Page 1

OPERATOR’S AND PARTS MANUAL

MESSAGE BOARD

MB 6220 Series

MODELS MB 6200

MB 5200

MB 6100

ALLMAND BROS. INC

P.O. BOX 888

HOLDREGE, NE 68949

PHONE: 308/995-4495, 1-800/562-1373

ALLMAND FAX: 308/995-5887

ALLMAND PARTS FAX: 308/995-4883

MESSAGE BOARD MESSAGE BOARD

MESSAGE BOARD

MESSAGE BOARD MESSAGE BOARD

For Parts and Updates visit Allmand on the Web at www.allmand.com

1

Page 2

TABLE OF CONTENTS

ALLMAND MESSAGEBOARD

Table of Contents Page 2

Glossary Page 3

Description and Features Page 4

Safety and Precautions Page 5

Set-up/Operating Instructions Page 6

Trailer Alignment (Illustration) Page 7

Safety and Warning Decals Page 8

Winch Operating Instructions Page 9

Periodic Maintenance Page 10

Array Maintenance Page 10

Battery Maintenance Page 11

BRICK and Component Description Page 12

Laptop Computer Software Page 16-23

Operation/HHT Users Guide Page 24

Assembling and Installing a Message Sign Page 35

Service and Maintenance Page 48

Troubleshooting Page 54

Brick Components Warranty Page 60

Parts and Accessories Page 61

Wiring Diagrams Page 68

2

Page 3

Glossary

BaseStation

Pentium®-based computer or notebook on which BRICKBuilder and

BaseStation Software Suite run. Can be used in remote or on-site environment.

BaseStation Software

Software on a central computer controlling and/or monitoring signs. (See

also BaseStation)

Bitmap

Digital representation of pixels that produces a sign display image.

BRICK

Patented display module comprised of columns and rows of LED pixels

and the fundamental building element of the Sign System.

Font

A type style for a set of characters (letters, numbers, punctuation marks,

and symbols).

Frame

The basic building block for a message sequence (for example ROAD

WORK AHEAD).

Hand-Held Terminal (HHT)

Small device, consisting of a keypad and display unit, that provides an interface between a user and a Single-Board Computer (SBC).

Jumper BRICK

A BRICK-like module without LEDs that electrically connects rails together.

Message

Consists of frames in a sequence. (See also Frame and Sequence)

Pixel

Smallest display element of the sign; a group of four LED’s.

Rail (Bus Bar)

Patented mount for the BRICK® that also provides electrical power and

communication signals.

Sequence

A group of one or more frames with display time-on and time-off associated with each frame. (See also Frame)

Single-Board Computer (SBC)

Printed circuit card assembly that is the interface between a hand-held

terminal or a base station computer, and the sign message.

Trim BRICK

BRICK-like module that is attached to the end of the rail of a multi-row

BRICK sign to provide a neat appearance to the sign.

3

Page 4

ALLMAND SOLAR ASSIST MESSAGE BOARD

DESCRIPTION AND FEATURES

The ALLMAND MESSAGE BOARD uses four 12V DC 8D deep cycle batteries, providing a nominal 12V DC to the operating system.

The battery enclosure is lockable, ventilated and designed to protect the batteries from theft or vandalism. The location of the

enclosure allows for easy maintenance or replacement of the battery bank. An electronic control system protects the batteries from

overcharging and gassing. The Low Voltage Disconnect (LVD) system protects the battery from excessive discharge which can

result in premature battery failure.

Solar charging is accomplished by a 150w class 12V DC single crystalline photovoltaic array located above the sign panel. This

provides maximum exposure of the array to the sun. The array location minimizes vandalism or theft. The array constantly charges the

batteries when exposed to the sun. A standard ALLMAND battery charger, specifically designed for this unit, allows the batteries to

be recharged using standard 115V AC line current.

The BRICK Modular Message Sign System provides a flexible, re-configurable message sign system.

Changeable Message Signs (CMS) (also called Variable Message Signs, Electronic Signs, Active Signs, and Dynamic Signs) have

provided useful information for the traveling public for years. Due of the success of CMS, and to ever-increasing traffic demands,

CMS are being used for new applications. Because of size, weight, production lead-time, and cost, traditional CMS cannot be used for

many of these new applications. The BRICK Modular Message Sign System solves many of the problems that occur with traditional

CMS.

With the BRICK Modular Message Sign System, you can:

• Rapidly re-configure and also re-use signs in ways not previously possible.

• Program a sign on-site via a hand-held controller, a base station computer or notebook.

• Use sign components for a custom job or application.

Individual BRICK Modular Message Sign System

Components

The system contains the following components:

• From 6 to 12 individual BRICKs that you use to construct the message sign.

• A rail assembly that carries both the 12 Vdc power and the communications data and provides mounting for each BRICK.

• A single-board computer (SBC) that provides control to the BRICK

• A jumper BRICK that transfers power between multiple lines of the signs.

• A trim BRICK that finishes the sign to ensure a neat appearance.

• Hold down locks that secure the BRICK, jumper BRICK, and SBC to the rail.

The following features are optional and provide user interface to the system:

• A hand-held terminal to use for on-site programming of the sign messages.

• An advanced controller to use for on-site modifications to frames, sequences, and messages.

• Base Station software (able to run on a Pentium PC) that provides the same functions as the hand-held controller,

plus additional functions.

BRICK Display Module

The BRICK display module consists of Light Emitting Diodes (LEDs) that can compose alphanumeric or graphic messages. The front

face of the BRICK is made from a UV-inhibited, polycarbonate material with a LJV, silk-screened mask that provides a high level of

contrast and readability. The body of the BRICK is made from a UV-inhibited, high-impact, ABS thermoplastic material. The BRICK is

environmentally sealed against contaminants, and the electrical component enclosure is completely sealed from the outside environment. Each BRICK has its own microprocessor that enables the BRICK to know its addressable location in the sign matrix. This

capability allows BRICKs to be moved anywhere in the sign matrix, without individually addressing each display with dip switches or

special wiring harnesses. The connectors that mate with the rail are on the reverse side of the BRICK. Each BRICK is installed by

pushing the BRICK onto the rail to make the connection. Each BRICK can be removed and replaced without disturbing other modules. A

vandal-resistant, hold-down lock device secures each BRICK onto the rail.

BRICK Configuration Options

The BRICK Modular Message Sign System consists of custornizable, re-configurable messages. The BRICK display modules attach to

a rail (bus bar) system that eliminates the need for wiring, acts as a support for the BRICKs , and carries electrical and communications signals. You can mount the rail to anything that can support the number of bricks used for the desired configuration.

The BRICK display module is a two-part, sealed thermoplastic box, with a front face made of ultraviolet (UV)-inhibited Lexan Polycarbonate. The display module tray holds a printed circuit board made of high-impact co-extruded ABS substrate. The front face of the

sign is silk-screened with an LJV-inhibited mask to provide a high level of contrast and readability. The BRICK display module is

environmentally sealed against contaminants.

4

Page 5

DESCRIPTION AND FEATURES

A low-voltage disconnect (LVD) system protects the batteries from damage if solar conditions fail

to adequately maintain a sufficient charge. This system features a red warning lamp which signals

low battery voltage and imminent shutdown of the system. This lamp is mounted on the rear of the

sign panel and is easily visible from the jobsite or roadway. If battery voltage becomes dangerously low, the red warning lamp will begin to flash. When voltage goes below an operative level,

the message board will shut down. At this time maintenance personnel will need to either recharge the batteries or replace them with fully charged units if necessary.

The trailer consists of a formed 10 GA steel deck with crossmembers and an integral battery

compartment with lockable cover. Four steel uprights welded to the deck support the sign panel

for operation and transportation. A positive mechanical lock secures the sign in both operating

and towing positions. The tongue is constructed of 3" structural steel channel and has a heavyduty combination 3" diameter pintle ring and 2" ball coupler. A folding screw jack is mounted to

the tongue immediately behind the pintle eye. Four adjustable corner stands (one at each corner

of the trailer) stabilize the trailer when in operation. They are constructed of 1-3/4" Telespar

tubing complete with footpads, locking pins, and clips. The trailer rides on a 1500 lb. tube-type

leaf spring axle with 5-lug hubs and 13" 4-ply rated tires and wheels. Raising and lowering of the

sign panel is accomplished by a ratchet-type hand crank winch and pulley system with safety

brake clutch and a single 3/16" braided steel cable that will raise and lower the sign panel

evenly. Flush mounted stop, turn, and taillights with a 4-contact male end connector on the cable

insures towing safety. Color coding of the wiring is in accordance with SAE practice, (SAE

J560A and SAE J895). The trailer is finished in high-visibility Safety Orange paint.

SAFETY AND PRECAUTIONS

A safe environment around the ALLMAND MESSAGE

BOARD is encouraged. The following recommendations

should be noted since the ALLMAND MESSAGE BOARD is

typically used in construction areas with greater traffic congestion, thereby increasing the risk of accidents or injuries.

The sign panel should always be in travel position (lowered)

and secured using the attached lock pins when towing the

ALLMAND MESSAGE BOARD at highway speeds. Make

sure that the hitch is properly engaged with the towing vehicle

and that the safety chains are properly fastened and all jacks

and/or jackstands are raised and secured before towing. Also

be certain that the taillights are connected and working properly before towing the unit.

5

Page 6

The trailer should be properly set up with the jack stabilizers, sand bags, etc. in position before

leaving the ALLMAND MESSAGE BOARD deployed in the traffic control area. Periodically

inspect the tongue, pins, safety chains, hitch, all nuts, bolts, cable clamps, wiring, etc. for wear

and repair or replace if necessary.

SAFETY NOTE/DISCLAIMER

ALLMAND BROS. INC. has taken precautions to ensure that the ALLMAND MESSAGE

BOARD is safe and reliable. ALLMAND BROS. INC., however, is not responsible for any

injuries, accidents or other mishaps as a result of the use or misuse of this or any other

ALLMAND product. It is the user’s responsibility to ensure that the manner in which the

ALLMAND MESSAGE BOARD is used is consistent with safe practices and the user is to

understand that he/she is the only liable party.

SET-UP/OPERATING INSTRUCTIONS

The following is a step-by-step procedure for set-up and operation of the ALLMAND MESSAGE

BOARD.

NOTE: Before transporting the trailer to the jobsite, be certain that the batteries are fully charged

using the ALLMAND ECLIPSE charger or any commercially available minimum 50 amp

battery charger designed to charge a deep-cycle battery bank of this size. Be certain that the

battery bank is charged completely, allowing the unit to operate as long as possible before lowvoltage shutdown occurs.

1. Block the wheels of the trailer first, then remove the trailer from the towing vehicle.

2. With the sign panel directed toward the traffic, level unit off the tires using the jacks and /or

jackstands.

CAUTION: For safe operation and maximum visibility, sight through the eyelets midway up the

right frame uprights to align the unit relative to the roadway and the horizon as illustrated on the

following page. Observe the operation of the machine from varying vantage points down the

roadway to ensure that maximum visibility is maintained throughout the controlled area.

Turn power switch on and determine that the display that has been selected is the desired mode

and that it is operating properly.

CAUTION: Always check for overhead obstructions before raising sign panel.

3. Remove sign panel spring pins and erect sign panel by cranking braking winch. See WINCH

OPERATING INSTRUCTIONS on page 8.

4. Insert spring pins into the trailer uprights to stabilize the sign.

5. Ensure that the display is operating correctly and is readable from an adequate distance

before leaving the worksite.

6

Page 7

TRAILER ALIGNMENT ILLUSTRATION

1 MILE

CAUTION: For safe operation and maximum visibility, sight through the eyelets midway up the

LEFTframe uprights to align the unit relative to the roadway and the horizon as illustrated above.

Observe the operation of the machine from varying vantage points down the roadway to ensure

that maximum visibility is maintained throughout the controlled area.

7

Page 8

SAFETY AND WARNING DECALS

ALWAYS REPLACE ANY SAFETY AND INSTRUCTIONS DECALS THAT BECOME

DAMAGED, PAINTED OVER, OR OTHERWISE ILLEGIBLE!

Refer to the following representations of the safety warning decals used on the ALLMAND

MESSAGE BOARD trailer to insure correct ordering if replacement becomes necessary.

8

Page 9

WINCH OPERATING INSTRUCTIONS

The winch is designed to lift load (“reel in”) when the crank is turned in a clockwise direction.

This action will produce a clicking sound. To lock load at any desired position, simply release

the hand crank. To lower load (“reel out”), turn the hand crank in a counter-clockwise direction.

To lock load in any desired position, turn handle crank clockwise until at least two clicks are

heard before releasing handle.

WARNING: Never exceed rated winch load. Excess load may cause premature failure and

could result in serious personal injury. This winch is rated at 1200 pounds with one layer of

cable on a 2-1/2" hub. Using more layers of cable increases the load on the winch.

CAUTION: Never apply load to winch with cable fully extended. Keep at least three full turns of

cable on the reel.

IMPORTANT: Sufficient load must be applied to the cable to overcome internal resistance

and operate brake properly. Otherwise, turning the hand crank counter-clockwise will only

remove the crank from the shaft as the reel will not turn. Minimum operating load requirement

for the DLB-1200 winch is 75 pounds.

NOT FOR MOVEMENT OF HUMAN BEINGS

WINCH LUBRICATION: This winch has been fully lubricated at the factory, but for continued

smooth performance and increased life, occasionally grease gears, reel shaft and handle

threads. An occasional drop of oil on drive shaft bearings is also recommended.

CAUTION: DO NOT OIL OR GREASE BRAKE MECHANISM

9

Page 10

PERIODIC MAINTENANCE

The ALLMAND MESSAGE BOARD has been designed to minimize maintenance. However

it will be necessary to inspect or test the following areas on a periodic basis.

ARRAY MAINTENANCE

1. Clean solar panels.

2. Check solar panels and wiring.

3. Check wiring to ensure that there is no damage caused by normal use, wear and tear, road

vibration, etc.

BATTERY MAINTENANCE

4. Check water level on each cell of the batteries. Top off when necessary using only distilled

water.

5. Check battery condition. Charge when necessary or when not in use.

GENERAL MAINTENANCE

6. Check taillights to ensure proper operation. Also check tongue, safety chains and pins.

7. Check sign panel for proper operation.

8. Check tires and wheel bearings.

9. Check all nuts and bolts for tightness.

ARRAY MAINTENANCE

Examine the entire array for the following:

Examine the top (photosensitive) surface of each module for cleanliness. Any visible accumu-

lation of dirt can impair energy production and should be removed. Use a soft cloth and either

plain water or a solution of mild detergent (such as dishwashing detergent) followed by a rinse

with plain water. Do not spray or direct a solid stream of water at the modules. No abrasive

material should be used in cleaning the modules. It is very important to note that water can

increase the chance of electrical shocks and burning. Care should be taken to use properly

insulated tools and rubber gloves when cleaning the modules.

Examine all electrical cabling. Make certain that connections are tight at the module junction

boxes, the controller, and the battery bank. Look for any signs of cable breaks and also for

damaged or missing insulation. If any worn or damaged wiring appears likely to interfere with

proper operation now or later, replace the damaged wire.

10

Page 11

ARRAY MAINTENANCE (cont)

The array may be tested by using a voltmeter to check the voltage across the array (+) terminal

and array (-) terminal of the sign connector. Expose array to full sunlight. Using a voltmeter, check

open circuit voltage across the leads. The meter should indicate a voltage reading of 16-20V

DC.

Check all bolts and nuts. Tighten as needed.

BATTERY MAINTENANCE

Check the level of electrolyte in each battery cell. If necessary, add DISTILLED water to bring the

electrolyte up to the required level. A hydrometer may be used to test the condition of each

individual cell or a voltmeter may be used to test the condition of each individual battery.

Examine all battery terminals for signs of corrosion. If any terminal is corroded, disconnect the

battery cable. Clean the battery terminal and the connector on the cable with appropriate wire

brushes. Reconnect the cable to the battery terminal.

NOTE: Batteries must be recharged periodically using an AC battery charger to avoid oversulfating plates and impairment of battery performance.

If the supplied ALLMAND BATTERY CHARGER is not used, a charge current of at least 50

amps must be provided to sufficiently charge batteries. Use extreme caution when using other

than ALLMAND charger to observe correct battery polarity and also to avoid over-charging

(“boiling”) of batteries.

CAUTION! Any battery is an infinite current source when the battery terminals are momentarily shorted which can lead to serious bodily injury or fire. Goggles and other

protective equipment should be worn to shield skin and eyes from battery acid.

11

Page 12

BRICK® Display Module

The BRICK display module consists of Light Emitting Diodes (LEDs) that can compose alphanumeric or

graphic messages. The front face of the BRICK is made from a UV-inhibited, polycarbonate material with

a UV, silk-screened mask that provides a high level of contrast and readability. The body of the BRICK is

made from a UV-inhibited, high-impact, ABS thermoplastic material. The BRICK is environmentally sealed

against contaminants. The electrical component enclosure is completely sealed from the outside environment. Each BRICK has its own microprocessor that enables the BRICK to know its addressable location in

the sign matrix. This capability allows BRICKs to be moved anywhere in the sign matrix, without individually addressing each display with dip switches or special wiring harnesses.

The connectors that mate with the rail are on the reverse side of the BRICK. Each BRICK is installed by

pushing the BRICK onto the rail to make the connection. Each BRICK can be removed and replaced

without disturbing other modules. A vandal-resistant, hold-down lock device secures each BRICK onto the

rail. The BRICK is a High density 96 pixel 384 LED configuration.

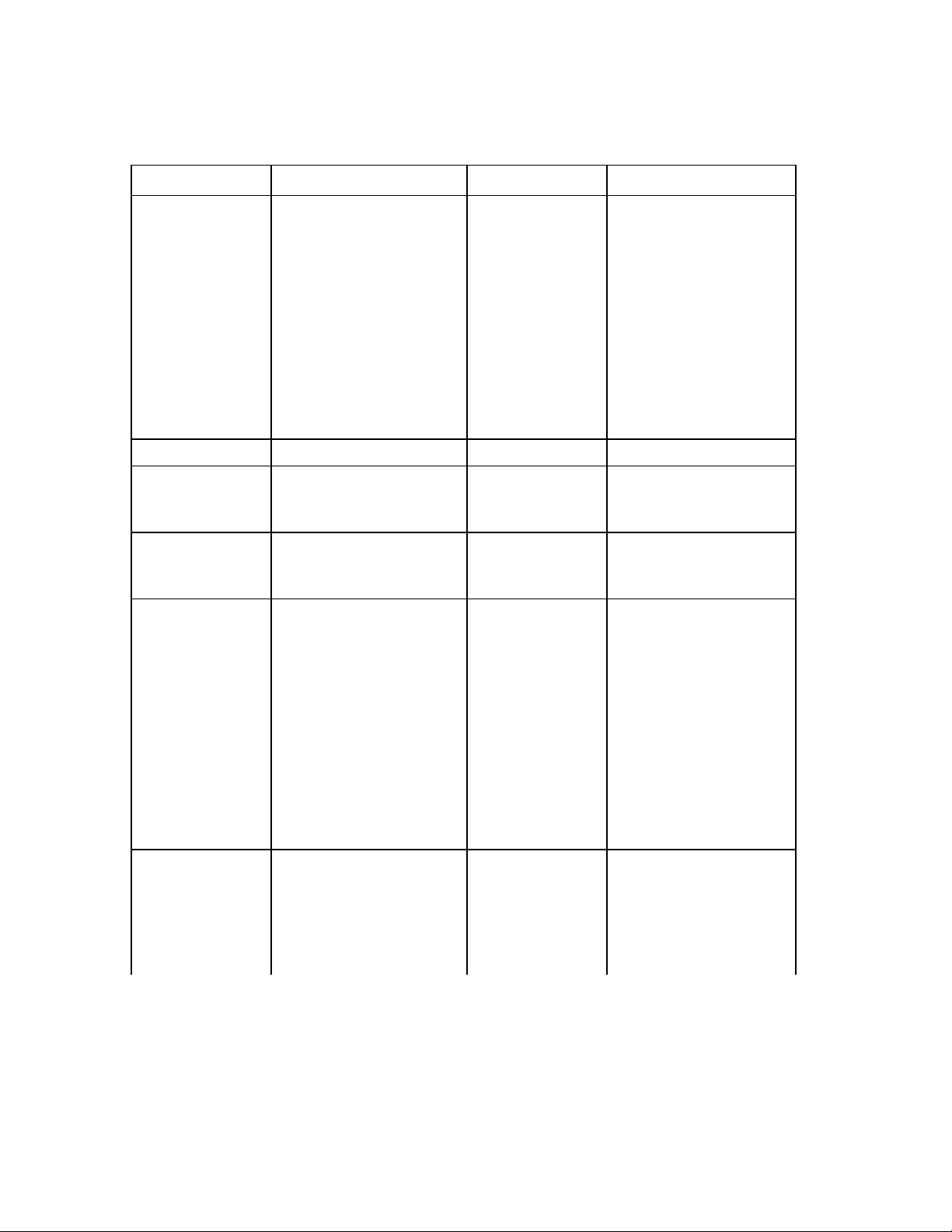

BRICK material and dimension information is summarized in the following table:

BRICK Information Details

Face material: UV-inhibited polycarbonate with UV, silk-

screened mask.

Body material: ABS thermoplastic.

Length: 19.25 in. (48.8 cm)

Width: 13.75 in. (34.9 cm)

Height: 2 in. (5.08 cm)

Weight: 4.25 lbs. (1.9 Kg)

Characteristic High Density

Pixel arrangement

Number of pixels 96

LEDs per pixel 4

Number of LEDs 384

LED spacing in pixel 1.625 in. (4.1 cm)

Pixel spacing 1.625 in. (4.1 cm)

LED type 592 NM amber.

Minimum character

size

Average 24-hour

current draw (see

definition below)

Absolute maximum

current draw (see

definition below)

Typical maximum

current draw (see

definition below)

Nominal voltage 12 Vdc.

Minimum voltage 10.5 Vdc.

Maximum voltage 16.0 Vdc.

8×12

10.5 in. (26.6 cm) (5×7)

7.0 in. (17.78 cm) (5×3)

11.5 Amps.

4.8 Amps.

3.1 Amps.

12

Page 13

Explanation of some BRICK operating current conditions described in previous table:

Power Supply Rating – Amount of power (Watts) needed per BRICK. This is a general rule of thumb to

allow for the potential of powering all LED pixels at full brightness.

Average 24-Hour Current – Current draw over 24 hour day (assume 12 hours daytime, 12 hours nighttime)

with an average text based display that utilizes approximately 30% of the LEDs pixels for High Density

BRICKs, 40% LEDs for Standard Density BRICKs.

Absolute Maximum Current – Current limit setting on a BRICK resulting in the worst case current draw in

the event of a failure.

Typical Maximum Current – Current draw for a BRICK in maximum ambient light conditions with all of the

pixels lit.

See also Connecting Power in Assembling and Installing a Message Sign section for additional information regarding BRICK system power source requirements.

Rail Assembly

The rail assembly consists of the following:

• Aluminum housing with mounting holes, grooves and flanges — for housing conductors and conductor

insulation as well as mounting to sign support system.

• Conductor (bus bar)

• Conductor insulation

The rail assembly:

• Carries both the 12V dc power and the communications data to each BRICK.

• Eliminates the need for character-to-character wiring, terminal blocks, connectors, and solder joints.

• Acts as a support for the BRICKs.

Rail assembly information and details are summarized in the following table:

Rail Information Details

Rail housing material Aluminum, painted black powder coat

Conductor material Copper alloy, metal plating; 0.062 by

1.0in.(0.15 by 2.54cm), cut to match rail

housing; strip fits into insulator

Insulator material Vinyl, cut to match rail housing; fits in

grooves in rail housing

Length (rail housing) 240 in. (609.6 cm) maximum: cut for

shorter lengths

Width (rail housing) 5 in. (12.7cm)

Depth (rail housing) 0.6 in (1.5cm)

13

Page 14

Single-Board Computer (SBC)

A single-board computer (SBC) controls the operation of the sign. It provides both power and communications input to the sign. The SBC is a module that attaches to the rail assembly in the same way as the

BRICKs.

The SBC:

1. Provides necessary non-volatile memory for storing up to 99 sequences.

2. Uses a built-in photocell that controls the brightness the LEDs output of the BRICKs. The brightness of

the BRICKs is regulated from 1% to 100% in 20 steps.

3. Controls the message display when the sign is turned on in one of the following modes:

• Sign turns on blank.

• Sign resumes the previously stored sequence.

Jumper BRICK

For multiple-row signs, the jumper BRICK transfers 12V dc power and communications data between

rows of BRICKs. The jumper BRICK attaches to the rail assembly in the same way as the BRICKs.

Trim BRICK

The trim BRICK neatly finishes a sign’s appearance. This BRICK attaches to the rail assembly in the same

way as the BRICKs.

User Interface Device

• Hand-Held Terminal (HHT): An HHT is used for on-site communications. The unit has 30 alphanu-

meric membrane keys and a 4-line by 20-character backlit, liquid crystal display (LCD). Each HHT has

15 feet (38 cm) of coiled communications cable that plugs into the SBC via the on/off switch. When

connected to the SBC, the HHT is used to select sequences from the stored library in the SBC to display

on the sign.

• Desktop or Notebook Computer (BaseStation): The computer provides the same functions as the

hand-held terminal. Creates, stores, and runs graphics via a Windows based interface.

14

Page 15

ALLMAND SOLAR ASSIST MESSAGE BOARD

SERIAL NUMBER LOCATIONS

ALLMAND

SERIAL NUMBER PLATE

LOCATED HERE

15

Page 16

Installing the BaseStation Software

The BRICK® Sign System comes with BaseStation Suite software. An additional, optional application

called BRICKBuilder may also be provided with your system. You use BRICKBuilder software before

you install a sign to determine how many BRICKs and related sign components you need to display your

messages. You need this application only if you are going to design new message SIGNS. See

Designing Message Signs in BRICKBuilder online help.

You use the BaseStation Suite after you install a sign to create and send messages.

The BaseStation Suite consists of two individual software applications. The individual applications are:

• SignComm. Communications server software you use to connect to signs.

• BaseStation. Software you use to create, modify, and send messages to signs.

See Operating the BaseStation in BaseStation online help.

To install the BRICKBuilder software on your personal computer or notebook (Windows 95, 98, or NT):

1. Insert the supplied CD-ROM in the CD-ROM drive (D:) on your computer.

Note

& The CD-ROM drive on your computer may have a different letter designation. If necessary, substi

tute that letter for the D: used in the install instructions.

Example: E:

The BaseStation Suite Setup dialog appears:

16

Page 17

To install BRICKBuilder, click

2.

The Welcome dialog appears:

•

•

Note: As each dialog appears:

Install BRICKBuilder

& Read the instructions.

Make a selection.

Click Yes or Next to continue to the next dialog.

.

The User Information dialog appears:

3. Click in the Name: field and type your name.

4. Click in the Company: field and enter your company name.

5. Click Next.

17

Page 18

The Choose Destination Location dialog appears:

Note

Clicking Next installs BRICKBuilder in this directory:

&&

C:\ADDCO\BRICKBUILDER:

If you wish to change or review any settings, click Back.

If you wish to install BRICKBuilder in another directory,

click Browse and select a different directory.

6. When finished selecting a destination directory, click Next.

Note

&&

Clicking Finish in the Setup Complete dialog finishes installing BRICKBuilder:

If you choose Yes, I want to view the README File, Setup immediately opens the

README file after you click Finish. After reading this file, Setup brings you to your desktop.

It is recommended that you view the README file after finishing Setup.

If you choose Yes, Launch the program file, Setup starts the software immediately after you

click Finish.

18

Page 19

1. To finish Setup, click Finish.

The installation wizard exits, leaving the following window open on your desktop:

The BRICKBuilder icon appears on your desktop:

8. To start the software, double click the BRICKBuilder icon.

Installing BaseStation Suite

Note

&&

The BaseStation Suite consists of two individual software applications. The individual applications are:

• SignComm. Communications server software you use to connect to signs.

• BaseStation. Software you use to create, modify, and send messages to signs.

For the software to function correctly, you must install these components in the following order:

1. SignComm.

2. BaseStation.

Note

&&

Any modems you wish to use to communicate with signs should already be installed using Control

Panel:Modems. If you need help with network setup or with modem installation, see your network

administrator.

If, during installation of either component, the software warns you that any of the files were

unable to Self-register, write down the name of the file(s) and continue installation. In most

instances, the software continues to function normally

19

Page 20

Installing SignComm

To install the SignComm component of the BaseStation Suite on your personal computer or notebook (Windows 95 98 or NT):

1. Insert the supplied CD-ROM in drive D: on your computer.

The CD-ROM drive on your computer may have a different letter designation. If necessary,

substi tute that letter for the D: used in the install instructions.

Example: E:

The BaseStation Setup dialog appears:

To install SignComm, click Install SignComm.

The Welcome dialog appears:

Note

&&

As each dialog appears:

• Read the instructions.

• Make a selection.

Click Yes or Next to continue to the next dialog.

20

Page 21

2. To finish Setup, click Finish.

The installation wizard exits, leaving the following window open on your desktop:

The SignComm icon appears on your desktop:

3. To start the software, double click the SignComm icon.

Installing BaseStation

1. To continue the BaseStation Suite Setup, click Install BaseStation.

21

Page 22

The Welcome dialog appears:

Note

&&

Setup determines files to be installed, creates software icons and updates initialization files.

When finished, the Setup Complete dialog appears:

As each dialog appears:

• Read the instructions.

• Make a selection.

Click Yes or Next to continue to the next dialog.

22

Note

&&

Clicking Finish in the Setup Complete dialog will finish installing BaseStation:

To restart your computer as part of finishing the installation, click the option provided.

To finish the installation without restarting your computer, click the option provided.

Page 23

2. When finished installing, click Finish.

The installation wizard exits.

Note

&&

The following additional icon appears on your desktop:

3. To start the software, double click the BaseStation icon.

Auto-Detecting Serial Ports and Modems

You must run SignComm once before you run BaseStation. SignComm is a communications server software program that auto-detects serial communications ports and modems.

The software places on your computer, a list of all serial communications ports in the SignComm database.

When you begin creating your own signs using BaseStation, the software uses the serial communication

port and modem information to communicate with signs.

To run SignComm:

1. Double click the SignComm icon.

The SignComm Events dialog appears.

2. Minimize the SignComm Events dialog.

If you choose to restart your computer, your

computer shuts down and restarts now.

23

Page 24

HHT User Guide

Introduction

This section provides a guide for using the Hand-Held Terminal (HHT) as a user interface to the SingleBoard Computer (SBC) on the message sign system. This section contains the following:

• Layout of HHT.

• Diagram of functions that can be implemented with HHT.

• Typical displays of HHT screens for each major user action.

• User action guide to implement desired feature.

• Explanation of each HHT screen’s function.

About the Hand-Held Terminal Unit

The hand-held terminal (HHT) provided with your system can be used to communicate directly with the

single board computer (SBC) on a sign.

The hand-held terminal has 30 alphanumeric membrane keys and a 4-line by 20-character backlit, LCD

display (see Figure 1). It has 15 feet (4.5 m) of coiled communications cable that plugs into the SBC:

• When connected to the SBC, you can use the HHT to:

– Select and run message sequences from the stored library.

– Erase any or all message sequences from the stored library.

– Configure the sign geometry and modem parameters.

– Restore the SBC to its factory default settings.

– Run test sequences.

– Observe system conditions to help troubleshoot sign.

Key Pad and Screen Layout

ADDCO

!

#

'

A

B

(

)

F

G

<

>

K

L

"

?

P

Q

/

:

U

V

C

1

H

4

M

7

R

=

W0X

*

D

2

I

5

N

8

S

-

E

3

J

6

O

9

T

.

Y

24

Z

Space

Shift

BKSP

ENTER

Figure 1. Hand-Held Terminal

Page 25

Hand-Held Terminal Features

Two features of the hand-held terminal used by the SBC program are:

• Sleep mode

• Backlight

Sleep Mode

To reduce battery power consumption, the hand-held terminal is automatically put into the sleep mode after

120 seconds of inactivity. To reactivate the terminal, press any key.

Backlight

After 90 seconds of inactivity, the backlight is automatically turned OFF. To turn the backlight ON, press

any key.

HHT Screen Navigation

HHT screen navigation is accomplished by pressing keys on the keypad. The following keys have the same

meaning in all screens:

Key Action

↑↑

↓↓

B

ENTER

Scroll up or increment a number by one.

Scroll down or decrement a number by one.

Go back one screen.

Dual purpose:

Chapter 1 If entering numbers, this key means accept the keys

pressed, validating the entry.

Chapter 2 From other menus, this key means execute the current

selection.

Numbered

Red Characters

Screens requiring numbered entries will accept the entry as a single

key press or as SHIFT, then the key press. Example: If you press H

or SHIFT+1, both are understood as 1.

Except for screens requiring number entries, you access the red

characters on the keys by first pressing SHIFT, followed by a key

with both red and black characters.

Power Up

When you power up the hand-held terminal, the following messages appear:

• Start Up

• Copyright

• Password

25

Page 26

Power Up Message

Immediately upon power up, the HHT displays this message. The screen continues to display this message

until the sign controller responds to the HHT (May take up to one minute).

P L E A S E W A I T

Copyright

After the sign controller has booted up, the HHT displays the Copyright notice for approximately 10 seconds, or until any key is pressed. The copyright and version information is read from the SBC. This screen

is also available from the utility menu.

C o p y r i g h t X X X X

V e r s i o n X X X

Password

Enter the password followed by the ENTER key.

Password is:

DOT

When you enter the correct password, the Main menu appears.

S B C

P A S S W O R D

- - - - - - - - - -

Key:

Key Action

ENTER

Password Error

If you enter an incorrect password, the password error screen appears. Press any key to redisplay the

password screen, ready to accept new input.

Validate the password entry.

S O R R Y

I N C O R R E C T P A S S W O R D

T R Y A G A I N

26

Page 27

Main Menu Screen

A = ARROWSP=PASSW

D

M A I N M E N U

S = S I G N T = T E S T

N = N O S I G N U = U T I L I T Y

Keys:

Key Action

S

T

P

U

N

A

Sign (sequence) control with access to detailed frame information.

Test screen.

Password screen.

Utility screen for configuration data and settings.

Blank the sign display (there is no prompt or feedback).

Arrow selection screen.

Special Screens

Items that are not compatible with your sign configuration may be included in appropriate menus so users have

complete information about program choices. If one of these is selected, the Special Message indicating that

the item is not currently available is displayed. To return to the program, press any key.

S O R R Y

T H E I T E M S E L E C T E D

I S C U R R E N T L Y N O T

A V A I L A B L E

SIGN Menu

The SIGN menu is used to view and/or change the sequence displayed on the sign.

Sign Sequence

When you access the SIGN screen, the first sequence shown is the sequence currently running:

Use the arrow or number keys to view a different sequence.

Use the ENTER key to display the sequence shown.

27

Page 28

Keys:

Key Action

B

↑↑

↓↓

F

ENTER

Numbered

User Prompts:

Prompt Description

RUNNING

ENTER=RUN

TESTING

ENTER=ACPT

Back to Main menu screen.

Scroll up one sequence. If at the maximum go back to the

beginning.

Scroll down one sequence. If at the minimum go to the maximum

sequence number.

Display the individual frames of the sequence shown.

Run the sequence you are currently viewing

View a sequence by pressing a 1- or 2-digit number, followed by

ENTER.

The viewed sequence is also the sequence displayed on the sign.

Pressing ENTER displays the sequence shown.

The test pattern is being exercised.

Pressing ENTER views the number selected via the numbered keys.

TEST menu

The functions of this screen are for running a predetermined test pattern and to reset the SBC software. If

the display is exercising the test pattern, the word TESTING appears on the screen.

Note

&&

Keys:

B

R

S

Z

The test pattern turns pixels on and off in order to isolate non-functioning pixels.

The pattern turns on one row at a time, then one column at a time, then all on,

then all off.

T E S T M E N U

R = R u n T e s t

S = S t o p T e s t

Z = R E S E T S B C

Key Action

Back to Main menu.

Run predefined test pattern.

Stop predefined test pattern. Sign will resume previous sequence.

Restart the SBC program.

28

Page 29

Utility Menu

The functions of this screen are used for display or modifying of SBC data.

U T I L I T Y M E N U

A = A / D I n f o V = V e r s i o n

C = C o n f i g

E = E r a s e

Keys:

Key Action

B

A

C

E

V

Backup to main menu

A-to-D LED (Light Levels) menu

Configuration menu

Erase sequences

Software version

Analog to Digital (LED Light Levels)

This screen displays the system voltage, photocell output voltage, and the Pulse Width Modulation (PWM)

values (for explanation of this term, see LED Light Level Adjust). The values on this screen are updated

once per second. Voltage is actual voltage at SBC with resolution of 0.1 volt. Photocell is a relative

number—lower numbers indicate dimmer display, higher numbers indicate brighter display

A - T O - D I N F O

V o l t a g e = _ _ _

P h o t o c e l l = _ _ _

P W M = _ _ _ J = A d j u s t

Keys:

Key Action

B

J

Back to Utility Menu

Call up the LED intensity level adjustment screen

29

Page 30

LED Light Level Adjust

The sign brightness is controlled by a factor called pulse width modulation (PWM). Factory settings should

be appropriate for majority of applications. However, you have the ability to adjust PWM values. A low

PWM means that the sign will be dim. A high PWM means the sign will be bright.

The PWM operating range is 4 (dimmest) to 255 (brightest). The PWM value displayed is the pre-adjusted

value plus/minus the upper/lower adjust value.

Caution

Adjusting the PWM to a higher value will consume more power.

Adjusting the PWM too low may make the sign difficult to read.

The PWM is adjusted by changing the upper (UPR) adjust value and/or changing the lower (LWR) adjust

value. A negative adjust value is subtracted from the PWM. The UPR is applied to pre-adjusted PWM

values of 105 and greater (daytime values). The LWR is applied to pre-adjusted values below 105 (nighttime values).

To change an adjust value, start by setting a number in amount (AMT), using the UP or DOWN arrow

keys. The UP arrow adds one to AMT. The DOWN arrow subtracts one from AMT. AMT has a range

from –5 to +5. Pressing U or L will algebraically add AMT to UPR or LWR. The UPR and LWR have

ranges from –125 to +125. An AMT value of zero clears (makes zero) the UPR or LWR.

Each time the U (or L) is pressed, the AMT is added to UPR (or LWR), and the UPR (or LWR) is added to

the pre-adjusted PWM. So, the PWM shown is the post-adjusted value.

30

Keys:

↑↑

↓↓

U

L

L I G H T L E V E L A D J

P W M = _ _ _ ↑ ↓ = A m t

U p r = _ _ _ _ U = C h g U p p e r

L w r = _ _ _ _ L = C h g L o w e r

Key Action

Increment the amount of change by one (to a maximum of 5).

Decrement the amount of change by one (to a minimum of –5).

Change the upper limit by the value of AMT.

Change the lower limit by the value of AMT.

Page 31

Configuration Menu

The COMMS allows selection of a different communication I.D. number.

The START UP screen selects which sequence will display if power is lost, then re-applied. The SIGN menu

defines the sign display dimensions.

The FACTORY choice configures the sign as follows:

• Full matrix.

• Horizontally mounted.

• High Density modules (12 pixels wide by 8 pixels high), on 3 vertically mounted rails with 4 modules each.

• The sign ID is factory set at 65,535. This is not user configurable.

• The start-up sequence is the last one displayed.

C O N F I G U R A T I O N

C = C o m m s U = S t a r t U p

F = F a c t o r y M = M d m S e t

S = S i g n W = M d m W a i t

Keys:

Key Action

B

C

U

F

M

S

W

Backup to previous menu

External SBC Communications

Start Up screen

Factory Defaults

Modem Settings

Sign Configuration

Modem Wait Parameters

Sign Configuration

The Sign Configuration screen shows the sign makeup and layout.

S I G N C O N F I G U R A T I O N

B X = _ _ B Y = _ _ S B C = _ , _

P X = _ _ P Y = _ _ R A I L = _ , _

P D X = _ _ _ P D Y = _ _ _

Keys:

Key Action

B

↑↑

↓↓

Numbered

ENTER

Backup to previous menu (cancel any edits not previously saved).

Move cursor up to the next parameter.

Move cursor down to the next parameter.

Use to select new values.

Rewrite to accept selected value.

31

Page 32

SBC BRICK Sign Parameters:

[]Enter=ACP

T

Parameter Description Factory Defaults

BX

BY

PX

PY

PDX

PDY

SBC

RAIL

BRICKs across (row) in the X direction or BRICKs per rail. 6

BRICKs down (column) in the Y direction or number of

rails.

Pixels across each BRICK (row) in the X direction. 12

Pixels down each BRICK (column) in the Y direction. 8

Number of pixel distances between the BRICK columns. 0

Number of pixel distances between the BRICK rows. 0

Physical location of the SBC (Left, Right, Top, Bottom). L, B

Orientation of the rails (Horizontal/Vertical, and

Same/Alternate).

2

H, A

Note

All RAIL parameters Same and Alternate mean that either all rails are mounted with the

&&

same orientation, or every other rail is upside down (alternates).

Mounting Information

• If the RESET connection from one RAIL to the next is placed at one end as shown, then adjacent

RAILS must be mounted upside down. The RAILS are reported by the SBC as Alternate.

• If the RESET connection is from the Left side on one RAIL to the Right side of the next, then the

RAILS are reported by the SBC as Same.

Startup Parameters

Changes to these parameters are stored in the SBC and take effect the next time the sign is started.

• To change the start up sequence you may use the arrows to scroll through the available sequences. Use

the ENTER key to SAVE the sequence number as indicated on the screen.

• Optionally you may manually enter sequence numbers by pressing the numbered keys, followed by

ENTER.

• You may press K or L to set the SBC to start up with no sequence (NONE) or the running sequence

(LAST) when the sign was shut down. Pending changes to the sequence number are displayed next to

the indicators. Remember that pending changes take effect by the ENTER=SAVE action when it is

available.

• At any time B (backup) will cancel any pending actions, discarding any changes.

S T A R T U P S E Q _ _

[ B L A N K ] ↑ ↓ K = B L A N K

[ S I G N ] L = L A S T

Keys:

Key Action

K

↑↑

↓↓

L

ENTER

Do not display any message when the sign is started.

Increment to next available sequence.

Decrement to the previous sequence.

Run the sequence that was currently being displayed when the sign

was turned OFF.

Saves the selected value for use when turning on the sign.

32

Page 33

Type:

BLANK

LAST

Empty

Sign Type Action

Sign is blanked at power up.

The last displayed sequence is displayed at power up. The sequence

shown is also the current display.

The sequence shown is the sequence that will be displayed at power

up.

Note

&&

ENTER appears on the start up screen only when there is an appropriate action

requiring its use.

Comms

The communication parameters are displayed on this screen.

• ADDR: SBC address is 65535. This is factory set and is not user configurable.

• RATE: Communication rate is 19,200 BAUD. This is factory set and is not user configurable.

• SIZE: Maximum size of communication packets is 1024 BYTES. This is factory set and is not user

configurable.

S B C C O M M S

A D D R = _ _ _ _ _

R A T E = _ _ _ _ _ B A U D

S I Z E = _ _ _ _ B Y T E S

Keys:

Key Action

B

Backup to previous screen or cancel SBC

address edits

Factory Defaults

This function will reset the SBC parameters to the factory default values. There is no menu for this

function.

Caution

Any SBC configuration data entered will be lost if Y is pressed. The sign

may not be usable until it is configured with appropriate controller software.

D O Y O U R E A L L Y W A N T

T O C H A N G E T O S B C

D E F A U L T S ?

Y = Y E S N = N O

Keys:

Key Action

Y YES TO ACCEPT THE SBC DEFAULT

N

No to cancel

33

Page 34

Erase Sequence Screen

This screen is used for permanent removal of stored SBC sequences.

E R A S E S E Q 0 1 O F 2 0

[ ] 0 = A L L S

[ S T O P ]

[ ] E n t e r = K I L L

Keys:

Key Action

B

↑↑

↓↓

0

Digits

ENTER

Backup to main menu

Increment to next available sequence

Decrement to the previous sequence

Enter a zero to Erase ALL sequences

Press any digit or its letter equivalent to

manually select a sequence to Erase

Chapter 1 When ENTER = KILL, Press

ENTER to Erase the selected sequence

Chapter 2 When ENTER = ACPT, Press

ENTER to Accept the selected sequence

(condition when sequence number is

entered)

S/W Version

Screen displays the SBC software version. Press any key to access the Main Menu screen. Otherwise, the

Main Menu screen will be displayed automatically in about 15 seconds.

Arrow Menu

Turns the sign into an arrow board. This feature works only for a 12-module, high-density, matrix sign, as

described in the Factory Configuration settings.

Keys:

Key Action

B

L

R

H

Return to the Main Menu to cancel the arrows and to run the last

sequence.

Cause the selection to be displayed indicating Left.

Cause the selection to be displayed indicating Right.

Cause the selection to be displayed indicating both Left and Right

arrows.

34

• To turn off the sign display (N), navigate to the Main menu

• To select another sequence, navigate to the Sign menu.

Page 35

Assembling and Installing a Message Sign

This chapter explains how to assemble and install a BRICK® System sign.

Before You Begin

Before you start assembling your BRICK system, make sure you have all the necessary parts and tools to

assemble the system.

Parts List

When you receive your BRICK system, check that you have received all parts on your shipping list. For

overall system information, see System Overview in the Introduction section (For drawing and part

information about individual components, see Parts/Wiring section. A BRICK system contains the following components:

Part

BRICK—high density or standard density

Single Board Computer (SBC)

Jumper BRICK(s)

Trim BRICK

Hold-down locks

Lock tool

Segmented character spacer (option)

Software application(s)

Batteries (option)

Power supply (option)

Solar regulator (option)

Solar panels (option)

Cable, PC harness (option)

Hand-held terminal

Rail assembly or individual rail assembly components:

-Rail

-Insulator

-Conductor, power and communications

-Conductor, reset

-Conductor spacer, reset

-Conductor sealer

Cable, power

Cable, communication

35

Page 36

Tools

Before assembling a system, have the following additional tools readily available: Socket set (1/4-inch or 3/

8-inch), hacksaw, wire stripper, wire crimper, open-end wrench (7/16-inch), and

rubber mallet.

Full Matrix

A full matrix sign forms a continuous array of BRICKs in a horizontal and vertical direction. There is no

spacing between the BRICKs. The software allows for creating larger fonts and graphics that may be

outside the boundary of an individual BRICK, providing the greatest flexibility in sign messaging. Individual

BRICKs may be configured in either horizontal (figure 3) or vertical (figure 4) orientations.

Installing a Full Matrix Sign

To install a full matrix sign:

1. Prepare the rail assembly.

See Preparing the Rail Assembly, if necessary*.

Note:

&

2. Install the conductors, if necessary*:

See Installing Insulators and Conductors.

3. Attach the rail assembly:

See Attaching the Rail Assembly.

4. Assemble the matrix sign:

See Assembling a Full Matrix Sign.

* Fully-assembled rail assemblies may also be purchased.

The rail assembly for a full matrix sign is identical

to that of a line matrix sign, provided the BRICKs

are mounted in the same orientation (horizontal

vs. vertical).

Preparing the Rail Assembly

The rail assembly is the mounting for the BRICKs. In addition, the rail assembly provides for the installation

of the electrical signals. It is an assembly of a rail (aluminum extrusion framework), insulators, and plated

copper conductors.

Complete rail assemblies in various lengths may be purchased. The next two procedures apply

to customers who have purchased individual rail components rather than completed rail assemblies.

1. If the rail itself was pre-cut by the factory for a specific sign, verify length in step 2. If correct, skip to

Installing Insulators and Conductors.

2. Determine rail length (figure 8) from the following table:

36

Orientation

Horizontal

Vertical

BRICK

(Number of BRICKs ×

(Number of BRICKs ×

Rail Length

in. (

19.25

in. (

13.75

mm)) + 10 in. (

4890

mm)) + 10 in. (

3490

2540

2540

mm)

mm)

Page 37

Rail

Locking Flange

Figure 8. Rail (Left End Orientation)

Installing Insulators and Conductors

1. If the conductors are installed in the rail at the factory, verify that the reset conductor lengths are correct

for the proper BRICK configuration (see following table). If correct, skip to step 4.

2. Determine insulator (figure 9) and conductor (figures 10 and 11) lengths from the following table:

BRICK

Orientation

Insulator and Rail

Length

Power (+12 Vdc

and GND) and

Reset Conductor Lengths

Communications

Conductor Length

Horizontal

Vertical

(Number of BRICKs ×

19.25 in. (4890 mm))

+ 10 in. (2540 mm)

(Number of BRICKs

13.75

in. (

3490

mm))

+ 10 in. (2540 mm)

1/2-inch (130 mm)

shorter than insulator

1/2-inch (130 mm)

×

shorter than insulator

Starting = 18.25 in. (4635 mm)

Interior =

Ending =

Starting =

Interior =

Ending =

17.25

8.25

13.25

11.75

8.00

in. (

in. (

in. (

in. (

in. (

4380

2095

3365

2980

2030

mm)

mm)

mm)

mm)

mm)

3. Cut to proper length.

4. Press the conductor insulator into grooves 1, 3, 4 and 5 (see figure 9). The left edge of the rail is determined by the orientation of the Locking Flange—see figure 8.

37

Page 38

Insulator

Groove 1 3 4 5

Figure 9. Left End of Rail with Insulators

Communications

conductor

Rail

38

Insulator

+12 Vdc conductor

Figure 10. Rail with Power and Communications Conductors

Caution

Risk of deforming conductor or conductor plating.

If you use metal hammers or a screwdriver for the

following operation, you may deform the conductor

or conductor plating.

Use a rubber mallet to gently tap conductors into their

grooves.

Ground conductor

Page 39

5. The conductor should start indented 1/4-inch (64 mm) from the left edge of the rail (the left edge of the

rail is determined by the orientation of the Locking Flange—see figure 8). When completed, the conductor should be indented 1/4-inch (64 mm) at both edges of the rail. Working from left to right, in groove 1,

press and tap in (with rubber mallet) the communications conductor into the conductor insulator until fully

seated (see figure 10).

6. For grooves 3 and 5, repeat step 5 (see figures 9 and 10).

7. Starting at the left edge of groove 4, install the starting reset conductor as in step 5. The conductor

should start indented 1/4-inch (64 mm) from the end of the rail (see figure 11).

8. Insert the first reset conductor spacer into the insulator, butted tightly next to the starting reset conductor.

It is important that no gap is left between the reset conductors and the conductor spacers.

9. Butt an interior reset conductor tightly next to the reset conductor spacer. It is important that no gap is

left between the reset conductors and the conductor spacers.

10. Continue this process, alternating interior reset conductors and reset conductor spacers until complete,

finishing with the ending reset conductor. This conductor should be indented 1/4-inch (64 mm) from the

edge of the rail.

11. After all conductors have been installed per steps five through ten, check to make sure they are properly

seated in the rail assembly insulators.

12. Conductors should protrude approximately 0.50 in. (127 mm) above rail assembly. If the conductor is

more than 0.50 in. (127 mm) above rail assembly, gently tap in place using a rubber mallet.

Starting reset

conductor

Insulator

Interior reset

conductor

Reset conductor

spacer

Rail

Figure 11. Complete Rail Assembly

39

Page 40

Attaching the Rail Assembly

1. Before continuing, verify that the conductors are installed. See Installing Insulators and Conductors.

Caution

Do not make pre-drilled mounting holes in rail assemblies

larger. Drilling of additional holes is not recommended.

2. For rail assembly spacing, see following table:

BRICK Orientation Rail Assembly Spacing Between Rows

Horizontal, Full Matrix

Vertical, Full Matrix

3. The mounting rail assembly must be supported approximately every 24 inches (6096 mm) on the side

4. Mount the lowest rail assembly with the reset conductor oriented towards the bottom edge. This will be

5. Mount next highest rail assembly with the reset conductor oriented towards the top edge. This will be

mounting housing. The mounting rail assembly is pre-drilled every 4 inches (1020 mm) to accept 1/4-inch

(64 mm) bolts. These holes are slotted to allow for minor adjustments to the mounting rail assembly for

overall BRICK sign alignment. Always use appropriate fasteners (1/4-inch (64 mm) socket head bolts,

lock washers, nuts, sheet metal screws, or lag screws) for your mounting application.

true for all Odd numbered rows (see figures 12 and 13).

true for all Even numbered rows (see figures 12 and 13). Also see in figure 13 the position of the slots,

which contain adjacent conductors, on the rail assembly.

8.75

14.25

in. (

in. (

mm)—see figure 12 for spacing reference

2223

mm)—see figure 12 for spacing reference

3620

40

rail spacing

Figure 12. Full Matrix Sign—Mounting Rail Assemblies—Horizontal Orientation

Page 41

Reset conductors

Odd row

Even row

Adjacent conductor slots

Odd row

Figure 13. Sign Rail Assembly Mounting—Side View (Three rows)

6. Repeat steps 4 and 5 for any remaining rail assembly mounting.

Assembling a Full Matrix Sign

Caution

1. Apply a small amount of conducting grease to Connecting Clips on each BRICK, Jumper BRICK, Trim

BRICK, and single board computer (SBC). For each BRICK, apply only to the Connecting Clips that will

be inserted unto the bus bar for that particular BRICK (see figure 15).

2. Mount the SBC in the lower left hand corner of the rail assembly. Power and communication connections must face downwards (see figure 14).

3. With both hands, seat the SBC onto the rail assembly. Make sure the SBC is flush with the end of the rail

assembly.

4. To fully engage the unit, push the SBC firmly in its center until it has been seated as far as it can go.

5. Determine whether the BRICKs are mounted horizontally or vertically:

The mounting procedures for both are similar. The difference is in the orientation of the BRICKs. For

horizontal orientation, make sure that BRICK Connector Clip labeled A in figure 15 inserts into the rail

assembly where two conductors are in adjacent slots (see figure 13). This means that for odd numbered rows, Clip A will be at the lower edge of the BRICK. For even numbered rows, Clip A will be at

the upper edge of the BRICK. For vertical orientation, make sure the BRICK Connector Clip labeled B

in figure 15 inserts into the rail assembly where two conductors are in adjacent slots (see figure 13).

This means that for odd numbered rows Clip B will be at the bottom edge of the BRICK. For even

numbered rows, Clip B will be at the top of the BRICK.

Prior to installing the SBC, BRICK, Right Jumper Brick, Left Jumper BRICK,

and Trim BRICK, make sure the connector clips for each are properly

aligned—either horizontally or vertically. Clips that are improperly aligned may

become broken or bent when units are installed on rail assembly.

41

Page 42

Single-

(a)

BRICK LED Pixel

(b)

board

computer

Power and communications connectors (not shown)

Figure 14. Full Matrix Sign Assembly—Horizontal Orientation—SBC

Serial Number Location

Connector Clip B

Connector Clip A

42

Figure 15. BRICK, 8 ×× 12 Pixels—Rear (a) and Front (b) View

Page 43

6. With two hands, seat the first BRICK over the rail assembly, making sure there is no gap between the

BRICK and the SBC.

7. To fully engage, push the BRICK firmly in its center until it has been seated go.

8. Mount the remaining BRICKs on the bottom row in the same manner.

Rules for installing Jumper BRICKs and TRIM BRICK:

• Install Jumper BRICK(s) whenever there is more than

one row of BRICKs--right Jumper BRICK when going

from odd to even numbered rows; left Jumper BRICK

when going from even to odd numbered rows

• Install the Trim BRICK at the end of a row when no

additional rows will be added. The Trim BRICK can be on

the right or left side of the sign--depending on whether

there is an even or odd number of rows.

9. When all of the BRICKs for the bottom row have been installed, install the right Jumper BRICK

(see figure 16). This provides the electrical power and signals between the conductors in the rail

assemblies, while creating a clean border around a portion of the sign. Install the lower portion of the

Jumper BRICK on the lower rail assembly in the same way you installed the BRICKs. Be sure the

full hole circle on the cover is placed on the outside edge of the sign. Then install the upper portion

of the Jumper BRICK to the next row.

Full hole

Right

Jumper

BRICK

Figure 16. Full Matrix Sign Assembly—Right Jumper BRICK

10. Now begin installing the second row of BRICKs, beginning next to the right Jumper BRICK and

proceeding right to left (see figures 17 and 18).

11. When all of BRICKs for the second row have been installed, you next install the left Jumper

BRICK (see figure 19). Install in a similar manner to the right Jumper BRICK. Be sure the full hole

circle on the cover is placed on the outside edge of the sign.

12. Repeat the above steps, alternating for Odd and Even rows.

13. When all the BRICKs are installed, a space similar to that of the SBC will remain on the top row.

Install the Trim BRICK in this location to complete the border of the sign.

14. After all components have been attached to the rail assemblies, begin installing the hold-down locks.

You may begin anywhere on the sign.

43

Page 44

Figure 17. Full Matrix Sign Assembly—Horizontal Orientation—With Rails for

SBC

Left Jumper BRICK Assembly

Two Odd and One Even Rows

Figure 18. Full Matrix Sign Assembly—Vertical Orientation—One Odd/One Even Row

Trim BRICK

44

Figure 19. Full Matrix Sign, 4×3—Horizontal Orientation—Completed

Page 45

Right Jumper BRICK Assembly

Trim BRICK

Left Jumper BRICK Assembly

Figure 20. Full Matrix Sign, 5×3—Vertical Orientation—Completed Sign

Caution

Failure to follow the lock down procedure correctly may result

in loose or fallen BRICKs. Make sure that the locking foot is

inserted and rotated 90 degrees clockwise.

15. For Odd numbered rows, begin with the locking foot in the three o’clock position. Install the hold-down

lock through the hole between BRICKs (see figure 21). Using the lock tool, press down to engage the

lock about 1/4-inch (64 mm) until the lock bottoms on the rail assembly. Turn 1/4-turn clockwise and

release the tool. The lock mechanism should remain inside the hold-down lock body.

16. For Even numbered rows, begin with the locking foot in the nine o’clock position. Install the holddown lock through the hole between BRICKs (see figure 22). Using the lock tool, press down to

engage the lock about 1/4-inch (64 mm) until the lock bottoms on the rail assembly. Turn 1/4-turn

clockwise and release the tool. The lock mechanism should remain inside the hold-down lock body.

45

Page 46

Clockwise

Locking Tool

Clockwise 90 degrees

Locking Foot—Three o’clock position

Figure 21. Full Matrix Sign Assembly—Hold-down Locks—Odd Rows

Figure 22. Full Matrix Sign Assembly—Hold-down Locks—Even Rows

46

Locking foot—nine o’clock position

Page 47

Connecting Power to BRICK system

1. Connect 12 VDC to the single-board computer (SBC).

2. The size of a power supply is generally specified by the total continuous power output capability. This is

usually given in Watts but may also be stated in current (Amps).

Power Supply

Rating Per

BRICK (see

definition

below)

BRICK:

High

Density

BRICK:

Standard

Density

Definition of BRICK operating parameters shown in previous table:

Power Supply Rating – Amount of power (Watts) needed per BRICK. This is a general rule of thumb to

allow for the potential of powering all LED pixels at full brightness.

Absolute Maximum Current – Current limit setting on a BRICK resulting in the worst case current draw in

the event of a failure.

Typical Maximum Current – Current draw for a BRICK in maximum ambient light conditions with all of the

pixels lit.

Average 24-Hour Current – Current draw over 24 hour day (assume 12 hours daytime, 12 hours nighttime)

with an average text based display that utilizes approximately 30% of the LEDs pixels for High Density

BRICKs, 40% LEDs for Standard Density BRICKs.

55 Watts 4.8 Amps 3.1 Amps 11.5 Amps

15 Watts 1.75 Amps 0.7 Amps 3.5 Amps

Absolute Maximum

Current Per

BRICK (see

definition below)

Typical Maximum

Current Per

BRICK (see

definition below)

Average 24-

Hour Current

Per BRICK

(see definition

below)

Wire Size Calculation

3. The wiring tables below are for general guidelines. All wiring and circuit protection devices should meet

National Electric Code (NEC) requirements. Wire size is important for two basic reasons: to meet proper

current carrying capacity defined by NEC and to minimize voltage drop for optimal performance. To

determine the wiring size required, find the total current using the following formula:

Total Current = Number of BRICKs × Absolute Maximum Current (table above)

47

Page 48

4. Next, find the wire size according to the distance between your power supply and the sign and the total

current in the following table:

Distance Total Current (Amps)

1-20 21-40 41-60 61-80 81-100

1-15 feet 10 10 8 6 6

16-30 feet

31-50 feet

Example: 10 High Density BRICK Sign, 16-30 feet from power supply

• Determine total current = 10 Bricks × 4.8 Amps = 48 Amps(previous calculation)

• From table, 16-30 feet, 41-60 Amps, results in 6-gauge wire.

10 8 6 4 4

8 6 4 2 2

Wire Gauge (AWG)

Service and Maintenance

The BRICK® Sign System is designed, manufactured, and assembled to require minimum maintenance.

Because of the operating environment the BRICK system is in, some maintenance is required. The table

below lists the items in the BRICK system that require maintenance, and the recommended interval for

providing that maintenance. The recommended intervals are based on average times from previous operating systems. The intervals for your system may vary from the recommended intervals because of your

operating environment.

Note

&&

For additional help regarding service and maintenance contact Technical Support or Customer Service at the

address and telephone numbers listed in Customer Service section.

Before performing any maintenance on the system, please read and

follow all instructions in Important Safety Information section

Customer Service

North America customers call ALLMAND BROS., Inc. at:

Main Telephone: 800/562-1373

Fax questions to: 308/995-5887

48

Page 49

Items that require Maintenance:

The table below lists the items in a system that need periodic maintenance as well as the recommended

maintenance interval. A more detailed maintenance procedure for each item follows the table.

Note

&&

Batteries

PV array

panels

BRICKs

Interconnect

cabling

BRICK to rail

assembly

connection

The items in the table can be used to support a BRICK system. Your

system may contain items that vary from those listed. If your system

does not contain any of the items listed, you can ignore any maintenance information other than what is specifically related to the

BRICKs themselves.

Item Maintenance Interval

(Operating Times)

Two weeks

One to two months

Two weeks PV array panel cleanliness

Two weeks BRICK face contamination

One month Loose or corroded connections; frayed

One year Contamination and debris

Maintenance Feature

Electrolyte level; loose or corroded

terminals

Specific gravity

or broken cabling; water damage

Bi-Weekly

Maintain the following items bi-weekly.

PV Array Panels

Note

&&

Warning

You can skip this maintenance requirement if your application

does not have the PV Array Panels.

The voltage and current generated by the photovoltaic (PV) arrays

and stored in the batteries on the BRICK system can cause

serious personal injury, death, or substantial equipment damage if

the correct procedures are not followed when working on the

electrical portion of the system.

Always used approved insulated tools when working on PV array

system.

49

Page 50

Before working on a PV array, disconnect the PV array from the solar regulator and the batteries by

placing the Breaker/Switch to the OFF position.

To optimize PV panel performance, keep the panels free of dirt, dust, snow, or any other contaminants that

prevents the sun from directly striking the panel. Avoid placing panels in areas where they are shaded at

any time. Remove dust and other items with soft cloth or sponge and water. A mild non-abrasive detergent

may be used on persistent contaminants. In areas where snowfall is possible, it is necessary to remove it as

the need arises.

Batteries

Note

&&

Warning

Electrolyte Levels

Bi-weekly:

Caution

You can skip this maintenance requirement if your application

does not have batteries.

Charging batteries produce hydrogen, which can explode when

proper operating procedures are not followed. To prevent

severe personal injury, death, or substantial property damage

when working around batteries, be extremely careful. Always

use approved eye protection, face shield, rubber gloves, and

insulated tools.

It is important to maintain the proper level of electrolyte in the batteries

at all times. If the level is too high the electrolyte will “boil” out of the

top of the battery during charging and corrode the terminal connections.

If the level is too low the battery life will be severely shortened.

Electrolyte levels should be just below the bottom of the vent well, about ½ to ¾ inch above the tops of the

separators. The electrolyte level should not drop below the top of the plates. See figure 1 for additional information.

50

Page 51

Figure 1. Battery (showing inside elements)

Loose or corroded connections create high resistance that could cause battery bank overcharging or

undercharging and possibly damage the battery bank.

To optimize sign message display, keep the display free of dirt, dust, snow, or any other contaminants.

Remove dust and other items with soft cloth or sponge and water. A mild non-abrasive detergent may be

used on persistent contaminants. In areas where snow is possible, it may be necessary to remove it.

Monthly

Maintain the following items monthly.

Normal Battery Maintenance

Warning Charging batteries produce hydrogen, which can explode when proper

operating procedures are not followed. To prevent severe personal

injury, death, or substantial property damage when working around

batteries, be extremely careful. Always use approved eye protection,

face shield, rubber gloves, and insulated tools.

Caution

It is important to maintain the proper level of electrolyte in the batteries

at all times. If the level is too high the electrolyte will “boil” out of the

top of the battery during charging and corrode the terminal connections.

If the level is too low the battery life will be severely shorten.

51

Page 52

The batteries on the system can become discharged for a number of reasons, for example:

• Operating conditions during the “winter” months of November through February, when the power

provided by the PV array is reduced.

• Improper maintenance, such as not cleaning the PV array.

• Loose or corroded battery terminal connections.

• Improper position of the system where the PV array in the shadow of an object, or tilted away from the

sun.

• Prolonged cloudy weather where the system is operating.

Maintenance of batteries, especially the proper voltage level, in the above situations should be performed as

required. In some instances, it will be necessary to provide multiple recharges from an external source or

replace with fresh batteries.

Use the following table to determine the status of each battery in the system:

6-Volt Battery 12-Volt Battery Specific Gravity State of Charge

6.36 or more 12.72 or more 1.295 or more 100%

6.15 to 6.36 12.30 to 12.72 1.250 to 1.295 75% to 100%

6.00 to 6.15 12.00 to 12.30 1.200 to 1.250 50% to 75%

5.85 to 6.00 11.70 to 12.00 1.175 to 1.200 25% to 50%

5.70 to 5.85 11.40 to 11.70 1.120 to 1.175 0% to 25%

1. Check the voltage levels with an approved digital voltmeter and the specific gravity with an approved

hydrometer.

2. Before taking any readings, run the system off the batteries for a few minutes. This removes any minor

surface charge on the battery plates. The surface charge will affect the accuracy of your readings.

3. Service or replace any battery with a specific gravity that is ten percent higher or lower than the average.

Additional Information for Storing and Handling Batteries

The electrolyte in discharged batteries may freeze if the outside air temperature drops below the freezing

point of water: 32°F (0°C). When a battery is discharged, the electrolyte solution in the battery is mostly

water. The electrolyte in a fully charged battery has a much higher concentration of sulfuric acid and

therefore freezes at a much lower temperature.

The Specific Gravity/Freeze Temperature chart provides information on specific gravity verses freezing

temperature for the batteries used in the system.

Specific Gravity Freeze Temperature

1.250 –62°F (–52°C)

1.200 –16°F (–27°C)

1.150 5

1.100 19

°F (–15°C)

°F (–7°C)

If the specific gravity of one battery cell is less than 0.020 or more than 0.050 the specific gravity of the

other two cells, use the AC charger’s equalize feature during charging. If the differences remain after

charging, replace the battery with an exact replacement.

52

Page 53

Caring for Stored Batteries