Page 1

Washer-Extractors

Cabinet Hardmount

Refer to Page 5 for Model Identification

NOTA: El manual en

español aparece después

del manual en inglés.

Installation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

CHM166C

Part No. F232135R6

June 2005

Page 2

Page 3

Table of

Contents

Safety Information.............................................................................. 3

Explanation of Safety Messages........................................................... 3

Important Safety Instructions ............................................................... 3

Introduction......................................................................................... 5

Model Identification ............................................................................. 5

Delivery Inspection............................................................................... 6

Nameplate Location.............................................................................. 6

Replacement Parts ................................................................................ 8

Customer Service.................................................................................. 8

Remove After Shipment (OPL Models Only)...................................... 8

Specifications and Dimensions........................................................... 9

Gap Setting for Vibration Switch

(Variable-Speed and Fixed-Speed Models) ................................... 12

Installation........................................................................................... 23

Dimensional Clearances ....................................................................... 23

Machine Foundation............................................................................. 24

Machine Anchoring .............................................................................. 27

Direct-to-Finished-Floor Installation............................................... 27

Mounting Bolt Template Part Numbers

(Without Elevated Base Frame)......................................................... 30

Mounting Bolt Hole Locations (Without Elevated Base Frames)........ 31

Mounting Bolt Hole Locations (Without Elevated Base Frames)........ 32

Mounting Bolt Hole Locations (With Elevated Base Frames)............. 33

Mounting Bolt Hole Locations (With Elevated Base Frames)............. 34

Elevated Base Frame Installation..................................................... 35

Concrete Foundation Installation..................................................... 37

Drain Connection.................................................................................. 40

Water Connection Requirements.......................................................... 42

Electrical Installation Requirements..................................................... 43

Input Voltage Requirements ............................................................ 43

Circuit Breakers ............................................................................... 43

Connection Specifications ............................................................... 44

Grounding ........................................................................................ 44

Phase Adder ..................................................................................... 44

Thermal Overload Protector ............................................................ 44

Troubleshooting............................................................................... 50

Steam Requirements (Steam Heat Option Only).................................. 50

Supply Dispensing (OPL Machines Only) ........................................... 51

Connection of External Liquid Supplies.......................................... 51

Control Function Test........................................................................... 54

© Copyright 2005, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 5

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, drycleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable, do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc., or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards and/or

panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: Underloading can cause out-of-balance

conditions that can shorten life of machine.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 7

Introduction

Model Identification

Information in this manual is applicable to these

models:

HC18MD2 HC25NR2 HC35SN2 HC60ACV HC80NRV SC25MD2 SC40AY2 SC60BNF UC20VN2

HC18MN2 HC25NX2 HC35VC2 HC60AL2 HC80NXV SC25ML2 SC40BC2 SC60BX2 UC25MN2

HC18MX2 HC25SN2 HC35VX2 HC60ALF HC80VCV SC25MN2 SC40BL2 SC60BXF UC27MN2

HC18NC2 HC25VC2 HC40AC2 HC60ALV HC80VNV SC25MX2 SC40BN2 SC60BY2 UC27PN2

HC18NR2 HC25VX2 HC40ACV HC60AX2 HC80VXV SC25MY2 SC40BX2 SC60BYF UC27VN2

HC18NX2 HC27MD2 HC40AL2 HC60AXF HC125BYV SC25NC2 SC40BY2 SC60MD2 UC27VNV

HC18SN2 HC27MN2 HC40ALV HC60AXV NC18NP2 SC25NR2 SC40MD2 SC60ML2 UC30BN2

HC18VC2 HC27MX2 HC40AX2 HC60AY2 NC27NP2 SC25NX2 SC40ML2 SC60MN2 UC30ML2

HC18VX2 HC27NC2 HC40AXV HC60AYF NC80NPV SC27MD2 SC40MN2 SC60MX2 UC30MN2

HC20AC2 HC27NR2 HC40AY2 HC60AYV SC125BYV SC27MN2 SC40MX2 SC60MY2 UC30MX2

HC20ACV HC27NX2 HC40AYV HC60BC2 SC125VNV SC27MX2 SC40MY2 SC60NC2 UC30PN2

HC20AL2 HC27SN2 HC40BC2 HC60BCF SC18MD2 SC27NC2 SC40NC2 SC60NCF UC30VN2

HC20ALV HC27VC2 HC40BL2 HC60BL2 SC18MN2 SC27NR2 SC40NR2 SC60NR2 UC35MD2

HC20AX2 HC27VX2 HC40BN2 HC60BLF SC18MX2 SC27NX2 SC40NX2 SC60NX2 UC35MN2

HC20AXV HC30AC2 HC40BX2 HC60BN2 SC18NC2 SC27VN2 SC40VN2 SC60NXF UC35PN2

HC20AY2 HC30ACV HC40BY2 HC60BNF SC18NR2 SC30AC2 SC40VNV SC60VN2 UC35VN2

HC20AYV HC30AL2 HC40MD2 HC60BX2 SC18NX2 SC30AL2 SC50BC2 SC60VNF UC35VNV

HC20BC2 HC30ALV HC40ML2 HC60BXF SC18VN2 SC30AY2 SC50BL2 SC60VNV UC40BN2

HC20BL2 HC30AX2 HC40MN2 HC60BY2 SC20AC2 SC30AX2 SC50BN2 SC80ACV UC40MN2

HC20BN2 HC30AXV HC40MX2 HC60BYF SC20AL2 SC30BC2 SC50BX2 SC80ALV UC40PN2

HC20BX2 HC30AY2 HC40MY2 HC60MD2 SC20AX2 SC30BL2 SC50BY2 SC80AXV UC40VN2

HC20BY2 HC30AYV HC40NC2 HC60ML2 SC20AY2 SC30BN2 SC50MD2 SC80AYV UC40VNV

HC20MD2 HC30BC2 HC40NR2 HC60MN2 SC20BC2 SC30BX2 SC50ML2 SC80BCV UC50BN2

HC20ML2 HC30BL2 HC40NX2 HC60MX2 SC20BL2 SC30BY2 SC50MN2 SC80BLV UC50MN2

HC20MN2 HC30BN2 HC40SN2 HC60MY2 SC20BN2 SC30MD2 SC50MX2 SC80BNV UC50PN2

HC20MX2 HC30BX2 HC40VC2 HC60NC2 SC20BX2 SC30ML2 SC50MY2 SC80BXV UC50VN2

HC20MY2 HC30BY2 HC40VX2 HC60NCF SC20BY2 SC30MN2 SC50NC2 SC80BYV UC50VNV

HC20SN2 HC30MD2 HC50BC2 HC60NR2 SC20MD2 SC30MX2 SC50NR2 SC80NCV UC60BN2

HC20VC2 HC30ML2 HC50BL2 HC60NX2 SC20ML2 SC30MY2 SC50NX2 SC80NRV UC60BNF

HC20VX2 HC30MN2 HC50BN2 HC60PN2 SC20MN2 SC30NC2 SC50VN2 SC80NXV UC60MN2

HC25AC2 HC30MX2 HC50BX2 HC60SN2 SC20MX2 SC30NR2 SC50VNV SC80NYV UC60PN2

HC25AL2 HC30MY2 HC50BY2 HC60VC2 SC20MY2 SC30NX2 SC60AC2 SC80VNV UC60VN2

HC25AX2 HC30NC2 HC50MD2 HC60VX2 SC20NC2 SC30VN2 SC60ACF UC125VNV UC60VNF

HC25AY2 HC30NR2 HC50ML2 HC80ACV SC20NR2 SC35MD2 SC60AL2 UC18MN2 UC60VNV

HC25BC2 HC30NX2 HC50MN2 HC80ALV SC20NX2 SC35MN2 SC60ALF UC18MX2 UC80BNV

HC25BL2 HC30SN2 HC50MX2 HC80AXV SC20VN2 SC35MX2 SC60AX2 UC18PN2 UC80VNV

HC25BX2 HC30VC2 HC50MY2 HC80AYV SC25AC2 SC35NC2 SC60AXF UC18VN2

HC25BY2 HC30VX2 HC50NC2 HC80BCV SC25AL2 SC35NR2 SC60AY2 UC18VNV

HC25MD2 HC35MD2 HC50NR2 HC80BLV SC25AX2 SC35NX2 SC60AYF UC20BN2

HC25ML2 HC35MN2 HC50NX2 HC80BNV SC25AY2 SC35VN2 SC60BC2 UC20MD2

HC25MN2 HC35MX2 HC50SN2 HC80BXV SC25BC2 SC35VNV SC60BCF UC20ML2

HC25MX2 HC35NC2 HC50VC2 HC80BYV SC25BL2 SC40AC2 SC60BL2 UC20MN2

HC25MY2 HC35NR2 HC50VX2 HC80NCF SC25BX2 SC40AL2 SC60BLF UC20MX2

HC25NC2 HC35NX2 HC60AC2 HC80NCV SC25BY2 SC40AX2 SC60BN2 UC20PN2

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Introduction

This manual is designed as a guide to the installation

of the Cabinet Hardmount Washer-Extractor.

NOTE: All information, illustrations, and

specifications contained in this manual are based

on the latest product information available at the

time of printing. We reserve the right to make

changes at any time without notice.

Delivery Inspection

Upon delivery, visually inspect crate, protective cover,

and unit for any visible shipping damage. If the crate,

protective cover, or unit is damaged or signs of

possible damage are evident, have the carrier note the

condition on the shipping papers before the shipping

receipt is signed, or advise the carrier of the condition

as soon as it is discovered.

Remove the crate and protective cover as soon after

delivery as possible. If any damage is discovered upon

removal of the crate and/or protective cover, advise the

carrier and file a written claim immediately.

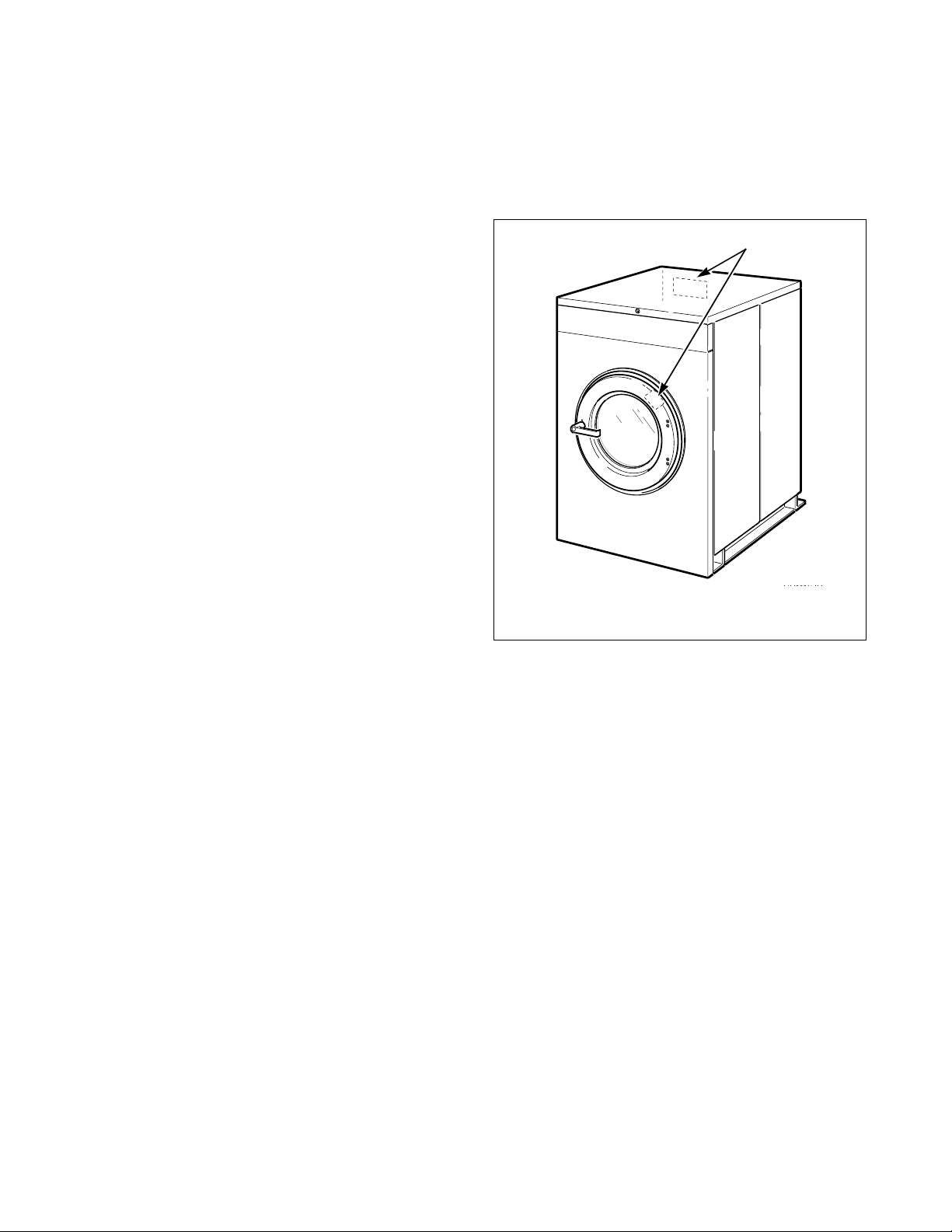

Nameplate Location

The nameplate is located at the rear of the machine and

inside door. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance. Refer to Figure 1.

1

1 Nameplate

CHM167R

Figure 1

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 9

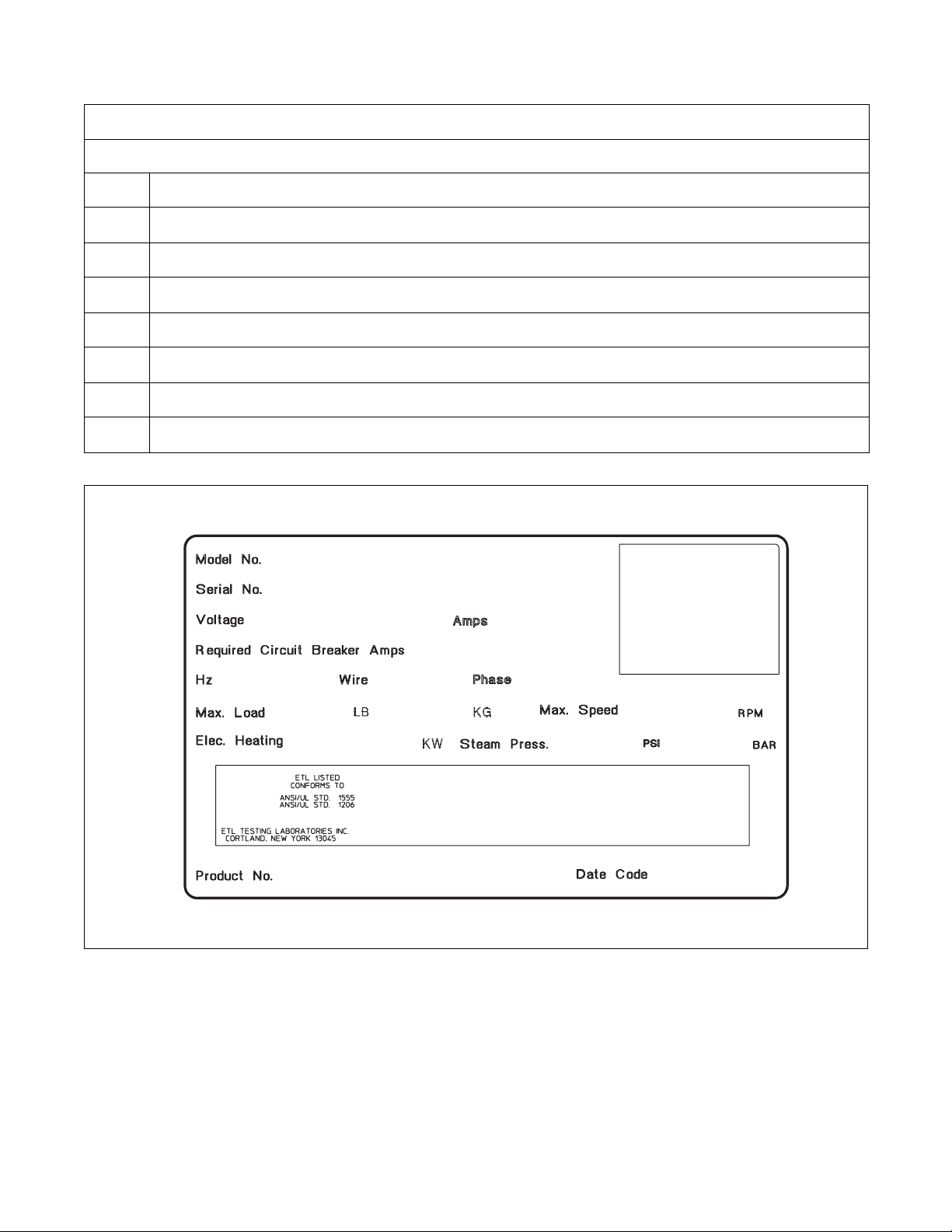

Model Number Familiarization Guide

Sample Model Number: *C40AC2OU60001

Introduction

*C

40

A

C

2

O

U6

0001

* Denotes Brand

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control

Actuation (C = Coin drop)

Washer-Extractor Speed Capability (2 = 2 speed)

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

*C40AC2OU60001

00000000000

208 – 240

7

3

60 3 3

60

18

N/A N/A

500000

EXAMPLE OF NAMEPLATE

Figure 2

470

0

CHM2008N

CHM2008N

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Introduction

Replacement Parts

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call (920) 748-3121, Ripon,

Wisconsin U.S.A.

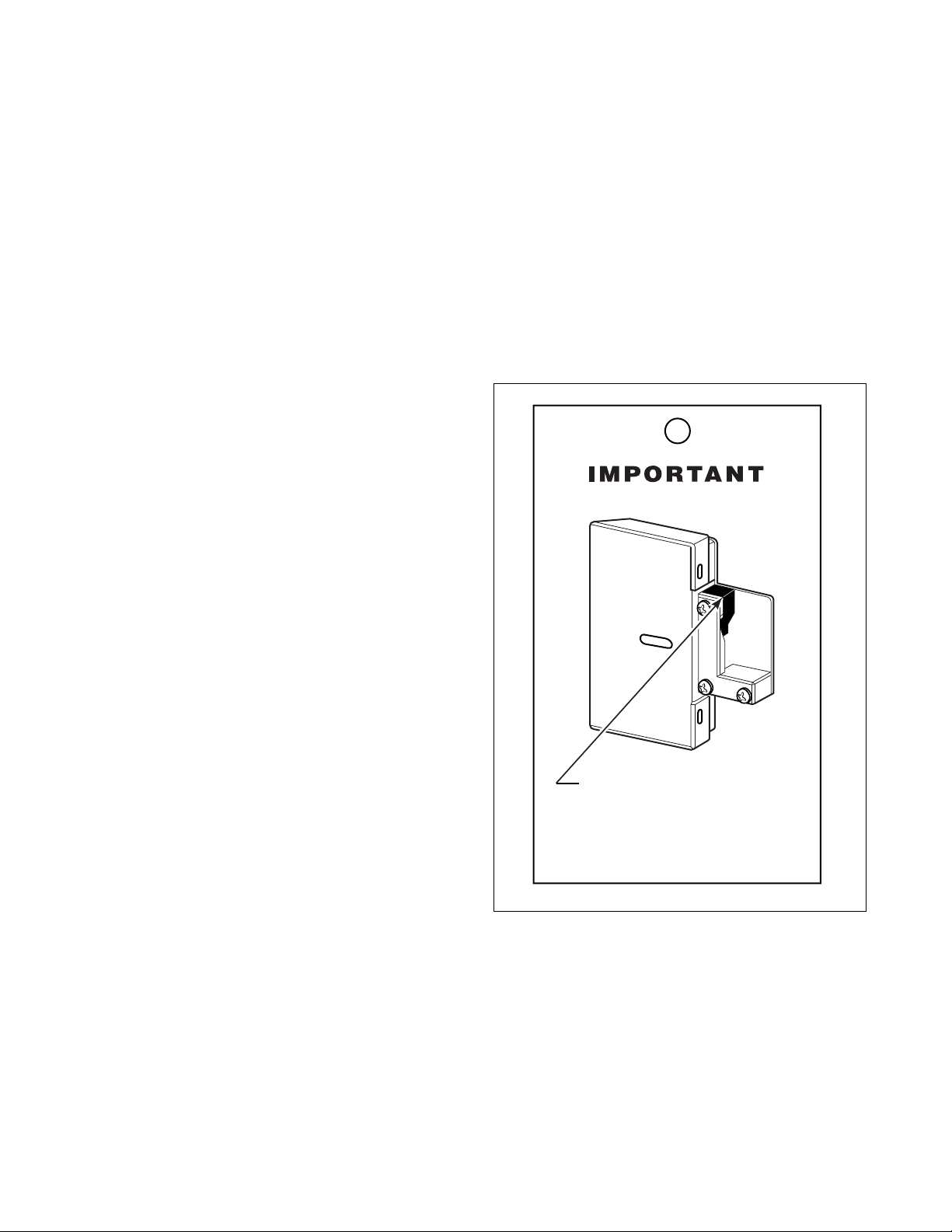

Remove After Shipment (OPL

Models Only)

A yellow retainer has been inserted in the door locks

of all cabinet hardmount on-premise laundry washerextractors to prevent the door from locking during

shipment. Remove the yellow retainer during

installation by pulling it off.

NOTE: Once retainer is removed, machine must be

powered to unlock door.

A tag has been attached to the washer-extractor’s door

handle as a reminder that the retainer must be removed

before operation. Refer to Figure 3.

Remove Yellow Retainer

Before Starting Machine.

Note: A Retainer has been

inserted to prevent the door from

locking during shipment.

CFS503N

Figure 3

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 11

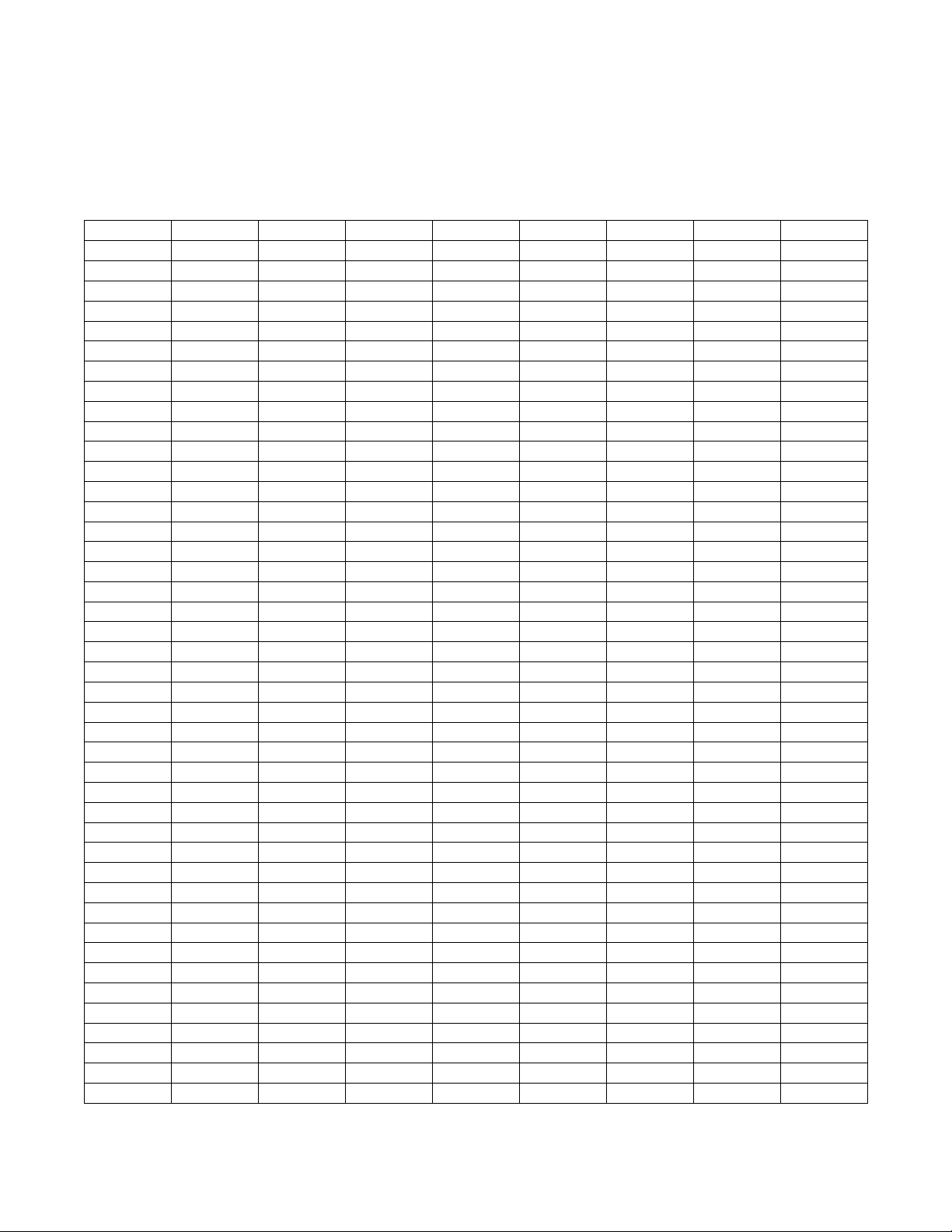

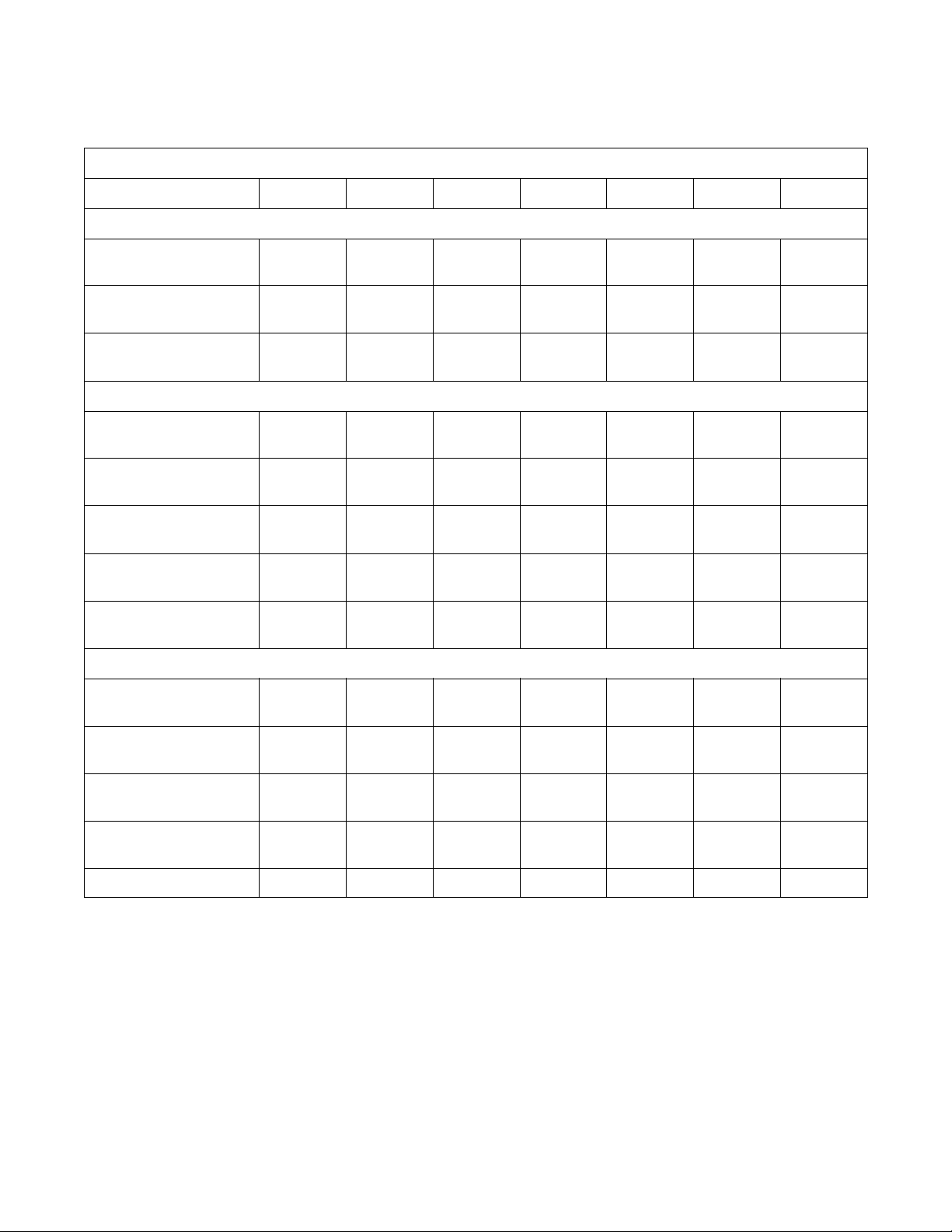

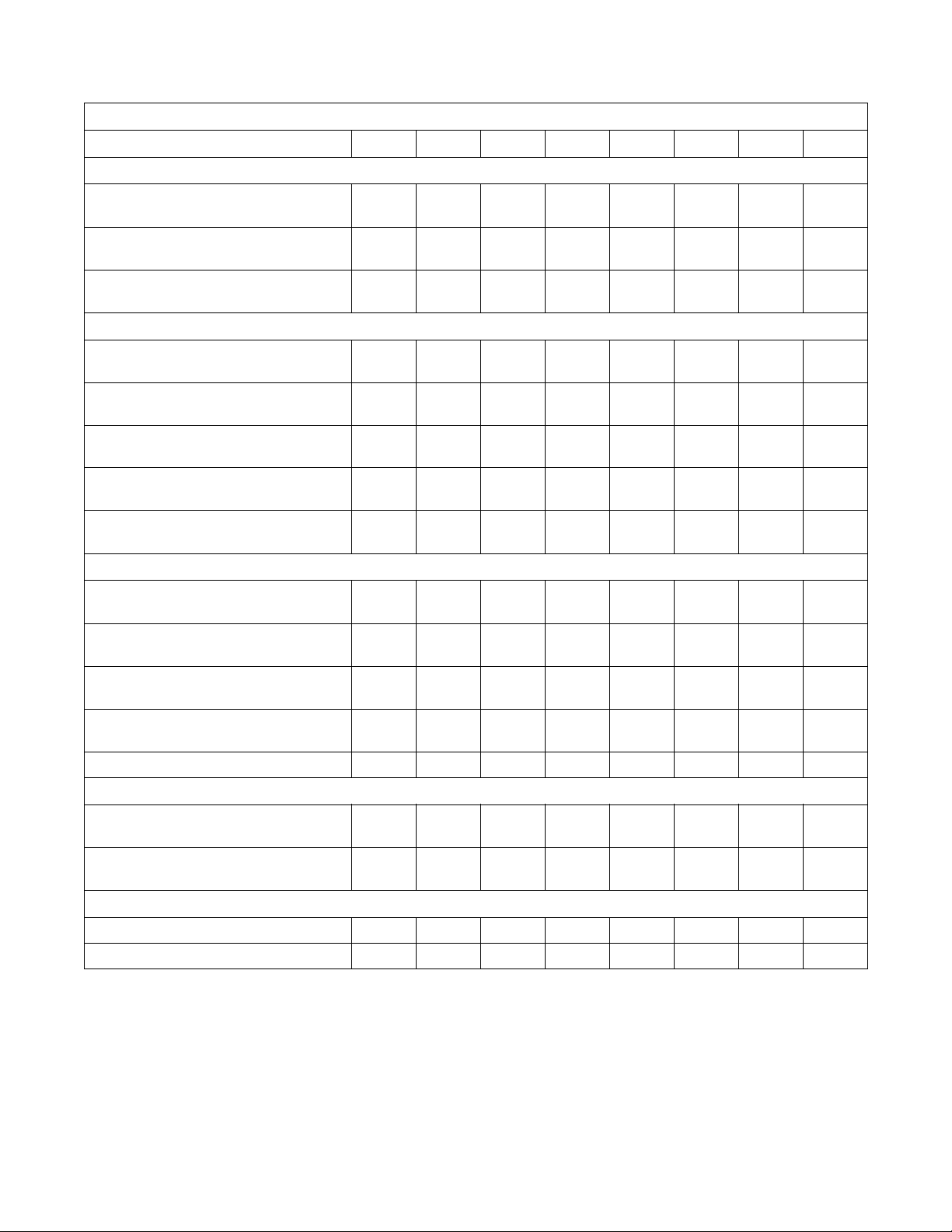

Specifications and Dimensions

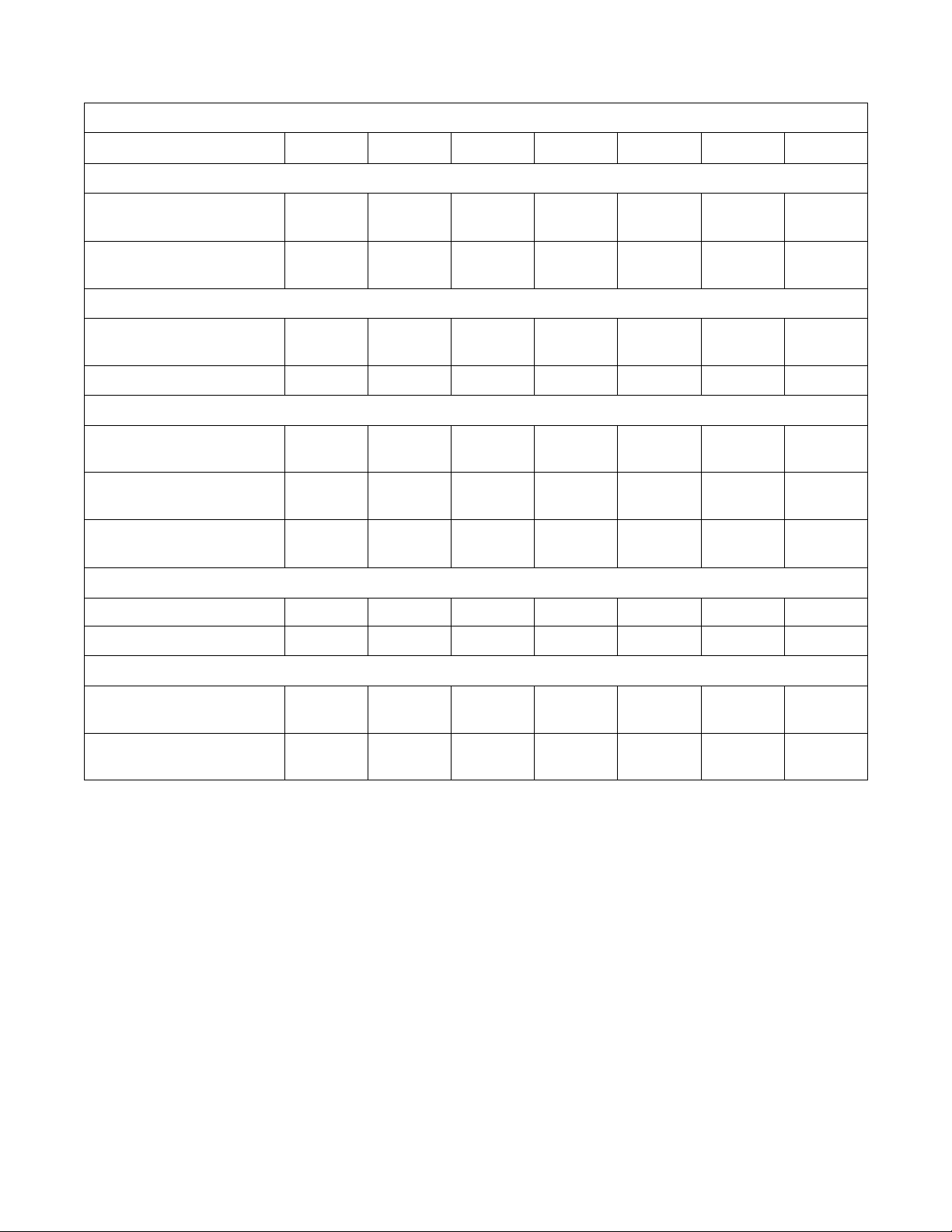

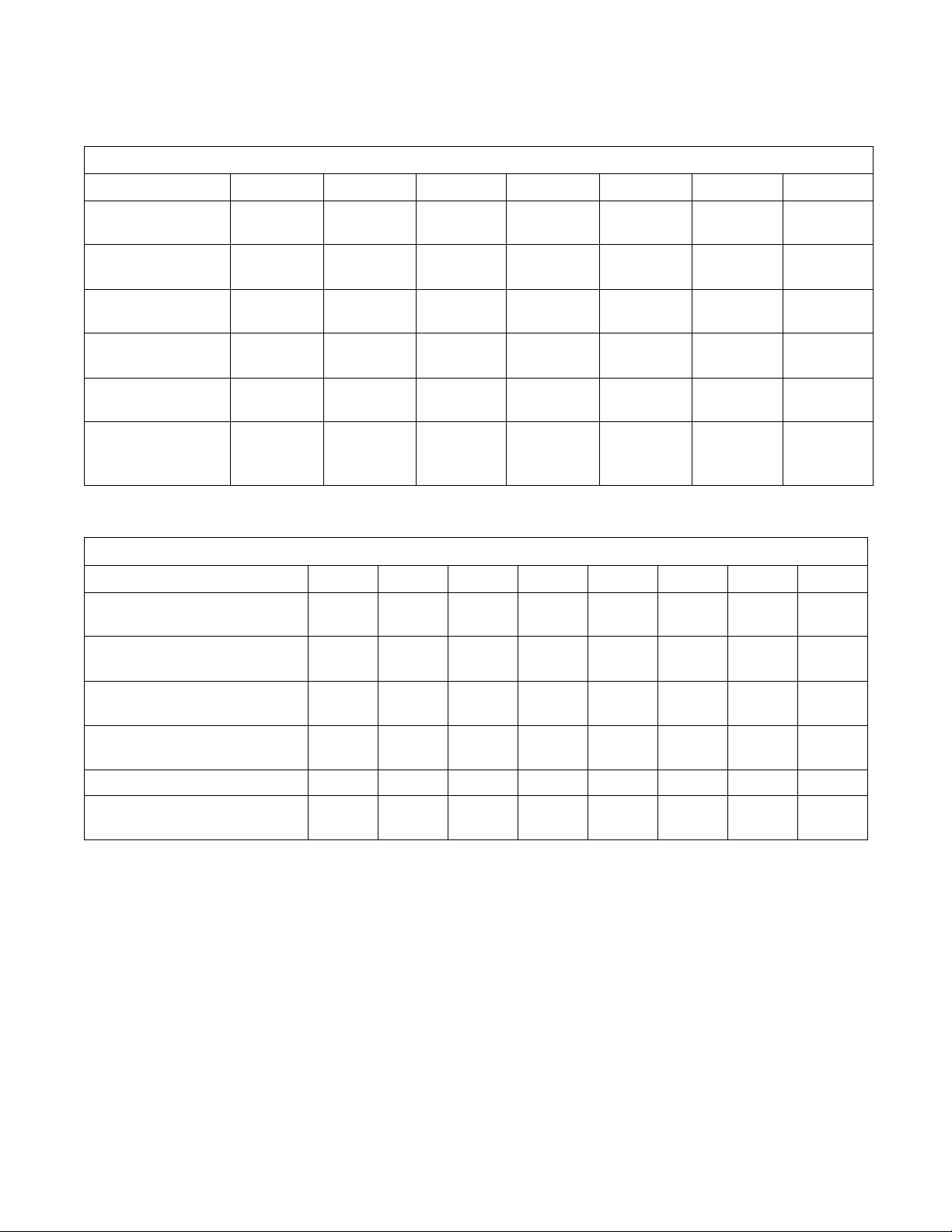

2 Speed Models

Specification 18, 20 25 27, 30 35 40 50 60

Overall Dimensions

Overall width, in. (mm) 26

(660)

Overall height, in. (mm) 42-7/8

(1089)

Overall depth, in. (mm) 29-13/16

(757)

Weight and Shipping Information

Net weight, lbs. (kg) 390

(177)

Domestic shipping weight,

lbs. (kg)

Domestic shipping

volume, ft

Export shipping weight

lbs. (kg)

Export shipping volume,

3

(m3)

ft

Wash Cylinder Information

Cylinder diameter,

in. (mm)

3

(m3)

428

(194)

28

(0.8)

480

(218)

30.1

(0.86)

21

(533)

26

(660)

45

(1143)

33-7/8

(860)

435

(198)

470

(214)

33

(0.9)

530

(241)

36.7

(1.03)

21

(533)

29

(737)

45-7/8

(1165)

34-13/16

(884)

498

(226)

545

(245)

35

(1.0)

588

(267)

39.6

(1.11)

24

(610)

30-1/8

(765)

47-1/4

(1200)

38-1/2

(978)

650

(295)

680

(309)

39

(1.09)

760

(345)

47.1

(1.32)

26-1/4

(667)

30-5/8

(778)

47-7/8

(1216)

40-3/16

(1021)

706

(321)

744

(338)

42.6

(1.19)

846

(385)

54.1

(1.51)

26-1/4

(667)

34-1/16

(865)

50-13/16

(1291)

41-13/16

(1087)

820

(373)

875

(398)

53

(1.5)

1020

(464)

58.7

(1.67)

30

(762)

34-1/16

(865)

50-13/16

(1291)

42-13/16

(1087)

826

(375)

881

(400)

53

(1.5)

1027

(466)

58.7

(1.67)

30

(762)

Cylinder depth, in. (mm) 13-3/4

(349)

3

Cylinder volume, ft

Perforation size, in. (mm) 0.188

Perforation open area, % 17 17 23 17 17.5 18 18

F232135

(l) 2.76

(78.1)

(4.76)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

18-3/4

(476)

3.76

(106.5)

0.188

(4.76)

16

(406)

4.19

(118.6)

0.188

(4.76)

18-3/8

(467)

5.76

(163.1)

0.188

(4.76)

20-1/4

(514)

6.34

(180)

0.188

(4.76)

20

(508)

8.18

(231.6)

0.188

(4.76)

22

(559)

9.00

(255)

0.188

(4.76)

9

Page 12

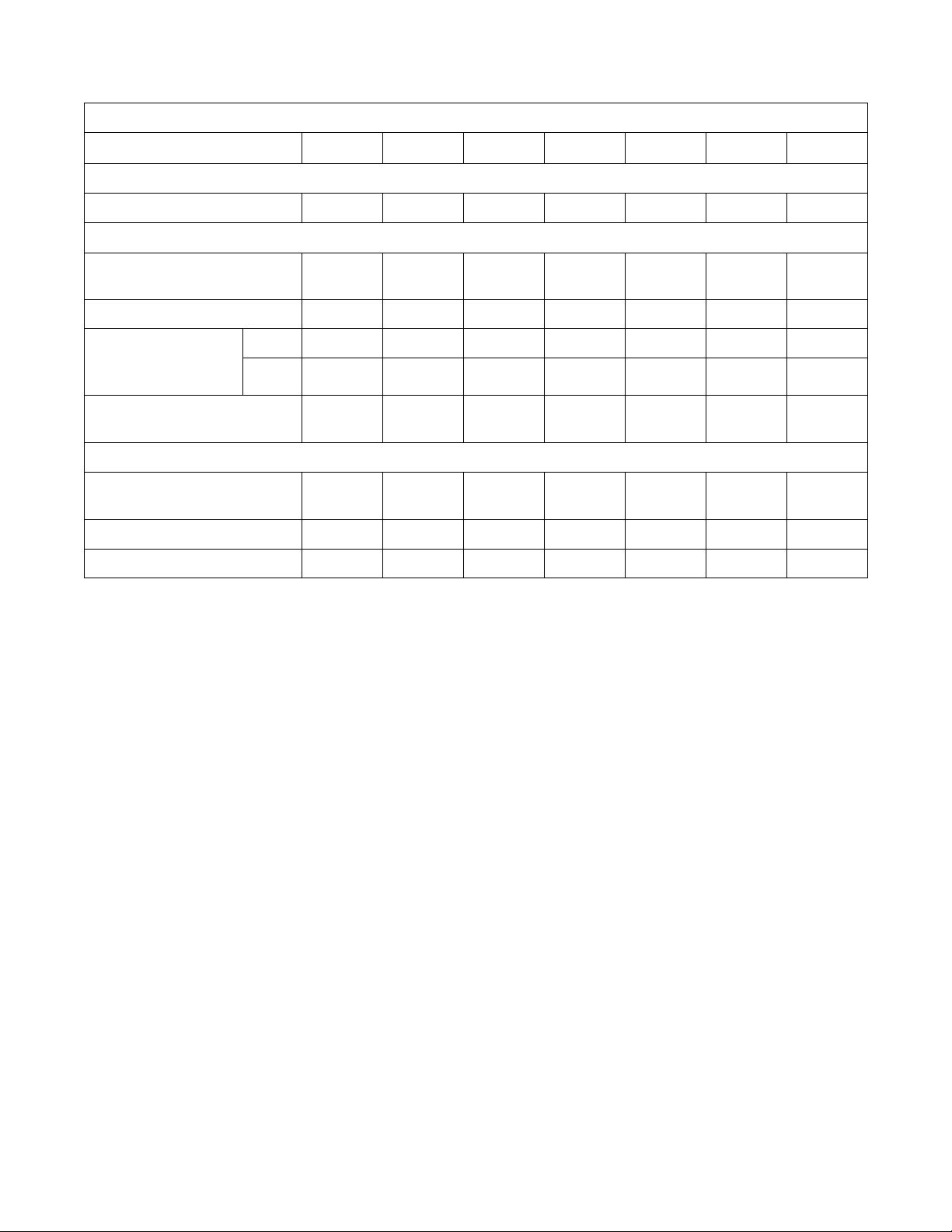

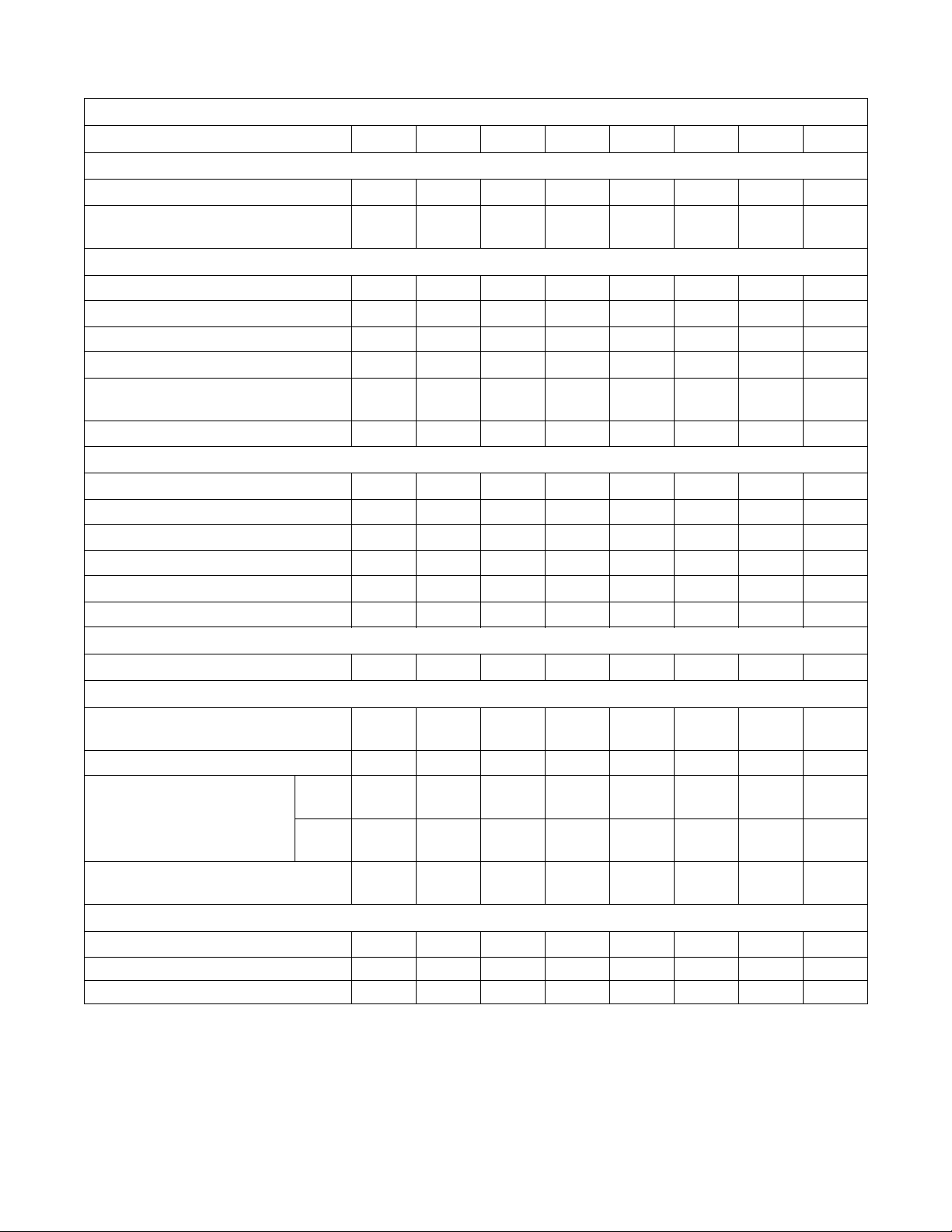

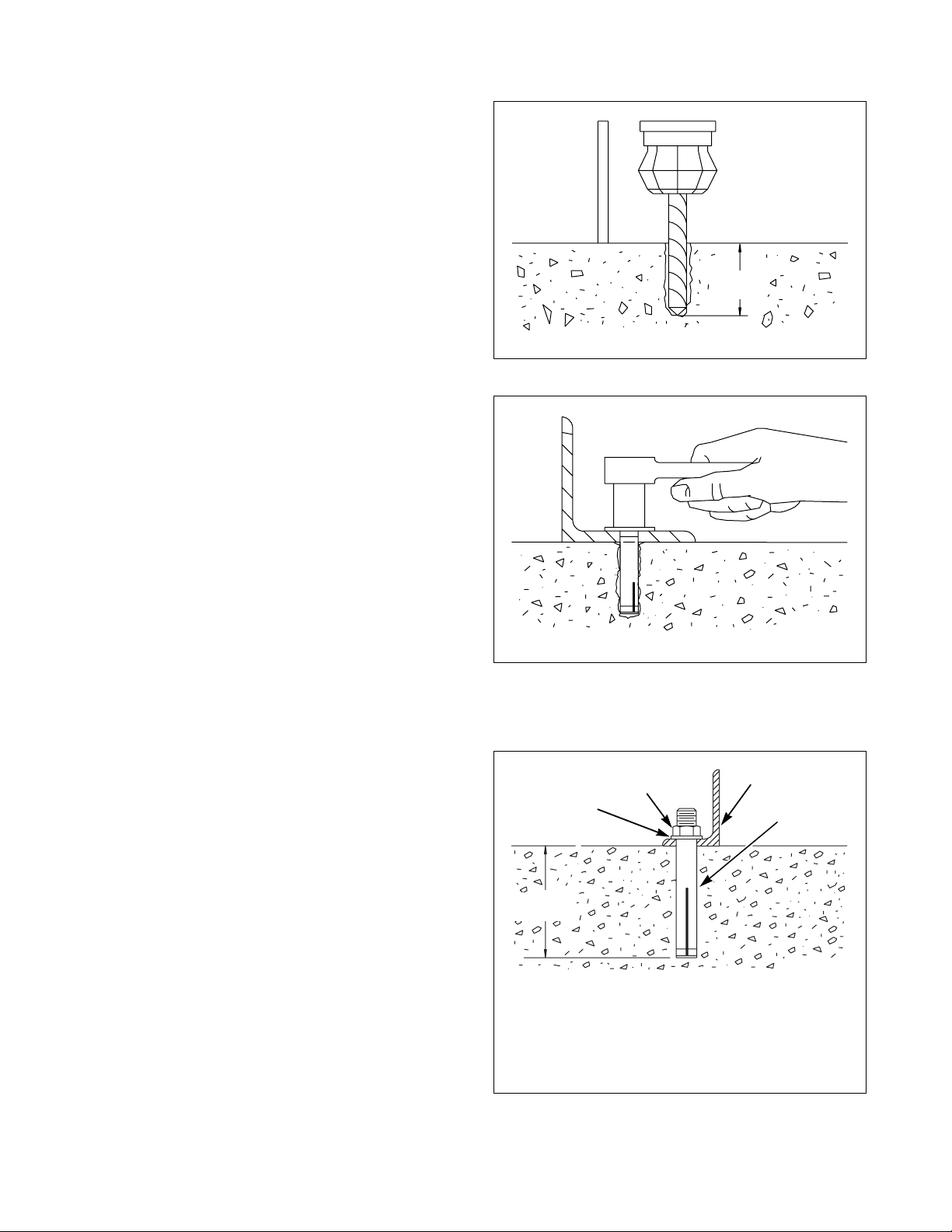

Specifications and Dimensions

Specification 18, 20 25 27, 30 35 40 50 60

Door Opening Information

Door opening diameter,

in. (mm)

Height of door bottom above

floor, in. (mm)

Power Consumption

12

(305)

14-3/8

(365)

2 Speed Models (Continued)

12

(305)

14-3/8

(365)

14-11/32

(364)

14

(356)

14-11/32

(364)

(406)

16

16-1/4

(413)

14-1/2

(368)

16-1/4

(413)

13-1/2

(343)

16-1/4

(413)

13-1/2

(343)

Average power used per cycle,

0.20 0.25 0.25 0.30 0.34 0.42 0.61

kW-hr

Average HVAC load, Btu/hr 425 400 400 510 510 700 700

Drive Train Information

Number of motors in drive

1111111

train

Wash/reverse power, HP (kW) 0.18

(0.13)

High extract power, HP (kW) 1.0

(0.746)

0.25

(0.19)

1.4

(1.04)

0.25

(0.19)

1.4

(1.04)

0.40

(0.30)

1.8

(1.3)

0.40

(0.30)

1.8

(1.3)

0.55

(0.41)

2.7

(2.01)

0.55

(0.41)

2.7

(2.01)

Cylinder Speeds

Wash/reverse speed, RPM53554747474444

High extract speed, RPM 525 540 480 470 470 450 450

Centrifugal Force Data

Wash/reverse centrifugal

0.85 0.90 0.75 0.82 0.82 0.825 0.825

force, Gs

High extract centrifugal force,

82.1 86.8 78.4 82.3 82.3 86.3 86.3

Gs

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 13

Specifications and Dimensions

2 Speed Models (Continued)

Specification 18/20 25 27, 30 35 40 50 60

Balance Detection

Vibration switch installed N/A N/A N/A N/A N/A N/A N/A

Direct Steam Heating (Optional)

Steam inlet connection size,

in. (mm)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

Number of steam inlets 1111111

Steam required to raise

bath water temperature

°F (6°C)

10

Average steam use per cycle,

bhp (kg)

LOW 1.05 (0.75) 1.4 (1.01) 1.44 (1.03) 2.06 (1.48) 2.09 (1.51) 2.76 (1.99) 2.76 (1.99)

HIGH 1.4 (1.01) 1.59 (1.15) 1.91 (1.37) 2.69 (1.94) 2.84 (2.04) 3.59 (2.59) 3.59 (2.59)

0.71

(11.1)

0.87

(13.6)

0.97

(15.2)

1.4

(21.6)

1.43

(22.4)

1.84

(28.9)

1.84

(28.9)

Electrical Heating (Optional)

Total electrical heating capacity,

7.8 7.8 7.8 15.6 15.6 23.4 23.4

kW

Electrical heating elements 3336399

Electrical heat element size, kW 2.6 2.6 2.6 2.6 5.2 2.6 2.6

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

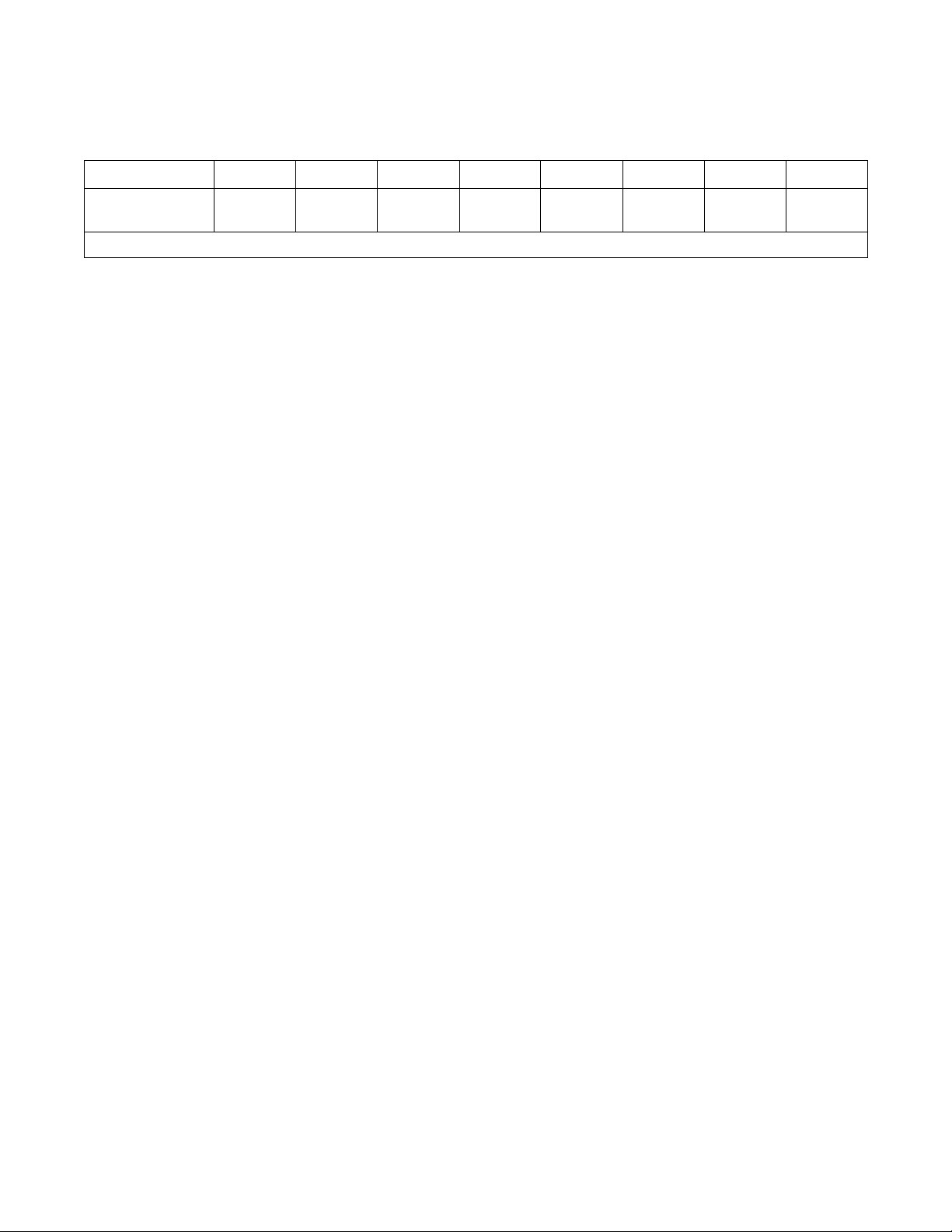

Specifications and Dimensions

Gap Setting for Vibration Switch (VariableSpeed and Fixed-Speed Models)

18, 20 27, 30 35 40 50 60 80 125

Switch gap setting*,

in. (mm)

* Gap setting should be made with “GO-NO-GO” type feeler gauge. Lower value must not trip switch. Upper value must trip switch.

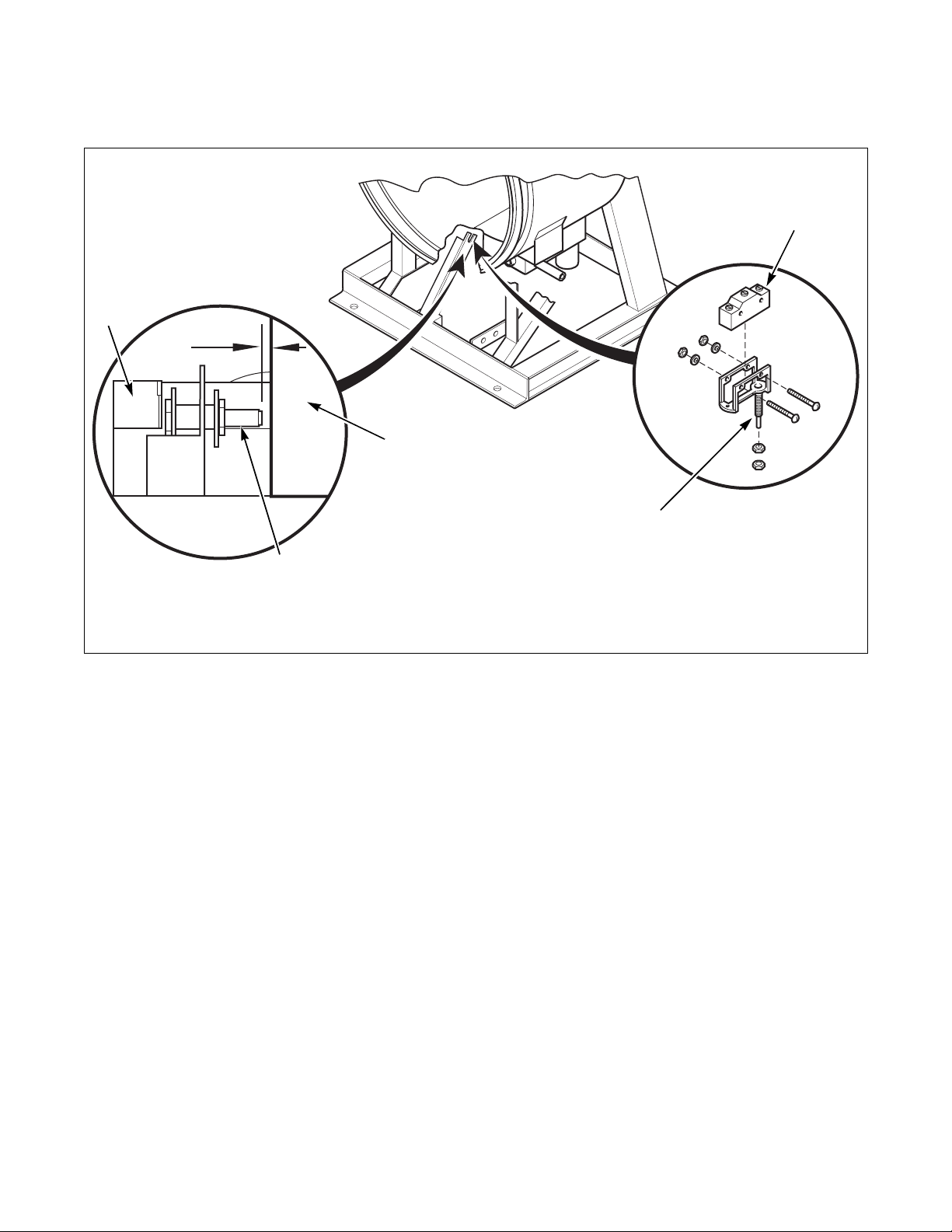

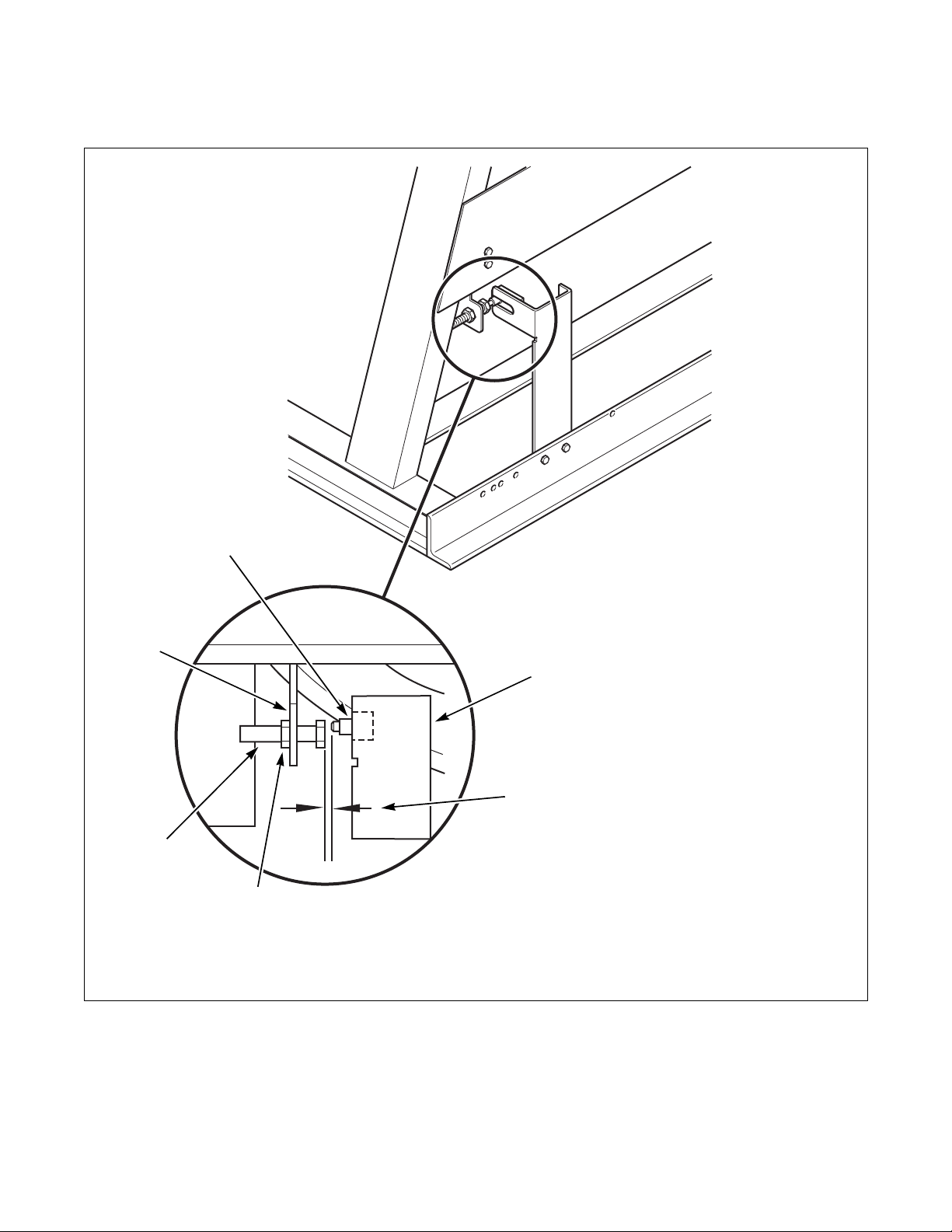

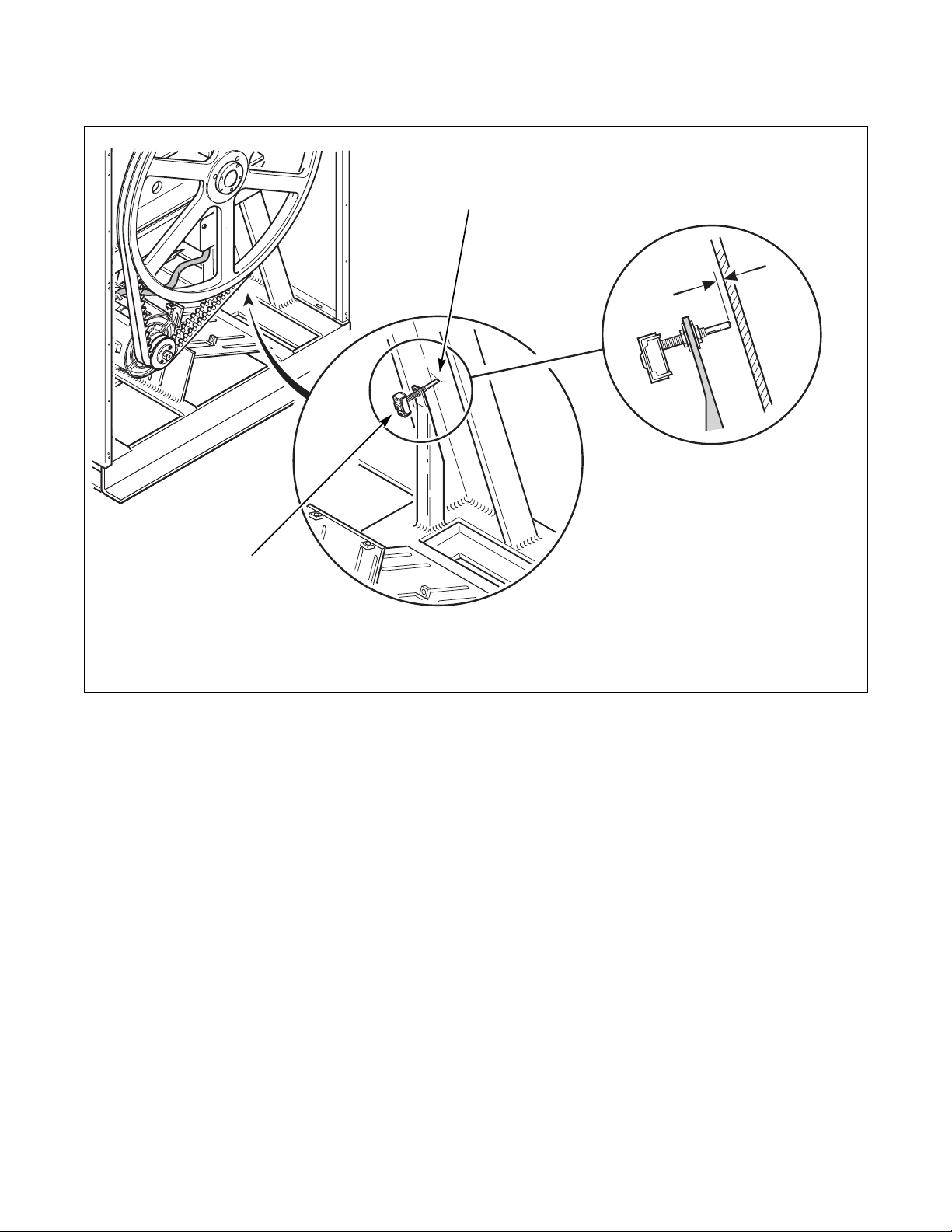

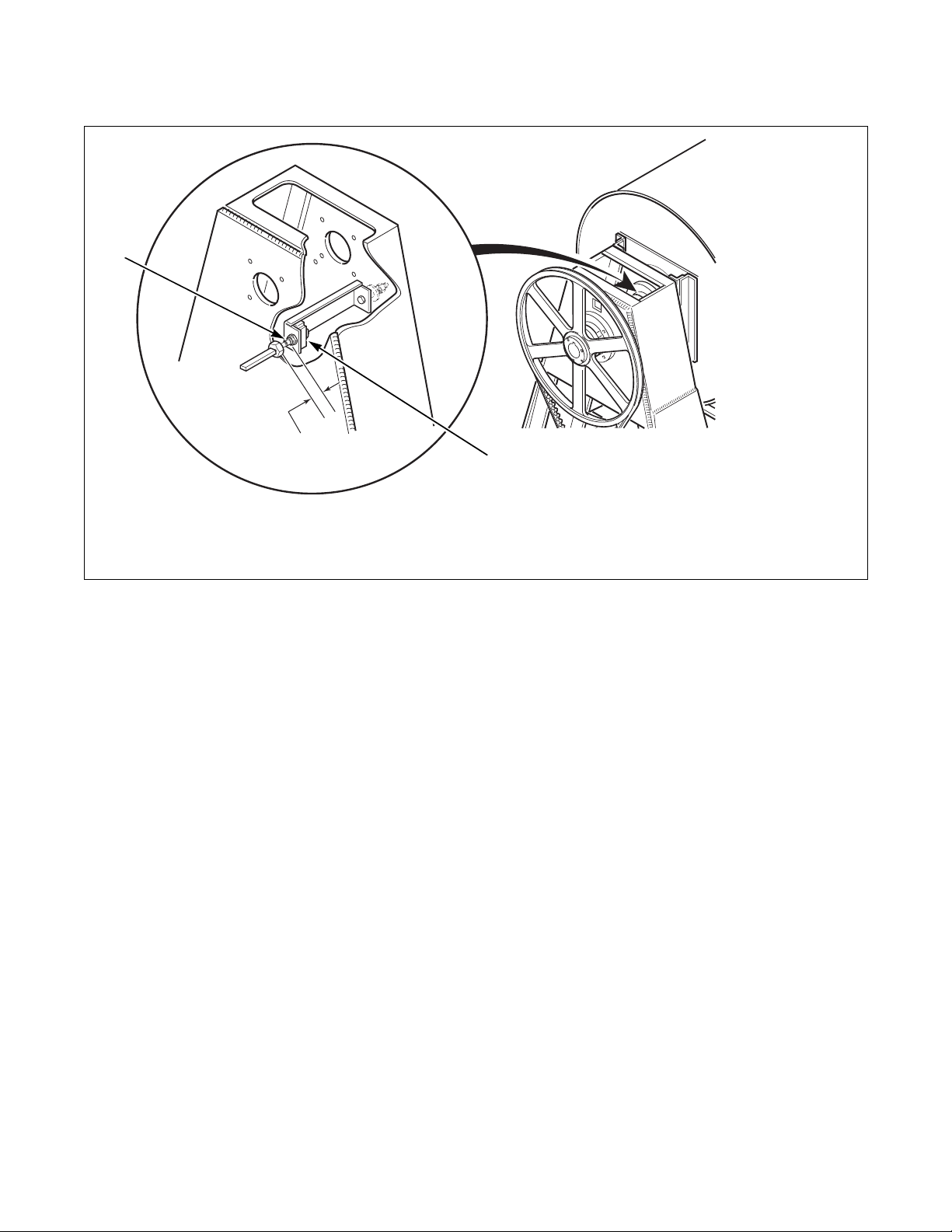

After the machine has been properly installed, the

vibration switch gap must be measured before

conducting the Control Function Test. Locate the gap

found between the vibration switch and the machine

structure. Refer to Figures 4, 5, 6, 7 and 8. To check

the gap setting of the switch, proceed as follows:

1. Remove the front panel on 18-50 models.

Remove the rear panel on 60-80 models. Remove

the top cover on the 125 model. The switch can

be seen inside the bottom right corner of the Aframe, mounted on a bracket. Refer to Figures 4,

5, 6, 7 and 8.

0.015-0.025

(0.38-0.64)

0.025-0.035

(0.64-0.89)

0.030-0.040

(0.76-1.02)

0.020-0.030

(0.51-0.64)

Table 1

0.025-0.035

(0.64-0.89)

0.013-0.015

(0.20-0.25)

0.009-0.011

(0.23-0.28)

0.006-0.008

(0.15-0.20)

2. Measure the gap distance when the switch is in

both the open and closed positions. The

specifications should be at the minimum switch

gap setting when the switch is open and at the

maximum switch gap setting when the switch is

closed. If these distances are not correct, adjust

the balance switch to these specifications.

NOTE: The standard position of the switch is open,

or non-tripped.

3. Tighten nuts on switch extension after adjusting

the gap. Measure the gap distance to verify

accurate setting.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 15

For 18, 20, 25, 27, 30 and 35 Pound

Capacity Machines

Specifications and Dimensions

3

2

1 Sump 3 Vibration Switch

2 Gap Distance 4 Switch Extension

1

4

Figure 4

CHM1995N

CHM1995N

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Specifications and Dimensions

For 40 and 50 Pound Capacity Variable-Speed

and Fixed-Speed Machines

3

2

1

3

4

4

1 Sump 3 Vibration Switch

2 Gap Distance 4 Switch Extension

Figure 5

CHM2000N

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 17

For 60 Pound Capacity Variable-Speed and

Fixed-Speed Machines

Specifications and Dimensions

2

3

2

1

6

4

5

1 Lower Bracket 4 Balance Bolt

2 Upper Bracket 5 Lock Nut

3 Vibration Switch 6 Gap Distance

CHM1999N

CHM1999N

F232135

Figure 6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Specifications and Dimensions

For 80 Pound Capacity Machines

1

2

3

1 Switch Extension 3 Vibration Switch

2 Gap Distance

Figure 7

CAB1998N

CHM1998N

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 19

For 125 Pound Capacity Machines

3

2

1

1 Vibration Switch 3 Switch Extension

2 Gap Distance

Specifications and Dimensions

CHM1993N

Figure 8

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Specifications and Dimensions

Variable-Speed and Fixed-Speed Models

Specification 20 30 35 40 50 60 80 125

Overall Dimensions

Overall width, in. (mm) 26

(660)

Overall height, in. (mm) 42-7/8

(1089)

Overall depth, in. (mm) 29-13/16

(757)

Weight and Shipping Information

Net weight, lbs. (kg) 386

(175)

Domestic shipping weight, lbs. (kg) 424

(191)

3

Domestic shipping volume, ft

Export shipping weight, lbs. (kg) 476

Export shipping volume, ft

(m3)28

(0.8)

(215)

3

(m3)30.1

(0.86)

29

(737)

45-7/8

(1165)

34-13/16

(884)

498

(226)

545

(245)

35

(1.0)

588

(267)

39.6

(1.11)

30-1/8

(765)

47-1/4

(1200)

38-1/2

(978)

621

(282)

670

(301)

39

(1.09)

731

(332)

47.1

(1.32)

30-5/8

(778)

47-7/8

(1216)

40-3/16

(1021)

706

(321)

744

(338)

42.6

(1.19)

846

(385)

54.1

(1.51)

34-1/16

(865)

50-13/16

(1291)

42-13/16

(1087)

767

(348)

818

(371)

53

(1.5)

967

(439)

58.7

(1.67)

34-1/16

(865)

41-1/2

(1054)48(1219)

50-13/16

(1291)56(1422)

42-13/16

(1087)

773

(350)

824

(373)

53

(1.5)

1020

(463)

58.7

(1.67)

51-5/8

(1311)

1406

(633)

1456

(655)

97

(2.7)

1506

(678)

109.5

(3.1)

70-1/2

(1791)

56-3/4

(1441)

2346

(1066)

2421

(1098)

153

(4.3)

2701

(1225)

173

(4.8)

Wash Cylinder Information

Cylinder diameter, in. (mm) 21

(533)

Cylinder depth, in. (mm) 13-3/4

(349)

3

Cylinder volume, ft

(l) 2.76

(78.1)

Perforation size, in. (mm) 0.188

(4.76)

24

(610)

16

(406)

4.19

(118)

0.188

(4.76)

26-1/4

(667)

18-3/8

(467)

5.76

(163.1)

0.188

(4.76)

26-1/4

(667)

20-1/4

(514)

6.34

(180)

0.188

(4.76)

30

(762)

20

(508)

8.18

(232)

0.188

(4.76)

30

(762)

22

(559)

9.00

(255)

0.188

(4.76)

36

(914)42(1060)

22

(559)

12.96

(367)

0.188

(4.76)

24

(609)

19.24

(545)

0.188

(4.76)

Perforation open area, % 17231717.518182717

Door Opening Information

Door opening size, in. (mm) 12

(305)

Height of door bottom above floor, in. (mm) 14-3/8

(365)

14-11/32

(364)

14

(356)

14-11/32

(364)

16

(406)

16-1/4

(413)

14-1/2

(368)

16-1/4

(413)

13-1/2

(343)

16-1/4

(413)

13-1/2

(343)

18-1/2

(470)

17-3/4

(451)

20

(508)

29

(737)

Power Consumption

Average power used per cycle, kW-hr 0.05 0.07 0.20 0.34 0.37 0.21 0.40 0.60

Average HVAC load, Btu/hr 400 450 510 510 750 750 950 1200

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 21

Specifications and Dimensions

Variable-Speed and Fixed-Speed Models (Continued)

Specification 20 30 35 40 50 60 80 125

Drive Train Information

Number of motors in drive train 11111111

Drive motor power, HP (kW) 2

(1.5)

Cylinder Speeds

Gentle wash/reverse speed, RPM 2927262624242227

Wash/reverse speed, RPM 5248464743434037

Distribution speed, RPM 8286737368776362

Low extract speed, RPM 366 343 328 328 307 307 280 260

Medium extract speed, RPM

534 500 478 478 447 447 408 380

(Not available on Electronic Control models.)

High extract speed, RPM 685 641 613 614 573 574 524 485

Centrifugal Force Data

Gentle wash centrifugal force, Gs 0.25 0.25 0.25 0.25 0.25 0.25 0.25 0.43

Wash/reverse centrifugal force, Gs 0.8 0.8 0.8 0.8 0.8 0.8 0.8 0.8

Distribution centrifugal force, Gs 22222222

Low extract centrifugal force, Gs 40 40 40 40 40 40 40 40

Medium extract centrifugal force, Gs 85 85 85 85 85 85 85 85

High extract centrifugal force, Gs 140 140 140 140 140 140 140 140

2

(1.5)

2

(1.5)

2

(1.5)

2

(1.5)

3

(2.2)

5

(3.7)

7.5

(5.6)

Balance Detection

Vibration switch installed* Standard Standard Standard Standard Standard Standard Standard Standard

Direct Steam Heating (Optional)

Steam inlet connection size,

in. (mm)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

1/2

(13)

3/4

(19)

Number of steam inlets 11111111

Steam required to raise bath water

temperature 10°F (6°C), lbs. (kg)

Average steam use per cycle, bhp (kg) 0.54

LOW 0.62

(0.28)

HIGH 0.88

(0.4)

(8.3)

0.92

(0.42)

1.31

(0.6)

0.73

(11.3)

2.1

(1.51)

2.69

(1.96)

1.4

(21.6)

2.09

(1.51)

2.84

(2.04)

1.43

(22.4)

2.8

(2.0)

3.6

(2.59)

1.8

(28.9)

3.6

(1.63)

5.5

(2.49)

2.32

(36.4)

4.1

(2.93)

6.0

(4.34)

2.93

(45.9)

6.8

(4.9)

8.9

(6.4)

4.5

(71)

Electrical Heating (Optional)

Total electrical heating capacity, kW 7.8 7.8 15.6

15.6

23.4 23.4 31.2 N/A

Electrical heating elements 33639912N/A

Electrical heat element size, kW 2.6 2.6 2.6 5.2 2.6 2.6 2.6 N/A

* Refer to Gap Setting for Vibration Switch (Variable-Speed and

Fixed-Speed Models) section for specifications.

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

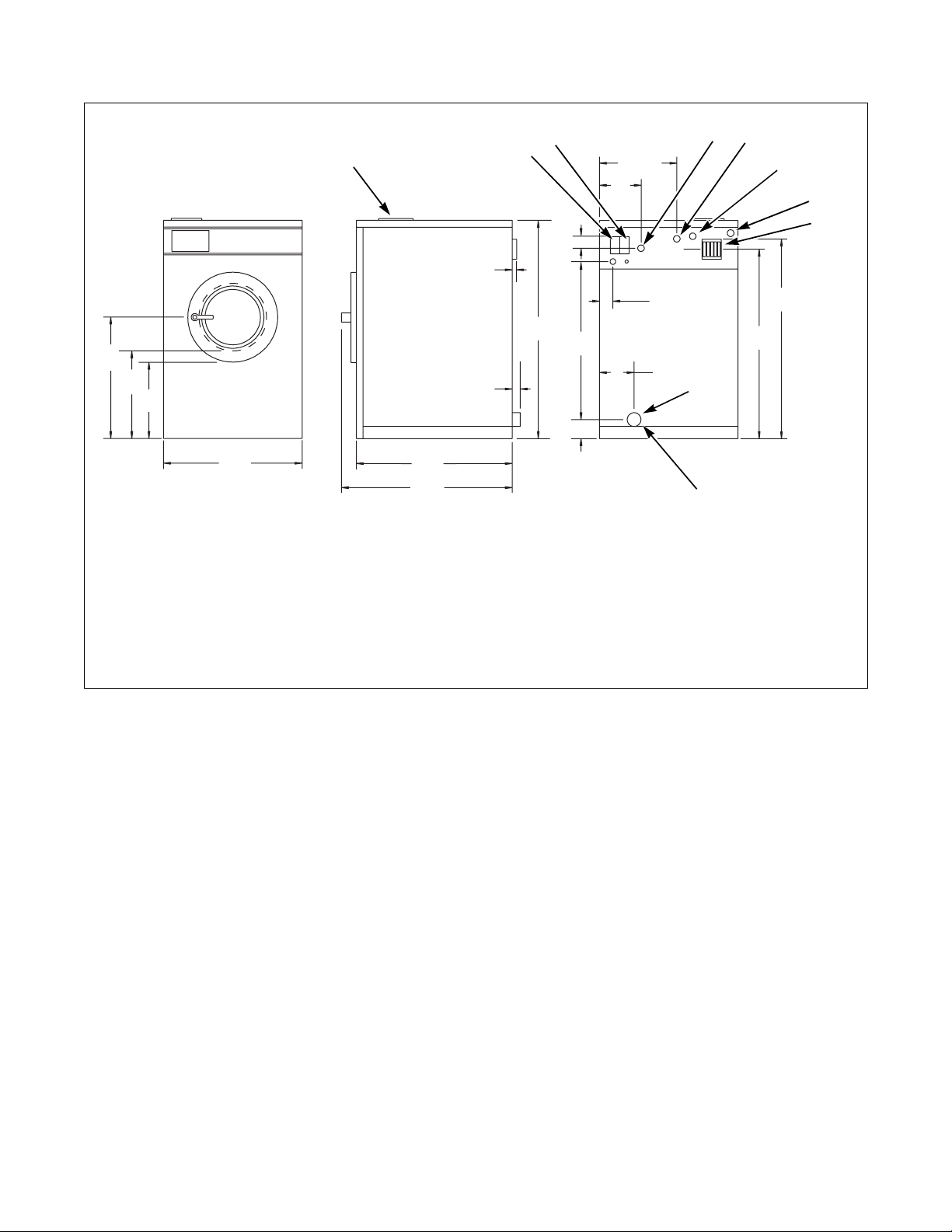

Specifications and Dimensions

4

3

1

2

I

5

6

J

7

8

S

R

H

L

A

B

C

G

N

D

E

F

18, 20, 25, 27, 30, 35, 40, 50, 60 AND 80 POUND CAPACITY MACHINES

1 Supply Dispenser 5 Hot Water Inlet

2 Input Power Block 6 Extra Inlet Valve

3 External Chemical Supply Signal Terminal Strip

(OPL only)

7 External Chemical Supply Inlet (OPL only)

8 Vacuum Breaker

4 Cold Water Inlet 9 Drain Outlet

Figure 9

K

Q

P

M

O

9

CHM2019N

CHM2019N

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 23

Specifications and Dimensions

Machine Capacity Dimensions

Dimensions 18, 20 25 27, 30 35 40 50 60 80

A

B

C

D

E

G

H

K

M

N

O

P

Q

R

S

22-15/16

in.

(583 mm)

in.

17-1/4

(438 mm)

in.

14-3/8

(365 mm)

in.

26

(660 mm)

in.

25-5/8

(650 mm)

F

29-13/16

(757 mm)

in.

0001-1/8

in.

42

(1062 mm)

in.

I

J

12-1/2

(318 mm)

in.

11-1/2

(292 mm)

in.

3-1/2

(89 mm)

in.

L

34-1/2

(876 mm)

in.

5-3/4

(146 mm)

in.

4-1/2

(114 mm)

in.

2

(51 mm)

36-3/16

in.

(919 mm)

38-1/2 in.

(978 m)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

23 in.

(584 mm)

17-1/4 in.

(438 mm)

14-3/8 in.

(365 mm)

26 in.

(660 mm)

30 in.

(762 mm)

34-3/16 in.

(868 mm)

45 in.

(1143 mm)

12-1/2

in.

(318 mm)

11-1/2 in.

(292 mm)

3-1/2 in.

(89 mm)

37-1/2 in.

(952 mm)

5-3/4 in.

(146 mm)

4-1/2 in.

(114 mm)

2 in.

(51 mm)

39-3/16 in.

(995 mm)

41-1/2 in.

(1054 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

24 in.

(610 mm)

17 in.

(432 mm)

14 in.

(356 mm)

29 in.

(737 mm)

30-5/8 in.

(775 mm)

34-13/16 in.

(884 mm)

45 in.

(1143 mm)

15-1/4

in.

(387 mm)

14-3/4 in.

(375 mm)

3-3/4 in.

(95 mm)

37-11/16

in.

(957 mm)

5-7/8 in.

(149 mm)

4 in.

(102 mm)

2 in.

(51 mm)

38-15/16

in.

(989 mm)

41 in.

(1041 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

26 in.

(660 mm)

19 in.

(483 mm)

16 in.

(406 mm)

30-1/8 in.

(765 mm)

34 in.

(864 mm)

38-1/8 in.

(968 mm)

in.

(29 mm)

47 in.

(1194 mm)

14-1/4 in.

(362 mm)

10-13/16

in.

(275 mm)

2-3/4

in.

(70 mm)

40-1/8

in.

(1020 mm)

7-5/16 in.

(186 mm)

4-3/4 in.

(121 mm)

2

in.

(51 mm)

41-15/16

in.

(1064 mm)

41-15/16 in.

(1064 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

25-3/4 in.

(654 mm)

18 in.

(457 mm)

14-1/2 in.

(368 mm)

30-5/8 in.

(778 mm)

36 in.

(914 mm)

40-3/16 in.

(1021 mm)

1/2 in.

(13 mm)

47 in.

(1194 mm)

15-7/16 in.

(392 mm)

14-7/16 in.

(367 mm)

3-13/16 in.

(97 mm)

39 in.

(990 mm)

5-1/2 in.

(140 mm)

4-3/4 in.

(121 mm)

3 in.

(76 mm)

42-1/8 in.

(1070 mm)

43-3/16 in.

(1097 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

26-3/8 in.

(670 mm)

18-1/4 in.

(464 mm)

13-1/2 in.

(343 mm)

34-1/16 in.

(865 mm)

37-3/4

in.

(959 mm)

41-13/16

in.

(1062 mm)

1/2 in.

(13 mm)

49-15/16 in.

(1268 mm)

20-3/4 in.

(527 mm)

19-3/4

in.

(502 mm)

3-1/2 in.

(89 mm)

41-1/2 in.

(1054 mm)

6-7/16 in.

(163 mm)

5 in.

(127 mm)

3

in.

(76 mm)

43-3/16 in.

(1097 mm)

45-1/2 in.

(1156 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

26-3/8 in.

(670 mm)

18-1/4

in.

(464 mm)

13-1/2 in.

(343 mm)

34-1/16 in.

(865 mm)

38-3/4 in.

(984 mm)

42-13/16 in.

(1087 mm)

1/2 in.

(13 mm)

49-15/16 in.

(1268 mm)

20-3/4 in.

(527 mm)

19-3/4 in.

(502 mm)

3-1/2 in.

(89 mm)

41-1/2 in.

(1054 mm)

6-7/16 in.

(163 mm)

5

in.

(127 mm)

3 in.

(76 mm)

43-3/8 in.

(1102 mm)

45-1/2 in.

(1156) mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

30-5/8 in.

(777 mm)

21-5/8

(549 mm)

17-3/4 in.

(451 mm)

41-1/2 in.

(1054 mm)

48 in.

(1219 mm)

51

(1295 mm)

1/2 in.

(13 mm)

56 in.

(1422 mm)

22-1/4 in.

(572 mm)

14-7/16 in.

(378 mm)

3-7/16 in.

(87 mm)

44-1/2 in.

(1130 mm)

6-3/8 in.

(162 mm)

5-3/4

(146 mm)

3 in.

(76 mm)

42-3/4 in.

(1086 mm)

50 in.

(1270 mm)

1-3/16 in.

(30 mm)

3 in.

(76 mm)

in.

in.

in.

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Specifications and Dimensions

1

2

J

K

L

M

N

O

I

3

4

5

6

R

S

A

B

C

D

1 Dry Chemical Dispenser

(Optional – OPL Models Only)

2 Cold Water Inlet 6 Steam Inlet (Optional)

3 Extra Water Inlet (Optional) 7 Drain Outlet

E

125 POUND CAPACITY MACHINES

F

G

4 Hot Water Inlet

5 Liquid Chemical Inlet

P

H

Machine Capacity Dimensions for 125 Pound Models

in. (1016 mm)

A

B

C

D

40

in. (768 mm)

30-1/4

in. (737 mm)

29

8

in. (203 mm)

K

L

M

N

Q

7

B023I

41 in. (1041 mm)

38-1/2 in. (978 mm)

33-1/2 in. (851 mm)

29-3/4 in. (756 mm)

T

B023I

22

48

E

F

G

H

I

J

in. (1219 mm)

50-1/2

in. (1283 mm)

in. (1422 mm)

56-3/4

1

in. (25 mm)

70-1/2

in. (1791 mm)

44-1/2

in. (1130 mm)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

O

P

Q

R

S

T

24 in. (610 mm)

13 in. (330 mm)

4-7/8 in. (124 mm)

63-7/8 in. (1622 mm)

64-7/8 in. (1648 mm)

66-5/8 in. (1692 mm)

F232135

Page 25

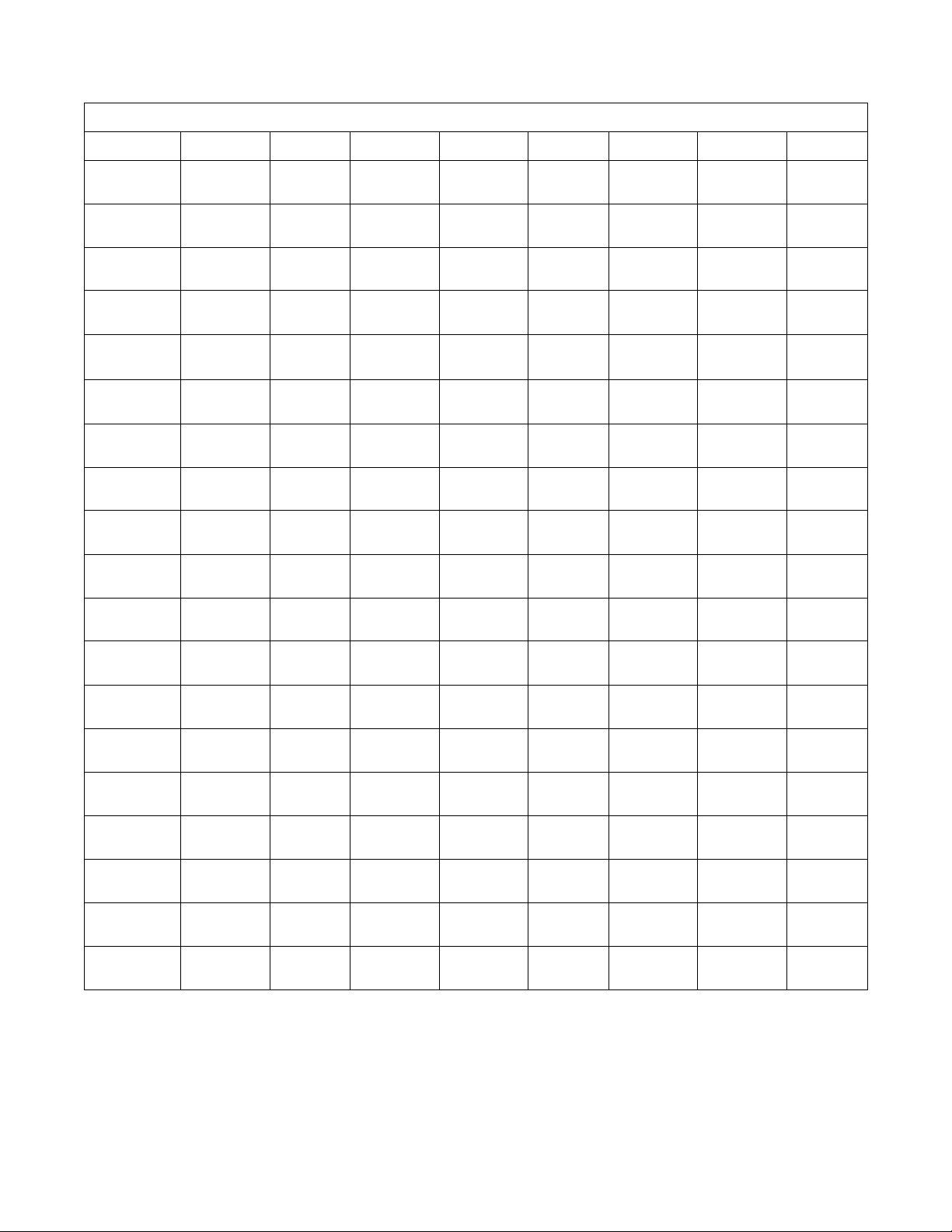

Dimensional Clearances

Installation

F

E

FRONT

A

Machine Capacity Dimensional Clearances

Dimensions 18, 20 25 27, 30 35 40 50 60 80 125

A

B

C

D

E

F

*For 80 pound models intended for standard mounting, clearance should be 6 in. (150 mm).

2 in.

(50 mm)

26 in.

(660 mm)

1 in.

(25 mm)

16-3/8 in.

(416 mm)

25-5/8 in.

(650 mm)

12 in.

(305 mm)

2 in.

(50 mm)

26 in.

(660 mm)

1 in.

(25 mm)

16-3/8 in.

(416 mm)

29-7/16 in.

(705 mm)

12 in.

(305 mm)

(50 mm)

(737 mm)

(25 mm)

19-1/4 in.

(490 mm)

30-1/2 in.

(775 mm)

(305 mm)

2 in.

29 in.

1 in.

12 in.

B

C

30-1/8 in.

(765 mm)

19-1/4 in.

(490 mm)

(864 mm)

(457 mm)

2 in.

(50 mm)

1 in.

(25 mm)

34 in.

18 in.

2 in.

(51 mm)

30-5/8 in.

(778 mm)

1 in.

(25 mm)

22 in.

(560 mm)

36 in.

(914 mm)

12 in.

(305 mm)

D

2 in.

(50 mm)

34-1/16 in.

(865 mm)

1 in.

(25 mm)

22 in.

(560 mm)

37-1/2 in.

(953 mm)

12 in.

(305 mm)

2 in.

(50 mm)

34-1/16 in.

(865 mm)

1 in.

(25 mm)

22 in.

(560 mm)

38-3/4 in.

(984 mm)

12 in.

(305 mm)

2 in.

(50 mm)

41-1/2 in.

(1054 mm)

1 in.*

(25 mm)

25 in.

(635 mm)

51-5/8 in.

(1311 mm)

24 in.

(610 mm)

24 in.

(600 mm)

48 in.

(1219 mm)

12 in.

(300 mm)

26-1/4 in.

(667 mm)

56-3/4 in.

(1441 mm)

24 in.

(610 mm)

U158M

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Installation

Machine Foundation

NOTE: Do not mount on wooden floors, above

ground level, or over basements or crawl spaces

because of the high extract speed and the G-forces

exerted.

The floor must be 3500 psi minimum reinforced

concrete set firmly in clean, compacted fill dirt.

Machine Foundation Requirements

Models

2 Speed and Fixed-Speed

(20-60 Models)

Variable-Speed

(20-60 Models)

Va ri ab le Speed

80 Models 9 in.

125 Models 12 in.

Foundation

Thickness

4

in.

(102 mm)

6 in.

(152 mm)

(229 mm)

(304 mm)

Floor

Thickness

4 in.

(102 mm)

6 in.

(152 mm)

6 in.

(152 mm)

6 in.

(152 mm)

The machine must be anchored to a smooth, level

surface so that the entire base of the machine is

supported and rests on the mounting surface. (Do not

support the machine on only four points.)

An elevated foundation must not exceed 8 inches

(203 mm).

Refer to Table 2 for foundation and anchoring

requirements.

Anchoring

Installation

Foundation

Method(s)

Direct-to-finished-floor,

elevated base frame, or

concrete foundation

Direct-to-finished-floor

or concrete foundation

Direct-to-finished-floor

or concrete foundation

Anchoring

Method(s)

Requirement

Expansion bolt

or J-bolt

J-bolt or

mounting bolt

J-bolt, mounting

bolt, or rebar

frame

Bolt

Diameter

Size

(minimum)

5/8 in.

5/8 in.

3/4 in.

Table 2

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 27

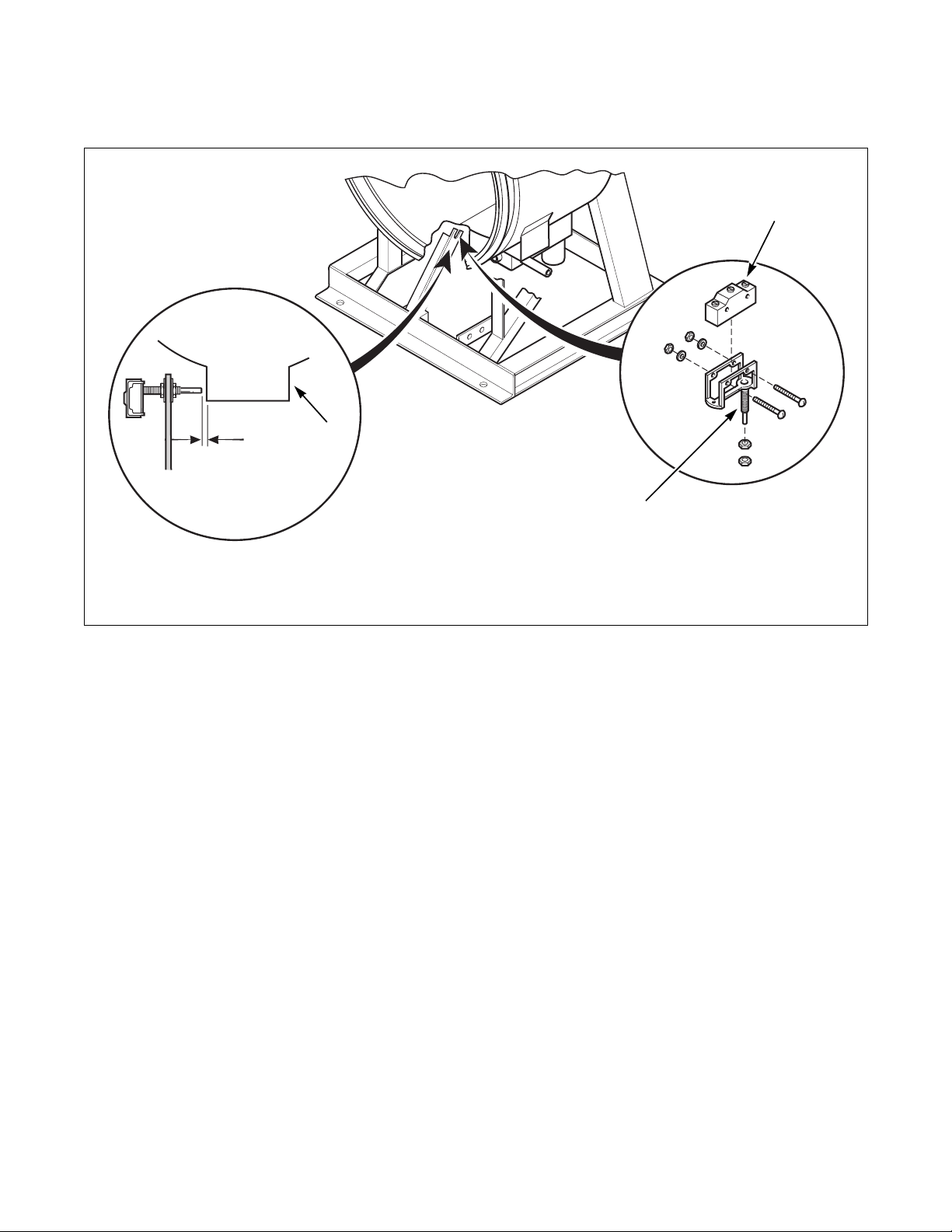

NOTE: For 80 and 125 pound models, a

bolt-locator fixture or rebar frame is available as

an option. This is designed to be embedded in

concrete. Refer to Figure 10.

IMPORTANT: Do not install any variable-speed

machine on an elevated base frame.

1

2

3

4

Installation

1 Machine Base

2 Mounting Bolt Threads

3 Grouting

4 Bolt-Locator Fixture or Rebar Frame

Figure 10

P035I

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Installation

Refer to Table 3 and Table 4 for static and dynamic

loads on the floor or foundation.

Floor Load Data, 2 Speed Models

Specification 18, 20 25 27, 30 35 40 50 60

Static floor load,

lbs. (kN)

Static pressure,

2

(kN-m2)

lbs-ft

Dynamic load,

lbs. (kN)

Dynamic pressure,

2

(kN-m2)

lbs-ft

Dynamic load

frequency, Hz

Maximum moment

about machine base,

lbs-ft (kN-m)

476

(2.12)

104

(4.96)

296

(1.31)

64.4

(3.08)

549

(2.44)

103

(4.94)

420

(1.87)

79.3

(3.80)

653

(2.90)

106.3

(5.10)

427

(1.90)

69

(3.33)

804

(3.58)

113

(5.41)

581

(2.58)

82

(3.91)

873

(3.88)

123

(5.89)

987

(4.4)

139

(6.7)

1041

(4.63)

117

(5.62)

860

(3.83)

97

(4.64)

8.75 9.00 8.00 7.83 7.80 7.50 7.50

565

(0.769)

832

(1.0)

847

(1.16)

1247

(1.6)

2118

(2.9)

1894

(2.4)

Tabl e 3

1015

(4.53)

115

(5.5)

1418

(6.3)

161

(7.6)

2470

(3.35)

Floor Load Data, Variable-Speed Models

Specification 20303540506080125

Static floor load, lbs. (kN) 513

(2.27)

Static pressure, lbs-ft

2

(kN-m2)112

(5.35)

Dynamic load, lbs. (kN) 512

(2.27)

Dynamic pressure, l

2

(kN-m2)

bs-ft

112

(5.35)

688

(3.01)

112

(5.35)

7.55

(3.36)

123

(5.88)

934

(4.1)

132

(6.3)

979

(4.35)

138

(6.60)

873

(3.88)

123

(5.89)

1123

(5)

158

(7.6)

1136

(5.0)

128

(6.1)

1397

(6.25)

159

(7.5)

914

(4.07)

103

(4.95)

1428

(6.3)

161

(7.6)

1972

(8.8)

144

(6.9)

2243

(9.98)

164

(7.84)

2316

(10.3)

145

(6.93)

3500

(15.5)

364

(17.4)

Dynamic load frequency, Hz 11.5 10.7 10.22 10.2 9.58 9.58 8.73 8.08

Maximum moment about

machine base, lbs-ft (kN-m)

979

(1.33)

1510

(2.05)

2122

(2.7)

2410

(3.3)

3071

(3.9)

3138

(4.25)

5749

(7.2)

11,667

(14.7)

Table 4

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 29

Machine Anchoring

2

Before anchoring the machine, refer to Ta ble 2 to

determine the appropriate method of anchoring for the

machine.

NOTE: Improper installation may void the

warranty. Consult the manufacturer or distributor

before varying from a procedure.

Installation

Direct-to-Finished-Floor Installation

Installing With Expansion Bolts

(2 Speed Models, Fixed-Speed and

A-Control Variable-Speed Models)

NOTE: Expansion bolts are not suitable VNV

machine installations.

1. Verify the floor meets the requirements given in

the Machine Foundation section.

2. Mounting surface should be level and machine

must be properly grouted.

NOTE: If replacing a 35 pound machine with a

40 pound machine, note differences in cabinet size.

Refer to pages 20, 21 and 32.

NOTE: If replacing a 50 pound machine with a

60 pound machine, note differences in cabinet size.

Refer to pages 20, 21 and 32.

3. Use the base of the machine as a template by

positioning the machine in the desired location

and marking the pre-drilled mounting holes on

the floor. Metal templates are available at cost

through Alliance Laundry Systems. Refer to

Table 5 for ordering information.

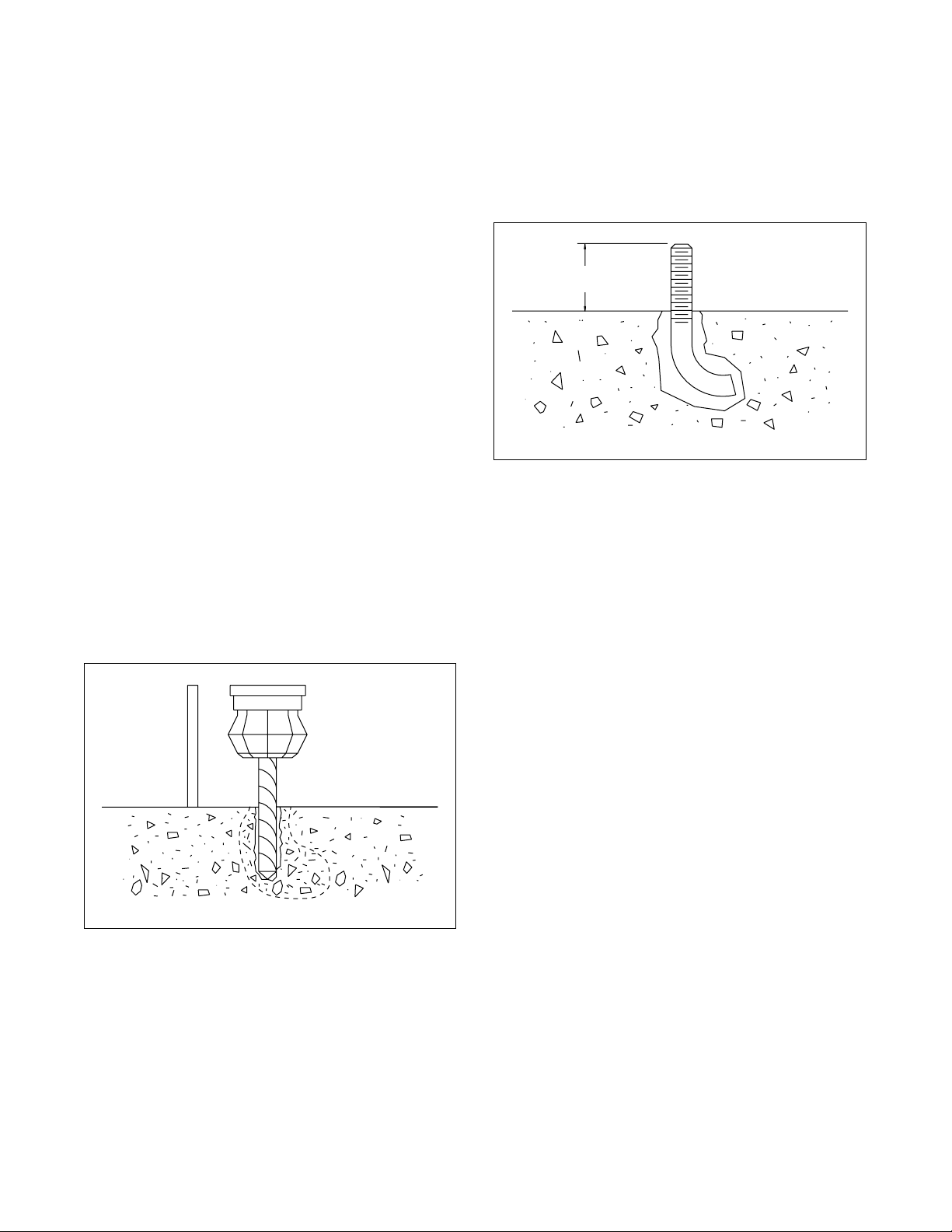

4. Set the drill depth gauge to 2-9/16 inches

(65 mm).

2-9/16 in.

(65 mm)

U137I

U137I

Figure 11

H029I

H029I

Figure 12

The completed expansion bolt installation is shown in

Figure 13.

2

1

3

4

5. Drill the holes to the set depth. Refer to Figure

11.

6. Use compressed air or a squeeze bulb to clean out

each hole.

7. Install the machine anchors, using the included

tool.

8. Secure the machine to the floor, using the bolts

furnished with the anchors. Tighten the locknuts

by even increments – one after the other – until

all are tightened evenly and the machine is

fastened securely to the floor. Refer to Figure 12.

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

2-9/16 in.

(65 mm)

CHM203

CHM2032N

1 Washer

2 Locknut

3 Machine Base

4 5/8 in. (19 mm) Diameter Expansion Bolt

Figure 13

27

Page 30

Installation

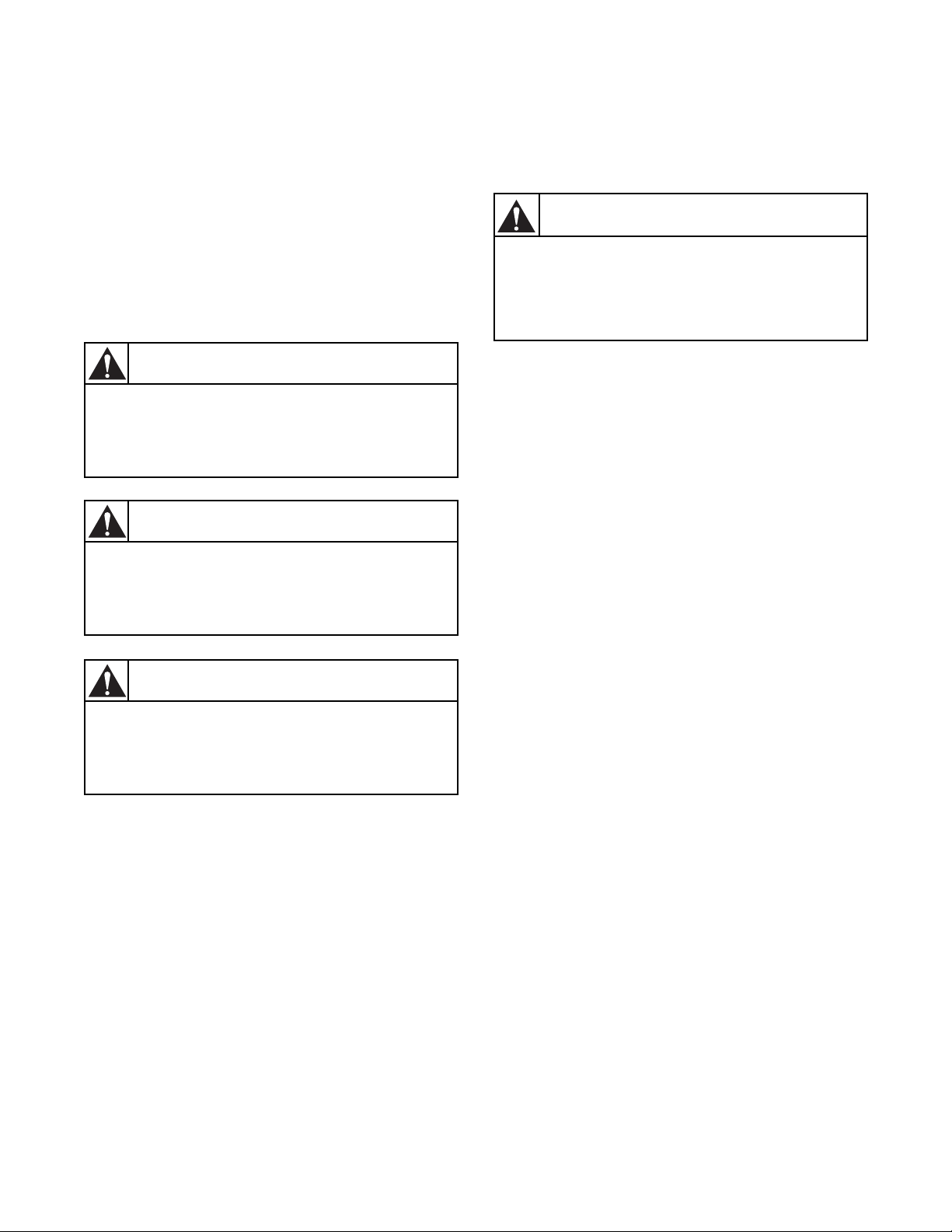

Installing With J-Bolts

1. Verify the floor meets the requirements given in

the Machine Foundation section.

2. Install J-bolts in concrete as shown in the

mounting bolt layouts (Figure 18 and Figure 19)

following these instructions.

NOTE: If replacing a 35 pound machine with a

40 pound machine, note differences in cabinet size.

Refer to pages 20, 21 and 32.

NOTE: If replacing a 50 pound machine with a

60 pound machine, note differences in cabinet size.

Refer to pages 20, 21 and 32.

NOTE: There are two different mounting bolt

layouts which may be used for the 80 pound

capacity machine. Refer to Figure 19. The bolt holes

marked “A” are to be used for close mounting –

machines installed with a 1 inch (25.4 mm)

clearance between machines. The bolt holes marked

“B” are to be used for standard mounting –

machines installed with a minimum clearance of

8 inches (203 mm) between machines.

5. Use compressed air or a squeeze bulb to remove

debris from each hole. Anchor J-bolt in place,

using an industry-accepted anchoring compound.

Verify that the J-bolts are in the correct locations

and that 1-1/2 inches (38 mm) of each J-bolt

protrude from the floor. Refer to Figure 15.

1-1/2 in.

(38 mm)

H032I

Figure 15

6. Place the machine carefully over the J-bolts.

Never attempt to lift the machine by the door

handle or by pushing on the cover panels.

3. Adjust the drill depth gauge to match the length

of the J-bolt, minus 1-1/2 inches (38 mm).

4. Drill and chisel out a conical hole large enough to

accept the J-bolt. Refer to Figure 14.

H031I

H031I

Figure 14

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 31

7. If grouting is not desired, position washers and

locknuts on J-bolts and tighten the locknuts by

even increments – one after the other – until all

are tightened evenly and the machine is fastened

securely to the floor. Refer to Figure 16.

8. If grouting is desired (or required by the

condition of the mounting surface), proceed

to step 11.

9. If the machine is a variable-speed model, the

machine must be grouted. Proceed to step 11.

Installation

10. Raise and level the machine 1/2 inch (13 mm) off

the floor on three points, using spacers such as

nut fasteners.

11. Fill the space between the machine base and the

floor with a good quality non-shrinking

machinery grout to ensure a stable installation.

Grout completely under all frame members.

12. Remove the spacers carefully, allowing the

machine to settle into the wet grout.

13. Before grout sets completely, make a drain

opening in the rear of the machine grouting with

a stiff piece of wire. This opening should be

approximately 1/2 inch (13 mm) wide to allow

any surface water build-up under the base of the

machine to drain away. Do not omit this step.

14. Position washers and locknuts on J-bolts and

fingertighten nuts to machine base.

15. After the grout is completely dry, tighten the

locknuts by even increments – one after the

other – until all are tightened evenly and the

machine is fastened securely to the floor.

16. Balance Switch Adjustment: After mounting,

reset balance switch to the correct gap switch

setting. Refer to Table 1 .

NOTE: Be sure to recheck the J-bolts 1 week after

installation.

H033I

H033I

Figure 16

Figure 17 shows the completed J-bolt installation with

grout.

2

1

1-1/2 in.

(38 mm)

1 Foundation

2 Locknut

3 Machine Base

4 1/2 in. (13 mm) Machinery Grout

5 J-Bolt

3

Figure 17

4

5

U139I

U139I

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Installation

Mounting Bolt Template Part

Numbers (Without Elevated Base

Frame)

Metal templates are available at cost through Alliance

Laundry Systems at (920) 748-3121. Refer to Tabl e 5

for specific Part Numbers when ordering.

Machine Part No.

18/20 F608707

25 F608708

27/30 F631796

35 F608709

40 F0637047-00

50/60 F608710

80 F609692

125 F601862

Table 5

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 33

Mounting Bolt Hole Locations (Without Elevated Base Frames)

26 in.

(660 mm)

26 in.

(660 mm)

Installation

2.68 in.

(68 mm)

31.75 in.

23.94 in.

(608 mm)

2.56 in.

0.75 in.

(19 mm)

(65 mm)

2.75 in.

(70 mm)

28.94 in.

(735 mm)

18.44 in.

(468 mm)

(806 mm)

20.88 in.

(530 mm)

18 AND 20 POUND

29 in.

(737 mm)

23.5 in.

(597 mm)

37.52 in.

(953 mm)

30.02 in.

(762 mm)

26 in.

2.56 in.

(65 mm)

2.75 in.

(70 mm)

(660 mm)

0.75 in.

(19 mm)

31.5 in.

(800 mm)

36 in.

27.94 in.

(710 mm)

2.56 in.

(65 mm)

3.28 in.

(83 mm)

(914 mm)

18.31 in.

(465 mm)

24.07 in.

(611 mm)

20.66 in.

(525 mm)

34.88 in.

(885 mm)

25 POUND

(700 mm)

(1191 mm)

27.69 in.

(705 mm)

20.88 in.

(530 mm)

34.06 in.

(865 mm)

27.5 in.

46.88 in.

37.44 in.

(951 mm)

2.68 in.

(68 mm)

3.28 in.

(83 mm)

30 in.

(762 mm)

2.56 in.

(65 mm)

37.5 in.

(953 mm)

0.75 in.

2.56 in.

(65 mm)

(19 mm)

23.88 in.

(607 mm)

27 AND 30 POUND

2.56 in.

(65 mm)

0.75 in.

(19 mm)

2.03 in.

(52 mm)

*For close mounting, use mounting bolt pattern labeled “A”; for standard mounting, use “B.”

Figure 18

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

30 in.

(760 mm)

50 POUND

2.03 in.

(52 mm)

CHM2020N

31

Page 34

Installation

Mounting Bolt Hole Locations (Without Elevated Base Frames)

34.06 in.

(865 mm)

17 in.

(432 mm)

28.5 in.

(724 mm)

32.5 in.

0.75 in.

4 in.

(102 mm)

5 in.

(127 mm)

0.75 in.

(19 mm)

4 in.

(102 mm)

36 in.

0.75 in.

(826 mm)

(19 mm)

3.28 in.

(83 mm)

(914 mm)

24.07 in.

2.03 in.

(52 mm)

(19 mm)

3.25 in.

(83 mm)

20 in.

(508 mm)

2.06 in.

(52 mm)

(611 mm)

27.5 in.

(700 mm)

46.88 in.

(1191 mm)

60 POUND

23.63 in.

(600 mm)

41.63 in.

(1057 mm)

35 POUND

33.5 in.

(851 mm)

A A

B B

B B

40 in.

(1016 mm)

31.5 in.

(800 mm)

37.44 in.

(951 mm)

30 in.

(760 mm)

30.13 in.

(765 mm)

31.88 in.

(810 mm)

26 in.

(660 mm)

AA

AAB B

3.28 in.

(83 mm)

CHM2005N

3.25 in.

(83 mm)

2.06 in.

(52 mm)

4 in.

(102 mm)

5 in.

(127 mm)

0.75 in.

(19 mm)

4 in.

(102 mm)

37.5 in.

2.03 in.

(52 mm)

CHM2005N

34 in.

(864 mm)

1 in.

(25 mm)

9.5 in.

(241 mm)

11 in.

(279 mm)

25 in.

(635 mm)

(953 mm)

47.5 in.

(1207 mm)

32.5 in.

(826 mm)

1.5 in.

(38 mm)

48 in.

(1219 mm)

20 in.

(508 mm)

0.75 in.

(19 mm)

41.63 in.

(1057 mm)

23.63 in.

(600 mm)

31.88 in.

(810 mm)

26 in.

(660 mm)

30.13 in.

(765 mm)

40 POUND

46.5 in.

(1181 mm)

61.5 in.

(1562 mm)

55.47 in.

(1409 mm)

48.94 in.

(1243 mm)

3.25 in.

(83 mm)

(914 mm)

36 in.

2.06 in.

(52 mm)

0.75 in.

(19 mm)

10 in.

(254 mm)

(381 mm)

15.25 in.

(388 mm)

15 in.

1 in.

(25 mm)

33.5 in.

(851 mm)

41.5 in.

(1054 mm)

23.25 in.

(591 mm)

(1219 mm)

80 POUND* 125 POUND

*For close mounting, use mounting bolt pattern labeled “A”; for standard mounting, use “B.”

Figure 19

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

48 in.

23.25 in.

(591 mm)

0.75 in.

(19 mm)

CHM2018N

F232135

Page 35

Mounting Bolt Hole Locations (With Elevated Base Frames)

26.4 in.

2.87 in.

(73 mm)

(670 mm)

2.87 in.

(73 mm)

26.4 in.

(670 mm)

Installation

23.94 in.

(608 mm)

2.75 in.

1.13 in.

(29 mm)

(70 mm)

(75 mm)

28.94 in.

(735 mm)

14.31 in.

(363 mm)

2.94 in.

18.44 in.

31.75 in.

(806 mm)

(530 mm)

18 AND 20 POUND

(597 mm)

(468 mm)

20.66 in.

(525 mm)

25.22 in.

(640 mm)

20.88 in.

29.4 in.

(747 mm)

23.5 in.

37.52 in.

(953 mm)

30.02 in.

(762 mm)

26.2 in.

2.75 in.

(70 mm)

2.94 in.

(75 mm)

2.87 in.

(73 mm)

27.94 in.

(665 mm)

1.13 in.

(29 mm)

31.2 in.

(792 mm)

(710 mm)

18.31 in.

(465 mm)

2.75 in.

(70 mm)

3.44 in.

(87 mm)

32.5 in.

(826 mm)

20 in.

(508 mm)

20.66 in.

(525 mm)

34.88 in.

(885 mm)

25 POUND

(1057 mm)

27.69 in.

(705 mm)

20.88 in.

(530 mm)

30.5 in.

(775 mm)

23.63 in.

(600 mm)

41.63 in.

31.88 in.

(810 mm)

2.87 in.

(73 mm)

3.44 in.

(87 mm)

30.2 in.

(767 mm)

2.75 in.

(70 mm)

34.75 in.

(883 mm)

2.75 in.

(70 mm)

1.13 in.

(29 mm)

2.25 in.

(57 mm)

1.13 in.

2.75 in.

(70 mm)

(29 mm)

23.88 in.

(607 mm)

27 AND 30 POUND

*For close mounting, use mounting bolt pattern labeled “A”; for standard mounting, use “B.”

Figure 20

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

26 in.

(660 mm)

35 POUND

2.25 in.

(57 mm)

CHM2021N

CHM2021N

33

Page 36

Installation

Mounting Bolt Hole Locations (With Elevated Base Frames)

32.5 in.

(826 mm)

2.38 in.

(61 mm)

20 in.

(508 mm)

3.47 in.

(88 mm)

3.62 in.

(92 mm)

36 in.

(914 mm)

2.44 in.

(62 mm)

3.47 in.

(88 mm)

36 in.

(914 mm)

24 in.

(610 mm)

2.22 in.

(56 mm)

1.13 in.

(29 mm)

27.5 in.

(700 mm)

46.88 in.

(1191 mm)

41.63 in.

(1057 mm)

23.63 in.

(600 mm)

31.88 in.

(810 mm)

26 in.

(660 mm)

30.88 in.

(784 mm)

40 POUND 50 POUND

34.5 in.

(876 mm)

27.5 in.

(700 mm)

3.47 in.

(88 mm)

34.5 in.

(876 mm)

37.44 in.

(951 mm)

30 in.

(762 mm)

3.47 in.

(88 mm)

38.25 in.

2.22 in.

(56 mm)

(972 mm)

46.88 in.

(1191 mm)

36 in.

(914 mm)

24 in.

(610 mm)

2.22 in.

(56 mm)

2.13 in.

(54 mm)

37.44 in.

(951 mm)

30 in.

(762 mm)

60 POUND

38.9 in.

2.22 in.

(56 mm)

(988 mm)

*For close mounting, use mounting bolt pattern labeled “A”; for standard mounting, use “B.”

Figure 21

CHM2022N

CHM2022N

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 37

Installation

Elevated Base Frame Installation

Factory-built elevated steel base frames are designed

to meet the specifications of the 20-60 2 speed,

F speed and A-control variable-speed model washerextractor only. Refer to Figure 22.

3. Adjust the drill depth gauge to match the length

of the J-bolt, minus 1-1/2 inches (38 mm).

4. Drill and chisel out a conical hole large enough to

accept the J-bolt. Refer to Figure 23.

H031I

H031I

Figure 23

5. Use compressed air or a squeeze bulb to remove

debris from each hole. Anchor J-bolt in place,

using an industry-accepted anchoring compound.

Verify that the J-bolts are in the correct locations

and that 1-1/2 inches (38 mm) of each J-bolt

protrude from the floor. Refer to Figure 24.

Figure 22

Installing With Elevated Base Frame

1. Verify the floor meets the requirements given in

the Machine Foundation section.

2. Use the elevated base frame as a template by

positioning the frame in the desired location and

marking the pre-drilled mounting holes on the

floor.

H035I

1-1/2 in.

(38 mm)

H032I

Figure 24

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

Installation

6. Raise and level the base frame 1/2 inch (13 mm)

off the floor on three points, using spacers such

as nut fasteners.

7. Fill the space between the frame base and the

floor with a good quality non-shrinking

machinery grout to ensure a stable installation.

Grout completely under all frame members.

8. Remove the spacers carefully, allowing the base

frame to settle into the wet grout.

9. Before grout sets completely, make a drain

opening in the rear of the base frame grouting

with a stiff piece of wire. This opening should be

approximately 1/2 inch (13 mm) wide to allow

any surface water build-up under the base of the

machine to drain away. Do not omit this step.

10. Position washers and locknuts on J-bolts and

fingertighten nuts to base frame.

11. After the grout is completely dry, tighten locknuts

by even increments – one after the other – until

all are tightened evenly and the base frame is

fastened securely to the floor. Refer to Figure 16.

12. Position the machine over the base frame, aligning

the mounting holes on the machine with the

corresponding holes on the frame.

13. Install a bolt, lockwasher, and nut in each

mounting hole. Use 5/8 inch – 18 x 2

grade 5 mounting bolts with 5/8 inch – 18

grade B nuts and 5/8 inch lockwashers.

14. Handtighten each nut.

15. Tighten the two rear nuts two turns.

16. Tighten the two front nuts two turns.

17. On 25, 27, 30, 35, 40, 50 and 60 models, tighten

the two middle nuts firmly.

18. Tighten the two front nuts firmly; tighten the two

rear nuts firmly.

NOTE: Recheck the elevated base frame

installation one week after installation.

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 39

Installation

Concrete Foundation Installation

A concrete foundation pad may be constructed to

elevate the machines. Refer to Figure 25, Figure 26 or

Figure 27 for a typical concrete foundation

installation.

NOTE: Expansion bolts should not be used in

single-machine concrete foundation installations.

1. Verify that the floor meets the requirements given

in the Machine Foundation section.

2. Excavate the floor to a depth of approximately

9 inches (230 mm) below the floor surface,

making certain that the sides of the hole slope

outwards from top to bottom. The bottom of the

hole should be 6 inches (152 mm) larger all

around than the top.

NOTE: When installation is complete, the top

of the foundation should extend a minimum of

4 inches (102 mm) out from the machine on all

sides.

3. Wet the hole well and brush the bottom and sides

with cement grout.

2

1

18, 20, 25, 27, 30, 35, 40, 50 AND 60 POUND CAPACITY MODELS

1 Pad height must not exceed 8 in. (203 mm)

2 1 in. (25 mm) Minimum

3 4 in. (102 mm) Minimum

3

3

CHM2033N

CHM2033N

Figure 25

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Installation

1

2

LENGTH FOR ONE MACHINE

2

34

2

COMPACTED FILL DIRT 18 in. (457 mm) DEPTH

COMPACTED FILL DIRT 18 in. (457 mm) DEPTH

80 POUND CAPACITY MODELS

1 9 in. (229 mm) 3 47-1/2 in. (1207 mm)

2 6 in. (152 mm) 4 4 ft. 6 in. (1372 mm)

Figure 26

1

2

1

3

1

LENGTH FOR ONE MACHINE

B153I

B153I

4

COMPACTED FILL DIRT 24 in. (609 mm) DEPTH

COMPACTED FILL DIRT 24 in. (609 mm) DEPTH

125 POUND CAPACITY MODELS

1 12 in. (305 mm) 3 48 in. (1219 mm)

2 6 in. (152 mm) 4 6 ft. (1829 mm)

Figure 27

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

B154I

B154I

F232135

Page 41

Installation

4. Use rebar or other appropriate material to ensure

that the concrete foundation will be sufficiently

connected to the existing floor.

5. If desired, prepare a form for the above-ground

portion of the foundation and fill form and

excavation with concrete to join the foundation.

Verify that top of foundation is level. The height

of the foundation must not exceed 8 inches

(203 mm).

6. Use the mounting bolt layout to properly position

the mounting bolts in the wet concrete. When

using J-bolts, allow 1-1/2 inches

(38 mm) to extend above the surface of the

concrete.

7. Allow concrete to dry.

8. Place the machine carefully over the mounting

bolts. Never attempt to lift the machine by the

door handle or by pushing on the cover panels.

NOTE: Grouting provides a uniform mounting

surface. Grouting is optional for 2 speed models

and is required for variable-speed models installed

on a concrete foundation. If grouting is not

required, proceed to step 13.

9. Raise and level the machine 1/2 inch (13 mm) off

the foundation on three points, using spacers

such as nut fasteners.

10. Fill the space between the machine base and the

foundation with a good quality non-shrinking

machinery grout to ensure a stable installation.

Grout completely under all frame members.

11. Remove the spacers carefully, allowing the

machine to settle into the wet grout.

12. Before grout sets completely, make a drain

opening in the rear of the machine grouting with

a stiff piece of wire. This opening should be

approximately 1/2 inch (13 mm) wide to allow

any surface water build-up under the base of the

machine to drain away. Do not omit this step.

13. Position washers and locknuts on J-bolts or

mounting bolts and fingertighten nuts to machine

base.

14. After the grout is completely dry, tighten the

locknuts by even increments – one after the

other – until all are tightened evenly and the

machine is fastened securely to the concrete

foundation.

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

Installation

Drain Connection

Use the supplied black rubber adapter and clamps to

transition from the machine drain outlet to the two

Figure 28 and Figure 29 show typical drain trough and

drain line installations.

Connect the drain outlet to a vented drain system using

only a flexible connection. The drain system must be

vented to prevent an air lock or siphoning.

inch schedule 40 PVC plumbing (20, 25 and 30

models) and the three inch schedule PVC plumbing

(40, 60 and 80 models).

If proper drain size is not available or practical, a surge

tank is required. A surge tank along with a sump pump

should be used when gravity drainage is not possible,

such as in below-ground-level installations.

DRAIN TROUGH

2

1

1 Drain Hose 4 Drain Tee

2 Drain Valve 5 Floor

3 Overflow Hose 6 Open Drain Trough

3

4

5

6

H050I

H050I

Figure 28

4

6*

1 ft.

(0.3 m)

3

DRAIN LINE

2

1

1 Drain Hose 4 Overflow Hose

2 Drain Valve 5 Vent Pipe

3 Drain Tee 6 Water Inlet Valve*

* 1 foot (0.3 m) minimum between water inlet valve and vent pipe.

Figure 29

5*

CHM2010N

40

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232135

Page 43

Installation

IMPORTANT: Increasing the drain hose length,

installing elbows, or causing bends will decrease

drain flow rates and increase drain times,

impairing machine performance.

Drain Information

18, 20 25 27, 30 35 40 50 60 80 125

Drain connection

size, OD

Number of drain

outlets

Drain flow

capacity

Recommended

drain pit size

* Also works with 3 inch OD PVC pipe if connected to inside of

drain tee connector.

2.38 in.

(60 mm)

111111111

20 gal-min

(76 l-min)

1.80 ft

(51 l)

3

2.38 in.

(60 mm)

25 gal-min

(95 l-min)

3

2.36 ft

(66.8 l)

2.38 in.

(60 mm)

25 gal-min

(95 l-min)

3

2.50 ft

(70.3 l)

2.38 in.

(60 mm)

35 gal-min

(132 l-min)

3.14 ft

(88.9 l)

Drain Line Sizing

Minimum Drain ID

Refer to Table 6 for capacity-specific drain

information.

NOTE: Installation of additional machines will

require larger drain connections. Refer to Table 7.

3

Table 6

3.5 in.*

(89 mm)

50 gal-min

(189 l-min)

4.52 ft

(128 l)

3

3.5 in.*

(89 mm)

50 gal-min

(189 l-min)

3

4.52 ft

(128 l)

3.5 in.*

(89 mm)

50 gal-min

(189 l-min)

3

4.52 ft

(128 l)

3.5 in.*

(89 mm)

50 gal-min

(189 l-min)

5.90 ft

(169 l)

3

3.5 in.*

(89 mm)

70 gal-min

(265 l-min)

3

13 ft

(368 l)

Model

18, 20

25

27, 30

35

40

50

60

80, 125

Number of Machines

12345

2

in. (52 mm) 3 in. (76 mm) 3 in. (76 mm) 4 in. (102 mm) 4 in. (102 mm)

2

in. (52 mm) 3 in. (76 mm) 3 in. (76 mm) 4 in. (102 mm) 4 in. (102 mm)

2

in. (52 mm) 3 in. (76 mm) 3 in. (76 mm) 4 in. (102 mm) 4 in. (102 mm)

in. (76 mm) 3 in. (76 mm) 3-1/2 in. (89 mm) 4 in. (102 mm) 4 in. (102 mm)

3

in. (76 mm) 4 in. (102 mm) 4 in. (102 mm) 4 in. (102 mm) 6 in. (152 mm)

3

3

in. (76 mm) 4 in. (102 mm) 4 in. (102 mm) 4 in. (102 mm) 6 in. (152 mm)

3

in. (76 mm) 4 in. (102 mm) 4 in. (102 mm) 4 in. (102 mm) 6 in. (152 mm)

3

in. (76 mm) 4 in. (102 mm) 4 in. (102 mm) 6 in. (152 mm) 6 in. (152 mm)

Table 7

F232135

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

Installation

Water Connection Requirements

Connections should be supplied by a hot and a cold

water line of at least the sizes shown in Table 8.

Installation of additional machines will require

proportionately larger water lines.

To connect water service to machine with rubber

hoses, use the following procedure:

1. Before installing hoses, flush the water system

for at least 2 minutes.

2. Check filters in the machine’s inlet hoses for

proper fit and cleanliness before connecting.

3. Hang hoses in a large loop; do not allow them to

kink.

If additional hose lengths are needed, use flexible

hoses with screen filters.

Model

18 – 60

80

125

Water Supply Line Sizing

Number

of

Machines

13/4 in. (19 mm) 1/2 in. (13 mm)

21

31-1/4

41-1/2

11 in. (25 mm) 3/4 in. (19 mm)

21-1/2

32

42

11-1/2 in. (38 mm) 1 in. (25 mm)

22

32

42-1/2

Supply Line Size

Main Hot/Cold

in. (25 mm) 3/4 in. (19 mm)

in. (32 mm) 1 in. (25 mm)

in. (38 mm) 1 in. (25 mm)

in. (38 mm) 1 in. (25 mm)

in. (50 mm) 1-1/4 in. (32 mm)

in. (50 mm) 1-1/2 in. (38 mm)

in. (50 mm) 1-1/2 in. (38 mm)

in. (50 mm) 2 in. (50 mm)

in. (70 mm) 2 in. (50 mm)

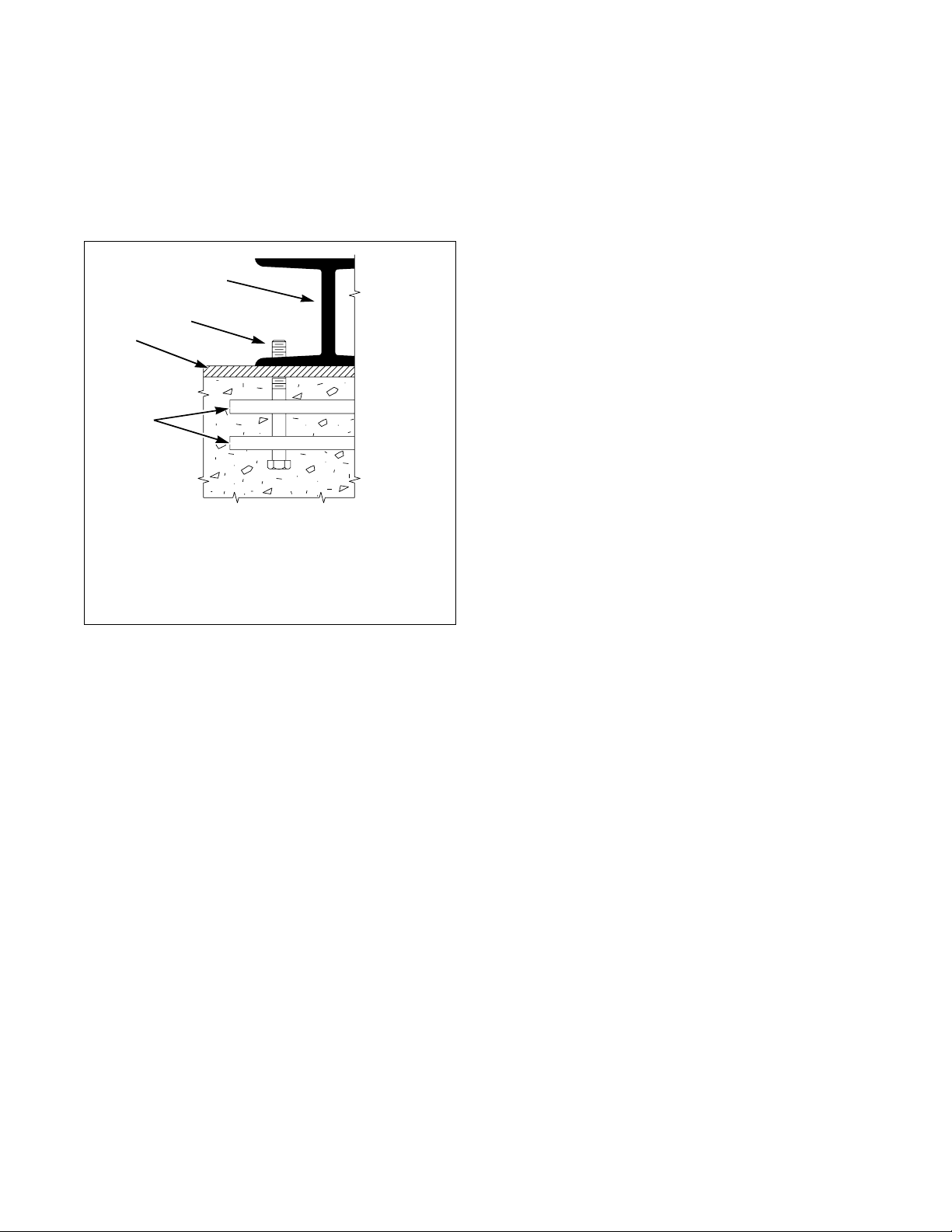

Suitable air cushions should be installed in supply

lines to prevent “hammering.” Refer to Figure 30.

2

1

MW008J

1 Water Supply Faucets

2 Air Cushions (Risers)