Page 1

SECTION E

Rev. 20 - 03/2011

Tek-CARE® NC150 and NC200

Intercom Nurse Call Systems

UL® 1069 Listed

IL380

Distributed by:

Alpha Communications

42 Central Drive

Farmingdale, NY 11735-1202

Phone: (631) 777-5500

Fax: (631) 777-5599

®

Operation, Installation and Service Manual

Website:

www.AlphaCommunications.com

Email:

info@alphacommunications.com

TOLL-FREE Technical #:

1-800-666-4800

Tek-CARE® NC150 and NC200 series Intercom Nurse Call Systems are designed for nursing

home or individual hospital ward use. The T ek-CARE® NC150 and NC200 systems provide

selective two-way audio and visual communication from master station to staff and patient

stations, as well as emergency signaling and call indication from remote locations.

Emergency calls are indicated by a rapid pulsing of all audible and visual signals associated

with the calling station. Emergency calls take precedence over normal calls and can only

be canceled at the point of origin.

Page 2

Operation, Installation and Service Manual

Copyright © 2001–2011 TekTone® Sound & Signal Mfg., Inc., All rights reserved.

No part of this publication may be copied without the express written permission of TekTone® Sound & Signal Mfg., Inc. The

content of this manual is furnished for informational use only, is subject to change without notice, and should not be construed as

a commitment by TekTone® Sound & Signal Mfg., Inc. TekTone® Sound & Signal Mfg., Inc. assumes no responsibility or liability

for any errors or inaccuracies that may appear in this documentation.

T ekTone, the T ekTone logo, T ek-Call, Tek-Care, Tek-Check-In, T ek-Com, Tek-Digicare, T ek-Door, Tek-Entry III, Tek-Guard, TekMicro, Tek-Micro II, Tek-MMARS II, TekNIOS, TekNIOS II, Tek-Paging, Tek-Phone, Tek-Safe, Tek-Select II, Tek-Sentry, TekSound, Tek-Status, Tek-Trio and Tek-View are either registered trademarks or trademarks of TekTone® Sound & Signal Mfg., Inc.

in the United States and/or other countries. All other trademarks are the property of their respective owners.

ii • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 3

Table of Contents ————————————————————

A Word About ESD (Electrostatic Discharge).......................................iv

System Operating Instructions...............................................................1

NC150N, NC200N Master Stations........................................................................... 1

IR150B Staff Stations ................................................................................................ 3

IR151B, IR152B Patient Stations .............................................................................. 5

IR155B Patient Stations ............................................................................................. 5

SF155B Emergency and SF156B Code Stations ....................................................... 5

LI150B Duty Stations ................................................................................................. 5

LI381 Corridor Lights ................................................................................................ 6

LI382 & LI382LED Corridor Zone Lights................................................................ 6

System Installation...................................................................................7

Installation Procedure ................................................................................................. 7

Equipment Locations .................................................................................................. 7

Wiring Installation ..................................................................................................... 8

Housing Installation ................................................................................................... 9

Wire Checkout .......................................................................................................... 10

Wire Connections .................................................................................................... 10

Connections Checkout .............................................................................................. 11

System Test Instructions........................................................................................... 11

System Checkout and Testing .................................................................................. 11

System Maintenance Instructions ........................................................ 13

NC150N, NC200N Master Stations......................................................................... 13

PK151A, PK152 Power & Control Units ................................................................ 14

IR150B Staff and IR155B Patient Stations.............................................................. 14

PK800A Secondary Power Supply ........................................................................... 14

FZ151 In-Line Fuse Holder ...................................................................................... 14

IR151B, IR152B Patient Stations ............................................................................ 15

SF155B Emergency and SF156B Code Stations ..................................................... 15

LI150B Duty Stations ............................................................................................... 15

LI381 Corridor and LI382 Corridor Zone Lights ................................................... 15

Replacement Parts .................................................................................................... 16

Illustrations & Wiring Diagrams

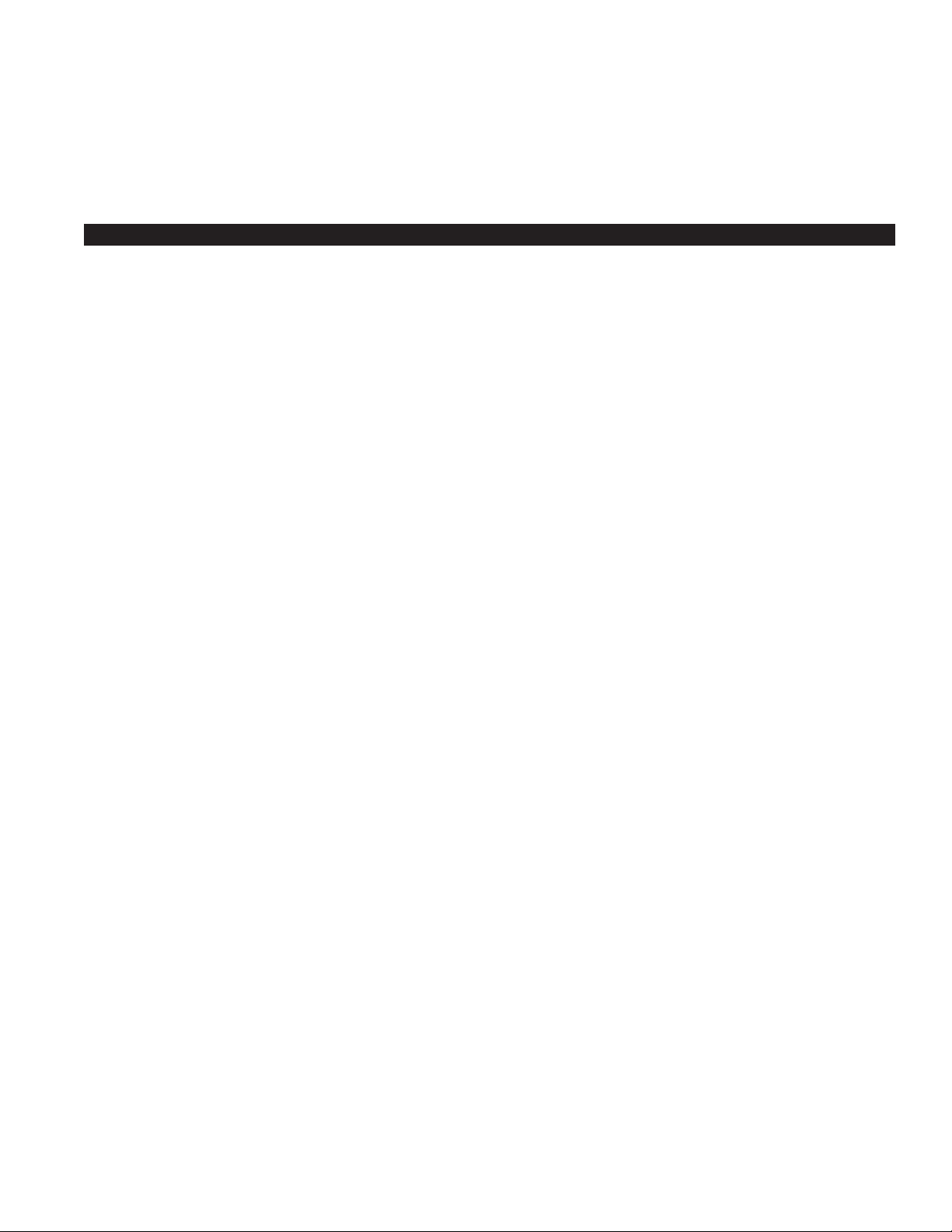

Figure 1—NC150N and NC200N Control Locations................................................ 2

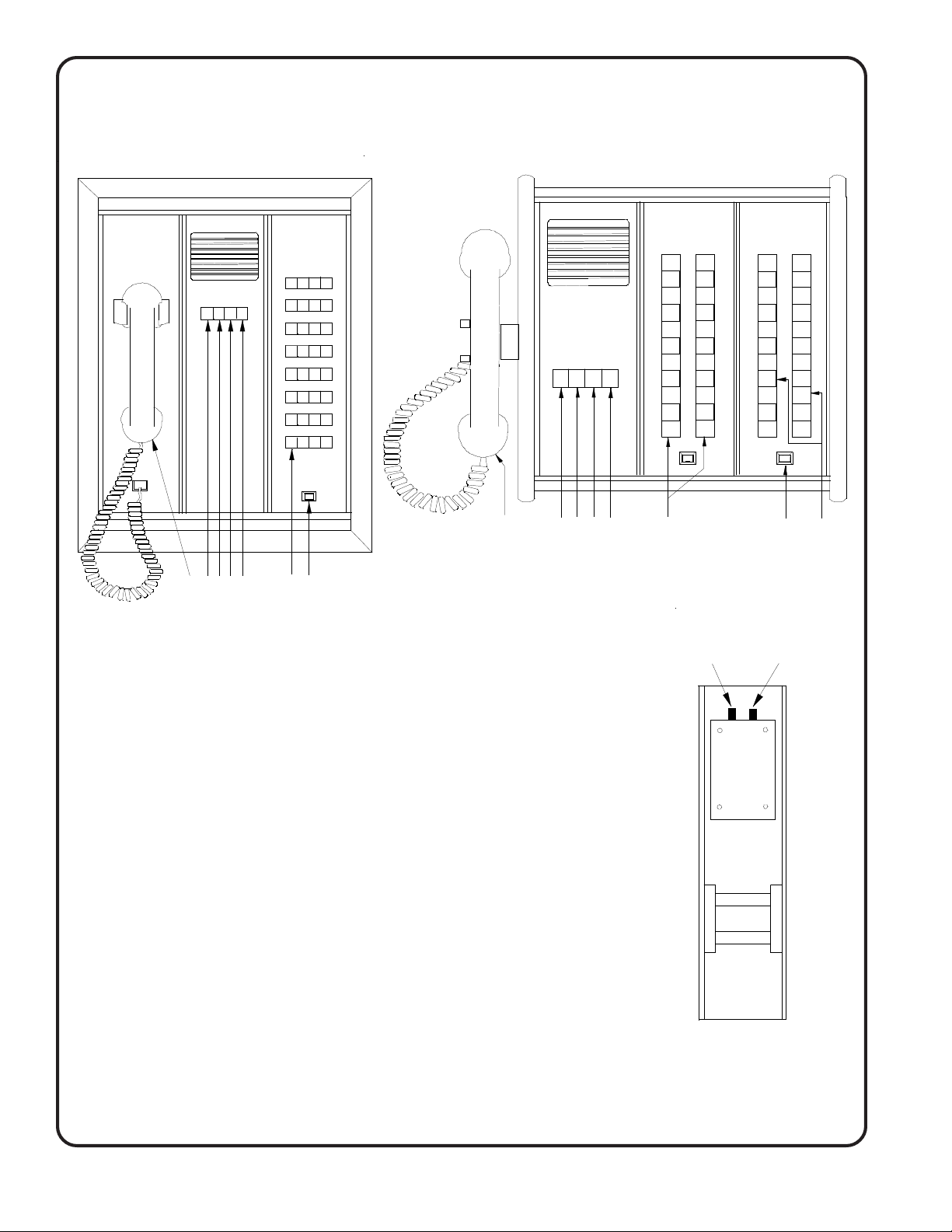

Figure 2—Duty, Staff, Patient, Emergency & Code Station Control Locations........ 4

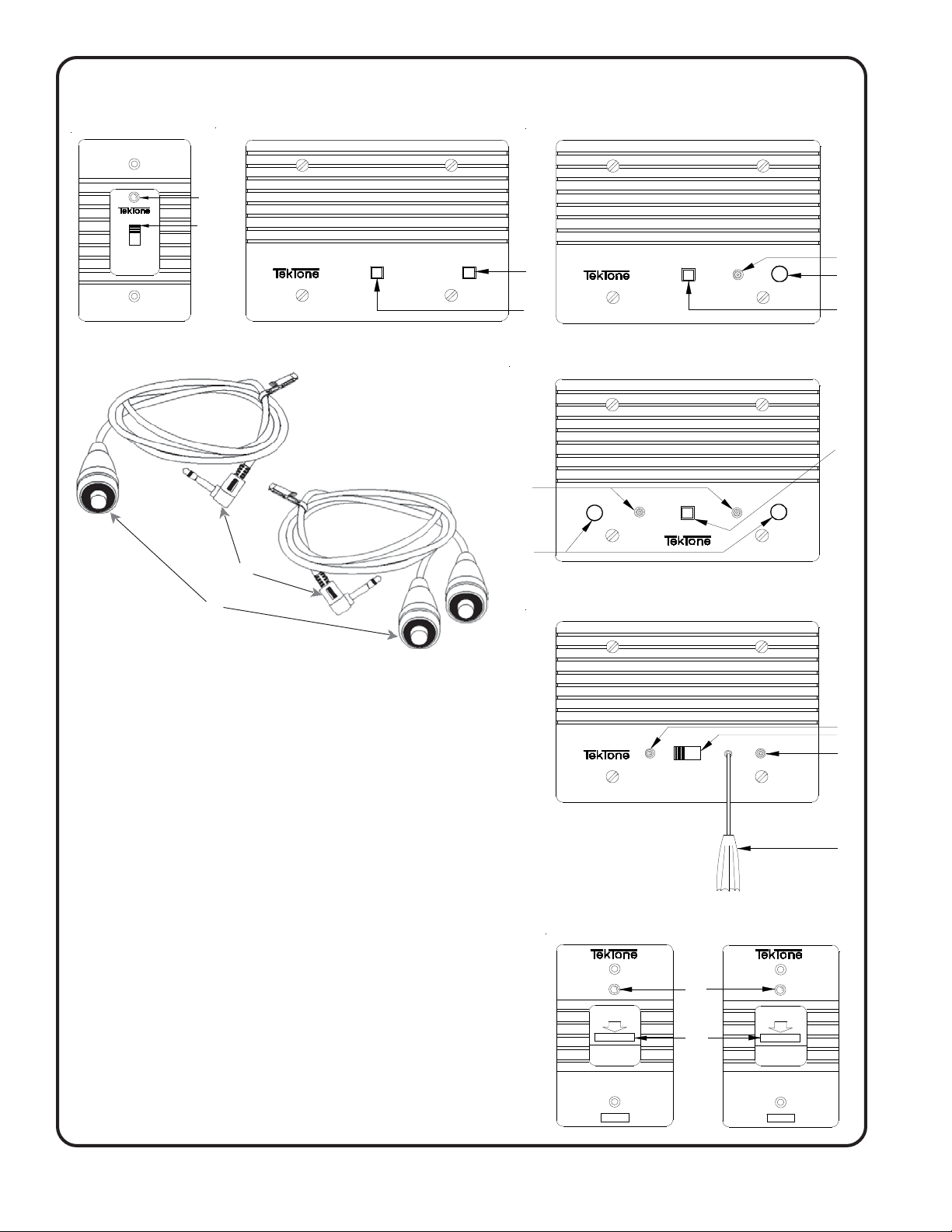

Figure 3—Master Panel Housing Chart and Wall Cut-Out Details ......................... 8

Figure 4—Panel Removal and Replacement ............................................................. 8

Figure 5—Ring and Back Box for IR150B, IR151B, IR152B and IR155B............. 9

Figure 6—Ring and Back Box for SF155B, SF156B, LI150B,

LI381, LI382 and LI382LED.............................................................................. 9

Figure 7—SS106 Transformer Installation ............................................................. 10

Figure 8—NC150N, NC200N Selector Lamp/Switch

Lens, Filter and Lamp Replacement ................................................................. 13

Figure 9—NC150N, NC200N Nurse Call Systems Notes and Electrical Ratings. 17

Figure 10—Block Wiring Diagram without Zone Lamps ..................................... 18

Figure 11—Block Wiring Diagram with Zone Lamps ............................................ 19

Figure 12—NC150N, NC200N Wiring Diagram ................................................... 20

Figure 13—NC150N, NC200N, Two Stations in Parallel....................................... 2 1

Figure 14—PK153 Wiring Diagram with Smoke Detector .................................... 22

Figure 15—PK153 Wiring Diagram with SF156B Code Station........................... 23

Figure 16—PK151A or PK152 to PK800A Interconnection .................................. 24

Figure 17—SK151N Switch Board PCB Assembly ................................................ 25

Figure 18—SF337C Cross Reference Diagram ....................................................... 26

Figure 19—SF339 Cross Reference Diagram.......................................................... 27

Figure 20—NC110N Hookup to NC150N, NC200N .............................................. 28

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • iii

Page 4

A Word about ESD (Electrostatic Discharge)————————

What Is It? Static electricity is a result of triboelectric charging of two dissimilar

nonconductive materials that are rubbed together, such as rubbing your feet on a carpet on

a cold winter day or in a dry climate. The resulting charge is detected when you reach out

to touch a doorknob or some other metallic object. The resulting discharge may only be

startling or, in severe cases, it may even be painful. The actual electrical char ge is dependant

on the materials being rubbed together, humidity, the rate of separation, and other factors.

What Can It Do? While this effect may be disturbing to humans, the effect on electronic

equipment is often more serious, ranging from operational disruption to actual component

damage. These effects result from the high voltages that may be developed. The simple act

of walking across a carpet may develop as much as 30,000 volts, and changing a bed sheet

may create a charge of 100,000 volts or more. Such voltages readily cause arcing (the

spark that can be observed when you grab a doorknob after walking across a carpet, etc.).

The arcing is evidence of the discharge path. Due to the high voltage involved, the discharge

current can jump to any nearby metallic or non-metallic object. If the discharge is to or

through an electronic device, such as the nurse call system, the operation of the device may

be affected. If the discharge current passes through internal components, these components

may be damaged or their operation degraded.

What Can We Do About It? The manufacturer of the nurse call equipment has already

taken steps to protect the equipment from electrostatic discharge (ESD) effects. However,

since the cause is not in the equipment, but in the environment, further measures are

required of the installer and the user to achieve complete protection.

What The Installer Can Do: In humid climates or in places where the relative humidity is

kept at 65% or greater, there will likely be few problems with ESD. Where problems may

occur the following measures can be taken.

• Ground all exposed metal surfaces. Grounding should be to a #16 gauge or larger

conductor.

• Install nurse call system wiring in metal conduit. This conduit may be used to ground

panels.

• Use shielded cable for nurse call system station-to-station wiring. The use of open

conductors invites inductive coupling of discharge currents, which can cause the

same problems as direct discharge currents.

• Ground your body before handling system components. This can be done by using a

wrist strap, or simply by contacting a grounded metal surface. Use caution to avoid

hazardous voltages while grounded.

What The User Can Do: The most common generation of ESD in hospitals is due to

changing linen on hospital beds while the patient call cord or pillow speaker is still connected

to the nurse call system. The following precautions will help.

Remove the call cord or pillow speaker from the bed before changing the linen. It will be

necessary for the nursing staff to discharge themselves by contacting a grounded metal

object before placing the call cord or pillow speaker back on the bed; otherwise a spark will

jump to the nurse call equipment, causing the very damage they are trying to avoid. To

avoid a shock while discharging static electricity on the body, hold a metal object, such as

a key, and use that object to contact the grounded surface.

This information is provided to make you aware of ESD problems so that precautions may

be taken to avoid damage and disruption of system operation.

iv • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 5

System Operating Instructions ——————————————

This section provides complete operating instructions for all Tek-CARE® functions, as

well as reference drawings for use in locating and describing all controls. System operators

must read the following operating instructions concerning system equipment and the terms

used in conjunction with the equipment.

NC150N, NC200N Master Stations

Refer to Figure 1 for locations, names, and functions of controls and indicators.

Answer Normal Calls:

Normal calls are indicated by simultaneous operation of the following signals:

• Steady illumination of the associated station selector lamp which is marked to

indicate call origin.

• Steady illumination of call lamp.

• Slowly pulsing audible tone. The audible call signal may be canceled for normal calls

by pressing the TONE OFF button. The button will then illuminate to indicate the tone

is silenced. Pressing the TONE OFF button when illuminated resets the call tone.

To establish conversation with the calling station, press the associated station selector

button. The remote station’s RESET lamp will illuminate. To speak to the caller, press

the TALK button while speaking and release to listen.

When the conversation is complete, press the associated station selector button to release

the station. The remote station’ s RESET indicator will turn of f. Normal calls placed from

an IR155B Station must be canceled at the point of origin.

Answer Normal Calls Using Optional TA150N or TA200N Handset:

To establish conversation with the calling station, press the associated station selector

button. The remote station’s RESET lamp will illuminate. To speak to the caller, lift the

handset from the cradle and begin normal two-way conversation. When the conversation

is complete, press the associated station selector button to release the station. The remote

station’s RESET lamp will turn off. Replace the handset in the cradle. Normal calls

placed from an IR155B Station must be canceled at the point of origin.

Answer Emergency Calls:

All emergency calls take precedence over any normal call signal. Emergency calls

must be answered in person and can only be canceled from point of origin. Emergency

calls are indicated by simultaneous operation of the following signals:

• Rapid flashing of the associated station selector lamp, which is marked to indicate

call origin.

• Rapid flashing of call lamp.

• Rapidly pulsing audible tone.

Answer Code Calls:

All code calls take precedence over any normal or emergency call signal. Code calls

must be answered in person and can only be canceled from point of origin. Code calls

are indicated by simultaneous operation of the following signals:

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

• Very rapid flashing of the associated station selector lamp (twice the rate of

emergency call), which is marked to indicate call origin.

• Very rapid flashing of call lamp (twice the rate of emergency call).

• Very rapidly pulsing audible tone (twice the rate of emergency call).

IL380 Tek-CARE® NC150 & NC200 Manual • 1

Page 6

NC150N

Figure 1—NC150N and NC200N Control Locations

NC200N

8

1 234

7

1 – Duty Button: Transfers call tones from master station to a selected patient

station when pressed.

2 – Tone Off Button: Silences normal call tone when depressed.

– Tone Off Lamp: Indicates tone silenced when illuminated.

3 – Call Button: Tone call to selected remote when pressed.

– Call Lamp: Indicates incoming call when illuminated. Indicates emergency

call when flashing.

4 – Talk Button: Talk when pressed. Listen when released.

5 – Station Selector Buttons (PM150/4N): Establishes conversation path with

associated remote station when depressed.

– Station Selector Lamps: Indicates incoming call from associated remote

when illuminated. Indicates emergency call from remote when flashing.

6 – Lamp Test Button (ST005D): Illuminates all lamps on panel when pressed.

7 – Telephone Handset (TA150N option): Lift from cradle to use for two-way

communication.

8 – Telephone Handset (TA200N option): Lift from cradle to use for two-way

communication.

9 – Group Call Button: Places call to all remote stations represented by row of

selector switches. Paging function only.

10 – Lamp Test Button: Illuminates all lamps on panel when pressed.

11 – Station Selector Buttons (PM200/20N): Establishes conversation path with

associated remote station when depressed.

– Station Selector Lamps: Indicates incoming call from associated remote

station when illuminated. Indicates emergency call from remote when flashing.

56

1234

9

Call Tone Intercom

Volume

Control

NC150N, NC200N

Rear View of

Speaker/Control Panel

10

Volume

Control

11

2 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 7

System Operating Instructions

Call a Remote:

• Locate the station selector button associated with the remote station to be called. Press

that selector button to establish a conversation path. The remote station’s RESET lamp

will illuminate.

• Press the

TALK button while speaking, and release button to listen. The remote area

may be monitored by selecting the remote station and releasing the TALK button.

• When conversation or monitoring is complete, press the station selector button to

release it. The remote station’s RESET lamp will turn off. NOTE: Normal and

emergency calls will be received even while the NC150N or NC200N Master

Station is in use. The normal audible tone signal will be silenced, but the

emergency tone and visual indicators will function as previously described.

Group Call Remote Stations (from NC200N only):

• Locate the row of selector buttons for which group call is desired. Press the button

labeled

GROUP CALL for that row. The remote stations’ RESET lamps will illuminate.

Group call may be selected for only one row at a time.

• Press the TALK button while speaking. NOTE: Group call serves as a paging

function only. No reply will be heard.

• When paging or announcement is completed, press the GROUP CALL button so it is

released. The remote stations’ RESET lamps will turn off.

Activate Nurse Follower Feature:

• Press the DUTY button and the associated station selector button to which calls are to

be transferred. All incoming emergency and normal calls to the master station will

be directed to the remote station selected.

• Calls may be answered at the master station only. When answering an emergency or

normal call, depress the DUTY button to release it and follow procedures for answering

calls as previously described. NOTE: Origination of a call will also be indicated

by associated corridor dome light, if installed.

IR150B Staff Stations

Test Station Selector Lamp:

Press lamp test button (one is included for each panel of station selector button/lamps).

All station selector lamps on that panel should illuminate. (See NC150N, NC200N

Master Stations in the System Maintenance Instructions section for proper procedures

and precautions in replacing defective lamps.)

Improper Operation:

• If the NC150N or NC200N Master Station fails to operate as described, contact

qualified maintenance personnel. There are no user replaceable parts on the NC150N

or NC200N Master Stations other than the station selector lamps.

• If a malfunction occurs during a call and causes a lack of indication of call origin on

the master station, first determine the origin of the call by observing which corridor

light and corridor zone light is illuminated, then inform qualified personnel.

Refer to Figure 2 for locations, names and functions of controls and indicators.

Call the NC150N or NC200N Master Station: Press the CALL button. The call-placed lamp

will illuminate to indicate call placement. When the call is answered, the call-placed

lamp will go off and the IN USE LED will illuminate to indicate a communication path

has been established to the master station. Speak in a normal voice.

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • 3

Page 8

Figure 2—Duty, Staff, Patient, Emergency & Code Station Control Locations

LI150B Duty Station

Tone Off

SF301A Call Cord

IR150B Staff Station

12

13

RESET CALL

1

2

IR151B Patient Station

RESET

CALL

3

4

2

IR152B Patient Station

2

SF302 Call Cord

3

4

CALL

RESET

CALL

5

6

1 – Call Button: Places a call when pressed.

– Call Placed Lamp: Indicates a call is placed when illuminated.

2 – Reset Button: Cancels the call when pressed.

– In Use LED: Indicates station is in use when illuminated.

3 – Call Placed Lamp: Indicates a call is placed when illuminated.

4 – Call Cord Jack: Receptacle for SF301A or SF302 call cord.

5 – Plug: Connects call cord to patient station when plugged into

call cord jack.

6 – Call Button: Places a call when pressed, if cord is connected

to patient station.

7 – In Use LED: Indicates station is in use when illuminated.

8 – Reset Switch: Cancels the call when pushed to the left.

9 – Call Cord: Places a call when pulled.

10 – Call Placed Lamp: Indicates a call is placed when flashing.

11 – Call/Cancel Switch: Places a call when pulled down. Cancels

the call when pushed up.

12 – Call Placed Lamp: Indicates a normal call is placed when

illuminated. Indicates an emergency call when flashing.

13 – Tone Off Switch: Silences normal audible tone signal when

pushed down.

IR155B Patient Station

RESET

CALL

SF155B Emergency & SF156B Code Stations

10

EMERGENCY

CODE

11

7

8

3

9

4 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 9

System Operating Instructions

IR151B, IR152B Patient Stations

Cancel a Call: Press the RESET button. CALL PLACED lamp will go off.

Improper Operation: Contact qualified service personnel if the station does not operate as

described. There are no user serviceable parts on the IR150B Staff Station.

Refer to Figure 2 for locations, names and functions of controls and indicators.

Call a Nurse: Press the CALL button located on the end of the call cord. The CALL PLACED

lamp will illuminate to indicate call placement. When the nurse answers, the CALL

lamp will go off and the IN USE LED will illuminate to indicate that a commu-

PLACED

nication path has been established with master station. When the nurse speaks, reply in

a normal voice. NOTE: If the call cord is pulled from its receptacle, a call will be

placed automatically and cannot be canceled until the call cord is replaced in the

receptacle.

Cancel a Call: Press the

Improper Operation: If the patient station does not operate as described, contact qualified

service personnel. There are no user serviceable parts on the IR151B, IR152B Patient

Stations other than call cords.

IR155B Patient Stations

Refer to Figure 2 for locations, names and functions of controls and indicators.

Call A Nurse: Pull the cord. The CALL PLACED lamp will illuminate to indicate call place-

ment. When the nurse answers, the CALL PLACED lamp will go off and the IN USE LED

will illuminate to indicate that a communication path has been established with the

master station. When the nurse speaks, reply in a normal voice.

Cancel a Call: Call must be canceled at the point of origin. Push the RESET switch to the

left. The CALL PLACED lamp will go off.

Improper Operation: If the station does not operate as described, contact qualified service

personnel. There are no user serviceable parts on the IR155B Patient Station.

SF155B Emergency and SF156B Code Stations

Refer to Figure 2 for locations, names and functions of controls and indicators.

Call a Nurse: Pull the call cord, or slide the call/cancel switch down. The CALL PLACED

lamp will flash. Wait for the nurse.

RESET button. The CALL PLACED lamp will go off.

Cancel a Call: Push the call/cancel switch up. The CALL PLACED lamp will go off.

Improper Operation: If the call station does not operate as described, contact qualified

LI150B Duty Stations

Refer to Figure 2 for locations, names and functions of controls and indicators.

Emergency Calls: Emergency calls are indicated by a flashing CALL PLACED lamp and a

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

service personnel. There are no user serviceable parts on the SF155B Emergency Call

and SF156B Code Call Stations.

rapidly pulsing audible tone. The audible tone signal cannot be silenced by the TONE

switch.

OFF

IL380 Tek-CARE® NC150 & NC200 Manual • 5

Page 10

System Operating Instructions

LI381 Corridor Lights

Normal Calls: Normal calls are indicated by steady illumination of the CALL PLACED lamp

and a slowly pulsing audible tone. Push the TONE OFF switch down to silence the audible

tone signal. Push the TONE OFF switch up to turn the audible tone signal on.

Improper Operation: If the call station does not operate as described, contact qualified

service personnel. There are no user serviceable parts on the LI150B Duty Station.

Emergency Calls: Emergency calls are indicated by rapid flashing of the corridor light

that is associated with the calling station.

Code Calls: Code calls are indicated by very rapid flashing of the corridor light that is

associated with the calling station.

Normal Calls: Normal calls are indicated by steady illumination of the corridor light that

is associated with the calling station.

Improper Operation: If corridor light does not operate as described, contact qualified

service personnel. There are no user serviceable parts on the LI381 Corridor Lights

other than lamps.

LI382. LI382LED Corridor Zone Lights

Emergency Calls: Emergency calls are indicated by rapid flashing of the red corridor zone

light associated with the zone or area from which an emergency call has been placed.

Code Calls: Code calls are indicated by very rapid flashing of the designated corridor zone

light associated with the zone or area from which a code call has been placed.

Normal Calls: Normal calls are indicated by steady illumination of the white corridor

zone light associated with the zone or area from which a normal call has been placed.

Concurrent Emergency and Normal Calls: If an emergency and normal call are placed in

the same zone at the same time, the red lamp connected to the emergency station from

which a call was placed will flash rapidly, while the white lamp associated with the

normal call will maintain a steady illumination.

Improper Operation: If corridor zone light does not operate as described, contact quali-

fied service personnel. There are no user serviceable parts on the LI382 Corridor Zone

Lights other than lamps. There are no user serviceable parts on the LI382LED Corridor Zone Lights.

6 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 11

System Installation ———————————————————

Installation Procedure

• Read the following instructions concerning system equipment and determine installation methods before proceeding.

• Determine equipment locations.

• Install wiring.

• Install housing.

• Check wires.

• Connect equipment.

• Check connections.

Equipment Locations

NC150N, NC200N Master Stations: Locate NC150N or NC200N Master Station within

easy reach of operating personnel. Do not exceed operating temperature of 10–30°C.

IR150B Staff Stations: Locate IR150B stations where convenient to operate, but not in the

same room as the NC150N or NC200N Master Station. Do not exceed operating temperature range of 10–40°C.

IR151B, IR152B, IR155B Patient Stations: Locate patient stations where convenient for

operation. Do not exceed operating temperature range of 10–40°C.

SF155B Emergency Switch: Locate emergency stations where convenient for operation.

A void areas where direct contact with water may occur. The SF155B includes a 6' long

pull cord permitting installation high enough to provide easy operation by the nurse

and by seated or prone patients. The SF155B may be used without the cord as a pulldown actuated switch.

SF156B Code Switch: Locate code stations where convenient for operation. Avoid areas

where direct contact with water may occur.

LI150B Duty Stations: Locate duty stations as needed and where convenient for opera-

tion. Location should provide for unobstructed visibility of the call indicator.

LI381 Corridor Lights: Locate corridor lights in the corridor above or beside the door of

the associated room. Location should provide for unobstructed visibility of the corridor

light in both directions.

LI382, LI382LED Corridor Zone Lights: Locate corridor zone lights in the corridor area

nearest the nurses central monitoring station. Location should provide for unobstructed

visibility of each corridor zone light from the central location.

SF301, SF302 Call Cords: Insert call cord plugs into the associated station jacks as indi-

cated on the stations. Call cords provided are 6' or 10' in length.

PK151A, PK152 Power & Control Units: Locate the PK151A or PK152 and IH151N

Junction Box in an accessible area. Do not exceed operating temperature range of 10–

30°C. Location should provide for convenient cable runs to remote and master stations.

Cable run from the PK151A or PK152 to the NC150N or NC200N Master S tation must

not exceed 100'.

PK800A Secondary Power Supply: Locate the PK800A in an accessible area within 2 feet

of the PK151A or PK152 that it is to be connected to. Do not exceed operating temperature range of 10–30°C. The PK800A is for use in applications that exceed the current

load capacity of the PK151A or PK152 (1 amp). The PK800A allows the current load to

be increased to 3 amps. The FZ151 Fuse Assembly must be located between the PK800A

and the PK151A or PK152. See Figure 16 for actual FZ151 connection points.

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • 7

Page 12

System Installation

Wiring Installation

SS100 24 VAC 100 VA Transformer: Locate the SS100 within 3 feet of the PK800A

Secondary Power Supply. Do not exceed operating temperature range of 10–30°C.

Run wiring conduit from corridor light to corridor light and terminate at the PK151A or

PK152 Power & Control Unit. Limit each run to 15 corridor lights, 16 stations and 500

feet of wire. Refer to Wiring Diagrams section for additional connection and cabling

information, starting with Figure 10. Select conduit size to accommodate the following

cables:

• 4 cond. #18 common to all stations (except LI150B Duty Stations). Add 2 cond. #18

common if LI382 or LI382LED Corridor Zone Lights are used.

• 2 cond. #22 selective for each IR150B, IR151B, IR152B and IR155B Station in the

system. Shielded cable must be used.

• 1 cond. #22 selective for each SF155B Emergency Station or SF156B Code Station

not used in conjunction with a patient station.

• 4 cond. #18 to one LI150B Duty Station.

Figure 3—Master Panel Housing Chart and Wall Cut-Out Details

Housing Wall Opening

Flush Surface Width (B) Height

OH202 OH302 8.5" 16.25"

16"

B

16.25"

B

In masonry walls, install 0.5"×4" wood

fillers at top and bottom of opening for

housing attachment.

OH203 OH303 12.5" 16.25"

OH204 OH304 16.5" 16.25"

OH205 OH305 20.5" 16.25"

3.75"

4" min.

66"

Finished Wall

16.25"

Finished Floor

Figure 4—Panel Removal

and Replacement

Panel Removal: First remove the

self-tapping metal screws located in

the top U-channel just above each

panel. Then lift up on panel to clear

bottom channel. After removal,

adequate space is available to grasp

B

and remove the remaining panels.

Panel Replacement: Insert top of

panel into top channel, push panel in

at bottom, and release. Panel should

fall into place in bottom channel.

Replace self-tapping metal screws.

8 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 13

System Installation

Housing Installation

NC150N Master Station:

Flush Wall Mounting: Provide wall cutout as shown in Figur e 3. Remove panels from

frame as shown in Figure 4. Fit back box and frame assembly into prepared opening.

Fasten assembly into place using screws provided in back box. Back box must be

®

TekTone

OH200 Series. Replace panels using the procedure as shown in Figure 4.

Surface Mounting: Remove panels from frame as shown in Figure 4. Fasten box and

frame assembly to wall through holes provided in back of box. Use suitable fasteners.

Back box must be TekTone

®

OH300 Series. Replace panels using the procedure as

shown in Figure 4.

NC200N Master Station: Desk Mounting: Use TekTone® IH200N series Desk Cabinets.

IR150B, IR151B, IR152B, IR155B Staff and Patient Stations: Ring and back box must

be UL® approved. Install the back box (Steel City #H3BD with Steel City #3GC plaster

ring or exact equivalent) as shown in Figure 5 for each station in system. If a smaller

back box is desired, use ARCO #2GB with ARCO #3GC ring. Minimum dimensions of

the back box to be not less than 8.6"×4.5"×2.5". Minimum clearance from live parts on

the station to dead metal parts to be not less than 0.5".

SF155B Emergency and SF156B Code Stations: Install single gang ring (or single gang

ring/double gang box) as shown in Figure 6 for each emergency or code station in

system. Ring and back box must be UL® approved. Minimum dimensions of back box

to be not less than 4"×4"×1.5". Minimum opening on ring to be not less than 1.75"×2.75".

Minimum clearance from live parts on station to dead metal parts to be not less than

0.5".

LI150B Duty Stations: Install single gang ring (or single gang ring/double gang box) as

shown in Figure 6 for each duty station. Ring and back box must be UL® approved.

Minimum dimensions are the same as for the SF155B Emergency Station previously

listed.

LI381 Corridor Lights and LI382 Corridor Zone Lights: Install double gang ring (or

double gang ring and box) as shown in Figure 6 for each corridor light in system. Ring

and back box must be UL® approved. Minimum dimensions of back box to be not less

than 4"×4"×1.5". Minimum opening on ring to be not less than 2.75"×2.75". Minimum clearance from live parts of station to dead metal parts to be not less than 0.5".

Figure 5—Ring and Back Box for IR150B, IR151B,

IR152B and IR155B

Figure 6—Ring and Back Box for SF155B, SF156B,

LI150B, LI381, LI382 and LI382LED

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Install ring with panel mounting holes at top and bottom, as shown.

IL380 Tek-CARE® NC150 & NC200 Manual • 9

Page 14

System Installation

Figure 7—SS106 Transformer Installation

LI382LED Corridor Zone Light: Install standard one- or two-gang box with one- or two-

gang ring as shown in Figure 6 for each corridor light in system. Ring and back box

must be UL® approved. Minimum clearance from live parts of station to dead metal

parts to be not less than 0.5".

Wire Checkout

PK151A or PK152 Power & Control Unit, IH151N Junction Box: Fasten IH151N Junc-

tion Box to wall using suitable fasteners. Mount PK151A or PK152 inside junction

box. Any alternate junction box must be UL® approved. Minimum dimensions of junction box must be not less than 12"×12"×4". Minimum clearance from live parts to dead

metal parts on housing must be 1".

Install SS106 Transformer in junction box as shown in Figure 7. Do not connect

transformer primary to power source until entire installation is completed and checked

for shorts and grounds.

Install transformer connection box as shown in Figure 7. Transformer box must be

UL® approved. Minimum dimensions must be not less than 1.75"×3.75"×1.5". The

junction box, transformer and power & control unit are also available preassembled

from the factory as part number IH151NK.

PK800A Secondary Power Supply: Fasten PK800A Secondary Power Supply to wall us-

ing suitable fasteners.

SS100 24 VAC 100 VA Transformer: Fasten SS100 24 VAC 100 VA Transformer to wall

using suitable fasteners. Do not connect transformer primary to power source until

entire installation is completed and has been checked for shorts and grounds.

Use an ohmmeter or other continuity checking device to test wires for shorts or grounds. If

shorts or grounds are encountered, find and correct the problem before continuing. Make

sure minimum number of conductors needed for all of the equipment being used in the

system are available.

10 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 15

System Installation

Wire Connections

Use crimp-style connectors for all wire connections. Do not use wire nuts.

NC150N, NC200N Master Stations: No internal wiring is necessary for the NC150N and

NC200N Master Stations.

IR150B, IR151B, IR152B, IR155B Staff and Patient Stations: Connect wires as shown

in Figure 12.

SF155B Emergency Stations: Connect wires as shown in Figure 12.

SF156B Code Stations: Connect wires as shown in Figure 15.

LI150B Duty Stations: Connect wires as shown in Figure 12.

LI381 Corridor Lights, LI382 and LI382LED Corridor Zone Lights: Connect wires as

shown in Figure 12.

PK151A, PK152 Power & Control Unit: Connect wires as shown in Figure 12. Also

connect secondary from the SS106 Transformer (24 VAC, 30 VA connections) to the

PK151A or PK152 as shown in Figure 12. Do not connect transformer primary to

power source until entire installation is completed and has been checked for shorts and

grounds.

Connections Checkout

System T est Instructions

PK800A Secondary Power Supply: Connect wires as shown in Figure 16.

SS100 24 VAC 100 VA Transformer: Connect wires as shown in Figure 16. Do not con-

nect transformer primary to power source until entire installation is completed and has

been checked for shorts and grounds.

Recheck all connections to equipment. If all wires and connections are satisfactory, connect

primary coil of SS106 Transformer to source of 117 VAC 60 Hz (40 watts max.) and

operation of system can be checked according to System Test Instructions next in this

section.

Before proceeding with a system test, set all stations to normal conditions as follows:

NC150N and NC200N Master Stations: All push buttons should be in the OUT position. A

depressed button may be released by pressing the button and then releasing it.

IR150B Staff Station: If the CALL PLACED lamp is illuminated, press the RESET button to

reset it.

IR151B, IR152B Patient Stations: Insert a call cord in each call cord jack. If the CALL

lamp is illuminated, press the RESET button to reset it.

PLACED

IR155B Patient Stations: If the call cord has been pulled, reset the station by pushing the

SF155B Emergency or SF156B Code Stations: If the pull cord has been pulled, or the

LI150B Duty Stations: Push the TONE OFF switch up.

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

reset switch to the left.

switch had been pulled down, reset the station by pushing the switch up.

IL380 Tek-CARE® NC150 & NC200 Manual • 11

Page 16

System Installation

System Checkout and Testing

IR151B, IR152B, IR155B Patient Stations: Test patient stations one at a time. Initiate a

call on each patient station: Press the button on the end of the call cord for IR151B and

IR152B Patient Stations (test both circuits on IR152B stations). Pull the call cord on the

IR155B.

Check for operation of the following signals:

• The CALL PLACED lamp on the patient station should be illuminated.

• The LI381, LI382 or LI382LED Corridor Light near the room entrance should be

illuminated.

• On the NC150N or NC200N Master Station, the call lamp should be illuminated and

the associated station selector lamp (marked to identify the calling station) should be

illuminated. A slowly repeating audible call tone should be heard. The normal call

tone may be silenced by the TONE OFF button, which should be illuminated to indicate

tone silencing.

• On all LI150B Duty Stations, the CALL PLACED lamp should be illuminated, and a

slowly repeating audible call tone should be heard. The normal call tone may be

silenced by the TONE OFF switch.

Reset the call at the patient station: Press the RESET button on IR151B and IR152B

Stations. Push the RESET switch to the left on IR155B Stations. All signals should be

canceled.

Test the intercom function:

• Initiate a call on each station as previously described.

• On the master station, select the calling station by pressing the illuminated station

selector button and check for the following:

1. The STATION SELECTOR lamp should be canceled.

2. The CALL lamp should turn off.

3. The audible call tone should be canceled.

4. The remote station’s IN USE LED should be illuminated.

• Press the CALL button and the TALK button on the master station. An electronic call

tone should be heard at the master station and at the patient station.

• Press the TALK button and speak in a normal voice. Release the button to hear the reply.

• At the patient station, the CALL PLACED lamp should turn off, and the IN USE LED

should be illuminated.

• When voice communication is heard, reply in a normal voice.

• Return all controls to the normal position.

On each IR150B Staf f Station, test operation the same as with the IR151B Patient Station,

except place a call using the CALL button instead of a call cord.

On each SF155B Emergency or SF156B Code station (one at a time), slide the call

switch down, and then check the following signals:

• The CALL PLACED lamp should be flashing.

• The LI381, LI382 or LI382LED Corridor Light near the room entrance should be

flashing.

• On the master station, the CALL lamp should be flashing, the associated station

selector lamp (marked to identify calling station) should be flashing, and an

intermittent audible call tone should be heard. The TONE OFF button must not cancel

the emergency code call tone.

On all LI150B Duty Stations, check the following signals:

• The CALL PLACED lamp should be flashing.

• The rapidly pulsing audible call tone should be heard. The TONE OFF switch must not

cancel the emergency call tone.

12 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 17

System Maintenance Instructions —————————————

Most of the equipment and parts used in the NC150N and NC200N Nurse Call Systems

are not user serviceable and cannot be replaced or repaired by the end user. Equipment

must be repaired by qualified service personnel only. Parts which are user serviceable are

listed in the following sections and their replacement explained.

NC150N, NC200N Master Stations

There are several user serviceable parts in the NC150N and NC200N Master Stations.

Only one of these parts is electrically operated. The user serviceable parts and replacement

procedures are explained below.

Refer to Figure 8 to identify replacement switch parts. A full list of replacement parts and

numbers appears in the Replacement Parts section.

Selector Lamp/Switch Lens Replacement:

• Remove lens by squeezing top and bottom together and pulling away from panel.

• Replace with same color lens by pushing new lens towards panel. The lens should

snap into place on the selector lamp/switch knob with a noticeable click.

Selector Lamp/Switch Filter Identification:

• Remove lens by squeezing top and bottom together and pulling away from panel.

• Remove white filter by lifting it out of selector lamp/switch knob.

• Identify filter by room number or other means using dry transfer lettering, labels, or

other similar methods. Be sure identified filter is replaced in knob so that lettering

is readable right side up.

Defective Lamp Replacement:

• Remove lens and filter by method described above.

• Using needle-nosed pliers, tweezers or similar tool, pull lamp out of socket by

gripping lamp at sides and moving it from side to side as it is pulled away from the

panel. WARNING: Do not squeeze too tightly, or it will break.

• Replace lamp by holding with tool and pushing into socket. Be sure lamp is turned

so that the base is lined up with the slot in the socket. Lamp must be pushed in below

the level of the filter.

• Push test button to make sure lamp has been placed in socket properly. If lamp does

not light, try pressing more firmly into socket. If lamp still does not light, repeat steps

above with new lamp until one works properly.

• Replace lens and filter in lamp/switch knob as previously described.

Figure 8—NC150N, NC200N

1

Selector Lamp/Switch Lens,

Filter and Lamp Replacement

2

3

4

1 – Lens

2 – Filter

3 – 24V Lamp

4 – Switch Knob

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • 13

Page 18

System Maintenance Instructions

Defective Handset Replacement:

• To remove handset from panel, grip end of modular plug on the handset cord firmly

and squeeze until cord is easily pulled straight away from panel.

• To replace handset, hold end of plug on the handset cord, squeeze and push straight

into jack on panel. Release and plug will click into place.

• To test handset, initiate a call to a remote station. The handset should operate as

described above.

PK151A, PK152 Power & Control Units

There are no user serviceable parts in the PK151A and PK152 Power & Control Units.

Notify qualified service personnel for repair or replacement.

IR150B Staff and IR155B Patient Stations

There are no user serviceable parts on these stations. Notify qualified service personnel for

repair or replacement.

PK800A Secondary Power Supply

FZ151 In-Line Fuse Holder

The only user serviceable part is a 4A, 125 VAC fuse (1.25"×0.25").

• Disconnect power to the associated SS100 transformer. If the SS100 is hard wired,

locate the associated breaker and turn it off. If a means cannot be established to

remove power to the SS100, then contact qualified service personnel and do not

proceed further. The SS106 powering the associated PK151A or PK152 should also

be powered down in the same fashion.

• Once power has been disconnected, firmly grasp the black fuse holder knob on the

side of the PK800A, push in and rotate it counterclockwise. Pull out on the knob and

the fuse will be exposed.

• Remove the fuse and insert the new fuse. Reinsert fuse holder knob. Restore power

to the system.

For repair or replacement of any other parts, contact qualified service personnel. A list of

replacement parts and numbers appears in the Replacement Parts section.

The only user serviceable part is a 4A, 125 VAC fuse (1.25"×0.25").

• Disconnect power to the associated SS100 transformer. If the SS100 is hard wired,

locate the associated breaker and turn it off. If a means cannot be established to

remove power to the SS100, then contact qualified service personnel and do not

proceed further. The SS106 powering the associated PK151A or PK152 should also

be powered down in the same fashion.

• Once power has been removed, firmly grasp both ends of the fuse holder, push in and

rotate in opposite directions. Pull out on both ends and the fuse will be exposed.

• Remove the fuse and insert the new fuse. Put fuse holder back together and verify that

both pieces are interlocked. Restore power to the system.

For repair or replacement of any other parts, contact qualified service personnel. A list of

replacement parts and numbers appears in the Replacement Parts section.

14 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 19

System Maintenance Instructions

IR151B, IR152B Patient Stations

The only user serviceable part on these stations is the call cord. To replace:

• To remove the call cord, grip end of plug firmly and pull straight away from patient

station.

• To replace the call cord, hold by end of plug and push straight into call cord jack on

patient station.

• To test, push the button at the end of the call cord. The CALL PLACED lamp should

illuminate. Push the RESET button to cancel the call.

For repair or replacement of any other parts, contact qualified service personnel. A list of

replacement parts and numbers appears in the Replacement Parts section.

SF155B Emergency and SF156B Code Stations

There are no user serviceable parts on these stations. Notify qualified service personnel for

repair or replacement.

LI150B Duty Stations

There are no user serviceable parts on these stations. Notify qualified service personnel for

repair or replacement.

LI381 Corridor and LI382 Corridor Zone Lights

• To remove cover, grip firmly by sides, and pull cover away from plate.

• To remove bulb, make sure that no call is placed, then push bulb in towards plate.

Turn bulb counterclockwise and pull bulb out of socket. On LI382, remove red bulb

cover before removing bulb.

• To replace bulb, hold by glass part and push metal end into socket. When resistance

is encountered, turn bulb clockwise until it falls into socket. (Metal part should be

below the top of the socket.) Push bulb again and turn clockwise until bulb stops

turning, and then release. On LI382, replace red bulb cover. Be sure to place bulb

cover over the same bulb from which it was removed.

• To test light, place call at the associated station. If light still does not work, repeat

steps above until corridor lamp and/or corridor zone lamps function properly.

• To replace cover, reverse instructions for removal.

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • 15

Page 20

System Maintenance Instructions

Replacement Parts

Part No. Description Used For

FZ010 4A Fuse PK800A Secondary Power Supply and FZ151 Fuse Asst.

LI014 24V Lamp NC150N, NC200N Control and Selector Module Lamps

LI028 28V Lamp LI381, LI382 Corridor Lights

RP021 Blank Filter NC150N, NC200N Selector Button Label

RP022 Orange Lens NC150N, NC200N Call and Selector Buttons

RP024 Green Lens NC150N, NC200N Talk Button

RP027 Clear Lens NC150N, NC200N Duty Button

RP028 Yellow Lens NC150N, NC200N Tone Off Button

RP037A Red Bulb Cover LI382 Corridor Zone Lights

SF301 Call Cord IR151B, IR152B

SF302 Dual Call Cord IR151B, IR152B

TA150N Handset NC150N Master Station

TA200N Handset NC200N Master Station

16 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 21

Figure 9—NC150N, NC200N Nurse Call Systems

Notes and Electrical Ratings

Wiring Notes:

1. Selector switch shown is representative of both NC150N and NC200N

Master Stations.

2. Terminal identifications shown are not in actual order.

3. Main supply circuit: Connect to 117 VAC, 60 Hz (40 watts max). Use

18 gauge wire minimum. SS106 Transformer rating is 24 VAC, 30 VA max.

4. Use shielded cable if not in a metal conduit. If shielded cable is used, shield

drain wire replaces conductor connected to Terminal C on

module.

5. All wiring is #18 gauge unless otherwise specified.

6. System wire description:

C = Audio common

R = Normal call

P = +24 VDC

Q = Emergency common

X = Audio selective

L = Lamp wire selective

TALK/LISTEN switch

Electrical Ratings (Maximum):

NC150N/NC200N Master Station ................24 VDC, .36 amps

PK151A Power & Control Unit........24 VAC, 60 Hz, 1.25 amps

PK152 Power & Control Unit .......... 24 VAC, 60 Hz, 1.25 amps

IR150B Staff Station ....................................24 VDC, .09 amps

IR151B Patient Station ................................ 24 VDC, .09 amps

IR152B Patient Station ................................ 24 VDC, .09 amps

IR155B Patient Station ................................ 24 VDC, .09 amps

SF155B Emergency Station ........................24 VDC, .03 amps

SF156B Code Station ..................................24 VDC, .06 amps

LI150B Duty Station..................................... 24 VDC, .03 amps

LI381 Corridor Light .....................................24 VDC, .06 amps

LI382 Corridor Zone Light..........................24 VDC, .068 amps

LI382LED Corridor Zone Light .....................24 VDC, .08 amps

PK800A Secondary Power Supply...................24 VAC, 60 Hz

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • 17

Page 22

Figure 10—Block Wiring Diagram without Zone Lamps

Trunk Cable

4 #18. These conductors are common to all rooms. (NOT

individual home runs.) Maximum 15 corridor lights, 16

stations and 500' per run.

Point Pair

2 #22 shielded per room, home run to the master. Shield

not required if run in metal conduit. Shield must be

continuous (no physical gaps) to IR station.

If shielded wire is used, the shield replaces the “C” line

on each station (terminated at “C” terminal); and the

shield can be ground at master end only.

If metal conduit is used, the conduit must be continuous

(no physical gaps); it must contain only intercom wiring;

and it should not be ground at multiple locations.

4 #18

TO

SYSTEM

MASTER

TRUNK CABLE

POINT PAIR

8

1

6

MASTER STATION

POINT

PAIRS

<OVERHEAD VIEW OF HOSPITAL CORRIDOR>

#

100'MAX

PK151N / PK151A / PK152

POWER & CONTROL UNIT

TRUNK

(4 #18)

2 #18

SS106

TRANSFORMER

TRUNK &

POINT PAIR

TRUNK &

POINT PAIR

TRUNK &

POINT PAIR

TRUNK &

POINT PAIR

4 #22

SF

SERIES

STATION

IR

SERIES

STATION

SF

SERIES

STATION

SF

SERIES

STATION

TRUNK &

POINT PAIR

TRUNK &

POINT PAIR

SF

SERIES

STATION

IR

SERIES

STATION

DOME

LIGHT

DOME

LIGHT

DOME

LIGHT

DOME

LIGHT

DOME

LIGHT

DOME

LIGHT

4 #22 plus

POINT PAIR

IR

SERIES

STATION

4 #22 plus 3 #22 plus

POINT PAIR POINT PAIR

SF

SERIES

STATION

4 #22 plus 4 #22 4 #22

POINT PAIR

IR

SERIES

STATION

4 #22 plus 4 #22 plus 3 #22 plus

POINT PAIR POINT PAIR POINT PAIR

SF

SERIES

STATION

Drawing Name & Number: IL380 NC150N NC200N Block Diagram 1 Rev3 100610 1

3 #22 plus

POINT PAIR

IR

SERIES

STATION

3 #22

SF

SERIES

STATION

18 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 23

Figure 1 1—Block Wiring Diagram with Zone Lamp s

Trunk Cable

6 #18 (4 #18 + 2 #18 for zone pair). The two additional conductors

extend from zone lamp through corridor. These conductors are

common to all rooms. (NOT individual home runs.) Maximum 15

corridor lights, 16 stations and 500' per run.

Point Pair

2 #22 shielded per room, home run to the master. Shield

not required if run in metal conduit. Shield must be

continuous (no physical gaps) to IR station.

If shielded wire is used, the shield replaces the “C”

line on each station (terminated at “C” terminal); and

the shield can be ground at master end only.

If metal conduit is used, the conduit must be continuous

(no physical gaps); it must contain only intercom wiring;

and it should not be ground at multiple locations.

ONE TRUNK COMMON, "P" PLUS

O

O

Z

6 #18

G

N

L

E

I

H

C

T

O

O

M

M

N

S

TO

SYSTEM

M

A

E

S

T

N

E

P

3 #18

T

TRUNK CABLE

POINT PAIR

Z

O

A

M

L

4 #18

R

W

8

1

#

MASTER STATION

POINT

PAIRS

<OVERHEAD VIEW OF HOSPITAL CORRIDOR>

6

100' MAX.

PK151N / PK151A / PK152

POWER/CONTROL UNIT

TRUNK

(4 #18)

2 #18

SS106

TRANSFORMER

TRUNK &

POINT PAIR

TRUNK &

POINT PAIR

R

U

T

N

K

&

POINT PAIR

R

U

T

N

K

&

P

I

O

N

T

P

A

I

6 #22 plus

POINT PAIR

DOME

LIGHT

DOME

LIGHT

D

M

O

E

LIGHT

DOME

I

G

L

H

R

T

IR

SERIES

STATION

6 #22 plus 4 #22 plus

POINT PAIR POINT PAIR

SF

SERIES

STATION

6 #22 plus 5 #22 5 #22

POINT PAIR

I

R

SERIES

STATION

s

l

u

p

2

2

#

6

POINT PAIR POINT PAIR POINT PAIR

SF

SERIES

STATION

2

2

#

5

SF

SERIES

STATION

IR

SERIES

STATION

SF

SERIES

STATION

6 #22 plus 4 #22 plus

SF

S

E

R

I

E

S

S

A

N

O

T

T

I

ZONE PAIR,

TRUNK &

POINT PAIR

ZONE PAIR,

TRUNK &

POINT PAIR

SF

SERIES

STATION

IR

SERIES

STATION

DOME

LIGHT

DOME

LIGHT

4 #22 plus

POINT PAIR

IR

SERIES

STATION

4 #22

SF

S

E

E

S

R

I

STATION

Drawing Name & Number: IL380 NC150N NC200N Block Diagram 2 Rev3 100610 1

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • 19

Page 24

Zone Light

LI382 or LI382LED

Red

Wires

See

Note 5

e

t

i

h

W

Common

R

C

P

Q

Combined Configuration

2

LI381

R

PXC

N

L

1

3

Combined Configuration

IR150B/151B/152B/155B

R

Combined Configuration

IR150N/151N/152N/153N/155N

Figure 12—NC150N, NC200N Wiring Diagram

ENCLOSURE

ENCLOSURE

PK152

PK151N / PK151A /

TALK/LISTEN

SWITCH MODULE

CENTRAL

NC150N/200N

EQUIPMENT

N

O

I

T

A

T

S

R

E

T

S

A

M

P

LI150N/LI150B

Power & Control Unit

RED (Q)

GREEN (L)

ORANGE (F)

YELLOW (V)

F

V

2

N

T

SELECTOR MODULE

BLUE (N.U.)

L

E

L

U

D

O

M

L

A

N

I

M

R

E

T

BROWN (P)

SF155B

C

J

J

8

1

.

O

N

P1

P

X

L

Y

D

D

SF151N

P

E

R

R

SF153N

P

G

Q

6

0

1

S

S

P

1

P

T

D

C

E

J

N

U

LI381

LI381

NO. 18

3

See

Note

8

1

.

O

N

N

Q

Q

X

L

L

X

L

XX

L

SF155B & IR157N

GREEN (L)

BLUE (N.U.)

SF155B

BLUE (N.U.)

LI381

RED (Q)

BROWN (P)

ORANGE (F)

YELLOW (V)

RED (Q)

GREEN (L)

BROWN (P)

ORANGE (F)

YELLOW (V)

Stand Alone Configuration

Chassis ground

2

2

.

O

N

E

X

L

X

L

X

L

X

L

SHIELDED SEE NOTE 4

.

r

e

d

r

o

l

a

u

t

c

a

n

i

t

o

n

e

r

a

NOTES

n

w

o

h

s

s

n

o

i

t

a

c

i

f

i

t

n

e

d

i

l

a

n

i

m

r

e

T

shield wire replaces conductor connected to terminal C on t alk / List en

Use 18 gauge wire minimum. SS106 Transformer rating is 24 VAC, 30 VA minimum.

4. Use shielded cable if not in a metal conduit. I f s hielded c able is used,

3. Main supply circuit: connect to 117 VAC, 60 Hz (40 watts max.).

module on NC150N.

5. Use 18 gauge wire for optional LI382, LI382LED zone lIght wiring.

IL380 NC150N NC200N Wiring Rev11 030411 1

1. Selector switch module shown is repr es ent ative of NC150N master station.

.

2

20 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 25

Red

Zone Light

LI382, LI382LED

Wires

Note 5

See

e

t

i

h

W

R

Common

Q

P

C

Combined Configuration

IR150N/151N/152N/153N/155N

Combined Configuration

IR150N/151N/152N/153N/155N

P

R

C

P

R

C

J

X

L

Y

X

L

Y

P

D

NOTE: Diodes are 1N4003 type.

E

LI150N/LI150B

BROWN (P)

SF155B

RED (Q)

GREEN (L)

BLUE (N.U.)

ORANGE (F)

YELLOW (V)

6

0

1

S

S

LI381

No. 18

See

Note 3

Chassis ground

1. Selector switch module shown is representative of NC150N master station.

NOTES

2. Terminal identifications shown are not in actual order.

3. Main supply circuit : Connect to 117 VAC, 60 Hz (40 watts max.). Use 18 gauge wire minimum.

SS106 Transformer rating is 24 VAC, 30 VA minimum.

conductor connected to terminal C on talk/Listen module on NC150N.

4. Use shielded cable if not in a metal conduit. If shielded cable is used, shield wire replaces

5. Use 18 gauge wire for optional LI382, LI382LED zone lIght wiring.

Figure 13—NC150N, NC200N, T wo S t ations in Parallel

J

PK152

Enclosure

PK151N / PK151A /

TALK/LISTEN

Switch Module

Power & Control Unit

No. 18

P1

P

D

C

E

J

UN

Central Equipment

NC150N/200N

Master Station Enclosure

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

No. 18

1

D

R

R

P

P

2

N

N

T

T

E

L

U

D

O

M

L

A

N

I

M

R

E

T

SELECTOR MODULE

E

Q

Q

X

L

L

X

L

XX

L

X

L

X

L

X

L

X

L

No. 22

Shielded, See Note 4

IL380 IL381 NC150N NC200N 2 Stations Parallel Rev5 030311 1

IL380 Tek-CARE® NC150 & NC200 Manual • 21

Page 26

Combined Configuration

Combined Configuration

IR150B/151B/152B/155B

IR150B/151B/152B/155B

SF155B

SF155B

P

V

C

R

Q

RED (Q)

GREEN (L)

BROWN (P)

BLUE (N.U.)

YELLOW (V)

ORANGE (F)

SF155B

RED (Q)

GREEN (L)

BROWN (P)

BLUE (N.U.)

YELLOW (V)

ORANGE (F)

LI381

IL380 PK153 Wiring Rev10 011411 1

RED (Q)

BROWN (P)

GREEN (L)

YELLOW (V)

ORANGE (F)

BLUE (N.U.)

N.O.

N.C.

Smoke

Detector

LI381

Combined Configuration

IR150B/151B/152B/155B

E

LI150B

LI150N

E2

PK153

Control unit

CENTRAL

ENCLOSURE

EQUIPMENT

Figure 14—PK153 Wiring Diagram with Smoke Detector

N

O

I

T

A

T

S

R

E

ENCLOSURE

T

NC150N/200N

S

TALK/LISTEN

A

M

SWITCH MODULE

PK151N / PK151A / PK152

Power & Control Unit

1

P

P

D

C

E

J

UN

J

SF155B

D

D2

D

RED (Q)

BROWN (P)

ORANGE (F)

J

P

E1D1P1

R

GREEN (L)

BLUE (N.U.)

YELLOW (V)

R

RED

N.O.

N.O.

N.C.

1

P

P

P

Smoke

P

1

2

N

T

T

E

L

U

D

O

M

L

A

N

I

M

R

E

T

SELECTOR MODULE

Detector

N

WHITE

LI382 or LI382LED

2

J1

V

J

Q

N

X

L

L

X

L

XX

L

E

Q

X

L

X

X L

L

X

L

Chassis ground

6

0

1

S

S

C

A

V

4

2

NC150N/200N wiring diagram and wiring notes.

2. The NC150N/200N provide only ancillary annunciation of fire signals.

1. This drawing to be used as a supplement to the standard

NOTES:

22 • IL380 Tek-CARE® NC150 & NC200 Manual

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 27

R

P

C

Q

V

Combined Configuration

Combined Configuration

IR150B/151B/152B/155B

IR150N/151N/152N/153N/155N

RED (Q)

GREEN (L)

BROWN (P)

SF155B

E

SF153N

SF151N

D

G

P

J

R

P

C

L

X

Y

LI150B

LI150N

BLUE (N.U.)

YELLOW (V)

ORANGE (F)

F

Q

L

V

P

SF156B

SF156

RED (Q)

GREEN (L)

BROWN (P)

G

P

BLUE (N.U.)

YELLOW (V)

ORANGE (F)

FVQ

RED

L

LI381

RED (Q)

GREEN (L)

SF156B

BROWN (P)

LI381

WHITE

LI382 or LI382LED

LI381

N.O.

BLUE (N.U.)

ORANGE (F)

YELLOW (V)

Stand Alone Configuration

N.C.

Smoke detector

Stand Alone Configuration

D2

D

E1D1P1

R

E2

PK153

Control unit

CENTRAL

ENCLOSURE

EQUIPMENT

Figure 15—PK153 Wiring Diagram with SF156B Code St ation

N

O

I

T

A

T

S

R

E

ENCLOSURE

T

NC150N/200N

S

A

M

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

t

i

n

u

l

o

r

t

n

J

o

C

/

r

e

w

o

PK151A / PK152

P

1

P

P

D

C

E

J

TALK/LISTEN

N

SWITCH MODULE

U

1

P

P

R

P

1

P

T

2

T

SELECTOR MODULE

N

N

N

X

L

E

L

U

L

D

O

M

X

L

A

L

N

I

M

XX

R

E

T

L

2

J1

V

J

Q

E

Q

X

L

X

X L

L

X

L

Chassis ground

6

0

1

S

S

C

A

V

4

2

NC150N/200N wiring diagram and wiring notes.

2. The NC150N/200N provide only ancillary annunciation of fire signals.

1. This drawing to be used as a supplement to the standard

NOTES:

IL380 PK153 Wiring2 Rev8 011411 1

IL380 Tek-CARE® NC150 & NC200 Manual • 23

Page 28

0

0

1

S

S

C

A

V

4

2

IL381 PK151A PK800A Interconnection Rev5 030111

T1 and T2 inputs when interconnecting PK800A

Do not connect SS106 Transformer to PK151A/PK152

Note:

y

l

p

A

p

0

u

0

s

8

r

e

K

P

w

o

P

Ground

Ground

Ground

Ground

24VAC

INLINE

Fuse Assy.

4A Fast-Blow

24VAC

24VDC

24VDC

24VDC

5VDC

5VDC

Secondary Power Supply!

5VDC

1

D

J

Control unit

Figure 16—PK151A or PK152 to PK800A Interconnection

PK151A / PK152

To master

J

D

R

R

P

P

E

P

N

2

T

T

24 • IL380 Tek-CARE® NC150 & NC200 Manual

Q

Q

E

Mount within 2 feet of each other.

All wiring shown is 18-gauge.

R

Q

P

N

N

To field

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 29

Figure 17—SK151N Switch Board PCB Assembly

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

IL380 Tek-CARE® NC150 & NC200 Manual • 25

Page 30

connected to "Q" common

and must be connected together.

Note: Both Orange & Blue wires are

need to be in up position!

Q

P

Not used

Brown

Red

Orange

Figure 18—SF337C Cross Reference Diagram

V

Yellow

Green

L

Q

Blue

Purple

F

NOTE: Both jumpers on back of station

on station

7 pin connector

EMERGENCY

26 • IL380 Tek-CARE® NC150 & NC200 Manual

DRAWING#: IL380 IL381 SF337C WIRING REV1 091603 1

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Page 31

Brown

Brown

P

P

Not used

Not used

Red

Red

Q

V

Q

V

Orange

Yellow

Orange

Yellow

connected to "Q" common

and must be connected together.

need to be in up position!

need to be in up position!

Note: Both Orange & Blue wires are

NOTE: Both jumpers on back of station

Q

L

Q

L

Green

Blue

Green

Blue

Purple

Purple

F

F

NOTE: Both jumpers on back of station

7 pin connector

7 pin connector

on station

on station

Figure 19—SF339 Cross Reference Diagram

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

DRAWING#: IL380 IL381 SF339 WIRING REV 3 091603 1

IL380 Tek-CARE® NC150 & NC200 Manual • 27

Page 32

NC110N

A

M

S

T

E

R

ENCLOSURE

CONTROL

MODULE

D

J

Figure 20—NC110N Hookup to NC150N, NC200N

T

A

S

T

I

O

N

#18

E

E1

D

SELECTOR MODULE

TERMINAL MODULE

L

N

L

P

L

N

L

P

#18

J

E

N

P

TO

NC150N, NC200N

PK151A / PK152

Total wire distance between

PK and NC150N/NC200N

must not exceed 100'.

TO

NC110N

IL381 NC110N NC150N NC200N Hookup Rev2 100110 1

28 • IL380 Tek-CARE® NC150 & NC200 Manual

#22

N

L

L

PK151A / PK152

TO

SELECTIVE LAMP

WIRE ON

L

NC150N, NC200N

Copyright © TekTone Sound & Signal Mfg., Inc. All Rights Reserved.

Loading...

Loading...