Page 1

Round Security Bar

Field Installation Manual

UPE-3, UPE-6, UPE-M3, UPE-M6, PN, CE and FPE Series,Enclosures

Effective: October, 2013

Page 2

Safety Notes

Review the drawings and illustrations contained in this document before proceeding. If there are any questions regarding

the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha representative. Save this

document for future reference.

To reduce the risk of injury or death and to ensure the continued safe operation of this product, the following symbols have

been placed throughout this manual. Where these symbols appear, use extra care and attention.

WARNING! ELECTRICAL HAZARD

ELECTRICAL HAZARD WARNING provides electrical safety information to PREVENT

INJURY OR DEATH to the technician or user.

WARNING! FUMES HAZARD

FUMES HAZARD WARNING provides fumes safety information to PREVENT INJURY OR

DEATH to the technician or user.

WARNING! FIRE HAZARD

FIRE HAZARD WARNING provides ammability safety information to PREVENT INJURY OR

DEATH to the technician or user.

There may be multiple warnings associated with the call out. Example:

WARNING! ELECTRICAL & FIRE HAZARD

This WARNING provides safety information for both Electrical AND Fire Hazards

CAUTION!

CAUTION provides safety information intended to PREVENT DAMAGE to material or equipment.

NOTE:

NOTE provides additional information to help complete a specic task or procedure.

ATTENTION:

ATTENTION provides specic regulatory/code requirements that may affect the placement of equipment and /or

installation procedures.

The following sections contain important safety information that must be followed during the installation and maintenance

of the equipment and batteries. Read all of the instructions before installing or operating the equipment, and save this

manual for future reference.

Page 3

Round Security Bar Field Installation Manual

UPE-3, UPE-6, UPE-M3, UPE-M6, PN, CE and FPE Series Enclosures

745-847-C1-001, Rev. B

Effective Date: October, 2013

Copyright 2013

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

this installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or the nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

TM

Contacting Alpha Technologies: www.alpha.com

For general product information and customer service (7 AM to 5 PM, Pacic Time), call

7 AM to 5 PM, Pacic Time or 24/7 emergency support

745-847-C1-001 Rev. B (10/2013)

or

1-800-863-3930

For complete technical support, call

1-800-863-3364

3

Page 4

Table of Contents

Safety Notes ....................................................................................................................................................... 5

1.0 Introduction ............................................................................................................................................... 6

1.1 Parts List ......................................................................................................................................... 6

1.2 Required Tools ................................................................................................................................ 6

2.0 Installation ................................................................................................................................................. 7

2.1 Dimensioned Enclosure Drawings .................................................................................................. 9

2.1.1 CE-3G ....................................................................................................................................... 9

2.1.2 CE-3X2 ................................................................................................................................... 10

2.1.3 CE-9G ......................................................................................................................................11

2.1.4 CE-9X2 ................................................................................................................................... 12

2.1.5 PN-3 ....................................................................................................................................... 13

2.1.6 PN-4 ....................................................................................................................................... 14

2.1.7 UPE-3 ..................................................................................................................................... 15

2.1.8 UPE-M3 .................................................................................................................................. 16

2.1.9 UPE-6 ..................................................................................................................................... 17

2.1.10 UPE-M6 .................................................................................................................................. 18

2.1.11 FPE ......................................................................................................................................... 19

Figures and Tables

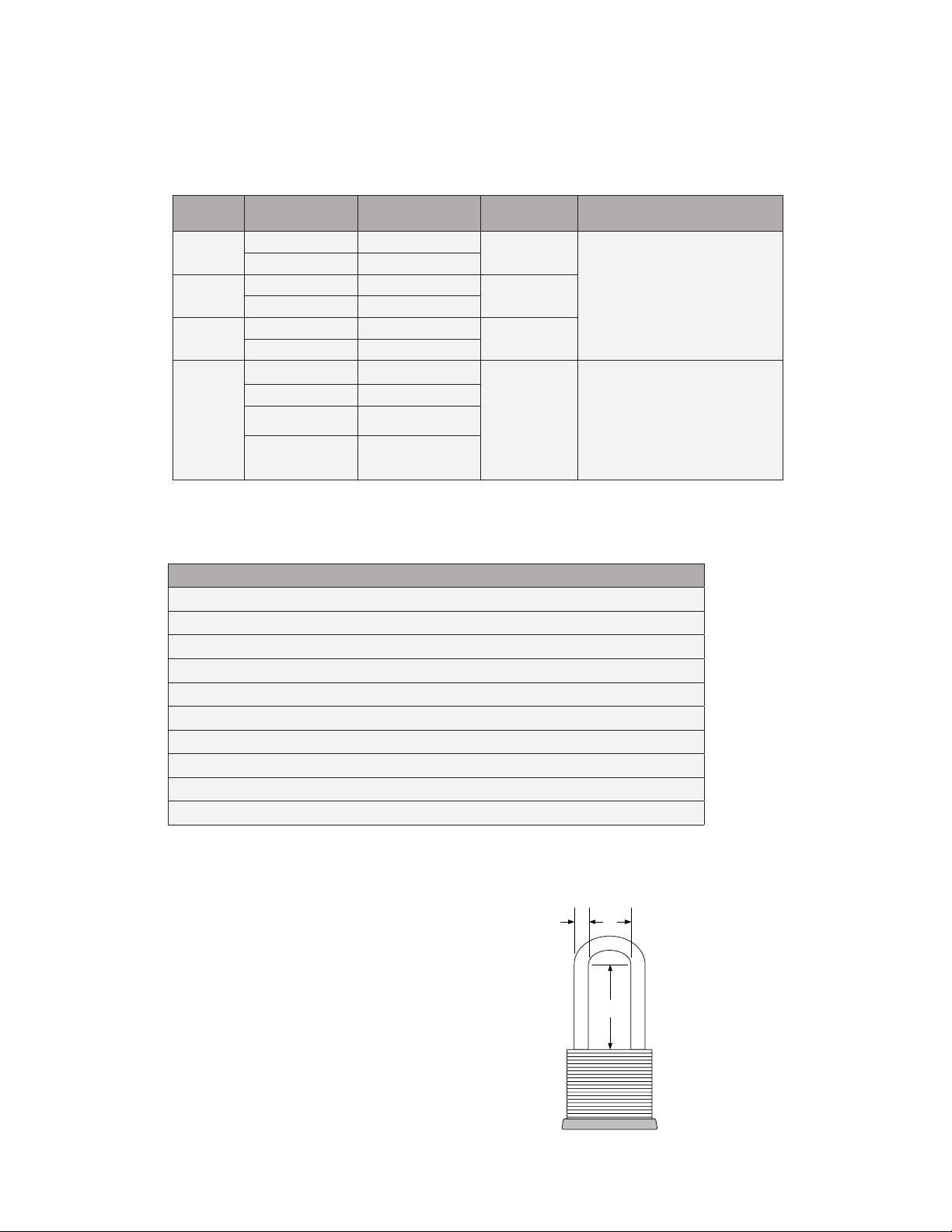

Fig. 1-1 Security Lock Dimensions ............................................................................................................... 6

Fig. 2-1 Marking Guide Lines ...................................................................................................................... 7

Fig. 2-2 Drill Holes ....................................................................................................................................... 7

Fig. 2-3 Side Bracket Assembly ................................................................................................................... 8

Fig. 2-4 Lock Bracket Assembly ................................................................................................................... 8

Fig. 2-5 Installation of the Lock Shroud on the Security Bar ........................................................................ 8

Fig. 2-6 CE-3G Enclosure Hole Locations ................................................................................................... 9

Fig. 2-7 CE-3X2 Enclosure Hole Locations ............................................................................................... 10

Fig. 2-8 CE-9G Enclosure Hole Locations ..................................................................................................11

Fig. 2-9 CE-9X2 Enclosure Hole Locations ................................................................................................ 12

Fig. 2-10 PN-3 Enclosure Hole Locations .................................................................................................... 13

Fig. 2-11 PN-4 Enclosure Hole Locations .................................................................................................... 14

Fig. 2-12 UPE-3 Enclosure Hole Locations .................................................................................................. 15

Fig. 2-13 UPE-M3 Enclosure Hole Locations .............................................................................................. 16

Fig. 2-14 UPE-6 Enclosure Hole Locations ................................................................................................. 17

Fig. 2-15 UPE-M6 Enclosure Hole Locations .............................................................................................. 18

Fig. 2-16 FPE Enclosure Dimple Locations ................................................................................................. 19

Table 1-1 Enclosure Part List and Component Descriptions .......................................................................... 6

Table 1-2 Installation Tools .............................................................................................................................. 6

4

745-847-C1-001 Rev. B (10/2013)

Page 5

Round Security Bar Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions regarding the

safe installation or operation of this product, contact Alpha Technologies or the nearest Alpha representative. Save this

document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following symbols

have been placed throughout this manual. Where these symbols appear, use extra care and attention.

WARNING! ELECTRICAL HAZARD

Electrical shock can KILL. Disconnect and remove or protect all electrical equipment within

the enclosure before drilling into the enclosure.

WARNING! FIRE HAZARD

CE Model Enclosures have integrated gas lines near the enclosure door jam. Turn off the gas

before installing the enclosure and ensure all drilling locations will not damage the gas lines

before proceeding.

CAUTION!

Drilling swarf can cause laceration and puncture wounds to eyes and skin. NEVER remove drilling swarf

with bare hands. Always wear safety glasses and gloves, and use a vacuum cleaner or brush to remove

swarf from within the enclosure.

745-847-C1-001 Rev. B (10/2013)

5

Page 6

1.0 Introduction

B

A

C

Each security bar kit contains the parts and accessories needed to secure one enclosure door. If the enclosure

has both a front and back door, it will require two kits, with exception of the FPE.

1.1 Parts List

Enclosure Color Alpha Part Number

UPE

PN

CE

FPE

Seafoam Green 745-847-20

Gray 745-847-21

Seafoam Green 745-847-20

Gray 745-847-21

Seafoam Green 745-847-20

Gray 745-847-21

Seafoam Green 745-847-22

Gray 745-847-23

Pine Green 745-847-24

White 745-847-25

Table 1-1, Enclosure Part List and Component Descriptions

1.2 Required Tools

Installation tools:

Tape measure

Masking tape

1/2" drive hand drill

Center punch

7/16" socket and socket wrench

Size "K" (9/32") drill bit

4 foot level

Pencil

Utility knife

Vacuum to remove metal shavings from enclosure interior

# of Required

Kits

1

2

2

1

Kit Components Description (Qty)

• Lock Bracket (2)

• Side Bracket (4)

• Security Bar (2)

• Lock Guard (2)

• Carriage Bolt 1/4"-20X3/4" (12)

• Lock Washer 1/4" (12)

• Flat Washer 1/4" (12)

• Hex Nut 1/4"-20 (12)

• Lock Bracket (4)

• Side Bracket (8)

• Security Bar (4)

• Lock Guard (4)

• Carriage Bolt 1/4"-20X3/4" (24)

• Lock Washer 1/4" (24)

• Flat Washer 1/4" (24)

• Hex Nut 1/4"-20 (24)

Table 1-2, Installation Tools

In addition:

To secure the enclosure, each bar requires a

security lock. Each user-supplied lock must meet

the following dimensions:

Where:

A = 5/16"

B = 3/4"

C = 2 1/2"

Fig. 1-1, Security Lock Dimensions

6

745-847-C1-001 Rev. B (10/2013)

Page 7

2.0 Installation

This procedure applies to each of the supported enclosures. Refer to Section 2.1 Dimensioned Enclosure

Drawings for specic information pertaining to the enclosure onto which the kit(s) will be installed.

All enclosures require installation of both side brackets and lock brackets. The side brackets hold the security bar,

and the lock brackets hold the security lock (refer to Figures 2-3 and Figure 2-4).

WARNING! FIRE HAZARD

A gas line runs behind the door jamb on the 5K generator enclosure (CE Series). Turn off the gas prior

to installing the security bar. Be careful not to puncture or damage the line. Upon completion of the

installation procedure, turn gas on and perform a leak test before leaving the site.

1. Use a 4-ft level to mark the front of the enclosure at the

height indicated for the enclosure (see Fig. 2-1).

2. Measure from the sides and mark the holes with a center

punch. These will be the top holes used by the side

brackets.

3. Remove the door.

4. Place cardboard or a similar material behind the door jamb

to protect the electronic equipment from the metal shavings

created while drilling. Use a vacuum cleaner to remove the

shavings when drilling is complete.

5. Drill the holes using a 9/32" drill bit.

Fig. 2-1, Marking Guide Lines

Drill Holes

See Diagrams

for Specic

Dimensions

Fig. 2-2, Drill Holes

6. Line up the top hole of the side bracket with the hole drilled in the enclosure in step 5. The side bracket

provides a template to accurately mark the bracket’s bottom hole locations.

7. Mark the bottom holes with the center punch.

8. Drill the bottom holes of the side brackets using a 9/32" drill bit.

9. On the door removed in step 3, measure and mark the top hole locations for the lock brackets and drill using

a 9/32" drill bit.

10. Line up the top hole of the lock bracket with the hole drilled in the door in step 9. The lock bracket acts as a

template.

11. Mark the locations of the bottom holes with the center punch and using a 9/32" drill bit, drill the bottom holes.

Guide Line

Drill

Holes

NOTE:

Where necessary, use the utility knife to trim and remove insulation from inside the door.

745-847-C1-001 Rev. B (10/2013)

7

Page 8

2.0 Installation

12. Use the hardware provided to mount the side brackets and lock brackets to the enclosure and to the door.

Fig. 2-3, Side Bracket Assembly

(enclosure door/sides removed for clarity)

NUT 1/4"-20 (2 PLACES)

LOCK WASHER 1/4" (2 PLACES)

FLAT WASHER 1/4" (2 PLACES)

ENCLOSURE DOOR

LOCK BRACKET

CARRIAGE BOLT

1/4"-20 X 3/4"

Fig. 2-4, Lock Bracket Assembly

13. To secure, slide lock guard over bracket, insert lock into guard, slide bar through the opening and close lock.

LOCK GUARD

LOCK BAR

LOCK

Fig. 2-5, Installation of the Lock Shroud on the Security Bar

8

745-847-C1-001 Rev. B (10/2013)

Page 9

2.0 Installation

2.1 Dimensioned Enclosure Drawings

The dimensioned enclosure drawings in this section provide specic hole placement locations for the

Security Bar bracket mounting hardware.

2.1.1 CE-3G

WARNING! FIRE HAZARD

CE Model Enclosures have integrated gas lines near the enclosure door jam. Turn off the gas

before installing the enclosure and ensure all drilling locations will not damage the gas lines

before proceeding.

2 1/8"

25 7/8"

Side Brackets

Location of bracket mounting holes

Lock Bracket

2 9/16"

25 7/16"

2 1/8"

9 1/16"

11/16"

11/16"

745-847-C1-001 Rev. B (10/2013)

1 1/16"

11/16"

11/16"

11 7/16"

Fig. 2-6, CE-3G Enclosure Hole Locations

All dimensions in inches.

2 9/16"

5 11/16"

11/16"

9

Page 10

2.0 Installation

FRONT VIEW

BACK VIEW

2.1 Dimensioned Enclosure Drawings, continued

2.1.2 CE-3X2

WARNING! FIRE HAZARD

CE Model Enclosures have integrated gas lines near the enclosure door jam. Turn off the gas

before installing the enclosure and ensure all drilling locations will not damage the gas lines

before proceeding.

Alternate Mounting position

when used with shrouded door

CE-3X2 with Security Option

2 1/8"

25 7/8"

2 1/8"

9 1/16"

Location of bracket mounting holes

ALTERNATE MOUNTING POSITION

2 9/16"

25 7/16"

2 9/16"

5 11/16"

10

11/16"

11 7/16"

4 9/16"

11/16"

11 7/16"

11/16"

Fig. 2-7, CE-3X2 Enclosure Hole Locations

All dimensions in inches.

1 1/16"

11/16"

745-847-C1-001 Rev. B (10/2013)

Page 11

2.0 Installation

FRONT VIEW BACK VIEW

2.1 Dimensioned Enclosure Drawings, continued

2.1.3 CE-9G

WARNING! FIRE HAZARD

CE Model Enclosures have integrated gas lines near the enclosure door jam. Turn off the gas

before installing the enclosure and ensure all drilling locations will not damage the gas lines

before proceeding.

2 1/8"

33 7/8"

2 1/8"

9 1/16"

Location of bracket mounting holes

2 9/16"

33 7/16"

2 9/16"

5 11/16"

11 7/16"

11/16"

1 1/16"

11/16"

Fig. 2-8, CE-9G Enclosure Hole Locations

All dimensions in inches.

745-847-C1-001 Rev. B (10/2013)

11/16"

11 7/16"

11/16"

11

Page 12

2.0 Installation

2.1 Dimensioned Enclosure Drawings, continued

2.1.4 CE-9X2

WARNING! FIRE HAZARD

CE Model Enclosures have integrated gas lines near the enclosure door jam. Turn off the gas

before installing the enclosure and ensure all drilling locations will not damage the gas lines

before proceeding.

2 1/8"

32 7/8"

2 1/8"

9 1/16"

Location of bracket mounting holes

2 9/16"

32 7/16"

2 9/16"

5 11/16"

12

11/16"

11 7/16"

FRONT VIEW

Fig. 2-9, CE-9X2 Enclosure Hole Locations

11/16"

11/16"

All dimensions in inches.

11 15/32"

BACK VIEW

745-847-C1-001 Rev. B (10/2013)

11/16"

1 1/32"

Page 13

2.0 Installation

FRONT VIEW BACK VIEW

2.1 Dimensioned Enclosure Drawings, continued

2.1.5 PN-3

2 1/8"

25 7/8"

2 1/8"

9 1/16"

Location of bracket mounting holes

2 9/16"

25 7/16"

2 9/16"

5 11/16"

11/16"

11 7/16"

745-847-C1-001 Rev. B (10/2013)

1 1/16"

11/16"

11/16"

11 7/16"

Fig. 2-10, PN-3 Enclosure Hole Locations

All dimensions in inches.

11/16"

13

Page 14

2.0 Installation

2.1 Dimensioned Enclosure Drawings, continued

2.1.6 PN-4

Location of bracket mounting holes

2 1/8"

32 7/8"

2 1/8"

9 1/16"

11/16"

11 7/16"

1 1/16"

11/16"

11/16"

11 7/16"

2 1/8"

32 7/16"

2 9/16"

5 11/16"

11/16"

14

FRONT VIEW BACK VIEW

Fig. 2-11, PN-4 Enclosure Hole Locations

All dimensions in inches.

745-847-C1-001 Rev. B (10/2013)

Page 15

2.0 Installation

FRONT VIEW

2.1 Dimensioned Enclosure Drawings, continued

2.1.7 UPE-3

Location of bracket mounting holes

2 1/8"

16 7/8"

2 1/8"

10 1/16"

7/16"

11 7/8"

2 9/16"

16 7/16"

2 9/16"

7 11/16"

7/16"

745-847-C1-001 Rev. B (10/2013)

Fig. 2-12, UPE-3 Enclosure Hole Locations

All dimensions in inches.

15

Page 16

2.0 Installation

FRONT VIEW

2 9/16

"

15 3/16

"

2 9/16

"

6 11/16

"

7/16

"

7/16

"

11 15/16

"

9 1/16

"

2 1/8

"

15 5/8

"

2 1/8

"

2.1 Dimensioned Enclosure Drawings, continued

2.1.8 UPE-M3

Location of bracket mounting holes

Fig. 2-13, UPE-M3 Enclosure Hole Locations

All dimensions in inches.

745-847-C1-001 Rev. B (10/2013)

16

Page 17

2.0 Installation

FRONT VIEW

2.1 Dimensioned Enclosure Drawings, continued

2.1.9 UPE-6

Location of bracket mounting holes

2 1/8"

26 7/8"

2 1/8"

10 1/16"

2 9/16"

26 7/16"

2 9/16"

7 5/8"

7/16"

745-847-C1-001 Rev. B (10/2013)

11 7/8"

7/16"

Fig. 2-14, UPE-6 Enclosure Hole Locations

All dimensions in inches.

17

Page 18

FRONT VIEW

2 1/8"

28 1/8"

2 1/8"

9 1/16"

7/8"

7/8"

11 15/16"

6 11/16"

2 9/16"

2 9/16"

27 11/16"

2.0 Installation

2.1 Dimensioned Enclosure Drawings, continued

2.1.10 UPE-M6

18

Fig. 2-15, UPE-M6 Enclosure Hole Locations

All dimensions in inches.

745-847-C1-001 Rev. B (10/2013)

Page 19

2.0 Installation

FRONT VIEW

18"

2 1/8"

25"

2 1/8"

10 1/16"

3/4"

17 1/4"

7 5/8"

7 1/2"

2 9/16"

26 7/16"

2 9/16"

3/4"

28 3/8"

2.1 Dimensioned Enclosure Drawings, continued

2.1.11 FPE

Location of bracket mounting dimples/drill locations

Fig. 2-16, FPE Enclosure Dimple Locations

All dimensions in inches; dimensions are for reference purposes.

745-847-C1-001 Rev. B (10/2013)

19

Page 20

Alpha Technologies Inc.

3767 Alpha Way

Bellingham, WA 98226

United States

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Alpha Technologies Ltd.

7700 Riverfront Gate

Burnaby, BC V5J 5M4

Canada

Tel: +1 604 436 5900

Fax: +1 604 436 1233

Toll Free: +1 800 667 8743

Alpha Industrial Power Inc.

1075 Satellite Blvd NW,

Suite 400

Suwanee, GA 30024

United States

Tel: +1 678 475 3995

Fax: +1 678 584 9259

Alpha Energy

1628 W Williams Drive

Phoenix, AZ 85027

United States

Tel: +1 602 997 1007

Fax: +1 623 249 7833

Alpha Technologies Europe Ltd.

Twyford House Thorley

Bishop’s Stortford

Hertfordshire, CM22 7PA

United Kingdom

Tel: +44 1279 501110

Fax: +44 1279 659870

Alpha Technologies

Suite 1903, Tower 1

33 Canton Road

Hong Kong, China

Phone: +852 2736 8663

Fax: +852 2199 7988

Alpha Technologies GmbH

Hansastrasse 8

D-91126

Schwabach, Germany

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec Ltd.

339 St. Andrews St.

Suite 101 Andrea Chambers

P.O. Box 56468

3307 Limassol, Cyprus

Tel: +357 25 375 675

Fax: +357 25 359 595

Alpha Innovations Brasil

Avenida Ibirapuera,

2120 – Cj 76

Moema - 04028-001

Santos SP, Brazil

Tel: +55 11 2476 0150

Fax: +55 11 2476 0150

Technologies Argus

First de Mexico

Anatole France Num. 17

Colonia Polanco

11560, México D.F.

Tel: +52 55 5280 6990

Alpha TEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1, Ofce 403

Moscow, 109028

Russia

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltic

S. Konarskio Street 49-201

Vilnius, LT-03123

Lithuania

Tel: +370 5 210 5291

Fax: +370 5 210 5292

Visit us at www.alpha.com

Due to continuing product development, Alpha Technologies reserves the right to change specications without notice.

Copyright © 2013 Alpha Technologies. All Rights Reserved. Alpha® is a registered trademark of Alpha Technologies.

745-847-C1-001 Rev. B (10/2013)

Loading...

Loading...