Page 1

™

AlphaNet

Series

External DOCSIS® Transponder

Technical Manual

Model XP-EDH-A2

Model XP-EDHEffective: October 2009

Alpha Technologies

Page 2

Alpha Technologies

Power

®

Page 3

AlphaNet™ Series

External DOCSIS Transponder

Model XP-EDH-A2

Technical Manual

745-838-B2-001, Rev. A

Effective Date: October 2009

Copyright © 2009

Alpha Technologies, Inc.

member of The Group

NOTE:

Alpha denies responsibility for any damage or injury involving its enclosures, power supplies, generators,

batteries or other hardware, manufactured by Alpha or members of the Alpha Group, when used for an

unintended purpose, installed or operated in an unapproved manner, or improperly maintained.

NOTE:

Photographs and drawings contained in this manual are only for illustrative purposes. These photographs and

drawings may not exactly match your installation.

NOTE:

Review the written and illustrative information contained in this manual before proceeding. If there are

questions regarding the safe installation or operation of this powering system or enclosure, please contact

Alpha Technologies or your nearest Alpha representative.

TM

Contacting Alpha Technologies: www.alpha.com

or

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

1-800-863-3930,

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacifi c Time or 24/7 emergency support

DOCSIS® is a Registered Trademark of CableLabs.

3745-838-B2-001 Rev. A

Page 4

Table of Contents

Safety Notes .......................................................................................................................... 6

1.0 Introduction .................................................................................................................7

1.1 System Overview ............................................................................................. 8

1.2 LED Indicators ................................................................................................. 9

1.3 MAC Address ................................................................................................... 9

2.0 Installation.................................................................................................................10

2.1 General Installation Information for Supported Power Supplies ....................10

2.1.1 Mounting the Transponder ...................................................................11

2.1.2 Disconnecting DC Power .....................................................................11

2.1.3 Confi guring the Interface Card .............................................................11

2.1.4 Wiring the Battery Harness ..................................................................11

2.1.5 Connecting the Power Supply Interface and Measurement Cables ...12

2.1.6 Confi rming the RF Drop ......................................................................12

2.1.7 Provisioning Network Connectivity ......................................................12

2.1.8 Confi guring AM MIBS .......................................................................... 12

2.1.9 Setting the DOCSIS Confi guration File Options.................................. 13

2.1.10 Verifying Operation.............................................................................. 13

3.0 Installation Instructions for Specifi c Power Supplies ................................................14

3.1 Alpha XM2 Series .......................................................................................... 14

3.1.1 USM2.5 Jumper Settings .................................................................... 15

3.1.2 Output Voltage Calibration .................................................................. 15

3.1.3 USM2 Jumper Settings ....................................................................... 16

3.1.4 Output Voltage Calibration .................................................................. 17

3.1.5 Connecting the XP-EDH-A2 to an XM2 Series Power Supply ............ 18

3.1.6 Provisioning the Network for the XM2 Series...................................... 19

3.2 Alpha XM Series Power Supply ..................................................................... 20

3.2.1 XM Series Jumper Settings................................................................. 21

3.2.2 Output Voltage Calibration .................................................................. 21

3.2.3 Connecting the XP-EDH-A2 to a XM Series Power Supply ................ 22

3.2.4 Provisioning the Network for the XM Series........................................ 23

3.3 Alpha AM/AP Series Power Supply ...............................................................24

3.3.1 Connecting the XP-EDH-A2 to an AM/AP Series Power Supply ........24

3.3.2 Output Voltage Calibration .................................................................. 26

3.3.3 Provisioning the Network for the AM/AP Series .................................. 26

4

745-838-B2-001 Rev. A

Page 5

3.4 Alpha/Lectro ZTT+ Series Power Supply ....................................................... 27

3.4.1 Alpha/Lectro ZTT+ Installation (Silver and Black) ............................... 27

3.4.2 Connecting the Alpha/Lectro ZTT+ (Silver and Black) ........................ 28

3.4.3 Connecting the Lectro ZTT ................................................................. 29

3.4.4 Alpha/Lectro ZTT+ Series Output Voltage Calibration ........................ 30

3.4.5 Provisioning the Network for the

Alpha/Lectro ZTT+ Series..................30

4.0 Proprietary Management Information Bases (MIBs)................................................. 31

5.0 Transponder Connector Pinouts ...............................................................................32

6.0 Cable Selection Guide .............................................................................................. 33

7.0 Dimensions ............................................................................................................... 36

7.1 Dimensions of XP-EDH-A2 ............................................................................ 36

7.2 Battery Cable Wiring Diagram ....................................................................... 37

8.0 Specifi cations............................................................................................................ 38

List of Figures and Tables

Fig. 1-1, AlphaNet Series Model XP-EDH-A2 External DOCSIS Status Monitor Front Panel .......................... 7

Fig. 1-2, XP-EDH-A2 Front Panel....................................................................................................................... 8

Fig. 1-3, XP-EDH-A2 Rear Panel ....................................................................................................................... 8

Fig. 1-4, LED Status ........................................................................................................................................... 9

Fig. 1-5, MAC Address Label.............................................................................................................................. 9

Fig. 3-1, USM2.5 Switch/Jumper Settings ........................................................................................................ 15

Fig. 3-2, USM2 Settings for <48V and <20A .................................................................................................... 16

Fig. 3-3, USM2 Settings for <48V and >20A .................................................................................................... 16

Fig. 3-4, USM2 Settings for 48V and <20A ...................................................................................................... 17

Fig. 3-5, USM2 Settings for 48V and >20A ...................................................................................................... 17

Fig. 3-6, XM2 Series Installation with Four Batteries........................................................................................ 18

Fig. 3-7, XM/XP Power Supply Universal Status Monitor ................................................................................. 21

Fig. 3-8, XM Series Installation with Three Batteries ........................................................................................ 22

Fig. 3-9, AM/AP Series Installation with Three Batteries .................................................................................. 25

Fig. 3-10, Lectro ZTT+ Series Power Supplies ................................................................................................27

Fig. 3-11, Alpha/Lectro ZTT+ Series Silver and Black Installation .................................................................... 28

Fig. 3-12, Lectro ZTT Series Installation .......................................................................................................... 29

Fig. 7-1, Outline Dimensions, XP-EDH-A2 ....................................................................................................... 36

Fig. 7-2, Battery Cable Wiring Diagram ............................................................................................................ 37

Table 1-1, Number of Batteries and Strings........................................................................................................ 8

Table 4-1, Proprietary MIBs .............................................................................................................................. 31

Table 5-1, Transponder Connector Pinouts ...................................................................................................... 32

5745-838-B2-001 Rev. A

Page 6

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

ATTENTION:

The use of ATTENTION indicates specifi c regulatory/code requirements that may affect the placement of

equipment and /or installation procedures.

NOTE:

A NOTE provides additional information to help complete a specifi c task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to the technician

or user.

6

745-838-B2-001 Rev. A

Page 7

1.0 Introduction

The AlphaNet™ Series Model XP-EDH-A2 External DOCSIS Transponder manages network

powering through the existing cable modem infrastructure.

A single transponder can monitor and manage one power supply and batteries. The transponder

transmits data to a management system over the network’s existing infrastructure. Standard SNMP

(Simple Network Management Protocol) provides access by any SNMP manager. Status Monitoring

information is compatible with ANSI/SCTE HMS standards.

The AlphaNet Series transponder provides the tools needed to manage today’s network power

requirements, and the ability to upgrade for tomorrow’s needs.

Features:

DOCSIS 2.0 certifi ed•

Compatible with ANSI/SCTE HMS standards •

Single transponder supports a variety of power supply models: XM2, XM, AM, ZTT series•

Embedded Web server for remote diagnostics•

USB Port enables on-site technician access•

™

Fig. 1-1, Front panel, AlphaNet Series Model XP-EDH-A2, External DOCSIS Transponder

7745-838-B2-001 Rev. A

Page 8

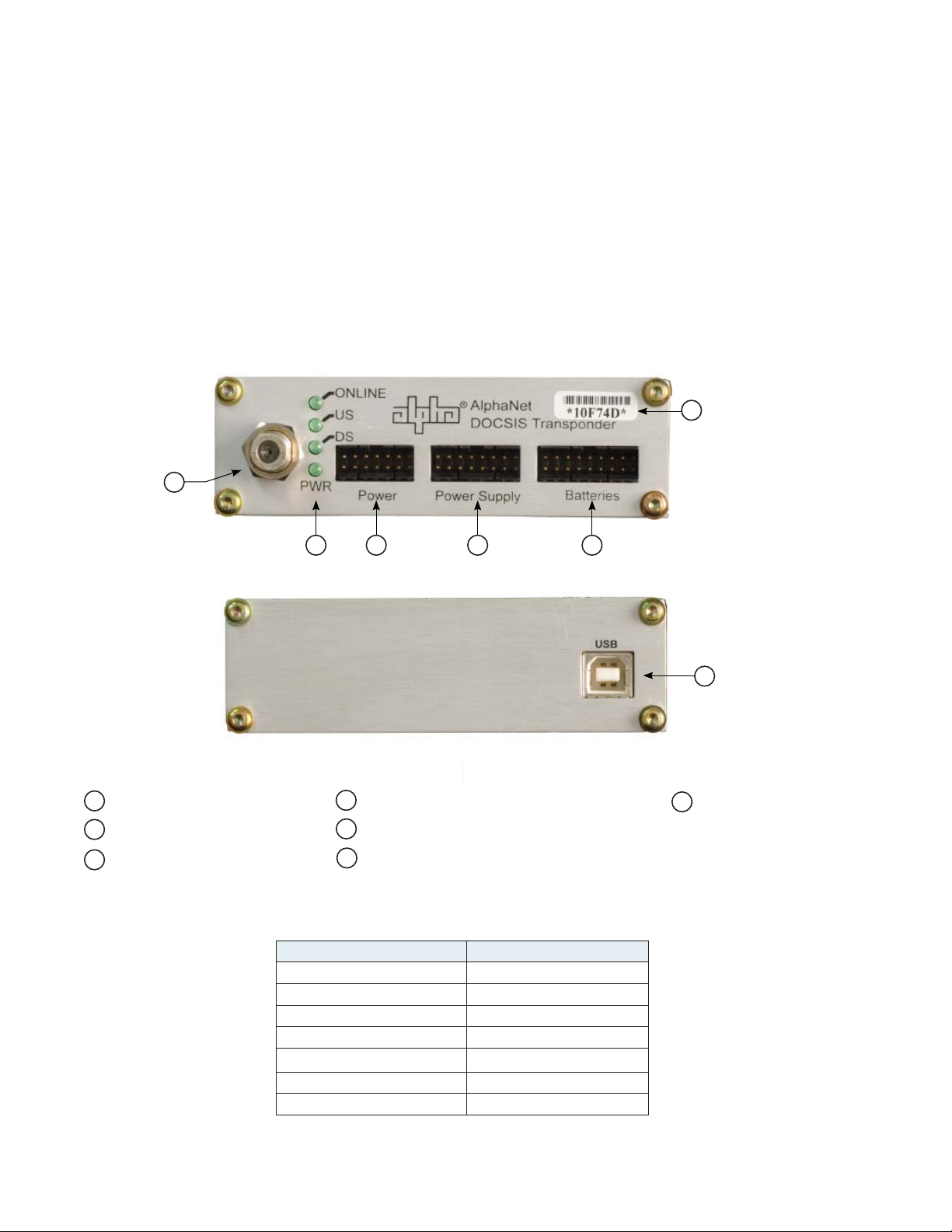

1.0 Introduction, continued

1.1 System Overview

The XP-EDH-A2 is designed for use with the following standby power supplies:

• XM2 • AM/AP

• XM • ZTT, ZTT+

The transponder hardware is the same for all applications and harness kits are available for

specifi c confi gurations.

The XP-EDH-A2 receives data from a Universal Status Monitoring Card on XM/XM2 series

power supplies, from the status monitor connector on Lectro ZTT power supplies, or from

the RPM card on AM power supplies. The transponder and power supply can be network

managed through your existing CMTS.

1

6

To CMTS

1

Status LEDs

2

(Optional) Voltage In, Voltage

3

Out, Current Out Sense Kits

2 3 4 5

Fig. 1-2, XP-EDH-A2 Front Panel

Fig. 1-3, XP-EDH-A2 Rear Panel

4

Power Supply Connection

5

Battery String Connection

The complete MAC address will have an

6

Organizational Unique Identifi er – OUI (e.g.,

00-03-08) in front of the MAC Address shown

on this label.

Number of Batteries (Voltage) Number of Strings

2 (24Vdc) 1

3 (36Vdc) 1

6 (36Vdc) 2

9 (36Vdc) 3

4 (48Vdc) 1

8 (48Vdc) 2

12 (48Vdc) 3

7

7

USB Port for local

diagnostics

Table 1-1, Number of Batteries and Strings

8

745-838-B2-001 Rev. A

Page 9

1.0 Introduction, continued

1.2 LED Indicators

The front panel has four LEDs which indicate the following:

POWER: Indicates device has power

OFF: No power

ON: Power on. (Battery harness connected to a battery string)

ONLINE: Indicates a two-way RF (radio frequency) connection.

OFF: No communication

Flickering ON: Scanning for CMTS connection

ON: Ongoing communication online with CMTS

US (Upstream activity): Indicates data being transferred to the transponder

Flashing ON and OFF: Normal operation

OFF: No power or malfunctioning transponder

DS (Downstream activity): Indicates data being transferred from the transponder

Flashing ON and OFF: Normal operation

OFF: No power or malfunctioning transponder

1.3 MAC Address

Each transponder is assigned a unique Media Access Control (MAC) address, which is used

to communicate with the network. The fi rst 6 digits of the MAC address (the Organizational

Unique Identifer (OUI)) for the transponder is 00-03-08. The complete address is located on

the label on the top of the device and in this example is 00 03 08 0B 10 F7 27.

MAC address

Fig. 1-4, LED Status

Fig. 1-5, MAC Address Label

9745-838-B2-001 Rev. A

Page 10

2.0 Installation

Before installing the XP-EDH-A2 into a power supply, review your system requirements and

determine the number of cable assemblies you need to monitor your HFC standby power supplies.

Note the following:

The types and quantities of each power supply type•

Number of individual batteries per site (if you plan to increase the number of batteries in the •

future, consider ordering additional battery harnesses)

Length of required battery harness (The standard 4 ft length battery harness is used in the typical •

power supply cabinet where one to three battery strings are mounted in the trays underneath the

power supply shelf. If necessary, a 20 ft battery harness is available)

The required type of interface cards (RPM, USM, USM2.5, etc.)•

Utility power available at the site, 110V or 220V.•

NOTE:

The procedure for installing the XP-EDH-A2 into any supported power supply involves general information,

(information that is common to all the power supplies), and information specifi c to an individual type of power

supply. These installation instructions are divided into two sections to refl ect this. It is recommended that you

read through the general instructions and then take note of any information specifi c to your power supply.

Also, installation of this product involves both fi eld installation and the confi guration of the system, including

network security, SNMP set-up, and other system provisioning. While those two procedures are handled

independently, they are presented together in the section specifi c to your power supply.

2.1 General Installation Information for Supported Power Supplies

There are a few basic steps to follow to install the XP-EDH-A2 into supported power supply

sites. The steps are either fi eld steps or system confi guration steps, and can be performed

independently.

Field installation steps are:

Transponder Placement1.

Disconnecting the DC power2.

Confi guring the Interface Card3.

Wiring the battery harness4.

Connecting the power supply interface and measurement cables5.

Confi rming the RF drop6.

System confi guration steps are:

Provisioning Network Connectivity7.

Confi guring the MIBS8.

Setting the DOCSIS confi guration fi le options9.

Completing and Testing the installation:

10

Verifying the operation10.

Detailed information on each of these steps follows.

745-838-B2-001 Rev. A

Page 11

2.0 Installation, continued

2.1 General Installation Information for Supported Power Supplies, continued

2.1.1 Transponder Placement

Place the transponder on the shelf inside the cabinet next to the power supply. •

Do not place the transponder on top of the power supply.

Maintain access to the front of the transponder to ease the connection of the •

cables.

Ensure the cabinet door can close without damaging the cables.•

Route and tie-wrap the cables in an orderly manner.•

NOTE:

Depending on the type of enclosure and the power supply you are using, it may be necessary to orient the

Service Power Inserter (SPI) vertically to provide space for the transponder. Re-torque the SPI to spec (130

in/lbs) if repositioning becomes necessary. This is important, as the output neutral is not tied to ground until

connected to the SPI /enclosure.

CAUTION!

Backup capability is suspended with the DC breaker in the OFF position.

2.1.2 Disconnecting the DC Power

Place the DC breaker in the OFF position.

2.1.3 Confi guring the Interface Card

Each power supply contains an interface card which provides the common

communication layer between the power supply and the transponder. The settings

needed for your power supply are located in Section 3.0, "Installation Instructions

for Specifi c Power Supplies".

2.1.4 Wiring the Battery Harness

CAUTION!

Incorrect connections may damage the equipment and invalidate the warranty. Double-check all connections.

Prior to connecting the cables to the transponder, make all harness connections •

to the batteries and interface connectors on the power supply. See the battery

diagrams for your specifi c power supply.

Double-check all connections. Incorrect connections may damage the •

transponder or the power supply. Correct connections at the batteries are

extremely important to the proper operation of the power supply.

Ensure that the high current carrying cables and jumpers (heavy gauge black •

and red cables) remain in direct contact to the battery terminals.

Never place the transponder battery harness lugs between the current carrying •

jumper/cable lugs and the battery terminals. See the power supply installation

manual for more information.

In some cases there are more battery harness leads than there are batteries. •

Connect all unused lugs to the same terminal as the V(-) lead, the same terminal

where the heavy gauge black cable from the inverter is connected. This prevents

stray voltages from being detected by the transponder.

11745-838-B2-001 Rev. A

Page 12

2.0 Installation, continued

2.1 General Installation Information for Supported Power Supplies, continued

2.1.5 Connecting the Power Supply Interface and Measurement Cables

Connect the power supply interface and measurement cables to the power •

supply. Connections are dependent on the type of power supply confi guration

you are using. See the section specifi c to your confi guration.

It is important to be able to measure the site input line voltage. If you are •

not using a USM2.5/XM2 power supply, then it is recommended you use a

transformer (110V and 220V available*) to sample the commercial power at

the site. While it does not power the transponder, it makes it possible for the

transponder to report the actual line voltage. An additional transformer is not

necessary when using a USM2.5/XM2 power supply.

Use a surge protector within the cabinet when you are using a transformer to •

measure line voltage. Most cabinets come equipped with a duplex outlet.

* 110V applications: CBL-PS-PWR-01-001, p/n 875-563-10

220V applications: CBL-PS-PWR-03-002, p/n 875-562-10

(3' cord with IEC C13 connector and 220V US NEMA 6-15 plug)

2.1.6 Confi rming the RF Drop

An RF drop is required at the power supply site. The RF drop should not have •

plant voltage.

The transponder contains a DOCSIS 2.0 cable modem. The downstream level •

(DS) into the transponder should be between -15 and +15 dBmV, with a recommended level of 0dBmV.

2.1.7 Provisioning Network Connectivity

The transponder’s cable modem must be recognized by the CMTS as a valid device,

obtain an IP address from the DHCP server, locate the TFTP and TOD servers, and

communicate with the SNMP management server (trap receiver). Different security

methods are used to insure network integrity, some common issues are:

A “subscriber account” (where the subscriber is the transponder) may be required •

for each transponder.

The transponder’s MAC address may have to be pre-loaded into the CMTS.•

MAC fi ltering may have to be modifi ed to allow MAC addresses starting with •

00:03:08xx:xx:xx to be registered.

For SNMP access, UDP ports 161 & 162 must not be blocked.•

Firewalls must allow communication between the cable modem and the various •

servers noted above.

If the address of the TFTP and/or TOD server is different than the DHCP server, •

the response from the DHCP server must contain the TFTP and TOD addresses.

12

2.1.8 Confi guring MIBs

This step is not performed in the fi eld, but at the network end of the installation. •

There are two propriety MIBs (Management Information Base) from Networks •

needed to confi gure the XP-EDH-A2. Refer to Section 4.0, "Proprietary

Management Information Bases (MIBs)" for detailed information.

745-838-B2-001 Rev. A

Page 13

2.0 Installation, continued

2.1 General Installation Information for Supported Power Supplies, continued

2.1.9 Setting the DOCSIS Confi guration File Options

This step is performed at the network end of the installation. •

This fi le supplies the security and community string settings for the system, as •

well as the software upgrade parameters. Set the community strings, matching

your DOCSIS cable modems. The following is an example:

Sets Read-Write

Community string. Set

the IP addresses and

community strings to fi t

your system.

Sets Read-Only

Community string. Set

the IP addresses and

community strings to fi t

your system.

Sets fi rmware

download parameters.

Sets Code Verifi cation

Certifi cate (CVC)

2.1.10 Verifying Operation

SNMP MIB Object (11) [Len=21]:docsDevNmAccessStatus.1/4

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslp.1/192.168.1.0

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslpMask.1/255.255.255.0

SNMP MIB Object (11) [Len=25]:docsDevNmAccessCommunity.1/"RWRWRWRW"

SNMP MIB Object (11) [Len=21]:docsDevNmAccessControl.1/3

SNMP MIB Object (11) [Len=21]:docsDevNmAccessStatus.2/4

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslp.2/192.168.1.0

SNMP MIB Object (11) [Len=21]:docsDevNmAccesslpMask.2/255.255.255.0

SNMP MIB Object (11) [Len=25]:docsDevNmAccessCommunity.2/"RORORORO"

SNMP MIB Object (11) [Len=21]:docsDevNmAccessControl.2/2

Software Upgrade Filename(9) [Len=24]:"MODEM_Firmware_file.bin”

SNMP MIB Object (11) [Len=20]:docsDevSwAdminStatus.0/2

Software Upgrade TFTP Server (21) [Len=4]:192.168.1.51

Manufacturer Code Verification Certificate (32) [Len=254]: 30 82 03 1A 30 82...

Manufacturer Code Verification Certificate (32) [Len=254]: 04 0A 13 11 41 4D...

Manufacturer Code Verification Certificate (32) [Len=254]: 04 0C 30 0A 06 01...

Manufacturer Code Verification Certificate (32) [Len=36]: 11 A3 41 A6 A7 D9....

After the connections are complete and the transponder’s online LED is on solid, •

indicating network connectivity, verify the site is visible on the appropriate cable

modem or computer network, and that all parameters being monitored are visible

and accurate.

Any standard Web browser on a personal computer confi gured for network •

connectivity to the transponder should be able to read the XP-EDH-A2

Web interface by simply pointing the Web browser to the IP address of the

transponder (for example, http://10.1.3.65).

Confi rm that all cable harnesses are neatly dressed within the enclosure.•

Verify that you can close the cabinet door, and move the battery tray in and out, •

without contacting or damaging any of the cables.

13745-838-B2-001 Rev. A

Page 14

3.0 Installation Instructions for Specifi c Power Supplies

These are specifi c installation instructions for standby power supplies supported by the XP-EDH-A2

transponder. Each set of instructions include the interface card settings, a system diagram, and the

output voltage calibration needed to successfully operate.

NOTE:

All settings and instructions specifi ed here supercede information found in previous manuals.

NOTE:

When monitoring commercial line power, the XM2 (with the USM2.5 card) does not require an input voltage

transformer because the USM2.5 card provides a scaled voltage representing the line input to the power

supply. In this situation, the transponder makes the measurement via the interface cable connected to the

USM2.5 card.

3.1 Alpha XM2 Series

NOTE:

The EDH-A2 supports AC Scaling for Output Voltage measurements as opposed to DC scaling for the EDH-A.

As a result the USM2/USM2.5 switch settings are different and calibration is no longer necessary. Refer to

the EDH-A Installation Manual for EDH-A installation procedures.

1. Determine the characteristics of the power supply, such as the inverter voltage (36V or

48V), and the maximum capable output current (typically <20A or >20A).

2. If commercial power is present at the site and the power supply is currently being

powered by commercial AC line voltage, turn the battery breaker OFF on the inverter

module.

NOTE:

Turning the battery breaker OFF disables standby power.

3. Slide the inverter drawer out to gain access to the switches or jumpers located on the

various types of USM2 and USM2.5 cards. If you need to install a USMx card, refer to

the manual supplied with the card and complete the installation process.

4. Refer to the following diagram and adjust the switch settings to match your power

supply.

5. Re-insert the inverter module and tighten the retaining screws.

ATTENTION:

Alpha's XM2 power supply installations using USM2 (both new and old versions) and USM2.5 cards require

switch/jumper settings to be made for proper operation.

14

745-838-B2-001 Rev. A

Page 15

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.1 Alpha XM2 Series, continued

3.1.1 USM2.5 Jumper Settings

SW1 Settings:

ON

SW1

ON

<48V and <20A

ON

FRONT PANEL

<48V and

>

20A

ON

48V and <20A

ON

48V and > 20A

POWER SUPPLY

CHASSIS

Legend:

ON

Fig. 3-1, USM2.5 Switch/Jumper Settings

NOTE:

The switch settings in this section apply only to the EDH-A2 and differ from the EDH-A. Refer to the EDH-A

Installation Manual for EDH-A installation procedures.

3.1.2 Output Voltage Calibration

EDH-A2 supports AC Scaling for Output Voltage measurements and does not require

USM2.5 potentiometer calibration.

15745-838-B2-001 Rev. A

Page 16

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.1 Alpha XM2 Series, continued

3.1.3 USM2 Jumper Settings

JP2

(AC SCALING OF OUTPUT VOLTAGE)

JP1 (5V POSITION)

POWER SUPPLY

CHASSIS

FRONT PANEL

SW 1

1

2

3

ON

ON

SW 2

Legend:

ON

Pins jumpered

FRONT PANEL

Fig. 3-2, USM2 Settings for <48V and <20A

JP2

(AC SCALING OF OUTPUT VOLTAGE)

1

2

3

ON

ON

SW 1

SW 2

JP1 (5V POSITION)

POWER SUPPLY

CHASSIS

Legend:

ON

Pins jumpered

16

Fig. 3-3, USM2 Settings for <48V and > 20A

745-838-B2-001 Rev. A

Page 17

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.1 Alpha XM2 Series, continued

3.1.3 USM2 Jumper Settings, continued

JP2

(AC SCALING OF OUTPUT VOLTAGE)

1

2

FRONT PANEL

3

ON

ON

JP1 (5V POSITION)

POWER SUPPLY

CHASSIS

Legend:

ON

FRONT PANEL

SW 1

SW 2

Fig. 3-4, USM2 Settings for 48V and <20A

1

2

3

ON

ON

SW 1

SW 2

Fig. 3-5, USM2 Settings for 48V and > 20A

Pins jumpered

JP2

(AC SCALING OF OUTPUT VOLTAGE)

JP1 (5V POSITION)

POWER SUPPLY

CHASSIS

Legend:

ON

Pins jumpered

NOTE:

The switch settings in this section apply only to the EDH-A2 and differ from the EDH-A. Refer to the EDH-A

Installation Manual for EDH-A installation procedures.

3.1.4 Output Voltage Calibration

EDH-A2 supports AC Scaling for Output Voltage measurements and does not require

USM2.5 potentiometer calibration.

17745-838-B2-001 Rev. A

Page 18

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.1 Alpha XM2 Series, continued

3.1.5 Connecting the XP-EDH-A2 to an XM2 Series Power Supply

Below is a cable installation guide diagram with interface, four batteries and power to

CAUTION!

Improper wiring may damage the unit and void the warranty.

Important!

Plug in the 13 pin connector

SSCOY

TMPR

13 PIN CONN

TEST

ESC

UNLATCH RIBBON CABLE RETAINER

BEFORE FULLY REMOVING MODULE.

ALARM

OUTPUT

module

inverter

m o d u l e

transformer

X M

S E R I E S

an Alpha XM2 power supply with DC powering.

D

RE

BATTERY 4

RED

V

6

toward the bottom of the

header so two pins remain

open at the top of the header

for the Tamper Switch cable.

RED

BLACKBLACK

RED

M

TEMP

PROBE

RED

INPUT

BLACK

BATTERY

BATTERY

BREAKER

BLK

OUTPUT 1

WHT

OUTPUT 2

LRI

N + 1

SSR

N + 1

L

N

OUTPUT

Power Supply Interface Cable

BATTERY 3

V

4

BATTERY STRING 1

BATTERY 2

BLACK

V

BATTERY 1

+V

3

+

PLACE

BETWEEN

BATTERIES

TEMP PROBE

BATT

TEMP

PROBE

2

+

2

1

+

-V

ACK

L

B

BATTERY CABLE

18

ONLINE

0A C4 36

AlphaNet

R

US

DOCSIS Transponder

DS

SYSTEM

RF CABLE IN

PWR

Battery

Power Supply

Power

18 PIN

16 PIN

14 PIN

Installation Note:

The + battery terminals

face the front of the

enclosure

POWER SUPPLY CABLE

USM2 power

supplies only

Fig. 3-6, XM2 Series Installation with Four Batteries

( OPTIONAL )

110V AC Line Input

745-838-B2-001 Rev. A

Page 19

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.1 Alpha XM2 Series, continued

3.1.6 Provisioning the Network for the XM2 Series

The transponder must be recognized by the CMTS as a valid device, be able to

obtain an IP address and communicate with the SNMP management server.

Load the transponder’s MAC address into the CMTS.1.

Compile the two MIBs using a network manager or MIB browser software.2.

Setup SNMP using two proprietary MIBs fi les.3.

Set the MIBS points for the XM2 as follows:4.

For XM2

Oid: 1.3.6.1.4.1.2183.2.3.3.1.2 set to (2) (power supply

selection)

Oid: 1.3.6.1.4.1.2183.2.3.6.5 set to (4) (output voltage

scaling)

Oid: 1.3.6.1.4.1.2183.2.3.6.6 set to (1)for 110V powered

supply or (2) for 220V

Install and confi gure the DOCSIS confi guration fi le. See Section 2.1.9 for a 5.

sample fi le.

Refer to Section 4.0, "Proprietary Management Information Bases (MIBs)" for

detailed information.

19745-838-B2-001 Rev. A

Page 20

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.2 Alpha XM Series Power Supply

NOTE:

You may require a chipset upgrade for the USM and XM inverter drawer for proper operation with the XPEDH-A2. Operating an XM series power supply with the XP-EDH-A2 with the wrong version chipset fi rmware

may result in intermittent or incorrect operation of the power supply. Contact your Alpha representative for

additional information.

NOTE:

The EDH-A2 supports AC Scaling for Output Voltage measurements as opposed to DC scaling for the EDH-A.

As a result the USM switch settings are different and calibration is no longer necessary. Refer to the EDH-A

Installation Manual for EDH-A installation procedures.

If commercial power is present at the site, and the power supply is currently being 1.

powered by commercial AC line voltage, turn the battery breaker OFF on the inverter

module.

NOTE:

When the battery breaker is turned OFF, standby power is disabled.

Slide the inverter drawer out to gain access to the USM card. Remove the USM/APM 2.

assembly from the inverter drawer. To install the USM and APM cards, refer to the

manual supplied with the cards and complete the installation process.

Refer to the following diagram and adjust the jumper settings to match your power supply.3.

Reinstall the USM/APM assembly into the connector on the inverter drawer. Secure with 4.

the screw and bracket.

Re-insert the inverter module.5.

20

745-838-B2-001 Rev. A

Page 21

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.2 Alpha XM Series Power Supply, continued

3.2.1 XM Series Jumper Settings

Remove the USM and set

the jumpers as follow:

Jumper Position

P1 2-3

P2 open

P3 open

P4 closed

P5 closed

P6 closed

P7 5V

P8 1-2

P9 1-2

P13 1-2

P14 1-2

SW4 0

SW2 SW3 SW4

SW1

3

P1

P2

P8

P9

1

1

2

2

3

3

DC

AC

CUR

12

1

2

3

P3

12

P7

AC Volts

P13

12

P4

P5

P6

5V

24V 15V

P14

1

2

3

R8

1

1

1

Set to 0

(SWs 1,2,3 may not be

present on some boards)

Potentiometer Adjuster

RJ Connector

PIN 1

Power Supply Interface

Legend:

Pins jumpered

Fig. 3-7, XM/XP Power Supply Universal Status Monitor

USM

(as viewed from rear of power supply with main control module partially removed)

NOTE:

The switch settings in this section apply only to the EDH-A2 and differ from the EDH-A. Refer to the EDH-A

Installation Manual for EDH-A installation procedures.

3.2.2 Output Voltage Calibration

EDH-A2 supports AC Scaling for Output Voltage measurements and does not require

USM2.5 potentiometer calibration.

21745-838-B2-001 Rev. A

Page 22

3.0 Installation Instructions for Specifi c Power Supplies, continued

RED

B

L

A

C

K

POWER SUPPLY

INTERFACE

P

o

w

e

r Sup

p

ly

P

W

R

Pow

e

r

110V AC Line Input

POWER

SUPPL

Y

CABLE

1

4

PIN

R

F CABLE I

N

SYSTEM

US

DS

Ba

tt

ery

18

P

I

N

16 PIN

C

BL-PS-BAT-04-0

0

4

(

4

FT LO

N

G)

BATT

E

RY

C

A

BL

E

PLACE

TEMP P

RO

B

E

BETWEEN

B

A

TT

ERIES

B

L

A

C

K

BATTERY

1

B

AT

T

TE

MP

PROB

E

-V

BA

TTER

Y

2

+12V

B

LA

C

K

+24V

B

A

TTER

Y

3

+

V

RED

+3

6V

BATTER

Y

S

T

R

I

NG

1

F

u

s

e

WAR

N

I

N

G

:

3

I

ND

I

C

A

TOR

L

AM

P

R

E

M

OT

E

ST

AT

US

R

E

L

A

Y

ST

AND

B

Y

1

2

O

UTP

UT

4

6

5

A

C

BLACK

R

E

D

BATTE

R

Y

C

O

N

N

E

C

T

OR

+

C

I

R

C

UIT

B

R

E

A

K

E

R

-

BATTE

R

Y

OF

F

Al

p

ha

S

E

R

I

E

S

Tec

hn

ol

i

gi

e

s

X M

B

LA

C

K

RED

WIRE

YELLOW

1

8

PIN

Bat

tery

Bl

ack

wire

Red/Green

wire

View

Side

Cut

Here

CUT AND REMOVE A

PIECE OF

RED/GREEN WIRE IF PRESENT

FOR XM SERIES ONLY

!

CUT THE WI R E

I

N UPPER LEFT POSITION

A

S SHOWN. ANY WIRE

COLOR.

DO

CSIS Transponder

A

lphaNet

0A C4 3

6

ON

L

I

NE

3.2 Alpha XM Series Power Supply, continued

3.2.3 Connecting the XP-EDH-A2 to an XM Series Power Supply

Follow the diagram below to make all connections between the transponder and the

power supply site. The diagram is the cable installation guide drawing with interface,

three batteries, and power to an Alpha XM power supply.

CAUTION!

Improper wiring may damage the unit and void the warranty.

Important!

Plug in the 13 pin connector

so the black wire is in pin one

(the top pin) and two open

pins are left at the bottom for

tamper switch connection.

Installation Note:

The + battery terminals

face the front of the

enclosure

Fig. 3-8, XM Series Installation with Three Batteries

22

745-838-B2-001 Rev. A

Page 23

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.2 Alpha XM Series Power Supply, continued

3.2.4 Provisioning the Network for the XM Series

The transponder must be recognized by the CMTS as a valid device, obtain an IP

address, and communicate with the SNMP management server.

Load the transponder’s MAC address into the CMTS.1.

Setup SNMP using two proprietary MIBs fi les.2.

Compile the two MIBs onto a network manager or MIB browser software.3.

Set the MIBS points for the XM as follows:4.

Oid: 1.3.6.1.4.1.2183.2.3.3.1.2 set to (3) (power supply

selection)

Oid: 1.3.6.1.4.1.2183.2.3.6.5 set to (4) (output voltage

scaling)

Oid: 1.3.6.1.4.1.2183.2.3.6.6 set to (1)for 110V powered

supply or (2) for 220V (input voltage measurement)

See Section 4.0, Proprietary Management Information Bases (MIBs) for detailed

information.

Install and confi gure the DOCSIS confi guration fi le. See Section 2.1.9 for a 5.

sample fi le.

23745-838-B2-001 Rev. A

Page 24

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.3 Alpha AM/AP Series Power Supply

WARNING!

Installing the XP-EDH-A2 transponder at an Alpha AM power supply site requires shutting

down the power supply. If a short power interruption is not feasible, you must use an

alternate source of system power during the installation of the transponder. This is

necessary to install the RPM interface card, and to make connections to the output of the

power supply to permit monitoring of the output voltage of the power supply.

If a short power interruption is not feasible, you must use an alternate source of system

power during the installation of the transponder.

If commercial power is present at the site, and the power supply is currently powered 1.

by commercial AC line voltage, turn the battery breaker OFF on the power supply and

disconnect the power supply from utility power.

If not already installed, install the RPM card. Refer to the instructions that come with this 2.

assembly.

NOTE:

The RPM card cannot be installed while the power supply is running on utility or battery power.

3.3.1 Connecting the XP-EDH-A2 to an AM/AP Series

Follow Fig. 3-9 to make connections between the transponder, the power supply site

and battery string.

24

745-838-B2-001 Rev. A

Page 25

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.3 Alpha AM/AP Series Power Supply, continued

3.3.1 Connecting the XP-EDH-A2 to a AM/AP Series, continued

CAUTION!

Improper wiring may damage the unit and void the warranty.

RED

RED

+V

PLACE

BETWEEN

BATTERIES

TEMP PROBE

+36

V

-

ACK

L

B

Important!

Plug in the 13 pin connector

to the right as shown so the

two open pins for the tamper

switch connector are to the

left. If present, cut the Violet

wire.

s

e

i

lig

o

n

h

a

c

h

e

p

l

T

A

RED

BLACK

TO

RED

BLACK

BATTERIES

-

+

BLACK

POWER SUPPLY INTERFACE

S

AP

I E

R

E

M/

S

A

RED

BLACK

CBL-PS-INTRFC-01-002

BATTERY STRING 1

BATTERY 3

BATTERY 2

BATT

TEMP

PROBE

V

4

2

+

V

+12

V

BATTERY 1

RED

BLACK

NO

NC

COM

10

-

+

LAMP

BATT

OUTPUT

3

789

456

2

1

BATTERY CABLE

WARNING:

0A C4 36

AlphaNet

R

US

ONLINE

DOCSIS Transponder

DS

SYSTEM

RF CABLE IN

Battery

Power Supply

Power

PWR

Installation Note:

The + battery terminals

face the front of the

enclosure

POWER SUPPLY INTERFACE

18 PIN

16 PIN

14 PIN

CBL-PS-BAT-04-004

CBL-PS-INTRFC-01-001

POWER SUPPLY CABLE

110V AC Line Input

s

ie

lig

o

hn

a

c

h

e

p

l

T

A

PIN 1

BLACK WIRE

S

E

I

R

E

S

AM/AP

RED

BLACK

RED

BLACK

NO

NC

COM

LAMP

OUTPUT

8

9

10

3

7

4

6

5

BLACK

-

+

BATT

2

1

LARGER PARTIAL VIEW

Fig. 3-9, AM/AP Series Power Supply, Transponder with Three Batteries

25745-838-B2-001 Rev. A

Page 26

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.3 Alpha AM/AP Series Power Supply, continued

3.3.2 Output Voltage Calibration

No calibration is necessary for the Alpha AM/AP power supply.

3.3.3. Provisioning the Transponder on the Network

The transponder must be recognized by the CMTS as a valid device and be able to

obtain an IP address and communicate with the SNMP management server.

Load the transponder’s MAC address into the CMTS.1.

Setup SNMP using the two propriety MIBs fi les.2.

Compile the two MIBs onto a network manager or MIB browser software.3.

Set the MIBS points for the AM/AP as follows:4.

Oid: 1.3.6.1.4.1.2183.2.3.3.1.2 set to (4) (power supply

selection)

Oid: 1.3.6.1.4.1.2183.2.3.6.5 set to (3) (acNormal for

output voltage measurement)

Oid: 1.3.6.1.4.1.2183.2.3.6.6 set to (1)for 110V powered

supply or (2) for 220V (input voltage measurement)

See Section 4.0, Proprietary Management Information Bases (MIBs) for detailed

information.

Install and confi gure the DOCSIS confi guration fi le. See Section 2.1.9 for a 5.

sample fi le.

26

745-838-B2-001 Rev. A

Page 27

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.4 Alpha/Lectro ZTT+ Series Power Supply

There are two models of the Lectro ZTT+ Series power supply inverter modules. You can

easily identify one type from the other by checking the round 6-pin DIN connector located on

the lower left side of the front panel:

Early units have a solid black DIN connector (pre-1998).•

More current units have a silver band around the DIN connector.•

Early (pre-1998) unit with solid black

connector

Fig. 3-10, Lectro ZTT+ Series Power Supplies

Procedures for installing the XP-EDH-A2 with both types of Lectro ZTT+ Series power

supplies follow and are differentiated by a silver or black designation.

Current unit with silver band on connector

CAUTION!

Installing the XP-EDH-A2 transponder at Alpha/Lectro ZTT+, or ZTT sites requires temporarily disconnecting

the output of the power supply to the cable plant to insert one of the transponder harnesses in series with the

power supply output. This is necessary so the transponder can measure both the output voltage and output

current.

If a short power interruption is not feasible, you must use an alternate source of system power during the

installation of the transponder.

3.4.1 Alpha/Lectro ZTT+ Installation (Silver and Black)

If commercial power is present at the site and the power supply is currently 1.

powered by commercial AC line voltage, turn the battery breaker OFF on the

power supply and disconnect the AC utility power.

NOTE:

Turning the battery breaker OFF disables the standby power supply.

Locate the transponder interface cable with the 6-pin type DIN connector. This 2.

harness has a selectable switch near the silver 6-pin shell. Place the switch in

the ZTT+ Silver position or in the Black position depending on what type of power

supply you are using.

Make all other harness connections following the diagram in Fig. 3-11.3.

If a site tamper switch is employed, connect the two lugs within the harness to 4.

the connections on the door switch.

Restore AC utility power and place the DC breaker back to the ON position.5.

27745-838-B2-001 Rev. A

Page 28

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.4 Alpha/Lectro ZTT+ Series Power Supply, continued

NOTE:

3.4.2 Connecting the Alpha/Lectro ZTT+ (Silver and Black)

The Lectro ZTT+ installation diagram is the same for both the black and silver connector with the

exception of the switch setting on the interface harness. For a black connector, set the switch to the ZTT+

black position and for a silver connector, set the switch to the silver position.

+V

D

E

R

PLACE

BETWEEN

BATTERIES

TEMP PROBE

BATT

TEMP

PROBE

+24V

V

2

1

+

Installation Note:

The + battery terminals face the front of the enclosure

BATTERY 1 BATTERY 2 BATTERY 3

6V

+3

V

-

ACK

L

B

RED

BLACK

BATTERY CABLE

TO

LOAD

TO FULLY REMOVE POWER

TURN OFF BOTH SWITCHES

MULTIPLE POWER INPUTS

CAUTION!

Improper wiring may damage the unit

and void the warranty.

RED

BLACK

TO

9VAC

120VAC

18 PIN

Battery

WITH TRANSFORMER

36 VDC

60/90 VAC

ZTT / Plus

_

+

CABLE

AC OUT

BATTERY

DC

ON

OFF

AC

V A

ALERT

FAULT / STANDBY

NORMAL

POWER OUTPUT CABLE

BLACK RING DIN , ZTT+

0A C4 36

AlphaNet

DOCSIS Transponder

R

Power SupplyPower

US

DS

ONLINE

PWR

TT

LVR

Z

BLK

S

+

+

SYSTEM

RF CABLE IN

SILVER RING DIN , ZTT+

TO THE " +BLK " POSITION

MOVE THE SWITCH ON CABLE ASSY

TO THE " +SLVR " POSITION

MOVE THE SWITCH ON CABLE ASSY

GROUND

R

E

P

ND

AM

U

T

RO

G

CBL-PS-INTFC-02-003

POWER SUPPLY

INTERFACE CABLE

TAMPER

28

Fig. 3-11, Alpha/Lectro ZTT+ Series Silver and Black Installation

745-838-B2-001 Rev. A

Page 29

3.0 Installation Instructions for Specifi c Power Supplies, continued

TAMPER

3.4 Alpha/Lectro ZTT+ Series Power Supply, continued

3.4.3 Connecting the Lectro ZTT

Installation of the Lectro ZTT is the same as that for the ZTT+ series except for

moving the switch located in the interface harness to the ZTT position.

V

+

RED

PLACE

BETWEEN

BATTERIES

TEMP PROBE

BATT

TEMP

PROBE

V

24

+

V

2

1

+

Installation Note:

The + battery terminals face the front of the enclosure

TO

LOAD

BATTERY 1 BATTERY 2 BATTERY 3

MULTIPLE POWER INPUTS

TURN OFF BOTH SWITCHES

TO FULLY REMOVE POWER

RED

RED

CABLE

AC OUT

36V

ACK

L

BLACK

BLACK

_

+

BATTERY

D

C

ON

OFF

A

C

+

V

-

B

BATTERY CABLE

TO

9VAC

120VAC

18 PIN

0

0

0

0

0

0

AC AMPERES

0

0

0

0

ZTT

36 VDC

90 VAC

0

0

0

0

0

0

AC VOLTS

0

0

0

0

WITH TRANSFORMER

POWER OUTPUT CABLE

AlphaNet

R

ONLINE

0A C4 36

Battery

DOCSIS Transponder

Power Power Supply

US

DS

PWR

POWER SUPPLY

GROUND

R

E

P

D

AM

N

U

T

O

R

G

CBL-PS-INTFC-02-002

INTERFACE CABLE

TT

LK

Z

B

SLVR

+

+

FLOAT

NORMAL

CHARGE

STANDBY

OVERLOAD

CHECK BAT

LO BAT OFF

LO BAT WARN

36V

ZTT POWER SUPPLY

MOVE THE SWITCH

Fig. 3-12, Lectro ZTT Series Installation

SYSTEM

RF CABLE IN

ON CABLE ASSY

TO THE " ZTT " POSITION

29745-838-B2-001 Rev. A

Page 30

3.0 Installation Instructions for Specifi c Power Supplies, continued

3.4 Alpha/Lectro ZTT+ Series Power Supply, continued

3.4.4 Alpha/Lectro ZTT+ Series Output Voltage Calibration

No calibration is necessary for the ZTT+ Series power supplies.

3.4.5. Provisioning the Network for the Alpha/Lectro ZTT+ Series

The transponder must be recognized by the CMTS as a valid device, obtain an IP

address and communicate with the SNMP management server.

Load the transponder’s MAC address into the CMTS.1.

Setup SNMP using the two propriety MIBs fi les.2.

Compile the two MIBs onto a network manager or MIB browser software.3.

Set the MIBS points for the Lectro ZTT+/ZTT(silver or black DIN) as follows:4.

Oid: 1.3.6.1.4.1.2183.2.3.3.1.2 set to (7) (ZTT+ power

supply selection)

Oid: 1.3.6.1.4.1.2183.2.3.6.5 set to (3) (acNormal for

output voltage measurement)

Oid: 1.3.6.1.4.1.2183.2.3.6.6 set to (1)for 110V powered

supply or (2) for 220V (input voltage measurement)

-or-

Oid: 1.3.6.1.4.1.2183.2.3.3.1.2 set to (6) (ZTT power supply

selection)

Oid: 1.3.6.1.4.1.2183.2.3.6.5 set to (3) (acNormal for

output voltage measurement)

Oid: 1.3.6.1.4.1.2183.2.3.6.6 set to (1)for 110V powered

supply or (2) for 220V (input voltage measurement)

See Section 4.0, Proprietary Management Information Bases (MIBs) for detailed

information.

Install and confi gure the DOCSIS confi guration fi le. See Section 2.1.9 for a 5.

sample fi le.

30

745-838-B2-001 Rev. A

Page 31

4.0 Proprietary Management Information Bases (MIBs)

You need to use two proprietary MIBs to successfully confi gure the XP-EDH-A2 to use the power

supplies described in this manual. Compile these two MIBs onto a network manager or MIB browser

software.

To see a specifi c example of a MIBs fi le for a particular power supply, see that section of the manual.

The objects available are:

Object Description

Oid: 1.3.6.1.4.1.2183.2.3.3.1.2

Set to the type of supply being monitored:

alphaXM2 (2) default

amDocsisDevicesTable

amDocsisOPVoltageScaling

amDocsisInputVoltageMeasScaling

alphaXM (3)

alphaAM/AP (4)

lectroSentryII (5)

lectroZTT (6)

lectroZTTPlus (7)

Oid: 1.3.6.1.4.1.2183.2.3.6.5

Set to 4 with Alpha XM2 type supplies using USM2 or USM2.5 cards.

Set to 4 with Alpha XM type supplies using USM cards.

Set to 3 for legacy power supplies (AM/AP, Lectro ZTT, ZTT+).

Oid: 1.3.6.1.4.1.2183.2.3.6.6

Set to 1 (default) for 110V powered supplies (Alpha or Lectro).

Set to 2 for 220V powered supplies (Alpha or Lectro).

Note: Presently this object is used in conjunction with Alpha’s 110V or

220V wall/brick transformers to sample the input line voltage.

The scaled voltage available in the Alpha USM2.5 cards report the

input line voltage.

Table 4-1, Proprietary MIBs

31745-838-B2-001 Rev. A

Page 32

5.0 Transponder Connector Pinouts

Connector Pinouts

Pins numbered right to left, facing front panel,

A = top row, B= bottom row

Battery Interface A1 Battery 5+

A2 Battery 6+

A3 Battery 7+

A4 Battery 9+

A5 Battery 10+

A6 Battery 11+

A7 N/C

A8 N/C

A9 Chassis Ground

B1 N/C

B2 Battery V+

B3 Battery 3+

B4 Battery 2+

B5 Battery 1+

B6 Battery Reference VB7 Temperature Probe Power

B8 Temperature Probe Signal

B9 Temperature Probe Ground

Power Supply Interface (16 Pin) Connector J1

A1 Charging Current

A2 Major Alarm

A3 Tamper

A4 Minor Alarm

A5 Inverter Status

A6 Output Current1

A7 Total Battery Voltage

A8 Output Current2

B1,B2 GND

B3 AC Input Voltage

B4 Inverter Control

B5 Spare Analog Input

B6 AC Power to the Transponder (Hot)

B7 AC Power to the Transponder (Neutral)

B8 Spare Input1

Power Supply Interface (14 Pin) Connector J2

A1 Output Current1

A2 Output Current2

A3 Output Current3

A4 N/C

A5 N/C

B1-B5 GND

A6 Scaled AC Line Voltage Input

B6 GND

A7 AC to the Transponder (Hot)

B7 AC to the Transponder (Neutral)

32

Table 5-1, Transponder Connector Pinouts

745-838-B2-001 Rev. A

Page 33

6.0 Cable Selection Guide

Interface cables :

XM , XM2 power supplies

CBL-PS-INTFC-01-003

(Alpha P/N 875-565-10)

AM / AP power supplies

CBL-PS-INTFC-01-002

(Alpha P/N 875-564-10)

CBL-PS-INTFC-01-003

CBL-PS-INTRFC-01-002

Lectro ZTT & ZTT+ power supplies

CBL-PS-INTFC-02-005

(Alpha P/N 875-566-10)

CBL-PS-INTFC-02-005

OT

H

NEUT

D

OUN

GR

TAM

P

E

R

BLA

Z

TT+

SIL

Z

C

TT+

K

V

ER

ZTT

3 POSITION

SWITCH

33745-838-B2-001 Rev. A

Page 34

6.0 Cable Selection Guide, continued

Battery Cables:

-V

+

1

2V

3 or 4 batteries

6 batteries

+24V

V

+36

V

+

2 +

2

4

2

+12

+

V

4

+2

1

12

+

1

-V

CBL-PS-BAT-04-004

Alpha P/N 875-552-10

4 FT

CBL-PS-BAT-06-004

Alpha P/N 875-558-10

4 FT

CBL-PS-BAT-04-XXX

CBL-PS-BAT-04-020

Alpha P/N 875-559-10

20 FT

CBL-PS-BAT-06-XXX

CBL-PS-BAT-06-020

Alpha P/N 875-557-10

20 FT

8 batteries

12 batteries

2

+

3

6V

2

+24V

2

+1

2

V

+V

1+

36

V

V

4

+2

1

+12V

1

V

-

CBL-PS-BAT-08-XXX

CBL-PS-BAT-08-004 CBL-PS-BAT-08-020

Alpha P/N 875-556-10 Alpha P/N 875-555-10

3

+

3

6

V

3

+

2

4

V

3

+12V

2

+3

6V

2

+

2

4V

2

+

1

2

V

+

V

1

+

3

6

V

24V

1+

V

12

+

1

V

-

CBL-PS-BAT-12-004

Alpha P/N 875-554-10

4 FT 20 FT

CBL-PS-BAT-12-XXX

CBL-PS-BAT-12-020

Alpha P/N 875-553-10

20 FT4 FT

34

745-838-B2-001 Rev. A

Page 35

6.0 Cable Selection Guide, continued

Line Voltage Cables:

XM , XM2 , AM/AP, 120Vac

CBL-PS-PWR-01-001

Alpha P/N 875-563-10

XM , XM2 , AM/AP, 220Vac

CBL-PS-PWR-03-002

Alpha P/N 875-562-10

Lectro ZTT, ZTT+, 120Vac

CBL-PS-PWR-02-002

Alpha P/N 875-718-10

220V US

NEMA 6-15P

120VAC

TO

9VAC

220VAC

TO

9VAC

IEC C13

3 FT CORD

120VAC

TO

9VAC

Lectro ZTT, ZTT+, 220Vac

CBL-PS-PWR-04-001

Alpha P/N 875-717-10

220V US

NEMA 6-15P

220VAC

TO

9VAC

3 FT CORD

IEC C13

35745-838-B2-001 Rev. A

Page 36

7.0 Dimensions and Specifi cations

7.1 Dimensions of XP-EDH-A2

Alpha P/N: 745-838-10-004 Model No: XP-EDH-A22

MAC ID: XXXXXXXXXXXX S/N: XXXXXXXX

Attention

This transponder measures scaled AC •

output voltage.

Verify the XM-USM or XM2-USM2/USM2.5 •

is confi gured for scaled AC output.

9.42"

(overall)

1.26"

4.55"

8.75"

36

PWR

ONLINE

US

DS

Power

R

AlphaNet

DOCSIS Transponder

Power Supply

0A C4 36

1.26"

Batteries

Fig. 7-1, Outline Dimensions, XP-EDH-A2

745-838-B2-001 Rev. A

Page 37

7.0 Dimensions and Specifi cations, continued

7.2 Battery Cable Wiring Diagram

CAUTION!

The following diagram shows wiring to three batteries using a six battery cable.

Installation Note:

The + battery terminals face the front of the enclosure

BATTERY

STRING 1

BATTERY 1

BATTERY 2

BATTERY 3

RED

RED

BLACK

BLAC

1+12V

K

2+24V

2+12V

-V

1+24V

BATT

TEMP

PROBE

PLACE

TEMP PROBE

BETWEEN

BATTERIES

+V

BATTERY CABLE

CBL-PS-BAT-06-004

Fig. 7-2, Battery Cable Wiring Diagram

37745-838-B2-001 Rev. A

Page 38

8.0 Specifi cations

odel:

y

s

2

de

S

,

.

General Speci cations

General

Model: XP-EDH-A2

Power Supplies Supported: XM2 (requires USM2 or USM2.5)

DOCSIS Compatibility

Monitoring Protocol: SNMPv1

:

RF Transmit/Receive

Tx Frequency Range: 5 to 42MHz

Output Power: 8 to 55dBmV

Channel Bandwidth: 6MHz

Receive Center Freq Range: 91 to 857MHz

Input Level: -15 to +15dBmV

Monitored Parameters

Power Supply Data

M

Major Alarm: X X X X

Minor Alarm: X X X X

Input Line Voltage: X X

Output Voltage: X X X X

Battery Voltage: X X X X

Output Current: X X X X

Standby/AC Line Fail: X X X X

Equipment/Test Fail: X X X

Enclosure Door Status: X X X X

Remote Test Control: X X X X

Notes:

1 Requires optional cable assembly

Number of Batter

Battery Data: Individual Battery Voltages

String

XM (requires USM)

AM (requires APM card)

Lectro ZTT, ZTT+

DOCSIS 2

0

NMPv

XM2

:

XM

1

X

One to three of 36V or 48V

Battery Compartment Temperature

2

c

(Standard, HRC, IRC channels)

AM

ZTT Series

1

Hardware

RF Cable Interface: F-connector, female, 75Ohm

Local Port Interface USB Type B

LED Indicators: CMTS Registration

Environmental: -40 to 65˚C

Emissions: EN50022 Class A and FCC Part 15 Class A

Immunity: Surge Test per Speci

Warranty: 2 years

Dimensi ons (in): 5.2D x 8.6W x 1.3H

Upstream Activity

Downstream Activity

Unit Power

10 to 90% non-condensing humidity

(Installed in power supply enclosure system)

ESD Protection:±8kV air discharge,±6kV contact

discharge as per (IEC 61000-4-2)

ion (IEEE C62.41-1991)

Management

NMS/EMS: • Standard SNMP Management Tools

1

X

1

1

HMS MIBs:

In addition to the standard DOCSIS MIBs, the transponder

supports the following HMS MIBs:

SCTE 25-3 (HMS-022): Interface

SCTE 36 (HMS-050): Root

MIB SCTE 37 (HMS-072): Tree

MIB SCTE 38-1 (HMS-026): Property

MIB SCTE 38-2 (HMS-023): Alarm MIB

SCTE 38-3 (HMS-024): Common

MIB SCTE 38-4 (HMS-027): Power Supply

MIB SCTE 38-6 (HMS-033): Generator

MIB SCTE 38-7 (HMS-050): TIB MIB

Ordering Information

Model Number Description

XP-EDH-A A

CBL-PS-INT-01-003 Interface cable, XM, XM2 power supplies

CBL-PS-INT-01-002 Interface cable, AM/AP power supply

CBL-PS-INT-02-005 Interface cable, Lectro ZTT, ZTT+ power supplies

CBL-PS-PWR-01-001 Line voltage cable, XM, XM2, AM/AP, 120V

CBL-PS-PWR-03-002 Line voltage cable: XM, XM2, AM/AP, 220V

CBL-PS-PWR-02-002 Line voltage cable, Lectro 120VAC

CBL-PS-PWR-04-001 Line voltage cable, Lectro 220VAC

CBL-PS-BAT-04-004 Wire Kit, Battery Sense, 1x36V or 1x48V, 4’

CBL-PS-BAT-06-004 Wire Kit, Battery Sense, 2x36V, 4’

CBL-PS-BAT-08-004 Wire Kit, Battery Sense, 2x48V, 4’

CBL-PS-BAT-12-004 Wire Kit, Battery Sense, 3x48V, 4’

* Other Battery Sense Wire Kits available

External DOCSIS Transpon

lphaNet

; contact Alpha for more information

r

38

745-838-B2-001 Rev. A

Page 39

Page 40

Alpha Technologies

®

Power

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Web: www.alpha.com

Alpha Technologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: +1 604 430 1476

Fax: +1 604 430 8908

Alpha Technologies

Europe Ltd.

Twyford House

Thorley

Bishop's Stortford

Hertfordshire

CM22 7PA

UNITED KINGDOM

Tel: +44 0 1279 501110

Fax: +44 0 1279 659870

Alpha Technologies GmbH

Hansastrasse 8

D-91126 Schwabach

GERMANY

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec, Ltd

P.O. Box 56468

Limassol, Cyprus

CYPRUS

Tel: +357 25 375675

Fax: +357 25 359595

AlphaTEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1

109028 Moscow

RUSSIA

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltics

S. Konarskio G. 49

Vilnius 2009

LITHUANIA

Tel: +350 5 210 5291

Fax: +350 5 210 5292

Alpha Technologies

34, Grande Rue

Bétheny, F-51450

France

Phone: +33 32 64990 54

Fax: +33 67 54289 44

Copyright © 2009 Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 745-838-B2-001, Rev.A.

Due to continuing product improvements, Alpha reserves the right to change specifi cations without notice.

Loading...

Loading...