Page 1

Automatic

Washers

Home Laundry

Installation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

W001C

W001C

Part No. 38900R8

April 2007

Page 2

Page 3

Table of

Contents

Replacement Parts .............................................................................. 3

Installation........................................................................................... 5

Roughing in Dimensions ...................................................................... 5

Before You Start ................................................................................... 6

Tools ................................................................................................ 6

Electrical .......................................................................................... 6

Water................................................................................................ 6

Installing the Washer ............................................................................ 7

Step 1: Remove the Shipping Brace and Shipping Plug.................. 7

Step 2: Wipe Out Inside of Washtub ............................................... 7

Step 3: Connect Fill Hoses............................................................... 8

Step 4: Connect Drain Hose to Drain Receptacle ............................ 9

Step 5: Position and Level the Washer ............................................ 12

Step 6: Connect the Washer to Electrical Power ............................. 13

Step 7: Add Water to the Washer .................................................... 13

Step 8: Check Lid Switch ................................................................ 13

Step 9: Check Installation ................................................................ 13

Electrical Requirements........................................................................ 14

120 Volt, 60 Hertz, With 3 Prong Grounding Plug ......................... 14

120 Volt/50 Hertz ............................................................................ 15

240 Volt/50 Hertz ............................................................................ 15

230 Volt/50 Hertz ............................................................................ 15

240 Volt/60 Hertz ............................................................................ 15

Earthing (Grounding) Instructions................................................... 15

Water Supply Requirements................................................................. 17

Water Temperature .......................................................................... 17

Water Pressure ................................................................................. 17

Risers................................................................................................ 18

Installer Checklist................................................................ Back Cover

© Copyright 2007, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 5

Replacement Parts

If replacement parts are required, contact the source

from which you purchased your washer, or contact:

Alliance Laundry Systems

Shepard Street

P.O . Bo x 99 0

Ripon, WI 54971-0990

Phone: (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Notes

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT 38900

Page 7

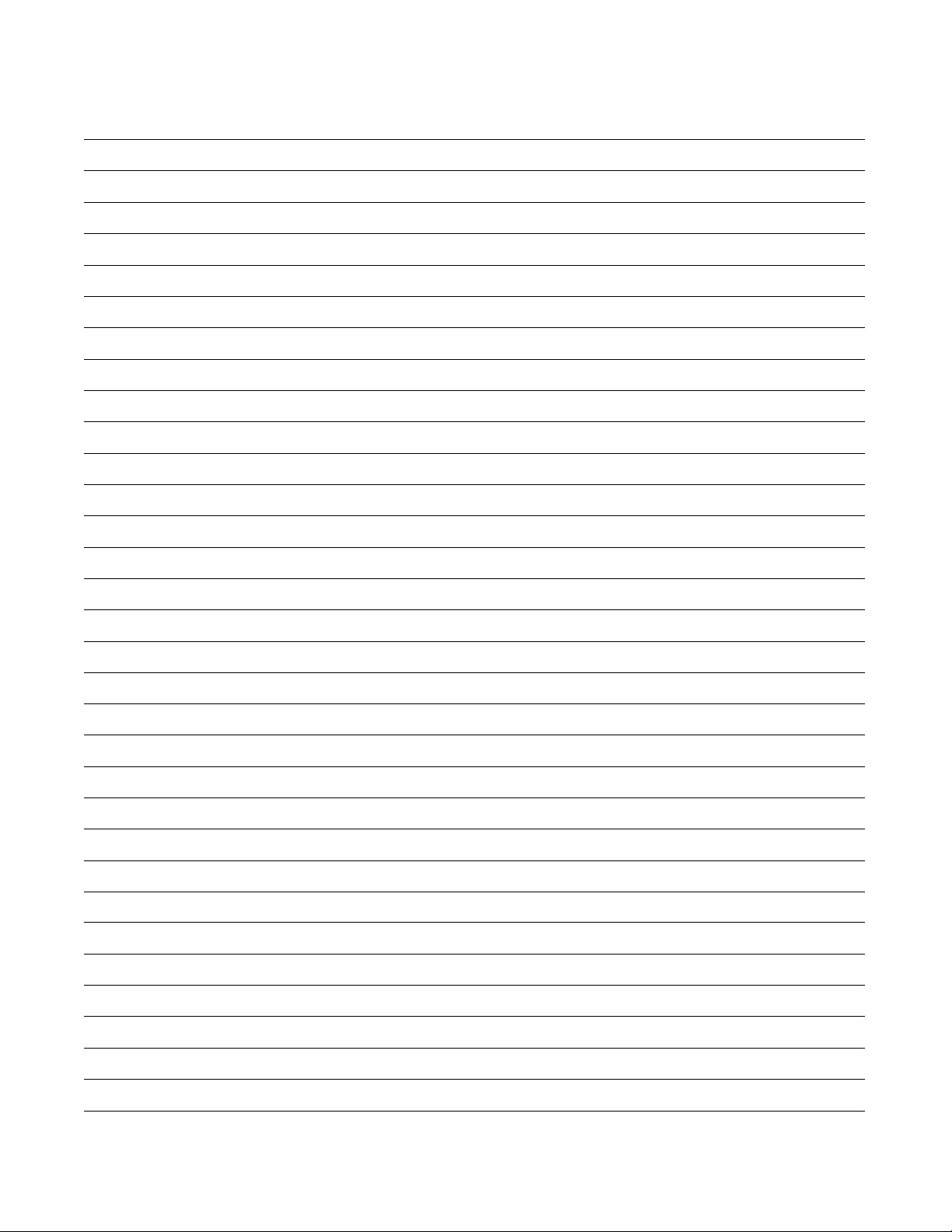

Roughing in Dimensions

Installation

71.1 cm

56.2 cm

(22.13 in.)

(28 in.)

*134.6 cm (53 in.)

65 cm

(25.6 in.)

*With leveling legs turned into base.

*73.7 cm (29 in.)

*109.2 cm (43 in.)

1 cm

(0.4 in.)

*102.2 cm (40.25 in.)

*91.4 cm (36 in.)

66 cm

(26 in.)

TLW2075N

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Installation

Before You Start

Tools

For most installations, the basic tools you will need

are:

2

1

1 Wrench

2 Screwdriver

3 Pliers

4 Level

3

4

D074I

Electrical

Refer to serial plate for specific electrical

requirements. For more detailed information, refer to

section on Electrical Requirements.

Water

Washer needs two standard 19.1 mm (3/4 inch) water

supply faucets with a pressure between 138 and

827 kPa (20 to 120 pounds per square inch). For more

detailed information, refer to section on Water Supply

Requirements.

Figure 1

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 9

Installation

Installing the Washer

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

Step 1: Remove the Shipping Brace and Shipping Plug

NOTE: Install dryer before washer. This allows

room for attaching exhaust duct.

Remove the shipping brace from under the lid. The

plastic shipping plug will be released from the base of

the washer when removing the cardboard base from

the washer.

Step 2: Wipe Out Inside of Washtub

Prior to first wash, use an all purpose cleaner, or a

detergent and water solution, and a damp cloth to

remove shipping dust from inside of washtub.

W371I

Figure 3

1

2

TLW521N

1 Shipping Brace

2 Shipping Plug

Figure 2

NOTE: Do not tilt washer to front or sides when

moving.

The shipping brace and plug should be saved and must

be reinstalled whenever washer is moved or

transported to a new location. This will prevent

damage to washer components.

NOTE: Refer to your Operating Instructions for

reinstalling shipping brace and shipping plug.

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Installation

C

H

Step 3: Connect Fill Hoses

NOTE: Refer to section on Water Supply

Requirements before connecting fill hoses.

The appliance is to be connected to the water mains

using new hose-sets and old hose-sets should not be

reused.

Turn on the water supply faucets and flush the lines for

approximately two minutes to remove any foreign

materials that could clog the screens in the water

mixing valve.

NOTE: When installing in newly constructed or

renovated building, it is very important to flush the

lines since build-up may have occurred during

construction.

Remove the two plain rubber washers and two filter

screens from accessories bag, and install them

according to Figure 4.

NOTE: Check filter screens for debris or damage

annually. Clean or replace them if necessary.

IMPORTANT: Thread hose couplings onto valve

connections finger-tight, then approximately 1/4

turn with pliers. DO NOT cross thread or

overtighten couplings.

Turn water on and check for leaks. If leaks are found,

retighten the hose couplings. Continue tightening and

rechecking until no leaks are found.

1

COLD

HOT

8

7

1 Filter Screen (Screen must be facing

outward)

2 Fill Hose

3 Rubber Washer (Plain)

4 Cold Water Connection

5 Hot Water Connection

6 Install this end of hose to valve connections

at rear of washer.

7 Install this end of hose to water supply

faucet. (Black colored coupling for metric)

8 Faucet

3

2

5

6

4

TLW1988N

Figure 4

IMPORTANT: Hoses and other natural rubber

parts deteriorate after extended use. Hoses may

develop cracks, blisters or material wear from the

temperature and constant high pressure they are

subjected to.

All hoses should be checked on a yearly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately. All hoses should be replaced

every 5 years.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 11

Installation

Step 4: Connect Drain Hose to Drain Receptacle

Remove the drain hose from its shipping position on

the rear of the washer by unhooking the hose from the

retainer clamp.

Find the instructions, on the following pages, that are

appropriate for your type of drain receptacle

(standpipe, high standpipe, low standpipe, sink, wall,

or laundry tub). Follow these instructions to properly

install the drain hose.

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 3.2 cm (1-1/4 inch) outside

diameter drain hose.

12

Standpipe Installation:

Place the hose into the standpipe.

Remove the beaded tie-down strap from accessories

bag and place around standpipe and drain hose,

approximately 30 cm (12 inches) down from the top of

pipe and tighten strap to hold hose to standpipe. This

will prevent the drain hose from dislodging from drain

receptacle during use.

IMPORTANT: To prevent siphoning, do not place

any ribbed portion of the drain hose into the

standpipe.

1

2

5

30 cm

(12 in.)

19.44 cm

(36 in.)

RECOMMENDED

HEIGHT

1 Retainer Clamp

2 Standpipe Adapter

Figure 5

W324I

4

1 Ribbed Portion of Drain Hose

2 Standpipe Adapter

3 Tie-Down Strap

4 Standpipe 5.08 cm (2 in.) or 4 cm (1-1/2 in.)

Diameter

5 Drain Hose Sleeve

3

TLW1961N

TLW1961N

Figure 6

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation

High Standpipe Installation:

Place the hose into the standpipe. Remove the beaded

tie-down strap from accessories bag and place around

standpipe and drain hose, approximately 30 cm

(12 inches) down from the top of pipe and tighten

strap to hold hose to standpipe. This will prevent the

drain hose from dislodging from drain receptacle

during use.

1

4

3

TLW1962N

2

TLW1962N

1 Drain Hose

2 Standpipe (Standpipes higher than 122 cm

[4 feet] are not recommended)

3 Tie-Down Strap

4 Standpipe Adapter

Low Standpipe Installation:

No. 562P3 Siphon Break Kit is required for this type

of installation. This kit is available (as optional

equipment at extra cost) through an authorized dealer

or parts distributor. Installation instructions are

supplied with the kit.

1

3

W512I

2

W512I

1 562P3 Siphon Break Kit

2 Standpipe

3 Drain Hose

Figure 8

10

Figure 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 13

Installation

Sink Installation:

For this type of installation, use the beaded tie-down

strap (supplied in accessories bag), or use a large wire

tie (available from your local hardware store) and

secure the drain hose to the cabinet top hinge. Refer to

Figure 9. This will prevent the drain hose from

dislodging during use.

1

1 Drain Hose

2 Tie-Down Strap or Wire Tie

3 Cabinet Top Hinge

2

3

TLW1963N

In the Wall Installation:

For installations of this type, the drain hose MUST be

secured to one of the inlet hoses using the beaded tiedown strap from accessories bag.

NOTE: End of drain hose must not be below height

of cabinet top.

1

2

W329I

1 Tie-Down Strap (Tape if necessary)

2 Standpipe Adapter

Figure 10

Figure 9

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Installation

Laundry Tub Installation:

For this type of installation, the drain hose MUST be

secured to the stationary tub to prevent hose from

dislodging during use. Use the beaded tie-down strap

(supplied in accessories bag) to secure hose.

1

TLW1964N

1 Tie-Down Strap (Tape if necessary)

Step 5: Position and Level the Washer

Position washer so it has sufficient clearance for

installation and servicing.

Place rubber feet on all four leveling legs.

Place washer in position on a clean, dry, and

reasonably firm floor. Installing the washer on any

type of carpeting is not recommended.

Loosen 7/8 inch locknuts and adjust the two front

leveling legs. Once adjusted, tilt the unit forward on

front legs and lower back down into position to set the

rear self-leveling legs.

Washer must not rock. After washer is at desired

height, tighten locknuts securely against bottom of

washer base. If these locknuts are not tight, washer

will not remain stationary during operation.

Improper installation or flexing of a weak floor will

cause excessive vibration.

Do not slide washer across floor once the leveling legs

have been extended, as legs and base could become

damaged.

Figure 11

Verify that washer doesn’t rock.

1

5

2

4

3

W179I

1 Level

2 Locknut

3 Leveling Leg

4 Rubber Cup

5 Washer Base

12

Figure 12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 15

Installation

Step 6: Connect the Washer to Electrical Power

Refer to section on Electrical Requirements and

connect the washer to an electrical power source.

D254I

D254I

Figure 13

Step 7: Add Water to the Washer

To prevent damage to pump, do not run washer before

adding at least one quart water to the tub. If the washer

is run before any water is added, the pump seal may

overheat causing the pump to leak. Once installed, the

water retained in the drain system from the previous

cycle will provide sufficient cooling to prevent pump

seal damage.

Step 8: Check Lid Switch

Washer should stop agitating and spinning when lid is

opened.

W376IE0A

W376I

Figure 15

Step 9: Check Installation

Refer to Installer Checklist on the back cover of this

manual and make sure that washer is installed

correctly.

NOTE: The agitator should not be removed except

for service. The washtub is designed to be selfcleaning.

W391I

W391I

Figure 14

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Installation

Electrical Requirements

NOTE: The wiring diagram is located in the

control hood.

WARNING

To reduce the risk of fire, electric shock or

personal injury, all wiring and earthing

MUST conform with the latest edition of the

National Electrical Code, ANSI/NFPA 70,

and such local regulations as might apply. It

is the customer’s responsibility to have the

wiring, fuses and circuit breakers checked

by a qualified electrician to make sure your

home has adequate electrical power to

operate the washer.

W129

120 Volt, 60 Hertz, With 3 Prong Grounding Plug

This washer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current), circuit

protected by a 15 ampere fuse, equivalent fusetron or

circuit breaker.

The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 110/120 Volts

AC (alternating current) 15 Amps. Refer to Figure 17

for determining correct polarity of the wall receptacle.

2

1

120 ± 12

V. A. C .

5

3

0 V.A.C.

DO NOT OVERLOAD CIRCUITS DO NOT USE ADAPTER DO NOT USE AN EXTENSION CORD

D009I

D009I

Figure 16

NOTE: Refer to the washer nameplate for proper

voltage and Hertz the washer is designed to operate

on. Refer to Figure 18.

120 ± 12

V.A.C.

4

STANDARD 120 VOLT, 60 HERTZ, 3 WIRE

EFFECTIVELY GROUNDED CIRCUIT

1 L1

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

Figure 17

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT. DO NOT OVERLOAD

CIRCUITS!

D090I

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 17

NOTE: Some models come without an electrical

plug installed. If washer is not hard wired (refer to

Figure 19), a suitable plug that meets local

electrical standards, including earthing

requirements, must be installed. Refer to the

washer nameplate for proper voltage and Hertz the

washer is designed to operate on. Refer to

Figure 18.

Installation

1

WARNING

To reduce the risk of electric shock or fire,

DO NOT use an extension cord or an

adapter to connect the washer to the

electrical power source.

W031

120 Volt/50 Hertz

This washer is designed to be operated on a separate

polarized three-wire, earth (grounded) 120 Volt,

50 Hertz, single-phase electrical circuit protected by a

15 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

240 Volt/50 Hertz

This washer is designed to be operated on a separate

polarized three-wire, earth (grounded) 240 Volt,

50 Hertz, single-phase electrical circuit protected by a

10 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

230 Volt/50 Hertz

W334I

1 Nameplate

Figure 18

240 Volt/60 Hertz

This washer is designed to be operated on a separate

polarized three-wire, grounded 240 Volt, 60 Hertz,

single-phase electrical circuit protected by a

10 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

Earthing (Grounding) Instructions

The washer must be earthed (grounded). In the event

of malfunction or breakdown, earthing will reduce the

risk of electric shock by providing a path of least

resistance for electric current. The washer is equipped

with a cord having an equipment-earthing conductor.

Some models are also equipped with a three-prong

earthing plug. The washer must be plugged or hard

wired into an appropriate power source that is properly

installed and earthed in accordance with all local codes

and ordinances.

This washer is designed to be operated on a separate

polarized three-wire, earth (grounded) 230 Volt,

50 Hertz single-phase electrical circuit protected by a

10 ampere fuse, equivalent fusetron or circuit breaker.

DO NOT OPERATE OTHER APPLIANCES ON

THE SAME CIRCUIT WHEN THE WASHER IS

OPERATING.

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING

Improper connection of the equipmentearthing conductor can result in a risk of

electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is properly

earthed.

W032

Do not modify the plug provided with the washer — if

it will not fit the outlet, have a proper outlet installed

by a qualified electrician.

15

Page 18

Installation

PLUG

W403I W402I

W403I W402I

HARD WIRED

NOTE: Electrical receptacle must be located so that it is easily accessible with machine in place. If machine is hard

wired, an intermediate shut-off box with a 3 mm gap is required to meet EN 60335-1, clauses 24.3 and 22.2 or 3.5 mm

gap is required to meet Standard IEC 60335-1, clauses 24.3 and 22.2. Gap is defined as the minimum contact

separation of each pole in the switch between the “ON” and “OFF” positions.

Figure 19

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 19

Installation

C

H

Water Supply Requirements

WARNING

Under certain conditions, hydrogen gas

may be produced in a hot water system that

has not been used for two weeks or more.

HYDROGEN GAS IS EXPLOSIVE. If the hot

water system has not been used for such a

period and before using the washer, turn on

all hot water faucets and let the water flow

from each for several minutes. This will

release any accumulated hydrogen gas.

The gas is flammable. Do not smoke or use

an open flame during this time.

W029

NOTE: Water supply faucets must fit standard

19.1 mm (3/4 inch) female garden hose couplings.

DO NOT USE SLIP-ON OR CLAMP-ON

CONNECTIONS.

NOTE: Water supply faucets should be readily

accessible to permit turning them off when washer

is not being used.

1

2

Water Temperature

Cold:

Recommended cold water temperature is 10° to

24° Celsius (50° to 75° Fahrenheit).

Hot:

Recommended hot water temperature is 60° to

66° Celsius (140° to 150° Fahrenheit).

Warm :

Mixture of hot and cold water. (Warm water

temperature is dependent upon the water temperature

and the pressure of both the hot and cold water supply

lines.)

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should turn

off water supply whenever there will be an

extended period of non-use.

NOTE: Longer fill hoses are available (as optional

equipment at extra cost) if the hoses (supplied with

the washer) are not long enough for the installation.

Order hoses as follows:

No. 20617 Fill Hose 2.44 m (8 feet)

No. 20618 Fill Hose 3.05 m (10 feet)

Water Pressure

1 Water Supply Faucets

2 Cold Water Connection

3 Hot Water Connection

4 Fill Hoses

Figure 20

WATER

MIXING

VALV E

Pressure must be a minimum of 138 to a maximum of

827 kPa (20 to 120 pounds per square inch) static

pressure measured at the faucet.

NOTE: Water pressure under 138 kPa (20 pounds

per square inch) will cause an extended fill time in

the washer.

34

W187I

38900

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Installation

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets. Refer to

Figure 21.

1

2

1 Risers (Air cushions)

2 Water Supply Faucets

Figure 21

W005I

W005I

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

38900

Page 21

Page 22

Installer Checklist

C

H

Fast Track for Installing the Washer

(Refer to the manual for more detailed information)

➋

• Remove the Shipping

Brace and Shipping

Plug.

CHECK

• Wipe Out Inside

of Washtub.

CHECK

TLW521N

W371IE0B

W371I

➎➊

➏

• Position and

Level the

Washer.

CHECK

• Connect the Washer

to Electrical Power.

CHECK

LEVEL

W316I

D255I

W316I

D254I

D254IE2A

➌

➍

• Connect Fill

Hoses.

CHECK

• Connect Drain Hose

to Drain Receptacle.

CHECK

COLD

HOT

TLW1988N

TLW1988N

➐

• Add Water to

the Washer.

TLW2056N

W391I

CHECK

• Check Lid Switch.

CHECK

W376I

W376IE0A

W315IE0A

W315IE0A

➑

Loading...

Loading...