Alliance Laundry Systems ATEE9AWP433AW01, FTEE5ASP303ZW01, BTGE6ASP113TW01, FTEE5ASP303NW10, FTGE5ASP303NW10 Troubleshooting Manual

...

Homestyle

SWD456C

Stacked Washer/

Dryers

Refer to Page 6 for Model Numbers

Troubleshooting

SWD456C

Table of

Section 1 – Safety Information ...............................................................3

Locating an Authorized Servicer...........................................................4

Contents

Section 2 – Introduction ..........................................................................5

Customer Service...................................................................................5

Nameplate Location...............................................................................5

Model Identification ..............................................................................6

Theory of Operation ..............................................................................7

Section 3 – General Troubleshooting.....................................................8

1. Keypad Combinations...................................................................8

2. Factory Test Procedure ...............................................................10

3. Motor Circuit...............................................................................16

4. Dipswitch Configuration.............................................................17

5. Troubleshooting Knocking Noise ...............................................18

6. Explanation of LEDs on Drive Control ......................................18

7. Door Fails to Unlock at End of Cycle.........................................18

8. No Spin .......................................................................................18

9. Excessive Vibration and/or Noise During Spin..........................20

10. Excessive Cycle Time.................................................................21

Section 4 – Dryer Control Troubleshooting ........................................22

7. Dryer Error Code Listing ............................................................22

8. Dryer Motor Does Not Run ........................................................24

9. Dryer Stops in Cycle; Quits After the First Few Loads;

Has a Burning Smell; Cycles On Motor Thermal Protector .......26

10. Dryer Motor Runs But Cylinder Does Not Turn ........................27

11. Dryer Motor Does Not Stop .......................................................28

12. Dryer Runs Only When Door is Open ........................................29

13. Dryer Heating Assembly Does Not Heat or

Burner Does Not Ignite...............................................................30

14. Igniter Does Not Glow (Gas Supply Sufficient)

– Gas Dryer Models ....................................................................32

15. Burner Ignites and Goes Out Repeatedly

– Gas Dryer Models ....................................................................33

16. Igniter Glows But Burner Does Not Ignite

– Gas Dryer Models ....................................................................34

17. Dryer Heater Assembly or Burner Shuts Off Prematurely .........35

18. Dryer Heater Assembly or Burner Repeatedly Cycles

Off On Limit Thermostat ............................................................36

19. Dryer Heater Assembly or Burner Does Not Shut Off ...............38

20. Clothes Do Not Dry in Dryer......................................................39

21. Timer Does Not Advance in Automatic Cycle ...........................40

22. Clothes Are Too Hot When Removed From Dryer ....................41

23. Excessive Chattering or Vibrating Noise in Dryer .....................42

24. Excessive Humming or Whistling Noise in Dryer......................43

1

Section 5 – Washer Control Troubleshooting.....................................44

25. Error Codes .................................................................................44

26. No keypad Function ....................................................................51

27. No Visible Display on Control....................................................52

28. Washer Will Not Start – “do” Displayed....................................54

29. Washer Will Not Start – “Er”, “dl” on Display ..........................56

30. Washer Will Not Fill (Machine Empty,

No “Er”, “PS” on Display)..........................................................58

31. Washer Overflows.......................................................................60

32. Pump or Drain Valve Does Not Operate ....................................62

33. Motor Does Not Run (“Ed”, “29” on Display) ...........................64

34. Washer Will Not Heat (Models Equipped with Heater)

(“Er”, “oP” or “Er”, “SH” Displayed) ........................................66

35. Washer Will Not Heat (Models Equipped with Heater) .............68

Section 6 – Adjustments ........................................................................70

36. Cabinet Leveling Legs ................................................................70

37. Washer Loading Door.................................................................71

38. Washer Motor Belt Tension........................................................72

39. Washer Door Catch.....................................................................73

40. Shipping Braces ..........................................................................75

41. Burner Flame (Gas Models)........................................................76

Section 7 – Dryer Test Procedures .......................................................77

42. Timer Contacts............................................................................77

43. Fabric Selector Switch ................................................................78

44. Drive Motor.................................................................................79

45. Motor Switch...............................................................................82

46. Burner System Operation............................................................84

47. Electrical Circuit To Ignition System (Gas Models) ..................85

48. Gas Valve Coils Check (Gas Models) ........................................85

49. Sensor Check (Gas Models)........................................................86

50. Igniter Check (Gas Models)........................................................86

51. Thermal Fuse (Electric Models) .................................................87

52. Heater Assembly (Electric Models)............................................87

53. Cycling or Limit Thermostat.......................................................87

54. Door Switch ................................................................................88

Section 8 – Internal Wiring of Dryer Motor Switch...........................89

Section 9 – Cycle Sequence Charts.......................................................90

2 806221

Section 1

• Failure to install, maintain, and/or operate this machine according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or

property damage.

• Do not repair or replace any part of the machine or attempt any servicing unless specifically

recommended or published in this Service Manual and that you understand and have the

skills to carry out.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded and to reduce the risk of fire,

electric shock, serious injury, or death.

W284

WARNING

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer, and those maintaining the machine.

DANGER

Danger indicates an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

WARNING

Warning indicates a hazardous situation that, if not avoided, could cause severe personal injury or death.

CAUTION

Caution indicates a hazardous situation that, if not avoided, may cause minor or moderate personal injury or property

damage.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

806221 3

Safety Information

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect all electric power to the machine and accessories before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start machine with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

re

connected to ensure that the machine is properly grounded.

• Washer motor not grounded! Disconnect electric power before servicing motor.

W502

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you, or the inexperienced person making such

repairs, to the risk of serious injury, electrical shock, or death.

W007

WARNING

If you or an unqualified person perform service on your machine, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W286

WARNING

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the machine.

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized technician

and using authorized factory parts.

4 806221

Section 2

SWD1716S

Nameplate

Nameplate

SWD1716S

Introduction

Nameplate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

806221 5

Introduction

Model Identification

Information in this manual is applicable to these models.

ATEE9AWP433AW01

ATGE9AWP303AW01

BTEE6ASP173TW01

BTEE6ASP283CW01

BTGE6ASP093CW01

BTGE6ASP113TW01

FTEE5ASP303NW10

FTEE5ASP303ZW01

FTGE5ASP303NW10

LTEE5ASP153TW01

LTEE5ASP173TW01

LTEE5ASP293CW01

LTEE5ASP303ZW01

LTEE5ASP333NW01

LTEE5ASP433AW01

LTEE5ASP433AW12

LTEE5ASP543NW23

LTGE5ASP113JW01

LTGE5ASP113TW01

LTGE5ASP303AW01

LTGE5ASP303AW12

LTLE5ASP543NW23

UTEE5ASP173TW01

UTEE5ASP173TW08

UTEE5ASP283CW01

UTGE5ASP113TW01

UTGE5ASP113TW08

YTEE5ASP173TW01

YTEE5ASP283CW01

YTGE5ASP093CW01

YTGE5ASP113TW01

6 806221

Introduction

Theory of Operation

General (Dryer)

The dryer uses heated air to dry loads of laundry.

When the motor is started, the exhaust fan pulls fresh

air in through louvers at the rear of the dryer and over

the heat source (burner flame for gas and heating

element for electric). The heated air moves through the

heater duct and into the cylinder, where it circulates

through the wet load. The air then passes through the

lint filter, air duct and exhaust fan, where it is vented

to the outdoors.

General (Washer)

This frontload washer provides some of the same

principles of operation as the typical topload washers.

It senses water level, it dispenses the desired laundry

detergent, agitates the clothes for good cleaning action,

removes the water out of the washer and spins the

clothing in preparation for the dryer.

The difference in operation is primarily the rotational

washing agitation created for the horizontal basket and

drum. This agitation tumbles the clothes in a clockwise,

pause, and counter-clockwise direction. This reversing

tumbling action provides an efficient washing process

and requires less laundry detergent and less water.

The cycle begins by locking the loading door after the

vend is satisfied. The type of cycle and water

temperature are determined by the appropriate pads on

the electronic control.

The inner basket starts agitating during the wash water

fill. A column of air is trapped in a pressure bulb and

hose. The air pressure continues to increase as the inner

basket fills with water with the pressure sensor

monitoring the water level.

The agitate step tumbles the clothing in a clockwise

direction for a period of time, pauses for a period of

time and then tumbles the clothing in a

counterclockwise direction for a period of time. This

agitation continues until the end of the wash cycle. The

machine then stops agitating and turns on the pump or

drain valve which removes the wash water.

After all the rinse cycles have been completed, the

washer goes into a final spin cycle to extract as much

water as possible from the clothing to prepare them for

the dryer. The spin speeds and duration of this final

spin cycle are determined by the type of wash cycle

selected.

NOTE: Washer may not reach 1200 RPM because

of an out-of-balance condition. Control may limit

speed to 1000, 800, 650 or 500 RPM depending on

severity of out-of-balance condition.

Technical (Washer)

The basic operational system of this washer consists of

the electronic control, the inverter control, pressure

sensor, water valves, electric pump (or drain valve)

and A.C. motor.

The electronic control performs all control and timing

functions. The electronic control sends simple speed

and output commands to the inverter control via serial

communication. The drive control powers the door

lock, pump (or drain valve), motor, water valves and

heater (if equipped).

The drive control powers the A.C. motor and performs

all motor control functions. The drive control also

powers the water valves, dispenser valves and door

lock. The drive control is powered through the door

switch and electronic control. The drive control also

alerts the electronic control to any errors in the motor.

Before entering any spin step the drive control

measures out-of-balance. The drive control will try to

redistribute the clothes if an out-of-balance condition

exists by limiting the spin speed to several speeds

depending on the severity of the out-of-balance

condition. If the out-of-balance condition is severe

enough the drive control will limit speed to 90 RPM

and will not spin.

NOTE: An additional out-of-balance switch is used

to detect any out-of-balance condition during spins.

If this switch opens during a spin step, the drive

control immediately stops and then restarts the

spin.

Upon completion of the wash cycle, the machine goes

into a rinse cycle. Fresh cold water is brought into the

inner basket via the mixing valve until the fill level is

satisfied. The rinse cycle consists of agitation for a

predetermined amount of time then a spin mode with

the pump running where the machine goes into a series

of spins.

806221 7

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

FLW1815S

1

2

3

5

6

7

8

9

10

11

12

16

17

21

28

22

23

26 27

25

24

13 18

14 19

15 204

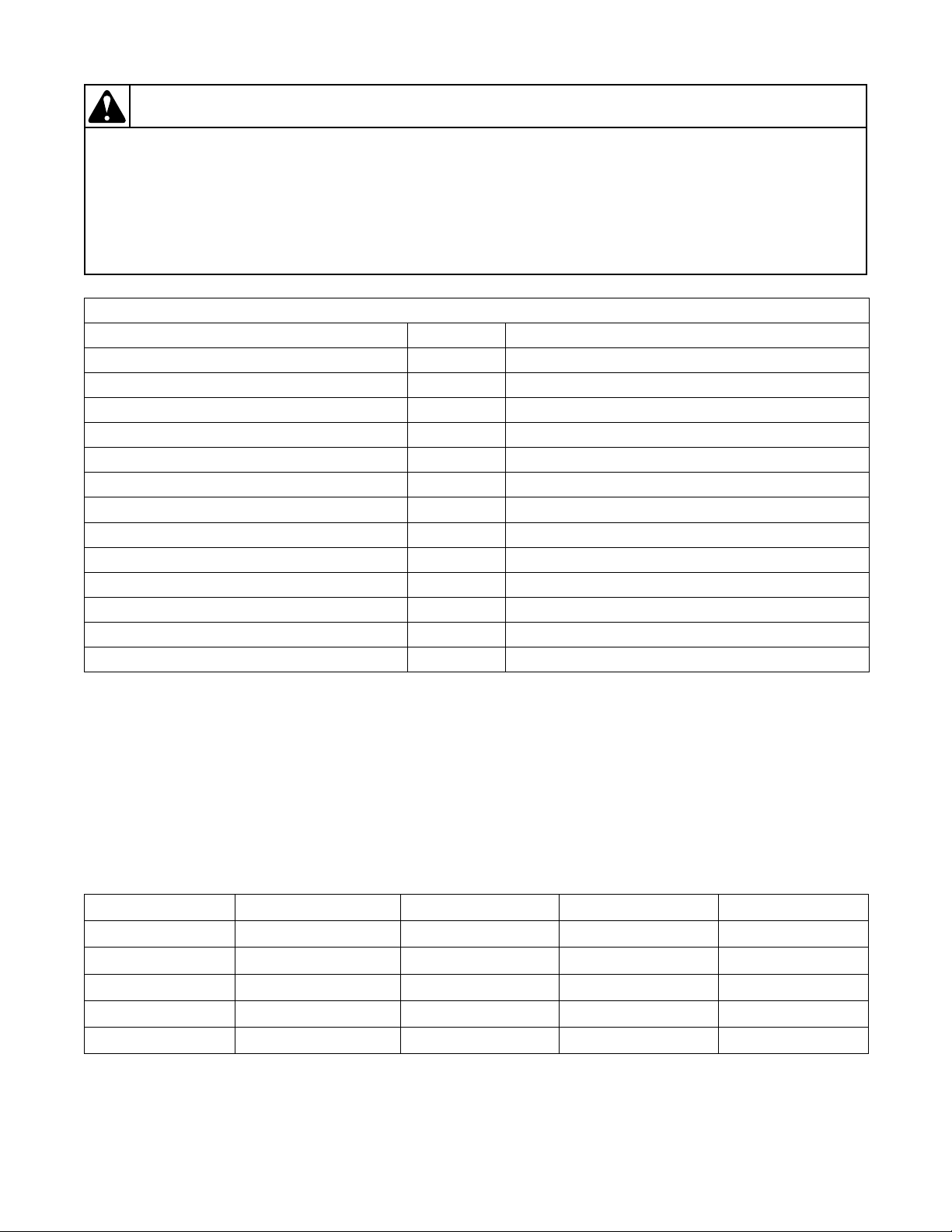

1. Keypad Combinations

Section 3

Figure 1

8 806221

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

Testing Mode Keypad Entry

Function Keys Entry State

Enter/Exit Software Version Display Mode 7+8 Start Mode

Turn On/Off Rainbow Pizzazz Display 9+10 Start Mode

Toggle Keypad Acknowledgement 13+14 Start Mode

Toggle Suds Extra Time Mode 2+3 Start Mode and powered for less than 5 minutes

Enter Factory Test Mode 2+7 Start Mode and powered for less than 5 minutes

Enter/Exit Audit Display Mode 3+9 Start Mode

Enter/Exit Factory Test Counter Display Mode 2+9 Start Mode

Enter/Exit Show Mode 3+8 Start Mode

Enter/Exit Extra Water Mode 8+14 Start Mode and Default/Extra Water Dipswitch On

Enter/Exit Drive Version Display Mode 3+14 Start Mode

Rapid Advance Through Current Cycle Step 7+13 Run Mode

Enter/Exit Spin Retry Extra Time Toggle Mode 8+ 13 Start Mode and powered for less than 5 minutes.

Enter/Exit Water Level Display Mode 4+14 Any Mode except if Control Lock is On

Table 1

Water Level Display Mode

The control will read the current water level. The

display will show the water level least significant digits

in 0.1 inch precision which will override any other

display.

If the water level is a negative value, then the right most

decimal point is lit. If the value is greater than or equal

to 10.0 inches, LED number 28 will be lit. If the value

will be lit. If the value is greater than or equal to 30.0

inches, LEDs 28, 22 and 23 will be lit.

To exit this mode, the user can either press the two keys

used to enter this mode, press the Power/Cancel key, or

unplug the machine. This mode only overrides the

display, the machine will continue running any other

modes that it is in.

is greater than or equal to 20.0 inches, LEDs 28 and 22

Value Display # 28 Light On? # 22 Light On? # 23 Light On?

4.5 inches 45 No No No

-3.2 inches 32. No No No

12.4 inches 24 Yes No No

20.8 inches 08 Yes Yes No

42.9 inches 29 Yes Yes Yes

Tab l e 2

806221 9

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

2. Factory Test Procedure

It is helpful to run the Factor Test Procedure first to

diagnose the machine’s issue. This procedure tests all

machine features and operations.

To Enter Factory Test Procedure

1. Be certain control is in Start Mode and less than

5 minutes after powering control.

2. Press keypads numbered 2 and 7 at the same time.

Refer to Figure 1.

3. When the control enters the Factory Test

Procedure, it will display the first test step,

Machine

4. To advance through the sequence of test step

press the Start/Pause keypad (No. 21). Refer to

Tabl e 3 for all tests in the Factory Test Procedure.

Type.

To Exit Factory Test Procedure

To exit the Factory Test Procedure, refer to Exit

column in Tabl e 3.

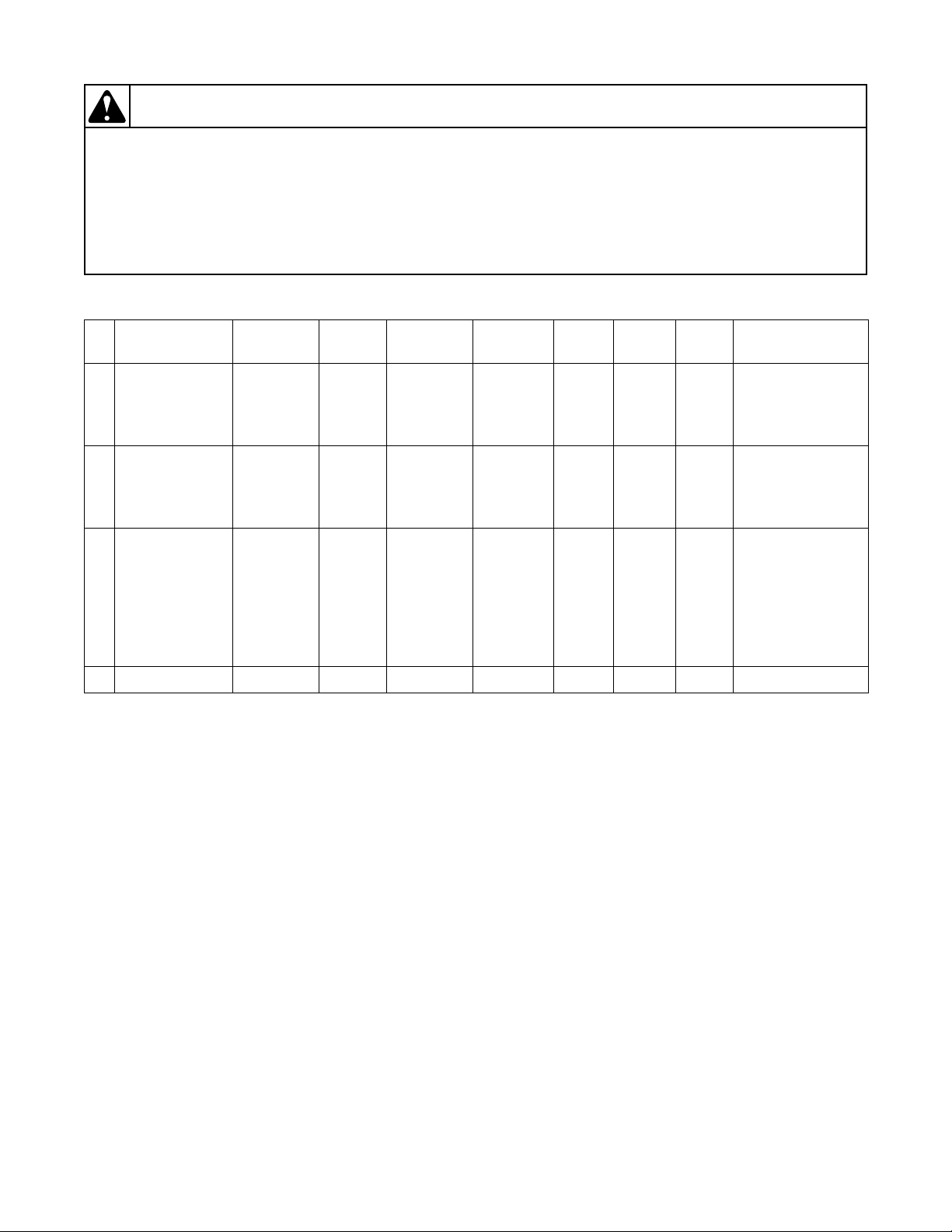

Factory Test Procedure Quick Reference Chart

NOTE: ES refers to the External Supply Outputs.

# Display

0 FL None Off None Unlocked Off Open 1 Control Type

1 XX None Off None Unlocked Off Open 1

2 HX None Off None Unlocked Off Open 1 Control Level

3 XX None Off None Unlocked Off Open 1

4 XX None Off None Unlocked Off Open 1

Status

LEDs Lit

Motor Valves Door Pump Dump Exit* Step

Software

Ve r s i o n #

Dipswitch Value

Display

Cycle

Configuration

s

Refer to

5PX

688

dO with door

7

10 806221

open

dC with door

closed

Keypad

Test

section

All plus

audio

signal on

high

None Off None Unlocked Off Open

Off None Unlocked Off Open 3 Keypad Test

Off None Unlocked Off Open 1 Show Mode

Table 3 (continued)

10

And

Then

1

Door Switch Test

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

Table 3 (continued)

# Display

Status

LEDs Lit

Motor Valves Door Pump Dump Exit* Step

8 db None Off None Unlocked Off Open

9 XX None Off None Unlocked Off Open

General Troubleshooting

10, 12

And

Then

Drive Type

1

10, 12

And

Then

Drive Version #

1

dL when door

10

locks

dU when door

None Off None Locked Off Open1And

unlocks

Cold,

11 Cd Wash Off

Detergent,

Locked Off Closed 1

ES 1

Hot,

12 HS Wash Off

Softener,

Locked Off Closed 1

ES 2

13 PS Wash Off Hot, Cold Locked Off Closed

14 XX None Off None Locked Off Closed 1 Or 5 Heater Test

Hot, Cold,

Detergent,

Softener,

15 OF Wash Off

ES

Locked Off Closed

1, 2, 3, 4,

Cycle

Output

ES 3,

Cycle

Locked Off Closed 1 Low Agitate

Output

ES 4 Locked Off Closed 1 Regular Agitate

Table 3 (continued)

16 LA Rinse

17 rA Rinse

Low

Agitate

Regular

Agitate

806221 11

2 And

Then

8 And

Then

Door Lock Check

7

Cold, Detergent,

Output 1

Hot, Softener,

Output 2

Pressure Sensor

1

Overflow

1

Test

Fill

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

# Display

Status

LEDs Lit

Pu for pump

18

installed

dr for gravity

Rinse Off None Locked On Open 9

drain installed

19 actual RPM Spin

Table 3 (continued)

Motor Valves Door Pump Dump Exit* Step

Pump/Gravity

Drain

Fac-

tory

Spin

None Locked On Open 1 Factory Spin

Profile

20 bA Spin

Break-

away

Agitate

Hot, Cold,

Detergent,

Softener,

ES

1, 2, 3, 4,

Cycle

Output

Unlocked On Open

1, 1

Again

Then

4

Then

11

Breakaway

21 Pd Spin Off None Unlocked Off Open 13 Power Down

Tab l e 3

EXIT column key:

1-exit by Start/Pause keypress

2-exit by fill level satisfaction

3-exit when all keypads are pressed

4-exit when door is unlocked

5-exit when temp reaches 40

°C

6-exit when step timed out

7-exit when door locks

8-exit when overflow level reached

9-exit when drum is empty

10-exit when door is closed

11-exit when door is opened

12-exit when drive communication is established

13-exit when machine unpowered

12 806221

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

Keypad Test

General Troubleshooting

Upon entry into this test, the control will display “P-”.

When a keypad is pressed the control will display “PX”

where X is the keypad number referenced in Tabl e 4.

For keypads 10 and greater the control will display

“XX” where XX is the keypad number. As each

keypad is pressed, the nearest LED

will light up and remain lit for the duration of the

keypad test. When all keypads have been pressed the

control will automatically advance to the next step.

Keypads that are not available on some controls do not

need to be tested. Refer to Figure 1 for keypad number

and LED references.

Keypad Numbers (some models may not have all keypads)

Display Key Number LED

P1

P2

P3 3 25

P4 4 24

P5 5 Next to keypad

P6 6 Next to keypad

P7 7 Next to keypad

P8 8 Next to keypad

P9 9 Next to keypad

10 10 Next to keypad

13 11 Next to keypad

1 22

2 26

14 12 Next to keypad

15 13 Next to keypad

16 14 Next to keypad

17 15 Next to keypad

18 16 Next to keypad

19 17 Next to keypad

20 18 Next to keypad

21 19 Next to keypad

22 20 Next to keypad

23 21 23

Tab l e 4

806221 13

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

Dipswitch Value Display Test

This step displays the state of the Control

Configuration Dip Switches in hex, where the least

significant bit is Dip Switch #1 and the most significant

bit is Dip Switch # 8.

If a dipswitch is set to ON, the corresponding bit is set

to 1, otherwise if the dipswitch is set to OFF, the bit is

set to 0. The most common configurations are listed in

Tabl e 5.

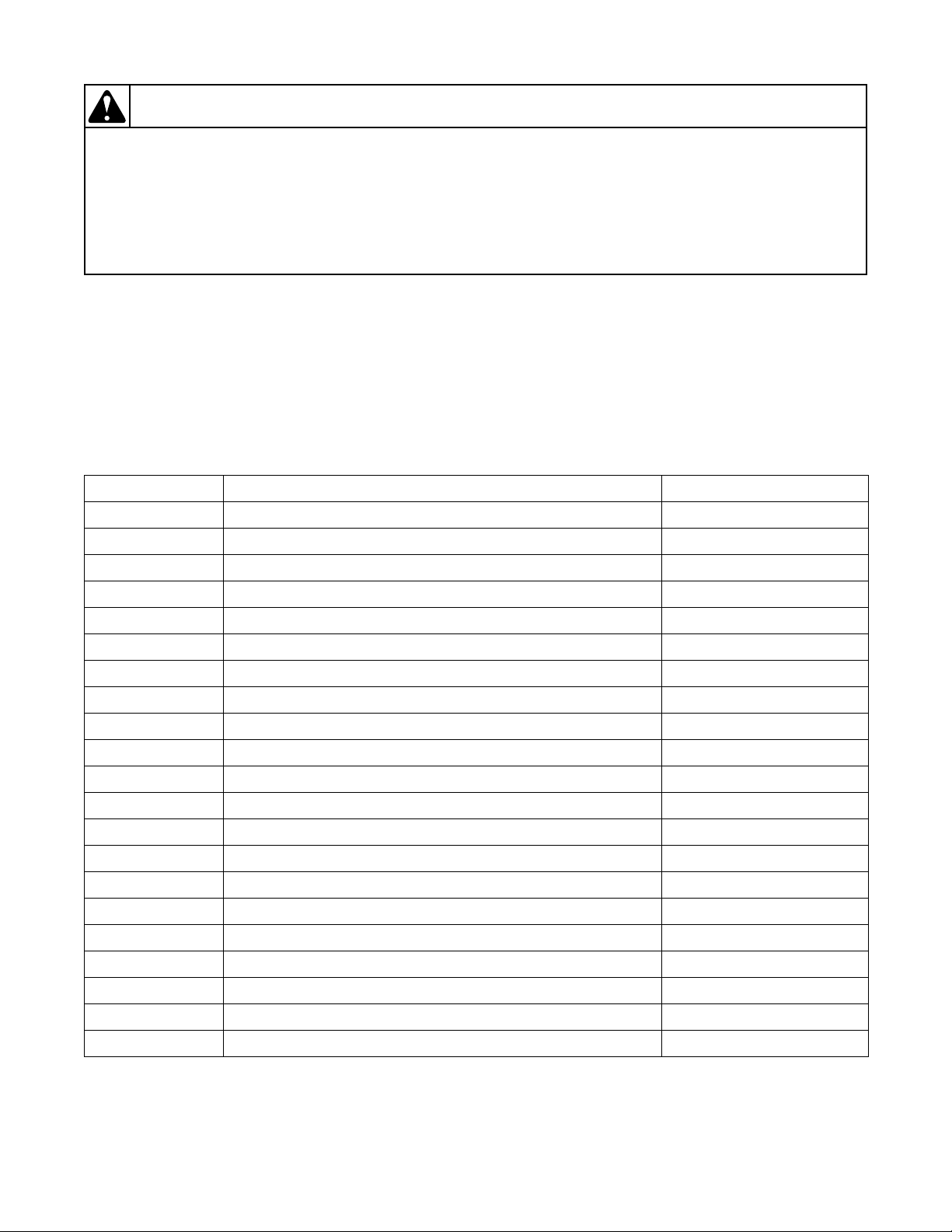

Dipswitch Value Display

Machine Configuration Value

120 Volt with Electric Pump 00

120 Volt with Gravity Drain 80

240 Volt with Electric Pump 01

240 Volt with Gravity Drain 81

240 Volt Heater Machine with Electric Pump and Cool Down Enabled 61

240 Volt Heater Machine with Gravity Drain and Cool Down Enabled E1

Table 5

Cycle Configuration Test

This step verifies which set of cycles are used.

Cycle Configuration Display

Cycle Set Models Display

Default With “T” and “C” in the 12

Australia With “A” in the 12

th

character of the model number “dE”

th

character of the model number “AU”

International All Other models “in”

Tab l e 6

Cold/Detergent Fill

This step checks the cold water valve and the detergent/

bleach valve. The cold water fill valve, the detergent/

bleach valve and the External Supply Valve 1 turn on.

The valves will shut off once a low fill level is reached.

Pressure Sensor Fill

This step checks the analog water level input. When the

water fill level is satisfied, the water valves are turned

off. The control will not advance to the next step until

the normal fill level is satisfied.

Hot/Softener Fill

This step checks the hot water valve and the softener

valve. The hot water fill valve, the softener valve and

the External Supply Valve 2 turn on. The valves will

shut off once a medium fill level is reached.

14 806221

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

Heater (Heater Models Only)

This step checks the heater operation. The display

shows “xx”, where xx is the temperature in degrees

Celcius. The control will heat the water to 40 degrees

Celcius while displaying the temperature as it rises at a

rate of 1 degree. If the temperature sensor is open or

shorted, the display will show “Er” and “OP” or “SH”.

Overflow Test

This test checks the overflow setting for the water level

sensor. When the overflow level is reached, the water

valves, all External Supply Valves and the Cycle Run

Output will automatically turn off. The control will not

advance to the next step until the overflow level is

satisfied.

Low Agitate

This step checks the Low Agitate speed. The display

shows “LA”, the Rinse LED is on, the Auxiliary Output

3 is on, Cycle Run Output is on, and the machine enters

a low agitate. The control will remain in this mode until

the Start/Pause keypad is pressed.

Regular Agitate

This step checks the Regular Agitate speed. The

display shows “rA”, the Rinse LED is on, the Auxiliary

Output 4 is on, and the machine enters a regular agitate.

The control will remain in this mode until the Start/

Pause keypad is pressed.

Pump/Gravity Drain Test

This step checks the Pump output. The display shows

“Pu” for an electric pump or “dr” for a gravity drain,

the Rinse LED is on, and the Pump is turned on or the

Gravity Drain is opened. The control will only advance

to the next test step after the Water Level Sensor

indicates that the drum is empty.

Factory Spin

This step checks the spin speeds. The display shows the

most significant two digits of the actual RPM.

806221 15

The machine steps through spin speeds and maintains

each speed for a few seconds. After 1200 RPMs, the

motor will stop.This step lasts 4 minutes. All Out of

Balance checking is done and if either the out of

balance switch is hit or the OBL check fails and needs

to re-spin, the time will be reset indefinitely to allow

the load to be rebalanced so that it can spin up and reach

full speed. The control will advance to the next step if

the Start/Pause keypad is pressed at any time during

this step.

During this step if 800 RPMs is reached, LED number

26 will be lit. If 1000 RPMs is reached, the LED

number 25 will be lit. If 1200 RPMs is reached, the

LED number 24 will be lit, and if 1100 RPMs is

reached, the LED number 27 will be lit to indicate that

a passing speed has been reached. Refer to Figure 1 for

LED number definition.

Breakaway

This step checks the breakaway speed and the door

unlock function. All valves will be open at the

beginning of this step to allow the blowing out of the

valves by the factory. The Start/Pause keypad must be

pressed to start exiting the test. The first Start/Pause

keypress will turn off the water valves, the second

Start/Pause keypress will stop the motor and start the

unlock process. The third Start/Pause keypress will

start the unlock process. Once the door unlocks, it

needs to be opened to finally exit the test. The water

level sensor will be trimmed in this step after a 20

second delay and once the Start/Pause key is pressed

the first time.

During this step the LEDs for indicating speeds

reached from the Factory Spin step will remain lit in

this step.

Power Down

This is the final step of factory test procedure. The

control will display “Pd” to signify that the procedure

has been completed and that the user can safely unplug

the machine. Cycling power to the machine is the only

way to resume normal operation.

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

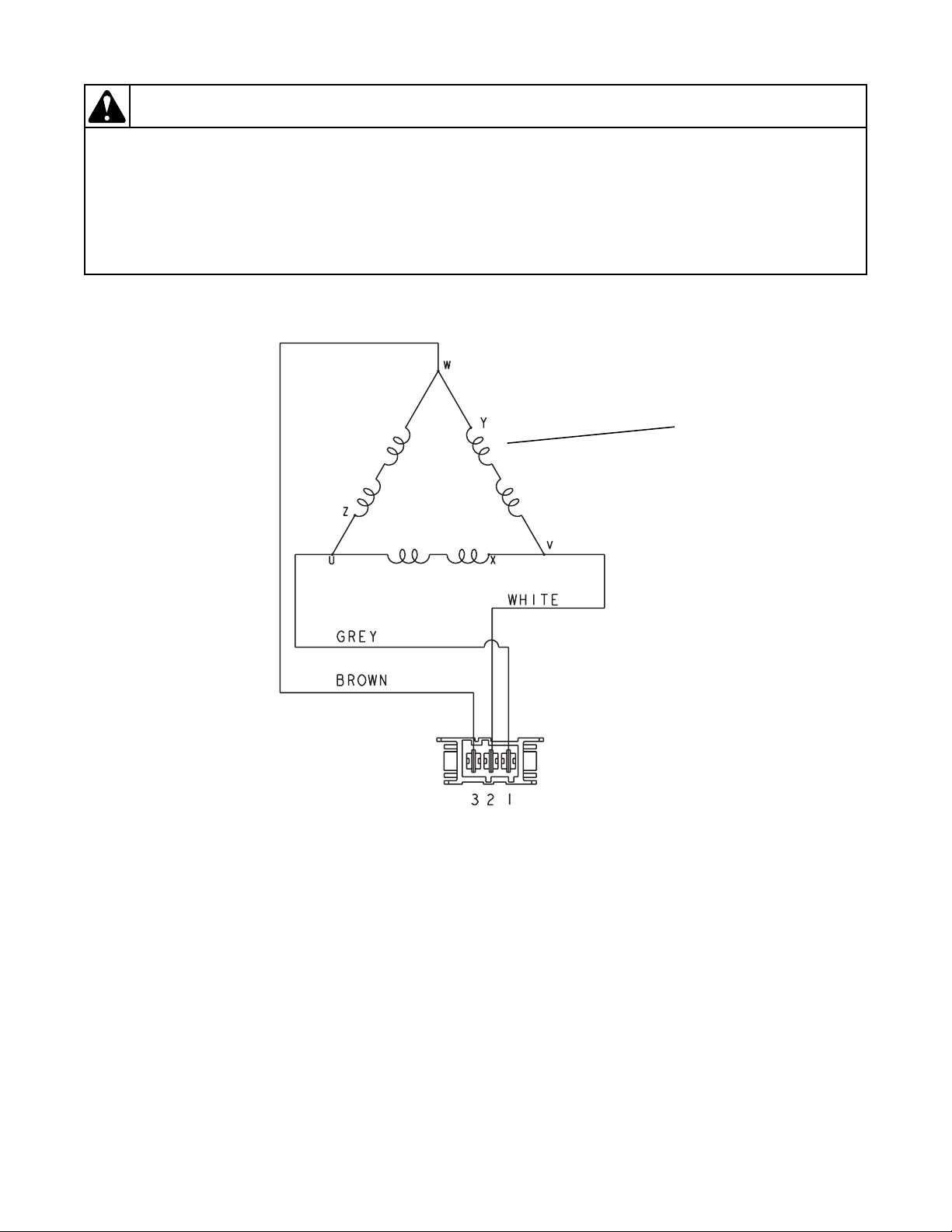

FLW1792S

Windings

FLW1792S

3. Motor Circuit

Windings Resistance:

Approx. 3.38 ohms

16 806221

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

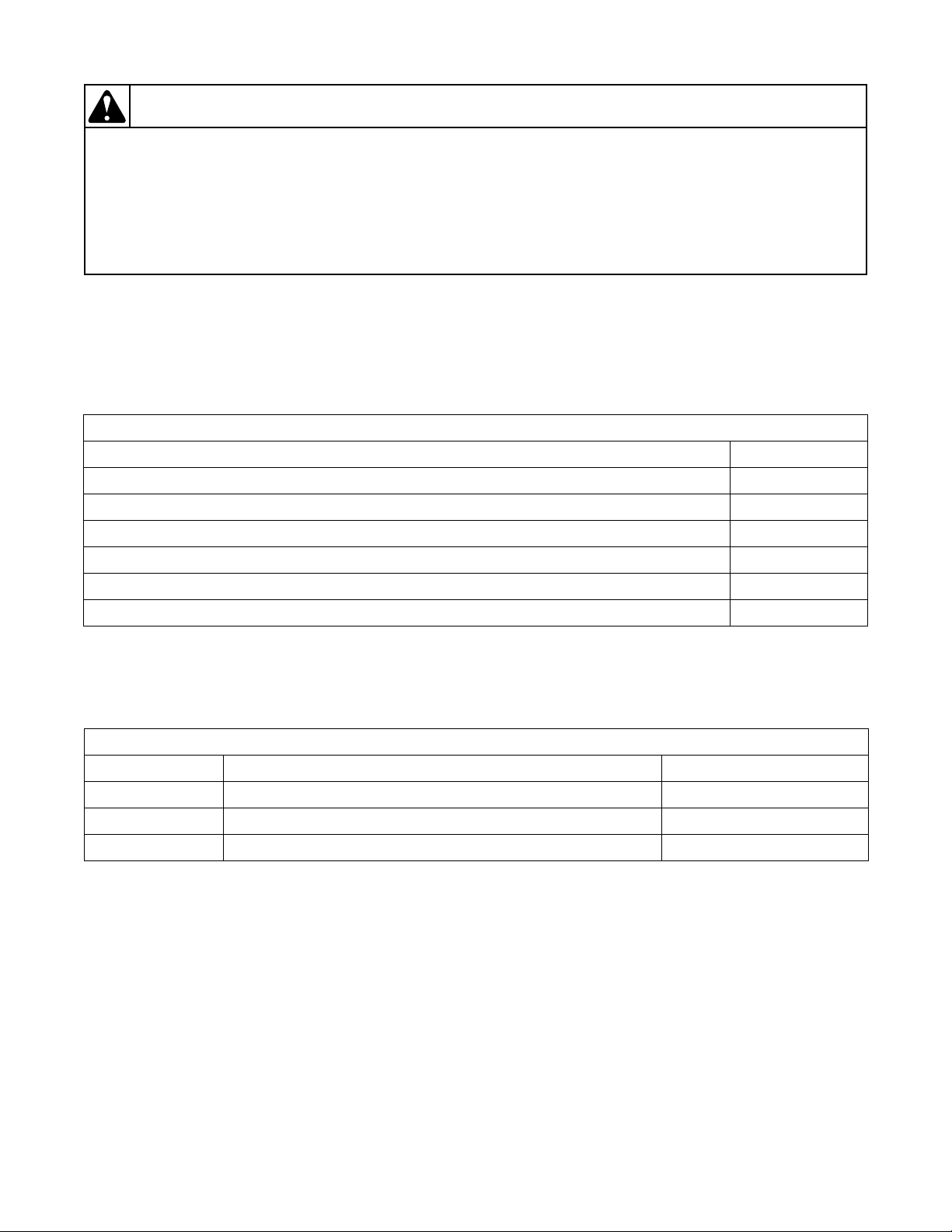

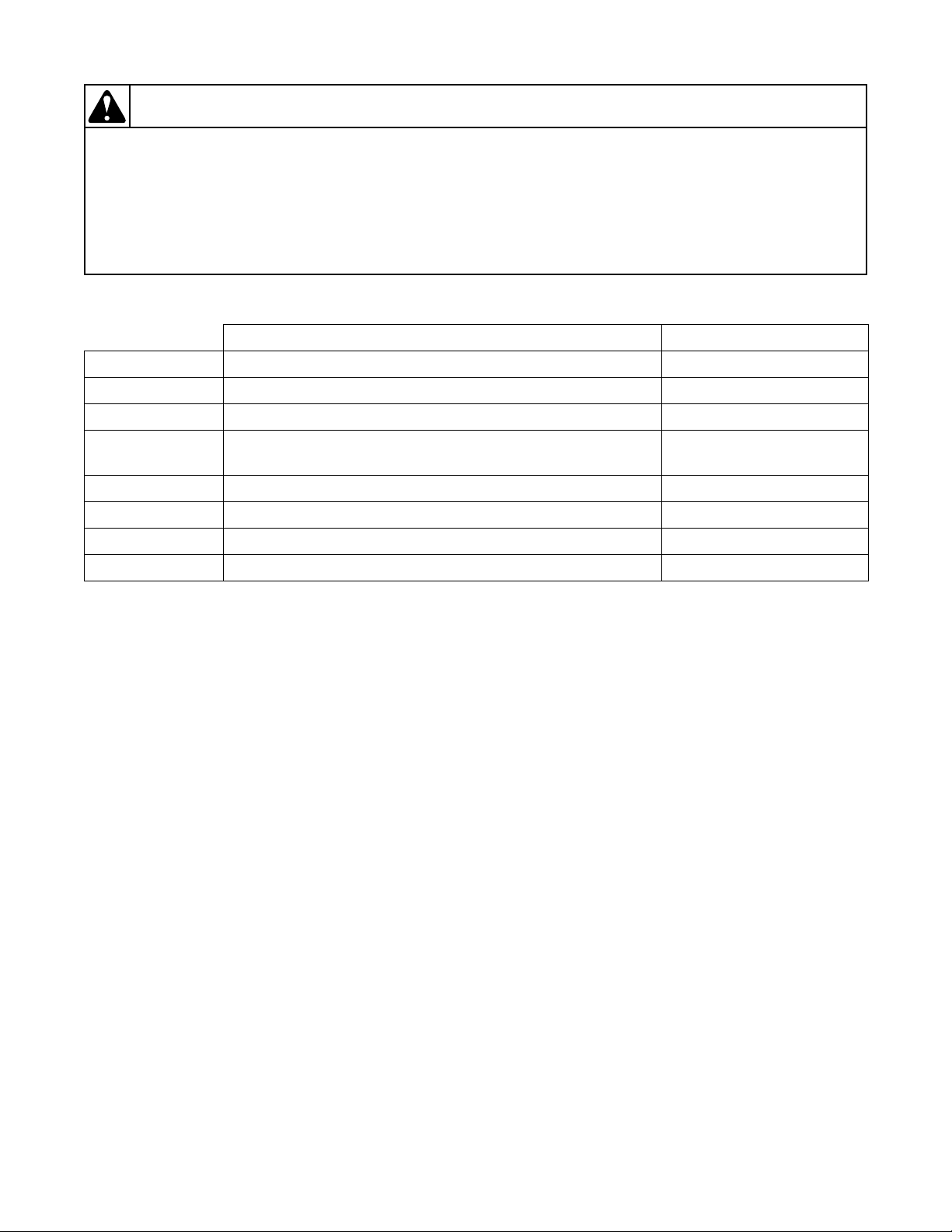

4. Dipswitch Configuration

OFF ON

Switch 1 120 Volt AC Supply 240 Volt AC Supply

Switch 2* Energy Saving Cycles Standard Cycles

Switch 3** Default Water Level Increased Water Level

Switch 4

Switch 5 Unused Unused

Switch 6 Cool Down Disabled Cool Down Enabled

Switch 7 Heater Disabled Heater Enabled

Leak and Slow Drain Errors Off

Leak and Slow Drain Errors

On

Switch 8 Electric Pump Gravity Drain

Tab l e 7

*Switch 2

When set to OFF, energy saving water and fill levels are used for the specific type/region of the machine. When set

to ON, energy saving cycle settings are not used.

**Switch 3

When set to OFF, the Default Water Levels are used. When set to ON, the owner can increase the water level using

the Extra Water Mode. Higher water levels are not recommended as they may result in water leaking from the

machine door.

806221 17

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

FLW1814S

1

4

3

2

5. Troubleshooting Knocking Noise

If a frontload washer produces a noise similar to a

kn

ock on a door, it might be due to a flat spot on

the belt. The knocking sound is made when

flat spo

during a ramp spin and fade after reaching a

higher RPM.

To correct this condition, replace the belt.

t hits the pulley. The knocking may occu

the

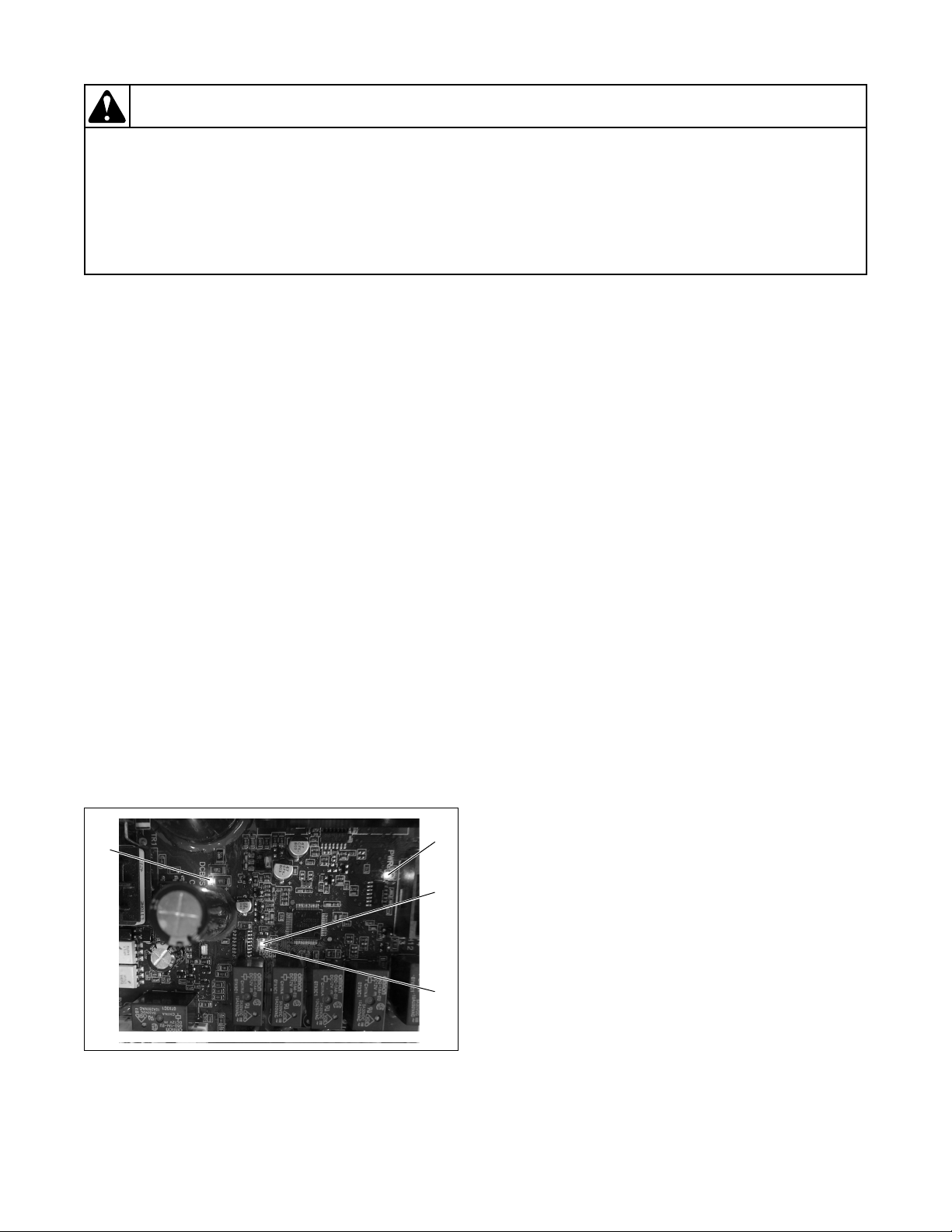

6. Explanation of LEDs on Drive Control

There are four LEDs on the control to assist with

troubleshooting (refer to Figure 2):

1. Green LED on constant = 5VDC power supp

sent

pre

2. Green LED flashing one second on/one second

off = drive control is active

3. Red LED flashing = drive contro

co

mmunicating with front end control

4. Red LED on constant = DC Bus Charged

NOTE: Drive is only powered when door is closed

and front end control turns it on.

l is

ly

7. Door Fails to Unlock at End of Cycle

If the door won’t unlock at the end of the cycle and the

r

cycle time is flashing in the display, the water might be

too hot to drain. Add a cool-down step to the cycle to

make sure the water will be cooled. Enable the cooldown feature by setting the cool down dip switch (#6)

to ON.

8. No Spin

A no spin condition is not caused by intermittent

operation of the motor or motor control (inverter

assembly). DO NOT replace these components for no

spin complaints if the unit passes the following

procedure:

Figure 2

18 806221

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must

be

re

connected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

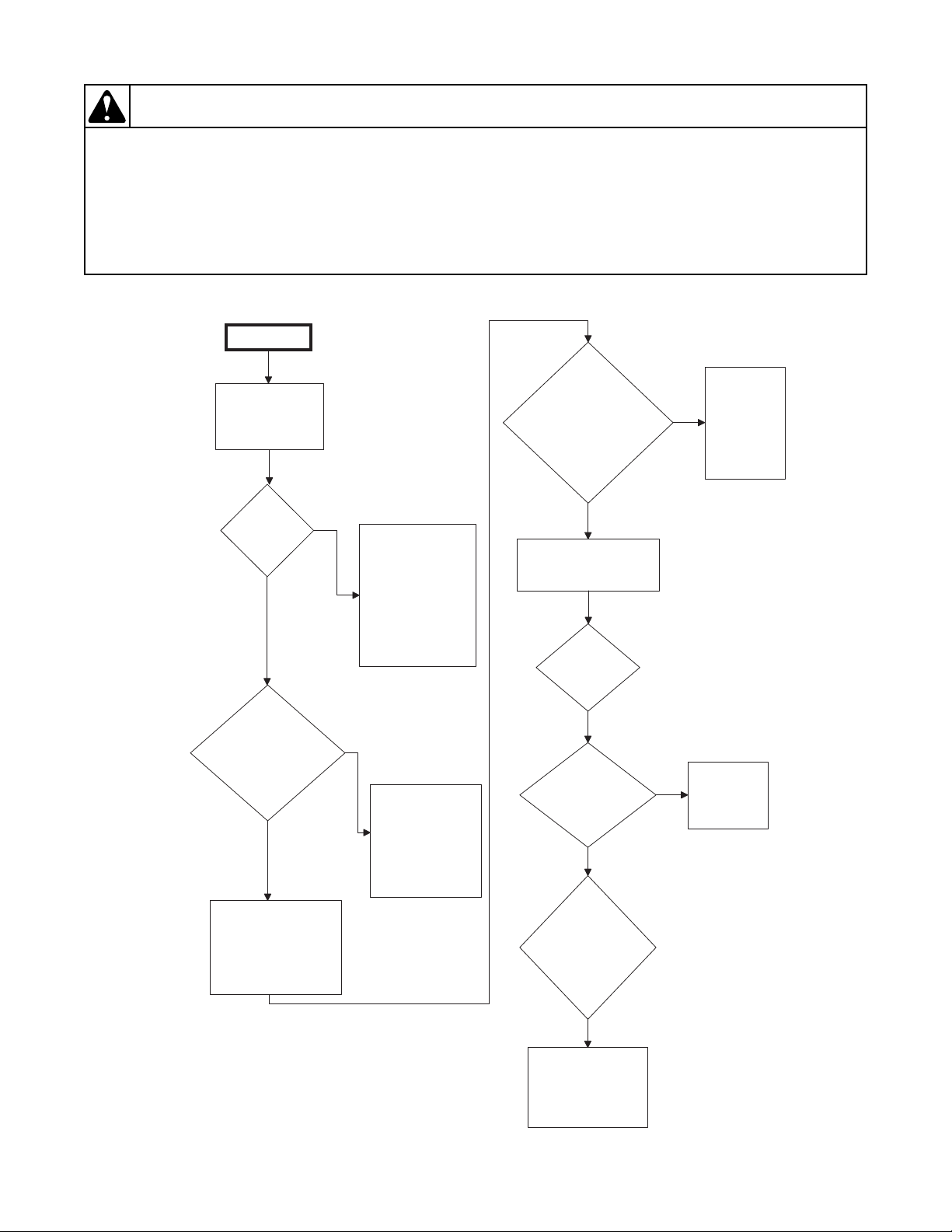

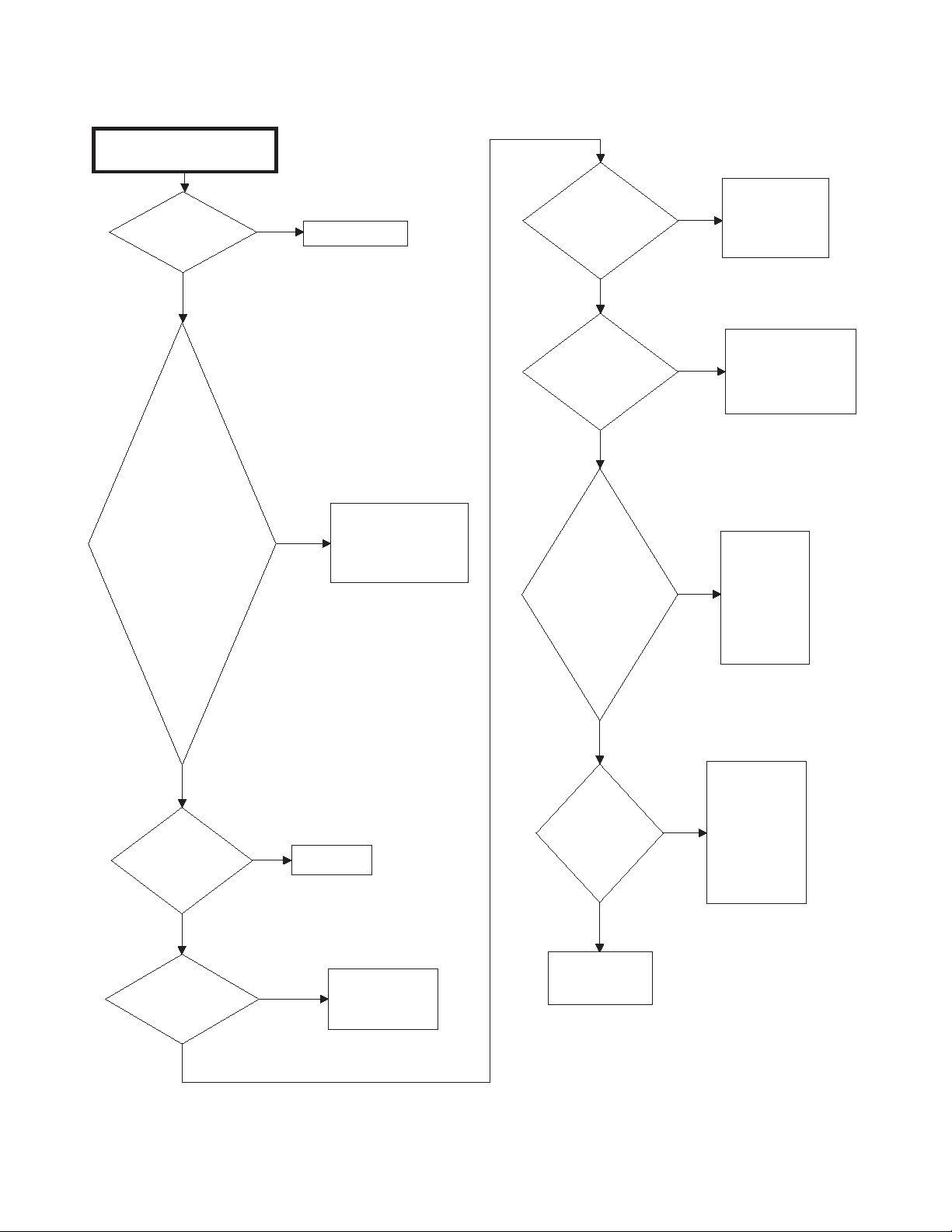

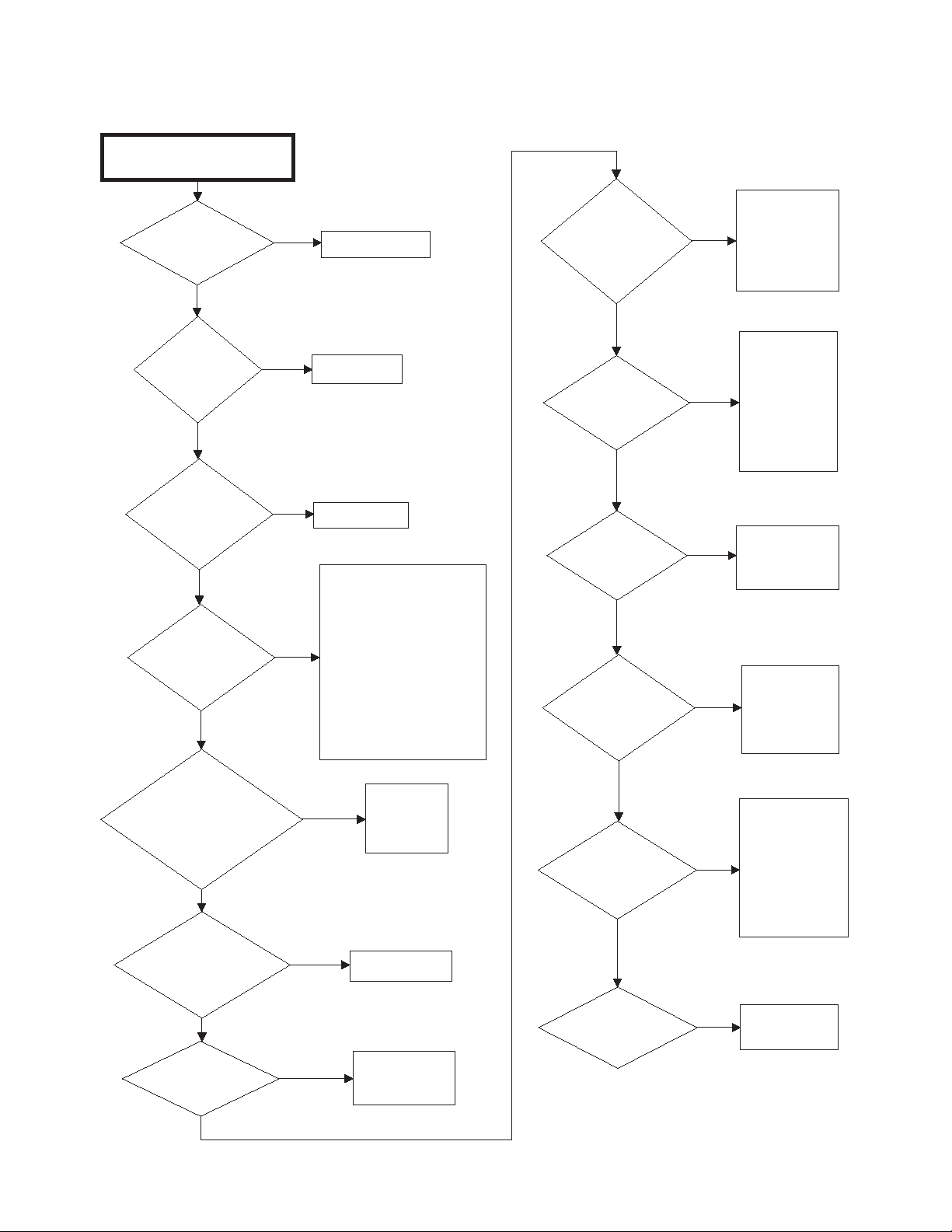

8. No Spin (continued)

FLW1816S

No spin

Allow unit to go

through complete

final spin cycle.

Does unit spin at

high speed?

Motor and

motor control

board are

operating

properly. Do

not replace

them.

Yes

Check for

obstruction

and damage

around drum.

No

With no load, rapid

advance to final spin

or run factory test

procedure to check

spin operation. Close

door and start washer.

BEFORE replacing

the motor control

board, conduct the

following tests.

No

Does

drum spin

freely by

hand?

Is load

out-of-

balance?

Unit makes multiple

attempts to rebalance out-ofbalance loads. If all

attempts fail, final

high speed spin is

aborted. ONLY

proper loading can

correct problem.

Yes

Is

there a slow

drain, clogged

pump or

oversudsing

condition?

Pressure sensor

must register an

"empty" condition

before unit will

enter spin. Clear

drain or pump. Use

less detergent.

Yes

No

No

Does unit

spin now?

No

Check for

broken shocks.

Yes

Using

Water Level

Display Mode, is

water level showing

below one inch

in spin

step?

Check pressure

hose for clog and

pressure sensor

wiring for connection

and damage.

No

FLW1816S

General Troubleshooting

806221 19

General Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

FLW1809S

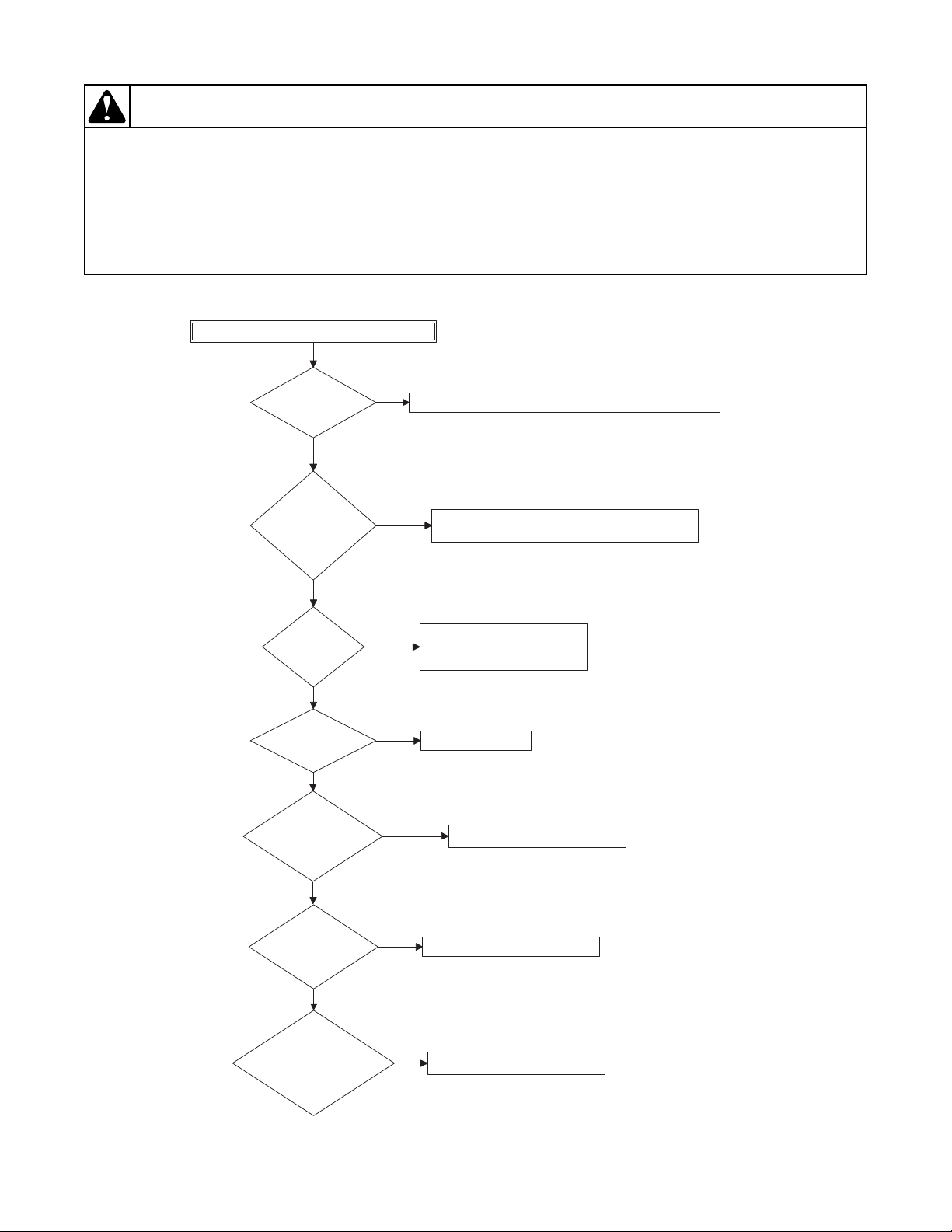

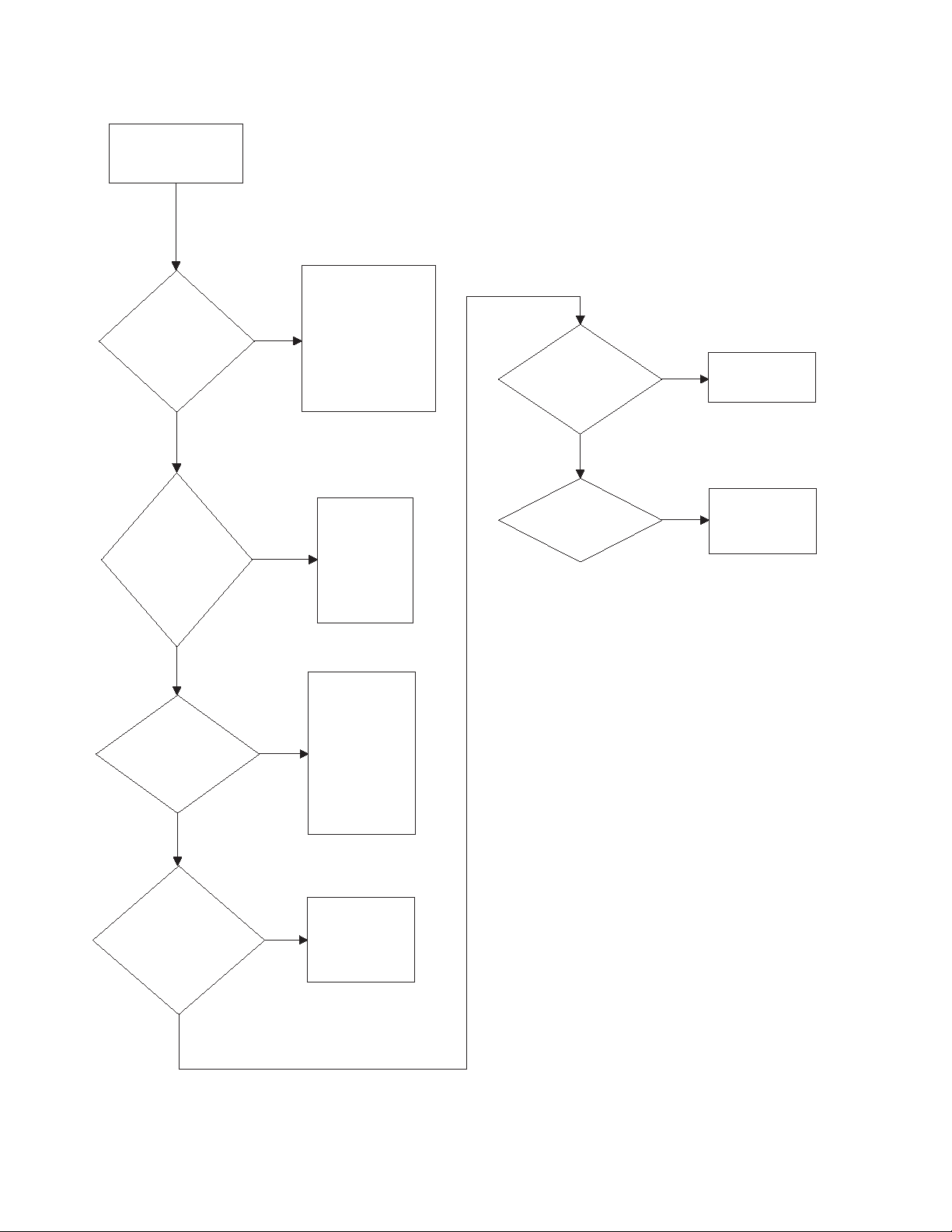

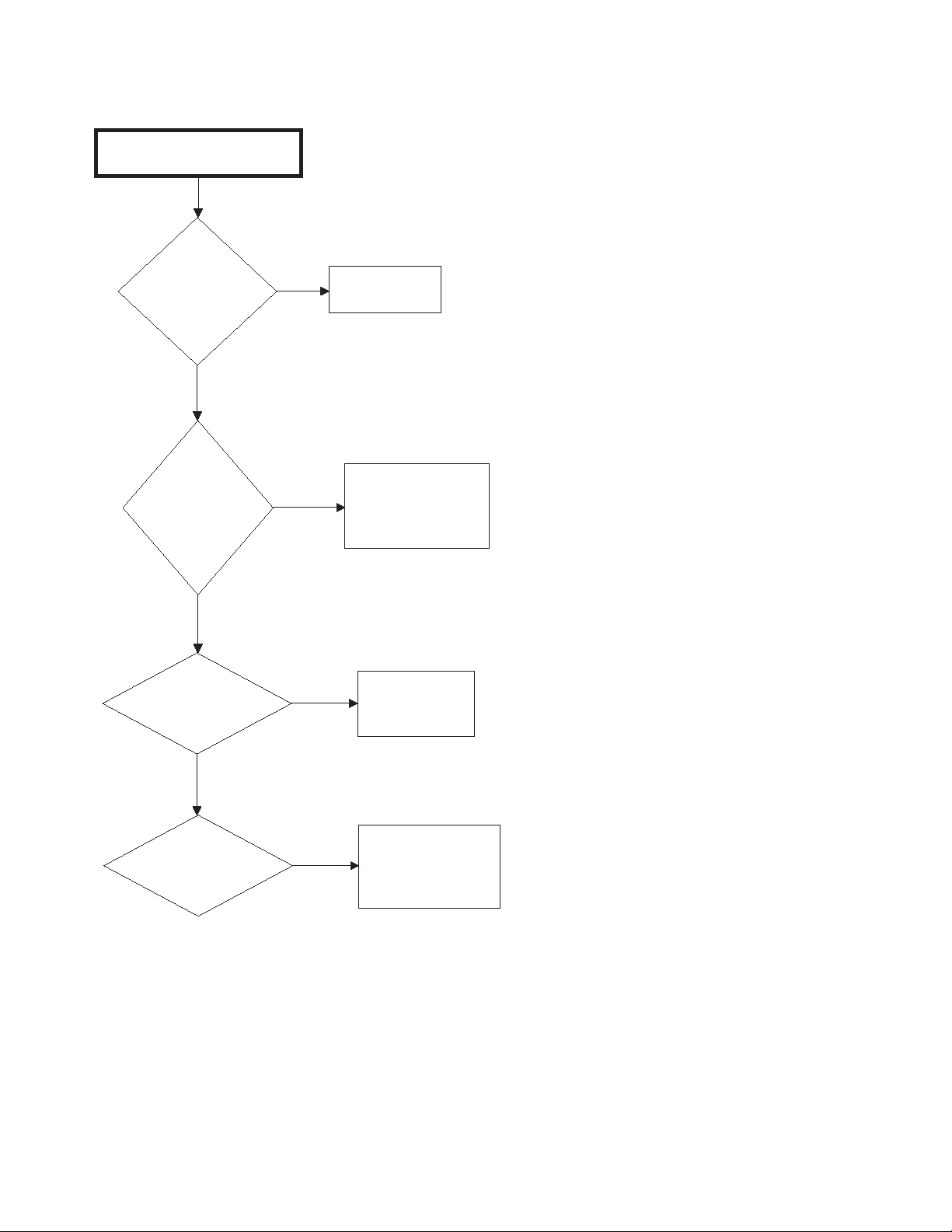

Excessive Vibration and/or Noise During Spin

Is

the load of proper

size?

Add or remove items as needed to ensure load size is correct.

No

Does

the wash load

contain the proper

mix of laundry

items?

Yes

Add or remove items as needed to ensure proper mix of

items (e.g. do not wash towels and sheets together).

No

Is

machine

level?

Yes

Level machine properly.

Refer to Installation Instructions.

No

Yes

Are

all panels on

machine?

Replace all panels.

No

Yes

Are

the front and rear

bearings making

excessive

noise?

Replace the bearings as needed.

Yes

Lift up on

the basket at the

front of the tub. Is there any

up and down play that would

indicate bearing

wear?

No

Replace the bearings as needed.

Yes

Are

motor and drive

pulleys aligned and

on tight?

Align/tighten pulleys as needed.

No

FLW1809S

9. Excessive Vibration and/or Noise During Spin

20 806221

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

• Motor not grounded! Disconnect electric power before servicing motor.

W485

WARNING

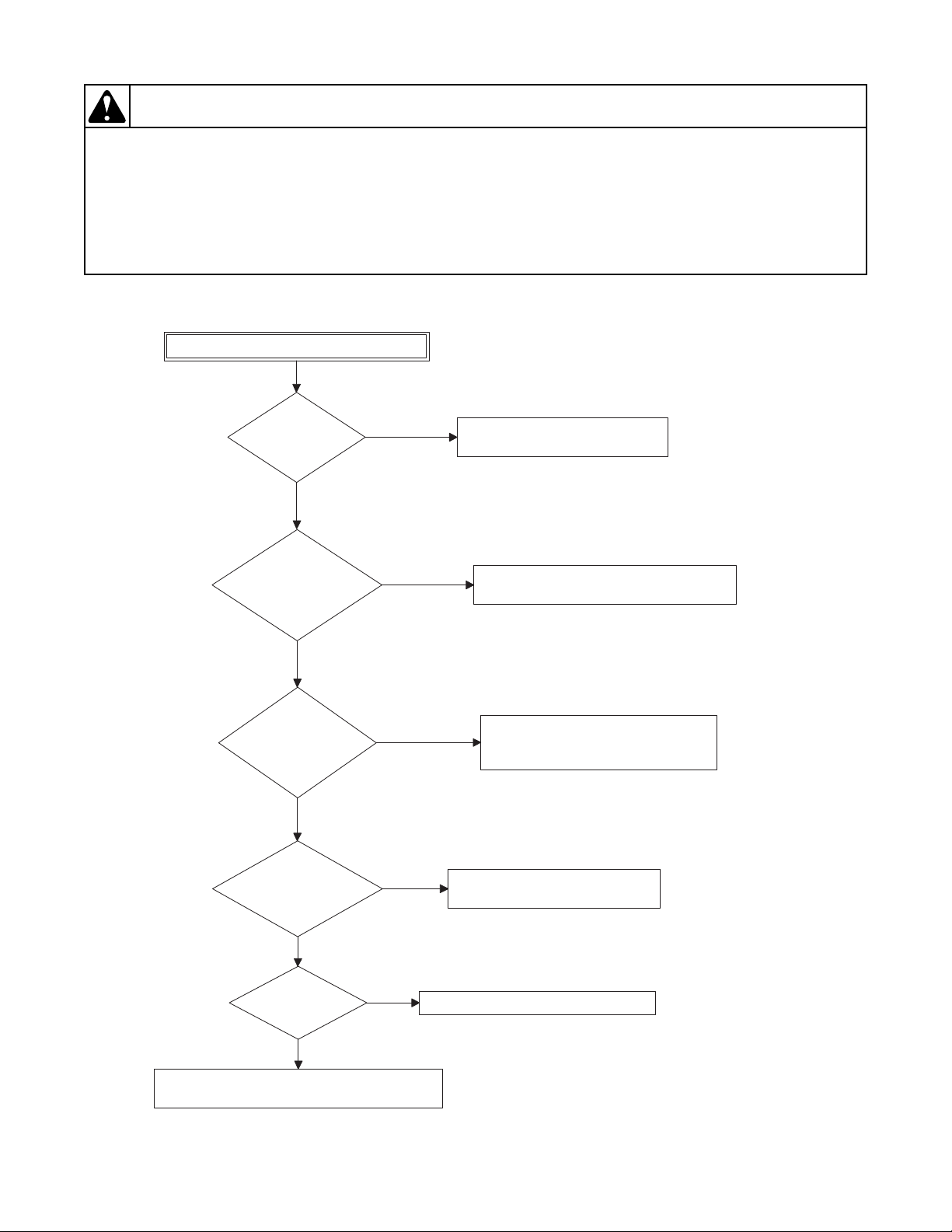

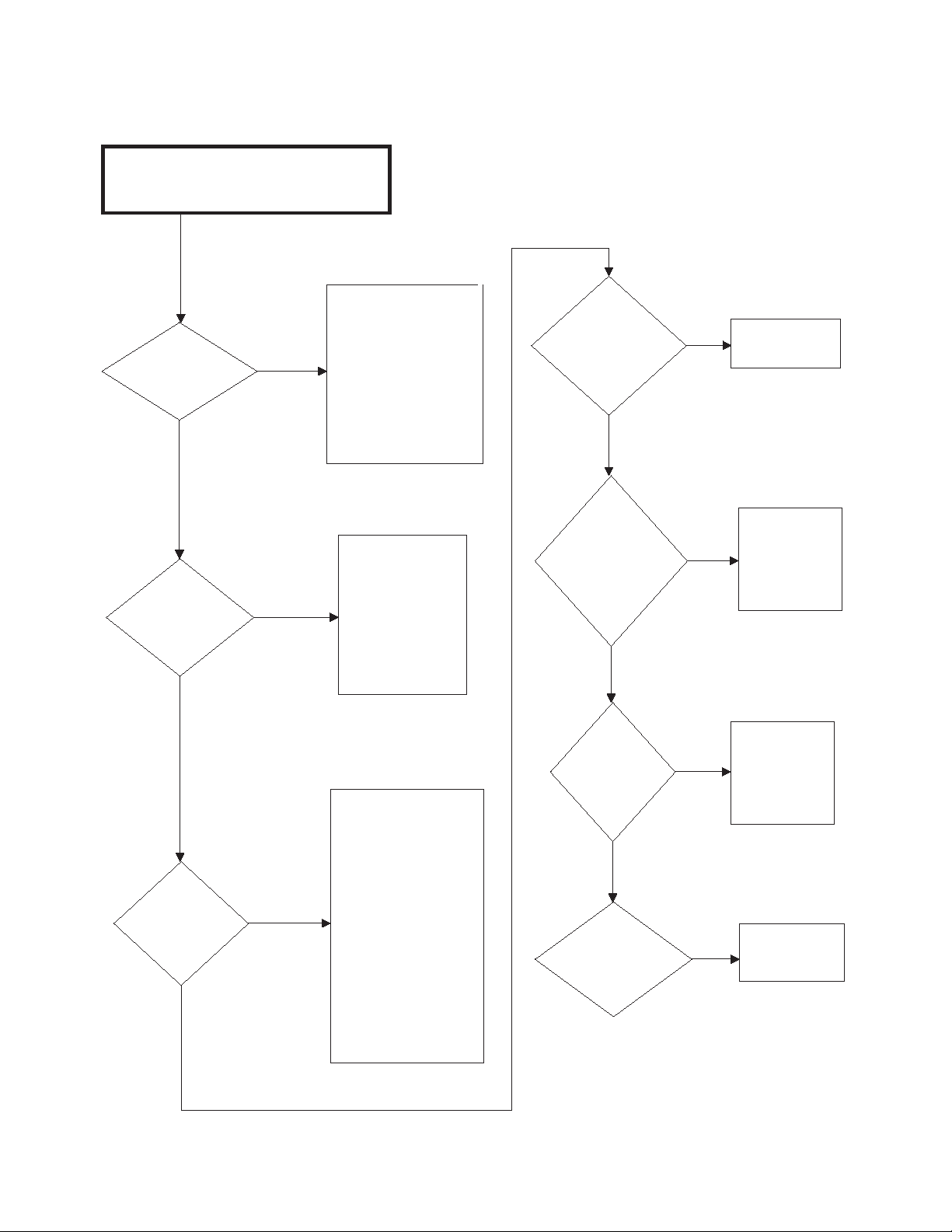

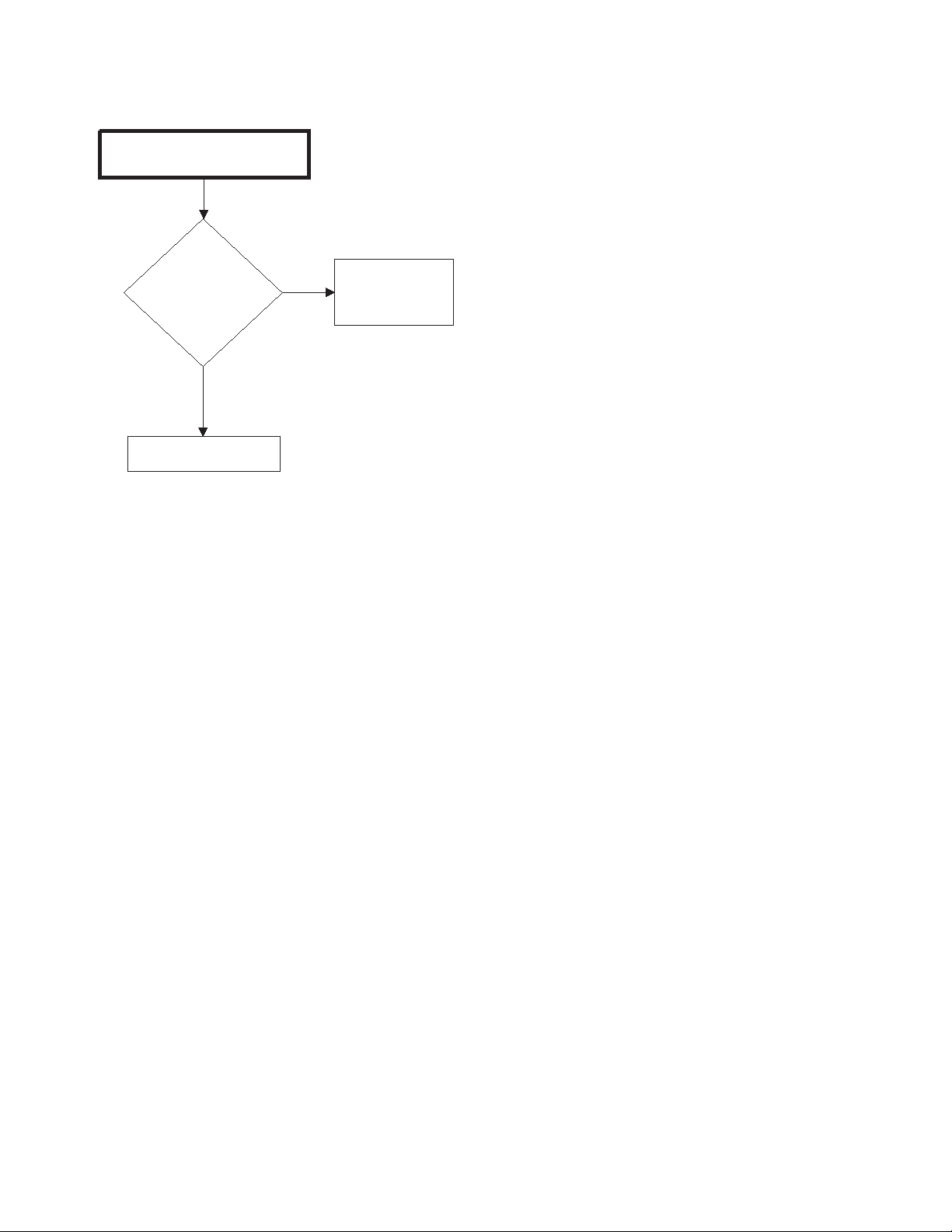

10. Excessive Cycle Time

FLW1819S

Excessive Cycle Time

Is water passing

through the drain during

fill?

Repair/replace drain valve as necessary.

Yes

Is the machine

slow to fill?

No

Check water pressure and/or check for

clogged screens in fill hoses.

Yes

Check pressure sensor and associated hoses for

obstructions or leaks. Repair/replace as necessary.

If

equipped with heat, is

it taking too long to

heat?

Troubleshoot heat output circuit.

No

Yes

Are

there load balance

issues?

Ensure machine is loaded properly.

Yes

No

No

Is there

an oversudsing

condition?

Reduce amount of detergent used.

Yes

No

FLW1819S

General Troubleshooting

806221 21

Section 4

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect all electric power to the machine and accessories before servicing.

• Close gas shut-off valve to gas dryer before servicing.

• Never start machine with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

re

connected to ensure that the machine is properly grounded.

• Washer motor not grounded! Disconnect electric power before servicing motor.

W502

WARNING

Dryer Control Troubleshooting

IMPORTANT: Refer to wiring diagram for aid in

testing dryer components.

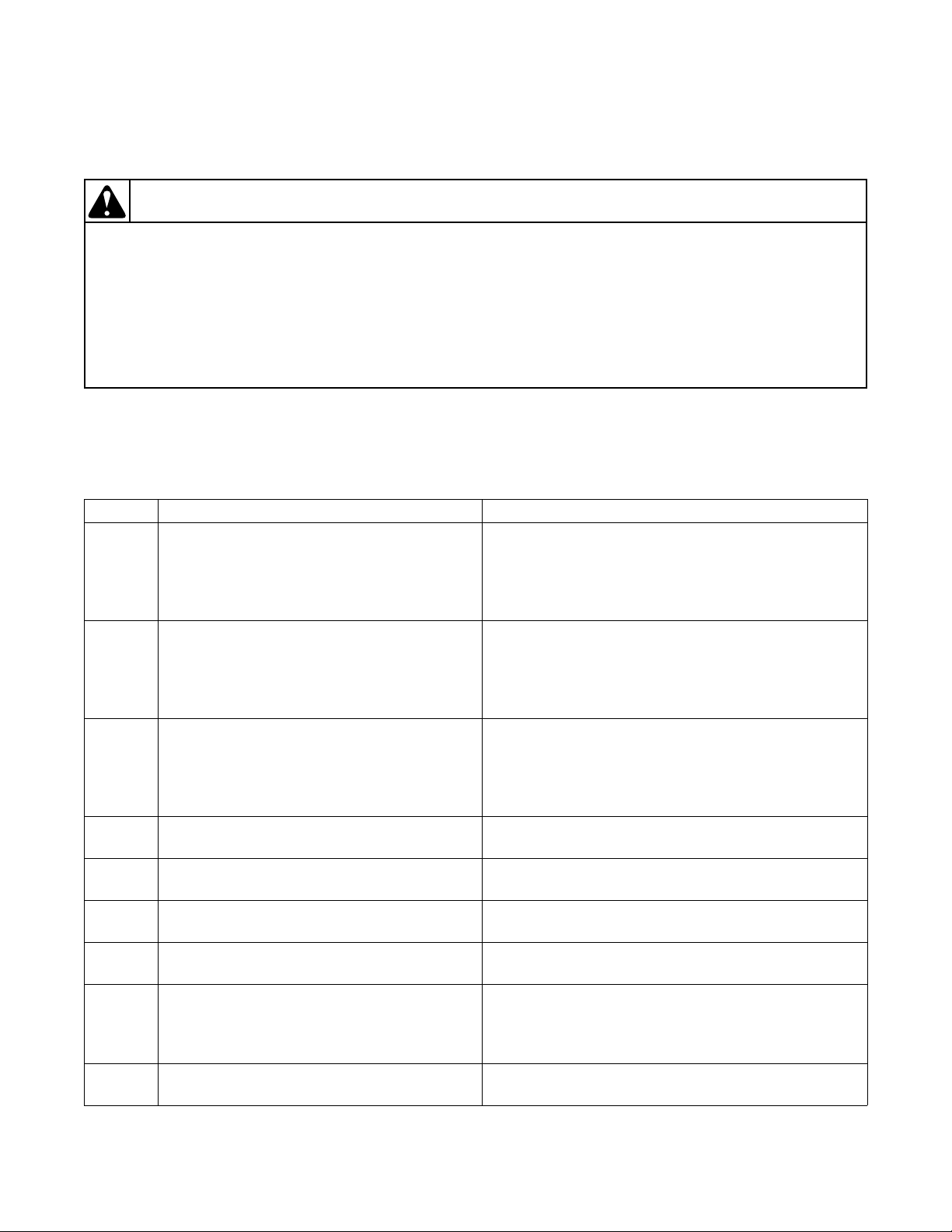

7. Dryer Error Code Listing

Display Description Cause/Corrective Action

Locked rotor error: The motor is not sensed as

rotating when it should be.

Open thermistor error: The thermistor circuit

is sensed as being physically open.

Shorted thermistor error: The thermistor

circuit is sensed as being shorted.

Motor output shorted error: Hardware error. Terminate cycle. Replace output board. Power down

Door input acquisition error: Hardware error. Terminate cycle. Replace output board. Power down

Centrifugal switch input acquisition error:

Hardware error.

High limit thermostat input acquisition error:

Hardware error.

Output board communication error:

Communication failure.

Output board not ready error: Hardware

failure.

(continued)

22 806221

Terminate cycle and check that nothing is obstructing

motor rotation. Check wire harness connection

between motor, user control and output board, or try

replacing the user control or the output board. Clear

error with a key press.

Remove any lint build up around thermistor. Check

wire harness connection between thermistor and

harness. If problem persists replace thermistor, harness

or output board. Thermistor must no longer be seen as

open to clear.

Remove any lint build up around thermistor. Check

wire harness connection between thermistor and

harness. If problem persists replace thermistor, harness

or output board. Thermistor must no longer be seen as

shorted to clear.

machine to clear.

machine to clear.

Terminate cycle. Replace output board. Power down

machine to clear.

Advance cycle to cool down. Replace output board.

Power down machine to clear.

Power down machine to clear, power up and try again.

If error persists, check harness connection between

user control and output board, or try replacing the user

control or the output board.

Terminate cycle. Replace output board. Power down

machine to clear.

Dryer Control Troubleshooting

(continued)

Display Description Cause/Corrective Action

Brownout/voltage configuration error:

Unexpected supply voltage.

Check the harness connections between the user

control and the output board. If the user control was

replaced, set dipswitch #1 to the same setting as the

previous control. If reworking the machine to use a

different supply voltage, the dip switch #1 setting may

need to be changed. If the dip switch #1 setting is

changed, power down machine, power up and try

again.

Board ID error: Incorrect replacement

control.

Terminate cycle. Replace user control or output board

with correct part. Power down machine to clear.

806221 23

Dryer Control Troubleshooting

8. Dryer Motor Does Not Run

Dryer motor does not run.

Is power cord

plugged in?

Yes

Is electrical

power off or fuse

blown? Check

laundry room for

blown or loose

fuse(s), or open

circuit

breaker(s). The

dryer itself

doesn't have an

electrical fuse.

No

Plug in cord.

Yes

Turn power on or

replace fuse. Check

both fuses for

electric models.

Is

timer/electronic

control improperly

set?

No

Is

timer/electronic

control

inoperative?

No

Are motor

starting

functions

inoperative,

does not

start, or motor

just hum?

Yes

Yes

Yes

Reset

timer/electronic

control or try

another cycle.

Te st

timer/electronic

control and replace

if inoperative.

Refer to

Adjustments

section to

check motor

switch and

motor

windings.

No

No

Is loading

door closed?

Yes

Is door switch

inoperative?

No

No

Yes

Close door.

Test switch and

replace if

inoperative.

Is motor

dead,

won't run?

No

Continued on

next page.

Refer to

Adjustments

section to

Yes

check motor

switch, motor

windings and

main windings.

SWD1706S-a

24 806221

8. Dryer Motor Does Not Run (continued)

SWD1706S-b

Continued from

previous page.

Is power cord

miswired?

Refer to wiring

diagram for

correct wiring.

Refer to wiring

diagram.

Is wiring

broken, loose

or incorrect?

Is motor wire

harness

connection

block loose?

Firmly press

connection

block onto

motor switch.

Remove belt

and

determine if

motor shaft

will spin.

Replace motor

if shaft is

locked up.

Is there a bind

in motor

bearing?

Is motor

centrifugal

switch sticky

or plugged

with lint?

Remove

dust or lint

and spray

with a

cleaner and

lubricant.

Wait two or three

minutes for

overload protector

to reset. If

protector cycles

repeatedly, refer

to next flowchart.

Has motor

overload

protector

cycled?

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

Dryer Control Troubleshooting

806221 25

Dryer Control Troubleshooting

Dryer stops in cycle, quits after first few

loads, has burning smell or cycles on

motor thermal protector.

Is voltage

incorrect?

Refer to nameplate in

door well for correct

voltage. Refer to

Installation

Instructions (supplied

with unit) for

electrical

requirements.

Yes

Is clothes

load too

large?

No

Remove part of

load. A normal

washer load is a

normal dryer load.

Maximum load:

dryer cylinder one

half full of wet

clothes.

Yes

Is clothes

cylinder

binding?

Check cylinder for

binding and "out of

round" condition.

Check front and rear

bulkheads for

warping. Check

support rollers for

binding. Check

cylinder seals and

glides for wear or

damage. Check for

clothes lodged

between cylinder

baffle and bulkhead.

No

Yes

Is there

broken, loose

or incorrect

wiring?

Refer to wiring

diagram.

Yes

Are motor

switch

functions

inoperative?

Refer to

Adjustments

section to

check switch

and windings.

Yes

Is there a

short in

motor

winding?

No

Is a clothes

item caught in

fan?

Check fan for

obstruction.

Yes

No

SWD1690S

Refer to

Adjustments

section to

check switch

and windings.

No

Yes

No

9. Dryer Stops in Cycle; Quits After the First Few Loads; Has a Burning Smell; Cycles On Motor Thermal Protector

26 806221

10. Dryer Motor Runs But Cylinder Does Not Turn

Dryer motor runs but

cylinder does not turn.

Is motor drive

pulley loose?

Tighten pulley.

Is belt

installed on

pulley?

No

Install belt.

No

Is cylinder

belt broken?

Replace belt.

Yes

Is clothes

cylinder

binding?

No

Check cylinder for

binding and "out of

round" condition. Check

front and rear

bulkheads for warping.

Check cylinder rollers

for binding. Check

cylinder seals and

glides for wear or

damage.

Is idler lever

spring broken,

weak or

disconnected?

Replace or

reconnect

spring.

Yes

Is there oil on

cylinder?

Wipe oil from

cylinder.

Yes

Is belt "inside

out" ?

Reinstall belt

with ribbed

surface

against

cylinder.

Yes

Is idler arm

binding?

Add grease

between idler

arm and

motor mount.

Replace idler

arm and bolt

if needed.

Yes

No

Is dryer

overloaded?

Remove some

laundry from

dryer.

Yes

No

SWD1691S

Yes

Yes

Yes

No

Is the wrong

motor

installed?

Refer to parts

manual for

correct motor

part number.

Is the wrong

belt installed?

Check belt

part number

against correct

part number in

parts manual

and replace

belt if needed.

Is idler arm

bent?

Replace idler

arm.

No

No

No

Yes

Yes

Yes

Is belt routed

on wrong side

of idler lever?

Reroute belt.

No

No

No

Yes

Dryer Control Troubleshooting

806221 27

Dryer Control Troubleshooting

11. Dryer Motor Does Not Stop

Dryer motor does not stop.

Is wiring to

motor switch

incorrect?

No

Is motor

centrifugal

switch sticky

or plugged

with lint?

No

Is door switch

inoperative?

Yes

Yes

Refer to wiring

diagram.

Remove dust or lint

and spray with a

cleaner and

lubricant.

Yes

Test switch and

replace if

inoperative.

No

Is

timer/electronic

Yes

control

inoperative?

28 806221

Te st

timer/electronic

control and replace

if inoperative.

SWD1707S

12. Dryer Runs Only When Door is Open

Dryer runs only when door is

open.

Is door switch

miswired?

Rewire door

switch. Refer to

wiring diagram.

Yes

SWD1693S

Replace door switch.

No

Dryer Control Troubleshooting

806221 29

Loading...

Loading...