Operating Manual

SG1 Vulcanizer Switchgear Control Box

ORDER NUMBER: BAT-SG1-001

Revised - April 2014

This manual was prepared to present the correct methods

and procedures of operating and maintaining your

ALMEX SG1 SWITCHGEAR CONTROL BOX

At the time of writing this manual, the instructions were up to date.

However, some of the information or appearance of the component parts may vary slightly from the SG1 delivered to you.

READ THIS MANUAL CAREFULLY BEFORE OPERATING YOUR SWITCHGEAR CONTROL BOX

49900-038

Table of Contents

1. SAFETY 3

1.1. Safety Symbols 3

1.2. Definition of Pictograms 3

1.2.1. Caution 3

1.2.2. Electrical Hazard 3

1.2.3. Burning Hazard 3

1.3. Work Area Safety 3

1.3.1. Keep Work Area Clean 3

1.3.2. Keep Visitors Away 3

1.4. Personal Safety 3

1.4.1. Stay Alert 3

1.4.2. Never Alter or Remove Safety Devices 4

1.4.3. Use Safety Equipment 4

1.5. Service and Maintenance Safety 4

1.5.1. Use Authorized Service Only 4

1.5.2. Use Only Authorized Replacement Parts 4

1.5.3. Never Use a Defective or

Abnormally Operating SG1 4

1.6. Limitation of Use 4

2. PRODUCT OVERVIEW 4

3. HARDWARE OVERVIEW 5

3.1. WiFi Antenna 6

3.2. Platen Set 1 and Platen Set 2 Switches 6

3.3. Auxiliary Switch 6

3.4. USB Cable Receptacle 6

3.5. Reset Button 6

3.6. Warning Alarm 6

3.7. Tablet Power Receptacle 6

3.8. Thermocouple Receptacles 6

3.9. Temperature Set Point Indicator 6

3.10. Platen Set 1 and 2 Temperature

Indicators 6

3.11. Platen ON LED 6

3.12. Set Point Reached LED 6

3.13. LCD User Interface 7

3.14. Wireless Pressure Sensor Antenna 7

3.15. Network Master Indicator 7

3.16. Left and Right Auxiliary Receptacles 7

3.17. Upper and Lower Platen Receptacle

(Set 1 & 2) 7

3.18. SG1 Networking Receptacle 7

3.19. Power Main Input Receptacle 7

3.20. Wireless Pressure Sensors and

Schrader Valves 7

3.21. Spare Fuses 7

3.22. Power Cable 7

3.23. Front Panel Dust Cover 7

3.24. Thermocouple Cables 7

3.25. Networking Cables 8

4. SETTINGS 8

4.1. Network Settings 8

4.2. Control Settings 8

4.2.1. Auto-Tuning Support 8

4.2.2. Temperature Offset 8

4.3. Alarm Settings 8

4.3.1. Maximum Pressure 8

4.3.2. Temperature Range 8

4.3.3. Minimum Current 9

4.3.4. Platen Disconnection 9

4.4. Interface Settings 9

4.4.1. Temperature Units 9

4.4.2. Language 9

4.4.3. Sounds 9

5. SENSOR READINGS 9

5.1. Pressure Readings 9

5.2. Pressure Sensor Registration Procedure 9

5.3. Current Readings 9

5.4. Thermocouple Readings 10

6. PREPARATION 10

6.1. Unpacking 10

6.2. Connection Assembly 10

7. OPERATION 11

7.1. Heating the Vulcanizer 11

7.1.1 Automatic Heating 11

7.1.2. Manual Heating 11

7.1.3. Cooling 11

7.1.4. Splice Resume 11

8. OPERATION WITH MULTIPLE SG1s 11

8.1. Description 11

8.2. Preparation 12

9. MAINTENANCE AND REPAIR 13

9.1. Replacing Fuses 13

9.1.1 Opening the SG1 13

9.1.2 Fuse Replacement 14

9.1.3. Closing the SG1 14

10. TROUBLESHOOTING 15

10.1 No Reading on Platen Set 1 and/or

Platen Set 2 Temperature Indicators 15

10.1.1 Power Supply or Cable is Faulty. 15

10.1.2. Control Circuit Fuse has Opened 15

10.2 “Err” Displayed on Platen Set 1 and/or

Platen Set 2 Temperature Indicators 15

10.2.1. Platen not Connected 15

10.2.2. Loose Connection in Cable or

Platen Connector 15

10.2.3. RTD Temperature Sensor is Faulty 15

10.3. Platens Not Heating 15

10.3.1. Power Supply or Cable is Faulty 15

10.3.2. Platen Switch Off 15

10.3.3. Temperature Set Improperly 15

10.3.4. No Continuity Between

SG1 and Platen 15

10.3.5. Loose Connection in the

SG1 Control Panel 15

10.3.6. Faulty RTD Temperature Sensor

in Platen 15

10.3.7. Faulty Heating Element in Platen 15

10.3.8. Faulty Contactor in SG1 Control Panel 15

10.3.9. Loose Connection in Cable

or Platen Connector 15

10.3.10. Faulty Temperature Controller

in SG1 Control Panel 15

10.4. Vulcanizer Overheating 16

10.4.1. Temperature Set Improperly 16

10.4.2. Faulty Contactor in SG1 Control Panel 16

10.4.3. Faulty RTD Temperature Sensor

in Platen 16

10.4.4. Faulty Temperature Controller in

in SG1 Control Panel 16

10.5. Unit Fails to Create SG1 Network 16

10.5.1. Improper Network Configuration 16

10.5.2. Faulty Network Connectors 16

10.5.3. Faulty Communication on

SG1 Motherboard 16

11. SG1 PARTS LIST 17

12. SERVICE 18

12.1. Emergency Service 18

12.2. Return of Goods Authorization 18

12.3. Guarantee 18

13. SCHEMATIC DIAGRAMS 18

Revised - April 2014 49900-038

22

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

SHAW ALMEX INDUSTRIES LIMITED

323 Glover Road, Stoney Creek, ON Canada L8E 5M2

Phone: 905-643-7750

toll free 800-418-2400 (Canada and US only)

Fax: 905-643-7788

Email: sail@almex.com

Web: www.almex.com

1. Safety

Your ALMEX SG1 Switchgear Box has been designed to provide

safe, efficient, trouble-free service for many years. Component

design and material selection have been carefully considered

to ensure operator safety. Our manufacturing procedures pro

vide a consistent, high-quality product.

The material presented in this operating manual has been com

piled to provide personnel with a complete understanding of

correct SG1 operating procedures.

PLEASE READ CAREFULLY

The following safety precautions should be read carefully and

understood thoroughly before you set-up or operate your SG1.

Failure to follow these precautions may result in personal injury

and/or equipment damage. All personnel should be trained in

the proper operation of the SG1.

Risks associated with operating the SG1 are identified through

out this manual with safety symbols.

1.1 SAFETY SYMBOLS

These international safety symbols are used to identify and

call attention to specific safety matters. The risks associated with operating the switchgear control are identified

throughout this manual with these symbols.

CAUTION

ELECTRICAL

HAZARD

BURNING

HAZARD

-

-

-

1.2 DEFINITION OF PICTOGRAMS

1.2.1. CAUTION

Indicate[s] a hazardous situation which, if not avoided,

could result in minor or moderate injury. CAUTION

[signs] without a safety alert symbol may be used to alert

against unsafe practices that can result in property dam

age only.

1.2.2. ELECTRICAL HAZARD

1. A qualified electrician should perform all maintenance

of the electrical components of the switchgear control

box. Service or maintenance performed by unqualified

personnel could result in risk of injury and will void war

ranty.

2. Electrical components contain live circuits. Do not

open or service any of the electrical equipment

without disconnecting the main power supply.

3. Incorrect voltage and phase may result in com

ponent damage and create a fire hazard.

4. Equipment power supplies must be properly

grounded or a severe shocking hazard may result.

5. Avoid using equipment in wet surroundings

or a severe shocking hazard may result.

6. If any cables or connectors are damaged, they must

be replaced or a fire and shock hazard may result.

1.2.3. BURNING HAZARD

There is not a burning hazard with the switchgear control

itself; however, improper use or component failure could

result in the vulcanizer overheating.

1.3 WORK AREA SAFETY

1.3.1 KEEP WORK AREA CLEAN

Cluttered areas and benches invite injuries.

1.3.2 KEEP VISITORS AWAY

Do not let visitors contact power cables or platen cables.

All visitors should be kept away from work area.

1.4 PERSONAL SAFETY

1.4.1 STAY ALERT

Watch what you are doing and use caution when operating

the SG1. A moment of inattention while operating power

equipment may result in serious personal injury or death.

-

-

-

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

49900-038Revised - April 2014

3

1. Safety CONTINUED

2. Product Overview

1.4.2 NEVER ALTER OR REMOVE SAFETY DEVICES

1.4.3 USE SAFETY EQUIPMENT

Always wear eye protection. Dust mask, hard hat or hearing

protection must be used for appropriate conditions. Nonskid, steel-toe safety shoes are required for safe operation,

due to the SG1’s weight.

1.5 SERVICE AND MAINTENANCE SAFETY

1.5.1 USE AUTHORIZED SERVICE ONLY

Service must be performed only by qualified personnel.

Service or maintenance performed by unqualified

personnel could result in risk of injury and will void warranty.

Contact your Almex representative to determine if service

is required by an Almex technician.

1.5.2 USE ONLY AUTHORIZED REPLACEMENT PARTS

When servicing SG1, use only identical replacement

parts. The use of unauthorized parts or failure to follow

“Maintenance Instructions” may result in electric shock or

injury.

1.5.3 NEVER USE A DEFECTIVE OR ABNORMALLY

OPERATING SG1

If the SG1 appears to be operating unusually, making a

strange noise or appears defective in any way, stop using

it immediately and make arrangements to have it repaired

by an Almex Technician.

1.6 LIMITATION OF USE

This equipment has been designed to control the temperature

of an ALMEX conveyor belt vulcanizer. The SG1 Switchgear

Control Box operates within a range of -30ºC to 45ºC (-22ºF to

113ºF). An ALMEX Switchgear Control Box must be used with

a ALMEX vulcanizer. The vulcanizer should never be allowed

to operate while unattended. Only use the SG1 for what it

is designed for, other use is not allowed without the written

permission of Shaw Almex.

The Almex SG1 Switchgear Control Box is the most advanced

vulcanizing control system in the world. It incorporates control of four

platens and has input for eight thermocouple leads so that redundancy

in temperature monitoring and recording is accomplished. It also

utilizes wireless sensors to record pressure bag readings.

The SG1 follows a user specified splice recipe that maintains a

dwell and cure temperature at a specified dwell time and cure

time. Using an advanced control method called PID, the SG1

reduces the effect of temperature overshoot by turning the platens

on and off in pulses. The splice can be started and stopped using

an ALMEXPAD or using the LCD display on the front panel of

the SG1.

Once begun, a splice continues automatically and does not

require intervention until the cure is finished and cooling

commences. The stages of the splicing process are displayed. (See

FIGURE 1) When no splice is specified and no heating or cooling is

taking place the splice-info screen will read “status: ready”.

When splice parameters are input and a splice starts, the device

starts in the “To Dwell” phase. When all connected platens reach the

dwell temperature, the platen begins the “At Dwell” phase. In this

phase of operation the SG1 maintains the set temperature for a set

time. Remaining dwell time can be viewed on the LCD display in the

“Splice Info” menu or on the ALMEXPAD Splice Monitor screen.

When the “At Dwell” phase is completed, the SG1 enters the

“To Cure” phase and heats up until all platens rise to meet the specified cure temperature called the “At Cure” phase. In this phase the

SG1 maintains the set temperature for a set time. (See FIGURE 1)

Once the Cure time elapses, the SG1 enters a “Cooling” state. At

this point, operators may pump coolant into the platens to speed

up the cooling phase with an ALMEX pressure pump. (See FIGURE

2) After all platens cool below the Cooling temperature, the splice

is complete.

NOTE: At any time during the operational phase the splice can

be emergency stopped by going to the “Splice Info” menu and

selecting the “Stop Splice” option.

FIGURE 1 - SPLICE GRAPH

Revised - April 2014 49900-038

4

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

FIGURE 2 - PRESSURE PUMP

3. Hardware Overview

FIGURE 3 -

SG1 FUNCTIONAL

DIAGRAM

Revised - April 2014

FIGURE 4 - SG1 FUNCTIONAL DIAGRAM

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

49900-038

5

3. Hardware Overview

SG1 FRONT PANEL

3.1. WIFI ANTENNA

Allows the SG1 Switchgear Box to connect wirelessly to

ALMEXPAD Senior and exchange data.

3.2. PLATEN SET 1 AND PLATEN SET 2 SWITCHES

The main heating controls are

located on the left side of the SG1

front panel.

Each control, can be

set in the AUTO, OFF, or

MANUAL position. In AUTO mode,

the SG1 controls the splice

according to the splice parameters

set using the ALMEXPAD or SG1

menus. Holding a platen switch

in the MANUAL position forces

the platens on without the

use of

the temperature controller.

(SEE FIGURE 5)

3.3. AUXILIARY SWITCH

Controls power to the auxiliary receptacles for an Almex Pressure Pump. Power is ON when set in the MANUAL position.

Note: The AUTO mode is non-operational at this time and

should not be used.

(SEE FIGURE 5)

3.4. USB CABLE RECEPTACLE

Allows the user to connect to the ALMEXPAD tablet. The connection

has a threaded cap to create a water-tight seal

3.5. RESET BUTTON

Restarts the SG1. (SEE FIGURE 6)

NOTE: The reset button does not need to be pressed to

prepare for the next heat cycle. This is handled automati

cally once a splice is completed.

3.6. WARNING ALARM

Indicates that the SG1 or attached press is operating outside of

recommended and/or desired operating conditions. The SG1

gives an audible signal if the splice is outside of a user specified

temperature range, current range, pressure range or if a platen

cable is disconnected. (SEE FIGURE 6) (For more information

SEE ALARMS, SECTION 4.3)

FIGURE 5 PLATEN SET

2 (TOP) AND

AUXILIARY

SWITCHES

(LEFT)

.

(SEE FIGURE 6)

-

FIGURE 6 - FROM LEFT TO RIGHT - USB CABLE RECEPTACLE, TABLET POWER

RECEPTACLE, RESET BUTTON, WARNING ALARM

3.8. THERMOCOUPLE RECEPTACLES

Located on the right side of the SG1 front panel. These

receptacles serve as further inputs for tracking and recording

platen temperature. NOTE: Use K-Type thermocouples only.

(SEE FIGURE 7)

FIGURE 7 - THERMOCOUPLE RECEPTACLES

3.9. TEMPERATURE SET POINT INDICATOR

Displays the goal termperature of the splice recipe’s current

phase. (SEE FIGURE 8)

3.10. PLATEN SET 1 AND 2 TEMPERATURE INDICATORS

Displays the current temperature of the connected platens.

(SEE FIGURE 8)

3.11. PLATEN ON LED

Illuminates if the platen is on. (SEE FIGURE 8)

3.12. SET POINT REACHED LED

Illuminates if the platen has reached the set point for the

current phase. (SEE FIGURE 8)

3.7. TABLET POWER RECEPTACLE

Provides DC power to charge and run ALMEXPAD Senior or

Junior Tablets.

Revised - April 2014 49900-038

6

(SEE FIGURE 6)

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

FIGURE 8 - BOTTOM LEFT - TEMPERATURE SET POINT INDICATOR

CENTRE TOP & BOTTOM - PLATEN SET 1 TEMPERATURE INDICATORS

RIGHT TOP & BOTTOM - PLATEN SET 2 TEMPERATURE INDICATORS

3. Hardware Overview CONTINUED

3.13. LCD USER INTERFACE

Allows the user to navigate SG1 features and has four input

buttons:

• MENU - navigates back to the HOME screen

• UP or DOWN - navigates to the different screen options

• ENTER - selects the desired option

When a numerical value must be entered in a menu option,

press ENTER, use the UP and DOWN buttons to increase or

decrease the number value in the given cell. Press ENTER

when the proper number has been inserted. When the final cell

contains the proper number, press ENTER to return to menu

selection. (SEE FIGURE 9)

FIGURE 9 - LCD USER INTERFACE

SG1 STANDARD ACCESSORIES

3.20. WIRELESS PRESSURE SENSORS

& SCHRADER VALVES

Used to measure vulcanizer bag pressure. (SEE FIGURE 10)

FIGURE 10 - WIRELESS PRESSURE SENSORS & SCHRADER VALVES

3.21. SPARE FUSES

FIGURE 11 - SPARE FUSES FIGURE 12 - POWER CABLE

3.22. POWER CABLE

3.14. WIRELESS PRESSURE SENSOR ANTENNA

Allows the Switchgear Box to connect to wireless pressure sensors,

that monitor the presses bag pressure in PSI. (SEE FIGURE 3) Two

wireless pressure sensors are included with SG1. (SEE FIGURE 10)

3.15. NETWORK MASTER INDICATOR

Indicates when two or more SG1’s are networked together. The

master SG1 LED reads solid. The network master indicator blinks

on the slave SG1(s). (SEE FIGURE 3)

SG1 BACK PANEL

3.16. LEFT AND RIGHT AUXILIARY RECEPTACLES

Used to power the ALMEX pressure pump. (SEE FIGURE 4)

3.17. UPPER & LOWER PLATEN RECEPTACLE (SET 1 & 2)

Powers two ALMEX platen sets. (SEE FIGURE 4)

3.18. SG1 NETWORKING RECEPTACLE

Networks up to four SG1s at a time. (SEE FIGURE 4)

3.19. POWER MAIN INPUT RECEPTACLE

Powers and activates the SG1. (SEE FIGURE 4)

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

SG1 OPTIONAL ACCESSORIES

3.23. FRONT PANEL DUST COVER

FIGURE 13 - FRONT PANEL DUST COVER

3.24. THERMOCOUPLE CABLES

FIGURE 14 - THERMOCOUPLE CABLES

49900-038Revised - April 2014

7

SG1 OPTIONAL ACCESSORIES CONTINUED

3.25. NETWORKING

CABLE

FIGURE 15

4. Settings

MENU ENTERMENU ENTER

6.

Wait until the display indicates that auto-tuning is complete.

The SG1 is now configured with the new PID constants. These

PID constants will remain until the next time the auto-tuning

procedure is run.

The SG1 will auto-tune output based only on the connected plat

ens. Circuits that are not connected will not have their PID constants

changed. Each output may have its own PID to take into account

differences between connected platen sets.

4.2.2. TEMPERATURE OFFSET

MENU ENTERMENU ENTER

FIGURE 16 - NAVIGATING TO SETTINGS SCREEN

Settings for the SG1 can be selected on the LCD User Interface

(SEE FIGURES 3 & 16). When the SG1 is powered up, the SPLICE

INFO SUB MENU appears. To get to the Home Screen, press the

MENU button.

4.1. NETWORK SETTINGS

An SG1 can be networked with up to three other SG1 Switchgear Boxes for the purpose of performing a large splice. (SEE

FIGURE 18 - TEMPERATURE OFFSET

If a given platen connection consistently reads an incorrect tem

perature due to degridation of the platen or platen cable, a

temperature offset may be applied to compensate. This process

may be performed on each sensor reading with a range of +/100°F or +/- 50°C. (SEE FIGURE 18)

4.3. ALARM SETTINGS

ENTER

SECTION 8).

4.2. CONTROL SETTINGS

4.2.1. AUTO-TUNING SUPPORT

MENU ENTERMENU ENTER

FIGURE 17 - AUTO TUNING

The auto-tuning method improves temperature rise-time and

decreases temperature overshoot. (SEE FIGURE 17)

1. Navigate to the“Control Settings” Menu.

2. Select the“Auto-tune”option.

3. Input the temperature that you want the auto-tuning to take

place at. It is recommended that you auto-tune close to your

application’s cure temperature.

4. Select “Start Auto-tuning”. The auto-tuning process will commence. During this time the auto-tuning can be canceled by selecting the “cancel auto-tune”option. If auto-tuning is canceled

the new PID constants will not be changed.

5. During the auto-tuning phase. The set point indicator will display

the target temperature and all connected platens will heat to the

target temperature. The platens will then fluctuate around the

target temperature as the new PID constants are calculated.

Revised - April 2014 49900-038

8

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

FIGURE 19 - ALARM SETTINGS

From the SG1 menu, users can enable alarms to monitor various parameters and fault conditions. Alarms will sound for the

five following reasons. (SEE FIGURE 19)

4.3.1. MAXIMUM PRESSURE

- An alarm will sound if the maximum pressure threshold is surpassed. The maximum pressure threshold, set by the operator

may be set anywhere from 0 PSI - 249 PSI. (SEE FIGURE 19)

4.3.2. TEMPERATURE RANGE

- In the “To Dwell” or “To Cure” phase, an alarm will sound if

the actual temperature rises above the target temperature by

more than the range indicated.

- In the “Dwell” or “Cure” phase, an alarm will sound if the

actual temperature drops below or rises above the target tem

perature by more than the range indicated. (SEE FIGURE 19)

-

-

4. Settings CONTINUED

4.3.3. MINIMUM CURRENT

- An alarm will sound if the current falls below the value speci-

fied. This can be used to determine if a platen phase has burnt

out. NOTE: if the process is in the middle of a splice and the

platen “Auto/Manual” switch is set in the “Off” position the

alarm will activate. (SEE FIGURE 19)

4.3.4. PLATEN DISCONNECTION

- An alarm will sound if a platen is disconnected during a splice.

4.4. INTERFACE SETTINGS

ENTER

FIGURE 20 - INTERFACE SETTINGS

From the SG1 menu, users can change the way the menu displays information or reacts to selections. (SEE FIGURE 20)

4.4.1. TEMPERATURE UNITS

Sets the temperature units to either degrees Celsius or degrees

Fahrenheit.

(SEE FIGURE 20)

4.4.2. LANGUAGE

Sets languages to either English or Spanis

h. (SEE FIGURE 20)

4.4.3. SOUNDS

Turns the menu sounds ON or OFF. When a selection is made, an

alert will sound.

(SEE FIGURE 20)

5. Sensor Readings

ENTER

FIGURE 21 - SENSOR READINGS

From the menu, users can monitor all sensor readings including

pressure, electrical current, and thermocouple readings.

5.1. PRESSURE READINGS

SG1s come with wireless pressure sensors.

These sensors read between 8 and 299 psi at a

distance of up to 300 ft., when line of sight is not

obstructed. Sensors attach to Schrader valves in

line with the bag pressure. These valves are con

nected in one of three configurations:

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

-

1. Directly attached to a tee fitting connected to each pressure bag.

2.

Attached to a manifold combining multiple pressure bags.

3. Connected directly to the pressurizing pump. In order to read

pressures, users must first register the sensors with the SG1.

After registration, the SG1 will continue to receive pressure

readings from that specific pressure sensor until either the

sensor registration process is repeated or until the pressure

sensor battery is completely depleted.

5.2. PRESSURE SENSOR REGISTRATION PROCEDURE

NOTE: Pressure Sensors can only be registered when there is

no splice in progress.

ENTER ENTER

MENU

FIGURE 22 - REGISTERING PRESSURE SENSORS

1. On the menu screen. Navigate to Sensors > Pressure

Sensors. Select “Enter” on the “Register sensors” line.

2. The LCD display will now show “Connect Sensor 1.” Con

nect the first pressure sensor you want to use to a pressure

source, and within 1 minute, the sensor will be registered.

3. The next prompt is: “Connect sensor 2.” Connect the second

sensor to a pressure source and wait until it is registered.

4. Up to four pressure sensors can be added. Press MENU at

any time to stop adding pressure sensors.

5. Press the “Reset” button after sensors have been registered.

6. To view the sensor readings, return to the Pressure Readings

screen. (SEE FIGURE 22)

NOTE: Pressure Sensors are battery powered and will run

out after use. The average life span is three years. Contact an

Almex distributor to purchase new pressure sensors.

-

5.3. CURRENT READINGS

ENTER

FIGURE 23 - CURRENT READINGS

1. CURRENT READING 2. NO CURRENT 3. ACTIVE CURRENT

The SG1 monitors and displays the total electrical current running

to each of the connected platens. Readings vary press to press.

(SEE FIGURE 23)

49900-038Revised - April 2014

9

5. Sensor Readings CONTINUED

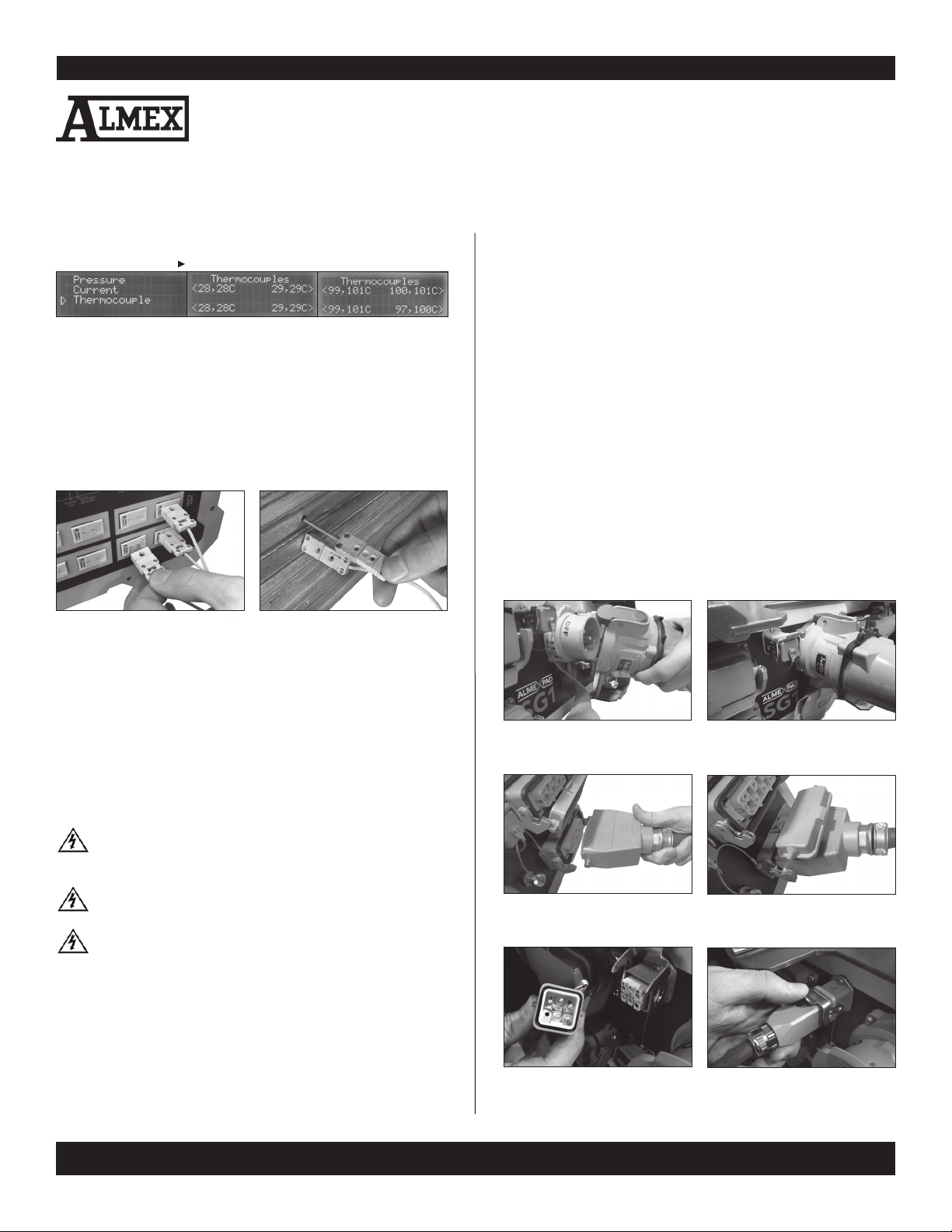

5.4. THERMOCOUPLE READINGS

ENTER

FIGURE 24 - THERMOCOUPLE READINGS

1. SENSOR READING 2. INTERNAL SG1 TEMP. 3. SPLICE TEMPERATURE

5.4. THERMOCOUPLE READINGS

Up to 8 thermocouple readings can be measured and displayed from the 8 thermocouple leads at the front of the SG1.

(SEE FIGURES 24, 25A & 25B)

NOTE: If a thermocouple is not connected; the reading

shown is that of the internal SG1 unit temperature.

FIGURE 25A - INSERT

THERMOCOUPLES INTO THE SG1

FIGURE 25B - INSERT

THERMOCOUPLES INTO THE PLATEN

6. Preparation

3. Connect the Blue Power Connector of the Supply Cable to the Power Main Input Receptacle on the

rear panel of the SG1. (See FIGURES 26A & 26B)

4. Lift the Platen Receptacle Covers on the rear panel of the

SG1 and connect the platen cables. (SEE FIGURE 27A &

27B) Press the plugs firmly into the receptacles and close the

latches to secure the plugs. When the cables are removed,

close the covers to protect the connector from contaminates

such as water or dirt.

5. Connect the pump or compressor if required. The connec

tors are keyed so that only an Almex pump with the correct

voltage can be connected. (SEE FIGURE 28A & 28B)

6. Connect the SG1 control cable to the power supply. Refer

to the electrical specifications indicated on the serial plate

and in the record of purchase. The SG1 will power on au

tomatically when connected to the power supply. To power

down (turn off) the SG1 control, simply disconnect it from

the power supply. (SEE FIGURES 26A & 26B)

-

-

6.1. UNPACKING

Carefully unpack the Switchgear control from the box and

inspect for damage. Any damage or shortage should be re

-

FIGURE 26A - REMOVE BLUE

POWER CONNECTOR COVER

FIGURE 26B - INSERT POWER CABLE

CONNECTOR UNTIL IT CLICKS

ported to the carrier and/or Shaw Almex Industries Limited

immediately.

6.2. CONNECTION ASSEMBLY

Safety: Ensure the voltage, phase and cycle on the

Switchgear control is the same as the power supply.

See serial number on rear panel of the SG1.

Safety: Never heat the vulcanizer unattended. Read

all safety information before turning on the SG1.

Safety: Do not turn power on until the SG1 and all

FIGURE 27A - OPEN PLATEN

CONNECTION LIFT COVER

FIGURE 27B - INSERT PLATEN

CONNECTOR FIRMLY

associated components are properly connected.

1. Ensure that the Auxiliary, Platen Set 1 and Platen Set 2 switch

-

es are in the OFF position.

2. Have a certified electrician install a suitable eletrical connec

tor to the non-terminated end of the power supply cable.

(SEE FIGURE 12) NOTE: For information on the voltage,

amperage and phase, refer to the electrical specifications,

located on the rear panel of the SG1.

Revised - April 2014 49900-038

10

1010

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

FIGURE 28A - REMOVE AUXILLARY

CAP AND ALIGN PINS

FIGURE 28B - INSERT PLUG INTO

RECEPTACLE & SECURE WITH LATCH

7. Operation

7.1. HEATING THE VULCANIZER

CAUTION: The vulcanizer must be pressurized to at

least 5 psi (0.3 bar) before heating, or damage will oc

cur to the connected platen element on the vulcanizer.

-

7.1.1. AUTOMATIC HEATING

The SG1 can automatically follow a given splice recipe. The

parameters for a splice recipe can be set using two methods:

1. Using the Splice Monitor application on the ALMEXPAD.

2. Using the LCD user interface on the SG1.

To use the AUTOMATIC function, platen switches must be

turned to the AUTO position

OPTION 1

Using SpliceMonitor on the ALMEXPAD

Connect the SG1 to the ALMEXPAD using the USB cable or via

WiFi. On the ALMEXPAD open SpliceMonitor and connect to

the SG1. Set the desired splice parameters for the Dwell, Cure

and Cool phases and start the splice. Please see the ALMEX

PAD and SpliceMonitor Operator’s Manuals for more details.

-

OPTION 2

Using the SG1 Front Panel Display

ENTER ENTER

MENU

When all connected platens reach the Set Point dwell temperature, the platen begins the “At Dwell” phase. In this phase of operation the SG1 maintains the set temperature for the set time.

Remaining Dwell time can be viewed on the LCD display in the

“Splice Info” menu or on the ALMEXPAD Splice Monitor screen.

When the “At Dwell” phase is completed, the SG1 enters the

“To Cure Temperature” phase and heats up until all platens rise

to meet the Set Point cure temperature. In this phase the SG1

maintains the set temperature for the set time. (See FIGURE 1)

Once the Cure time elapses, the SG1 enters a “Cooling” state.

At this point, operators may pump coolant into the platens to

speed up the cooling phase. After all platens cool below the

Cooling temperature, the splice is complete.

7.1.2. MANUAL HEATING

If there is a temperature controller malfunction or platen temperature sensor failure, the platen can be heated manually by

turning the platen switch to the MANUAL position and holding

it there. (SEE FIGURE 5) When using this function, the platen

temperature should be manually monitored with thermocou

ples and/or stem thermometers.

-

7.1.3. COOLING

Manual cooling must be used with this version of the SG1.

See the User manual for the specific press being used.

NOTE: Automatic cooling is not available at this time.

ENTER ENTER

FIGURE 29 - AUTOMATIC HEATING

Navigate to the Splice Info submenu using the LCD user inter

face, from there, select the Splice Parameters option and set

the desired splice parameters for the Dwell, Cure and Cool

phases. Afterward, from the Splice Info sub-menu, press Start

Splice. (SEE FIGURE 29)

Safety: Once the splice has begun the platens will be

hot to the touch.

When the splice recipe parameters have been chosen and the

“Start Splice” has been selected, the SG1 will begin heating up

in the Dwell Phase.

When the Set Point is reached for each phase, the “Set Point

Reached” LED will illuminate. The SG1 and control tablet will

start timing the dwell and cure period from the time all appli

cable platens have reached the Set Point.

Revised - April 2014

-

-

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

7.1.4. SPLICE RESUME

In the case of a power failure or interruption, the SG1 can

resume a splice. When the SG1 unit is repowered, the first

screen shown will give users an option to resume the most re

cent splice. Selecting “Yes” restores all splice parameters and

continues the splice from the time that the splice was halted.

Select “No” if you wish to start a new splice. (SEE FIGURE 30)

FIGURE 30 - RESUME SPLICE

-

8. Operation with

Multiple SG1s

8.1. DESCRIPTION

Up to four SG1s supporting 16 platens, can be networked together for the purpose of combining sectional presses to complete one large splice. When networked, SG1s can share sensor

readings and coordinate heating and cooling.

49900-038

11

8. Operation with Multiple SG1s CONTINUED

In an SG1 network, one unit is designated as a network master.

It is responsible for synchronizing communication between all

SG1s in the network. The Master has full control of the other

units and is the single point of contact for communication with

ALMEXPADs. The master SG1 can be identified because its

Network Master LED is emitting a solid, non-flashing light.

All other units are referred to as Slave units. These units have

less functionality and are for the most part controlled by the

master unit. They are identified by flashing LEDs.

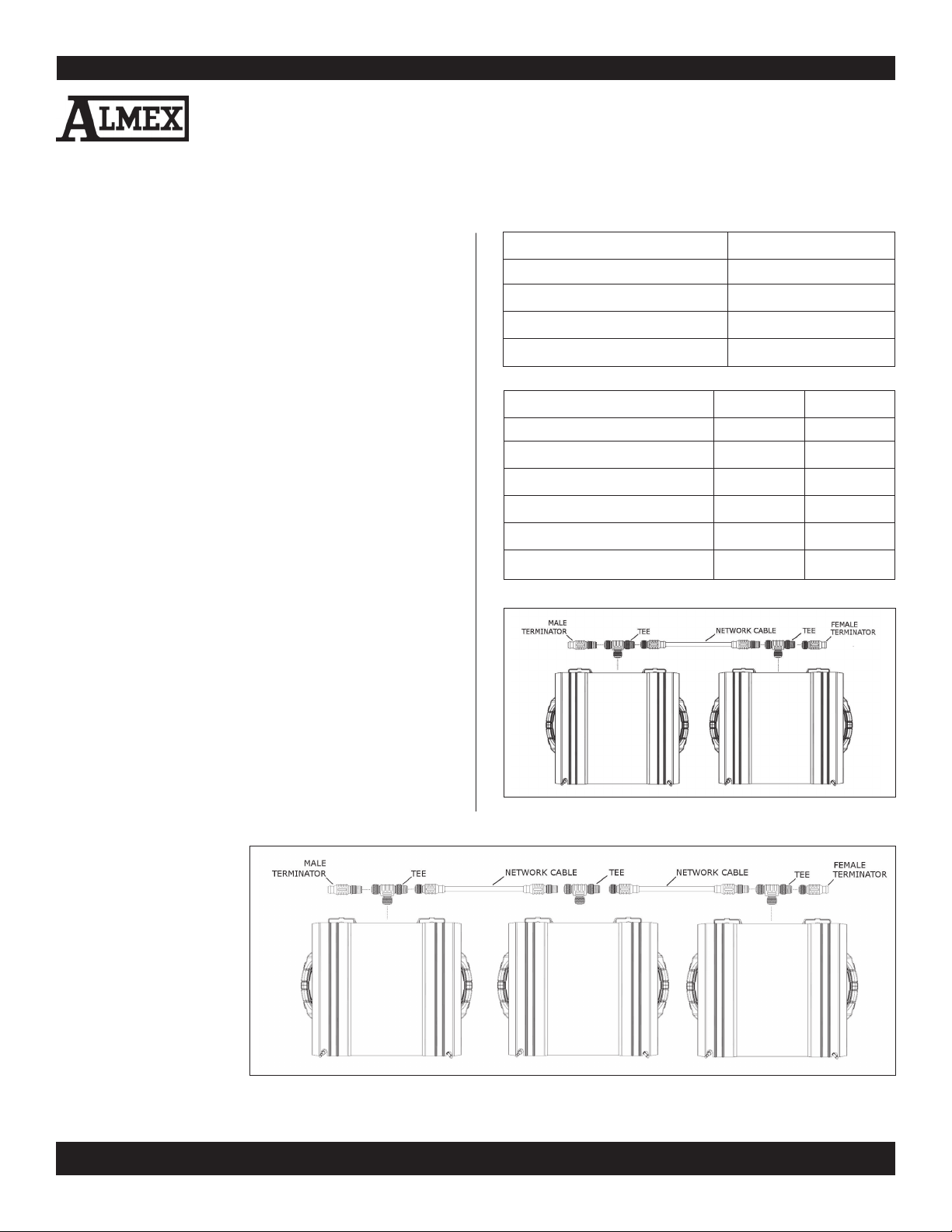

8.2. PREPARATION

The SG1s are connected via DeviceNet network cables. These

cables are industrial rated for use in electrically noisy environ

ments and are designed to be immune to inductive interference. The steps you will need to perform in order to form an

SG1 network are as follows:

1. Connect each tee fitting to the networking receptacle on the

rear panel of each SG1.

2. Connect the network cables in between adjacent SG1s.

3. Add the male and female terminators to the 2 unterminated

tees of the end SG1s. (See FIGURES 31 & 32)

4. Power up all SG1s.

5. Select a single SG1 to be the master. For best performance

select the central SG1 (one without a terminator in a network

with 3 or 4 SG1s). On that unit navigate to the “Settings”menu

and select the network type option to initialize the unit as the

“master”. Connected SG1s (unless they are active in a splice

operation) will automatically be configured as slaves. After

network configuration, the master can be operated in the

same way as a single basic unit. A splice can be configured

and started from the “Splice Info” menu. The master SG1

can communicate with

and be controlled by an

ALMEXPAD via USB or

WiFi.

6. The Platen Switches on

each unit must be set to

AUTO in order to oper

ate under a networked

splice.

-

-

ITEM QUANTITY

FEMALE TERMINATOR 1

MALE TERMINATOR 1

TEE FITTING 1 PER CONNECTED SG1

NETWORK CABLE 1 PER CONNECTED SG1

FUNCTIONALITY SLAVE MASTER

SET SPLICE PARAMETERS

START SPLICE

E-STOP SPLICE

MODIFY ALARMS

USB COMMUNICATION

WIFI COMMUNICATION

FIGURE 31: CONNECTIONS FOR AN SG1 NETWORK WITH 2 UNITS

•

•

• •

• •

•

•

FIGURE 32: CONNECTIONS FOR A NETWORK WITH 3 SG1 UNITS

Revised - April 2014 49900-038

12

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

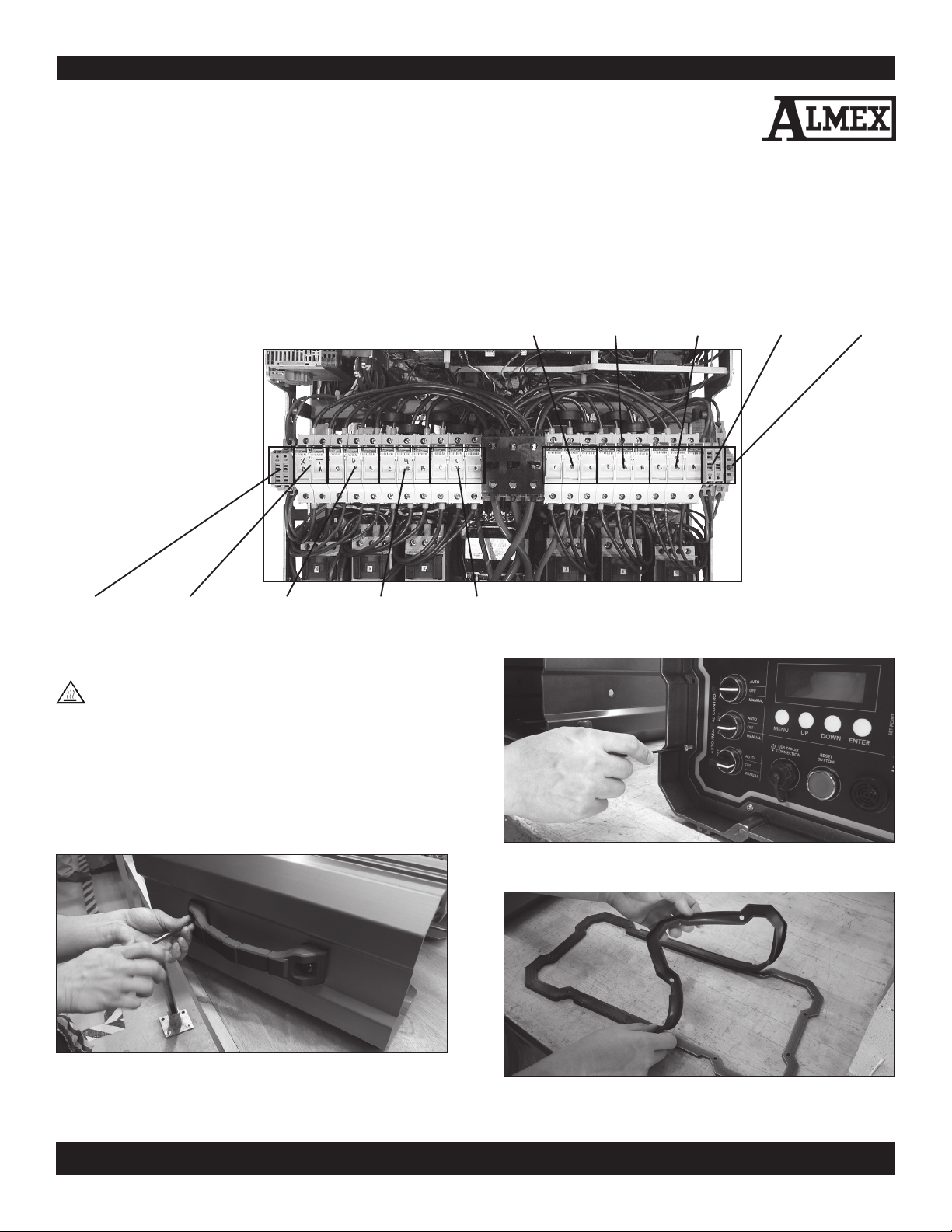

9. Maintenance & Repair

9.1. REPLACING FUSES

The SG1 has 25 fuses along the main fuse strip. Each platen connection and each auxiliary connection has 3 fuses. The transformer has

2 fuses and there are 5 low voltage fuses for the rectifiers, tempera

ture controller, and motherboard. (SEE FIGURE 33)

-

BOTTOM

LEFT PLATEN

FUSES

TOP LEFT

PLATEN

FUSES

RIGHT

AUXILIARY

FUSES

LOW

VOLTAGE

GLASS FUSES

MOTHERBOARD

BLADE

TYPE FUSE

TABLET POWER

GLASS FUSES

TRANSFORMER

FUSES

LEFT

AUXILIARY FUSES

PLATEN SET 2

BOTTOM FUSES

PLATEN SET 2

TOP FUSES

9.1.1. OPENING THE SG1

Safety: Disconnect the power supply and all other

cables before opening the SG1.

The SG1 Switchgear Control Box must be opened to replace

fuses. To access the circuits, a 5/16” hex allen key and a 1/8”

hex allen key are required.

NOTE: Each SG1 may sealed using one of two sealing processes.

1. A reusable moulded silicone gasket

2. Removable silicone caulk

FIGURE 33 FUSE DIAGRAM (TOP VIEW)

FIGURE 35 - STEP 2. USING THE 1/8” HEX ALLEN KEY, REMOVE ALL

BOLTS HOLDING THE FRONT AND REAR SEALING RINGS IN PLACE.

EIGHT

FIGURE 34 - STEP 1. USING THE 7/32” HEX ALLEN KEY, REMOVE

THE FOUR BOLTS SECURING THE HANDLES.

Revised - April 2014

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

FIGURE 36 - STEP 3.

PROVIDED OR THE SILICONE RESIDUE.

REMOVE THE SEALING RING AND SILICONE GASKET

49900-038

13

9. Maintenance and Repair CONTINUED

9.1.1. OPENING THE SG1 (CONTINUED)

FIGURE 37 - STEP 4. PULL

THE CENTRAL TRAY OUT OF THE ENCLOSURE.

9.1.2. FUSE PLACEMENT

9.1.3. CLOSING THE SG1 (CONTINUED)

FIGURE 40 - STEP 7. BOLT BOTH HANDLES ONTO THE ENCLOSURE USING THE

FIGURE 41 - STEP 8 - OPTION 1.

7/32” HEX ALLAN KEY.

PLACE THE REUSABLE SILICONE GASKET

ONTO THE FRONT OR BACK PANEL OF SG1.

FIGURE

38 - STEP 5. FLIP UP THE REQUIRED FUSE HOLDERS.

REPLACE BROKEN FUSES WITH THE APPROPRIATE FUSE TYPE

(SEE 11. SG1 PARTS LIST)

9.1.3. CLOSING THE SG1

FIGURE 39 - STEP 6. PUSH THE CENTRAL TRAY INTO THE ENCLOSURE, BE

Revised - April 2014

14

CAREFUL TO AVOID PINCHING WIRES. ENSURE THAT THE

HANDLE BOLT HOLES ON THE TRAY ALIGN WITH THE

BOLT HOLES ON THE ENCLOSURE.

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

FIGURE 42 - STEP 8 - OPTION 2. APPLY “DRAFT ATTACK” SEALANT TO THE

GAP BETWEEN THE FRONT PANEL AND THE ENCLOSURE.

FIGURE 43 - STEP 9. PROPERLY POSITION THE SEALING RING IN THE

SEALING GASKET OR ON THE DRAFT ATTACK AND SECURE

USING EIGHT 1/8” HEX ALLEN BOLTS.

49900-038

10. Troubleshooting

10.1. NO READING ON PLATEN SET 1 AND/OR PLATEN SET 2 TEMPERATURE INDICATORS

10.1. NO READING ON PLATEN SET 1 AND/OR PLATEN SET 2 TEMPERATURE INDICATORS

FAULT CORRECTION

FAULT CORRECTION

10.1.1. Power supply or cable is faulty. Ensure that the power cable is connected properly and that the power

supply is turned on.

10.1.2. Control circuit fuse has opened. Disconnect power, open control box and replace fuses.

See “9. Maintenance and Repair.”

10.2. “ERR” DISPLAYED ON PLATEN SET 1 AND/OR PLATEN SET 2 TEMPERATURE INDICATORS

FAULT CORRECTION

10.2.1.

cables are connected and secured properly.

10.2.2. Loose connection in cable or platen Remove electrical connector insert from platen housing and tighten

10.2.3.

Platen not connected.

connector. all connections.

RTD temperature sensor is faulty.

Err is displayed any time a platen cable is not connected. Ensure the platen

Refer to the Maintenance Section in the Operator’s Manual for the Almex Press .

10.3. PLATENS NOT HEATING

FAULT CORRECTION

10.3.1. Power supply or cable is faulty. Ensure that the power cable is connected properly and that the

power supply is turned on.

10.3.2. Platen switch OFF. Turn platen switch to AUTO or MANUAL.

10.3.3. Temperature set improperly. Ensure that Temperature Set Point is correct.

10.3.4. No continuity between SG1 and platen.

10.3.5. Loose connection in SG1 control panel. Disconnect power supply, open the control cabinet and check

for loose wire connections.

Check power supply, fuses (inside panel) and cable connections.

10.3.6. Faulty RTD temperature sensor in platen. Refer to the Maintenance Section in the Operator’s Manual of

the Almex Press.

10.3.7. Faulty heating element in platen. Refer to the Maintenance Section in the Operator’s Manual of

the Almex Press.

10.3.8. Faulty Contactor in SG1 control panel.

10.3.9. Loose connection in cable or

platen connector.

10.3.10. Faulty temperature controller in SG1

control panel.

Revised - April 2014

Replace Contactor. (SEE SG1 PARTS LIST & SCHEMATIC DIAGRAM)

Remove electrical connector insert from housing and tighten all connections.

Replace Omron Temperature Controller.

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

49900-038

15

10. Troubleshooting CONTINUED

10.4. VULCANIZER OVERHEATING

FAULT CORRECTION

10.4.1. Temperature set improperly. Ensure that Temperature Set Point is correct. (SEE SECTION 7.1.1.)

10.4.2. Faulty Contactor in SG1 control panel. Replace Contactor. (SEE SG1 PARTS LIST &SCHEMATIC DIAGRAM)

10.4.3. Faulty RTD Temperature Sensor in platen. Refer to the Maintenance Section in the Operator’s Manual

of the Almex Press.

10.4.4. Faulty Temperature Controller in SG1 Replace Omron Temperature Controller.

control panel.

10.5. UNIT FAILS TO CREATE SG1 NETWORK

FAULT CORRECTION

10.5.1. Improper network configuration. Ensure network is connected according to (SEE SECTION 8)

10.5.2. Faulty network connectors. Check network cables for continuity. Replace cables and terminators

if necessary.

10.5.3. Faulty communication on SG1 motherboard Contact Shaw Almex.

NOTE: IF TROUBLESHOOTING STEPS HAVE BEEN PERFORMED AND THE PROBLEM PERSISTS,

PLEASE CALL SHAW ALMEX FOR FURTHER SERVICE. (SEE SECTION 12)

HEATING ELEMENT RESISTANCE

RTD PROBE RESISTANCE

FIGURE 44 - PLATEN CONNECTOR - REFERENCE ONLY

Revised - April 2014 49900-038

16

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

11. SG1 Parts List

ITEM QTY DESCRIPTON PART #

PER UNIT

Power - 60A Option 1 600 V, 60 A Connector Body - DSN60 11-PWR-INC-08

1 600 V, 60 A Handle - DSN60 11-PWR-INC-09

1 600 V, 60 A Handle - DSN60 (Australia only) 11-PWR-INC-13

4 600 V. 3-phase, 18 A midi-contactor 11-PWR-OUT-04

2 600 V, 3-phase 9 A midi-contactor 11-PWR-OUT-03

2 250 VAC, 1 A 5 x 20 mm fast-acting glass fuse 11-PWR-INC-13

6 600 VAC, 20 A CC-type fuse (In fuse blocks 1 - 4) 11-PWR-FUS-04

2 600 VAC, 9 A CC-type fuse (In fuse blocks 5 - 6) 11-PWR-FUS-02

2 600 VAC, 1 A FNQ-CC type fuse (In fuse block TX) 11-PWR-FUS-01

Power - 100A Option 1 Metric DR100 Poly Receptacle - 600 V 100 A 3P+G 11-PWR-INC-02

1 Metric DR100 Poly Handle with built-in draw grips 11-PWR-INC-03

4 600 V 3-PHASE, 32A midi-contactor 11-PWR-OUT-02

2 600 V, 3-phase 9 A midi-contactor 11-PWR-OUT-03

2 250 VAC, 1 A 5 x 20 mm fast-acting glass fuse 11-PWR-FUS-04

6 600 VAC, 30 A CC-type fuse (In fuse blocks 1 - 4) 11-PWR-FUS-03

2 600 VAC, 9 A CC-type fuse (In fuse blocks 5 - 6) 11-PWR-FUS-02

2 600 VAC, 1 A FNQ-CC type fuse (In fuse block TX) 11-PWR-FUS-01

Pressure Sensing 2 TPMS Wireless Pressure Sensors, 250 psi 11-WLS-PSN-02

2 Schrader Valve for TPMS Wireless Pressure Sensor 11-WLS-VLV-01

Thermocouple Temperature 8 10’ K-type Thermocouple extension cable, mini male, mini female 11-THR-OTH-02

Sensing Optional 8 12” length, 1/8” diameter K-type round probe, mini male 11-THR-OTH-01

Switchgear Networking 1 DeviceNet Female Terminator 11-NET-OPA-01

Optional 1 DeviceNet Male Terminator 11-NET-OPA-02

N-1 DeviceNet Chordset Straight Male/Female 8M (thin) 11-NET-OPA-03

1 DeviceNet Mini T-Connector 11-NET-OPA-04

Miscellaneous 1 DAP Draft Attack sealant caulking 11-STR-ENC-11

1 Dust Cover 11-STR-ENC-10

1 Silicon Gasket 11-STR-GAS-01

1 SG1 Protective Carrying Case 11-STR-ENC-12

Documentation 1 Operating Manual

1 Commissioning Report (QA)

Revised - April 2014

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

49900-038

17

12. Service

12.1 EMERGENCY SERVICE

Contact: Service Department

Telephone: 705-746-5884

Toll Free: 1-800-461-4351

(Canada and U.S. Only)

Fax: 705-746-9484

SHAW ALMEX INDUSTRIES LIMITED

Mail: P.O. Box 430, Parry Sound

Ontario, Canada P2A 2X4

Email: service@almex.com

12.2 RETURN OF GOODS AUTHORIZATION

The service department of Shaw Almex Industries Limited MUST

be contacted for the necessary authorization and documentation

prior to returning goods to the factory.

The service department may be reached at the numbers shown

in the left column.

12.3 GUARANTEE

Your ALMEX Switchgear Box is guaranteed against defective

parts, material and workmanship for a period of 12 months

from the date of purchase. For complete details, refer to the

Warranty Card.

13. Schematic Diagrams

FIGURE 45 - SG1 WIRING SCHEMATIC - 60A

Revised - April 2014 49900-038

18

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

13. Schematic Diagrams CONTINUED

FIGURE 46 - SG1 WIRING SCHEMATIC - 100A

Revised - April 2014

Shaw Almex Industries | 1.800.461.4351 | www.almex.com

49900-038

19

SHAW ALMEX INDUSTRIES LIMITED

1-800-461-4351

www.almex.com

Revised - April 2014

49900-038

Loading...

Loading...