

ON22A48USM2- 5 AM4822

OFF

OFF

Out I

Scale

volts/amp

.4VDC

12

Table 3-2; USM2.5 Transponder Output Voltages

704-683-B0-004, Rev. D

Page 13

3. Configuration

3.2 USM2.5 Configuration,

Figure 3-1; USM2.5 Switch Location

(Old Version )

continued

Figure 3-2; USM2.5 Switch Location

(New Version )

Always verify USM2.5 configuration especially after upgrading or modifying the XM Series 2

Power Supply.

Function Switch SW1 Reference

The following information describes each switch position (1–8) for the DIP switch SW1. SW1

is an eight switch component used primarily to select analog scaling and digital signal

polarity for the USM2.5 card.

SW1 (1 and 2): Inverter Battery Voltage Scaling Select

SW1, positions 1 and 2 are used together to select the appropriate scaling for the XM

Series 2 battery voltage measurement, measured at J4 pin 5.

SW1 (1)SW1 (2)Battery Scaling

OFF OFF 0.1VDC/VDC

OFF ON 0.3VDC/VDC

ON OFF 0.3VDC/VDC Same as previous setting.

ON ON 0.5VDC/VDC

SW1 (3): Output Current Scaling

SW1, position 3 is used to select the appropriate scaling for the XM Series 2 AC OUTPUT

CURRENT#1, measured at J4 pin 8 and AC OUTPUT CURRENT #2 pin 13.

SW1 (3)Output Current #1, #2

OFF 0.4VDC/AAC for Power Supply Output Current rating less than 20A.

ON 0.4VDC/AAC for Power Supply Output Current rating equal to or greater than 20A.

NOTE: Switch 1-3 should always be ON for units equipped with the ONU option.

704-683-B0-004, Rev. D

13

Page 14

3. Configuration

3.2 USM2.5 Configuration,

SW1 (4) and (8): Auxiliary DC Voltage Select

SW1, position 4 and 8 are used to select the voltage of the AUX DC delivered to the

transponder, measured at J4 pin 2.

SW1 (4) SW1 (8) Aux DC Voltage

OFF OFF + 5 VDC

ON OFF + 24 VDC

OFF ON + 15 VDC

ON ON N/A Incorrect Switch Setting

SW1 (5) and (6): Output Voltage AC or DC Scaling Select

SW1, position 5 and 6 is used to select the AC or DC representation of the XM

Series 2 AC OUTPUT VOLTAGE measurement, measured at J4 pin 4.

SW1 (5) SW1 (6) Output Volts (DC)

OFF OFF N/A No output at J4 pin 4

OFF ON 0.5 VAC Per Volt AC Output

ON OFF 0.15 VDC Per Volt AC Output

ON ON N/A Incorrect Switch Setting

NOTE: DC setting accuracy can be calibrated by adjusting the front panel potentiometer

(see Fig 2-4).

continued

SW1 (7): Tamper Status Polarity Select

SW1, position 7 is used to select between inverted or non-inverted signal polarity

for the system’s transponder measured at J4 pin 7.

SW1 (7) Tamper Status

OFF Not inverted (switch opens; Tamper Status goes HIGH)

ON Inverted (switch opens; Tamper Status goes LOW)

14

704-683-B0-004, Rev. D

Page 15

4. Signal Definitions

4.1 USM2.5 Signal Definition

IMPORTANT NOTE: For the USM2.5 to function correctly, OUTPUT (N) must be grounded to

the chassis of the XM Series 2. In a typical installation, this is automatically done

through the SPI, but during bench testing this connection will have to be manually made

by placing a jumper between the power supply Output Neutral and chassis ground.

HIGH is typically defined as AUX DC Voltage ± 10% (+5VDC, +15VDC, or +24VDC as set by

configuration). Voltage exceeding AUX DC is abnormal, but will not likely damage the

USM2.

(90%AUX DC < HIGH < AUX DC)

LOW is typically defined as 0VDC, however any nonnegative voltage between 0VDC and +1VDC

will be accepted by the USM2.5 as LOW.

(0VDC < LOW < 1VDC)

Sample 1 XMS 2

USM2.5

External

Acterna

USM2.5

AM

USM2.5

TG

Au xiliar y D C Out N/A +5VDC +15VDC +5V DC

AC Output Voltage 63VAC 31.5VAC 31.5VAC 9.45V D C

Bat ter y V ol tage

(36 VDC Nominal)

41.4VDC 20 .7V D C 20.7VDC 4.14VDC

Output Current 7A 2.8VD C 2.8VDC 2.8VDC

AC In p u t V oltage 240VA C N/A N/A N/A

Sample 2 XMS 2

USM2.5

External

Acterna

USM2.5

External

AM

USM2.5

External

TG

Au xiliar y D C Out N/A +5VDC +15VDC +5V DC

AC Output Voltage 87VAC 43.5VAC 43.5VAC 13.05VDC

Bat ter y V ol tage

(36 VDC Nominal)

39.6VDC 19 .8V D C 19.8VDC 3.96VDC

Output Current 14A 5.6VDC 5.6VDC 5.6VDC

AC In p u t V oltage 120VA C N/A N/A N/A

* Input voltages will me as ure approximately 2.7 VAC for 240 VAC input and 2.5 VA C for 120 VAC input.

USM2.5

Internal

Acterna

+24VDC

31.5VAC

20.7VDC

2.8VDC

Approx.

2.7VAC*

USM2.5

Internal

Acterna

+24VDC

43.5VAC

20.7VDC

2.8VDC

Approx.

2.5VAC*

704-683-B0-004, Rev. D

Table 4-1; USM2.5 Output Scaling Samples

15

Page 16

4. Signal Definitions

4.1 USM2.5 Signal Definition,

This Section provides specific details of all signals (input and output) provided on the XPDR

and TMPR Connectors when set up as a USM2.5 (default setting).

Tamper swi t ch return (GND)

Tamper switch sensor

Output current 1

for ONU equipped units

Output current 2

for ONU equipped units

Output current 2 13

Ground 12

Test / Reset 11

Output fail 10

AC input voltage 9

Output current 1 8

Tamper status

Equipment Fail

Battery voltage

AC output voltage

Standby / Line fail

Aux DC output

Ground

continued

2

1

7

6

5

4

3

2

1

J5

Tamper Switch Input

J4

Transponder I/O

DC Scaling Adjust

Pin 1

Figure 4-1; USM2.5 Signal Connections

Name: Common

Pin: J4-1

Signal Type: Ground reference / return

Referenced to: N/A

Description: Ground / return reference for ALL signals (analog, input & output) on

the USM2.5. Same as pins J4-12 and J5-2.

Name: Auxiliary DC Out

Pin: J4-2

Signal Type: Power

Referenced to: Common (J4-1, J4-12)

Description: This pin provides power for transponder pull up resistors as needed.

Auxiliary DC Out is not intended to provide complete logic &

transceiver power to the transponder, except in the case of internal

transponders

Parameters: Current drawn from this pin should NOT exceed 100mA under any

circumstance. Auxiliary DC Out is overcurrent protected by the

foldback of the switching power supply

How to test: Verify voltage on pin #2 is +5VDC, +15VDC, or +24VDC; (all within

10% tolerance) as set by configuration.

Name: Standby / Line Fail

Pin: J4-3

Signal Type: USM2.5 Discrete output

Referenced to: Common (J4-1, J4-12)

Description: This USM2.5 output indicates the state of the XM2 inverter.

Active Means: The XM2’s inverter is ON, and/or the AC line input has failed.

Active State: LOW

Inactive Means: The XM2’s inverter is NOT ON.

Inactive State: HIGH

How to test: With the XM2’s inverter ON, verify LOW on J4-3.

16

704-683-B0-004, Rev. D

Page 17

4. Signal Definitions

4.1 USM2.5 Signal Definition,

Name: AC Output Voltage

Pin: J4-4

Signal Type: USM2.5 Analog Output

Referenced to: Common (J4-1, J4-12)

Description: This pin provides a scaled, analog representation of the XM2’s

output voltage.

Parameters: This analog output should be 0.5VAC or 0.15VDC per VAC of the

XM2’s output. The calculated voltage should be within 5% of the

measured output voltage.

How to test: Verify voltage on pin #4 is 0.5VAC, or 0.15VDC per VAC of the

XM2’s output, as set by configuration. Front panel potentiometer

can be used to adjust the DC scaled voltage.

Name: Battery Voltage

Pin: J4-5

Signal Type: USM2.5 Analog Output

Referenced to: Common (J4-1, J4-12)

Description: This pin provides a scaled, analog representation of the XM2’s

battery string voltage.

Parameters: This analog output should read 0.1VDC, 0.3VDC, or 0.5VDC per

VDC of the XM2’s battery voltage, as set by configuration

SW1(pins 1 and 2).

How to test: Verify voltage on J3-5 is 0.1 VDC, 0.3VDC, or 0.5VDC per VDC of

the XM2’s battery voltage, as set by configuration.

continued

Name: Equipment Fail Alarm

Pin: J4-6

Signal Type: USM2.5 Discrete Output

Referenced to: Common (J4-1, J4-12, J5-2)

Description: This USM2.5 output indicates the general health of the XM2.

Active Means: An active Equipment Fail Alarm pin indicates a ‘latched’ failure of

an automated, local or remote inverter test or some other major

alarm within the XM2. No matter the cause, an Equipment Fail

Alarm indicates the XM2 will NOT perform as required and

should be serviced. Once this condition has been detected by

the USM2.5, the Equipment Fail Alarm will stay active until reset

by the successful completion of a Self Test (either locally or

remotely).

Active State: LOW

Inactive Means: Utility AC line input is present and no inverter failures have been

detected.

Inactive State: HIGH

How to Test: Verify that Equipment Fail Alarm is not currently latched HIGH.

With utility AC line and batteries present, initiate a remote

inverter test (see description of Pin 11 Test/Reset). Next,

simulate a battery failure by Switching XM2’s battery circuit

breaker OFF, the Equipment Fail Alarm should go LOW. Close

the battery circuit breaker; the Equipment Fail Alarm will stay

LOW. To clear the Equipment Fail Alarm, initiate an inverter test,

wait one minute, stop the inverter test.

704-683-B0-004, Rev. D

17

Page 18

4. Signal Definitions

4.1 USM2.5 Signal Definition,

Name: Tamper Switch Status

Pin: J4-7

Signal Type: USM2.5 Discrete Output

Referenced to: Common (J4-1, J4-12)

Description: USM2.5 output indicates the current state of the XM2’s enclosure

tamper switch. This is a non-latching type alarm.

Active Means: The enclosure door is opened or the tamper switch is

disconnected.

Active State: HIGH

Inactive Means: The enclosure tamper switch is properly connected and the door

is closed.

Inactive State: LOW

How to Test: Disconnect any tamper switch from the USM2.5 TMPR

connector. Short USM2.5 TMPR connector; the USM2.5 tamper

status (pin #7) should go LOW. Remove the short on USM2.5

TMPR connector (open circuit) and the Tamper Status output

should go HIGH.

NOTE: The tamper output polarity can be switched using SW1-7

continued

Name: Output Current #1

Pin: J4-8 (J4-13 for ONU equipped units)

Signal Type: USM2.5 Analog Output #1

Referenced to: Common (J4-1, J4-12)

Description: This USM2.5 analog output is a DC approximation of the total

XM2 AC output #1 current.

Parameters: 0.4VDC per AC ampere XM2 output.

How to Test: Verify voltage on J4-8 is 0.4VDC per AC ampere XM2 output #1.

(± 5% tolerance)

NOTE: The output current scale is dependant upon SW1-3

Name: AC Input Voltage (formerly not used on USM2 cards)

Pin: J4-9

Signal Type: USM2.5 Analog Input

Referenced to: Common (J4-1, J4-12)

Parameters: This analog output should be 0.0211 VRMS per VAC output for

120 VAC systems or 0.0113 VRMS per VAC output for 240 VAC

systems. (Approx. 2.5 VAC.)

How to Test: Verify that the voltage on J4 pin 9 is .0211 VRMS or .0113 VRMS per VAC

of the XM2’s input voltage (true RMS voltmeter must be used to read this

signal). (Approx. 2.7 VAC.)

18

704-683-B0-004, Rev. D

Page 19

4. Signal Definitions

4.1 USM2.5 Signal Definition,

Name: Output Fail Alarm

Pin: J4-10

Signal Type: USM2.5 Discrete Output

Referenced to: Common (J4-1, J4-12)

Description: This USM2.5 signal indicates the state of the AC output. A non-

latching signal, the Output Alarm will match the state of the

power supply output in real-time.

Active Means: The XM2’s AC output has failed.

Active State: LOW

Inactive Means: The XM2’s AC output is OK.

Inactive State: HIGH

NOTE: Removing the output fuse will result in a loss of power to the cable system (load).

Do not attempt this test without first transferring the load to a Service Power Supply

How to Test: Remove the XM2’s AC output fuse; verify J4-10 is LOW. Return

the XM2’s fuse; verify J4-10 is HIGH.

Name: Test/Reset

Pin: J4-11

Signal Type: USM2.5 Discrete Input

Referenced to: Common (J4-1, J4-12)

Description: This USM2.5 input controls remote test of the XM2’s inverter and

allows reset of a latched USM2.5 Equipment Fail Alarm. This

control signal originates from the transponder.

Active Means: An active Test / Reset pin indicates that the XM2 has been

commanded to initiate and hold a remote inverter test.

Active State: LOW, a transition from HIGH to LOW will indicate to the USM2.5

that the Test/Reset pin has been activated. The pin will be

considered active by the USM2.5 for the duration that the pin is

held LOW.

Inactive Means: The XM2 is not commanded to perform or hold a remote inverter

test. Any previously held test will be ended when the input is

transitioned from active to inactive.

Inactive State: HIGH

How to test: To perform a test at the XM2, disconnect the transponder from

the USM2.5. With line and battery applied to the XM2, carefully

short and hold the Test/Reset J4-11 to ground (J4-1), the XM2 will

immediately start inverter test mode. Wait at least 1 minute then

release J4-11 from ground and the inverter test mode will end,

and any latched Equipment Fail Alarm should clear.

continued

Resetting a latched Equipment Fail Alarm:

704-683-B0-004, Rev. D

If a USM2.5 Equipment Fail Alarm is latched when the Test/

Reset pin is made active and a successful inverter test is

completed, the Equipment Fail Alarm will be cleared (i.e. J4-6

change to inactive).

19

Page 20

4. Signal Definitions

4.1 USM2.5 Signal Definition,

Name: Common

Pin: J4-12

Signal Type: Ground reference / return

Referenced to: N/A

Description: Ground / return reference for ALL signals (analog, input & output)

on the USM2.5. Same as J4 pin 1 and J5 pin 2.

Name: Output Current #2

Pin: J4-13 (J4-8 for ONU equipped units)

Signal Type: USM2.5 Analog Output #2

Referenced to: Common (J4-1, J4-12)

Description: This USM2.5 analog output is a DC approximation of the total

XM2 AC output #2 current.

Parameters: 0.4VDC per AC ampere XM2 output.

How to Test: Verify voltage on J4-13 is 0.4VDC per AC ampere XM2 output #2

(±5% tolerance).

NOTE: The output current scale is dependant upon SW1-3

Name: Tamper Switch In

Pin: J5-1

Signal Type: USM2.5 Discrete Input (dry contact switch)

Referenced to: J5-2

Description: Dry contact tamper switch input. Left open circuit, this USM2.5

input will be pulled up to +5VDC.

Active Means: The enclosure’s door is open or the tamper switch is not

connected.

Active State: OPEN

Inactive Means: The enclosure’s door is closed.

Inactive State: SHORT

How to test: See ‘How to Test’ for J4-7 (page 17).

continued

20

Name: Tamper Switch Return

Pin:J5-2

Signal Type: Ground Reference/return

Referenced to: N/A

Description: Return / ground for Tamper switch.

NOTE: ALL values are provided for troubleshooting and reference purposes ONLY.

704-683-B0-004, Rev. D

Page 21

5.1 USM2.5 Operations

USM2.5 Start up and Test Procedure

The XM Series 2 power supply should be fully tested before attempting any USM2.5 operations.

Refer to the XM Series 2 technical manual for details. Once the power supply has been

verified as “GOOD” the USM2.5 can then be tested as follows:

1. Verify the USM2.5 installation by checking:

• Configuration settings of switch SW1.

• USM2.5 is properly installed onto Communication Module, and that the

Communication Module is correctly installed into the XM Series 2 power supply.

• Tamper switch is properly installed and connected.

• Data cable from the USM2.5 to the transponder is correctly installed.

2. Unplug transponder’s data cable from the USM2.5.

3. Using a true RMS multimeter, verify the USM2.5’s analog data (set by configuration) on

the J4 connector by checking (ground on J4-1):

• Auxiliary DC output on J4-2

• AC Output Voltage Level on J4-4

• Battery Level output on J4-5

• Output Current#1 level on J4-8 (J4-13 for ONU equipped units)

• Output Current#2 level on J4-13 (J4-8 for ONU equipped units)

• AC input voltage level on J4 pin 9

5. Operation

4. Using a true RMS multimeter, verify the USM2.5’s Digital data (set by configuration) on

the J3 connector by checking (ground on J4-1):

• Standby Status Alarm J4-3, active any time inverter in ON.

• Equipment Fail Alarm J4-6, active if test failure or low battery condition.

• Tamper Alarm J4-7, active when the enclosure’s door is open.

NOTE: Removing the output fuse will result will result in a loss of power to the

cable system (load).

load to a Service Power Supply.

• Output Alarm J4-10, active when the XM Series 2’s AC output has failed.

5. Verify remote USM2.5 control on the J2 connector by shorting Pin11 to ground (J4-1):

• Test/Reset J4-11, shorted XM Series 2 inverter Test ON, open inverter Test OFF.

NOTE: Successful completion of test steps 1-5 above is a very good indication that the

USM2.5 is operating correctly, if the unit fails any of the tests, repeat the test to verify

failure, and replace USM2.5 as needed.

6. Plug transponder’s data cable back into the USM2.5. Repeat test steps 3-5; local results

should remain the same. If results do NOT remain the same, this is an indication of a

possible transponder failure.

7. Review analog data at status monitoring center. The reported data should be similar to

values seen at the power supply.

8. Initiate an inverter test command from the status monitoring center. The power supply

should go into test as commanded. Monitor command signals from the transponder on

the USM2.5 connector J2 using a multimeter by checking:

• Test/Reset J4-11, active XM Series 2 inverter ON, inactive inverter OFF.

Do not attempt this test without first transferring the

NOTE: Test steps 6-8 are used to verify the transponder and the status monitoring

704-683-B0-004, Rev. D

system, if any of the tests fail; retest, verify failure, troubleshoot status monitoring

system (less USM2.5) as needed.

21

Page 22

6. Troubleshooting

6.1 Troubleshooting the Communications Link

Occasionally the communications link between the XM Series 2 power supply and the headend

site may appear to break down. Updates to and from the power supply may not take place,

or data received may be faulty. When this happens, isolate and correct the failed elements in

a precise fashion to avoid extended troubleshooting times or the possibility spreading a

potential failure from site to site.

Symptom: No Remote Control (Inverter Test)

Diagnosis: To start, verify that USM2.5 J4-11 (Test/Reset) are HIGH; change

Repair Solution: If the remote commands are present, goes from HIGH to LOW,

Symptom: Incorrect Scaling voltage reported.

Diagnosis: Verify that the USM2.5 is configured correctly; then verify the

Repair Solution: If the scaling voltage reported is NOT correct, replace the

state via remote command pins should go LOW.

replace the USM2.5; if not, troubleshoot the transponder and RF

section.

XM2 Output in question; verify USM2.5 scaling.

USM2.5. If scaling voltages are correct, troubleshoot the

transponder and RF section.

Symptom: Status monitoring reports “Comm Error”.

Diagnosis: Verify that the USM2.5 is correctly connected to the transponder,

and that the transponder is correctly powered (per transponder

documentation).

Repair Solution: Correct connections as needed.

Symptom: No Auxiliary DC output

Diagnosis: Verify Auxiliary DC output by checking voltage on J4-2 with the

USM2.5 disconnected from the status monitor; if voltage is

correct, reconnect status monitor and check again.

Repair Solution: With the USM2.5 disconnected from the transponder the

Auxiliary DC voltage is NOT correct, replace the USM2.5. If AUX

DC voltages is correct with transponder, troubleshoot the

transponder and RF section.

22 704-683-B0-004, Rev. D

Page 23

7.1 Parts

The following parts can be purchased by calling your local Alpha representative:

7. Parts

Part Name:

Ribbon Cable

2 x 9 Header

Hardware Kit

Includes:

2 x 9 Header

Plastic Standoffs

Screws

Sheet Metal Kit

Includes:

Faceplate with silkscreen

Mounting Hardware

Alpha Part Number:

874-992-20

540-581-10

745-153-22

745-153-21

704-683-B0-004, Rev. D

23

Page 24

8. Reference

8.1 USM2.5 Signals, Quick Reference

PIN

2

1

13

12 Ground

11

10

9

8 Analog Scaled analog representation of UPS output current #1. Scaling: 0.4 VDC per AMP output

7 Tamper Status

Signal

Name

Tamper Switch

Return

Tamper Switch

Output Current 2

(Output Current

1 for ONU

equipped units)

Test / Reset

Output Fail

Alarm

AC Input

Voltage

Output Current 1

(Output Current

2 for ONU

equipped units

Type

(Ground)

Discrete

(In)

Analog

Ground

Discrete

(in)

Discrete

(Out)

Analog

Discrete

(Out)

Signal Description

Return for Tamper Switch input to USM2-5 (same as J4 pins 1 and 12)

Tamper Switch input to USM

Scaled analog representation of UPS output current #2. Scaling: 0.4 VDC per Amp output

Ground reference for all signal and power (same as J5 pin 2 and J4 pin 1).

Command to UPS to initiate and hold a UPS battery and inverter test. Pulling the signal to ground for >

100ms will initiate the inverter test. Releasing the signal will allow the test to end. If the UPS has a

latched alarm, successful completion of the test will clear the alarm.

Indicates the state of the UPS output. Signal pulled up to AUX DC.

Scaled representation of the UPS input voltage. Scaling se t by UPS, input voltage can be

.0211 (120 in) or .0113 (240 in) Volts per input volt.

Indicates state of the enclosure tamper switch. Signal pulled up to AUX DC. Polarity of signal

determined by configuration.

Equipment Fail

6

5 Battery Voltage Analog

4

3

2

1 G round Ground Ground reference for all signal and power (same as J5 pin 2 and J4 pin 12).

Alarm

AC Output

Voltage

Standby / Line

Fail Alarm

Auxiliary DC

Out

Discrete

(Out)

Analog

Discrete

(Out)

Power Auxiliary output power for transponder. Voltage set by configuration; +5, +15, or +24 VDC

Indicates power supply equipment failure. Signal pulled up to AUX DC.

Scaled analog representation of UPS battery pack voltage. Scaling set by configuration. Can be

.5 VDC or .15 VDC per battery volt.

Scaled representation of the UPS output voltage. Scaling set by configuration. Can be .5 VDC or

.15 VDC per output volt.

Indicates the state of the UPS inverter. Signal pulled up to AUX DC.

IMPORTANT NOTE: In order for the USM2.5 to function correctly, OUTPUT (N) must be grounded to

the XM Series 2’s chassis! During normal operation this is automatically done though the SPI, but

during bench testing this ground will have to be manually maintained, by placing a jumper between

the Output Neutral and chassis ground.

24

704-683-B0-004, Rev. D

Page 25

8. Reference

8.2 Testing and Troubleshooting, Quick Reference

USM2.5 Start up and Test Procedure

The XM Series 2 power supply should be fully tested before attempting any USM2.5 operations.

Refer to the XM Series 2 technical manual for details. Once the power supply has been verified as

“GOOD” the USM2.5 can then be tested as follows:

1. Verify the USM2.5 installation by checking:

• Configuration settings of switch SW1.

• USM2.5 is properly installed onto Communication Module, and that the

Communication Module is correctly installed into the XM Series 2 power supply.

• Tamper switch is properly installed and connected.

• Data cable from the USM2.5 to the transponder is correctly installed.

2. Unplug transponder’s data cable from the USM2.5.

3. Using a true RMS multimeter, verify the USM2.5’s analog data (set by configuration) on

the J4 connector by checking (ground on J4-1):

• Auxiliary DC output on J4-2

• AC Output Voltage Level on J4-4

• Battery Level output on J4-5

• Output Current#1 level on J4-8

• Output Current#2 level on J4-13

• AC input voltage level on J4 pin 9

4. Using a true RMS multimeter, verify the USM2.5’s Digital data (set by configuration) on

the J3 connector by checking (ground on J4-1):

• Standby Status Alarm J4-3, active any time inverter in ON.

• Equipment Fail Alarm J4-6, active if test failure or low battery condition.

• Tamper Alarm J4-7, active when the enclosure’s door is open.

NOTE: Removing the output fuse will result will result in a loss of power to the

cable system (load).

load to a Service Power Supply.

• Output Alarm J4-10, active when the XM Series 2’s AC output has failed.

5. Verify remote USM2.5 control on the J2 connector by shorting Pin11 to ground (J4-1):

• Test/Reset J4-11, shorted XM Series 2 inverter Test ON, open inverter Test OFF.

NOTE: Successful completion of test steps 1-5 above is a very good indication that the

USM2.5 is operating correctly, if the unit fails any of the tests, repeat the test

to verify failure, and replace USM2.5 as needed.

6. Plug transponder’s data cable back into the USM2.5. Repeat test steps 3-5; local results

should remain the same. If results do NOT remain the same, this is an indication of a

possible transponder failure.

7. Review analog data at status monitoring center. The reported data should be similar to

values seen at the power supply.

8. Initiate an inverter test command from the status monitoring center. The power supply

should go into test as commanded. Monitor command signals from the transponder on

the USM2.5 connector J2 using a multimeter by checking:

• Test/Reset J4-11, active XM Series 2 inverter ON, inactive inverter OFF.

Do not attempt this test without first transferring the

NOTE: Test steps 6-8 are used to verify the transponder and the status monitoring

system, if any of the tests fail; retest, verify failure, troubleshoot status monitoring

system (less USM2.5) as needed.

704-683-B0-004, Rev. D

25

Page 26

Page 27

Page 28

Alpha Technologies

Power

Alpha T echnologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Web: www.alpha.com

Alpha T echnologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: +1 604 430 1476

Fax: +1 604 430 8908

Alpha T echnologies

Europe Ltd.

Twyford House

Thorley

Bishop’s Stortford

Hertfordshire

CM22 7PA

UNITED KINGDOM

T el: +44 0 1279 501 1 10

Fax: +44 0 1279 659870

Alpha T echnologies GmbH

Hansastrasse 8

D-91126 Schwabach

GERMANY

T el: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec, Ltd

P .O. Box 56468

Limassol, Cyprus

CYPRUS

T el: +357-25-375675

Fax: +357-25-359595

AlphaTek, ooo

Khokhlovskiy Pereulok 16

Stroenie 1

109028 Moscow

RUSSIA

Tel: +7 095 916 1854

Fax: +7 095 916 1349

Alphatec Baltics

S. Konarskio G . 49

Vilnius 2009

LITHUANIA

Tel: +350 5 210 5291

Fax: +350 5 210 5292

Alpha T echnologies

5 Avenue Victor Hugo

F-92140 Calmart France

FRANCE

Tel: +33 3 41 90 07 07

Fax: +33 1 41 90 93 12

Copyright © 2006 Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 704-683-B0-004, Rev. D.

Due to continuing product improvements, Alpha reserves the right to change specifications without notice.

®

Loading...

Loading...