Page 1

AlphaCell™ GelCell Series

AlphaCellTM GelCell Battery Users Guide

Storage, Maintenance, and Deployment

Effective: April, 2013

Alpha Technologies

Page 2

Alpha Technologies

Power

®

Page 3

AlphaCell

Storage, Maintenance and Deployment

745-680-C0-002, Rev. B1

TM

GelCell Battery Users Guide

Effective Date: April 2013

Copyright© 2013

Alpha Technologies, Inc.

member of The Group

NOTE:

Photographs contained in this manual are for illustrative purposes only. These photographs may not match

your installation.

NOTE:

Operator is cautioned to review the drawings and illustrations contained in this manual before proceeding. If

there are questions regarding the safe operation of this product, please contact Alpha Technologies or your

nearest Alpha representative.

NOTE:

Alpha shall not be held liable for any damage or injury involving its enclosures, power supplies, generators,

batteries, or other hardware if used or operated in any manner or subject to any condition not consistent with

its intended purpose, or is installed or operated in an unapproved manner, or improperly maintained.

TM

Contacting Alpha Technologies: www.alpha.com

or

For general USA sales information and customer service (7 AM to 5 PM, Pacic Time), call

For Sales information and Technical Support in Canada, call

745-680-C0-002, Rev. B1

1 800 863 3930

For complete technical support in the USA, call

7 AM to 5 PM, Pacic Time or 24/7 emergency support

1 800 863 3364

1 800 667 8743

3

Page 4

Table of Contents

Safety Notes ....................................................................................................................................................... 6

Battery Maintenance Guidelines......................................................................................................................... 7

Recycling and Disposal Instructions ................................................................................................................... 7

Storage ............................................................................................................................................................... 8

Electrical Safety .................................................................................................................................................. 8

Chemical and Mechanical Safety ....................................................................................................................... 9

1.0 Introduction .......................................................................................................................................... 10

1.1 Description ..............................................................................................................................11

2.0 Preparing for Maintenance .................................................................................................................. 12

2.1 Required Tools and Equipment .............................................................................................. 12

3.0 Periodic Maintenance Tasks and Schedule ......................................................................................... 13

3.1 Monthly Remote Status Monitoring ........................................................................................ 13

3.2 Quarterly Preventive Maintenance ......................................................................................... 14

3.3 AlphaCellTM Battery Maintenance Log .................................................................................... 16

3.4 Battery Evaluation Procedures ............................................................................................... 18

3.5 Battery Refurbishment Plan .................................................................................................... 19

4.0 Battery System Float Charging ............................................................................................................ 20

4.1 Alpha Power Supply Charging Prole .................................................................................... 21

5.0 Battery Symptoms and Solutions ........................................................................................................ 22

6.0 Battery Parameters by Model Number ................................................................................................ 25

7.0 Warranty and Return Information ........................................................................................................ 27

7.1 AlphaCell

7.2 Battery Maintenance Report for Return Authorizations .......................................................... 29

TM

Limited Warranty.................................................................................................. 27

4

745-680-C0-002, Rev.B1

Page 5

Figures and Tables

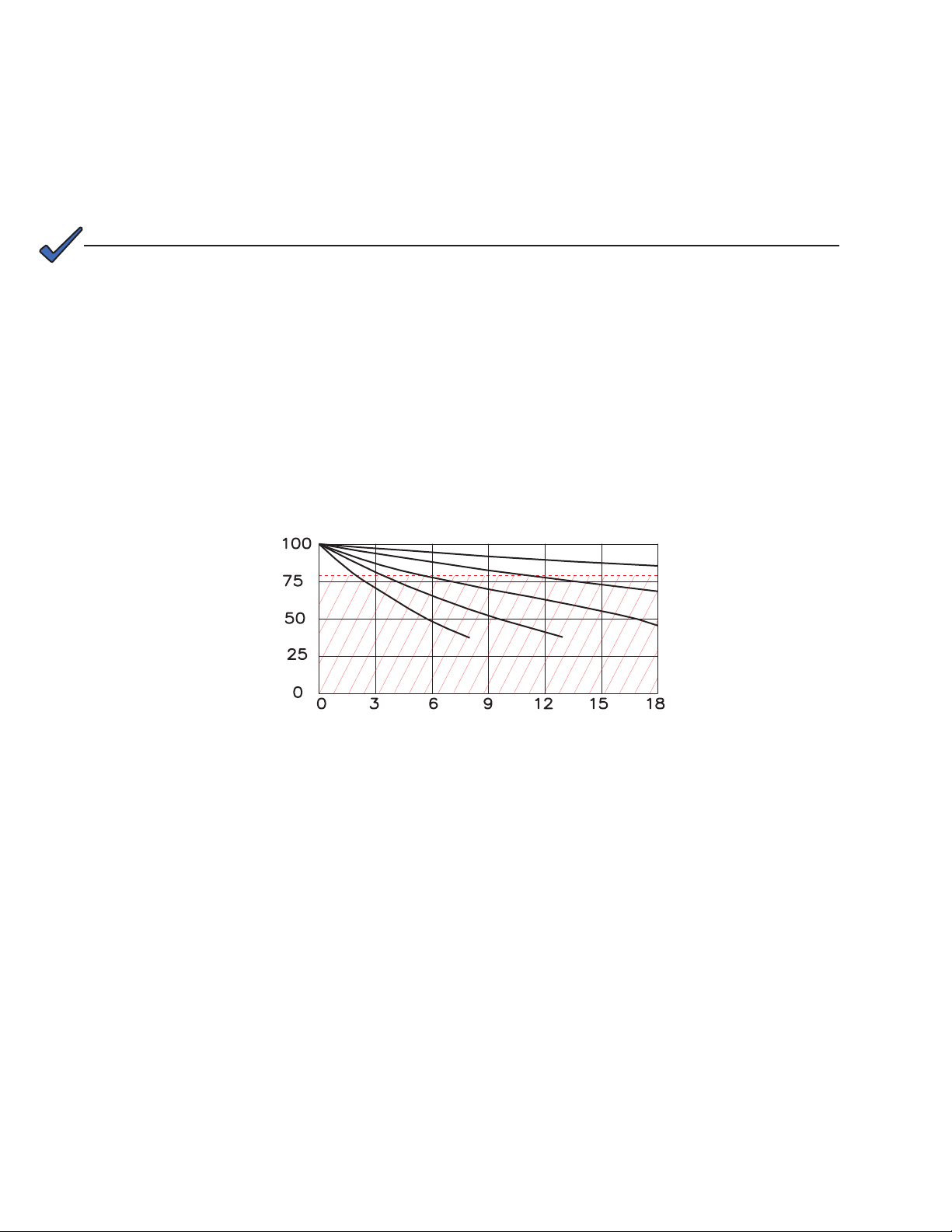

Fig. 1, Capacity vs Storage Time ........................................................................................................... 8

Fig. 2, Series Connected String of Batteries ........................................................................................11

Fig. 3, Parallel String of Batteries .........................................................................................................11

Fig. 4, Flow Chart, Monthly Status Monitoring ..................................................................................... 13

Fig. 5, Flow Chart, Quarterly Preventive Maintenance ........................................................................ 14

Fig. 6 Flow Chart for Battery Refurbishment Plan ............................................................................... 19

Fig. 7, Charger Modes ......................................................................................................................... 21

Table 1, Conductance values, new vs. suspect batteries .................................................................... 18

Table 2, Battery Symptoms and Solutions ........................................................................................... 22

Table 3, Battery Parameters, Current Models (threaded insert terminals) .......................................... 25

Table 4, Battery Parameters, Legacy Models (threaded insert terminals) ........................................... 26

Table 5, Battery Parameters, Legacy Models, (Lead ag insert terminals) ......................................... 26

Table 6, Warranty Periods for AlphaCellTM batteries ............................................................................ 28

745-680-C0-002, Rev. B1

5

Page 6

Safety Notes

Review the drawings and illustrations contained in this manual before proceeding. If there are any questions

regarding the safe installation or operation of the system, contact Alpha Technologies or the nearest Alpha

representative. Save this document for future reference.

To reduce the risk of injury or death, and to ensure the continued safe operation of this product, the following

symbols have been placed throughout this manual. Where these symbols appear, use extra care and

attention.

ATTENTION:

The use of ATTENTION indicates specic regulatory/code requirements that may affect the placement of

equipment and installation procedures.

NOTE:

A NOTE provides additional information to help complete a specic task or procedure.

CAUTION!

The use of CAUTION indicates safety information intended to PREVENT DAMAGE to material or

equipment.

WARNING!

A WARNING presents safety information to PREVENT INJURY OR DEATH to the

technician or user.

6

745-680-C0-002, Rev.B1

Page 7

WARNING!

Lead-acid batteries contain dangerous voltages, currents, and corrosive material. Battery

installation, maintenance, service, and replacement must only be performed by authorized

personnel.

Battery Maintenance Guidelines

• For optimal performance, inspect batteries every 3 months for:

Signs of battery cracking, leaking or swelling. The battery should be replaced immediately

by authorized personnel using a battery of the identical type and rating (match conductance,

voltages, and date codes as specied in this document).

Signs of battery cable damage. Battery cable should be replaced immediately by

authorized personnel using replacement parts specied by vendor.

Loose battery connection hardware. Refer to documentation for the correct torque and

connection hardware for the application.

• Do not attempt to remove the vents (valves) from the AlphaCell GelCell battery or add water. This is a

safety hazard and voids the warranty.

• Apply NO-OX grease on all exposed connections.

• When necessary, clean up any spilled electrolyte in accordance with all federal, state, and local

regulations or codes.

• Follow approved storage instructions.

• Always replace batteries with those of an identical type and rating. Never install untested batteries.

• Do not charge batteries in a sealed container. Each individual battery should have at least 1/2 inch of

space between it and all surrounding surfaces to allow for convection cooling.

• All battery compartments must have adequate ventilation to prevent an accumulation of potentially

dangerous gas. Never place batteries in a sealed enclosure. Extreme caution should be used when

maintaining and collecting data on the battery system.

Recycling and Disposal Instructions

• Spent or damaged batteries are considered environmentally unsafe as they contain lead and dilute

sulfuric acid. They should not be "thrown away" with common refuse.

• Always recycle used batteries in accordance with federal, state, provincial, and local regulations. The

Alpha Group provides recycling services. Call 800 863 3930 or contact your local Alpha representative.

745-680-C0-002, Rev. B1

7

Page 8

Important Storage Practices

All lead acid batteries experience self-discharge while in open circuit storage. This causes circuit

voltage and capacity to decrease (see Fig.1). This is especially true if the batteries are stored for

long periods of time at higher temperatures. Storage of the batteries in the shaded area of Figure

1 is not recommended, as higher temperatures combined with longer periods of storage will result

in diminished residual capacity — hence a shorter battery lifespan.

NOTE:

The product warranty is void if the batteries are not stored and recharged in accordance with these guidelines.

During storage please note:

• The self-discharge rate is related to ambient temperature. The lower the temperature, the less

the discharge. Batteries should be stored in a clean, ventilated, and dry location with an ambient

temperature of 32ºF to 68ºF (0ºC to 20ºC).

• It is important to track open circuit voltage which is related to the density of the electrolyte. If

the open circuit voltage is lower than 12.6V or the batteries have been stored beyond the limits

shown in Figure 1, the batteries should be charged to avoid damage caused by self-discharge.

• All batteries should be fully charged before storage. Record the storage date and next

supplemental charge date in a maintenance record and on the battery.

• Upon battery deployment, verify all batteries within each string measure in the range of

+/- 0.3Vdc of the string average.

Residual Capacity (%)

32ºF (0ºC)

50ºF (10ºC)

1

0

4ºF

(

40

8

6ºF (

3

º

C)

0ºC

68

ºF

(2

0

º

C

)

)

Storage Time (Months)

Fig. 1, Capacity vs. Storage Time

Electrical Safety

• Lethal voltages are present within the power supply and electrical enclosures. Never assume that

an electrical connection or conductor is not energized. Check circuits with a volt meter prior to any

installation or removal procedure.

• Observe circuit polarities.

• Always use the buddy system when working under hazardous conditions.

• Ensure no liquids or wet clothes contact internal components.

• Hazardous electrically live parts inside this unit are energized from batteries even when the AC input

power is disconnected.

• Use an insulated blanket to cover exposed portions of the battery system when performing extended

maintenance that could result in personal or equipment contact with the energized conductors.

• Certain types of rectier circuits used in charging the battery may not include a line isolating transformer.

In these cases extreme caution should be used when maintaining and collecting data on the battery

system.

8

745-680-C0-002, Rev.B1

Page 9

WARNING!

Chemical Hazards

Any gelled or liquid emissions from a valve-regulated lead-acid (VRLA) battery contains dilute sulfuric acid,

which is harmful to the skin and eyes. Emissions are electrolytic and are electrically conductive and corrosive.

To avoid injury:

• Servicing and connection of batteries shall be performed by, or under the direct supervision of, personnel

knowledgeable of batteries and the required safety precautions.

• Always wear eye protection, rubber gloves, and a protective vest when working near batteries. To avoid

battery contact, remove all metallic objects, (such as rings or watches), from your person.

• Batteries produce explosive gases. Keep all open ames and sparks away from batteries.

• Use tools with insulated handles, do not rest any tools on top of batteries.

• Batteries contain or emit chemicals known to the State of California to cause cancer and birth defects

or other reproductive harm. Battery post terminals and related accessories contain lead and lead

compounds. Wash hands after handling (California Proposition 65).

• If any battery emission contacts the skin, wash immediately and thoroughly with water. Follow your

company’s approved chemical exposure procedures.

• Neutralize any spilled battery emission with the special solution contained in an approved spill kit or with

a solution of one pound (454g) bicarbonate of soda to one gallon (3.8l) of water. Report a chemical spill

using your company’s spill reporting structure and seek medical attention if necessary.

• Always replace batteries with those of an identical type and rating (match conductance, voltages, and

date codes as specied in this document).

• Never install old or untested batteries.

• Prior to handling the batteries, touch a grounded metal object to dissipate any static charge that may have

developed on your body.

• Use special caution when connecting or adjusting battery cabling. An improperly or unconnected battery

cable can make contact with an unintended surface that can result in arcing, re, or a possible explosion.

• A battery showing signs of cracking, leaking, or swelling should be replaced immediately by authorized

personnel using a battery of identical type and rating.

Mechanical Safety

• Keep hands and tools clear of fans.

• Fans are thermostatically controlled and will turn on automatically.

• Power supplies can reach extreme temperatures under load.

• Use caution around sheet metal components, especially sharp edges.

• Depending on the model, batteries can weigh anywhere from 25 to 100 pounds (11kg to 45kg). Exercise

care when handling and moving batteries. Use proper handling equipment.

745-680-C0-002, Rev. B1

9

Page 10

1.0 Introduction

The purpose of this guide is to provide the user with the necessary information to maintain batteries in storage

and deploy batteries in Alpha Powering systems, as well as perform battery testing, install replacements and

recycling.

This manual guides you through periodic maintenance checks and troubleshooting of the AlphaCell GelCell

batteries of 50 through 107 ampere hours capacity.

Adherence to the procedures and practices detailed in this guide will not only insure the battery operates per

specications, but also provides the proper backup for the Alpha Powering system in which it is installed.

To achieve these goals, this guide will address the following topics:

• The storage and maintenance of new battery inventory.

• Deployment of AlphaCell batteries into Alpha Power systems.

• Proper preventiative maintenance practices for AlphaCell batteries.

• Replacement and recycling of AlphaCell batteries.

• Warehousing, testing, and redeployment of reuseable AlphaCell assets.

• How to keep proper maintenance records for troubleshooting and/or Warranty claims.

10

745-680-C0-002, Rev.B1

Page 11

1.1 Description

The AlphaCell GelCell battery is a lead acid battery that facilitates an oxygen recombination

cycle. The net result, under normal conditions, is minimal gas emission and water loss from

the electrolyte. The electrolyte is immobilized in either a gel form or is absorbed within an

absorbent separator between the plates. Consequently, there is no requirement to add water

to the cells or to measure the electrolyte specic gravity.

A 12V battery is made up of six 2V cells internally connected to provide 12 volts.

The battery system is a group of 12V batteries connected in a series string to provide a

higher voltage system. In Fig. 2, three of the nominal 12V batteries are connected in series to

provide an 18 cell system with a nominal voltage of 36V.

to power supply: red (+), black (-)

inline fuse

3A 1A2A

Fig. 2, Series String of Batteries

(For illustration purposes, a 36Volt string is shown. 48Volt strings are also available)

You can connect multiple strings of batteries in parallel. This provides a system whose

capacity equals the sum capacity of all the strings. For example, in Fig. 3, two 36V 90Ah

capacity strings are connected in parallel to provide a nominal 36V at 180Ah.

WARNING!

Alpha highly recommends fusing in single and parallel string congurations.

power supply: red (+), black (-)

to

3A

1A2A

745-680-C0-002, Rev. B1

inline fuse

inline

fuse

2B3B

1B

[Front]

Fig. 3, Parallel String of Batteries

upper tray

lower

tray

11

Page 12

2.0 Preparing for Maintenance

The battery system should be remotely monitored monthly and physically inspected quarterly. If the

battery system has an automatic monitoring system to gather the electrical and environmental data,

the monthly checks should consist of evaluating the recorded data and visiting any site that does not

meet the specications listed in the detailed procedures below. At a minimum each site needs to be

physically inspected every three months.

You do not have to measure the electrolyte specic gravity or add water to the cells.

All batteries in the string should be numbered to facilitate recording and analysis of data unique to

each unit.

Notify anyone affected by the intended maintenance or troubleshooting activity. This should include

but not be limited to anyone responsible for the status monitoring equipment at the head-end or NOC.

2.1 Required Tools and Equipment

Prior to beginning maintenance, ensure that all required tools and equipment, including safety

equipment, is available and functional.

The following is a list of the minimum equipment required to maintain and troubleshoot the

AlphaCell GelCell battery:

• Digital voltmeter

• Socket wrenches, insulated

• Box end wrenches, insulated

• Torque wrench calibrated in inch/lbs

• Rubber gloves

• Full face shield

• Safety Glasses

• Plastic apron

• Portable eyewash

• Spill kit, including sodium bicarbonate solution

• Fire extinguisher

• Optional equipment, depending on the type of maintenance being performed,

includes:

• True RMS Volt Meter with DC Amp Clamp

• Midtronics Conductance Meter

• 100 amp momentary load test set

• System load bank (DC if to be performed at the battery and AC if to be performed

by loading a power supply output— contact your Alpha Sales Representative for

purchasing information).

• NO-OX Corrosion Inhibitor

• Paper Towels and/or rags

12

745-680-C0-002, Rev.B1

Page 13

3.0 Periodic Maintenance Tasks and Schedule

The following tasks are to be performed on a monthly and quarterly schedule.

The following maintenance procedure requires a fully functional status monitoring system capable of

remotely measuring and recording the following data on a periodic basis:

• Battery Temperature

• Individual Battery Voltage

• Total Battery String Voltage

Please note: If status monitoring is not available these checks need to be made during the quarterly

onsite visit and any batteries not meeting the minimum requirement must be addressed at such time.

3.1 Monthly Remote Status Monitoring

Review Status

Monitoring Data

Battery Voltage

>0.5V Above/Below

String Average

Yes

No No

RTS

Temperature >10C

above Ambient

Yes

Perform

Quarterly PM

Monitor as per PM

Program

Fig. 4, Flow Chart for Monthly Remote Status Monitoring

Procedure

1. If any individual battery voltage varies more than 0.5V above or below the average for the

string then a site visit is required.

Example V1 = 13V, V2 = 13V, V3=14V

Average voltage = 13.3V

If V3 greater than average by 0.5V, then a site visit is required

2. If the RTS temperature is greater than 10 degrees C above the current regional ambient

temperature then a site visit is required.

3. Prioritize site visits based on highest RTS temperatures and battery voltages

4. Visit the site within 30 days and remedy the problem by replacing the bad battery or

batteries and reset quarterly maintenance.

745-680-C0-002, Rev. B1

13

Page 14

3.2 Quarterly Preventive Maintenance

Yes

No

Yes

Yes

No

Replace the individual failed battery with

a battery that is within +/- .3 Volts of the string average.

Battery String

Float Current

>0.5A

Log each battery’s

conductance and

voltage

Disconnect

Batteries

Record Information

on Site Visit Record

Monitor as per PM

Program

Site Visit

Battery

Refurbishment

Plan

Return battery to

warehouse

Remote Status

Monitoring

Procedure

Ensure Power

Supply is in Float

Mode

Battery

> 0.5V

from the average

string voltage

No

Does the individual battery pass

the Evaluation Procedure #1

outlined in Section 3.4?

(see page 18)

Replace the string

Required Equipment

• True RMS Volt Meter with DC Amp Clamp

• Midtronics Conductance Battery Tester

14

Fig. 5, Flow Chart for Quarterly Preventive Maintenance

745-680-C0-002, Rev.B1

Page 15

3.2 Quarterly Preventive Maintenance, continued

Procedure

1. Verify the power supply is in Float mode.

2. Use the DC Amp clamp to measure and record each individual battery string’s oat current.

3. If the individual string oat current is greater than 0.5 amps, replace the battery string. Measure

and record the individual battery conductance and voltage on the Site Visit Record.

4. If the string oat current is less than 0.5 amps,

4.1 Disconnect the batteries from the system

4.2 Measure the battery conductance. If any reading is below the suspect level, refer to Table 1,

page 18, for mhos values for battery models.

4.3 Measure the battery voltage. If any reading is less than 12.6V then replace all those batteries

in the string.

4.4 If any individual battery voltage varies more than 0.5V above or below the average for the

string then replace the string.

Example: V1 = 13V, V2 = 13V, V3=14V

Average voltage = 13.3V

If V3 is greater than average by 0.5V, then the batteries should be replaced.

Batteries removed from the site should then be tested per Section 3.5,

"Battery Refurbishment Plan".

4.5 Log the site location, battery location, model, manufacturer date codes, voltage and

conductance readings for all batteries.

5. Record data on Battery Maintenance log.

6. Verify the spacing between the batteries from front to back is at least 1/2" or 13mm, and adjacent

batteries do not touch one another.

7. Ensure the enclosure is clean and free of debris.

8. Measure and record the top center battery's temperature. This is typically the warmest battery in

the string.

9.Visually inspect the batteries for:

Cleanliness

Terminal damage or evidence of heating or overheating

Container or cover damage

10. Check terminal posts for signs of corrosion. If corrosion is present, neutralize with a solution of

1 lb (454g) sodium bicarbonate (baking soda) to 1 gallon (3.8l) of water. Rinse and dry.

11. Verify terminal posts are coated with NO-OX grease or a spray-on protectant. Reapply as

needed.

12. Retorque all the interunit connecting hardware to the values noted in Table 3 on page 25.

745-680-C0-002, Rev. B1

15

Page 16

3.3 AlphaCell

Node / Location

Power Supply Type

Load (kW)

TM

Battery Maintenance Log

Follow this sample when lling out the maintenance log (following page).

Evaluation Procedure #1Evaluation Procedure #2Evaluation Procedure

Vdc

Conductance

Float

No

Battery

String

A 1 195GXL 4/08 3/08 .2 70° 13.4 1100

A 2 195GXL 4/08 3/08 .2 70° 13.5 1080

A 3 195GXL 4/08 3/08 .2 70° 13.4 1120

B 1 195GXL 4/08 3/08 .1 70° 13.4 1090

B 2 195GXL 4/08 3/08 .1 70° 13.4 1105

B 3 195GXL 4/08 3/08 .1 70° 13.6 1060

A 1 195GXL 4/08 3/08 7/8 .1 85° 13.3 1120

A 2 195GXL 3/08 7/8 .1 85° 13.3 1100

A 3 195GXL 3/08 7/8 .1 85° 13.4 1105

B 1 195GXL 3/08 7/8 .1 85° 13.2. 1070

B 2 195GXL 3/08 7/8 .1 85° 13.2 1100

B 3 195GXL 3/08 7/8 .1 85° 13.2 1080

Initial Install Date

Battery Type

Mfr. Date Code

PM Date

Float Current

Battery Temp

Load

mhos @

77°F

Vdc 24

Hour

OCV

Conductance

mhos @

77°F/25°C

Vdc @

100A after

10 seconds

#3

Vdc 24

Hour

OCV

16

745-680-C0-002, Rev.B1

Page 17

3.3 AlphaCell

Node / Location

Power Supply Type

Load (kW)

TM

Battery Maintenance Log

String

Battery

Initial Install Date

Battery Type

Mfr. Date Code

PM Date

Float Current

Battery Temp

Evaluation Proce-

dure #1

Vdc

Conductance

Float

No

Load

mhos @

77°F

Evaluation Procedure #2Evaluation Procedure

Vdc 24

Conductance

Hour

OCV

mhos @

77°F/25°C

Vdc @

100A after

10 seconds

#3

Vdc

24

Hour

OCV

745-680-C0-002, Rev. B1

17

Page 18

3.4 Battery Evaluation procedures for AlphaCell™ GXL,

GXL-HP and Gold-HP batteries

To help identify batteries approaching end of life in an operating power system, test #1 should be performed at each

maintenance interval. For batteries not installed in an operating power system, test #2 or #3 may be performed. For

accuracy, tests must be performed on fully charged batteries.

A battery failing any of the following combined tests is dened as a faulty battery. The battery will be replaced under the

terms of the warranty if within the dened warranty period.

Evaluation Procedure 1

Conductance/Impedance Test – Measure the conductance of each battery. Any battery that possesses a conductance

that is 50% less than the initial reading taken at the point of install can be considered suspect of being below 70%

capacity and should be evaluated further. The battery temperature must be approximately the same each time this reading

is taken (see Table 1 below). Use temperature compensation feature when using Midtronics meter.

AND

Float Voltage Test – Measure the oat voltage of each battery in the string that is on oat charge. Any battery in the string

measured at 13.2 volts or less is a suspect battery and should be further evaluated with the steps below. Any battery

below 12.6 volts should be replaced. The 13.2 & 12.6 voltage values are based on a 77˚F (25˚C) temperature. Adjust the

voltage for higher or lower temperatures by 0.0168 Volts per battery per degree Fahrenheit. The higher the temperature

above 77˚ F (25˚C) the lower the voltage will have to be adjusted and vice-versa for temperature below 77˚F (25˚C). (i.e.:

at a temp of 89˚F (32˚C) would have a corresponding oat voltage of 13.0 volts).

Evaluation Procedure 2

Conductance/Impedance Test – Measure the conductance of each battery. Any battery that possesses a conductance

that is 50% less than the initial reading taken at the point of install can be considered suspect of being below 70%

capacity and should be evaluated further. The battery temperature must be approximately the same each time this reading

is taken. Consult table 1 below for guidance. Use temperature compensation feature when using Midtronics meter.

AND

24 Hour Open Circuit Test – Measure the open circuit voltage of the suspected battery 24 hours after the battery has

come off of oat charge. Care must be taken to ensure that the battery is at full state of charge when it is disconnected

from the power supply. The battery should exhibit a voltage about 12.60V. A battery below this voltage should be replaced.

A fully charged battery below 12.6 volts is below 70% capacity, but a battery above 12.6 volts is not necessarily above

70% in capacity. Batteries that have been sitting for extended periods should be recharged after 6 months or when they

reach 12.48 volts (75% capacity), which ever comes rst depending on the storage temperature.

Evaluation Procedure 3

24 Hour Open Circuit Test – Measure the open circuit voltage of the suspected battery 24 hours after the battery has

come off of oat charge. Care must be taken to ensure that the battery is at full state of charge when it is disconnected

from the power supply. The battery should exhibit a voltage about 12.60 volts. A battery below this voltage should be

replaced. A fully charged battery below 12.6 volts is below 70% capacity, but a battery above 12.6 volts is not necessarily

above 80% in capacity. Batteries that have been sitting for extended periods should be recharged after 6 months or when

they reach 12.48 volts (75% capacity), which ever comes rst depending on the storage temperature.

AND

100A Load Test – Measure the voltage of each battery at the end of a 10 second 100-amp load test. Again, the

temperature must be equivalent to that of the original test performed at the point of installation. A signicant drop in

voltage versus the previous test will indicate deterioration of the battery. A 12-volt battery that falls below 10.80 volts

should be considered faulty and should be replaced.

NOTE:

To maintain consistent test results, ensure the same Midtronics conductance tester is used for each test cycle.

Midtronics Conductance

Models 3200/micro CELLTRON

Approximate Conductance Values (mhos)

Healthy Battery @ 77°F (25°C)

Suspect Battery @ 77°F (25°C) in mhos <520 <240 <450 <520 <400 <440 <400 <480 <440 <480

18

170XLT 85 GXL-HP 135 GXL 160 AGM 165 GXL 195 GXL 195 GXL 220 GXL 195 GOLD-HP 220 GOLD-HP

1040-1560 480-720 900-1350 1040-1560 800-1200 880-1320 800-1200 960-1400 880-1320 960-1400

Table 1, Conductance values, healthy vs. suspect batteries

745-680-C0-002, Rev.B1

Page 19

3.5 Battery Refurbishment Plan

Battery

Refurbishment

Plan

Batteries Returned

from Site. Measure

and document 24

hour Open Circuit

Voltage (OCV).

(

Must occur within 24

hours of removal from

charger)

Does battery meet

No

Measure

Conductance

Yes

the minimum

conductance values

per Table 1?

Measure

Battery

Voltage

No Yes

Sort Batteries per

Conductance &

Properly recycle

batteries per EPA

requirements

Group re-deployable

batteries as indicated for

future deployment as

Batteries stored in

warehouses for

extended periods of

time refer to “Important

Storage Practices” on

Measure

Battery

Voltage

Voltage

Does battery meet

the minimum of

12.6 Volts for the 24

hour OCV?

Group 1 – Voltage 12.6 to 12.9 and conductance 600 to 900 mhos.

Group 2 – Voltage 12.6 to 12.9 and conductance 900 to 1200 mhos.

Group 3 – Voltage 12.9 to 13.2+ and conductance 600 to 900 mhos.

Group 4 – Voltage 12.9 to 13.2+ and conductance 900 to 1200 mhos.

Manufacture date codes should be within

strings

page 8.

18 months for batteries in string

Fig. 6, Flow Chart for Battery Refurbishment Plan

745-680-C0-002, Rev. B1

19

Page 20

4.0 Battery System Float Charging

Battery System Float Charging Voltage

Encountering temperature extremes

When you encounter temperature extremes, temperature compensate the oat

charging voltage. The temperature compensation coefcient is -0.0028 V/C per °F

(-0.005 V/C per °C).

For example if the normal battery temperature is 90°F (13° above 77°F) you should

reduce the average oat charging voltage range by 0.036 V/C (13° x -0.0028 V/C per

°F) to between 2.21 and 2.26 V/C. For an 18 cell battery this is 39.78 to 40.86 VDC.

This helps reduce the potential for thermal runaway at elevated temperatures.

If the battery operates at cold temperatures, (60°F, 17° below 77°F, for example), you

can increase the charging voltage to improve recharging time.

For example, increase the charging voltage range by -17° x -0.0028 V/C per degree

or 0.048 V/C. For the 180 cell string this is 41.36 to 42.26 Vdc.

Under or overcharging

If the battery is undercharged for a period of time during which there are multiple

discharges, the battery does not fully recharge after each discharge and provides

progressively lower capacity.

Excessive overcharging causes premature aging of the battery and loss of capacity,

noted by excessive oat current, corrosion of the plate grids, and gassing and drying

of the limited amount of electrolyte.

Severe overcharging over extended periods of time can induce a thermal runaway

condition. This requires replacing the battery system.

NOTE:

The following set points are recommended for AlphaCell Batteries when used with the XM

Series 2 or GMX Power Supply.

AlphaCellTM GelCell Batteries

Bulk / Float 2.27 V/C

Accept 2.40 V/C

Temp Comp -5mV/C/C

AlphaCellTM 195GXL FT

Bulk / Float 2.26 V/C

Accept 2.35 V/C

Temp Comp -4mV/C/C

20

AlphaCellTM IGL Series

Bulk / Float 2.25 V/C

Accept 2.32 V/C

Temp Comp -3mV/C/C

745-680-C0-002, Rev.B1

Page 21

4.0 Battery System Float Charging, continued

NOTE:

The following information specically pertains to Alpha XM Series 2 Power Supplies.

4.1 AlphaPowerSupplyChargingProle

BULK charge is a “Constant Current” charge. This current is the maximum the charger

is capable of delivering: 10A for 615, 906/915/915HV, and 922/922HV. As the charge is

returned to the batteries, their voltage increases to a specic threshold (2.27VDC per cell).

The BULK charger mode generally returns the battery charge state to 80 percent of rated

battery capacity. Bulk mode is not temperature compensated. The charger then automatically

switches to ACCEPT mode.

ACCEPT charge is a “Constant Voltage” charge. This voltage, 2.40VDC per cell (14.40VDC),

is manually adjustable if needed and temperature-compensated to ensure longer battery life

and proper completion of the charge cycle.

This cycle is complete when the charging current into the batteries becomes less than 0.5A,

or approximately six hours elapses from the time ACCEPT mode was entered. When the

batteries are fully recharged the charger switches to the FLOAT mode of operation.

FLOAT charge is a temperature-compensated charge, averaging about 2.27VDC (adjustable)

per cell. During FLOAT mode, the batteries are fully charged and ready to provide backup

power.

During ACCEPT and FLOAT modes, the cell voltage is temperature-compensated at -

0.005VDC per cell per degree C (adjustable) to ensure a safe battery cell voltage and to

maximize battery life.

For AlphaCell GelCell batteries, the recommended battery system oat charge voltage is

equal to the number of cells in the system multipled by the range of 2.25 to 2.30 volts per cell

at 77°F(25°C).

For example, oat charge a string of 3 each 12 volt (6 cell) batteries within a range of 40.5 to

41.4 VDC (18 cells x 2.25 V/C minimum and 18 x 2.30 V/C maximum) at 77°F(25°C).

Severe overcharging over extended periods of time can induce a thermal runaway condition.

This requires replacing the battery system.

745-680-C0-002, Rev. B1

Fig. 7, Charger Modes (dashed line indicates HV models)

21

Page 22

5.0 Battery Symptoms and Solutions

Problem with Symptom Possible Causes Possible Result Corrective Actions

Reduced operat-

Capacity Test

Results

Visual Battery

Checks

ing time at 77°F

(25°C) with

smooth voltage

decline

Reduced operating time at 77°F

(25°C) with steep

voltage decline or

voltage plateaus

Excessive initial

voltage drop even

to the point of

dropping load in

the rst several

seconds

Cover or container

crack

Cover or container

explosion

Burned area on

container

Permanently

deformed

(swollen) container

Rotten egg odor

Melted grease at

terminals

Corrosion at

terminals

Normal life cycle

Individual low capacity cells

• Battery is extremely cold

• Cabling is too small

gauge

• High resistance

connections

• Battery is undersized

• Shorted cells

Handling or impact damage

Ignition of cell internal gasses

due to external source,

fusing, or internal conductive

path or internal spark due

to shorting. Potential exists

for ill-maintained batteries or

those left in service beyond

useful life.

Crack in container wicking

electrolyte to grounded rack.

Ground fault

Thermal runaway possible

caused by high temp.,

environment, overcharging,

excessively high recharge

current, shorted cells, ground

fault, or a combination

Possible caused by high

temperatuare environment,

overcharging, excessively

high recharge current, shorted

cells, ground fault, or a

combination of these.

Hot connections due to

excessive resistance caused

by loose connections, dirty

contact surfaces or corrosion

within connection

Possibly electrolyte leaking

from battery terminal seal

attacking the interunit

container

Eventual failure to support the

load followed by potential for

shorted cells

Reversed cells during discharge

Reversed cells will become very

hot and will not fully recharge

• Excessive voltage drop

• Cells will become hot, could

develop thermal runaway;

internal arcing could result in

an explosion

Cell dryout or ground fault.

Potential internal gas ignition

• Personal injury and equip-

ment damage at time of

explosion.

• Failure to support load.

Could result in

• personal hazard due to

conductive path to rack

• smoke or battery re

• thermal runaway

Could result in the emission of

hydrogen sulde, detectable as a

rotten egg odor, battery re, and

inability to support the load

Odor is a product of thermal

runaway

• Excessive voltage drop

perhaps leading to short

operating time or damaged

terminals

• In extreme case could lead

to melted terminal and

ignition of the battery cover

Increased connection resistance

and resulting increase in the

connection heating and voltage

drop at high rate discharge.

Replace battery system

when at 70% of rated

capacity or before

Replace the isolated low

capacity batteries

• Heat the battery

• Run parallel cables

or increase gauge of

cables

• Clean and reassemble

connections

• Add required parallel

strings

• Replace isolated

units with shorts and

evaluate entire string

Replace damaged unit.

Replace damaged unit and

evaluate balance of string.

Clear the ground fault and

replace defective unit. Evaluate balance of string.

Replace the battery system

and correct the items leading

to the theramal runaway

condition

Replace the battery system

and correct items leading to

thermal runaway condition

• Clean and reassemble

connection if damaged

• Replace batteries with

damaged terminals

Disassemble connection,

clean, coat connecting

surfaces and terminal area,

seal with anti-oxidation

grease, reassemble the

connection. If leakage about

terminal area is obvious, the

battery should be replaced.

22

Table 2, Battery Symptoms and Solutions

745-680-C0-002, Rev.B1

Page 23

5.0 Battery Symptoms and Solutions, continued

Problem with Symptom Possible Causes Possible Result Corrective Actions

Overcharging causes

excessive gassing and

drying out of electrolyte

and contributes to potential

thermal runaway.

Undercharging results in

gradual loss of operating

time and capacity with

successive discharge cycles.

If persistant, an irreversible

level of lead sulfate develops

on the plates resulting in a

permanent capacity loss

Reduced operating time

under load. Increased oat

current. Heating of cell during

discharge. Contributes to

potential thermal runaway.

Failure to support load. Could

result in an internal arc, could

ignite gasses within the cell.

• Personnel shock hazard

resulting in serious

injury or electrocution.

• Potential burning of

container at damaged

area or battery re.

Reduced battery life

• Reduced battery life

• Reduced life and

potential thermal

runaway

• Normal if not exceeding

18°F increase

Normal if not exceeding

18F/10C increase over

ambient

Reset the charger output

voltage to recommended

value.

• Reset the charger

output voltage to

recommended value.

• Equalize battery system

from 48 to 72 hours

and perform capacity

test. If capacity loss is

permanent, replace the

total battery system.

Replace individual battery.

Replace individual battery.

Determine the source of

ground fault and replace

battery.

Cool room or accept reduced

battery life

• Improve room air

conditioning

• Improve cabinet

ventilation

• Limit recharge current

• Limit recharge current

• Reduce within

specications

• Replace shorted cells

and evaluate total string.

DC Voltage

Checks

Temperature

Checks

System oat voltage >

2.3V/C average 77°F

(25°C)

System oat voltage <

2.25V/C average 77°F

(25°C)

Individual battery oat

voltage > 13.3 VDC

Individual battery oat

voltage 14.5 VDC for

6 cell

DC voltage measured

between battery system

output terminals and

ground (rack) or a

ground fault indicated

by automatic monitoring

equipment.

Elevated room temperature

Elevated battery temp.

High current recharge

Charger output set

incorrectly

Charger output set

incorrectly

• Potentially the

individual battery has

shorted cell

• Verify with impedance

or conductance check

Potentially open cells in

individual battery. Conrm

by checking for zero oat

current or check for very

high impedance of the

battery.

Damaged container allowing electrolyte to wick out

to grounded surface (rack).

Lack of adequate air conditioning or ventilation

• Elevated room temp.

• Inadequate cabinet

ventilation

• Discharge - charge

cycle

• High charging voltage

• Shorted cells

745-680-C0-002, Rev. B1

Table 2, Battery Symptoms and Solutions, continued

23

Page 24

5.0 Battery Symptoms and Solutions, continued

Type Symptom Possible Causes Possible Result Corrective Action

• Failure to support load. If an

internal arc occurs during

discharge, can ignite gasses

internal to cell.

• If there is an open/loose

connection in external conductive path, can damage

termination under load.

• Not at 100% capacity

• Conducive to thermal

runaway

• Thermal runaway results in

eventual meltdown of battery

and potential of hydrogen

sulde emissions and re.

Perhaps reduced operating time. Fully recharge battery.

• Reduced operating time.

• Conducive to thermal

runaway

• Will not support load

• Reduced operating time

• Conducive to thermal

runaway

• Will not support load

• Loose connections result

in heat damaged or melted

terminals during high rate

discharge.

• Excessive voltage drop

during high rate discharge

and resulting reduced

operating time

Loose connections result in heat

damaged or melted terminals

during high rate discharge

Excessive AC ripple could cause

the battery to cycle at the ripple

frequency and result in heating

and deterioration of the plate active material

• Reduced operating time.

• Potential conditions could

be conducive to thermal

runaway.

Replace battery with

open cell or repair

open/loose external

connection.

Determine specic

cause; take corrective

action.

Charge, retest battery

or replace as required.

Charge and retest

battery or replace as

required.

• Retorque

connection as

required

• Correct source

of contamination,

clean contact

surface areas,

grease contact

surfaces with antioxidant grease,

reassemble.

Retorque the

connection as required

Improve the charger

output ltering.

Verify battery condition.

Replace as required.

Float Charging

Current

Checks

High Rate 10

Second Load

Test

Battery

Impedance/

Conductance

Test

Connection

Hardware

Resistance

/ Tightness

Check

AC Ripple

Voltage

Checks

Float current to

string is zero

Float current

exceeds 3.0

milliamperes per

ampere hour of

rated capacity at

77°F(25°C) at oat

voltage.

Terminal voltage

marginally below

minimum voltage

specied for 10

second point.

Terminal voltage

signicantly below

minimum voltage

specied for 10

second point.

Impedance /

resistance increase

by 50% from

original values

or conductance

decline to 50% of

the value when new.

Connection

resistance increase

20% or more from

original value.

Connection

hardware tightness

is less than the

specied "retorque"

value.

AC ripple (p-p)

voltage on system

<4% of the value of

the DC oat voltage

Individual battery in

string exhibits AC

ripple voltage twice

that of other typical

batteries in string.

A battery or connection in series

string is open. Verify via the oat

voltage check or AC ripple voltage

or impedance check of individual

batteries.

• Batteries not fully recharged.

• Batteries above 77°F(25°C)

• Potentially shorted cells in

battery

• Depending on degree, bat-

tery entering or in thermal

runaway

Battery perhaps not fully charged

or is older, in service battery and

has somewhat lower capacity.

• Battery discharged of

battery conductive path,

plate grid, or active material

or electrolyte volume

deterioration.

• Shorted.

• Open cells.

• Battery discharged or battery

conductive path, plate grid or

active material, or electrolyte

volume deterioration.

• Shorted cells

• Open cells

• Repetitive cycles results

in heating and cooling of

connection, resulting in

relaxation of torque, increase

in connection resistance.

• Contamination within

the connection results in

corrosion and high terminal

resistance.

Repetitive cycles results in heating and cooling of connection resulting in relaxation of torque and

increase in connection resistance.

Poor ltering of charger output.

Battery with high AC ripple

voltage has proportionately

higher impedance. Evaluate

for performance. Subject

battery could have deteriorating

conductive path or dry, shorted or

open cell.

24

Table 2, Battery Symptoms and Solutions, continued

745-680-C0-002, Rev.B1

Page 25

6.0 Battery Parameters by Model Number

Parameter

Terminal Type

Bolt Size 1/4"-20 UNC Bolt 1/4"-20 UNC Bolt 1/4"-20 UNC Bolt 1/4"-20 UNC Bolt

Annual Retorque Inch-Lb / N•m 110In-lb / 12.4N•m 110In-lb / 12.4N•m 110In-lb / 12.4N•m 110In-lb / 12.4N•m

Open Circuit Voltage 12.84 12.84 12.84 12.84

Average Float Voltage Range (volts/unit)

20-Hour Ampere Rate to 1.75 V/C 5.45 5.45 5.00 5.00

Typical Impedance @ 60Hz ohms 0.0050 0.0050 0.0050 0.0050

Typical Conductance 7Hz mohms 960 to 1400 960 to 1400 880 to 1320 880 to 1320

Typical 10 Sec. Voltage @ 100 amp 11.4 11.4 11.3 11.3

Parameter

Terminal Type 16mm Insert Threaded Insert Threaded Insert Threaded Insert

Bolt Size M6 thread 1/4"-20 UNC Bolt 1/4"-20 UNC Bolt 10-32 UNC Bolt

Annual Retorque Inch-Pounds / N•m 110In-lb / 12.4N•m 110In-lb / 12.4N•m 110In-lb / 12.4N•m 25In-lb / 2.8N•m

Open Circuit Voltage 12.84 12.84 12.84 12.84

Average Float Voltage Range (volts/unit)

20-Hour Ampere Rate to 1.75 V/C 5.50 4.30 3.75 2.50

Typical Impedance @ 60Hz ohms 0.0050 0.0055 0.0055 0.0040

Typical Conductance 7Hz mohms 800 to 1200 800 to 1200 900 to 1350 480 to 720

Typical 10 Sec. Voltage @ 100 amp 10.8 11.2 11.2 11.6

220 GOLD-HP 220GXL 195 GOLD-HP 195GXL

Threaded Insert Threaded Insert Threaded Insert Threaded Insert

13.5 to 13.8 13.5 to 13.8 13.5 to 13.8 13.5 to 13.8

195GXL FT 165GXL 135AGM-P 85GXL-HP

13.5 to 13.8 13.5 to 13.8 13.5 to 13.8 13.5 to 13.8

Model Number

Model Number

Table 3, Battery Parameters, Current Models (threaded insert terminals)

745-680-C0-002, Rev. B1

25

Page 26

6.0 Battery Parameters by Model Number, continued

Parameter

Terminal Type Threaded Insert Threaded Insert Threaded Insert Threaded Insert

Bolt Size 1/4"-20 UNC Bolt 1/4"-20 UNC Bolt 1/4"-20 UNC Bolt 1/4"-20 UNC Bolt

Annual Retorque Inch-Pounds / N•m

Open Circuit Voltage 12.84 12.84 12.84 12.84

Average Float Voltage Range (volts/unit)

20-Hour Ampere Rate to 1.75 V/C 5.35 5.30 4.75 4.68

Typical Impedance @ 60Hz ohms 0.0050 0.0050 0.0050 0.0050

Typical Conductance 7Hz mohms 960 to 1400 960 to 1400 880 to 1320 880 to 1320

Typical 10 Sec. Voltage @ 100 amp 11.4 11.4 11.3 11.3

215 GOLD HP 210GXL 190 GOLD HP 180GXL

110In-lb / 12.4N•m 110In-lb / 12.4N•m 110In-lb / 12.4N•m

13.5 to 13.8 13.5 to 13.8 13.5 to 13.8 13.5 to 13.8

Model Number

110In-lb / 12.4N•m

Table 4, Battery Parameters, Legacy Models (threaded insert terminals)

Parameter

Terminal Type Lead Flag Lead Flag Lead Flag Lead Flag

Bolt Size 1/4"-20 1/4"-20 1/4"-20 1/4"-20

Annual Retorque Inch-Pounds / N•m 65 in-lb / 7.3N•m 65 in-lb / 7.3N•m 65 in-lb / 7.3N•m 65 in-lb / 7.3N•m

Open Circuit Voltage 12.84 12.84 12.84 12.84

Average Float Voltage Range (volts/unit)

20-Hour Ampere Rate to 1.75 V/C 5.30 4.68 4.30 4.40

Typical Impedance @ 60Hz ohms 0.0050 0.0050 0.0055 0.0040

Typical Conductance 7Hz mohms 960 to 1400 880 to 1320 800 to 1200 1040 to 1560

Typical 10 Sec. Voltage @ 100 amp 11.4 11.3 11.2 11.6

210GXL-HP/GXL 180GXL-HP/GXL 165GXL 160A

13.5 to 13.8 13.5 to 13.8 13.5 to 13.8 13.5 to 13.8

Model Number

26

Table 5, Battery Parameters, Legacy Models, (Lead ag insert terminals)

745-680-C0-002, Rev.B1

Page 27

7.0 Warranty and Return Information

7.1 AlphaCell™ Limited Warranty

Float Service Outdoor VRLA Batteries

This limited warranty applies only to the original purchaser (“User”) of the Product supplied under the Supply Agreement.

A Battery will be considered defective, and can be replaced, when it fails to deliver 70% of its rated capacity during stated

warranty period provided that it has been used in accordance with the conditions listed below. Standard Warranty periods

are outlined in Table 6.

When a defective battery is identied the User should promptly notify manufacturer. Should manufacturer conrm the

Batteries to be defective they will replace the material found to be defective F.O.B. its Factory without charge except for

freight.

CONDITIONS AND LIMITATIONS: (all claims are subject)

1) Warranty date is based on Ship Date code stamped on battery.

2) Warranty applies in accordance with Table 6 of this section.

3) The standard warranty shown in Table 6 applies to AlphaCell Batteries used in Alpha enclosures in

conjunction with Alpha Power Supplies.

4) A baseline Two Year Warranty applies to AlphaCell Batteries used in other applications not dened in item #3

shown above. AlphaCell batteries are not recommended for solar applications so please consult Alpha Applications

Engineering for an alternative battery solution for solar applications. Extended warranties beyond two years may

be available for unique enclosure/charger applications based on preapproval by Alpha Engineering. Consult your

salesperson for details.

5) Each Battery must be of proper size, design and capacity for its application in order for the warranty to apply.

6) Each Battery must be charged, discharged, stored and serviced in accordance with the AlphaCell owners manual

and user's guide.

7) Warranty is void if Battery is subject to misuse, abuse or physical damage or if Battery becomes unserviceable due

to re, wreckage, freezing, or any act of God.

8) Battery must be used with a temperature compensation charger having characteristic charging curves (voltage and

current) acceptable with standard manufacturer’s charging practices as outlined in the AlphaCell owners manual

and user's guide.

9) User agrees that manufacturer’s representative shall have access to equipment furnished hereunder for purpose of

inspection at reasonable hours and intervals in order for the warranty to apply.

10) All defective and replacement Batteries, if returned, become property of manufacturer.

11) Field Batteries replaced through limited warranty terms and conditions will receive the balance of original warranty.

TM

12) Standard AlphaCell

outlined in the AlphaCell owners manual and user's guide.

Warranty requires a minimum semiannual preventive maintenance schedule with records as

CLAIMS:

1) Contact original point of purchase for instructions on applicable warranty claim procedures.

2) Upon satisfactory proof of claim as determined by manufacturer, manufacturer shall repair or replace, at its option,

any defective Battery based upon the purchase price, exclusive of freight and labor.

3) Manufacturer does not accept any product for return, credit or exchange unless expressly authorized by

manufacturer in writing and returned prepaid to its plant.

ALPHA SHALL NOT BE LIABLE FOR, AND USER SHALL INDEMNIFY AND SAVE ALPHA HARMLESS FROM ANY CLAIMS

AND LIABILITIES ARISING OUT OF THE USE, MAINTENANCE, TRANSPORTATION, OR INSTALLATION OF ANY EQUIPMENT

WARRANTED HEREUNDER. THE FOREGOING LIMITED WARRANTY IS IN LIEU OF ALL WARRANTIES EXPRESSED OR

IMPLIED, INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THE SOLE

LIABILITY OF IS SET FORTH UNDER THE CLAIMS PARAGRAPH ABOVE. SHALL NOT HAVE ANY LIABILITY FOR ANY SPECIAL

INCIDENTAL INDIRECT OR CONSEQUENTIAL DAMAGES. THIS LIMITED WARRANTY APPLIES ONLY TO THE ORIGINAL

PURCHASER (USER) OF THE EQUIPMENT, AND IS NON-TRANSFERABLE.

745-680-C0-002, Rev. B1

27

Page 28

7.1 AlphaCell™ Standard Limited Warranty, continued

The table below indicates the warranty periods for AlphaCellTM Batteries used with Alpha approved power supplies and enclosures.

Battery Model Description Mfg Date Warranty Warranty Warranty

US/Canada International

220GOLD -HP Threaded Insert Gel Silver Alloy Post June 2009 6 Years 2 Years 5 Years

220GXL Threaded Insert Gel Silver Alloy Post June 2009 4 or 5 Years 2 Years 5 Years

195GOLD-HP Threaded Insert Gel Silver Alloy Post July 2009 6 Years 2 Years 5 Years

195GXL Threaded Insert Gel Silver Alloy Post July 2009 4 or 5 Years 2 Years 5 Years

165GXL Threaded Insert Gel Silver Alloy Post Jan 2007 4 or 5 Years 2 Years 5 Years

215GOLD-HP Threaded Insert Gel Silver Alloy Pre Jan 2007 6 Years 2 Years 5 Years

190GOLD-HP Threaded Insert Gel Silver Alloy Pre Jan 2007 6 Years 2 Years 5 Years

210GXL Threaded Insert Gel Silver Alloy Pre July 2009 4 or 5 Years 2 Years 5 Years

180GXL Threaded Insert Gel Silver Alloy Pre July 2009 4 or 5 Years 2 Years 5 Years

210GXL-HP Lead Flag Gel Silver Alloy Pre Dec 2006 5 Years 1.5 Years 4 Years

180GXL-HP Lead Flag Gel Silver Alloy Pre Dec 2006 5 Years 1.5 Years 4 Years

180/165 GXL Lead Flag Gel Silver Alloy Pre Oct 2005 N/A 1.5 Years 3 Years

180/165 G Lead Flag Gel Pre Oct 2005 N/A 1 Year 1 Year

Standard

International

Northern Climates

210/180/165 GXL-5 Lead Flag Gel Pre Dec 2006 5 Years N/A N/A

210/180/165 GXL-4 Lead Flag Gel Pre Dec 2006 4 Years N/A N/A

210/180/165 GXL-3 Lead Flag Gel Pre Dec 2006 3 Years N/A N/A

85GXL-HP Threaded Insert Gel Silver Alloy Post Jan 2007 5 Years 2 Years 5 Years

85GXL-HP Threaded Insert Gel Silver Alloy Pre Dec 2006 5 Years 1.5 Years 4 Years

160 A/AGM/AGM-P Lead Flag AGM All 1 Year 1 Year 1 Year

170XLT Lead Flag AGM - North of 38th parallel Post Aug 2007 4 Years N/A 4 Years

135 AGM-P Threaded Insert AGM Silver Alloy Post Jan 2007 4 Years N/A N/A

135 GXL-5 Threaded Insert AGM Silver Alloy Pre Dec 2006 5 Years N/A N/A

135 GXL-4 Threaded Insert AGM Silver Alloy Pre Dec 2006 4 Years N/A N/A

195GXL-FT FT Gel north of 38th parallel All 3 2 2

195GXL-FT FT Gel south of 38th parallel All 3 2 2

Table 6, Warranty periods for AlphaCellTM batteries

28

745-680-C0-002, Rev.B1

Page 29

7.2 Battery Maintenance Report for Return Authorizations

Contact your Alpha Customer Service representative for assistance in processing your AlphaCellTM

warranty claim.

Alpha Customer Service (800) 421-8089, or fax# (360) 671-4936

This form, in conjunction with Alpha's Battery Evaluation Procedure is intended as a method of collecting

data critical to the efcient processing of your warranty battery claims. Record battery oat voltage

while the battery is still connected to the system. Record battery open circuit voltage (OCV) 24 hours

following removal from the system. Describe the problem encountered with the battery as compared to

the remaining batteries in the battery string. The ZRE# will be provided after you submit your request to

Alpha for processing.

Original Purchase Order (if available)

Company Name

Address

CSZ

Contact Name

Phone

Email address

Replacement Units Address

CSZ

Contact Name

Phone

Email address

Initial

Install

Date

Mfr.

Date

Code

PM

History

Float

Current

Battery

Temperature

Evaluation Procedure #1Evaluation Procedure #2Evaluation Procedure

Vdc Float

No Load

Conductance

mhos @

77°F

Vdc 24

Hour OCV

Conductance

mhos @

77°F

Vdc @ 100A

after 10

seconds

#3

Conductance

mhos @

77°F

745-680-C0-002, Rev. B1

29

Page 30

This page intentionally blank

Page 31

This page intentionally blank

Page 32

Alpha Technologies

Power

®

Alpha Technologies Inc.

3767 Alpha Way

Bellingham, WA 98226

United States

Tel: +1 360 647 2360

Fax: +1 360 671 4936

Alpha Technologies Europe Ltd.

Twyford House Thorley

Bishop’s Stortford

Hertfordshire, CM22 7PA

United Kingdom

Tel: +44 1279 501110

Fax: +44 1279 659870

Alpha Technologies

Suite 1903, Tower 1,

33 Canton Road, Kowloon

Hong Kong City, China

Phone: +852 2736 8663

Fax: +852 2199 7988

Alpha Technologies Ltd.

7700 Riverfront Gate

Burnaby, BC V5J 5M4

Canada

Tel: +1 604 436 5900

Fax: +1 604 436 1233

Toll Free: +1 800 667 8743

Alpha Technologies GmbH

Hansastrasse 8

D-91126

Schwabach, Germany

Tel: +49 9122 79889 0

Fax: +49 9122 79889 21

Alphatec Ltd.

339 St. Andrews St.

Suite 101 Andrea Chambers

P.O. Box 56468

3307 Limassol, Cyprus

Tel: +357 25 375 675

Fax: +357 25 359 595

Alpha TEK ooo

Khokhlovskiy Pereulok 16

Stroenie 1, Ofce 403

Moscow, 109028

Russia

Tel: +7 495 916 1854

Fax: +7 495 916 1349

Alphatec Baltic

S. Konarskio Street 49-201

Vilnius, LT-03123

Lithuania

Tel: +370 5 210 5291

Fax: +370 5 210 5292

Visit us at www.alpha.com

Due to continuing product development, Alpha Technologies reserves the right to change specications without notice.

Copyright © 2013 Alpha Technologies. All Rights Reserved. Alpha® is a registered trademark of Alpha Technologies.

745-680-C0-002 Rev. B1 (04/2013)

Loading...

Loading...