Page 1

Assembly, Operator's and

Parts Manual

Part No. P4166

07/02

Page 2

WARRANTY REGISTRATION AND POLICY

Buhler Manufacturing products are warranted for a period of twelve (12) months from

original date of purchase, by original purchaser, to be free from defects In material and

workmanship under correct, normal agricultural use and proper applications.

Buhler Manufacturing’s obligations under this warranty shall be limited to the repair or

exchange, at Buhler Manufacturing’s option, of any Buhler Manufacturing product or

part which proves to be defective as provided. Buhler Manufacturing reserves the right

to either inspect the product at the buyer’s location or have it returned to the factory for

inspection.

The above warranty does not extend to goods damaged or subject to accident, abuse

or misuse after shipment from Buhler Manufacturing’s factory, nor to goods altered or

repaired by anyone other than an authorized Buhler Manufacturing representative.

Buhler Manufacturing makes no Express Warranties other than those which are

specifically described. Any description of goods, including any references and

specifications In catalogues, circulars and other written material published is for the sole

purpose of identifying goods and shall conform to such descriptions. Any sample or

model is for illustrative purposes only and does not create an Express Warranty that the

goods conform to sample or model shown.

The purchaser is solely responsible for determining suitability of goods sold. This

warranty Is expressly in lieu of all other warranties expressed or implied. Buhler

Manufacturing will in no event be liable for any incidental or consequential damages

whatsoever, nor for any sum in excess of the price received for the goods for which

liability is claimed.

WARRANTY CLAIMS:

Warranty requests must be prepared on Buhler Manufacturing Warranty Claim Forms

with ail requested Information properly completed. Warranty Claims must be submitted

within a thirty (30) day period from date of failure repair.

WARRANTY LABOR:

Any labor subject to warranty must be authorized by Buhler Manufacturing. The labor

rate for replacing defective parts, where applicable, will be credited at a rate determined

by the Company, Buhler Manufacturing.

IMPORTANT FACTS:

Buckets and Bucket Tines Carry No Warranty

Bent Spears Carry No Warranty

Snowblower Fan Shafts Carry No Warranty

Mower Blades Carry No Warranty

Portable Auger Parts Have Two (2) Year Warranty

Loader Parts Have Two (2) Year Warranty

PRINTED IN CANADA

Page 3

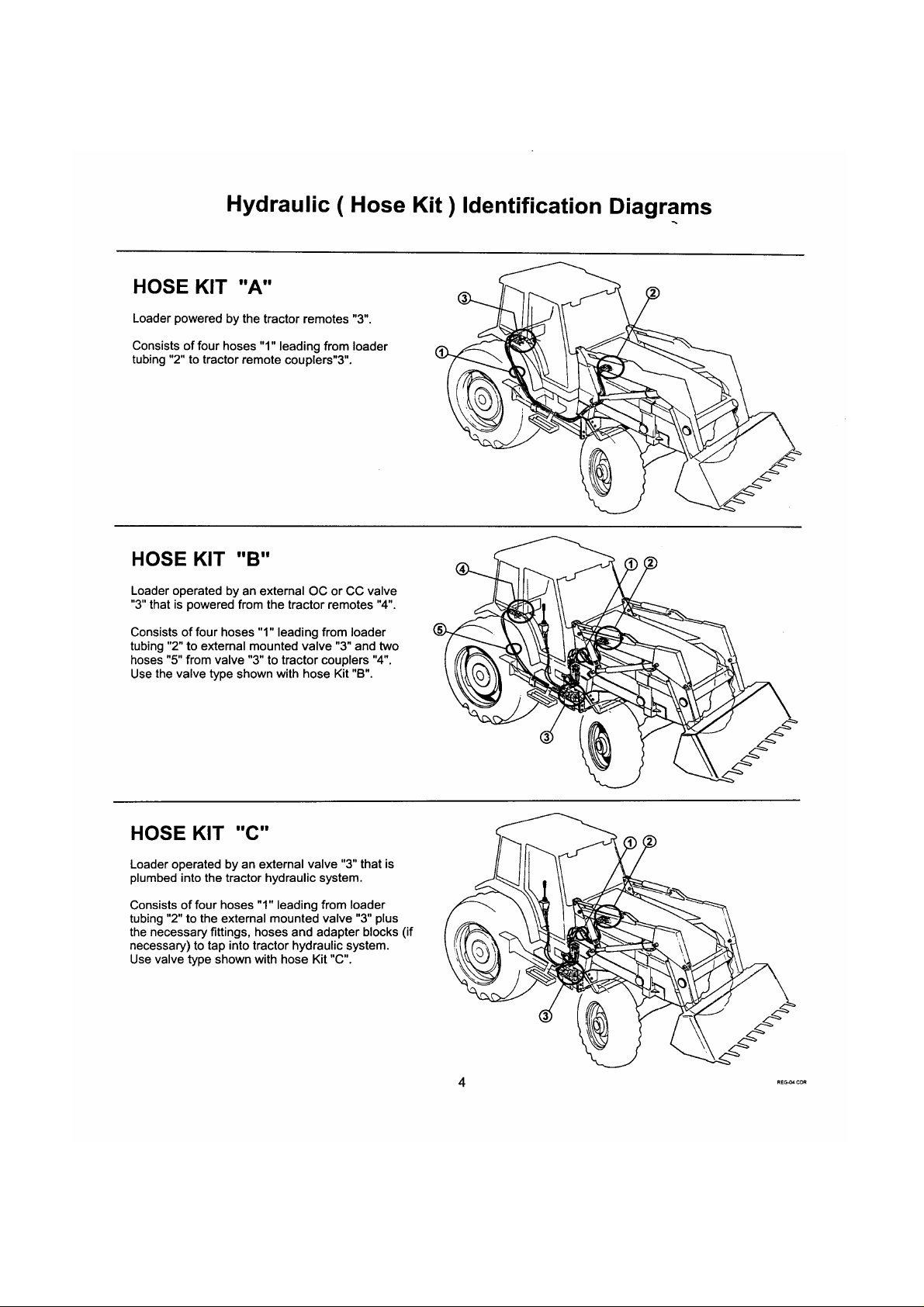

Page 4

Page 5

Page 6

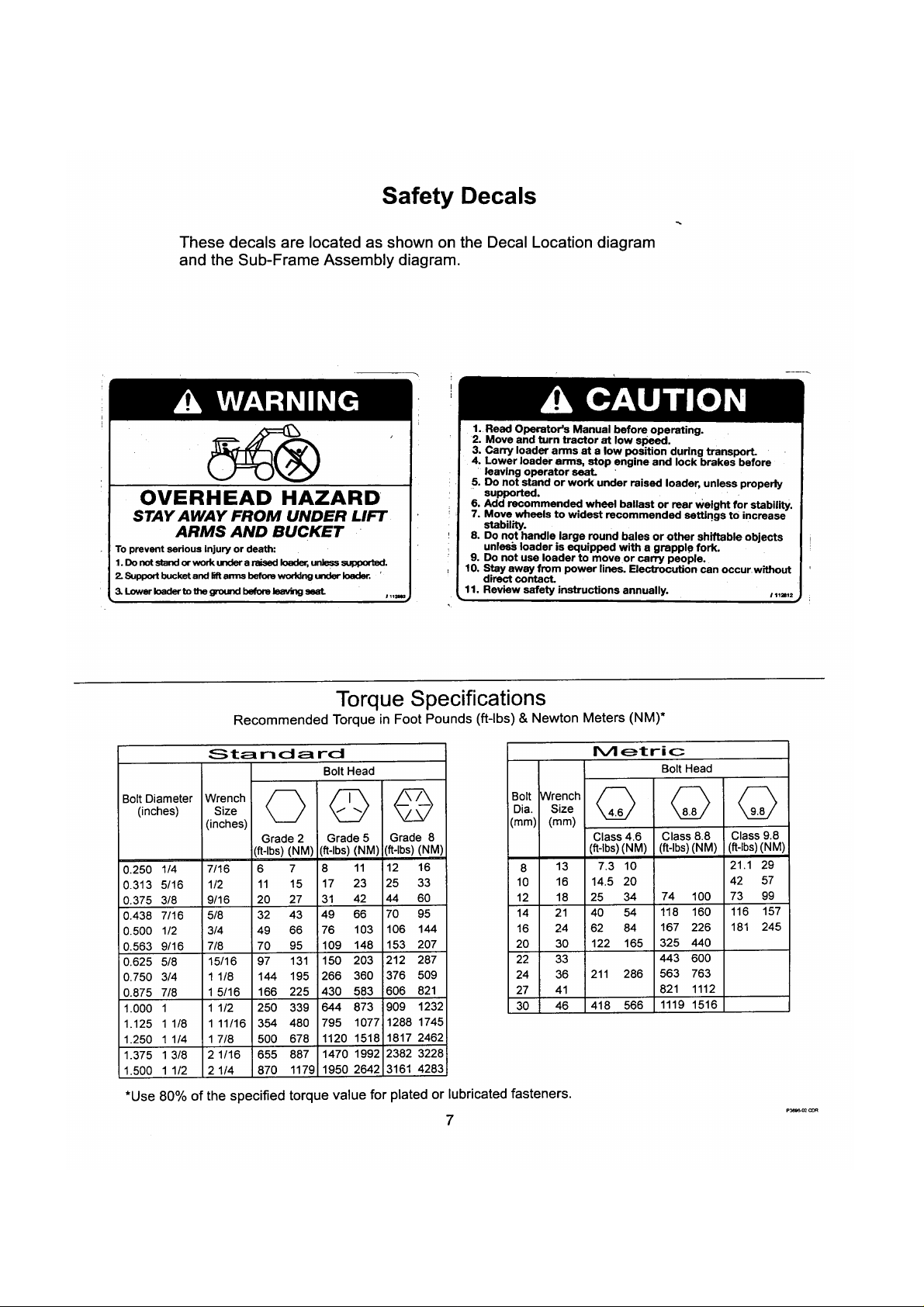

Page 7

Page 8

Page 9

Page 10

Page 11

General Instructions and Information

As with any piece of equipment, the care with which your loader is operated

and maintained wiii greatly affect it's iife and the safety of the people using it.

1. Keep ali pivots weli iubricated for ionger bushing iife. Inspect every 500

hours of operation for wear.

2. Periodicaliy check ali boits for tightness. If any bolt is damaged, replace it

with a boit of equivaient grade or strength.

3. Foliow the recommendations of the tractor manufacturer in regards to the

quantity of oii used.

4. Check oii level frequently to ensure the system is fuii.

5. When making an oii check, be sure iift cylinders are retracted.

6. Before operating the loader, particularly if the loader is left standing for

any length of time, check the hydrauiic system and oil level.

7. When installing hydrauiics, foilow the circuit carefuiiy. See hydraulic

hook-up section and make sure the hoses do not contact any hot

manifolds or sharp edges on tractor. After assembly, raise the loader slowly

and check to make sure that the hoses do not bind in all positions.

CAUTION I

The pressure of the relief and open centre valves is set at the factory. Do

not tamper with the setting. Serious injury to the operator or damage to the

loader or tractor hydraulics may occur. Warranty will be void if the loader is

operated above recommended pressure.

8. When servicing any hydraulic components, care must be taken to prevent

any foreign matter from entering the system.

9. Do not neglect oil leaks. Leaks affect loader operation, are dangerous and

can result in personal injury or damage to the hydraulic system.

10. Never leave the cylinder shafts exposed when loader is not in use.

11. Worn or damaged components should be replaced as soon as possible with

only the manufacturer's recommended component or equivalent.

Page 12

Page 13

Page 14

Page 15

Page 16

Page 17

Page 18

Page 19

Trouble Shooting

PROBLEM

Loader slow and/or will not dump. Quick couplers leaking.

Loader chatters or vibrates when

raising and lowering.

Excessive movement at pivots

Pump noisy Inlet line restricted or leaking.

Oil leaks.

Insufficient lift capacity

Slow leakdown.

Excessive wear on bottom oil bucke Float position not used while operati Use float position provided on valve,

and wear pads. loader.

Hydraulic cylinders inoperative.

Pump operating continually on clos Tractor control valve relief stuck

center tractor hydraulic system. open.

Loader lift and bucket tilt controls d Hoses improperly connected,

not work according to decal.

Valve noisy and/or hot

Tractor loads/pump squeals

POSSIBLE CAUSE

Hydraulic oil too heavy.

Oil filter plugged.

Hydraulic pump worn.

Oil line restricted or leaking.

Control valve does not shift properly. Inspect, clean, repair or replace valve.

Air in hydraulic system. Cycle lift cylinders and bucket cylinders

Cylinder leaks internally. Replace seals.

Faulty valve. Repair or replace valve.

Air leak in pump inlet line.

Air in hydraulic system.

Oil level too low.

Worn bushings and/or pins.

Oil level too low.

Pump worn or damaged.

Damaged fittings or hoses.

Loose connections.

Worn or damaged O-ring wiper

seal in cylinder rod end.

Worn or damaged O-rings in valve.

Improper hydraulic pump operation. Repair or replace pump.

Load is greater than boom lift capaci Check loader specifications.

Internal boom cylinder leakage. Replace any worn parts and install

Improper hydraulic valve operation. Repair or replace valve.

Worn control valve.

Worn cylinder piston seals.

Hose from control valve improperly

connected.

Hydraulic control valve set too low.

Open center control valve on closed Replace relief valve with closed center plug

center tractor. and plug the power beyond adapter on valve.

Closed center control valve on open Install open center plug on optional valve,

center tractor. Replace closed center plug with relief and

REMEDY

Check connections and compatibility or

replace.

Change or replace filter.

Clean or replace filter.

Repair or replace pump.

Check all hoses and tubes for leaks,

damage or restrictions. Replace damaged

or restricted hoses or tube lines.

several times to free system of air.

Check, tighten or replace inlet line.

Cycle lift cylinders and bucket cylinders.

Add oil as required.

Replace bushings and/or pins.

Check for air leaks, restrictions or collapsed

hose. Tighten or replace hose. Clean

filter if necessary.

Add oil as required.

Repair or replace pump.

Replace damaged parts.

Tighten fittings.

Install a seal repair kit.

Install an O-ring repair kit.

a seal repair kit.

Have authorized dealer replace seals.

Have authorized dealer replace seals.

Referto plumbing diagrams.

See your tractor manual for proper

adjustment or Loader dealer for loader

valve. (3000 PSI is maximum pressure

relief setting recommended.)

Adjust valve in accordance with manual.

Refer to plumbing diagrams

and correct hose connections.

install short plug in place of power beyond

adapter.

17

Page 20

Page 21

95,195 Sub Frame Parts Table

Item Part No. Description

1 -

^245T8 Upright Weldment

2 24509

3

5 113555

6 113556

24519

113427

......

TT3557

8 113558 Shim

9 113462

.j-Q -

“T13460

11 113444

12

113418

13 113281

14a

113387 Loader Lift Lock 95 Ldr

14b 115758

15 813059

16

813060

17 812026

18

19

87553

81627

20 812088

21

"^1966

22 113685

23 81677

24^ T428T2” Decal General Caution

25

26

28

113481 Decal - 95

113501 Decal -195

27^

“113474 Decal Cross Member

112982

29 113661

195 Subframe Weldment (Left)

195 Subframe Weldment (Right)

Strut Arm

Hook Weldment

Plate Clamp

Spacer Blocfr

Grill Guard Weldment

Grill Guard Bracks

Cross Member Weldment

Pivot Shaft 1.5 dia. x 5.5 long

Bolt Retainer Weldment

Loader Lift Lock 195 Ldr

Bolt Carr. 0.5 X 2.0 nc gr5 pi

Bolt Carr. 0.5 X 3.0 nc gr5 pi

Bolt Hex 0.313 X 1.0 nc gr5 pi

Bolt Hex 0.5 X 1.75 nc gr5 pi

Bolt Hex 0.5 X 3.0 nc gr5 pi

Bolt Hex 0.625 x 7.0 nc gr5 pi

NuTLock 0.5 nc pi

Washer Boot

Washer Lock 0.625 pi

Decal Lift Lock Instruction

Wrench

95

2~

- 1

-

4

- 2

-

- 8

-

1

1

2

2

2

-

-

2

8

2

2

12

2

2

2

2

-

-

-

1

195

-

1

-

2

2

-

1

2

2

-

2

4

8

2

-

-

2

12

2

2

2

-

2

2

2

1

19

Page 22

Page 23

95,195 Main Frame Parts Table

Item Part No.

24520

1

2

2

3

24528

XI344 48.0" Bucket

XI345

113467

4 113463

113465

5”

E~~

16035

12779

113535

113565

104719

6

7

8

9

106674

13“

T6~

113428

113473

- Bucket Cylinder

-

810640

84277

84541

81344

81966

113576

113577

112613

112983

52281-000

11

12

14

15

17

18

19

20

21

22

23

24

^5 8TOZ

Description

95 Mainframe Weldment

195 Mainframe Weldment

60.0" Bucket

Loader Stand L.H.

Loader Stand R.H.

Stand Arm

Pin 0.5 dia.

Hair Pin Clip # 9 Western Wire

LevBlIing Rod

Levelling Rod

Pin 1.0 dia. X 6.0 long

Pin 0.75 dia. X 6.0 long

Pin 0.75 dia. x 5.0 long

Tube Cover

Lift Cylinder

Bolt Hex 0.313nc x 2.0 gr5 pi

Bolt Hex 0.50nc X 1.50gr5pl

Nut Lock (nylon) 0.313nc pi

Nut Lock (nylon) 0.375nc pi

Nut Lock (nylon) O.bOnc pi

Bushing 0.75 ID X 1.0 OD

Bushing 1.0 ID X 1.25 OD

Decal - Allied x 1.40

Decal - No Standing Under

Bright Orange Scotchcal # 72368

Cotter

95 195

-

-

- -

- -

1 1

1 1

2 2

2 2

2 2

1

-

2 2

6 6

4

1 1

2

2

12

2

12

2

4

-

-

2

2

6ft

1

-

1

4

2

2

12

2

12

2

4

2

2

2

2

7ft

XI755 DECAL REPLACEMENT KIT 95LDR

XI756 DECAL REPLACEMENT KIT 195LDR

21

Page 24

Page 25

95,195 Plumbing Parts Table

Item Part No. Description

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

-

-

813104

113684

113683

113450

113451

113452

113453

113454

113455

113456

812296

811918

812313

11362

81344

113483

Bucket Cylinder

Lift Cylinder

Hose 3/8 X 16.0 long 9/16 SWFJIC x 9/16 SWFJIC

Hose 3/8 X 10.0 long 9/16 SWFJIC x 9/16 MORB

Hose 3/8 X 14.0 long 9/16 SWFJIC x 9/16 MORB

Tubing - Lift Cyl. Top Drop

Tubing - Lift Cyl. Common (12.0")

Tubing - Lift Cyl. Common (15.0")

Tubing - Lift Cyl. Bottom ( Raise )

Tubing - Bucket Cyl. Bottom ( Rollback )

Tubing - Bucket Cyl. Top ( Dump )

Tubing - Bucket Cyl. Cross Tube

Elbow 90 - 9/16 MJIC X 9/16 MJIC

Elbow 90 - 9/16 MORB x 9/16 MJIC

Tee 9/16 MJIC x 9/16 MJIC x 9/16 MJIC

Clip Pipe Std.

Nut Lock ( nylon ) 0.375 nc pi

Hose 3/8 X 20.0 long 9/16 SWFJIC x 9/16 SWFJIC

95 195

2 2

2 2

6 2

2

-

1 1

1 1

1

1 1

1

1

2

4

6

4

5

3

-

2

2

1

1

1

2

4

4

4

5

3

2

23

Page 26

Page 27

Page 28

Page 29

Loading...

Loading...