Allied Vision Prosilica GE1050C, Prosilica GE680, Prosilica GE1650, Prosilica GE1650C, Prosilica GE1660 Technical Manual

...

Technical Manual

GigE Vision Cameras

V2.2.1

2017-Apr-07

Allied Vision Technologies GmbH

Taschenweg 2a, 07646 Stadtroda, Germany

Allied Vision Prosilica GE

Prosilica GE Technical Manual V2.2.1

2

Legal notice

For customers in the U.S.A.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a residential environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful interference to radio

communications. However, there is no guarantee that interferences will not occur in a

particular installation. If the equipment does cause harmful interference to radio or television

reception, the user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the distance between the equipment and the receiver.

• Use a different line outlet for the receiver.

• Consult a radio or TV technician for help.

• You are cautioned that any changes or modifications not expressly approved in this manual

could void your authority to operate this equipment. The shielded interface cable

recommended in this manual must be used with this equipment in order to comply with the

limits for a computing device pursuant to Subpart A of Part 15 of FCC Rules.

For customers in Canada

This apparatus complies with the Class A limits for radio noise emissions set out in the Radio

Interference Regulations.

Pour utilisateurs au Canada

Cet appareil est conforme aux normes classe A pour bruits radioélectriques, spécifiées dans le

Règlement sur le brouillage radioélectrique.

Life support applications

These products are not designed for use in life support appliances, devices, or systems where

malfunction of these products can reasonably be expected to result in personal injury. Allied

Vision Technologies customers using or selling these products for use in such applications do so

at their own risk and agree to fully indemnify Allied Vision Technologies for any damages

resulting from such improper use or sale.

Trademarks

Unless stated otherwise, all trademarks appearing in this document of Allied Vision

Technologies are brands protected by law.

Warranty

The information provided by Allied Vision Technologies is supplied without any guarantees or

warranty whatsoever, be it specific or implicit. Also, excluded are all implicit warranties

concerning the negotiability, the suitability for specific applications or the non-breaking of laws

and patents. Even if we assume that the information supplied to us is accurate, errors and

inaccuracy may still occur.

Copyright

All texts, pictures and graphics are protected by copyright and other laws protecting intellectual

property. It is not permitted to copy or modify them for trade use or transfer, nor may they be

used on websites.

Allied Vision Technologies GmbH 04/2017

All rights reserved.

President/CEO: Frank Grube

Tax ID: DE 184383113

Headquarters:

Taschenweg 2a, 07646 Stadtroda, Germany

Tel: +49 (0)36428 677-0

Fax: +49 (0)36428 677-28

Email: info@alliedvision.com

Prosilica GE Technical Manual V2.2.1

3

Contents

Contacting Allied Vision.................................................................................................... 6

Introduction................................................................................................................................... 7

Document history................................................................................................................................. 7

Manual conventions............................................................................................................................. 9

Styles ............................................................................................................................................... 9

Symbols ........................................................................................................................................... 9

Precautions......................................................................................................................................... 10

Cleaning optics ................................................................................................................................... 10

Identifying debris .......................................................................................................................... 11

Locating debris.............................................................................................................................. 11

Color cameras with IR filter .......................................................................................................... 11

Cleaning with air ........................................................................................................................... 11

Contact cleaning ........................................................................................................................... 12

Conformity .................................................................................................................................... 13

Specifications............................................................................................................................ 14

Prosilica GE680, GE680C.................................................................................................................... 14

Absolute QE .................................................................................................................................. 15

Prosilica GE1050, GE1050C................................................................................................................ 16

Absolute QE .................................................................................................................................. 17

Prosilica GE1650, GE1650C................................................................................................................ 18

Absolute QE .................................................................................................................................. 19

Prosilica GE1660, GE1660C................................................................................................................ 20

Absolute QE .................................................................................................................................. 21

Prosilica GE1900................................................................................................................................. 22

Absolute QE .................................................................................................................................. 23

Prosilica GE1910, GE1910C................................................................................................................ 24

Absolute QE .................................................................................................................................. 25

Prosilica GE2040, GE2040C................................................................................................................ 26

Absolute QE .................................................................................................................................. 27

Prosilica GE4000, GE4000C................................................................................................................ 28

Absolute QE .................................................................................................................................. 29

Prosilica GE4900, 4900C ................................................................................................................... 30

Absolute QE .................................................................................................................................. 31

Camera attribute highlights ...................................................................................... 32

IRC30 filter................................................................................................................................... 33

Camera dimensions............................................................................................................. 34

Prosilica GE C-Mount (adjustable) ..................................................................................................... 34

Prosilica GE Technical Manual V2.2.1

4

Prosilica GE F-Mount.......................................................................................................................... 36

Prosilica GE large format F-Mount .................................................................................................... 37

Tripod adapter ................................................................................................................................... 38

C-Mount flange focal distance........................................................................................................... 39

Adjustment of C-Mount................................................................................................................ 39

Lens protrusion for C-Mount cameras ......................................................................................... 40

F-Mount flange focal distance ........................................................................................................... 41

Adjustment of F-Mount ................................................................................................................ 41

Camera interfaces ................................................................................................................ 42

Status LEDs ......................................................................................................................................... 42

Gigabit Ethernet port ......................................................................................................................... 43

Camera I/O connector pin assignment ............................................................................................. 44

I/O definition ...................................................................................................................................... 45

Camera power .............................................................................................................................. 45

Isolated IO GND ............................................................................................................................ 46

RxD RS232 and TxD RS232 ........................................................................................................... 46

Input triggers................................................................................................................................. 46

Output signals ............................................................................................................................... 47

Auto iris video type....................................................................................................................... 47

Reserved........................................................................................................................................ 48

Camera I/O connector internal circuit diagram ................................................................................ 48

Camera I/O connector external circuit example ............................................................................... 49

In 1, Out 1 external circuit example .................................................................................................. 50

Trigger timing diagram....................................................................................................................... 51

Notes on triggering ....................................................................................................................... 51

Firmware update .................................................................................................................... 53

Resolution and ROI frame rate ................................................................................ 54

Prosilica GE680, GE680C.................................................................................................................... 55

Prosilica GE1050, GE1050C................................................................................................................ 55

Prosilica GE1650, GE1650C................................................................................................................ 56

Prosilica GE1660, GE1660C................................................................................................................ 56

Prosilica GE1900................................................................................................................................. 57

Prosilica GE1910, GE1910C................................................................................................................ 57

Prosilica GE2040, GE2040C................................................................................................................ 58

Prosilica GE4000, GE4000C................................................................................................................ 58

Prosilica GE4900, GE4900C................................................................................................................ 59

Prosilica GE model comparison ........................................................................................................ 60

Camera data path.................................................................................................................. 61

Prosilica GE: monochrome cameras.................................................................................................. 61

Prosilica GE: color cameras................................................................................................................ 61

Additional references........................................................................................................ 62

Prosilica GE Technical Manual V2.2.1

5

Index....................................................................................................................................................63

Prosilica GE Technical Manual V2.2.1

6

Contacting Allied Vision

Contacting Allied Vision

Info

• Technical information:

https://www.alliedvision.com

• Support:

support@alliedvision.com

Allied Vision Technologies GmbH (Headquarters)

Tasche n w e g 2 a

07646 Stadtroda, Germany

Tel.: +49 36428-677-0

Fax: +49 36428-677-28

Email: info@alliedvision.com

Allied Vision Technologies Canada Inc.

300-4621 Canada Way

Burnaby, BC, V5G 4X8, Canada

Tel.: +1 (604) 875-8855

Fax: +1 (604) 875-8856

Email: info@alliedvision.com

Allied Vision Technologies Inc.

38 Washington Street

Newburyport, MA 01950, USA

Toll Free number +1 (877) USA-1394

Tel.: +1 (978) 225-2030

Fax: +1 (978) 225-2029

Email: info@alliedvision.com

Allied Vision Technologies Asia Pte. Ltd.

82 Playfair Road, #07-02 D’Lithium

Singapore 368001

Tel.: +65 6634-9027

Fax: +65 6634-9029

Email: info@alliedvision.com

Allied Vision Technologies (Shanghai) Co., Ltd.

2-2109 Hongwell International Plaza

1602# ZhongShanXi Road

Shanghai 200235, China

Tel.: +86 (21) 64861133

Fax: +86 (21) 54233670

Email: info@alliedvision.com

Prosilica GE Technical Manual V2.2.1

7

Introduction

Introduction

This Prosilica GE Technical Manual describes in depth the technical

specifications of the Prosilica GE camera family including dimensions, feature

overview, I/O definition, trigger timing waveforms, and frame rate

performance.

For information on software installation read the GigE Installation Manual. For

detailed information on camera features and controls specific to the Prosilica

GE refer to the GigE Features Reference and GigE Camera and Driver

Attributes documents.

Document history

www

Prosilica GE documentation

https://www.alliedvision.com/en/support/technicaldocumentation/prosilica-ge-documentation

Version Date Remarks

V2.0.0 2011-Jul-14 New Manual - Release status

V2.0.1 2013-Jul-05 • Renamed Camera IO signals

• Reworked Cleaning optics section

• Reworked the absolute QE plots and frame rate vs. height plots

• Updated the RoHS directive

• Updated the exposure control values in the specifications chapter

• Added Status LEDs section

• Updated the pixel format naming according to the GenICam naming

convention

• Added frame rate formulas in the Resolution and ROI frame rates chapter

• Added Vimba SDK link in Additional references section

• Updated recommended cabling to category 6 or higher in the Gigabit

Ethernet port section

• Added contact information for Allied Vision Technologies (Shanghai) Co.

Ltd.

• Updated the links to GigE Installation Manual

• Added links to GigE Camera and Driver Features document

Table 1: Document history

Prosilica GE Technical Manual V2.2.1

8

Introduction

V2.0.2 2013-Oct-02 • Added optical flange focal distance and maximum lens protrusion

information

• Added a note on locking screw cables

• Updated Cleaning optics section

• Updated vertical binning values in the Specifications chapter

• Updated Table 12

• Updated links for PvAPI SDK

V2.0.3 2013-Nov-26 • Added chapter Description of the data path

• Updated the Index

V2.0.4 2014-Oct-15 • Replaced the optical flange focal distance section with the following

sections:

– C-Mount flange focal distance

–F-Mount flange focal distance

• Added description of power barrel connector

• Updated datapath diagram for Prosilica GE color cameras

• Added Prosilica GE C-Mount (adjustable)

• Updated Prosilica GE tripod mount mechanical drawing

• Truesense references renamed to ON Semiconductor

V2.1.0 2015-Mar-20 • Updated Allied Vision logo

• Replaced old links with new Allied Vision website links

• Changed file name from ‘GigE Camera and Driver Features’ to ‘GigE

Features Reference’

• Changed chapter name from ‘Description of data path’ to ‘Camera data

path’

V2.2.0 2017-Feb-10 • Updated the absolute QE plots for Prosilica GE models with ON

Semiconductor CCD sensors to reflect the changes in the Gen 2 CFA

material change made by ON Semiconductor

• Removed the Prosilica GE1900C. For more information, refer to the

Product Change Notification on the Allied Vision website

• Added REACH and WEEE statements to the Conformity chapter

• Updated the address for the Canadian office

• Various minor updates and corrections

V2.2.1 2017-Apr-07 • Added cable color to camera I/O connector pin assignment including pin

assignment figure and cross reference to the Allied Vision I/O cable data

sheet

Version Date Remarks

Table 1: Document history (continued)

Prosilica GE Technical Manual V2.2.1

9

Introduction

Manual conventions

To give this manual an easily understandable layout and to emphasize

important information, the following typographical styles and symbols are

used:

Styles

Symbols

Style Function Example

Bold Programs, inputs, or highlighting

important information

bold

Courier Code listings etc. Input

Upper case Register REGISTER

Italics Modes, fields, Publications Mode

Blue Links Link

Table 2: Styles

Note

This symbol highlights important information.

Caution

This symbol highlights important instructions. You have to

follow these instructions to avoid malfunctions.

www

This symbol highlights URLs for further information. The URL

itself is shown in blue.

Example:

https://www.alliedvision.com

Prosilica GE Technical Manual V2.2.1

10

Introduction

Precautions

Cleaning optics

Caution

Do not disassemble the camera housing. Warranty is void if

camera has been disassembled.

This camera contains sensitive internal components.

Caution

Keep shipping material

Poor packaging of the product may cause damage during

shipping.

Caution

Verify all external connections

Verify all external connections in terms of voltage levels,

power requirements, voltage polarity, and signal integrity

prior to powering the device.

Caution

Cleaning

This product can be damaged by some volatile cleaning

agents. Avoid cleaning the image sensor unless absolutely

necessary. Please see instructions on optics cleaning in this

document.

Caution

Do not exceed environmental specifications

See environmental specifications limits in the Specifications

chapter of this document. Special care must be taken to

maintain a reasonable operating temperature. If the camera

is operated in temperatures higher than the specified range,

the camera should be mounted on a heat sink.

Caution

Allied Vision does not warranty against any physical damage

to the sensor, filter, protection glass or lenses. Use utmost

care when cleaning optical components.

Prosilica GE Technical Manual V2.2.1

11

Introduction

Identifying debris

Debris on the image sensor or optical components appears as a darkened area

or smudge on a camera image. Do not confuse this with a pixel defect which

appears as a distinct point.

Locating debris

First determine whether the debris is on the sensor glass, IR filter (if used), or

lens. The farther away the debris is from the sensor, the blurrier the debris

appears on a camera image.

Stream a live image from the camera using a uniform target, such as a piece

of paper. To determine if the debris is on the camera lens, rotate the lens

independent of the camera. If the spot moves, the debris is on the lens.

Otherwise, the debris is on the IR filter (if used) or sensor glass.

Color cameras with IR filter

Prosilica GE color cameras are equipped with an IR filter. With no lens or lens

cap on a camera, the IR filter is exposed and debris can accumulate on it. This

is the most probable location for debris. It should not be necessary to remove

the IR filter for cleaning. Clean the outside of the IR filter glass using the

techniques explained in the next section.

If it is determined that the debris is on the inside surface of the filter glass, or

on the sensor glass, IR filter removal is necessary. Depending on the

manufacturing date of your Prosilica GE camera, the IR filter may be slot type,

or pinhole type. Slot type filters can be removed using a small flat head screw

driver. Pinhole type filters require a pin spanner wrench for removal.

Cleaning with air

Blow directly on the contaminated surface with moderate pressure, clean

compressed air.

Caution

Do not touch any optics with fingers. Oil from fingers can

damage fragile optical coatings.

Note

A pin spanner wrench suitable for IR filter removal is available

for purchase from Allied Vision.

Order code: E9020001

Prosilica GE Technical Manual V2.2.1

12

Introduction

View a live image with the camera after blowing. If debris is still present,

repeat the process until it is determined that the particulate cannot be

dislodged. If this is the case, proceed to the contact cleaning technique.

Contact cleaning

Only use this method if the above air cleaning method does not sufficiently

clean the surface. Use 99% pure isopropyl alcohol and clean cotton swabs.

Wet the swab in the alcohol. Quickly wipe the optics in a single stroke.

Prolonged exposure of alcohol on the swab can cause the swab glue to loosen

and transfer to the optic glass. Do not reuse the same swab. Repeat this

process until the debris is removed. If this process fails to remove the debris,

contact Allied Vision.

Caution

Do not exceed 6 bar (90 psi). If using canned air,

approximately ~ 4.8 bar (70 psi) when full, do not shake or tilt

the can, as extreme changes in temperature due to sudden

cold air can crack the optic glass.

Prosilica GE Technical Manual V2.2.1

13

Conformity

Conformity

Allied Vision Technologies declares under its sole responsibility that all

standard cameras of the Prosilica GE family to which this declaration relates

are in conformity with the following standard(s) or other normative

document(s):

• CE, following the provisions of 2004/108/EG directive

• FCC Part 15 Class A

• RoHS (2011/65/EU)

We declare, under our sole responsibility, that the previously described

Prosilica GE cameras conform to the directives of the CE.

REACH

All ie d Vision Tech no logies produc ts are in compli an ce with the Regu la tion (EC)

No 1907/2006 REACH.

WEEE

This product must be disposed of in compliance with the directive 2002/96/EC

on waste electrical and electronic equipment (WEEE).

This equipment has been tested and found to comply with the limits for a Class

A digital device, pursuant to part 15 of the FCC Rules. These limits are designed

to provide reasonable protection against harmful interference in a residential

environment. This equipment generates radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful

interference to radio communications. Any modifications not expressly

approved in this manual may void your authority to operate this equipment.

Prosilica GE Technical Manual V2.2.1

14

Specifications

Specifications

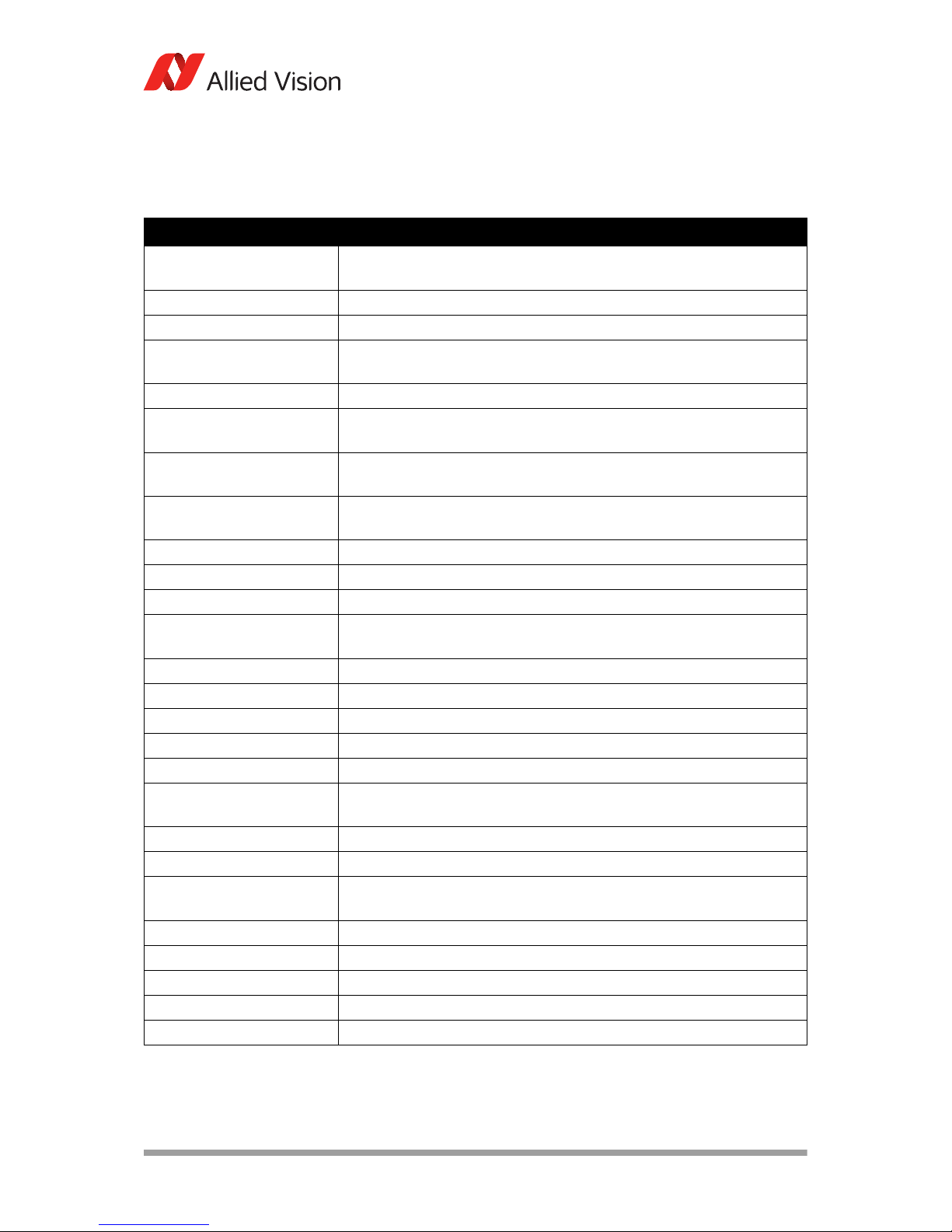

Prosilica GE680, GE680C

Feature Specification

Resolution 640 (H) × 480 (V)

0.3 MP

Sensor ON Semiconductor KAI-0340

Sensor type Interline CCD, Progressive Scan

Sensor size Type 1/3

5.920 mm diagonal

Cell size 7.4 µm × 7.4 µm

Lens mount Standard: C-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE680: No filter

Prosilica GE680C: IRC30 IR cut filter

Maximum frame rate at full

resolution

205 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE680: Mono8, Mono12, Mono12Packed

Prosilica GE680C: Mono8

Color formats (YUV) YUV411Packed

Color formats (RGB) RGB8Packed, BGR8Packed, RGBA8Packed, BGRA8Packed, RGB12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 25 µs to 53.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 4.5 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 169 g

Body dimensions (L × W × H) 80 × 51 × 39 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Table 3: Prosilica GE680, GE680C camera specifications

Prosilica GE Technical Manual V2.2.1

15

Specifications

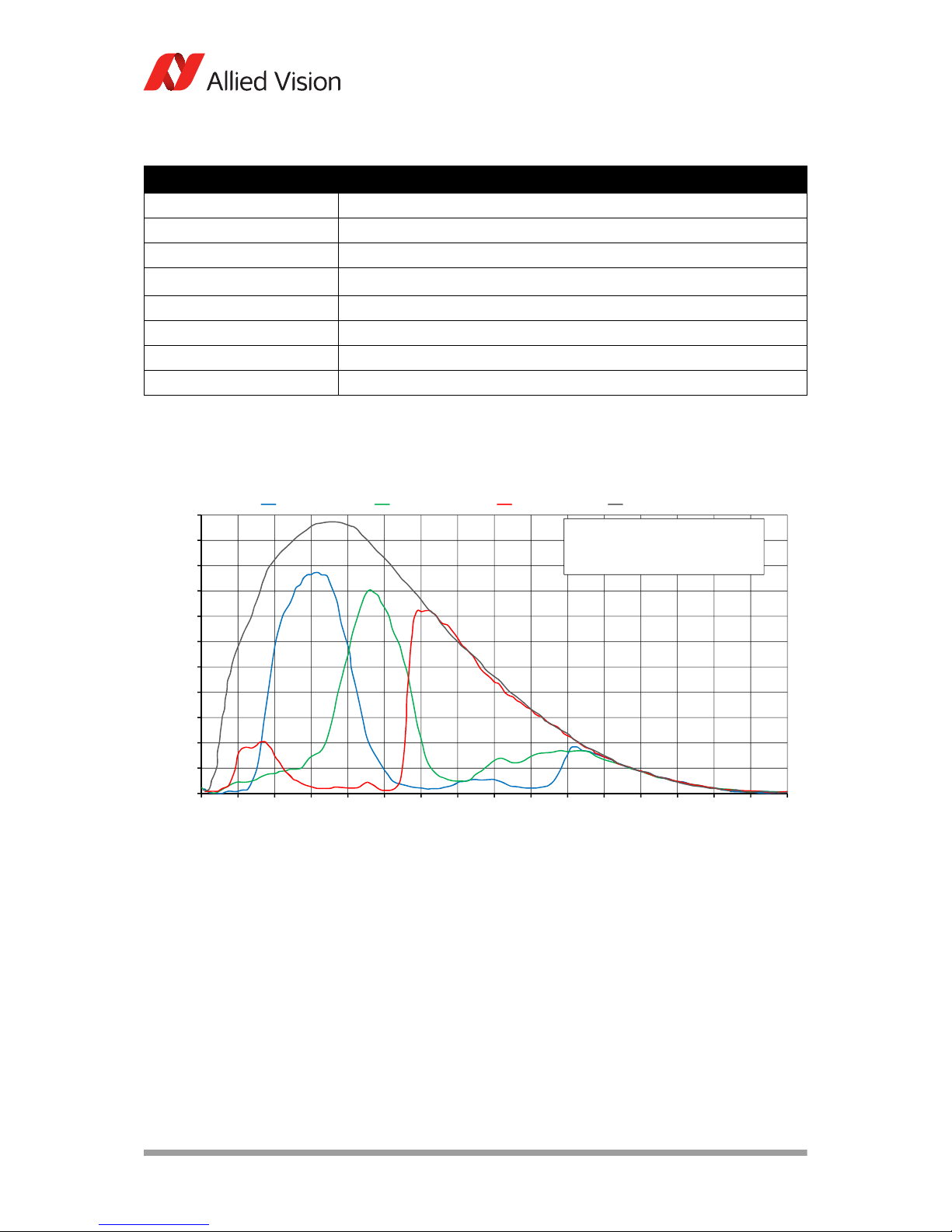

Absolute QE

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Trigge r l a tency 1.2 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

Figure 1: Prosilica GE680, GE680C (ON Semiconductor KAI-0340) absolute QE

Feature Specification

Table 3: Prosilica GE680, GE680C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ0340absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

16

Specifications

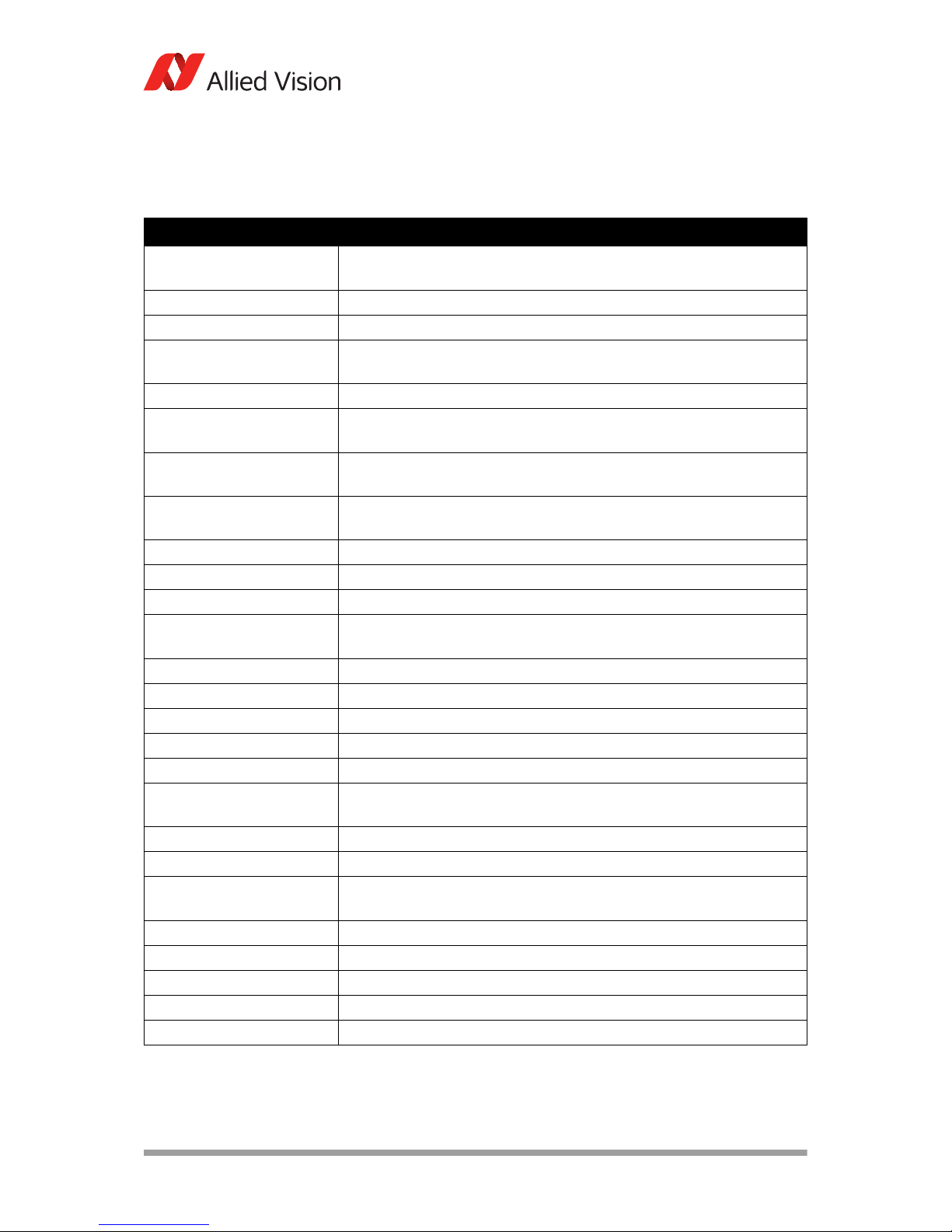

Prosilica GE1050, GE1050C

Feature Specification

Resolution 1024 (H) × 1024 (V)

1 MP

Sensor ON Semiconductor KAI-01050

Sensor type Interline CCD, Progressive Scan

Sensor size Type 1/2

7.96 mm diagonal

Cell size 5.5 µm × 5.5 µm

Lens mount Standard: C-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE1050: No filter

Prosilica GE1050C: IRC30 IR cut filter

Maximum frame rate at full

resolution

59 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE1050: Mono8, Mono12, Mono12Packed

Prosilica GE1050C: Mono8

Color formats (YUV) YUV411Packed

Color formats (RGB) RGB8Packed, BGR8Packed, RGBA8Packed, BGRA8Packed, RGB12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 10 µs to 53.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 5 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 178 g

Body dimensions (L × W × H) 80 × 51 × 39 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Table 4: Prosilica GE1050, GE1050C camera specifications

Prosilica GE Technical Manual V2.2.1

17

Specifications

Absolute QE

Trigge r l a tency 5 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

Figure 2: Prosilica GE1050, GE1050C (ON Semiconductor KAI-01050) absolute QE

Feature Specification

Table 4: Prosilica GE1050, GE1050C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ01050absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

18

Specifications

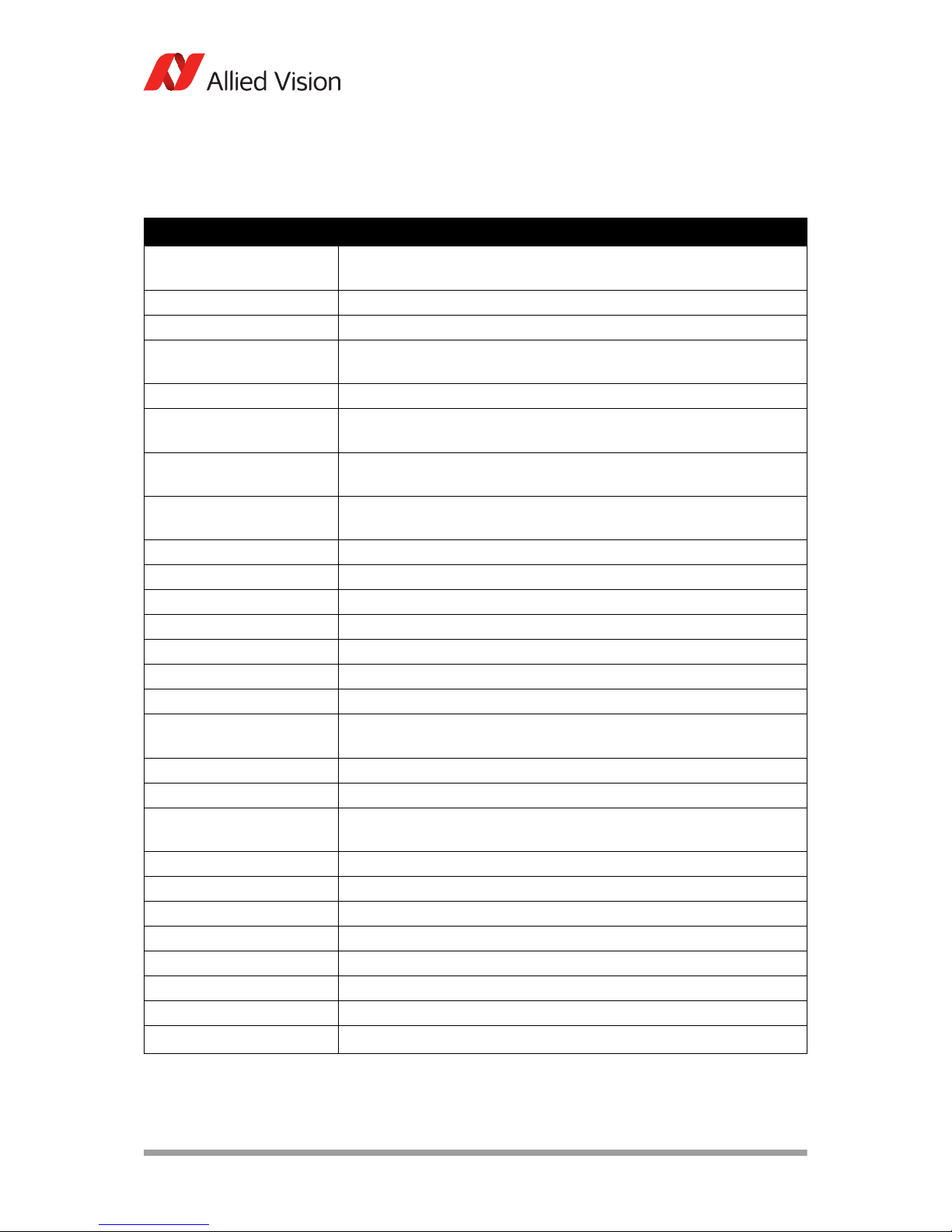

Prosilica GE1650, GE1650C

Feature Specification

Resolution 1600 (H) × 1200 (V)

1.9 MP

Sensor ON Semiconductor KAI-2020

Sensor type Interline CCD, Progressive Scan

Sensor size Type 1

14.80 mm diagonal

Cell size 7.4 µm × 7.4 µm

Lens mount Standard: C-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE1650: No filter

Prosilica GE1650C: IRC30 IR cut filter

Maximum frame rate at full

resolution

32 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE1650: Mono8, Mono12, Mono12Packed

Prosilica GE1650C: Mono8

Color formats (YUV) YUV411Packed

Color formats (RGB) RGB8Packed, BGR8Packed, RGBA8Packed, BGRA8Packed, RGB12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 50 µs to 53.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 5 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 169 g

Body dimensions (L × W × H) 80 × 51 × 39 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Table 5: Prosilica GE1650, GE1650C camera specifications

Prosilica GE Technical Manual V2.2.1

19

Specifications

Absolute QE

Trigge r l a tency 5 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

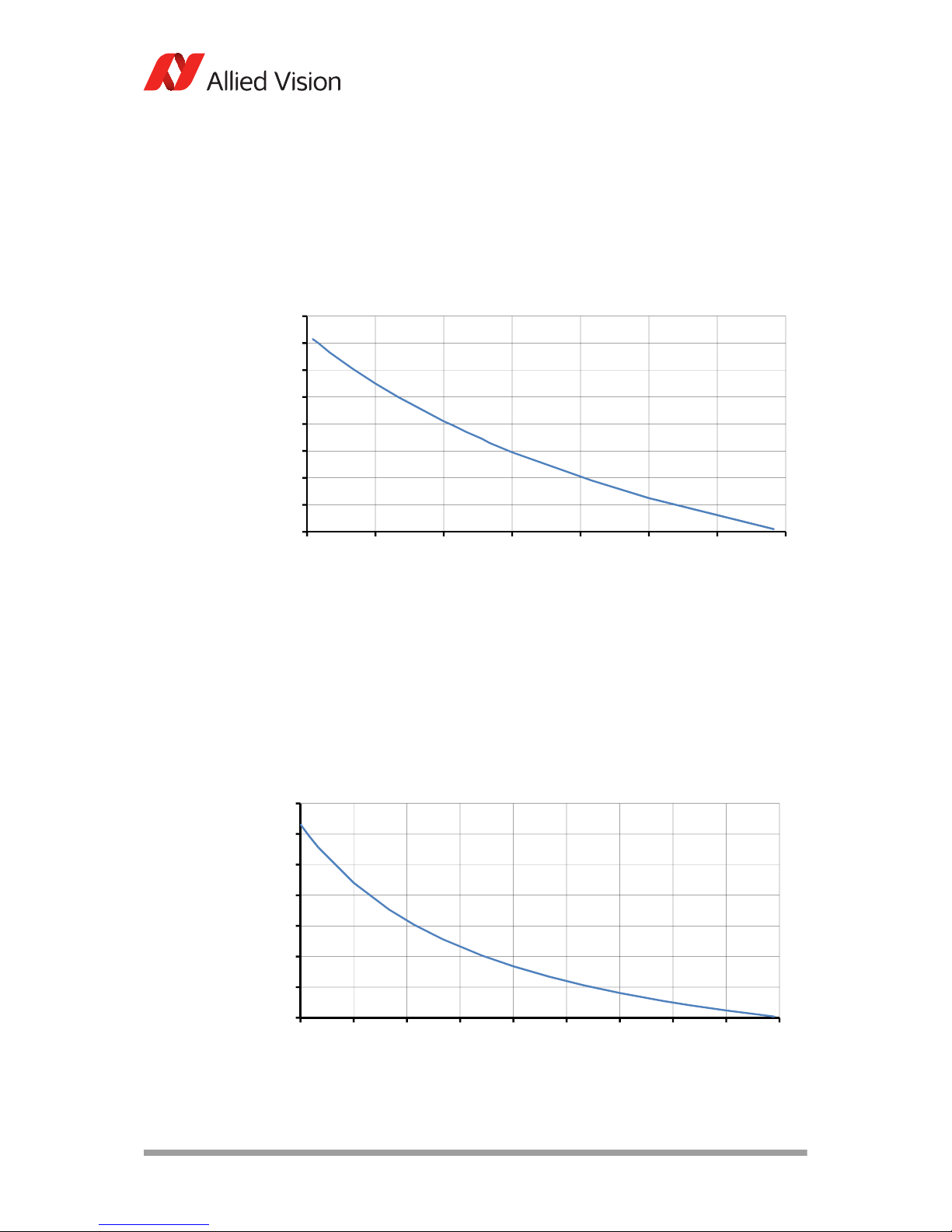

Figure 3: Prosilica GE1650, GE1650C (ON Semiconductor KAI-2020) absolute QE

Feature Specification

Table 5: Prosilica GE1650, GE1650C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ2020absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithMARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

20

Specifications

Prosilica GE1660, GE1660C

Feature Specification

Resolution 1600 (H) × 1200 (V)

1.9 MP

Sensor ON Semiconductor KAI-02050

Sensor type Interline CCD, Progressive Scan

Sensor size Type 2/3

11.0 mm diagonal

Cell size 5.5 µm × 5.5 µm

Lens mount Standard: C-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE1660: No filter

Prosilica GE1660C: IRC30 IR cut filter

Maximum frame rate at full

resolution

34.6 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE1660: Mono8, Mono12, Mono12Packed

Prosilica GE1660C: Mono8

Color formats (YUV) YUV411Packed

Color formats (RGB) RGB8Packed, BGR8Packed, RGBA8Packed, BGRA8Packed, RGB12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 10 µs to 53.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 5 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 178 g

Body dimensions (L × W × H) 80 × 51 × 39 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Table 6: Prosilica GE1660, GE1660C camera specifications

Prosilica GE Technical Manual V2.2.1

21

Specifications

Absolute QE

Trigge r l a tency 5 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

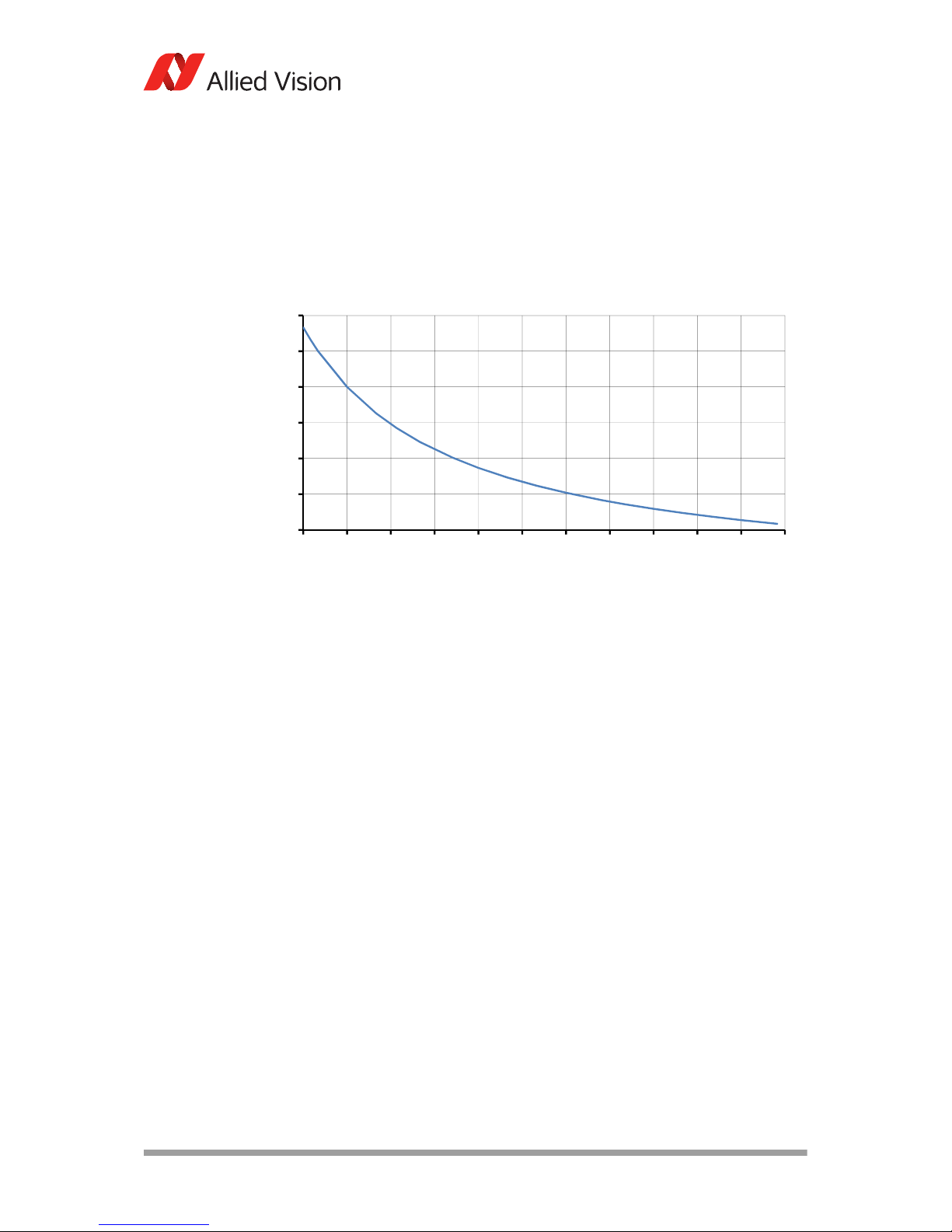

Figure 4: Prosilica GE1660, GE1660C (ON Semiconductor KAI-02050) absolute QE

Feature Specification

Table 6: Prosilica GE1660, GE1660C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ02050absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyinmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

22

Specifications

Prosilica GE1900

Feature Specification

Resolution 1920 (H) × 1080 (V)

2.1 MP

Sensor ON Semiconductor KAI-2093

Sensor type Interline CCD, Progressive Scan

Sensor size Type 1

16.3 mm diagonal

Cell size 7.4 µm × 7.4 µm

Lens mount Standard: C-Mount

Optional: See the Modular Concept

Optical filter No filter

Maximum frame rate at full

resolution

30 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Mono8, Mono12, Mono12Packed

Exposure control 50 µs to 53.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 5 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 169 g

Body dimensions (L × W × H) 80 × 51 × 39 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Trigge r l a tency 5 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Table 7: Prosilica GE1900 camera specifications

Prosilica GE Technical Manual V2.2.1

23

Specifications

Absolute QE

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

Figure 5: Prosilica GE1900 (ON Semiconductor KAI-2093) absolute QE

Feature Specification

Table 7: Prosilica GE1900 camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ2093absoluteQE

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

MonochromeQE

Prosilica GE Technical Manual V2.2.1

24

Specifications

Prosilica GE1910, GE1910C

Feature Specification

Resolution 1920 (H) × 1080 (V)

2.1 MP

Sensor ON Semiconductor KAI-02150

Sensor type Interline CCD, Progressive Scan

Sensor size Type 2/3

12.1 mm diagonal

Cell size 5.5 µm × 5.5 µm

Lens mount Standard: C-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE1910: No filter

Prosilica GE1910C: IRC30 IR cut filter

Maximum frame rate at full

resolution

32 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE1910: Mono8, Mono12, Mono12Packed

Prosilica GE1910C: Mono8

Color formats (YUV) YUV411Packed

Color formats (RGB) RGB8Packed, BGR8Packed, RGBA8Packed, BGRA8Packed, RGB12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 10 µs to 53.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 5 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 178 g

Body dimensions (L × W × H) 80 × 51 × 39 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Table 8: Prosilica GE1910, GE1910C camera specifications

Prosilica GE Technical Manual V2.2.1

25

Specifications

Absolute QE

Trigge r l a tency 5 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

Figure 6: Prosilica GE1910, GE1910C (ON Semiconductor KAI-02150) absolute QE

Feature Specification

Table 8: Prosilica GE1910, GE1910C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ02150absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

26

Specifications

Prosilica GE2040, GE2040C

Feature Specification

Resolution 2040 (H) × 2048 (V)

4.2 MP

Sensor ON Semiconductor KAI- 04022

Sensor type Interline CCD, Progressive Scan

Sensor size Type 1.2

21.43 mm diagonal

Cell size 7.4 µm × 7.4 µm

Lens mount Standard: C-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE2040: No filter

Prosilica GE2040C: IRC30 IR cut filter

Maximum frame rate at full

resolution

15 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE2040: Mono8, Mono12, Mono12Packed

Prosilica GE2040C: Mono8

Color formats (YUV) YUV411Packed

Color formats (RGB) RGB8Packed, BGR8Packed, RGBA8Packed, BGRA8Packed, RGB12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 75 µs to 53.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 5.5 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 169 g

Body dimensions (L × W × H) 80 × 51 × 39 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Table 9: Prosilica GE2040, GE2040C camera specifications

Prosilica GE Technical Manual V2.2.1

27

Specifications

Absolute QE

Trigge r l a tency 4.2 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

Figure 7: Prosilica GE2040, GE2040C (ON Semiconductor KAI-04022) absolute QE

Feature Specification

Table 9: Prosilica GE2040, GE2040C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

60%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ04022absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

28

Specifications

Prosilica GE4000, GE4000C

Feature Specification

Resolution 4008 (H) × 2672 (V)

10.7 MP

Sensor ON Semiconductor KAI-11002

Sensor type Interline CCD, Progressive Scan

Sensor size Type 35 mm

43.3 mm diagonal

Cell size 9 µm × 9 µm

Lens mount Standard: F-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE4000: No filter

Prosilica GE4000C: IRC30 IR cut filter

Maximum frame rate at full

resolution

5 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE4000: Mono8, Mono12, Mono12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 140 µs to 68.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 6 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 402 g

Body dimensions (L × W × H) 110 × 66 × 66 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Trigge r l a tency 4.2 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Table 10: Prosilica GE4000, GE4000C camera specifications

Prosilica GE Technical Manual V2.2.1

29

Specifications

Absolute QE

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

Figure 8: Prosilica GE4000, GE4000C (ON Semiconductor KAI-11002) absolute QE

Feature Specification

Table 10: Prosilica GE4000, GE4000C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

55%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ11002absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

30

Specifications

Prosilica GE4900, 4900C

Feature Specification

Resolution 4872 (H) × 3248 (V)

15.8 MP

Sensor ON Semiconductor KAI-16000

Sensor type Interline CCD, Progressive Scan

Sensor size Type 35 mm

43.3 mm diagonal

Cell size 7.4 µm × 7.4 µm

Lens mount Standard: F-Mount

Optional: See the Modular Concept

Optical filter Prosilica GE4900: No filter

Prosilica GE4900C: IRC30 IR cut filter

Maximum frame rate at full

resolution

3 frames per second

A/D 12-bit

Image buffer 32 MB

Image bit depth 8/12

Monochrome formats Prosilica GE4900: Mono8, Mono12, Mono12Packed

RAW formats BayerGR8, BayerGR12, BayerGR12Packed

Exposure control 625 µs to 68.7 s; 1 µs increments

Gain control 0 to 34 dB

Binning Horizontal: 1 to 8 columns

Vertical: 1 to full resolution

TTL I/Os 1 input, 3 output

RS232 1

Voltage requirements 5 to 16 VDC: Cameras SN: 02-XXXXA-XXXXX, 02-XXXXB-XXXXX

5 to 25 VDC: Cameras SN: 02-XXXXC-XXXXX

Power consumption Typical < 6 W @ 12 VDC (full resolution and maximum frame rate)

Mass (typical) 391 g

Body dimensions (L × W × H) 110 × 66 × 66 mm

Operating temperature 0 to +50 °C ambient temperature (without condensation)

Storage temperature -10 to +70 °C ambient temperature (without condensation)

Trigge r l a tency 4.2 µs

Trigger jitter ±10 ns

Propagation delay (t

pd

) 90 ns

Table 11: Prosilica GE4900, GE4900C camera specifications

Prosilica GE Technical Manual V2.2.1

31

Specifications

Absolute QE

Operating humidity 20 to 80% non-condensing

Interface IEEE 802.3 1000BASE-T, 100BASE-TX

Interface standard GigE Vision Standard 1.2

Regulations CE, RoHS, REACH, WEEE, FCC

Figure 9: Prosilica GE4900, GE4900C (ON Semiconductor KAI-16000) absolute QE

Feature Specification

Table 11: Prosilica GE4900, GE4900C camera specifications (continued)

0%

5%

10%

15%

20%

25%

30%

35%

40%

45%

50%

300 350 400 450 500 550 600 650 700 750 800 850 900 950 1000 1050 1100

QuantumEfficiency

Wavelength[nm]

ONSemiconductorKAIͲ16000absoluteQE

ONSemiconductorGen2CFAmaterialforcolorsensors

Note:MeasuredwithARcoatedcoverglass.

TheuncertaintyofmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

BlueQE GreenQE RedQE MonochromeQE

Prosilica GE Technical Manual V2.2.1

32

Camera attribute highlights

Camera attribute highlights

Allied Vision cameras support a number of standard and extended features.

The table below identifies a selection of interesting capabilities of the Prosilica

GE camera family.

www

A complete listing of camera controls, including control

definitions can be found online:

PvAPI users: GigE Camera and Driver Attributes document

Vimba users: GigE Features Reference

Control Description

Gain control Manual and auto

Exposure control Manual and auto

White balance Red and blue channel; manual and auto control

External trigger event Rising edge, falling edge, any edge, level high, level

low

External trigger delay 0 to 60* s; 1 µs increments

Fixed rate control 0.001 fps to maximum frame rate

Imaging modes Free-running, external trigger, fixed rate, software

trigger

Sync out modes Trigger ready, trigger input, exposing, readout,

imaging, strobe, GPO

Region of interest Independent x and y control with 1 pixel resolution

Multicast Streaming to multiple computers

Event channel In-camera events including exposure start and

trigger are asynchronously broadcasted to the host

computer

Chunk data Captured images are bundled with attribute

information such as exposure and gain value

*May vary depending on the camera model

Table 12: Prosilica GE camera and driver attribute highlights

Prosilica GE Technical Manual V2.2.1

33

IRC30 filter

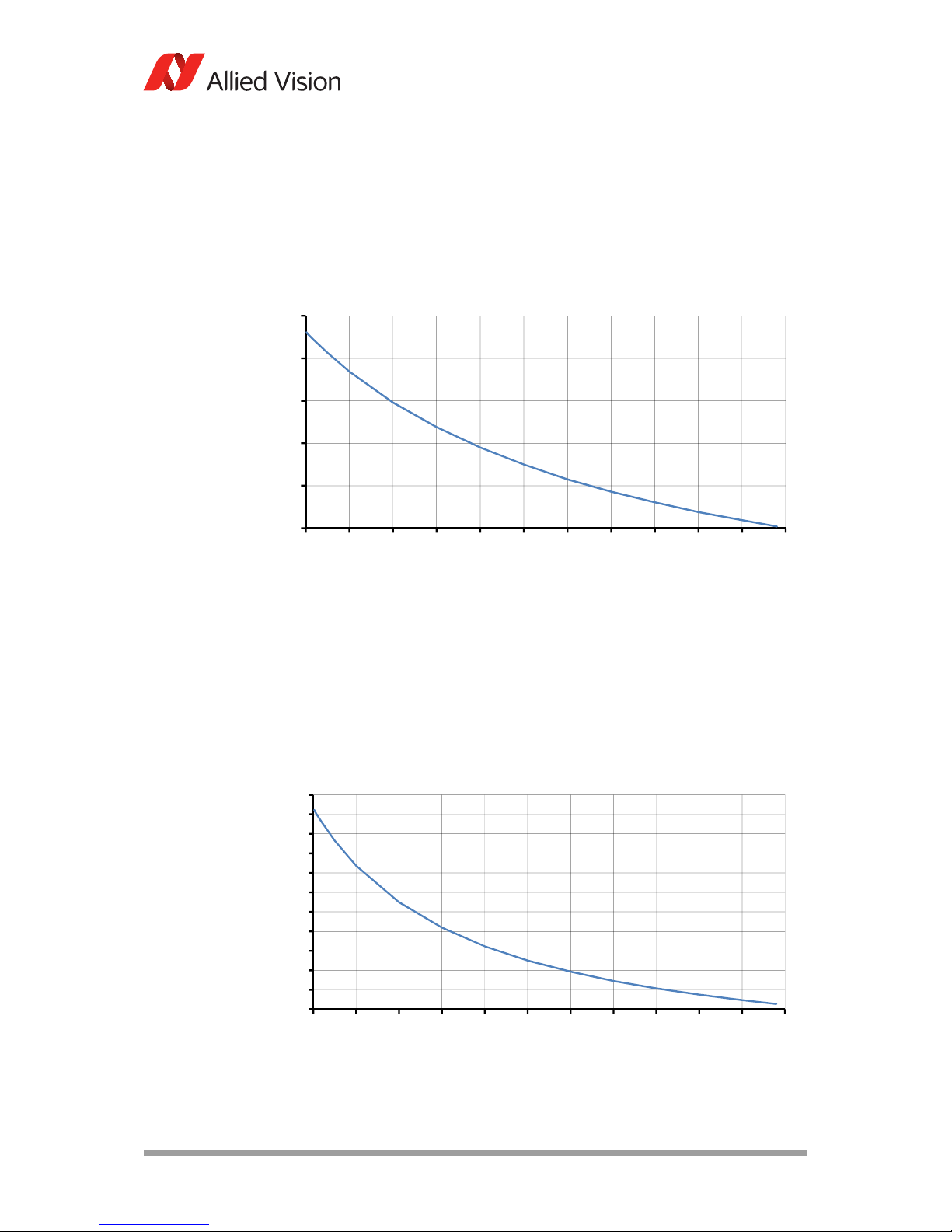

IRC30 filter

All Prosilica GE color models are equipped with an infrared block filter (IR

filter). This filter is employed to prevent infrared wavelength photons from

passing to the sensor. In the absence of IR filter, images are dominated by red

and incapable of being properly color balanced. Monochrome cameras do not

employ an IR filter.

The figure below shows the filter transmission response for the IRC30 filter

employed in the Prosilica GE cameras.

Figure 10: IRC30 filter transmission response

60

70

80

90

100

0

10

20

30

40

Transmission [%]

Wavelength [nm]

50

350 450 550 650 750 850 950

Prosilica GE Technical Manual V2.2.1

34

Camera dimensions

Camera dimensions

Prosilica GE C-Mount (adjustable)

Prosilica GE680, GE680C

Figure 11: Prosilica GE680 adjustable C-Mount mechanical dimensions

79.6*

M3x3 (4x)

50

20.2*

26

M3x3 (2x)

26

64

*Nominal value. Add 0.3mm for

GE680C.

51.6

39.4

Prosilica GE Technical Manual V2.2.1

35

Camera dimensions

Prosilica GE1050, GE1650, GE1660, GE1900,

GE1910, GE2040

Figure 12: Prosilica GE adjustable C-Mount models mechanical dimensions

*Nominal value. Add 0.3mm for

color cameras.

80.4*

51.6

39.4

M3x3 (4x)

57

13.9*

26

M3x4 (4x)

35

40

M3x3 (2x)

26

64

Prosilica GE Technical Manual V2.2.1

36

Camera dimensions

Prosilica GE F-Mount

Prosilica GE2040

Figure 13: Prosilica GE F-Mount mechanical dimensions

*Nominal value. Add 0.3mm for

color cameras.

51.6

39.4

59.7

M3x3 (2x)

26

64

M3x3 (4x)

26

57

42.3

*

Prosilica GE Technical Manual V2.2.1

37

Camera dimensions

Prosilica GE large format F-Mount

Prosilica GE4000, GE4900

Figure 14: Prosilica GE large format F-Mount mechanical dimensions

26 TYP

50 TYP

49*

*Nominal value. Add 0.3mm for

color cameras.

66

66

109.7*

59.7

M3x3 (16x)

Prosilica GE Technical Manual V2.2.1

38

Camera dimensions

Tripod adapter

A Prosilica GE camera can be mounted on a camera tripod by using a tripod

adapter. The same mounting plate can be used for all models within the

Prosilica GE camera family.

Note

Prosilica GE tripod adapter is available for purchase from

Allied Vision.

Order code: 02-5000A

Figure 15: Prosilica GE tripod mount mechanical drawing

6

4

20

12.8

20

32.5

62.5

6.5

10

6

8 PLCS TYP.

R1.6

12

0.5

0.5

50 3

7

6 PLCS TYP.

3.4 THRU

6 THRU

2814

26

2

2

1/4-20 Tapped Hole THRU

Prosilica GE Technical Manual V2.2.1

39

Camera dimensions

C-Mount flange focal distance

Flange focal distance is the optical distance from the mounting flange to image

sensor die. Prosilica GE C-Mount cameras are optically calibrated to a

standard 17.526 mm optical flange focal distance, with a ±10 µm tolerance.

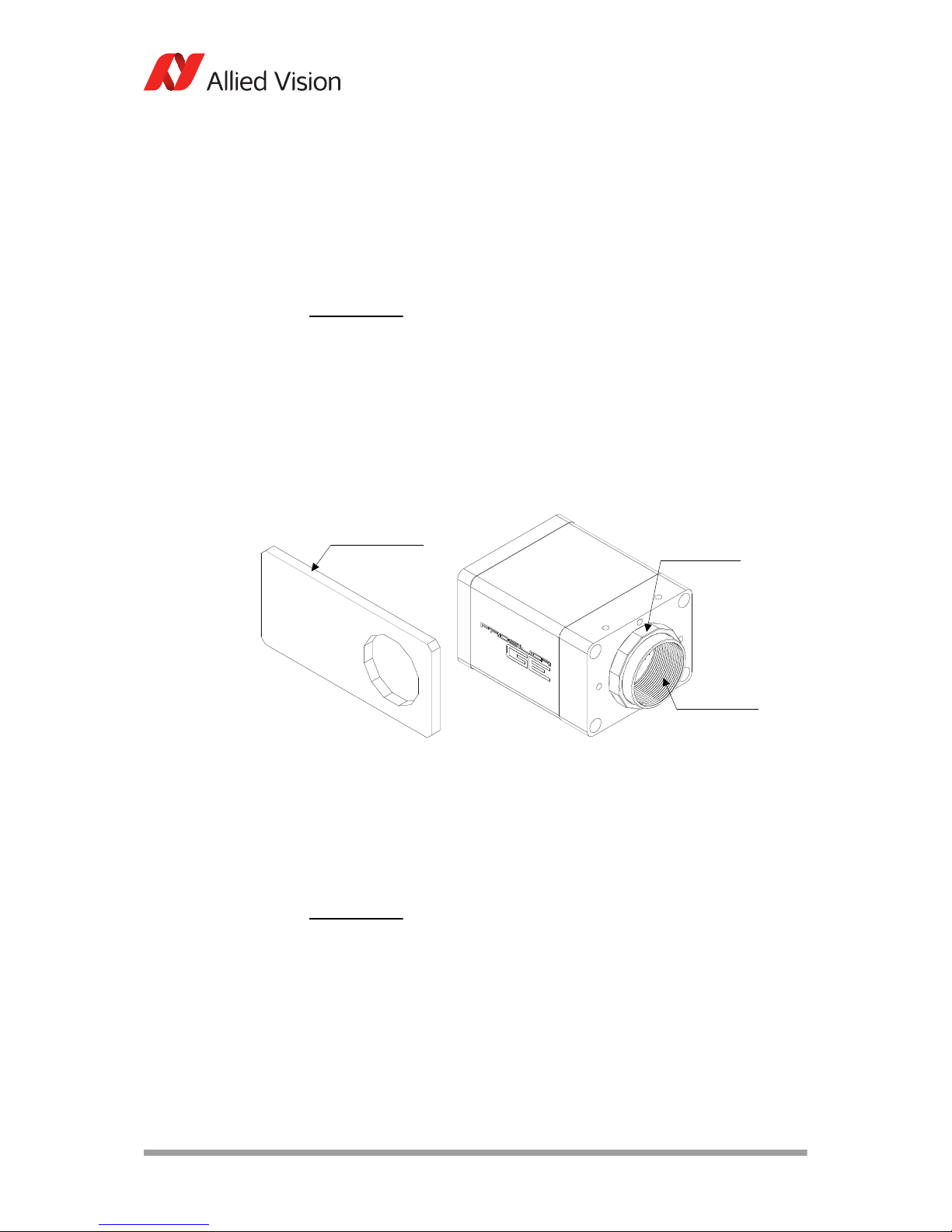

Adjustment of C-Mount

The C-Mount is adjusted at the factory and should not require adjusting. If for

some reason the lens mount requires adjustment, use the following method.

Loosen locking ring

Use an adjustable wrench to loosen the locking ring. Be careful not to scratch

the camera. When the locking ring is loose, unthread the ring a few turns from

the camera face.

www

Prosilica GE cameras are shipped with adjustable C-Mount.

The camera can also be built with a CS-Mount with a standard

12.50 mm optical flange focal distance and a ± 10 µm

tolerance.

See Modular Concept for more information.

Figure 16: Prosilica GE C-Mount camera and locking wrench

Note

A wrench suitable for this procedure is available for purchase

from Allied Vision.

Order code: E9020001

LOCKING WRENCH

LOCKING RING

C-MOUNT RING

Prosilica GE Technical Manual V2.2.1

40

Camera dimensions

Image to infinity

Use a C-Mount compatible lens that allows an infinity focus. Set the lens to

infinity and image a distant object; 10 to 15 m should suffice. Make sure the

lens is firmly threaded onto the C-Mount ring. Rotate the lens and C-Mount

ring until the image is focused. Carefully tighten the locking ring and recheck

focus.

Lens protrusion for C-Mount cameras

Lens protrusion is the distance from outer edge of C-Mount ring to contact

point of first surface internal to C-Mount ring. For color cameras this surface

is the IR-filter holder, and for mono cameras this surface is the internal camera

front plate (see figure 17:). Table 13 presents lens protrusion values for

Prosilica GE cameras with C-Mount.

Figure 17: Cross section of typical Prosilica GE front assembly with C-Mount

Model Lens protrusion [mm] Model Lens protrusion [mm]

Prosilica GE680 13.64 Prosilica GE1660C 9.67

Prosilica GE680C 9.01

Prosilica GE1900 13.64

Prosilica GE1050 13.64

Prosilica GE1900C 9.15

Prosilica GE1050C 9.71

Prosilica GE1910 13.64

Prosilica GE1650 13.64

Prosilica GE1910C 9.67

Prosilica GE1650C 9.20

Prosilica GE2040 13.64

Prosilica GE1660 13.64

Prosilica GE2040C 13.64

Table 13: Lens protrusion for Prosilica GE cameras with C-Mount

Lens protrusion

Section A-A for C-Mount

monochrome cameras

Front Plate

IR cut lter

holder

Lens protrusion

Section A-A for C-Mount

color cameras

A

A

Prosilica GE Technical Manual V2.2.1

41

Camera dimensions

F-Mount flange focal distance

Flange focal distance is the optical distance from the mounting flange to image

sensor die. Prosilica GE F-Mount cameras are optically calibrated to a standard

46.5 mm optical flange focal distance.

Adjustment of F-Mount

The F-Mount is adjusted at the factory and should not require adjusting. If for

some reason, the lens mount requires adjustment, use the following method.

Attach F-Mount compatible lens

Use an F-Mount compatible lens that allows an infinity focus. Attach the lens

to the camera using a counter-clockwise rotation of about a quarter turn. The

lens should snap into place such that the lens flange and camera flange mate

over the full circumference.

Loosen F-Mount front assembly

Use a 1.5 mm hex wrench to loosen the three set screws than hold the FMount front assembly to the camera body.

Image to infinity

Set the lens to infinity and image a distant object; 10 to 15 m should suffice.

Gently move the F-Mount front until focused and lock it in place.

Figure 18: Prosilica GE F-Mount isometric view

M3 SET SCREW: 3 PLACES

F-MOUNT FRONT ASSEMBLY

Prosilica GE Technical Manual V2.2.1

42

Camera interfaces

Camera interfaces

This chapter provides information on Gigabit Ethernet port, inputs and

outputs, and trigger features.

Status LEDs

The color of the LEDs have the following meaning:

www

Accessories

Please contact the Allied Vision Sales team or your local Allied

Vision distribution partner for information on accessories:

https://www.alliedvision.com/en/about-us/where-weare.html

Figure 19: Prosilica GE connection ports

LED color Status

LED1 Flashing/solid green Ethernet activity

LED2 Flashing green Camera is powered

Solid green Camera is booted, and link with the host is

established

Table 14: Prosilica GE status LEDs

IN 1

I/O PORT:

CAMERA POWER

EXTERNAL SYNC IO

RS232 TX/RX

GIGABIT ETHERNET PORT

OUT 1

LED2

LED1

GIGABIT ETHERNET CABLE MOUNTING HOLES

Prosilica GE Technical Manual V2.2.1

43

Camera interfaces

Gigabit Ethernet port

The Gigabit Ethernet port conforms to the IEEE 802.3 1000BASE-T standard

for Gigabit Ethernet over copper. Allied Vision recommends using Category 6

or higher compatible cabling and connectors for best performance.

Note

Once the camera is booted, LED2 will remain solid green as

long as the camera is powered, even if connection with the

host is lost.

www

The GigE Installation Manual offers detailed instructions for

using Prosilica GE cameras.

https://www.alliedvision.com/en/support/technicaldocumentation/prosilica-ge-documentation.html

Note

See the Hardware Selection for Allied Vision GigE Cameras

application note for a list of recommended Ethernet adapters:

https://www.alliedvision.com/en/support/technical-papersknowledge-base.html

Note

A standard Ethernet adapter is available for purchase from

Allied Vision:

Order code: 02-3002A

Model: Intel Pro 1000/PT

Note

Cable lengths up to 100 m are supported.

The 8P8C RJ45 jack has the pin assignment according to the

Ethernet standard (IEEE 802.3 1000BASE-T).

Note

Prosilica GE cameras support cables with horizontal locking

screw connector for a secured connection (see figure 19:).

Allied Vision recommends using locking-screw cables from

Components Express, Inc. for a perfect fit. Visit the CEI

product configurator to customize the cable according to your

needs.

Prosilica GE Technical Manual V2.2.1

44

Camera interfaces

Camera I/O connector pin assignment

Camera side Hirose HR10A-10R-12SB connector

Pin Signal Direction Level Description

Trigger cable

color code

1 In 1 In TTL Maximum 5 V Camera input

galvanic isolated

(SyncIn1)

Blue

2 Out 2 Out TTL Maximum 5 V Camera output 2

galvanic isolated

(SyncOut2)

Red

3 Out 3 Out TTL Maximum 5 V Camera output 3

galvanic isolated

(SyncOut3)

Pink

4 RxD RS232 In RS232 Terminal receive data

Grey

5 TxD RS232 Out RS232 Terminal transmit

data

Yel low

6 Reserved --- --- ---

Green

7 Reserved --- --- ---

Brown

8 Reserved --- --- ---

White

9 Reserved --- --- ---

Black

10 Isolated IO

GND

In/Out Common GND

for In/Out

Isolated input and

output signal ground

Orange

11 Isolated IO

GND

In/Out Common GND

for In/Out

Isolated input and

output signal ground

White/Black

12 Isolated IO

GND

In/Out Common GND

for In/Out

Isolated input and

output signal ground

White/Brown

Table 15: Camera I/O connector pin assignment and Prosilica GE trigger cable color coding

9 1

2

3

4

5

6

7

8

12 11

10

Prosilica GE Technical Manual V2.2.1

45

Camera interfaces

The general purpose I/O port uses a Hirose HR10A-10R-12SB connector on the

camera side. The mating cable connector is Hirose HR10A-10P-12P.

I/O definition

Camera power

The Prosilica GE camera family supports a wide input power voltage range.

The camera will not power in reverse polarity. Exceeding the voltage range

specified below will damage the camera.

Note

For cable color and pin out information, see the Allied Vision

I/O cable data sheet:

https://www.alliedvision.com/en/support/technicaldocumentation/accessories-data-sheets.html

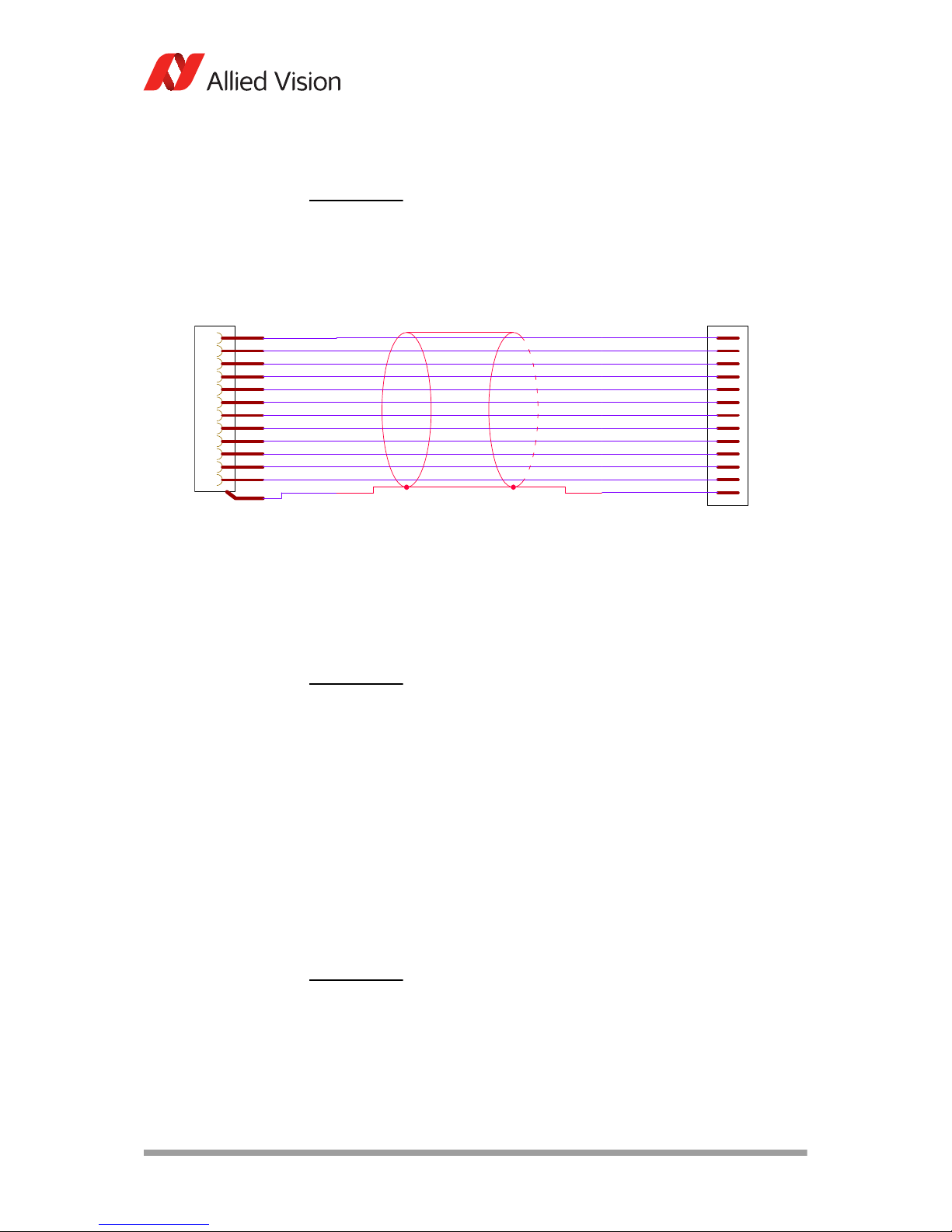

Figure 20: Prosilica GE cable color coding

Note

This cable side Hirose connector can be purchased from Allied

Vision.

Order code: K7600039

Caution

5 to 24 V. 12 V nominal.

Hirose HR10A

.

.

.

.

.

.

.

.

.

.

.

.

SHIELD

1

2

3

4

5

6

7

8

9

10

11

12

.

BLUE

RED

PINK

GREY

YELLOW

GREEN

BROWN

WHITE

BLACK

ORANGE

WHITE/BLACK

WHITE/BROWN

Open End

.

.

.

.

.

.

.

.

.

.

.

.

TRANSPARENT

.

.

.

.

.

.

.

.

.

.

.

.

.

Prosilica GE Technical Manual V2.2.1

46

Camera interfaces

Isolated IO GND

Isolated IO GND must be connected to the user’s external circuit ground if In

1, Out 1, Out 2, Out 3, RxD RS232, and TxD RS232 is to be used. Note that

Isolated IO GND is common with power ground; however, it is good practice

to provide a separate ground connection for power and signaling when

designing the cabling.

RxD RS232 and TxD RS232

These signals are RS232 compatible. These signals allow communication from

the host system via the Ethernet port to a peripheral device connected to the

camera. Note that these signals are not isolated; therefore, cabling should be

carefully designed for the noisy environments.

Input triggers

In 1

In 1 allows the camera to be synchronized to an external event. The camera

can be programmed to trigger on the rising edge, falling edge, both edges, or

level of this signal. The camera can also be programmed to capture an image

at some programmable delay time after the trigger event.

The Mini-SMB trigger input is internally connected to the In 1 of the general

purpose I/O port. The Mini-SMB port on the camera uses an Amphenol 903406J-51R connector. A suitable mating cable connector is Amp 413985-3

which can be used with RG174 coaxial cable.

Note

Prosilica GE has a built-in power barrel connector (Switchcraft

PC712a). A 12 V power adapter with barrel connection plug

(Switchcraft 760K)is available for purchase from Allied Vision:

• Order code: 02-8005C North America Supply.

• Order code: 02-8010C Universal Supply.

Caution

Do not exceed 5.5 V on In 1.

Note

SMB to SMB cables are available for purchase from Allied

Vision with various lengths. Example:

Order code: 02-6007A

Prosilica GE Technical Manual V2.2.1

47

Camera interfaces

Output signals

Out 1

This Mini-SMB trigger output is not internally connected to other camera

output pins of the Camera I/O connector described above. This connector is

particularly useful for triggering multiple cameras in a “daisy chain” fashion. It

can be configured as follows:

Any of the above signals can be set for active high or active low. The Mini-SMB

port on the camera uses an Amphenol 903-406J-51R connector. A suitable

mating cable connector is Amp 413985-3 which can be used with RG174

coaxial cable.

Out 2 and Out 3

Out 2 and Out 3 can be configured to active high or active low. The internal

camera signals are listed as follows:

Auto iris video type

This signal can be used to drive the video input of a video iris lens.

Exposing Corresponds to when camera is integrating light

Trigger Ready Indicates when the camera will accept a trigger signal

Trigger Input A relay of the trigger input signal used to “daisy chain” the

trigger signal for multiple cameras

Readout Valid when camera is reading out data

Imaging Valid when camera is exposing or reading out

Strobe Programmable pulse based on one of the above events

GPO User programmable binary output

Note

SMB to BNC cables are available for purchase from Allied

Vision.

Order code: 02-6014A

Exposing Corresponds to when camera is integrating light

Trigger Ready Indicates when the camera will accept a trigger signal

Trigger Input A relay of the trigger input signal used to “daisy chain” the

trigger signal for multiple cameras

Readout Valid when camera is reading out data

Imaging Valid when camera is exposing or reading out

Strobe Programmable pulse based on one of the above events

GPO User programmable binary output

Prosilica GE Technical Manual V2.2.1

48

Camera interfaces

Reserved

These signals are reserved for future use and should be left disconnected.

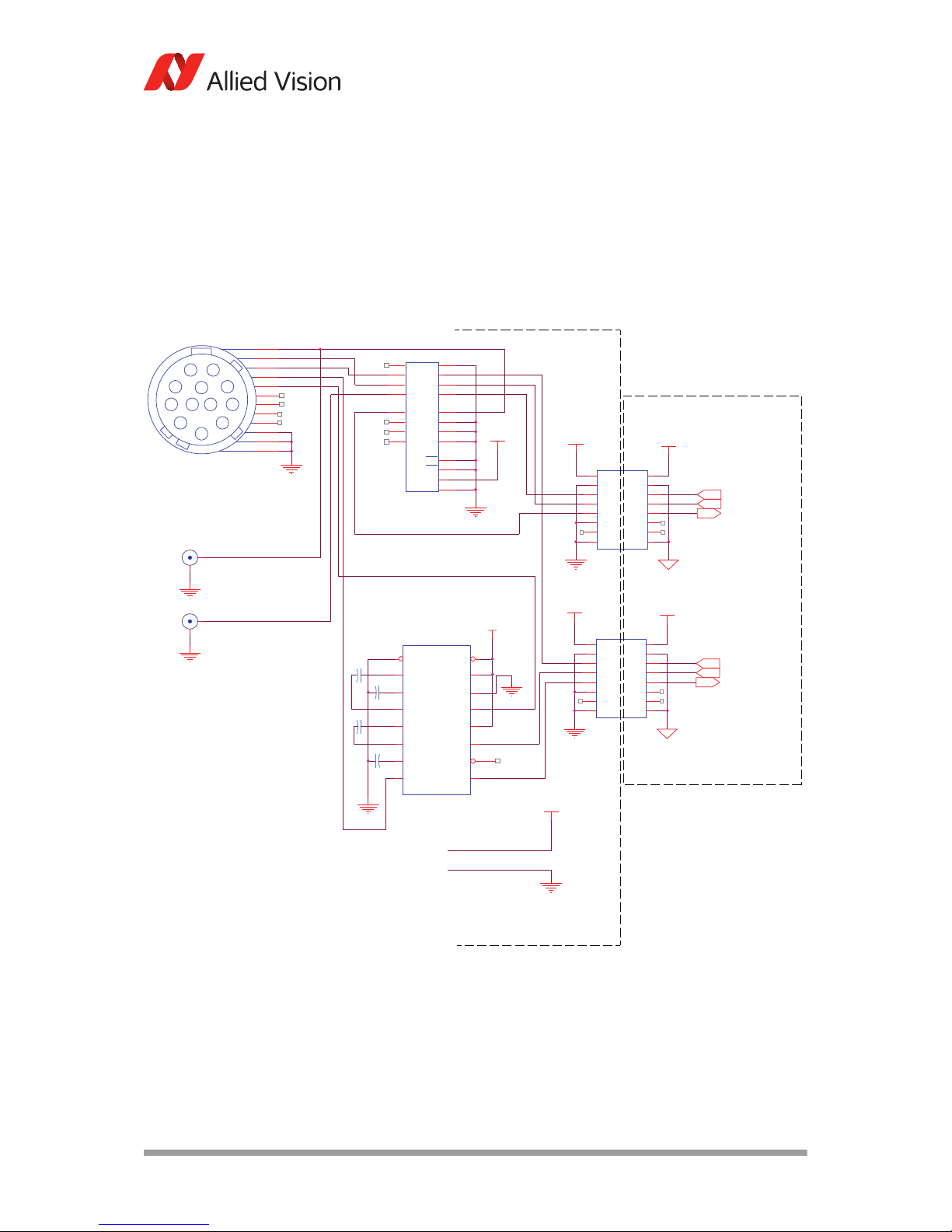

Camera I/O connector internal circuit diagram

Figure 21: Prosilica GE internal circuit diagram

HIROSE HR10A-10R-12SB

1

2

3

4

5

6

7

8

9

10

11

12

AS SEEN FROM

CAMERA REAR VIEW

1

2

3

4

5

6

7

8

9

10

12 11

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

EN

C1+

V+

C1-

C2+

C2-

V-

RIN

FORCEOFF

VCC

GND

DOUT

FORCEON

DIN

INVALID

ROUT

0.1μ

0.1μ

MAXIM

MAX3221CPWR

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

VDD2

GND2

OUT1

OUT2

IN3

IN4

NC

GND2

VDD1

GND1

IN1

IN2

OUT3

OUT4

NC

GND1

1A4

1A3

1A2

1A1

2A4

2A3

2A2

2A1

VCC

2OE

GND

1OE

1Y4

1Y3

1Y2

1Y1

2Y4

2Y3

2Y2

2Y1

3

5

7

9

12

14

16

18

8

6

4

2

17

15

13

11

10

20

19

1

ISO+5V

VDD -3.3

NVE

IL7 16-3

LOGIC SYNC OUT 1

LOGIC SYNC OUT 2

LOGIC TRIGGER INPUT

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

VDD2

GND2

OUT1

OUT2

IN3

IN4

NC

GND2

VDD1

GND1

IN1

IN2

OUT3

OUT4

NC

GND1

ISO+5V

VDD -3.3

NVE

IL7 16-3

LOGIC SYNC OUT 3

LOGIC TXD

LOGIC RXD

ISO+5V

MINI-SMB

MINI-SMB

OUT

IN

TRIGGER INPUT

SYNC OUT 1

TRIGGER INPUT

ISO+5V

ISO+5V

RS232-TXD

ISO RXD

ISO TXD

ISOLATED 5V POWER

ISOLATED GROUND

RS232-RXD

SYNC OUT 2

SYNC OUT 3

RS-232 RXD

RS-232 TXD

CAMERA INTERNAL CIRCUIT

GALVANIC ISOLATION BOUNDARY

0.1μ

0.1μ

TEXAS INSTRUMENTS

SN74ACT244PWR

Prosilica GE Technical Manual V2.2.1

49

Camera interfaces

Camera I/O connector external circuit example

The trigger circuit is connected to a Texas Instruments SN74ACT244PWR

buffer/driver inside the camera.

Maxim MAX3221CPWR

Used to drive the RS232 signal logic via the external

connector.

Texas Instruments SN74ACT244PWR

Used as trigger buffer/driver. The required trigger

input current is less than 10 µA and the maximum

sync output current is 24 mA.

Figure 22: Prosilica GE external circuit

Caution

Input: Incoming trigger must be able to source 10 µA.

Output: Sync output current is 24 mA.

1

2

3

4

5

6

7

8

9

10

11

12

1

2

3

4

5

6

7

8

9

10

1211

TRIGGER INPUT

OUT 2

OUT 3

HIROSE HR10A-10P-12P

CABLE SIDE

IN 1 (5 V TTL DRIVER)

OUT 2 (5 V TTL RECEIVER)

OUT 3 (5 V TTL RECEIVER)

Prosilica GE Technical Manual V2.2.1

50

Camera interfaces

In 1, Out 1 external circuit example

The trigger circuit is connected to a Texas Instruments SN74ACT244PWR

buffer/driver inside the camera. Note that the trigger input signal is not

terminated to match the cable impedance.

Figure 23: Prosilica GE In 1, Out 1 external circuit

Caution

Input: The required trigger input current is less than 10 µA.

Output: The maximum sync output current is 24 mA.

MINI-SMB

MINI-SMB

OUT

IN

IN 1 (5 V TTL DRIVER)

OUT 1 (5 V TTL RECEIVER)

RG-174 COAX CABLE

RG-174 COAX CABLE

TRIGGER INPUT

OUT 1

Prosilica GE Technical Manual V2.2.1

51

Camera interfaces

Trigger timing diagram

Notes on triggering

Figure 24: Prosilica GE internal signal timing waveforms

Te rm Definition

User trigger Trigger signal applied by the user (hardware

trigger, software trigger)

Logic trigger Trigger signal seen by the camera internal logic

(not visible to the user)

t

pd

Propagation delay between the user trigger and

the logic trigger

Exposure High when the camera image sensor is integrating

light

Readout High when the camera image sensor is reading out

data

Trigger latency Time delay between the user trigger and the start

of exposure

Trigger jitter Error in the trigger latency time

Table 16: Explanation of signals in timing diagram

User trigger

Logic trigger

Exposure

Readout

Trigger ready

Imaging

Interline time

Idle

Tpd

Trigger

latency

Exposure

start delay

Trigger

jitter

Registered

exposure time

Readout time

NN+1

NN+1

Note: Jitter at the

beginning of an exposure

has no eect on the

length of exposure.

Prosilica GE Technical Manual V2.2.1

52

Camera interfaces

Trigger rules

• The end of exposure will always trigger the next readout.

• The end of exposure must always end after the current readout.

• The start of exposure must always correspond with the interline time if

readout is true.

• Exposure start delay equals the readout time minus the registered

exposure time.

Triggering during the idle state

For applications requiring the shortest possible Trigger Latency and the

smallest possible Trigger Jitter the User Trigger signal should be applied when

Imaging is false and Idle is true. In this case, Trigger Latency and Trigger Jitter

are as indicated in the camera specifications.

Triggering during the readout state

For applications requiring the fastest triggering cycle time whereby the

camera image sensor is exposing and reading out simultaneously, apply the

User Trigger signal as soon as a valid Trigger Ready is detected. In this case,

Trigger Latency and Trigger Jitter can be up to 1 row time since Exposure must

always begin on an Interline boundary.

Trigger ready Indicates to the user that the camera will accept

the next trigger

Registered exposure

time

Exposure time value currently stored in the camera

memory

Exposure start delay Registered exposure time subtracted from the

readout time and indicates when the next

exposure cycle can begin such that the exposure

will end after the current readout

Interline time Time between sensor row readout cycles

Imaging High when the camera image sensor is either

exposing and/or reading out data

Idle High if the camera image sensor is not exposing

and/or reading out data

Note

The user trigger pulse width should be at least three times the

width of the trigger latency as indicated in Chapter

Specifications on page 14.

Te rm Definition

Table 16: Explanation of signals in timing diagram (continued)

Prosilica GE Technical Manual V2.2.1

53

Firmware update

Firmware update

Firmware updates are carried out via the GigE connection. Allied Vision

provides an application for all Prosilica GE cameras that loads firmware to the

camera using a simple interface. New feature introductions and product

improvements motivate new firmware releases. All users are encouraged to

use the newest firmware available and complete the firmware update if

necessary.

www

Download the latest GigE firmware loader from the Allied

Vision website:

https://www.alliedvision.com/en/support/firmware

www

For more information on GigE firmware update:

https://www.alliedvision.com/en/support/technical-papersknowledge-base.html