Allied Vision Prosilica GC660C, Prosilica GC1290C, Prosilica GC1600H, Prosilica GC1380CH, Prosilica GC1290 Technical Manual

...

GigE VISION CAMERAS

Prosilica GC

Technical Manual

V2.4.1

Allied Vision Technologies GmbH // Taschenweg 2a, 07646 Stadtroda / Germany 2018-Jun-19

Prosilica GC at a glance

Prosilica GC cameras have a GigE port and work with GigE hardware and cable

lengths up to 100 meters. Prosilica GC cameras are GigE Vision V1.2 and GenICam

SFNC V1.2.1 compliant.

Applied standards

Prosilica GC at a glance

GigE Vision®

GenICam™

The GigE Vision standard is an interface standard for digital machine vision

cameras administered by the AIA that is widely supported in the machine vision

industry. In contrast, Gigabit Ethernet is the network GigE Vision is built upon.

GenICam is a machine vision standard hosted by the EMVA. The aim of GenICam is

to provide a generic configuration interface for cameras and devices independent

of the used interface technology (for example, GigE Vision, USB3 Vision, DCAM

IEEE 1394, Camera Link). This approach enables proper interoperability between

GenICam compliant hardware and software solutions without the need for

customization.

The GenICam standard consists of multiple modules that specify tasks to be solved.

Allied Vision cameras and software make use of these modules, like the SFNC that

standardizes feature names and types via an XML file or the transport layer

interface (GenTL) that is used to grab images.

What else do you need?

Content URL

Camera data sheets

GigE Features Reference

Modular Concept

3D CAD STEP files

Software and firmware downloads

Technical papers and knowledge base https://www.alliedvision.com/en/support/

https://www.alliedvision.com/en/support/

technical-documentation/prosilica-gcdocumentation.html

technical-papers-knowledge-base.html

Read this manual carefully

Learn how to protect your camera from damage and fully understand its functions.

2Prosilica GC Technical Manual V2.4.1

Contact us

Connect with Allied Vision by function

https://www.alliedvision.com/en/meta-header/contact.html

Find an Allied Vision office or Allied Vision distribution partner

https://www.alliedvision.com/en/about-us/where-we-are.html

Email

For general inquiries, please contact info@alliedvision.com

For technical support, please contact support@alliedvision.com

Headquarters

Allied Vision Technologies GmbH

Taschenweg 2a, 07646 Stadtroda, Germany

Contact us

T// +49 36428-677-0 (Reception)

T// +49 36428-677-230 (Sales)

F// +49 36428 -677-28

President/CEO: Frank Grube

Registration Office: AG Jena HRB 208962

Tax ID: DE 184383113

3Prosilica GC Technical Manual V2.4.1

Contents

Contents

Prosilica GC at a glance 2

Applied standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

What else do you need? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Contact us 3

Document history and conventions 8

Document history . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Manual conventions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Styles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Product naming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Acronyms and abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Compliance and intended use 15

Compliance notifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

For customers in Europe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

For customers in the USA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

For customers in Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Pour utilisateurs au Canada . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Avoid electromagnetic interferences . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Camera applications and intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Use in medical devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Copyright and trademarks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Installation and hardware 18

General cautions and warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Electrical connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Optical components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Configuring the host computer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Installing the Ethernet adapter driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Optional: Modifying Ethernet adapter IP address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Ethernet adapter driver settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Enabling jumbo packets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connecting your camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Optics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Downloading camera drivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Powering up the camera. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Connecting to host application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Allied Vision software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Third-party software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications 27

4Prosilica GC Technical Manual V2.4.1

Contents

Notes on specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Frame memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Resolution and ROI frame rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Absolute QE plots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Spectral response plots . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Specifications common to all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Prosilica GC660, GC660C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Prosilica GC1290, GC1290C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Prosilica GC1380H, GC1380CH. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Prosilica GC1600H, GC1600CH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Prosilica GC2450, GC2450C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ROI frame rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Prosilica GC model frame rate comparison. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Prosilica GC model comparison . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Camera feature highlights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Camera feature comparison. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Image data flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Mechanical dimensions 50

Prosilica GC model housing (C-Mount) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Tripod adapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Flange focal distance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

C-Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Adjustment of C-Mount . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Lens protrusion for C-Mount cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Sensor position accuracy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

IR cut filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Camera interfaces 57

Back panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

GigE port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

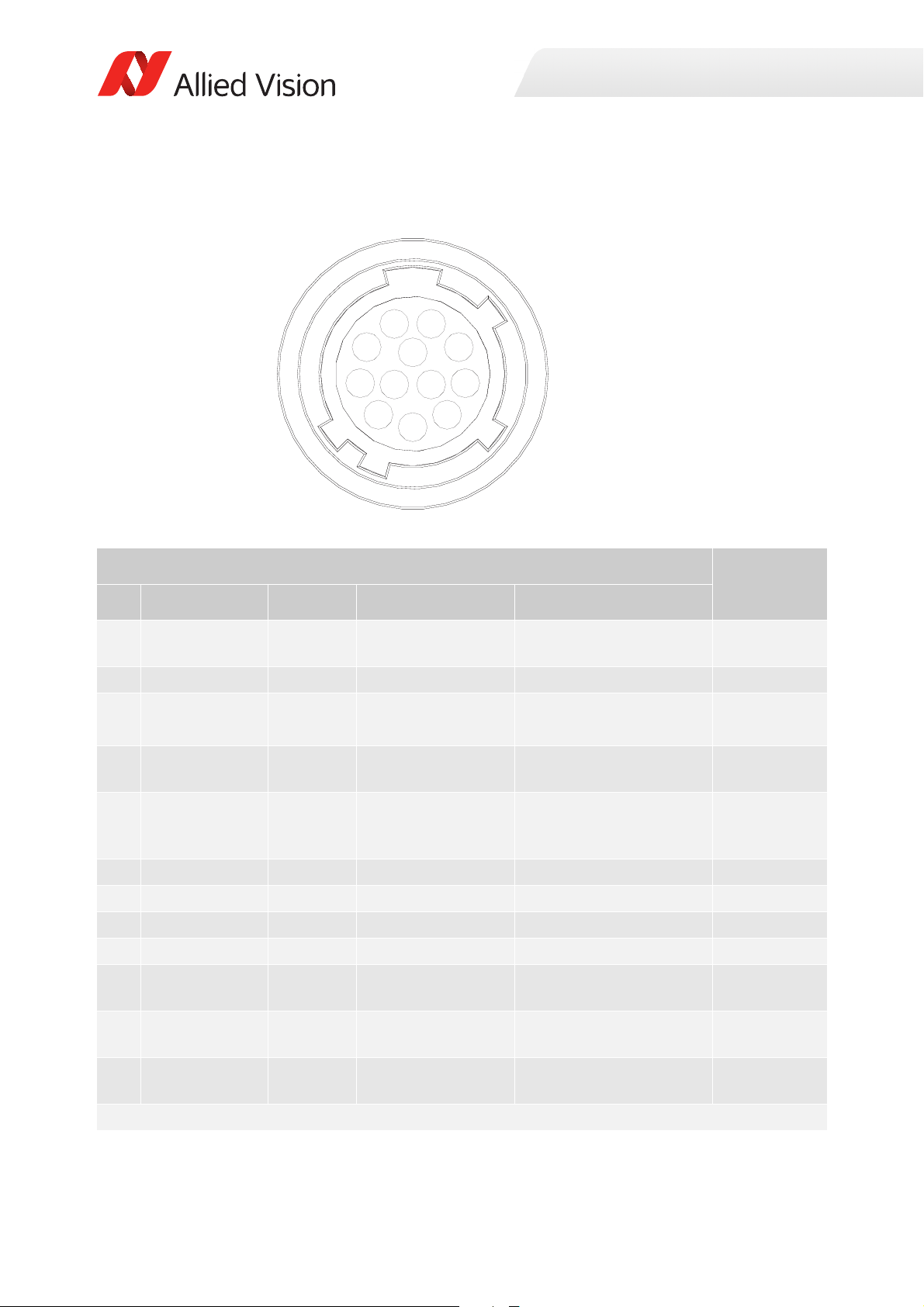

Camera I/O connector pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

I/O definition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Camera power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5Prosilica GC Technical Manual V2.4.1

Contents

Isolated IO ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

RxD RS232 and TxD RS232 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Input triggers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Output signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Signal ground . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Video iris . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Reserved . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

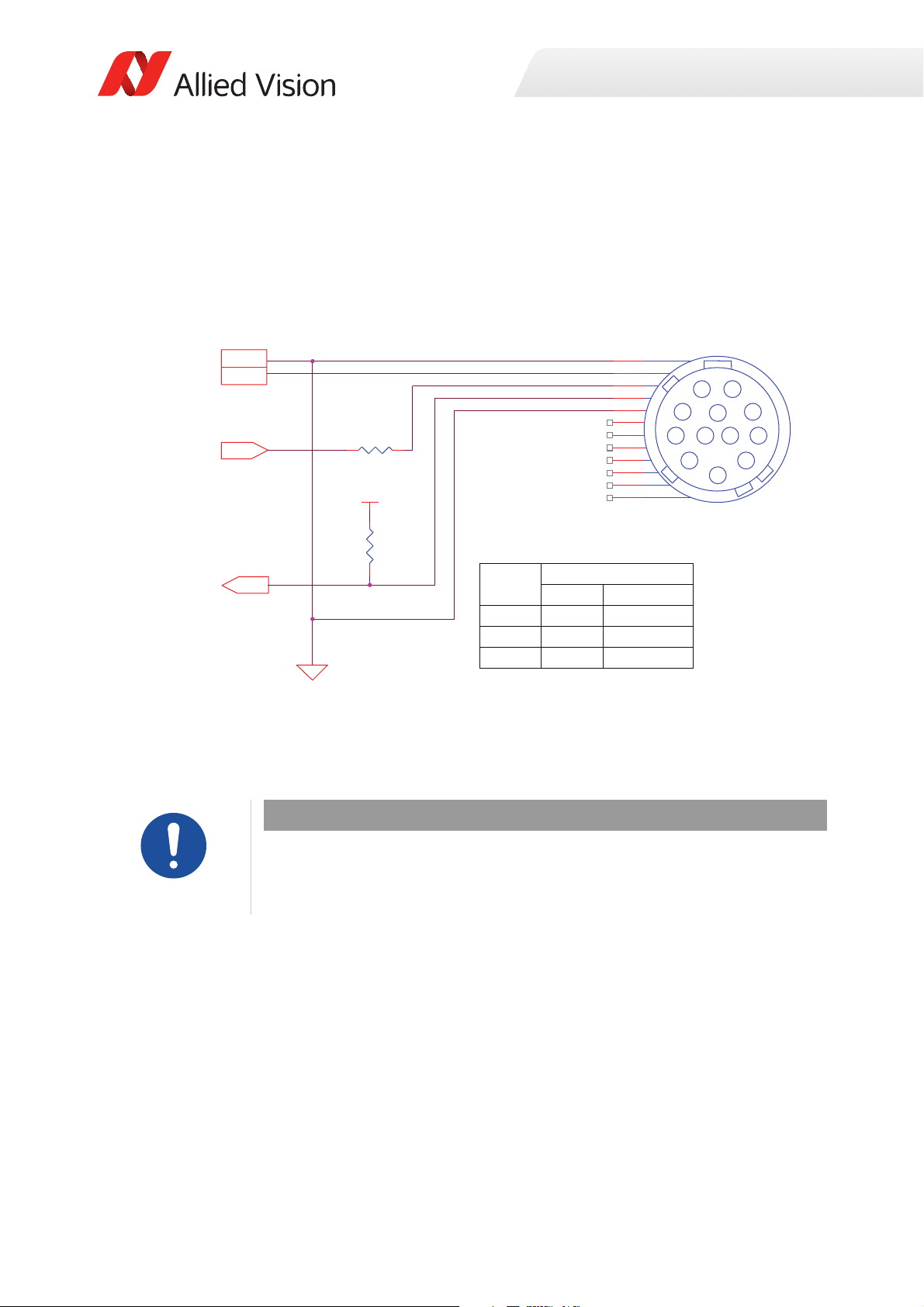

Video iris output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Camera trigger. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Camera I/O opto-isolated user circuit example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Camera I/O non-isolated user circuit example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Trigger timing diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Notes on triggering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Trigger rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Cleaning optical components 71

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Keep optical components clean . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Identifying impurities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Locating impurities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

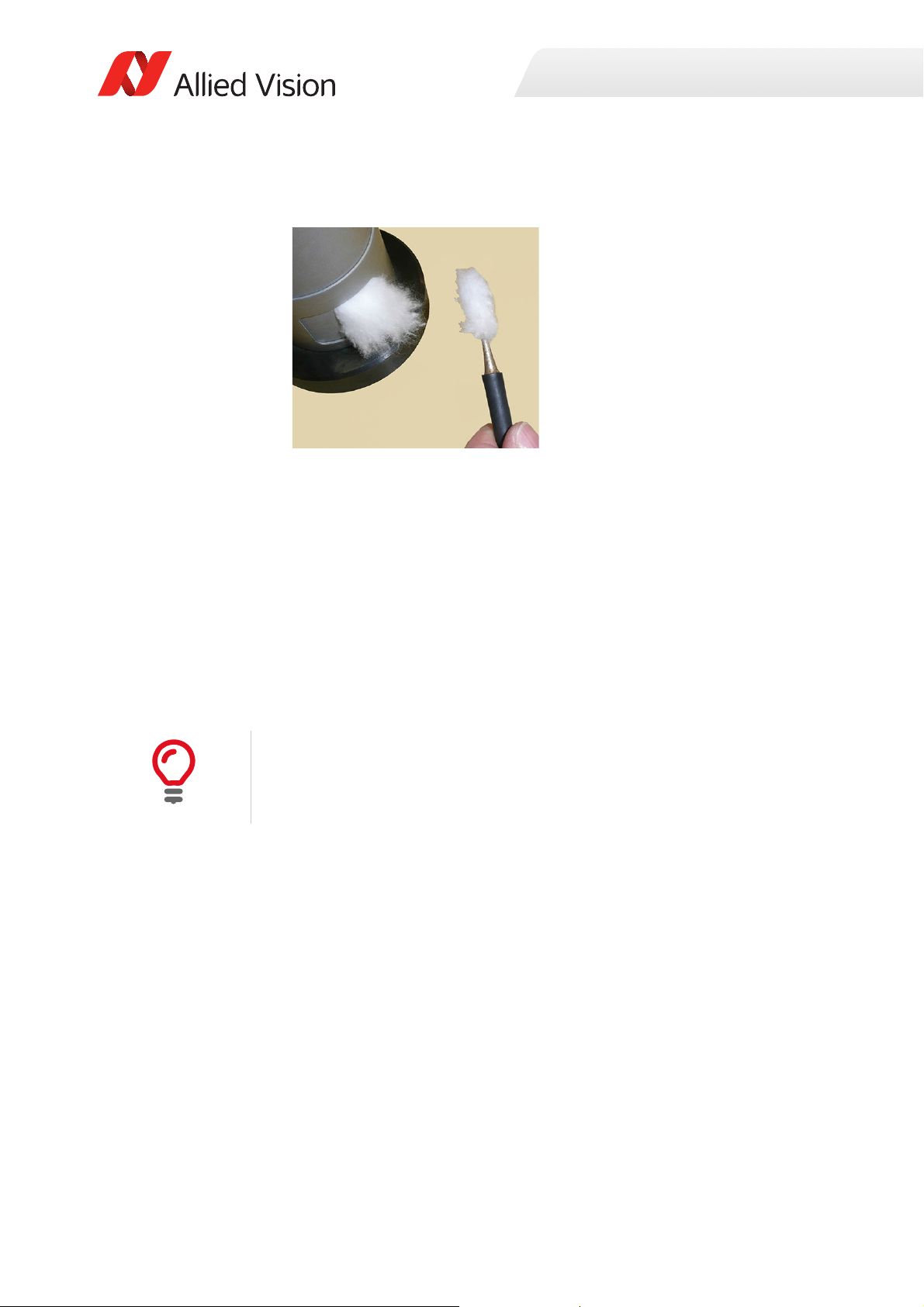

Materials for cleaning optical components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Cleaning Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Cleaning with compressed air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Firmware update 77

Appendix 82

Specifications common to all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Prosilica GC650, GC650C (02-2110A, 02-2111A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Prosilica GC655, GC655C (02-2115A, 02-2116A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Prosilica GC750, GC750C (02-2160A, 02-2161A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Prosilica GC780, GC780C (02-2117A, 02-2118A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Prosilica GC1020, GC1020C (02-2165A, 02-2165B, 02-2166A, 02-2166B) . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Prosilica GC1350, GC1350C (02-2130A, 02-2131A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

6Prosilica GC Technical Manual V2.4.1

Contents

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Prosilica GC1380, GC1380C (02-2140A, 02-2141A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Prosilica GC1600, GC1600C (02-2150A, 02-2151A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

Absolute QE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Spectral response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

ROI frame rate. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Camera feature comparison. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Image data flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Prosilica GC monochrome models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Prosilica GC color models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Prosilica GC750C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Mechanical dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Prosilica GC CCD model housing (C-Mount). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Prosilica GC CMOS model housing (C-Mount) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Lens protrusion for C-Mount cameras . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Index 116

7Prosilica GC Technical Manual V2.4.1

Document history and conventions

This chapter includes:

• Document history

• Layout styles and symbols used in this manual

• Product naming

• Acronyms and abbreviations used in this manual

Prosilica GC Technical Manual V2.4.1 8

Document history and conventions

Document history

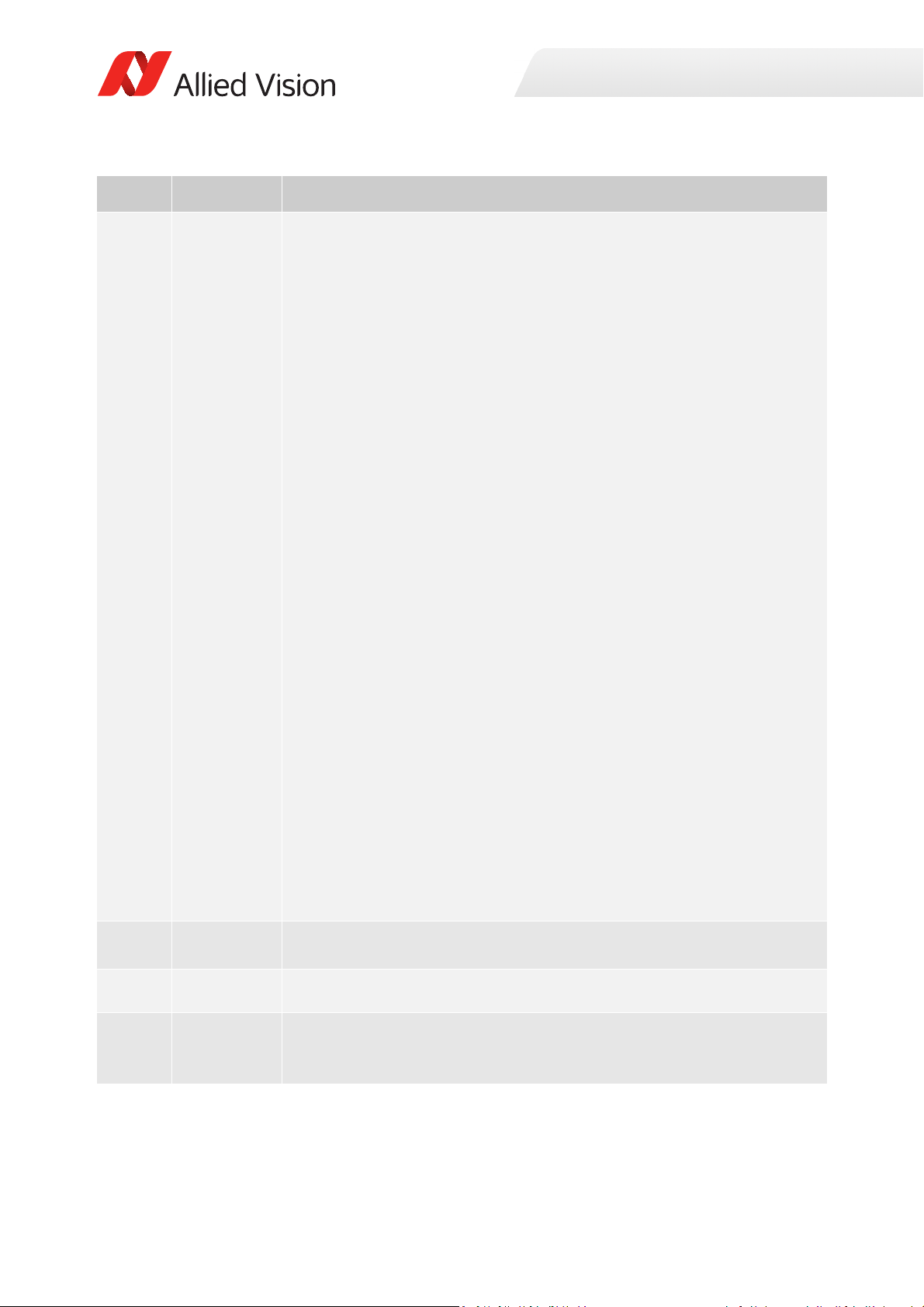

Version Date Remarks

V2.0.0 2011-Jul-22 New manual release status

V2.0.1 2011-Oct-07 Added note to figure 34

V.2.0.2 2012-Sep-21 Renamed Camera IO signals

Reworked cleaning optics section

V.2.0.3 2013-Jan-14 Updated the exposure control values

Updated the Frame rate vs. Height graphs

Removed the internal I/O circuit diagram

V2.0.4 2013-Mar-26 Added Status LEDs section

Added appendix

Updated the RoHS directive

Updated the pixel format naming according to the GenICam naming convention

Added caution regarding the drive voltage for the video iris lens

Added frame rate formulas in the Resolution and ROI frame rates chapter

V2.0.5 2013-May-07 Updated the exposure control values in the Specifications chapter

Added Vimba SDK link in the Additional references section

Updated Allied Vision recommended cabling to Cat 6 or higher in the Gigabit

Ethernet interface section

V2.0.6 2013-Jul-05 Added contact information for Allied Vision Technologies (Shanghai) Co. Ltd.

Updated the links to Allied Vision GigE Installation Manual

Added links to Allied Vision GigE Camera and Driver Features document

V2.0.7 2013-Oct-02 Added optical flange focal distance and maximum lens protrusion information

Updated Cleaning optics section

Updated vertical binning values in Specifications chapter

Updated Tab l e 1 7

Updated links for PvAPI SDK

V2.0.8 2013-Nov-26 Added chapter Description of the data path

Updated the Index

V2.1.0 2015-Mar-20 Updated Allied Vision logo

Replaced old links with new Allied Vision website links

Changed file name from ‘GigE Camera and Driver Features’ to ‘GigE Features

Reference’

Changed chapter name from ‘Description of data path’ to ‘Camera data path’

Replaced the optical flange focal distance section with C-Mount flange focal distance

section

Updated datapath diagram for Prosilica GC: color models

Updated exposure control and power requirements in Specifications chapter

Table 1: Document history

9Prosilica GC Technical Manual V2.4.1

Document history and conventions

Version Date Remarks

V2.2.0 2016-July-04 Changed the technical manual layout

Changed chapter name from Camera dimensions to Mechanical dimensions

Moved Sensor position accuracy section from Appendix to Mechanical dimensions

chapter

Added Appendix for all older Prosilica GC hardware revision A models

Added Cleaning optical components chapter to replace Cleaning optics section in

V2.1.0

Added Contact us section to replace Contacting Allied Vision section in V2.1.0

Added D revision feature changes for Prosilica GC660, GC660C, GC1290, GC1290C,

GC1380H, GC1380CH, GC1600H, GC1600CH, GC2450, GC2450C

Added Installation chapter

Removed image flow chapter and added the diagrams to the Appendix

Added new image flow diagram for new Prosilica GC hardware revision D models at

the end of the Specifications chapter

Updated frame rate information

Aligned the information in the Specification tables with the information on the

product web pages

Various other minor improvements and corrections

New trigger latency and trigger jitter values for Prosilica GC hardware revision D

models

Updated absolute QE plots and new spectral response plots for all hardware revision

D models

For Prosilica GC660 and GC660C, the image width was changed from 659 to 658. It

was changed to 658 so that the color version would image with Vimba when using

default values.

Prosilica GC hardware revision A models support five user sets. Prosilica GC hardware

revision D models support three user sets.

Added optical filter information to specification tables

New features for hardware revision D models include:

• Gamma correction

• Three look-up tables

• Hue, saturation, and color transformation

• Main board temperature readout

V2.2.1 2017-Feb-10 Updated QE plot and added spectral response plots

Corrected error in Installation and hardware chapter

V2.2.2 2017-Apr-07 Added cable color to camera I/O connector pin assignment including pin assignment

figure and cross reference to the Allied Vision I/O cable data sheet

V2.2.3 2017-May-24 Corrected the measurements for the Prosilica GC750

Added note to all models that dimensions include connectors and C-Mount

Updated the measurements to reflect the dimensions shown in the technical drawing

Table 1: Document history (continued)

10Prosilica GC Technical Manual V2.4.1

Document history and conventions

Version Date Remarks

V2.3.0 2017-Oct-18 Removed references to Prosilica GC660, GC1290, GC1380H, GC1600H, GC2450

hardware revision A models in the Appendix. The last time shipment period for these

models ended on June 30, 2017 as detailed in PCN AVTPR-112. These hardware

revision A models were replaced by hardware revision D models.

Changed Cell size terminology to Pixel size

Various other minor improvements and corrections

V2.4.0 2017-Dec-15 Updated exposure time values (GC660, GC1290, GC1380H, GC2450) and gain values

(GC1600H, GC2450) for latest firmware

Added Specifications common to all models to simplify the model specific tables

Simplified the Contact us section, please click the link to find contact information

for your region or email us at one of the provided email addresses.

Various other minor enhancements and corrections

V2.4.1 2018-Jun-19

Updated symbols used in this manual

Updated RoHS statement to include amendment 2015/863/EU

Table 1: Document history (continued)

Manual conventions

To give this manual an easily understood layout and to emphasize important

information, the following typographical styles and symbols that are used.

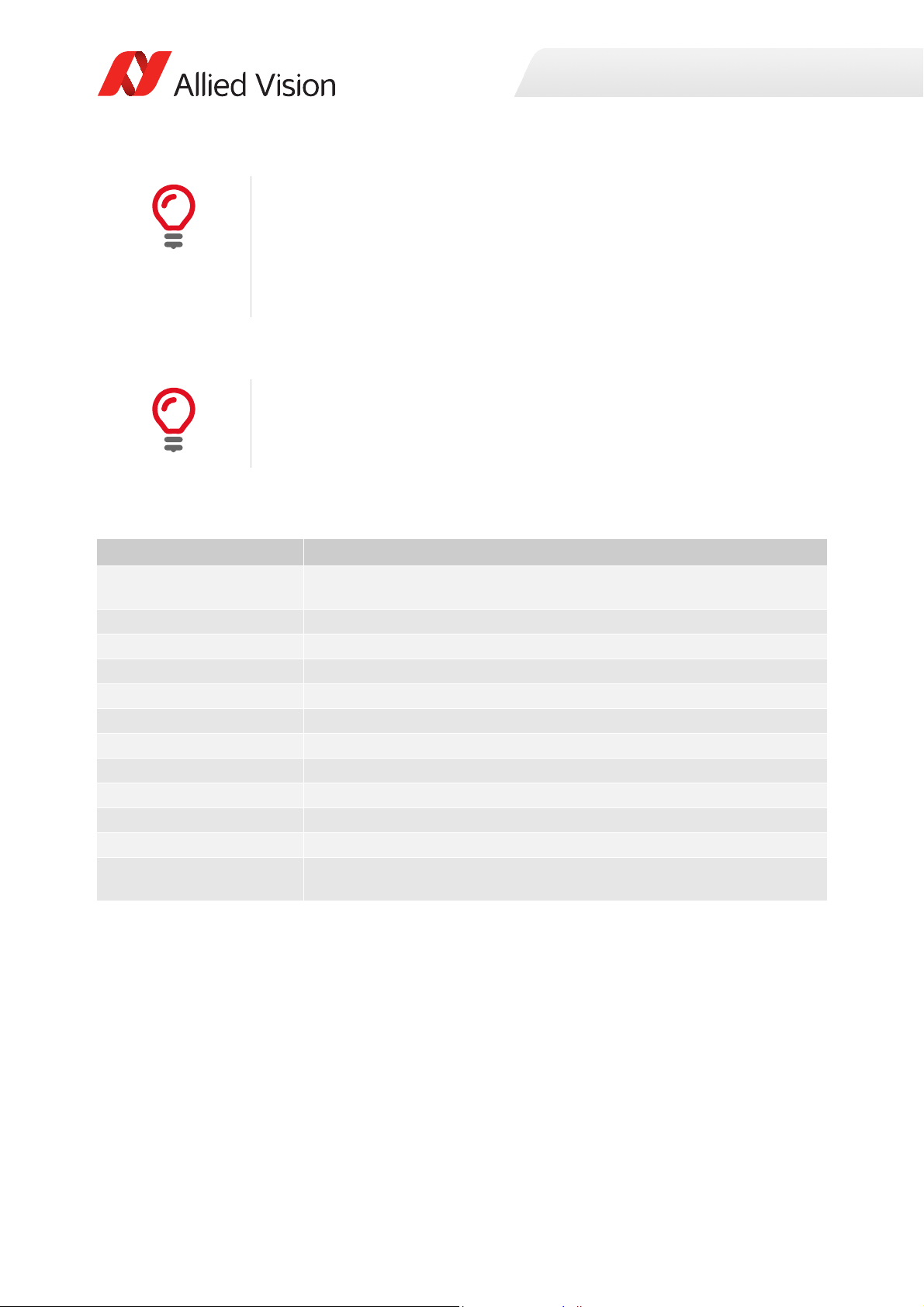

Styles

Style Function Example

Bold Program names, UI elements, highlighting

Italics Publication names, chapter titles, UI non-

Courier New Code listings, feature names Input

Courier New Italics Feature options Mode

Blue Cross references, web page links, email links Link

Table 2: Character styles used in this manual

bold

important things

Italics

interactive elements

11Prosilica GC Technical Manual V2.4.1

Document history and conventions

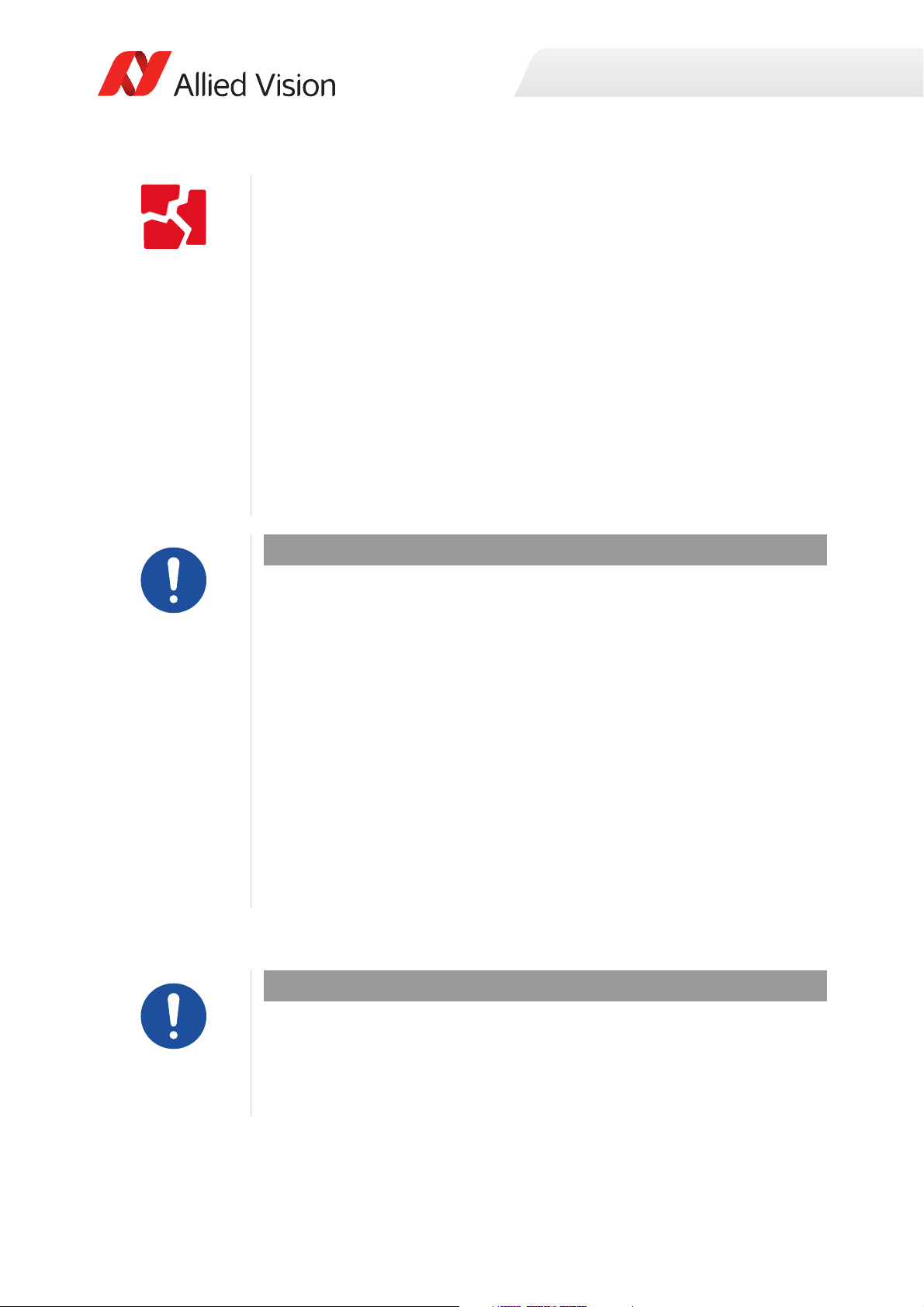

i

Symbols

NOTICE

Material damage

Precautions as described.

NOTICE

Material damage by electrostatic discharge (ESD)

Precautions as described.

CAUTION

Personal injuries

Precautions as described.

Safety-related instructions to avoid malfunctions

This symbol indicates important or specific instructions or procedures that are

related to product safety. You have to follow these instructions to avoid

malfunctions.

Practical hint

This symbol highlights a practical hint that helps to better understand the camera‘s

features and functions, and to make better use of it.

Further information available online

This symbol highlights URLs for further information. The URL itself is shown in blue.

Example:

https://www.alliedvision.com

Product naming

Names of third-party products in this document are shortened to ease reading.

Nevertheless, we respect all manufacturer rights and trademarks.

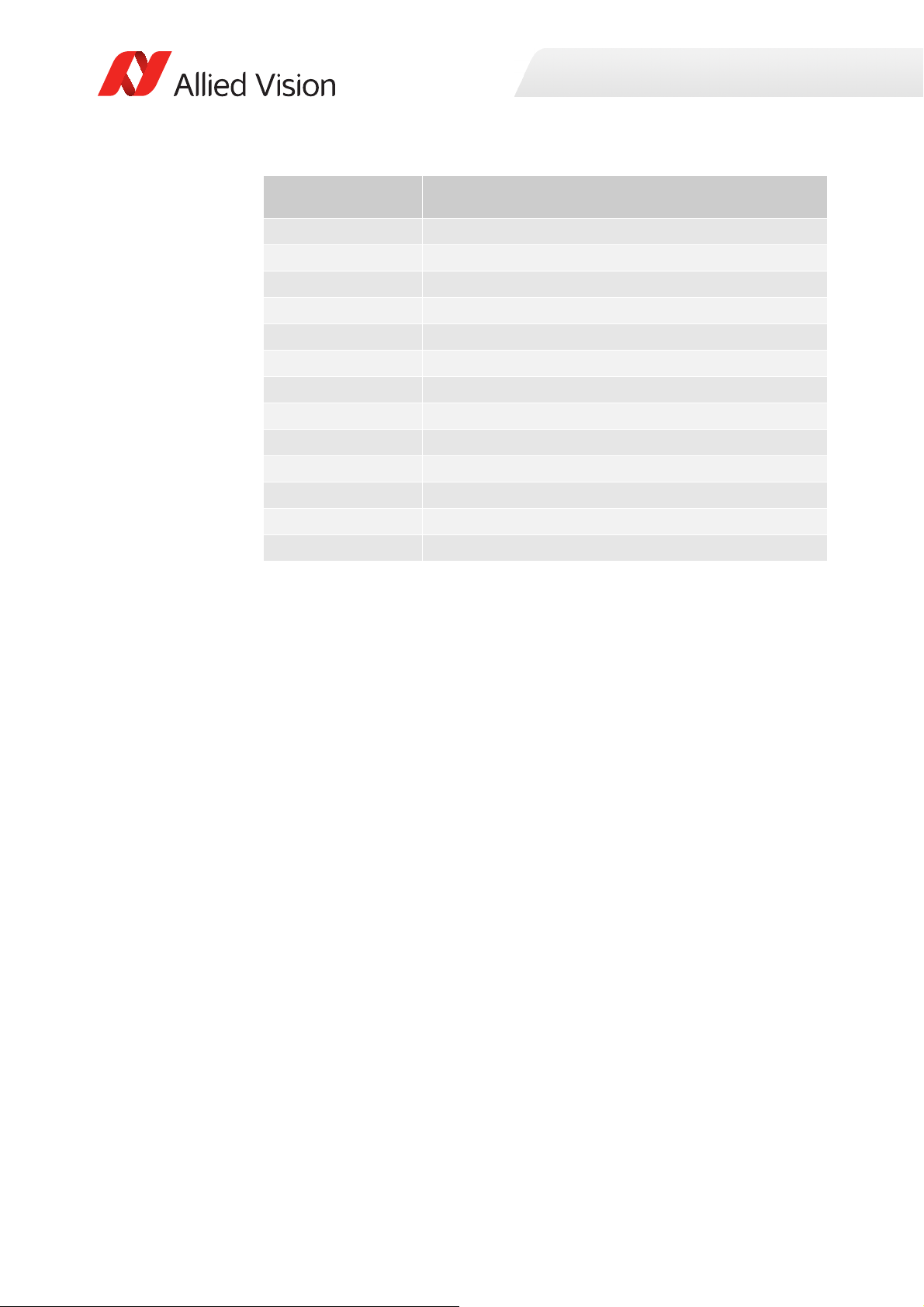

Official product name Naming in this manual Manufacturer website

Sony Semiconductor Solutions Sony http://www.sony-semicon.co.jp/

ON Semiconductor ON Semi http://www.onsemi.com/

Table 3: Third-party product naming used in this manual

12Prosilica GC Technical Manual V2.4.1

Document history and conventions

Acronyms and abbreviations

The following table provides a list of abbreviations used in this document.

Acronym or

Abbreviation

°C

AIA Automated Imaging Association

CAD Computer aided design

Cat 6 Category 6, Ethernet cable

CCD Charge-coupled device

CMOS Complementary metal-oxide semiconductor

dB

DHCP Dynamic Host Control Protocol

EMVA European Machine Vision Association

Description

Degrees Celsius

Decibel

ESD Electrostatic discharge

FIFO First-in first-out

fps Frames per second

g Grams

GigE Gigabit Ethernet

GND Ground (power)

GVSP GigE Vision Streaming Protocol

H × V Horizontal × Vertical (sensor resolution measurement)

I/O Input/Output

KΩ Kiloohm

mA Milliampere

MB Megabyte

Mbps Megabits per second

mm Millimeter

MP Megapixel

MSDS Material safety data sheet

nm Nanometer

ns Nanosecond

psi Pound per square inch (atmospheric pressure)

QE Quantum efficiency

RoHS Restriction of Hazardous Substances Directive

ROI Region of interest

Table 4: Acronyms and abbreviations used in this document

13Prosilica GC Technical Manual V2.4.1

Document history and conventions

Acronym or

Abbreviation

Description

s Second

SDK Software Development Kit

SFNC Standard Feature Naming Convention

TTL I/O Transistor-transistor logic input/output

TxD and RxD

Transmit and receive

V Volts

VDC Volts of direct current

W Watts

WEEE Waste of Electric and Electronic Equipment

XML Extensible Markup Language

µA Microampere

μm

µs

Micrometer or micron

Microsecond

Table 4: Acronyms and abbreviations used in this document (continued)

14Prosilica GC Technical Manual V2.4.1

§

Compliance and intended use

This chapter includes:

• Information about the legal requirements and

restrictions for Prosilica GC cameras based on

current and relevant regulations

• Particular emphasis has been given to Europe,

the U.S., and Canada

• Intended use statements

Prosilica GC Technical Manual V2.4.1 15

Compliance notifications

For customers in Europe

Allied Vision has demonstrated the fulfillment of the requirements relating to the

Prosilica GC camera family:

• Directive 2014/30/EU (Electromagnetic compatibility)

• Directive 2011/65/EU, including amendment 2015/863/EU (RoHS)

• Directive 2012/19/EU (WEEE)

For customers in the USA

Class A digital device

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

We caution the user that changes or modifications not expressly approved by the

party responsible for compliance could void the user's authority to operate the

equipment.

Compliance and intended use

For customers in Canada

This apparatus complies with the Class A limits for radio noise emissions set out in

the Radio Interference Regulations.

CAN ICES-003

Pour utilisateurs au Canada

Cet appareil est conforme aux normes classe A pour bruits radioélectriques,

spécifiées dans le Règlement sur le brouillage radioélectrique.

CAN ICES-003

Avoid electromagnetic interferences

For all power and interface connections, only use shielded cables or cables

recommended by Allied Vision.

16Prosilica GC Technical Manual V2.4.1

Compliance and intended use

Camera applications and intended use

General use

• The user is responsible for operating the camera within the specifications that

are defined in this document, and within appropriate environmental

conditions and technical prerequisites, to ensure trouble-free camera

operation.

• The camera is compliant with current data communication standards;

however, those standards do not allow for self-monitoring. Thus, the camera

cannot be used as a standalone device for security-related monitoring

operations.

• The camera is a hardware product. Only when used with appropriate

accompanying software, the camera will produce the desired results. The

realization of intelligent solutions requires additional software that is suitable

to run with the camera.

• The camera is a component, it is neither a complete product, nor is it a readymade technical solution.

• The camera-supporting software can be obtained and installed separately

from the camera. Usage of the software is solely the responsibility of the user.

• The camera must not be opened. For all repair tasks, contact Allied Vision or

one of Allied Vision's authorized representatives.

• Observe the intended use. The camera must only be used for purposes that

are in conformity with the stated intended use.

• Additionally, refer to the warranty information on the Allied Vision website.

Use in medical devices

The camera provides basic adequacy to be used in medical devices as well,

however, is not specially designated for operation in medical devices. When used

as part of a medical device, a review of the specific application is necessary. Users

who integrate the camera into an application must comply with the rules and

regulations concerning medical devices.

Copyright and trademarks

All text, pictures, and graphics are protected by copyright and other laws

protecting intellectual property. All content is subject to change without notice.

All trademarks, logos, and brands cited in this document are property and/or

copyright material of their respective owners. Use of these trademarks, logos, and

brands does not imply endorsement.

Copyright © 2018 Allied Vision GmbH. All rights reserved.

17Prosilica GC Technical Manual V2.4.1

Installation and hardware

This chapter describes the components required for

your vision system including configuring the host

computer, Ethernet adapter settings, and connecting

your Prosilica GC camera.

Prosilica GC Technical Manual V2.4.1 18

General cautions and warnings

Electrical connections

NOTICE

Material damage by electrostatic discharge (ESD)

The phenomenon is commonly known: when walking on a carpet, we get charged.

Touching a door handle, we get an electric shock. ESD is dangerous for electronic

devices, especially when tools or hands get in contact with connectors. We

recommend measures to avoid damage by ESD:

• Unpacking: Remove the camera from its anti-static packaging only when your

body is grounded.

• Workplace: Use a static-safe workplace with static-dissipative mat and air

ionization.

• Wrist strap: Wear a static-dissipative wrist strap to ground your body.

• Clothing: Wear ESD-protective clothing. Keep components away from your

body and clothing. Even if you are wearing a wrist strap, your body is

grounded but your clothes are not.

Installation and hardware

NOTICE

Do not operate the camera beyond the environmental specifications

See environmental specifications limits in the Specifications section of this

document. Special care must be taken to maintain a reasonable operating

temperature.

NOTICE

Verify all external connections

Verify all external connections in terms of voltage levels, power requirements,

voltage polarity, and signal integrity prior to powering the device.

19Prosilica GC Technical Manual V2.4.1

Installation and hardware

Operation outside the allowed temperature range can damage the camera. For

best performance and to protect the camera from damage, keep the housing

temperature between the specified operating temperature.

Observe the following:

• To avoid camera crashes, operate the camera with a lens or lens adapter

attached only.

• For maximum heat dissipation, affix the camera to a heat sink, using the

mounting threads.

- Use mounting base and heat sink with large surface areas.

- Use a mounting base with a high thermal conductivity.

• Reduce ambient temperature. For example, in an outdoor application with

direct sunlight, provide shading by an enclosure.

• Provide ventilation or other active cooling of camera, mounting base, and heat

sink.

NOTICE

Heat dissipation

Operation outside the allowed temperature range can damage the camera. For

best performance and to protect the camera from damage, keep the housing

temperature between the specified operating temperature.

Observe the following:

• To avoid camera crashes, operate the camera with a lens or lens adapter

attached only.

• For maximum heat dissipation, affix the camera to a heat sink, using the

mounting threads.

- Use mounting base and heat sink with large surface areas.

- Use a mounting base with a high thermal conductivity.

• Reduce ambient temperature. For example, in an outdoor application with

direct sunlight, provide shading by an enclosure.

• Provide ventilation or other active cooling of camera, mounting base, and heat

sink.

Optical components

NOTICE

Image sensor

Image sensors are sensitive to excessive radiation: focused sunlight, lasers, and

x-rays can damage the sensor. Monochrome models are not fitted with filter or

protection glass. Consider, when removing the lens or dust cap on these cameras,

the sensor is not protected against dirt or scratches.

20Prosilica GC Technical Manual V2.4.1

Installation and hardware

NOTICE

Cleaning optical components

This product can be damaged by some volatile cleaning agents. Avoid cleaning the

image sensor unless absolutely necessary. See instructions on optics cleaning in

this document.

Allied Vision can clean your camera as a service for you, if necessary. For more

information, contact Allied Vision support at https://www.alliedvision.com/en/

support/contact-support-and-repair.html.

NOTICE

Lenses

Provide the following conditions to keep dirt and droplets out of the optical system

of camera and lens:

• Dust-free environment

• Low relative humidity

•No condensation

To keep dirt out of the lens mount, hold the camera with the lens mount facing the

ground. Keep filter and camera back lens clean, because dirt becomes more visible

the closer it gets to the sensor.

21Prosilica GC Technical Manual V2.4.1

Configuring the host computer

Allied Vision GigE Vision cameras can operate on 10/100 or Gigabit speed Ethernet

adapters. In order to reach the maximum camera frame rate, a Gigabit speed

Ethernet adapter with jumbo packet support is required.

If your host computer has an available Ethernet port, this can be used with Allied

Vision GigE cameras. We recommend that your camera system uses a dedicated

Ethernet port not shared with Internet or local area networks. If more ports are

needed, or your existing Ethernet adapter is unable to operate at GigE speeds,

installing additional hardware may be required.

Usage on mixed-use networks (with printers, Internet, email) is possible but may

impact camera performance (for example, framerate). Check with your IT

administrator if required for network configuration.

Installing the Ethernet adapter driver

Installation and hardware

Install the network card driver from your network card manufacturer. If no

installation application is provided, update the driver manually.

To update the driver manually

1. Click the Start icon and select Control Panel in the menu.

2. Click View by Large Icons and select Device Manager in the list.

3. Under Network Adapters, locate the Ethernet network adapter, right-click the

entry, and select Update Driver Software in the menu.

4. Select the Search automatically for updated driver software or Browse my

computer for driver software.

5. Click Close once the driver has been installed.

Optional: Modifying Ethernet adapter IP address

After initial Ethernet adapter hardware installation, connect the Ethernet adapter

directly to the camera. The default configuration assigns an IP address

automatically using the Link-Local Address range of 169.254.xxx.xxx or an address

defined by the DHCP server, if present.

Users can fix the adapter address to minimize the time required for a camera to be

recognized by the host application. Systems that employ multiple Ethernet

adapters connected to multiple cameras will also be required to fix the address of

the Ethernet adapter.

To connect to the camera, edit the host PC’s adapter settings and configure the

following settings:

• IP Address: 169.254.100.1

• Subnet mask: 255.255.0.0

• Default gateway: blank

22Prosilica GC Technical Manual V2.4.1

Installation and hardware

i

Ethernet adapter driver settings

The Ethernet adapter should be adjusted to improve system performance when

using a GigE Vision camera. This performance is related to minimizing CPU usage

and dropped or resent packets.

Edit the Ethernet adapter driver properties according to the values in the following

table. The names and availability of the properties listed may vary depending on

adapter manufacturer and model.

Property Value

Packet size or maximum transmission unit (MTU) 8228 bytes or larger

Interrupt Moderation Enable

Interrupt Moderation Rate Extreme

Receive Buffers Maximum value configurable

Transmit Buffers 256 bytes

Default packet size

The default packet size of Allied Vision GigE cameras is 8228 bytes. The host

network adapter needs to support a packet size of equal or larger size to stream

from the camera.

Ethernet adapter

For desktop systems, use a PCI Express bus Ethernet adapter. For laptops, use an

expansion slot via an ExpressCard®.

A list of Allied Vision recommended Ethernet adapters is available on the Allied

Vision website. See the Hardware Selection for Allied Vision GigE Cameras

application note at https://www.alliedvision.com/en/support/technical-papers-

knowledge-base.html.

Ethernet adapter settings

The Ethernet adapter settings may also vary depending on your system

configuration and the network adapter manufacturer.

Enabling jumbo packets

Jumbo Frames or Jumbo Packets

The properties listed for the network adapter may include either Jumbo Packet or

Jumbo Frames depending on the manufacturer. If neither is listed under

properties, your network card may not support this feature. You must use a

network adapter that supports Jumbo Frames or Jumbo Packets.

To enable jumbo packets

1. Click the Start icon and select Control Panel in the menu.

23Prosilica GC Technical Manual V2.4.1

2. Click View by Large Icons and select Device Manager in the list.

i

i

3. Under Network Adapters, locate the Ethernet network adapter, right-click the

entry, and select Properties in the menu.

4. Select the Advanced tab.

5. Select the property Jumbo Packet and set the value to 9014 Bytes.

6. Click OK to save the setting.

Connecting your camera

Use a Cat 6 or higher rated Ethernet cable to connect the camera to the host

adapter. Crossover cabling is not required but does work. The camera has circuitry

to determine if a crossover cable is being used.

Allied Vision recommends Cat 6 or higher rated Ethernet cables for Prosilica GC

cameras. A different rating may not sustain peak interface bandwidth; leading to

lost connectivity or image data coming from the camera.

Installation and hardware

Optics

Allied Vision Prosilica GC cameras offer various mechanical interfaces for installing

a lens including C-Mount and CS-Mount. Lenses can be purchased directly from

Allied Vision or from an Allied Vision distributor. Users need to select the desired

focal length and appropriate optical format for the target camera model.

Accessories

Allied Vision offers a wide range of accessories for the use of Allied Vision GigE

cameras and the easy integration in already existing applications including:

• GigE accessories including standard GigE components.

For more information on mechanical interface options for your Prosilica GC

camera, see the Modular Concept at https://www.alliedvision.com/en/support/

technical-documentation.html.

Contact your Allied Vision Sales team or your local Allied Vision distribution

partner for information on accessories and lens recommendations:

https://www.alliedvision.com/en/about-us/where-we-are.html

24Prosilica GC Technical Manual V2.4.1

• Lenses for corresponding sensor sizes and resolutions.

i

i

i

Contact your Allied Vision Sales team or your local Allied Vision distribution

partner for information on accessories and lens recommendations:

https://www.alliedvision.com/en/about-us/where-we-are.html

Recommended accessories

A list of Allied Vision recommended accessories is available on the Allied Vision

website. See the Hardware Selection for Allied Vision GigE Cameras Application

Note at https://www.alliedvision.com/en/support/technical-papers-knowledge-

base.html.

Downloading camera drivers

Installation and hardware

Allied Vision GigE cameras work with the following software options.

Vimba Viewer or Vimba SDK:

https://www.alliedvision.com/en/products/software

Third-party software solutions:

https://www.alliedvision.com/en/products/software/third-party-libraries.html

Powering up the camera

A camera power adapter for each GigE camera is available from Allied Vision. See

Specifications on page 27 for connector definition and voltage specifications.

For Prosilica GC cameras

• Use only DC power supplies with insulated cases.

• For all power connections use only shielded cables to avoid electromagnetic

interferences.

NOTICE

Connecting to host application

Once you have installed the Vimba Viewer or third-party application to your host

computer, you can connect your Allied Vision GigE camera via an Ethernet cable.

Connect the Hirose cable to power the camera to power the camera.

25Prosilica GC Technical Manual V2.4.1

Installation and hardware

Allied Vision software

All software packages provided by Allied Vision are free of charge and contain the

following components:

•Drivers

• SDK for camera control and image acquisition

• Examples based on the provided APIs of the SDK

• Documentation and release notes

• Viewer application to operate and configure the cameras

Vimba Viewer documentation

Vimba Viewer documentation is included with the software download. Once

Vimba Viewer is installed on your host PC, documentation is located under

\Program Files\Allied Vision\Vimba.

Third-party software

In addition to the software provided by Allied Vision, there are numerous GigE

Vision standard compliant third-party software options available. In general, thirdparty software provides increased functionality such as image processing and

video recording.

Allied Vision’s Vimba SDK is based on the GenICam standard. GenICam-based

third-party software automatically connects with Vimba's transport layers.

Additionally, Vimba includes the Cognex Adapter for VisionPro.

26Prosilica GC Technical Manual V2.4.1

Specifications

This chapter provides:

• Technical specifications

• Absolute QE plots

• Spectral response plots

• ROI height vs. frame rate plots

• Camera feature comparison for hardware revision

D models (serial number 02-21XXD-XXXXX)

• Image data flow diagram

Prosilica GC Technical Manual V2.4.1 27

Notes on specifications

Dimensions and mass

Dimensions include C-Mount and connectors but not the tripod and lens.

Mass does not include the tripod and lens.

Hardware revision

This chapter includes camera specifications for all Prosilica GC models (hardware

revision D). For previous Prosilica GC models (hardware revision A) see Appendix

on page 82.

Hardware revision incompatibility

Prosilica GC hardware revision D models and firmware are not compatible with

Prosilica GC hardware revision A models.

Specifications

NOTICE

Monochrome models

As monochrome models do not have an optical filter always attach a dust cap

when a lens is not attached to minimize the possibility of contaminants falling on

the sensor surface.

Frame memory

Normally, an image is captured and transported in consecutive steps. The image is

taken, read out from the sensor, digitized and sent over the GigE network. Prosilica

GC cameras are equipped with an image buffer. The memory operates according to

the FIFO principle. Specification tables show how many frames can be stored by

each model.

Number of frames

The number of frames (

format, and GVSP packet size. The stated number of frames is typical for full

resolution, Mono8 or Bayer8, and a

packet.

StreamHoldCapacity) depends on resolution, pixel

GevSCPSPacketSize = 8192 bytes per

28Prosilica GC Technical Manual V2.4.1

Specifications

Resolution and ROI frame rate

This section charts the resulting frame rate from changing sensor height from full

image to a single line. Unless otherwise noted, sensors do not give an increase in

readout speed with a reduction in width.

Resolution and ROI measurements

• Data was generated using

bandwidth) and an 8-bit pixel format. Frame rates may be lower if using

network hardware incapable of 124 Mbps.

• ROIs are taken as center image for maximum speed advantage, where feature

OffsetY = (full sensor height – ROI height)/2.

BinningVertical is horizontal row summing on CCD before readout. The

•

frame rate for an ROI at the same effective height as binning is slower because

the CCD still needs to read out the “fast readout rows” in ROI mode.

Frame rate and readout

StreamBytesPerSecond = 124 Mbps (full

Although the sensor is capable of higher frame rates, readout is limited by GigE

bandwidth and exposure value. You can improve frame rates with a reduced ROI

and shorter exposure values.

Absolute QE plots

Important notice before reading the QE plots

All measurements were done without protection glass or IR cut filter. With

protection glass or filters, QE decreases by approximately 10%.

The uncertainty in measurement of the QE values is 10.25%. This is mainly due

to uncertainties in the measuring apparatus itself (Ulbricht sphere, optometer).

Manufacturing tolerance of the sensor increases overall uncertainty.

Absolute QE plots for Sony CCD sensors

Sony provides relative response curves in their sensor data sheets. To create the

absolute QE plots shown in this chapter, the relative response was converted to a

normalized QE response and then adjusted as per three measured QE values (at

448 nm, 529 nm, 632 nm) for color sensors and one measured QE value (at 529

nm) for monochrome sensors.

Absolute QE plots for ON Semi CCD sensors

The curves in the absolute QE plots shown in this chapter are from the sensor

manufacturer data sheet. The information was correct at the time of publishing.

Sensor specifications may change without notice.

29Prosilica GC Technical Manual V2.4.1

Specifications

Wavelength

The wavelength range in the absolute QE plots is based on the information

available in the sensor manufacturer data sheet at the time of publishing. Many

color sensors are documented by the sensor manufacturer only for wavelengths

from 400 nm to 700 nm.

For additional wavelength information, contact the sensor manufacturer.

Spectral response plots

Sony provides relative response curves in their sensor data sheets. To create the

spectral response plots shown in this chapter, the relative response was adjusted

as per three measured QE values (at 448 nm, 529 nm, 632 nm) for color sensors

and one measured QE value (at 529 nm) for monochrome sensors.

Specifications common to all models

Feature Specification

Lens mount Default: C-Mount

Optional: CS-Mount

TTL (non-isolated) I/Os 1 input, 1 output

Opto-isolated I/Os 1 input, 1 output

RS232 1

Operating temperature 0 °C to +50 °C ambient temperature (without condensation)

Storage temperature -10 °C to +70 °C ambient temperature (without condensation)

Operating humidity 20% to 80% non-condensing

Power requirements 5 to 25 VDC

Interface IIEEE 802.3 1000BASE-T (GigE)

Interface standard GigE Vision® Standard V1.2

Camera control standard GenICam SFNC V1.2.1

Temperature monitoring Available for main board only.

Resolution: 0.031; Accuracy: ± 1 °C

Table 5: Specifications common to all Prosilica GC models

30Prosilica GC Technical Manual V2.4.1

Specifications

Prosilica GC660, GC660C

Specification

Feature

Resolution 658 (H) × 494 (V)

Sensor Sony ICX618ALA with EXview HAD

CCD™ technology

Sensor type Interline CCD, Progressive Scan

Shutter type Global

Sensor format Typ e 1/4

Sensor size 4.5 mm diagonal

Pixel size 5.6 μm × 5.6 μm

Optical filter Default: No filter

Optional: See the Modular Concept

Maximum frame rate at full

resolution

Bit depth 8-bit, 12-bit

A/D 12-bit

Image buffer 64 MB

StreamHoldCapacity Up to 194 frames at full resolution

Monochrome pixel formats Mono8, Mono12, Mono12Packed Mono8

YUV color pixels formats YUV411Packed, YUV422Packed,

RGB color pixel formats RGB8Packed, BGR8Packed

RAW pixel formats BayerRG8, BayerRG12,

Exposure time control 10 µs to 72.9 s; 1 µs increments

Gain control 0 to 34 dB; 1 dB increments

Binning (Sum) Horizontal: 1 to 8 columns

Power consumption 3.0 W at 12 VDC

Trigger latency 0.9 µs for non-isolated I/O; 0.9 µs for isolated I/O

Trigger j i t ter ±50 ns for non-isolated I/O; ±50 ns for isolated I/O

Propagation delay (tpd) 10 ns for non-isolated I/O; 1.3 µs for isolated I/O

Body dimensions (L × W × H) 58.7 × 45.7 × 33 mm 59 × 45.7 × 33 mm

Mass (typical) 105 g

Prosilica GC660 Prosilica GC660C

0.3 MP

Sony ICX618AQ with EXview HAD

CCD™ technology

Default: IRC30 IR cut filter

Optional: See the Modular Concept

121 fps

YUV444Packed

BayerRG12Packed

Vertical: 1 to 14 rows

Table 6: Prosilica GC660, GC660C model specifications

31Prosilica GC Technical Manual V2.4.1

Absolute QE

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

400 450 500 550 600 650 700 750 800 850 900 950 1000

QuantumEfficiency[%]

Wavelength[nm]

SonyICX618absoluteQE

AllmeasurementsweredonewithoutprotectionglassorIRcutfilter.

Withprotectionglassorfilters,quantumefficiency(QE)decreasesbyapproximately10%.

TheuncertaintyinmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

RedQE GreenQE BlueQE MonochromeQE

0.0000

0.1000

0.2000

0.3000

0.4000

400 450 500 550 600 650 700 750 800 850 900 950 1000

SpectralResponse[A/W]

Wavelength[nm]

SonyICX618spectralresponse

RedResponse GreenResponse BlueResponse MonochromeQE

Specifications

Figure 1: Prosilica GC660, GC660C (Sony ICX618) absolute QE

Spectral response

Figure 2: Prosilica GC660, GC660C (Sony ICX618) spectral response

32Prosilica GC Technical Manual V2.4.1

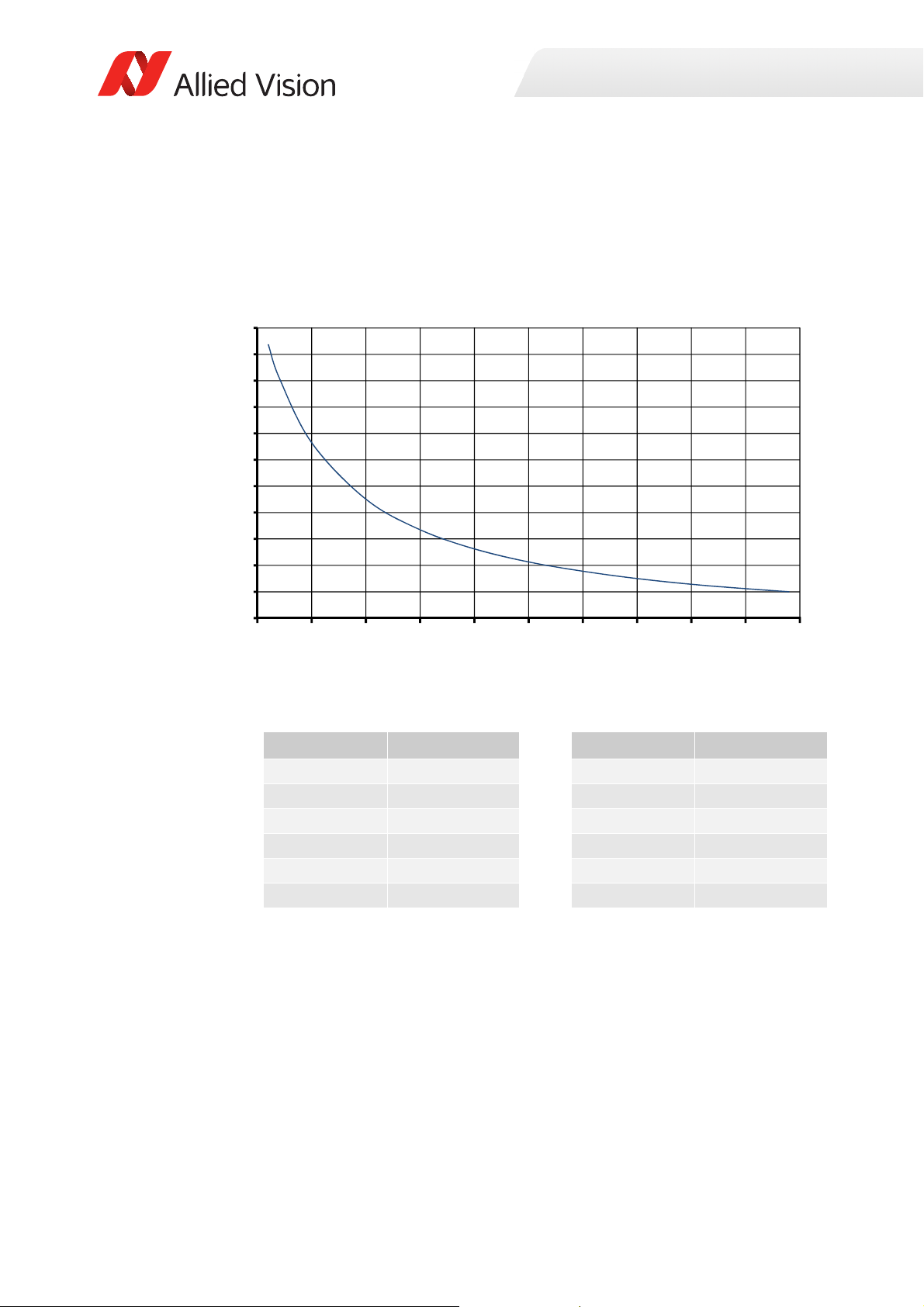

ROI frame rate

100

160

220

280

340

400

460

520

10 60 110 160 210 260 310 360 410 460 510

Framerate[fps]

ROIheight[pixels]

Specifications

Figure 3: Frame rate as a function of ROI height

Height (pixels) Frame rate (fps) Height (pixels) Frame rate (fps)

494 121.18 200 226.23

450 130.23 150 265.35

400 142.31 100 320.82

350 156.86 50 405.61

300 174.32 20 482.06

250 197.16 10 514.37

Width=658 pixels

Table 7: Frame rate as a function of ROI height

33Prosilica GC Technical Manual V2.4.1

Specifications

Prosilica GC1290, GC1290C

Specification

Feature

Resolution 1280 (H) × 960 (V)

Sensor Sony ICX445ALA with EXview HAD

CCD™ technology

Sensor type Interline CCD, Progressive Scan

Shutter type Global

Sensor format Typ e 1/3

Sensor size 6.0 mm diagonal

Pixel size 3.75 μm × 3.75 μm

Optical filter Default: No filter

Optional: See the Modular Concept

Maximum frame rate at full

resolution

Bit depth 8-bit, 12-bit

A/D 12-bit

Image buffer 64 MB

StreamHoldCapacity Up to 52 frames at full resolution

Monochrome pixel formats Mono8, Mono12, Mono12Packed Mono8

YUV color pixels formats YUV411Packed, YUV422Packed,

RGB color pixel formats RGB8Packed, BGR8Packed

RAW pixel formats BayerRG8, BayerRG12,

Exposure time control 12 µs to 72.4 s; 1 µs increments

Gain control 0 to 24 dB; 1 dB increments

Binning (Sum) Horizontal: 1 to 8 columns

Power consumption 3 W at 12 VDC

Trigger latency 1.7 µs for non-isolated I/O; 1.7 µs for isolated I/O

Trigger j i t ter ±50 ns for non-isolated I/O; ±50 ns for isolated I/O

Propagation delay (tpd) 10 ns for non-isolated I/O; 1.3 μs for isolated I/O

Body dimensions (L × W × H) 58.7 × 45.7 × 33 mm 59 × 45.7 × 33 mm

Mass (typical) 106 g

Prosilica GC1290 Prosilica GC1290C

1.2 MP

Sony ICX445AQA with EXview HAD

CCD™ technology

Default: IRC30 IR cut filter

Optional: See the Modular Concept

33 fps

YUV444Packed

BayerRG12Packed

Vertical: 1 to 14 rows

Table 8: Prosilica GC1290, GC1290C model specifications

34Prosilica GC Technical Manual V2.4.1

Absolute QE

0%

10%

20%

30%

40%

50%

60%

400 450 500 550 600 650 700 750 800 850 900 950 1000

QuantumEfficiency[%]

Wavelength[nm]

SonyICX445absoluteQE

AllmeasurementsweredonewithoutprotectionglassorIRcutfilter.

Withprotectionglassorfilters,quantumefficiency(QE)decreasesbyapproximately10%.

TheuncertaintyinmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

RedQE GreenQE BlueQE MonochromeQE

0.0000

0.1000

0.2000

0.3000

400 450 500 550 600 650 700 750 800 850 900 950 1000

SpectralResponse[A/W]

Wavelength[nm]

SonyICX445spectralresponse

RedResponse GreenResponse BlueResponse MonochromeResponse

Specifications

Figure 4: Prosilica GC1290, GC1290C (Sony ICX445) absolute QE

Spectral response

Figure 5: Prosilica GC1290, GC1290C (Sony ICX445) spectral response

35Prosilica GC Technical Manual V2.4.1

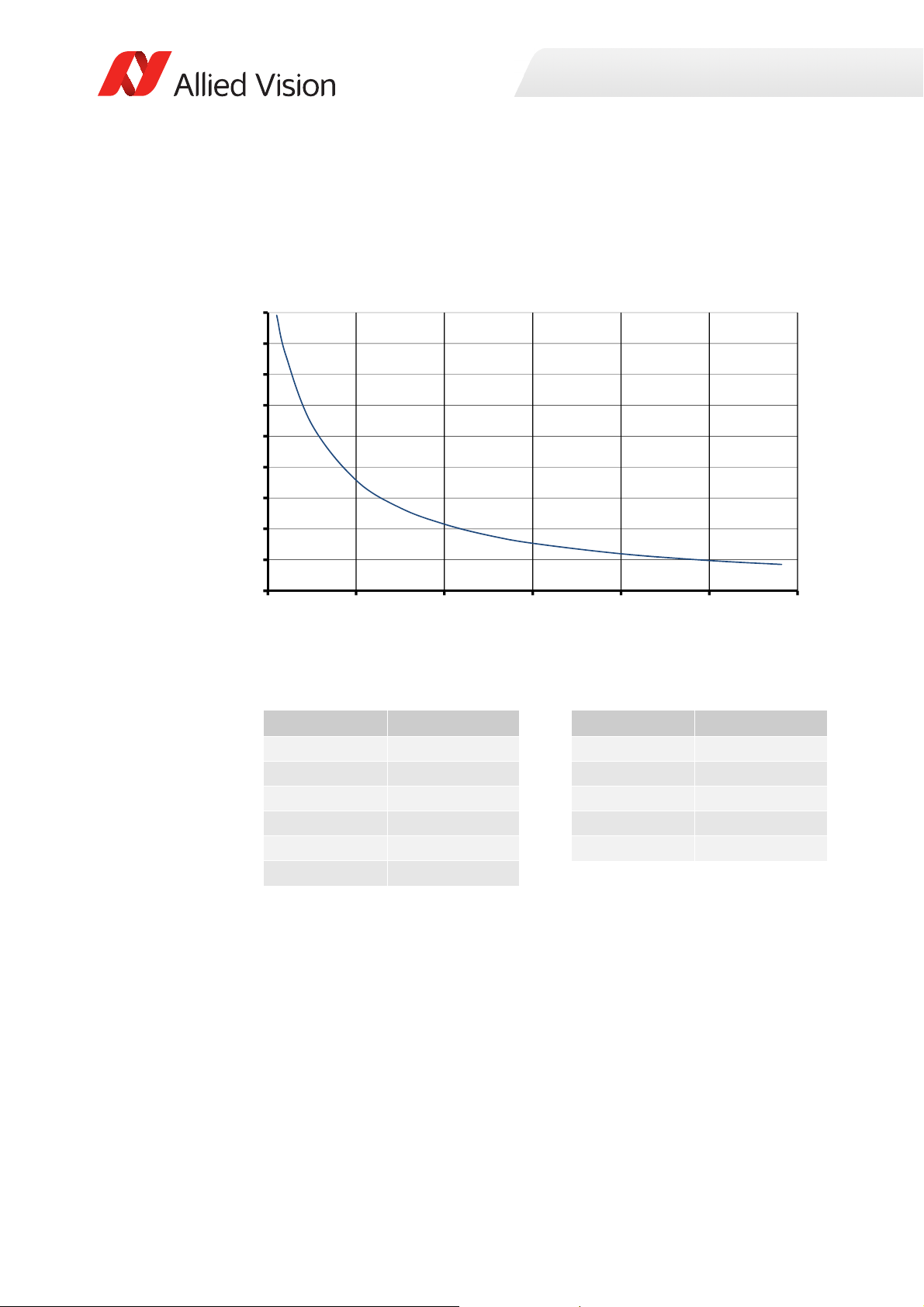

ROI frame rate

0

50

100

150

200

250

300

350

0 100 200 300 400 500 600 700 800 900 1000

Framerate[fps]

ROIheight[pixels]

Specifications

Figure 6: Frame rate as a function of ROI height

Height (pixels) Frame rate (fps) Height (pixels) Frame rate (fps)

960 33.31 300 87.96

900 35.30 200 117.07

800 39.21 100 174.96

700 44.10 50 232.41

600 50.38 20 289.45

500 58.75 10 315.23

400 70.45 2 339.43

Width=1280 pixels

Table 9: Frame rate as a function of ROI height

36Prosilica GC Technical Manual V2.4.1

Specifications

Prosilica GC1380H, GC1380CH

Specification

Feature

Resolution 1360 (H) × 1024 (V)

Sensor Sony ICX285AL with EXview HAD

CCD™ technology

Sensor type Interline CCD, Progressive Scan

Shutter type Global

Sensor format Typ e 2/3

Sensor size 11.0 mm diagonal

Pixel size 6.45 μm × 6.45 μm

Optical filter Default: No filter

Optional: See the Modular Concept

Maximum frame rate at full

resolution

A/D 12-bit

Image buffer 64 MB

StreamHoldCapacity Up to 46 frames at full resolution

Bit depth 8-bit, 12-bit

Monochrome pixel formats Mono8, Mono12, Mono12Packed Mono8

YUV color pixels formats YUV411Packed, YUV422Packed,

RGB color pixel formats RGB8Packed, BGR8Packed

RAW pixel formats BayerRG8, BayerRG12,

Exposure time control 10 µs to 72.9 s; 1 µs increments

Gain control 0 to 33 dB; 1 dB increments

Binning (Sum) Horizontal: 1 to 8 columns

Power consumption 3.3 W at 12 VDC

Trigger latency 1.9 µs for non-isolated I/O; 1.9 µs for isolated I/O

Trigger j i t ter ±50 ns for non-isolated I/O; ±50 ns for isolated I/O

Propagation delay (tpd) 10 ns for non-isolated I/O; 1.3 μs for isolated I/O

Body dimensions (L × W × H) 58.7 × 45.7 × 33 mm 59 × 45.7 × 33 mm

Mass (typical) 111 g

Prosilica GC1380H Prosilica GC1380CH

1.4 MP

Sony ICX285AQ with EXview HAD

CCD™ technology

Default: IRC30 IR cut filter

Optional: See the Modular Concept

30 fps

YUV444Packed

BayerRG12Packed

Vertical: 1 to 14 rows

Table 10: Prosilica GC1380H, GC1380CH model specifications

37Prosilica GC Technical Manual V2.4.1

Absolute QE

0%

10%

20%

30%

40%

50%

60%

400 450 500 550 600 650 700 750 800 850 900 950 1000

QuantumEfficiency[%]

Wavelength[nm]

SonyICX285absoluteQE

AllmeasurementsweredonewithoutprotectionglassorIRcutfilter.

Withprotectionglassorfilters,quantumefficiency(QE)decreasesbyapproximately10%.

TheuncertaintyinmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

RedQE GreenQE BlueQE MonochromeQE

0.0000

0.1000

0.2000

0.3000

400 450 500 550 600 650 700 750 800 850 900 950 1000

SpectralResponse[A/W]

Wavelength[nm]

SonyICX285spectralresponse

RedResponse GreenResponse BlueResponse MonochromeResponse

Specifications

Figure 7: Prosilica GC1380H, GC1380CH (Sony ICX285) absolute QE

Spectral response

Figure 8: Prosilica GC1380H, GC1380CH (Sony ICX285) spectral response

38Prosilica GC Technical Manual V2.4.1

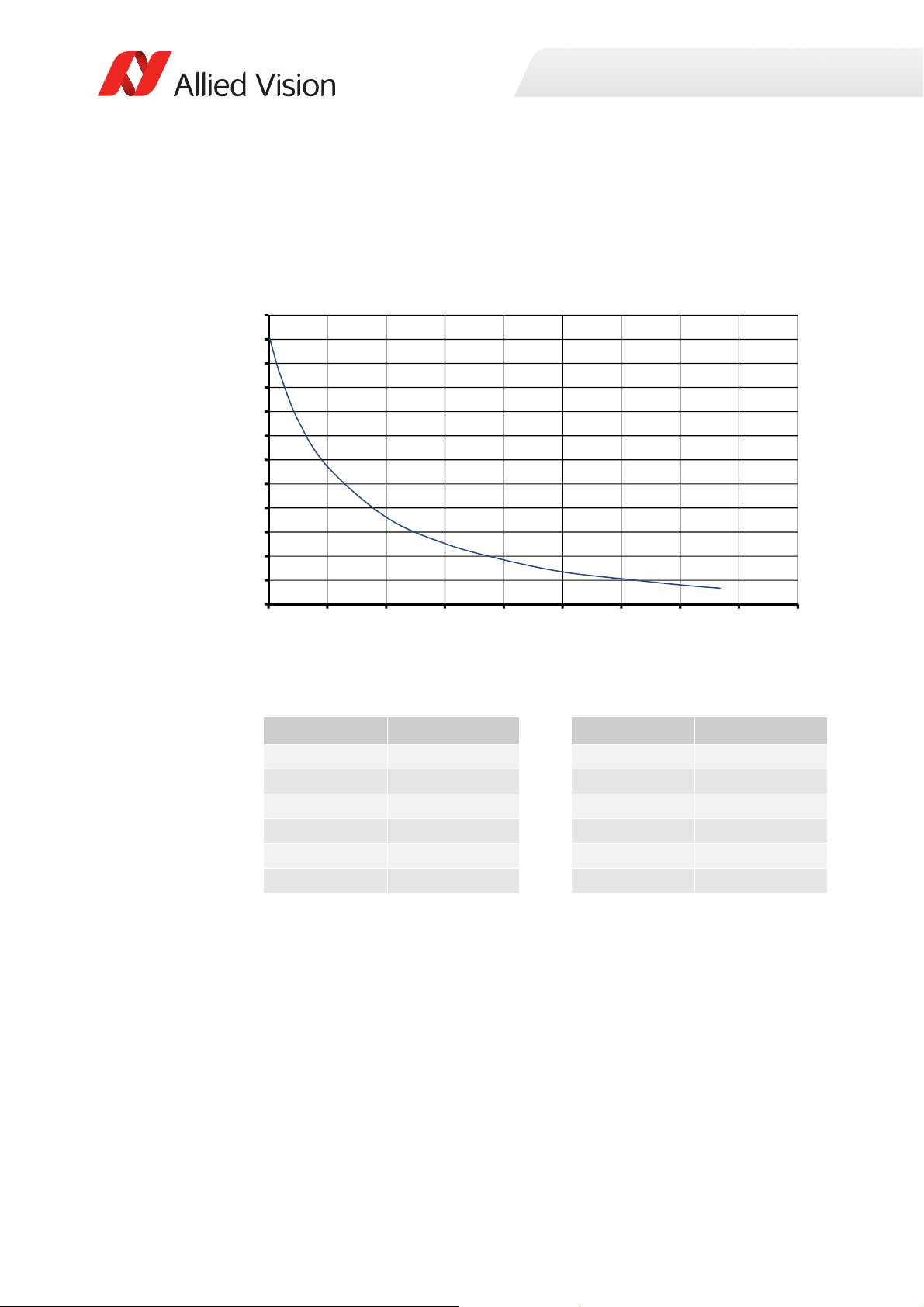

ROI frame rate

20

40

60

80

100

120

140

160

180

200

220

0 150 300 450 600 750 900 1050

Framerate[fps]

ROIheight[pixels]

Specifications

Figure 9: Frame rate as a function of ROI height

Height (pixels) Frame rate (fps) Height (pixels) Frame rate (fps)

1024 30.48 300 76.89

1000 31.1 200 97.36

900 34 100 132.68

800 37.48 50 162.08

700 41.76 20 186.93

600 47.15 10 197.01

500 54.13 2 205.88

400 63.53

Width=1360 pixels

Table 11: Frame rate as a function of ROI height

39Prosilica GC Technical Manual V2.4.1

Specifications

Prosilica GC1600H, GC1600CH

Specification

Feature

Resolution 1620 (H) × 1220 (V)

Sensor Sony ICX274AL with Super HAD

CCD™ technology

Sensor type Interline CCD, Progressive Scan

Shutter type Global

Sensor format Type 1/1. 8

Sensor size 8.923 mm diagonal

Pixel size 4.4 μm × 4.4 μm

Optical filter Default: No filter

Optional: See the Modular Concept

Maximum frame rate at full

resolution

A/D 12-bit

Image buffer 64 MB

StreamHoldCapacity Up to 33 frames at full resolution

Bit depth 8-bit, 12-bit

Monochrome pixel formats Mono8, Mono12, Mono12Packed Mono8

YUV color pixels formats YUV411Packed, YUV422Packed,

RGB color pixel formats RGB8Packed, BGR8Packed

RAW pixel formats BayerRG8, BayerRG12,

Exposure time control 10 µs to 68.7 s; 1 µs increments

Gain control 0 to 30 dB; 1 dB increments

Binning (Sum) Horizontal: 1 to 8 columns

Power consumption 3.3 W at 12 VDC

Trigger latency 1.2 µs for non-isolated I/O; 1.2 µs for isolated I/O

Trigger j i t ter ±50 ns for non-isolated I/O; ±50 ns for isolated I/O

Propagation delay (tpd) 20 ns for non-isolated I/O; 0.5 μs for isolated I/O

Body dimensions (L × W × H) 58.7 × 45.7 × 33 mm 59 × 45.7 × 33 mm

Mass (typical) 105 g

Prosilica GC1600H Prosilica GC1600CH

2 MP

Sony ICX274AQ with Wfine Super HAD

CCD™ technology

Default: IRC30 IR cut filter

Optional: See the Modular Concept

25 fps

YUV444Packed

BayerRG12Packed

Vertical: 1 to 14 rows

Table 12: Prosilica GC1600H, GC1600CH model specifications

40Prosilica GC Technical Manual V2.4.1

Absolute QE

0%

10%

20%

30%

40%

50%

60%

70%

80%

400 450 500 550 600 650 700 750 800 850 900 950 1000

QuantumEfficiency[%]

Wavelength[nm]

SonyICX274absoluteQE

AllmeasurementsweredonewithoutprotectionglassorIRcutfilter.

Withprotectionglassorfilters,quantumefficiency(QE)decreasesbyapproximately10%.

TheuncertaintyinmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

RedQE GreenQE BlueQE MonochromeQE

0.0000

0.1000

0.2000

0.3000

400 450 500 550 600 650 700 750 800 850 900 950 1000

SpectralResponse[A/W]

Wavelength[nm]

SonyICX274spectralresponse

RedResponse GreenResponse BlueResponse MonochromeResponse

Specifications

Figure 10: Prosilica GC1600H, GC1600CH (Sony ICX274) absolute QE

Spectral response

Figure 11: Prosilica GC1600H, GC1600CH (Sony ICX274) spectral response

41Prosilica GC Technical Manual V2.4.1

ROI frame rate

0

50

100

150

200

250

300

350

0 150 300 450 600 750 900 1050 1200 1350

Framerate[fps]

ROIheight[pixels]

Specifications

Figure 12: Frame rate as a function of ROI height

Height (pixels) Frame rate (fps) Height (pixels) Frame rate (fps)

1220 25.82 400 67.72

1100 28.39 300 84.42

1000 30.96 200 112.06

900 34.04 100 166.62

800 37.8 50 220.22

700 42.49 20 272.89

600 48.52 10 296.53

500 56.53 2 318.62

Width=1620 pixels

Table 13: Frame rate as a function of ROI height

42Prosilica GC Technical Manual V2.4.1

Specifications

Prosilica GC2450, GC2450C

Specification

Feature

Resolution; 2448 (H) × 2050 (V)

Sensor Sony ICX625ALA with Super HAD

CCD™ technology

Sensor type Interline CCD, Progressive Scan

Shutter type Global

Sensor format Typ e 2/3

Sensor size 11.016 mm diagonal

Pixel size 3.45 μm × 3.45 μm

Optical filter Default: No filter

Optional: See the Modular Concept

Maximum frame rate at full

resolution

A/D 12-bit

Image buffer 64 MB

StreamHoldCapacity Up to 12 frames at full resolution

Bit depth 8-bit, 12-bit

Monochrome pixel formats Mono8, Mono12, Mono12Packed Mono8

YUV color pixels formats YUV411Packed, YUV422Packed,

RGB color pixel formats RGB8Packed, BGR8Packed

RAW pixel formats BayerRG8, BayerRG12,

Exposure time control 10 µs to 48.0 s; 1 µs increments

Gain control 0 to 24 dB; 1 dB increments

Binning (Sum) Horizontal: 1 to 8 columns

Power consumption 3.8 W at 12 VDC

Trigger latency 0.8 µs for non-isolated I/O; 0.8 µs for isolated I/O

Trigger j i t ter ±50 ns for non-isolated I/O; ±50 ns for isolated I/O

Propagation delay (tpd) 20 ns for non-isolated I/O; 1.3 μs for isolated I/O

Body dimensions (L × W × H) 58.7 × 45.7 × 33 mm 59 × 45.7 × 33 mm

Mass (typical) 106 g

Prosilica GC2450 Prosilica GC2450C

5 MP

Sony ICX625AQA with Super HAD

CCD™ technology

Default: IRC30 IR cut filter

Optional: See the Modular Concept

15 fps

YUV444Packed

BayerRG12Packed

Vertical: 1 to 14 rows

Table 14: Prosilica GC2450, GC2450C model specifications

43Prosilica GC Technical Manual V2.4.1

Absolute QE

0%

10%

20%

30%

40%

50%

60%

400 450 500 550 600 650 700 750 800 850 900 950 1000

QuantumEfficiency[%]

Wavelength[nm]

SonyICX625absoluteQE

AllmeasurementsweredonewithoutprotectionglassorIRcutfilter.

Withprotectionglassorfilters,quantumefficiency(QE)decreasesbyapproximately10%.

TheuncertaintyinmeasurementoftheQEis+/Ͳ 10.25%.

Thevaluesaretypicalandaresubjecttominorvariations.

RedQE GreenQE BlueQE MonochromeQE

0.0000

0.1000

0.2000

0.3000

400 450 500 550 600 650 700 750 800 850 900 950 1000

SpectralResponse[A/W]

Wavelength[nm]

SonyICX625spectralresponse

RedResponse GreenResponse BlueResponse MonochromeResponse

Specifications

Figure 13: Prosilica GC2450, GC2450C (Sony ICX625) absolute QE

Spectral response

Figure 14: Prosilica GC2450, GC2450C (Sony ICX625) absolute QE

44Prosilica GC Technical Manual V2.4.1

ROI frame rate

10

20

30

40

50

60

70

80

90

0 300 600 900 1200 1500 1800 2100

Framerate[fps]

ROIheight[pixels]

Specifications

Figure 15: Frame rate as a function of ROI height

Height (pixels) Frame rate (fps) Height (pixels) Frame rate (fps)

2050 15.11 600 35.84

2000 15.42 400 44.21

1800 16.79 200 57.66

1600 18.42 100 68

1400 20.4 50 74.7

1200 22.87 20 79.4

1000 26.01 10 81.1

800 30.14 2 82.51

Width=2448 pixels

Table 15: Frame rate as a function of ROI height

45Prosilica GC Technical Manual V2.4.1

Specifications

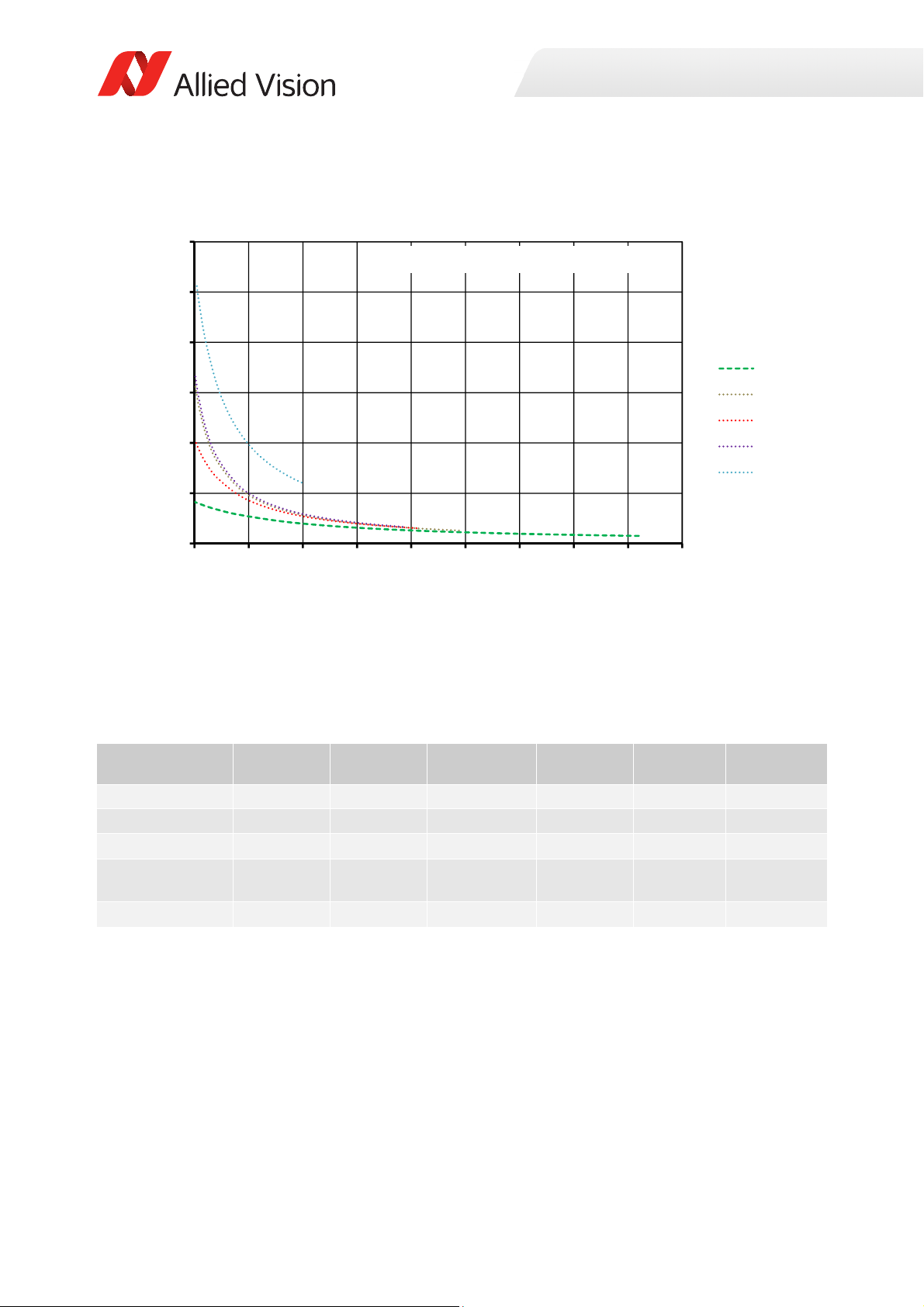

0

100

200

300

400

500

600

0 250 500 750 1000 1250 1500 1750 2000 2250

Framerate[fps]

Height[pixels]

ProsilicaGCmodelcomparison

GC2450

GC1660

GC1380

GC1290

GC660

Prosilica GC model frame rate comparison

Figure 16: Maximum frame rate comparison for select models

Prosilica GC model comparison

Model Sensor Sensor type Sensor format Resolution Frame rate

GC660, GC660C Sony ICX618 CCD Typ e 1/4 658 × 494 121 fps 194 frames

GC1290, GC1290C Sony ICX445 CCD Type 1/ 3 1280 × 960 33 fps 52 frames

GC1380, GC1380C Sony ICX285 CCD Type 2/ 3 1360 × 1024 30 fps 46 frames

GC1600H,

GC1600CH

GC2450, GC2450C Sony ICX625 CCD Type 2/ 3 2448 × 2050 15 fps 12 frames

Sony ICX274 CCD Type 1/1.8 1620 × 1220 25 fps 33 frames