All Power APC4008 Owner’s Manual

AIR

/

/

2

ACCESSORIES

an

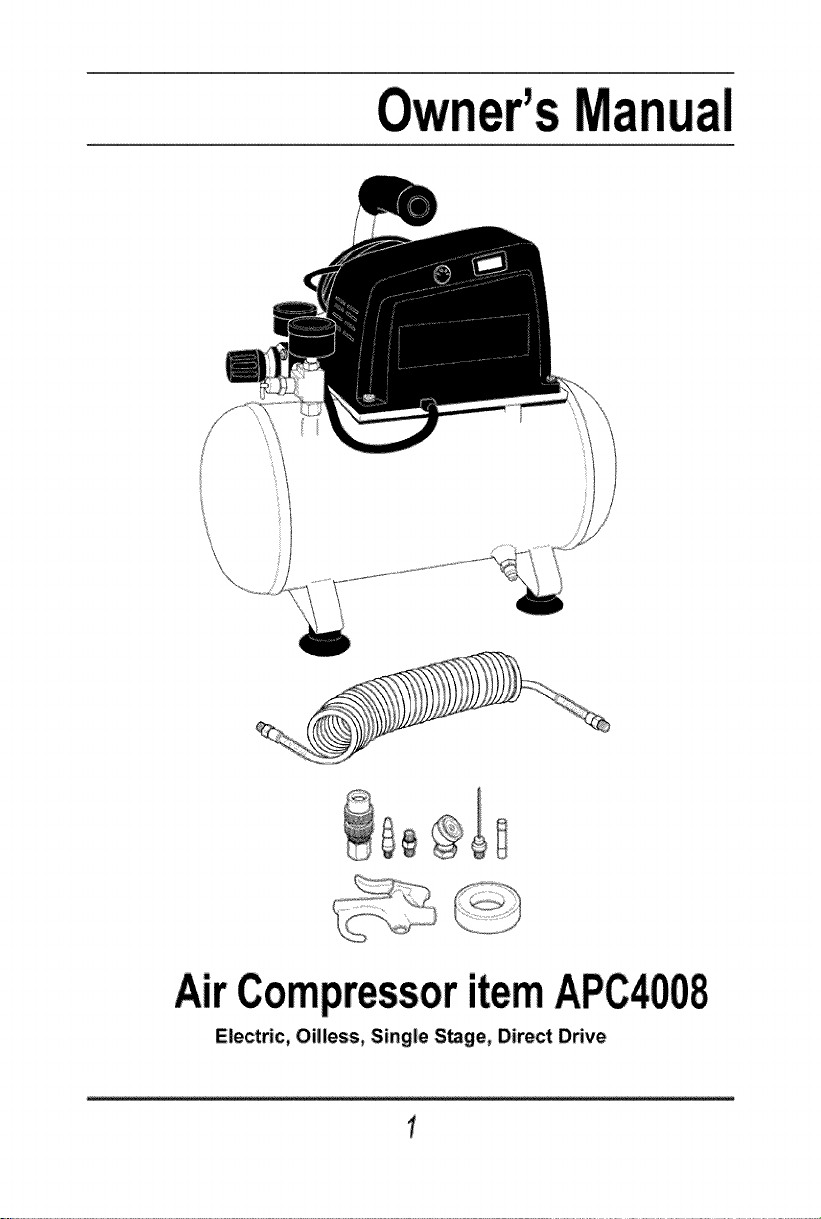

irCompressoritem

Electric, Oiliess, Single S_ge, Direct Drive

1

Manual

WARNING!READANDUNDERSTANDALLSAFETYPRECAUDONSIN

THISMANUALBEFOREOPERATING.FAILURETOCOMPLYWITH

INSTRUCTIONSINTHISMANUALCOULDRESULTIN PERSONAL

INJUR_ PROPERTYDAMAGE,AND/OR VOIDINGOF"fOUR

WARRANTYNIKOTAUSAWILLNOTBELIABLEFORANYDAMAGE

BECAUSEOFFAILURETOFOLLOWTHESEINSTRUCTIONS_

Compressor Inspection

Prior to installation and usage, thoroughly inspect air _mpressor

for damage or flaws.

• Check tank, compressor, compressor motor and pump for

any signs of damage or _rrosion.

• Check all screws, bolts, nuts and fasteners. Confirm that they

are secure.

• Confirm, that all fittings, tank petcock and hardware are free

of paint, rust and corrosion.

• Confirm, that all compressor settings are correct prior to

set-up and usage.

Air Tool Inspection

Prior to connecting to compressor and usage, thoroughly inspect

each air tool for damage or flaws.

• Check entire tool assembly for any signs of damage or

corrosion.

• Check all assembly screws, bolts, nuts and fasteners and

confirm that they are secure.

• Confirm, that all fittings, bits and hardware for integrity.

• Confirm that tool settings are correct prior to connection and

usage.

2

AirCompressor

SafetyGuidelines- Definitions

This manual contains important information that you need to know and

understand in order to protect YOUR SAFETY and to PREVENT

EQUIPMENT PROBLEMS. The following symbols help you recognize this

information. Please read the manual and pay attention to these sections.

WARNING!WARNINGSINDICATEA CERTAINTYORSTRONG

A OSSIBILITYOFPERSONALINJURYORDEATHIFINSTRUCTIONS

_k EQUIPMENT DAMAGE IF INSTRUCTIONS ARE NOTFOLLOWED.

ARE NOTFOLLOWED.

CAUTION." CAUTIONS INDICATE A POSSIBILITY OF

Note: Notes give helpful information.

WARNING!IMPROPEROPERATIONORMAINTENANCEOFTHIS

PRODUCTCOULDRESULT/IVSERIOUStNJURYANDPROPERTY

DAMAGE.READANDUNDERSTANDALLWARNINGSANDOPERATING

INSTRUCTIONSBEFOREUSINGTHISEQUIPMENT,WHENUSINGAIR

TOOLS,BASICSAFETYPRECAUTIONSSHOULDALWAYSBE

FOLLOWEDTOREDUCETHERISKOFPERSONALINJURY.

SaveTheseImportantSafety

Instructionst

Read and understand all of these safety instructions. Be

sure to retain them for future use.

3

Owner'sManual

HazardWarnings

Dust

WARNfNG!SOMEDUSTCREATEDBY POWERSANDING,SAWING,

GRINDING,DRILLING,ANDOTHERCONSTRUCTIONACTIVITIES

CONTAINSCHEMICALSKNOWNTO THESTATEOFCALIFORNIATO

CAUSECANCERBIRTHDEFECTSOROTHERREPRODUCtiVEHARM.

These chemicals may include (but are not limited to) the following:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals: work in a well

ventilated area, and work with approved safety equipment, always wear

MSHAJNIOSH approved, properly fitting face masks or respirators when

using such tools.

Always follow basic safety precautions when using air tools to reduce the

risk of personal injury.

Bursting

Rust can weaken the tank. Drain the condensed water from the tank after

each use to reduce rusting. If a leak is detected in the tank, replace the tank

immediately. Do not weld, drill or modify the air tank of this compressor.

Welding or modifications on the air compressor tank can severely impair

tank strength and cause an extremely hazardous condition. Welding or

modifying the tank in any manner will void the warranty.

Check the manufacturer's maximum pressure rating for air tools and

accessories. Compressor outlet pressure must be regulated so as to never

exceed the maximum pressure rating of the tool. Relieve all pressure

through the hose before attaching or removing accessories.

Do not adjust the pressure switch or relief valve for any reason. Doing so

voids all warranties. They have been preset at the factory for the maximum

pressure of this unit. Personal injury and/or property damage may result if

the pressure switch or the relief valve are tampered with.

Do not use plastic or pvc pipe for compressed air. Use only galvanized steel

pipe and fittings for compressed air distribution lines.

4

Air Compressor

Hazard Warnings (cont'd)

Riskof Eyeor HeadInjury

What could happen:

• Air powered equipment and power tools are capable

of propelling materials such as fasteners, metal chips,

saw dust, and other debris at high speed, which could

result in serious eye injury.

• Compressed air can be hazardous. The air stream

can cause injury to soft tissue areas such as eyes,

oars, etc. Particles or objects propelled by the stream

can cause injury.

• Tool attachments can become loose or break and fly

apart propelling particles at the operator and others in

the work area.

How to prevent it:

• Always wear ANSI approved Z87.1 safety glasses with side shields.

• Never leave operating tool unattended. Disconnect air hose when tool is

not in use.

• For additional protection, use an approved face shield in addition to

safety glasses.

• Make sure that any attachments are securely assembled.

• Never point any nozzle or sprayer toward a person or any part of the

body. Equipment can cause serious injury if the spray penetrates the

skin.

5

Owner'sManual

HazardWarnings (cont'd)

Riskof Fireor Explosion

What could happen:

Abrasive tools such as sanders and grinders, rotating

tools such as drills, and impact tools such as nailers,

staplers, wrenches, hammers, and reciprocating saws

are capable of generating sparks which could result in

ignition of flammable materials.

It is normal for the compressor motor and pressure

switch to produce sparks while operating. Ifsparks

come into contact with vapors from gasoline or other

solvents, they may ignite, causing fire or explosion.

Exceeding the maximum pressure rating of tools or

accessories could cause an explosion resulting in

serious injury.

How to prevent it:

• Never operate tools near flammable substances such as gasoline,

cleaning solvents, etc.

• Work in a clean, well ventilated area free of combustible materials.

• Never use oxygen, carbon dioxide or other bottled gases as a power

source for air tools.

• Use compressed air regulated to maximum pressure at or below the

rated pressure of any attachments.

• Never connect to an air source that is capable of exceeding 200 psi.

• Always verify prior to using the tool that the air source has been

adjusted to the rated air pressure range.

• Never spray flammable liquids in a confined area. Do not spray where

sparks or flame are present.

• Do not smoke while spraying.

• Keep compressor as far from spray area as possible.

5

Air Compressor

HazardWarnings(cont'd)

Riskof HearingLoss

What could happen:

• Long term exposure to noise produced from the

operation of air tools can lead to permanent hearing

loss.

How to prevent it:

Always wear ANSI $3.19 hearing protection when using a compressor.

Riskto Breathing/Inhalation

Hazard

What could happen:

• Abrasive tools such as grinders, sanders, and cut-off

tools generate dust and abrasive materials which can

be harmful to human lungs and respiratory system.

Some materials such as adhesives and tar contain chemicals whose

vapors could cause serious injury with prolonged exposure.

How to prevent it:

• Always wear MSHA!NIOSH approved, properly fitting face mask or

respirator when using such tools. Read all instructions and be sure that

your respirator mask will protect you.

• Always work in a clean, dry, well ventilated area.

• Never directly inhale the compressed air produced by a compressor. Itis

not suitable for breathing purposes.

• Re certain to read all labels when you are spraying paints or toxic

materials, and follow the safety instructions.

Owner'sManual

Hazard Warnings (cont'd)

Riskof Injury

What could happen:

Tools left unattended, or with the air hose attached

can be activated by unauthorized persons leading to

their injury and/or injury to others.

Air tools can propel fasteners or other materials

throughout the work area.

A wrench or key that is left attached to a rotating part

of lhe tool increases the risk of personal injury.

Using inflator nozzles for duster applications can

cause serious injury.

Air tools can become activated by accident during

maintenance or tool changes.

Air tools can cause the work-piece to move upon

contact leading to injury,

Loss of control of the tool can lead to injury to self or

others.

Poor quality, improper, or damaged tools such as

grinding wheels, chisels, sockets, drills, nailers,

staplers, etc., can fly apart during operation,

propelling, particles throughout the work area causing

serious Inlury.

Fasteners could ricochet or be propelled causing

serious injury or property damage.

Improperl,y maintained tools and accessories can

cause senous injury.

There is a risk of bursting if the tool is damaged.

The compressor unit starts automatically. Serious

injury could occur from contact with moving parts.

8

Loading...

Loading...