Alliance Laundry Systems HX018PVQM7, HX18PVQM7, HX018PVXM7, HX18PVQM6, HX18PVQU6 Programming Manual

...Page 1

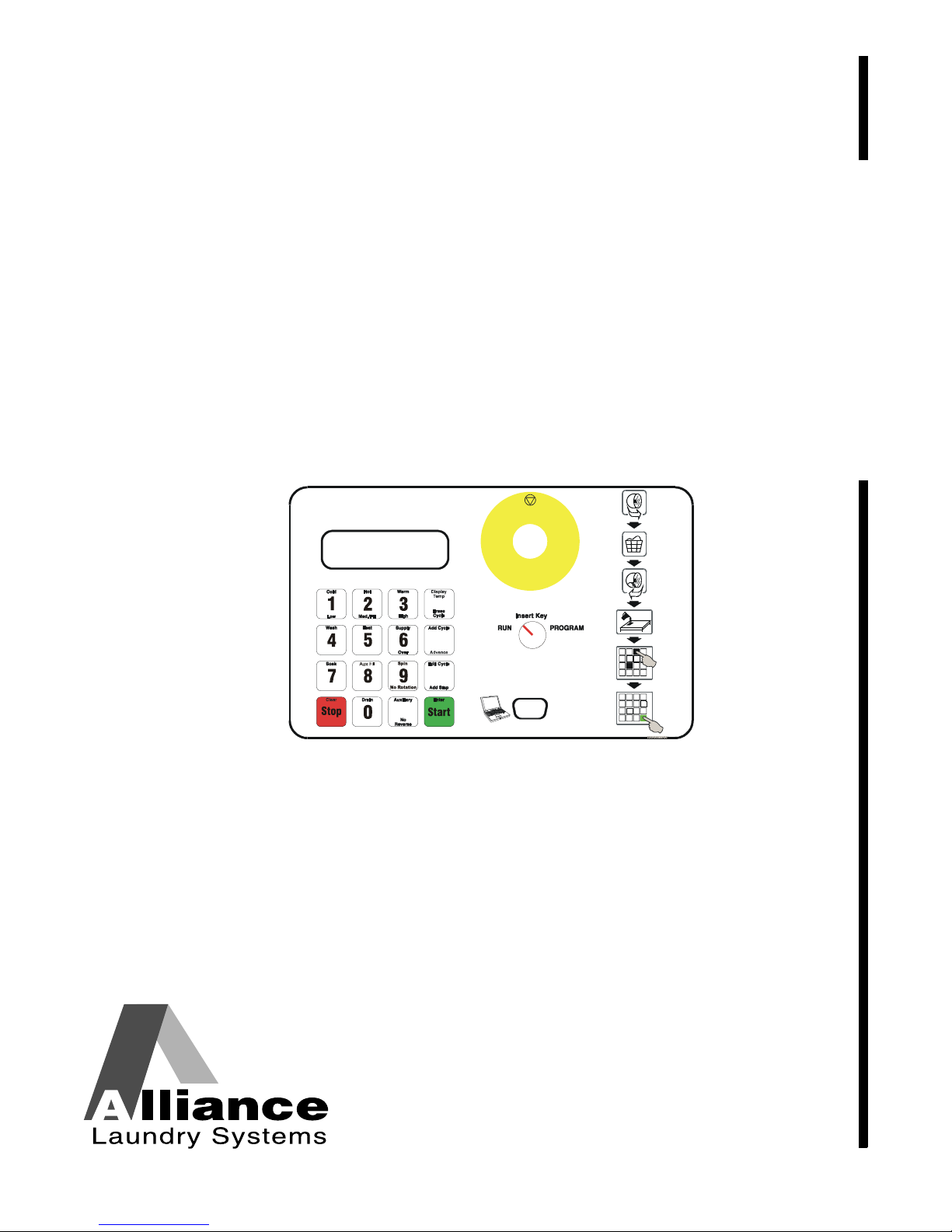

Washer-Extractors

Cabinet Freestanding

WE-8 Computer

Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

Part No. 9001889R7

July 2011

Page 2

Page 3

NOTE: The WARNING and IMPORTANT instructions appearing in this manual are not meant to cover all

possible conditions and situations that may occur. It must be understood that common sense, caution, and

carefulness are factors which cannot be built into these washers. These factors MUST BE supplied by the

person(s) installing, maintaining, or operating the washer.

Always contact the distributor, service agent, or the manufacturer about any problems or conditions you do not

understand.

Failure to install, maintain, and/or operate this machine according to the manufacturer's

instructions may result in conditions which can produce bodily injury and/or property

damage.

W030

WARNING

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT9001889

1

Page 4

Table of

Introduction......................................................................................... 3

Model Identification ............................................................................. 3

Contents

Programming ...................................................................................... 4

Setup of the Machine............................................................................ 4

Version of Control ................................................................................ 7

Language on Display (Version 1.15 and later ONLY) .................... 7

Setup of the Chemical Hold Feature

(Version 1.11 and later ONLY)...................................................... 7

Program Storing Mode ......................................................................... 7

Explanation of the Step Functions........................................................ 8

Example Making a New Program......................................................... 14

Edit a Cycle........................................................................................... 18

Change a Complete Step.................................................................. 18

Changing the Time of a Step ........................................................... 20

Delete a Step .................................................................................... 22

Insert a Step...................................................................................... 23

Delete a Cycle....................................................................................... 25

Reloading Previous Settings................................................................. 26

Cycle Count .......................................................................................... 27

Reading Cycle Count ....................................................................... 27

Calibration of the Machine ................................................................... 28

Speed Calibration.................................................................................. 29

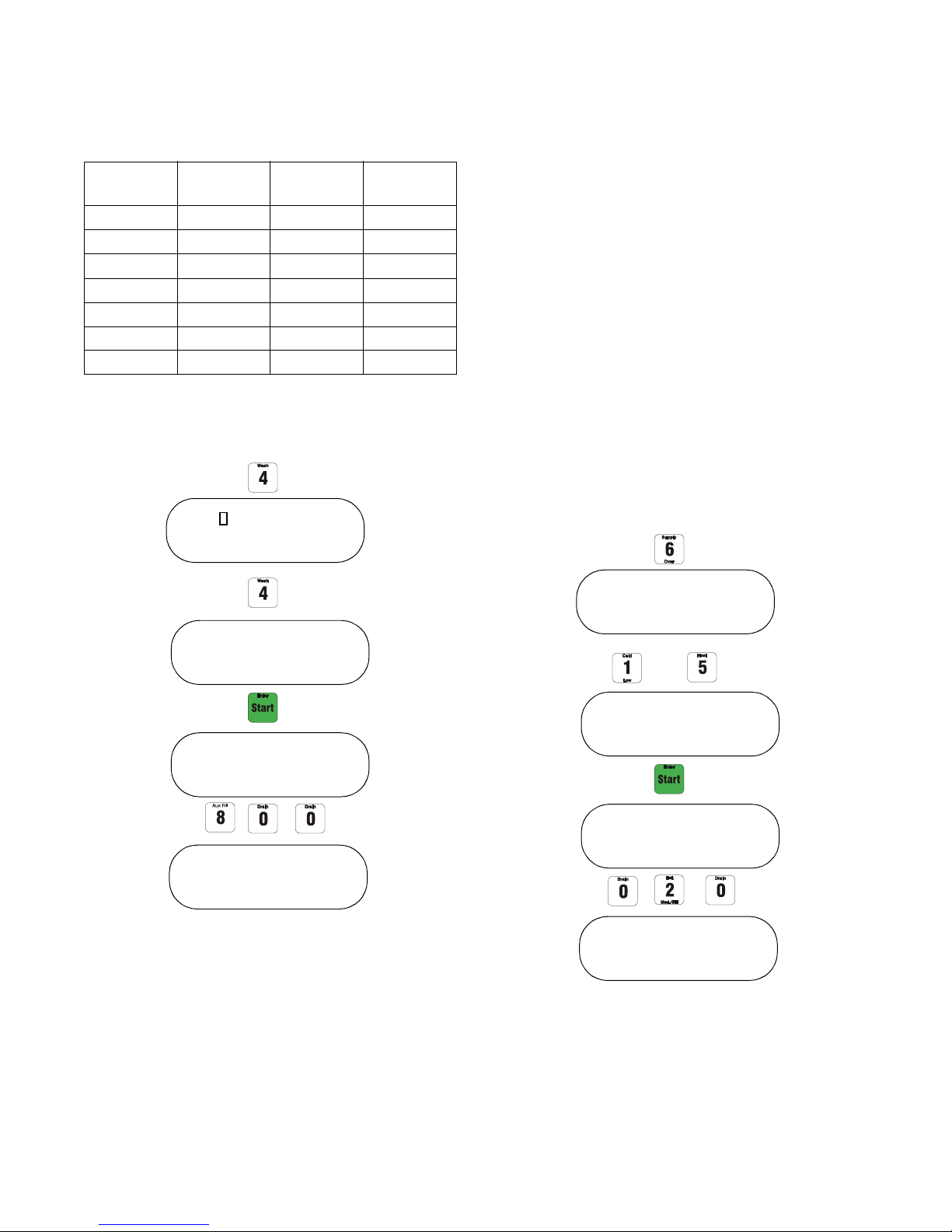

Pre-Programmed Cycles .................................................................... 30

Inverter Drive Error Codes............................................................... 56

© Copyright 2011, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 5

Introduction

Model Identification

Information in this manual is applicable to these

models:

18

25

33

35

40

55

75

100

135

165

200

HX018PVQM7

HX018PVXM7

HX18PVQM6

HX18PVQM7

HX18PVQU6

HX18PVXM6

HX18PVXM7

HX025PVQM7

HX025PVXM7

HX25PVQM6

HX25PVQM7

HX25PVQU6

HX25PVXM6

HX25PVXM7

UX33PVNA7 UX33PVPA7 UX33PVQA7 UX33PVQM7 UX33PVXA7 UX33PVXM7

HX035PVQM7

HX035PVXM7

HX35PVQM6

HX35PVQM7

HX35PVQU6

HX35PVXM6

HX35PVXM7

UX40PVNA7 UX40PVPA7 UX40PVQA7 UX40PVQM7 UX40PVXA7 UX40PVXM7

HX055PVNU7

HX055PVQU7

HX055PVXU7

HX55PVNU6

HX55PVNU7

HX55PVQU6

HX075PVNU7

HX075PVPU7

HX075PVQU7

HX75PVNU6

HX75PVNU7

HX100PVNU6

HX100PVNU7

HX100PVPU7

HX135PVNU6

HX135PVNU7

HX135PVPU7

HX165PVNU6

HX165PVNU7

HX165PVPU7

HX200PVNU7

HX200PVPU7

HX18PVXU6

SX018PVPA7

SX018PVQM7

SX018PVXM7

SX18PVPA7

SX18PVQM6

SX18PVQM7

HX25PVXU6

SX025PVQM7

SX025PVXM7

SX25PVQM6

SX25PVQM7

SX25PVQU6

SX25PVXM6

HX35PVXU6

SX035PVNM7

SX035PVQM7

SX035PVXM7

SX35PVNM7

SX35PVQM6

SX35PVQM7

HX55PVQU7

HX55PVXU6

HX55PVXU7

SX055PVNU7

SX055PVPU7

SX055PVQU7

HX75PVPU7

HX75PVQU6

HX75PVQU7

SX075PVNU7

SX075PVPU7

HX100PVQU6

HX100PVQU7

SX100PVNU6

HX135PVQU6

HX135PVQU7

SX135PVNU6

HX165PVQU6

HX165PVQU7

SX165PVNU6

HX200PVQU7

SX200PVNU7

SX18PVQU6

SX18PVXM6

SX18PVXM7

SX18PVXU6

UX018PVNA7

UX018PVPA7

UX018PVQA7

SX25PVXM7

SX25PVXU6

UX025PVNA7

UX025PVPA7

UX025PVQA7

UX025PVQM7

UX025PVXA7

SX35PVQU6

SX35PVXM6

SX35PVXM7

SX35PVXU6

UX035PVNA7

UX035PVPA7

UX035PVQA7

SX055PVXU7

SX55PVNU6

SX55PVNU7

SX55PVPU6

SX55PVPU7

SX55PVQU6

SX075PVQU7

SX75PVNU6

SX75PVNU7

SX75PVPU7

SX75PVQU6

SX100PVNU7

SX100PVPU7

SX100PVQU6

SX135PVNU7

SX135PVPU7

SX135PVQU6

SX165PVNU7

SX165PVPU7

SX165PVQU6

SX200PVPU7

SX200PVQU7

UX018PVQM7

UX018PVXA7

UX018PVXM7

UX18PVNA6

UX18PVNA7

UX18PVNU6

UX18PVPA6

UX025PVXM7

UX25PVNA6

UX25PVNA7

UX25PVNU6

UX25PVPA6

UX25PVPA7

UX25PVPU6

UX035PVQM7

UX035PVXA7

UX035PVXM7

UX35PVNA6

UX35PVNA7

UX35PVNU6

UX35PVPA6

SX55PVQU7

SX55PVXU6

SX55PVXU7

UX055PVNU7

UX055PVPU7

UX055PVQU7

SX75PVQU7

UX075PVNU7

UX075PVPUU

X075PVQU7

UX75PVNU6

SX100PVQU7

UX100PVNU6

UX100PVNU7

SX135PVQU7

UX135PVNU6

UX135PVNU7

SX165PVQU7

UX165PVNU6

UX165PVNU7

UX200PVNU7

UX200PVPU7

UX18PVPA7

UX18PVPU6

UX18PVQA6

UX18PVQA7

UX18PVQM6

UX18PVQM7

UX18PVQU6

UX25PVQA6

UX25PVQA7

UX25PVQM6

UX25PVQM7

UX25PVQU6

UX25PVXA6

UX25PVXA7

UX35PVPA7

UX35PVPU6

UX35PVQA6

UX35PVQA7

UX35PVQM6

UX35PVQM7

UX35PVQU6

UX055PVXU7

UX55PVNU6

UX55PVNU7

UX55PVPU6

UX55PVPU7

UX55PVQU6

UX75PVNU7

UX75PVPU6

UX75PVPU7

UX75PVQU6

UX75PVQU7

UX100PVPU6

UX100PVPU7

UX100PVQU6

UX135PVPU6

UX135PVPU7

UX135PVQU6

UX165PVPU6

UX165PVPU7

UX165PVQU6

UX200PVQU7

UX18PVXA6

UX18PVXA7

UX18PVXM6

UX18PVXM7

UX18PVXU6

UX25PVXM6

UX25PVXM7

UX25PVXU6

UX35PVXA6

UX35PVXA7

UX35PVXM6

UX35PVXM7

UX35PVXU6

UX55PVQU7

UX55PVXU6

UX55PVXU7

UX100PVQU7

UX135PVQU7

UX165PVQU7

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

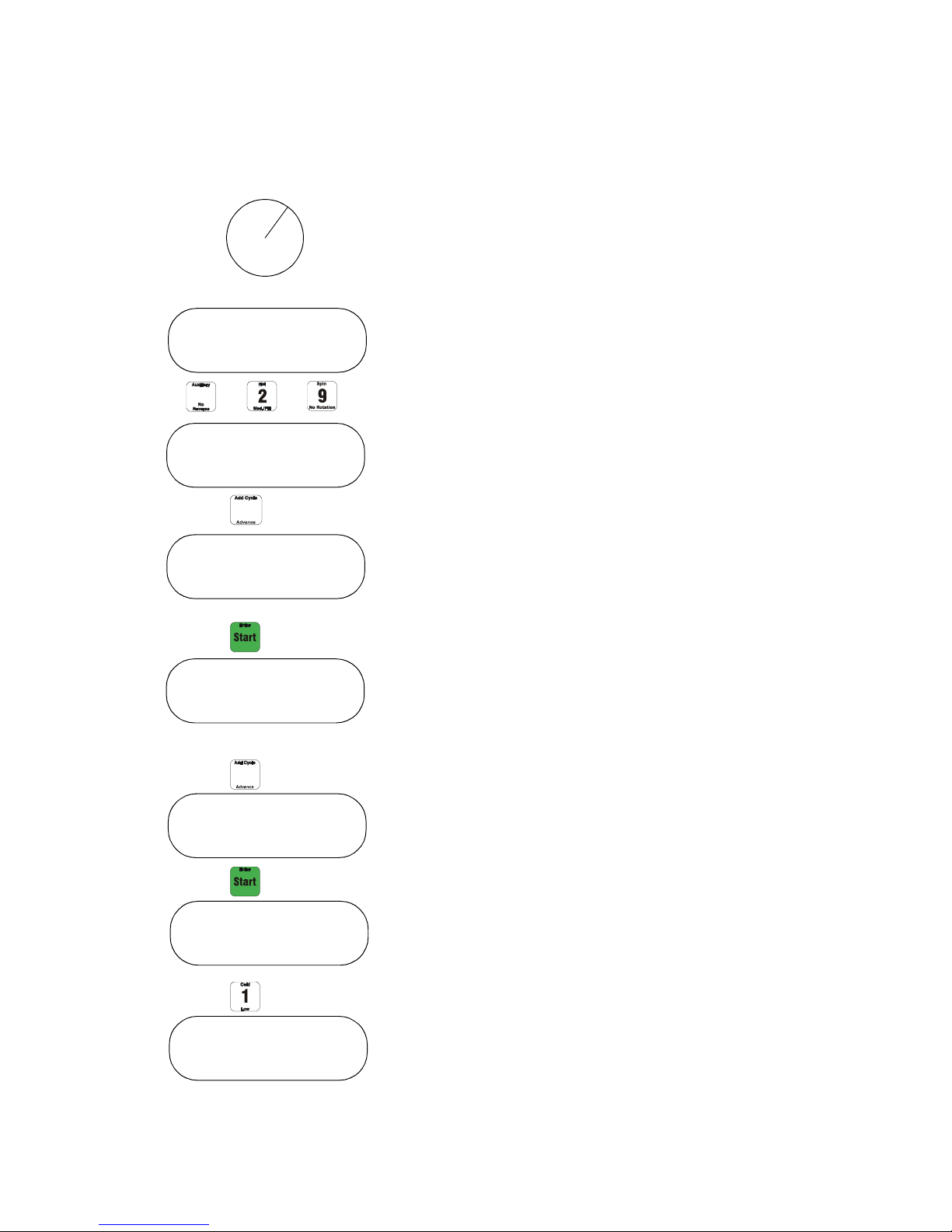

Setup of the Machine

Program Cycle 00

Units: English

System Program

_X18PV

System Program

_X25PV

Units: Metric

Drain 1 : Valve

Drain 2 : None

Drain 1 : Pump

Drain 2 : None

RUN PROGRAM

Programming

Turn key from Run to Program

To go to the main setup of the machine, press

“Auxiliary”, “2”, “9”.

To change the machine type, press the “Advance”

button.

The following types are possible:

_X18PV _X40PV _X135PV

_X25PV _X55PV _X165PV

_X33PV _X75PV _X200PV

Press the “Advance” button until the right type of

machine is selected. Press the “Enter” button.

Select the desired units.

NOTE: English means level in inch and

temperature in °F.

Metric means level in cm and temperature in °C.

Press the “Advance” button to change the units.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 9001889

Press the “Enter” button.

Select the type of drain valve.

Press “1” to change drain 1 to pump or valve.

Press “2” to change drain 2 to pump, valve or none.

Page 7

Programming

Options :

Advance : Yes

Advance : No

Options :

Aux Fill

Heating : 6 kW

Heating : 9 kW

Press the “Enter” button to select options.

Press the “Aux Fill” button for auxiliary fill option or

press “Enter” for heating.

If heating is selected, the user can fill in the kW of the

electrical heating (example: 9 kW).

Press “0”, “9”.

Press “Enter” to select advance mode in run mode yes

or no.

Press “Advance” to change between yes and no.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Programming

Level : hyst 2"

Enter to save ?

Program Cycle 00

Temp : hyst 3°F

Spin retries : 5

Address : 0

Press “Enter” to set the hysteresis level (level at which

water drops before it senses it must refill).

If English is selected for units, this value will be in

inches. If Metric is selected for units, this value will be

in cm.

Select between 1 to 9 cm or inches.

Press “Enter” to select the temperature hysteresis

(level at which temperature drops before machine

senses it must reheat).

If English is selected for units, this value will be in °F.

If Metric is selected for units, this value will be in °C.

Select 1 to 9 °C or °F.

Press the “Enter” button to set the spin retries.

Select 1 to 9 spin retries.

Press “Enter” to set the network address of the

machine. If this is not used, press “Enter”.

The address of the machine has to be set if you

network the machine. Each machine should have a

different address.

Fill in between 00 and 99.

Press “Enter” to finish the settings.

Press “Enter” to save the settings or press “Stop” to

exit without saving.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 9

Programming

Version of Control

To determine control version, apply power to machine.

Control will display version of control (i.e., 1.15).

Language on Display (Version 1.15 and

later ONLY)

To set a different language on the WE-8 display:

1. Turn key from RUN to PROGRAM.

2. Press “Auxiliary”, “2” and “9” to enter set-up

mode.

3. English will display. Press “Advance” until

desired language displays (French, Italian,

Spanish and German).

4. Press “Enter” keypad.

5. Press “Enter” to advance through set-up mode.

6. Wait until information is saved.

7. Turn key from PROGRAM to RUN.

8. Display will read language chosen for all cycles.

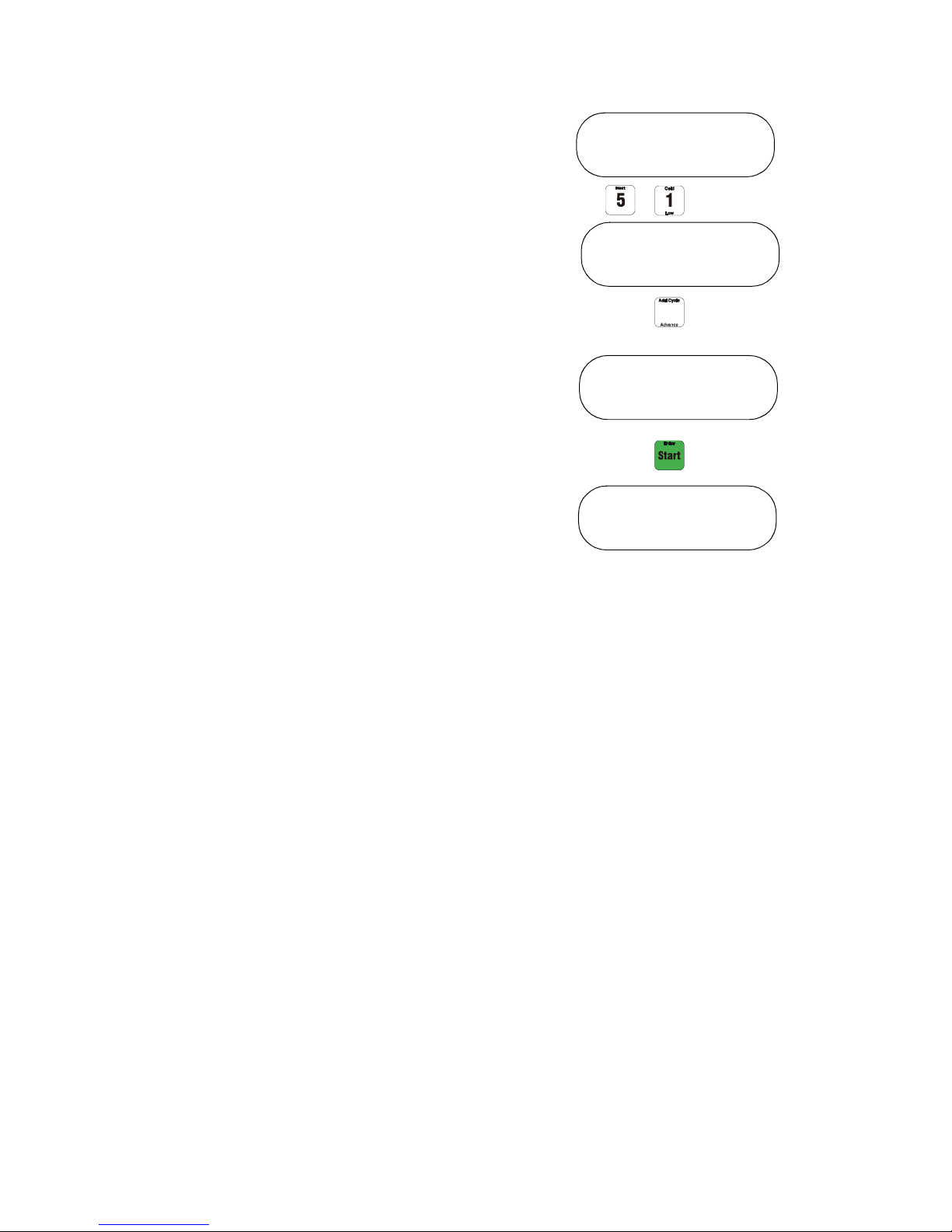

Setup of the Chemical Hold Feature

(Version 1.11 and later ONLY)

At power up, verify that model is at least

version 1.11. Refer to version of Control Section.

Earlier versions do not have this chemical hold

feature.

Insert key into key switch and turn to Program.

NOTE: If chemical hold is off, then supplies 4

through 9 are controlled exactly like supplies 1

through 3. A switch closure/opening between pins 1

and 4 of the COIN header on the output board will

have no effect.

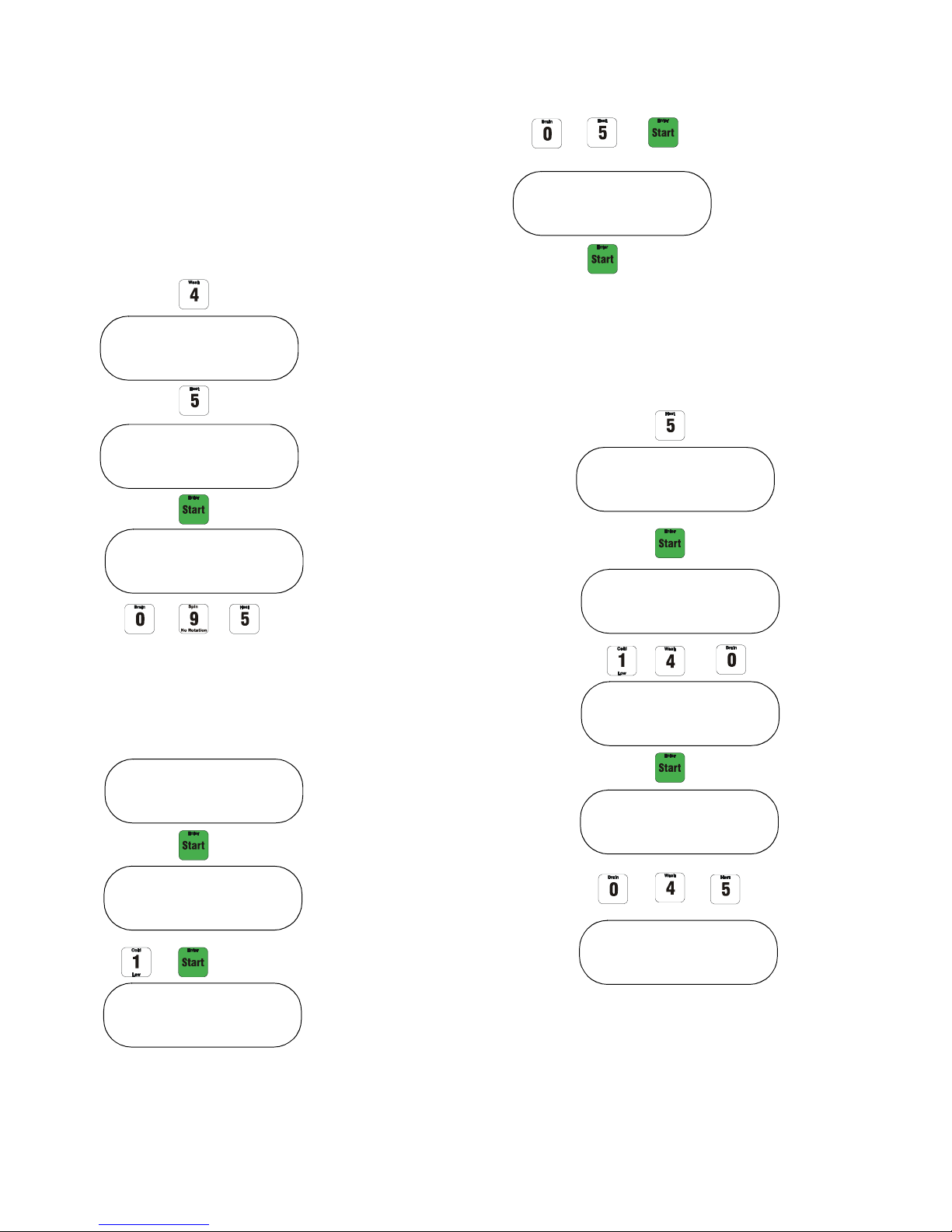

Program Storing Mode

The WE-8 control is capable of 99 total cycles. One

cycle contains 1 or more steps.

One step is a function of the wash program

(example: heat).

Choose between the following functions:

Fill: To fill the machine with water.

Wash: Wash action of the machine.

Supply: To add detergent to the wash (liquid or

powder).

Cooldown: Cool to programmed temperature

Heat: To heat the water.

Soak: The wash will be soaked for a

programmed time and a programmed

temperature.

Aux: A relay contact will close for a

programmed time.

Spin: To spin the machine for a programmed

time and RPM.

Drain: To drain the water from the machine.

Push the Auxiliary key, the 2 key, and the 9 key

in succession to enter System Program Mode.

Push the Start key 10 times to arrive at the

Chemical hold choice.

Push the Add Cycle/Advance key to toggle the

Chemical hold feature either Yes (on) or No (off).

Push the Start key twice to save changes and exit

System Program Mode.

Turn key switch to Run.

NOTE: If chemical hold is on, then a switch

closure/opening between pins 1 and 4 of the COIN

header on the output board will control supplies 4

through 9. A closure will turn the programmed

supply/ies on and count down the time for the

supply to be on. An opening will turn the

programmed supply/ies off and halt the time for

the supply to be on.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Programming

Step XX Cycle XX

Warm

Step XX Cycle XX

Warm Low

Step XX Cycle XX

0 min

Step XX Cycle XX

5 min 30 sec

Explanation of the Step Functions

Fill:

Choose between 4 water inlet configurations and

3 water levels.

Water Inlet Configurations:

Cold: Only opens the cold water valve.

Hot: Only opens the hot water valve.

Warm: Opens the cold and hot water valves.

Aux Fill: Opens an auxiliary water valve

if installed.

Water Levels:

Low: Low water level.

Med: Medium water level.

High: High water level.

The inlet configurations and the fill levels appear on

the keypad, keys 1, 2, 3 and 8.

Example: Warm Low (time limit 5 minutes

30 seconds)

Be sure to select first the inlet configuration and then

the water level.

Then you will be asked for the step time limit.

NOTE: If a fill error occurs, then machine has

2 minutes to finish filling. If after 2 minutes it has

not finished filling, cycle is aborted.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 11

It is possible to more accurately control the

Step XX Cycle XX

Warm

Step XX Cycle XX

Warm Low

Step XX Cycle XX

0°F

Step XX Cycle XX

95°F

Step XX Cycle XX

95°F Low

Step XX Cycle XX

0 min

Step XX Cycle XX

5 min 30 sec

temperature of water coming in to the machine during

a fill step. This does not apply to “Aux Fill” step. The

control will mix the hot and cold water inlet to the

temperature programmed in the fill function. To fill in

the temperature, select the water inlet type and the

water level. Press the “Heat” button and the control

will ask the temperature. In this way the water inlet

type selected is of no use because the control will mix

between the cold and hot water inlet to reach the

temperature.

Example: Fill to low level and 95°F (step time limit:

5 minutes 30 seconds).

Programming

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Programming

Step XX Cycle XX

Wash

Step XX Cycle XX

Wash 4 10/20

Step XX Cycle XX

0 min

Step XX Cycle XX

8 min 00 sec

Step XX Cycle XX

Supply

Step XX Cycle XX

Supply 1 5

Step XX Cycle XX

0 min

Step XX Cycle XX

0 min 20 sec

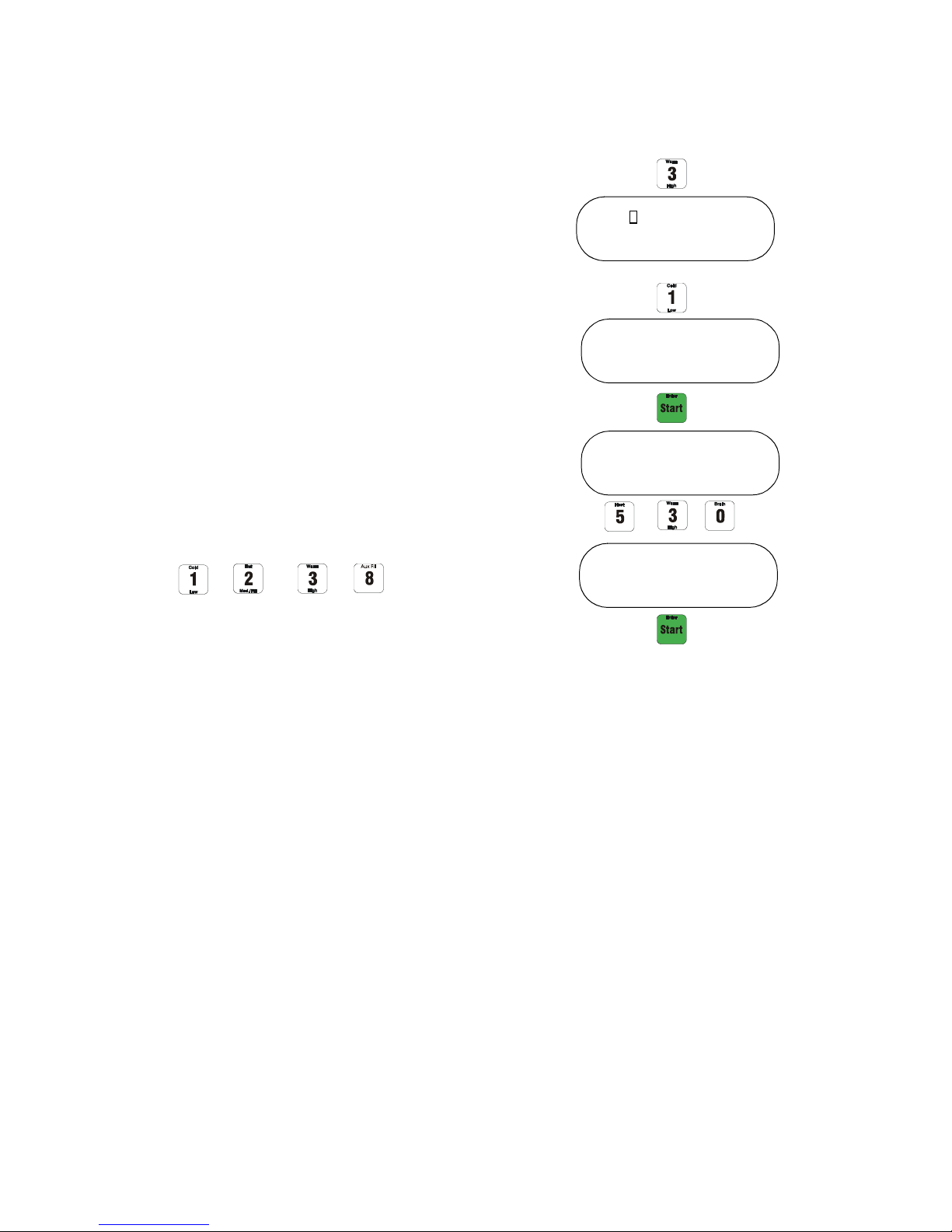

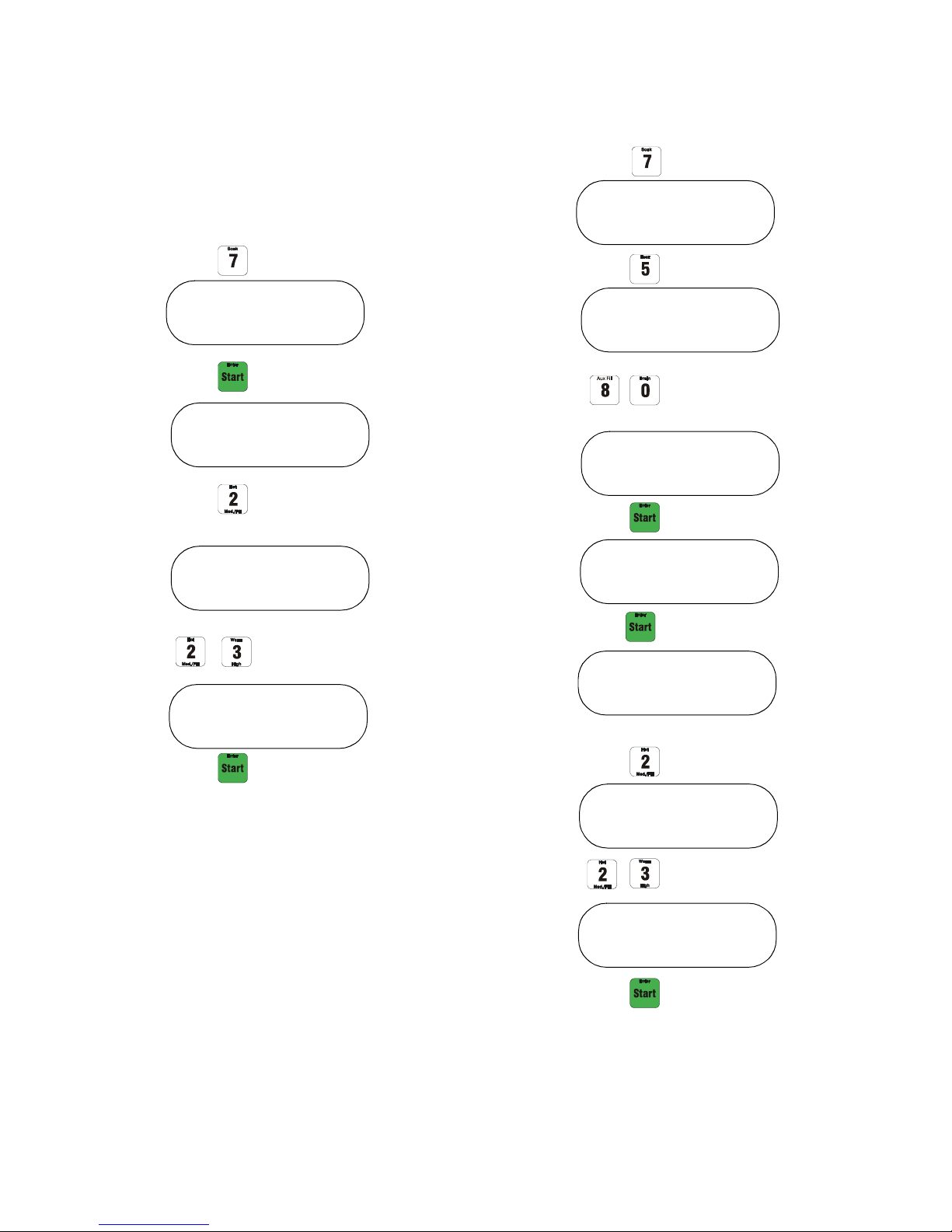

Heat:

Was h :

Choose between 7 different preset wash actions.

Action

Time (sec)

Stop Time

(sec)

G-force

Wash 1 18 3 0.5

Wash 2 3 27 0.5

Wash 3 0 0 0

Wash 4 10 20 0.5

Wash 5* 18 3 0.5

Wash 6 4 56 0.5

Wash 7 0 0 0

The “Wash” button is button 4 on the display.

Example: Wash 4 for 8 minutes 00 seconds.

Supply:

Choose between 9 different supplies.

Supply 1: Turns on the water valve in compartment

A of the supply box.

Supply 2: Turns on the water valve in compartment

B of the supply box.

Supply 3: Turns on the water valve in compartment

C of the supply box.

Supply 4: Activates supply pump 1.

Supply 5: Activates supply pump 2.

Supply 6: Activates supply pump 3.

Supply 7: Activates supply pump 4.

Supply 8: Activates supply pump 5.

Supply 9: Activates supply pump 6.

The Supply button is button 6.

Example: Supply 1 and 5 for 20 seconds.

* Refer to section on Wash 5 Thermal Cool-Down.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 13

Chemical Hold Feature

Step XX Cycle XX

Wash

Step XX Cycle XX

0°F (or 0°C)

Step XX Cycle XX

Wash 5

Enter desired temperature for load to

cool down to. Three digits must be used

for temperature. If Fahrenheit, the valid

temperature range is 80° – 200°F. If

Celcius, valid temperature range is

25° – 90°C (example: 95°F).

Step XX Cycle XX

95°F

Step XX Cycle XX

0 hours

Step XX Cycle XX

1 hours 00 min

Thermal Cool-Down

is Wash 5.

Step XX Cycle XX

1 hours 05 min

Enter time in minutes

and press “Enter”

(example: 5 min).

Step XX Cycle XX

Heat

Step XX Cycle XX

0°F

Step XX Cycle XX

140°F

Step XX Cycle XX

0 hours 45 min

Step XX Cycle XX

0 hours

Chemical supply injection can be paused. Refer to

Setup of Chemical Hold Feature.

Wash 5 Thermal Cool-Down

Immediately after a heat step, a temperature-controlled

thermal cool-down may be programmed to prevent

fiber shock from sudden cool-down.

Programming

The “Heat” button is number 5.

Example: Heat up to 140°F with the time limit of

45 minutes.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Programming

Step XX Cycle XX

Soak

Step XX Cycle XX

0 hours

Step XX Cycle XX

2 hours 00 min

Step XX Cycle XX

2 hours 23 min

Use the key pad to fill in

the hours of the soak time

(example: 2 hours).

Now you can fill in the

minutes (example:

23 minutes).

Press “Enter”.

Step XX Cycle XX

Soak

Step XX Cycle XX

0°F

Step XX Cycle XX

32°F

Step XX Cycle XX

2 hours 00 min

Step XX Cycle XX

Soak 32°F

Use the key pad to fill in

the soak temperature

(example: 32°F).

Fill in the minutes

(example: 23 minutes).

Press “Enter”.

Step XX Cycle XX

2 hours 23 min

Step XX Cycle XX

0 hours

Use the key pad to fill in

the hours of the soak time

(example: 2 hours).

Soak:

Button 7 is the “Soak” button.

By pressing button 7, “Soak” will appear on the

display. Press “Enter” to fill in the soak time.

Example: Soak for 2 hours.

Example: Soak time of 2 hours with 32°F.

The temperature of the soak will be the temperature

programmed in the previous step. You can also change

the temperature by pressing first “Soak” and then

“Heat”.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 15

Programming

Step XX Cycle XX

Spin

Step XX Cycle XX

Spin 3

Step XX Cycle XX

0 min

Step XX Cycle XX

5 min 30 sec

Step XX Cycle XX

5 min 00 sec

Select the spin number

(example: 3).

Enter the spin time. Enter

minutes first and then

seconds (example:

5 minutes 30 seconds).

Step XX Cycle XX

Drain

Step XX Cycle XX

Drain 2

Step XX Cycle XX

0 min

Step XX Cycle XX

1 min 10 sec

Step XX Cycle XX

1 min 00 sec

Select Drain 1 or 2.

If you only have 1 drain,

you can only select 1.

Enter the drain time

(example: 1 minute

10 seconds).

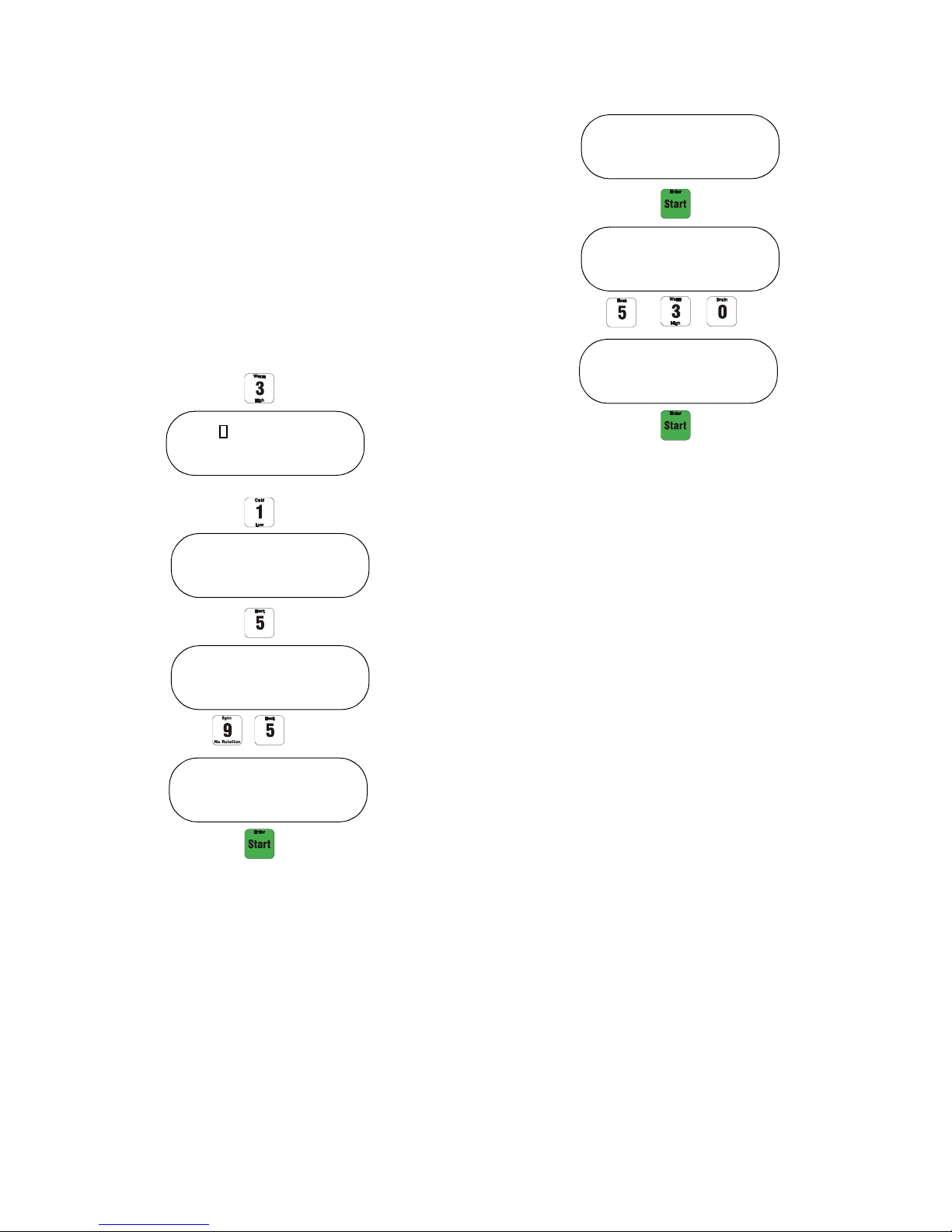

Spin:

Choose between 4 preset spin speeds.

Spin 1

18-75

Models

500 500 500

100/135

Models

Models

RPM

Spin 2

650 650 650

RPM

Spin 3

800 800 750

RPM

Spin 4

1000 80 750

RPM

“Spin” is button 9.

165

200

Models

Drain:

This function drains the water.

If you have 2 drains, select which drain has to be

opened.

NOTE: With the WE-8 control, it is NOT necessary

to program a drain step before spin. The spin step

incorporates the balancing routine and draining

before beginning high speed spin (as a sub part of

the spin step). A programmed drain step will be

skipped if spin step is programmed immediately

after it.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

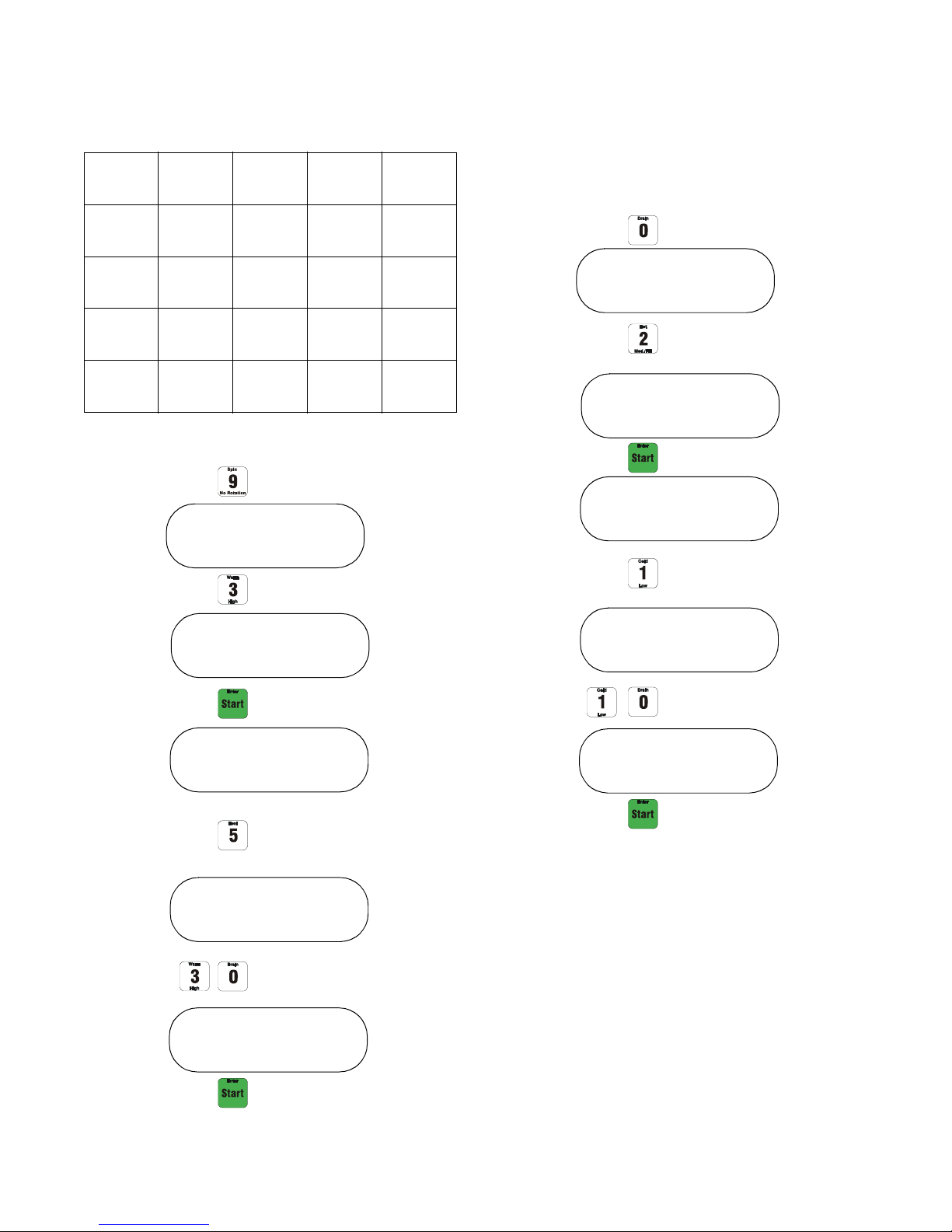

Page 16

Programming

Program Cycle 00

Program Cycle 51

Step 01 Cycle 51

Add Cycle 51

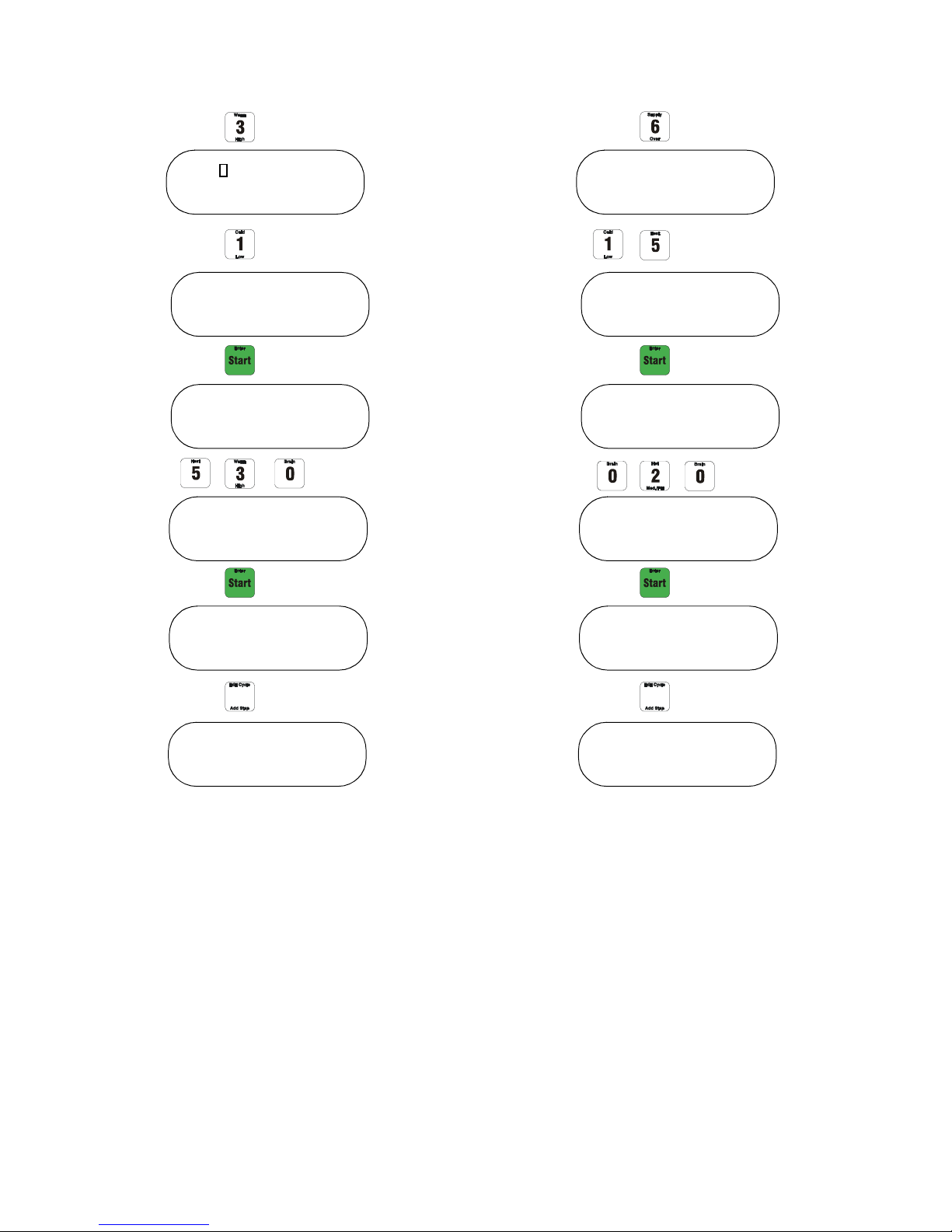

Example Making a New Program

Program 51

Step 1: Fill warm water to low level

(5 minutes 30 seconds time limit)

Step 2: Supply 1 and 5 for 20 seconds

Step 3: Heat up to 140°F (45 minutes time limit)

Step 4: Wash action 4 for 8 minutes 00 seconds

Step 5: Drain 1 for 1 minutes 25 seconds

Step 6: Spin 3 for 8 minutes 30 seconds

To program or edit cycles turn the key into the

Program Mode.

“Program Cycle xx” will be shown on the display.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 17

Programming

Step 01 Cycle 51

Warm

Step 01 Cycle 51

Warm Low

Step 01 Cycle 51

0 min

Step 01 Cycle 51

5 min 30 sec

End Cycle 51

Step 02 Cycle 51

Step 02 Cycle 51

Supply

Step 02 Cycle 51

Supply 1 5

Step 02 Cycle 51

0 min

Step 02 Cycle 51

0 min 20 sec

End Cycle 51

Step 03 Cycle 51

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Programming

Step 03 Cycle 51

Heat

Step 03 Cycle 51

0°F

Step 03 Cycle 51

140°F

Step 03 Cycle 51

0 hours

Step 03 Cycle 51

0 hours 45 min

Step 04 Cycle 51

End Cycle 51

Step 04 Cycle 51

Wash

Step 04 Cycle 51

Wash 4 10/20

Step 04 Cycle 51

0 min

Step 04 Cycle 51

8 min 00 sec

End Cycle 51

Step 05 Cycle 51

Step 05 Cycle 51

0 min

Step 05 Cycle 51

Drain 1

Step 05 Cycle 51

1 min 25 sec

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 19

End Cycle 51

Step 06 Cycle 51

Step 06 Cycle 51

Spin 1

Step 06 Cycle 51

Spin 3

Step 06 Cycle 51

0 min

End Cycle 51

Step 06 Cycle 51

8 min 30 sec

Enter to save ?

Program Cycle 51

Programming

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Programming

Program Cycle 00

Program Cycle 51

Edit Cycle 51

Name Cycle 51:

Cycle 51

Step 01 Cycle 51

Warm Low

Step 02 Cycle 51

Wash

Step 02 Cycle 51

Wash 1 18/3

Step 02 Cycle 51

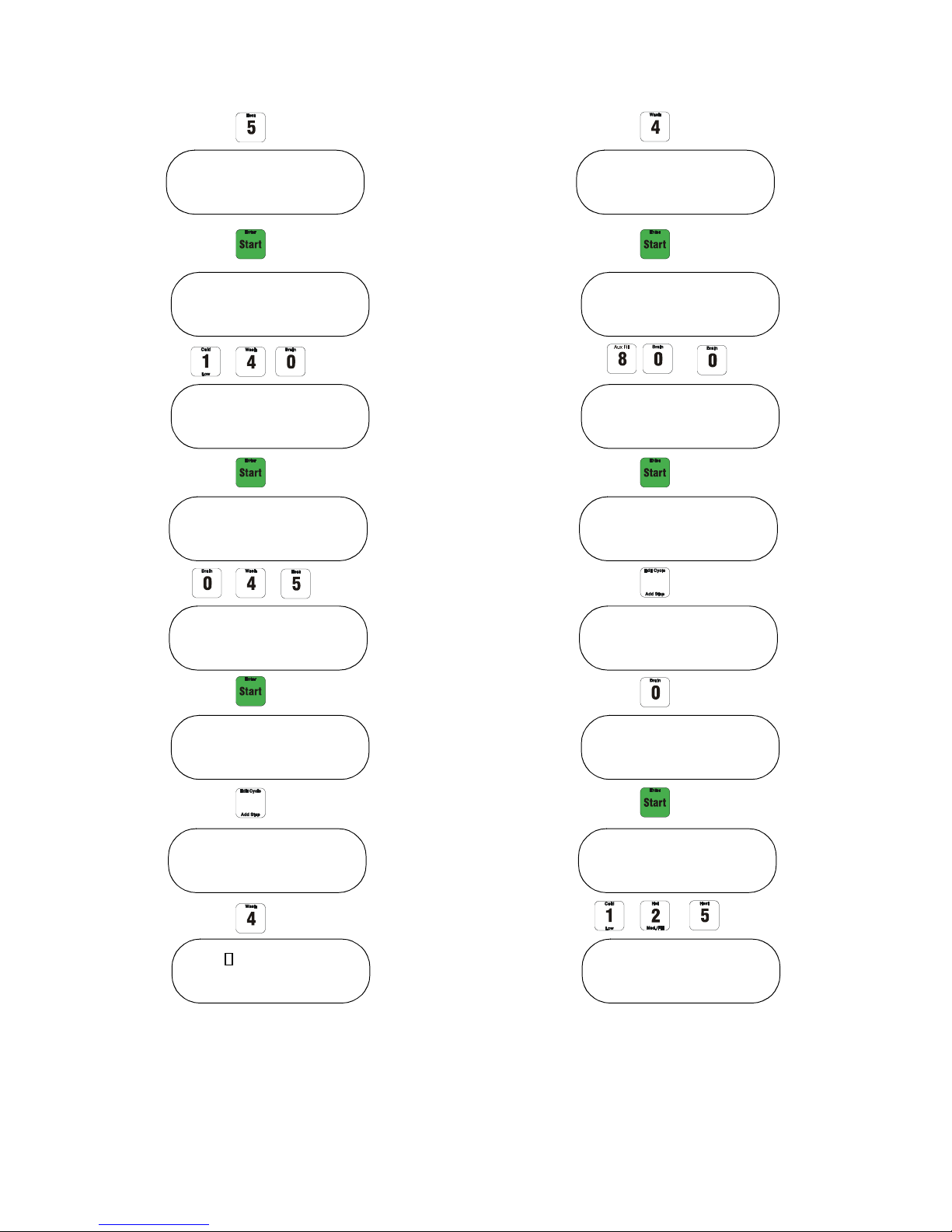

Edit a Cycle

Change a Complete Step

To edit a cycle enter the cycle number

(example: cycle 51).

Press the “Edit Cycle” button.

Press the “Enter” button to edit the cycle.

Press “Enter” to continue.

The first step of cycle 51 will display.

Select the step being edited by using the “Advance”

button to go to the next step or the “Previous” button

to go to the previous step.

If you would like to change the step, press the “Clear”

button.

Select another wash action or press the “Clear” button

to change the function.

Fill in the function desired (example: soak for 1 hour

30 minutes).

Press the “Soak” button.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 21

Step 02 Cycle 51

Soak

Step 02 Cycle 51

0 hours

Step 02 Cycle 51

1 hours 00 min

Step 02 Cycle 51

1 hours 30 min

Step 03 Cycle 51

XXXXXXXX

End Cycle

Enter to save ?

Programming

The control is then in the next step of cycle 51. Press

“Advance” until the display shows “End Cycle 55”.

Press “Enter” to confirm.

Press “Enter” to save or “Stop” to ignore the changes.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Programming

Program Cycle 00

Program Cycle 51

Edit Cycle 51

Name Cycle 51:

Cycle 51

Step 01 Cycle 51

Warm Low

Step 02 Cycle 51

Wash 1 18/3

Step 02 Cycle 51

5 min 00 sec

Step 01 Cycle 51

5 min

Changing the Time of a Step

To edit a cycle, enter the cycle number

(example: cycle 51).

Press the “Edit Cycle” button.

Press the “Enter” button to edit the cycle.

Press “Enter” to continue.

The first step of cycle 51 will display.

Select the step being edited by using the “Advance”

button to go to the next step or the “Previous” button

to go to the previous step.

20

Press “Enter” to change the time of the wash action.

Press “Clear” to change the time.

Fill in another time (example: 6 minutes 20 seconds).

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 23

Step 02 Cycle 51

6 min 00 sec

Step 02 Cycle 51

6 min 20 sec

Step 03 Cycle 51

XXXXXXX

End Cycle 51

Enter to save ?

Programming

Press “Enter” to go to the next step.

Press the “Advance” button until display shows “End

Cycle 51”.

Press “Enter” to confirm.

Press “Enter” to save or “Stop” to ignore the changes.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Programming

Program Cycle 00

Program Cycle 51

Edit Cycle 51

Name Cycle 51:

Cycle 51

Step 01 Cycle 51

Warm Low

Step 02 Cycle 51

Wash 1 18/3

Step 02 Cycle 51

Wash

Step 02 Cycle 51

Step deleted

Delete a Step

To edit a cycle, enter the cycle number

(example: cycle 51).

Press the “Edit Cycle” button.

Press the “Enter” button to edit the cycle.

Press “Enter” to continue.

The first step of cycle 51 will display.

Select the step being edited by using the “Advance”

button to go to the next step or the “Previous” button

to go to the previous step.

Press the “Clear” button to change the step.

Press the “Clear” button again.

Press the “Clear” button once more.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

The step is deleted. Press the “Advance” button to end

cycle 51 and press “Enter” 2 times to save the settings.

9001889

Page 25

Program Cycle 00

Program Cycle 51

Edit Cycle 51

Name Cycle 51:

Cycle 51

Step 01 Cycle 51

Warm Low

Step 02 Cycle 51

Wash 1 18/3

Step 02 Cycle 51

Step 02 Cycle 51

Supply

Programming

Insert a Step

To edit a cycle, enter the cycle number

(example: cycle 51).

Press the “Edit Cycle” button.

Press the “Enter” button to edit the cycle.

Press “Enter” to continue.

The first step of cycle 51 will display.

Select the position where you would like to add a step

by using the “Advance” button to go to the next step or

the “Previous” button to go to the previous step.

Push the “Add Step” button to add a step.

The control will insert a step before the step selected.

Select the function (example: supply).

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Press the supply number (example: supply 7).

23

Page 26

Programming

Step 02 Cycle 51

Supply 7

Step 02 Cycle 51

0 min

Step 02 Cycle 51

0 min 00 sec

Step 02 Cycle 51

0 min 23 sec

Step 03 Cycle 51

Wash 1 18/3

End Cycle 51

Enter to save ?

Press “Enter” to confirm.

Enter the time to activate the supply

(example: 0 minutes 23 seconds).

Press “Enter” to confirm.

Press the “Advance” button until

“End Cycle 51” is displayed.

Press “Enter” to confirm.

Press “Enter” to save or “Stop” to ignore the changes.

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 27

Program Cycle 00

Erase Cycle 00

Erase Cycle 55

Enter to save ?

Programming

Delete a Cycle

Press the “Erase Cycle” button.

Press the number of the cycle being erased

(example: 55).

Press “Enter” to confirm.

Press “Enter” to save or “Stop” to ignore the changes.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Programming

Program Cycle 00

Enter to reload

earlier settings

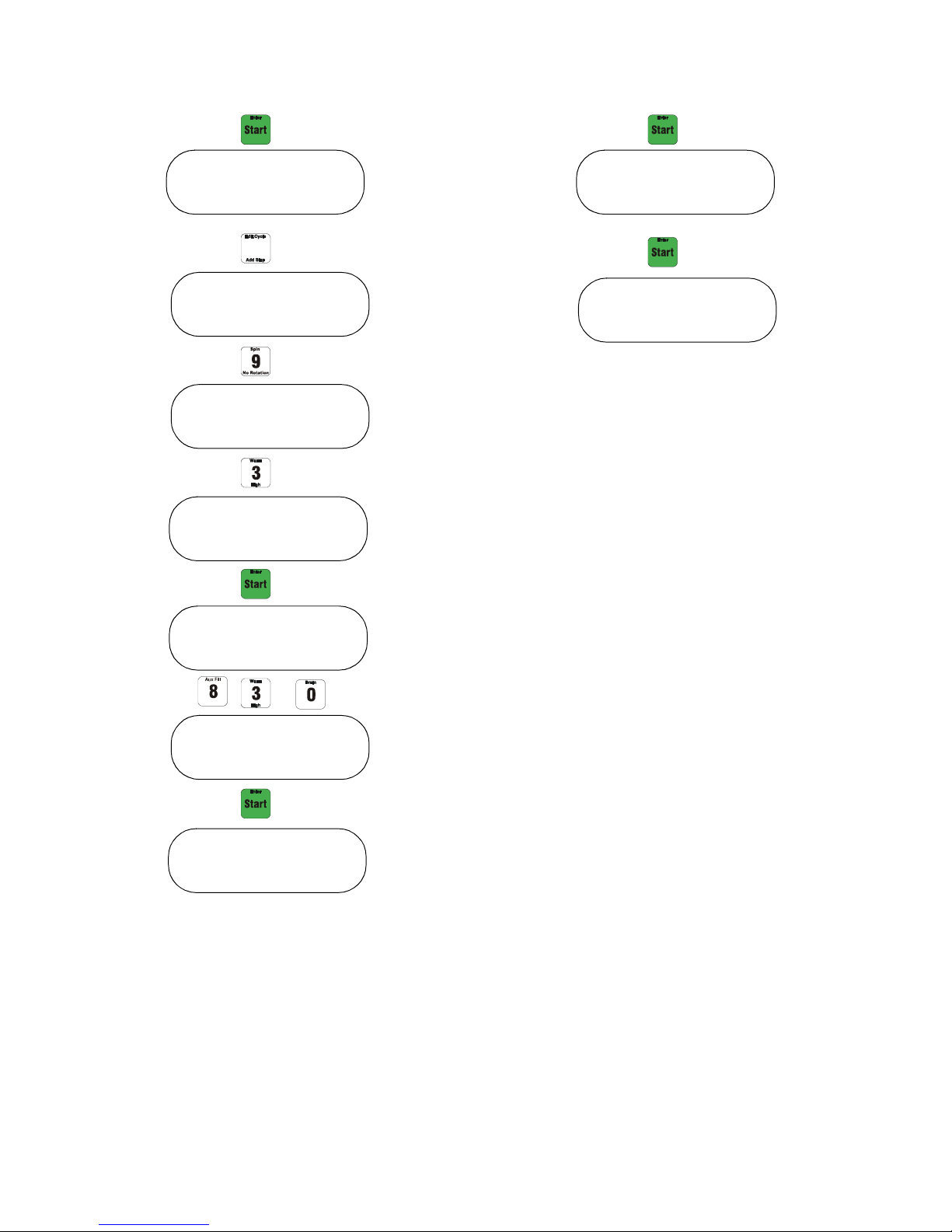

Reloading Previous Settings

This special function allows previous settings to be

restored.

Press “Auxiliary”, “3”, “0”.

The control will ask if earlier settings are desired.

Press “Enter” to confirm the settings.

NOTE: This function only goes back to the last

programming function entered.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 29

Cycle Count

Program Cycle xx

RUN

PROGRAM

Program Cycle xx

Total Working

Hours 347

Tot al C y cle : 5

OR...

Programming

Reading Cycle Count

1. Enter Program Mode by turning key to

PROGRAM position (xx represents a cycle

number from 00 to 99).

2. Press “Auxiliary” key, then “3” key, then “1” key.

3. The total hours of cycle operation (actual run

time) will display. Press “Advance” key to

continue.

Example display shows 347 total hours (of all

cycles).

4. Display now shows total cycle count. Press

“Advance” key to continue into calibration

mode, or press “Clear/Stop” key to exit.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Example display shows 5 total cycles have been

run.

27

Page 30

Programming

Program Cycle 00

Total working

hours : 0

level : 0.0 “

Enter to zero

Spin

XXX rpm

Reference x.xx

Calibration of the Machine

The _x__PV should reflect the size selected in earlier

steps.

Turn key to Program Mode.

Press “Auxiliary”, “3”, “1”.

The total hours the machine was running will be

displayed.

Press “Advance” and screen will show total cycles.

Press “Advance” to calibrate the water level sensor.

If the value is not zero, press “Enter” and the value

will change to zero.

Press “Advance” to calibrate the motor.

The board will lock the door and let the motor spin at

approximately 500 rpm (Firmware version 1.12 or

higher). The rpm will increase on the display. If the

machine reached approximately 500 rpm, the display

will show a reference value.

After the reference value is shown, the machine will

coast down to stop. When the machine stands still, the

board will unlock the door.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 31

Speed Calibration

Total working

hours : #

Total Cycle:

#

Calibration

and testing

level: 0.0"

Enter to zero

If shell is empty of

water and display reads

0.0", then press “Add

Cycle/Advance”.

Motor Control

Distribute Speed

# rpm

Spin

# rpm

Calibrate 1

100 rpm

Spin

# rpm

Calibrate 2

500 rpm

Ref: #

Offset: #

Coast down

Please wait

Program Cycle #

End of Calibration

This function automatically calibrates water level,

distribution speed and spin speed.

Programming

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Pre-Programmed Cycles

Cycle 01

Sheets Light Soil

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 2, 4, 5 0:45

3 Wash 1 18/3 (32°F) 7:00

4 Drain 1 1:00

5 Hot Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7 Drain 1 1:00

8Spin 1 1:00

9 100°F Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 1 18/3 (32°F) 4:00

12 Drain 1 1:00

Cycle 02

Sheets No Bleach

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 7:00

4 Drain 1 1:00

5 Hot Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7 Drain 1 1:00

8Spin 1 1:00

9 100°F Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 1 18/3 (32°F) 4:00

12 Drain 1 1:00

13 Spin 1 3:00

13 Spin 1 3:00

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 9001889

Page 33

Pre-Programmed Cycles

Cycle 03

Towels Light Soil

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 2, 4, 5 0:45

3 Wash 1 18/3 (32°F) 7:00

4Drain 1 1:00

5 Hot Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7Drain 1 1:00

8Spin 1 1:00

9 110°F Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 1 18/3 (32°F) 5:00

12 Drain 1 1:00

Cycle 04

Towels No Bleach

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 7:00

4 Drain 1 1:00

5 Hot Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7 Drain 1 1:00

8Spin 1 1:00

9 110°F Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 1 18/3 (32°F) 4:00

12 Drain 1 1:00

13 Spin 4 6:00

13 Spin 4 6:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Pre-Programmed Cycles

Cycle 05

Sheets Medium Soil

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 6:00

4 Drain 1 1:00

5 Hot Fill to Low Level 5:00

6 Supply 2, 5 0:45

7 Wash 1 18/3 (32°F) 6:00

8 Drain 1 1:00

9 Hot Fill to High Level 5:00

10 Wash 1 18/3 (32°F) 2:00

11 Drain 1 1:00

12 Spin 1 1:00

Cycle 06

Towels Medium Soil

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 6:00

4Drain 1 1:00

5 Hot Fill to Low Level 5:00

6 Supply 2, 5 0:45

7 Wash 1 18/3 (32°F) 6:00

8Drain 1 1:00

9 Hot Fill to High Level 5:00

10 Wash 1 18/3 (32°F) 2:00

11 Drain 1 1:00

12 Spin 1 1:00

13 100°F Fill to Low Level 5:00

14 Supply 3, 6, 7 0:30

15 Wash 1 18/3 (32°F) 4:00

16 Drain 1 1:00

17 Spin 1 3:00

13 110°F Fill to Low Level 5:00

14 Supply 3, 6, 7 0:30

15 Wash 1 18/3 (32°F) 4:00

16 Drain 1 1:00

17 Spin 4 6:00

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 35

Pre-Programmed Cycles

Cycle 07

Blankets Warm

Step Description Min:sec

1 Warm Fill to High Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 6:00

4 Drain 1 1:00

5 Warm Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 5:00

7 Drain 1 1:00

8Spin 1 1:00

9 Warm Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 2 3/27 (32°F) 4:00

12 Drain 1 1:00

Cycle 08

Spreads Cold

Step Description Min:sec

1 Cold Fill to High Level 5:00

2 Supply 1, 4 0:45

3 Wash 2 3/27 (32°F) 6:00

4 Drain 1 1:00

5 Cold Fill to High Level 5:00

6 Wash 2 3/27 (32°F) 1:30

7 Drain 1 1:00

8Spin 1 1:00

9 Cold Fill to High Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 2 3/27 (32°F) 4:00

12 Drain 1 1:00

13 Spin 4 4:00

13 Spin 4 4:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Pre-Programmed Cycles

Cycle 09

Towels Heavy Soil

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 7:00

4 Hot Fill to High Level 5:00

5 Supply 2, 5 1:00

6 Wash 1 18/3 (32°F) 7:00

7Drain 1 1:00

8Spin 1 1:00

9 Warm Fill to High Level 5:00

10 Wash 1 18/3 (32°F) 2:00

11 Drain 1 1:00

12 Spin 1 1:00

Cycle 10

Rinse and Spin

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Wash 1 18/3 (32°F) 1:00

3Drain 1 1:00

4Spin 1 1:00

5Spin 4 4:00

13 Warm Fill to Low Level 5:00

14 Supply 3, 6, 7 1:00

15 Wash 1 18/3 (32°F) 4:00

16 Drain 1 1:00

17 Spin 4 6:00

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 37

Pre-Programmed Cycles

Cycle 11

Health Care Sheets Light Soil

Step Description Min:sec

1 Warm Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1, 2, 4, 5 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 2 0:45

6 Wash 1 18/3 (32°F) 8:00

7Drain 1 1:00

8 Hot Fill to High Level 5:00

9 Wash 1 18/3 (32°F) 3:00

10 Drain 1 1:00

11 Spin 1 1:00

12 100°F Fill to Low Level 5:00

Cycle 12

Health Care Towels Light Soil

Step Description Min:sec

1 Warm Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 2, 4, 5 0:45

6 Wash 1 18/3 (32°F) 8:00

7Drain 1 1:00

8 Hot Fill to High Level 5:00

9 Wash 1 18/3 (32°F) 3:00

10 Drain 1 1:00

11 Spin 1 1:00

12 110°F Fill to Low Level 5:00

13 Supply 3, 6, 7 0:30

14 Wash 1 18/3 (32°F) 4:00

15 Drain 1 1:00

16 Spin 1 4:00

13 Supply 3, 6, 7 0:30

14 Wash 1 18/3 (32°F) 4:00

15 Drain 1 1:00

16 Spin 4 4:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

Pre-Programmed Cycles

Cycle 13

Health Care Sheets Heavy Soil

Step Description Min:sec

1 32°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3Drain 1 1:00

4 120°F Fill to High Level 5:00

5 Wash 1 18/3 (32°F) 2:00

6Drain 1, 4 1:00

7 Hot Fill to Low Level 5:00

8 Supply 1 0:45

9 Wash 1 18/3 (32°F) 7:00

10 Drain 1 1:00

11 Hot Fill to Low Level 5:00

12 Supply 2, 5 0:45

Cycle 14

Health Care Towels Heavy Soil

Step Description Min:sec

1 32°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 120°F Fill to High Level 5:00

5 Wash 1 18/3 (32°F) 2:00

6 Drain 1 1:00

7 Hot Fill to Low Level 5:00

8 Supply 1, 4 0:45

9 Wash 1 18/3 (32°F) 7:00

10 Drain 1 1:00

11 Hot Fill to Low Level 5:00

12 Supply 2, 5 0:45

13 Wash 1 18/3 (32°F) 7:00

14 Drain 1 1:00

15 Hot Fill to High Level 5:00

16 Wash 1 18/3 (32°F) 3:00

17 Drain 1 1:00

18 Spin 1 1:00

19 100°F Fill to Low Level 5:00

20 Supply 3, 6, 7 0:30

21 Wash 1 18/3 (32°F) 4:00

22 Drain 1 1:00

23 Spin 1 3:00

13 Wash 1 18/3 (32°F) 7:00

14 Drain 1 1:00

15 Hot Fill to High Level 5:00

16 Wash 1 18/3 (32°F) 3:00

17 Drain 1 1:00

18 Spin 1 1:00

19 110°F Fill to Low Level 5:00

20 Supply 3, 6, 7 0:30

21 Wash 1 18/3 (32°F) 4:00

22 Drain 1 1:00

23 Spin 4 6:00

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 39

Pre-Programmed Cycles

Cycle 15

Health Care Cotton Blankets

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 2, 4, 5 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to High Level 5:00

9 Wash 1 18/3 (32°F) 3:00

10 Drain 1 1:00

11 Spin 1 1:00

12 110°F Fill to Low Level 5:00

13 Supply 3, 6, 7 0:30

Cycle 16

Health Care Diapers Heavy Soil

Step Description Min:sec

1 32°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 Hot Fill to High Level 5:00

5 Wash 1 18/3 (32°F) 2:00

6 Drain 1 1:00

7 Hot Fill to Low Level 5:00

8 Supply 1, 4 0:45

9 Wash 1 18/3 (32°F) 7:00

10 Drain 1 1:00

11 Hot Fill to Low Level 5:00

12 Supply 1, 4 0:30

13 Wash 1 18/3 (32°F) 7:00

14 Wash 1 18/3 (32°F) 4:00

15 Drain 1 1:00

16 Spin 4 6:00

14 Drain 1 1:00

15 Hot Fill to Low Level 5:00

16 Supply 2, 5 0:30

17 Wash 1 18/3 (32°F) 7:00

18 Drain 1 1:00

19 Hot Fill to High Level 5:00

20 Wash 1 18/3 (32°F) 4:00

21 Drain 1 1:00

22 Spin 1 2:00

23 110°F Fill to High Level 5:00

24 Wash 1 18/3 (32°F) 2:00

25 Drain 1 1:00

26 110°F Fill to Low Level 5:00

27 Supply 3, 6, 7 0:30

28 Wash 1 18/3 (32°F) 4:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29 Drain 1 1:00

30 Spin 1 1:00

31 Spin 4 6:00

37

Page 40

Pre-Programmed Cycles

Cycle 17

Health Care Personal Bleach

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 2, 4, 5 0:45

3 Wash 1 18/3 (32°F) 6:00

4 Drain 1 1:00

5 Hot Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7 Drain 1 1:00

8Spin 1 1:00

9 110°F Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 1 18/3 (32°F) 4:00

12 Drain 1 1:00

Cycle 18

Health Care Personal No Bleach

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 6:00

4 Drain 1 1:00

5 110°F Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7 Drain 1 1:00

8Spin 1 1:00

9 110°F Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 1 18/3 (32°F) 4:00

12 Drain 1 1:00

13 Spin 1 3:00

13 Spin 1 3:00

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 41

Pre-Programmed Cycles

Cycle 19

Health Care Pads Polyester

Step Description Min:sec

1 110°F Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 3:00

4 130°F Fill to High Level 5:00

5 Wash 1 18/3 (32°F) 2:00

6 Drain 1 1:00

7 Hot Fill to Low Level 5:00

8 Supply 1, 4 0:45

9 Wash 1 18/3 (32°F) 7:00

10 Drain 1 1:00

11 Hot Fill to Low Level 5:00

12 Supply 2, 5 0:45

Cycle 20

Table Linen Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 2, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

13 Wash 1 18/3 (32°F) 7:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 Spin 1 1:00

20 110°F Fill to Low Level 5:00

21 Supply 3, 6, 7 0:30

22 Wash 1 18/3 (32°F) 3:00

23 Drain 1 1:00

24 Spin 4 4:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to Low Level 5:00

17 Supply 3, 6 0:30

18 Wash 1 18/3 (32°F) 2:00

19 Supply 6, 8 0:30

20 Wash 1 18/3 (32°F) 5:00

21 Drain 1 1:00

22 Spin 2 4:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

Pre-Programmed Cycles

Cycle 21

Table Linen No Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 2, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

Cycle 22

Table Color Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 1, 4 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to Low Level 5:00

17 Supply 3, 6, 7 0:30

18 Wash 1 18/3 (32°F) 4:00

19 Drain 1 1:00

20 Spin 1 3:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to Low Level 5:00

17 Supply 3, 6 0:30

18 Wash 1 18/3 (32°F) 4:00

19 Supply 8 0:30

20 Wash 1 18/3 (32°F) 5:00

21 Drain 1 1:00

22 Spin 2 4:00

40

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 43

Pre-Programmed Cycles

Cycle 23

Table Color No Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 1, 4 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

Cycle 24

Visa Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 3:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 2, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to Low Level 5:00

17 Supply 3, 6, 7 0:30

18 Wash 1 18/3 (32°F) 4:00

19 Drain 1 1:00

20 Spin 1 4:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 110°F Fill to Low Level 5:00

20 Supply 3, 6 0:30

21 Wash 1 18/3 (32°F) 2:00

22 Supply 8 0:30

23 Wash 1 18/3 (32°F) 5:00

24 Drain 1 1:00

25 Spin 2 3:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

Pre-Programmed Cycles

Cycle 25

Visa No Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 3:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 2, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

Cycle 26

Visa Color Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 3:00

3 Drain 1, 4 1:00

4 Hot Fill to Low Level 5:00

5Supply 1 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 1, 4 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 110°F Fill to Low Level 5:00

20 Supply 3, 6 0:30

21 Wash 1 18/3 (32°F) 4:00

22 Drain 1 1:00

23 Spin 1 3:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 110°F Fill to Low Level 5:00

20 Supply 3, 6 0:30

21 Wash 1 18/3 (32°F) 2:00

22 Supply 8 0:30

23 Wash 1 18/3 (32°F) 4:00

24 Drain 1 1:00

25 Spin 2 3:00

42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 45

Pre-Programmed Cycles

Cycle 27

Visa Color No Iron

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 3:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 1, 4 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

Cycle 28

Shirt Color Starch

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 7:00

4Drain 1 1:00

5 Hot Fill to Low Level 5:00

6 Supply 1, 4 0:45

7 Wash 1 18/3 (32°F) 5:00

8Drain 1 1:00

9 Hot Fill to High Level 5:00

10 Wash 1 18/3 (32°F) 3:00

11 Drain 1 1:00

12 Spin 1 1:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 110°F Fill to Low Level 5:00

20 Supply 3, 6 0:30

21 Wash 1 18/3 (32°F) 4:00

22 Drain 1 1:00

23 Spin 1 3:00

13 Cold Fill to High Level 5:00

14 Supply 3, 6 0:30

15 Supply 5 0:30

16 Wash 1 18/3 (32°F) 4:00

17 Drain 1 1:00

18 Spin 2 3:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

43

Page 46

Pre-Programmed Cycles

Cycle 29

Shirt Bleach Starch

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 7:00

4Drain 1 1:00

5 Hot Fill to Low Level 5:00

6 Supply 2, 5 0:45

7 Wash 1 18/3 (32°F) 7:00

8Drain 1 1:00

9 Hot Fill to High Level 5:00

10 Wash 1 18/3 (32°F) 3:00

11 Drain 1 1:00

12 Spin 1 1:00

Cycle 30

Shirt Color No Bleach

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 7:00

4 Drain 1 1:00

5 Hot Fill to Low Level 5:00

6 Supply 1, 4 0:45

7 Wash 1 18/3 (32°F) 5:00

8 Drain 1 1:00

9 Hot Fill to High Level 5:00

10 Wash 1 18/3 (32°F) 3:00

11 Drain 1 1:00

12 Spin 1 1:00

13 Cold Fill to High Level 5:00

14 Supply 3, 6 0:30

15 Supply 2, 8 0:30

16 Wash 1 18/3 (32°F) 4:00

17 Drain 1 1:00

18 Spin 2 3:00

13 Cold Fill to High Level 5:00

14 Supply 3, 6 0:30

15 Supply 4 0:30

16 Wash 1 18/3 (32°F) 4:00

17 Drain 1 1:00

18 Spin 2 3:00

44

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 47

Pre-Programmed Cycles

Cycle 31

Shirt Delicate

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Wash 2 3/27 (32°F) 2:00

3Drain 1 1:00

4 Warm Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 2 3/27 (32°F) 5:00

7Drain 1 1:00

8 Warm Fill to High Level 5:00

9 Wash 2 3/27 (32°F) 2:00

10 Drain 1 1:00

11 Warm Fill to High Level 5:00

12 Wash 2 3/27 (32°F) 2:00

Cycle 32

Starch Extract

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 2, 8 0:30

3 Wash 1 18/3 (32°F) 7:00

4Drain 1 1:00

5Spin 2 3:00

13 Drain 1 1:00

14 Cold Fill to High Level 5:00

15 Supply 3, 6, 7 0:30

16 Supply 4 0:30

17 Wash 2 3/27 (32°F) 3:00

18 Drain 1 1:00

19 Spin 2 1:30

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

45

Page 48

Pre-Programmed Cycles

Cycle 33

Uniforms Bleach

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 3:00

3Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 2, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

Cycle 34

Uniforms No Bleach

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 4 0:45

3 Wash 1 18/3 (32°F) 6:00

4 Drain 1 1:00

5 110°F Fill to Low Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7 Drain 1 1:00

8Spin 1 1:00

9 110°F Fill to Low Level 5:00

10 Supply 3, 6, 7 0:30

11 Wash 1 18/3 (32°F) 4:00

12 Drain 1 1:00

13 Wash 1 18/3 (32°F) 3:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 110°F Fill to Low Level 5:00

20 Supply 3, 6, 7 0:30

21 Wash 1 18/3 (32°F) 4:00

22 Drain 1 1:00

23 Spin 1 3:00

13 Spin 1 3:00

46

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 49

Pre-Programmed Cycles

Cycle 35

Rags Heavy Soil

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 2, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

Cycle 36

Mops in Bags

Step Description Min:sec

1 110°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 4 0:45

6 Wash 1 18/3 (32°F) 7:00

7Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 2, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

13 Wash 1 18/3 (32°F) 2:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to Low Level 5:00

17 Supply 3, 6 0:30

18 Wash 1 18/3 (32°F) 4:00

19 Drain 1 1:00

20 Spin 4 6:00

13 Wash 1 18/3 (32°F) 2:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to Low Level 5:00

17 Supply 3, 6 0:30

18 Wash 1 18/3 (32°F) 4:00

19 Drain 1 1:00

20 Spin 4 4:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

47

Page 50

Pre-Programmed Cycles

Cycle 37

Rewash/Reclaim

Step Description Min:sec

1 130°F Fill to High Level 5:00

2 Wash 1 18/3 (32°F) 2:00

3 Drain 1 1:00

4 Hot Fill to Low Level 5:00

5 Supply 1, 2, 4, 5 0:45

6 Wash 1 18/3 (32°F) 4:00

7 Drain 1 1:00

8 Hot Fill to Low Level 5:00

9 Supply 1, 2, 4, 5 0:45

10 Wash 1 18/3 (32°F) 7:00

11 Drain 1 1:00

12 Hot Fill to High Level 5:00

Cycle 38

Supply Setup

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2Supply 1 2:00

3Supply 2 2:00

4Supply 3 2:00

5Supply 4 2:00

6Supply 5 2:00

7Drain 1 1:00

8 Warm Fill to Low Level 5:00

9Supply 6 2:00

10 Supply 7 2:00

11 Supply 8 2:00

12 Supply 9 2:00

13 Wash 1 18/3 (32°F) 4:00

14 Drain 1 1:00

15 Spin 1 1:00

16 110°F Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 110°F Fill to High Level 5:00

20 Supply 3, 6 0:30

21 Wash 1 18/3 (32°F) 4:00

22 Supply 3, 6 0:30

23 Wash 1 18/3 (32°F) 4:00

24 Drain 1 1:00

25 Spin 4 4:00

13 Wash 1 18/3 (32°F) 0:30

14 Drain 1 1:00

48

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 51

Pre-Programmed Cycles

Cycle 39

Test Program

Step Description Min:sec

1 Cold Fill to High Level 0:30

2 Drain 1 0:10

3 Hot Fill to Low Level 5:00

4 Auxiliary Fill to Med Level 5:00

5Heat (150°F) 1h00

6 Cold Fill to High Level 5:00

7 Supply 1 0:30

8 Supply 2 0:30

9 Supply 3 0:30

10 Supply 4 0:30

11 Supply 5 0:30

12 Drain 1 1:00

13 Warm Fill to Low Level 0:30

14 Supply 6 0:30

15 Supply 7 0:30

Cycle 39

Test Program

Step Description Min:sec

36 Wash 1 18/3 (32°F) 0:15

37 Drain 1 1:00

16 Supply 8 0:30

17 Supply 9 0:30

18 Wash 2 3/27 (32°F) 0:30

19 Wash 3, no agitation (32°F) 0:30

20 Wash 4 10/3 (32°F) 0:30

21 Wash 1, no reverse (32°F) 0:30

22 Drain 1 1:00

23 Auxiliary 1 0:05

24 Auxiliary 2 0:05

25 Auxiliary 3 0:05

26 150°F Fill to High Level 5:00

27 Cold Fill to Overflow 5:00

28 Soak (150°F) 2h00

29 Drain 1 1:00

30 Spin 1 2:00

31 Spin 2 2:00

32 Spin 3 2:00

33 Spin 4 2:00

34 Auxiliary 3 0:15

35 Cold Fill to Med Level 5:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

49

Page 52

Pre-Programmed Cycles

Cycle 40

Energy Hot

Step Description Min:sec

1 Hot Fill to Low Level 5:00

2 Supply 1, 2 0:15

3 Wash 1 18/3 (32°F) 4:00

4Drain 1 1:00

5 Cold Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7Drain 1 1:00

8 Cold Fill to High Level 5:00

9 Supply 3 0:15

10 Wash 1 18/3 (32°F) 2:00

11 Spin 4 3:00

Cycle 41

Energy Warm

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 1, 2 0:15

3 Wash 1 18/3 (32°F) 4:00

4Drain 1 1:00

5 Cold Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7Drain 1 1:00

8 Cold Fill to High Level 5:00

9Supply 3 0:15

10 Wash 1 18/3 (32°F) 2:00

11 Spin 4 3:00

50

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 53

Pre-Programmed Cycles

Cycle 42

Energy Cold

Step Description Min:sec

1 Cold Fill to Low Level 5:00

2 Supply 1, 2 0:15

3 Wash 1 18/3 (32°F) 4:00

4Drain 1 1:00

5 Cold Fill to High Level 5:00

6 Wash 1 18/3 (32°F) 2:00

7Drain 1 1:00

8 Cold Fill to High Level 5:00

9 Supply 3 0:15

10 Wash 1 18/3 (32°F) 2:00

11 Spin 4 3:00

Cycle 50

Normal 95°C

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 1, 4 0:30

3 Heat (104°F) 1h00

4 Wash 1 18/3 (32°F) 2:00

5Drain 1 1:00

6 Hot Fill to Low Level 5:00

7 Supply 1, 2, 4, 5 0:30

8 Heat (203°F) 1h00

9 Wash 1 18/3 (32°F) 6:00

10 Cold Fill to High Level 5:00

11 Wash 1 18/3 (32°F) 2:00

12 Drain 1 1:00

13 Cold Fill to High Level 5:00

14 Wash 1 18/3 (32°F) 2:00

15 Drain 1 1:00

16 Cold Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 Cold Fill to High Level 5:00

20 Wash 1 18/3 (32°F) 2:00

21 Drain 1 1:00

22 Spin 1 1:00

23 Cold Fill to High Level 5:00

24 Supply 3, 6, 7 0:30

25 Wash 1 18/3 (32°F) 3:00

26 Drain 1 1:00

27 Spin 4 5:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

51

Page 54

Pre-Programmed Cycles

Cycle 51

Normal 60°C

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 1, 4 0:30

3Heat (104°F) 1h00

4 Wash 1 18/3 (32°F) 2:00

5Drain 1 1:00

6 Hot Fill to Low Level 5:00

7 Supply 1, 2, 4, 5 0:30

8Heat (140°F) 1h00

9 Wash 1 18/3 (32°F) 6:00

10 Cold Fill to High Level 5:00

11 Wash 1 18/3 (32°F) 2:00

12 Drain 1 1:00

Cycle 52

Normal 40°C

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 1, 4 0:30

3 Heat (104°F) 1h00

4 Wash 1 18/3 (32°F) 2:00

5Drain 1 1:00

6 Hot Fill to Low Level 5:00

7 Supply 1, 2, 4, 5 0:30

8 Heat (104°F) 1h00

9 Wash 1 18/3 (32°F) 6:00

10 Cold Fill to High Level 5:00

11 Wash 1 18/3 (32°F) 2:00

12 Drain 1 1:00

13 Cold Fill to High Level 5:00

14 Wash 1 18/3 (32°F) 2:00

15 Drain 1 1:00

16 Cold Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 Cold Fill to High Level 5:00

20 Wash 1 18/3 (32°F) 2:00

21 Drain 1 1:00

22 Spin 1 1:00

23 Cold Fill to High Level 5:00

24 Supply 3, 6, 7 0:30

25 Wash 1 18/3 (32°F) 3:00

26 Drain 1 1:00

27 Spin 4 5:00

13 Cold Fill to High Level 5:00

14 Wash 1 18/3 (32°F) 2:00

15 Drain 1 1:00

16 Cold Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 Cold Fill to High Level 5:00

20 Wash 1 18/3 (32°F) 2:00

21 Drain 1 1:00

22 Spin 1 1:00

23 Cold Fill to High Level 5:00

24 Supply 3, 6, 7 0:30

25 Wash 1 18/3 (32°F) 3:00

26 Drain 1 1:00

27 Spin 4 5:00

52

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 55

Pre-Programmed Cycles

Cycle 53

Gentle Cold

Step Description Min:sec

1 Cold Fill to High Level 5:00

2 Supply 1, 4 0:30

3 Wash 2 3/27 (32°F) 2:00

4Drain 1 1:00

5 Cold Fill to High Level 5:00

6 Wash 2 3/27 (32°F) 2:00

7Drain 1 1:00

8Spin 1 1:00

9 Cold Fill to High Level 0:30

10 Supply 3, 6, 7 0:30

11 Wash 2 3/27 (32°F) 3:00

12 Drain 1 1:00

Cycle 54

Perm Press 95°C

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 1, 4 0:30

3 Heat (104°F) 1h00

4 Wash 1 18/3 (32°F) 2:00

5Drain 1 1:00

6 Hot Fill to Low Level 5:00

7 Supply 1, 2, 4, 5 0:30

8 Heat (203°F) 1h00

9 Wash 1 18/3 (32°F) 6:00

10 Cold Fill to High Level 5:00

11 Wash 1 18/3 (32°F) 2:00

12 Drain 1 1:00

13 Spin 1 2:00

13 Cold Fill to High Level 5:00

14 Wash 1 18/3 (32°F) 2:00

15 Drain 1 1:00

16 Cold Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 Cold Fill to High Level 5:00

20 Wash 1 18/3 (32°F) 2:00

21 Drain 1 1:00

22 Spin 1 1:00

23 Cold Fill to High Level 5:00

24 Supply 3, 6, 7 0:30

25 Wash 1 18/3 (32°F) 3:00

26 Drain 1 1:00

27 Spin 1 3:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

53

Page 56

Pre-Programmed Cycles

Cycle 55

Perm Press 60°C

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 1, 4 0:30

3Heat (104°F) 1h00

4 Wash 1 18/3 (32°F) 2:00

5Drain 1 1:00

6 Hot Fill to Low Level 5:00

7 Supply 1, 2, 4, 5 0:30

8Heat (140°F) 1h00

9 Wash 1 18/3 (32°F) 6:00

10 Cold Fill to High Level 5:00

11 Wash 1 18/3 (32°F) 2:00

12 Drain 1 1:00

Cycle 56

Perm Press 40°C

Step Description Min:sec

1 Warm Fill to Low Level 5:00

2 Supply 1, 4 0:30

3 Heat (104°F) 1h00

4 Wash 1 18/3 (32°F) 2:00

5Drain 1 1:00

6 Hot Fill to Low Level 5:00

7 Supply 1, 2, 4, 5 0:30

8 Heat (140°F) 1h00

9 Wash 1 18/3 (32°F) 6:00

10 Cold Fill to High Level 5:00

11 Wash 1 18/3 (32°F) 2:00

12 Drain 1 1:00

13 Cold Fill to High Level 5:00

14 Wash 1 18/3 (32°F) 2:00

15 Drain 1 1:00

16 Cold Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 Cold Fill to High Level 5:00

20 Wash 1 18/3 (32°F) 2:00

21 Drain 1 1:00

22 Spin 1 1:00

23 Cold Fill to High Level 5:00

24 Supply 3, 6, 7 0:30

25 Wash 1 18/3 (32°F) 3:00

26 Drain 1 1:00

27 Spin 1 3:00

13 Cold Fill to High Level 5:00

14 Wash 1 18/3 (32°F) 2:00

15 Drain 1 1:00

16 Cold Fill to High Level 5:00

17 Wash 1 18/3 (32°F) 2:00

18 Drain 1 1:00

19 Cold Fill to High Level 5:00

20 Wash 1 18/3 (32°F) 2:00

21 Drain 1 1:00

22 Spin 1 1:00

23 Cold Fill to High Level 5:00

24 Supply 3, 6, 7 0:30

25 Wash 1 18/3 (32°F) 3:00

26 Drain 1 1:00

27 Spin 1 3:00

54

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9001889

Page 57

Cycle 57

Gentle 30°C

Step Description Min:sec

1 Cold Fill to High Level 5:00

2 Supply 1, 4 0:30

3 Wash 2 3/27 (32°F) 2:00

4Drain 1 1:00

5 Cold Fill to High Level 5:00

6 Supply 1, 2, 4, 5 0:30

7 Heat (86°F) 1h00

8 Wash 2 3/27 (32°F) 3:00

9Drain 1 1:00

10 Cold Fill to High Level 5:00

Pre-Programmed Cycles

11 Wash 2 3/27 (32°F) 2:00

12 Drain 1 1:00

13 Spin 1 1:00

14 Drain 1 1:00

15 Cold Fill to High Level 5:00

16 Supply 3, 6, 7 0:30

17 Wash 2 3/27 (32°F) 3:00

18 Drain 1 1:00

19 Spin 1 2:00

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

55

Page 58

Operation

Panel

Indication

Inverter Drive Error Codes

Name Description and NOTES Check point Corrective action

Overcurrent

shut-off during

acceleration

Overcurrent

shut-off during

constant speed

Overcurrent

shut-off during

deceleration

Regenerative

overvoltage

shut-off during

acceleration

Regenerative

overvoltage

shut-off during

constant speed

Regenerative

overvoltage

shut-off during

deceleration or

stop

Motor overload

shut-off

(electronic

overcurrent

protection)

When the inverter output current reaches

or exceeds approximately 200% of the

rated current during acceleration, the

protective circuit is activated to stop the

inverter output.

When the inverter output current reaches

or exceeds approximately 200% of the

rated current during constant speed, the

protective circuit is activated to stop the

inverter output.

When the inverter output current reaches

or exceeds approximately 200% of the

rated current during deceleration (other

than acceleration or constant speed), the

protective circuit is activated to stop the

inverter output.

If regenerative energy causes the

inverter’s internal main circuit DC voltage

to reach or exceed the specified value, the

protective circuit is activated to stop the

inverter output. It may also be activated

by a surge voltage generated in the power

supply system.

If regenerative energy causes the

inverter’s internal main circuit DC voltage

to reach or exceed the specified value, the

protective circuit is activated to stop the

inverter output. It may also be activated

by a surge voltage generated in the power

supply system.

If regenerative energy causes the

inverter’s internal main circuit DC voltage

to reach or exceed the specifed value, the

protective circuit is activated to stop the

inverter output. It may also be activated

by a surge voltage generated in the power

supply system.

The electronic overcurrent protection in

the inverter detects motor overheat due to

overload or reduced cooling capability

due to overload or reduced cooling

capability during constant-speed operation

to stop the inverter output. When a multipole motor or two or more motors are run,

provide a thermal relay in the output side

of the inverter.

Check the motor

cable insulation and

connection for output

short-circuit/ground

fault.

Check the motor

cable insulation and

connection for output

short-circuit/ground

fault.

Check for sudden

speed reduction.

Check the motor

cable insulation and

connection for

output short-circuit/

ground fault.

Check to make sure

the machine is loaded

properly and that the

load is balanced.

Check to make sure

the machine is loaded

properly and that the

load is balanced.

Check to make sure

the machine is loaded

properly and that the

load is balanced.

Verify that the AC

drive’s parameters are

correct.

Repair the wiring.

Repair the wiring.

Contact Alliance

Laundry Systems’

Customer Service

department.

Repair the wiring.

Load the machine

properly to distribute

the load evenly.

Load the machine

properly to distribute

the load evenly.

Load the machine

properly to distribute

the load evenly.

Contact Alliance

Laundry Systems’

Customer Service

department.

56

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 9001889

Page 59

Operation

Panel

Indication

Inverter Drive Error Codes

Name Description and NOTES Check point Corrective action

Inverter

overload shutoff (electronic

overcurrent

protection)

If a current of more than 150% of the rated

output current flows and overcurrent shutoff does not occur (200% or less) inversetime characteristics cause the electronic

overcurrent protection to be activated to

Verify that the AC

drive’s parameters are

correct.

Contact Alliance

Laundry Systems’

Customer Service

department.

stop the inverter output in order to protect

the output transistors.

Note: Resetting the inverter initializes

the internal heat integrating data of the

electronic overcurrent protection.

Fin overheat If the cooling fin overheats, the overheat

sensor is actuated to stop the inverter

output.

Check for too

high ambient

temperature.

Check for

cooling fin clogging

Verify that the AC

drive’s parameters are

correct.

Contact Alliance

Laundry Systems’

Customer Service

department.

Brake transistor

alarm detection

Internal Circuit Error Contact Alliance

Laundry Systems’

Customer Service

department.

Output side

ground fault

overcurrent

protection

This function stops the inverter output if a

ground fault overcurrent flows due to a

ground fault which occurred in the

inverter’s output (load) side. Use Pr. 249

“ground fault detection at start” to set

Check the motor cable

insulation and

connection for output

short-circuit/ground

fault.

Repair the wiring.

whether the protective function is to be

activated or not. (In the 400V class, the

protective function is always active.)

External thermal

relay operation

If the external thermal relay designed for

motor overheat protection or the internally

mounted temperature relay in the motor

switches on (contacts open), the inverter

output is stopped. If the relay contacts are

reset automatically, the inverter will not

Check for motor

overheating.

Check to make sure

the machine is loaded

properly and that the

load is balanced.

Load the machine

properly to distribute

the load evenly.

restart unless it is reset.

Stall prevention The running frequency has fallen to 0 with

stall prevention activated.

Check the motor for a

“locked rotor”

condition.

Verify that the AC

drive’s parameters are

correct.

Contact Alliance

Laundry Systems’

Customer Service

department.

Output phase

failure

protection

This function stops the inverter output if

one of the three phases (U, V, W) on the

inverter’s output side (load side) results in

open phase.

Fan fault For the inverter which contains a cooling

fan, FN appears on the operation panel

Check the wiring.

Check the motor for a

fault.

Check the cooling

fan’s operation.

Tighten the wire

connections.

Replace the

connectors as needed.

Replace the fan as

needed.

when the cooling fan fails.

9001889

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

57

Page 60

Inverter Drive Error Codes

STOP

RESET

STOP

RESET

Operation

Panel

Name Description and NOTES Check point Corrective action

Indication

Stall prevention

(overcurrent)

Stall prevention

(overvoltage)

PU stop A stop made by pressing the key of

During acceleration–If a current of more

than 150% of the rated inverter current

flows in the motor this function stops the

increase in frequency until the overload

current reduces to prevent the inverter

from resulting in overcurrent shut-off.

When the overload current has reduces

below 150%, this function increases the

frequency again.

During constant-speed operation–If a

current of more than 150%, this function

lowers the frequency again.

When the overload current has reduces

below 150%, this function increases the

frequency again.

During deceleration–If a current of more

than 150% of the rated inverter current

flows in the motor, this function stops the

decrease in frequency until the overload

current reduces to prevent the inverter

from resulting in overcurrent shut-off.

When the overload current has reduced

below 150%, this function decreases the

frequency again.

During deceleration-If the regenerative

energy of the motor exceeds the brake

capability, this function stops the decrease

in frequency to prevent overvoltage

shutoff. As soon as the regenerative

energy has reduced, deceleration resumes.

the PU has been set in Pr. 75 “PU stop

selection”.

This alarm appears if:

The RES signal is on;