Page 1

AlphaNet™ DSM3 Series DOCSIS® Status Monitor for the XM3 CableUPS

Technical Manual

Effective: March 2014

®

Page 2

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions regarding

the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha representative. Save this

document for future reference.

To reduce the risk of injury or death and to ensure the continued safe operation of this product, the following symbols have

been placed throughout this manual. Where these symbols appear, use extra care and attention.

WARNING! GENERAL HAZARD

GENERAL HAZARD WARNING provides safety information to PREVENT INJURY OR

DEATH to the technician or user.

WARNING! ELECTRICAL HAZARD

ELECTRICAL HAZARD WARNING provides electrical safety information to PREVENT

INJURY OR DEATH to the technician or user.

WARNING! FUMES HAZARD

FUMES HAZARD WARNING provides fumes safety information to PREVENT INJURY OR

DEATH to the technician or user.

WARNING! FIRE HAZARD

FIRE HAZARD WARNING provides ammability safety information to PREVENT INJURY OR

DEATH to the technician or user.

There may be multiple warnings associated with the call out. Example:

WARNING! ELECTRICAL & FIRE HAZARD

This WARNING provides safety information for both Electrical AND Fire Hazards

CAUTION!

CAUTION provides safety information intended to PREVENT DAMAGE to material or equipment.

NOTE:

NOTE provides additional information to help complete a specic task or procedure.

ATTENTION:

ATTENTION provides specic regulatory/code requirements that may affect the placement of equipment and /or

installation procedures.

The following sections contain important safety information that must be followed during the installation and maintenance

of the equipment and batteries. Read all of the instructions before installing or operating the equipment, and save this

manual for future reference.

Page 3

AlphaNet

DOCSIS® Status Monitor for XM3-HP CableUPS

TM

DSM3 Series

®

745-814-B11-001, Rev. C

Effective Date: March 2014

©

2014 by Alpha Technologies, Inc.

Disclaimer

Images contained in this manual are for illustrative purposes only. These images may not match your installation.

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If there are

questions regarding the safe operation of this powering system, please contact Alpha Technologies or your nearest Alpha

representative.

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators, batteries or

other hardware if used or operated in any manner or subject to any condition not consistent with its intended purpose or is

installed or operated in an unapproved manner or improperly maintained.

Contact Information

Sales information and customer service in USA

(7AM to 5PM, Pacic Time):

Complete technical support in USA

(7AM to 5PM, Pacic Time or 24/7 emergency support):

Sales information and technical support in Canada:

Website: www.alpha.com

Page 4

Table of Contents

1.0 Introduction ......................................................................................................................................................................8

2.0 Overview .................................................................................................................................................................... 10

2.1 System Diagram ................................................................................................................................................ 10

2.2 Network Connectivity ......................................................................................................................................... 11

2.3 System Conguration and Installation ............................................................................................................... 11

2.4 DSM3 Series Start Up and Reboot Routine ......................................................................................................12

3.0 Network Conguration .................................................................................................................................................... 13

3.1 Provisioning the DHCP Server with the MAC Addresses .................................................................................. 13

3.2 Establishing IP Connectivity ..............................................................................................................................14

3.3 The DOCSIS Conguration File ........................................................................................................................14

3.3.1 Setting Modem Community Strings — DOCSIS 2.0 (IPv4) Method ........................................................14

3.3.2 Setting Modem Community Strings — DOCSIS 2.0+IPv6 Method .......................................................... 15

3.3.3 Setting SNMP Trap Destination Addresses — DOCSIS 2.0 (IPv4) Method.............................................15

3.3.4 Setting SNMP Trap Destination Addresses — DOCSIS 2.0+IPv6 Method ..............................................16

3.3.5 Sample DOCSIS Conguration File Entries — DOCSIS 2.0 (IPv4) ......................................................... 17

3.3.6 Sample DOCSIS Conguration File Entries — DOCSIS 2.0+IPv6 .......................................................... 18

3.3.7 Proprietary Conguration File ‘atidoc03.cfg’ ............................................................................................19

3.3.8 Changing Default atidoc03.cfg Download Settings .................................................................................. 19

3.4 Setting Communication Options ........................................................................................................................ 20

4.0 Web Interface .................................................................................................................................................................21

4.1 Local Web Server Access .................................................................................................................................. 21

4.2 Remote Web Server Access ..............................................................................................................................24

4.3 Navigating the Web Page ..................................................................................................................................25

4.3.1 Web Interface Security Levels .................................................................................................................26

4.4 Verifying Communication Parameters ...............................................................................................................27

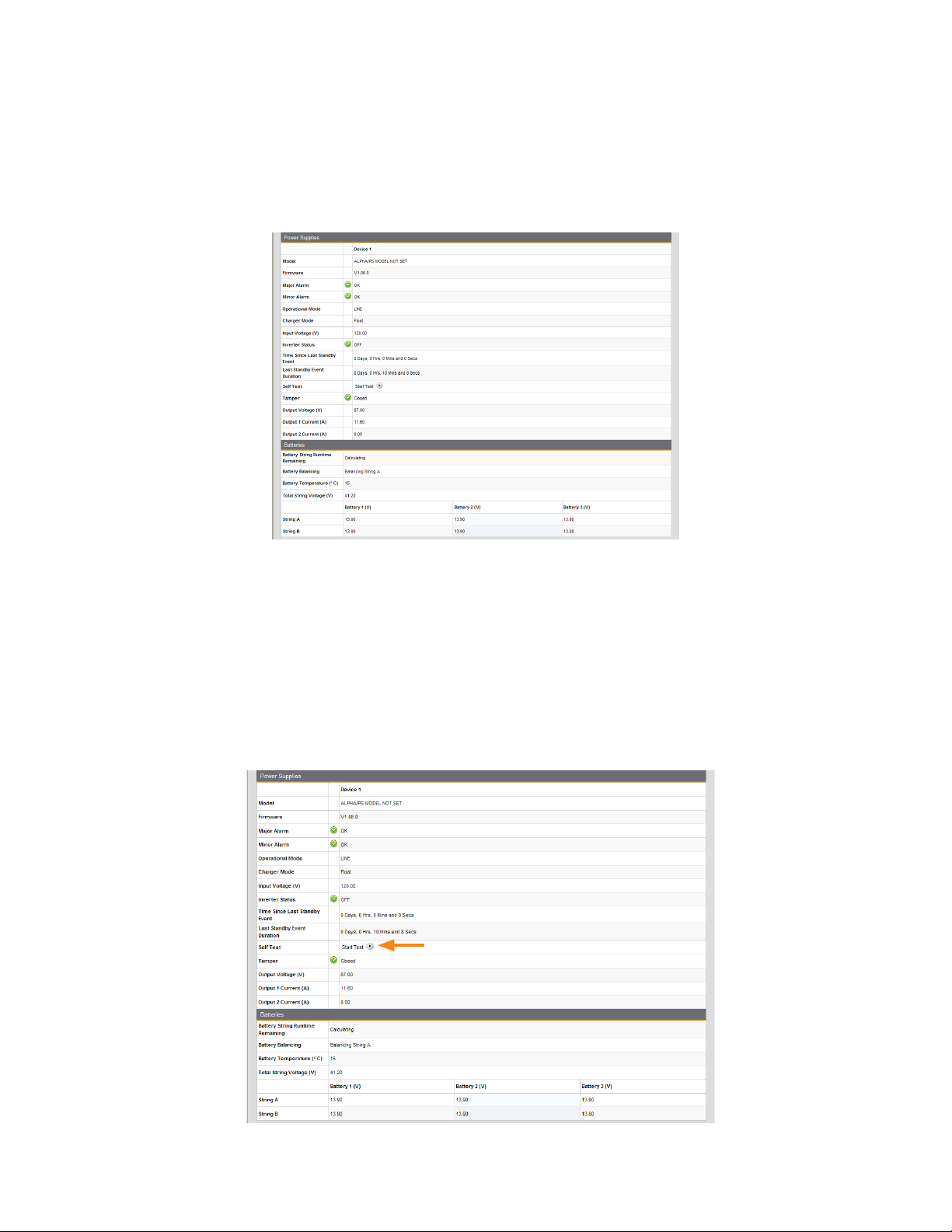

4.5 Verifying Power Supply and Battery Parameters ...............................................................................................28

4.6 Remote Self Tests via the Web Page ................................................................................................................ 28

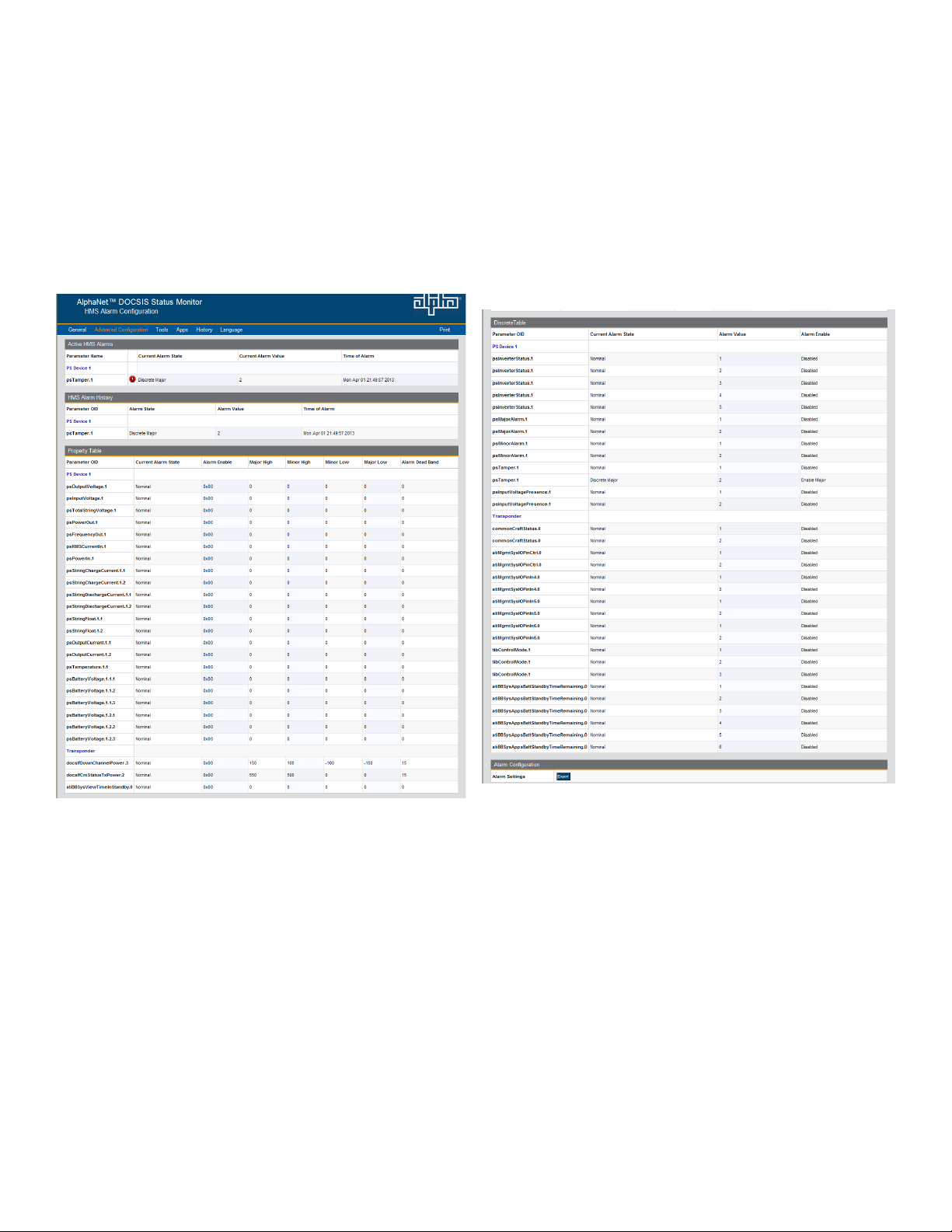

4.7 Viewing HMS Alarm Status via the Web Page ..................................................................................................29

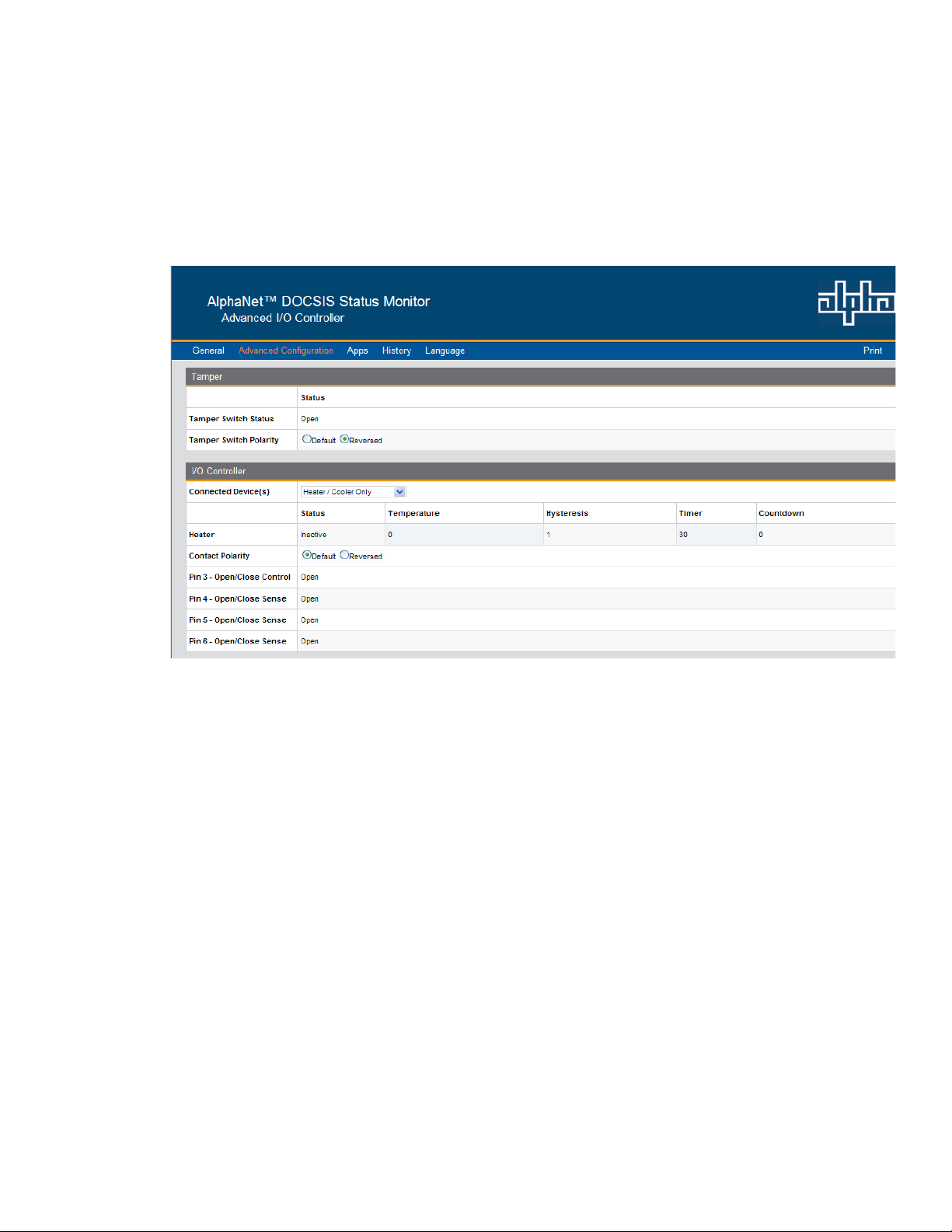

4.8 Setting the I/O Controller via the Web Page ......................................................................................................30

4.9 Viewing and Conguring Power Supply settings via the Web Page ..................................................................31

4.10 Viewing and Conguring Generator Settings via the Web Page .....................................................................33

4.11 Tools Menu – Constellation and Microreections ............................................................................................ 34

4.11.1 QAM Constellation Tool .......................................................................................................................... 34

4.11.2 QAM Constellation Common Impairments ............................................................................................. 35

4.11.3 Microreections Tool ............................................................................................................................... 39

4.12 Viewing AlphaApps Information via the Web Page .........................................................................................40

4.13 Battery Management .......................................................................................................................................41

4.14 Viewing Power Supply Event and Conguration Logs ....................................................................................43

4.15 Battery Event Log ............................................................................................................................................ 47

4.16 Viewing the Modem Event Log via the Web Page ..........................................................................................47

5.0 Upgrading Firmware ....................................................................................................................................................... 48

5.1 Upgrading DSM3 Series Modem Firmware ....................................................................................................... 48

5.1.1 Identifying the Modem and Obtaining Firmware Files .............................................................................. 48

5.1.2 Modem Firmware Upgrade SNMP Parameters .......................................................................................48

5.1.3 Upgrading Manually by Setting SNMP Parameters .................................................................................49

5.1.4 Upgrading via the DOCSIS Conguration File ......................................................................................... 49

6.0 Data Management .......................................................................................................................................................... 50

6.1 SCTE-HMS MIBs .............................................................................................................................................. 50

6.2 SCTE-HMS MIB Alarms ....................................................................................................................................51

6.2.1 SCTE-HMS Congurable Alarms .............................................................................................................51

6.2.2 SNMP Traps .............................................................................................................................................56

6.2.3 General Power Supply Alarms .................................................................................................................58

6.2.4 Battery Alarms .......................................................................................................................................... 60

6.3 The Alpha MIBs .................................................................................................................................................61

6.3.1 The Alpha MIB Structure .......................................................................................................................... 63

4

745-814-B11-001, Rev. C (03/2014)

Page 5

Table of Contents, continued

7.0 Installation .................................................................................................................................................................... 64

7.1 Verifying Power Supply Device Address ...........................................................................................................64

7.2 Installation / Replacement Procedure in XM3 Power Supplies .........................................................................65

7.3 DSM3x LEDs and Connections ......................................................................................................................... 67

7.4 DSM3 LEDs and Connections ........................................................................................................................... 68

7.5 DPM LEDs and Connections ............................................................................................................................. 69

7.6 Connecting the RF Drop .................................................................................................................................... 70

7.7 Front Panel Connections ................................................................................................................................... 70

7.8 I/O Connections (TPR, ENV) ............................................................................................................................. 71

7.8.1 Tamper (TPR) Switch Interface ................................................................................................................ 71

7.8.2 I/O Port Interface ...................................................................................................................................... 72

7.8.3 Conguring I/O Port Connections ............................................................................................................72

7.8.4 I/O Port: Generic Device ..........................................................................................................................73

7.8.5 Connecting a Generic I/O Device ............................................................................................................74

7.8.6 Conguring and Monitoring a Generic I/O Device ...................................................................................74

7.8.7 I/O Port: Lightning Arrestor (LA-P-SM) ....................................................................................................74

7.8.8 Lightning Arrestor (LA-P-SM) Installation .................................................................................................75

7.8.9 Conguring the LA-P-SM .........................................................................................................................75

7.8.10 I/O Port: Heater Mat Control ..................................................................................................................76

7.8.11 Connecting the Battery Heater Mat Controller .......................................................................................76

7.8.12 Conguring the Battery Heater Mat Controller ....................................................................................... 77

7.8.13 I/O Port: Emergency DC Generator (GEN) ............................................................................................ 78

7.8.14 Conguring and Monitoring the DC Emergency Generator ...................................................................78

8.0 Battery Sense Wire Kits..................................................................................................................................................79

8.1 36V Single and Dual Strings ..............................................................................................................................79

9.0 Start Up and Verication .................................................................................................................................................80

9.1 Initial Start Up and Local Verication .................................................................................................................80

9.2 Verifying Correct Hardware Interconnection ......................................................................................................82

9.3 System Status Indicators and Reset Button ...................................................................................................... 83

9.3.1 Detailed LED Descriptions .......................................................................................................................83

9.3.2 Resetting the Communications Module ...................................................................................................85

9.4 Verifying Communications via the Headend ......................................................................................................85

10.0 Alpha MIB Parameters..................................................................................................................................................86

10.1 Denitions and Settings ................................................................................................................................... 86

11.0 Specications ................................................................................................................................................................94

12.0 Glossary .................................................................................................................................................................... 96

13.0 Dual IP Mode (Addendum) ...........................................................................................................................................97

13.1 Overview .......................................................................................................................................................... 97

13.2 Web Comparison, Single IP Mode/Dual IP Mode ............................................................................................98

13.3 Conguring Dual IP Mode ...............................................................................................................................99

13.3.1 atidoc03.cfg in Dual IP Mode ...............................................................................................................101

13.3.2 Changing Default atidoc03.cfg Download Settings in Dual IP Mode ...................................................101

13.3.3 Specifying atidoc03.cfg name and location via DHCP Tags ................................................................ 102

13.4 Dual IP SNMP Community Strings ................................................................................................................103

13.5 Security in Dual IP Mode ...............................................................................................................................103

5745-814-B11-001, Rev. C (03/2014)

Page 6

Figures & Tables

Fig. 1-1, AlphaNet DSM3x .....................................................................................................................................................8

Fig. 1-2, AlphaNet DSM3 .......................................................................................................................................................8

Fig. 1-3, AlphaNet DPM .........................................................................................................................................................8

Fig. 1-4, Side view, AlphaNet DSM3 Series ..........................................................................................................................9

Fig. 2-1, Representative System Arrangement ....................................................................................................................10

Fig. 3-1, Locations of MAC Address Labels ........................................................................................................................13

Fig. 3-2, Sample DOCSIS Conguration File — DOCSIS 2.0 (IPv4) ..................................................................................17

Fig. 3-3, Sample DOCSIS Conguration File — DOCSIS 2.0+IPv6 ...................................................................................18

Fig. 4-1, DSM3 Series Web Page .......................................................................................................................................21

Fig. 4-2, Local Area Connection Properties Screen, Windows XP ...................................................................................... 22

Fig. 4-3, Internet Protocol (TCP/IP) Properties Screen, Windows XP ................................................................................. 22

Fig. 4-4, Local Area Connection Properties Screen, Windows 7 .........................................................................................23

Fig. 4-5, Internet Protocol (TCP/IP) Properties Screen, Windows 7 ....................................................................................23

Fig. 4-6, Web Server Home Page .......................................................................................................................................24

Fig. 4-7, DSM3 Series Navigation Bar Items ....................................................................................................................... 25

Fig. 4-8, Communication Parameters .................................................................................................................................. 27

Fig. 4-9, Advanced Communication Parameters .................................................................................................................27

Fig. 4-10, Power Supply and Battery Parameters ...............................................................................................................28

Fig. 4-11, Location of Start Test Button for Self Test ..........................................................................................................28

Fig. 4-12, HMS Alarm Conguration ....................................................................................................................................29

Fig. 4-13, Advanced I/O Controller Status Screen ...............................................................................................................30

Fig. 4-14, Advanced Power Supply Settings Screen ..........................................................................................................31

Fig. 4-15, Advanced Generator Status Screen ...................................................................................................................33

Fig. 4-16, QAM Constellation Tool ....................................................................................................................................... 34

Fig. 4-17, Normal - (Good Quality) and Individual Cell Characteristics ............................................................................... 35

Fig. 4-18, Fuzzy (Low CNR and/or Low MER) and Individual Cell Characteristics ............................................................. 36

Fig. 4-19, Doughnuts (Coherent Interference) and Individual Cell Characteristics .............................................................36

Fig. 4-20, Gaussian Noise and Individual Cell Characteristics ............................................................................................ 37

Fig. 4-21, Rectangular vs. Square (I-Q Imbalance) and Entire Constellation Shape .......................................................... 37

Fig. 4-22, Corners Squeezed to Center (Gain Compression) and Entire Constellation Shape ........................................... 38

Fig. 4-23, Circular Smear (Phase Noise) and Entire Constellation Shape ......................................................................... 38

Fig. 4-24, Twisted or Skewed (Quadrature Distortion) and Entire Constellation Shape ...................................................... 39

Fig. 4-25, Microreections Tool ............................................................................................................................................ 39

Fig. 4-26, Alpha Apps and Utility Status Parameters ...........................................................................................................40

Fig. 4-27, Battery Management ........................................................................................................................................... 41

Fig. 4-28, Battery Model Selection ......................................................................................................................................42

Fig. 4-29, DSM3 System Log ..............................................................................................................................................43

Fig. 4-30, Power Supply Event Log ..................................................................................................................................... 45

Fig. 4-31, Power Supply Conguration Log ......................................................................................................................... 46

Fig. 4-32, Battery Event Log ................................................................................................................................................ 47

Fig. 4-33, Docsdev Event Log Screen ................................................................................................................................. 47

Fig. 6-1, Sample Raw SNMP Alarm Trap ............................................................................................................................56

Fig. 6-2, Sample Translated SNMP Alarm Trap ................................................................................................................... 56

Fig. 7-1, Captive Screw Locations ....................................................................................................................................... 65

Fig. 7-3, Connecting the Communications Module to the Inverter Module .........................................................................66

Fig. 7-2, The 18-pin Connector ............................................................................................................................................66

Fig. 7-4, DSM3x LEDs and Connectors ..............................................................................................................................67

Fig. 7-5, DSM3 LEDs and Connectors ................................................................................................................................68

Fig. 7-6, DPM LEDs and Connectors ..................................................................................................................................69

Fig. 7-7, Connecting the RF Drop ........................................................................................................................................70

Fig. 7-8, System Interconnection Diagram ..........................................................................................................................70

Fig. 7-9, I/O (ENV) and Tamper Switch Interface (TPR) Connection Locations .................................................................. 71

Fig. 8-1, 36V System, Single String .....................................................................................................................................79

Fig. 8-2, 36V System, Dual String .......................................................................................................................................79

6

745-814-B11-001, Rev. C (03/2014)

Page 7

Figures & Tables, continued

Fig. 9-1, XM3 Smart Display Screens .................................................................................................................................80

Fig. 9-2, Communications Section - General Page .............................................................................................................81

Fig. 9-3, Power Supply Section - General Page ................................................................................................................. 82

Fig. 9-4, LED Functionality and Indications ......................................................................................................................... 83

Fig. 9-5, DSM3 Series Web Page, RF Power Level Indicators ...........................................................................................85

Fig. 13-1, Simplied Block Diagram Single IP Mode ...........................................................................................................97

Fig 13-2, Simplied Block Diagram Dual IP Mode ...............................................................................................................97

Fig. 13-3, Single IP DSM3 Series Web Page ......................................................................................................................98

Fig. 13-4, Dual IP DSM3 Series Web Page .........................................................................................................................98

Fig. 13-5, Dual IP Conguration Settings for DSM3 Web Server Communications Page .................................................100

Fig. 13-6, Dual IP Parameters for DSM3 Web Server General Page ................................................................................100

Table 1-1, DSM3 Series Model Specications ....................................................................................................................... 8

Table 2-1, LEDs and Indications ..........................................................................................................................................12

Table 3-1, Modem Community String Parameters — DOCSIS 2.0 (IPv4) Method .............................................................. 14

Table 3-2, Modem Community String Parameters — DOCSIS 2.0+IPv6 Method ...............................................................15

Table 3-3, Trap Destination Addresses — DOCSIS 2.0 (IPv4) Method ...............................................................................15

Table 3-4, Trap Destination Addresses — DOCSIS 2.0+IPv6 Method ................................................................................16

Table 3-5, Default atidoc.cfg Download Settings .................................................................................................................19

Table 3-6, Communications Parameters .............................................................................................................................20

Table 4-1, DSM3 Series Webpage Security ........................................................................................................................ 26

Table 4-2, DSM3 Series Communications Module Security Levels ..................................................................................... 26

Table 4-3, Time Offset Values and Location Reference (offset +/- GMT) ............................................................................ 44

Table 5-1, Modem Firmware Upgrade SNMP Parameters .................................................................................................. 48

Table 5-2, SNMP Parameters .............................................................................................................................................. 49

Table 5-3, DOCSIS Congurations File Values ...................................................................................................................49

Table 6-1, SCTE-HMS MIB Files ......................................................................................................................................... 50

Table 6-2, Binary to Hex Conversions for Alarm Settings .................................................................................................... 51

Table 6-3, Recommended Settings for DSM3 Series Analog Alarms .................................................................................52

Table 6-4, Recommended Settings for Discrete Alarms ..................................................................................................... 53

Table 6-5, DSM Alarm Setting Paramters ............................................................................................................................ 55

Table 6-6, Status of Alarm Setting Download Parameters ...................................................................................................55

Table 6-7, SNMP Alarm Trap Varbinds and Explanations ................................................................................................... 57

Table 6-8, Power Alarms: Classications, Causes and Corrections .................................................................................... 59

Table 6-9, Battery Alarms: Classications, Causes and Corrections ................................................................................... 60

Table 6-10, Alpha MIB Hierarchy ......................................................................................................................................... 62

Table 6-11, Alpha MIBs Examples .......................................................................................................................................63

Table 7-1, Tamper (TPR) Switch Specications ..................................................................................................................71

Table 7-2, ENV Connector and Pin Descriptions .................................................................................................................72

Table 7-3, I/O Port Specications ........................................................................................................................................ 73

Table 7-4, I/O Port: Generic Device Specications .............................................................................................................. 73

Table 7-5, LA-P-SM Monitoring Values ................................................................................................................................ 75

Table 7-6, I/O Port: Heater Mat Control Specications ........................................................................................................ 76

Table 7-7, Heater Mat OIDs and Functionality ..................................................................................................................... 77

Table 7-8, Heater Mat MIB Reports ..................................................................................................................................... 77

Table 7-9, Generator Monitoring Values .............................................................................................................................. 78

Table 9-1,SCTE-HMS Property Table ..................................................................................................................................84

Table 9-2, Rx/Tx Power LED Color Ranges ........................................................................................................................84

Table 13-1, Single IP Mode versus Dual IP Mode ............................................................................................................... 97

Table 13-2, Enabling Dual IP mode ..................................................................................................................................... 99

Table 13-3, CPE Communications Module IP Settings ....................................................................................................... 99

Table 13-4, Available Download Options ........................................................................................................................... 101

7745-814-B11-001, Rev. C (03/2014)

Page 8

1.0 Introduction

The AlphaNet DSM3 Series Embedded DOCSIS Communications Module allows monitoring of Alpha power

supplies through existing cable network infrastructure. Advanced networking services provide quick reporting

and access to critical powering information. This manual focuses on the three models of the DSM3 Series

Communications Module complementing the XM3-HP CableUPS.

The DSM3 Series Communications Modules utilize Simple Network Management Protocol (SNMP) and

Management Information Bases (MIBs) to provide network status monitoring and diagnostics. A Web interface

enables authorized personnel direct access to advanced diagnostics using a common Web browser. No custom

software is required. See Table 1-1 for model specications.

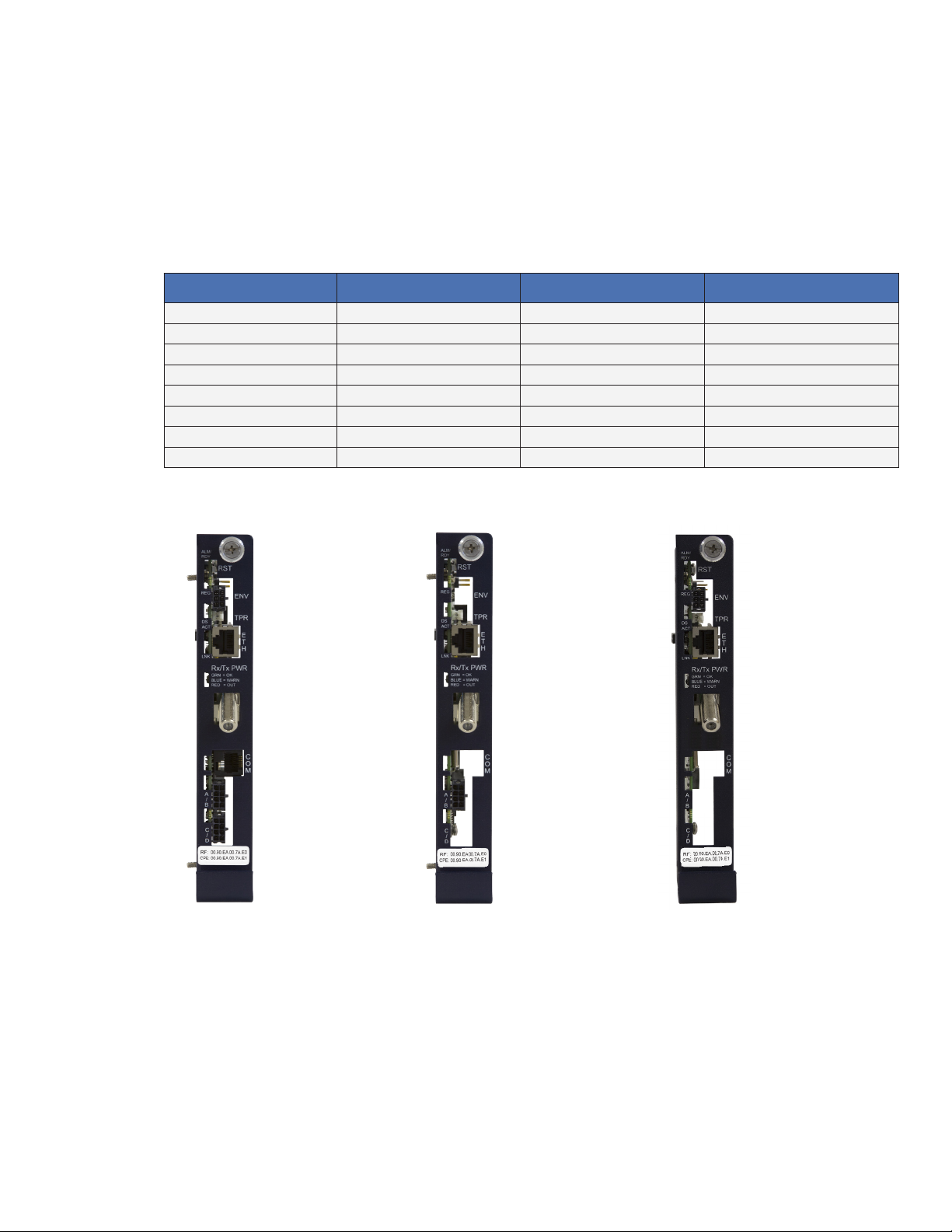

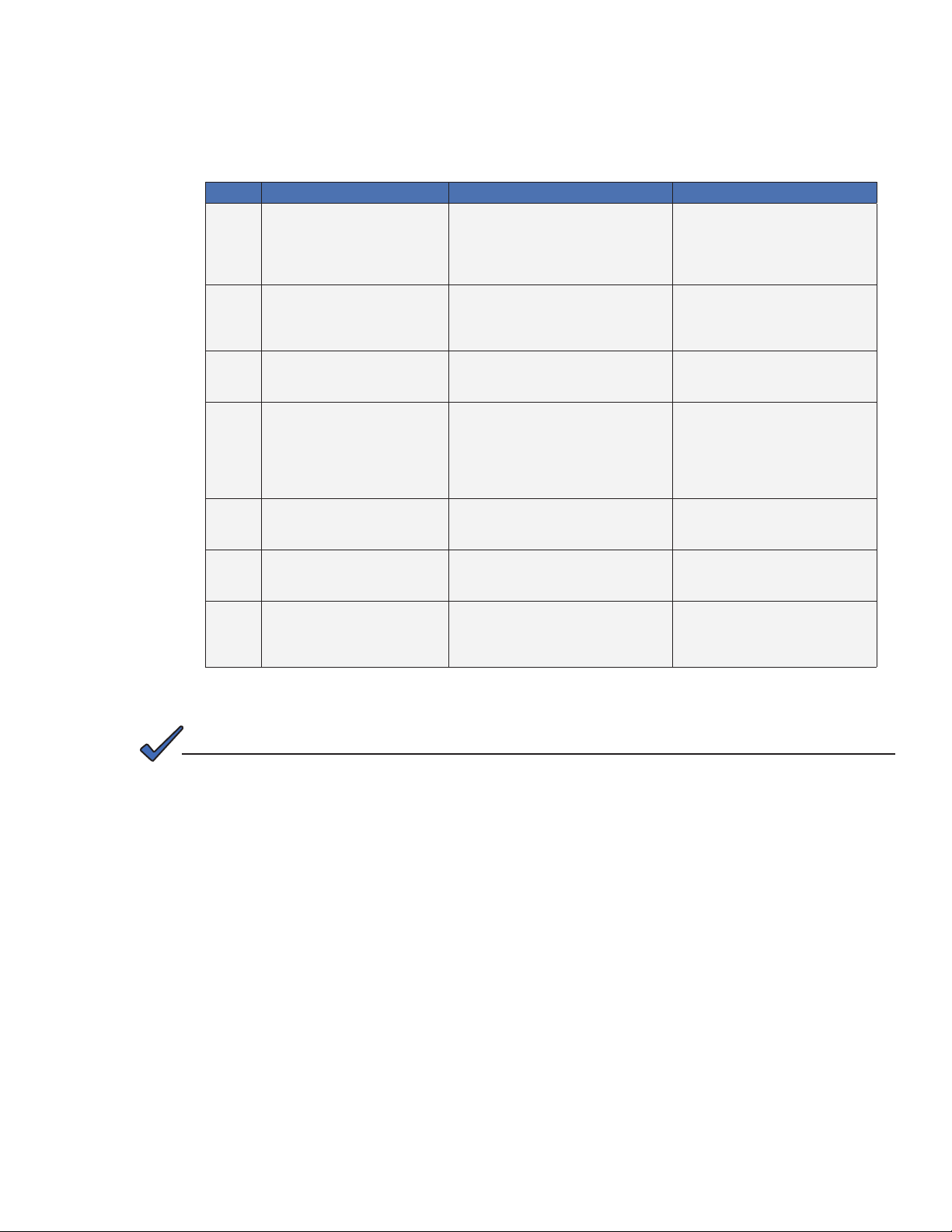

Model DSM3x (E) DSM3 (E) DPM (E)

Part Number 746-097-20 (746-097-23) 746-097-21 (746-097-24) 746-097-22 (746-097-25)

Capacity 5 power supplies (plus generator) 1 power supply 1 power supply

1 & 2 Battery Strings Yes Yes Yes with SAG option

3 & 4 Battery Strings Yes No Yes with SAG option

Tamper Switch Yes Yes Yes

External I/O Monitoring and Control Yes No Yes

COM Port (AlphaBus) Yes No No

Ethernet Port Yes Yes Yes

Table 1-1, DSM3 Series Model Specications

Fig. 1-1, AlphaNet DSM3x Fig. 1-2, AlphaNet DSM3 Fig. 1-3, AlphaNet DPM

Primary Features:

• 10/100 Mbps auto-negotiating standard Ethernet interface

• Supports SNMPv1, v2c

• Extensive power supply diagnostic MIBs

• Embedded Web server for direct diagnostics

• Environmentally hardened DOCSIS cable modem and Communications Module

• Local Ethernet port provides technician on-site access to extensive power supply diagnostics*

• Angled RF connector reduces cable bend radius

• Diagnostic LEDs

• North American or Euro DOCSIS available

* Ethernet port also permits the connecting of external CPE devices

8

745-814-B11-001, Rev. C (03/2014)

Page 9

1.0 Introduction

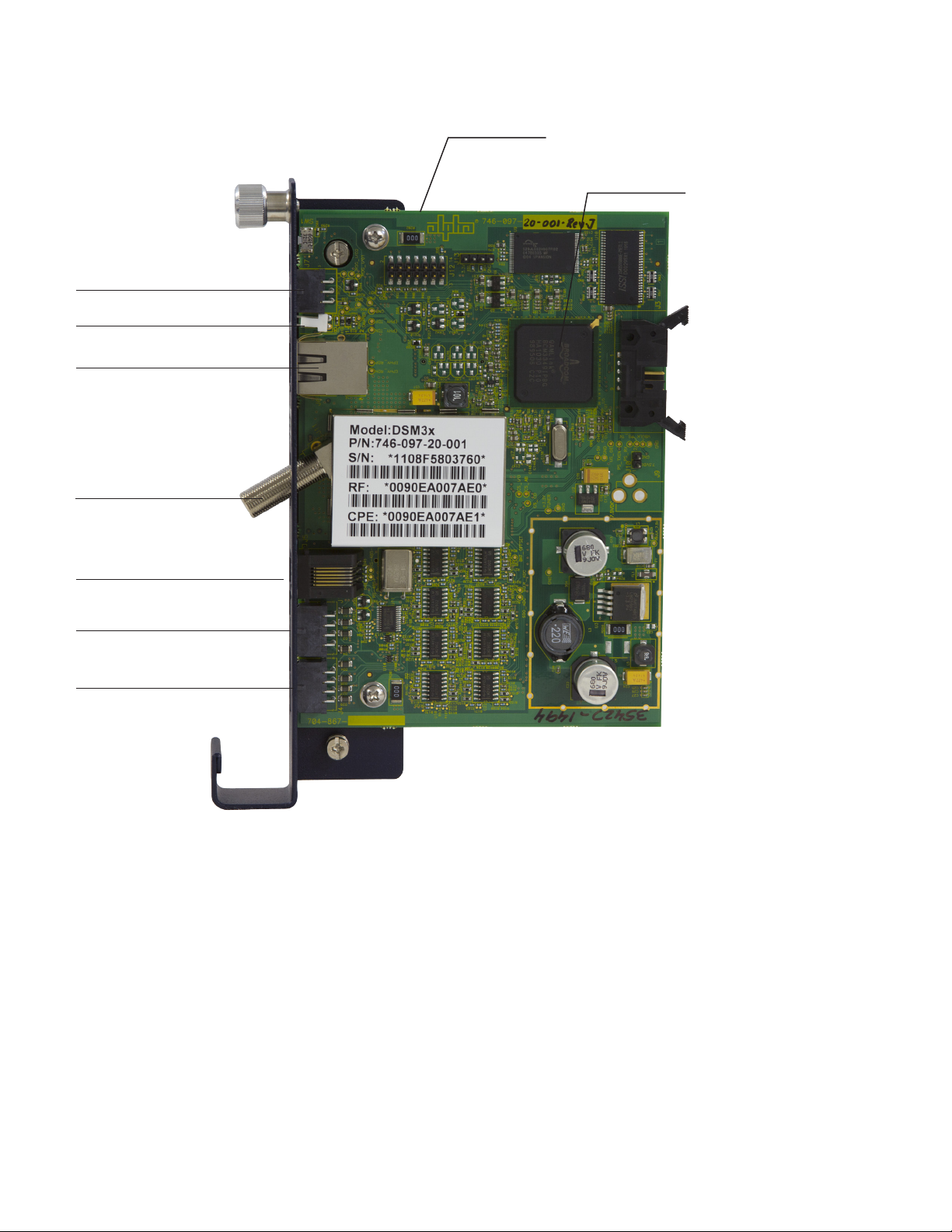

Environmental IO Connector (DSM3X

and DPM only)

Tamper Connector

Ethernet Port for Local Diagnostics

RF Connector

Intelligent CableUPS Interface

(located on other side of the board)

Single Microcontroller Cable

Modem Design

COM Port (DSM3X only)

Battery Monitoring Connection A/B (DSM3

and DSM3X only)

Battery Monitoring Connection C/D (DSM3X

only)

Fig. 1-4, Side view, AlphaNet DSM3 Series

9745-814-B11-001, Rev. C (03/2014)

Page 10

2.0 Overview

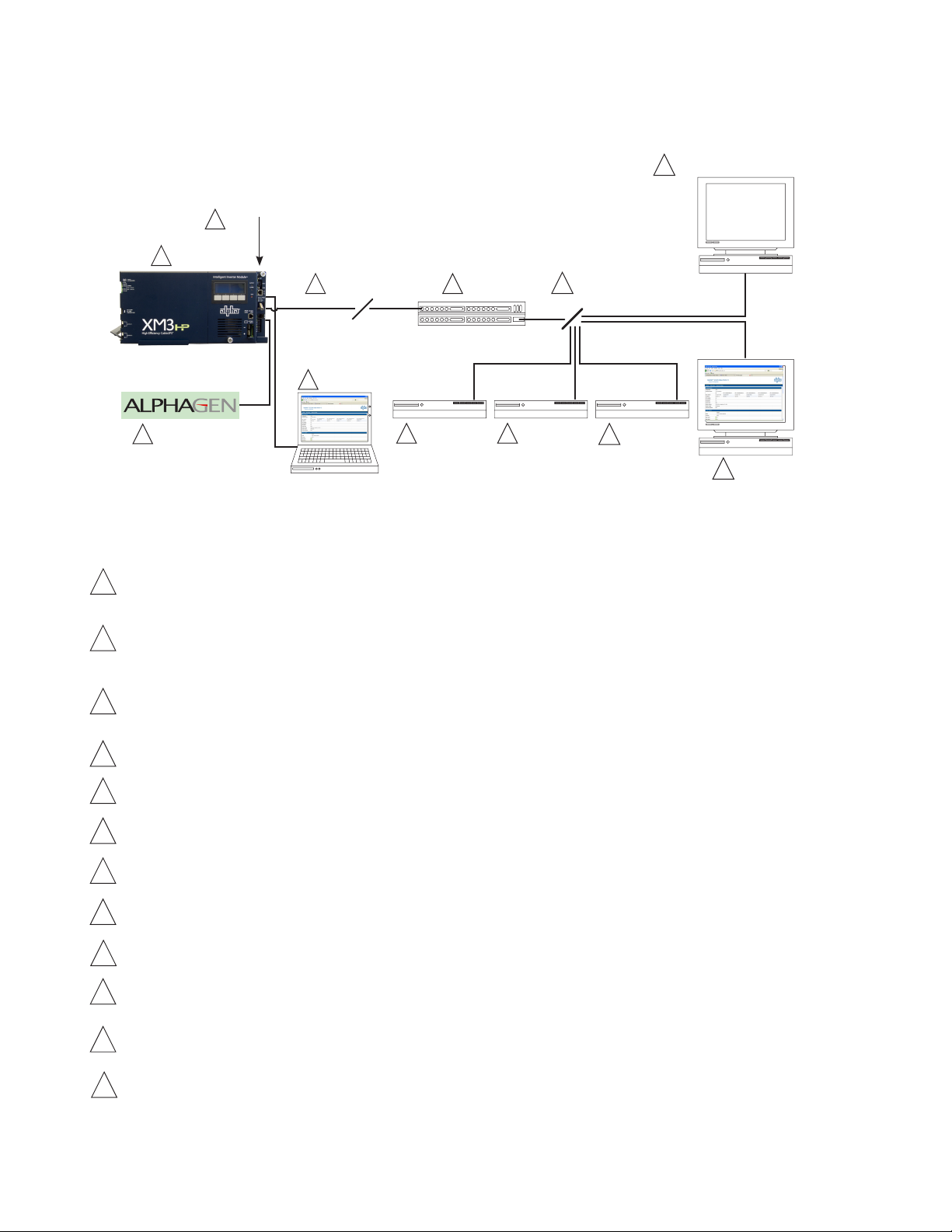

2.1 System Diagram

Power Supply

1

2

DSM3

Series

SNMP-based Network Management System

10

3

External Generator

Coax/HFC Network

5

Local Computer

4

7

6

DHCP Server

CMTS

TCP/IP Network

12

TFTP Server TOD Server

8

9

Web Browser

11

Fig. 2-1, Representative System Arrangement

All power supply data is stored in the power supply Inverter Module's class information base (CIB) tables in the power supply.

1

2

3

This data is accessible directly via the power supply’s Smart Display (see the power supply’s technical manual for details).

The CIB tables are the source of the Communications Module's data.

The DSM3 Series contains both SCTE-HMS Management Information Base (MIBs) and the proprietary Alpha MIB tables.

The SCTE-HMS MIBs are industry standard MIB tables that store power supply, battery and generator data from the CIB

tables (DSM3x only) (See Section 6.0, Data Management). The Alpha MIB contains all the data of the SCTE-HMS MIBs

plus additional power supply settings and values as well as DSM3 Series conguration values.

An external generator or additional power supplies may be connected through the COM (AlphaBus) port permitting

monitoring locally through the Ethernet connector or remotely via the Web page or SNMP-based Network Management

System (DSM3x only).

4

5

6

7

8

9

Power supply and Communications Module parameters can be monitored and set locally using a personal computer and a

standard Ethernet cable.

The DSM3 Series transmits data via its cable modem directly over the Coax or Hybrid Fiber Coax network.

The Cable Modem Termination System (CMTS) is the bridge between the cable network and the TCP/IP network. The DSM3

Series’ cable modem communicates directly with the CMTS.

The Dynamic Host Control Protocol (DHCP) server needs to be provisioned with the DSM3’s cable modem CM MAC

address and the MAC address needs to be assigned a DOCSIS Conguration File.

The DOCSIS Conguration File and rmware les should be available in the Root Directory of the Trivial File Transfer

Protocol (TFTP) Server.

The Time of Day (TOD) Server provides the cable modem with the current date and time via the SNTP protocol.

A Network Management System (NMS) or MIB Browser allows remote monitoring of parameter values and changing of

10

settings in SNMP MIB tables. SCTE-HMS and Alpha MIBs must be installed in the browser. Alarms and traps can be set and

monitored.

11

12

The power supply and generator data may be accessed remotely through the Communications Module's Web page by

placing its IP address into a standard Internet Web browser.

The following ports of the Transmission Control Protocol/Internet Protocol network must be opened: 161=SNMP, 162=SNMP,

Traps, 69=TFTP, 80=HTTP.

10

745-814-B11-001, Rev. C (03/2014)

Page 11

2.0 Overview

2.2 Network Connectivity

The DSM3 Series cable modem must be recognized by the CMTS as a valid device to be assigned an IP

address from the DHCP server, to locate the TFTP and TOD servers and to communicate with the SNMP

management server (trap receiver).

Data from both the cable modem and power supply are accessed and managed through the modem’s IP

address on the secure private modem network. The Communications Module is not accessible from the

public Customer Premises Equipment (CPE) network. Consequently, the Network Management System

(NMS) that monitors the power supplies must have access to the same private modem network.

CMTS and system vendors use different security methods to insure network integrity, but common

considerations are:

• Network MAC ltering may have to be modied to allow the cable modem OUI of 00:90:EA for North

• For SNMP access, UDP ports 161 and 162 must not be blocked.

• For TFTP access, port 69 must not be blocked.

• For HTTP access, port 80 must not be blocked.

• For SNTP access, port 37 must not be blocked.

America, and 00:03:08 for European models.

• Firewalls must allow TFTP, DHCP, SNMP and TOD communication to the cable modem.

• If the address of the TFTP or TOD server is different than the DHCP server, the response from the

DHCP server must contain the TFTP and TOD addresses.

2.3 System Conguration and Installation

NOTE:

Before installation, read all of Section 2.0, Overview.

DSM3 Series installation and setup is comprised of three basic steps:

1. Conguring the Network: Provisioning the DHCP Server with the Communications Module’s MAC

address and assigning it a DOCSIS Conguration File.

2. Setting Options: The DSM3 Series is designed for out of the box, "plug and play" operation, but

non-default settings such as SNMP trap destination addresses may be required for the Network

Management System (NMS). SNMP trap addresses can be set automatically via the DOCSIS

Conguration File per RFC 4639 (IPv4), or through SNMPv3 Notication settings (IPv6), while DSM3

Series proprietary options may be set through type-11 TLV entries. The SCTE-HMS and Alpha MIBs

may need to be compiled into a MIB browser before it can be used to monitor or set Communications

Module and power supply parameters.

3. Field Installation of the DSM3 Series into the power supply, connecting the battery string wire

harnesses, Tamper, and Environmental Control (as applicable) and verifying operation.

These steps can be performed independently of one another. However, conguring the network prior

to eld installation will allow the installation to be veried while personnel are still on-site. Performing

eld installation before network conguration and before the installation can be veried, might result in

additional eld service calls to correct mistakes.

Carefully read the following section in order to understand the dependencies within the system before

performing system conguration or hardware installation.

11745-814-B11-001, Rev. C (03/2014)

Page 12

2.0 Overview

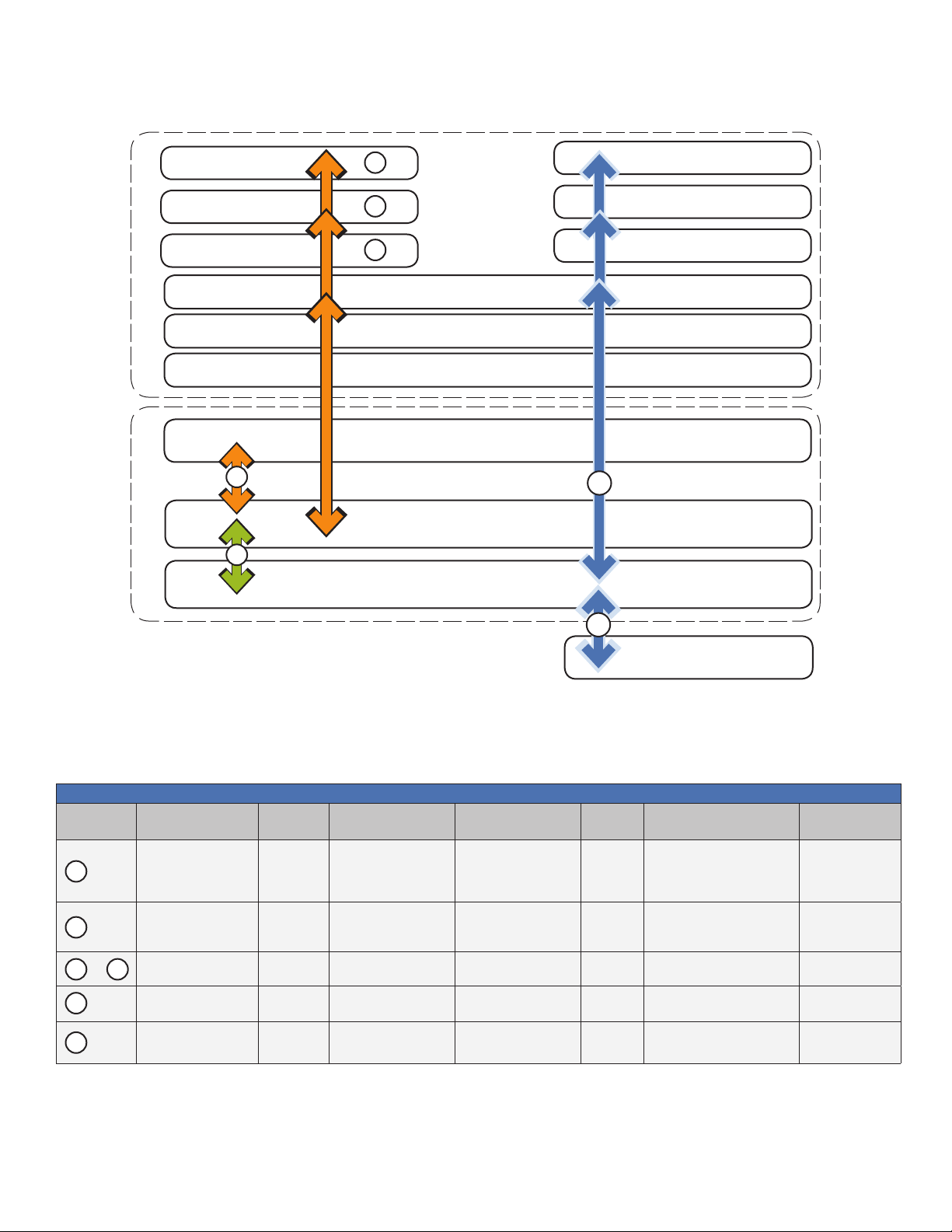

2.4 DSM3 Series Start Up and Reboot Routine

TFTP Server

TOD Server

DHCP Server

TCP/IP NetworkHFC Network

5

4

3

Switches

Routers

Firewalls

Network Management System

MIB Browser

Web Browser

CMTS

2

6

DSM3 Series

1

Power Supply

7

Local Laptop

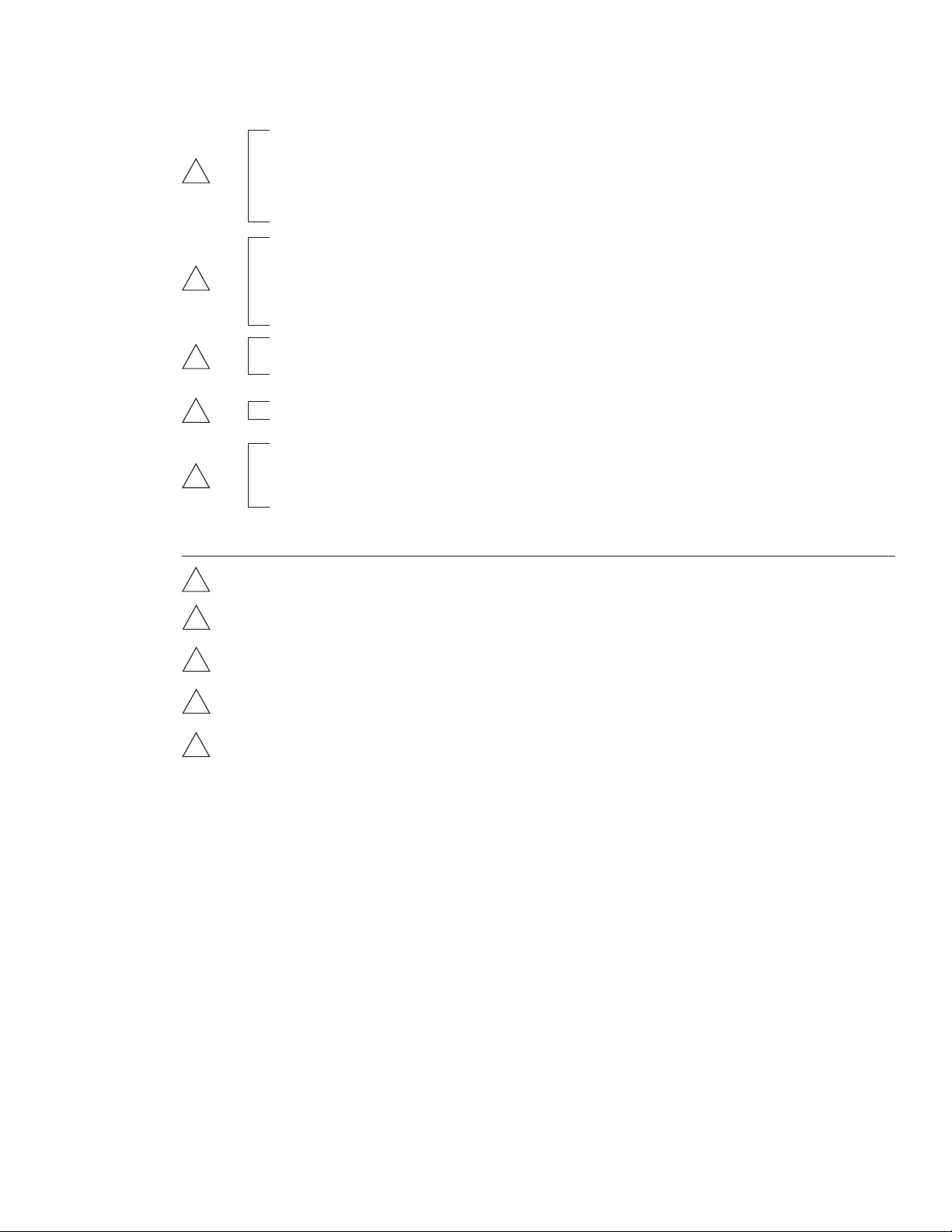

The above diagram, read left to right, indicates the order of operations as the Communications Module comes

online. There are certain conditions that must exist for each step to occur, resulting in successful data monitoring

and management. The numbers below correspond to the numbered arrows above.

LEDs and Indications

Ref #

1

2

to

3 5

6

7

Communications

State

Communications Module

Initializing/Searching for

Downstream DOCSIS

channel

DOCSIS channel locked Completing upstream and

network registration

Online - registration

complete

DSM3 Series fully

functional

Laptop connected

ALM/RDY Downdstream (DS) Registration (REG)

Flashing

(Green)

Flashing

(Green)

Flashing

(Green)

Flashing

(Green)

Flashing

(Green)

Flashing OFF OFF OFF OFF

ON Flashing ON (Green) OFF OFF

ON ON ON (Green) OFF and ON OFF

ON ON ON (Green)

ON ON ON (Green) Bursts

Rx/Tx

Power

Communications (COM) Ethernet (ETH)

Bursts when communicating to

multiple power supplies

OFF

LNK - ON

ACT - Bursts

12

• Blue Rx/Tx Power LED indicates Rx/Tx Power at a warning level. Make the necessary RF level adjustments.

• Red Rx/Tx Power LED indicates Rx/Tx Power at an alert level. Make the necessary RF level adjustments.

Table 2-1, LEDs and Indications

745-814-B11-001, Rev. C (03/2014)

Page 13

3.0 Network Conguration

3.1 Provisioning the DHCP Server with the MAC Addresses

On the DHCP server, assign the cable modem’s CM MAC address with a DOCSIS Conguration File to

set modem communication options. (See Section 3.3, The DOCSIS Conguration File for instructions

on how to create a DOCSIS Conguration File).

The CM and CPE MAC addresses are located in two places on the DSM3 Series and on the packing slip,

see below. The CM MAC address may be labeled as the RF MAC address on some DSM3 Series units.

Identier label

Fig. 3-1, Locations of MAC Address Labels

Cable Modem

and CPE MAC

address label

13745-814-B11-001, Rev. C (03/2014)

Page 14

3.0 Network Conguration

3.2 Establishing IP Connectivity

The DSM3 Series supports the CableLabs DOCSIS 2.0+IPv6 implementation. The main benet of

IPv6 is its expanded addressing capability, increasing the address space from 32 to 128 bits, providing

virtually unlimited number of networks and systems. The DSM3 Series determines the IP provisioning

mode via the CableLabs SNMP MIB parameter docsIf3CmMdCfgIpProvMode (SNMP OID: 1.3.6.1.4.1

.4491.2.1.20.1.31.1.1). The DSM3 Series will support the following congurable IP Provisioning Mode

Override policies:

• Honor MDD: The cable modem of the DSM3 Series unit will acquire an IPv6 or IPv4 address as

directed by the MAC Domain Descriptor (MDD) message for provisioning and operation.

• IPv4 only: The cable modem of the DSM3 Series unit will acquire a single IPv4 address for the CM

management stack, overriding the TLVs in the MDD message.

• IPv6 only: The cable modem of the DSM3 Series unit will acquire a single IPv6 address for the CM

management stack, overriding the TLVs in the MDD message.

3.3 The DOCSIS Conguration File

A cable modem’s DOCSIS Conguration File is a type-length-value (TLV) le that contains important

operational parameters as dened by the DOCSIS standards. It provides certain settings for the cable

modem. In addition to standard entries, settings in the DOCSIS Conguration File should include the

modem’s community strings and if an upgrade is necessary, rmware upgrade parameters. Place the

Conguration File in the TFTP root directory.

The DSM3 Series cable modem interface can support both IPv4 and IPv6 addressing schemes. The

required DOCSIS Conguration File operational parameters will differ depending on company policies,

cable modem rmware versions and IP addressing schemes. The following DOCSIS Conguration File

details listed in this manual are general guidelines. Please consult the published DOCSIS Specication

resources (CableLabs) for additional DOCSIS Conguration File details and guidelines.

To build a DOCSIS Conguration File, use a DOCSIS TLV editor program.

See the example Conguration Files in Sections 3.3.5 and 3.3.6.

NOTE:

The modem community strings should be set in the DOCSIS Conguration File. Failure to set community strings

will result in a less secure system. For automatically updating modem rmware with the DOCSIS Conguration File,

see Section 5.1, Upgrading DSM3 Series Modem Firmware.

3.3.1 Setting Modem Community Strings — DOCSIS 2.0 (IPv4) Method

Set the modem community strings with the DOCSIS Conguration File by including the following

SNMP parameters:

MIB Parameter Object ID Description Value

docsDevNmAccessIp 1.3.6.1.2.1.69.1.2.1.2.x The IP address (or subnet) of the network

management station

docsDevNmAccessIpMask 1.3.6.1.2.1.69.1.2.1.3.x The IP subnet mask of the network

management stations

docsDevNmAccessCommunity 1.3.6.1.2.1.69.1.2.1.4.x The community string matched to this IP

address net mask entry

docsDevNmAccessControl 1.3.6.1.2.1.69.1.2.1.5.x The level of access granted 1= none

docsDevNmAccessInterfaces 1.3.6.1.2.1.69.1.2.1.6.x Species the set of interfaces from which

requests from this NMS will be accepted

docsDevNmAccessStatus 1.3.6.1.2.1.69.1.2.1.7.x Controls and reects the status of rows in

this table

Note: X denotes the index of the SNMP entry

Table 3-1, Modem Community String Parameters — DOCSIS 2.0 (IPv4) Method

e.g. 10.20.30.0

e.g. 255.255.255.0

alphanumeric string

2= read only

3= read/write

0x40 : Cable interface (typical)

0x80 : Ethernet interface

0xC0 or 0x00 : Both interfaces

4

14

745-814-B11-001, Rev. C (03/2014)

Page 15

3.0 Network Conguration

3.3 The DOCSIS Conguration File

3.3.2 Setting Modem Community Strings — DOCSIS 2.0+IPv6 Method

Set the modem community strings with the DOCSIS Conguration File for a IPv6 network by

including the following SNMP parameters:

TLV Type TLV Parameter Description Value

53 SNMPv1v2c Coexistence Conguration This object species the SNMPv1v2c Coexistence Access

53.1 SNMPv1v2c Community Name This sub-TLV species the Community Name (community

53.2 SNMPv1v2c Transport Address Access This sub-TLV species the Transport Address and Transport

53.2.1 SNMPv1v2c Transport Address Species the Transport Address to use in conjunction with

53.2.2 SNMPv1v2c Transport Address Mask Species the Transport Address Mask to use in conjunction

53.3 SNMPv1v2c Access View Type Species the type of access to grant to the community name

53.4 SNMPv1v2c Access View Name Species the name of the view that provides the access

Control conguration of the CM. This TLV creates entries in

SNMPv3 tables as specied in [DOCSIS OSSIv3.0]

string) used in SNMP requests to the CM.

Address Mask pair used by the CM to grant access to the

SNMP entity querying the CM.

the Transport Address Mask used by the CM to grant access

to the SNMP entity querying the CM. Length is 6 bytes for

IPv4 and 18 bytes for IPv6. Two additional bytes are added

to the IP address length for the port number.

with the Transport Address used by the CM to grant access

to the SNMP entity querying the CM. Length is 6 bytes for

IPv4 and 18 bytes for IPv6. Two additional bytes are added

to the IP address length for the port number.

of this TLV. If not specied, default read-only is used.

indicated in sub-TLV SNMPv1v2c Access View Type.

Composite

Text

e.g. AlphaRead

Variable

Transport Address

0.0.0.0/0

or

0:0:0:0:0:0:0:0/0

Transport Address Mask

0.0.0.0/0

or

0:0:0:0:0:0:0:0/0

1=Read-only

2=Read-write

String

e.g.docsisManagerView

Table 3-2, Modem Community String Parameters — DOCSIS 2.0+IPv6 Method

3.3.3 Setting SNMP Trap Destination Addresses — DOCSIS 2.0 (IPv4) Method

Set the SNMP Trap Destination Addresses via the DOCSIS Conguration File by including the

following SNMP parameters:

MIB Parameter Object ID Description Value

docsDevNmAccessIP 1.3.6.1.2.1.69.1.2.1.2.x IP address of trap destination, e.g. NMS

server

docsDevNmAccessIpMask 1.3.6.1.2.1.69.1.2.1.3.x Must be set to 255.255.255.255 per RFC 4639 255.255.255.255

docsDevNmAccessCommunity 1.3.6.1.2.1.69.1.2.1.4.x Community string used by NMS to query

Communications Module

docsDevNmAccessControl 1.3.6.1.2.1.69.1.2.1.5.x Level of SNMP access to DSM3 Series from

IP address specied in

docsDevNmAccessIpMask

docsDevNmAccessInterfaces 1.3.6.1.2.1.69.1.2.1.6.x Species the set of interfaces from which

requests from this NMS will be accepted

docsDevNmAccessStatus 1.3.6.1.2.1.69.1.2.1.7.x Controls and reects the status of rows in

this table

Note: X denotes the index of the SNMP entry

e.g. 10.20.30.40

alphanumeric string

4=Read/Only plus Trap

5=Read/Write plus Trap

6=Trap only, no SNMP access

0x40 : Cable interface (typical)

0x80 : Ethernet interface

0xC0 or 0x00 : Both interfaces

4

Table 3-3, Trap Destination Addresses — DOCSIS 2.0 (IPv4) Method

15745-814-B11-001, Rev. C (03/2014)

Page 16

3.0 Network Conguration

3.3.4 Setting SNMP Trap Destination Addresses — DOCSIS 2.0+IPv6 Method

Set the SNMP Trap Destination Addresses via the DOCSIS Conguration File by including the

following SNMP parameters:

TLV Type TLV Parameter Description Value

38 SNMPv3 Notication Receiver This cong le element species a

38.1 SNMPv3 Notication Receiver IP

Address

38.2 SNMPv3 Notication Receiver UDP Port

Number

38.3 SNMPv3 Notication Receiver Trap

Type

38.4 SNMPv3 Notication Receiver Timeout This sub-TLV species the timeout value to

38.5 SNMPv3 Notication Receiver Retries This sub-TLV species the number of times

38.6 SNMPv3 Notication Receiver Filtering

Parameters

Network Management Station that will receive

notications from the modem when it is in

Coexistence mode. Up to 10 of these elements

may be included in the conguration le.

This sub-TLV species the IP address of the

notication receiver.

This sub-TLV species the UDP port number

of the notication receiver. If this sub-TLV is not

present, the default value of 162 should be used.

This sub-TLV species the type of trap to send. The trap type may take values:

use when sending an Inform message to the

notication receiver.

to retry sending an Inform message if an

acknowledgement is not received.

Object Identier of the snmpTrapOID value

that identies the notications to be sent to the

notication receiver. This notication and all

below it will be sent.

Composite

0:0:0:0:0:0:0:0

e.g.fc00:168:1:0:0:0:0:32

0.0.0.0

e.g. 10.11.0.1

UDP port number

e.g. 162

1 = SNMP v1 trap in an SNMP v1 packet

2 = SNMP v2c trap in an SNMP v2c packet

3 = SNMP inform in an SNMP v2c packet

4 = SNMP v2c trap in an SNMP v3 packet

5 = SNMP inform in an SNMP v3 packet

Time in milliseconds

e.g. 15000

Number of retries

e.g. 3

Filter OID

e.g. 1.3.6

Table 3-4, Trap Destination Addresses — DOCSIS 2.0+IPv6 Method

NOTE:

As an alternative to the docsDevNmAccessTable or SNMPv3 trap parameters, SNMP Trap

Destination Addresses may be set through the DSM3 proprietary MIB atiMgmtSnmpTrapTable (OID:

1.3.6.1.4.1.926.1.3.1.1) using a SNMP MIB Browser or as an entry in the Proprietary Conguration File

‘atidoc03.cfg’ in Section 3.3.6, Sample DOCSIS Conguration File Entries — DOCSIS 2.0+IPv6.

16

745-814-B11-001, Rev. C (03/2014)

Page 17

3.0 Network Conguration

3.3.5 Sample DOCSIS Conguration File Entries — DOCSIS 2.0 (IPv4)

SNMP MIB Object (11) [Len=21]:docsDevNmAccessStatus.1/4

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslp.1/10.56.21.0

A

B

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslpMask.1/255.255.255.0

SNMP MIB Object (11) [Len=25]:docsDevNmAccessCommunity.1/"RW STRING"

SNMP MIB Object (11) [Len=25]:docsDevNmAccessInterfaces.1/"@"

SNMP MIB Object (11) [Len=21]:docsDevNmAccessControl.1/3

SNMP MIB Object (11) [Len=21]:docsDevNmAccessStatus.2/4

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslp.2/10.20.30.40

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslpMask.2/255.255.255.255

SNMP MIB Object (11) [Len=25]:docsDevNmAccessCommunity.2/"RW Trap string"

SNMP MIB Object (11) [Len=25]:docsDevNmAccessInterfaces.2/"@"

SNMP MIB Object (11) [Len=21]:docsDevNmAccessControl.2/5

C

D

E

Legend:

A

B

C

D

E

Software Upgrade Filename(9) [Len=24]:"ModemFirmwareFile.bin"

SNMP MIB Object (11) [Len=20]:docsDevSwAdminStatus.0/2

Software Upgrade TFTP Server (21) [Len=4]:10.56.48.15

Manufacturer Code Verication Certicate (32) [Len=254]: 30 82 03 1A 30 82...

Manufacturer Code Verication Certicate (32) [Len=254]: 04 0A 13 11 41 4D...

Manufacturer Code Verication Certicate (32) [Len=254]: 04 0C 30 0A 06 01...

Manufacturer Code Verication Certicate (32) [Len=36]: 11 A3 41 A6 A7 D9....

Sets Read-Write community string. Set the IP address, netmask and community string to t your system.

Sets the IP address of where the SNMP traps will be sent. This is typically set to match the IP address of the Network

Managements System Server.

Sets rmware download parameters.

Species the IP address of the TFTP server used for upgrading rmware.

Sets Code Verication Certicate (CVC) for rmware upgrade security per the DOCSIS specication.

Fig. 3-2, Sample DOCSIS Conguration File — DOCSIS 2.0 (IPv4)

17745-814-B11-001, Rev. C (03/2014)

Page 18

3.0 Network Conguration

3.3 The DOCSIS Conguration File

3.3.6 Sample DOCSIS Conguration File Entries — DOCSIS 2.0+IPv6

SNMPv1v2c Coexistence Conguration

SNMPv1v2c Community Name:ReadWrite

SNMPv1v2c Transport Address Access

A

SNMPv1v2c Transport Address:0.0.0.0/0

SNMPv1v2c Transport Address Mask:0.0.0.0/0

SNMPv1v2c Transport Address Access

SNMPv1v2c Transport Address:0:0:0:0:0:0:0:0/0

SNMPv1v2c Transport Address Mask:0:0:0:0:0:0:0:0/0

SNMPv1v2c Access View Type:read-write

SNMPv1v2c Access View Name:docsisManagerView

Docsis V3 Notication Receiver

UDP Port number of trap receiver:162

B

Type of trap:SNMP v1 trap in an SNMP v1 packet

Timeout for sending inform:15000

Number of retries:3

Filtering Parameters:1.3.6

IPv6 Address of trap receiver:fc00:168:1:0:0:0:0:32

Docsis V3 Notication Receiver

IP Address of trap receiver:192.168.1.51

UDP Port number of trap receiver:162

Type of trap:SNMP v1 trap in an SNMP v1 packet

Timeout for sending inform:15000

Number of retries:3

Filtering Parameters:1.3.6

Software Upgrade Filename:ModemFirmwareFile.bin

C

Software Upgrade IPv6 TFTP Server:fc00:168:1:0:0:0:0:51

D

Manufacturer Code Verication Certicate:3082031B30820…

E

Manufacturer Code Verication Certicate:040A1312414C5…

Manufacturer Code Verication Certicate:FF040C300A060…

Manufacturer Code Verication Certicate:257939C848CE0…

Legend:

Sets Read-Write community string. Set the IP address, netmask and community string to t your system.

A

Sets the IP address of where the SNMP traps will be sent. This is typically set to match the IP address of the Network

B

Managements System Server.

C

Sets rmware download parameters.

Species the IP address of the TFTP server used for upgrading rmware.

D

Sets Code Verication Certicate (CVC) for rmware upgrade security per the DOCSIS specication.

E

Fig. 3-3, Sample DOCSIS Conguration File — DOCSIS 2.0+IPv6

NOTE:

DOCSIS conguration les vary from system to system. Take into consideration your company's policies, and

test the le on a local system prior to widescale deployment.

18

In previous versions of the DSM product line, an additional conguration le (also known as a Setup File)

could be used for distributing custom Alpha MIB settings to all DSMs on a network. This is still the case,

with the only difference being the name of the le, which for the DSM3 Series is atidoc03.cfg. It may be

used if preferred, but is not required.

745-814-B11-001, Rev. C (03/2014)

Page 19

3.0 Network Conguration

3.3 The DOCSIS Conguration File

3.3.7 Proprietary Conguration File ‘atidoc03.cfg’

The DSM3 Series will attempt to download a TLV-formatted le ‘atidoc03.cfg’ from the modem’s

provisioning TFTP server at start up and every 24 hours thereafter. The atidoc03.cfg proprietary

conguration le is optional and provides an alternative method to the modem’s DOCSIS

conguration le for deploying Alpha proprietary SNMP MIB parameters to eld-installed DSM3 Series

Communications Modules.

The atidoc03.cfg le should be used if the following conditions are true:

1. Non-default settings, such as SNMP Trap Destination Addresses need to be distributed to all

DSM3 Series Communications Modules.

2. The operator does not desire to place Alpha-proprietary parameters into the modem’s DOCSIS

conguration le.

NOTE:

The recommended method for setting the SNMP trap address(es) is through the modem DOCSIS conguration le

(See Section 3.3, The DOCSIS Conguration File). Alpha-proprietary parameters may also be set through the

modem’s DOCSIS conguration le, eliminating the need for the atidoc03.cfg proprietary conguration le.

To build the atidoc03.cfg le, enter the desired SNMP OIDs and values from the Alpha MIB into a

TLV le as TLV type-11 entries using a TLV editor (Refer to sample entries below). The DSM3 Series

proprietary conguration Setup le must be named “atidoc03.cfg” and placed in the root directory of

the TFTP server. DSM3 settings are updated according to values dened in this le at start up and

after every 24 hours of operation.

Sample atidoc03.cfg Entries:

Network Access Control (3) [Len - 1]: 1

SNMP MIB Object (11) [Len = 24]: atiMgmtSnmpTrapAddress.1 / 10.20.30.40

SNMP MIB Object (11) [Len = 24]: atiMgmtSnmpTrapAddress.2 / 10.20.30.50

SNMP MIB Object (11) [Len = 23]: atiMgmtSysTamperPolarity.0 / 1

3.3.8 Changing Default atidoc03.cfg Download Settings

By default the DSM3 Series will download the atidoc03.cfg le from the provisioning TFTP server

every 24 hours. However, these settings may be adjusted per the tables below by placing the

respective SNMP varbinds into the modem’s DOCSIS conguration le.

Parameter Type Description Value

atiMgmtSysDownloadCongName

1.3.6.1.4.1.926.1.3.2.1.9.0

atiMgmtSysDownloadReCfgTime

1.3.6.1.4.1.926.1.3.2.1.13.0

Search

Order

Parameter Type Description Value

atiMgmtSysDownloadCongAddress

1

OID 1.3.6.1.4.1.926.1.3.2.1.10.0

Alphanumeric

String

Integer

IP Address

Name of proprietary

conguration le

Download interval for

atidoc03.cfg (hours)

Overrides default

location

"atidoc03.cfg"

(Default)

24 (Default)

0.0.0.0 (Default)

docsDevServerCongTftpAddress

2

1.3.6.1.2.1.69.1.4.11.0

docsDevSwServerAddress

3

1.3.6.1.2.1.69.1.3.7.0

4 Software Upgrade Server IP Address

IP Address

IP Address

Table 3-5, Default atidoc.cfg Download Settings

Default location (no

change necessary)

Set via DOCSIS

conguration le

Set via DOCSIS

conguration le

CM's TFTP

Server Address

Congurable

Congurable

19745-814-B11-001, Rev. C (03/2014)

Page 20

3.0 Network Conguration

3.4 Setting Communication Options

Communications Settings may be changed through the Alpha MIB remotely using an SNMP MIB browser

or automatically by placing the SNMP parameters into the DOCSIS Conguration File.

See Section 6.0, Data Management for an explanation of the Alpha MIB.

NOTE:

Before setting options, verify UDP ports 37, 69, 161, 162 and TCP port 80 are not blocked.

SNMP Parameter Type Description Value

atiMgmtSnmpTrapOnNormal

OID: 1.3.6.1.4.1.926.1.3.1.5.1.0

atiMgmtSysDownloadReCfgTime

OID: 1.3.6.1.4.1.926.1.3.2.1.13.0

atiMgmtSysSnmpTimeout

OID: 1.3.6.1.4.1.926.1.3.1.5.3.0

atiMgmtSysHttpAccess

OID: 1.3.6.1.4.1.926.1.3.2.2.4.1.0

See Section 10.0, MIB Parameters for complete parameter denitions.

Integer Send SNMP trap when alarmed condition

Integer Download interval for DSM3 Series-specic

Integer

Integer

returns to normal state

items in atidoc03.cfg cong le (hours)

Time DSM3 Series will wait before reset if

SNMP trafc is not detected (minutes)

HTTP Web Server

1 = Disabled

2 = Enabled (Default)

24 (Default)

240 (Default)

Note: If set to zero, watchdog will be

disabled.

1 = Disabled

2 = Enabled (default)

Table 3-6, Communications Parameters

NOTE:

The DSM3 Series will inherit the cable modem community string settings provided by the DOCSIS

Conguration File.

20

745-814-B11-001, Rev. C (03/2014)

Page 21

4.0 Web Interface

Overview

The DSM3 Series Communications Module provides an embedded Web server interface to allow operations

personnel the ability to connect locally or remotely via TCP/IP over Ethernet with a laptop/computer to verify the

status of common data points and to congure various operating parameters.

4.1 Local Web Server Access

The DSM3 Series Communications Module’s Ethernet port (comparable to the Craft port on some

Communications Module models) will typically be used as a local connection point allowing the user to

connect directly to the DSM3 Series Web server interface to verify/congure common communication

parameters and view power supply status and battery values. The Ethernet port on the DSM3 Series is a

fully functional standard Ethernet port, capable of providing all the functionality of any standard Ethernet

connection.

To access the DSM3 Series Communications Module Web server locally utilizing a Web browser, use the

following procedure:

NOTE:

The following Web Browser settings should be

‘enabled’ for proper rendering/download of the

web pages:

• Java Script

• Cookies

• ActiveX Controls

• Downloads

• Active Scripting

• Show Pictures

These settings are typically enabled in the Web

Browser by default.

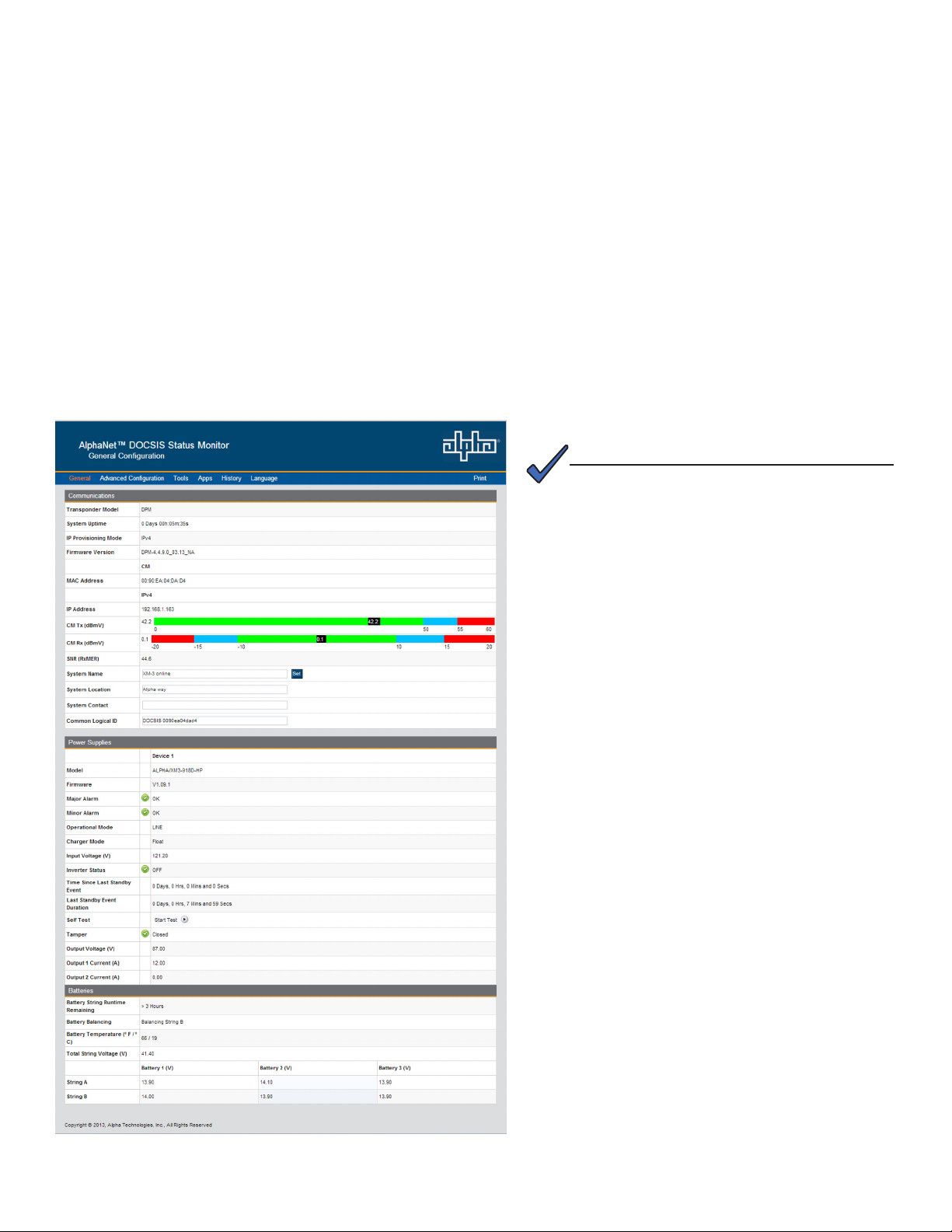

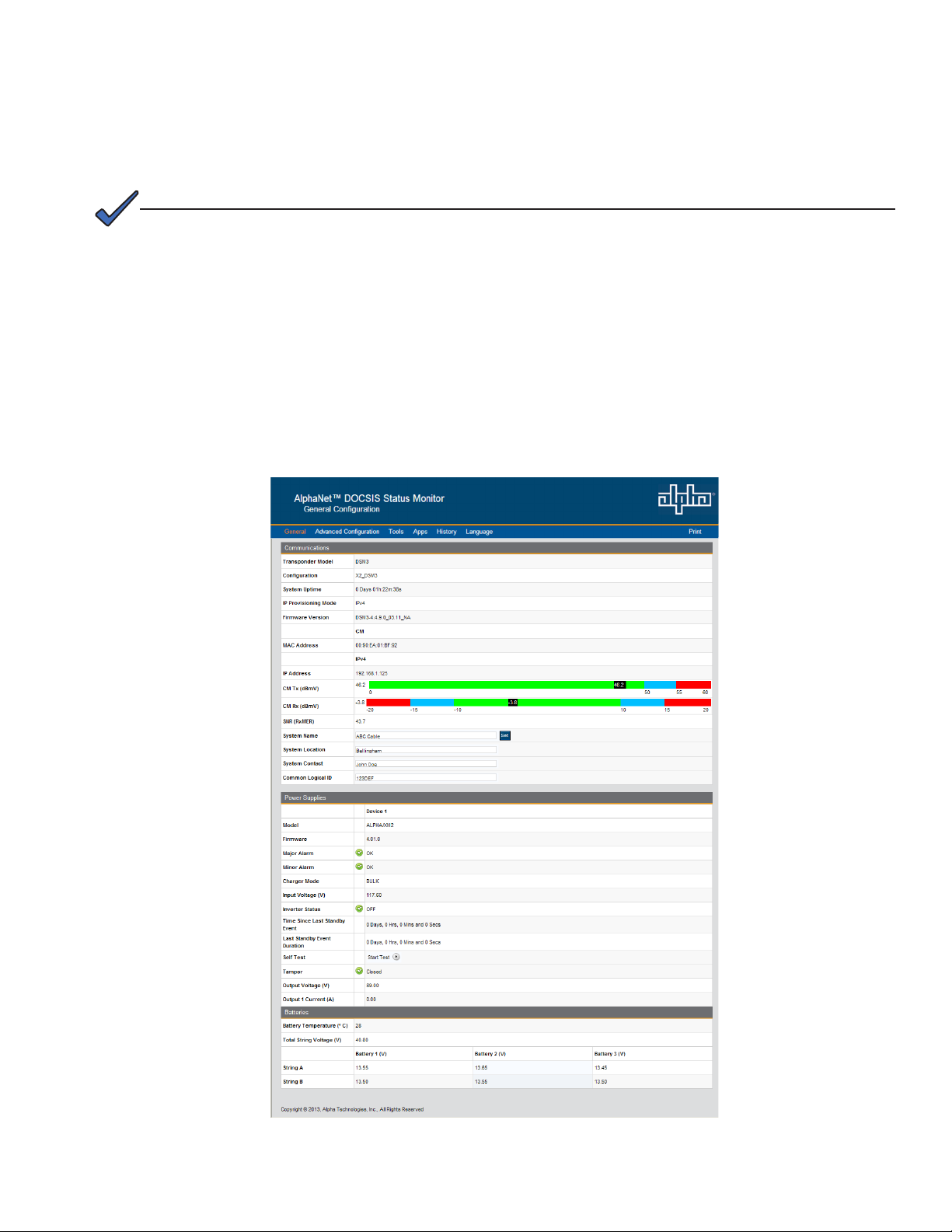

Fig. 4-1, DSM3 Series Web Page

(data values shown for illustration purposes only)

1. Connect a standard Ethernet cable (CAT5)

between the DSM3 Series Communications

Module Ethernet port (ETH) and a laptop or

computer’s network interface port.

2. Launch a Web browser.

3. Enter the Communications Module's default IP

address (192.168.100.1) or the DHCP assigned

IP address into the Web browser’s address eld.

4. The Communications Module’s Web server

home page will appear (Fig. 4-1). Note: For the

DSM3 Series, this may take up to 45 seconds

when the Communications Module is initially

powered up with no RF connection.

5. Click the Language menu to select a desired

language for the text information on the Web

page. The language choices are English

(default), Spanish, Portuguese, French &

German.

21745-814-B11-001, Rev. C (03/2014)

Page 22

4.0 Web Interface

4.1 Local Web Server Access

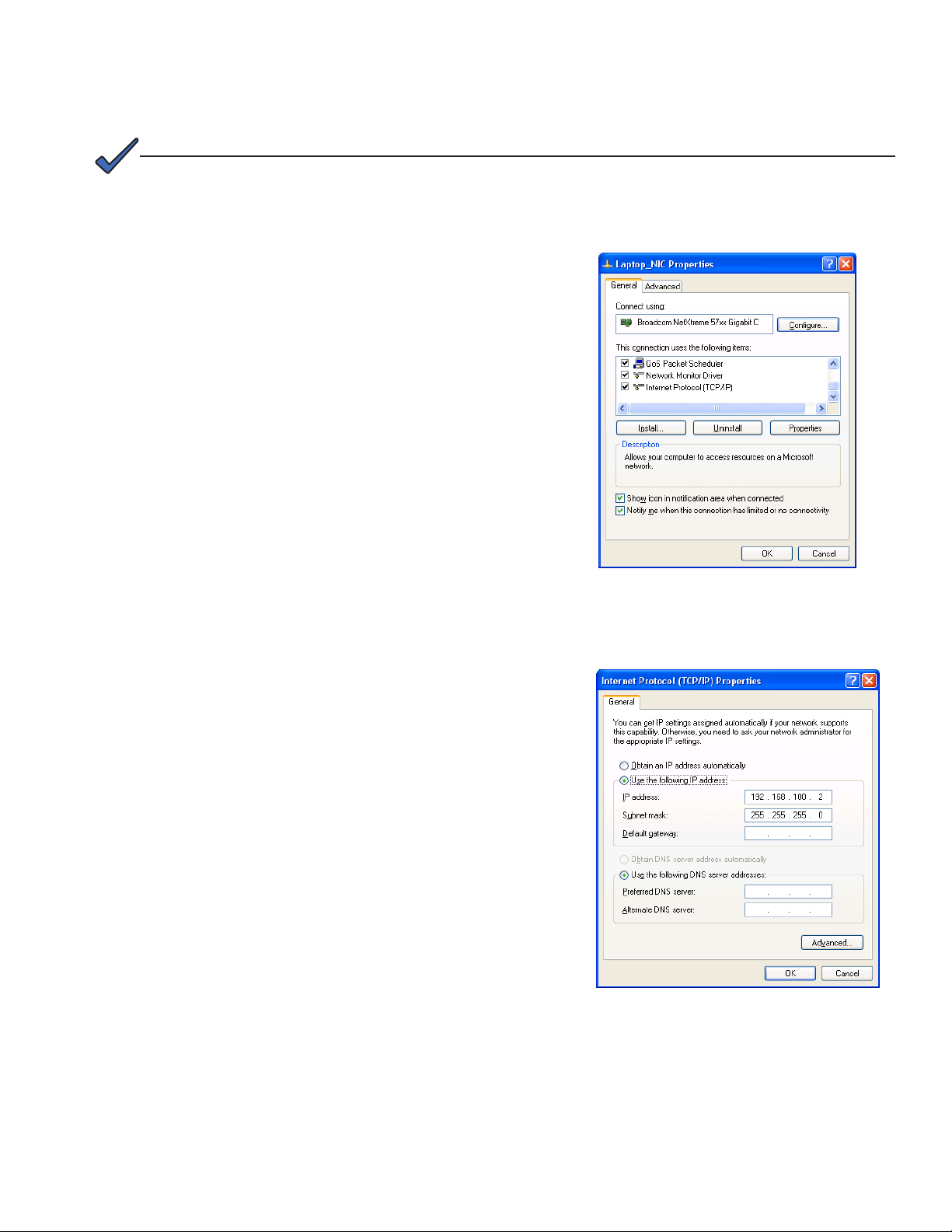

NOTE:

If you are unable to view the home page of the DSM3 Series using IP address 192.168.100.1, the network

conguration on the computer that is being used to connect to the DSM3 Series Communications Module

may require a temporary static IP address (192.168.100.2) to be congured.

Use the following procedure to congure a static IP

address on a laptop or computer with the Windows XP

operating system:

1. Click the Start button (lower left button on most

Windows® computers).

2. When the window pops up, click Control Panel

(usually about half the way down the second

column).

3. Click Network Connections.

4. Right-Click Local Area Connection link to open

menu box.

5. Click the bottom option Properties.

6. You will see a dialog box much like Fig. 4-2; select

Internet Protocol (TCP/IP) and then click the

Properties button.

7. The Internet Protocol (TCP/IP) Properties

dialog box will open (Fig. 4-3). Select "Use

the following IP address". Enter the values

as shown (i.e. IP address 192.168.100.2,

or DHCP assigned IP address, and Subnet

mask 255.255.255.0). Record the existing IP

address and Subnet mask in order to later

return the computer to its original state.

8. Click the OK button and try to connect to

the DSM3 Series Communications Module

once again using 192.168.100.1 in the Web

browser.

9. To restore network settings, repeat Steps 1

through 6.

Fig. 4-2, Local Area Connection

Properties Screen, Windows XP

22

Fig. 4-3, Internet Protocol (TCP/IP)

Properties Screen, Windows XP

745-814-B11-001, Rev. C (03/2014)

Page 23

4.0 Web Interface

4.1 Local Web Server Access

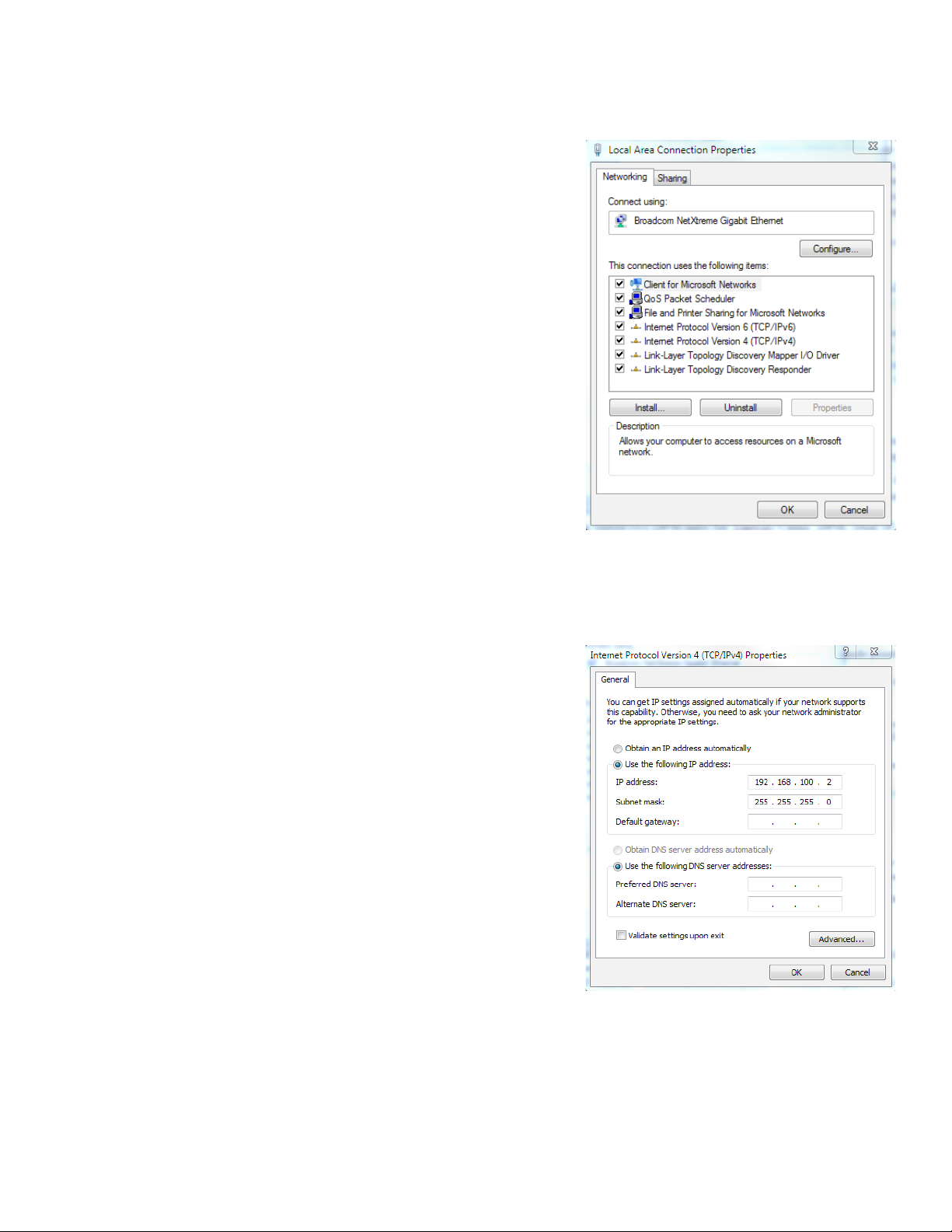

Use the following procedure to congure a static IP

address on a laptop or computer with the Windows 7

operating system:

1. Click the Start button (lower left button on most

Windows® computers).

2. When the window pops up, click Control Panel

(usually about half the way down the second

column).

3. Click Network and Sharing Center.

4. Click Local Area Connection.

5. Click the Properties button.

6. You will see a dialog box much like Fig. 4-4; click

Internet Protocol (TCP/IPv4) and then click the

Properties button.

7. The Internet Protocol (TCP/IP) Properties

dialog box will open (Fig. 4-5). Select "Use

the following IP address". Enter the values

as shown (i.e. IP address 192.168.100.2

and Subnet mask 255.255.255.0). Record

the existing IP address and Subnet mask

in order to later return the computer to its

original state.

8. Click the OK button and try to connect to

the DSM3 Series Communications Module

once again using 192.168.100.1 in the Web

browser.

9. To restore network settings, repeat Steps 1

through 6.

Fig. 4-4, Local Area Connection

Properties Screen, Windows 7

Fig. 4-5, Internet Protocol (TCP/IP)

Properties Screen, Windows 7

23745-814-B11-001, Rev. C (03/2014)

Page 24

4.0 Web Interface

4.2 Remote Web Server Access

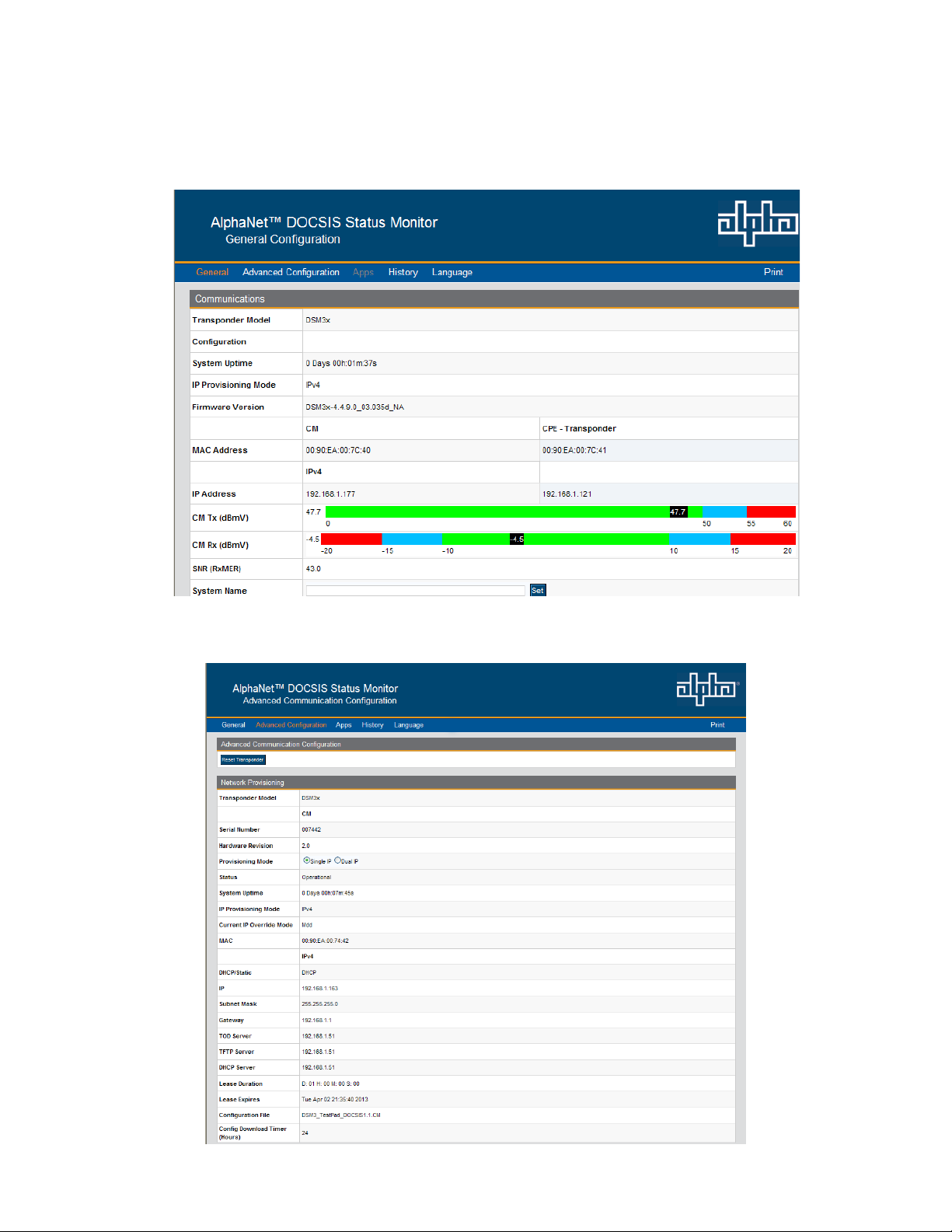

To remotely access the DSM3 Series Communications Module Web server utilizing a Web browser, use

the following procedure:

NOTE:

For Web server (HTTP) access, port 80 must not be blocked.

1. Connect the laptop or computer’s network interface port to the company’s Ethernet network.

2. Open a Web browser.

3. Enter the DSM3 Series' DHCP designated IP address (e.g., 192.168.1.124) into the Web browser’s

address eld. Use square brackets when entering IPv6 IP addresses (e.g. [FC00:168:40::124]) into

the Web browser's address eld.

4. The DSM3 Series Communications Module’s Web server home page will appear (Fig. 4-6).

5. Click on the Language menu to select a desired language for the text information on the Web page.

The language choices are English (default), Spanish, Portuguese, French and German.

24

Fig. 4-6, Web Server Home Page

(data values shown for illustration purposes only)

745-814-B11-001, Rev. C (03/2014)

Page 25

4.0 Web Interface

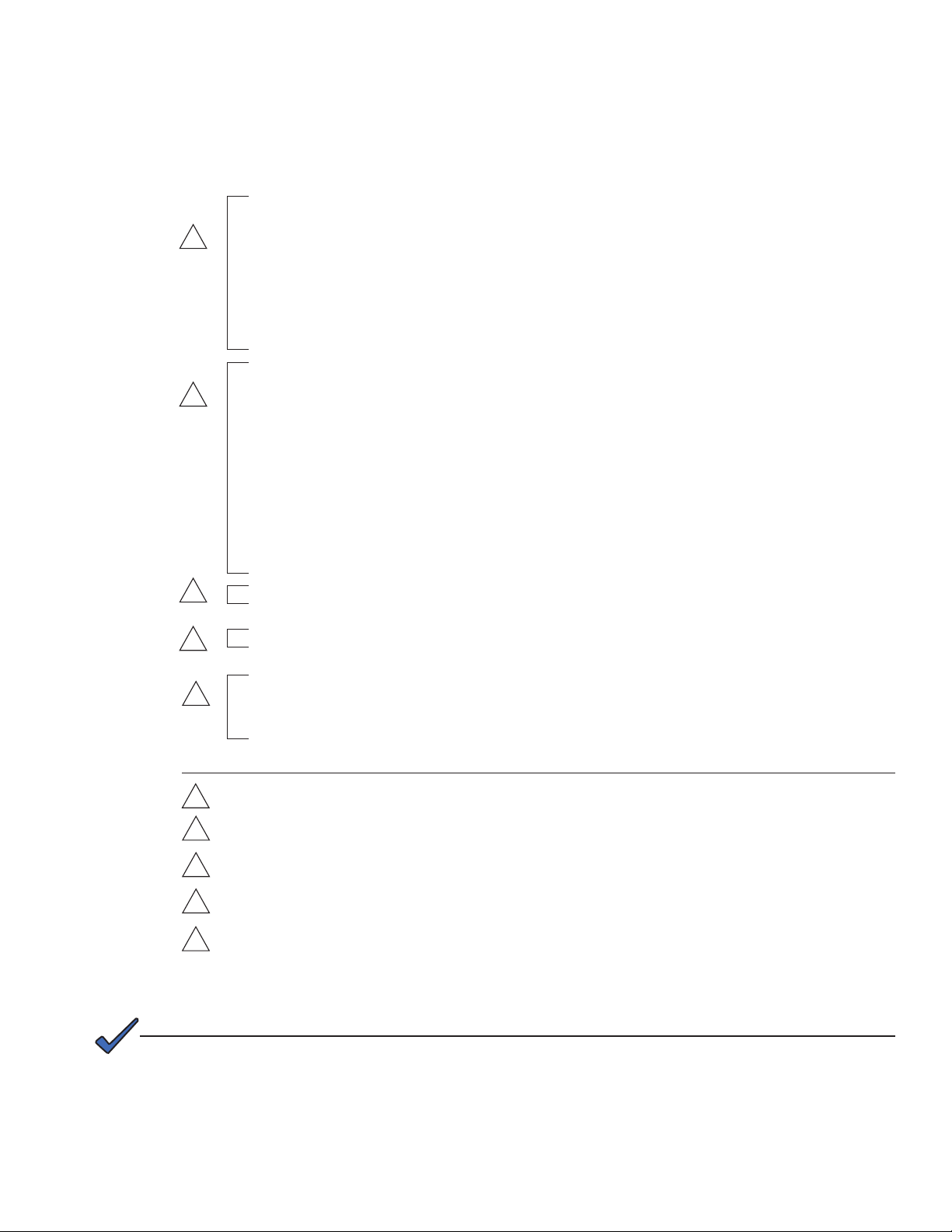

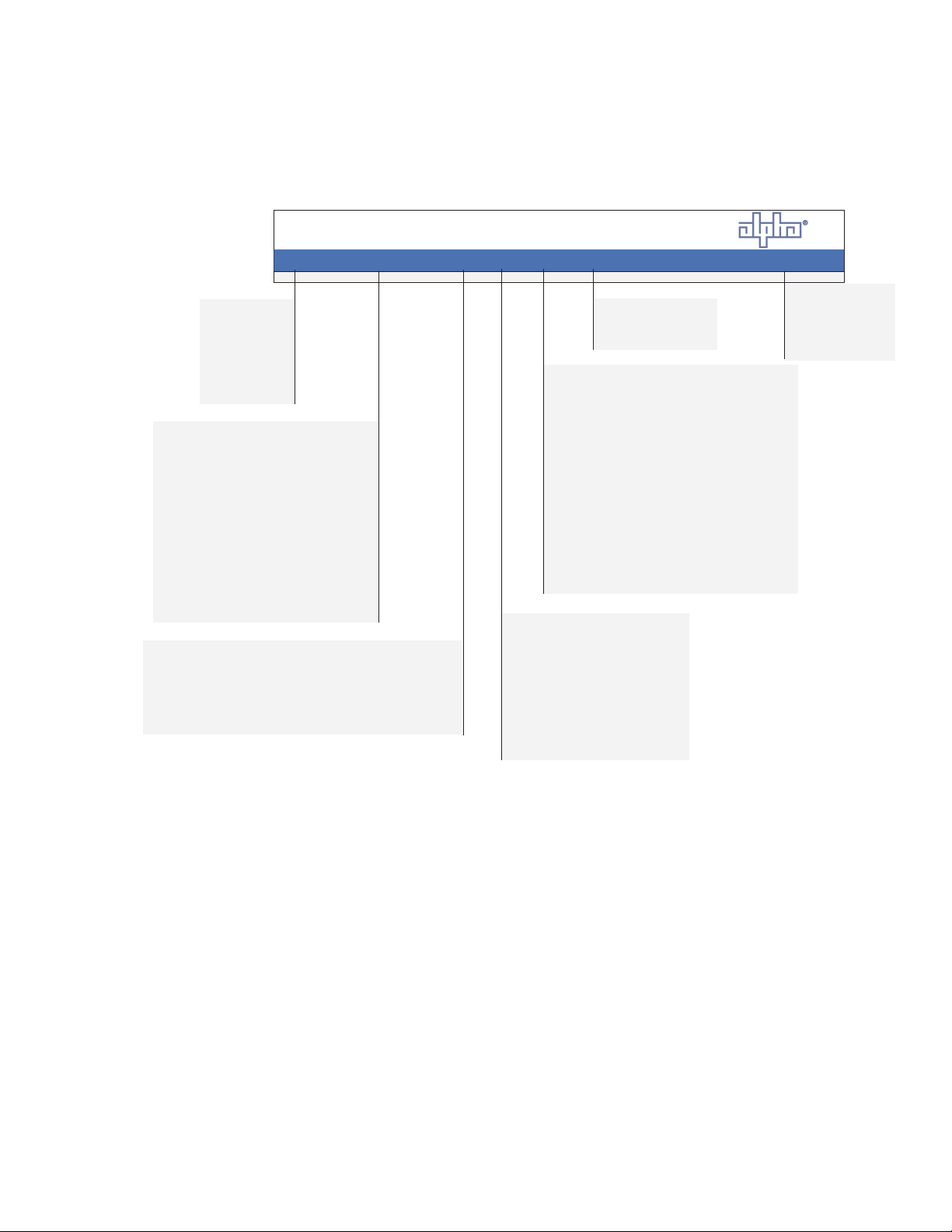

4.3 Navigating the Web Page

Once the Web page has been successfully accessed, the operator is able to select a link on the header

bar and the page specic to the topic will open enabling real-time data to be observed.

See Fig. 4-7 for DSM3 Series navigation bar items.

Commonly used

parameters for

quick diagnostics

of Power Supply,

Communications,

Batteries and

Generator.

Communications: Comprehensive

communications diagnostic parameters

Power Supply: Comprehensive Power

Supply conguration and congurable

parameters

Generator: Comprehensive Generator

conguration and diagnostic parameters

IO - Environment: Status and conguration

of Tamper polarity and external I/O devices

HMS Alarms: Status of SCTE-HMS active

alarms, alarm history and alarm threshold

settings.

Constellation: Provides a constellation view of the DOCSIS

channel for troubleshooting impairments.

Microreections: Provides details about impairments on the

network and the approximate distance(s) of those impairment(s).

Requires the Adaptive equalization feature to be enabled on the

CMTS.

TM

AlphaNet

DOCSIS Status Monitor

General Conguration

General Advanced Conguration To ol s Apps History Language Print

The Web page content

will be displayed in the

selected language

System Logs (requires AlphaApp card): Log

overview page provides snapshot of rst 5 entries

from each of the system logs.

Power Supply Events (requires AlphaApp card):

Records daily Power Supply system events.

Power Supply Conguration (requires

AlphaApp card): Records power supply system

conguration events, many of which are set during

the initial installation.

Battery Events (requires AlphaApp card):

Records battery conductance measurements and

manufacturing dates.

Cable Modem Log: Web page representation of

the DOCSIS modem event log.

(Requires AlphaApp card)

Overview: Provides AlphaApp card

version and status, plus Utility power

health information.

Battery Management: Congure

technician ID, battery conductance

measurements, battery model and

battery manufacturing dates for

runtime and battery life calculations.

Sends the contents

of the selected

Web page to the

computer’s default

printer.

Fig. 4-7, DSM3 Series Navigation Bar Items

25745-814-B11-001, Rev. C (03/2014)

Page 26

4.0 Web Interface

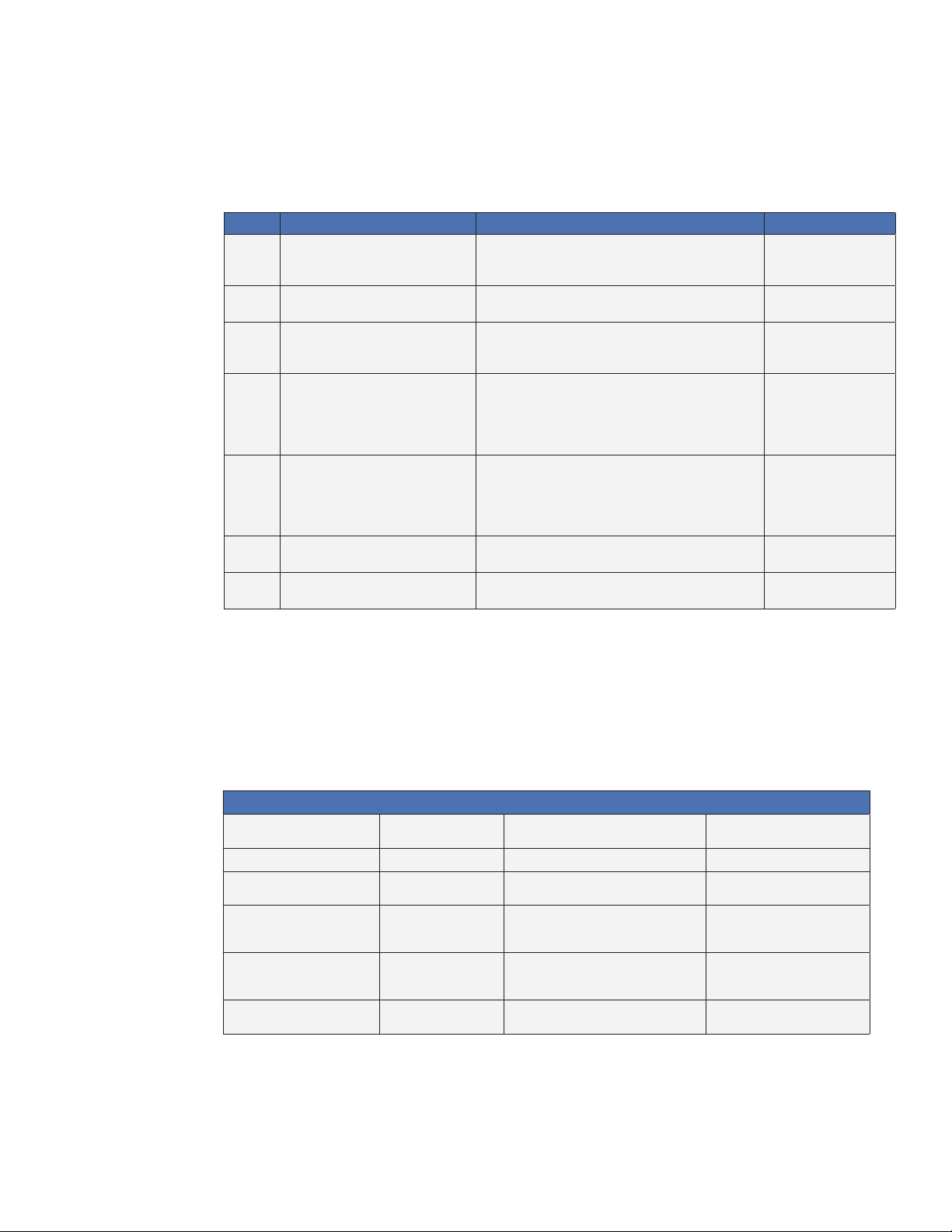

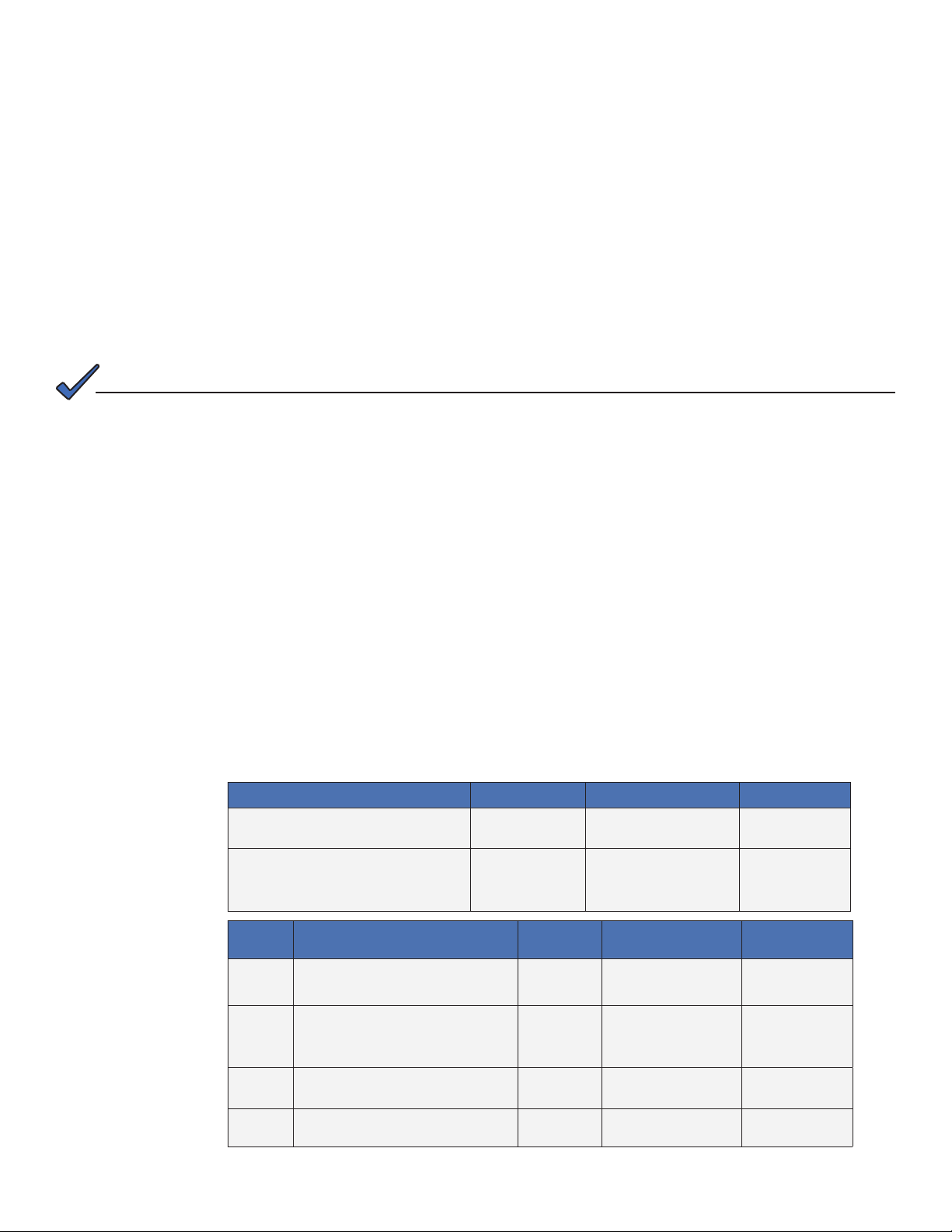

4.3.1 Web Interface Security Levels

The DSM3 Series Communications Module has two levels of function-specic security. General

operations are Level 1. Conguration-related functions are Level 2. Refer to Table 4-1 for default

User Name and Security Passwords.

DSM3 Series Web Page Security

OID Function Value

1.3.6.1.4.1.4413.2.2.2.1.1.3.3.0 Level 1 User Name Alpha

1.3.6.1.4.1.4413.2.2.2.1.1.3.4.0 Level 1 Security Password AlphaGet

1.3.6.1.4.1.4413.2.2.2.1.1.3.1.0 Level 2 User Name Alpha

1.3.6.1.4.1.4413.2.2.2.1.1.3.2.0 Level 2 Security Password AlphaSet

Table 4-1, DSM3 Series Web Page Security

Web Page Function Security Level

System Name, System Contact, System Location,

General

Advanced Communications

Advanced Power Supply Congure/Save 2

Advanced Generator

Modem Log [Event Log] Reset Log 1

Advanced I/O

HMS Alarms Export Alarm Cloning File 2

Apps Overview Congure/Save 2

Battery Management Congure/Save 2

Constellation Number of Samples 2

Common Logical ID

Power Supply Self Test 1

Generator Self Test 1

Reset Communications Module 1