Page 1

AFFIX LABEL HERE

INSTALLATION AND SERVICING INSTRUCTIONS

UPFLOW, DOWNFLOW OR HORIZONTAL

TWO STAGE HEAT VARIABLE SPEED

GAS-FIRED NON-CONDENSING

WARM AIR FURNACE

TABLE OF CONTENTS

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Issue 0527

Gas Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Furnace Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Furnace Wiring Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Location/Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Air for Combustion & Ventilation . . . . . . . . . . . . . . . . . . . . . . . . 8

Ducting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE

Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

Installation and service must be performed

by a qualified installer, service agency or

the gas supplier. Installation by an

unqualified person may lead to equipment

damage and/or a hazardous condition

which may cause bodily injury and harm

and, as such, at the sole discretion of the

manufacturer, the entire warranty may be

voided and be of no further force and

effect.

Control Board & Variable Speed Motor Features . . . . . . . . . . . . . 17

Unit Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Start-Up Operation & Checkout . . . . . . . . . . . . . . . . . . . . . . . . . 19

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Servicing The Furnace . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Control System Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

WHAT TO DO IF YOU SMELL GAS:

• Do not try to light any appliance.

• Extinguish any open flame.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier from

a neighbor's phone. Follow the gas

supplier's instructions.

• If you cannot reach your gas supplier,

call the fire department.

20571201 Issue 0527 Page 1 of 28

Page 2

SAFETY

The following is a list of safety precautions and their locations in this manual.

These safety rules and precautions must be followed when installing this furnace.

1. Use only with type of gas approved for this furnace. Refer to the furnace rating

plate.

2. Install this furnace only in a location and position as specified in The

Location/Placement Section on page 7 of these instructions.

3. Provide adequate combustion and ventilation air to the furnace space as

specified in Air for Combustion and Ventilation section on page 8 of these

instructions.

4. Combustion products must be discharged outdoors. Connect this furnace to an

approved vent system only, as specified in Venting on page 12 of these

instructions.

5. Never test for gas leaks with an open flame. Use a commercially available

soap solution made specifically for the detection of leaks to check all

connections, as specified in The Gas Connection section on page 16 of these

instructions.

6. Always install furnace to operate within the furnace's intended temperature-rise

range with a duct system which has an external static pressure within the

allowable range, as specified in Furnace Specifications on page 3 of these

instructions. See furnace rating plate.

7. When a furnace is installed so that supply ducts carry air circulated by the

furnace to areas outside the space containing the furnace, the return air shall

also be handled by duct(s) sealed to the furnace casing and terminating outside

the space containing the furnace. See page 11 for Ducting.

8. A gas-fired furnace for installation in a residential garage must be installed as

specified in The Location / Placement section on page 7 of these instructions.

9. It is not recommended that this furnace be used as a construction heater during

any phase of construction. Very low return air temperatures, harmful vapors

and operation of the unit with clogged or misplaced filters will damage the unit.

The unit may only be used for heating of buildings or structures under

construction, if the conditions listed on page 6 in the "Introduction" section of

these instructions are met.

20571201 Issue 0527 Page 2 of 28

Page 3

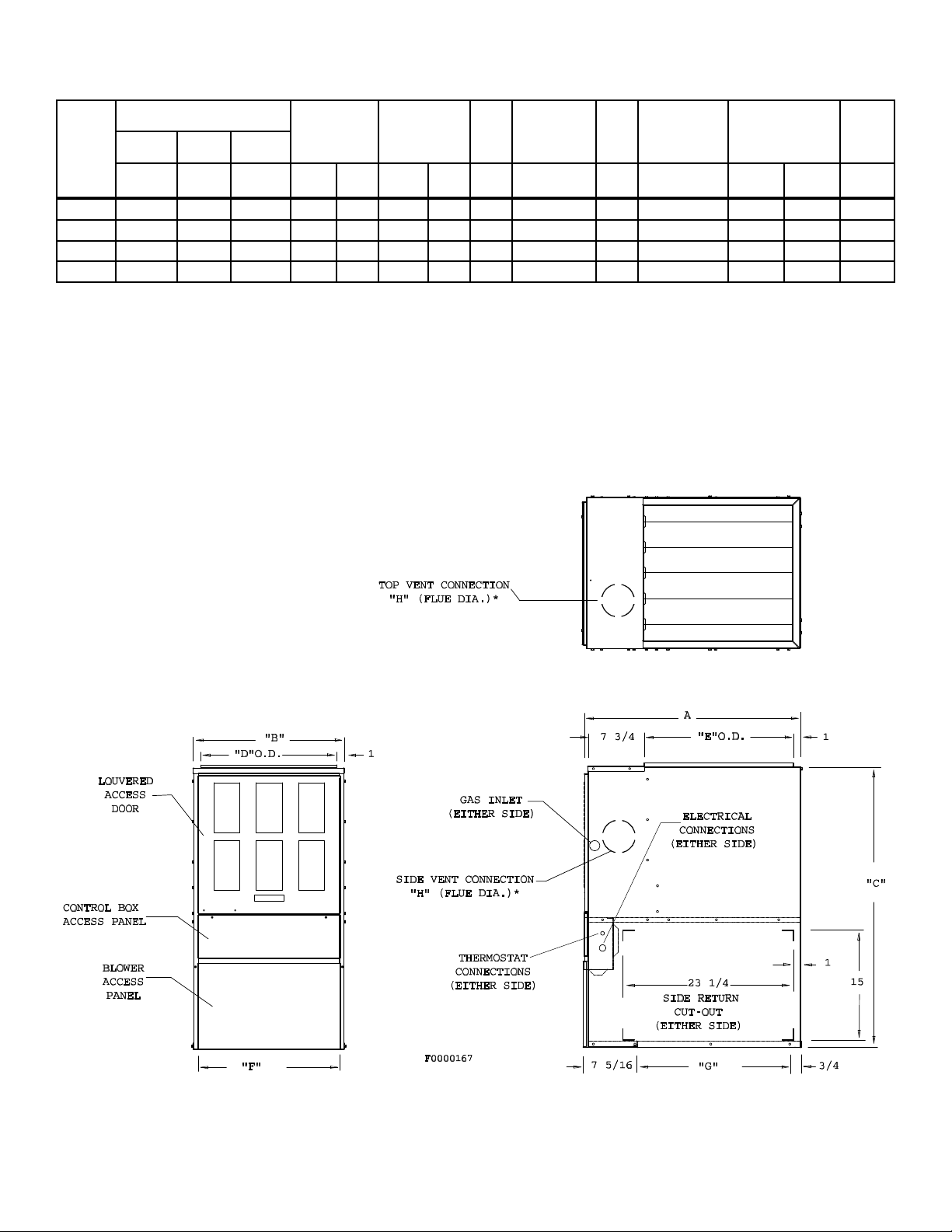

FURNACE SPECIFICATIONS

UNIT DIMENSIONS

MODEL

AV050B3 29 1/2 13 1/2 38 1/4 11 1/2 20 3/8 12 21 5/8 4 15 9.9 14 30 - 60 40 - 70 105

AV075B3 29 1/2 13 1/2 38 1/4 11 1/2 20 3/8 12 21 5/8 4 15 9.9 14 30 - 60 40 - 70 113

AV100B4 29 1/2 17 38 1/4 15 20 3/8 15 1/2 21 5/8 4 15 11.7 14 30 - 60 40 - 70 141

AV125B5 29 1/2 20 1/2 38 1/4 18 1/2 20 3/8 19 21 5/8 4 20 11.7 14 30 - 60 40 - 70 167

LENGTH WIDTH HEIGHT

A B C D E F G H

DUCT SUPPLY

OPENING

DUCT RETURN

OPENING

VENT

PIPE

DIA.

MAX. OVER

CURRENT

PROTECTION

AMPS

MAX.

UNIT

ELECTRICAL

SUPPLY MIN.

WIRE

SIZE(AWG)

TEMPERATURE

RISE

RANGE

LOW

FIRE

HIGH

FIRE

WEIGHT

* REDUCER SUPPLIED WITH FURNACE WHEN CONNECTION SIZE

IS DIFFERENT THAN PIPE DIA. REQUIRED (H) FOR FLUE VENT

PIPE.

NET

LBS

20571201 Issue 0527 Page 3 of 28

Page 4

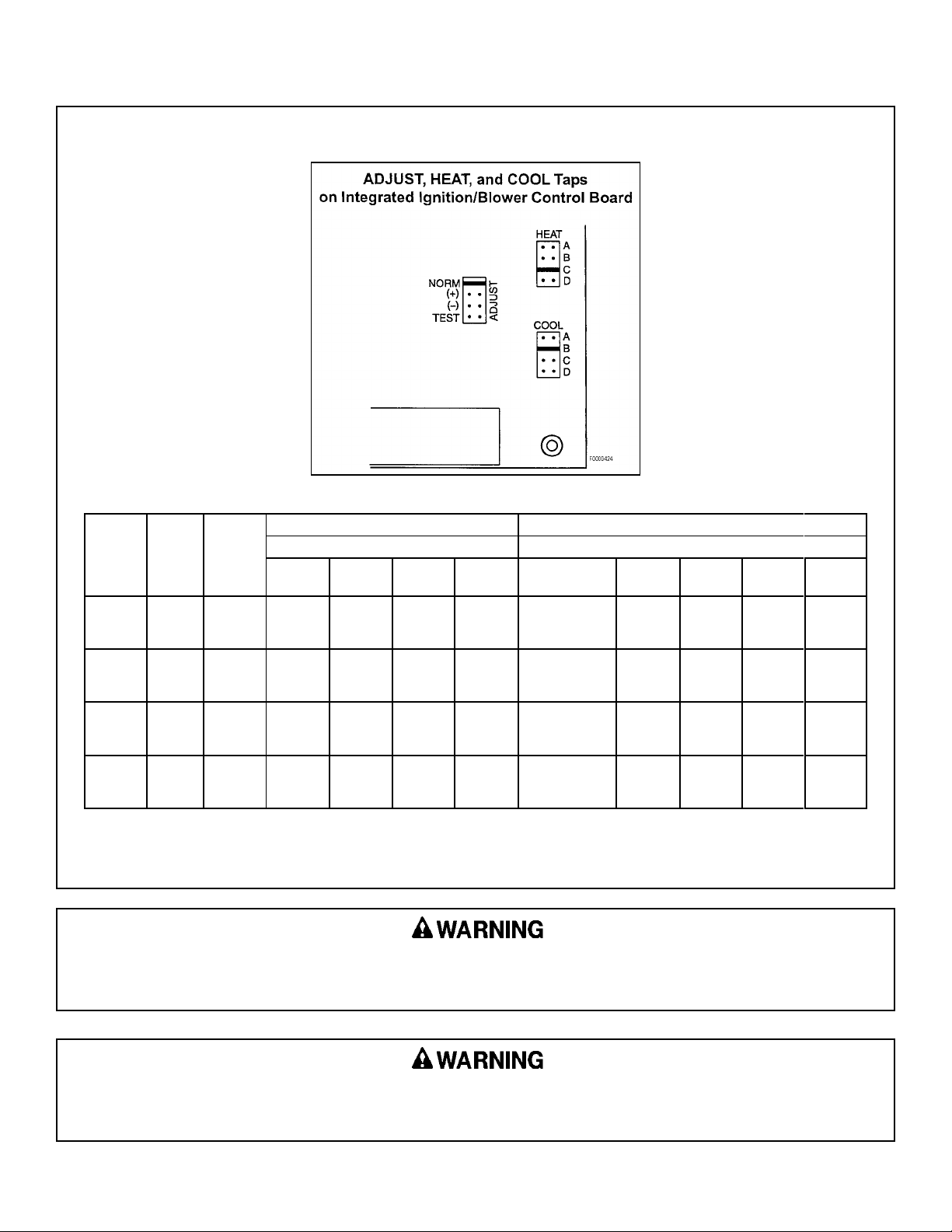

BLOWER MOTOR SPECIFICATIONS AND AIRFLOW ADJUSTING DATA

Adjusting Airflow

HEAT SETTINGS COOL SETTINGS

MODEL

AV050B3 1/2 10 X 6 525 425 325 625

AV075B3 1/2 10 X 6 740 640 540 840

AV100B4 3/4 12 X 9 1250 1150 1050 1350

AV125B5 3/4 12 X 12 1650 1550 1450 1750

THE UNIT, AS SHIPPED, IS FACTORY SET AT SETTING "A" TO RUN AT THE MIDDLE OF THE HEATING RISE RANGE SHOWN ON THE

UNIT RATING LABEL.

MOTORHPBLOWER

WHEEL

HEATING CFM @ .50 STATIC COOL CFM @ .50 STATIC

SETTING

"A"

SETTING

"B"

SETTING

"C"

SETTING

"D"

COOLING

ADJUSTMENT

NORM

( + )

( - )

NORM

( + )

( - )

NORM

( + )

( - )

NORM

( + )

( - )

SETTING

"A"

1200

1380

1020

1200

1380

1020

1600

1800

1360

2000

2200

1700

SETTING

"B"

1000

1150

850

1000

1150

850

1400

1610

1190

1800

2070

1530

SETTING

"C"

800

920

680

800

920

680

1200

1380

1020

1600

1840

1360

SETTING

"D"

600

690

510

600

690

510

1000

1150

850

1400

1610

1190

When operating the furnace in the heating mode, the static pressure and the temperature rise (supply air temperature

minus return air temperature) must be within those limits specified on the rating label. Failure to follow this warning

could lead to severe furnace damage.

Turn OFF all gas and electrical power to furnace before performing any maintenance or service on unit. (Unless

specific test requires gas and electrical supplies.) Failure to take this precaution may result in personal injury due

to electrical shock or uncontrolled gas leakage.

20571201 Issue 0527 Page 4 of 28

Page 5

FURNACE WIRING SPECIFICATIONS

20571201 Issue 0527 Page 5 of 28

Page 6

The furnace cabinet must have an uninterrupted or unbroken electrical ground to minimize personal injury if an

electrical fault should occur. The unit must also be electrically grounded in accordance with local codes, or in the

absence of local codes, with the latest edition of the (U.S.) National Electrical Code ANSI/NFPA No. 70 or CSA

Standard C22.1; Part 1 Canadian Electrical Code, if an external electrical source is utilized. DO NOT use gas piping

as an electrical ground.

INTRODUCTION

This furnace is design certified by CSA International as a Category I furnace using air from inside the structure for

combustion.

It is shipped as a packaged unit, complete with burners and controls, and requires a line voltage (115V) connection to

the junction box, a thermostat hook-up as per the wiring diagram and a gas line connection, ducting and flue piping. This

furnace can be installed in either upflow, downflow or horizontal airflow positions, at no time should this unit be

operated on its back. The design of this furnace is NOT CSA Certified for installation in recreation vehicles, in

manufactured (mobil) homes, outdoors or as a construction heater.

This furnace has been designed to interface with split system cooling equipment (approved by a nationally recognized

testing laboratory) so as to provide "year round air conditioning". The blower has been sized for both heating and cooling

and the furnace controls include a cooling fan relay.

The furnace installation must conform with local building codes or in the absence of local codes, with the latest edition

of the (U.S.) National Fuel Gas Code ANSI Z223.1 (NFPA-54) or Canadian Natural Gas and Propane Installation Codes

CSA B149.1.

For complete information on installation standards consult the (U.S.) National Fuel Gas Code, obtainable from the

National Fire Protection Association, Inc., Batterymarch Park, Quincy, MA 02269 or the American Gas Association, 1515

Wilson Boulevard Arlington, VA 22209 or the Canadian installation codes obtainable from Canadian Standards Association,

178 Rexdale Boulevard, Etobicoke, Ontario, Canada M9W 1R3.

This furnace is designed for minimum continuous return-air temperature of 60°F dB or intermittent operation down to

55°F dB such as when used with a night setback thermostat. Return-air must not exceed a maximum continuous

temperature of 85°F dB.

The furnace may be used for heating of buildings or structures under construction, if the following conditions are met:

• The vent system must be permanently installed per these instructions.

• A room thermostat must control the furnace. The use of fixed jumpers that will provide continuous heating is not

allowed.

• The return air duct must be provided and sealed to the furnace.

• Return air temperature range between 60° F and 80° F must be maintained.

• Air filters must be installed in the system and must be maintained during construction.

• Air filters must be replaced upon construction completion.

• The input rate and temperature rise must be set per the furnace rating plate.

• One hundred percent (100%) outdoor air must be provided for combustion air requirements during construction.

Temporary ducting may supply outdoor air to the furnace. Do not connect combustion air duct directly to the

furnace. Size the temporary duct following these instructions in the section "Air for Combustion & Ventilation" for

air in a confined space with air from outside.

• The furnace heat exchanger, components, duct system, air filters and evaporator coils must be thoroughly cleaned

following final construction clean-up.

• All furnace operating conditions (including ignition, input rate, temperature rise and venting) must be verified

according to these installation instructions.

These instructions are written for individual residential installation only. For multi-unit installation or

commercial applications, please contact manufacturer for recommendations.

20571201 Issue 0527 Page 6 of 28

Page 7

LOCATION / PLACEMENT

Site Selection: This furnace may be located in an attic, closet, basement, crawl space, alcove or suspended from the

ceiling of a utility room or basement. Select a location that will meet all requirements for safety,

clearances, ventilation and combustion air, ductwork design, gas piping, electrical wiring and venting.

Clearances: The following minimum clearances, or greater, must be provided between the furnace and adjacent

construction.

TABLE 1 MINIMUM INSTALLATION CLEARANCES

"UPFLOW" POSITION "DOWNFLOW" POSITION "HORIZONTAL" POSITION

Suitable for alcove or closet

installation† on combustible

flooring at minimum

clearance from adjacent

construction not less than

the following:

Top Sides Back Front Vent

2" 1" 1" 6" 6" with single wall vent

2" 1" 1" 3" 1" with B1 vent

† For closet installation see Air for Combustion and Ventilation.

Suitable for alcove or closet installation† on noncombustible flooring at minimum clearance from

adjacent construction not less than the following:

* Installation on combustible flooring only when

installed on special base (see model & rating label

for proper special base).

Suitable for attic, alcove or closet installation† on

combustible flooring at minimum clearance from

adjacent construction not less than the following:

* Line contact only permissible between lines

formed by intersection of the top and two sides of

the furnace jacket and building joist, studs, or

framing.

Failure to comply with all of the clearances will

create a fire hazard.

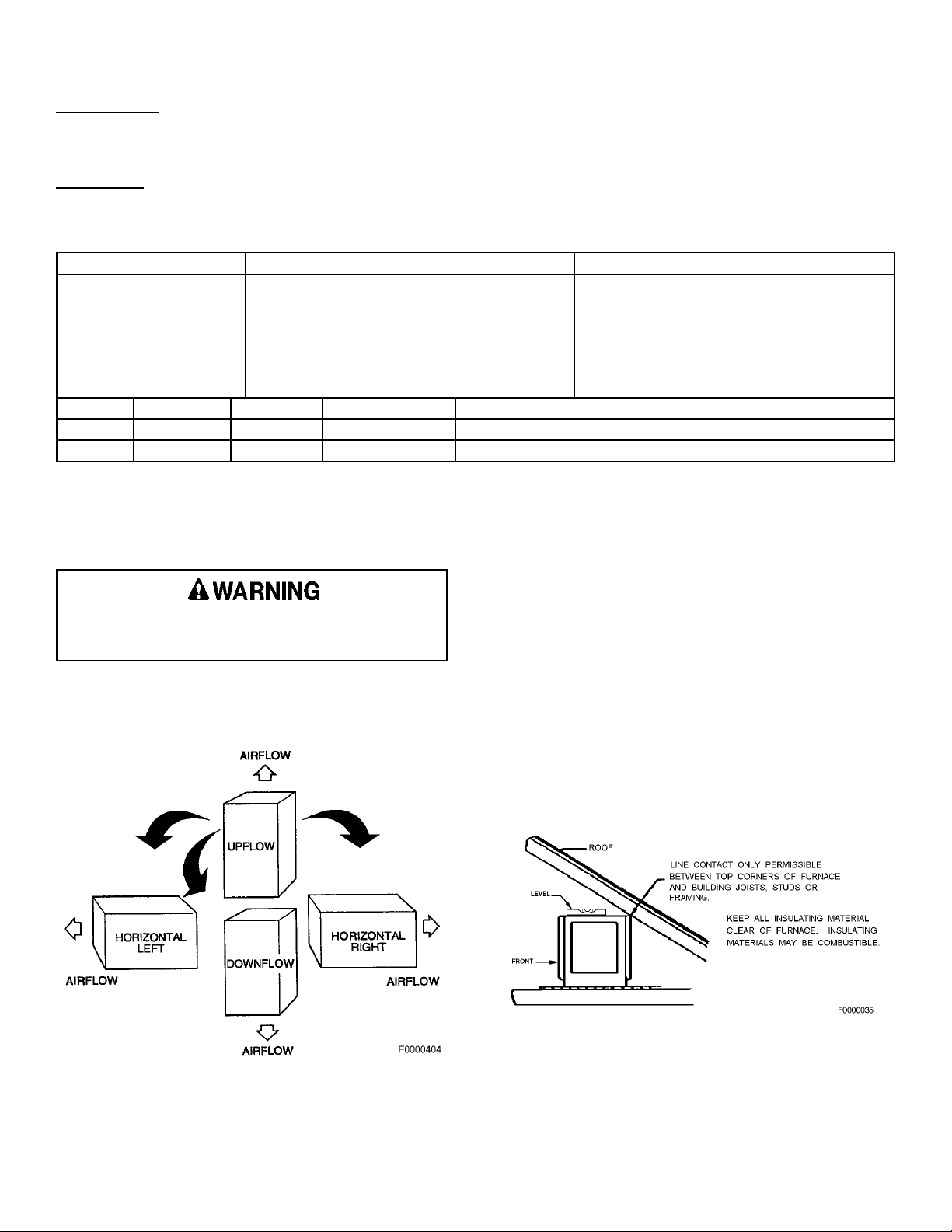

INSTALLATION POSITIONS

flooring, on wood flooring in the upflow or horizontal

positions, however, it must not be installed directly on

carpeting, tile or any other combustible material. In

the downflow position, it must be installed on noncombustible flooring, on the special base listed on the

rating label OR on a cased coil.

In a horizontal position, line contact with combustibles

is only permissible between lines formed by the

intersection of the furnace top, the front and back sides,

and building joists, studs or framing (See Figure 1).

Figure 1

HORIZONTAL LINE CONTACT

Furnace must not lean back. It must be level or

tilt up to 2° to the front. (See Figure 1.)

The furnace should also be located as near to the

center of the air distribution system as possible, and

should be installed level.

This furnace may be installed on non-combustible

20571201 Issue 0527 Page 7 of 28

A clearance of at least 30" should be provided at the

front of the unit for servicing. For attic installations, the

passageway and servicing area adjacent to the furnace

should be floored.

Page 8

If the furnace is to be installed in a crawl space,

consult local codes. (Use of a concrete pad 1" to 2" thick

is recommended.)

If the furnace is to be suspended from the ceiling, it

will be necessary to use steel pipe straps around each

end of the furnace. These straps should be attached to

the furnace with sheet metal screws and to the rafters

with bolts. The furnace may also be suspended by using

an angle iron frame bolted to the rafters. (See Table on

page 3 for size and weight of furnace.) Care must be

taken to allow for service access.

If a furnace is to be installed in a residential garage,

it must be installed so the burners and the ignition source

are located not less than 18" above the floor and the

furnace must be located or protected to avoid physical

damage by vehicles.

AIR FOR COMBUSTION AND VENTILATION

Do not place combustible material on the furnace

jacket. Failure to comply with this warning will

create a fire hazard.

This furnace is not watertight and is not designed

for outdoor installation. This furnace shall be

installed in such a manner as to protect the

electrical components from water. Outdoor

installation would lead to a hazardous electrical

condition and to premature furnace failure.

Contaminated Combustion Air:

This furnace is not to be installed in a structure

defined as having contaminated combustion air. Allowing

exposure to substances containing chlorine or fluoride

could harm the furnace and void the warranty.

Substances to avoid include, but are not limited to:

• Permanent wave solutions

• Chlorinated waxes and cleaners

• Chlorine based swimming pool chemicals

• Water softening chemicals

• De-icing salts or chemical

• Carbon tetrachloride

• Halogen type refrigerants

• Cleaning solvents (such as perchloroethylene)

• Printing inks, paint removers, varnishes, etc.

• Hydrochloric acid

• Cements and glues

• Antistatic fabric softeners for clothes dryers

• Masonry acid washing materials

• Unrefined gases

Contaminated combustion air may cause premature

failure of the heat exchanger that may lead to a

hazardous condition and/or bodily harm, or loss of

life.

Adequate Ventilation and Combustion Air:

This section is provided to give guidelines for the

introduction of air for ventilation and combustion air. The

total quantity of air provided to the installation area must

equal the requirements of all gas appliances in the area.

Adequate facilities for providing air for combustion

and ventilation must be provided in accordance with the

latest edition of the National Fuel Gas Code ANSI

Z223.1/NFPA54 or CSA B149.1 Natural Gas and Propane

Installation Codes, or applicable provisions of the local

building codes.

The furnace shall be installed in a location in which

the facilities for ventilation permits satisfactory combustion

of gas, proper venting and maintenance of ambient

temperature at safe limits under normal conditions of use.

The furnace shall be located so as not to interfere with

proper circulation of air.

In addition to air needed for combustion, ventilation in

the form of process air must be provided as required for:

cooling of equipment or material, controlling dew point,

heating, drying, oxidation or dilution, safety exhaust and

odor control. Air must be supplied for ventilation,

including all air required for comfort and proper working

conditions for personnel.

For purposes of this instruction the following

definitions apply:

Confined Space: A space whose volume is less

than 50 cubic feet per 1000

Btu/hr of the aggregate input

rating of all appliances installed

in that space.

Unconfined Space: A space whose volume is not

less than 50 cubic feet per 1000

Btu/hr of the aggregate input

rating of all appliances installed

in that space. Rooms

communicating directly with the

space in which the appliances

are installed, through openings

not furnished with doors, are

considered a part of the

unconfined space.

20571201 Issue 0527 Page 8 of 28

Page 9

If the installation area meets the definition of

"Unconfined Space" and does not have additional air

requirements as described, the furnace may be installed

without making special provisions for combustion and

ventilation air.

Do not block the combustion or ventilation air

openings in the furnace. Any blockage will result in

improper combustion and may result in a fire

hazard or unsafe condition.

Whenever this furnace is installed in an area along

with one or more gas appliances, the total Btu/hr

input of all appliances must be included when

determining the free area requirements for

combustion and ventilation air openings.

If ventilation and/or combustion air must be supplied to the "Confined Space" from inside the building structure, two

permanent openings to an additional room of sufficient volume as to combine the volumes of the spaces to meet the

criteria for an "Unconfined Space" must be created. Each opening must have a free area of not less than one square

inch per 1000 Btu per hour of total input of all appliances within the "Confined Space" (but not less than 100 square

inches). These openings must be located 12 inches from the top and bottom of the furnace area respectively and must

be at least 3 inches long on the smaller side of the opening (See Figure 2). Neither opening can be blocked at any time.

Figure 2 CONFINED SPACE / INDOOR AIR

TOTAL INPUT

(Btuh)

40,000

60,000

80,000

100,000

120,000

140,000

160,000

EXAMPLE:

50,000 Btuh Furnace & 10,000 Btuh Water

Heater = 60,000 Btuh Total Input = 12"

Dia. Round Duct.

MIN. FREE AREA

(Sq. In.)

100

100

100

100

120

140

160

ROUND DUCT

(Dia. In.)

12

12

12

12

13

14

15

If ventilation and/or combustion air must be supplied to the "Confined Space" from outside the building structure,

two permanent openings to the outdoors must be created. Each opening must have a free area of not less than one

square inch per 4000 Btu per hour of total input of all appliances within the "Confined Space". These openings must

be located 12 inches from the top and bottom of the furnace area respectively (See Figures 3, 4, and 5). Neither

opening can be blocked at any time.

Figure 3 CONFINED SPACE / OUTDOOR AIR

TOTAL INPUT

(Btuh)

40,000

60,000

80,000

100,000

120,000

140,000

160,000

MIN. FREE AREA

(Sq. In.)

10

15

20

25

30

35

40

ROUND DUCT

(Dia. In.)

4

5

5

6

6

7

8

EXAMPLE:

50,000 Btuh Furnace & 10,000 Btuh Water

Heater = 60,000 Btuh Total Input = 5" Dia.

Round Duct.

20571201 Issue 0527 Page 9 of 28

Page 10

Figure 4

Figure 5

CONFINED SPACE / OUTDOOR AIR

FROM ATTIC

CONFINED SPACE / OUTDOOR AIR

FROM ATTIC & CRAWL SPACE

When horizontal ducts are used to supply air from the

outdoors, they must be of the same cross sectional area

as the free area of the openings to which they connect.

The minimum dimension of rectangular air ducts must not

be less than 3 inches. Each opening must have a free

area of not less than one square inch per 2,000 Btu per

hour of total input of all appliances within the "Confined

Space". These openings must be located 12 in. from the

top and bottom of the furnace area. Neither opening can

be blocked at any time (See Figure 6).

Figure 6

CONFINED SPACE / OUTDOOR

AIR THROUGH HORIZONTAL DUCTS

Furnaces installed with combustion air drawn from

a heated space which includes exhaust fans,

fireplaces, or other devices that may produce a

negative pressure should be considered confined

space installations.

For an attic installation it is important to keep

insulation 12" or more away from any furnace

openings. Some types of insulating materials may

be combustible.

20571201 Issue 0527 Page 10 of 28

Page 11

DUCTING

The proper sizing of warm air ducts is necessary to insure satisfactory heating operation. Ductwork should be in

accordance with the latest editions of (U.S.) NFPA-90A (Air Conditioning Systems) and NFPA-90B (Warm Air Heating

and Air Conditioning Systems) or Canadian equivalent.

Ductwork Recommendation:

The supply duct work should be attached to the

flanged opening provided at the discharge end of the

furnace. See page 3 "Furnace Specificatons" for the

dimensions of this opening.

A left, right, or bottom return air opening must be

used as determined by the layout of the installation. The

back must not be cut out for return connections. An

externally mounted air filter is required.

This furnace has a two piece bottom panel. For

bottom or end duct return, remove the back portion of the

bottom panel by removing the four (4) screws - two (2) on

each side toward the back of the furnace (See Figure 7).

Tilt furnace toward the front, the back portion of the panel

will drop down. Then the back portion can be removed

by pulling toward the back of the furnace.

Figure 7

BOTTOM PANEL REMOVAL

be of such a size that the heat exchanger can be

viewed for possible openings using light assistance or

a probe can be inserted by sampling the air stream.

The access panel shall be designed so as to prevent

leaks when locked in position. If an air conditioning

coil is installed, the access panel to the coil can be

used for this purpose.

When supply ducts carry air circulated by the

furnace to areas outside the spaces containing the

furnace, the return air shall also be handled by a

duct sealed to the furnace casing and terminating

outside the space containing the furnace. Incorrect

ductwork termination and sealing will create a

hazardous condition that could lead to bodily harm.

Air openings, intake and outlet pipes, return air

grilles and warm air registers must not be

obstructed.

Knockouts are provided on both sides of the furnace

to facilitate the cutout required to the return air ductwork.

Furnace cutouts must be the full size specified by the

corner markers. Undersized cutouts will adversely

affect the airflow capability of the furnace and could

cause overheating of the heat exchanger.

The following recommendations should be followed

when installing the ductwork:

1. Install locking-type dampers in all branches of the

individual ducts to balance out the system. Dampers

should be adjusted to impose the proper static at the

outlet of the furnace.

2. Noncombustible flexible duct connectors are

recommended to connect both the supply and return

ducts to the furnace.

3. In cases where the return air grille is located close to

the blower inlet, there should be at least one 90° air

turn between blower and return grille. Further

reduction in sound can be accomplished by installing

acoustical air turning vanes and/or lining the inside of

the duct with acoustical material.

4. It is recommended that the supply duct be provided

with a removable access panel. This opening shall

be accessible when the furnace is installed and shall

To Convert to Downflow Position:

1. Convert the combustion blower to side flue exit, as

outlined on page 14.

2. Install proper special base per Table 2 for installation

on combustible flooring (follow instructions supplied

with special base).

3. It is recommended that the return air be connected to

the bottom panel of the furnace when it is installed in

the downflow position.

NOTE: SPECIAL SUB-BASE NOT REQUIRED WHEN

FURNACE IS MOUNTED ON A METAL CASED

EVAPORATOR COIL.

Table 2

SPECIAL BASE INSTALLATION

MODEL

AV050B3

AV075B3

AV100B4 20066502 68L78

AV125B5 20066503 68L79

NOTE: Installation on combustible flooring only when

SPECIAL BASE

NUMBER

20066501 68L77

CAT. NO.

installed on one of the above listed special bases

or as identified on the furnace model and rating

label.

20571201 Issue 0527 Page 11 of 28

Page 12

Filters:

Air filters must be used in every installation. For side

return installations, air filters must be installed external to

the furnace casing. An external filter rack kit with filter

(parts No. 20069901 or Cat. No. 68L75 12 / 15½" x 25"

sizes and 20069902 or Cat. No. 68L76 for 15½" / 19" x

25" sizes) is available as an optional accessory.

For bottom (end) return installations, the above

optional external rack may be used, if the unit was not

provided with a internal filter. Minimum filter size and

suggested filter materials are shown in Table 3. (If

different type filter is used, it must be an equivalent high

airflow capacity.)

Table 3 EXTERNAL FILTER RACK SIZE

MODEL

050-3

075-3

100-4 15 ½ X 25 15 ½ X 25

125-5 15 ½ X 25 19 X 25

SIDE

RETURN

15 ½ X 25 12 X 25

BOTTOM/END

RETURN

This furnace may use either a disposable filter,

permanent filter, electronic or high efficiency media air

cleaner. Consult filter/cleaner manufacturers for

maintience service and static pressure drop for air moving

requirements.

When installing the furnace with cooling equipment for

year round operation, the following recommendations

must be followed for series or parallel air flow:

1. In series flow applications, the evaporator coil is

mounted after the furnace in an enclosure in the

supply air stream. The furnace blower is used for

both heating and cooling airflow.

2. In parallel flow installation, dampers must be provided

to direct air over the furnace heat exchanger when

heat is desired and over the cooling when cooling is

desired. At no time may the evaporator coil be

located on the return air side of the heat exchanger.

IMPORTANT: The dampers should be adequate to

prevent cooled air from entering the

furnace, and if manually operated, must

be equipped with means to prevent

operation of either the cooling unit or

furnace unless the damper is in the full

cool or full heat position.

The coil MUST be installed on the air discharge

side of the furnace. Under no circumstances

should the air flow be such that cooled, conditioned

air can pass over the furnace heat exchanger. This

will cause condensation in the heat exchanger and

possible failure of the heat exchanger that could

lead to a fire hazard and/or hazardous conditions

that may lead to bodily harm. Heat exchanger

failure due to improper installation will not be

covered by warranty.

VENTING

Venting for this category I furnace must be to the

outside and in accordance with local codes or

requirements of the local utility. In the absence of local

codes, venting must conform to the applicable sections of

the latest edition of the (U.S.) National Fuel Gas Code

ANSI Z223.1/NFPA54, and/or CSA B149.1 Natural Gas

and Propane Installation Codes, and the vent

manufacturers instructions.

This furnace is CSA International certified as a

Category I forced air appliance and can not be vented

into a vent system with any Category II, III or IV

appliance. It must be vented vertically, or nearly

vertically, unless installed with a listed mechanical venter

in accordance with horizontal venting instructions. It must

not be connected to any portion of a mechanical draft

system operating under positive pressure

The 3" (in.) to 4" (in.) vent adaptor coupling (supplied

with unit) MUST BE USED. It must be connected directly

to the outlet of the combustion blower using a field

supplied corrosion resistant sheet metal screw (See

Figure 8).

Figure 8

VENT ADAPTOR MOUNTING

Pre-Installation Vent System Inspection:

Before this furnace is installed, it is highly

recommended that any existing vent system be

completely inspected.

For a chimney or "B" vent, this should include the

following:

1. Inspection for any deterioration in the chimney or "B"

20571201 Issue 0527 Page 12 of 28

Page 13

vent. If deterioration is discovered, the chimney must

be repaired or the "B" vent must be replaced.

2. Inspection to ascertain that the vent system is clear

and free of obstructions. Any blockage must be

cleared before installing this furnace.

3. Cleaning the chimney or "B" vent if previously used

for venting a solid fuel burning appliance or fireplace.

4. Confirming that all unused chimney or "B" vent

connections are properly sealed.

5. Verification that the chimney is properly lined and

sized per the applicable codes.

Masonry Chimney:

This furnace can be common vented into an existing

tile lined masonry chimney provided:

1. The chimney is currently serving at least one

drafthood equipped appliance.

2. The vent connectors and chimney are sized in

accordance with the applicable sections of the (U.S.)

National Fuel Gas Code ANSI Z223.1/NFPA54,

and/or CSA B149.1 Natural Gas and Propane

Installation Codes.

This furnace must NOT vented ALONE into an

existing masonry chimney (either tile lined or unlined)

unless the chimney is also lined with either a type B vent

system or a listed single wall, metal lining system. Both

of these systems must be sized in accordance with the

applicable sections of the (U.S.) National Fuel Gas Code

ANSI Z223.1/NFPA54, and/or CSA B149.1 Natural Gas

and Propane Installation Codes.

Before venting this furnace into a chimney, check the

chimney for deterioration and repair if necessary. This

furnace must not be vented into a chimney serving a

separate appliance designed to burn solid fuel. Type"B"

vent connectors must be used on all installations and it

must be sized per the applicable sections of the (U.S.)

National Fuel Gas Code ANSI Z223.1/NFPA54, and/or

CSA B149.1 Natural Gas and Propane Installation Codes.

Type "B" Vent:

The furnace is also approved for use with a "B" vent

that terminates through the roof. Refer to the applicable

sections of the (U.S.) National Fuel Gas Code ANSI

Z223.1/NFPA54, and/or CSA B149.1 Natural Gas and

Propane Installation Codes for proper sizing and set-up

of this furnace with "B" vent for a dedicated vent system

or a common vented system.

Horizontal Venting:

This furnace is design certified by CSA International

for horizontal venting through an outside wall by use of

one of the following auxiliary draft inducer kits:

Table 4 AUXILIARY DRAFT INDUCERS

Vent Kit MFR Model * Furnace Input

Field Controls Co.

Tjernlund Products Inc.

* See rating label on this furnace for input

Vent Length: Max. 60 ft. - Min. 12 ft.

Follow instructions included with venting kit for proper installation and setup.

SWG-4G

SS1 OR SS1C

GPAK-J 50000, 75000 or 100000

GPAK-1 100000 or 125000

Vent Diameter: 4 in.

50000, 75000, 100000 or

125000

50000, 75000, 100000 or

125000

Location Requirements for Horizontal Venting:

Locate the vent terminal adhering to the following

minimum clearances and as specified in the auxiliary draft

inducer vent kit:

1. Vent terminal must be located at least one (1') foot

above the grade or at least one (1') foot above the

normal expected snowfall.

2. Avoid installing vent terminal above public walkways.

If this is not possible, install the terminal at least

seven (7') feet above the walkway.

3. Vent terminal should be at least four (4') feet to the

side of and at least one (1') foot above doors and

windows.

4. Vent terminal should be at least three (3') feet above

any forced air inlet located within ten (10') feet.

5. Vent terminal should be located at least six (6') feet

from the combustion air intake of another appliance.

6. Vent terminal should be located at least four (4') feet

above any electric or gas meters, regulators, and

relief equipment.

General Venting Requirements:

This furnace may be common vented only with other

Category I appliances. Common venting is allowed as

permitted by National and/or local codes. Refer to the

applicable sections of the (U.S.) National Fuel Gas Code

ANSI Z223.1/NFPA54, and/or CSA B149.1 Natural Gas

and Propane Installation Codes for proper sizing and set

up.

The vent must be terminated with a listed vent cap.

This venting must be installed in accordance with the vent

manufacturer's instructions and be in accordance with all

local codes and/or National Codes. Follow Figure 9 for

vent exit options.

The following requirements are provided for a proper

venting system:

1. Be sure that the chimney flue is clear of any dirt or

debris.

2. Be sure that the chimney is not servicing an open

fireplace.

3. Never reduce the pipe size below the outlet size of

the furnace without checking the applicable sections

of the (U.S.) National Fuel Gas Code ANSI

Z223.1/NFPA54, and/or CSA B149.1 Natural Gas and

Propane Installation Codes.

20571201 Issue 0527 Page 13 of 28

Page 14

4. All pipe should be supported using the proper clamps

and/or straps. These supports should be at least

every four (4') feet.

5. All horizontal runs of pipe should have at least a 1/4"

(in.) per foot of upward slope from the furnace to the

vent terminal.

6. All runs of pipe should be as short as possible with

as few turns as possible.

7. Seams should be tightly joined and checked for

leaks.

8. The flue pipe must not extend into the chimney but

be flush with the inside wall.

9. The chimney or vent pipe must extend at least three

(3') feet above the highest point where it passes

through a roof of a building and at least two (2') feet

higher than any portion of a building within a

horizontal distance of ten (10') feet. It shall also

extend at least five (5') feet above highest connected

equipment flue collar.

Figure 9

VENT EXIT OPTIONS

3. Remove the four (4) screws that secure the

combustion blower adaptor plate to the flue collector

box, taking care to support the blower assembly so

that it does not fall.

4. Rotate the blower 90° (degrees) clockwise, so that

the outlet of the blower is pointing toward the right

side panel of the furnace.

5. Insure that the gasket is in place between the blower

adaptor plate and the flue collector box. Reattach the

blower assembly to the flue collector box, using the

four (4) screws removed in step 3. Be sure that the

screws are properly tightened and that the gasket

seals the plate to the box.

6. Reconnect the pressure switch tubing to the

combustion blower.

7. (Optional) Install vent pipe guard.

Kit Number 20284801.

Figure 10

VENT PIPE GUARD KIT

For Horizontal Positions:

It is not necessary to reposition any of the

components of the furnace in order to install it in either

horizontal position. As outlined above, it is permissible to

use the side vent exit for the horizontal-left position, if

desired.

10. The 3" to 4" vent adaptor coupling must be used to

connect to the combustion blower outlet. It must be

installed directly to the combustion blower outlet (See

Figure 8).

Checking For Vent Oversizing:

If this furnace is replacing a furnace that is attached

to a venting system serving other appliances, the venting

system is likely to be too large to properly vent all of the

attached appliances. An improperly sized venting system

To Convert to Side Flue Exit:

can lead to condensation, leakage, or spillage.

1. Remove the louver door from the furnace. (Be sure

the side vent exit knock-out is removed from the right

side panel of the cabinet. See Figure 9.)

2. Disconnect the pressure switch tubing from the

combustion blower.

20571201 Issue 0527 Page 14 of 28

Page 15

CARBON MONOXIDE POISONING HAZARD

Failure to follow the steps outlined below for each appliance connected to the venting system being placed

into operation could result in carbon monoxide poisoning or death.

The following steps shall be followed for each appliance connected to the venting system being placed into

operation, while all other appliances connected to the venting system are not in operation:

1. Seal any unused openings in the venting system.

2. Inspect the venting system for proper size and horizontal pitch, as required in the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or the CSA B149.1, Natural Gas and Propane Installation Codes and these

instructions. Determine that there is no blockage or restriction, leakage, corrosion and other deficiencies

which could cause an unsafe condition.

3. As far as practical, close all building doors and windows and all doors between the space in which the

appliance(s) connected to the venting system are located and other spaces of the building.

4. Close fireplace dampers.

5. Turn on clothes dryers and any appliance not connected to the venting system. Turn on any exhaust fans,

such as range hoods and bathroom exhausts, so they are operating at maximum speed. Do not operate

a summer exhaust fan.

6. Follow the lighting instructions. Place the appliance being inspected into operation. Adjust the thermostat

so appliance is operating continuously.

7. Test for spillage from draft hood equipped appliances at the draft hood relief opening after 5 minutes of main

burner operation. Use the flame of a match or candle.

8. If improper venting is observed during any of the above tests, the venting system must be corrected in

accordance with the National Fuel Gas Code, ANSI Z223.1/NFPA 54 and/or CSA B149.1, Natural Gas and

Propane Installation Codes.

9. After it has been determined that each appliance connected to the venting system properly vents when

tested as outlined above, return doors, windows, exhaust fans, fireplace dampers and any other gas-fired

burning appliance to their previous conditions of use.

ELECTRICAL CONNECTIONS

When installed, the furnace must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the (U.S.) National Electrical

Codes, ANSI/NFPA 70 or CSA Standard C22.1; Part 1

Canadian Electrical Code. For proper installation refer to

furnace rating label for electrical ratings and for the field

wiring of this unit refer to furnace wiring specifications on

page 5 or alternately from the wiring diagram on page 27.

In all instances, other than wiring for the thermostat, the

wiring to be done and any replacement of wire shall

conform with the temperature limitation for Type T wire

[63°F rise (35°C)].

The electrical connections and the thermostat

connections are made at the openings on either side

panel of the unit in the control box area. Either side may

be used as convenient, but the provided hole plugs must

be inserted in the unused holes.

The control system depends on the correct polarity of

the power supply. Connect "Hot" (H) wire and "Ground"

(G) wire as shown in furnace wiring specification on

wiring diagram. Use reference Table on page 3 (Furnace

Specifications), for over current protection, max unit amp

rating and wire size. Use copper wire only for 115Vsupply service to unit. When replacing any original

internal wiring, use only 105°C, 16 AWG copper wire.

Thermostat:

Instructions for wiring the thermostat are packed in

the thermostat (field supplied) box. Make the thermostat

connections as shown in furnace wiring specifications at

the 24-volt terminal board located in the control box.

Single Stage Thermostat Operation:

The automatic heat staging option allows a single stage

thermostat to be used with a two stage furnace. To

activate this option, move the jumper pin (see Figure 11)

to desired setting (5 minutes or 10 minutes). The furnace

will start on first (1ST) stage heat and stay at first (1ST)

stage heat for the duration of the selected time before

switching to 2nd stage heat.

20571201 Issue 0527 Page 15 of 28

Page 16

Figure 11

AUTOMATIC HEAT STAGING JUMPER

When installing optional accessories to this appliance,

follow the manufacturer's installation instructions included

with the accessory.

GAS CONNECTIONS

Gas piping shall be of such size and so installed as

to provide a supply of gas sufficient to meet maximum

demands without undue loss of pressure between the gas

meter and the furnace. It is recommended that the gas

line to the furnace shall be a separate line direct from the

meter, unless the existing gas line is of ample capacity.

Refer to gas pipe capacity table in the National Fuel Gas

Code ANSI Z223.1/NFPA54, and/or CSA B149.1 Natural

Gas and Propane Installation Codes.

If local codes allow the use of a flexible gas appliance

connector, always use a new listed connector. Do no use

a connector which has previously serviced another gas

appliance.

Use a joint compound (pipe dope) that is resistant to

the action of liquefied petroleum gases or any other

chemical constituents of the gases to be conducted

through the piping.

For proper furnace operation the maximum gas

supply pressure is 14" w.c. and the minimum gas

supply pressure is 4.5" w.c. - Natural (11" w.c. - LP)

as shown on rating label.

Before any system of gas piping is finally put into

service, it should be carefully tested to determine if it is

gas tight. Check all piping for leaks using soapy water

and a brush. The piping must stand a pressure of six (6)

inches of mercury (3 PSIG) for a period of ten (10)

minutes or as required by local authority.

The unit cabinet must have an uninterrupted or

unbroken electrical ground to minimize personal

injury if an electrical fault should occur. This may

consist of electrical wire or approved conduit when

installed in accordance with existing electrical

codes. Do not use gas piping as an electrical

ground. Failure to follow this warning can result in

an electrical shock, fire, bodily harm, or loss of life.

The furnace and its individual shutoff valve

must be disconnected from the supply piping

system during any pressure testing of that system

at test pressures in excess of 1/2 PSIG (3.5kPa or

14"w.c.).

The furnace must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure testing of

the gas supply piping system at pressures equal to

or less than 1/2 PSIG (3.5kPa or 14"w.c.). Failure

to follow the above procedures could lead to a

hazardous condition and bodily harm.

Figure 12-A

GAS CONTROL PIPING

FIRE OR EXPLOSION HAZARD

Failure to follow the safety warnings exactly

Figure 12-B

TYPICAL GAS SERVICE CONNECTION

could result in serious injury, death or property

damage.

Never test for gas leaks with an open flame.

Use a commercially available soap solution made

specifically for the detection of leaks to check all

connections. A fire or explosion may result causing

property damage, personal injury or loss of life.

20571201 Issue 0527 Page 16 of 28

Page 17

This furnace is manufactured for use with Natural gas

and must be converted using the proper LP conversion kit

for use with LP (Propane) gas. For LP (Propane) gas, a

tank regulator is required to reduce supply pressure to

12"-13"w.c. For manifold pressure see Table 6.

A main manual shut off valve must be used in the

gas piping. The shut off type and location must follow

local codes and should always be in an accessible but

protected location. In the absence of local codes the

recommended methods for installing the gas piping to the

furnace are shown in Figures 12-A and 12-B.

The gas valve contains two threaded ports for a 1/8"

NPT tap in order to test incoming gas pressure and

outgoing manifold pressure (See Figure 13).

CONTROL BOARD & VARIABLE SPEED MOTOR FEATURES

Humidifier Connections:

Terminals are provided on the blower control board

for connections to a 120-volt optional humidifier. The

"HUM" terminal is energized whenever the thermostat

calls for heat. Refer to furnace wiring diagram for specific

connection information.

Many soaps used for leak testing are corrosive to

certain metals. Piping must be rinsed thoroughly

with clean water after leak check has been

completed.

Never use an open flame when testing for gas

leaks! Use of an open flame could lead to a fire or

explosion.

setup, the variable speed motor will operate at a 10%

reduction in the normal cooling airflow rate when there is

a call for dehumidification.

Both dehumidification methods described above can

be utilized on the same furnace.

Electronic Air Cleaner Connections:

Terminals are provided on the blower control board

for connection of a 120-volt optional electronic air cleaner.

The "EAC" terminal is energized whenever the thermostat

calls for heat, cooling, or continuous blower. Refer to the

furnace wiring diagram for specific connection information.

Continuous Blower Operation:

The comfort level of the living space can be

enhanced when using this feature by allowing continuous

circulation of air between calls for cooling or heating. The

circulation of air occurs at half the full cooling airflow rate.

To engage the continuous blower operation, place the

fan switch on the thermostat into the ON position. A call

for fan from the thermostat closes R to G on the ignition

control board. The control waits for a 1 second

thermostat debounce delay before responding to the call

for fan by ramping the circulating blower up to 50% of the

cooling speed, but not less than 425 cfm's. When the call

for continuous fan is satisfied, the control immediately deenergizes the circulating blower.

Dehumidification:

For situations where humidity control is a problem, a

dehumidification feature has been built into the variable

speed motor. At the start of each cooling cycle, the

variable speed motor will run at 82% of the rated airflow

for 7.5 minutes. After 7.5 minutes has elapsed, the motor

will increase to 100% of the rated airflow.

Additional dehumidification can be achieved by

connecting a humidistat to the DEHUM and R terminals

on the integrated ignition/blower control board. In this

Variable Speed Features:

The furnace is equipped with a variable speed

circulation air blower motor that will deliver a constant

airflow within a wide range of external static pressures.

Other features of this variable speed motor include:

Soft Start:

The variable speed motor will slowly ramp up to

normal operating speed. This minimizes noise and

increases comfort by eliminating the initial blasts of air

encountered with standard motors.

Soft Stop:

At the end of a cooling or heating cycle, the variable

speed motor will slowly ramp down after a short blower

"off" delay. If continuous blower operation has been

selected, the variable speed motor will slowly ramp down

until it reaches the airflow for that mode.

Circulating Airflow Adjustments

Heating Mode:

The unit, as shipped, is factory set (setting "A") to run

at the middle of the heating rise range as shown on the

unit rating plate. Adjustments can be made to the heating

airflow by repositioning the jumper plug marked HEAT-A,

B, C, D (see AirFlow Adjustment Table on page 4) based

on the information found in the table. Heating rise must

always be within the rise range shown on the rating

plate.

20571201 Issue 0527 Page 17 of 28

Page 18

Cooling Mode:

The units are factory set for the highest airflow for

each model. Adjustments can be made to the cooling

airflow by repositioning the jumper plug marked COOL A, B, C, D (see AirFlow Adjustment Table on page 4)

based on the information found in the table.

By moving the ADJUST jumper plug (see Table on

page 4) from the NORM position to the (+) or (-) position

will also cause the cooling airflow setting to be raised or

lowered by 15%.

The TEST position on the ADJUST tap is not used.

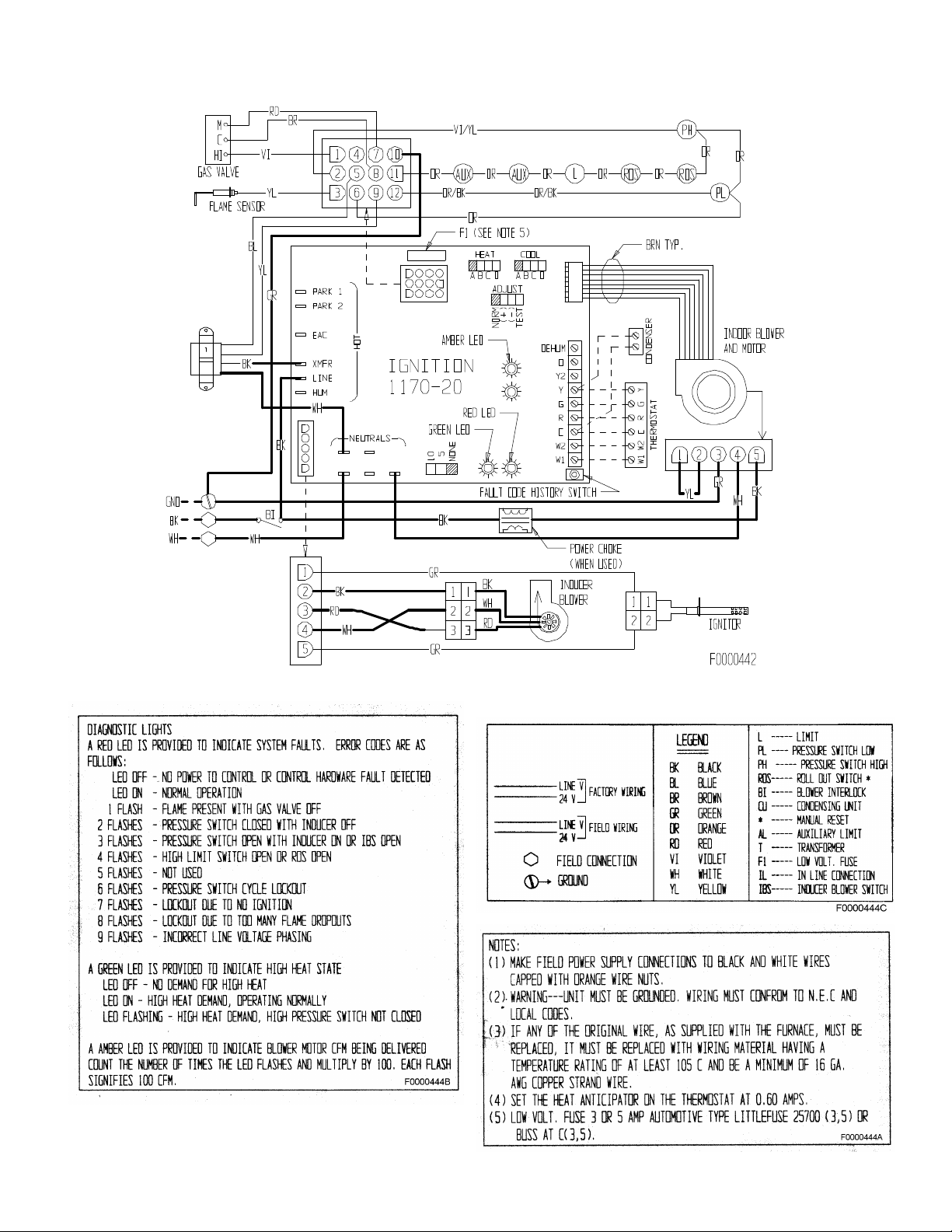

UNIT SEQUENCE OF OPERATION

To determine what CFM the motor is delivering at any

time, count the number of times the amber LED on the

control board flashes. Each flash signifies 100 CFM;

count the flashes and multiply by 100 to determine the

actual CFM delivered (for example: 10 flashes x 100 =

1000 CFM).

Here's How Your Heating System Works:

Standby Mode

When the control is in standby mode, it continually

monitors thermostat input, rollout switch, and flame

sense.

Call For Heat

On a call for 1st stage heat (W1) from the room

thermostat, the ignition control performs a 1-second selfcheck. The control verifies the limit switch is closed and

both low and high pressure switches are open. The

control always starts on low-fire and ignores 2nd stage call

for heat until low heat is established and heat blower on

delay is complete. The induced draft blower is energized

to high speed and waits for the low pressure switch to

close before starting a 15-second pre-purge period. Upon

completion of the pre-purge the hot surface igniter is

energized for a period of 7 seconds (15 seconds on

retries) before the gas valve is energized on 1st stage and

main burners ignite. The induced draft blower remains on

high speed with the gas on low fire for the first 15

seconds of steady heat and ignores any 2nd stage

demand. After the 15 second period the control switches

the inducer to low speed. After a 30 seconds blower "on"

delay, the control energizes the low heat circulating air

blower. The blower runs at reduced CFM (approximately

400 CFM) for 30 seconds then ramps up to 1st stage heat

speed.

If 1st stage heating operation is not sufficient to satisfy

the heating demand, the room thermostat initiates a call

for 2nd stage heat (W1 and W2). The control changes the

inducer from low to high speed and confirms the high-fire

pressure switch contacts are closed and the gas valve

energizes on 2nd stage heat. The circulating air blower

then ramps up to 2nd stage heat speed.

When the 2nd stage call for heat is satisfied, the

control shuts off the gas valve and runs the combustion

air blower for a post purge period of 5 seconds. The

circulating air blower continues to run for approximately 3

minutes before ramping down. If the thermostat W2 call

ends and W1 remains, the control de-energizes the high

gas output, changes the inducer speed from high to low

and the gas valve drops back to 1st stage heat. After

approximately 2 minutes the circulating air blower ramps

down to 1st stage heat speed.

In the event the unit loses ignition, the control will

attempt to recycle up to five times before it goes into a 1hour lockout. Lockout may be manually reset by

removing power from the control for more than 1 second

or removing the thermostat call for heat for more than 3

seconds.

If during a heating cycle the limit control senses an

abnormally high temperature and opens, the ignition

control de-energizes the gas valve and the combustion

blower while the circulating blower ramps up to 2nd stage

heat speed. The circulating blower remains energized

until the limits are closed.

Should overheating occur, or the gas supply fail to

shut OFF, turn OFF the manual gas valve to the

appliance BEFORE turning OFF the electrical

supply. A failure to adhere to this warning can

result in a fire or explosion and bodily harm.

Fan "ON"

A call for continuous fan from the thermostat closes

R to G on the control board. The control waits for a 1second debounce delay before responding by energizing

the circulating air blower at 50% of the cooling speed.

When the call for fan is turned off, the control deenergizes the circulating blower.

Cooling

A call for cooling from the thermostat closes R to Y

and R to G on the blower control board. The control

waits for a 1-second thermostat debounce delay before

energizing the circulating air blower to 82% of the cooling

speed. After 7.5 minutes, the circulating blower

automatically ramps up to 100% of the cooling speed.

When a call for cooling is satisfied, the circulating blower

ramps back down to 82% of the cooling speed for 60

seconds then shuts off.

20571201 Issue 0527 Page 18 of 28

Page 19

STARTUP AND OPERATIONAL CHECKOUT

It is not recommended that this furnace be used as

a construction heater during any phase of

construction. Very low return air temperatures,

harmful vapors and operation of the unit with

clogged or misplaced filters will damage the unit.

The unit may only be used for heating of buildings

or structures under construction, if the conditions

listed on page 6 in the "Introduction" section of

these instructions are met.

The automatic gas valve controls the flow of gas to

the main burners. The control circuit built into the

automatic valve body has 2 positions: "OFF" and "ON"

(Figure 13). To shut off gas manually: Switch from "ON"

to "OFF" position. When in "OFF" position, the main

burners are extinguished.

This furnace is equipped with an automatic hotsurface ignition control and does not require the manual

lighting for furnace operation.

1. Be sure all electrical power is OFF.

2. Check all wiring using proper wiring diagram on

inside of the control box cover.

3. Turn ON the electrical power.

4. Set the ignition system control switch in the "ON"

position.

5. Set the thermostat above room temperature.

6. The hot-surface ignitor will heat-up to an "orange"

glow, the main burners will ignite.

Figure 14

TYPICAL FLAME APPEARANCE

(Main Burners)

Figure 13

GAS CONTROL DIAGRAM

Do not attempt to manually light the burners.

Failure to follow this warning can lead to electrical

shock that could result in bodily harm.

7. Recheck for leaks in the manual shut off valve, gas

control valve and gas connections using a soap

solution.

Never use an open flame when testing for gas

leaks! Use of an open flame could lead to a fire or

explosion.

Many soaps used for leak testing are corrosive to

certain metals. Piping must be rinsed thoroughly

with clean water after leak check has been

completed.

Manifold Pressure Adjustment:

Turn OFF the gas and electrical before

After the ductwork connections have been made, gas

piping and electrical wiring completed and the furnace

has been properly vented, the unit should be started and

adjusted for proper operation. Check off the following

preceeding! Remove the manifold pressure tap pipe

plug from the gas valve (Figure 13 outlet pressure tap)

and install a pressure tap and connect it to a manometer.

Turn on the gas and electrical supplies.

steps as they are completed.

20571201 Issue 0527 Page 19 of 28

Page 20

The gas control (Figure 13) has two separate

pressure regulator adjustment screws, one for 1st stage

(marked "LO") and the second one for 2nd stage (marked

"HI"). The adjusting screws are positioned on either

side of the barbed fitting. The pressure regulator

adjustment is sensitive: one turn of the adjusting

screw will result in a relatively large change in

manifold pressure. Turn regulator-adjusting screws

IN (clockwise) to increase pressure, OUT

(counterclockwise) to decrease presure.

Set the unit on high fire and adjust the 2nd stage high

fire pressure regulator to the required setting. Disconnect

the violet wire from the "HI" terminal on the gas control

and the burners will drop down to the 1st stage low fire,

then adjust the 1st stage pressure regulator setting as

required. Gas input must never exceed the value shown

on the furnace rating label. These units are equipped for

rated input at manifold pressures of 2.3" w.c. (1st stage)

and 3.5" w.c. (2nd stage) for natural gas. When these

furnaces have been converted for use with LP (propane)

gas, the manifold pressures are 6.4" w.c. (1st stage) and

10.0" w.c. (2nd stage). After proper adjustments,

reconnect violet wire and furnace should go up to 2

stage high fire. Turn OFF gas, replace manifold pressure

tap pipe plug, regulator adjustment vent cap, and turn ON

gas.

At higher altitudes and varying heating valves,

manifold pressure or orifice changes maybe

required. Consult Tables 7 and 8 for appropriate

values. Failure to follow this warning could lead to

a hazardous furnace operating condition and result

in serious bodily injury or loss of life.

TABLE 5

Gas Rate (Cubic Feet per Hour)

TEST DIAL

Seconds for

One

Revolution

10 160 360 720

12 150 300 600

14 129 257 514

16 113 225 450

18 100 200 400

20 90 180 360

22 82 164 325

24 75 150 300

26 69 138 276

28 64 129 258

30 60 120 240

32 56 113 226

34 53 106 212

1/2

Cubic

Feet

Cubic

1

Foot

2

Cubic

Feet

Seconds for

One

Revolution

36 50 100 200

38 47 95 190

40 45 90 180

42 43 86 172

44 41 82 164

46 39 78 156

48 37 75 150

50 36 72 144

52 35 69 138

54 34 67 134

56 32 64 128

58 31 62 124

60 30 60 120

1/2

Cubic

Feet

TEST DIAL

1

Cubic

Foot

2

Cubic

Feet

4. Calculate the furnace input using the following

formula:

nd

BTUH = Cubic Ft/Hr x BTU/Cubic Foot

The local gas supplier should be able to provide the

heating value of the gas, in BTU/cubic foot. If a

specific value is not available, use 1000 BTU/cubic

foot for Natural gas or 2500 BTU/cubic foot for

Propane (LP).

Furnace input should be maintained within ± 2% of

the value on the rating plate or appropriate altitude

derate. Adjust manifold pressure or change

orifices size if required.

Determining Furnace Input - Natural Gas Only

NOTE: All access doors must be in place when checking

gas input.

1. Turn OFF all other gas appliances (except for pilot

burners) served by the same gas meter.

5. Calculate the unit's actual input rate.

Example: If the heating value of the natural gas is 1015

Btu/cu. and it takes 60 seconds to burn 2 cu.

ft. of gas then:

Input = 1015 Btu/cu. ft. X 1 rev X 2 cu. ft./rev. X 3600

60 sec.

2. With furnace operating in full heat cycle, note how

many seconds it takes for one full revolution of the

Input = 121,800 Btu/hr.

smallest dial on the meter. Typically, this will be a

1/2 - or - 1 - cubic foot test dial.

3. Using the number of seconds for one revolution and

the size of the meter dial, determine the cubic foot

per hour of gas flow by using the formula provided

below or Table 5.

Cubic Ft/Hr =

20571201 Issue 0527 Page 20 of 28

Number of Dial Revolutions x Cubic Foot/Revolution x 3600

Time (in seconds) Required for Number of Timed Revolutions

Page 21

Burner Orifice Sizing:

The furnace is supplied with standard orifices for the

gas shown on the rating plate. Table 6 shows

combinations of heating values and specific gravities for

various gases, from which proper input can be obtained.

If changing orifices is required, remove the manifold

from the furnace (following the instructions found on page

24) and replace orifices as required by Table 6, the

altitude derating section of this instruction or as local code

dictates.

TABLE 6

Burner Orifice Selection

Type of Gas@Manifold Press.

(Heating Value-Specific Gravity)

Btu per Cu. Ft.

Orifice

Size

(Drill #)

Natural Manifold Press.= 3.5"w.c.

800-0.6

900-0.6

1000-0.6

1100-0.6

40

41

42

43

Propane Manifold Press.= 10"w.c.

2500-1.53

54

After securing the manifold assembly, replace all

other components and/or wiring, being sure that all

connections and screws are tightened properly.

Altitude Derating:

The following information is provided as guidelines for

altitude derating and is not meant to supersede any state

or local codes. Local codes have priority over any others

and in some case might limit your options in dealing with

an altitude derate situation.

NOTE: In Canada for altitudes up to 4500 ft. (1372 m)

see the rating label on this furnace for proper

manifold pressure and orifice size. Certification

for installations at altitudes over 4500 ft. (1372 m)

is the jurisdiction of local authorities.

TABLE 7

High Altitude Manifold Pressure Derate

(with standard 42 orifice Natural / 54 orifice LP sizes)

Altitude

(Feet)

0-999 4.32 3.88 3.50 3.16 2.84 10

1000-1999 4.32 3.88 3.50 3.16 2.84 10

2000-2999 3.67 3.29 2.97 2.68 2.41 8.46

3000-3999 3.38 3.04 2.74 2.47 2.22 7.74

4000-4999 3.11 2.79 2.52 2.27 2.04 7.05

* Heating-Value based on atmospheric pressure of 30 inhg and 60°F temperature.

*Heating Value of Natural Gas

(BTU/FT3)

900 950 1000 1050 1100 2500

LP

Propane

If local codes require an orifices change the

appropriate orifice size based on the elevation and the

heating value can be found in Table 8. Sizing of the

orifice must be based on the previously mentioned 4%

derate for each 1,000 feet for installations at/or above

2,000 feet rule and the orifices must be drilled in such a

way as to assure concentricity. Hand drilling of orifices

is unacceptable.

TABLE 8

High Altitude Orifice Size Derate

Altitude

(Feet)

2000-2999 N.C. N.C. 43 43 44 N.C.

3000-3999 N.C. N.C. 43 44 44 N.C.

4000-4999 43 43 44 44 45 55

* Heating-Value based on atmospheric pressure of 30 inhg and 60°F temperature.

*Heating Value of Natural Gas

(BTU/FT3)

900 950 1000 1050 1100 2500

LP

Propane

Hand drilling of orifices is never acceptable since it

could lead to delayed ignition, overfiring, improper

combustion, flashback and flame rollout. All these

conditions could lead to a fire hazard and bodily

harm, or loss of life.

Check with your local gas company to find out if the

gas supply in your area is derated. Gas deration negates

the necessity of performing any adjustment on the

furnace.

If your gas supply is not derated, regardless of the

type of gas used, installation of this furnace at elevations

above 2,000 ft. requires an input reduction at the rate of

four percent (4%) for each 1,000 ft. above sea level.

Unless an orifice change is specified by an applicable

code, the recommended method of altitude derating this

furnace is to appropriately lower your manifold pressure.

The appropriate manifold pressures based on the

elevation and the heating value can be found in Table 7.

Blower Adjustment Checkout:

This furnace is equipped with a variable speed

circulation air blower motor that will deliver a constant

airlfow within a wide range of external static pressures.

The unit as shipped is factory set to run at the middle of

the heating rise range as shown on the unit rating plate.

For low heat to high heat transition the control

changes the blower speed from low heat speed to high

heat speed. Check the temperature rise between the

return and supply plenums to make sure it is within the

rise range shown on the rating plate.

Heat blower off delay is a fixed 180 second delay.

After the 180 second delay the motor will slowly ramp

down to a soft stop. N0 adjustments need to be made in

the heating mode.

20571201 Issue 0527 Page 21 of 28

Page 22

Limit Control Checkout:

After the furnace has been in operation for at least 15

minutes, restrict the return air supply by blocking the

filters or closing the return registers and allow the furnace

to shut down on high limit. The main burners will shut

OFF and the main blower and combustion blower should

continue to run. Remove the restriction and the burners

should come back on in a few minutes.

Flame Rollout Switch:

This unit is equipped with two (2) manual reset flamerollout switches that protects against improper venting of

the flue gases from the heat exchanger due to blockage

causing heat (or flames) to "rollout" into the burner box

from the heat exchangers, either safety device will

activate and shut off power to the automatic gas valve

before there is damage to the furnace. The loss of power

to the gas valve will shut off the gas burners. Should this

occur, it will be necessary to determine the cause of the

rollout, correct the condition that caused it, and reset the

flame-rollout switch.

Pressure Switch Check:

To check the operation of the pressure switch vent

safety control, remove the vent adaptor from the

combustion blower. Place the furnace into operation for

high fire. Gradually cover up the blower outlet; the

furnace should first drop to low fire and with further

restriction of the opening, the main burners should shut

OFF. Remove the restriction and the unit should relight.

Replace the vent adaptor and reseal the opened joints as

required.

The operational checkout is now complete. Be sure

to adjust the thermostat to the desired setting and inform

the homeowner how to operate the furnace system before

leaving the job site.

If the pressure switch activates to shut the furnace

down, the vent system must be checked and

cleared. Failure to do so may result in serious

bodily harm or nuisance furnace shutdown and/or

a hazardous condition that may lead to property

damage, personal injury or death.

The furnace should be allowed to cool-off before

attempting to reset the switch. Failure to follow

these instructions could result in injury due to burns!

The switches are located behind the front access

door. Remove front access door from the furnace and

reset by pushing in the button in the middle of the switch

(between the two wire connections - See Figure 16).

Very little force is required to push the reset button, and

a "click" should be heard when the switch resets.

Figure 16

FLAME ROLLOUT SWITCH

20571201 Issue 0527 Page 22 of 28

Page 23

SEQUENCE OF OPERATION

DIRECT IGNITION SYSTEM CONTROL

20571201 Issue 0527 Page 23 of 28

Page 24

SERVICING THE FURNACE

ELECTRICAL SHOCK, FIRE OR EXPLOSION

HAZARD

Failure to follow safety warnings exactly could result

in dangerous operation, serious injury, death or

property damage.

Improper servicing could result in dangerous

operation, serious injury, death or property damage.

• Before servicing, disconnect all electrical

power to furnace.

• Wehn servicing controls, label all wires

prior to disconnecting. Reconnect wires

correctly.

• Verify proper operation after servicing.

The ability to properly perform maintenance on this

equipment requires certain mechanical skills and

tools. If you are at all uncertain, contact your

dealer for qualified maintenance and service since

improper service could lead to furnace shutdown or

a hazardous condition which could lead to an

unsafe condition and bodily harm.

Combustion Component Check:

The heat exchanger, gas burners and venting system

must be checked each year, prior to the heating season,

by a qualified dealer/serviceman.

The following procedures should be performed:

1. Remove the burner/manifold assembly from the

furnace, follow the instructions found on this page.

2. Place the burner/manifold assembly on a flat work

area and vacuum the burners. It might be necessary

to use a soft bristly brush to remove dirt and then

vacuum.

3. Disconnect wiring to combustion blower.

4. Disconnect wiring to pressure switches, and remove

pressure switches.

5. Remove the burner opening inlet plate and the flue

collector box with the combustion blower attached.

This will expose both the burner and flue openings of

the primary heat exchangers.

6. Vacuum the length of each heat exchanger tube

using a straight attachment into the burner openings

and the flue openings.

7. Replace the flue collector box, burner opening inlet

plate, and burner/manifold assembly. Insure that all

gaskets are properly positioned and that no leaks

exist.

8. Reattach all wiring and piping as per the wiring

diagram and installation instructions.

9. Turn on utilities and check for leaks using soapy

water and a brush.

10. A visual check of the main burner should be made at

the beginning of each heating season.

11. Check the input rate and adjust if necessary.

12. Perform a safety check of the limit control and

pressure switch.

13. Check the air filter, clean and/or replace as

necessary.

14. Replace the appropriate access panels or door.

Never use an open flame when testing for gas

leaks! Use of an open flame could lead to a fire or

explosion!

Many soaps used for leak testing are corrosive to

certain metals. Piping must be rinsed thoroughly

with clean water after leak check has been

completed.

Manifold (or Burner/Manifold) Removal/Replacement:

1. Make sure that all utilities (gas and electricity) are

turned off upstream of the furnace.

2. Remove the louvered access door by sliding the door

straight up, swinging the bottom of the door away

from the furnace, and pulling the door down and out

of the furnace (See Figure 17).

3. Disconnect the gas line from the gas valve. Be sure

that a wiring diagram is available, or be ready to

mark any wires that are disconnected. Unplug the

three connectors from the gas valve.

Figure 17

FURNACE PANEL REMOVAL

20571201 Issue 0527 Page 24 of 28

Page 25

4. Disconnect wires from rollout switch.

5. Remove manifold or burner/manifold assembly.

Manifold ONLY

a. Remove the No. 10 screws that secure the

manifold pipe to both legs of the manifold

assembly. The manifold pipe must be

supported during this step, or it could fall and

damage the furnace or cause bodily injury!

b. Slide the manifold pipe (with valve and orifice)

forward, out of the furnace.

Burner/Manifold Assembly

a. Remove the No. 10 screws that secure the

burner/manifold assembly legs to the furnace.

The manifold pipe must be supported during

this step, or it could fall and damage the

furnace or cause bodily injury!

b. Slide the burner/manifold assembly forward, out

of the furnace until the assembly is clear of the

manifold retention pins.

c. Rotate the assembly slightly, in order for the legs

to clear the sides of the cabinet, and remove

through the front of the furnace.

8. To reinstall the manifold pipe or burner/manifold

assembly, reverse the above steps.

Replacement