Page 1

AlphaCell SMU

Technical Manual

AlphaCell SMU

Effective: January 2007

Alpha Technologies

Page 2

Alpha Technologies

Power

®

Page 3

AlphaCell SMU Technical Manual

745-680-B9-001, Rev. A

Effective Date: January, 2007

Copyright© 2007

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this powering system, please contact Alpha Technologies

or your nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

TM

Contacting Alpha Technologies: www.alpha.com

or

For general product information and customer service (7 AM to 5 PM, Pacifi c Time), call

1-800-863-3930,

For complete technical support, call

1-800-863-3364

7 AM to 5 PM, Pacifi c Time or 24/7 emergency support

To report errors in this document, send email to :

Techpubs@alpha.com

Page 4

Table of Contents

Safety Notes .......................................................................................................................... 6

Battery Safety Notes.............................................................................................................. 7

Chemical Hazards ................................................................................................................. 7

Recycling and Disposal Instructions ...................................................................................... 7

1.0 Introduction ................................................................................................................. 8

2.0 Theory of Operation .................................................................................................... 8

3.0 Specifi cations.............................................................................................................. 8

3.1 General Specifi cations ..................................................................................... 9

3.2 Battery Internal Resistance .............................................................................. 9

4.0 Temperature, Battery Capacity, and Battery Life ...................................................... 10

4.1 Battery Capacity and Ambient Temperature .................................................. 10

4.2 Battery Life and Ambient Temperature ............................................................11

5.0 Charging ....................................................................................................................11

5.1 Floating Charge Voltage and Ambient Temperature .......................................11

5.2 Boost Charging .............................................................................................. 12

6.0 Maintenance ............................................................................................................. 12

6.1 Monthly Maintenance ..................................................................................... 12

6.2 Quarterly Maintenance................................................................................... 13

6.3 Yearly Maintenance ....................................................................................... 13

6.4 Three-year Maintenance ................................................................................ 13

7.0 Storage ..................................................................................................................... 13

8.0 Installation................................................................................................................. 14

9.0 Appendix A: Specifi cations ....................................................................................... 16

10.0 Appendix B: Choosing the Right Capacity ................................................................ 20

10.1 Telecom Applications ..................................................................................... 20

10.2 Power Applications......................................................................................... 20

11.0 Appendix C: Forms ................................................................................................... 22

4

745-680-B9-001

Page 5

Figures

Fig. 3-1, Battery Construction ................................................................................................ 8

Fig. 4-1, Capacity as a Function of Temperature ................................................................. 10

Fig. 8-2, Battery Connector Detail ....................................................................................... 15

Fig. 8-1, Frame Construction ............................................................................................... 15

Fig. 8-3, Sample Battery Installation (SMU-500) ................................................................. 15

Fig. 9-1, Discharge Performance......................................................................................... 16

Fig. 9-2, Discharge Curve at One Minute (25°C) ................................................................ 16

Fig. 9-3, Discharge Curve at Five Seconds (25°C) ............................................................. 17

Fig. 9-4, Shock Discharge Curve at Different Rates after Discharge of One Hour (25°C) .. 17

Fig. 9-5, Shock Discharge Curves at Different Rates After .5h Discharge (25°C) ............... 18

Fig. 9-6, Recharge Characteristics of SMU-500, 0.1C

Fig. 9-7, Recharge Characteristics of SMU-500, 0.1C10A, 2.23Vpc (25°C). ........................ 19

Fig. 10-1, Single Cell Discharge Curves (Final Voltage: 1.80 Vpc; 25°C) ........................... 20

Fig. 10-2, Curves With Stairs Loading Calculation Method (25°C) ..................................... 20

Fig. 10-3, Curves with Voltage Control Method (25°C) ....................................................... 21

A, 2.35Vpc (25°C). ........................ 18

10

Tables

Table 3-1, General Specifi cations .......................................................................................... 9

Table 3-2, Internal Resistance and Short Circuit Current (25°C) ........................................... 9

Table 5-1, Floating Voltage and Temperature .......................................................................11

Table 9-1, Discharge Specifi cations .................................................................................... 19

745-680-B9-001

5

Page 6

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of this product, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

ATTENTION:

The use of ATTENTION indicates specifi c regulatory/code requirements that may affect the placement of

equipment and /or installation procedures.

NOTE:

A NOTE provide additional information to help complete a specifi c task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING!

WARNING presents safety information to PREVENT INJURY OR DEATH to the technician

or user.

6

745-680-B9-001

Page 7

Battery Safety Notes

WARNING!

Lead-acid batteries contain dangerous voltages, currents and corrosive material. Battery

installation, maintenance, service and replacement must be performed only by authorized

personnel.

Chemical Hazards

Any gelled or liquid leakage from a valve-regulated lead-acid (VRLA) battery contains dilute sulfuric acid,

which is harmful to the skin and eyes. Emissions are electrolytic, electrically conductive, and corrosive.

To avoid injury:

•

Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

•

Always wear eye protection, rubber gloves, and a protective vest when working near batteries. Remove all metallic

objects from hands and neck.

•

Batteries produce explosive gases. Keep all open fl ames and sparks away from batteries.

•

Use tools with insulated handles. Do not rest any tools on top of batteries.

•

Lead-acid batteries contain or emit chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm. Battery post terminals and related accessories contain lead and lead compounds. Wash

hands after handling (California Proposition 65).

•

Wear protective clothing (insulated gloves, eye protection, etc.) when installing, maintaining, servicing, or replacing

batteries.

•

If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your company’s

approved chemical exposure procedures.

•

Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with a solution

of one pound bicarbonate of soda to one gallon of water. Report a chemical spill using your company’s spill reporting

structure and seek medical attention if necessary.

•

Always replace batteries with those of an identical type and rating. Never install old or untested batteries.

•

Do not charge batteries in a sealed container. Each individual battery should have at least 0.5 inches of space

between it and all surrounding surfaces to allow for convection cooling.

•

All battery compartments must have adequate ventilation to prevent accumulation of potentially dangerous gas.

Ventilation should prevent trapped hydrogen gas pockets from exceeding a 1% concentration as per regulation 70E

of the National Fire Protection Agency (NFPA).

•

Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have developed

on your body.

•

Never use uninsulated tools or other conductive materials when installing, maintaining, servicing, or replacing

batteries.

•

Use special caution when connecting or adjusting battery cabling. An improperly connected battery cable or an

unconnected battery cable can make contact with an unintended surface that can result in arcing, fi re, or possible

explosion.

•

A battery showing signs of cracking, leaking, or swelling should be replaced immediately by authorized personnel

using a battery of identical type and rating.

Equipment Cautions

Do not operate NiCd and lead-acid batteries in the same room. NiCd emissions will neutralize the lead-acid solution,

•

rendering the battery useless.

Overcharging the battery can result in a loss of capacity and excess release of gas.

•

Recycling and Disposal Instructions

Spent or damaged batteries are considered environmentally unsafe. Always recycle used batteries or dispose of the

batteries in accordance with all federal, state and local regulations.

745-680-B9-001

7

Page 8

1.0 Introduction

The AlphaCell SMU battery with sealed gas recombination technology is specifi cally designed

for telecommunication applications, and is available with capacities from 200Ah to 2,000Ah. The

AlphaCell SMU Series of batteries require less space than conventional VRLA batteries and are

structurally arranged to eliminate dislodging and slippage caused by vibrations over time.

Features and Benefi ts:

• 10+ year life

• Recombination effi ciency approaching 99.9%

• Low self discharge maximizes shelf life

• Strong, corrosion resistant grid design

• Modular unit structure allows for minimal footprint

• Unique, fl exible connectors that make for convenient installation and effi cient connections

• Shockproof external design

2.0 Theory of Operation

Valve Regulated Lead Acid (VRLA) batteries make use of a process called recombination. By

reforming the water lost during electrolysis, recombination eliminates the need for regular battery

checks and for refi lling the battery water. The chemical reactions are as follows:

Pb + PbO2 + 2H2SO4 2PbSO4 + 2H2O

Discharge

Charge

2Pb + O2 2PbO

PbO + H2SO4 PbSO4 + H2O

3.0 Specifi cations

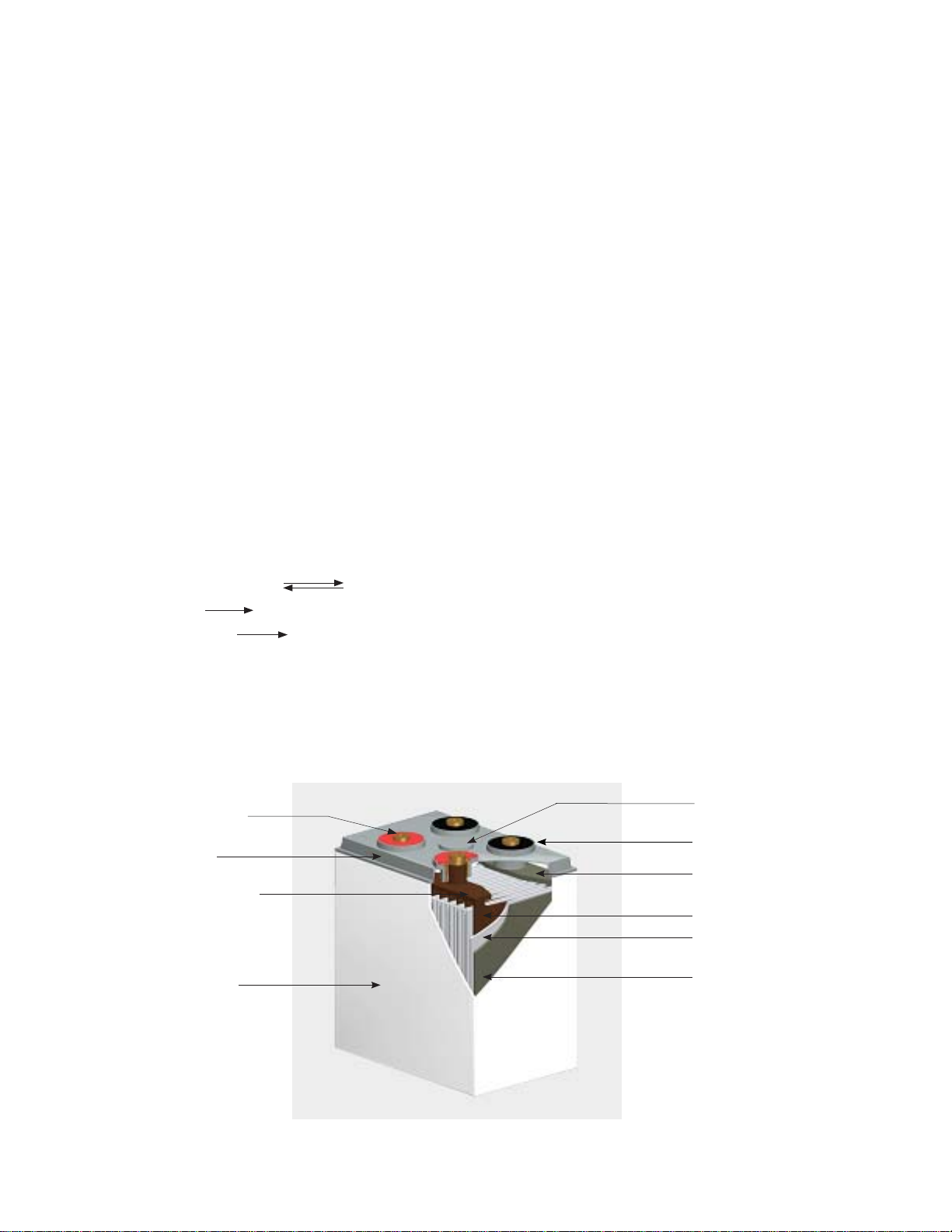

Terminal (+)

Cover

Positive Strap

Container

Safety Valve

Terminal (-)

Negative Strap

Positive Plate

Separator

Negative Plate

Fig. 3-1, Battery Construction

8

745-680-B9-001

Page 9

3.0 Specifi cations, continued

3.1 General Specifi cations

Model

SMU 2200-FR

SMU 2300-FR

SMU 2400-FR

SMU2

-500-FR

SMU 2600-FR

SMU 2800-FR

SMU 2-

1000-FR

SMU 2-

1500-FR

SMU 2-

2000-FR

Rated

Voltage

1.80Vpc (C

Rated Capacity (Ah) Dimensions (in/mm)

10hr. to

)

1.80Vpc (C3)

10

3hr. to

1hr. to

1.80Vpc (C1)

Length Width Height

Number

of Poles

2 200 150 110 4.25/120 8/200 15/385 2 35/16

2 300 225 165 6/161 8/200 15/385 2 50/23

2 400 300 220 8/201 8/200 15/385 2 66/30

2 500 375 275 9.5/242 8/200 15/385 2 84/38

2 600 450 330 11/283 8/200 15/385 4 99/45

2 800 600 440 7/183 9.5/244 24.5/629 4 136/62

2 1000 750 550 8.5/218 9.5/244 24.5/629 4 167/76

2 1500 1125 825 12/305 9.5/244 24.5/629 6 244/111

2 2000 1500 1100 14.5/369 9/228 24.25/617 8 337/153

Weight

(lb./Kg)

3.2 Battery Internal Resistance

CAUTION!

Table 3-1, General Specifi cations

Battery internal resistance is a nonlinear parameter that changes with changes in battery

temperature and discharge state. The internal resistance is lowest when the battery is fully

charged. At full charge and 25°C the internal resistances and short circuit currents are as

follows:

Model Internal Resistance (m Ω) Short Circuit Current (A)

SMU 2-200-FR 0.514 3940

SMU 2-300-FR 0.363 5588

SMU 2-400-FR 0.297 6816

SMU2 -500-FR 0.218 9361

SMU 2-600-FR 0.175 11576

SMU 2-800-FR 0.223 9153

SMU 2-1000-FR 0.189 10804

SMU 2-1500-FR 0.152 13237

SMU 2-2000-FR 0.115 17391

Table 3-2, Internal Resistance and Short Circuit Current (25°C)

A short circuit will drop the battery voltage to zero and physically damage its internal components,

poles, and connectors.

745-680-B9-001

9

Page 10

4.0 Temperature, Battery Capacity, and Battery Life

There are several factors that affect the capacity and the life-span of a battery. These include

charging method, discharge depth, end voltages, and ambient temperature. The most signifi cant

of these is temperature. In order to maximize capacity and life-span, ambient temperature should

be controlled and the battery’s fl oat voltage should be set to the appropriate value (for fl oat voltage

specifi cations see section 5.1).

CAUTION!

Excessive temperatures (over 50°C, 120°F) may cause the heat generated in the recombination

process to exceed the rate at which the heat can be transferred out of the battery and thermal

runaway may begin. Thermal runaway is a dangerous cycle that can severely damage equipment.

4.1 Battery Capacity and Ambient Temperature

The capacity of the battery is directly linked to ambient temperature: The lower the

temperature the lower the capacity; the higher the temperature the higher the capacity. The

standard capacity data are based on an optimal 25°C ambient temperature. The effect of

temperature on capacity is as follows:

110

100

90

80

70

Percent of Rated Capacity

60

50

-20 -10 0 10 20 25 30 40 50

Ambient Temperature (°C)

Fig. 4-1, Capacity as a Function of Temperature

10

745-680-B9-001

Page 11

4.0 Temperature, Battery Capacity, and Battery Life, continued

4.2 Battery Life and Ambient Temperature

The expectant life-span of 10+ years is based on a 25°C ambient temperature. Temperatures

above this optimum increase the rate of plate corrosion and of water loss, which shortens

battery life. For temperatures above 25°C, the relationship between temperature and life-span

is expressed in the following equation:

25

/ 2

(T-25)/10

tT = t

Where, tT= the actual life span; T= the actual temperature; t25= the rated life span at 25°C.

For example, if the actual ambient temperature is 35°C then the expectant life-span is 5

years.

NOTE:

While an ambient temperature slightly below 25°C may help the battery reach its potential life-span, it will

not signifi cantly increase that life-span. In addition, the capacity of the battery and it’s ability to discharge

signifi cantly decrease at temperatures below 5°C. The battery’s optimal operating range is 15°C to 25°C.

5.0 Charging

In order to ensure the battery performs to its potential, it is very important that it is:

• Float-charged in order to remain in a fully charged condition

• Completely recharged as soon as possible after a discharge, in order to ensure maximum battery

life

• Charged properly

5.1 Floating Charge Voltage and Ambient Temperature

The fl oat charge keeps the battery in

a fully charged state with a small but

constant current which automatically

covers capacity lost from self and other

discharges.

In order to maximize capacity and life

span, the battery’s fl oat voltage must be

set for the ambient temperature range in

which the battery operates.

CAUTION!

A fl oat voltage set higher than specifi ed accelerates the corruption of the grid, shortens the life

of the battery, and increases the risk of thermal runaway. A fl oat voltage set lower than specifi ed

inhibits the battery from holding a charge; this increases sulfation on the plates, decreases the

capacity and shortens the life of the battery.

Ambient Temperature

(°C)

0–10 2.29

11–15 2.26

16–25 2.23

26–30 2.21

31–35 2.20

36–40 2.19

Table 5-1, Floating Voltage and Temperature

Float Voltage

(Vpc) +/-5%

745-680-B9-001

11

Page 12

5.0 Charging, continued

5.2 Boost Charging

NOTE:

• In general a boost charge should not take more than three hours. If it does, either the batteries or the

charger are likely defective.

• Take and record measurements before and after charging and during discharge to help track changes

and problems. Wait two hours after charging before you take fi nal measurements so the electrolyte can

cool suffi ciently.

The conditions under which the battery needs to be boost charged beyond its fl oat charging

are:

The cell fl oating charge voltage is less than 2.18V.

•

The battery has been in a unused state for more than 3 months.

•

The battery has been running in a state of fl oating charge for over one year.

•

The preferred boost charging method is:

• Charge the battery with a current less than .25 C10A (0.1 C10A to 0.2 C10A is

recommended) at a charge voltage of 2.30 to 2.35 Vpc.

• The charge is fi nished when the current drops to less than 0.006 C10A.

6.0 Maintenance

The SMU battery is maintenance free only in regards to the electrolyte. For assurance of reliability it

is important to perform the recommended periodic maintenance.

WARNING!

To avoid damage to the equipment or injury to the technician, follow these precautions:

• All maintenance work should be performed by a trained technician.

• Remove all jewelry.

• Do not smoke or use fi re near batteries.

• Use insulted tools when installing or maintaining the batteries. Do not lay metal tools on the

batteries.

• Do not remove the safety valves from the batteries or add anything to the batteries.

• Do not clean the batteries with organic cleaners.

• Do not use defective or damaged batteries.

6.1 Monthly Maintenance

• Make sure the battery room is clean.

12

• Measure and record the ambient temperature of the battery room.

• Make sure the batteries are clean.

• Check for damage, or evidence of over-heating on the terminals, containers, and lids.

• Measure and record the total voltage and fl oating current of the battery system.

745-680-B9-001

Page 13

6.0 Maintenance, continued

6.2 Quarterly Maintenance

• Repeat monthly inspection.

• Measure and record the fl oating voltage of every cell. If more than two cells’ voltages are

less than 2.18V, the batteries need to be boost charged (see Section 5.2). If the problem

persists, conduct annual and then three-year maintenance.

6.3 Yearly Maintenance

• Repeat quarterly maintenance and inspection.

• Ensure all connections are clean and tight.

• Check the load of the batteries by conducting a capacity (discharge) test: discharge the

batteries to between 30% and 40% of rated capacity.

6.4 Three-year Maintenance

• Conduct a capacity (discharge) test. Replace any battery with a capacity less than 80%

of rated capacity.

7.0 Storage

Storage procedures:

• Before storing, fully charge the batteries. Storing a battery in a discharged state will negatively

affect its life span and capacity.

• All lead acid batteries experience self-discharge in open circuit. The self-discharge rate is largely

determined by ambient temperature: the lower the temperature, the lower the discharge rate

and the higher the temperature, the higher the discharge rate. Store batteries in a clean, well

ventilated location with temperatures between 0°C and 35°C.

• In order to avoid permanent damage to the plate caused by self-discharge, the batteries should

be boost charged after every three months in storage (see section 5.2).

• Record all dates and services performed. See page 22 for form.

745-680-B9-001

13

Page 14

8.0 Installation

About the site:

Maintain a distance of at least 20" (508mm) between the battery and electrical switches and

•

outlets.

Do not expose the battery to organic solvents and corrosive gasses.

•

Maintain a distance of at least 7.87" (200mm) between batteries and battery groups to provide

•

proper ventilation.

Create a pathway at least 47.24" (1200mm) wide next to each battery group for access during

•

routine maintenance.

Verify that the maximum weight capacity of the fl oor is not exceeded.

•

The ideal operating temperature is 77ºF (25ºC). If possible, install air-conditioning or forced

•

ventilation to keep temperatures between 59ºF (15ºC) and 95ºF (30ºC).

CAUTION!

All the cells in the system must be of the same capacity. Alpha recommends the cells be close in

age.

Tools needed:

• Socket and wrench sets

• Torque wrench

Procedure:

1. Check the cells and frame modules for damage. Do not install damaged cells.

2. Remove the retaining bars and the cells from the frame modules.

3. Fasten the two channel bars to one module with M8x30 bolts, nuts, fl at washers, and lock

washers. The bigger diameter holes on the channel bars should face down for anchoring to the

fl oor. The channel bars can be mounted with their open side facing either in or out depending on

installation and maintenance convenience.

4. Fasten the second frame module to the top of the fi rst with four M8x20 bolts, nuts, fl at washers,

and lock washers. Continue stacking and fastening together modules. Alpha recommends

stacking no more than four modules. However, the system can accommodate up to six. If

applicable, blot parallel stacks to each other with two bolts, one in the front and one in the back,

on each row.

5. Torque all nuts to 130 in/lb. (15N/m).

6. Fasten the two lead terminals to the top module. One terminal can be fastened to each side of the

module or both can be fastened to the same side.

7. Starting with the bottom module (to prevent tipping), slide the battery cells into the assembled

frame. Orient the positive and negative poles of the batteries as shown in Fig 8-3.

8. Fasten the retaining bars to the modules to secure the cells.

9. Connect the cells using the fl exible connectors according to color and polarity (red=positive;

blue=negative), as shown in Figures 8-2 and 8-3. Torque all connections to 130 in/lb. (15N/m).

10. Check the voltage and polarity of the battery string with a voltameter.

11. Connect the positive poles of the cell at one end of the string to the positive terminal. Connect the

negative poles of the cell on the other end of the string to the negative terminal (see Fig. 8-3).

CAUTION!

Take care not to create a short circuit when connecting the battery string to the lead terminals.

12. Install the plastic terminal covers to the terminals and the cover plate to the top of the top module.

14

745-680-B9-001

Page 15

8.0 Installation, continued

Cover Plate

Plastic Terminal Cover

Lead Terminal

(one of two)

Module 2

M8x20 Bolts

M8x30 Bolts

Channel Bar

Module 1

Fig. 8-1, Frame Construction

Positive Lead Terminal

Negative Lead Terminal

Plastic Terminal Cover

8mm Allen Bolt

Washer

Fig. 8-2, Battery Connector Detail

745-680-B9-001

Connector

Terminal Post

Fig. 8-3, Sample Battery Installation (SMU-500)

15

Page 16

9.0 Appendix A, Specifi cations

Voltage

Time (h)

Fig. 9-1, Discharge Performance

2.1

2.0

1.9

Voltage

1.8

1.7

1.6

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Discharge Rate K

(Kch=I

ch

dis/C10

)

Fig. 9-2, Discharge Curve at One Minute (25°C)

16

745-680-B9-001

Page 17

9.0 Appendix A: Specifi cations, continued

2.1

2.0

1.9

Voltage

1.8

1.7

1.6

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

Discharge Rate Kch (Kch= I

dis/C10

)

Fig. 9-3, Discharge Curve at Five Seconds (25°C)

3

2.

2.2

2.1

2.0

1.9

Voltage

1.8

1.7

1.6

1.5

0.0 0.5 1.0 1.5 2.0 2.5 3.0

Discharge Rate Kch (Kch= I

dis/C10

)

Float Voltage

Open Circuit

0.1 C

10

0.2 C

10

0.3 C

10

0.4 C

10

0.5 C

10

745-680-B9-001

Fig. 9-4, Shock Discharge Curve at Different Rates after Discharge of One Hour (25°C)

17

Page 18

9.0 Appendix A: Specifi cations, continued

2.1

2.0

1.9

1.8

Voltage

1.7

1.6

1.5

0.0 0.5 1.0 1.5 2.0 2.5 3.0

Discharge Rate Kch (Kch= I

dis/C10

)

Fig. 9-5, Shock Discharge Curves at Different Rates After .5h Discharge (25°C)

Charge current of 0.1C10A and a voltage limit of 2.35Vpc (25°C).

4

60

50

40

2.

Voltage

Current

2.3

Capacity Charged

2.2

0.1 C

0.2 C

0.3 C

0.4 C

0.5 C

1.

1.2

1.0

0.8

10

10

10

10

10

4

18

30

Current

20

10

0

2.1

Voltage

2.0

1.9

0 4 8 12162024

Time (h)

Fig. 9-6, Recharge Characteristics of a 100% discharged SMU-500.

0.6

0.4

Capacity Charged Rate

0.2

0.0

745-680-B9-001

Page 19

9.0 Appendix A: Specifi cations, continued

50

40

30

20

Current

10

0

Charge current of 0.1C10A and a voltage limit of 2.23Vpc (25°C).

Voltage

Capacity Charged

2.

2.1

Current

2

Voltage

2.0

1.9

04812162024

Time (h)

Fig. 9-7, Recharge Characteristics of a 100% discharged SMU-500.

1.

3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

Capacity Charged Rate

0.3

0.2

0.1

0.0

End Discharge Voltage 1.75/Cell (Amps)

Typ e Mi nute s Hours

5101520304050609023456789101224

SMU 2-200-FR

SMU 2-300-FR

SMU 2-400-FR

SMU 2-500-FR

SMU 2-600-FR

SMU 2-800-FR

SMU 2-1000-FR

SMU 2-1500-FR

SMU 2-2000-FR

End Discharge Voltage 1.80/Cell (Amps)

Typ e Mi nute s Hours

SMU 2-200-FR

SMU 2-300-FR

SMU 2-400-FR

SMU 2-500-FR

SMU 2-600-FR

SMU 2-800-FR

SMU 2-1000-FR

SMU 2-1500-FR

SMU 2-2000-FR

277.1 252.8 233.3 213.2 171.0 148.0 128.8 114.0 86.4 70.6 52.4 42.8 3 6.4 32.0 28.3 25. 5 23.2 21.2 18.0 9.8

415.6 379.2 350.0 319.7 256.5 222.0 193.2 171.0 129.6 106 .0 78.6 64.2 54.6 48.0 42.5 3 8.2 34.7 31.9 27.0 14.6

554.1 505.6 466.7 426.3 342.0 29 6.0 257.6 228.0 172. 8 141.3 104.8 85.6 72.8 64.0 56.6 51.0 4 6.3 42.5 36.0 19.5

692.6 6 32.1 583.3 532.9 427.5 370.0 322.0 285.0 216.0 176.6 131.0 107.0 91.0 80.0 70.8 63.7 57.9 53.1 45.0 24.4

831.1 758.5 700.0 639.5 513.0 444.0 386.4 342.0 259. 2 211.9 157.2 128.4 109.2 96.0 85.0 76.4 69.5 63.7 54.0 29.3

972.7 897.9 825.4 755.7 615.2 547.2 491.2 446.4 349.9 292.8 216.0 174.2 147.2 127.3 112.3 101.1 92.0 84.3 72. 4 39.2

1215.8 1122.4 1031.7 94 4.6 769.0 684.0 614.0 558.0 4 37.3 36 6.0 270.0 217.8 184.0 159.1 140. 4 126.4 115.0 105.4 90.5 4 9.0

1823.8 168 3.6 1547.5 1416.9 1153.5 1026.0 921.0 837.0 656.0 5 49.0 40 5.0 326.6 276.0 238 .7 210.6 189.6 172.5 158.1 135.8 73.4

2431.7 2244.8 2063.4 1889.2 1538.0 1368.0 1228.0 1116.0 874.7 732.0 540.0 435. 5 368.0 318.2 280.9 252.8 23 0.0 210.8 181.0 97.9

5101520304050609023456789101224

266.5 240.2 220.0 201.1 160.0 137.2 120.0 106. 8 81.4 67.6 50. 8 41.4 35.6 31.2 27.8 25.0 22.7 20.8 17.6 9.6

399.7 36 0.3 330.0 301.6 240.0 205.8 180.0 160.2 122.1 101.4 76.2 62.0 53.3 46.8 41.8 37.5 3 4.0 31.1 26. 3 14.4

533.0 4 80.4 440.0 402.1 320.0 274.4 240.0 213.6 162.8 135. 2 101.6 82.7 71.1 62.4 55.7 50.0 45.4 41.5 3 5.1 19.2

666. 2 600.5 550.0 502.6 40 0.0 343.0 300.0 267.0 203.5 169.0 127.0 103.4 88.9 78.0 69.6 62.5 56.7 51.9 43.9 24.0

799.5 720.5 660.0 603.2 480.0 411.6 360.0 320.4 244.2 202 .8 152.4 124.1 106.7 93.6 83.5 75.0 68.0 62.3 52.7 28.8

918.9 841.1 769.7 697.9 576.0 519.2 460.8 424.0 336.0 284.0 211.2 171.2 143.8 124.8 110.5 99.2 90.8 83. 2 71.6 38.3

1148.6 1051.4 962. 2 872.4 720.0 649.0 576.0 53 0.0 420.0 355.0 264.0 214.0 179.8 156.0 138.1 124.0 113.4 104.0 89. 5 47.9

1723.0 1577.0 1443.2 1308.5 1080.0 973.5 864.0 795.0 630.0 532.5 39 6.0 321.0 26 9.7 234.0 207.2 186.0 170.2 156.0 134.3 71.9

2297.3 2102.7 1924.3 1744.7 1440.0 1298.0 1152.0 1060.0 840.0 710.0 528.0 428.0 359.6 312.0 276.3 24 8.0 226.9 208.0 179.0 95.8

745-680-B9-001

Table 9-1, Discharge Specifi cations

19

Page 20

10.0 Appendix B: Choosing the Right Capacity

10.1 Telecom Applications

Discharge Time

+RXU0LQXWH

Discharge Current (A)

Fig. 10-1, Single Cell Discharge Curves (Final Voltage: 1.80 Vpc; 25°C)

10.2 Power Applications

1.1

1.0

0.9

0.8

)

0.7

10

0.6

0.5

0.4

Capacity (C/C

0.3

0.2

0.1

0.0

110

1

2

3

4

Discharge Time (h)

End Voltage

1 1.60

2 1.70

3 1.80

4 1.90

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

5

20

Fig. 10-2, Curves With Stairs Loading Calculation Method (25°C)

745-680-B9-001

Page 21

10.0 Appendix B: Choosing the Right Capacity, continued

0

10.2 Power Applications, continued

1.3

1.2

4

3

1.1

2

End Voltage

1 1.90

1

2 1.80

3 1.70

4 1.60

/C

discharge

= I

Ch

K

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0.1

0.0

0 60 120 180 240 300 360 420 48

Time (min)

Fig. 10-3, Curves with Voltage Control Method (25°C)

745-680-B9-001

21

Page 22

11.0 Forms

Charging Recording Form

Record before charging and two hours after

Model of Battery

Battery Bank No.

Charging Current

Remarks

Cell # Voltage Siemans Conductance Rating Notes

Date

Room Temperature

Total Battery Voltage

NOTE:

Wait two hours after charging before you take fi nal measurements so the electrolyte can cool suffi ciently.

22

745-680-B9-001

Page 23

11.0 Forms, continued

Discharge Recording Form

Model of Battery

Battery No.

Charging Current

Remarks

Cell # Initial

Voltage

Date

Room Temperature

Total Battery Voltage

Cell Voltage at Time Period End

15min 30min 1hr 2hr 3hr 4hr 4:30hr 5 hr

745-680-B9-001

23

Page 24

Alpha Technologies

Power

®

Alpha Technologies

3767 Alpha Way

Bellingham, WA 98226

USA

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Web: www.alpha.com

Alpha Technologies Ltd.

4084 McConnell Court

Burnaby, BC, V5A 3N7

CANADA

Tel: +1 604 430 1476

Fax: +1 604 430 8908

Alpha Technologies

Europe Ltd.

Twyford House

Thorley

Bishop's Stortford

Hertfordshire

CM22 7PA

UNITED KINGDOM

Tel: +44 0 1279 501110

Fax: +44 0 1279 659870

Alpha Technologies GmbH

Hansastrasse 8

D 91126 Schwabach

GERMANY

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec, Ltd

P.O. Box 56468

Limassol, Cyprus

CYPRUS

Tel: +357 25 375675

Fax: +357 25 359595

AlphaTEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1, offi ce 403

109028 Moscow

RUSSIA

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltics

S. Konarskio G. 49

Vilnius 2009

LITHUANIA

Tel: +370 5 2138822

Fax: +370 5 2137799

Alpha Technologies

5 Avenue Victor Hugo

F 92140 Clamart France

FRANCE

Tel: +33 1 41 90 07 07

Fax: +33 1 41 90 93 12

Copyright © 2007 Alpha Technologies, Inc. All rights reserved. Alpha is a registered trademark of Alpha Technologies. 745-680-B9-001 Rev. A.

Due to continuing product improvements, Alpha reserves the right to change specifi cations without notice.

Loading...

Loading...