Almatec A 08,A 50 Operating and Installation Instructions

A-Series

A 08 – A 50

Pneumatic Diaphragm Pumps made of Polymer Material

Operating and

Installation Instructions

ought to be studied before installing the pump

A-SERIES · page 2

Introduction

The ALMATEC Maschinenbau GmbH is certified as a modern, quality-orientated enterprise according to

EN ISO 9001. Before release for dispatch, any pump of the A-Series has to undergo an extended final control.

The performance data registered during this are archiv ed in our records and can be read back at any time.

Before putting any pump into operation, make sure, that the materials of construction are resistant to the

chemical to be pumped. To check this, the exact pump code is required. This code, as well as the serial number, can be found in the following. Besides, these data are noted on the identification plates on the pump itself.

Pump code Serial-No.

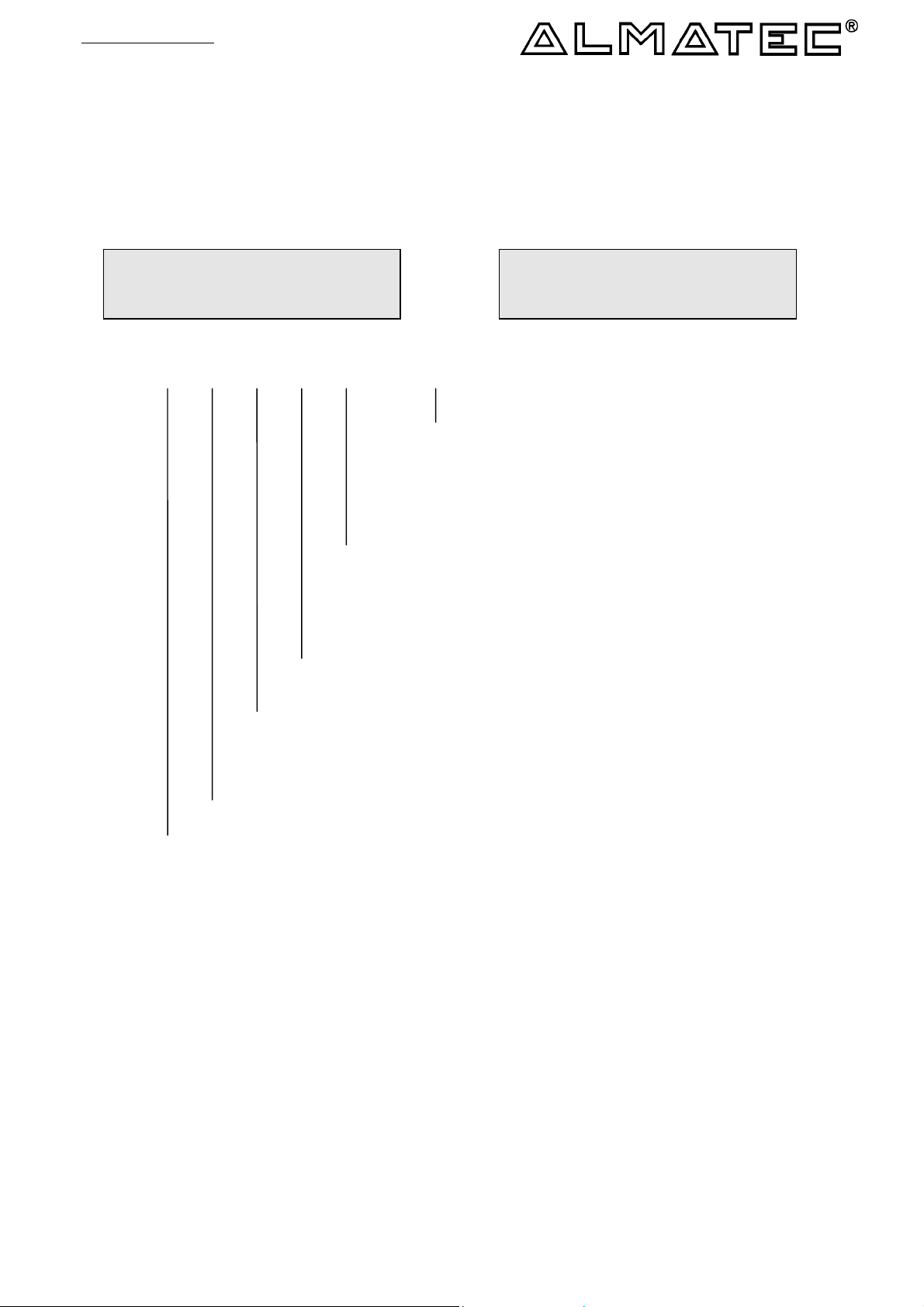

Here is an example to clarify the system of the ALMATEC pump codes:

A 15 T T T - B

Optional equipments:

B Barrier chamber

C Stroke counting

D Diaphragm monitoring

F Flange connection PN 10

R Back flushing system

Type and material E Ball valves, EPDM

of product valves: T Ball valves. PTFE

S Ball valves, stainless steel

Y Cylinder valves, PE

Z Cylinder valves, PTFE

Diaphragm material: E EPDM

T PTFE/EPDM-compound

Housing material: E PE

F PE-conductive

T PTFE

U PTFE-conductive

Size and port dimension

ALMATEC Pneumatic diaphragm pump, A-Series

For inflammable liquids as well as for applications in explosion protected areas, only pumps with housings and

fittings in conductive polymer materials may be used. Pneumatic diaphragm pumps of the A-Series with the

housing codes F (PE-conductive) and U (PTFE-conductive) meet this requirement. The pump has to be

grounded. An earthing connection to ground the pump is included in the center housing [2]. The connection of

all other housing parts is conductive, therefore it is not necessary to ground single parts.

The number in brackets, which is added to every part mentioned in the following explanations, refers to its

position in the spare part list and the exploded view.

Product ports

The product ports are integrated into the center housing [2]. Different port configurations can be obtained. The

standard configuration of the A-Series at delivery is with the suction inlet horizontally at the bottom and the

discharge outlet horizontally at the top. Further possible configurations:

• Suction inlet vertically at the bottom, the discharge outlet horizontally at the top:

To obtain this configuration, the plug of the center housing [8] has to be removed and set in the standard

inlet.

• Suction inlet horizontally at the bottom, the discharge outlet vertically at the top:

Unscrew the housing bolts [15], take off the side housings [1] and turn the center housing [2]. Remount

the pump and adjust the plug [8] accordingly.

The mounting and dismounting of the pump will be described further on.

A-SERIES · page 3

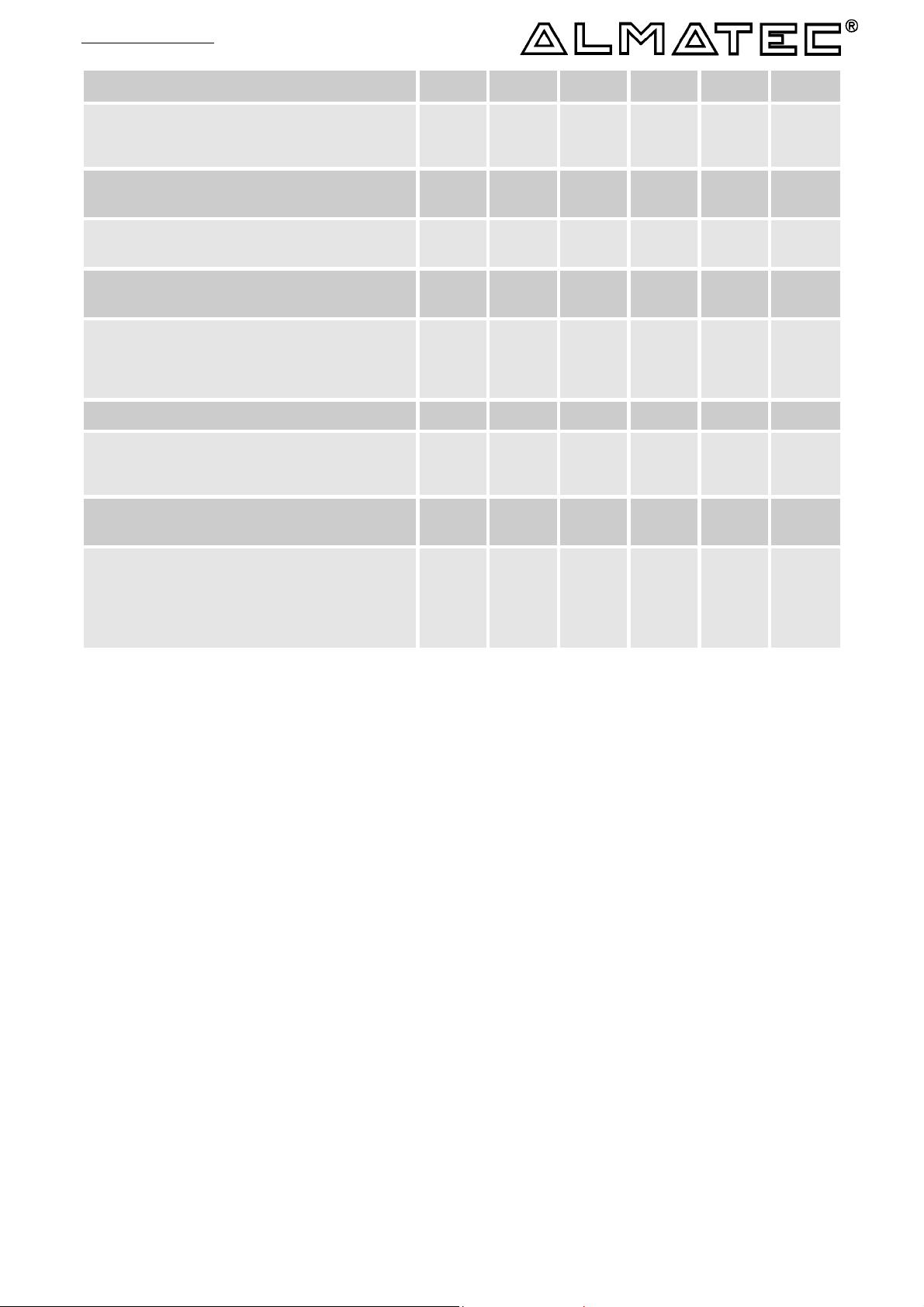

Technical data

Dimensions (mm): length

width

height

Nominal port size (NPT)

Air connection

Weight (kg): PE

PTFE

Max. particle size of solids (mm)

for pumps with ball valves

Suction lift, dry (mWC):

cylinder valves

ball valves

Suction lift, wet (mWC)

Max. operating pressure (bar) 7 7 7 7 7 7

Max. operating temperature (°C):

PE

PTFE

Theoretical displacement volume

per single stroke (l)

A 08 A 10 A 15 A 25 A 40 A 50

90

113

129

1/4“

R 1/8

-

2

2 3 4 6 9 11

1

0.5

9

-

100

0.0075 0.0215 0.1 0.34 0.98 2.6

110

127

169

3/8“

R 1/8

-

4

2

1.5

9

-

100

166

176

240

1/2“

R 1/4

5

10

3

2

9.5

70

120

220

231

320

1“

R 1/4

13

25

4

3

9.5

70

120

280

326

432

1 1/2“

R 1/2

29

60

5

4

9.5

70

120

360

396

552

2“

R 1/2

58

120

5

4

9.5

70

120

Sound pressure level acc. to DIN 45635,

part 24, depending on the operating data

[dB (A)]: driving pressure 3 bar

driving pressure 5 bar

driving pressure 7 bar

These technical data are for ALMATEC A-Series pumps without optional equipments.

Installation and Operation

In general, the pump has to be connected load free. Neglecting this causes leakage and maybe even

damages. To avoid vibrations, pulsation dampers and compensators are recommended. Before connecting the

pump, take the yellow blind plugs out of the suction and discharge connections as well as the air inlet [19] in

the center housing [2]. The connections of ALMATEC pneumatic diaphragm pumps in polymer materials have

slightly tapered threads. Use threadseal only sparingly, otherwise the connections could be damaged.

The nominal width of the connection pipes has to be chosen in accordance to the connections of the pump.

A smaller piping can cause cavitation (suction line) as well as a loss of performance (suction and discharge

line). In case the pipe is too big, the dry suction capacity of the pump can decrease. Connect the suction line to

the lower connection in the center housing [2]. Seal the suction line diligently; hosepipes should be suitably

armoured. A suction line continuously rising will prevent the formation of air locks in the line which would affect

the suction lift.

The air inlet [19] is located in the middle of the center housing [2]. To supply the pump with driving air

sufficiently, the pipe diameter should match the size of the air inlet. Take care that no dirt or particles can

intrude into the pump during the connection, as these can accumulate inside the pump and can cause

malfunctions. An air filter [20] directly behind the air inlet [19] (not included in A 08 and A 10) prevents the entry

of bulk particles.

The integrated air control system PERSWING P® is a precision-control that requires oil-free, dry and clean

compressed air for optimal function. If humidity is expected, a water separator or air dryer has to be fitted to

protect the pump from blocking by ice. The ideal condition is the dewpoint of air at -20°C. In humid

surroundings, icing from the outside may occur despite the driving air is dried. If so, a prolonged waste-airexhaust (ca. 500 mm by pipe or hose) can be helpful. When installing the pump into boards or cabinets, it has

to be ensured that cold air does not get caught behind the muffler.

68-70

71-74

71-76

68-70

71-73

72-75

68-71

73-75

74-78

69-71

71-75

73-76

63-65

64-68

69-74

65-70

69-74

73-78

Loading...

Loading...