Page 1

Underground Battery Vault

Site Preparation and Installation

Effective: August 2006

Alpha Technologies

Page 2

Alpha Technologies

Power

®

Page 3

Underground Battery Vault

Site Preparation and Installation

031-040-B0-002 Rev. B

Effective Date: August 2006

Copyright

© 2006

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

TM

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

031-040-B0-002 Rev. B

Contacting Alpha Technologies: www.alpha.com

or

1-800-863-3930

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacifi c Time and24/7 emergency support

3

Page 4

Contents

Safety Notes ..........................................................................................................................5

Battery Safety Notes..............................................................................................................6

Mechanical Safety ................................................................................................................. 6

1. INTRODUCTION ...............................................................................................................8

1.1 Underground Battery Vault .......................................................................................................8

2. INSTALLATION .................................................................................................................9

2.1 Site Prep and Installation ..........................................................................................................9

2.2 Battery Placement .................................................................................................................. 10

2.3 Battery Connection ................................................................................................................. 12

2.4 Battery Covers ........................................................................................................................ 18

2.4.1 Installing the Battery covers ............................................................................................. 19

2.5 Temperature Sensor ............................................................................................................... 21

List of Figures

Fig. 1-1 Underground Battery Vault (UBV) ............................................................................................ 8

Fig. 2-1 Typical Site for UBV ................................................................................................................. 9

Fig. 2-2 Terminal Connection without Battery Sense Wiring ...............................................................12

Fig. 2-3 Terminal Connection with Battery Sense Wiring ....................................................................13

Fig. 2-4 AG-CMT-3SC Wiring for Single 36V Battery String ................................................................ 14

Fig. 2-5 AG-CMT-3SC Wiring for Dual 36V Battery String ..................................................................15

Fig. 2-6 AG-CMT-4SC Wiring for Single 48V Battery String ................................................................ 16

Fig. 2-7 AG-CMT-4SC Wiring for Dual 48V Battery String ..................................................................17

Fig. 2-8 165 GXL Battery Cover .......................................................................................................... 18

Fig. 2-9 180 GXL Battery Cover .......................................................................................................... 18

Fig. 2-10 165 AGM Battery with Cover in Place ..................................................................................20

Fig. 2- 11 180 GXL Battery with Cover in Place .................................................................................. 20

Fig. 2-12 Location of Temperature Probe on Battery ........................................................................... 21

Fig. 2-13 Temp Probe Connector ........................................................................................................ 21

4

031-040-B0-002 Rev. B

Page 5

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

WARNING!

Any gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contains dilute sulfuric acid,

which is harmful to the skin and eyes. Emissions are electrolytic and are electrically conductive and corrosive.

Chemical Hazards

To avoid injury:

Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

•

knowledgeable of batteries and the required safety precautions.

Always wear eye protection, rubber gloves, and a protective vest when working near batteries. To avoid

•

battery contact, remove all metallic objects, (such as rings or watches), from your person.

Batteries produce explosive gases. Keep all open fl ames and sparks away from batteries.

•

Use tools with insulated handles, do not rest any tools on top of batteries.

•

Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects

•

or other reproductive harm. Battery post terminals and related accessories contain lead and lead

compounds. Wash hands after handling (California Proposition 65).

If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your

•

company’s approved chemical exposure procedures.

•

Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with

a solution of one pound bicarbonate of soda to one gallon of water. Report a chemical spill using your

company’s spill reporting structure and seek medical attention if necessary.

Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

•

Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

•

developed on your body.

Use special caution when connecting or adjusting battery cabling. An improperly or unconnected battery

•

cable can make contact with an unintended surface that can result in arcing, fi re, or a possible explosion.

A battery showing signs of cracking, leaking, or swelling should be replaced immediately by authorized

•

personnel using a battery of identical type and rating.

031-040-B0-002 Rev. B

5

Page 6

Safety Precautions, continued

• Do not allow live battery wires to contact the enclosure chassis. Shorting battery wires can result in a fi re

or possible explosion.

• Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Avoid using uninsulated tools or other conductive materials when handling batteries or working inside the

enclosure.

• Remove all rings, watches and other jewelry before servicing batteries.

• Spent or damaged batteries are environmentally unsafe. Always recycle used batteries. Refer to

local codes for proper disposition of batteries

Battery Safety Notes

• Always refer to the battery manufacturer’s recommendation for selecting correct “FLOAT” and “ACCEPT”

charge voltages. Failure to do so can damage the batteries.

• Verify the Power Supply’s battery charger “FLOAT” and “ACCEPT” charger voltage settings.

• Batteries are temperature sensitive. During extremely cold conditions, a battery’s charge acceptance is

reduced and requires a higher charge voltage; during extremely hot conditions, a battery’s charge

acceptance is increased and requires a lower charge voltage. To compensate for changes in temperature,

the battery charger used in the power supply is temperature compensating. Refer to Section 2.5 for

instructions on connecting the Remote Temperature Sensor (RTS).

• If the batteries appear to be overcharged or undercharged, fi rst check for defective batteries and then

verify the correct charger voltage settings.

• To ensure optimum performance, inspect batteries every three to six months for signs of cracking,

leaking, or unusual swelling (note that some swelling is normal).

• Check battery terminals and connecting wires. Clean battery terminal connectors periodically and

retighten to approximately 50 inch-pounds. Spray the terminals with an approved battery terminal

coating such as NCP-2.

Mechanical Safety

Power supplies can reach extreme temperatures under load.

•

Use caution around sheet metal components, especially sharp edges.

•

Depending on the model, batteries can weigh anywhere from 25 to 100 pounds. Exercise care when

•

handling and moving batteries. Use proper handling equipment.

6

031-040-B0-002 Rev. B

Page 7

IMPORTANT INSTALLATION NOTES

THE SYSTEM SHOULD BE INSTALLED ONLY BY QUALIFIED SERVICE PERSONNEL.

ALWAYS CONSULT LOCAL CODES FOR CONCRETE PAD REQUIREMENTS.

CONSULT LOCAL UTILITY CODES FOR ADDITIONAL CABINET GROUNDING AND UTILITY REQUIREMENTS.

CONSULT THE LOCAL GAS COMPANY FOR CORRECT METER TYPE AND RISER LOCATION.

THE ENCLOSURE SHOULD BE INSTALLED ABOVE FLOOD ZONES WHENEVER POSSIBLE.

THE PAD MUST BE AT LEAST 6” THICK AND CAPABLE OF HOLDING 4,000 LBS (MINIMUM). REBAR SHOULD

BE PLACED IN A CROSSHATCH PATTERN FOR PAD REINFORCEMENT.

IF THE PAD IS TO BE LOCATED IN AN AREA WITH A DEEP FROST LINE OR UNSTABLE SOIL, CONCRETE

PYLON FOOTINGS (4” DIA. X 4’ DEEP, OR 1’ DEEPER THAN THE REGIONAL FROST LINE) SHOULD BE

PLACED BELOW THE CONCRETE PAD, IN FRONT OF AND BELOW THE (6) MOUNTING FEATURES.

THE HEIGHT OF THE PAD MUST BE AT LEAST 4” ABOVE GRADE TO REDUCE THE BUILDUP OF DEBRIS

AROUND THE BASE OF THE CABINET.

ADEQUATE SPACE SHOULD BE ALLOWED FOR CABLE TV INPUT / OUTPUT CONDUIT; PLANT GROUNDING

ELECTRODE CONDUCTOR(S); RF CABLE ENTRANCE VIA (1) 4”, (2) 3” OR (3) 2 1/2” RIGID CONDUIT

SWEEP(S) WITH 2’ BEND RADIUS (MINIMUM); AND FIBER OPTIC CABLE ENTRANCE (REFER TO FIBER

MANUFACTURER’S SPECIFICATION FOR MINIMUM BEND RADIUS REQUIREMENTS).

PRIOR TO POURING CONCRETE, ANY WIRE RUNNING THROUGH THE PAD MUST HAVE A THERMAL

EXPANSION JACKET (I.E., PVC) TO PREVENT CRACKING OF THE CONCRETE DURING LIGHTNING

STRIKES.

ALPHA TECHNOLOGIES IS NOT RESPONSIBLE FOR BROKEN WELDS OR OTHER DAMAGE TO THE

CABINET CAUSED BY IMPROPER INSTALLATION.

A BEAD OF SILICONE MUST BE PLACED AROUND THE OUTSIDE PERIMETER OF CABINET’S BASE TO

SEAL OUT RAIN. A 25 YEAR VAPOR BARRIER MUST BE USED BETWEEN THE CONCRETE PAD AND THE

BASE OF THE ENCLOSURE TO FURTHER INHIBIT THE INGRESS OF MOISTURE. ALPHA TECHNOLOGIES

IS NOT RESPONSIBLE FOR WATER DAMAGE OR MOISTURE DAMAGE RESULTING FROM IMPROPER

INSTALLATION.

CONCRETE FILLED, 6” DIAMETER STEEL POSTS (OR EQUIVALENT) SHOULD BE PLACED AT THE

CORNERS OF THE PAD TO REDUCE EXPOSURE TO ACCIDENTAL TRAFFIC DAMAGE. POSTS MUST ALSO

BE PLACED IN FRONT OF THE GAS UTILITY RISER TO PROTECT THE GAS REGULATOR FROM IMPACT

AND / OR DAMAGE FROM LAWN EQUIPMENT.

ALL DIMENSIONS ARE GIVEN IN INCHES.

FOR FURTHER INFORMATION REGARDING THIS INSTALLATION, CONTACT APLHA TECHNOLOGIES OR

YOUR NEAREST ALPHA REPRESENTATIVE.

031-040-B0-002 Rev. B

7

Page 8

1. INTRODUCTION

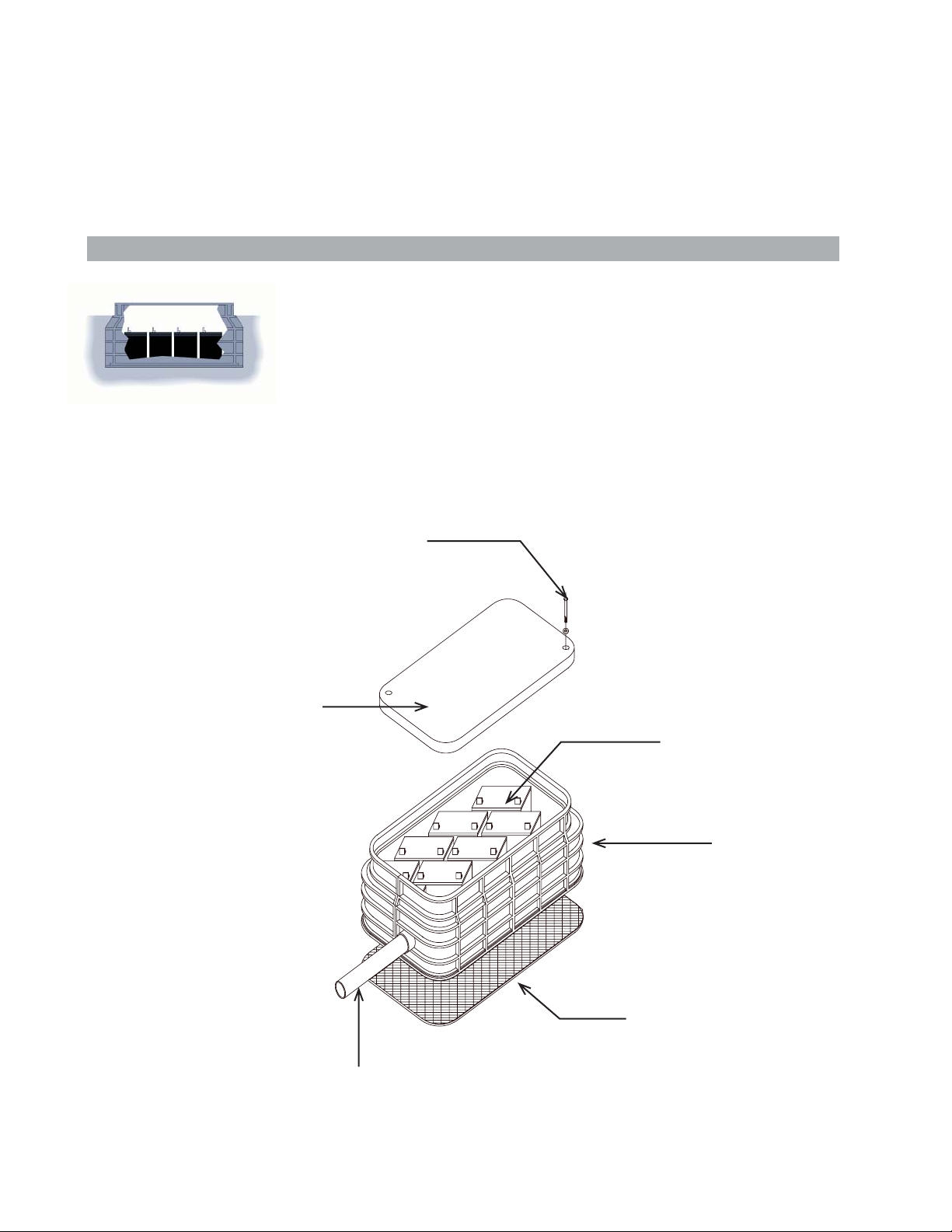

1.1 Underground Battery Vault

Alpha’s UBV Series Underground Battery Vaults and BVE enclosures meet municipal and

state regulations involving line of sight restrictions. These utility approved vaults are manufactured from high density polyethylene (HDPE) and can house up to eight batteries. Several options are available including combinations with ground and pole mount power supply

enclosures.

UBV Underground Battery Vaults

Standard Features

HDPE Vault

(in): 43.5L x 31.75W x 18H

(mm): 105L x 806W x 457H

HDPE Lid

(in): 35.6L x 24.1W

(mm): 904L x 612W

Accommodates up to 8 batteries

Hex-head bolts (standard)

Penta-head hardware optional)

Cover

Optional Features

•

BCK-UBV3 Fused Battery Cable Kit - 3 batteries

•

BCK-UBV4 Fused Battery Cable Kit - 4 batteries

•

BCK-UBV6 Fused Battery Cable Kit - 6 batteries

•

BCK-UBV8 Fused Battery Cable Kit - 8 batteries

•

BCK-EXT 15 BCK extension - 5' for XM2 Series

•

BCK-EXT 20 BCK extension - 20' for XM2 Series

•

BCK-EXT 25 BCK extension - 25' for XM2 Series

•

UBV-SH Tamper-proof Security Hardware

•

UBV-ST Security Tool

•

UBV-BT Battery Tray & Hardware (max. 6 AlphaCell

batteries)

•

UBV-BG Battery Grate for Vault

•

UBV-BC Individual Battery Cover - Protects battery from

water, dirt & corrosion

•

RTS-4 Remote Temperature Sensor 4'

•

RTS-25 Remote Temperature Sensor 25'

™

Batteries

Box, High density

polyethelyne

1” thick grate

2.5” PVC Conduit

Fig. 1-1 Underground Battery Vault (UBV)

2 x 48VDC battery string confi guration (maximum capacity)

8

031-040-B0-002 Rev. B

Page 9

2.1 Site Prep and Installation

For installations where the optional concrete pad is not used:

1. Excavate the site approximately 6” deeper than the overall height of the vault. The length and width

of the hole should be 4” to 6” more than the width and depth of the vault.

2. Use 6” of compacted gravel as a base for the vault. Level the gravel so the top of the vault is fl ush

with grade.

3. Finish installation by adding backfi ll and compacting.

For installations where the optional concrete pad is used:

1. Excavate the site approximately 6” deeper than the overall height of the vault. The length and width

of the hole should be 4” to 6” more than the width and depth of the vault.

2. Use 6” of compacted gravel as a base for the vault. Level the gravel so the top of the vault is fl ush

with grade.

3. Install shims on each side and end to prevent defl ection.

4. Add backfi ll and compact to a depth of 8” below grade.

5. Build form around vault to make a 6” wide collar around the vault.

6. Once concrete sets, fi nish backfi ll to grade.

2. INSTALLATION

Compacted backfi ll

2” PVC conduit for wiring

(provided by installer),

broken out of enclosure at

appropriate location for

installation.

Optional concrete pad

(4” to 6” thick)

Vault & Lid

Undisturbed soil

Compacted

backfi ll

031-040-B0-002 Rev. B

Drainage gravel

(6” deep typical)

Fig. 2-1 Typical site for UBV

9

Page 10

2. INSTALLATION

2.2 Battery Placement

-

+

-

+

+

-

-

+

-

+

-

+

-

+

-

+

10

11232

To install two 48 VDC battery strings in the UBV, load them in this order (observe indicated orientation with

respect to battery polarity):

1. Install batteries in the corners.

2. Install either of these pairs of batteries next.

3. Install this pair last.

031-040-B0-002 Rev. B

Page 11

+

-

+

-

+

-

2.2 Battery Placement, continued

2. INSTALLATION

Single 36V battery string with AG-CMT-3SC-P

Dual 36V battery string with one

AG-CMT-3SC-P per string (2 total)

+

+

-

-

-

+

+

-

-

-

+

+

-

+

-

+

+

-

Single 48V battery string with AG-CMT-4SC-P

Dual 48V battery string with one

AG-CMT-4SC-P per string (2 total)

031-040-B0-002 Rev. B

-

+

+

-

-

+

-

-

+

+

-

+

-

+

+

-

+

-

+

-

-

+

-

+

11

Page 12

2. INSTALLATION

2.3 Battery Connection

Depending on the size of the vault, strings of 3, 4, 6, or 8 batteries may be installed, along with

an optional AlphaGuard Battery Monitoring system. After securing the UBV, and installing the

batteries, make the wire connections to the batteries as shown.

Installation and Connection Procedure:

1. Label the batteries.

2. Install the batteries into the underground battery vault.

3. Spray terminal and hardware with battery corrosion inhibitor before assembly,

4. Connect terminal hardware in sequence as shown below. Cables are marked with

a RED sleeve to indicate the (+) positive battery terminal.

5. If an optional AlphaGuard Battery Sense Monitor is incorporated into the battery system,

connect the battery sense wires as shown in fi gures 2-4 through 2-7.

6. Reapply corrosion inhibitor to terminal assembly after tightening.

NOTE:

Verify the battery voltage and polarity are correct before proceeding.

NOTE:

Route the battery cable connectors from the enclosure, ring lugs fi rst to the UBV.

12

Fig. 2-2 Terminal Connection without

Battery Sense Wiring

Fig. 2-3 Terminal Connection with Battery Sense Wiring

031-040-B0-002 Rev. B

Page 13

2.3 Battery Connection, continued

2.3.1 Charge Management Technology (CMT)

The AlphaGuard monitors and protects the batteries by spreading the charge voltage equally across

all the batteries in a string, ensuring that every battery in the string, whether old or new, is properly

charged. With an ideal voltage always across each battery, life and runtime are optimized. Individual

batteries in a string can be replaced as they fail, allowing batteries to be left in service longer.

The AlphaGuard unit installs directly on top of one of the batteries in the string. A wire harness

connects the AlphaGuard to each of the batteries in the string. Both 36V (3 battery) and 48V (4

battery) versions are available. One AlphaGuard is required per battery string. The AlphaGuard

performs electrical compensation for differences in individual batteries in the string. The unit can be

confi gured to pass measurements from the battery string to a status monitoring device (EDSM card,

DOCSIS transponder, etc.) via an interface cable.

AlphaGuard Charge Management System

2. INSTALLATION

Part Number Model Description

012-306-30 AG-CMT-3SC-P-C

012-306-32 AG-CMT-3SC-P

012-306-31 AG-CMT-4SC-P-C

012-306-33 AG-CMT-4SC-P

012-306-20 AG-CMT-3SC

012-306-21 AG-CMT-4SC

AlphaGuard Charge Management SC, CMT-3SC-P-C 36VDC

Potted with 6ft sense wires

AlphaGuard Charge Management SC, CMT-3SC-P 36VDC

Potted without sense wires

AlphaGuard Charge Management SC, CMT-4SC-P-C 48VDC

Potted with 6ft sense wires

AlphaGuard Charge Management SC, CMT-4SC-P 48VDC

Potted without sense wires

AlphaGuard Charge Management SC, CMT-3SC-P-C 36VDC

With 6ft sense wires

AlphaGuard Charge Management SC, CMT-3SC-P-C 48VDC

With 6ft sense wires

Battery Monitoring Cables

Part Number Model Description

875-510-20 AG-EDSM-S9-Cable 36/48V Voltage Sense Cable, Single String, 9’

875-510-21 AG-EDSM-D9-Cable 36/48V Voltage Sense Cable, Dual String, 9’

875-510-23 AG-EDSM-S35-Cable 36/48V Voltage Sense Cable, Single String, 35’

875-510-22 AG-EDSM-D35-Cable 36/48V Voltage Sense Cable, Dual String, 35’

031-040-B0-002 Rev. B

13

Page 14

2. INSTALLATION

2.3 Battery Connection, continued

2.3.1 Single 36V Battery String Wiring Diagram

To BATTERY INPUT

connector

-

+

To TEMP PROBE

connector

Remote temperature sensor

To

Status

Monitoring

Card

12V 24V 36V

Black

Brown

Locate this connection above

high water mark or source of

high humidity

Battery Monitoring cable

-

+

-

+

-

Fuse on battery terminal

+

Orange

Yellow

AG-CMT-3SC-P-C

14

Fig. 2-4 AG-CMT-3SC-P-C Wiring for Single 36V Battery String

031-040-B0-002 Rev. B

Page 15

2.3 Battery Connection, continued

2.3.2 Dual 36V Battery String Wiring Diagram

AG-CMT-3SC-P-C

To BATTERY INPUT

connector

2. INSTALLATION

Locate this connection above high

water mark or source of high humidity

To

Status

Monitoring

Card

Brown

Black

-

12V 24V 36V

+

-

12V 24V 36V

+

Remote temperature sensor attached to

side of central battery

-

+

-

+

To TEMP PROBE connector

-

Yellow

Orange

Fuse on battery

terminal

+

-

Fuse on battery

terminal

+

031-040-B0-002 Rev. B

To

Second

AlphaGuard

Battery Monitoring

cable

Fig. 2-5 AG-CMT-3SC-P-C Wiring for Dual 36V Battery String

Black

Brown

Locate this connection above high water

mark or source of high humidity

Orange

Yellow

AG-CMT-3SC-P-C

15

Page 16

2. INSTALLATION

2.3 Battery Connection, continued

2.3.3 Single 48V Battery String Wiring Diagram

To BATTERY INPUT

connector

-

+

To TEMP PROBE connector

Remote temperature sensor

attached to side of central battery

To

Status

Monitoring

Card

-

12V 24V 36V

Black

Brown

Battery Monitoring cable

9’ cable : Alpha p/n 875-510-20

35’ cable: Alpha p/n 875-510-23

+

-

+

-

+

AG-CMT-4SC-P-C shown

48V

-

+

Fuse on battery

terminal

Yellow

Orange

16

Fig. 2-6 AG-CMT-4SC Wiring for Single 48V Battery String

031-040-B0-002 Rev. B

Page 17

2.3 Battery Connection, continued

2.3.4 Dual 48V Battery String Wiring Diagram

AG-CMT-4SC-P-C

To BATTERY INPUT

connector

-

+

Black

2. INSTALLATION

Locate this connection above high

water mark or source of high humidity

To

Status

Monitoring

Card

Yellow

Brown

Orange

-

12V 24V 36V

+

-

12V 24V 36V

+

-

+

-

+

Remote temperature sensor

To TEMP PROBE connector

-

+

-

+

48V

48V

-

Red

Fuse on

battery

+

terminal

-

Fuse on

+

battery

terminal

AlphaGuard

Battery Monitoring

cable

031-040-B0-002 Rev. B

To

Second

Black

Brown

Yellow

Locate this connection above high water

mark or source of high humidity

Fig. 2-7 AG-CMT-4SC Wiring for Dual 48V Battery String

AG-CMT-4SC-P-C

Red

Orange

17

Page 18

2. INSTALLATION

2.4 Battery Covers

Battery covers for the 165 and 180 series batteries are available and protect the

batteries from water, dirt and corrosion. The battery covers for the 165 GXL and 180 GXL

batteries are different sizes. The 180 GXL battery cover is the larger of the two. The battery

specifi c covers are not interchangeable.

18

Fig. 2-8 165 GXL Battery Cover

Group 27

(Alpha p/n 745-778-20)

Fig. 2-9 180 GXL Battery Cover

Group 31

(Alpha p/n 744-524-20)

031-040-B0-002 Rev. B

Page 19

2.4 Battery Covers, continued

2.4.1 Installing the Battery covers

For the 165GXL battery, the cover locking mechanism fi ts

under the battery handle tab molded into the battery case. To

properly seat the cover, the battery handle must be pushed

down as shown to allow space for the cover latch to engage

at “X”.

2. INSTALLATION

X

For the 180 GXL battery, the carry strap does not need to be

pushed down. The cover will latch at “X”.

Place the cover over the battery , route the battery cables and

battery sense wires down through the molded channels in the

cover.

Flex the side panels out and place the cover over the battery .

The cover will snap into place.

Press down evenly and fi rmly on the cover to fully seat it in place.

Repeat for the rest of the batteries in the string.

X

To ensure the battery covers are properly seated, pull up on

the center of the cover. If the cover comes off, repeat the above

steps.

031-040-B0-002 Rev. B

19

Page 20

2. INSTALLATION

2.4 Battery Coovers, continued

2.4.1 Installing the Battery Covers, continued

Fig. 2-10 165 AGM Battery with Cover in Place

20

Fig. 2- 11 180 GXL Battery with Cover in Place

031-040-B0-002 Rev. B

Page 21

2.5 Temperature Sensor

Temp Probe Connector: The Remote Temperature Sensor (RTS) plugs directly into the temperature

probe (RJ-11C type) connector. The sensor end of the RTS is routed to the battery compartment and

taped directly to the side of the center battery (See Fig. 2-12). The RTS provides battery temperature

measurements used to adjust the battery charge voltage. Attach the probe to the side of the battery so

that it is protected by the cover.

2. INSTALLATION

Fig. 2-12 Location of Temperature Probe on Battery

031-040-B0-002 Rev. B

Fig. 2-13 Temp Probe Connector

21

Page 22

Page 23

Page 24

Alpha Technologies

Power

®

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: +1 360 647 2360

Fax: +1 360 6714936

Web: www.alpha.com

Alpha Technologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: +1 604 430 1476

Fax: +1 604 430 8908

Alpha Technologies

Europe Ltd.

Twyford House

Thorley

Bishop's Stortford

Hertfordshire

CM22 7PA

UNITED KINGDOM

Tel: +44 0 1279 501110

Fax: +44 0 1279 659870

Alpha Technologies GmbH

Hansastrasse 8

D-91126 Schwabach

GERMANY

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec, Ltd

P.O. Box 56468

Limassol, Cyprus

CYPRUS

Tel: +357 25 375675

Fax: +357 25 359595

AlphaTEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1

109028 Moscow

RUSSIA

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltics

S. Konarskio G. 49

Vilnius 2009

LITHUANIA

Tel: +350 5 210 5291

Fax: +350 5 210 5292

Alpha Technologies

5 Avenue Victor Hugo

F-92140 Calmart France

FRANCE

Tel: +33 3 41 90 07 07

Fax: +33 1 41 90 93 12

Copyright © 2006 Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 031-040-B0-002 Rev. B

Due to continuing product improvements, Alpha reserves the right to change specifi cations without notice.

Loading...

Loading...