Alliance Laundry Systems CA050L, CA050N, CU050N, DR50G2-BA050N, DR50G2-BA050L Installation Manual

...

Tumble Dryers

TMB795C

50 Pound Capacity

75 Pound Capacity

Starting Serial No. 0904004427

Refer to Page 5 for Model Identification

Installation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

TMB795C

Part No. 70420301ENR8

July 2012

Installation must conform with local codes or, in the absence of local codes, with:

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in your building.

– Clear the room, building or area of all occupants.

– Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

– If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

W052

FOR YOUR SAFETY, the information in this manual must be followed to minimize the risk

of fire or explosion or to prevent property damage, personal injury or death.

W033

WARNING

In the U.S.A.

NFPA 54 “National Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric Code.”

In Canada

Installation Code and CSA C22.1, latest edition, Canadian Electric Code, Part I.

In Australia and New Zealand

Part 1: General Installations.

, installation must conform to the latest edition of the American National Standard Z223.1/

, installation must comply with Standards CAN/CSA-B149.1 or Natural Gas and Propane

, installation must comply with the Gas Installations Standard AS/NZS 5601

IMPORTANT: Information must be obtained from a local gas supplier on instructions to be followed if the

user smells gas. These instructions must be posted in a prominent location. Step-by-step instructions of the

above safety information must be posted in a prominent location near the tumble dryer for customer use.

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

The following information applies to the state of Massachusetts, USA.

• Installation of unit must be performed by a qualified installer.

• Install tumble dryer according to manufacturer’s instructions and local codes.

• DO NOT install a tumble dryer with flexible plastic venting materials. If flexible metal (foil

type) duct is installed, it must be of a specific type identified by the appliance manufacturer

as suitable for use with tumble dryer. Refer to section on connecting exhaust system.

Flexible venting materials are known to collapse, be easily crushed, and trap lint. These

conditions will obstruct tumble dryer airflow and increase the risk of fire.

W752R1

WARNING

FOR YOUR SAFETY

Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

W053

• This appliance can only be installed by a Massachusetts licensed plumber or gas fitter.

• This appliance must be installed with a 36 inch (91 cm) long flexible gas connector.

• A “T-Handle” type gas shut-off valve must be installed in the gas supply line to this appliance.

• This appliance must not be installed in a bedroom or bathroom.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

Table of

Contents

Introduction......................................................................................... 5

Model Identification ............................................................................. 5

Customer Service.................................................................................. 7

Wiring Diagram .................................................................................... 7

Serial Plate Location............................................................................. 7

Safety Information.............................................................................. 8

Important Safety Instructions ............................................................... 9

Specifications and Dimensions........................................................... 11

Cabinet Dimensions.............................................................................. 12

Exhaust Outlet Locations...................................................................... 13

Gas Connection Locations.................................................................... 14

Electrical Connection Locations........................................................... 15

Steam Connection Locations ................................................................ 16

Installation........................................................................................... 17

Pre-Installation Inspection .................................................................... 17

Location Requirements......................................................................... 18

Position and Level the Tumble Dryer................................................... 19

Bolt-On Angle Option .......................................................................... 19

To Reverse the Loading Door............................................................... 21

Before Placing Tumble Dryer into Service .......................................... 24

Required for CE Models Only.............................................................. 25

Installing CE Gas Drying Tumble Dryers ............................................ 25

General Information......................................................................... 25

Basic Configuration ......................................................................... 27

Specific Conversion Procedures ...................................................... 27

Exhaust Requirements ....................................................................... 30

Layout ................................................................................................... 30

Make-Up Air......................................................................................... 30

Venting ................................................................................................. 30

Individual Venting ........................................................................... 31

Manifold Venting............................................................................. 31

Gas Requirements............................................................................... 35

Gas Supply Pipe Sizing and Looping ................................................... 37

High Altitude Burner Orifice Sizing..................................................... 39

Electrical Requirements..................................................................... 40

Grounding Instructions ......................................................................... 41

For CE Models Only........................................................................ 41

Service/Ground Location ................................................................. 42

To Connect Electrical Service To The Tumble Dryer.......................... 43

Jumper Configuration Instructions ....................................................... 44

Ferrite Ring Installation........................................................................ 44

50 Pound Gas and Steam Models ......................................................... 45

75 Pound Gas and Steam Models ......................................................... 46

50 and 75 Pound Electric Models......................................................... 47

© Copyright 2012, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Steam Requirements........................................................................... 48

Piping Recommendations ..................................................................... 49

Installing Steam Trap and Making Condensate

Return Connections ............................................................................ 49

Thermal Oil Prep .................................................................................. 49

Single Drop Timer .............................................................................. 51

Power-Up Mode.................................................................................... 51

Ready Mode.......................................................................................... 51

Start Mode ............................................................................................ 51

Run Mode ............................................................................................. 51

Setting Dry Time Dipswitches.............................................................. 51

Resetting Cycle Time to Zero............................................................... 51

Dipswitch Settings................................................................................ 52

Adjustments......................................................................................... 54

Gas Burner Air Shutter ......................................................................... 54

Airflow Switch...................................................................................... 55

Loading Door Switch............................................................................ 55

Loading Door Catch ............................................................................. 55

Drive Belt.............................................................................................. 56

Nonreversing Models....................................................................... 56

Reversing Models ............................................................................ 56

Removing Tumble Dryer from Service............................................. 59

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

Introduction

Model Identification

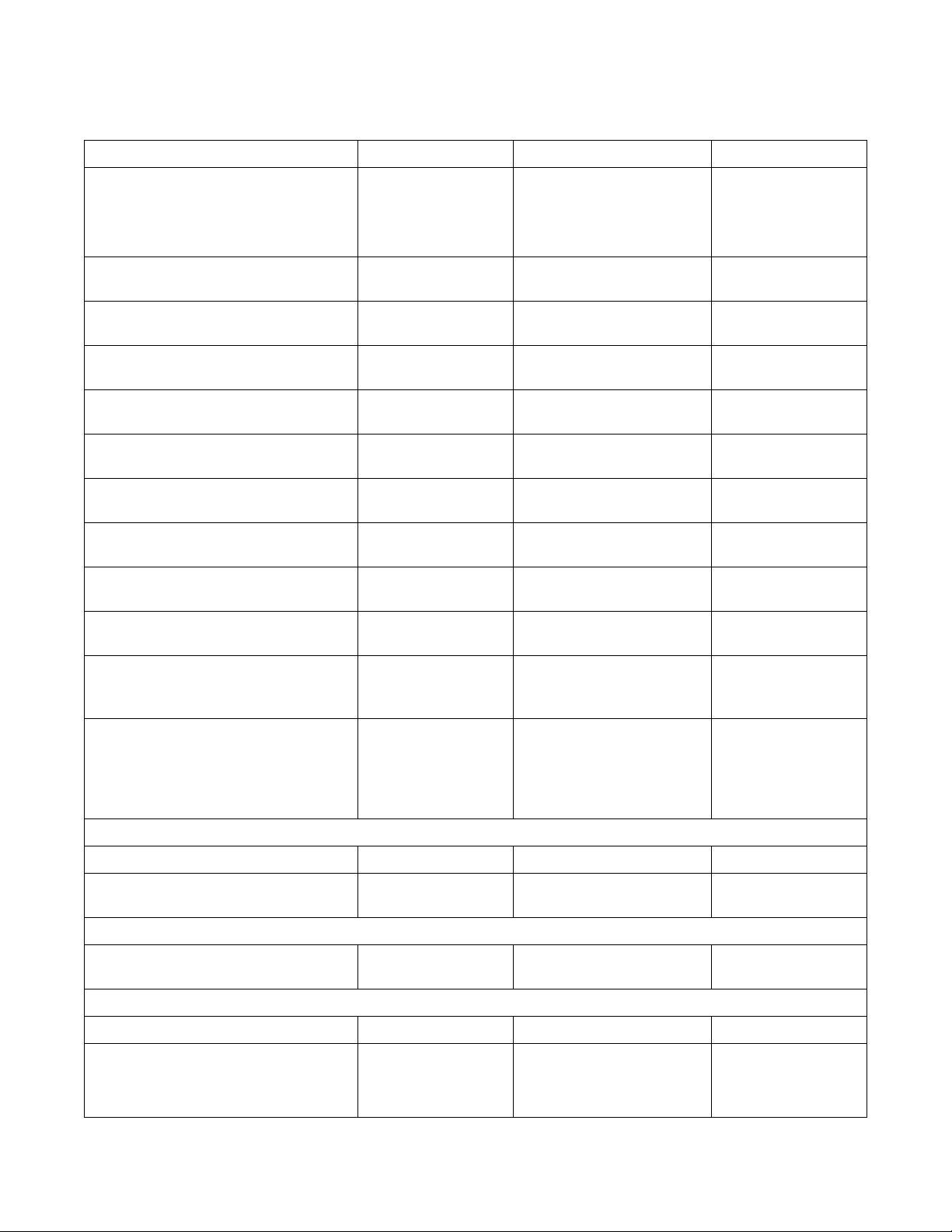

Information in this manual is applicable to these models:

Gas Steam/Thermal Oil Electric

CA050L

CA050N

CT050L

CT050N

CU050L

CU050N

DR50G2-BA050L

DR50G2-BA050N

DR50G2-BT050D

DR50G2-BT050L

50 Pound

DR50G2-BT050N

DR50G2-BU050L

DR50G2-BU050N

DR55G2-BA050L

DR55G2-BA050N

DR55G2-BT050D

CA075L

CA075N

CT075L

CT075N

CU075L

CU075N

DR75G2-BA075L

DR75G2-BA075N

DR75G2-BT075D

DR75G2-BT075L

75 Pound

DR75G2-BT075N

DR75G2-BU075L

DR75G2-BU075N

DR80G2-BA075L

DR80G2-BA075N

DR80G2-BT075D

DR80G2-BT075L

DR55G2-BT050L

DR55G2-BT050N

DR55G2-BU050L

DR55G2-BU050N

HA050L

HA050N

HT050D

HT050L

HT050N

HU050L

HU050N

IPD50G2-IT050L

IPD50G2-IT050N

SA050L

SA050N

ST050D

DR80G2-BT075N

DR80G2-BU075L

DR80G2-BU075N

HA075L

HA075N

HT075D

HT075L

HT075N

HU075L

HU075N

IPD75G2-IT075L

IPD75G2-IT075N

SA075L

SA075N

ST075D

ST075L

ST075N

ST050L

ST050N

SU050L

SU050N

UA050L

UA050N

UT050L

UT050N

UU050L

UU050N

YT050L

YT050N

YU050L

YU050N

STF75L

STF75N

SU075L

SU075N

UA075L

UA075N

UT075L

UT075N

UTF75L

UTF75N

UU075L

UU075N

YT075L

YT075N

YU075L

YU075N

(see next page for control suffixes)

CT050S

CT050T

CU050S

CU050T

DR50S2-BT050S

DR50S2-BT050T

DR50S2-BU050S

DR50S2-BU050T

DR55S2-BT050S

DR55S2-BT050T

DR55S2-BU050S

DR55S2-BU050T

HT050S

HT050T

HU050S

HU050T

CT075S

CT075T

CU075S

CU075T

DR75S2-BT075S

DR75S2-BT075T

DR75S2-BU075S

DR75S2-BU075T

DR80S2-BT075S

DR80S2-BT075T

DR80S2-BU075S

DR80S2-BU075T

HT075S

HT075T

HU075S

HU075T

IPD50S2-IT050S

IPD50S2-IT050T

ST050S

ST050T

SU050S

SU050T

UT050S

UT050T

UU050S

UU050T

YT050S

YT050T

YU050S

YU050T

IPD75S2-IT075S

IPD75S2-IT075T

ST075S

ST075T

SU075S

SU075T

UT075S

UT075T

UU075S

UU075T

YT075S

YT075T

YU075S

YU075T

CT050E

CU050E

DR50E2-BT050E

DR50E2-BU050E

DR55E2-BT050E

DR55E2-BU050E

HT050E

HU050E

IPD50E2-IT050E

ST050E

SU050E

UT050E

UU050E

YT050E

YU050E

CT075E

CU075E

DR75E2-BT075E

DR75E2-BU075E

DR80E2-BT075E

DR80E2-BU075E

HT075E

HU075E

IPD75E2-IT075E

ST075E

SU075E

UB075E

UT075E

UU075E

YT075E

YU075E

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Introduction

Includes models with the following control suffixes:

3B – reversing DX4 vended

3O – DX4 OPL

3V – DX4 vended

3W – reversing DX4 prep for coin

3X – DX4 prep for coin

BB– reversing basic electronic, coin

BC – basic electronic, coin

BL – basic electronic, central pay

BW – reversing basic electronic, prep

for coin

BX – basic electronic, prep for coin

BY – basic electronic, prep for card

BZ – reversing basic electronic, prep

for card

DO – DMP OPL

DV – DMP vended

DX – DMP prep for coin

EO – OPL electronic

KB – reversing single coin

KC – single coin

KW – reversing prep for coin

KX – prep for coin

KY – prep for card

KZ – reversing prep for card

LB – reversing network adaptable coin

LC – network adaptable coin

LW – reversing network adaptable,

prep for coin

LX – network adaptable, prep for coin

LY – network adaptable, prep for card

LZ – reversing network adaptable,

prep for card

OM – OPL micro

QT – dual digital timer

R3 – reversing DX4 OPL

RD – reversing DMP OPL

RE – reversing OPL electronic

RM – reversing OPL micro

RQ – reversing dual digital timer

RU – reversing UniLinc OPL

SD – single drop

SX – single drop, prep for coin

UO – UniLinc OPL

WB – reversing network ready coin

WC – network ready coin

WW – reversing network ready, prep

for coin

WX – network ready, prep for coin

WY – network ready, prep for card

WZ – reversing network ready, prep

for card

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

Introduction

1

0

2

0

4

0

3

0

5

0

6

0

0

1

0

5

PUSH

TO

START

HEAT

COOL

DOWN

HIGH

TEMP

ERATUR

E

LOW

1

5

0

1

1

Customer Service

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call (920) 748-3121.

Wiring Diagram

The wiring diagram is located in the junction or

contactor box.

The wiring diagram part number is in the lower

portion of the electrical data on the serial plate.

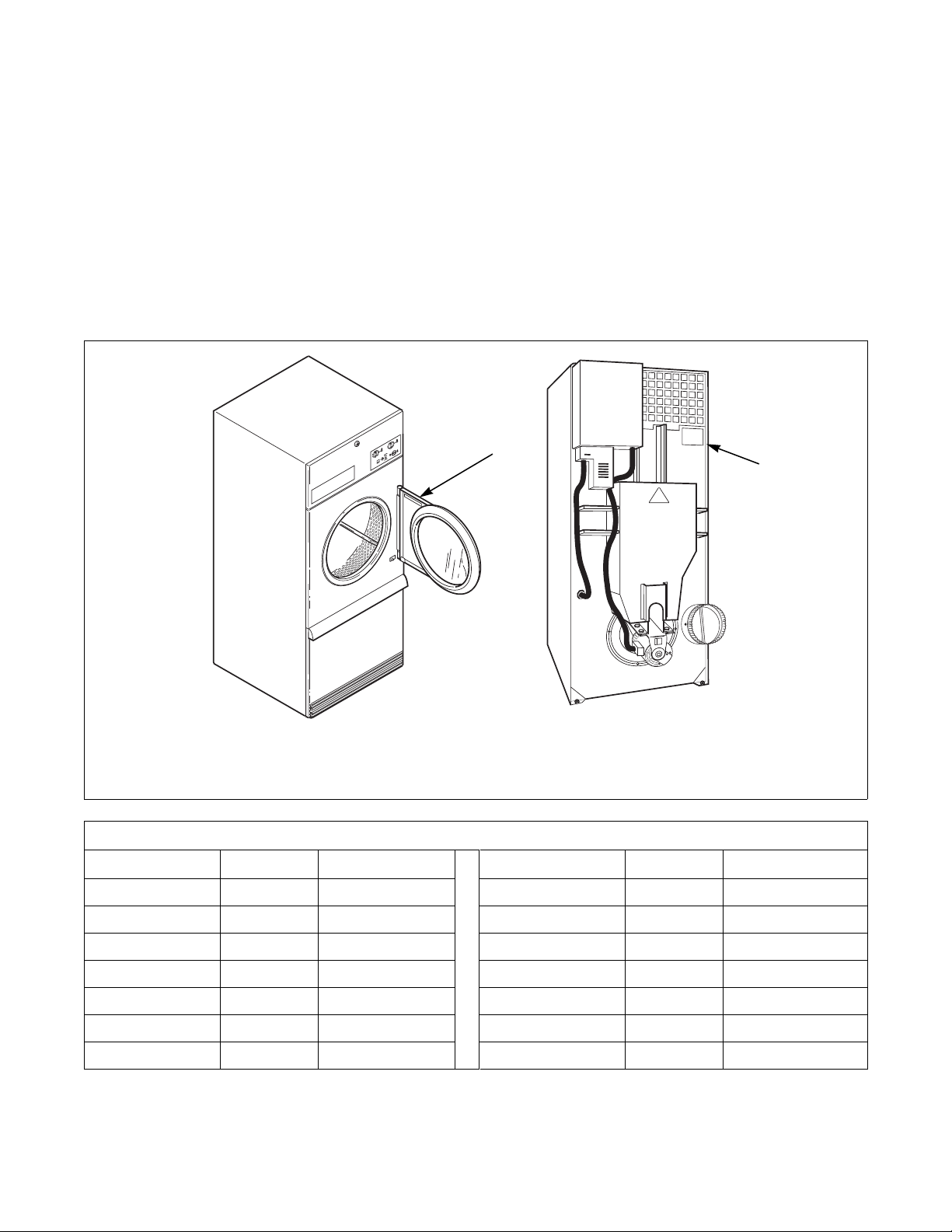

Serial Plate Location

When calling or writing for information about your

product, be sure to mention model and serial numbers.

Model and serial numbers are found on serial plate on

the rear of machine and inside door.

1 Serial Plate

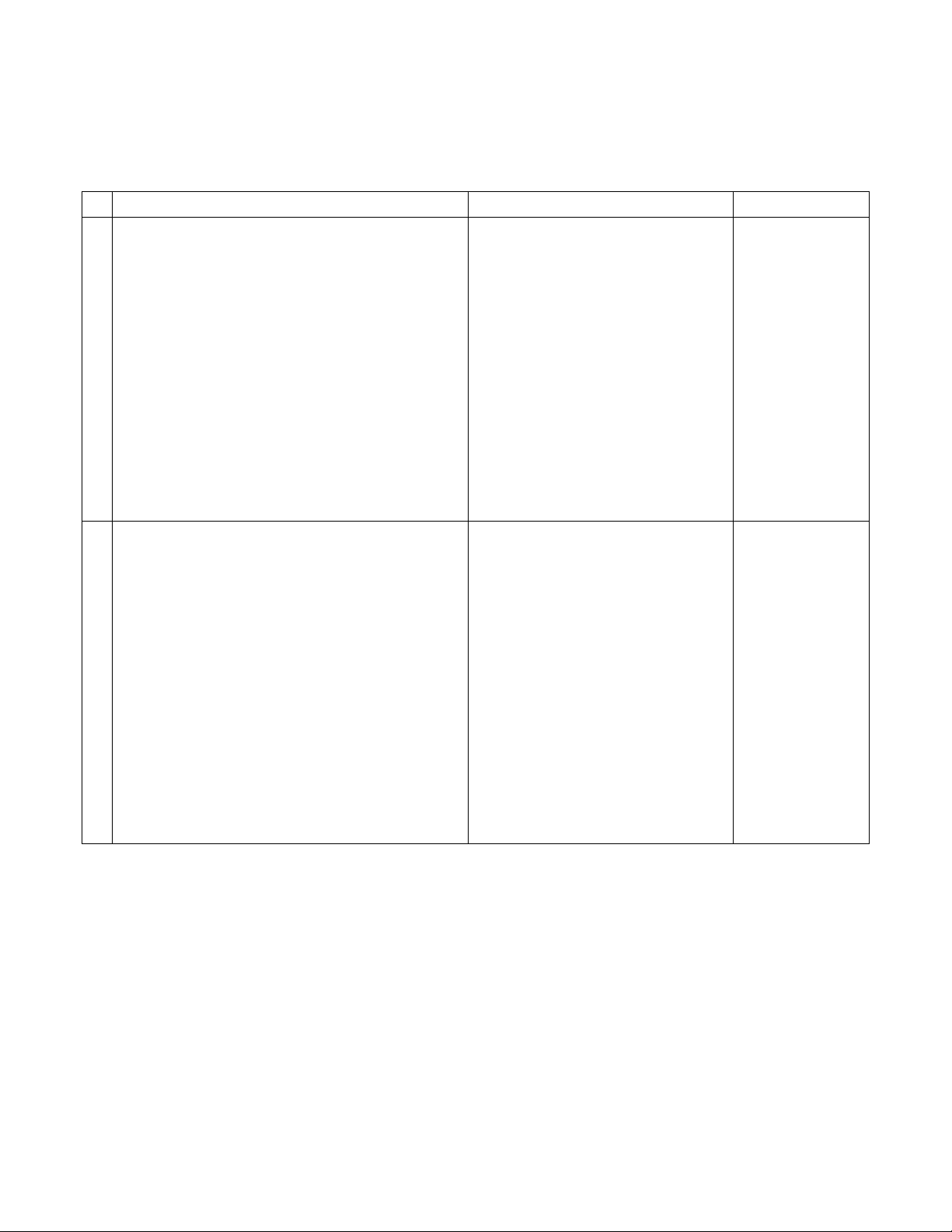

Conversion Table

Multiply By To Obtain Multiply By To Obtain

Btu 0.252 kCal Pounds/sq. inch 0.06895 Bars

Btu 1055 Joules Pounds/sq. inch 0.070 kg/sq. cm

Inch 25.4 Millimeters Pounds (lbs.) 0.454 Kilograms

Inches W.C. 0.036 Pounds/sq. inch Boiler Horsepower 33,479 Btu/hr.

Inches W.C. 0.249 kPa Boiler Horsepower 34.5 lbs. steam/hr.

lb./inch

ft

70420301 (EN)

2

(psi) 6.895 kPa CFM 0.471 liters/second

3

28.32 Liters kW 3414 Btu/hr.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TMB2235N

7

Safety Information

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

CAUTION

Failure to install, maintain, and/or operate

this machine according to manufacturer’s

instructions may result in conditions which

can produce serious injury, death and/or

property damage.

W051R1

WARNING

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

NOTE: The WARNING and IMPORTANT

instructions appearing in this manual are not

meant to cover all possible conditions and

situations that may occur. It must be understood

that common sense, caution and carefulness are

factors which CANNOT be built into this tumble

dryer. These factors MUST BE supplied by the

person(s) installing, maintaining or operating the

tumble dryer.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

Always contact your dealer, distributor, service agent

or the manufacturer on any problems or conditions you

do not understand.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

Save These Instructions

Hazardous Voltage. Can cause shock, burn

or cause death. Allow machine power to

remain off for two minutes prior to working

in and around AC inverter drive.

W359

WARNING

Safety Information

Important Safety Instructions

1. Read all instructions before using the tumble

dryer.

2. Refer to the GROUNDING INSTRUCTIONS

for the proper grounding of the tumble dryer.

3. Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry cleaning solvents, other flammable

or explosive substances as they give off vapors

that could ignite or explode.

4. Do not allow children on or in the tumble dryer.

This appliance is not intended for use by young

children or infirm persons without supervision.

Young children should be supervised to ensure

that they do not play with the appliance.

5. Before the tumble dryer is removed from service

or discarded, remove the door to the drying

compartment and the door to the lint

compartment.

6. Do not reach into the tumble dryer if the cylinder

is revolving.

7. Do not install or store the tumble dryer where it

will be exposed to water and/or weather.

8. Do not tamper with the controls.

9. Do not repair or replace any part of the tumble

dryer, or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out.

13. Keep area around the exhaust opening and

adjacent surrounding area free from the

accumulation of lint, dust and dirt.

14. The interior of the tumble dryer and the exhaust

duct should be cleaned periodically by qualified

service personnel.

15. If not installed, operated and maintained in

accordance with the manufacturer’s instructions

or if there is damage to or mishandling of this

product’s components, use of this product could

expose you to substances in the fuel or from fuel

combustion which can cause death or serious

illness and which are known to the State of

California to cause cancer, birth defects or other

reproductive harm.

16. Tumble dryer will not operate with the loading

door open. DO NOT bypass the door safety

switch to permit the tumble dryer to operate with

the door open. The tumble dryer will stop

tumbling when the door is opened. Do not use the

tumble dryer if it does not stop tumbling when

the door is opened or starts tumbling without

pressing or turning the START mechanism.

Remove the tumble dryer from use and call for

service.

17. Tumble dryer will not operate with lint panel

open. DO NOT bypass lint panel safety switch to

permit the tumble dryer to operate with the lint

panel open.

18. Do not put articles soiled with vegetable or cooking

oil in the tumble dryer, as these oils may not be

removed during washing. Due to the remaining

oil, the fabric may catch on fire by itself.

19. To reduce the risk of fire, DO NOT put clothes

which have traces of any flammable substances

such as machine oil, flammable chemicals,

thinner, etc. or anything containing wax or

chemicals such as in mops and cleaning cloths, or

anything dry-cleaned at home with dry-cleaning

solvent in the tumble dryer.

10. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

11. To reduce the risk of fire, DO NOT DRY plastics

or articles containing foam rubber or similarly

textured rubberlike materials.

12. Always clean the lint filter daily.

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

20. Use the tumble dryer only for its intended

purpose, drying fabrics.

21. ALWAYS disconnect and lockout the electrical

power to the tumble dryer before servicing.

Disconnect power by shutting off appropriate

breaker or fuse.

9

Safety Information

WARNING

To reduce the risk of serious injury, install

lockable door(s) to prevent public access

to rear of tumble dryers.

W055R1

22. Install this tumble dryer according to the

INSTALLATION INSTRUCTIONS. All

connections for electrical power, grounding, and

gas supply must comply with local codes and be

made by licensed personnel when required.

23. Remove laundry immediately after tumble dryer

stops.

24. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of reach of children at all times

(preferably in a locked cabinet).

25. Do not tumble fiberglass curtains and draperies

unless the label says it can be done. If they are

dried, wipe out the cylinder with a damp cloth to

remove particles of fiberglass.

26. Always follow the fabric care instructions

supplied by the garment manufacturer.

27. Never operate the tumble dryer with any guards

and/or panels removed.

28. DO NOT operate the tumble dryer if it is

smoking, grinding, has missing or broken parts.

29. DO NOT bypass any safety devices.

30. Solvent vapors from dry-cleaning machines

create acids when drawn through the heater of the

drying unit. These acids are corrosive to the

tumble dryer as well as to the laundry load being

dried. Be sure make-up air is free of solvent

vapors.

31. Failure to install, maintain, and/or operate this

machine according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

Specifications and Dimensions

Specifications 50 Pound 75 Pound F75

Noise level measured during

operation at operator position of

3.3 feet (1 meter) in front of

machine and 5.2 feet (1.6 meters)

from floor.

Net Weight (approximate):

Pounds (kg)

Standard Packaging Weight:

Pounds (kg)

Standard Packaging Shipping

Dimensions: Inch (mm)

Slat Crate Packaging Weight:

Pounds (kg)

Slat Crate Shipping Dimensions:

Inch (mm)

Cylinder Size:

Inches (mm)

Cylinder Capacity (dry weight):

Pounds (kg)

Air Outlet Diameter:

Inches (mm)

Maximum Static Back Pressure:

W.C.I. (mbar)

Maximum Airflow:

C.F.M. (L/sec.)

60 dBA 65 dBA 67 dBA

545

(247)

602

(273)

41.5 x 52.1 x 81

(1054 x 1323 x 2057)

669

(303)

44.5 x 55 x 87.75

(1130 x 1397 x 2229)

37 x 30

(940 x 762)

50

(22.7)

8

(203)

0.5

(1.3)

750

(354)

(1054 x 1433 x 2057)

44.5 x 59.25 x 87.75

(1130 x 1505 x 2229)

Gas/Steam 60 Hz 920 (434)

Gas/Steam 50 Hz 750 (354)

Electric 750 (354)

615

(279)

677

(307)

41.5 x 56.4 x 81

742

(337)

37 x 36

(940 x 914)

75

(34)

8

(203)

0.5

(1.3)

710

(322)

772

(350)

41.5 x 56.4 x 81

(1054 x 1433 x 2057)

837

(380)

44.5 x 59.25 x 87.75

(1130 x 1505 x 2229)

37 x 36

(940 x 914)

75

(34)

10

(254)

0.5

(1.3)

1100

(519)

Motor Horsepower:

Nonreversing

Reversing

Fan

Cylinder

Gas Connection

Gas Burner Rating:

Btu/hr. (Mj/hr.)

Heating Element Rating:

Kilowatts (kW)

Steam Connection

Steam Coil Rating at 100 psig:

Boiler Horsepower (Btu/hr.)

(recommended operating

pressure 80-100 psig)

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1/2

1/3

1/3

Gas Models

1/2 in. NPT 1/2 in. NPT 3/4 in. NPT

130,000

(137.2)

Electric Models

21 kW (240 V/50 Hz)

30 kW (other voltages)

Steam Models

3/4 in. NPT 3/4 in. NPT Not Applicable

5.1

(177,500)

3/4

1/3

1/3

165,000

(174.1)

30 kW Not Applicable

6.1

(210,300)

Not Applicable

Not Applicable

1

1/3

225,000

(237.4)

11

Specifications and Dimensions

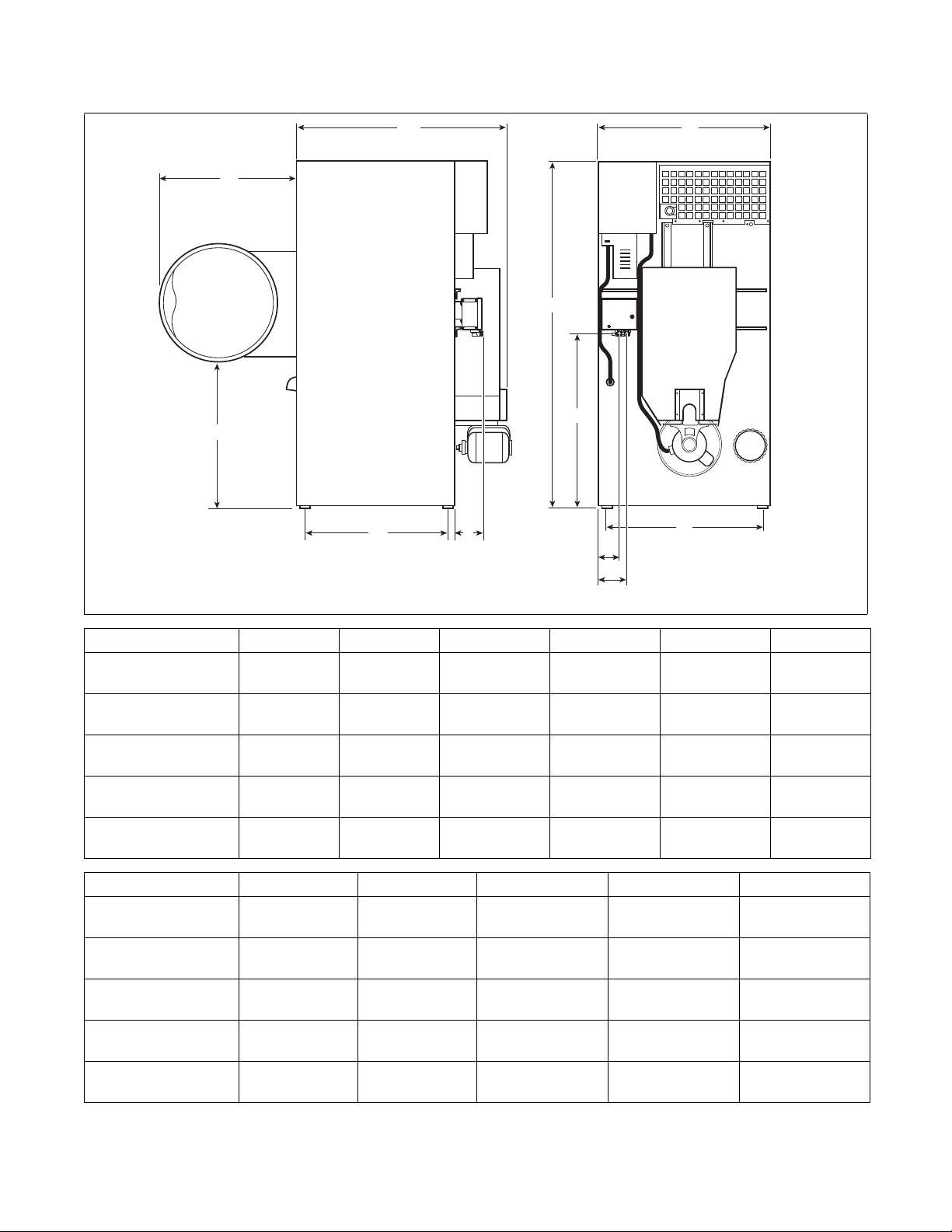

TMB2293N

C

B

F

D

A

K

G

J

E

I

H

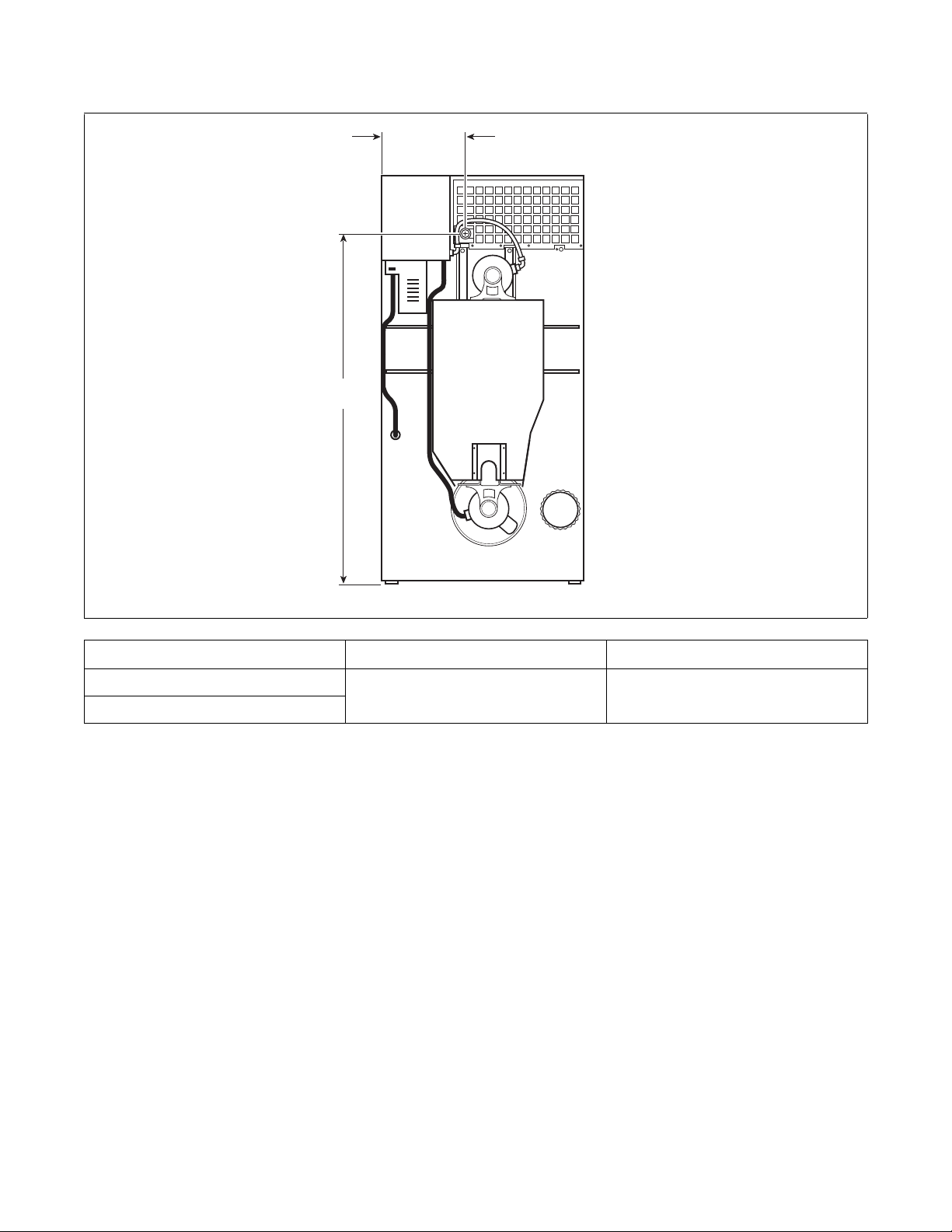

Cabinet Dimensions

Models A B C D E* F

50 Pound

Gas and Electric

50 Pound

Steam

75 Pound

Gas and Electric

75 Pound

Steam

F75

Gas

30.75 in.

(781 mm)

30.75 in.

(781 mm)

30.75 in.

(781 mm)

30.75 in.

(781 mm)

30.75 in.

(781 mm)

33.87 in.

(860 mm)

33.87 in.

(860 mm)

33.87 in.

(860 mm)

33.87 in.

(860 mm)

33.87 in.

(860 mm)

Models G H* I* J* K

50 Pound

Gas and Electric

50 Pound

Steam

75 Pound

Gas and Electric

75 Pound

Steam

F75

Gas

* Fire suppression system optional - may not be on machine.

33 in.

(838 mm)

33 in.

(838 mm)

33 in.

(838 mm)

33 in.

(838 mm)

33 in.

(838 mm)

7.1 in.

(180 mm)

7.1 in.

(180 mm)

7.1 in.

(180 mm)

7.1 in.

(180 mm)

7.1 in.

(180 mm)

48.25 in.

(1226 mm)

48.25 in.

(1226 mm)

54.25 in.

(1378 mm)

54.25 in.

(1378 mm)

54.25 in.

(1378 mm)

(140 mm)

(140 mm)

(140 mm)

(140 mm)

(140 mm)

5.5 in.

5.5 in.

5.5 in.

5.5 in.

5.5 in.

76.625 in.

(1946 mm)

80 in.

(2032 mm)

76.625 in.

(1946 mm)

80 in.

(2032 mm)

76.625 in.

(1946 mm)

(914 mm)

(914 mm)

(914 mm)

(914 mm)

(914 mm)

6.53 in.

(166 mm)

6.53 in.

(166 mm)

6.53 in.

(166 mm)

6.53 in.

(166 mm)

6.53 in.

(166 mm)

36 in.

36 in.

36 in.

36 in.

36 in.

TMB2293N

38.625 in.

(981 mm)

38.625 in.

(981 mm)

38.625 in.

(981 mm)

38.625 in.

(981 mm)

38.625 in.

(981 mm)

29.5 in.

(749 mm)

29.5 in.

(749 mm)

35.5 in.

(902 mm)

35.5 in.

(902 mm)

35.5 in.

(902 mm)

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

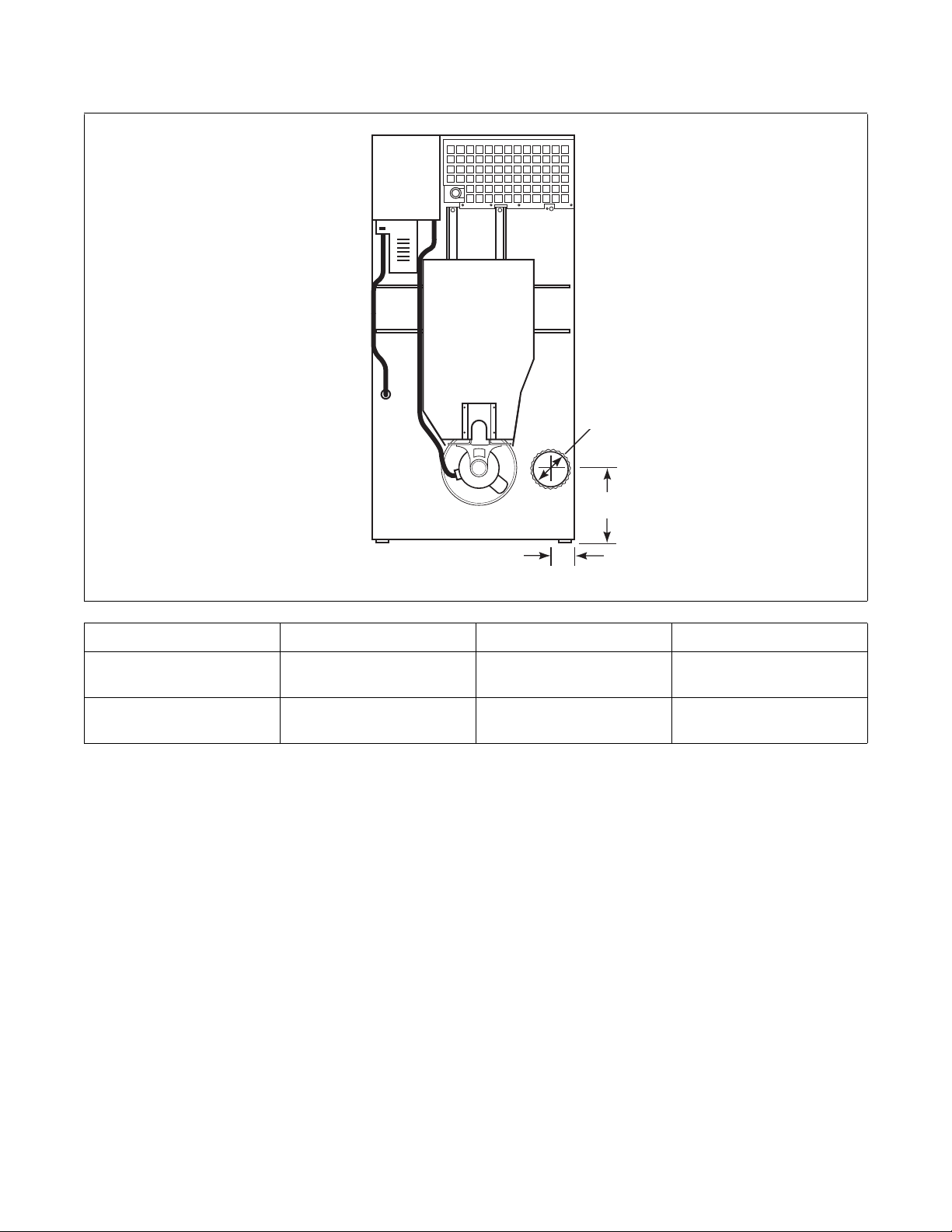

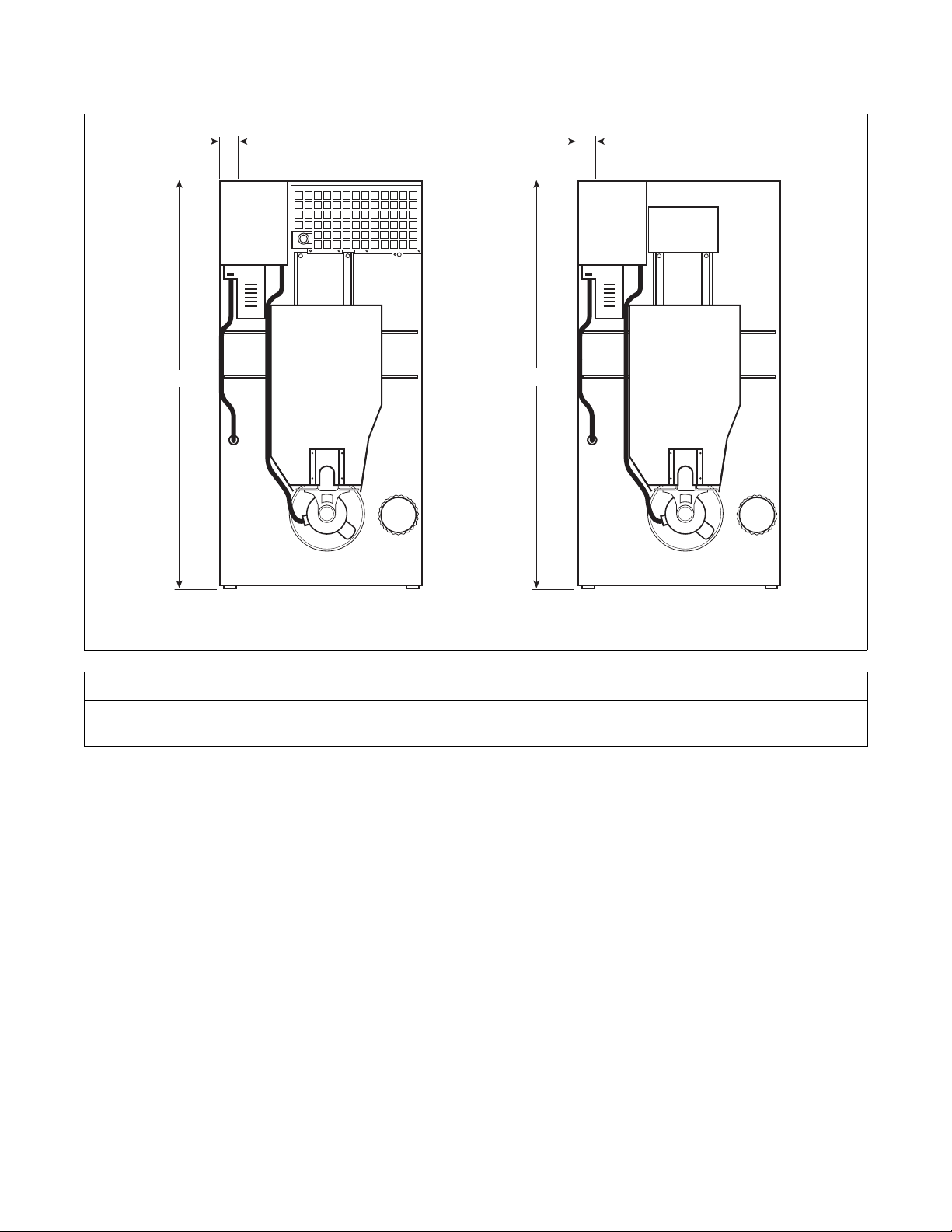

Exhaust Outlet Locations

A

B

C

Specifications and Dimensions

TMB2238N

ModelsABC

50/75 Pound

F75

5.375 in.

(137 mm)

6.5 in.

(165 mm)

8 in.

(203 mm)

10 in.

(254 mm)

13.375 in.

(340 mm)

6.5 in.

(165 mm)

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

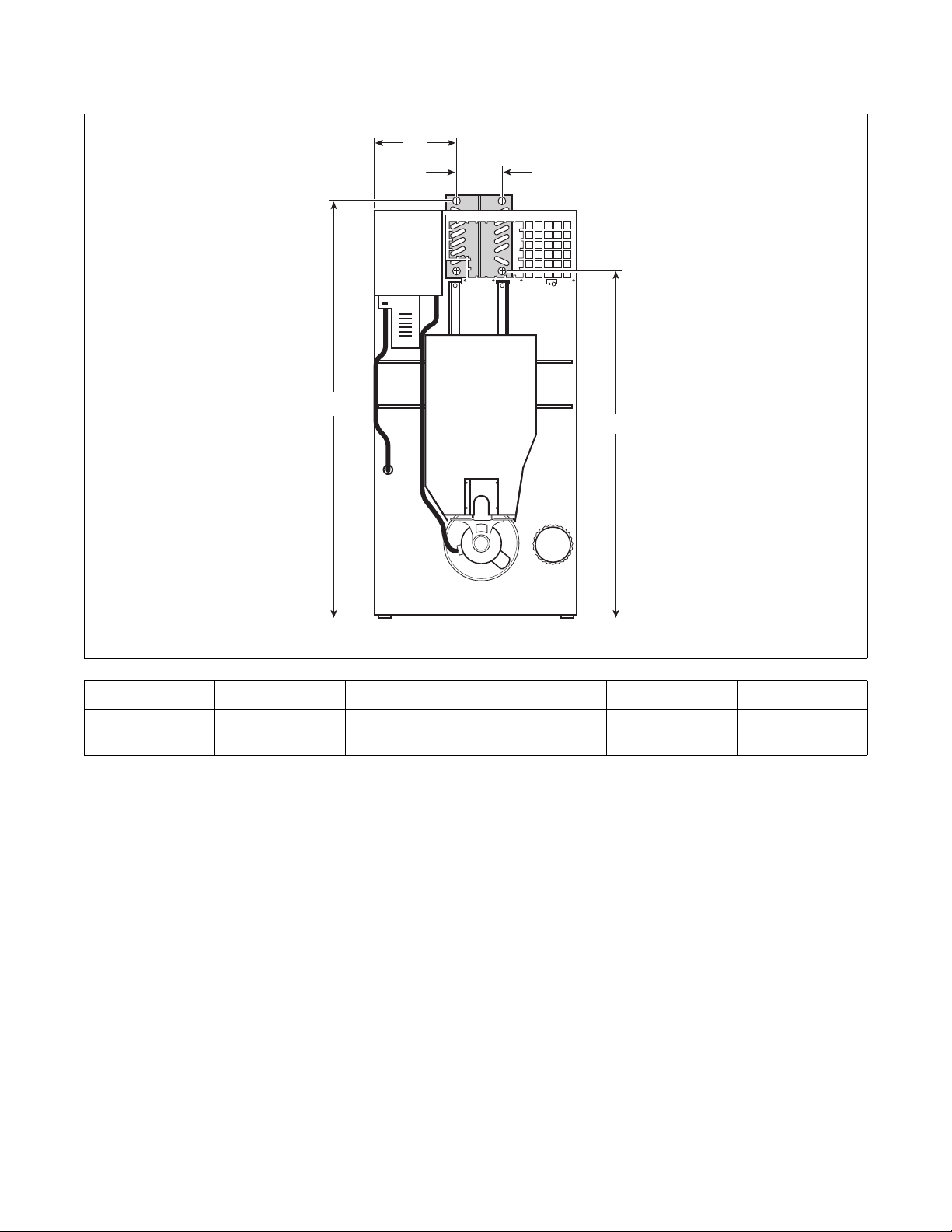

Specifications and Dimensions

A

B

Gas Connection Locations

Diameter A B

75 – 1/2 in. NPT 14.75 in.

F75 – 3/4 in. NPT

(375 mm)

TMB2239N

65.75 in.

(1670 mm)

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

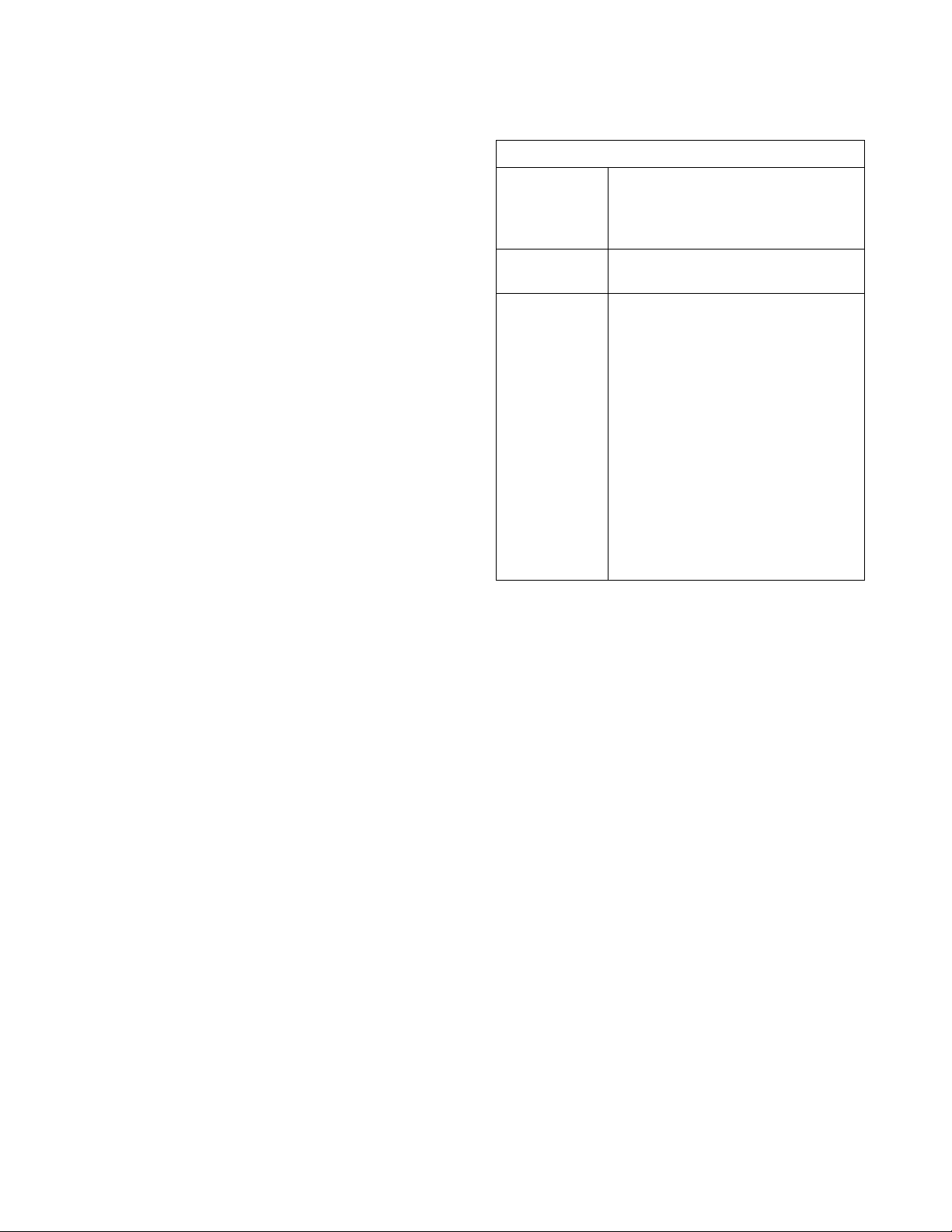

Electrical Connection Locations

GAS AND STEAM

ELECTRIC

A

A

B

B

Specifications and Dimensions

AB

3.25 in.

(83 mm)

NOTE: These figures are approximate dimensions only.

TMB2240N

75.5 in.

(1918 mm)

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Specifications and Dimensions

C

A

B

D

Steam Connection Locations

TMB2241N

ModelsDiameterABCD

50/75 Pound

3/4 in. NPT 15.5 in.

(394 mm)

78.25 in.

(1988 mm)

7.5 in.

(190 mm)

64.75 in.

(1645 mm)

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

70420301 (EN)

Installation

Pre-Installation Inspection

Upon delivery, visually inspect the crate, carton and

parts for any visible shipping damage. If the crate,

carton, or cover is damaged or signs of possible

damage are evident, have the carrier note the condition

on the shipping papers before the shipping receipt is

signed, or advise the carrier of the condition as soon as

it is discovered.

Remove the crate and protective cover as soon as

possible and check the items listed on the packing list.

Advise the carrier of any damaged or missing articles

as soon as possible. A written claim should be filed

with the carrier immediately if articles are damaged or

missing.

IMPORTANT: Remove the shipping tape from the

two back draft dampers located in the exhaust

outlet.

IMPORTANT: Warranty is void unless tumble

dryer is installed according to instructions in this

manual. Installation should comply with minimum

specifications and requirements detailed in this

manual and applicable local gas fitting regulations,

municipal building codes, water supply regulations,

electrical wiring regulations, and any other

relevant statutory regulations. Due to varied

requirements, applicable local codes should be

thoroughly understood and all pre-installation

work arranged for accordingly.

Materials Required (Obtain Locally)

One Single Pole fused disconnect

All Models

Gas Models

Steam Models

switch or circuit breaker on 1 Phase

models.

Circuit breaker on 3 Phase models.

One gas shut-off valve for gas service

line to each tumble dryer.

One steam shut-off valve for steam

service line to be connected upstream of

solenoid steam valve.

Two steam shut-off valves for each

condensate return line.

Flexible steam hoses with a 125 psig

(pounds per square inch gauge)

(8.79 kg/sq. cm) working pressure for

connecting steam coils. Refer to

Figure 22 for sizing and connection

configurations.

Two steam traps for steam coil outlets

to condensate return line.

Optional – Two vacuum breakers for

condensate return lines.

IMPORTANT: Keep tumble dryer area clear and

free from combustible materials, gasoline and other

flammable vapors and liquids.

NOTE: 3 Phase Only – Each tumble dryer must be

connected to its own individual branch circuit

breaker, not fuses, to avoid the possibility of “single

phasing” and causing premature failure of the

motor(s).

70420301 (EN)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Loading...

Loading...