Page 1

LPE Enclosure

Installation and Operation Manual

LPE Enclosure

Effective: 05/2010

member of The Group

™

Page 2

Alpha Technologies

Power

®

Page 3

LPE Enclosure

Installation and Operation Manual

031-302-B0-001, Rev. A

Effective Date: May 2010

Copyright© 2010

Alpha Technologies, Inc.

member of The Group

NOTE:

Alpha denies responsibility for any damage or injury involving its enclosures, power supplies, generators,

batteries or other hardware, manufactured by Alpha or members of the Alpha Group, when used for an

unintended purpose, installed or operated in an unapproved manner, or improperly maintained.

NOTE:

Photographs and drawings contained in this manual are only for illustrative purposes. These photographs and

drawings my not exactly match your installation.

NOTE:

Review the written and illustrative information contained in this manual before proceeding. If there are

questions regarding the safe installation or operation of this product, please contact Alpha Technologies or

your nearest Alpha representative.

™

Contacting Alpha Technologies: www.alpha.com

For general product information and customer service (7 AM to 5 PM, Pacic Time), call

031-302-B0-001 Rev A

or

1-800-863-3930

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacic Time or 24/7 emergency support

3

Page 4

Table of Contents

Safety Notes .......................................................................................................................... 5

1.0 Introduction ................................................................................................................. 9

1.1 LPE Enclosures ............................................................................................... 9

1.2 LPE Specications and Options..................................................................... 10

2.0 Installation..................................................................................................................11

2.1 Enclosure Installation, Wall-mount ..................................................................11

2.2 Enclosure Installation, Steel or Concrete Pole............................................... 12

2.3 Enclosure Installation, Ground-mount............................................................ 13

2.3.1 Pre-installation .................................................................................... 13

2.3.2 Enclosure Grounding: Ground-mount ................................................ 15

2.3.3 Ground-mount Installation ................................................................... 16

2.4 Dimensions .................................................................................................... 18

2.5 Connecting Utility Power ................................................................................ 19

2.5.1 Service Power ..................................................................................... 20

2.5.2 Connecting Coaxial Cable................................................................... 22

2.6 Battery Installation ......................................................................................... 25

2.6.1 Battery Terminal Connections ............................................................. 27

2.7 Power Supply Installation............................................................................... 28

3.0 LPE Enclosure Maintenance .................................................................................... 29

List of Figures

Fig. 1-1, LPE Enclosure.................................................................................................................................... 9

Fig. 2-1, Mounting Bracket ..............................................................................................................................11

Fig. 2-2, Ground-mount Positioning and Safety ............................................................................................. 14

Fig. 2-3, Suggested Grounding Method ......................................................................................................... 15

Fig. 2-4, LPE Enclosure Pedestal................................................................................................................... 17

Fig. 2-5, Location of (3) Knockouts for Enclosure-to-Pedestal Mounting ....................................................... 17

Fig. 2-6, 120Vac Service Entrance Wiring ...................................................................................................... 20

Fig. 2-7, 520-R Receptacle Wiring ................................................................................................................. 21

Fig. 2-8, SPI and SPI RF Mounting Locations ................................................................................................ 24

Fig. 2-9, Battery Identication Label ............................................................................................................... 25

Fig. 2-10, Hardware stack-up, Threaded Battery insert .................................................................................... 27

Fig. 2-11, Hardware stack-up, Threaded Battery Insert with optional in-line fuse ............................................ 27

4

031-302-B0-001 Rev A

Page 5

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

ATTENTION

The use of ATTENTION indicates specic regulatory/code requirements that may affect the placement of

equipment and /or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to the technician

or user.

031-302-B0-001 Rev A

5

Page 6

Battery Maintenance Guidelines

The battery maintenance instructions listed below are for reference only. Battery manufacturer’s instructions

for transportation, installation, storage or maintenance take precedence over these instructions.

• To prevent damage, inspect batteries every 3 months for:

Signs of battery cracking, leaking or swelling. The battery should be replaced immediately by

authorized personnel using a battery of the identical type and rating.

Signs of battery cable damage. Battery cable should be replaced immediately by Authorized Personnel

using replacement parts specied by vendor.

Loose battery connection hardware. Refer to battery manufacturer’s documentation for the correct

torque and connection hardware for the application.

• Apply battery manufacturer’s specied antioxidant compound on all exposed connections.

• Verify battery terminals and/or exposed connection hardware is not within 2 inches of a conductive

surface. Reposition batteries as necessary to maintain adequate clearance.

• Clean up any electrolyte (battery emission) in accordance with all federal, state, and local regulations or

codes.

• Proper venting of the enclosure is recommended. Follow the Battery Manufacturer’s approved

transportation and storage instructions.

• Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least 0.5

inches of space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially

dangerous gas.

Recycling and Disposal Instructions

Spent or damaged batteries are considered environmentally unsafe. Always recycle used batteries or dispose

of the batteries in accordance with all federal, state and local regulations.

Electrical Safety

• Lethal voltages are present within the power supply and electrical boxes. Never assume that an electrical

connection or conductor is not energized. Check the circuit with a volt meter with respect to the grounded

portion of the enclosure (both AC and DC) prior to any installation or removal procedure.

• Always use the buddy system when working under hazardous conditions.

• A licensed electrician is required to install permanently wired equipment.

• Input voltages can range up to 120 Vac. Ensure that utility power is disabled before beginning installation

or removal.

• Ensure no liquids or wet clothes contact internal components.

• Hazardous electrically live parts inside this unit are energized from batteries even when the AC input

power is disconnected.

Mechanical Safety

• Keep hands and tools clear of fans. Fans are thermostatically controlled and will turn on automatically.

• Power supplies can reach extreme temperatures under load.

• Use caution around sheet metal components and sharp edges.

6

031-302-B0-001 Rev A

Page 7

Battery Safety Notes

WARNING!

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service and replacement must be performed only by authorized

personnel.

Chemical Hazards

Any gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contain dilute sulfuric

acid, which is harmful to the skin and eyes. Emissions are electrolytic, and are electrically conductive and

corrosive.

To avoid injury:

• Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

• Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove

all metallic objects from hands and neck.

• Batteries produce explosive gases. Keep all open ames and sparks away from batteries.

• Use tools with insulated handles, do not rest any tools on top of batteries.

• Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm. Battery post terminals and related accessories contain lead and lead

compounds. Wash hands after handling (California Proposition 65).

• Wear protective clothing (insulated gloves, eye protection, etc.) whenever installing, maintaining,

servicing, or replacing batteries.

• If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your

company’s approved chemical exposure procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with

a solution of one pound Bicarbonate of soda to one gallon of water. Report chemical spill using your

company’s spill reporting structure and seek medical attention if necessary.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially

dangerous gas.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

developed on your body.

• Never use uninsulated tools or other conductive materials when installing, maintaining, servicing or

replacing batteries.

• Use special caution when connecting or adjusting battery cabling. An improperly connected battery cable

or an unconnected battery cable can make contact with an unintended surface that can result in arcing,

re, or possible explosion.

031-302-B0-001 Rev A

7

Page 8

Grounding Connection Notes

In order to provide a ready, reliable source of backup power, it is necessary to connect the power supply to an

effective grounding and Earthing system that not only provides for the safety of the service personnel responsible

for its operation and maintenance, but also facilitates the proper operation and protection of the equipment within

the network. Such a grounding system provides protection with respect to operator safety, system communication,

and equipment protection.

Safety Ground

The safety ground is a two-part system, comprised of the utility service and the Alpha system.

1. First, utility service;

As a minimum requirement for the protection of Alpha equipment, the local utility service must provide a lowimpedance path for fault current return to earth. This must meet or exceed the requirements of the US National

Electrical Code. The connection between the Alpha Power Supply and the utility must also meet or exceed the

requirements of the US National Electrical Code.

2. Second, the Alpha grounding system;

The Alpha grounding system consists of a low-impedance connection between the enclosure and an Earth Ground

(located at least 6' away from the Utility Earth connection).

This impedance between the enclosure and Earth must be 25 Ohms or less at 60 Hertz.

Local soil conditions will determine the complexity of the grounding system required to meet the 25 Ohm

(maximum) resistance specied above.

For example, a single 8' ground rod may be sufcient to meet the requirement. In some cases, a more elaborate

system may be required such as multiple ground rods connected by a #6AWG solid copper cable buried 8-12"

below the surface. Where this is not possible, contact a local grounding system expert for alternate methods that

will meet the 25 Ohm (maximum) specication.

NOTE:

All ground rod connections must be made by means of a listed grounding clamp suitable for direct burial or

exothermically welded.

Strike (Lightning) Ground

Lightning strikes, grid switching, or other aberrations on the power line and/or communications cables have the

potential to cause high-energy transients which can damage the powering or communications systems. Without

a low-impedance path to the ground, the current, when traveling through wires of varying impedance, produce

damaging high voltage. The most viable method available to protect the system from damage is to divert these

unwanted high-energy transients along a low-impedance path to ground. A low-impedance path to ground

prevents these currents from reaching high voltage levels and posing a threat to equipment. The single-point

grounding system provides a low-impedance path to ground, and the key to its success is the proper bonding of the

grounding rods, so the components of the grounding system appear as a single point of uniform impedance. Alpha

recommends the use of a surge arresting device electrically bonded to the Alpha Ground System.

WARNING!

Low-impedance grounding is mandatory for personnel safety and critical for the proper

operation of the cable system.

8

031-302-B0-001 Rev A

Page 9

1.0 Introduction

1.1 LPE Enclosures

The LPE Enclosures may be equipped with an optional AC service entrance, AC distribution

and are supported with a wide range of accessories, including the AlphaCellTM GXL batteries

and HPL-FT front terminal batteries providing extended standby runtime and life.

The LPE is specically designed for indoor or outdoor installations requiring lower power, a

smaller footprint and embedded DOCSIS® status monitoring capability. The LPE is available

in pole, wall or ground mount congurations. The LPE is an ideal solution for back-up power

where traditional equipment is too large and bulky.

031-302-B0-001 Rev A

Fig. 1-1, LPE Enclosure

9

Page 10

1.0 Introduction, continued

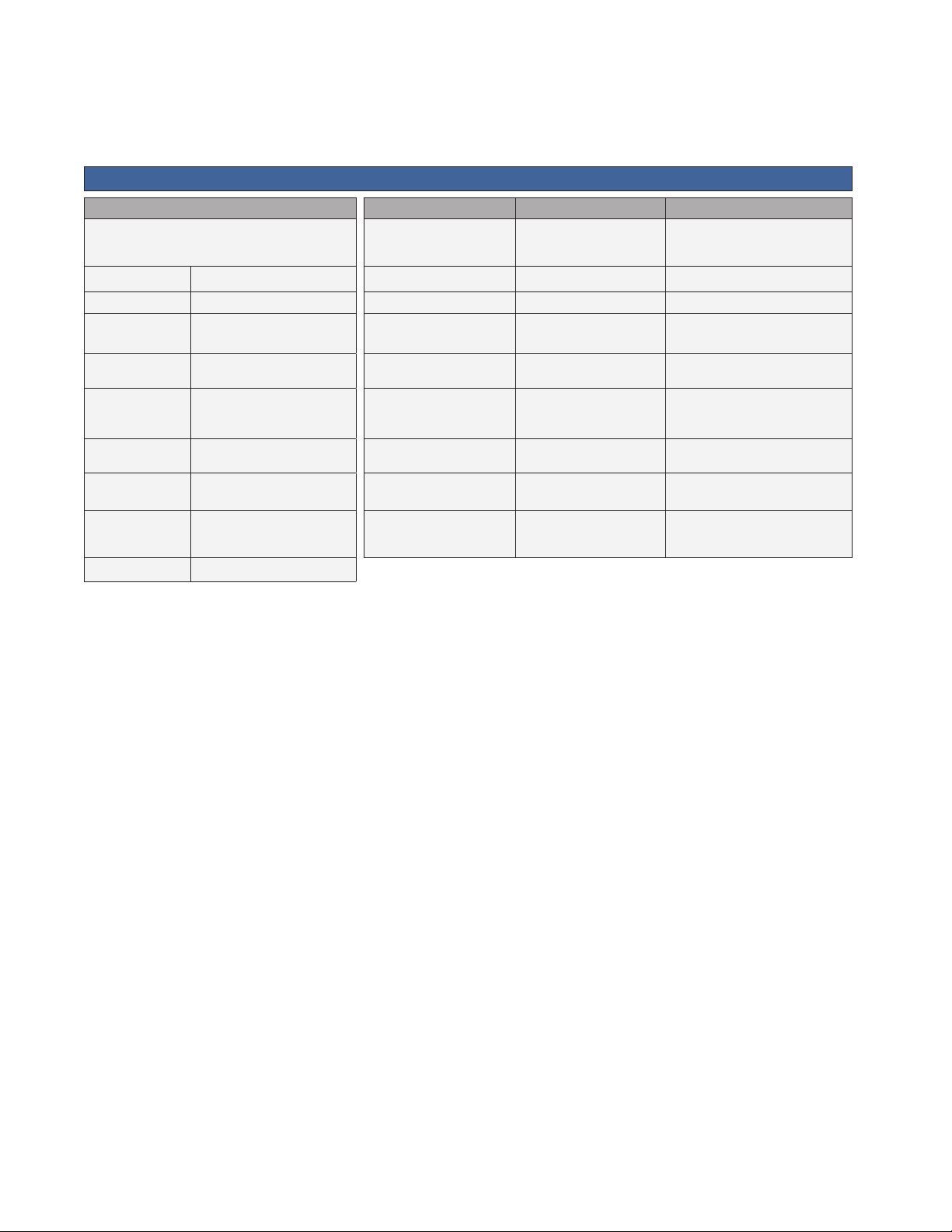

1.2 LPESpecicationsandOptions

Specications

Mechanical Option Part Number Description

Dimensions Batter y Harness: 875- 838 -20

746-152-20

H x W x D (in): 26 X 16.25 X 12 Batter y Heater Mat 746-130-20 Used in cold-climate applications

(mm) 660 X 413 X 305 Battery Retaining Bar (BRB) 605-948-A1 Secures batteries within enclosure

Weight (lb/ kg): 25 / 11.3 Coax Connection: 020- 019-3 5 SPI, 20A (1-2)

021-080-21 SPI RF, 20A (1)

12V Batter y Cable Kit (BCK)

12V Batter y Cable Kit - 2 Batteries

(BCK-2)

SPI, 20A (1-2)

Material: Exter ior powdercoated

aluminum

Battery: 220 GXL or two 70 HPL-FT Lightning Arrester 020- 098-24

Door and Lid Seal: Poron gasketing Service Entrance: 74 4- 656 -20 70A available

Color: Gray, white, and seafoam

green

Lid: Removable Surge Protection: 162-027-10

Door: Hinged, removable

Door Loc ks: 744-229-20 Provisions optional GEM

162-046 -10

745 -9 46-20

Status Indicators: 740-139-25 Local/Remote Indicator (LRI)

162-028-10

162-029 -10

LA- P+ 120V

LA -P-120 T

Surge Arrester Kit

75 Ω Coax, MF

75 Ω Coax, FF, w/Gnd

75 Ω Coax, FF

10

031-302-B0-001 Rev A

Page 11

2.0 Installation

CAUTION!

Never transport the unit with installed batteries. Doing so can cause injury to the installer or damage

the enclosure and equipment. Install the batteries after you transport the unit to the site and secure

it to the pad.

2.1 Enclosure Installation, Wall-mount

CAUTION!

The populated cabinet weighs approximately 150 lbs [68kg]. Installer needs to ensure the wall

is capable of supporting the loaded enclosure. Direct mounting to wall studs and 3/4" plywood

backing is required.

ATTENTION:

Before installing an enclosure, the location and method of mounting must be approved by the utility.

Recommended Tools and Materials:

• Ratchet with 1/2" and 9/16" socket (or metric equivalent)

• Level

• Two user supplied 3/8" x 4 1/2" (or larger) lag bolts (or metric equivalent)

• Two 3/8" stainless steel at washers, 1.00" max diameter x .08" min thickness

• Stud nder (optional)

• Drill with 1/4" drill bit or metric equivalent

• Tape measure

Tab

Installation Procedure:

1. Position the bracket on a wall capable of supporting 150 lbs

(68.0kg). Use a 3/4" plywood backing plate.

2. Maintain a minimum distance of 6" (153mm) from the bottom of the

bracket to the ground for proper enclosure ventilation.

3. Level the bracket vertically with the tab facing up. Center the

bracket on a wall stud.

4. Secure the bracket to the wall using two user-supplied 3/8" x 4 1/2"

(or larger) lag bolts and at washers specied above. The hardware

must sit ush inside the bracket dimples for proper installation.

Verify there is at least a 6" spacing between the bracket and the

ground.

5. Hang the enclosure on the bracket.

6. Securely fasten the enclosure to the bracket using the six 5/16"

bolts, lock washers and fender washers (supplied).

Fig. 2-1, Mounting Bracket

Lag Bolt

Lag Bolt

6" min from ground

031-302-B0-001 Rev A

11

Page 12

2.0 Installation, continued

2.2 Enclosure Installation, Steel or Concrete Pole

To mount the LPE on concrete or steel poles, two user-supplied mounting straps are required

(straps must be stainless, galvanized or equivalent). Most codes require the base of the

enclosure to be located a minimum height from the ground. Always verify height restrictions

before proceeding.

ATTENTION:

The majority of poles are the property of the local utility. Before installing an enclosure, the location and

method of mounting must be approved by the utility.

Required Tools and Materials:

• Two user-supplied pole straps to t pole (straps must be

stainless, galvanized, or equivalent)

• Ratchet with 1/2" socket

Installation Procedure:

1. Position the bracket so that the bottom of the bracket is

at least 6" off of the ground. Also make sure that the tab

is facing up. Secure it to the pole using the pole straps.

2. Hang the enclosure on the bracket.

Tab

12

3. Securely fasten the enclosure to the bracket using the six

5/16" bolts, lock washers and fender washers (supplied).

031-302-B0-001 Rev A

Page 13

2.0 Installation, continued

2.3

Enclosure Installation, Ground-mount

CAUTION!

Never transport the unit with installed batteries. Doing so can cause injury to the installer or damage

the enclosure and equipment. Install the batteries after you transport the unit to the site and secure

it to the pad.

ATTENTION:

It is the responsibility of the installer to meet the requirements of all applicable national and local codes. Alpha

Technologies assumes no responsibility or liability for failure of the installer to comply with the requirements of

all applicable local and national codes.

2.3.1 Pre-Installation

Before choosing a location and beginning installation, consider the following:

Provide adequate room for service personnel to remove the doors for battery •

installation and removal.

Wherever possible, select a site that is above the 100-year ood plain and away •

from residences.

Locate in the shade to minimize the effects of solar loading.•

Locate in an area with good airow.•

Locate at least 4" from the backside of the LPE to any wall.•

Locate away from sprinkler systems or other sources of forced water.•

Locate out of the prevailing wind to minimize the buildup of snow or accumulation •

of wind-borne dust.

Avoid locating the enclosure where it will be an obstruction or will inhibit visibility.•

Evaluate the soil conditions for suitability for the installation of the grounding •

system applicable to your particular installation.

Is utility power cabling run to and terminated at the site? •

NOTE:

The appropriate grounding method for a particular location depends on soil type, available space, local codes,

NEC (National Electric Code), and other site-specic characteristics.

031-302-B0-001 Rev A

13

Page 14

2.0 Installation, continued

PAD

POSTS

SPRINKLER HEAD

SIDEWALK

10’ (3m)

2.3 Enclosure Installation, Ground-mount

2.3.1 Pre-Installation, continued

Alpha Technologies, Inc. cannot anticipate all the ways a vehicle could threaten an

installed system or the specic type of protection that is appropriate for a particular

location. The following installation drawing for Alpha’s Standby Power systems are

general recommendations and not intended to be a specic guideline for protecting

the equipment. The numbers of bollard posts (or other protection devices) depend

upon equipment locations.

, continued

PAD

14

Fig. 2-2, Ground-mount Positioning and Safety

031-302-B0-001 Rev A

Page 15

2.0 Installation, continued

4

1

2

2' min.

2

2

2

2.3 Enclosure Installation, Ground-mount

, continued

2.3.2 Enclosure Grounding: Ground-mount

NOTE:

• Alpha generally recommends using the grounding method illustrated below. However, the grounding

method appropriate for a particular site depends on local codes, the NEC (National Electric Code), and

other site-specic characteristics.

• Alpha Technologies recommends 5 ohms maximum ground resistance between enclosure and ground

rods, in accordance with IEEE 1100-1999 Powering and Grounding Electronic Equipment.

• Alpha Technologies assumes no responsibility or liability for failure of the installer to comply with the

requirements of all applicable local and national codes. Where allowed, exothermic welding may be used

as an alternative to Burndy clamps and connectors.

CAUTION!

Corrosion-proof, twenty-ve-year connections suitable for direct burial must be used.

Burndy YGHP58C2W-2TN or Equivalent

Burndy YGHP58C2W-3 or Equivalent

Terminate at Service Entrance Ground Bar

8' (2.4m) Ground Rods

6’ (1.8m) Apart (min.)

031-302-B0-001 Rev A

Terminate at Enclosure Ground Bar

2' (0.6m)

min.

#2 AWG

3

Fig. 2-3, Suggested Grounding Method

Service Grounding (required)

#6 bare copper wire from service entrance ground bar, with two 1/2" X 8' (12.7mm x 2.4m) copper

1

ground rods, driven at least six feet (1.8 meters) apart.

Lightning Protection (optional)

2

Four 1/2" X 8' (12.7mm x 2.4m) copper ground rods, driven at least two feet from pad.

3

#6 bare copper wire loop, at least 30" (762mm) below grade, and terminated at each ground rod.

4

#6 bare copper wire from loop to enclosure ground bar in service entrance.

15

Page 16

2.0 Installation, continued

2.3 Enclosure Installation, Ground-mount

, continued

2.3.3 Ground-mount Installation

NOTE:

LPE enclosures require a pedestal mount kit for ground installation. Pedestal kit part number: 746-146-20

(gray); 746-146-21 (white); 746-146-22 (seafoam green)

Tools and Materials Required (customer supplied):

• Four 3/8-16” (10mm) anchor bolts (Hilti-style recommended)

• Four 3/8” (10mm) size stainless steel washers

• 2' x 2' (.6m x .6m) continuous vapor barrier (e.g. 30 lb. felt, neoprene pond liner,

or a heavy grade tar paper)

• Hammer drill

• 3/8” (10mm) drill bit

• 9/16” (14mm) wrench

• Metal punch

• Mallet or hammer

• Torque wrench

• Tape measure

• 3/8" socket

CAUTION!

A 25+ year continuous vapor barrier must be placed between the pedestal and the pad to prevent

moisture ingress and corrosion caused by metal-to-concrete contact.

Procedure:

1. Place the vapor barrier material on concrete pad.

2. Using the pedestal as a template, mark the vapor barrier material in the locations

of the four anchor bolts holes.

3. Drill 3/8" (10mm) holes through the vapor barrier and into the pad at the four

marked anchor points.

4. Position the pedestal over holes and insert anchor bolts. Torque the anchor bolts

to bolt manufacturer specications. If Hilti-style bolts are used, torque until head

pops.

5. On the enclosure, remove the three 3/4" (19mm) diameter knock-outs located on

the bottom of the enclosure shelf.

6. Lift the enclosure onto the pedestal. Align the three enclosure mounting holes

with the mounting holes on the top of the pedestal. Secure the enclosure to the

pedestal using the provided 1/4" (11mm) hardware. Torque to 75 in-lbs (8.5 Nm).

7. Trim away excess vapor barrier material.

16

8. The enclosure is now ready for the utility connection, power module, and

batteries.

031-302-B0-001 Rev A

Page 17

2.0 Installation, continued

2.3 Enclosure Installation, Ground-mount

2.3.3 Ground-mount Installation, continued

OUTSIDE OF PEDESTAL

INNER FLANGE

PAD

349.25

PEDESTAL ANCHOR HOLES

, continued

13.75

ENCLOSURE MOUNTING HOLES

PEDESTAL ANCHOR HOLES

203.20

8.00

Fig. 2-4, LPE Enclosure Pedestal

1115.14mm

43.90in

457.20mm

18.00in

509.93mm

20.08in

286.08mm

11.26in

031-302-B0-001 Rev A

Fig. 2-5, Enclosure-to-Pedestal Mounting

17

Page 18

2.0 Installation, continued

2.4 Dimensions

1

[304.80]

12.00

4

[111.13]

4.38

3

2

[391.41]

15.41

[657.94]

25.90

[153]

6 (to ground)

1

Optional SPI or SPI RF

2

Pole/wall mount bracket

3

Enclosure ground point

4

Removable lid

[250.57]

9.87

6

5

7

Knockouts for optional ACI, LRI indicator Lamps

6

Lockable door latch

7

Optional GEM lock

8

Hinged, removable door

9

8

9

18

5

Optional service entrance

031-302-B0-001 Rev A

Page 19

2.0 Installation, continued

2.5 Connecting the Utility Power

WARNING!

ONLY qualied personnel should connect the utility power. Power must be connected in

compliance with local electrical codes, and common safety practices must be observed.

ATTENTION

• Connection to utility power must be approved by the local utility before installing the power supply.

• Electrical codes require that a service disconnect switch be connected between the utility power source and

the Alpha power supply.

• Connection to the power supply must include an appropriate service entrance weather head.

Utility power enters the enclosure through an .875" knockout on the side or rear of the LPE. The

enclosure accepts a standard electrical tting.

A “high-magnetic” trip circuit breaker must be used in order to accommodate the high-inrush currents

associated with the start-up of transformers (400A, no-trip, rst-half cycle). Do not replace this circuit

breaker with a conventional service entrance circuit breaker. Alpha Technologies offers a high-

magnetic Square D circuit breaker and a BBX option (a UL Listed service entrance). Contact your

local sales representative for more information.

Description Alpha Part Number Square D Part Number

120V Installation — High-Magnetic (20A) 470-017-10 QO120HM

120V Installation — High-Magnetic (15A) 470-013-10 QO115HM

US BBX — External Service Disconnect 744-656-20 QO2-4L70RB

CAN BBX — External Service Disconnect 744-656-21 QO2-L70RB

031-302-B0-001 Rev A

19

Page 20

2.0 Installation, continued

2.5 Connecting the Utility Power, continued

2.5.1 Service Power

ATTENTION

Connecting to utility power must be performed by qualied service personnel in compliance with local

electrical codes and common safety practices. Connection to utility power must be approved by the local

utility before installing the power supply.

Electrical codes require that a listed service disconnect switch be installed between the power source and the

power supply. Connection to the power supply must include an appropriate service entrance weather head.

NOTE:

Utility power enters the enclosure through a 70A rainproof SUSE-rated breaker box.

The service entrance is wired as shown in the diagram below.

L1 (Black)

Copper Ground Wire

#8AWG minimum

Breaker

Grounding Point

(made to enclosure wall)

Fig. 2-6, 120Vac Service Entrance Wiring

From Utility

Neutral (White)

Neutral Bus

to Enclosure receptacle

20

031-302-B0-001 Rev A

Page 21

2.0 Installation, continued

2.5 Connecting the Utility Power, continued

2.5.1 Service Power, continued

The breaker option is wired as shown in the diagram below.

Neutral (White)

L1 (Black)

Ground (Green)

Fig. 2-7, 520-R Receptacle Wiring

031-302-B0-001 Rev A

21

Page 22

2.0 Installation, continued

2

3

1

2.5 Connecting the Utility Power, continued

2.5.2 Connecting Coaxial Cable

WARNING!

To prevent injury, DO NOT remove SPI cover until all sources of power have been

removed.

1. Verify SPI IS NOT connected to power supply.

2. Remove the two screws holding cover onto SPI chassis.

3. Remove SPI cover, exposing circuit board and seizure screw assembly.

Seizure Screw

Assembly

4. Insert Coaxial Termination into Output Port on bottom of SPI.

Circuit Board

Seizure Screw

Assembly

Stinger

Side View

of

SPI Case

Output Port

22

Coaxial Termination

031-302-B0-001 Rev A

Page 23

2.0 Installation, continued

ALT ON

2.5 Connecting the Utility Power, continued

2.5.2 Connecting Coaxial Cable, continued

5. Insert coaxial termination fully inside Seizure Screw assembly and tighten

Seizure Screws to 35 Inch-Pounds to prevent arcing and failure of unit.

6. Replace SPI cover and reinstall the screws.

7. Verify switch on top of SPI is in the ON position.

7

6

6

6

031-302-B0-001 Rev A

Fig. 2-18, Cover Replaced,

SPI Switched On

23

Page 24

2.0 Installation, continued

2.5 Connecting the Utility Power, continued

2.5.2 Connecting Coaxial Cable, continued

SPI OR SPI RF SIDE MOUNTING LOCATION

SPI OR SPI RF PRIMARY MOUNTING LOCATION

SECONDARY SPI MOUNTING LOCATION

24

Fig. 2-8, SPI and SPI-RF Mounting Locations

031-302-B0-001 Rev A

Page 25

2.0 Installation, continued

Battery Date Code located in this box

(1210 = DEC. 2010)

1 2 1 0

2.6 Battery Installation

WARNING!

Battery systems represent a risk of electrical shock and high short circuit currents.

The following precautions must be observed when maintaining batteries:

• Remove all personal metal objects (watches, rings, etc.).

• Use insulated tools.

• Wear eye protection and rubber gloves.

• Observe circuit polarities.

• Do not make or break live circuits.

• Do not lay metal tools and hardware on top of the batteries.

The batteries are enclosed in cabinets with limited access. Again, extreme caution must be exercised

when maintaining and collecting data on the battery system.

BatteryIdentication

Each battery contains a DATE CODE usually located on a sticker between the battery posts. This

date code must be recorded in the battery’s maintenance log. If batteries other than those installed by

Alpha are used, consult the battery’s documentation for date code type and placement.

031-302-B0-001 Rev A

Fig. 2-9, Battery Identication Label

25

Page 26

2.0 Installation, continued

2.6 Battery Installation, continued

WARNING!

To prevent arcing, never allow live battery cables to make contact with the enclosure.

Disconnect battery leads, or wrap the cable lugs with electrical tape.

CAUTION!

Threaded insert terminals require the use of 3/4" bolts. The use of 1" bolts will seriously damage the

battery. The only exception is the terminal with the large spacer for the in-line fuse link.

NOTE:

In battery congurations made up of multiple battery strings, Alpha strongly recommends the use of in-line

fuses.

Procedure:

1. Place the batteries on the enclosure’s battery shelf. Position the batteries to allow

maximum ventilation space between the batteries.

2. To make identication and record keeping easier, number and label the batteries. Record

each battery’s number and date code in the power supply maintenance log.

3. Using the battery arrangement diagram as a reference, achieve 12Vdc. Torque terminal

connections according to battery recommendations (see battery label for AlphaCell

batteries).

4. Check the polarity and voltage of the battery cable connector with a voltmeter to verify

correct connections. Do Not connect the battery string or strings to the power supply at this

time.

5. The power supply battery charger collects battery temperature compensation information

with a Remote Temperature Sensor (RTS) attached to one of the batteries. Refer to the

diagrams to determine which battery to attach the RTS to. Co-term the RTS onto the

negative battery terminal. Route the RTS connector onto the power supply shelf and

attach to provided cable clip. Do Not connect the RTS to the power supply at this time.

CAUTION!

Recheck the polarity and voltage of the battery cable connector before proceeding.

6. Route the battery cable connector into the power supply compartment. Do Not connect to

the batteries to the power supply at this time.

26

031-302-B0-001 Rev A

Page 27

2.0 Installation, continued

2.6 Battery Installation, continued

2.6.1 Battery Terminal Connections

NOTE:

Various types of batteries with different mounting styles and hardware may be shipped with the system.

ALWAYS refer to the battery manufacturer’s specifi cations for correct mounting hardware and torque

requirements. Use only the hardware and torque recommended by the battery manufacturer.

CAUTION!

Threaded insert terminals require the use of 3/4" bolts. The use of 1" bolts will seriously damage the

battery. The only exception is the terminal with the large spacer for the in-line fuse link.

3/4" x 1/4-20 Bolt

Split Washer

Flat Washer

Nut

Split Washer

Flat Washer

Battery Cable

In-Line Fuse Link

Flat Washer

1" or 3/4" x 1/4-20 Bolt

Battery Cable

Battery Terminal

Fig. 2-10, Hardware stack-up, Threaded Battery Insert

1" x 1/4-20 Bolt

Split Washer

Flat Washer

Fuse

Spacer

Battery Terminal

031-302-B0-001 Rev A

Fig. 2-11, Hardware stack-up, Threaded Battery Insert with optional in-line fuse

27

Page 28

2.0 Installation, continued

2.7 Power Supply Installation

For XM2-300 HP initial setup, please refer to the XM2-300 HP Quick Start Guide (p/n

017-877-B0-001), or the XM2-300 HP Technical Manual (p/n 017-877-B1-001).

For ELPM 300-48D initial setup, please refer to the ELPM 300-48D Installation

Manual (p/n 010-322-C0-003).

28

031-302-B0-001 Rev A

Page 29

3.0 LPE Enclosure Maintenance

Preventive Maintenance must be performed every three to six months. By establishing a routine

maintenance program and following the guidelines contained in this manual, the LPE Enclosure will

continue to provide years of trouble free operation.

Inspect the LPE Enclosure

Perform a complete inspection of the LPE Enclosure. Look for signs of rust and corrosion, paying

particular attention to the battery tray. Clean any rust or corrosion immediately.

Inspect the Mounting Brackets and Hardware

Carefully inspect the LPE Enclosure’s Mounting Bracket and mounting hardware. Look for signs of

unusual wear and loose hardware. Correct all mounting hardware failures immediately.

Check Battery Terminals and Connecting Wires

Care of the batteries is a critical step in any maintenance program. In addition to voltage checks,

visually inspect the batteries for signs of cracking, leaking, or swelling. To aid in quick identication

and tracking of voltages in the maintenance log, number the batteries inside the enclosure using

labels or masking tape, etc. Batteries are temperature sensitive and susceptible to overcharging

and under-charging. Since batteries behave differently in the winter than in the summer, Alpha’s

battery chargers automatically compensate for changes in temperature by adjusting oat and accept

charge voltages. See the power supply Operator’s and Technical Manual for complete Power Supply

Preventive Maintenance instructions.

Check each battery terminal and connection. Verify the posts are clean and the crimped connectors

are tight. Terminal connectors must be torqued to manufacturer specications at installation. If there

is an “in-line” or battery-mounted fuse in the battery cable, check the fuse holder and fuse. Verify the

terminals are properly greased with an approved battery terminal corrosion inhibitor such as NCP-2.

Record date of maintenance in the maintenance log.

Check Battery Open Circuit Voltage

Switch the power supply’s BATTERY BREAKER to the OFF position. Disconnect the battery

connector from the Inverter Module and measure the individual voltage across each battery. The

difference between any battery in the string must not be greater than 0.3 Vdc. Defective or marginal

batteries must be replaced with an identical type of battery. Record the unloaded battery voltages in

the maintenance log.

NOTE:

Whenever the power supply’s BATTERY BREAKER is turned OFF or the batteries are not connected, the

power supply will not operate in Inverter Mode in the event of a utility power failure.

031-302-B0-001 Rev A

29

Page 30

Page 31

Alpha Technologies Inc.

3767 Alpha Way

Bellingham, WA 98226

United States

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Alpha Technologies Ltd.

7700 Riverfront Gate

Burnaby, BC V5J 5M4

Canada

Tel: +1 604 436 5900

Fax: +1 604 436 1233

Toll Free: +1 800 667 8743

Alpha Industrial Power Inc.

1075 Satellite Blvd NW,

Suite 400

Suwanee, GA 30024

United States

Tel: +1 678 475 3995

Fax: +1 678 584 9259

Alpha Energy

1628 W Williams Drive

Phoenix, AZ 85027

United States

Tel: +1 602 997 1007

Fax: +1 623 249 7833

Alpha Technologies Europe Ltd.

Twyford House Thorley

Bishop’s Stortford

Hertfordshire, CM22 7PA

United Kingdom

Tel: +44 1279 501110

Fax: +44 1279 659870

Alpha Technologies

Unit 504, 5/F,

Fourseas Building

No 208-212 Nathan Road

Kowloon, Hong Kong

Tel: +852 2736 8663

Fax: +852 2199 7988

Alpha Technologies GmbH

Hansastrasse 8

D-91126

Schwabach, Germany

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec Ltd.

339 St. Andrews St.

Suite 101 Andrea Chambers

P.O. Box 56468

3307 Limassol, Cyprus

Tel: +357 25 375 675

Fax: +357 25 359 595

Alpha Innovations Brasil

Avenida Ibirapuera,

2120 – Cj 76

Moema - 04028-001

Santos SP, Brazil

Tel: +55 11 2476 0150

Fax: +55 11 2476 0150

Technologies Argus

First de Mexico

Anatole France Num. 17

Colonia Polanco

11560, México D.F.

Tel: +52 55 5280 6990

Alpha TEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1, Ofce 403

Moscow, 109028

Russia

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltic

S. Konarskio Street 49-201

Vilnius, LT-03123

Lithuania

Tel: +370 5 210 5291

Fax: +370 5 210 5292

Visit us at www.alpha.com

Due to continuing product development, Alpha Technologies reserves the right to change specications without notice.

Copyright © 2010 Alpha Technologies. All Rights Reserved. Alpha® is a registered trademark of Alpha Technologies. 031-302-B0-001 Rev. A (05/2010)

Loading...

Loading...