Page 1

Nominal data:

Nominal voltage UN: 2.0 V x number of cells

Nominal capacity CN = C10: 10 hour discharge

(see type plate and technical data in these

instructions)

Nominal discharge current: IN = I10:

Final discharge voltage Us:

see technical data in these instructions

Nominal temperature TN: 20°C

"LA": antimony content < 2% in the grids

(earthcarriers) of the positive electrodes

Non-compliance with operating instructions, repairsmade with other than original

parts, tamperingor use of additives for the

electrolyte (alleged"enhancing agents")

render the warrantynull and void.

1. Commissioning of filled and charged

batteries

Before commissioning all blocks must be

inspected

for mechanical damage, cells must be

connected with the correct polarity and connectors firmly seated. The following torques

apply for screw connectors:

M 10 with 17 Nm +/ _ 1 Nm

If necessary the terminal covers must be put

on.

Check the electrolyte level in all cells. If necessary

top up to maximum level with purified water

as under DIN 43530 Part 4.

With charger off and loads isolated connect

battery to the direct current power supply

maintaining correct polarity (positive terminal

to positive post).

Switch on the charger and charge as under

Section 2.2.

2. Operation

For the operation of stationary battery

installationsDIN VDE 0510 Part 1 (draft) and

DIN VDE 0510 Part 2 apply.

2.1 Discharging

Never allow the final discharge voltage of the

battery to drop below that assigned for the

discharge current. Unless the manufacturer

has specified otherwise, no more than the

nominal capacity is to be consumed. Charge

immediately after discharge as well as partial

discharge.

2.2 Charging

All charging procedures with their limit values

may be employed as under

DIN 41773 (IU characteristic)

DIN 41774 (W characteristic

DIN 41776 (I characteristic).

Depending on charger type and charging

characteristic alternating currents flow through

the battery superimposing onto the direct current.

These alternating currents and the reaction of

the loads lead to an additional warming of the

battery and strain on the electrodes with possible resulting damage (see 2.5).

Depending on the system at hand charging

may be carried out under the following operations:

a) S

tand-by parallel operation and floating

operation

Here the load, direct current and battery are

continuously connected in parallel.

Thereby the charging voltage is the operating

voltage of the battery and at the same time

the battery installation voltage.

With st

and-by parallel operation the direct current is at any time capable of supplying the

maximum load current and the battery charging current. The battery only supplies current

when the direct current source fails. The

charge voltage should be set at 2.23 V +/_1%

x number of cells measured at the battery's

terminals. To reduce the recharging time a

charging stage canbe applied in which the

charging voltage is 2.33 to 2.4 V x number of

cells (stand-by parallelparallel

operation with recharging stage). Automatic

changeover to the charging voltage of 2.23 V

+/_ 1% x number of cells follows.

With the floating operation

the direct current

source is not able to supply the maximum

load current at all times. The load current

intermittent

Iy supercedes the nominal current of the

direct current source. During this period the

battery supplies power. It is not fully charged

at all times.

Therefore, depending on the load the charge

voltage must be set at 2.23 to 2.30 V x

number of cells.

b) Switch mode operation

When charging the battery is separated from

the load. Towards the end of the charging

process the charge voltage of the battery is

2.6 - 2.75 V/cell. The charging process must

be monitored (see Sections 2.4, 2.5 and 2.6)

On reaching a fully charged state the charging

process must be stopped or switched to float

chargeas under Section 2.3.

c) Battery operation (charge/discharge opera

tion)

The load is supplied only by the battery.

Hereby the charge voltage of the battery

towards the end of the charging process is 2.6

- 2.75 V/ cell. The charging process must be

monitored (see Sections 2.4, 2.5 and 2.6). On

reaching a fully charged state the charging

process must be

switched off. The battery can be switched to

the load as necessary.

2.3 Maintaining the full charge

(float charge)

Devices complying with the stipulations under

DIN 41773 must be used. They are to be set

so that the average cell voltage is

2.23 V +/_ 1% and the electrolyte density

does not decrease over a protracted period.

2.4 Equalizing charge

Because it is possible to exceed the permitted

load voltages, appropriate measures must be

taken, e.g. switch off the load.

Equalizing charges are required after exhaustive discharges and after inadequate charges;

they can be carried out as follows:

- up to 72 hours at constant voltage of max.

2.4 V/cell - as under Table 1 with I and W

characteristic.

On exceeding the maximum temperature of

55°C charging must either be stopped or proceed with reduced current or be switched to

float charge to allow the temperature to drop.

The equalizing charge is completed when the

electrolyte densities and cell voltages no

longer increase within 2 hours.

2.5 Alternating currents with periodic

deviations

On recharging up to 2.4 V/cell as under operation modes a) to c) the actual value of the

alternating current is ocassionally permitted to

reach max. 20 Aper 100 Ah nominal capacity.

Above 2.4 V/cells 10 Aper 100 Ah nominal

capacity may not be

exceeded.

In a fully charged state with a charge voltage

of 2.23 to 2.30 V/cell the actual value of the

alternating current may not exceed 5 Aper

100 Ah nominal capacity.

Observe operating instructions

and affix close within sight of the

battery!

Work on batteries only under

instrustions of skilled personnel!

Smoking prohibitet! Do not

expose battery to open flame

glowing fire or sparks as explosion and fire hazard exists!

When working on batteries wear

protective glasses and

clothing!Observe the accident

prevention rules as well as DIN

VDE 0510, VDE 0105 part 1 !

Explosion and fire hazard, avoid

short circuits!

Caution! Metal parts of the battery

cells are always live, therefore do

not place items or tools on the

battery!

Electrolyte is strongly corrosive!

Monobloc batteries/cells are very

heavy! Ensure secure installation!

Only use suitable transport equipment!

Dangerous voltage!

Acid splashes in the eyes or on

the skin must be washed out or

off with plenty of water.Then see

a doctor immediately. Acid on

clothing should be washed out

with water!

Assembled by:____________________________

on:______________________________________

Start-up by:_______________________________

on:______________________________________

Safety marking

affixed by:________________________________

on:______________________________________

OPERATING INSTRUCTIONS

Stationary vented lead-acid batteries OGi bloc

Page 2

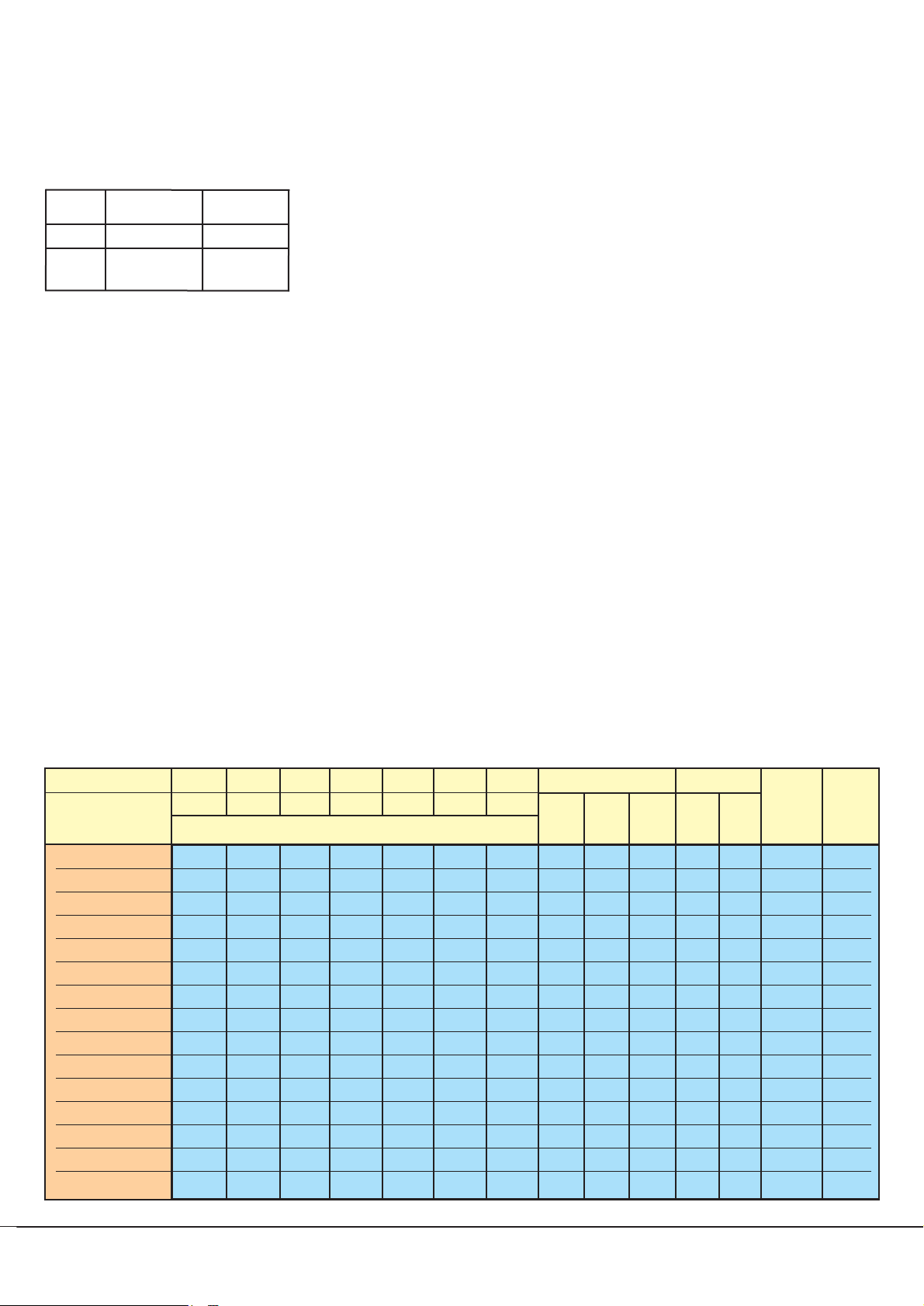

Ue (V/cell) 1.80 1.75 1.75 1.70 1.65 1.65 1.60 Dimensions Masse/Weight

C10 C5 C3 C1 C1/2 C1/6 C1/12 L W Hmax Bat.+el. el. Ri Ik

TYPE C (Ah) (mm) (mm) (mm) (kg) (kg) (mΩ/bl.) (kA)

12V 1 OGi 25 29.0 25.5 22.5 16.8 14.3 9.2 6.7 272 205 375 33 11 16.97 0.72

12V 2 OGi 50 55.0 49.5 44.7 32.8 28.0 18.0 13.1 272 205 375 41 10.9 8.91 1.41

12V 3 OGi 75 80.0 74.5 67.5 49.6 42.2 27.3 19.8 272 205 375 49 10.8 5.94 2.11

12V 4 OGi 100 105.0 98.5 89.4 65.7 56.1 36.1 26.1 272 205 375 58 10.7 4.46 2.81

12V 5 OGi 125 135.0 123.0 111.3 81.6 69.0 44.3 31.7 380 205 375 78 15.7 3.57 3.52

12V 6 OGi 150 165.0 148.5 133.8 98.2 82.5 52.7 37.1 380 205 375 86 15.5 2.97 4.22

6V 7 OGi 175 193.0 172.5 156.0 114.1 94.0 58.7 40.8 272 205 375 49 11.3 1.27 4.93

6V 8 OGi 200 228.0 197.5 178.8 130.0 108.0 67.3 46.8 272 205 375 53 11.1 1.11 5.63

6V 9 OGi 225 254.0 221.5 200.7 145.8 121.5 75.5 52.6 380 205 375 68 16.4 0.99 6.36

6V 10 OGi 250 270.0 247.0 223.5 161.7 133.0 80.5 55.3 380 205 375 72 16.3 0.89 7.04

6V 11 OGi 275 304.0 271.5 245.1 177.6 146.0 88.5 60.7 380 205 375 75 16.2 0.81 7.78

6V 12 OGi 300 320.0 296.0 268.2 194.4 159.5 96.5 66.3 380 205 375 79 16 0.74 8.44

2V 24 OGi 600 684.0 592.5 536.4 390.0 324.0 201.9 140.4 205 272 375 53 11.1 0.13 16.42

2V 30 OGi 750 810.0 741.0 670.5 485.1 399.0 241.5 165.9 205 380 375 72 16.3 0.10 21.89

2V 36 OGi 900 960.0 888.0 804.6 583.2 478.5 289.5 198.9 205 380 375 79 16 0.08 24.63

2.6 Charging currents

The charging currents are not limited to

2.4 V/ cell. When exceeding the charging

voltage of 2.4 V/cell greater water decomposition occurs.

The charging currents per 100 Ah nominal

capacity shown in Table 1 may not be

exceeded.

2.7 Temperature

The recommended operating temperature for

lead-acid batteries is 10°C to 30°C. The technical data apply for the nominal temperature

20°C. The ideal operating temperature is

20°C +/_ 5 K. Higher temperatures shorten

the service life. Lower temperatures reduce

the available capacity. The maximum temperature of 55°C may not be exceeded.

2.8 Temperature-related charge voltage

A temperature-related adjustment of the

charge voltage within the operating temperature of 10°C to 30°C is not necessary.

Should the temperature range be lower than

10°C and/or higher than 30°C a temperature

related adjustment of the charge voltage

should be made. The temperature correction

factor is (-0.004 V/C per K).

Should the temperature constantly rise above

40°C, then the factor is (0.003 V/C per K).

2.9 Electrolyte

The electrolyte is diluted sulphuric acid. The

nominal electrolyte density is based on 20°C

and the nominal electrolyte level when fully

charged maximum +/ _ 0.01 kg/l.

Higher temperatures reduce the electrolyte

density, lower temperatures increase the

electrolyte density. The associated correction

factor is 0.0007 kg/l per K.

Example: electrolyte density of 1.23 kg/l at

35°C corresponds to a density of 1.24 kg/l at

20°C or electrolyte density of 1.25 kg/l at 5°C

corresponds to a density of 1.24 kg/l at 20°C.

3. Battery maintenance and control

The electrolyte level must be checked regularly. If it has dropped to the lowest electrolyte level mark, purified water must be

added as under DIN 43530 Part 4, maximum

conducting capacity 30 _S/cm.To avoid leakage currents keep the battery

clean and dry. Cleaning the battery should

be carried out as specified in the ZVEI pamphlet on battery cleaning.

Plastic battery components, in particular the

vent caps, must only be cleaned with water

containing no additives. At least every 6

months the following must be measured and

recorded:

- battery voltage

- voltage of a few selected cells/monobloc

batteries

- electrolyte density of a few selected

monobloc batteries

- electrolyte temperature of a few selected

monobloc batteries

The following must be measured and recorded annually:

- voltage of all bloc batteries

-electrolyte density of all bloc batteries

- electrolyte temperature of a few selected

bloc batteries

Should the float charge voltage in one cell

deviate more than + 0.1 V or - 0.05 V from

the average value (see 2.3), customer services must be called in.

Annual visual checks:

- on bolted connectors, check that unsecured

bolt connectors are firmly seated

- on battery installation or arrangement

- on ventilation.

4. Tests

Tests must be conducted according to DIN

43539 Part 1 and 4. In addition, special test

instructions such as under DIN VDE 0107

and DIN VDE 0108 must be observed.

5. Faults

Should faults be detected in the battery or

the

charging device, customer services should

be

called in immediately. Measurement data

under

Section 3 simplify fault detection and

removal.

A service contract with us facilitates the timely detection of faults.

6. Storage and taking out of operation

Should cells/batteries be stored or taken out

of operation for a longer period of time they

mustbe placed, fully charged, in a dry, frostfree room.

To avoid damage the following-charging

methods can be chosen:

1. Equalizing charges on a quarterly basis as

under Section 2.4. In average ambient temperatures of more than 30°C monthly equalizing charges may be necessary.

2. Float charging as under Section 2.3.

7. Transport

Batteries which show no damage of any kind

are not treated as dangerous goods under

the road and railway transport regulations

(GGVS and GGVE) if they are secured

against short circuits, sliding, overturning or

damage and stacked and secured appropriately on palettes

(GGV's margin No. 2801 a). The batteries

ready for dispatch must not show any external dangerous traces of acid.

For all sealed batteries and cells whose elements are leaking or damaged the exceptional regulation No. 69 applies.

8. Technical data

The nominal voltage, the number of blocks,

the nominal capacity (C10 = CN) and the

battery type are obtained from the type plate.

Other capacities (Cn) at different discharge

voltages (In) with the corresponding discharge times (tn)can be obtained from the

OGi tables.

Charging Monobloc battery Cell

procedure OGi bloc, OGi voltage

I-charact. 5,0 A 2,6-2,75 V

W-charac- 7,0 A at 2,4 V

teristic 3,5 A at 2,65 V

For more information visit www.alpha.com

United States Suwanee, Georgia Tel: 800 996 6104 Fax: 678 584 9259

Canada Burnaby, British Columbia Tel: 604 439 3009 Fax: 604 439 3039

Alpha Industrial Power

MTI and Alpha Industrial Power reserve the right to make changes to the products and information contained in this document without notice.

Copyright © 2009 MTI and Alpha Industrial Power. All Rights Reserved. Alpha® is a registered trademark of Alpha Technologies.

member of The Alpha Group™ is a trademark of Alpha Technologies. AlphaCell™ is a trademark of Alpha Technologies.

MTI Systems

Loading...

Loading...