Page 1

Installation Instructions

Alpha Twin Pipe Flue Systems

Suitable for use with the

Alpha CB 24/28, C and SY range of gas fired

combination boilers

after Boiler Serial No. B04500001

For Technical help or for Service call ...

ALPHA HELPLINE

Tel: 0870 3001964

Nepicar House, London Road,

Wrotham Heath, Sevenoaks,

Kent TN15 7RS

These instructions must be read in conjunction with the Installation instructions supplied with the boiler.

Only flue components supplied by Alpha may be used with Alpha boilers, failure to comply will invalidate

the boiler's warranty and CE approval, and may be unsafe.

Page 2

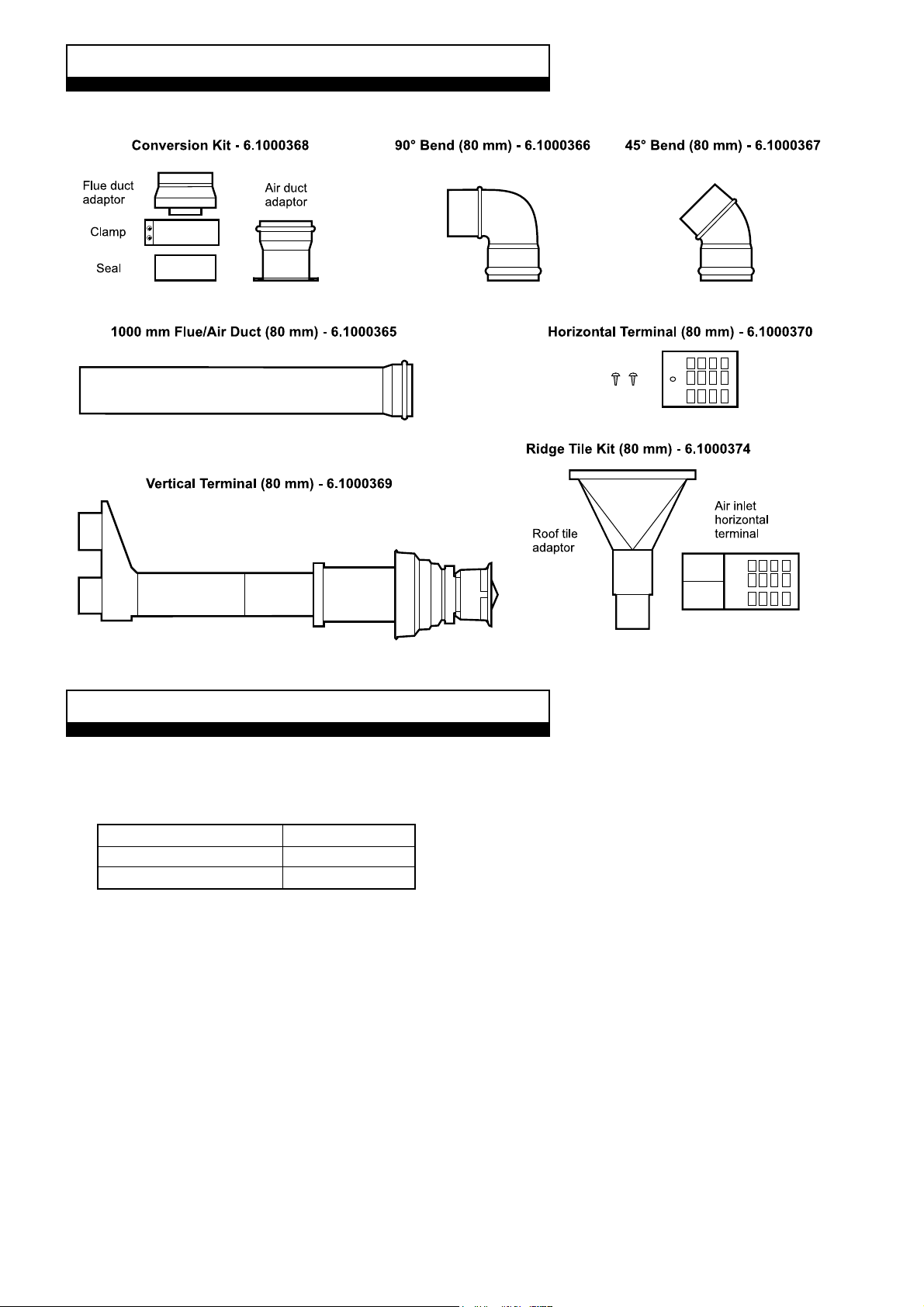

1 COMPONENTS AVAILABLE TO ORDER

2 INTRODUCTION

1. The flue system must be installed in accordance with BS 5440:1.

2. The boiler must be installed in accordance with the Installation and Servicing instructions supplied with the boiler.

3. The maximum equivalent flue lengths are as given below. (Refer to illustrations in section 3).

Alpha Boiler

Horizontal Flue

Vertical Flue (Inc. Terminal)

Note: Ensure the flue length does not exceed the equivalent shown in the table above.

4. Each 90° Bend (80 mm) is equivalent to 1.0 m of flue length.

Each 45° Bend (80 mm) is equivalent to 0.5 m of flue length.

Note: i) Up to a maximum of four bends (90° or 45°) per flue exhaust or air inlet duct may be used.

ii) A 90° bend must not be used with a vertical flue.

5. Refer to the flue options shown to determine the equivalent length of flue pipe required. Ensure that this does not

exceed the maximum equivalent flue length given in the table above.

6. The vertical flue terminal is equivalent to 1 m of flue length and must be positioned above the roof line as shown in Fig. 3.

7. If a bend is to be fitted directly to the boiler, a clearance of 260 mm is required above the boiler.

8. Refer to the Installation and Servicing instructions supplied with the boiler for details of permissible flue terminal positions

9. For horizontal flues ensure there is a slight downward slope towards the terminal and there is no part of the flue system where

condensate will collect. Where flue lengths are more than 6 m, consideration should be given to fitting a condensate trap.

10. All parts of the exhaust flue duct must be at least 25 mm from any combustible material. When passing through a wall,

floor or roof, the flue duct must be separated from any combustible material or plastic by a non-combustible sleeve

providing a circular air space of at least 25 mm around the flue duct.

11. Any portion of the flue duct which could be touched must be encased or shielded to prevent access. This does not apply

to the air inlet duct.

CB/SY range

10 m

7 m

Twin Pipe Flue Systems

2

Page 3

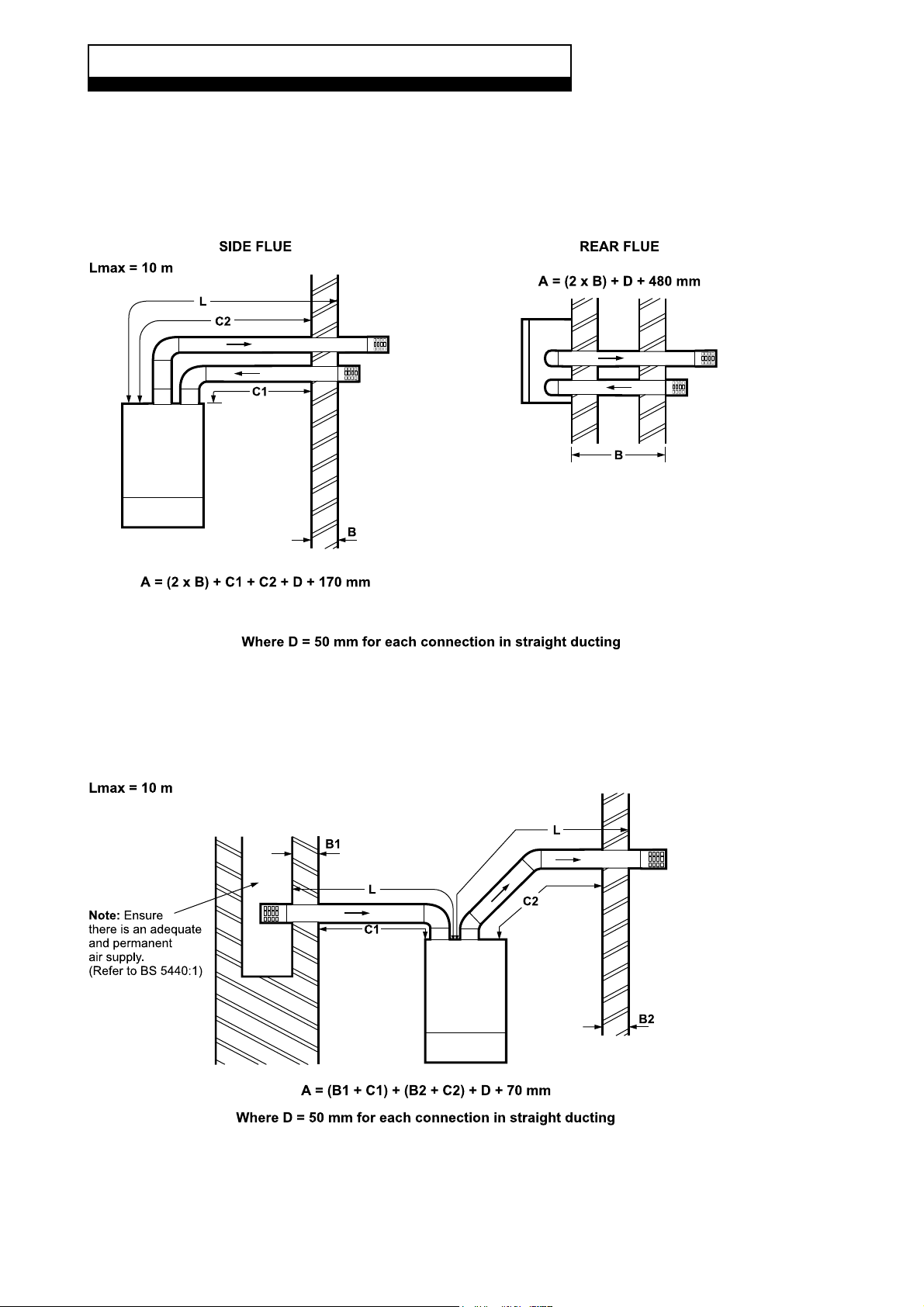

3 FLUE OPTIONS

3.1 HORIZONTAL FLUE OPTIONS - Lmax = 10 m

L = Equivalent length of flue or air duct (a 90° bend is equivalent to 1.0 m of flue length and a 45° bend is equivalent to 0.5 m

of flue length).

Note: No more than four bends (90° or 45°) must be used on the flue exhaust or air inlet duct.

A = Total length of flue/air ducting required.

Fig. 1

Fig. 2

Twin Pipe Flue Systems

3

Page 4

3.2 VERTICAL FLUE OPTION - Flat or pitched roof

The vertical flue terminal is equivalent to 1 m of flue length.

Note: A 90° bend must not be used with a vertical flue.

No more than four bends (90° or 45°) must be used on the flue exhaust or air inlet duct.

3.3 VERTICAL FLUE OPTION - Ridge tile

Fig. 3

Twin Pipe Flue Systems

4

Fig. 4

Page 5

4 INSTALLATION

4.1 INSTALL THE BOILER

Mount the boiler on the wall and connect the pipework as described in the Installation and Servicing instructions supplied with

the boiler.

4.2 CONVERT THE BOILER (see Fig. 5)

Modify the top of the boiler to enable a 2-pipe flue system to be connected using conversion kit 6.1000368 as follows:-

1. Place the flue duct adaptor in position onto the boiler flue adaptor and secure with the clamp and seal.

2. Select the required position of the air duct adaptor and remove the three screws securing the cover plate.

3. Using the same three screws and gasket secure the air duct adaptor in position.

Fig. 5

Fig. 6

Twin Pipe Flue Systems

5

Page 6

4.3 ASSEMBLE THE FLUE DUCTS

Particular site conditions will dictate the sequence in which the flue is assembled. However, start assembling the flue system

at the boiler noting the following:-

1. Cut 85 mm holes for plain flue/air ducts. Cut 100 mm holes for flue/air ducts with connection sockets.

Note: All parts of the flue duct must be at least 25 mm from combustible material.

2. Depending on the type of socket, sockets take a full engagement of either 50 mm or 40 mm. Always fully engage

flue/air ducts into the socket.

3. Cut only plain ends of the duct and always deburr.

4 When assembled it must not be possible to disengage any part of the flue assembly. If necessary, secure ducts

together by drilling a 3 mm diameter hole through the socket and secure with a screw.

5. Ensure all lengths of flue/air ducting are adequately supported.

4.4 FIT THE FLUE TERMINALS

The air inlet and flue outlet ducts are fitted with the horizontal terminals 6.1000370 or a vertical terminal 6.1000369. The ridge

tile kit 6.1000374 is used where the flue duct is terminated as in Fig. 4. For ridge tile applications a different horizontal terminal

is provided in the kit for the air inlet.

1. Horizontal terminal (Figs 7, 8, 9, 10)

i) Drill 3 mm holes into the duct in the positions shown in Fig. 7, and secure the terminal to the duct with the screws

supplied.

ii) Where the air and flue ducts terminate on separate external walls, refer to Figs. 8 and 9 for the minimum

protrusion from the wall.

iii) Where the terminals are located on the same wall, the minimum dimensions given in Fig. 10 must be adhered to.

3 mm dia. holes

Fig. 7

20 to 25

Twin Pipe Flue Systems

6

Page 7

HORIZONTAL TERMINAL POSITIONING

Separated flue duct terminal Separated air duct terminal

100

Fig. 8 Fig. 9

Flue and air ducts located together on the same wall

Fig. 10

2. Vertical terminal (see Fig. 3)

i) Refer to Fig. 3 for positioning of the vertical terminal in the roof.

Note: Under no circumstances must the terminal be shortened in length.

ii) To enable direct connection of the flue and air ducts to the terminal the duct centres must be 120 mm apart.

iii) At the required position cut a hole and/or remove tiles so that there is at least a 170 mm diameter hole in the

roof. Ensure there is at least a 25 mm gap between the outer duct and any combustible material.

iv) Fit a weathering slate, suitable for a 125 mm outside diameter flue, over the hole in the roof. A suitable

weathering slate is available from Alpha Therm Ltd.

v) Fit the terminal assembly into the weathering slate and place it in position, ensuring the minimum distances given

in Fig. 3 are maintained.

vi) After assembly of the ducts to the terminal, ensure it is not possible to disengage any part of the flue assembly

and ensure the weathering slate is fitted correctly.

3. Ridge tile kit (see Fig. 4)

As supplied, the ridge tile kit enables the 80 mm flue duct to be connected to a standard ridge terminal. It is only for

connection to the flue products exhaust duct on the boiler.

The air duct should terminate horizontally using the terminal supplied in the ridge tile kit, preferably on an external wall

or via a purpose designed ducting system or area that will always ensure a permanent and adequate air supply (refer

to BS 5440:1).

Twin Pipe Flue Systems

7

Page 8

FLUE TERMINAL LOCATION

Fig. 11

Terminal position

A Directly below an opening, air brick, windows, etc.

B Below gutters, soil pipes or drain pipes

C Below eaves

D Below balconies or car port roof

E From a vertical drain pipe or soil pipe

F From an internal or external corner

G Above ground, roof or balcony level

H From a surface facing the terminal

I From a terminal facing the terminal

J From an opening in the car port (e.g. door, window) into dwelling

K Vertically from a terminal on the same wall

L Horizontally from a terminal on the same wall

Min. distance

300 mm

75 mm

25 mm

25 mm

25 mm

25 mm

300 mm

600 mm

1200 mm

1200 mm

1500 mm

300 mm

The flue terminal must be exposed to the external air and the position must allow the free passage of air across it at all times.

In certain weather conditions the terminal may emit a plume of steam. Avoid positioning the terminal where this may cause a

nuisance.

If the terminal is fitted within 850 mm of a plastic or painted gutter or 450 mm of painted eaves or 300 mm of a plastic car port

roof or drain/soil pipe, an aluminium shield at least 1 m long should be fitted to the underside of the gutter, roof or painted

surface. If the terminal is fitted less than 2 m above a surface to which people have access, the terminal must be protected by a

terminal guard.

A suitable guard (type K3 - G.C. No. 393 554) is available from:

Tower Flue Components Ltd., Vale Rise, Tonbridge, Kent TN9 1TB.

Alpha Therm Limited.

Nepicar House, London Road, Wrotham Heath,

Sevenoaks, Kent TN15 7RS

Tel: 0870 3001964

email: info@alphatherm.co.uk

website: www.alpha-innovation.co.uk

Compiled and designed by Publications 2000, Tel (01670) 356211

These instructions have been carefully prepared but we reserve the right to

alter the specification at any time in the interest of product improvement.

© Alpha Therm Limited 2004.

Part No. 1.01663.2

08/04/D132

Loading...

Loading...