Page 1

Installation Instructions

Alpha Top Easy-Flue 500 mm

(Kit Part No. 1000377)

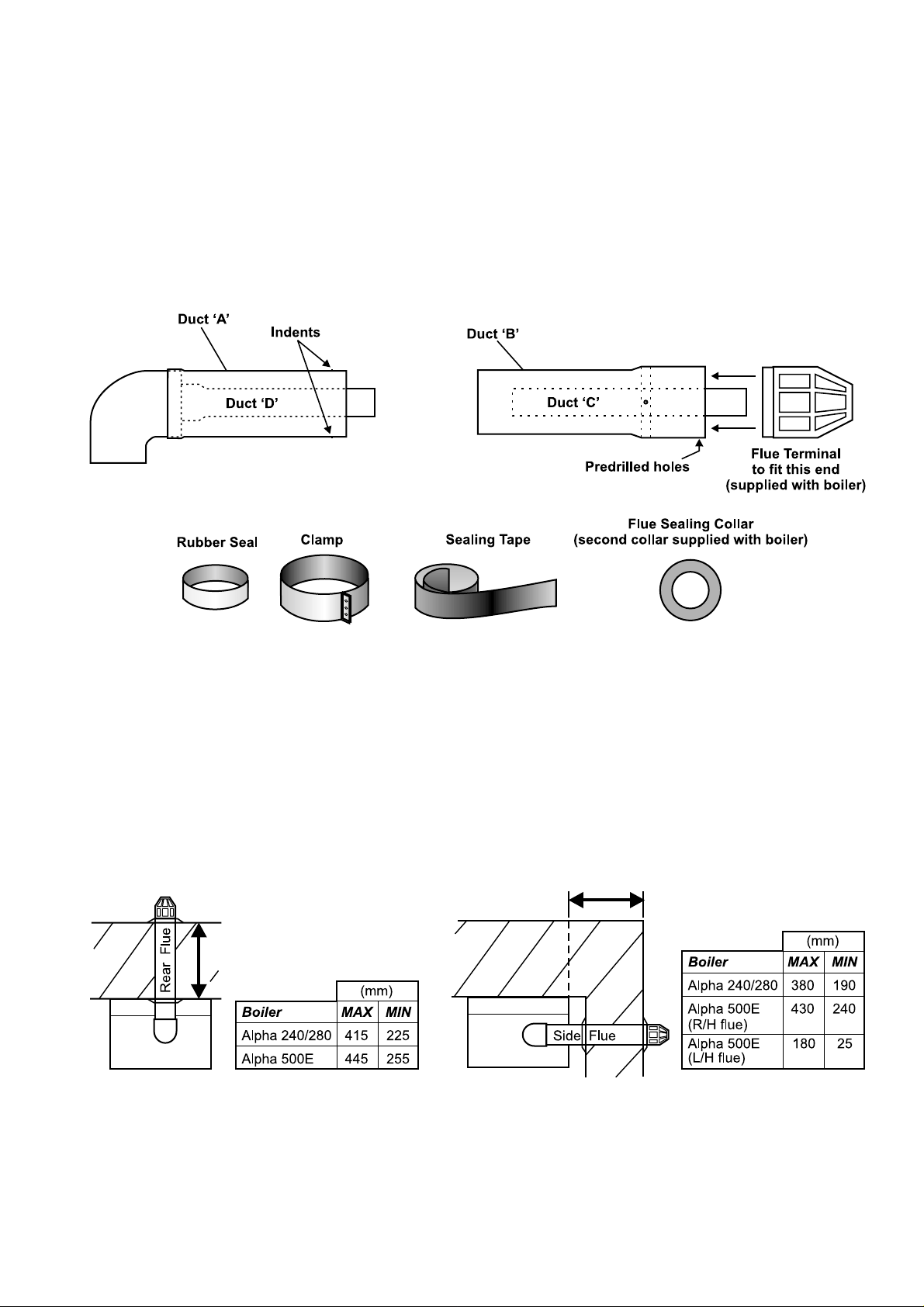

KIT CONTENTS

1. GENERAL

a. The Alpha Easy-Flue is suitable for straight horizontal flues only and can be extended up to the maximum lengths

given in Fig. 1 and 2.

b. The Easy-Flue includes a 90° bend, (no separate 90° bend is required).

c. Ensure that there is a slight downward slope of the flue to outside.

d. The flue system must be installed in accordance with BS 5440:1:1990.

e. The Easy-Flue is suitable for use in the flue length ranges given in Fig. 1 and 2.

Fig. 1 - Rear Flue Fig. 2 - Side Flue

Note: Where the length is less than the minimum or more than the maximum, refer to Appendix 2.

Page 2

2. INSTALLATION INFORMATION

a. Use the template (supplied with the boiler) to mark the flue position and cut a 130 mm diameter hole for the flue (use

a 127 mm core drill). This size of hole provides sufficient room for the flue to be fitted to the top of the boiler.

Note: If a 110 mm hole is cut for the flue, it is difficult to locate the flue onto the boiler flue adaptor, disconnect the duct

from the bend by removing the fixing screw. After installation ensure the duct is re-assembled onto the bend correctly.

Mount the boiler on the wall as described in the boiler Installation and Servicing instructions.

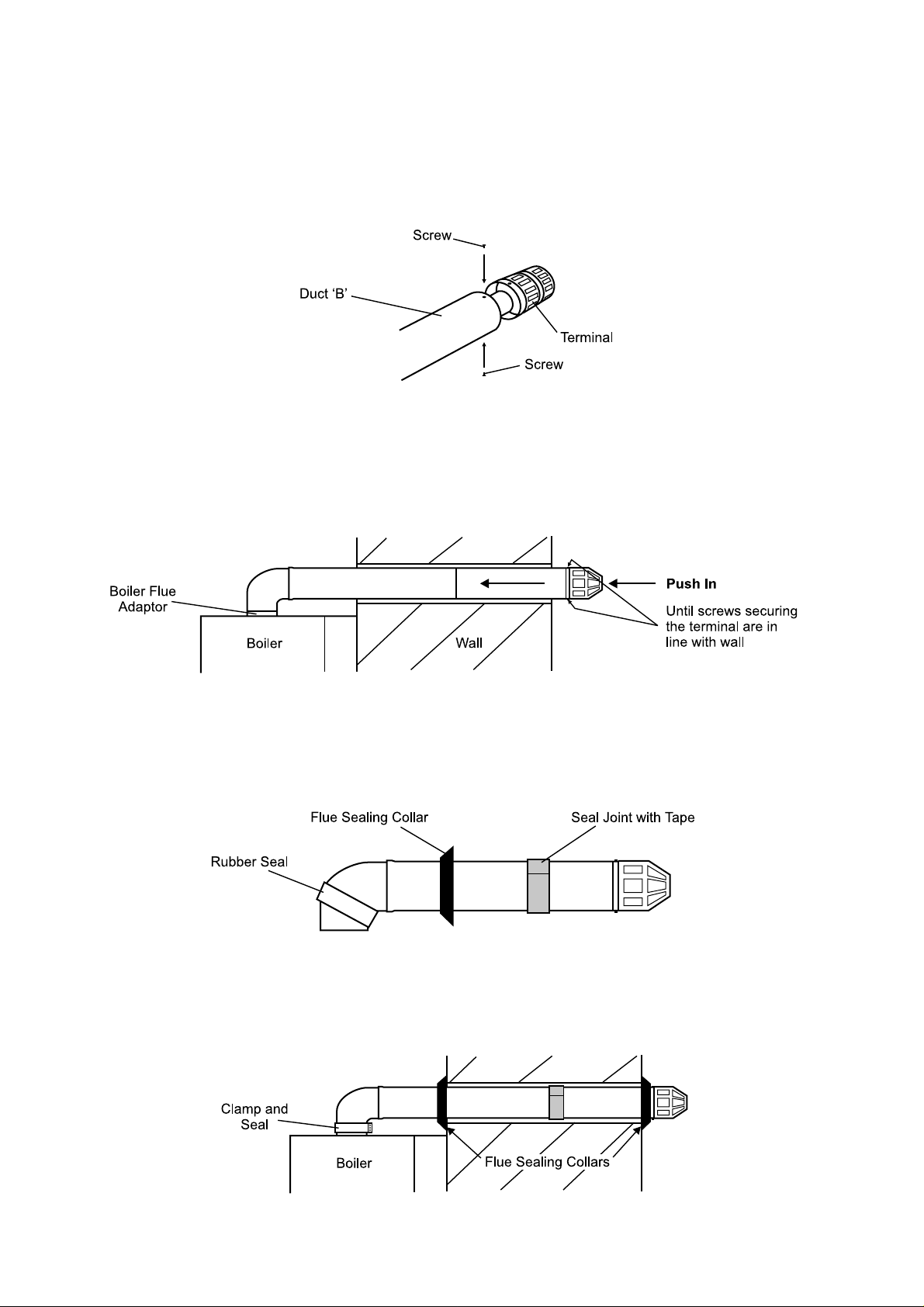

b. Fit the flue terminal (supplied with the boiler) to the enlarged end of Duct 'B'. Secure with two screws supplied with

the terminal as shown in Fig. 3.

Fig. 3

c. Extend the telescopic flue to its full length. From the inside, pass the assembly through the wall. Seat the flue bend

onto the boiler flue adaptor.

d. From outside, push the terminal in towards the wall until the screws securing the terminal are in line with the outside wall.

See Fig. 4.

Note: If there is no access to the outside wall, refer to Appendix 1.

Fig. 4

e. Carefully remove the flue assembly from the wall. Seal and secure the joint between the ducts with the sealing tape

supplied.

f. Position the rubber seal over the 90° bend as shown in Fig. 5.

g. Fit the inside flue sealing collar over the flue, see Fig. 5. From the inside, pass the flue assembly through the wall.

Fig. 5

h. Secure the 90° bend to the boiler using the clamp and rubber seal. Ensure that the seal covers the bend and adaptor

joint. See Fig. 6.

i. Make good the inside and outside walls with the flue collars. See Fig. 6.

Note: The second flue collar is supplied with the boiler.

Alpha Top Easy-Flue

2

Fig. 6

Page 3

Appendix 1 - Installation from inside the building (no access to outside wall).

a. Using the tables below, determine the flue length (L) required. See Fig. 7.

Fig. 7

Alpha 240/280 Range

Rear Flue L = Wall thickness + 230 mm

Side Flue L = Wall thickness + distance between boiler and wall + 265 mm

Alpha 500E

Rear Flue L = Wall thickness + 200 mm

Side Flue (to right) L = Wall thickness + distance between boiler and wall + 215 mm

Side Flue (to left) L = Wall thickness + distance between boiler and wall + 465 mm

b. Adjust the flue to the distance 'L' then seal and secure the joint between the ducts with the sealing tape supplied.

c. Position the rubber seal over the 90° bend as shown in Fig. 7.

d. Fit the inside flue sealing collar over the flue. Fit the second flue sealing collar (supplied with the boiler) onto the flue

immediately before the terminal. Push the flue assembly through the hole, so that the collar completely passes

through the wall. Then pull back into the correct position. See Fig. 8.

Fig. 8

e. Secure the 90° bend to the boiler using the clamp and rubber seal. Ensure that the seal covers the bend and adaptor

joint. See Fig. 9.

f. Make good the inside wall by pushing the inside collar up to the wall.

Fig. 9

Alpha Top Easy-Flue

3

Page 4

Appendix 2 - When the flue length required is less than the minimum or more

than the maximum stated in Fig. 1 and 2.

Rear Flue Side Flue

Fig. 10

Alpha 240/280 Range

Rear Flue Side Flue Comments

Up to Max:- 3890 mm 3855 mm Alpha 750 flue extension (Part No. 1000320) is required

to extend the range of the telescopic flue. Refer to

Appendix 3 for instructions on how to extend the flue.

Note: A 130 mm flue hole (127 mm core drill) is required

in the wall.

Between:- 225 mm

and 415 mm

Less than:- 225 mm Terminal may protrude somewhat from the outside wall.

But if it is:-

105 mm

or less

190 mm

and 380 mm

190 mm

70 mm

or less

Within the standard telescopic range.

Discard Ducts 'B' and 'C' and fit the terminal to Duct 'A' (small

indents marked on Duct 'A' indicate where to drill 4 mm

holes for the terminal fixing screws.

Alpha 500E

Rear Flue RH Side Flue Comments

Up to Max:- 3920 mm 3905 mm Alpha 750 flue extension (Part No. 1000320) is required

Between:- 255 mm

and 445 mm

Less than:- 255 mm Terminal may protrude somewhat from the outside wall.

240 mm

and 430 mm

240 mm N/A

LH Side Flue

3655 mm

25 mm

and 180 mm

to extend the range of the telescopic flue. Refer to

Appendix 3 for instructions on how to extend the flue.

Note: A 130 mm flue hole (127 mm core drill) is required

in the wall.

Within the standard telescopic range.

But if it is:-

Alpha Top Easy-Flue

4

135 mm

or less

120 mm

or less

N/A

Discard Ducts 'B' and 'C' and fit the terminal to Duct 'A' (small

indents marked on Duct 'A' indicate where to drill 4 mm

holes for the terminal fixing screws.

Page 5

Appendix 3 - Extending the Top Easy-Flue 500

a. Use the template (supplied with the boiler) to mark the flue position and cut a 130 mm diameter hole for the flue (use

a 127 mm core drill). This size of hole provides sufficient room for the flue to be fitted to the top of the boiler.

Mount the boiler on the wall as described in the boiler Installation and Servicing instructions.

b. Fit the flue terminal (supplied with the boiler) to the enlarged end of Duct 'B'. Secure with two screws supplied with

the terminal as shown in Fig. 11.

Fig. 11

c. Remove the Duct B assembly from Duct A by pulling in the direction of the arrows. See Fig. 12.

Fig. 12

d. Fit a 750 flue extension (Part No. 1000320) to Ducts A and D using the clamps and seal supplied, as shown in Fig. 13.

Connect any additional extension in the same way.

Note: Ensure that the end of the outer duct with the two holes is connected to Duct A.

Fig. 13

e. Continue to add flue extensions until the assembly is within 200 mm of the outside wall, ensuring that the overall

maximum length with Duct B fitted, will not be more than that given in Appendix 2.

Note: To gain the correct length, only cut the flue extension ducts (ensure that the cuts are square, free from burrs

and the ducts are not distorted). Do Not cut the Easy-Flue ducts.

Alpha Top Easy-Flue

5

Page 6

f. Engage Duct 'B' into the flue extension as shown in Fig. 14. Duct B goes inside Duct A and Duct C goes over Duct D.

Note: If there is any difficulty in locating the ducts together, ensure that all engaging ducts have no burrs and are not

distorted.

Fig. 14

g. When the telescopic section of the flue has been adjusted to the correct length, seal and secure the joint with the

sealing tape supplied. See Fig. 15.

Important Note: Ensure that the inner duct is connected securely throughout the flue assembly.

Fig. 15

h. Continue to fit the complete assembly to the boiler as described in section2, paragraphs f to i.

Alpha Therm Limited.

Nepicar House, London Road, Wrotham Heath

Sevenoaks, Kent TN15 7RS

email: info@alphatherm.co.uk

website: www.alpha-innovation.co.uk

Compiled and designed by Publications 2000, Tel (01670) 356525

These guidelines have been carefully prepared but we reserve the right to

alter the specification at any time in the interest of product improvement.

© Alpha Therm Limited 1999.

Part No. 0001126

07/99/D117

Loading...

Loading...