Page 1

n Operator’s Manual

n Redundant Control Unit

FOR CFR UNINTERRUPTIBLE POWER SUPPLIES

FROM ALPHA TECHNOLOGIES

Page 2

TABLE OF CONTENTS

1. Introduction.......................................................................................................1

1.1 The Alpha Redundant Control Unit (RCU)................................................................... 1

1.2 A Tour of the RCU ........................................................................................................ 2

1.2.1 Front P anel......................................................................................................... 2

1.2.2 RCU Interior....................................................................................................... 4

1.2.3 Rear Panel......................................................................................................... 6

2. Installation.........................................................................................................7

2.1 Unpacking and Inspection Checklist............................................................................ 7

2.2 Rack Mount Installation................................................................................................ 8

2.3 Wall Mount Installation.................................................................................................9

3. Operation....................................................................................................10

3.1 RCU Start–Up and Test Procedure............................................................................ 10

3.2 RCU Voltage Configuration ....................................................................................... 13

4. Maintenance ...............................................................................................15

4.1 Internal Fuse Replacement ....................................................................................... 15

4.2 Troubleshooting.........................................................................................................16

4.3 RCU Wiring Diagrams ............................................................................................... 17

4.4 Return Instructions..................................................................................................... 18

4.5 Specifications ............................................................................................................ 19

4.6 Warranty ....................................................................................................................20

Page 3

1 Introduction

g

y

y

1.1 The Alpha Redundant Control Unit (RCU)

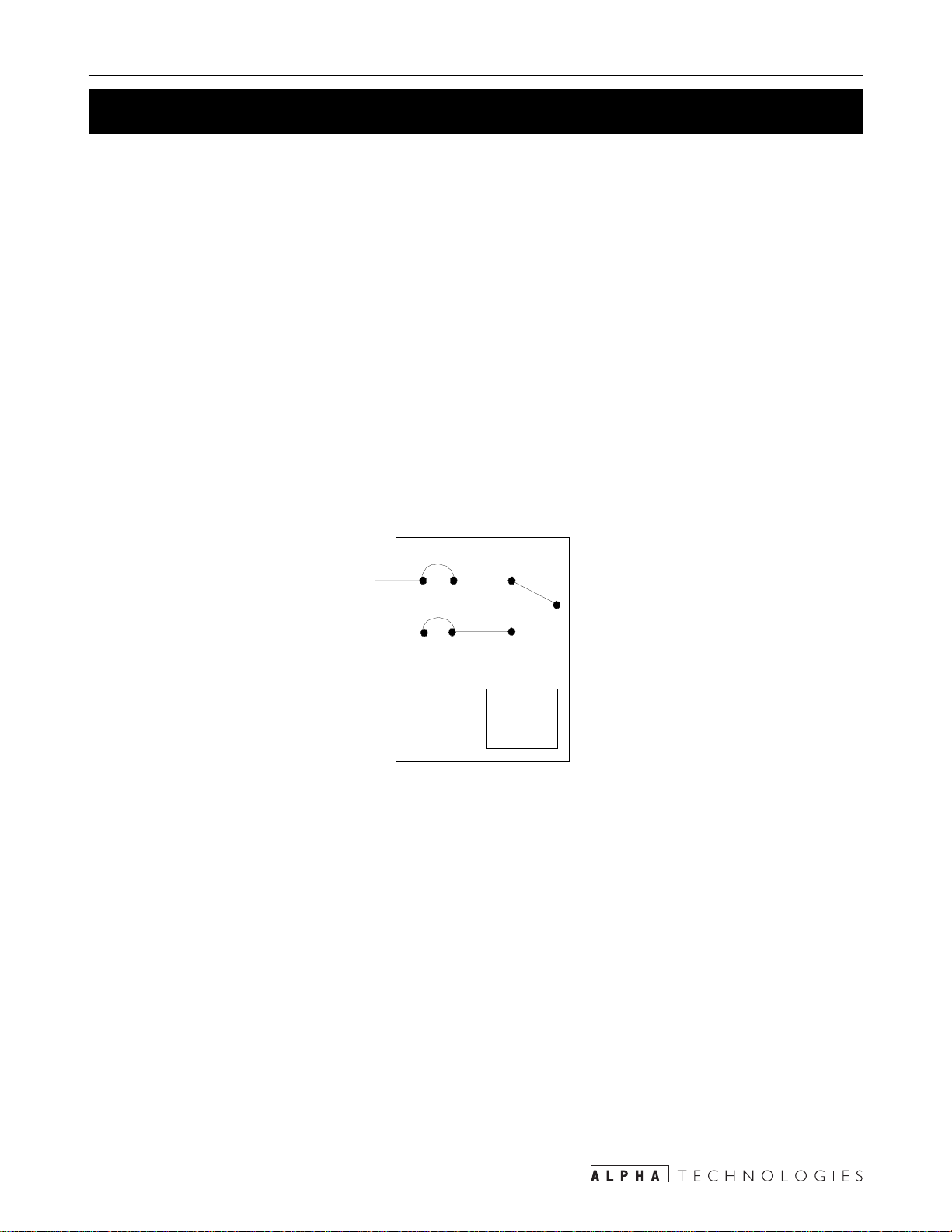

Purpose: Describes the operation of Alpha’s Redundant Control Unit (Figure

1.1)

Alpha’s Redundant Control Unit (RCU) provides a dual–redundant configuration, ensur ing

power is always supplied to the critical load. Both input voltages are monitored, so if power is

lost at input 1, the RCU transfers to input 2. Input 1 is the primary source of power so the RCU

automatically returns to it when power is restored. Before transferring, it waits about 1 minute

to allow input voltage and frequency to stabilize.

The RCU has two contactors, one for each po wer source . They both cannot be on at the same

time. If there is a f ailure in either contactor or the control logic , the Type C alarm contact on the

rear panel is activated and the “Red Alert” LED turns on. Alarm conditions are: logic f ailure;

Contactor 1 or 2 fails to open; Contactor 1 or 2 f ails to close or open internal fuses. The front

panel LEDs shows the RCU’s status.

Inputs

Secondar

Primar

Contactor 1

Contactor 2

Figure 1.1

RCU Operating Diagram

Lo

Output

ic

1

Page 4

1 Introduction

1.2 A Tour of the RCU

Purpose: Describes the RCU’s controls, displays and terminal blocks

(Figures 1.2, 1.3, 1.4, 1.5).

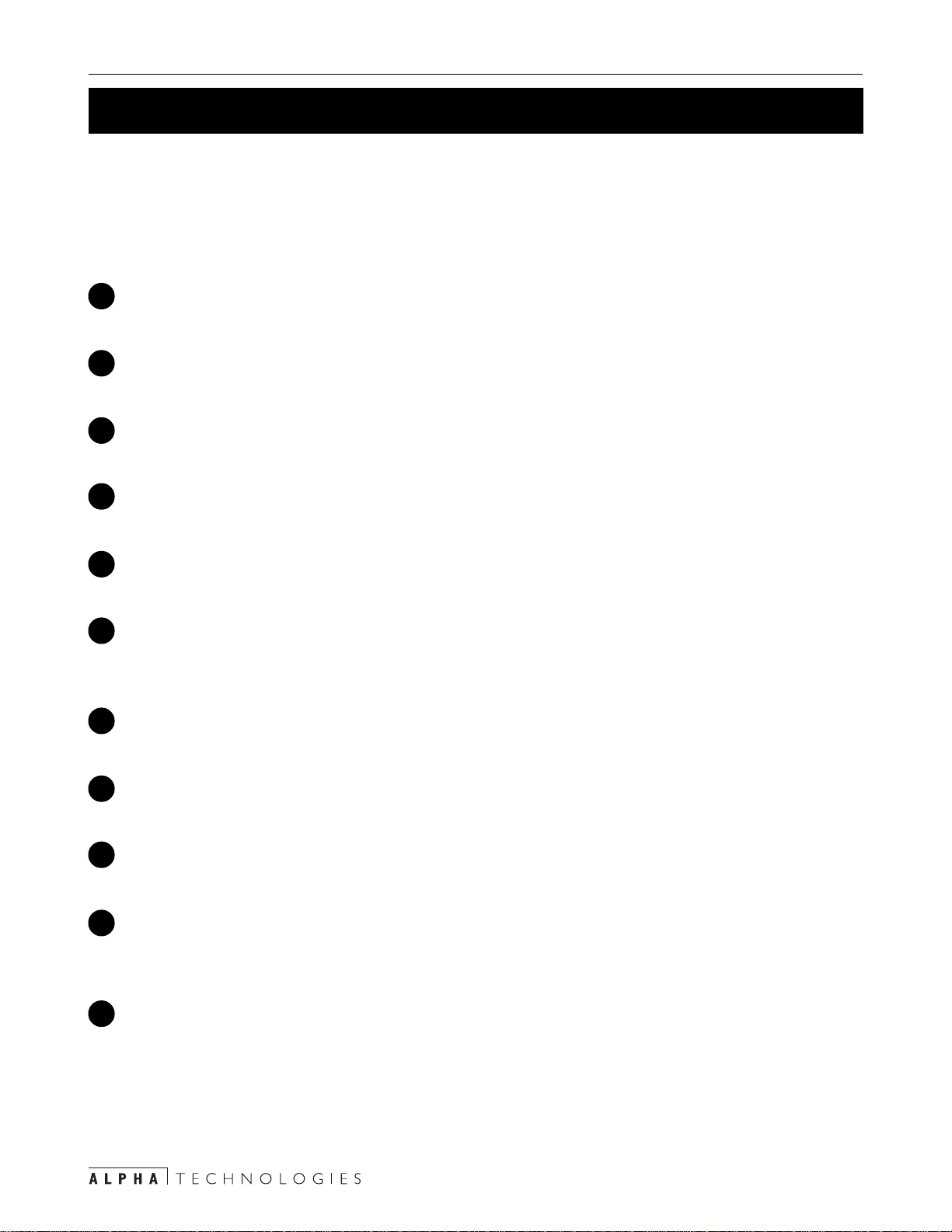

1.2.1 Front Panel (Figure 1.2)

1

Input 1 LED:

Shows the presence of AC power at Input 1.

2

Input 2 LED:

Shows the presence of AC power at Input 2.

3

Contactor 1 LED:

Shows Contactor 1 is closed, providing primary power to the output.

4

Contactor 2 LED:

Shows Contactor 2 is closed, providing secondary power to the output.

5

Output LED:

Shows there is power at the output.

6

Manual T ransfer LED:

Shows both primary and secondary power sources are in phase and that a manual transfer

can be done with the make–before–break manual bypass switch.

7

Red Alert LED:

Shows that one of the contactors or the control logic has failed.

8

Input 1 Circuit Breaker:

Provides circuit breaker protection to the primary input and acts as an ON/OFF switch.

9

Input 2 Circuit Breaker:

Provides circuit breaker protection to the secondary input and acts as an ON/OFF switch.

10

Select 1 Switch:

Opens the secondary contactor before closing the primary to provide Input 1 power to the

output.

11

Select 2 Switch:

Opens the primary contactor before closing the secondary to provide Input 2 power to the

output.

2

Page 5

1 Introduction

1.2 A Tour of the RCU

1.2 A Tour of the RCU (Continued)

1.2.1 Front Panel (Continued)

12

Alarm Reset Switch:

Shuts off the audible Red Alert alarm.

13

Attachment Screws:

These two screws secure the front panel to the RCU .

Front Panel:

14

This hinged panel opens downward to access the interior for voltage configuration, fuse

changing or troubleshooting.

13

1 10 5

2

11

3

4

6

127

Figure 1.2

RCU Front Panel

14

13

9

8

3

Page 6

1 Introduction

1.2 A Tour of the RCU

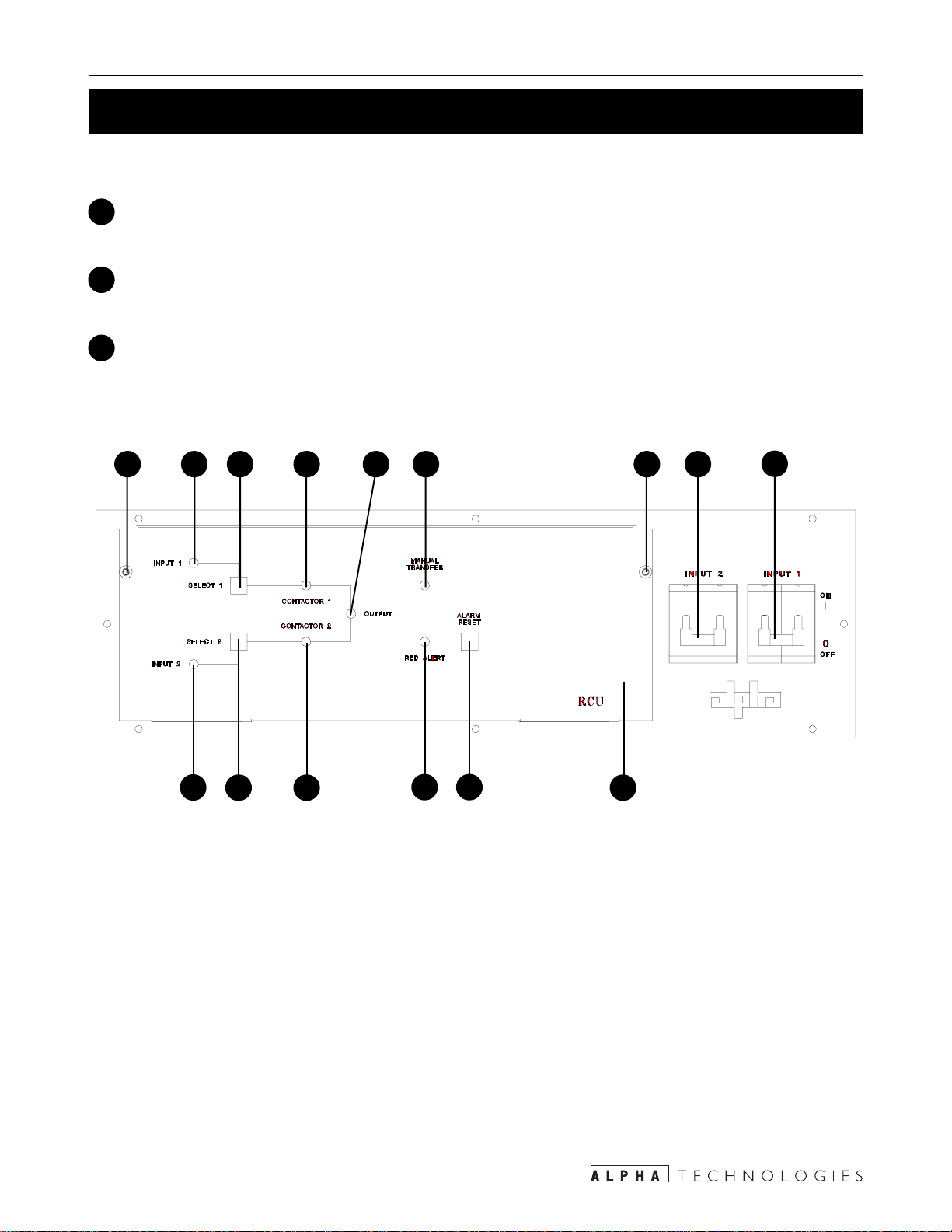

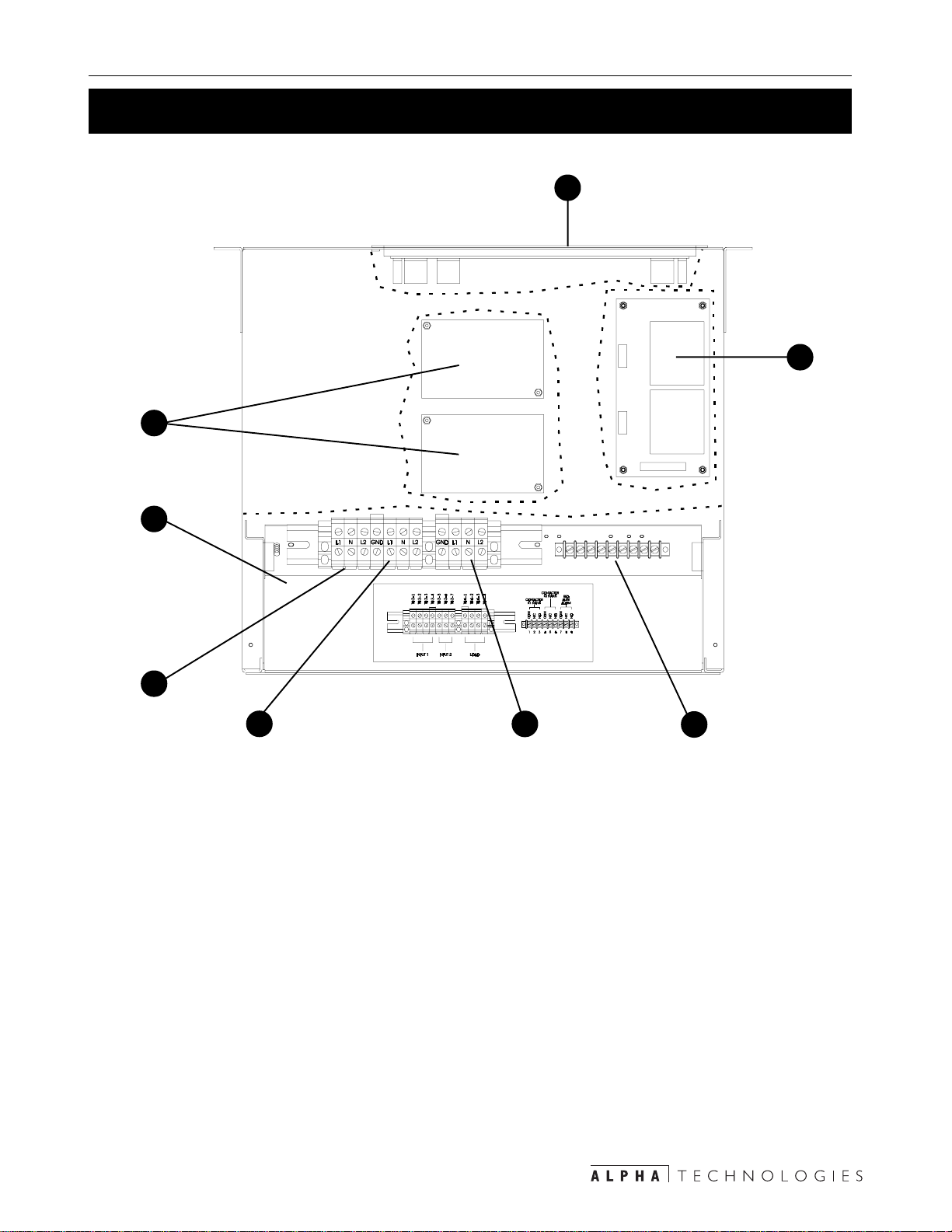

1.2.2 RCU Interior (Figure 1.3)

Front Panel:

1

This hinged panel opens downward to allow the operator access to the RCU interior to

configure the input/output voltage, replace fuses or f or troub leshooting. Two , 3.15 Amp

fuses are located here.

2

Contactors:

The primary and secondary contactors.

3

Sliding Panel:

This panel slides back and forth for access to the RCU’s input, output and alarm terminal

blocks.

4

Input 1 Terminal Block:

This terminal block is the primary power input.

5

Input 2 Terminal Block:

This terminal block is the secondary power input.

6

Output T erminal Bloc k:

This terminal block is the RCU’ s output.

Alarm Terminal Block:

7

This terminal block is the RCU’s alarm connection.

8

Power Board:

The RCU is configured here for 120, 208 or 240 VA C operation. Two, 500 mA fuses are

located on this board.

4

Page 7

1.2 A Tour of the RCU

1 Introduction

1.2.2 RCU Interior (Continued)

2

3

1

8

4

5

Figure 1.3

RCU Interior (Cutaway View)

6

7

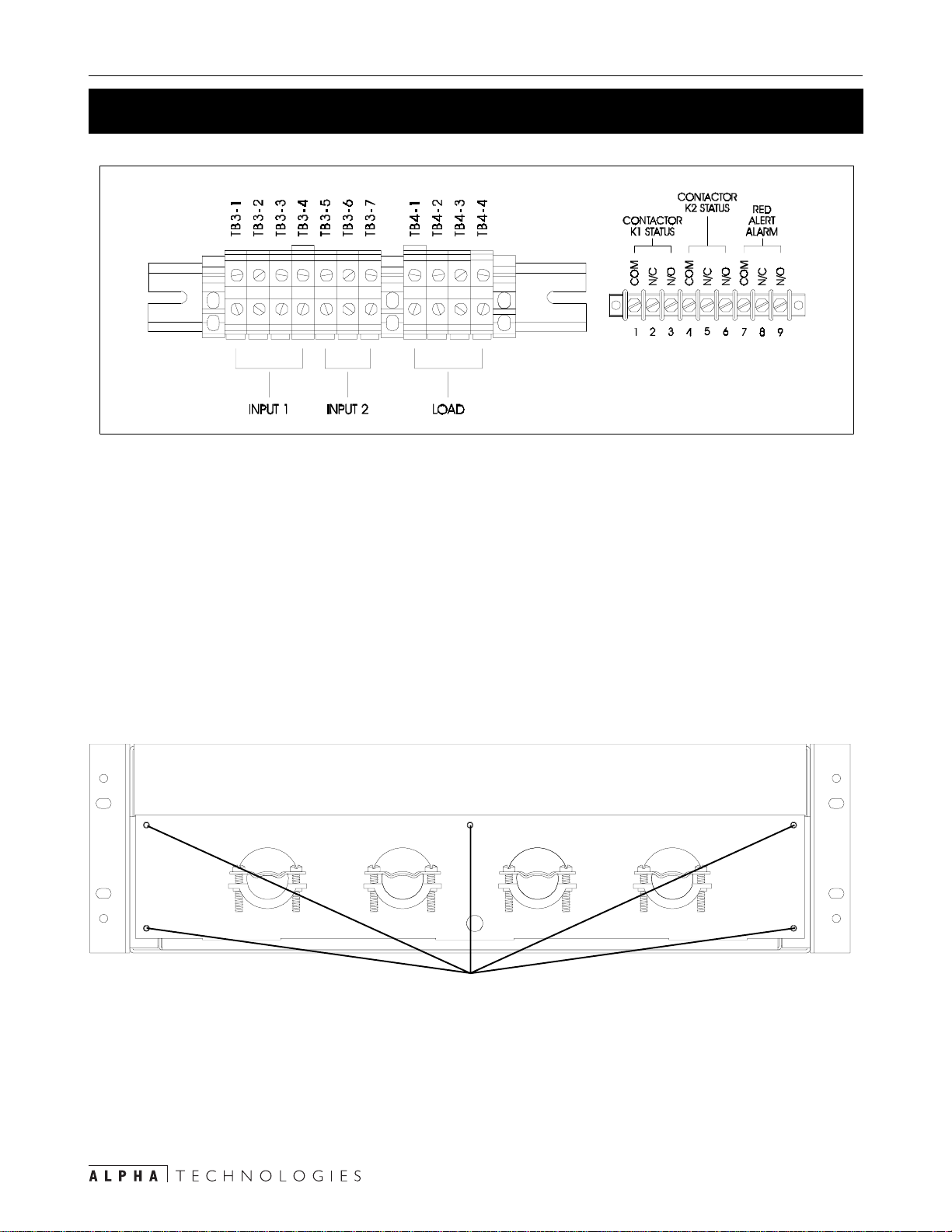

Wiring:

The wiring diagram for the terminal blocks is shown in Figure 1.4. Both Inputs share a common ground.

The alarm terminal block has Type C contacts to provide Contactor and Alarm status to the

monitoring system.

• Contactor K1 is normally closed.

• Contactor K2 is normally open.

• Red Alert Alarm is open when the system is operating normally.

5

Page 8

1 Introduction

1.2 A Tour of the RCU

L1

L2 L2

L1

NN

L2

GNDGND

L1N

Legend:

COM: Common, N/C: Normally Closed, N/O: Normally Open

Figure 1.4

RCU Wiring Diagram

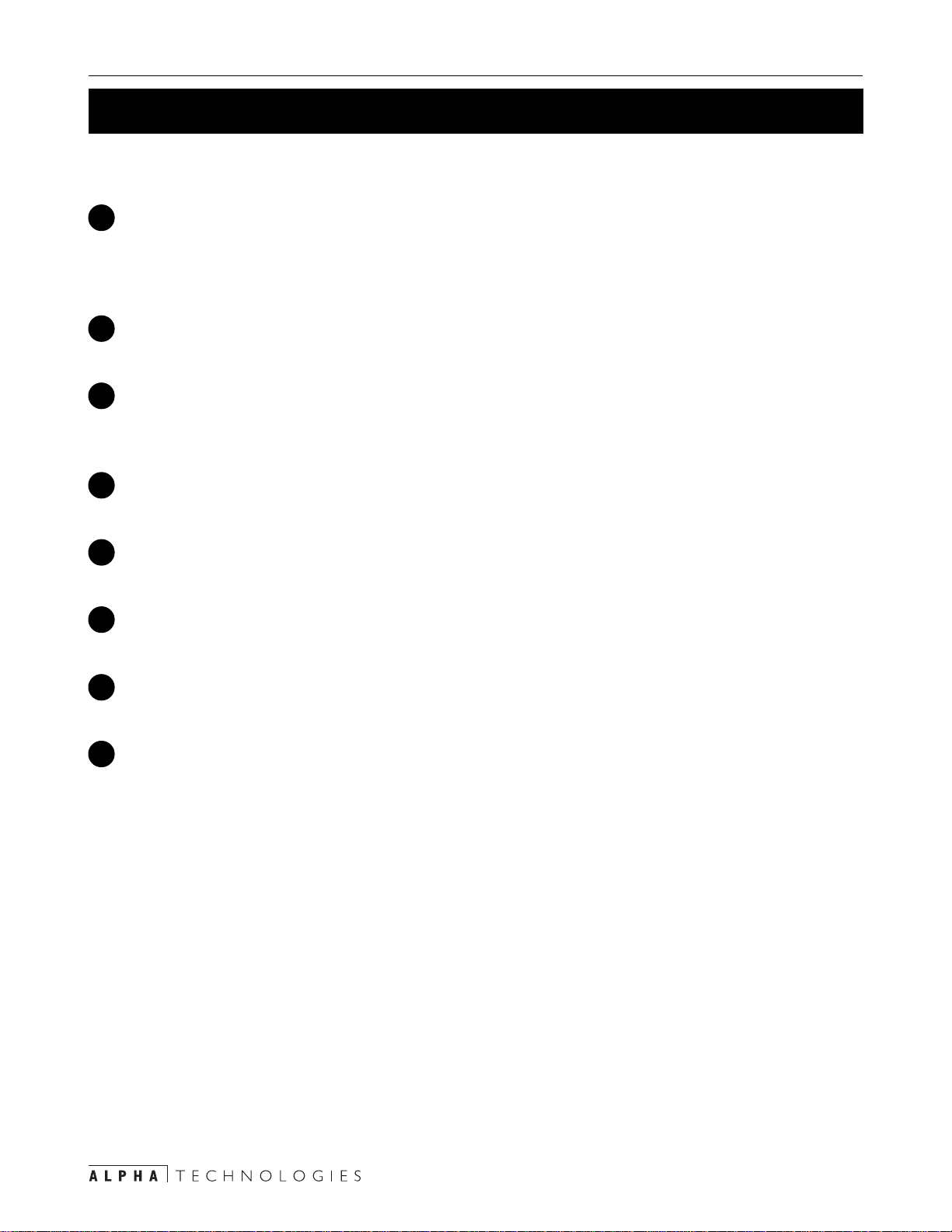

1.2.3 Rear Panel (Figure 1.5)

To access the terminal blocks, unscrew the five attachment screws then remove the panel.

SOURCE 1 SOURCE 2 OUTPUT ALARMS

Attachment Screws

Figure 1.5

RCU Rear Panel

6

Page 9

2 Installation

2.1 Unpacking and Inspection Checklist

Carefully inspect the contents. If items appear damaged or missing, contact Alpha Technologies and the shipping company immediately. Most shipping companies have only a short

claim period. Make sure the following have been included:

Redundancy Control Unit and mounting kit.

Operator’ s Manual

Any other ordered options

SAVE THE ORIGINAL SHIPPING CONTAINER

If the RCU is returned for servicing, pack it in its original shipping

container. Alpha Technologies is not responsible for damage

caused by improper packaging of returned units.

READ THE OPERATOR’S MANUAL

Become familiar with the RCU by reviewing the procedures and

drawings in this manual before installation. If you have questions

contact Alpha Technologies.

COMPLETE THE FOLLOWING FOR Y OUR RECORDS:

Model

Serial Number

Options

Purchase Date

This Unit was purchased from:

Dealer Name

City

State/Province

ZIP/Postal Code

Country

Telephone/ Fax Number

E–Mail

7

Page 10

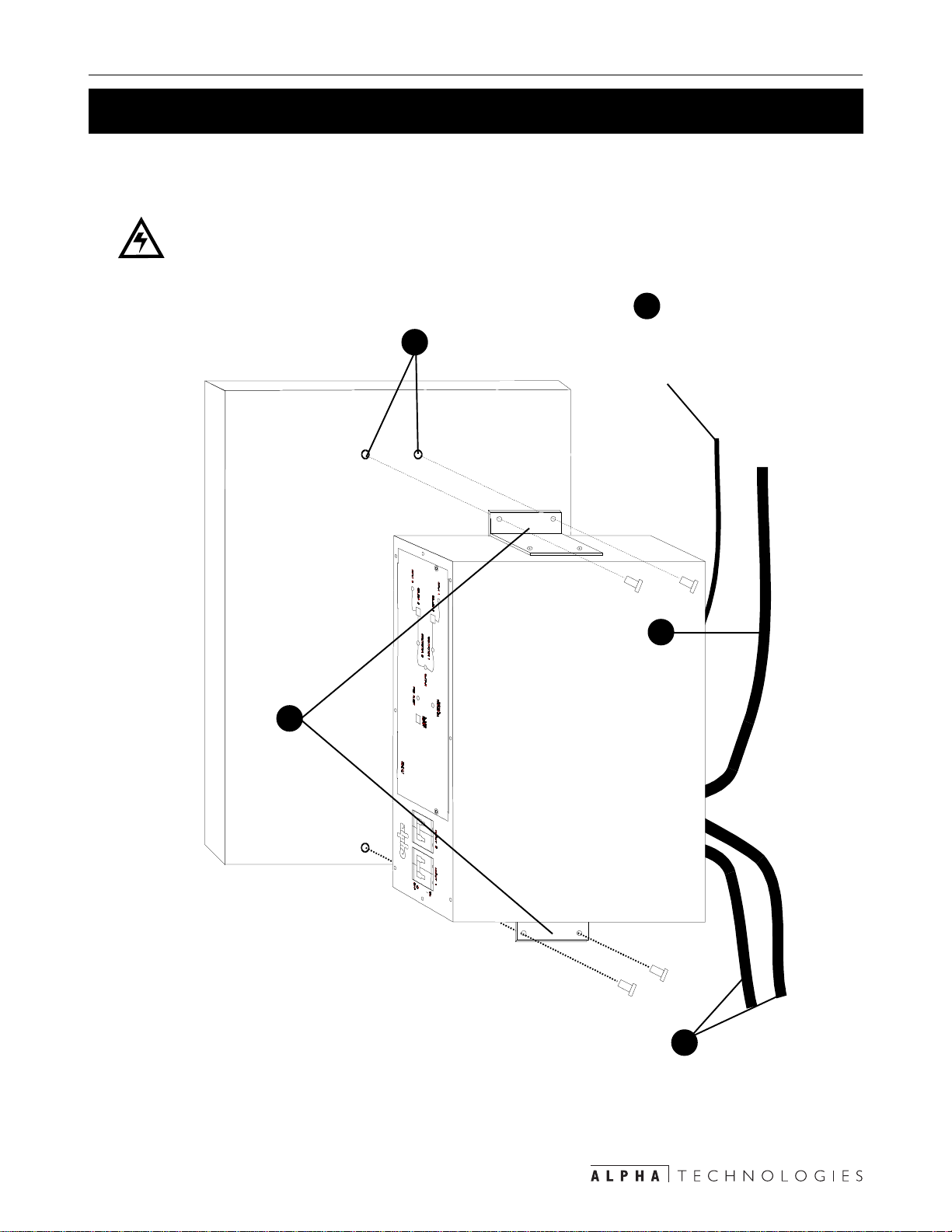

2 Installation

2.2 Rack Mount Installation

NOTES: 1) The RCU can be mounted in either a 19 or 23 inch ra c k b y adjusting the configur a-

tion of the rack mount brackets.

2) Use #4 AWG f or connecting the input and output terminal bloc ks and #18–22 AWG

solid wire for connecting the communication terminal block.

3) DANGER: Before installation, make sure the Input 1 and 2 circuit breakers are

OFF.

4

Wire the load(s)

to the output

terminal block with

#4 AWG

3

Wire the communication

lines to the communication

terminal block with #18–22

gauge solid wire

Mid Mount

Attachment Points

1

5

Wire the inputs

to the input

terminal block with

#4 AWG

Attach the RCU

2

to the rack

Attach the rack mount brackets

to the RCU in either the front

or mid mount position

Figure 2.1

RCU Rack Mounting

8

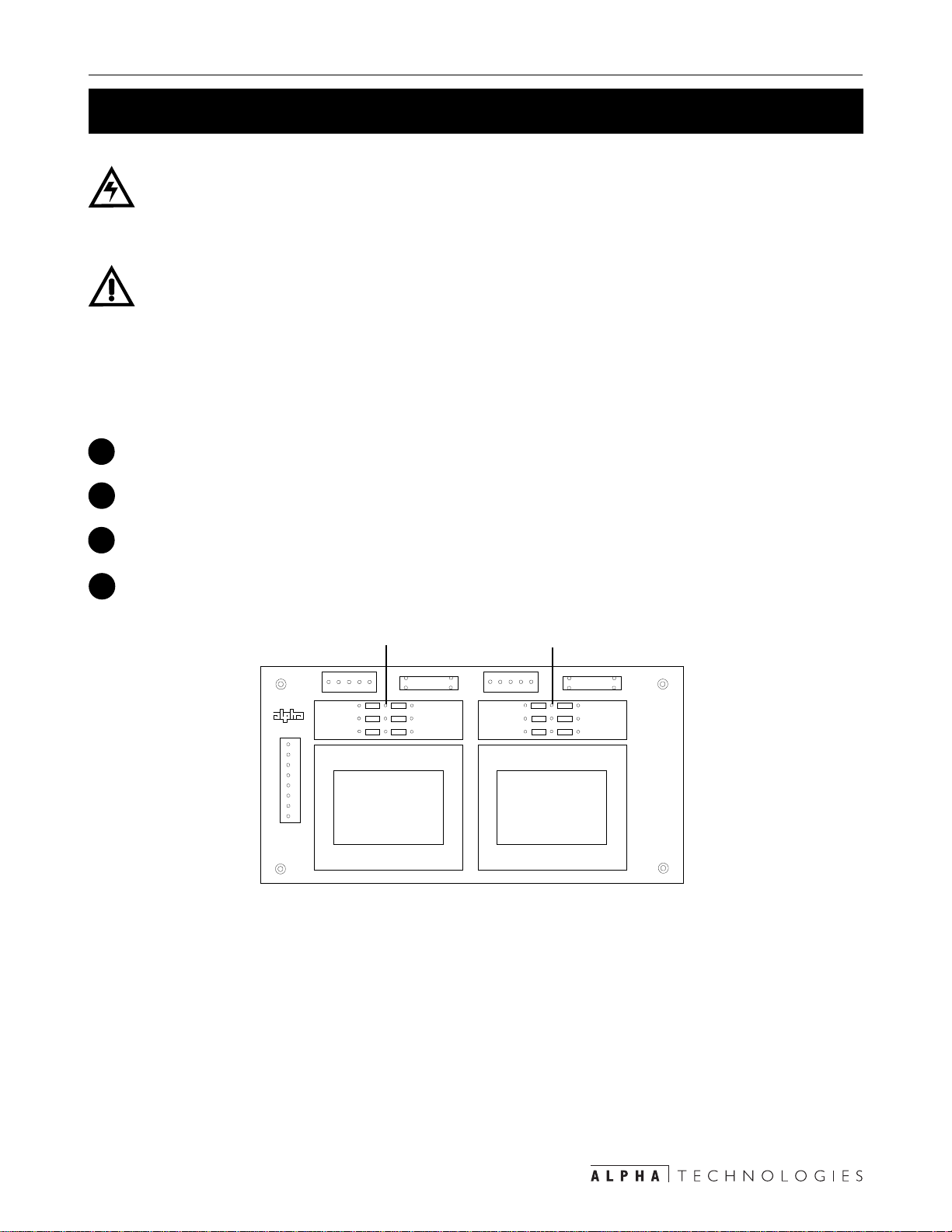

Page 11

2 Installation

2.3 Wall Mount Installation

NOTES: 1) Use #4 AWG for connecting the input and output terminal bloc ks and #18–22 AWG

solid wire for connecting the communication terminal block.

2) DANGER: Bef ore installation, mak e sure the Input 1 and 2 circuit break ers are

OFF.

3

Wire the communication

Attach the RCU to the wall

2

lines to the communication terminal block with

#18–22 AWG solid wire

Attach the rack mount

brackets to the RCU

Wire the load(s)

to the output

terminal block with

#4 AWG

1

Figure 2.2

RCU Wall Mounting

4

5

Wire the inputs

to the input

terminal block with

#4 AWG

9

Page 12

3 Operation

3.1 RCU Start–Up and Test Procedure

WARNING: Before starting, turn OFF the Input 1 and 2 Circuit Breakers and the Load(s).

NOTE: If there is an y type of logic or contact f ailure during the system start-up, test or opera-

tion, the Red Alert LED turns ON.

STEP 1: RCU Power Up

Press the Select 1

contactor switch.

2

Figure 3.1

RCU Power Up

Switch ON both

1

circuit breakers.

STEP 2: Test Primary Power

1

Switch the Input 1 circuit breaker OFF.

The Input 1 LED on the front panel will go out, showing the loss of primary power. As the

RCU transfers to the secondary power source the Contactor 2 LED turns ON.

NOTE: There will be a five second delay between the transf er from Input 1 to Input 2. This

conforms to the automatic transfer switch safety code.

Input 1 LED

Contactor 2 LED

Figure 3.2

Testing Primary Power

10

T urn OFF

Input 1 circuit breaker

Page 13

3 Operation

3.1 RCU Start–Up and Test Procedure

STEP 3: Restore Primary Power

Switch the Input 1 circuit breaker ON.

1

The Input 1 LED lights, showing the return of primary power. The RCU transf ers back to

Input 1 after about 30 seconds, after the voltage and frequency stabilizes . When done, the

Contactor 1 LED turns ON.

Turn ON

Input 1 LED

Contactor 1 LED

Input 1 circuit breaker

Figure 3.3

Return Primary Po wer

STEP 4: Test Secondary Power

1

Switch the Input 2 circuit breaker OFF.

The Input 2 LED on the front panel turns OFF, indicating the loss of secondary power.

There should be no transfer or an y other change in the status of the RCU.

Switch the Input 2 circuit breaker ON to return to normal status.

2

T urn OFF

Input 2 LED

Input 2 circuit breaker

Figure 3.4

Test Secondary Power

11

Page 14

3 Operation

3.1 RCU Start–Up and Test Procedure

STEP 5: Test Secondary Contactor

1

If the RCU’s Contactor 1 LED is ON:

Press the Select 2 switch. As the RCU transfers to the Secondary power source the

Contactor 2 LED turns ON.

Press the Select 1 switch to return to primary power.

2

Select 2 Switch

Contactor 2 LED Red Alert LED

Contactor 1 LED

Figure 3.5

Test Secondary Contactor

STEP 6: Turn On The Loads

If the Manual Tr ansf er LED is ON, turn on the load(s).

12

Page 15

3.2 RCU Voltage Configuration

DANGER: This procedure should be done only by qualified personnel.

DANGER: V erify the power is OFF before opening the front panel.

NOTE: The Input 1 and 2 voltages must be configured identically.

The RCU is designed so it is voltage configurable for 120/208/240 VAC.

PROCEDURE:

Switch the Input 1 and 2 circuit breakers OFF.

1

2

Remove the two Phillips screws on the sides of the front panel.

3 Operation

3

Carefully lower the panel 45 degrees.

Locate the Input 1 and 2 pin jumpers on the power board.

4

Input 1 Pin Jumpers Input 2 Pin Jumpers

J 1

1122334455

R 3 R 4

R 2

120 V

R 1

J 3

12345678

F 1

R 5

R 6

208 V

or

240 V

J 2

R 9

120 V

R 8

R 7

Figure 3.6

Input 1 and 2 Pin Jumpers on the Power Board

R 10

R 11

R 12

F 2

208 V

or

240 V

13

Page 16

3 Operation

3.2 RCU Configuration Procedure

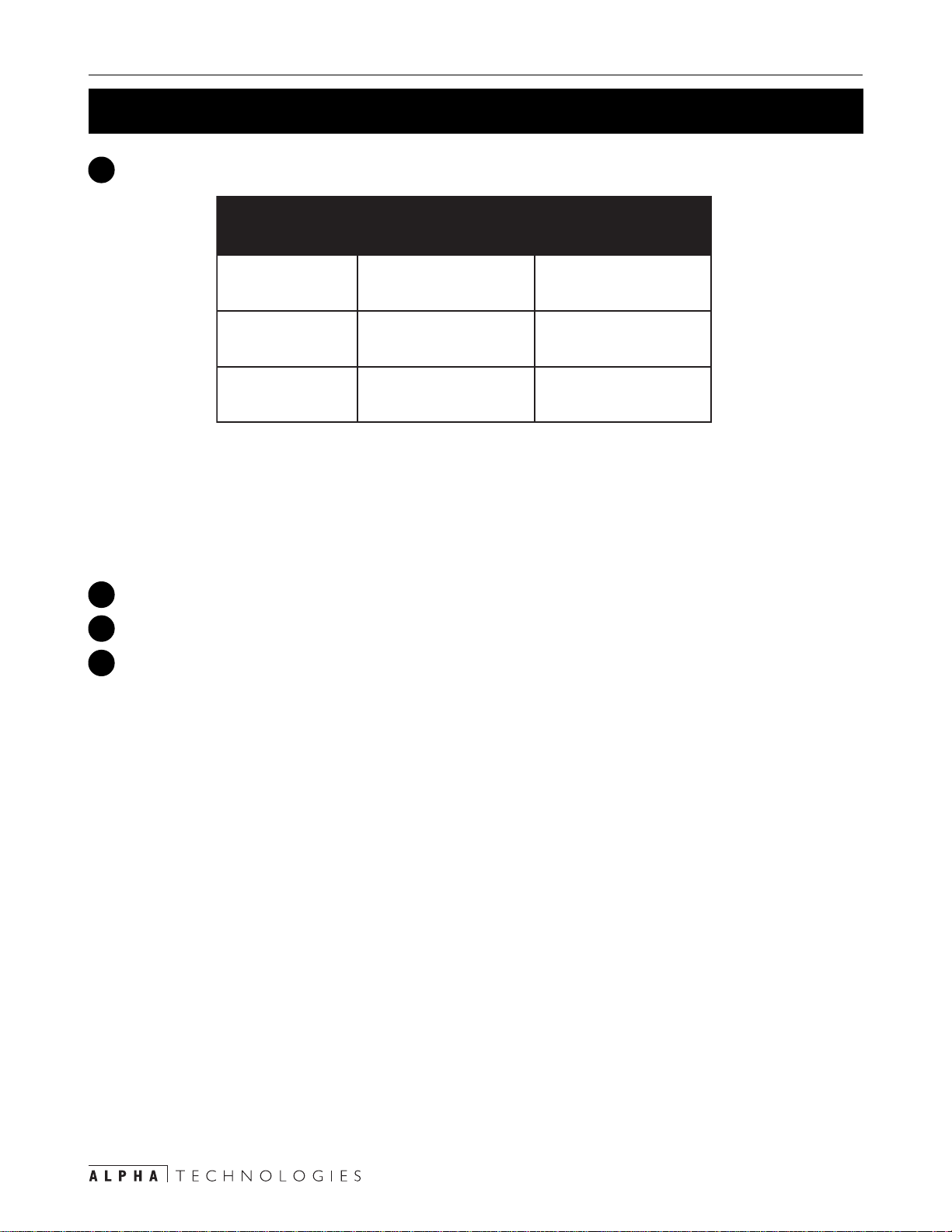

Position jumpers or 0 Ohm resistors according to the following chart.5

deriuqeRderiuqeR

deriuqeRderiuqeR

deriuqeR

segatloV

tnemecalPrepmuJtnemecalPrepmuJ

tnemecalPrepmuJtnemecalPrepmuJ

tnemecalPrepmuJ

*1tupnI

tnemecalPrepmuJtnemecalPrepmuJ

tnemecalPrepmuJtnemecalPrepmuJ

tnemecalPrepmuJ

*2tupnI

CAV021CAV021

CAV021CAV021

CAV021

CAV802CAV802

CAV802CAV802

CAV802

CAV042CAV042

CAV042CAV042

CAV042

* NOTE: Input 1 and Input 2 must always

be configured for the same voltage

Figure 3.7

Input 1 and 2 Jumper Configuration

6

Verify the Input 1 and 2 voltages are configured identically.

7

Close the front panel.

Test it for proper operation (Section 3.1) and required v oltages .

8

3R,2R,1R9R,8R,7R

6R,5R,4R21R,11R,01R

6R,5R,4R21R,11R,01R

14

Page 17

4 Maintenance

4.1 Internal Fuse Replacement

DANGER: Fuse replacement should be done only by qualified personnel.

DANGER: Make sure the power is OFF before opening the front panel.

The RCU has four internal fuses that are accessible from the front panel.

To lower the front panel:

1

Switch OFF the Input 1 and 2 circuit breakers.

Remove the two Phillips screws on the RCU front panel.

2

3

Carefully lower the front panel forward 45 degrees.

Two fuses are located on the power board: Input 1: F1 and Input 2: F2 (both are 500 mA).

Input 1 Fuse

(500 mA)

J 1

1122334455

R 3 R 4

R 2

120 V

R 1

J 3

12345678

F 1

J 2

120 V

R 9

R 8

R 7

208 V

R 5

or

240 V

R 6

Input 2 Fuse

(500 mA)

F 2

R 10

208 V

R 11

or

240 V

R 12

Figure 4.1

Power Board Fuse Location

Two fuses are located on the logic board: Contactor 1: F1 and Contactor 2: F2 (both are

3.15 Amps).

Logic Board

K1

K3

F1

3.15 Amp

Figure 4.2

Logic Board Fuse Location

15

F2

3.15 Amp

Page 18

4 Maintenance

4.2 Troubleshooting

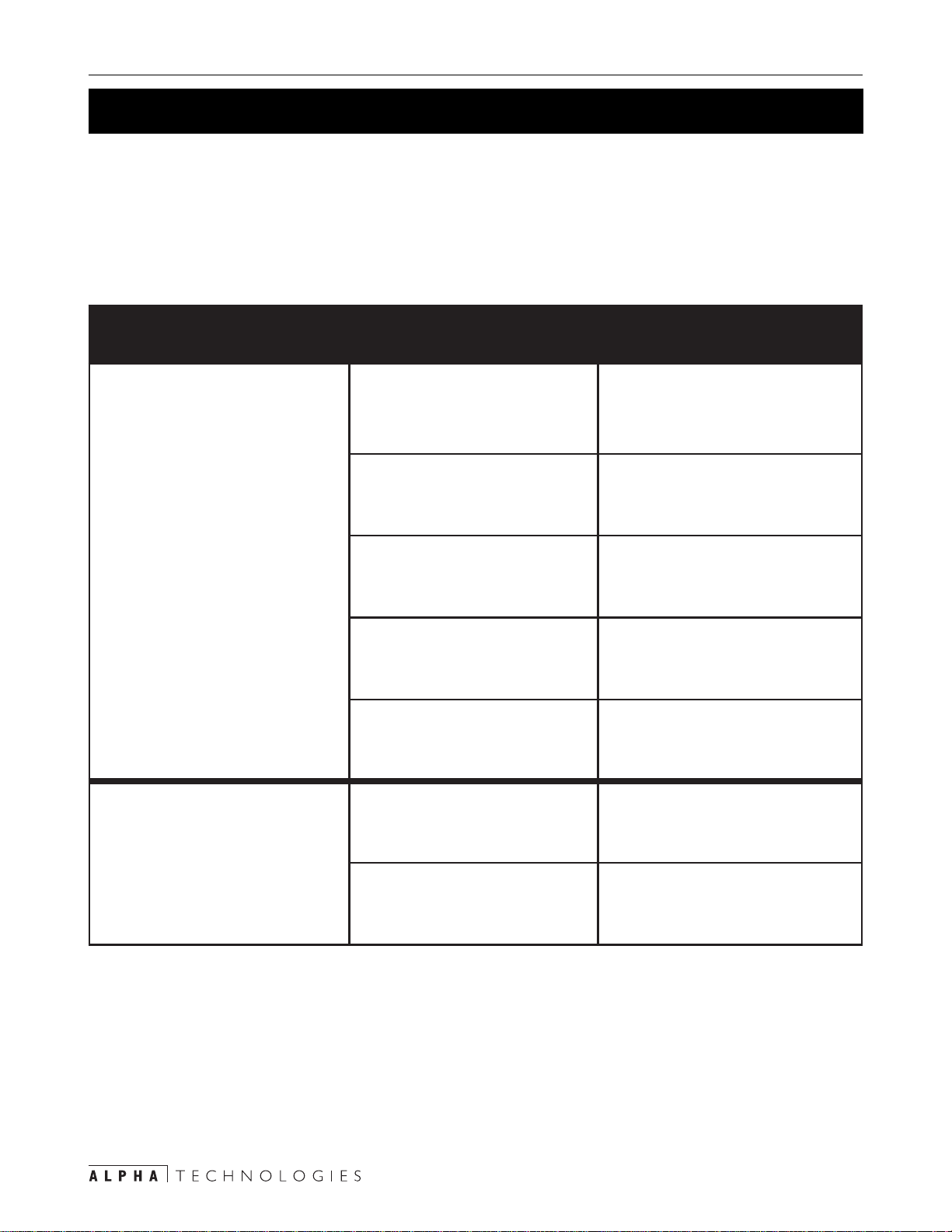

The most common problems, symptoms and causes are listed in Figure 4.3. It starts off with

the simplest problems, working to the most complex. If the operator can’t resolve the problem,

contact Alpha Technologies. Maintenance and troubleshooting should be done only by qualified personnel.

MOTPMYSMOTPMYS

MOTPMYSMOTPMYS ESUACELBABORPESUACELBABORP

MOTPMYS

rehto

refsnarttonlliwUCRrefsnarttonlliwUCR

refsnarttonlliwUCRrefsnarttonlliwUCR

refsnarttonlliwUCR

ehtottupnInomorf

ESUACELBABORPESUACELBABORP NOITULOSNOITULOS

ESUACELBABORP

deppirtrekaerbtiucriCrekaerBteseR

wolootegatloVegatlovkcehC*

NOITULOSNOITULOS

NOITULOS

draobcigolnoesufnepOesuFecalpeR*

neporodesufrotcatnoCUCRecalpeR*

no"KOssapyBlaunaM"no"KOssapyBlaunaM"

no"KOssapyBlaunaM"no"KOssapyBlaunaM"

no"KOssapyBlaunaM"

nonruttonlliwUCR

esahp

deppirtrekaerbtiucriCrekaerBteseR

*

These Items are to be performed only by a qualified technician

Figure 4.3

Troubleshooting Chart

cigollortnochtiwmelborPUCRecalpeR*

fotuo2tupnIdna1tupnI

yrassecensa

tcerrocdnagnisahpkcehC*

16

Page 19

Input

y

CB Panel

Bypass

Input

W1

W5

Input

Breaker

Static

Switch

Battery

Breaker

Battery

Charger

CFR UPS

Inverte r

Normally

OFF

Isolation/Output

Wa ve form C on tro l

Output

Breaker

W 4

W 2

Input 1

Input 2

RCU

Logic

W 3

Optional Manual Bypass

Option XFMR

Line

RCU

Bypass

UPS

W 8

(W 9)

4.3 RCU Wiring Diagrams

Output

17

Input

CB Panel

Bypass

Input

Battery

W1

W5

Figure 4.4

RCU Wiring Diagram

CFR UPS

Static

Switch

Input

Breaker

Battery

Breaker

Battery

Charger

Battery

Inverter

Normall

OFF

Isolation/Output

W a ve form Co n tro l

Figure 4.5

RCU Wiring Diagram

(Without Manual Bypass Switch)

Output

Breaker

W 4

W 2

Input 1

Input 2

RCU

Logic

W 3

Output

4 Maintenance

Page 20

4 Maintenance

4.4 Return Instructions

Before returning an RCU to Alpha Technologies for repair, obtain a Return Material Authorization (RMA) number from Alpha’s customer service department. Clearly write it on the original

shipping container. If you do not have it, pack the substitute container with at least three inches

of shock–absorbing material. Do not use popcorn–type material. Returns should be prepaid

and insured (COD and freight collect cannot be accepted).

NOTE: Alpha Technologies does not assume responsibility for damage caused by improper packaging of returned units.

For parts and service, contact the Alpha Technologies Customer Service Department at:

setatSdetinU0632-746)063(

adanaC6741-034)406(

modgniKdetinU011224-9721-44+

ynamreG303799-2219-94+

tsaEelddiM576573-5-753+

ailartsuA6687-4982)0(16+

To obtain complete technical support (7

days a week, 24 hours a day) call:

USA 1–800–322–5742

CANADA 1–800–667–8743

18

Page 21

4.6 Specifications

4 Maintenance

snoitacificepSlareneGsnoitacificepSlareneG

snoitacificepSlareneGsnoitacificepSlareneG

snoitacificepSlareneG

spmA05spmA05

spmA05spmA05 spmA001spmA001

spmA05

*CAV,egatloVtupnI042/802ro021

zH,ycneuqerFtupnI36-74

spmA,tnerruCtupnI05001

spmA,rekaerBtupnI05001

spmA001spmA001

spmA001

,emiTrefsnarTlacipyT

06-04

)cesm(

gnitarepO

O

(erutarepmeT

)C

04+ot0

)mm/sehcnI(htdiW234/71

)mm/sehcnI(thgieH331/52.5

)mm/sehcnI(htpeD183/51

)gk/sbl(thgieW61/53

* Primary and secondary power source must have the same nominal voltage.

19

Page 22

4 Maintenance

4.6 Warranty

LIMITED 24-MONTH WARRANTY

AC PRODUCTS

Alpha Technologies warrants its equipment to be free of manufactur ing defects in material and workmanship

for a period of 24 months from the date of manufacture. The liability of Alpha Technologies under this warranty

is solely limited to repairing, replacing, or issuing credit for such equipment (at the discretion of Alpha

Technologies), provided that:

1.Alpha Technologies’ Customer Service Department is promptly notified, by facsimile or telephone, that a

failure or defect has occurred.

2.Alpha Technologies’ Customer Service Department issues a Return Materials Authorization (RMA) number,

and designates the service location. The RMA must be clearly marked on the outside of the shipping

container.

3. Purchaser is responsible for all in-bound shipping and handling charges (COD and freight collect will not

be accepted without prior approval from Alpha Technologies); Alpha Technologies will pay out-bound

surface shipping charges for return of repaired equipment.

4.A satisfactory examination of the returned unit by Alpha Technologies’ Service personnel shall disclose

that defects have not been caused by misuse, neglect, improper installation, repair, alteration, or accident,

or failure to follow instructions furnished by Alpha Technologies. If Alpha Technologies’ Service personnel

determine that the unit has been damaged due to one of these causes, or if the unit is free of defects, a

handling or repair fee may be assessed prior to returning the unit.

WITH RESPECT TO BATTERIES, PERIPHERAL DEVICES, ATTACHMENTS OR APPARATUS NOT

MANUF ACTURED BY ALPHA TECHNOLOGIES, ALPHA WILL ASSIGN T O THE PURCHASER ITS RIGHTS

UNDER THE ORIGINAL MANUF A CTURER’S W ARRANTY OF SUCH BA TTERIES , PERIPHERAL DEVICES,

ATTACHMENTS OR APPARATUS, BUT OFFERS NO ADDITIONAL WARRANTIES IN CONNECTION

THEREWITH.

THIS LIMITED 24-MONTH W ARRANTY IS IN LIEU OF ALL OTHER WARRANTIES , EXPRESS OR IMPLIED ,

INCLUDING, BUT NOT LIMITED TO , IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR

A PARTICULAR PURPOSE.

IN NO CASE SHALL ALPHA TECHNOLOGIES BE LIABLE FOR ANY INCIDENTAL, SPECIAL OR

CONSEQUENTIAL DAMA GES WHATSOEVER, INCLUDING WITHOUT LIMITA TION ANY CLAIM FOR LOST

PROFITS OR REVENUES, EVEN IF ALPHA TECHNOLOGIES HAS BEEN AD VISED OF THE POSSIBILITY

OF SUCH, FOR BREACH OF THIS OR ANY O THER WARRANTY, EXPRESS OR IMPLIED.

Any action for breach of this limited 24-month warranty must be brought within a period of 24 months from

date of manufacture.

This limited 24-month warranty does not extend to any unit that has been repaired or altered by any party

other than Alpha Technologies or its Authorized Service Center.

Alpha Technologies reserves the right to discontinue particular models and to make modifications in design

and/or function at any time, without notice and without incurring obligations to modify previously purchased

units.

8/96

20

Page 23

USA, LA TIN AMERICA & ASIA

P ACIFIC

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

Tel: (360) 647–2360

Fax: (360) 671–4936

CANADA

Alpha Technologies

7033 Antrim Ave.,

Burnaby BC V5J 4M5

Tel: (604) 430–1476

Fax: (604) 430–8908

UNITED KINGDOM,

EUROPE & AFRICA

Alpha Technologies

Cartel Business Estate

Edinburgh W ay

Harlow, Essex

CM20 2DU

Tel: +44–1279–422110

Fax: +44–1279–423355

GERMANY

Alpha Technologies

Hansastrasse 8

D-91126 Schwabach

Tel: +49–9122–79889–0

Fax: +49–9122–79889–21

MIDDLE EAST

Alphatec

P.O. Box 6468

3307 Limassol, Cyprus

Tel: +357–5–375675

Fax: +357–5–359595

AUSTRALIA/SOUTH P A CIFIC

Alpha Technologies

8 Anella A ve., Unit 6

Castle Hill, NSW 2154

Tel: +61–2–9894–7866

Fax: +61–0–2–9894-0234

http://www.alpha.com

Alpha sales and service offices located throughout the world

Printed In Canada

020–145–B0–001 01/00

© 1999 Alpha Technologies

Loading...

Loading...