Page 1

Installation and Operation Manual

UPE-3L and UPE-6L Enclosures

Effective: January, 2003

®

Page 2

Alpha Technologies

Power

®

Page 3

UPE-3L, UPE-6L

Enclosure Installation Manual

031-178-C0-001, Rev. A

Effective Date: January, 2003

Copyright© 2003

Alpha Technologies, Inc.

NOTE: Alpha denies responsibility for any damage or injury involving its

enclosures, power supplies, generators, batteries, or other

hardware when used for an unintended purpose, installed or

operated in an unapproved manner, or improperly maintained.

NOTE: Photographs contained in this manual are for illustrative purposes

only. These photographs may not exactly match your installation.

NOTE: Review the drawings and illustrations contained in this manual

before proceeding. If there are questions regarding the safe

operation of this powering system, please contact Alpha

Technologies or your nearest Alpha representative.

Contacting Alpha Technologies:

For general product information and customer service

1-800-863-3930

(7:00 AM to 5:00 PM Pacific Time )

For complete technical support

1-800-863-3364

(7:00 AM to 5:00 PM Pacific Time, or 24/7 emergency support)

Page 4

Preface

Series

UPE

Preface Topic Page

Overview 4

About This Manual 4

Table of Contents 5

List of Figures 5

Product Safety 6

Battery Safety Notes 9

Installation Notes 10

Enclosures

Overview: The purpose of this UPE Series Enclosure Installation

Manual is to provide a high-level overview of the system

and to detail the installation procedure for the

enclosures.

Audience: This manual intended for the installers of the system.

About this manual:

Contents: This Installation Manual is comprised of two sections.

Section 1 Pre-Installation. This section describes site

selection, pad layout, and enclosure grounding.

Section 2 Installation. This section describes the installation

of the enclosure to the pad, and the installation of

batteries and power supplies

4

031-178-C0-001 Rev. A

Page 5

Series

UPE

SECTION ONE Pre-Installation

1.1 Site considerations ................................................................................. 10

1.2 Enclosure Dimensions ........................................................................... 11

1.3 Pedestal support .................................................................................... 13

1.4 Enclosure Grounding ............................................................................. 15

SECTION TWO Installation

2.1 Enclosure Protection .............................................................................. 17

2.2 Transportation and Lifting ....................................................................... 18

2.3 Enclosure Installation ............................................................................. 19

2.4 Utility Power Connection ........................................................................ 20

2.5 Power Supply Placement ....................................................................... 27

2.6 Battery Installation .................................................................................. 27

2.7 Battery Temperature Sensor .................................................................. 31

2.8 Lightning Arrester Option ....................................................................... 32

2.9 Battery Heater Mat and LRI-ACI Lamp Options ..................................... 33

2.10 Enclosure Door Tamper Switch / Rain Deflector Options ...................... 34

Enclosures

Table of Contents

Preface

List of Figures

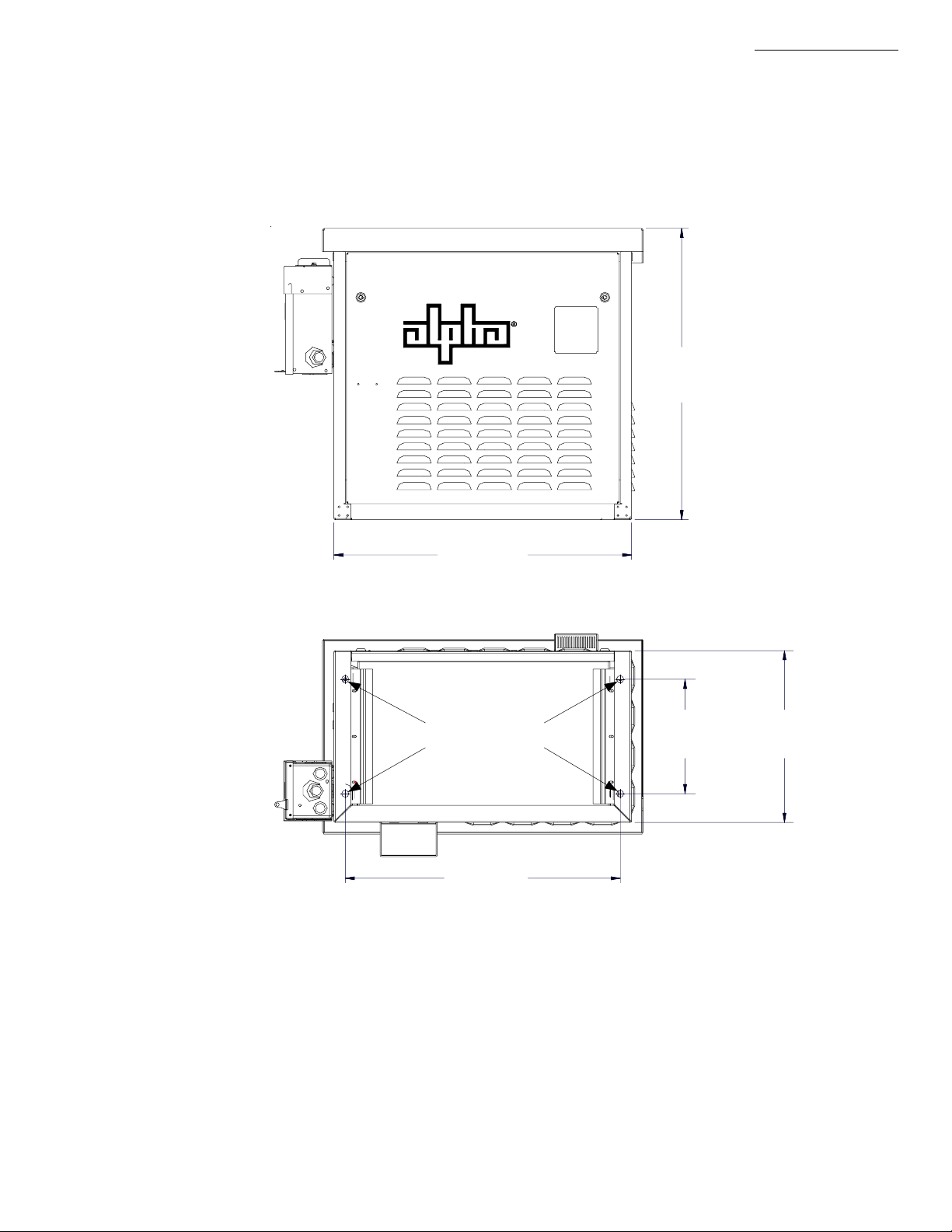

Fig. 1-1 UPE-3L Enclosure Dimensions....................................................................... 11

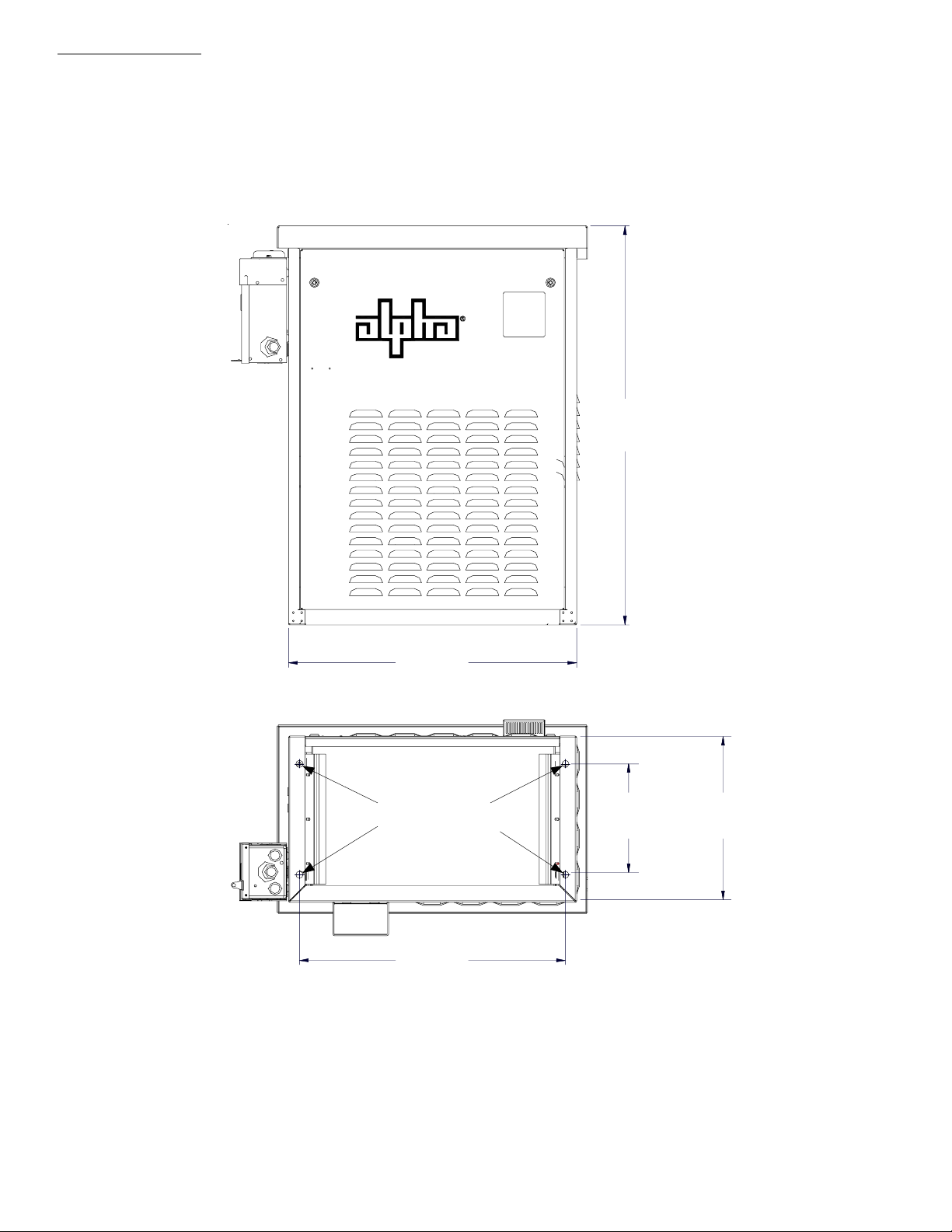

Fig. 1-2 UPE-6L Enclosure Dimensions....................................................................... 12

Fig. 1-3 Typical Pedestal Configurations ...................................................................... 13

Fig. 1-4 Typical Pedestal Installation ........................................................................... 14

Fig. 1-5 Enclosure Grounding ...................................................................................... 16

Fig. 2-1 Post placement .............................................................................................. 17

Fig. 2-2 External Coax Raceway ................................................................................. 20

Fig. 2-3 Service Entrance Option ................................................................................ 22

Fig. 2-4 Typical Service Entrance Wiring ..................................................................... 23

Fig. 2-5 Breaker-Quad-Option Wiring ........................................................................... 24

Fig. 2-6 120 and 240VAC UL Wiring (030-051-C7-A) .................................................... 25

Fig. 2-7 Battery Hazard Warning Label ......................................................................... 27

Fig. 2-8 Battery Terminal Connections ......................................................................... 28

Fig. 2-9 UPE-3L Battery placement ............................................................................. 30

Fig. 2-10 UPE-6L Battery placement ............................................................................. 30

Fig. 2-11 RTS Placement .............................................................................................. 31

Fig. 2-12 LAP Plus ........................................................................................................ 32

Fig. 2-13 Surge Arrester ................................................................................................ 32

Fig. 2-14 ACI/LRI Wiring ................................................................................................ 33

Fig. 2-15 Tamper Switch Wiring ..................................................................................... 34

031-178-C0-001 Rev. A

5

Page 6

Preface

Important Safety Instructions Contained in This

Manual

CAUTION

HAZARDOUS CONDITION

To reduce the risk of electrical shock, injury or death caused by explosion of fuel or moving

parts, and to ensure the safe operation of this unit, the following symbols have been

placed throughout the manual. Where these symbols appear, servicing should be

performed only by qualified personnel.

DANGEROUS VO LTAGE

This symbol indicates a “dangerous voltage” exists in this area of the

product. Use caution whenever working in the area to prevent

electrical shock.

INHALATION HAZARD - DON’T BREATHE VAPORS

This symbol indicates an “inhalation hazard” exists in this area of the

product. Use caution whenever working in the area to prevent possible

inhalation of harmful (fuel or exhaust) vapors.

NO MATCHES OR OPEN FLAMES

This symbol indicates a fire or explosive hazard exists in this area of

the product. Use caution whenever working in the area to prevent

possible combustion fuel vapors.

MECHANICAL OR MOVING PARTS HAZARD

These symbols indicate the presence of a “mechanical or moving parts

hazard” in this area of the product. Use caution whenever working in

the area to prevent possible injury to the operator or service personnel.

LEAK HAZARD

This symbol indicates a “leak hazard” exists in this area of the product.

Use caution whenever working in the area to prevent and correct any

leaks detected.

CRUSH HAZARD

This symbol indicates the presence of crushing hazard in this area.

Keep hands clear of areas under extended battery trays and equipment

drawers.

ATTENTION

This symbol indicates important installation, operation or maintenance

instructions. Always follow these instructions closely.

6 031-178-C0-001 Rev. A

Page 7

Warnings

NOTE: This power supply and its associated hardware (enclosure, batteries, cabling)

Preface

A “Warning” identifies conditions and actions that pose a hazard to the user.

A “Caution” identifies conditions and actions that may damage the power

supply or associated equipment.

may contain equipment, batteries or parts which have accessible hazardous

voltage or currents.

To avoid injury

:

• This power supply and its associated hardware must be serviced by authorized personnel

only.

• The enclosure which contains the power supply and associated equipment must remain

locked at all times, except when authorized service personnel are present.

• Remove all conductive jewelry or personal equipment prior to servicing equipment, parts,

connectors, wiring, or batteries.

• Read and follow all installation, equipment grounding, usage, and service instructions

included in this manual.

• Use proper lifting techniques whenever handling equipment, parts, or batteries.

• Batteries contain dangerous voltages, currents and corrosive material. Battery installation,

maintenance, service and replacement must be performed by authorized personnel only.

• Never use uninsulated tools or other conductive materials when installing, maintaining,

servicing or replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly connected

battery cable or an unconnected battery cable can result in arcing, a fire, or possible

explosion.

• A battery that shows signs of cracking, leaking or swelling must be replaced immediately by

authorized personnel using a battery of identical type and rating.

• Avoid any contact with gelled or liquid emissions from a valve-regulated lead-acid (VRLA)

battery. Emissions contain dilute sulfuric acid which is harmful to the skin and eyes.

Emissions are electrolytic, which are electrically conductive and are corrosive. Follow the

Chemical Hazards notes if contact occurs.

• Do not smoke or introduce sparks in the vicinity of a battery.

7 031-178-C0-001 Rev. A

Page 8

Preface

Battery Safety Notes

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service and replacement must be performed by authorized personnel

only.

Chemical Hazards

NOTE: Any gelled or liquid emissions from a Valve-Regulated lead-acid (VRLA)

battery contain dilute sulfuric acid, which is harmful to the skin and eyes.

Emissions are electrolytic, which are electrically conductive and

corrosive.

To avoid injury:

• Wear protective clothing (insulated gloves, eye protection, etc) whenever installing,

maintaining, servicing, or replacing batteries.

• If any battery emission contacts the skin, wash immediately and thoroughly with water.

Follow your company’s approved chemical exposure procedures.

• If any battery emission contacts the eye, wash immediately and thoroughly with water for

10 minutes with pure water or a special neutralizing eye wash solution and seek

immediate medical attention. Follow your company’s approved chemical exposure

procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved

spill kit or with a solution of 1 lb. bicarbonate of soda to 1 gal of water. Report chemical

spill using your company’s spill reporting structure and seek medical attention if

necessary.

• Always replace batteries with those of an identical type and rating. Never install old or

untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least

0.5 inches of space between it and all surrounding surfaces to allow for convection

cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of

potentially dangerous gas.

8 031-178-C0-001 Rev. A

Page 9

Important Installation Notes

The system must be installed ONLY by qualified service personnel.

Consult local utility codes for additional cabinet grounding and utility requirements.

ALPHA TECHNOLOGIES is not responsible for broken welds or other damage to the

cabinet caused by improper installation.

All dimensions are given in inches.

For further information regarding this installation, contact ALPHA TECHNOLOGIES or your

nearest ALPHA representative.

For general product information and Customer Service

7:00AM to 5:00PM Pacific Time

1-800-863-3930

Preface

To obtain complete Technical Support,

7:00AM to 5:00PM Pacific Time

or

For after-hours Emergency support

7 days per week, 24 hours a day

1-800-863-3364

NOTE:

Alpha Technologies’ products are subject to change

through continual improvement processes. Therefore,

specifications and/or design layouts may vary slightly

from descriptions included in this manual. Updates to the

manual will be issued when changes affect form, fit or

function.

Save these instructions for future reference

9 031-178-C0-001 Rev. A

Page 10

1. Pre-Installation

1.1 Site considerations

The site must be planned so that the enclosure will receive good air flow. If

possible, in areas of extreme heat, it is best to position the enclosure so that it

will be shaded from the afternoon sun. If no shade is available, a factory installed

fan kit is highly recommended. In areas of prevailing winds, it is best that the

enclosure be located so that the sides of the cabinet face the winds instead of the

doors. This will greatly reduce the buildup of sand or snow against the enclosure’s

air vents.

In areas of potential flooding, the geographical site and concrete pad must be

located above the 100 year flood plain.

The enclosure must be placed where it will be free of obstructions, allowing

easy access to the doors for service or equipment access. For ventilation and

maintenance, allow a minimum space of 36 inches in the front and 36 inches in

the rear, between the enclosure and other solid structures.

Place the enclosure well away from sources of forced water, such as

underground sprinkler systems and direct roadway splash.

The concrete pad drawing provided in this manual contains all of the required

mounting details, including electrical service and cable plant entrances.

For ease of installation, lightweight polymer concrete pads are available from

Alpha Technologies for all UPE series enclosures.

The vapor barrier material (such as 30 lb. felt, neoprene pond liner, or heavy

grade tar paper) must initially extend at least 6" in all directions around the

perimeter of the enclosure and be trimmed closer to the enclosure. Contact local

utilities, building maintenance departments and cable/pipe locating services to

ensure that this installation does not interfere with existing utility or building

cables or piping. It is the responsibility of the installer/owner to position and

protect the enclosure to minimize/prevent traffic related hazards.

WARNING: Never transport the unit with batteries installed.

Batteries must ONLY be installed after the unit is

transported to the site and secured to the pad.

Transporting the unit with batteries installed may

cause a short circuit, fire, explosion, and/or damage

to the battery pack, enclosure and installed

equipment. Damage caused by improper shipping or

transporting a unit with batteries installed is not

covered by the warranty.

The batteries used in this application may vary slightly depending upon

optional configurations, battery types, or customer requirements. The batteries are

typically gelled-electrolyte, valve-regulated such as the Alpha Cell. Should a

battery be found damaged, refer to the battery manufacturer's documentation

regarding the safe handling of the battery.

10 031-178-C0-001 Rev. A

Page 11

1.2 Enclosure dimensions

1. Pre-Installation

25.5 in.

647 mm

26 in.

660 mm

(front view)

Mounting Holes

24 in.

609 mm

(bottom View)

Figure 1-1 UPE-3L Enclosure Dimensions

10 in.

254 mm

15 in.

381 mm

11 031-178-C0-001 Rev. A

Page 12

1. Pre-Installation

1.2 Enclosure dimensions,

continued

36 in.

914 mm

26 in.

660 mm

(front view)

Mounting Holes

254 mm

24 in.

609 mm

(bottom View)

Figure 1-2 UPE-6L Enclosure Dimensions

10 in.

15 in.

381 mm

12 031-178-C0-001 Rev. A

Page 13

1. Pre-Installation

1.3 Precast Enclosure Pedestal Support

Alpha’s precast pedestal support system provides a quick, one-step solution for installing

the UPE series enclosures.

Contact Alpha Technologies Customer Service (1-800-863-3930) to determine which

Pedestal Support is needed for your installation.

Cover

Alpha P/N 564-911-10

PS6 Pedestal

Alpha P/N 745-324-20

Drill here for

extern al load

center, if used.

Drill here for

extern al servi ce

entrance, if used.

Fig. 1-3 Typical Pedestal Configurations

Drill here for UP E-6

ECR

Drill here for UP E-3

ECR

PS-6 XL Pedestal

Alpha P/N 745-324-21

13 031-178-C0-001 Rev. A

Page 14

1. Pre-Installation

1.3 Precast Enclosure Pedestal Support,

continued

For detailed installation instructions, refer to the Manufacturer’s Installation

Documentation included with the Pedestal Support Package.

UTILITY

UNDISTURBED GROUND

Fig. 1-4 Typical Pedestal Installation

PRECAST PAD

PEDESTAL SUPPORT

6 to 12 Inches

Compacted Gravel

GRADE

BACK-FILL

OUTPUT SWEEP

14 031-178-C0-001 Rev. A

Page 15

1. Pre-Installation

1.4 Enclosure Grounding

In order to provide a ready, reliable source of backup power it is necessary to establish a

grounding system that not only provides for the safety of the service personnel responsible for

its operation and maintenance, but also facilitates the proper operation and protection of the

equipment within the network. Such a grounding system will provide protection with respect to

operator safety, system communication, and equipment protection.

Safety Ground

The safety ground is a two-part system. The first part is a return path for stray current back to

the input breaker, and the second is a return path from the Alpha enclosure to a second ground

rod.

Typically, the safety, or utility ground, provides a return path to the input breaker or fuse panel

by means of a connection to an appropriate driven ground rod at the base of the power pole.

This path must meet National Electric Code (NEC) as well as local codes to ensure the breaker

will open, preventing unwanted current flow from posing a hazard to service personnel.

The second part of the safety ground arrangement is the ground path between the Alpha

enclosure and a second ground rod located at least 6 feet away from the driven ground rod at

the power pole. The second ground rod and enclosure are connected via an AWG #6 solid

copper wire buried at a depth of 8-12 inches. The wire is connected to the cabinet by means of

a ground lug on the back of the cabinet (for pole-mounted enclosures), or to a ground lug inside

the cabinet (for ground-mounted enclosures), and connected to the ground rod by means of a

listed grounding clamp suitable for direct burial, or exothermic weld. Normally it is specified that

the impedance of this ground can be no greater than 25 ohms at 60 Hertz. If, however, dual

ground rods are installed approximately eight feet apart, it is not necessary to measure the

impedance of the ground rods to meet the maximum 25 ohms specification—it is assumed that

the impedance specification is met.

Signal Ground

For proper operation, the Service Power Inserter must be securely grounded to the enclosure

chassis. This is of particular importance in systems utilizing an external status monitoring

transponder. The transponder chassis is grounded via a separate ground wire to the SPI case.

For systems utilizing an embedded transponder, the ground connection is made either through a

separate chassis ground block, or by means of the internal mounting hardware which then

grounds the transponder through the XM Series 2 Power Supply.

Strike (Lightning) Ground

Lightning strikes, grid switching, or other aberrations on the power line all have the potential to

cause “fast rise-time currents” which can cause damage to the powering system. Without a lowimpedance path to ground, the current, while traveling through wires of varying impedance, can

produce high voltages which will damage the powering equipment. The most viable method

available to protect the system from damage is to divert these unwanted “fast rise-time

currents” along a low-impedance path to ground. A low-impedance path to ground will prevent

these currents from reaching high voltage levels and posing a threat to equipment. The singlepoint grounding system provides a low-impedance path to ground, and the key to its success is

the proper bonding of the ground rods, so the components of the grounding system appear as a

single point of uniform impedance.

Low impedance grounding is not only critical for the proper operation of the cable system, but

also is mandatory for personnel safety.

15 031-178-C0-001 Rev. A

Page 16

1. Pre-Installation

1.4 Enclosure Grounding

NOTE: Alpha Technologies recommends using the grounding method illustrated below. The

grounding method for a particular site will be dependant upon soil type, available space,

local codes, NEC (National Electric Code), and other site-specific characteristics.

It is the responsibility of the installer to ensure the requirements of all applicable

national and local codes are met. Alpha Technologies assumes no responsibility or

liability for failure of the installer to comply with the requirements of all applicable

local and national codes. Where allowed, exothermic welding may be used as an

alternative to Burndy clamps and connectors.

Connection made with Burndy connector

(P/N YGH R58C2W-3 or equivalent)

Ter minate at enc losure grou nd

Term inate at s ervice

entran ce ground

#6 AW G

8' ground rods 6' apart minimum.

Note: M ay require add itional gr ound rods t o meet

NEC minimum gr ounding standard (25 Ohms or

less).

Service Grounding (required)

4

Enclosure Footprint

1

#2 AW G

Connection made with Burndy connector

(P/N YGHP58C2W -2TN or equivalent)

2

Fig. 1-5 Enclosure Grounding

t

e

e

f

2

)

n

i

m

(

3

1

#6 bare copper wire from Service Neutral / Ground Bar with 2 ground rods located 6'

apart.

Lightning Protection (optional)

2

3

1/2" x 8' copper ground rod, four places, driven about 2 feet (typical) from the corners

of the pad.

#6 bare copper wire loop terminated to each ground rod and buried below grade 30

inches min. Corrosion-proof connections (25+ year life-span) and hardware suitable

for direct burial MUST be used.

4

#6 bare copper wire from loop to the enclosure

16 031-178-C0-001 Rev. A

Page 17

2.1 Enclosure Protection

Alpha Technologies, Inc. cannot anticipate all of the ways a vehicle may

potentially threaten an installed system or the specific type of protection that is

appropriate for a particular location. The determination of the threat to the

equipment and the means of protection are the responsibility of the end user of the

equipment and the authority having jurisdiction. The following installation drawing

for Alpha’s Standby Power systems are general recommendations and not intended

to be a specific guideline for protecting the equipment. The numbers of Bollard

posts (or other protection devices) depend upon equipment locations, site surveys,

traffic patterns and local codes.

2. Installation

PAD

POSTS

10' Min.

Sprinkler

Head

SIDEW ALK

Fig. 2-1 Post placement

17 031-178-C0-001 Rev. A

Page 18

2. Installation

2.2 Transportation and Lifting

A safe means of transportation to the site and a safe procedure for unloading the enclosure is

necessary. At least two installation personnel are required to place the enclosures on the pad.

Installation team must assess the transport path for all obstructions. An obstruction free path

should be selected for transport. Use safe lifting practices.

Approximate shipping weight:

Enclosure

UPE-3L 56 Pounds

UPE-6L 68 Pounds

Approximate

Shipping Weight

NOTE: Enclosure must always remain in the upright position during the

shipping, storage and installation process. Damage may result

from enclosure being shipped or stored on its side.

NOTE: Electronic modules, batteries or other components must not be

installed until the enclosure is securely set in place at its permanent

location.

NOTE: DO NOT lift the enclosure by the cover, unless empty.

18 031-178-C0-001 Rev. A

Page 19

2.3 Enclosure Installation

2.3.1 Attaching enclosure to the Pedestal Support or Pad

Tools Required:

Ratchet set with 6” extension.

Vapor Barrier

Utility Knife

Procedure:

2. Installation

NOTE: A 25+ year

between the enclosure and pad to prevent moisture

ingress and possible corrosion caused by metal to

concrete contact. The vapor barrier material (such as

30 lb. felt, neoprene pond liner, or heavy grade tar

paper) should initially extended at least 6" in all

directions around the perimeter of the enclosure and

later be trimmed closer to the enclosure.

1. Unwrap the enclosure and inspect the contents. If items are

missing or damaged, contact Alpha Technologies and the shipper

immediately.

2. Place the vapor barrier material on the pad.

3. Unbolt the enclosure from the shipping pallet.

4. With no less than 2 installation personnel, lift the enclosure off the

shipping pallet, and place over the mounting studs on the pad.

5. Secure the enclosure to the pad using the hardware supplied

with the Precast Pad or Pedestal Support.

6. Trim the vapor barrier material.

continuous vapor barrier

must be used

19 031-178-C0-001 Rev. A

Page 20

2. Installation

2.3 Enclosure Installation,

2.3.2 Attaching the External Coax Raceway

The external coax raceway is held in place by two tabs at the bottom of the raceway

that fit into slots at the bottom of the enclosure, and a wingnut at the top.

continued

Wing-Nut

SPI

Fig. 2-2 External Coax Raceway

SPI

External Coax

Raceway

Rear wall of UPE

Retaining Tab

20 031-178-C0-001 Rev. A

Page 21

2. Installation

2.4 Utility Power Connection

CAUTION: The “Utility Power Connection” procedure must ONLY be performed by qualified

service personnel and in compliance with local electrical codes and common

safety practices. Connection to utility power must be approved by the local

utility before installing the power supply.

NOTE: CSA and NEC require that a service disconnect switch be provided

by the installer and be connected between the power source and the ALPHA

power supply. Connection to the power supply must include an appropriate

service entrance weather head.

Wiring the Utility Service

Utility power enters the enclosure through the side or bottom of the UPE. The enclosure

accepts a standard electrical fitting. The UPE Series can be equipped with an optional circuit

breaker assembly located in the enclosure’s module compartment.

NOTE: A “high-magnetic” or HACR (Heating, Air Conditioning, Refrigeration) circuit

breaker must be used in order to accommodate the high-inrush currents

normally associated with the start-up of ferroresonant transformers

(400 Amp, no-trip, first-half cycle). Do not replace this circuit breaker with a

conventional service entrance circuit breaker. Alpha recommends Square D

circuit breakers ONLY, because of increased reliability in this powering

application.

240VAC Service (XM Series 2 915-240 Power Supply for UPE-3L and UPE-6L): Enclosures used

with the XM Series 2 915-240 is equipped with one or two 240VAC duplex receptacles to provide

power to the power supply and peripheral equipment. The receptacle, NEMA 6-15R, is protected

by a single, 2-pole, common trip 15 Amp circuit breaker located inside the service entrance.

Wiring is typically 14AWG per NEC code, a grounding clamp, located on the enclosure, facilitates

dedicated grounding.

120VAC 20A Service (XM Series 2 915-120 Power Supply):

Enclosures used with the XM Series 2 915-120 are equipped with one or two 120VAC duplex

receptacles to provide power to the power supply and peripheral equipment. The receptacle,

NEMA 5-20R, is protected by a single pole 20 Amp circuit breaker located inside the service

entrance. Wiring is typically 12AWG per NEC code, a grounding clamp, located on the enclosure,

facilitates dedicated grounding.

NOTE: Alpha recommends wiring with 12AWG, in case the enclosure is

to be upgraded from 240 VAC 15 Amp to 120 VAC 20 Amp

21 031-178-C0-001 Rev. A

Page 22

2. Installation

2.4 Utility Power Connection,

The UPE Series enclosures may be configured with the following service options. Please

contact your Alpha Technologies representative for assistance selecting the configuration

that best suits your requirements.

continued

BBX

Fig. 2-3 Service Entrance Option

22 031-178-C0-001 Rev. A

Page 23

2. Installation

2.4 Utility Power Connection,

Ground

Optional Line

Surge Arrester

continued

ON

OFF

NeutralLine 1From Utility

Utility

To Enclosure

120V

Black

Green

Alpha P/N

162-026-10

Line 2

Optional Line

Surge Arrester

120 VAC Service Entrance

NeutralLine 1Ground From Utility

ON

OFF

Utility

To Enclosure

120V

120V

240V

Green

Black

Black

Alpha P/N

162-025-10

240 VAC Service Entrance

Figure 2-4 Typical Service Entrance Wiring

23 031-178-C0-001 Rev. A

Page 24

2. Installation

2.4 Utility Power Connection,

Neutral

Ground

Line

ON

OFF

BQO, 120 VAC 20 Amp Circuit

Ground

Line2

Line1

ON

continued

OFF

BQO, 240 VAC 15 Amp Circuit

Neutral

Ground

Line2

Line1

ON

OFF

BQO, 120 / 240 VAC 15 Amp Circuit

Figure 2-5 Breaker-Quad-Option Wiring

24 031-178-C0-001 Rev. A

Page 25

2. Installation

2.4 Utility Power Connection,

continued

ON

2

0

OFF

GroundLine 2Neutralline 1

Neutral should be bonded to ground

in PRIMARY service entrance only.

240 VAC Meter Base

GroundNeutralline 1

ON

Neutral should be bonded to ground

OFF

in PRIMARY service entrance only.

120 VAC Meter Base

Figure 2-6 120 and 240VAC UL Wiring

25 031-178-C0-001 Rev. A

Page 26

2. Installation

2.4 Utility Power Connection,

continued

Coaxial Cable Connection

1. DO NOT remove SPI cover until all sources

of power have been removed. Verify SPI IS

NOT connected to power supply

2. Remove the two screws holding the cover

onto the SPI’s chassis.

3. Remove the SPI’s cover, exposing the

circuit board and seizure screw assembly.

1

Seizure

Screw

Assembly

2

3

5. Tighten the Seizure Screw to 35 Inch Pounds.

5

4. Insert the Coaxial Termination into the

Output Port on the bottom of the SPI.

Circuit

Board

Seizure Screw

Assembly

Coaxial Termination

Stinger

4

Side View

SPI Case

Output Port

of

NOTE: To prevent arcing, and failure of the

unit, the center conductor (stinger) of

the coaxial termination must go fully

inside the seizure screw assembly.

6. Replace the SPI’s cover and reinstall the

screws.

7. Verify the switch on the top of the SPI is in

the ON position.

7

6

ALT ON

6

26 031-178-C0-001 Rev. A

Page 27

2.5 Power Supply Placement

2.5.1 Placement

Place the power supply on the top shelf over the vent louvers on the right.

Do not connect any cables or connectors to the power supply at this time.

2.6 Battery Installation

2.6.1 Battery Safety

WARNING: Battery systems represent a risk of electrical shock and high short

circuit currents. The following precautions must be observed when

maintaining batteries:

• Remove all personal metal objects (watches, rings, etc.)

• Use insulated tools.

2. Installation

• Wear eye protection and rubber gloves.

• Observe circuit polarities.

• Do not make or break live circuits.

• Do not lay metal tools and hardware on top of the batteries.

The battery is enclosed in cabinets with limited access. Again, extreme caution

must be exercised when maintaining and collecting data on the battery system.

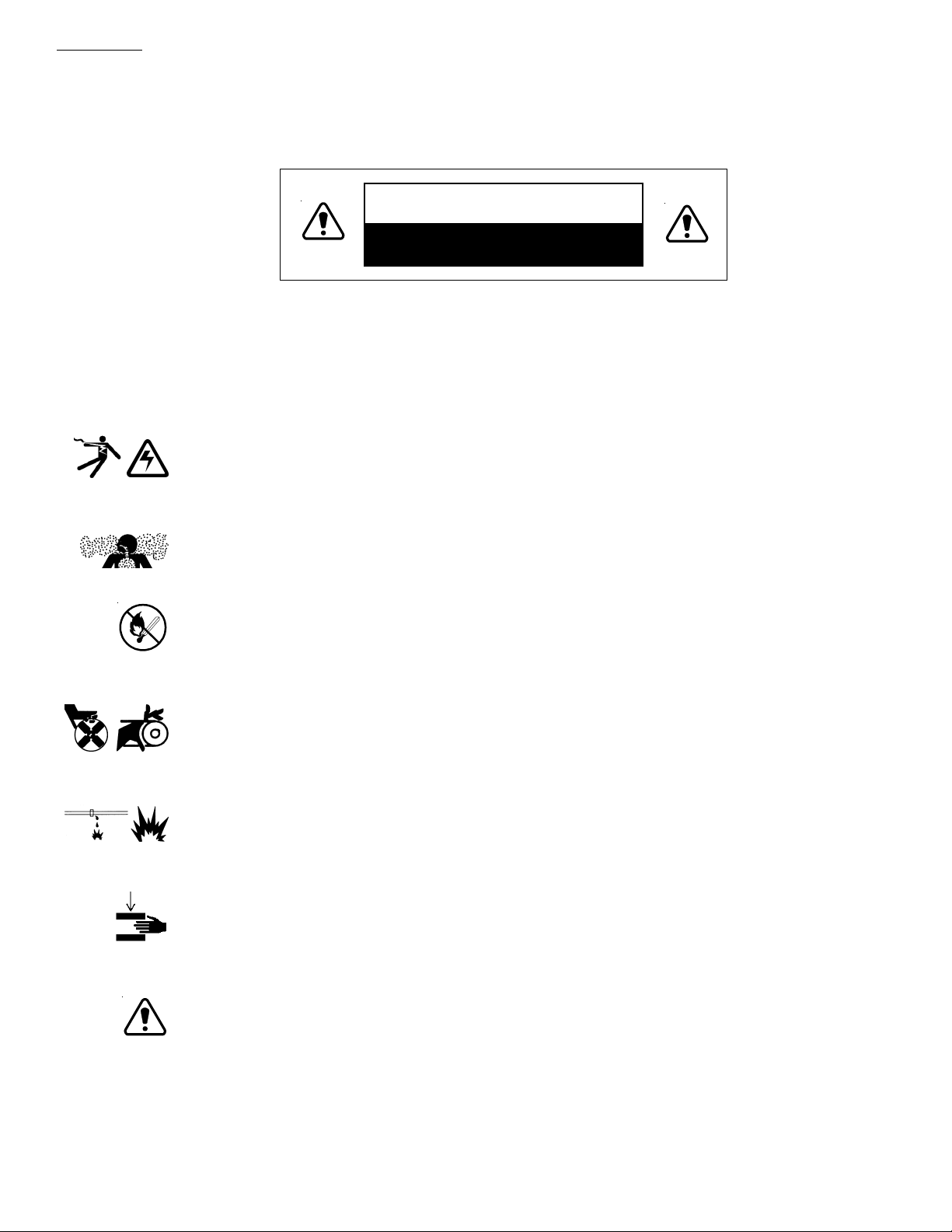

2.6.2 Battery Identification

Each battery contains a DATE CODE usually located on a sticker near the center of

the battery or stamped in white ink near the POS terminal. This date code must be

recorded in the battery’s maintenance log. If batteries other than those installed by

Alpha are used, consult the battery’s manufacturers’ documentation for date code

type and placement.

Battery Date Code

DANGER/POISON

SHIELD EYES EXPLOSIVE GASES

CAN CAUSE BLINDNESS OR INJURY

NO SPARKS, FLAMES, OR SMOKING

SULFURIC ACID CAN CAUSE

BLINDNESS OR SEVERE BURNS

CALIF. PROPOSITION 65

WARNING

Battery posts, terminals

and related accessories

contain lead and lead

compounds, chemicals

known to the state of Calif.

to cause cancer and

reproductive harm. Wash

hands after handling.

MMYY

located in this box

(0103 = Jan. 2003)

FLUSH EYES IMMEDIATELY WITH WATER

GET MEDICAL HELP FAST. KEEP OUT OF REACH OF CHILDERN

Fig. 2-7 Battery Hazard Warning Label

27 031-178-C0-001 Rev. A

Page 28

2. Installation

2.6 Battery Installation,

2.6.3 Battery Terminal Connections

The accompanying drawings are for

with different mounting styles and hardware may be shipped with the system. ALWAYS

refer to the battery manufacturers’ specifications for correct mounting hardware and torque

requirements. During maintenance procedures, refer to the manufacturers' specifications

for the maintenance torque requirements.

For AlphaCell batteries, use 65 Inch-Pounds upon installation, torque to 50 Inch-Pounds

during maintenance.

A corrosion inhibitor should be used on all bare metal connections and crimps

Mounting hardware requirements may vary with battery manufacturers. Use only the

hardware recommended by your particular battery manufacturer.

Battery Post

continued

illustrative

purposes only. Various types of batteries

Battery Cable to Next

Battery

3/8" Spacer

Flat Washer

Lock Washer

Nut

Fuse

Fig. 2-8 Battery Terminal Connections

28 031-178-C0-001 Rev. A

Page 29

2. Installation

2.6 Battery Installation,

2.6.4 Battery Connection

Tools Needed:

Two 7/16” open end wrenches

DC Voltmeter

Torque wrench 0-100 In-Lbs

Battery Cable Kit - For part numbers and descriptions of Cable Kits,

Procedure:

For UPE-3L:

1. Unlatch and slide the battery tray out to the stops.

2. Install three batteries, position batteries as shown in Fig. 2-5.

3. Wire in accordance with Fig. 2-5. Torque connections to manufacturers

recommendation. Apply corrosion inhibitor to terminals and connections.

DANGER: Battery drawer slides may be damaged if drawer is forced into enclosure

while slide latch is engaged.

continued

Please refer to the power supply Order Guide

4. Unlatch and slide the tray evenly into the enclosure.

5. Using a DC Meter, measure the voltage at the power supply connector,

verify that the voltage is between 36 and 40.5 VDC.

6. DO NOT connect the battery pack to the power supply at this time.

For UPE-6L:

1. Unlatch and slide the upper battery tray out to the stops.

2. Install three batteries, position batteries as shown in Fig 2-6.

3. Wire in accordance with Fig. 2-6. Torque connections to manufacturers

recommendations. Apply corrosion inhibitor to terminals and connections.

DANGER: Battery drawer slides may be damaged if drawer is forced into enclosure

while slide latch is engaged.

4. Unlatch and slide the upper battery tray evenly into the enclosure.

5. Unlatch and slide the lower battery tray out to the stops.

6. Install three batteries, position batteries as shown in Fig 2-6.

7. Wire in accordance with Fig. 2-6.

8. Unlatch and slide the lower battery tray evenly into the enclosure.

9. Using a DC Meter, measure the voltage at the power supply connector,

verify that the voltage is between 36 and 40.5 VDC.

10. DO NOT connect the battery pack to the power supply at this time.

29 031-178-C0-001 Rev. A

Page 30

2. Installation

2.6 Battery Installation,

RTS

Probe

Fig. 2-9 UPE-3L Battery Placement

continued

1A

12V

2A

3A

24V 36V

RTS

Probe

Upper Shelf

Lower Shelf

1A

12V

1B

12V

2A

3A

24V 36V

2B

3B

24V 36V

Fig. 2-10 UPE-6L Battery Placement

30 031-178-C0-001 Rev. A

Page 31

2.7 Battery Temperature Sensor

Tools Needed:

Adhesive Tape

Procedure:

NOTE: For enclosures with multiple battery strings, the RTS must be located

with the warmest (normally the topmost) battery string. This ensures proper

operation of the battery charger’s temperature compensation circuit. Failure to

locate the RTS with the warmest battery string could result in overcharging and

premature battery failure.

1. Attach the RTS Probe to the inner side of battery 2A with adhesive tape.

2. The other side of the RTS Probe is attached to the front panel of the

XM2 power supply, in the jack labeled TEMP PROBE.

2. Installation

Fig. 2-11 RTS Placement

31 031-178-C0-001 Rev. A

Page 32

2. Installation

2.8 Lightning and Surge Arrester Options

Alpha’s LA Series voltage suppressors provide reliable protection of power supplies and

related equipment from the damaging powerline disturbances common to cable TV and

broadband applications. The LA Series incorporates MOV’s that effectively limit voltage

surges and absorb excessive energy levels. Housed in a durable polymer casings with

standard electrical plugs, the LA Series plugs directly into any electrical outlet.

NOTE: LED On - Operation Normal, LED Off - LAP has failed, Replace LAP

LA - P PLUS

120VAC 20A 50/60Hz

RATED AMBIENT 55 C MAX

P/N 020-098-24

R

REPLACE UNIT WHEN

LAMP BE COMES DIM

OR IS OUT

P/N 020-098-24

R

LED

LA - P PLUS

240VAC 20A 50/60Hz

RATED AMBIENT 55 C MAX

P/N 020-098-25

R

R

REPLACE UNIT WHEN

LAMP BECOMES DIM

OR IS OUT

P/N 020-098-25

LED

Fig. 2-12 LAP Plus

This hard-wired surge arrester is designed to protect against lightning induced surges for

electrical equipment and wiring. When installed, the arrester will quickly divert to ground the

lightning surges attempting to enter your electrical system. Refer to Fig.2-2 for wiring. The

surge protector is designed to handle repetitive operations. Excessive severe lightning can

cause the device to fail, and it should be replaced under the following conditions: If any

portion of the indicating window is black, of if the indicating window is completely black.

P/N 162-026-10 (120V)

P/N 162-025-10 (240V)

Fig. 2-13 Line Surge Arrester

32 031-178-C0-001 Rev. A

Page 33

2.9 Battery Heater Mat, and LRI-ACI Lamp Option

Battery Heater Mat Option

Battery Heater Mats are designed to increase battery capacity in cold environments. To install the

mats:

1. Remove the batteries from the tray(s).

2. Place the heater mat in the bottom of the tray(s).

3. Replace the batteries.

4. Plug the AC line cord into the closest receptacle.

The heater mat is thermally fused at 180o F. The thermostat is set to open on rise at 50o F, and close

at 40o F.

LRI Option

The LRI lamp (red lamp) is located on the outside, on either the right or left side of the enclosure. The

lamp comes ON only when the power supply is running on backup power (STANDBY). During

normal AC line operation, the lamp remains OFF. Whenever a fault is detected, the lamp flashes to

indicate that service is required. The LRI can be used as a simple form of status monitoring by

allowing cable technicians to check the operational status of the power supply without having to

climb the pole and open the enclosure. Connect the LRI lamp to the jack on the front of the power

supply labeled LRI.

2. Installation

ACI Option

The AC indicator (green lamp) is located on the outside, on either the right or left of the enclosure.

When the lamp is ON, it indicates AC power is available at the power supply output. This allows a

cable technician to drive by and determine the status of the power supply without having to climb the

pole. Connect one connector of the ACI lamp to the OUTPUT 1 jack on the front of the power supply,

and the other to the SPI.

LRI Lamp ACI Lamp SPI

'Output 1'

'LRI'

ACI Lamp

WHT

WHT

BLK

BLK

Enclosure

Wall

Fig. 2-14 ACI/LRI Wiring

LRI Lamp

RE

D

BL

K

33 031-178-C0-001 Rev. A

Page 34

2. Installation

2.10 Enclosure Door Tamper Switch Option

Tamper Switch

The Tamper Switch is located on the edge of the power supply shelf, opposite the power supply. The

switches are available in Normally Closed (P/N 740-216-21) and Normally Open (740-216-26). The

USM2, USM-2.5, or DSM options are required to monitor the Tamper Switch.

Tamper Switch

Magnet

Tamper Switch

Sensor

Fig. 2-15 Tamper Switch Wiring

34 031-178-C0-001 Rev. A

Page 35

Page 36

Page 37

Alpha Technologies

Power

®

Corporate

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: (360) 647-2360

Fax: (360) 671-4936

Web: www.alpha.com

Alpha Technologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: (604) 430-1476

Fax: (604) 430-8908

Alpha Technologies

Europe Ltd.

Cartel Business Estate

Edinburgh Way

Harlow, Essex CM20 2TT

UNITED KINGDOM

Tel: +44-1279-422110

Fax: +44-1279-423355

Alpha Technologies

Hansastrasse 8

D-91126 Schwabach

GERMANY

Tel: +49-9122-79889-0

Fax: +49-9122-79889-21

Alphatec

339 St. Andrews Street

Suite 101

Andrea Chambers

Limassol, Cyprus

CYPRUS

Tel: +357-25-375675

Fax: +357-25-359595

Alpha Technologies

Unit R5-R7 Regents Park Estate

Corner Park Rd and Prince’s Rd East

Regents Park, NSW 2143

AUSTRALIA

Tel: +61-2-9722-3320

Fax: +61-2-9722-3321

Copyright © 2003 by Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 031-178-C0-001 Rev. A.

Due to continuing product improvements, Alpha reserves the right to change specifications without notice.

Loading...

Loading...