Page 1

Instructions for Installation

Alpha Plus DH Units for Domestic Hot

Water and Direct Central Heating

Alpha Therm Ltd

Nepicar House

London Rd

Wrotham Heath

Kent

TN15 7RS

Leave these instructions with the User

Page 2

1/ INTRODUCTION

The Alpha Plus district heating units are hydraulic units designed for various

heating applications within individual domestic dwellings served by a district heating

scheme. The units are:-

(i) Domestic Hot Water Unit – Model DHW (Part No 6.3000100)

This unit provides instantaneous hot water indirectly from a district heating

circuit via a plate heat exchanger. The main components are pre-assembled

mounted on a back panel. Isolation valves and strainer are supplied with wall

fixings and thermostat sensor.

(ii) Direct Central Heating Unit – Model DCH (Part No 6.3000200)

This unit must be used in conjunction with the DHW Unit and will provide

central heating to the dwelling directly from the district heating circuit. The

central heating radiators used must be suitable for at least 8 bar working

pressure.

Note: Differential pressure control valves and an automatic by-pass valve for

fitting to the district heating circuit are not provided in the above units and

need to be supplied by the installer.

An optional outer cover (Part no 6.3000400) enclosing the main components of the DHW

unit is available, if required.

The above district heating units comply with the following requirements:

Electrical requirements of BS EN60335 – 1

EMC requirements of BS EN55014 – 2, BS EN50081 – 1, BS EN61000 - 3 - 2 / 3

UK Water Regulations / Byelaws (Scotland)

Northern Ireland Water Regulations

IMPORTANT

The installation should be in accordance with the following British Standards and requirements:

All current Building Regulations issued by the Department of the Environment, i.e. Approved

Document L1

Building Standards (Scotland) (Consolidation) Regulations issued by the Scottish Development

Department

UK Water Regulations/Byelaws (Scotland)

Health & Safety Document No. 635 (The Electricity At Work Regulations 1989)

BS 5449: 1990 Forced circulation hot water system

BS 5546: 2000 Installation of hot water supplied for domestic purposes

BS 6700: 1997 Design, installation, testing and maintenance of services supplying water

BS 7983: 1992 Code of Practice for treatment of water in heating systems

BS 7671: 2001 Requirements for electrical installations, IEE Wiring Regulations

Note: Manufacturer’s instructions must NOT be taken in any way as over-riding statutory obligations

2

Page 3

2/

TECHNICAL DATA

2.1

District Heating Circuit and Direct Central Heating

Max Working Pressure 8 bar

Min Working Pressure 1 bar

Max Flow Temperature 95°C

Max Differential Pressure 4 bar

Flow connection 22mm

Return connection 22mm

2.2

Secondary Circuit (Domestic Hot Water)

Max Working Pressure 8 bar

Min Working Pressure 0.2 bar

Heat Output to water (approx) 20 to 28kW

DH circuit flow rate reqd for max output 15 to 20 l/min

Max Flow Rate at 35°C rise (approx) 12 l/min

Min required Flow Rate 2.5 l/min

Adjustable Outlet temperature up to 60°C

Max Outlet Temperature (approx) 62°C

Mains inlet connection 15mm

DHW outlet connection 15mm

2.3

Components

Heat Exchanger Stainless Steel 23 plates

Hot Water Thermostatic Valve Brass body with removable t/sensor

CH/DHW on/off 2-way Valve Brass body with removable actuator

DHW Flow Switch with Strainer Nylon with ½” Brass connection

Strainer for DH and CH Brass 22mm comp with S/S filter

DH/CH Isolation Valves Brass 22mm comp.

Cold Water Inlet Valve Brass 15mm comp

3

Page 4

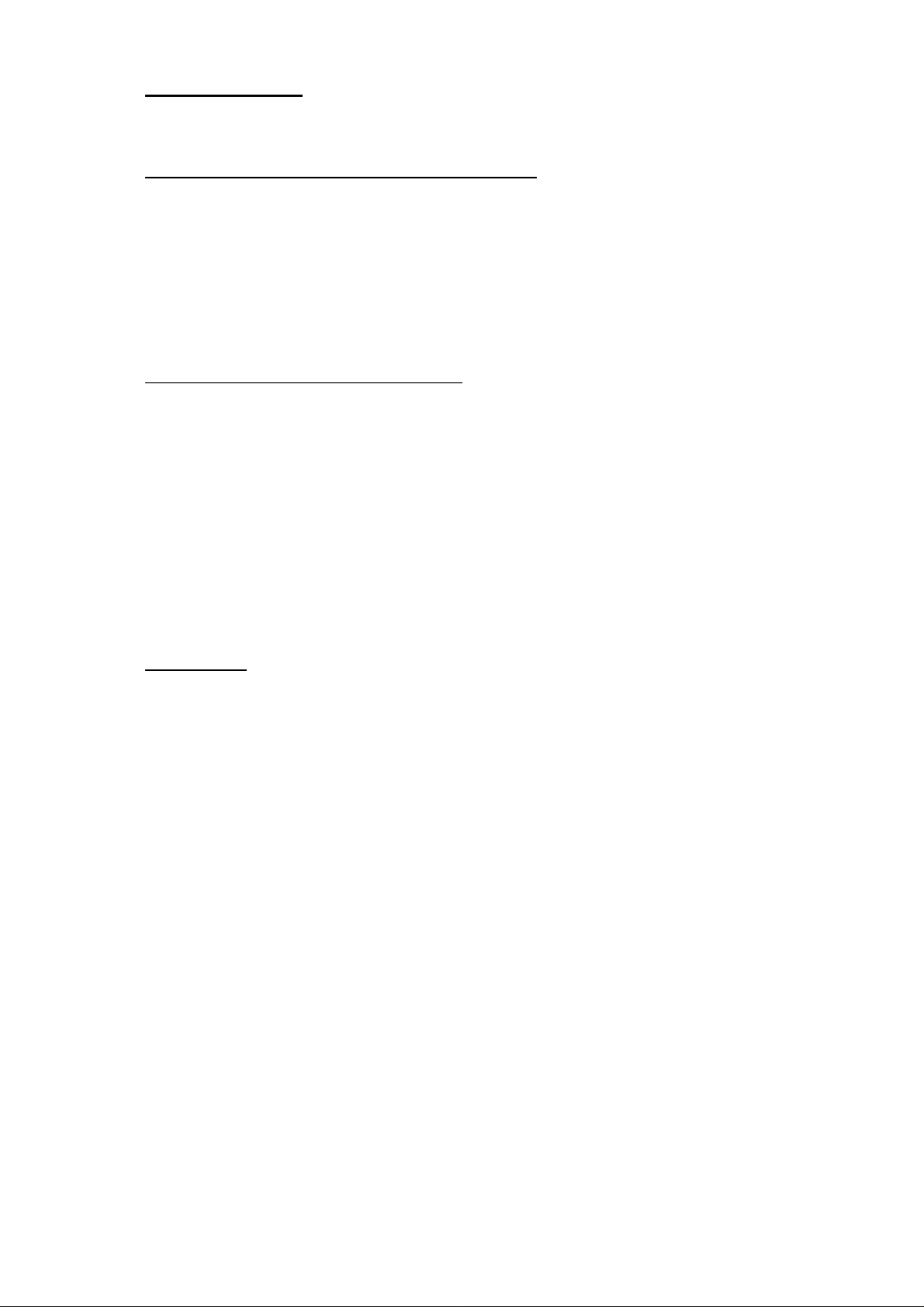

2.4 Electrical

Supply – 230/240V – 50 Hz

External fuse - 3 A

Power Consumption – 6W

2.5

Installation

Dimensions of assembled Unit Height 500mm

(Including Cover) Width 300mm

Depth 220mm

Min clearances required Top 5mm

Bottom 200mm

Sides 5mm

Front 450mm

Assembled weight of Units DHW1 7.4kg

DCH1 1.4kg

4

Page 5

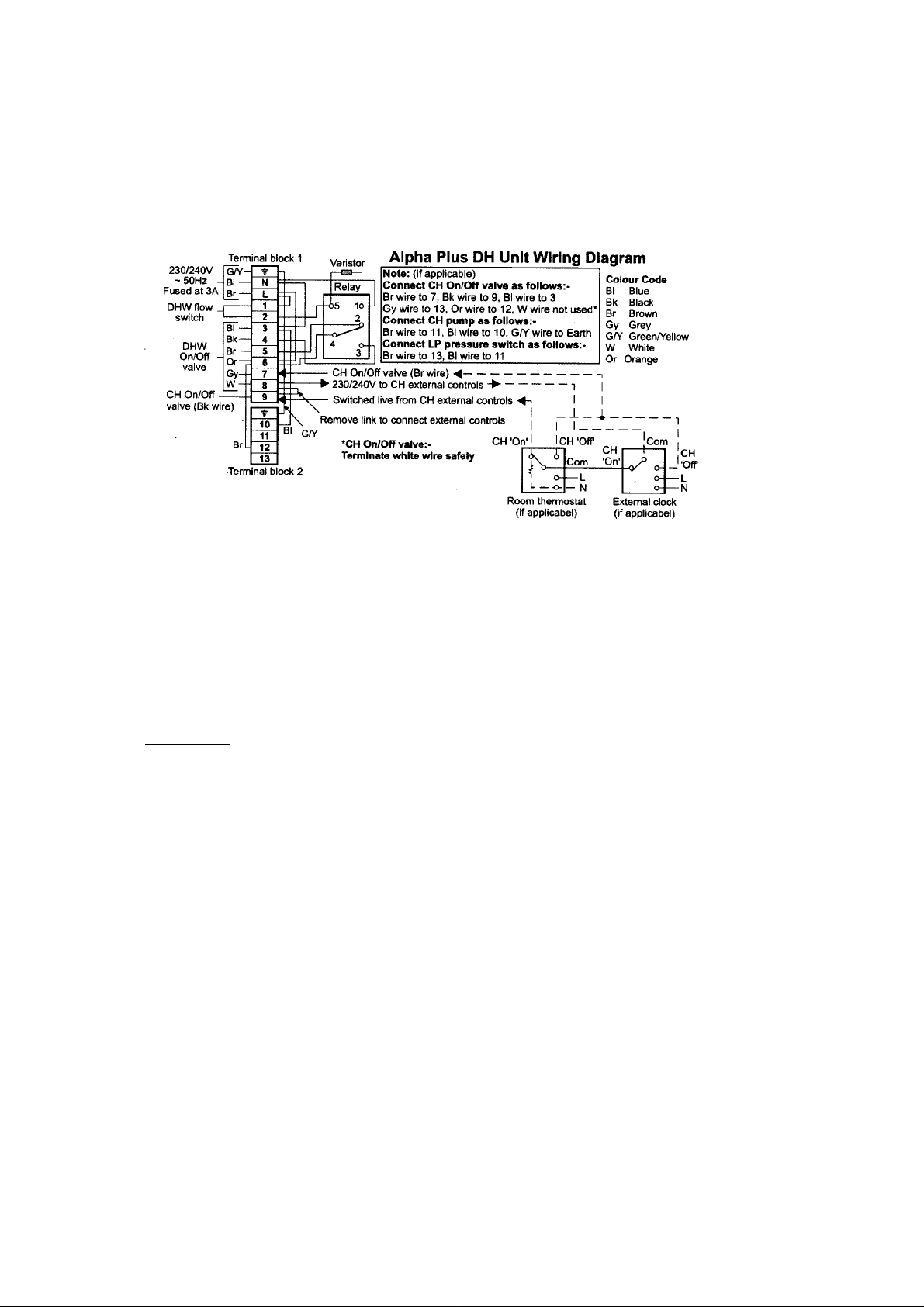

2.6 Schematic Diagram

5

Page 6

3/ OPERATION

Domestic hot water is available continuously and always takes priority over central

heating. If a demand for hot water is required during a central heating period the

controls will automatically switch to the hot water mode until the demand is

satisfied. This interruption in the central heating is only when the demand for hot

water is present and should not be noticed by the User.

3.1 Domestic Hot Water mode

When a demand for hot water is sensed by the flow switch, the DHW valve is

opened via a relay and district heating water is circulated to the plate heat

exchanger thus heating the incoming mains water. The hot water is maintained at

the set temperature by the hot water thermostatic valve regulating the district

heating water flow to the heat exchanger. When the flow switch senses that hot

water is no longer required the DHW valve closes.

3.2 Direct Central Heating

If there is a call for heating from an external control the CH valve will open and

allow district heating water to circulate to the dwelling’s radiator circuit. When there

is no demand for heating the CH valve will close. If there is a demand for hot water

the CH valve will be closed and will not be allowed to open until the hot water

demand has been satisfied.

4/ INSTALLATION

4.1

DCH Box - CH valve, two 22mm isolation valves

Unpacking

(1) The contents of each box is as follows:-

DHW Box - Assembled unit panel mounted with heat exchanger,

flow switch, DHW valve, hot water controller, control box

and pipework

Thermostat and sensor

Thermostat sensor kit, screws and wall plugs

Two 22mm isolation valves, strainer, 15mm Isolation valve

(2) Unpack and remove loose items

6

Page 7

4.2 Unit Location

(1) The unit is not suitable for external installation. It must be installed vertically on

a flat vertical wall which is capable of supporting its weight.

(2) Decide upon the position of the unit taking into consideration the clearances

required (Refer Sect 2.5)

(3) Refer to diagram below for the layout and location of the two units:

7

Page 8

4.3 Fit the DHW Unit

(1) Drill four fixing holes (5mm dia) through the back panel of the unit to accept

the No. 8 screws supplied.

(2) Hold the unit on the wall in the required position ensuring it is level and mark the

position of the fixing holes. Then drill the fixing holes (6mm dia) in the wall to

accept the No.8 wall plugs.

(3) Using the screws supplied secure the unit to the wall.

4.4 Fit the Ther mostat and Sensor (Refer Diagram 4.2.3)

(1) Unscrew the plastic cap on the hot water control valve body and remove.

(2) Locate and secure the thermostat onto the valve body by tightening the loose

nut by hand onto the thread of the body.

(3) With care unwind the capillary tube and position the sensor onto the location

provided on the outlet pipe from the heat exchanger.

(4) Secure the sensor in position using the tape supplied. Then locate the

insulation supplied around the sensor and secure with the two straps provided.

4.5 Connect the Pipework (Refer Diagram 4.2.3)

(1) Thoroughly flush out ALL the

pipework.

(2) Connect the 15mm isolating valve to the cold inlet pipe of the unit and then

connect the domestic hot water pipework.

(3) Using a ‘T’ connection, connect the central heating pipework to the DH flow and

return of the DHW unit and fit the CH valve and isolating valves in the positions

shown in the diagram 2.6.

Note:

Ensure the CH valve is located within 600mm of the DHW unit. This will

allow it’s cable to be directly connected into the unit’s control box .

(4) Connect the 22mm strainer supplied to the DH flow pipe and then connect the

two isolation valves to the DH flow and return pipes.

Note:

Ensure the strainer is always fitted after the valves. This will allow

isolation for cleaning of the filter (Refer diagram 2.6)

4.6 Connect the CH Valve Electrical Cable (Refer Sect 2.4)

(1) Gain access to the DHW terminal block by releasing the 4 screws securing

the control box cover.

(2) Pass the CH valve’s electrical cable through a cable clamp and connect the

wires as follows (refer to diagram 2.4);

Brown to terminal 7, Black to terminal 9, Blue to terminal 3, Grey to terminal 13,

Orange to terminal 12, White is not used, therefore terminate safely.

(3) Tighten the cable clamp by hand until the cable is secured.

8

Page 9

4.7 Connect the Electrical Supply (Refer Sect 2.4)

The Unit requires a 230/240V ~ 50Hz mains supply, fused at 3A

The Unit must be earthed.

There must be only one common isolator, providing complete electrical isolation, for

the Unit and any external controls.

Using PVC insulated cable not less than 0.75mm

the Unit should be connected to a fused three pin plug and uns witched shuttered

socket outlet (both complying with BS1363), or a fused double pole switch with a

contact separation of at least 3mm in both poles.

Wiring external to the Unit must be in accordance with the current IEE Wiring

Regulations (BS7671).

NOTE:

The procedure is as follows:

(1) Gain access to the terminal block as in 4.6.1.

(2) Pass the mains supply cable through the cable clamp and connect as follows:-

(3) If an external control i.e. room thermostat or external clock is to be fitted,

(4) Ensure there is sufficient free cable to allow the control box cover to be

(5) Carry out electrical system checks – short circuit, polarity, earth continuity

If external controls are fitted, they MUST be suitable for 230/240V

switching and MUST be single pole, 2 way / Changeover switching

Brown to L, Blue to N and Green/Yellow to earth. Ensure correct polarity.

Note:

Ensure that the length of the earth wire is such that if the supply cable

is pulled out of its clamp the live and neutral wires become taut before

the earth wire.

remove the link between terminals 8 and 9. Pass the cable through the cable

clamp and connect to terminals 8 & 9 using terminal 9 as switched live.

removed giving easy access to the main terminal block, then tighten the cable

clamps by hand.

and resistance to earth with a suitable multimeter.

² (24 x 0.2mm) to BS6500 Table 16,

9

Page 10

(6) Ensure terminal block 2 is correctly located into the control box as shown below.

(7) Replace the control box cover and secure with the 4 screws previously

removed.

10

Page 11

5/ COMMISSIONING

(1) Fill the DHW pipework.

Open the cold mains inlet valve. Turn on all the hot water taps and allow water

to flow until there is no air present. Turn off the taps and check for water

soundness, rectifying if necessary.

(2) Fill the DH circuit pipework.

Open the DH flow and return isolation valves.

Manually open the DHW valve to allow water to flow by pushing the white lev er

down to midway and in on the valve’s actuator. This will hold the valve in the

open position. Check for water soundness, rectifying if necessary.

(3) Fill the Direct Central Heating system.

Open the CH flow and return isolation valves and allow DH water to flow into the

system. Vent each radiator etc to remove any air and check for water

soundness, rectifying if necessary.

(4) Turn on the electrical supply.

Open a hot water tap and check that the DHW valve opens, the CH valv e closes

and hot water is supplied. Set the outlet temperature as required by adjusting

the thermostat’s knob (Setting 9 gives approximately 55 to 60’C). Turn off the

tap and check the DHW valve closes and the CH valve opens.

6/ SERVICING and COMPONENT REPLACEMENT

Each component is easily removable for replacement or cleaning without needing

to remove other components

11

Page 12

7/ SHORT PARTS LIST

Description Alpha Pt. No.

DHW Heat Exchanger 1.020259

DHW Flow Switch 1.015142

Pipe 1 – Mains Inlet/Flow Sw 1.019921

Pipe 2 – Flow Sw/HE 1.019922

Pipe 3 – DHW Outlet 1.019923

Pipe 4 – DH Flow 1.019924

Pipe 6 – DH Return 1.020254

Pipe 7 – 22 x 60mm 6.3000144

Elect Plug Flow Switch 6.3000111

Relay (Control box) 6.3000112

Control Box 6.3000110

DHW/CH Valve 6.3000120

Thermostat Body 6.3000131

Thermostat Head 6.3000130

15mm Isolation Valve 6.3000141

22mm Isolation Valve 6.3000142

22mm Strainer 6.3000143

Thermostat & Fixing Kit 6.3000136

DHW Flow Regulator 10L 1.016595

12

Page 13

13

Page 14

These instructions have been carefully prepared but we reserve the right to alter the

specification at any time in the interest of product improvement. Alpha Therm Ltd 2005

Part no 6.3000160

04/05

14

Loading...

Loading...