Page 1

x900 Series Switch and SwitchBlade® x908

Installation and Safety Guide

AT-8948

x900-48FE

x900-48FE-N

x900-48FS

AT-9924T

AT-9924SP

AT-9924Ts

x900-12XT/S

x900-24XT

x900-24XT-N

x900-24XS

SwitchBlade® x908

Page 2

x900 Series Switch and SwitchBlade® x908

Installation and Safety Guide

AT-8948 AT-9924Ts

x900-48FE x900-12XT/S

x900-48FE-N x900-24XT

x900-48FS x900-24XT-N

AT-9924T x900-24XS

®

AT-9924SP SwitchBlade

Download the complete document set from

www.alliedtelesis.com/support/software

x908

Page 3

x900 Series Switch and SwitchBlade® x908

x900 Series Switch and SwitchBlade® x908 Installation and Safety Guide

Document Number C613-04052-00 REV P

© 2011 Allied Telesis, Inc. All rights reserved. No part of this publication may be

reproduced without prior written permission from Allied Telesis, Inc.

Allied Telesis, Inc. reserves the right to change specifications and other

information in this document without prior written notice. The information

provided herein is subject to change without notice. In no event shall Allied

Telesis, Inc. be liable for any incidental, special, indirect, or consequential

damages whatsoever, including but not limited to lost profits, arising out of or

related to this manual or the information contained herein, even if Allied Telesis,

Inc. has been advised of, known, or should have known, the possibility of such

damages.

Allied Telesis, AlliedWare, AlliedWare Plus, and SwitchBlade are trademarks or

registered trademarks in the United States and elsewhere of Allied Telesis, Inc.

Adobe, Acrobat, and Reader are either registered trademarks or trademarks of

Adobe Systems Incorporated in the United States and/or other countries.

Microsoft and Visio are either registered trademarks or trademarks of Microsoft

Corporation in the United States and/or other countries. Additional brands,

names and products mentioned herein may be trademarks of their respective

companies.

2

Page 4

Installation and Safety Guide

Contents

About this Guide .............................................................................................................. 4

Package Contents ............................................................................................................. 4

Selecting a Site ................................................................................................................... 6

Installing the Switch ......................................................................................................... 7

Applying Power to the Switch ..................................................................................... 11

Connecting to the Switch ............................................................................................. 17

Checking LEDs ................................................................................................................ 25

Obtaining Documentation and Resources ............................................................... 30

Standards .......................................................................................................................... 32

Safety ................................................................................................................................. 33

Sicherheit .......................................................................................................................... 35

Sikkerhed .......................................................................................................................... 37

Veiligheid ........................................................................................................................... 39

Sécurité ............................................................................................................................. 41

Turvallisuus ....................................................................................................................... 43

Norme di Sicurezza ........................................................................................................ 45

Sikkerhet ........................................................................................................................... 47

Segurança .......................................................................................................................... 49

Seguridad .......................................................................................................................... 51

Säkerhet ............................................................................................................................ 53

3

Page 5

x900 Series Switch and SwitchBlade® x908

About this Guide

This Installation and Safety Guide describes how to install and log in to the

following switches:

■ AT-8948 ■ x900-12XT/S

■ x900-48FE ■ AT-9924Ts

■ x900-48FE-N ■ x900-24XT

■ x900-48FS ■ x900-24XT-N

■ AT-9924T ■ x900-24XS

■ AT-9924SP ■ SwitchBlade

You can download the complete document set for x900 Series switches and

SwitchBlade

x908 from www.alliedtelesis.com/support/software. For more

information about the document set and other resources, see “Obtaining

Documentation and Resources” on page 30.

Package Contents

Depending on the model, the switch is factory-fitted with the following power

supply and fan options:

■ AT-8948, AT-9924Ts, x900-24XT, x900-24XT-N, and x900-24XS switches

have a PSU and a FOM installed.

■ AT-9924T, AT-9924SP, x900-48FE, x900-48FE-N, and x900-48FS switches

have a PSU and a blanking plate installed.

■ x900-12XT/S has a fixed PSU installed.

■ SwitchBlade x908 has dual chassis fan modules and blanking plates installed,

but no PSUs. Power supplies must be ordered separately.

®

x908

Power supply units (PSU) can be:

■ AT-PWR01, either AC or DC power supply unit

■ AT-PWR02, AC only power supply unit

■ AT-PWR05, either AC or DC power supply unit

How to install a PSU or fan in the switch is described in the Removable Power

Supply and Fan Installation Guide.

4

Page 6

Installation and Safety Guide

The following items are shipped with each switch. Contact your authorised

distributor or reseller if any are damaged or missing.

All models ship with:

■ one cable for connecting the switch to a terminal or PC

■ two rack-mount brackets

■ depending on the switch, an appropriate number of M4 screws for

rack-mount brackets

■ this Installation and Safety Guide

■ one warranty card

All models except the SwitchBlade x908 also ship with:

■ AC power cord(s) (AC models only)

■ one power cord retaining kit (AC models only)

• 1 retaining clip

• 2 retaining plates

•2 screws

■ depending on the switch, four or five rubber feet with screws for mounting

the switch on a level surface

Some products also ship with a Documentation and Tools CD-ROM containing

documentation and utilities. For more information, see “Obtaining

Documentation and Resources” on page 30.

5

Page 7

x900 Series Switch and SwitchBlade® x908

Selecting a Site

Before you install the switch, review the following considerations about its

location.

■ AT-8948, x900-48FE, x900-48FS, and AT-9900 switches require an ambient

temperature from 0º

■ AT-9924Ts, x900-12XT/S, x900-24XT, x900-24XT-N, x900-24XS, and

SwitchBlade

x908 switches require an ambient temperature from 0º C to

40º C (32º F to 104º F).

■ There should be adequate airflow around the switch and its vents.

■ The site should be dust-free and without moisture.

■ Humidity can be from 5% to 80% non-condensing.

■ You need a reliable and earthed (grounded) power supply source, preferably

dedicated and filtered.

■ Cabling must not be exposed to sources of electrical noise, such as radio

transmitters, broadband amplifiers, power lines, electric motors, and

fluorescent fixtures.

■ Switch ports are suitable for intra-building connections, or where

non-exposed cabling is required.

■ Related network devices can be connected to the switch but cannot exceed

maximum cable lengths specified in the Hardware Reference.

■ You may need to remove cabinet doors from the equipment rack to

accommodate cords and cables.

■ Ensure easy access to the switch’s power and cable connections.

■ The SwitchBlade x908 should only be installed in locations where access to

the system is controlled. The SwitchBlade

use. If installed in a school, it should only be installed in a location restricted

to service personnel.

C to 50ºC (32º F to 122º F).

x908 is not intended for home

6

Page 8

Installation and Safety Guide

Installing the Switch

Ports on the switch are suitable only for connections within buildings (intrabuilding) and with cables unexposed to the outside.

You can install the switch on a level surface, such as a desktop or bench, or in a

standard 19-inch rack. Some switches are heavier at the rear than at the front.

Use the brackets supplied with the switch when rack-mounting because they are

designed to fully support the weight.

Before you begin

■ Read the safety information.

For your well-being and that of the equipment, read the safety information in

this document. You can also download this document from

www.alliedtelesis.com/support/software.

■ Verify the package contents if you have not already done so.

See “Package Contents” on page 4. If any items are damaged or missing,

contact your authorised distributor or reseller.

■ Gather necessary tools and equipment:

• Phillips # 2 screwdriver to loosen the blanking plate, if any.

• Rack-mount screws and nuts, and a suitable screwdriver. The

SwitchBlade x908 requires eight sets of screws and nuts. All other

switches required four sets.

• For DC installations, you need an appropriate DC power source, DC

supply cable, ring connectors, and a crimp tool for screw terminal style

connectors or appropriate connectors for the PSU model.

■ Prepare the cabinet in a suitable location

Follow guidelines described in “Selecting a Site” on page 6 to choose an

appropriate location and modify the rack as necessary.

■ Because the switch is deep, we recommend two people mount the switch in

the rack and tighten the screws.

Preparation for NEBS

For Network Equipment Building System (NEBS) installations of the x900-24XT-N,

do the following to ensure rack-mounted installations are earthed:

■ Remove non-conductive coatings, such as lacquer and enamel, from the rack

rail where hardware will contact it. Remove coatings from unplated

connectors, braided strap, and bus bars, and bring them to a bright finish.

Coat them with an antioxidant before connecting them. During installation,

thread-forming screws with star washers may be used for this purpose.

7

Page 9

x900 Series Switch and SwitchBlade® x908

Front of Switch

Underside

Rear of Switch

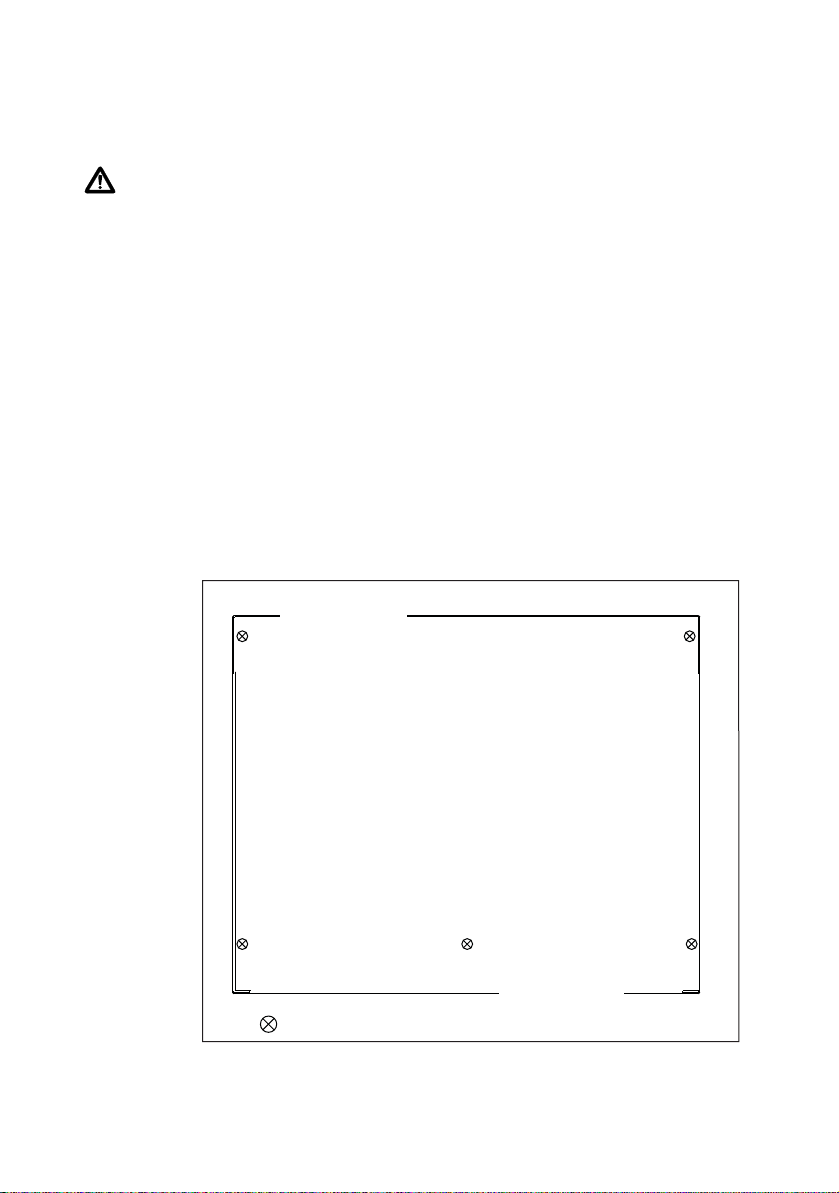

Screw holes for rubber feet

12

345

■ All bare conductors must be coated with an appropriate antioxidant

compound before making crimp connections.

Warning Both AC and DC versions of this equipment must be earthed through

the power cables provided.

On a level surface

1. Ensure the area has sufficient space for the switch and its cables.

If you have not already done so, review considerations in “Selecting a Site”

on page 6.

2. Unpack the switch.

3. Fit rubber feet, if supplied.

All models except the SwitchBlade x908 ship with rubber feet. They stop

the switch from slipping and protect the surface from scratches. The

x900-12XT/S switch has four feet. All other models have five feet. Using the

screws provided, screw the rubber feet in the holes on the underside of the

switch. Use the following diagram to locate the screw holes. For the

x900-12XT/S, use positions 1, 2, 3, and 5.

8

4. Place the switch in the desired location for operation.

Page 10

Installation and Safety Guide

In a 19-inch rack

1. Ensure the rack has sufficient space for the switch and its cables. For the

switch’s requirements, see “Selecting a Site” on page 6.

2. Install cage nuts at the front of the rack so they are ready for the rackmount screws in the following steps.

3. Unpack the switch.

It may be helpful to temporarily remove any PSU or FOM so that the switch

is lighter and easier to manipulate during installation. For more information,

see the Removable Power Supply and Fan Installation Guide.

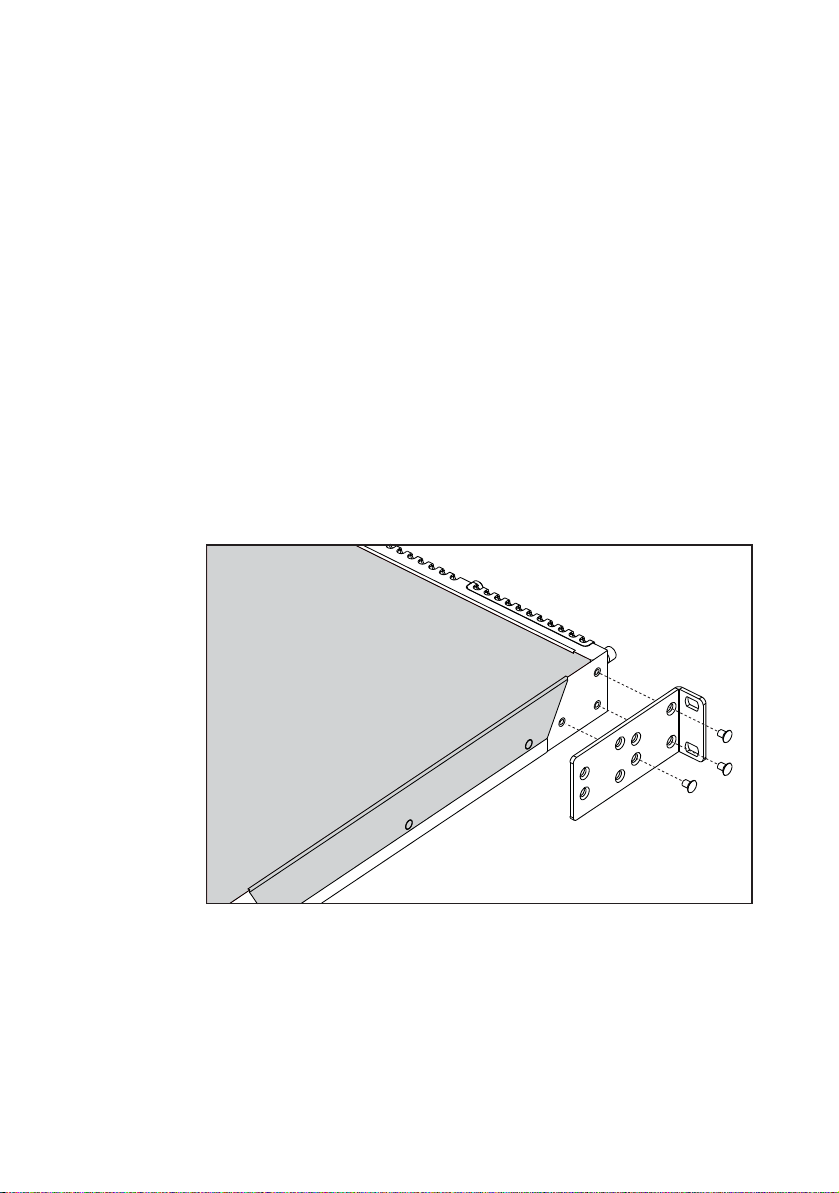

4. Screw one bracket to each side of the switch using the M4 screws provided.

On the x900-12XT switch, you can use the alternative set of holes on the

rack mount bracket to mount the switch further back in the rack.

For NEBS ensure the rack and hardware have been pre-treated, as

described in “Preparation for NEBS” on page 7.

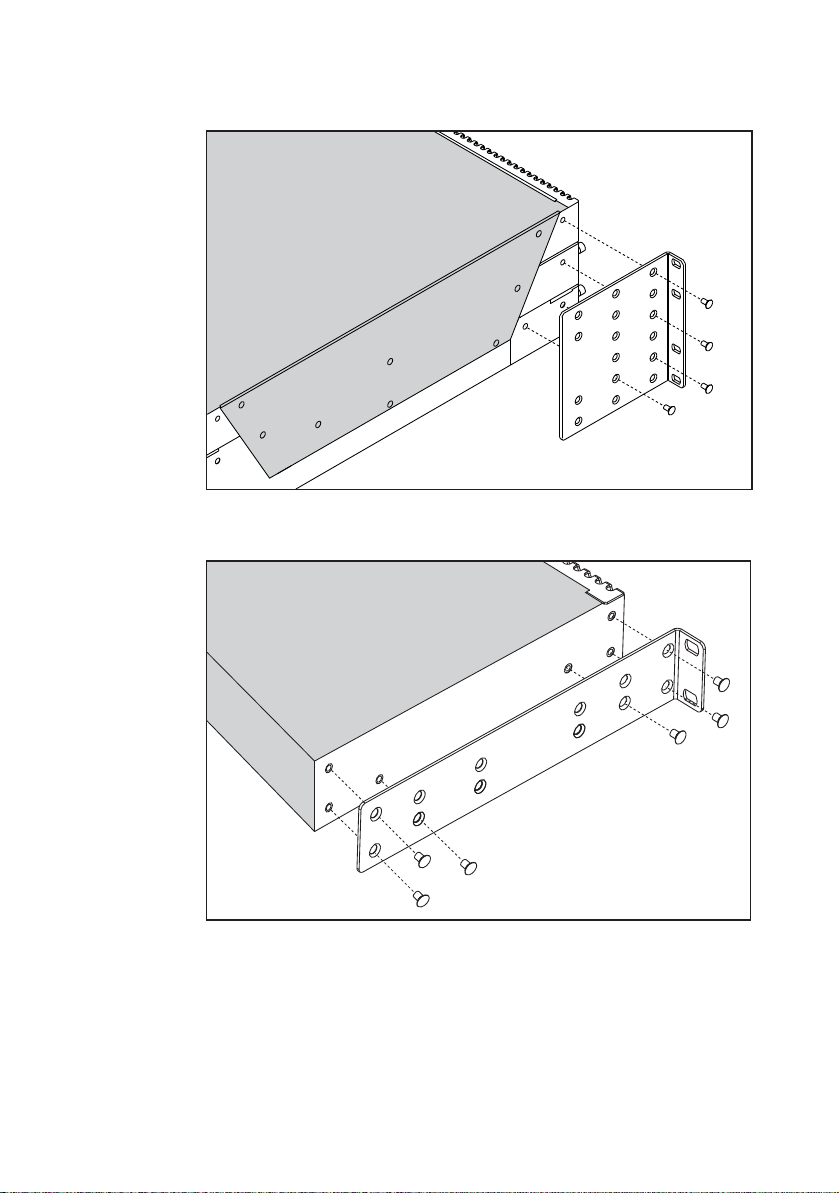

Fitting a bracket on an x900-12XT/S switch

9

Page 11

x900 Series Switch and SwitchBlade® x908

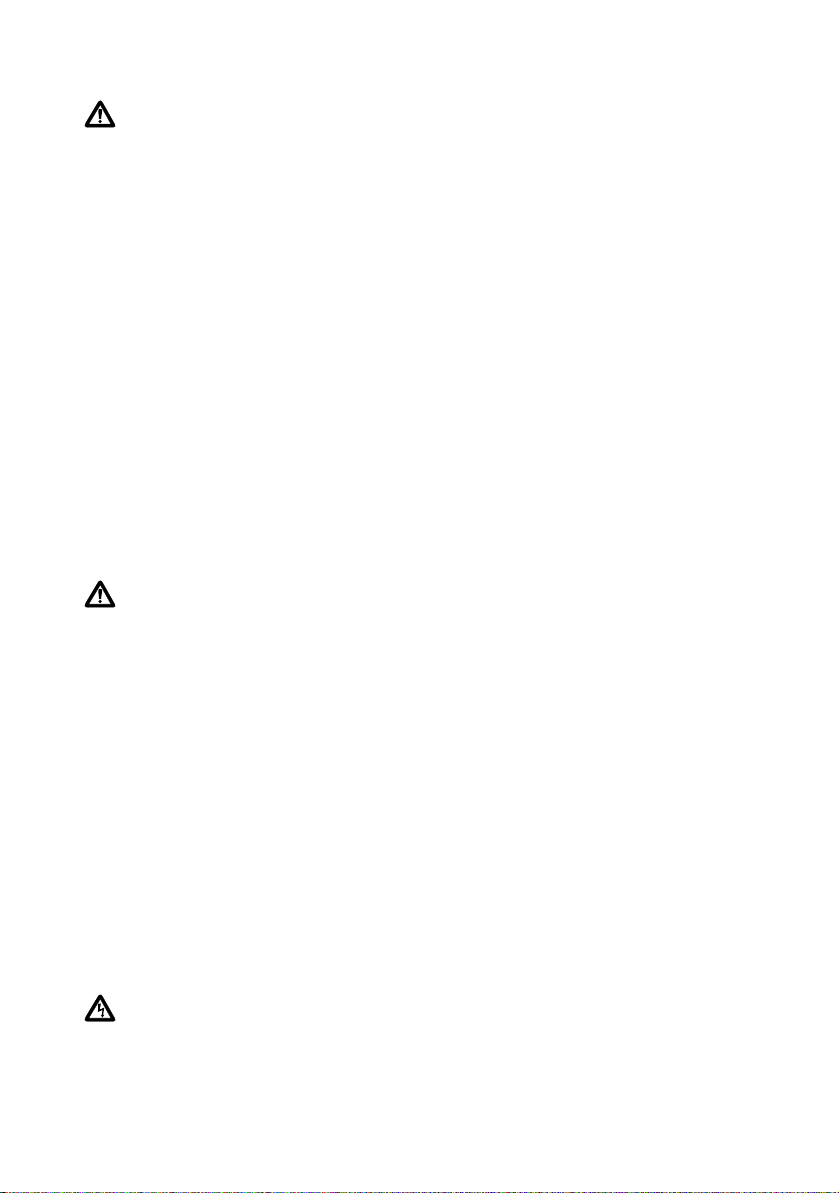

Fitting a bracket on a SwitchBlade x908 switch

Fitting a bracket on all other x900 Series switches

10

5. Mount the switch into the rack from the front, and tighten the rack-mount

screws.

Two people are required at this point. One person can lift the switch into

the rack and attach it to the front rails while the second person safely

supports it from the rear.

Page 12

Installation and Safety Guide

Applying Power to the Switch

Power supply bays are in the rear of the switch. Depending on the model, the

switch may have a PSU, FOM, or blanking plate over a power supply bay.

Connecting an AC power supply

Follow these instructions to connect one of the following to an AC power supply:

■ an AT-PWR01, AT-PWR02, or AT-PWR05 AC PSU

■ an x900-12XT/S switch

Warning The AT-PWR01 AC PSU has a fuse rating of 250 V, 5 A for FH101 and

FH102.

Warning The AT-PWR01 AC PSU has double pole/neutral fusing. Electric

shock is possible since there are dual primary fuses, one on the phase circuit and

one on the neutral circuit. If the neutral opens, the phase may still be live.

Warning When x900-24 units are connected with VCS stacking cables (XEMSTK-CBL) ensure that all the PSUs are appropriately grounded. This is to avoid

large circulating ground currents that could damage the stacking cables. To

achieve this ensure that:

■ AT-PWR01 AC is grounded by the 3-pin AC power connector

■ All grounding points are at the same ground level. That is, all power

connectors share a common power distribution unit.

Warning For x900-24 models, when using an AT-PWR01 AC power supply and

an AT-PWR01 DC power supply in the same switch, then the ground-terminal of

the DC power connector must be connected to the same ground as the AC

ground pin of the AC power connector.

If this is not possible, then you must ground the AT-PWR01 AC only, and leave

the AT-PWR01 DC power connector ungrounded. In this case, as a safety

precaution, ensure that the rack is also grounded.

Warning For SwitchBlade x908 AC models the grounding stud on the rear of

the unit is for supplemental grounding only. The system must be supplied by a

grounded 3 wire AC source through the power supply cord.

Warning When SBx908 devices are connected with VCS stacking cables (either

HS-STK-CBL or XEM-STK-CBL), each individual stack member chassis must be

additionally grounded by using the rear grounding-terminal on each device. In

order to avoid large circulating ground currents, the wires of each grounding

cable must be 18AWG or thicker.

11

Page 13

x900 Series Switch and SwitchBlade® x908

1. Plug the AC power cord that is provided into the power inlet on the PSU.

2. Connect the power cord to the main power source.

3. On the AT-PWR05, set the Run/Standby switch to Run.

4. Check that the PSU LED on the front panel of the switch is lit green. If the

LED does not light, refer to the Hardware Reference for troubleshooting

information.

Connecting a DC power supply

Follow these instructions to connect an AT-PWR01 or an AT-PWR05 DC PSU

to a DC power supply. Only trained and qualified personnel should connect a

DC power supply.

For centralised DC power connection, the switch should be installed in

restricted access areas only, such as dedicated equipment rooms or

equipment closets, in accordance with Articles 110-16, 110-17, and 110-18 of

the National Electrical Code, ANSI/NFPA 70.

Warning In order to avoid damaging the PSU, make sure that the PSU terminals

are wired to the correct polarity.

Warning When x900-24 units are connected with VCS stacking cables (XEMSTK-CBL) ensure that all the PSUs are appropriately grounded. This is to avoid

large circulating ground currents that could damage the stacking cables. To

achieve this ensure that:

• AT-PWR01 DC is grounded at the GND terminal. In order to avoid

large circulating ground currents, the wires of each grounding cable

must be 18AWG or thicker.

• All grounding points are at the same ground level. That is, all power

connectors share a common power distribution unit.

12

Warning When mounting one or two AT-PWR01 DC PSUs to a grounded rack,

ensure that the ground level of the rack and the DC power connector are the

same.

Warning For x900-24 models, when using an AT-PWR01 AC power supply and

an AT-PWR01 DC power supply in the same switch, then the ground-terminal of

the DC power connector must be connected to the same ground as the AC

ground pin of the AC power connector.

If this is not possible, then you must ground the AT-PWR01 AC only, and leave

the AT-PWR01 DC power connector ungrounded. In this case, as a safety

precaution, ensure that the rack is also grounded.

Page 14

Installation and Safety Guide

Warning When SBx908 devices are connected with VCS stacking cables (either

HS-STK-CBL or XEM-STK-CBL), each individual stack member chassis must be

additionally grounded by using the rear grounding-terminal on each device. In

order to avoid large circulating ground currents, the wires of each grounding

cable must be 18AWG or thicker.

PWR01

DC

PWR01 DC

Power supply specifications:

■ functional range 40 to 60 V, 48 V nominal

■ supports either positive grounded or negative grounded operation

■ a 15 Amp certified/listed circuit breaker is required for circuit protection

Supply cable specifications:

■ tray cable should be UL listed Type TC tray cable (or equivalent)

■ three-core cable is required

■ minimum core size: 3.3 mm

■ minimum cable rating: 600 V, 90 degrees C

Warning Disconnect the power supply cable before starting this procedure.

1. Remove the transparent protective terminal cover.

2. Strip the supply cable wires to expose 7.5 mm (0.31 in.) of bare conductor.

Terminate the wire with a nylon insulated solderless ring tongue terminal,

JST FN5.5-5 or equivalent, using a crimp tool.

3. Connect the ground wire to the ground terminal. Use the diagram on the

rear panel of the switch to identify terminals. Tighten the terminal to

between 2.4 and 4.0 Nm (21.3 and 35.4 lbf in).

2

(12 AWG) high strand count copper wire

4. Connect the positive feed to the + (positive) terminal and the negative feed

to the - (negative) terminal. Tighten the terminals to between 2.4 and

4.0 Nm (21.3 and 35.4 lbf in).

Note that the DC return input terminal must be connected as an Isolated

DC return (DC-I).

5. Ensure that there are no exposed cable strands.

6. Replace the cover. You must replace the transparent plastic terminal cover

before continuing.

7. Secure the supply cable to the rack framework or a similar object to ensure

that connections are isolated from any force applied to the cable.

13

Page 15

x900 Series Switch and SwitchBlade® x908

8. Ensure that the circuit breaker is off for the supply circuit and the Run/

Standby switch on the PSU. Release the Run/Standby switch so that it is not

pushed in (which is the Off position).

9. Connect the supply cable wires to the circuit breaker.

10. Turn on the PSU by pushing in the Run/Standby switch.

11. Confirm that the switch is receiving power.

Check that at least one of the PSU LEDs on the front panel of the switch is

lit green. If no LEDs light, refer to the Hardware Reference for

troubleshooting information.

14

Page 16

Installation and Safety Guide

DC

IN

LED

RUN/STANDBY

SWITCH

CAPTIVE

SCREW

DC

OUT

LED

FAUL T

LED

N/C

GREEN

( GND )

RED

( + )

BLACK

( - )

PWR05

DC

PWR05 DC

Power supply specifications:

■ functional range 40 to 60 V, 48 V nominal

■ supports either positive grounded or negative grounded operation

■ a 30 Amp certified/listed circuit breaker is required for circuit protection

Supply cable specifications:

■ tray cable should be UL listed Type TC tray cable (or equivalent)

■ three-core cable is required

■ minimum core size: 3.3 mm

■ minimum cable rating: 600 V, 90 degrees C

Warning When mounting one or two AT-PWR05 DC PSUs to a grounded rack,

ensure that the ground level of the rack and the DC power connector are the

same.

2

(12 AWG) high strand count copper wire

1. Ensure that the circuit breaker for the supply circuit and the Run/Standby

switch on the PSU are off (slide to position O).

2. Plug the DC power cord into the power inlet on the PSU.

3. Connect the supply cable wires to the circuit breaker and switch the circuit

breaker ON.

4. Turn on the PSU by sliding in the Run/Standby switch to position 1.

15

Page 17

x900 Series Switch and SwitchBlade® x908

5. Confirm that the switch is receiving power.

Check that the PSU LED on the front panel of the switch corresponding to

the PSU bay lights green. If the LED does not light green, check the Run/

Standby switch. See the Hardware Reference for more troubleshooting

information.

16

Page 18

Installation and Safety Guide

Connecting to the Switch

All x900 Series switches and the SwitchBlade x908 can be configured using the

Command Line Interface (CLI) and the Graphical User Interface (GUI).

The procedure and command syntax varies depending on whether the switch is

running the AlliedWare® operating system or the AlliedWare Plus™ operating

system.

Before configuring the switch, you must make some basic connections explained

in the following procedures:

■ “Using the AlliedWare Plus Operating System CLI” on page 17

■ “Using the AlliedWare Plus Operating System GUI” on page 20

■ “Using the AlliedWare Operating System CLI” on page 22

■ “Using the AlliedWare Operating System GUI” on page 24

Before starting these procedures, ensure that the switch is connected to a

power supply and receiving power.

Using the AlliedWare Plus Operating System CLI

Depending on the model, an ASYN0/CONSOLE and/or ETH0 port is on the

front of the switch for installation and maintenance.

Note that AlliedWare Plus does not have a default IP address configured on the

ETH0 port. If you want to connect via the ETH0 port using Telnet on your PC

you must connect via the ASYN0/CONSOLE port to configure an IP address on

the ETH0 port before you connect to the ETH0 port to use Telnet on your PC.

1. To use the ETH0 port, you must first assign an IP address to the port.

Log in via the ASYN0/CONSOLE port as described in steps 2 and 3 below,

then enter the following commands:

awplus>enable

awplus#configure terminal

awplus(config)#interface eth0

awplus(config-if)#ip address <address/mask>

where <address/mask> is an IP address and mask in slash notation, for

example 192.168.242.242/24.

Physically connect the ETH0 port to a terminal or PC, and check that the

port’s LEDs are lit. This means a link has been established between the port

and the PC. For NEBS compatibility, the cable must be shielded and

grounded at both ends, especially if permanently connected.

17

Page 19

x900 Series Switch and SwitchBlade® x908

When x900-24XT, x900-24XT-N, x900-24XS, or SwitchBlade x908

switches are connected to form a virtual chassis stack (VCS), the ETH0

port has additional operational functions. See the Hardware Reference for

more information.

From the terminal or PC, Telnet to the IP address of the ETH0 port.

2. To use the ASYN0/CONSOLE port, physically connect it to the

terminal or PC with the RJ-45 DB9 cable that is supplied. For NEBS

compatibility, the cable must be shielded and grounded at both ends,

especially if permanently connected.

Set communication parameters on your terminal or terminal emulation

program to the following:

• bit rate: 9600

• data bits: 8

•parity: None

• stop bits: 1

• flow control: None

For information about terminal emulation, see Using Windows Terminal and

HyperTerminal in the Hardware Reference.

3. Log in at the prompt.

If using the ASYN0/CONSOLE port, the login prompt is displayed after the

switch has booted. If not, press the Enter key two or three times.

When the switch boots for the first time, it automatically creates an

account with manager privileges. The login name for the account is manager

and the password is friend.

At the login prompt, enter the login name and password as follows:

Login: manager

Password: friend

The switch’s command prompt is displayed upon successful login.

18

4. Change the password.

A manager account with the default password is a serious security risk.

Remember the new password because there is no way to retrieve it if you

forget it.

To change the account password, use the following commands:

awplus>enable

awplus#configure terminal

awplus(config)#username manager password <password>

Page 20

Installation and Safety Guide

5. Configure the switch.

Refer to the AlliedWare Plus™ Operating System Software Reference for

detailed information about configuring the software.

For online help, type ? after:

• the prompt, to list all commands available in the command mode you

are in

• one or more parameters, to list parameters that can come next in the

partial command

• one or more letters of a parameter, to list matching parameters

To complete a keywords, press the Tab key after part of the command. If

only one keyword matches the partial command, the CLI fills in that

keyword. If multiple keywords match, it lists them.

6. Save the configuration.

Save the current configuration as the default startup configuration by using

the commands:

awplus>enable

awplus#copy running-config startup-config

Alternatively, you can save the current configuration with a different file

name and then set the switch to load this file when it restarts by using the

commands:

awplus>enable

awplus#copy running-config <filename>.cfg

awplus#configure terminal

awplus(config)#boot config-file <filename>.cfg

19

Page 21

x900 Series Switch and SwitchBlade® x908

Using the AlliedWare Plus Operating System GUI

Follow this procedure to establish a connection to an x900 or x908 series

switch, so you can use the GUI to configure the switch.

1. Select a PC to use and identify its subnet.

You can browse to the switch from any PC running a supported operating

system with a supported browser with JavaScript enabled. You may need to

install and run the latest Java Runtime Environment that you can download

from the Sun site so your browser can support the GUI Java applet.

2. Connect the PC to the switch.

Use an Ethernet cable to connect an Ethernet card on the PC to any of the

switch ports. You can browse to the router through any VLAN as long as

you give it an IP address. These instructions assume you are using vlan1. All

switch ports belong to vlan1 by default.

3. Access the CLI from the PC as described in “Using the AlliedWare Plus

Operating System CLI” on page 17.

4. Assign an IP address to connect to the GUI using these CLI commands:

awplus>enable

awplus#configure terminal

awplus(config)#interface vlan1

awplus(config-if)#ip address <address/mask>

where <address/mask> is an IP address and mask in slash notation, for

example 192.168.242.242/24.

20

5. Configure your switch with a default gateway using these CLI commands:

awplus(config-if)#exit

awplus(config)#ip route 0.0.0.0/0 <gateway-address>

where <gateway-address> is an IP address for your gateway device.

Note that you do not need to define a default gateway if you browse to the

switch from within its own subnet.

6. Create a user account to log into the GUI using the below CLI command:

awplus(config)#username <username> privilege 15

guiuser password <password>

Note that you can create multiple users to log into the GUI. See the

AlliedWare Plus Software Reference for information about the username

command and all other AlliedWare Plus CLI commands shown here.

Page 22

Installation and Safety Guide

7. Save the configuration.

Save the current configuration as the default startup configuration by using

the commands:

awplus>enable

awplus#copy running-config startup-config

Alternatively, you can save the current configuration with a different file

name and then set the switch to load this file when it restarts by using the

commands:

awplus>enable

awplus#copy running-config <filename>.cfg

awplus#configure terminal

awplus(config)#boot config-file <filename>.cfg

8. On the PC’s web browser, bypass the HTTP proxy server, if necessary.

9. Point your web browser at the IP address configured in step 4.

10. At the login screen, enter the user name and password you set in step 6.

The System Status page is displayed. Select options from tabs to configure

and manage the switch. For online help, click the Help button on each tab.

21

Page 23

x900 Series Switch and SwitchBlade® x908

Using the AlliedWare Operating System CLI

Depending on the model, an ASYN0/CONSOLE and/or ETH0 port is on the

front of the switch for installation and maintenance.

1. To use the ETH0 port, physically connect it to the terminal or PC, and

check that the port’s LEDs are lit. This means a link has been established

between the port and the PC. For NEBS compatibility, the cable must be

shielded and grounded at both ends, especially if permanently connected.

The default configuration contains the following commands:

enable ip

add ip int=eth0 ip=192.168.242.242

Set the PC to an IP address in the 192.168.242.0 subnet, and then establish

a Telnet session to 192.168.242.242.

2. To use the ASYN0/CONSOLE port, physically connect it to the

terminal or PC with the RJ-45 DB9 cable that is supplied. For NEBS

compatibility, the cable must be shielded and grounded at both ends,

especially if permanently connected.

Set communication parameters on your terminal or terminal emulation

program to the following:

• bit rate: 9600

• data bits: 8

•parity: None

• stop bits: 1

• flow control: Hardware

For information about terminal emulation, see Using Windows Terminal and

HyperTerminal in the Hardware Reference.

22

3. Log in at the prompt.

If using the ASYN0/CONSOLE port, the login prompt is displayed after the

switch has booted. If not, press the Enter key two or three times.

When the switch boots for the first time, it automatically creates an

account with manager privileges. The login name for the account is manager

and the password is friend.

At the login prompt, enter the login name and password as follows:

Login: manager

Password: friend

The switch’s command prompt is displayed upon successful login.

Page 24

Installation and Safety Guide

4. Change the password.

A manager account with the default password is a serious security risk.

Remember the new password because there is no way to retrieve it if you

forget it.

To change the account password, use the set password command.

5. Configure online help.

To use online help you must first configure the help file by using one of

these commands:

For AT-8948, x900-48FE, x900-48FE-N, x900-48FS, and AT-9900 switches,

use:

set help=<filename>.hlp

For AT-9924Ts, x900-24XT, x900-24XT-N, and x900-24XS switches, use:

set install=preferred help=help-filename

Help files have an HLP extension. To see the help files on your switch, use

the command:

show system

6. Configure the switch.

Refer to the x900 Series Switch AlliedWare® Operating System Software

Reference for more information about configuring the software.

Alternatively, if you do not know the command syntax, use any of the

following to help you:

• To display a list of help topics, use the help command.

• To display help on a specific topic, use the help <topic> command.

• To display a list of valid options, type a question mark or press the Tab

key at the end of a partial command.

• To complete a parameter after you have typed enough letters to

uniquely match the desired one, press the Tab key.

7. Save the configuration.

Save your configuration to a new file by using the command:

create config=<filename>.cfg

Then set the switch to load this file when it restarts by using the command:

set config=<filename>.cfg

23

Page 25

x900 Series Switch and SwitchBlade® x908

Using the AlliedWare Operating System GUI

Follow this procedure to establish a connection to an AT-9900 series switch, so

you can use the GUI to configure the switch.

1. Select a PC to use and identify its subnet.

You can browse to the switch from any PC running a supported operating

system with a supported browser. See Using the Graphical User Interface

(GUI) on AT-9900 Series Switches in the AlliedWare

Reference for a list of supported combinations. JavaScript must be enabled.

While using the GUI, disable any toolbars or plug-ins on your browser that

block pop-ups. The GUI displays detailed configuration options and

information in pop-up windows.

2. Connect the PC to the switch.

Use an Ethernet cable to connect an Ethernet card on the PC to any of the

switch ports. You can browse to the router through any VLAN as long as

you give it an IP address. These instructions assume you are using vlan1. All

switch ports belong to vlan1 by default.

3. Access the CLI from the PC as described in “Using the AlliedWare

Operating System CLI” on page 22.

4. Enable IP.

enable ip

®

Operating System Software

24

5. Assign the vlan1 interface an IP address in the same subnet as the PC.

add ip interface=vlan1 ip=ipaddress mask=mask

enable http server

6. Save the configuration and set the switch to use it on bootup.

create config=your-name.cfg

set config=your-name.cfg

7. On the PC’s web browser, bypass the HTTP proxy server, if necessary.

8. Point your web browser at the IP address for vlan1.

9. At the login prompt, enter the user name and password.

User Name: manager

Password: friend

The System Status page is displayed. Select options from the sidebar menu

to configure and manage the switch.

For context-sensitive online help, click the Help button at the top of the

sidebar menu or on any pop-up page.

Page 26

Installation and Safety Guide

Checking LEDs

The following LEDs report operations and faults on x900 Series and

SwitchBlade

■ “System LEDs” on page 25

■ “Stacking LEDs” on page 27

■ “PWR01 LEDs” on page 27

■ “PWR02 LEDs” on page 27

■ “PWR05 AC LEDs” on page 28

LEDs for Ethernet ports and Small Form Factor Pluggable (SFP) ports are

described in the Hardware Reference.

x908 switches:

System

LEDs

The following table describes how LEDs on the switch report operations and

faults.

LED State Description

PSU 1

and

PSU 2

Green The PSU is installed and supplying power to the

switch. The voltage output is within specification.

Red One of the following:

• The PSU is installed in the switch, and a fan has

failed or the PSU has exceeded its recommended

temperature threshold.

• A FOM is installed in the switch and a fan has

failed. The x900-12XT/S and SwitchBlade x908

switches do not support FOMs.

• The bay is empty. Applies to AT-8948, AT-9924Ts,

x900-24XT, x900-24XT-N, and x900-24XS

switches which require a FOM when only one

PSU is installed.

• Dual PSUs are installed, but the PSU is not

receiving power.

• The standby switch has been turned off.

Off A FOM is installed and operating at an acceptable

speed. For AT-9924T, x900-48FE, x900-48FE-N,

x900-48FS, and SwitchBlade

x908 switches, a blanking

plate is installed.

25

Page 27

x900 Series Switch and SwitchBlade® x908

LED State Description (cont)

POWER Green The PSU is operating and supplying power to the

switch. The voltage output is within specification.

Valid for the x900-12XT/S switch.

Fault Red The switch or management software is

malfunctioning.

Red flashing The following flash sequences indicate a hardware-

related fault. After sequences of two or more flashes,

the LED stops briefly, then repeats the sequence. If

multiple faults occur, the LED flashes each sequence in

turn, stops briefly, then repeats the sequences.

1 Flash One or more heatsink fans has failed or is operating

below the recommended speed.

2 Flashes For SwitchBlade x908 switches, one or both of the

chassis fans are not installed, or the fans are operating

below the recommended speed.

3 Flashes For AT-9924T, AT-9924SP, AT-9924Ts, x900-24XT,

x900-24XT-N, and x900-24XS switches, the ability to

monitor temperature and fans has failed, and it cannot

report whether they are in the supported ranges.

4 Flashes For switches running the AlliedWare Plus operating

system, a XEM failed to initialise or is incompatible.

6 Flashes The switch’s temperature has exceeded the

recommended threshold.

26

Slow

flashing at

startup

Rapid

flashing at

startup

CF Green

flashing

The SDRAM (DIMM) has not been detected. Does

not apply to AT-9924Ts, x900-12XT/S, x900-24XT,

x900-24XT-N, x900-24XS, and SwitchBlade

switches.

The SDRAM (DIMM) is not compatible with the

switch. Does not apply to AT-9924Ts, x900-12XT/S,

x900-24XT, x900-24XT-N, x900-24XS, and

SwitchBlade

The CompactFlash memory card is active and should

not be ejected. The card can be safely ejected when

the LED remains off. Valid for AT-8948, x900-48FE,

x900-48FE-N, x900-48FS, AT-9924T, and AT-9924SP

switches.

x908 switches.

x908

Page 28

LED State Description (cont)

Installation and Safety Guide

Stacking

LEDs

PWR01

LEDs

SD Green

The following table describes how LEDs on the SwitchBlade x908 report

operations and faults on the rear panel stacking ports.

LED State Description

STATUS Green The switch is the stack master.

PORT 1

and

PORT 2

The following table describes LEDs on the PWR01 power supply unit.

LED State Description

flashing

Amber The switch is a stack member.

Green

flashing

Off The switch is not a stack member.

Green A link has been established.

Amber

flashing

The Secure Digital memory card is active and should

not be ejected. The card can be safely ejected when

the LED remains off. Valid for AT-9924Ts,

x900-12XT/S, x900-24XT, x900-24XT-N,

x900-24XS, and SwitchBlade

The switch is in the process of learning the stack

topology and selecting the stack master.

The link has a transmission fault.

x908 switches.

PWR02

LEDs

Fault Red The temperature on the PSU has exceeded the limit of

75º C (167º

PWR Green A PSU is installed in the switch and is delivering power.

A FOM does not have this LED.

The following table describes LEDs on the PWR02 power supply unit.

LED State Description

Fault Red The temperature on the PSU has exceeded the limit of

75º C (167º

PWR Green A PSU is installed in the switch and is delivering power.

A FOM does not have this LED.

F), or the fan failed.

F), or the fan failed.

27

Page 29

x900 Series Switch and SwitchBlade® x908

PWR05

LEDs

PWR05

AC

LEDs

The following is a diagram of the LEDs in the PWR05 power supply units:

IN

OUT

FAULT

LED

LED

LED

POWER

CONNECTOR

The following table describes LEDs on the PWR05 AC power supply unit for the

SwitchBlade x908.

LED State Description

~

IN

OUT

FAULT

Green AC input voltage is within 90-264 VAC, 47-63Hz.

Off AC input voltage is outside the acceptable range.

Green DC output voltage is within 12VDC +/- 10%.

Off DC output voltage is outside the acceptable range, or

the Standby switch is Off. If a fault occurs then the

FAULT LED will display and the OUT LED will be Off.

Red A fault has occurred. There is either a fan failure, or the

temperature has exceeded its limit of 70º

Off No fault conditions detected.

C (158º F).

28

Page 30

Installation and Safety Guide

PWR05

DC

LEDs

The following table describes LEDs on the PWR05 DC power supply unit for

the SwitchBlade

LED State Description

IN

OUT

FAULT

x908.

Green DC input voltage is within 40 VDC to 60 VDC.

Off DC input voltage is outside the acceptable range.

Green DC output voltage is within 12VDC +/- 10%.

Off DC output voltage is outside the acceptable range, or

the Standby switch is Off. If a fault occurs then the

FAULT LED will display and the OUT LED will be Off.

Red A fault has occurred. There is either a fan failure, or the

temperature has exceeded its limit of 70º

Off No fault conditions detected.

C (158º F).

29

Page 31

x900 Series Switch and SwitchBlade® x908

Obtaining Documentation and Resources

The complete document set for x900 Series switches and SwitchBlade x908

includes:

■ this Installation and Safety Guide

■ the x900 Series Switch and SwitchBlade

contains detailed information on x900 Series and SwitchBlade x908 switches

and their hardware features

■ the Removable Power Supply and Fan Installation Guide, which describes how to

install power supply units and fan-only modules in x900 Series and

SwitchBlade

■ the x900 Series Switch and SwitchBlade

Guide, which describes how to install expansion modules in x900 Series and

SwitchBlade

■ the AT-9900s Series Switch Expansion Module Installation Guide, which

describes how to install expansion modules in AT-9900s Series switches

■ the x900 Series Switch

contains detailed information on configuring switches running the

AlliedWare operating system

■ the

detailed information on configuring switches running the AlliedWare Plus

operating system

x908 switches

x908 switches

AlliedWare® Operating System Software Reference

AlliedWare Plus™ Operating System Software Reference

®

x908 Hardware Reference, which

®

x908 Expansion Module Installation

, which

, which contains

30

You can download these documents and updates from

www.alliedtelesis.com/support/software.

You need Adobe® Acrobat® Reader® software to view, search, or print these

documents. You can download it from www.adobe.com.

Other resources

How-To Notes describe a range of standard Allied Telesis solutions, and include

technical tips and guides to configuring specific hardware and software features.

You can download the latest How-To Notes from

www.alliedtelesis.com/resources/literature/howto.aspx.

MIBs supported by Allied Telesis products can be downloaded from

www.alliedtelesis.com/support/software.

Microsoft® Visio® stencils for Allied Telesis products can be downloaded from

www.alliedtelesis.com/resources/images/visio.aspx.

Page 32

Installation and Safety Guide

AT-TFTP Server for Windows is a TFTP (Trivial File Transfer Protocol) server for

transferring software versions, configuration scripts and other files between a

PC and the switch. You download AT-TFTP Server from

www.alliedtelesis.com/support/software.

CD-ROM

Some AlliedWare products ship with a Documentation and Tools CD-ROM,

which includes:

■ the complete document set

■ Adobe

■ AT-TFTP Ser ver

■ Supported MIBs

■ How-To Notes, white papers, Microsoft

®

Acrobat® Reader

®

®

Visio® stencils and other

resources

■ Tryouts of networking software

Contacting us

With locations covering all of the established markets in North America, Latin

America, Europe, Asia, and the Pacific, Allied Telesis provides localized sales and

technical support worldwide. To find the representative nearest you, visit us on

the Web at

www.alliedtelesis.com.

31

Page 33

x900 Series Switch and SwitchBlade® x908

Standards

Where applicable, the products in this document meet the following standards:

Category Approval Agency and Requirement

Safety

Electromagnetic FCC CFR47 Part 15 Class A

NEBS GR-63-Core NEBS Level 3

ETSI ETSI 300 019

WEEE Meets requirements of Directive 2002/96/EC of the European Parliament

RoHS Meets requirement of Directive 2002/95/EC of the European Parliament

RADIATED ENERGY

Note: This equipment has been tested and found to comply with the limits for a Class A digital device

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with this instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Note: Modifications or changes not expressly approved by the manufacturer or the FCC can void

your right to operate this equipment.

UL60950-1

CAN/CSA-C22.2 No. 60950-1-03

EN60950-1

AS/NZS 60950.1

EN55022 Class A

VCCI Class A

AS/NZS CISPR22 Class A

GR-1089-Core NEBS Level 3

ETSI 300 132

and of the council of 27 January 2003

and of the council of 27 January 2003

U.S. Federal Communications Commission

EN 60825-1

EN 60825-2

21 CFR 1040

CNS 13438 Class A

EN61000-3-2/3

EN55024

ETSI 300 386

Canadian Department of Communications

This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.

32

Page 34

Installation and Safety Guide

Safety

WARNING: In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

WARNING: Class 1 Laser product.

WARNING: Do not stare into the laser beam.

CAUTION: Use of controls or adjustments of performance or procedures

other than those specified herein may result in hazardous radiation exposure.

ELECTRICAL NOTICES

WARNING: ELECTRIC SHOCK HAZARD

To prevent ELECTRIC shock, do not remove the cover. No user-serviceable

parts inside. This unit contains HAZARDOUS VOLTAGES and should be

opened only by a trained and qualified technician.

LIGHTNING DANGER

DANGER: DO NOT WORK on equipment or CABLES during periods of

LIGHTNING ACTIVITY.

CAUTION: POWER CORD IS USED AS A DISCONNECTION DEVICE. TO

DE-ENERGIZE EQUIPMENT, disconnect the power cord.

ELECTRICAL - TYPE CLASS 1 EQUIPMENT

THIS EQUIPMENT MUST BE EARTHED. Power plug must be connected to a

properly wired earth ground socket outlet. An improperly wired socket outlet

could place hazardous voltages on accessible metal parts.

PLUGGABLE EQUIPMENT, the socket outlet shall be installed near the

equipment and shall be easily accessible.

CAUTION: Air vents must not be blocked and must have free access to the

room ambient air for cooling.

OPERATING TEMPERATURE: The AT-8948, x900-48FE, x900-48FE-N,

x900-48FS, and AT-9900 series switches are designed for a maximum ambient

temperature of 50 degrees C. The AT-9924Ts, x900-12XT/S, x900-24XT,

x900-24XT-N, x900-24XS, and SwitchBlade

maximum of 40 degrees C. Derate the x900-24XT, x900-24XT-N, x900-24XS,

and SwitchBlade

ELECTRICAL - AC MAINS CIRCUIT OVERLOADING

When installing product, consideration must be given to the accumulative

nameplate ratings when connecting the equipment to the AC supply wiring.

CAUTION: MECHANICAL LOADING - Mounting of the equipment in the

rack should be such that a hazardous condition is not achieved due to uneven

loading.

x908 switches by 1degree C per 305 Meters (1000 ft).

x908 switches are designed for a

33

Page 35

x900 Series Switch and SwitchBlade® x908

Lithium Battery - Should be changed only by authorised service personnel.

CAUTION: Danger of explosion if battery is incorrectly replaced. Replace only

with Lithium Battery, type CR2032, and dispose of in accordance with the

manufacturer’s recommendations and all local codes.

ALL COUNTRIES: Install product in accordance with local and National

Electrical Codes.

WARNING: For centralized DC power connection, install only in a restricted

access area.

A tray cable is required to connect the power source if the unit is powered by

centralized DC power. The tray cable must be UL listed Type TC tray cable and

rated at 600 V and 90 degrees C, with three conductors, minimum 12 AWG.

WARNING: Only trained and qualified personnel are allowed to install or

replace this equipment.

WARNING: As a safety precaution, a 15 Amp circuit breaker should be

installed at the supply end of the cable to be used with this LAN equipment.

Always connect the wiring to the LAN equipment first before connecting the

wiring to the breaker. To avoid the danger of physical injury from electrical

shock, do not work with HOT feeds. Always be sure that the breaker is in the

Off position before connecting the wiring to the breaker.

WARNING: Do not strip more than the recommended amount of wire.

Stripping more than the recommended amount can create a safety hazard by

leaving exposed wire on the terminal block after installation.

WARNING: When installing this equipment, always ensure that the frame

ground connection is installed first and disconnected last.

WARNING: “Safety Hazard” - Check to see if there are any exposed

copper strands coming from the installed wires. When this installation is done

correctly, there should be no exposed copper wire strands extending from the

terminal block. Any exposed wiring can conduct harmful levels of electricity to

persons touching the wires.

DC versions of this system will work with a positive grounded or negative

grounded DC system.

34

Page 36

Installation and Safety Guide

Sicherheit

WARN UNG: Bei Verwendung zu Hause kann dieses Produkt Funkstörungen

hervorrufen. In diesem Fall müßte der Anwender angemessene

Gegenmaßnahmen ergreifen.

WARN UNG Laserprodukt der Klasse 1.

WARN UNG Nicht direkt in den Strahl blicken.

ACHTUNG: GEFÄHRLICHE SPANNUNG

Das Gehäuse nicht öffnen. Das Gerät enthält keine vom Benutzer wartbaren

Teile. Das Gerät steht unter Hochspannung und darf nur von qualifiziertem

technischem Personal geöffnet werden.

GEFAHR DURCH BLITZSCHLAG

GEFAHR: Keine Arbeiten am Gerät oder an den Kabeln während eines

Gewitters ausführen.

VORSICHT: DAS NETZKABEL DIENT ZUM TRENNEN DER

STROMVERSORGUNG. ZUR TRENNUNG VOM NETZ, KABEL AUS DER

STECKDOSE ZIEHEN.

GERÄTE DER KLASSE 1

DIESE GERÄTE MÜSSEN GEERDET SEIN. Der Netzstecker darf nur mit einer

vorschriftsmäßig geerdeten Steckdose verbunden werden. Ein

unvorschriftsmäßiger Anschluß kann die Metallteile des Gehauses unter

gefährliche elektrische Spannungen setzen.

STECKBARES GERÄT: Die Anschlußbuchse sollte in der Nähe des Gerätes

angebracht werden und leicht zugänglich sein.”

VORSICHT

Die Entlüftungsöffnungen dürfen nicht blockiert sein und müssen zum Kühlen

freien Zugang zur Raumluft haben.

BETRIEBSTEMPERATUR: AT-8948, x900-48FE, x900-48FE-N, x900-48FS,

AT-9900 series produkt wurde für den Betrieb in einer Umgebungstemperatur

von nicht mehr als 50 grad C entworfen. Die AT-9924Ts, x900-12XT/S,

x900-24XT, x900-24XT-N, x900-24XS, SwitchBlade

den Betrieb in einer Umgebungstemperatur von nicht mehr als 40 grad C

entworfen.

NETZSICHERUNG

Bei der Installation muß der auf dem Typenschild angezeigte Nennwert des

Gerätes für den Anschluß an das Netz beachtet werden.

VORSICHT: RAHMENEINBAU

Die Geräte müssen so in den Rahmen montiert werden, daß keine Gefahren

durch unebenen inbau des Rahmens verursacht werden.

x908 produkt wurde für

35

Page 37

x900 Series Switch and SwitchBlade® x908

Lithium-Batterie - Sollte nur von einem geschulten qualifizierten Techniker

ausgetauscht werden.

VORSICHT: Explosionsgefahr bei unsachgemäßem Austausch der Batterie.

Nur mit einer gleichen Batterie oder einem gleichwertigen Batterietyp nach

Empfehlung des Herstellers ersetzen. Gebrauchte Batterien nach Anweisungen

des Herstellers beseitigen.

ALLE LÄNDER: Installation muß örtlichen und nationalen elektrischen

Vorschriften entsprechen.

Warnung: Bei zentralisierten gleichstromverbindungen sollte die installation

nur an einem standort mit beschränktem zugang erfolgen.

Hinweis: Für den Anschluß der Stromquelle ist ein für den Einsatz in

Kabelrinnen geeignetes Installationskabel (Tray Cable) erforderlich, falls die

Einheit durch zentralisierten Gleichstrom angetrieben wird. Das

Installationskabel muß ein dem UL-Standard entsprechendes Kabel des Typs TC

mit einer Nennspannung von 600 V und einer Nenntemperatur von 90 grad C

sein, das drei Leiter hat. Stärke mind. 12 AWG (American Wire Gage –

amerikanische Einheit für Drahtdurchmesser).

Warnung: INSTALLATION UND WARTUNG DIESER EINRICHTUNG NUR

DURCH AUSGEBILDETES FACHPERSONAL.

Warnung: Aus Sicherheitsgründen sollte am Netzteilende des mit dieser LANEinrichtung verwendeten Kabels ein 15-Ampere-Leistungsschalter installiert

werden.

Nehmen Sie STETS zuerst die Verkabelung der LAN-Einrichtung vor, bevor Sie

die Kabel an den Leistungsschalter anschließen. Arbeiten Sie nie mit

SPANNUNGSFÜHRENDEN Kabeln, um Körperverletzungen durch

Stromschlag zu vermeiden. Achten Sie stets darauf, daß sich der

Leistungsschalter in der Position Off (Aus) befindet, bevor Sie Kabel an den

Leistungsschalter anschließen.

Warnung: Ziehen Sie nicht mehr als die empfohlene Drahtlänge ab. Wird mehr

als die empfohlene Länge abisoliert, stellt dies ein Sicherheitsrisiko dar, da auf

dem Anschlußklemmblock nach der Installation möglicherweise freiliegende

Drähte verbleiben.

Warnung: Bei der Installation dieser Einrichtung ist stets sicherzustellen, daß

der Masseanschluß jeweils zuerst installiert und zuletzt getrennt wird.

Warnung: “Sicherheitsrisiko” Prüfen Sie, daß aus dem installierten Draht

keine freiliegenden Kupferlitzen herausragen. Bei korrekter Installation sollten

aus dem Anschlußklemmblock keine freiliegenden Kupferlitzen vorstehen.

Freiliegende Kabel führen genug Spannung, um Personen zu gefährden, die diese

Drähte berühren.

Hinweis: Dieses System kann mit positiv geerdeten oder negativ geerdeten

Gleichstromsystemen betrieben werden.

36

Page 38

Installation and Safety Guide

Sikkerhed

ADVARSEL: I et hjemligt miljø kunne dette produkt forårsage radio

forstyrrelse. Bliver det tilfældet, påkræves brugeren muligvis at tage

tilstrækkelige foranstaltninger.

ADVARSEL Laserprodukt av klasse 1.

ADVARSEL Stirr ikke på strålen.

ELEKTRISKE FORHOLDSREGLER

ADVARSEL: RISIKO FOR ELEKTRISK STØD

For at forebygge ELEKTRISK stød, undlad at åbne apparatet. Der er ingen indre

dele, der kan repareres af brugeren. Denne enhed indeholder LIVSFARLIGE

STRØMSPÆNDINGER og bør kun åbnes af en uddannet og kvalificeret tekniker.

FARE UNDER UVEJR

FARE: UNDLAD at arbejde på udstyr eller KABLER i perioder med

LYNAKTIVITET.

ADVARSEL: DEN STRØMFØRENDE LEDNING BRUGES TIL AT AFBRYDE

STRØMMEN. SKAL STRØMMEN TIL APPARATET AFBRYDES, tages ledningen

ud af stikket.

ELEKTRISK - KLASSE 1-UDSTYR

DETTE UDSTYR KRÆVER JORDFORBINDELSE. Stikket skal være forbundet

med en korrekt installeret jordforbunden stikkontakt. En ukorrekt installeret

stikkontakt kan sætte livsfarlig spænding til tilgængelige metaldele.

UDSTYR TIL STIKKONTAKT, stikkontakten bør installeres nær ved udstyret og

skal være lettilgængelig.

ADVARSEL: Ventilationsåbninger må ikke blokeres og skal have fri adgang til

den omgivende luft i rummet for afkøling.

BETJENINGSTEMPERATUR: AT-8948, x900-48FE, x900-48FE-N,

x900-48FS, AT-9900 series apparat er konstrueret til en omgivende temperatur

på maksimum 50 grader C. AT-9924Ts, x900-12XT/S, x900-24XT,

x900-24XT-N, x900-24XS, SwitchBlade

omgivende temperatur på maksimum 40 grader C.

ELEKTRISK-OVERBELASTNING AF SPÆNDINGSKREDSLØBET

Ved installation af produktet, bør der tages hensyn til den kumulative kapacitet

der angives på navneskiltet, når udstyret forbindes med vekselstrømsledningen.

ADVARSEL: MEKANISK OPSTILLING-Udstyret skal opstilles i stativet, på en

sådan måde, at der kke opstår fare p.g.a. ujævn opstilling.

Lithium batteri - Bør kun udskiftes af uddannet og kvalificeret tekniker.

ADVARSEL : Eksplosionsfare, hvis batteriet udskiftes ukorrekt. Udskift kun

x908 apparat er konstrueret til en

37

Page 39

x900 Series Switch and SwitchBlade® x908

med samme eller en tilsvarende type der anbefales af producenten. Kassér

brugte batterier i overensstemmelse med producentens instruktioner.

ALLE LANDE: Installation af produktet skal ske i overensstemmelse med lokal

og national lovgivning for elektriske installationer.

Advarsel: ETABLERES FORBINDELSEN TIL ET JÆVNSTRØMSNET, BØR

INSTALLERING FORETAGES I ET OMRÅDE HVOR UVEDKOMMENDE IKKE

HAR ADGANG.

Bemærk: Hvis switchen forbindes til jævnstrømsnet skal den føres med

skinnekabel, der skal være UL mærket type TC normeret til 600 V, 90 grader C‘

med tre ledere af mindst tykkelse 12 AWG (amerikansk ledningsmål).

Advarsel: INSTALLERING OG UDSKIFTNING AF DETTE UDSTYR BØR

KUN UDFØRES AF AUT. EL-INSTALLATØR.

Advarsel: Der bør indskydes en 15 A automatsikring på forsyningsenden af

kablet til dette LAN-udstyr.

Man skal ALTID først forbinde ledningerne med LAN-udstyret inden de

forbindes med automatsikringen. Ved ledningsarbejde skal strømmen altid være

AFBRUDT til forebyggelse af fare for elektrisk stød. Man skal altid SLUKKE

automatsikringen inden man forbinder ledninger med den.

Advarsel: Man bør ikke afisolere mere af ledningerne end anvist, for så kan

sådanne blanke ledninger udgøre et faremoment efter montering på

klemmerækken.

38

Advarsel: Ved installering af dette udstyr skal steljord altid forbindes først og

aftages sidst.

Advarsel: “Fare” Se omhyggeligt efter om der stikker blanke kobbertråde ud

fra klemmeforbindelserne. Ved korrekt montering er det ikke tilfældet. Enhver

afisoleret leder kan lede farlig strømstyrke til personer, som kommer til at røre

ved dem.

Bemærk: Dette udstyr kan køre både på jævnstrøm med positiv og med

negativ jord.

Page 40

Installation and Safety Guide

Veiligheid

WAARSCHUWING: Binnenshuis kan dit product radiostoring veroorzaken,

in welk geval de gebruiker verplicht kan worden om gepaste maatregelen te

nemen.

WAARSHUWING Klasse-1 laser produkt.

WAARCHUWING Neit in de straal staren.

WAARSCHUWINGEN MET BETREKKING TOT ELEKTRICITEIT

WAARSCHUWING: GEVAAR VOOR ELEKTRISCHE SCHOKKEN

Verwijder het deksel niet, teneinde ELEKTRISCHE schokken te voorkomen.

Binnenin bevinden zich geen onderdelen die door de gebruiker onderhouden

kunnen worden. Dit toestel staat onder GEVAARLIJKE SPANNING en mag

alleen worden geopend door een daartoe opgeleide en bevoegde technicus.

GEVAAR VOOR BLIKSEMINSLAG

GEVAAR: NIET aan toestellen of KABELS WERKEN bij BLIKSEM.

WAARSCHUWING: HET TOESTEL WORDT UITGESCHAKELD DOOR

DE STROOMKABEL TE ONTKOPPELEN.OM HET TOESTEL STROOMLOOS

TE MAKEN: de stroomkabel ontkoppelen.

ELEKTRISCHE TOESTELLEN VAN KLASSE 1

DIT TOESTEL MOET GEAARD WORDEN. De stekker moet aangesloten zijn

op een juist geaarde contactdoos. Een onjuist geaarde contactdoos kan de

metalen onderdelen waarmee de gebruiker eventueel in aanraking komt onder

gevaarlijke spanning stellen.

AAN TE SLUITEN APPARATUUR, de contactdoos wordt in de nabijheid van de

apparatuur geïnstalleerd en is gemakkelijk te bereiken.”

OPGELET: De ventilatiegaten mogen niet worden gesperd en moeten de

omgevingslucht ongehinderd toelaten voor afkoeling.

BEDRIJFSTEMPERATUUR: De omgevingstemperatuur voor AT-8948, x90048FE, x900-48FE-N, x900-48FS, AT-9900 series produkt mag niet meer

bedragen dan 50 graden C. De omgevingstemperatuur voor AT-9924Ts, x90012XT/S, x900-24XT, x900-24XT-N, x900-24XS, SwitchBlade

niet meer bedragen dan 40

ELEKTRISCH: OVERBELASTING VAN WISSELSTROOM HOOFDCIRCUIT

Tijdens de installatie van het produkt dient men rekening te houden met de

gecombineerde waarden op de naamplaatjes bij het aansluiten van het toestel op

de wisselstroom-voedingsdraden.

OPGELET: MECHANISCH LADEN - De montage van het toestel in het rek

dient zo uitgevoerd te worden dat geen gevaar ontstaat door een ongelijke

lading.

graden C.

x908 produkt mag

39

Page 41

x900 Series Switch and SwitchBlade® x908

Lithium batterij. Mag alleen worden vervangen door een daartoe opgeleide en

bevoegde technicus.

OPGELET: Gevaar voor ontploffing indien de batterij verkeerd wordt

vergangen. Alleen vervangen door hetzelfde of een gelijkwaardig, door de

fabrikant aanbevolen type.

ALLE LANDEN: het toestel installeren overeenkomstig de lokale en nationale

elektrische voorschriften.

Waarschuwing: BIJ GECENTRALISEERDE DC-AANSLUITING: INSTALLATIE

UITSLUITEND UITVOEREN IN EEN GEBIED MET BEPERKTE TOEGANG.

Opmerking: U hebt een PVC/nylon-kabel nodig voor aansluiting op de

voedingsbron als de eenheid van stroom wordt voorzien door een

gecentraliseerde DC-voeding. De PVC/nylon-kabel moet een TC-kabel zijn (met

een vermelding op de UL-lijst), die geschikt is voor 600 V en 90 graden C met

drie geleiders en een minimumdikte van 12 AWG.

Waarschuwing: ALLEEN GESCHOOLD EN GEKWALIFICEERD PERSONEEL

MAG DEZE APPARATUUR INSTALLEREN OF VERVANGEN.

Waarschuwing: Op de kabel die op de LAN-apparatuur wordt aangesloten

dient een zekering van 15 amp te worden gemonteerd aan de zijde van de

aansluiting op de voeding.

Sluit bedrading ALTIJD eerst op de LAN-apparatuur aan en pas daarna op de

zekering. Voorkom het risico op een elektrische schok en schakel eerst de

voeding uit. Controleer voordat u de bedrading op de zekering aansluit altijd of

de zekering zich in de stand UIT bevindt.

Waarschuwing: Verwijder niet meer dan de aanbevolen hoeveelheid

isolatiemateriaal. Als u meer dan de aanbevolen hoeveelheid verwijdert, kan dit

een veiligheidsrisico veroorzaken doordat draden bloot blijven liggen na

aansluiting op het blok.

40

Waarschuwing: Zorg er tijdens installatie van de apparatuur altijd voor dat de

aardeaansluiting van het frame als eerste wordt geplaatst en als laatste wordt

losgemaakt.

Waarschuwing: “Veiligheidsrisico” Controleer of er bij de aangesloten

bedrading geen koper blootligt. Als de installatie juist is uitgevoerd, is er bij het

aansluitblok geen koperdraad zichtbaar. Blootliggende bedrading kan schadelijke

elektriciteitsniveaus geleiden naar personen die met de draden in aanraking

komen.

Opmerking: Dit systeem werkt met positief geaarde of negatief geaarde DCsystemen.

Page 42

Installation and Safety Guide

Sécurité

MISE EN GARDE : dans un environnement domestique, ce produit peut

provoquer des interférences radioélectriques. Auquel cas, l’utilisateur devra

prendre les mesures adéquates.

ATTENTION Producit laser di classe 1.

ATTENTION Ne pas fixer le faisceau des yeux.

INFORMATION SUR LES RISQUES ÉLECTRIQUES

AVERTISSEMENT: DANGER D’ÉLECTROCUTION

Pour éviter toute ÉLECTROCUTION, ne pas ôter le revêtement protecteur du

matériel. Ce matériel ne contient aucun élément réparable par l’utilisateur. Il

comprend des TENSIONS DANGEREUSES et ne doit être ouvert que par un

technicien dûment qualifié.

DANGER DE FOUDRE

DANGER: NE PAS MANIER le matériel ou les CÂBLES lors d’activité

orageuse.

ATTENTION: LE CORDON D’ALIMENTATION SERT DE MISE HORS

CIRCUIT. POUR COUPER L’ALIMENTATION DU MATÉRIEL, débrancher le

cordon.

ÉQUIPEMENT DE CLASSE 1 ÉLECTRIQUE

CE MATÉRIEL DOIT ÊTRE MIS A LA TERRE. La prise de courant doit être

branchée dans une prise femelle correctement mise à la terre car des tensions

dangereuses risqueraient d’atteindre les pièces métalliques accessibles à

l’utilisateur.

EQUIPEMENT POUR BRANCHEMENT ELECTRIQUE, la prise de sortie doit

être placée près de l’équipement et facilement accessible”.

ATTENTION: Ne pas bloquer les fentes d’aération, ceci empêcherait l’air

ambiant de circuler librement pour le refroidissement.

TEMPÉRATURE DE FONCTIONNEMENT: AT-8948, x900-48FE,

x900-48FE-N, x900-48FS, AT-9900 series est capable de tolérer une

température ambiante maximum de ou 50 degrés C. AT-9924Ts, x900-12XT/S,

x900-24XT, x900-24XT-N, x900-24XS, SwitchBlade x908 est capable de tolérer

une température ambiante maximum de ou 40 degrés C.

SURCHARGE DES CIRCUITS PRINCIPAUX DE COURANT ALTERNATIF

ÉLECTRIQUE

Lors de l'installation du matériel, il faut prendre en compte la somme des

puissances indiquées sur les étiquettes au moment de connecter le matériel à

une source de courant alternatif.

41

Page 43

x900 Series Switch and SwitchBlade® x908

ATTENTION : RÉPARTITION DE LA CHARGE MÉCANIQUE - Le montage

du matériel dans le bâti doit être effectué de telle manière que la répartition de

la charge mécanique ne pose aucun danger.

Pile en Lithium-Doit uniquement être remplacée par un technicien dûment

qualifié

ATTENTION : Un danger d'explosion existe en cas de remplacement

incorrect de la pile. Remplacer uniquement avec une pile du même type ou d'un

type recommandé par le fabricant. Mettre au rebut lespiles usagées

conformément aux instructions du fabricant).

POUR TOUS PAYS: Installer le matériel conformément aux normes

électriques nationales et locales.

Avertissement: POUR UNE CONNEXION A UNE SOURCE

D’ALIMENTATION C.C. CENTRALISEE, L’INSTALLATION DOIT ETRE

UNIQUEMENT EFFECTUEE DANS UNE ZONE D’ACCES LIMITE.

Remarque: Un câble de chariot est requis pour connecter la source de

courant si l’unité est alimentée par une source de C.C. centralisée. Il doit s’agir

d’un câble agréé UL de type TC, d’une puissance de 600 V et de 90 degrés C,

avec trois fils conducteurs et un calibre minimum de 12 AWG (norme

américaine exprimant la section des fils).

Avertissement: SEUL UN PERSONNEL QUALIFIE ET ENTRAINE EST

AUTORISE A INSTALLER OU REMPLACER CET EQUIPEMENT.

42

Avertissement: Par mesure de sécurité, un disjoncteur de 15 A doit être

installé au point d’alimentation électrique du câble devant être utilisé avec cet

équipement de réseau local (LAN).

Connectez TOUJOURS le câblage à l’équipement LAN avant de le connecter

au disjoncteur. Pour éviter tout risque de blessure corporelle par électrocution,

ne travaillez pas lorsque le matériel est sous tension. Assurez-vous toujours que

le disjoncteur est bien en position d’ARRET avant de le connecter au câblage.

Avertissement: Ne coupez pas une quantité de câble supérieure à celle qui est

recommandée. Cela pourrait constituer un risque de sécurité en laissant du

câblage à nu sur le bornier après l’installation.

Avertissement: Lors de l’installation de cet équipement, vérifiez toujours que

la connexion de terre du châssis est installée en premier et débranchée en

dernier.

Avertissement: “Risque de sécurité” Vérifiez qu’aucun fil de cuivre dénudé

ne sort du câble installé. Lorsque cette installation est effectuée correctement,

aucun fil de cuivre ne devrait dépasser du bornier. Tout câblage dénudé peut être

conducteur de tensions dangereuses pour les personnes touchant les câbles.

Page 44

Installation and Safety Guide

Remarque: Ce système peut fonctionner avec des systèmes C.C. dotés d’une

mise à la terre positive ou négative.

Turvallisuus

VAROIT US: Kotiolosuhteissa tämä laite voi aiheuttaa radioaaltojen häiröitä,

missä tapauksessa laitteen käyttäjän on mahdollisesti ryhdyttävä tarpeellisiin

toimenpiteisiin.

VAROIT US Luokan 1 Lasertuote.

VAROIT US Älä katso säteeseen.

SÄHKÖÖN LIITTYVIÄ HUOMAUTUKSIA

VAROIT US: SÄHKÖISKUVAARA

Estääksesi SÄHKÖISKUN älä poista kantta. Sisällä ei ole käyttäjän huollettavissa

olevia osia. Tämä laite sisältää VAARALLISIA JÄNNITTEITÄ ja sen voi avata vain

koulutettu ja pätevä teknikko.

SALAMANISKUVAARA

HENGENVAARA: ÄLÄ TYÖSKENTELE laitteiden tai KAAPELEIDEN

KANSSA SALAMOINNIN AIKANA.

HUOMAUTUS: VIRTAJOHTOA KÄYTETÄÄN

VIRRANKATKAISULAITTEENA. VIRTA KATKAISTAAN irrottamalla virtajohto.

SÄHKÖ - TYYPPILUOKAN 1 LAITTEET

TÄMÄ LAITE TÄYTYY MAADOITTAA. Pistoke täytyy liittää kunnollisesti

maadoitettuun pistorasiaan. Virheellisesti johdotettu pistorasia voi altistaa

metalliosat vaarallisille jännitteille.

PISTORASIAAN KYTKETTÄVÄ LAITE; pistorasia on asennettava laitteen lähelle

ja siihen on oltava esteetön pääsy.”

HUOMAUTUS: Ilmavaihtoreikiä ei pidä tukkia ja niillä täytyy olla vapaa yhteys

ympäröivään huoneilmaan, jotta ilmanvaihto tapahtuisi.

KÄYTTÖLÄMPÖTILA: Tämä AT-8948, x900-48FE, x900-48FE-N,

x900-48FS, AT-9900 series katkaisin on suunniteltu ympäröivän ilman

maksimilämpötilalle 50° C. Tämä AT-9924Ts, x900-12XT/S, x900-24XT,

x900-24XT-N, x900-24XS, SwitchBlade

ilman maksimilämpötilalle 40° C.

SÄHKÖ-VAIHTORVIRTASÄHKÖPIIRIN YLIKUORMITUS

Tuotetta asennettaessa on otettava huomioon osien nimikilvissä osoitettu teho

silloin kun osat liitetetään vaihtovirtaverkkoon.

HUOMAUTUS: MEKAANINEN KUORMITUS--Osien asennuksen alustaan

tulee tapahtua siten, että epätasainen kuormitus ei aiheuta vaaraa.

x908 tuote on suunniteltu ympäröivän

43

Page 45

x900 Series Switch and SwitchBlade® x908

Litiumparisto - Vaihdon voi suorittaa vain koulutettu ja pätevä teknikko.

Varoitus: Räjähdysvaara, jos paristo on vaihdettu väärin. Vaihda vain samaan tai

vastaavaan tyyppiin, jota valmistaja suosittelee. Hävitä käytetyt paristot

valmistajan ohjeiden mukaan.

KAIKKI MAAT: Asenna tuote paikallisten ja kansallisten

sähköturvallisuusmääräysten mukaisesti.

Varoitus: KESKITETTY TASAVIRTAKYTKENTÄ ASENNETTAVA

AINOASTAAN TILAAN, JOHON ON RAJOITETTU PÄÄSY.

Huomaa: Virtalähteen kytkemiseen tarvitaan levykaapeli, jos yksikkö saa

tehonsa keskitetystä tasavirtalähteestä. Levykaapelin on oltava UL-luetteloitu

tyypin TC levykaapeli ja nimellisarvoiltaan 600 V ja 90° C, kolmijohtiminen,

minimi 12 AWG (American Wire Gauge -lankamitta).

Varoitus: TÄMÄN LAITTEEN SAA ASENTAA TAI VAIHTAA AINOASTAAN

KOULUTETTU JA AMMATTITAITOINEN HENKILÖKUNTA.

Varoitus: Tämän LAN-laitteen kanssa käytettävän kaapelin syöttöpäähän tulee

turvallisuussyistä asentaa 15 A virrankatkaisin.

Yhdistä johdot AINA ensin LAN-laitteeseen ennen virrankatkaisimeen

kytkemistä. Sähköiskusta johtuvien vammojen välttämiseksi älä käsittele

JÄNNITTEELLISIÄ johtoja. Varmista aina, että virrankatkaisin on pois päältä (off)

ennen kuin yhdistät johdot katkaisimeen.

Varoitus: Älä poista johtimesta päällystettä enempää kuin on suositeltu.

Päällysteen poistaminen suositusta pidemmältä matkalta voi aiheuttaa

turvallisuusriskin, sillä riviliittimeen jää asennuksen jälkeen paljaita johtimia.

Varoitus: Kun asennat tätä laitetta, varmista aina, että runkomaadoitettu liitin

kytketään ensin ja irrotetaan viimeiseksi.

Varoitus: Turvallisuusriski Tarkista, ettei asennetusta johtimesta näy paljaita

kuparisäikeitä. Kun asennus suoritetaan oikein, riviliittimestä ei pitäisi näkyä

paljaita kuparijohdinsäikeitä. Paljaat johtimet voivat aiheuttaa sähköiskuvaaran,

jos niihin kosketaan.

Huomaa: Tämä järjestelmä toimii positiivisesti tai negatiivisesti maadoitettujen

tasavirtajärjestelmien kanssa.

44

Page 46

Installation and Safety Guide

Norme di Sicurezza

AVVERTENZA: in ambiente domestico questo prodotto potrebbe causare

radio interferenza. In questo caso potrebbe richiedersi all’utente di prendere gli

adeguati provvedimenti.

AVVERTENZA Prodotto laser di Classe 1.

AVERT ENZA Non fissare il raggio con gli occhi.

AVVERTENZE ELETTRICHE

ATTENZIONE: PERICOLO DI SCOSSE ELETTRICHE

Per evitare SCOSSE ELETTRICHE non asportare il coperchio. Le componenti

interne non sono riparabili dall’utente. Questa unità ha TENSIONI

PERICOLOSE e va aperta solamente da un tecnico specializzato e qualificato.

PERICOLO DI FULMINI

PERICOLO: NON LAVORARE sul dispositivo o sui CAVI durante

PRECIPITAZIONI TEMPORALESCHE.

ATTENZIONE: IL CAVO DI ALIMENTAZIONE È USATO COME

DISPOSITIVO DI DISATTIVAZIONE. PER TOGLIERE LA CORRENTE AL

DISPOSITIVO staccare il cavo di alimentazione.

ELETTRICITÀ - DISPOSITIVI DI CLASSE 1

QUESTO DISPOSITIVO DEVE AVERE LA MESSA A TERRA. La spina deve

essere inserita in una presa di corrente specificamente dotata di messa a terra.