Page 1

Washer-Extractors

Cabinet Hardmount

B-Series Microcomputer for OPL Models

2 Speed and Variable-Speed

Refer to Page 5 for Model Identification

NOTA: El manual en

español aparece después

del manual en inglés.

Operation/Maintenance

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

CHM166C

Part No. F232219R1

November 2005

Page 2

Page 3

Table of

Contents

Safety Information.............................................................................. 3

Explanation of Safety Messages........................................................... 3

Important Safety Instructions ............................................................... 3

Introduction......................................................................................... 5

Model Identification ............................................................................. 5

Introduction........................................................................................... 5

Electronic Control Unit......................................................................... 5

Control Output Fuse Board................................................................... 6

Harnessing........................................................................................ 6

Nameplate Location.............................................................................. 7

Replacement Parts ................................................................................ 7

Customer Service.................................................................................. 7

Summary of Control Outputs and Inputs.............................................. 7

Outputs............................................................................................. 7

Inputs................................................................................................ 7

Control Voltage................................................................................ 7

Operation............................................................................................. 9

Control Panel ........................................................................................ 9

Summary of Major Features................................................................. 10

Display Indicators................................................................................. 11

Operating Instructions .......................................................................... 13

Maintenance ........................................................................................ 15

Daily ..................................................................................................... 15

Beginning of Day............................................................................. 15

End of Day ....................................................................................... 15

Weekly.................................................................................................. 16

Monthly................................................................................................. 16

Quarterly ............................................................................................... 19

Care of Stainless Steel .......................................................................... 20

© Copyright 2005, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 5

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer and those maintaining the

machine.

DANGER

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

WARNING

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, drycleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

CAUTION

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards

and/or panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 7

Introduction

Model Identification

Information in this manual is applicable to these models:

HC20BN2 HC50BN2 HC80BNV SC40BN2 SC60BNF UC30BN2 UC60BN2

HC30BN2 HC60BN2 SC20BN2 SC50BN2 SC80BNV UC40BN2 UC60BNF

HC40BN2 HC60BNF SC30BN2 SC60BN2 UC20BN2 UC50BN2 UC80BNV

Introduction

The “B” electronic control is composed of the

electronic control unit and the control fuse board with

wiring harness. Only an authorized person should look

inside the machine. First TURN OFF POWER, open

lid and remove any cover present. Make sure door lock

circuit has fully discharged. The door unlock capacitor

can retain high electrical charge, even when the

machine’s electrical inputs are disconnected, until it

has discharged. Some machines are equipped with an

“amber” indicator light facing upward in the control

compartment. If this is on, wait until it goes off

(indicating when high voltage in the door lock circuit

has discharged).

Electronic Control Unit

This portion of the control contains the “intelligence” –

the micro-controller and the miscellaneous components

on the printed circuit (PC) board. The board has a

metal cover, which MUST be in place at all times

during machine operation. Operation of the machine

without this cover installed will void the warranty.

The control unit monitors and responds to input, gives

information about the status of the washer and

monitors and responds to inputs from the user

interface (keypad). The control provides signals to the

control output unit, which in turn operates the

components that control the machine functions. This is

located behind the machine control panel.

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Introduction

Control Output Fuse Board

This portion of the control contains the power supply

for the control unit, and also the switching devices

which power the components in the machine, all of

which are on the output PC board. The switching

devices are controlled by the control unit, and are solid

state.

Harnessing

Wiring harnesses are modular – harnesses common to

various configurations are similar, while those specific

to a certain configuration can be added. There are

harnesses for inputs to the control unit, for outputs

from the control power/output unit to the machine

components, and for the main incoming power to the

control power/output unit.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 9

Introduction

Nameplate Location

The nameplate is located at the rear of the machine and

inside door. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance.

1

Summary of Control Outputs and

Inputs

Outputs

General outputs provide signals to operate the

following components.

1. Hot Fill Valve

2. Cold Fill Valve

3. Drain Valve (normally open)

4. Door Lock Solenoid Coil

5. Door Unlock Solenoid Coil

6. Supply 1 (detergent)

7. Supply 2 (bleach)

8. Supply 3 (sour/softener)

9. Supply 4

10. Supply 5 or Optional 3rd (auxiliary) Fill Inlet

(governed by the configuration settings)

11. Optional Heat

CHM2060N

1 Nameplate

Figure 1

Replacement Parts

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call: (920) 748-3121 Ripon,

Wisconsin.

For standard models, the components for outputs

shown as “optional” will not be populated on the

output printed circuit board.

AC outputs are solid state outputs that operate either

120 Volt AC or 220 Volt AC (nominal voltage)

components, depending on the control voltage

configuration. Outputs are fused appropriately.

Inputs

1. Low Water Level

2. Medium Water Level

3. High Water Level

4. Door

5. Temperature Signal (only for machines with heat

option)

Control Voltage

The control power supply can be configured to operate

on 110 Volt AC nominal RMS input voltage

50/60 Hertz, OR 220 Volt AC nominal RMS input

voltage 50/60 Hertz.

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Introduction

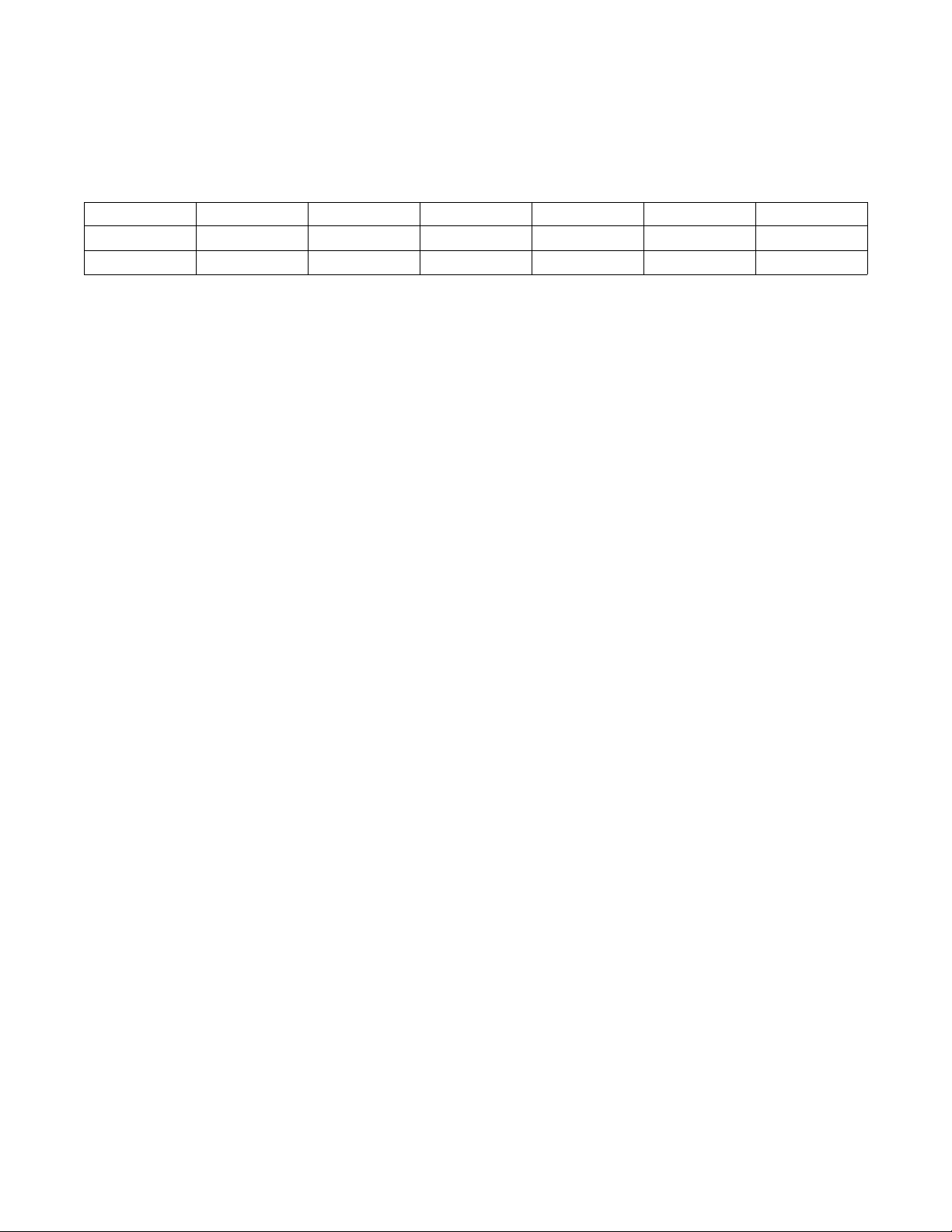

Model Number Familiarization Guide

*C

60

B

N

2

O

U6

0001

* Denotes Brand

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control (B = B - Control)

Actuation (N = Non-Coin)

Washer-Extractor Speed Capability (2 = 2 speed)

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

Sample Model Number:

*C60BN2OU60001

00000000000

*C60BN2OU60001

208 – 240

7

3

60 3 3

60

18

N/A N/A

500000

EXAMPLE OF NAMEPLATE

Figure 2

470

0

CHM487R

CHM487R

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 11

Control Panel

C

Operation

16 17 18 19

1

2

16 17 18 19

2

5

15

14

13

12

11

10

NORMAL

PERM PRESS

WASH

ADD

BLEACH

RINSE

SPIN

DOOR

CLEAN

FILTER

START

4

39

DOMESTIC MODELS INTERNATIONAL MODELS

HOT

LIGHT SOIL

HOT

HEAVY SOIL

HOT HOT

STAINED

HOT

HOT

VISA

WARM

UNIFORMS

DELICATE

COLD

TM

CHM522N

CHM522N CHM1764C

15

6

14

13

7

12

8

11

10

4

39

1 Cycle 1 11 Door Open LED

2 Cycle 2 12 Spin Cycle LED

3 Cycle 3 13 Rinse Cycle LED

4 Cycle 4/Up Edit 14 Add Bleach LED

5 Cycle 5 15 Wash Cycle LED

6 Cycle 6 16 Out-of-Balance Indicator Dot

7 Cycle 7 / Set Up (*) Keypad † (Variable-speed only)

8 Cycle 8/Down Edit 17 High Water Level Indicator Dot

9 START Keypad 18 Medium Water Level Indicator Dot

10 CLEAN FILTER Indicator LED

19 Low Water Level Indicator Dot

(Active for all C80, and C60 X Voltage ONLY

models)

1

95C 95C

60C 60C

40C 40C

<

CHM1764

5

6

7

8

30C

<

Figure 3

†Set Up(*) keypad is used in cycle programming in program mode. Refer to Programming Manual.

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Operation

Summary of Major Features

LED for Machine Functions LED lights inform operator which machine function is active. DOOR LED lights to

inform operator that the door can be opened or should be closed. The circle LED

indicates that the filter needs cleaning.

Water Levels Three (3) – Contacts from pressure switch (test cycle)

Main LED display 4 digit LED display counts down cycle time. Lights in LED display indicate out-of-balance

conditions and, in test cycle, water level. Display shows “01” as the final spin time.

Cycle selection keypads Eight (8) cycle select keypads with LED indicator to show selected cycle. LED lights

will flash to prompt user to press a keypad.

START keypad Press to start a cycle after cycle selection is made. LED light will flash to prompt user to

press keypad.

Test Cycle with “Advance” For troubleshooting. Advance rapidly through test cycle by pressing the UP keypad.

Refer to PROGRAMMING manual.

Fill Temperatures Cold, Hot, Warm

Supplies Five (5) or Four (4) with extra fill value option.

Agitation Types Normal or Gentle

Drain Options Normally open gravity drain

Cycle Count 0 to 9999 cannot be reset – Rolls over after 9999

Rapid Advance Mode Rapid Advance can be enabled or disabled. Enabled allows user to advance through a

cycle. Refer to the Programming Manual.

Table 1

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 13

Display Indicators

Table 2 lists the various displays and what they

mean. The operator should become familiar with

these machine displays.

Display Meaning

Operation

tESt

SPIn

SUP1

SUP2

SUP3

SUP4

SUP5

SdLY

CFIL

HFIL

bFIL

bLCH

PASS

FAIL

bAL?

CY__

Diagnostic test cycle selected or enabled

Spin (extract) step

Supply signal 1 (“S1” output), normally detergent

Supply signal 2 (“S2” output), normally bleach

Supply signal 3 (“S3” output), normally softener

Supply signal 4

Supply signal 5

Spin coast (motor coasts after high speed extract)

Cold Fill

Hot Fill

Warm Fill (cold + hot)

Control will also light “add bleach” indicator

Variable-speed ONLY – balance “PASS” condition; shows in “test” cycle only

Variable-speed ONLY – balance “FAIL” condition; shows in “test” cycle only

Variable-speed ONLY – meaning: “Do you wish to enter balance detection test routine?”

Cycle number (followed by a space and number 1 through highest cycle number)

nor

gEnt

SPn1

SPn2

For

rEv

dISt

LO

nEd

HI

CEL

FAr

___C

n

Normal agitation selected

Gentle (reduced) agitation selected

Variable-speed ONLY – low spin speed (the lower of 2 spin speeds)

Variable-speed ONLY – high spin speed (the higher of 2 spin speeds)

Wash speed forward (during test cycle)

Wash speed reverse (during test cycle)

Variable-speed ONLY – distribution speed (during test cycle)

Low water level

Medium water level

High water level

Display all temperatures in degrees Celsius

Display all temperatures in degrees Fahrenheit

The first 3 digits are reserved for temperature reading, C indicates “degrees Celsius”

Table 2 (Continued)

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Operation

Table 2 (Continued)

Display Meaning

___F

FILL

door

SHUt/ door

CAnt/OPEn

USH1

USH2

USH3

USH4

rIn1

rIn2

rIn3

rIn4

donE

drAI

The first 3 digits are reserved for temperature reading, F indicates “degrees Fahrenheit”

“Fill error” – machine did not fill to programmed water level within 10 minutes; also

displays during Rapid Advance Mode.

“Door” opened during cycle

Machine user must “shut door” of the washer to allow the cycle to begin

Control cannot unlock the door

“Wash 1” segment

“Wash 2” segment

“Wash 3” segment

“Wash 4” segment

“Rinse 1” segment

“Rinse 2” segment

“Rinse 3” segment

“Rinse 4” segment (final rinse)

Cycle has concluded

Drain selected for segment; also indicates in drain step during 2 speed version test cycle or

during Rapid Advance Mode.

----

Adv

noAd

Erdn

Erfl

E Pr

CyC

Flashes for a period of time (for safety) after power up while keeping outputs OFF

Machine set up for Rapid Advance

Machine is not set up for Radid Advance

Drain count error (depending on model)

Fill error count (depending on model)

The number of times power has been interrupted during a cycle (will display in certain

models)

Cycle counter

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 15

Operation

Operating Instructions

1. Turn on main power source (circuit breaker) with

right hand.

2. With left hand, push and hold white rocker

button. Refer to Figure 4.

3. Push button and turn handle clockwise to open.

Refer to Figure 4.

CHM2027N

Figure 4

4. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 5.

NOTE: Underloading can cause out-of-balance

conditions that can shorten machine life.

5. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 6.

U005I

U005I

Figure 6

6. The default wash cycle will display.

NOTE: Perm Press Hot is the default cycle if none

is selected.

NORMAL

PERM PRESS

WASH

ADD

BLEACH

RINSE

SPIN

DOOR

CLEAN

FILTER

START

HOT

LIGHT SOIL

HOT

HEAVY SOIL

HOT HOT

STAINED

HOT

HOT

VISA

WARM

UNIFORMS

DELICATE

COLD

TM

F232219

DOMESTIC MODELS

U003I

Figure 5

INTERNATIONAL MODELS

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 7

95C 95C

60C 60C

40C 40C

30C

<

CHM522N

<

CHM1764C

13

Page 16

Operation

7. If desired, select a different cycle at this point.

The LED indicator for that cycle will light.

8. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 8.

a. Add detergent to compartment 1.

b. Add softener to compartment 3.

3

1

2

CHM486R

CHM486R

1 Detergent

2 Bleach

3 Softener

9. When applicable, add bleach to compartment 2

when the ADD BLEACH LED is lit.

10. Press the desired wash cycle keypad if none is

selected.

11. Press the START keypad.

12. During first fill, the desired wash cycle can be

changed. After first fill has ended, the wash cycle

active at that moment remains the chosen wash

cycle.

13. When cycle is complete, display shows “donE”.

Figure 8

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 17

Maintenance

WARNING

Sharp edges can cause personal injury.

Wear safety glasses and gloves, use

proper tools and provide lighting when

handling sheet metal parts.

W366R1

4. Check door interlock before starting operation:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

IMPORTANT: Replace all panels that are removed

to perform service and maintenance procedures.

Do not operate the machine with missing guards or

with broken or missing parts. Do not bypass any

safety devices.

Daily

IMPORTANT: Door lock should be checked daily

to ensure proper operation. Also check that all

safety and instruction stickers are on the machine.

Any missing or illegible safety instructions stickers

should be replaced immediately.

Beginning of Day

1. Inspect water inlet valve hose connections on the

back of the machine for leaks.

2. Inspect steam hose connections for leaks (where

applicable).

3. Verify that insulation is intact on all external

wires and that all connections are secure. If

exposed wire is evident, call a service technician.

c. Close and lock the door, and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

End of Day

1. Clean the door gasket of residual detergent and

all foreign matter.

2. Clean automatic supply dispenser lid and general

area. Flush dispenser with clean water.

3. Clean the machine’s top, front and side panels

with mild detergent. Rinse with clean water.

4. Leave loading door open at the end of each day to

allow moisture to evaporate.

NOTE: Unload the machine promptly after each

completed cycle to prevent moisture buildup. Leave

loading door open after each completed cycle to

allow moisture to evaporate.

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Maintenance

Weekly

1. For variable-speed models only, clean the AC

drive box filter(s) weekly or more frequently as

needed:

NOTE: If fan filter service indicator light is on, fan

filter must be cleaned immediately to prevent

possible damage. Thermostat automatically resets

after drive compartment cools down. LED will then

extinguish after cycle run.

IMPORTANT: If filter indicator is ignored,

repeated resets might shorten life of drive. Clean

filter regularly to avoid indicator prompt.

a. Open the top cover.

b. Grasp the filter handle and pull straight up to

remove filter.

c. Wash the filter with warm water and allow

filter to air-dry. As an alternative, the filter

may be vacuumed clean.

IMPORTANT: The control module cover and fan

filter must be in place for the fan to properly cool

the AC inverter drive. Failure to observe this

warning will void the warranty and could lead to

expensive AC inverter drive repair.

Monthly

NOTE: Disconnect power to the machine at its

source before performing the monthly maintenance

procedures.

1. Use the following procedures to determine if

V-belt(s) require replacement or adjustment. Call

a qualified service technician in either case.

a. Check V-belt(s) for uneven wear and frayed

edges.

b. Verify pulley alignment by placing a

straightedge across both pulley faces. The

straightedge should make contact with the

pulleys in four places. Refer to Figure 9.

1

4

2

3

2. Check the machine for leaks.

a. Start an unloaded cycle to fill the machine.

b. Verify that door and door gasket do not leak.

c. Verify that the drain valve is operating and

that the drain system is free from obstruction.

If water does not leak out during the first wash

segment, the drain valve is closed and

functioning properly.

H040I

1 Motor

2 Motor Pulley

3 Straightedge

4 Basket Pulley

Figure 9

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 19

c. For flat-pulley drive systems, verify allowable

distance of belt from edge of pulley. Refer to

Table 3 below.

Flat-Pulley Alignment

Maintenance

Model

Allowable

Distance from Edge

20 3/32 in. (2 mm)

25 3/32 in. (2 mm)

30 3/32 in. (2 mm)

40 3/32 in. (2 mm)

50 – 60 3/8 in. (10 mm)

Table 3

1 Deflection

2 Span Length

d. For variable-speed models only, verify that

V-belts are properly tensioned by applying a

set force to the belts and measuring the

deflection to determine the belt tension. Refer

to Table 4 for the acceptable belt’s tension

ranges. Belt tension measurements should be

taken as close to the center of the belt span as

possible. Refer to Figure 10.

Belt Tension Testing for Variable-Speed Models

Model Belt Belt Span Deflection Range

1

2

H039I

Figure 10

Force

Min – Max

35, 40 Motor-Basket 16.9 in. (428 mm) 5/16 – 11/32 in. (7.9 – 8.7 mm) 6.1 – 7.4 lbs. (27 – 33 N)

50, 60 Motor-Basket 16.8 in. (426 mm) 9/32 – 5/16 in. (7.1 – 7.9 mm) 6.1 – 7.4 lbs. (27 – 33 N)

80 Motor-Basket

22.1 in. (561 mm) 15/32 – 1/2 in. (11.9 – 12.7 mm) 4.9 – 7.3 lbs. (21.8 – 31.5 N)

Single Belt

80 Motor-Basket

22.1 in. (561 mm) 7/32 – 1/4 in. (5.08 – 6.35 mm) 23 – 26 lbs. (102.3 – 115.6 N)

Banded Belt

Tab l e 4

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Maintenance

1

2

1 Bearing Grease Fitting

2 Seal Grease Fitting

2. For 80 pound capacity models only, lubricate

bearings and seals each month OR after every

200 hours of operation. Refer to Figure 11.

a. Use a premium-grade lithium-based #2

grease. Never mix two types of grease, such

as petroleum and silicone.

H047I

Figure 11

b. Pump the grease gun slowly, permitting only

the following number of strokes:

● Bearing grease fitting, 2 strokes

● Seal grease fitting, 1 stroke

Do not pump the grease gun until grease

comes out of the bearing housing. This can

result in overlubrication, causing damage to

bearings and seals.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Page 21

Maintenance

I

3. Remove back panel and check overflow hose and

drain hose for leaks.

4. Unlock the hinged lid and check the supply

dispenser hoses and hose connections.

5. Clean inlet hose filter screens:

a. Turn water off and allow valve to cool, if

necessary.

b. Unscrew inlet hose and remove filter screen.

c. Clean with soapy water and reinstall. Replace

if worn or damaged.

6. Tighten motor mounting bolt locknuts and

bearing bolt locknuts, if necessary.

7. Use compressed air to clean lint from motor.

8. Clean interior of machine, both basket and shell,

by wiping with a water-soaked sponge or cloth.

9. Use compressed air to ensure that all electrical

components are free of moisture and dust.

10. For variable-speed models only, clean AC drive

cooling fan blades monthly (more often if

required by the condition of the air).

4. Check all painted surfaces for exposed metal.

(Matching paint is available from the

manufacturer.)

● If bare metal is showing, paint with primer or

solvent-based paint.

● If rust appears, remove it with sandpaper or by

chemical means.

Then paint with primer or solvent-based paint.

5. Clean customer-supplied steam filter, where

applicable. Refer to Figure 12.

a. Turn off steam supply and allow time for the

valve to cool.

b. Unscrew cap.

c. Remove element and clean.

d. Replace element and cap.

a. Open the top cover and remove the control

module cover.

b. Gently wipe the fan blades clean with a dry

cloth.

Quarterly

NOTE: Disconnect power to the machine before

performing the quarterly maintenance procedures.

1. Tighten door hinges and fasteners, if necessary.

2. Tighten anchor bolts, if necessary.

3. Verify that the drain motor shield is in place and

secure, if so equipped.

1

2

H042

H042I

1 Cap

2 Filter Element

Figure 12

F232219

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Maintenance

Care of Stainless Steel

● Remove dirt and grease with detergent and water.

Thoroughly rinse and dry after washing.

● Avoid contact with dissimilar metals to prevent

galvanic corrosion when salty or acidic solutions

are present.

● Do not allow salty or acidic solutions to

evaporate and dry on stainless steel. Wipe clean

of any residues.

● Do not leave sanitizers or sterilizing solutions on

stainless steel equipment for prolonged periods

of time.

● When an external chemical supply is used, ensure

no siphoning of chemicals occurs when the

washer-extractor is not in use. Highly

concentrated chemicals can cause severe damage

to stainless steel and other components with the

machine. Damage of this kind is not covered by

the manufacturer’s warranty. Locate the pump

below the washer-extractor’s injection point to

prevent siphoning of chemicals into the machine.

● If the stainless steel appears to be rusting, the

source of the rust may actually be a foreign piece

of iron or steel part not made of stainless steel,

such as a nail or screw contacting the stainless

steel surface. Tip: Paint all carbon steel parts with

a heavy protective coating. Stainless steel

fasteners should be used whenever possible.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232219

Loading...

Loading...