Page 1

Washer-Extractors

Pocket Hardmount

A-Series Microcomputer

UW35AV

UW60AV

UW80AV

UW100AV

UW125AV

®

NOTA: El manual en

español aparece después

del manual en inglés.

Operation/Maintenance

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

PHM1379C

PHM1379C

Part No. F232227

January 2006

Page 2

Page 3

Table of

Contents

Safety Information.............................................................................. 3

Explanation of Safety Messages........................................................... 3

Important Safety Instructions ............................................................... 3

Introduction......................................................................................... 5

Introduction........................................................................................... 5

Electronic Control Unit......................................................................... 5

Control Output Fuse Board................................................................... 5

Harnessing........................................................................................ 5

Delivery Inspection............................................................................... 5

Nameplate Location.............................................................................. 6

Replacement Parts ................................................................................ 6

Customer Service.................................................................................. 6

Summary of Control Outputs and Inputs.............................................. 6

Outputs............................................................................................. 6

Inputs................................................................................................ 6

Control Voltage................................................................................ 6

Operation............................................................................................. 9

Control Panel ........................................................................................ 9

Summary of Major Features................................................................. 10

Display Indicators................................................................................. 11

Operating Instructions .......................................................................... 13

Maintenance ........................................................................................ 15

Daily ..................................................................................................... 15

Beginning of Day............................................................................. 15

End of Day ....................................................................................... 16

Weekly.................................................................................................. 16

Monthly................................................................................................. 16

Quarterly ............................................................................................... 18

Care of Stainless Steel .......................................................................... 19

Daily Preventive Maintenance Checklist.............................................. 20

Weekly Preventive Maintenance Checklist.......................................... 21

Monthly Preventive Maintenance Checklist......................................... 22

Quarterly Preventive Maintenance Checklist ....................................... 23

Removal from Service ........................................................................ 25

Decommissioning ................................................................................. 25

© Copyright 2006, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 5

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer and those maintaining the

machine.

DANGER

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

WARNING

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, drycleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

CAUTION

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards

and/or panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 7

Introduction

Introduction

The “A” electronic control is composed of the

electronic control unit and the output board with

wiring harness. Only an authorized person should

service components inside the machine. TURN OFF

POWER, open lid and remove any cover present.

Electronic Control Unit

This portion of the control contains the “intelligence” –

the micro-controller and the miscellaneous components

on the printed circuit (PC) board. The board has a

metal cover, which MUST be in place at all times

during machine operation. Operation of the machine

without this cover installed will void the warranty.

The control unit monitors and responds to input, gives

information about the status of the washer and

monitors and responds to inputs from the user

interface (keypad). The control provides signals to the

control output unit, which in turn operates the

components that control the machine functions. This is

located behind the machine control panel.

Control Output Fuse Board

This portion of the control contains the power supply

for the control unit, and also the switching devices

which power the components in the machine, all of

which are on the output PC board. The switching

devices are controlled by the control unit, and are solid

state.

Harnessing

Wiring harnesses are modular – harnesses common to

various configurations are similar, while those specific

to a certain configuration can be added. There are

harnesses for inputs to the control unit, for outputs

from the control power/output unit to the machine

components, and for the main incoming power to the

control power/output unit.

Delivery Inspection

Upon delivery, visually inspect crate, protective cover,

and unit for any visible shipping damage. If the crate,

protective cover, or unit is damaged or signs of

possible damage are evident, have the carrier note the

condition on the shipping papers before the shipping

receipt is signed, or advise the carrier of the condition

as soon as it is discovered.

Remove the crate and protective cover as soon after

delivery as possible. If any damage is discovered upon

removal of the crate and/or protective cover, advise the

carrier and file a written claim immediately.

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Introduction

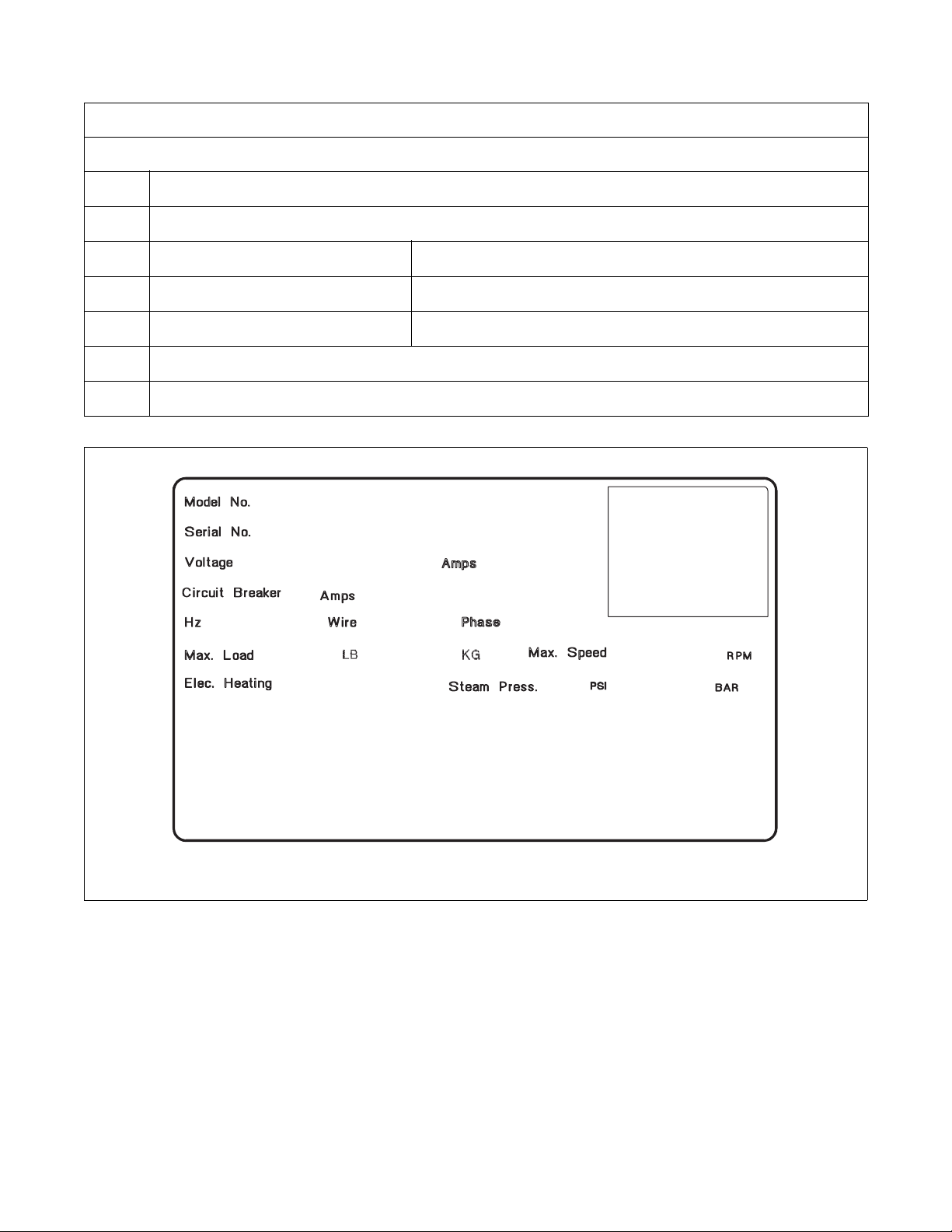

Nameplate Location

The nameplate is located at the rear of the machine and

near supply valves. Always provide the machine’s

serial number and model number when ordering parts

or when seeking technical assistance. Refer to

Figure 1.

2

P

U

S

H

1 Near Supply Valves

2 Top of Module

Figure 1

1

PHM598N

PHM598N

Summary of Control Outputs and

Inputs

Outputs

General outputs provide signals to operate the

following components.

1. Hot Fill Valve

2. Cold Fill Valve

3. Drain Valve (normally open)

4. Door Unlock Solenoid Coil

5. Supply 1 (detergent)

6. Supply 2 (bleach)

7. Supply 3 (sour/softener)

8. Supply 4

9. Supply 5 or Optional 3rd (auxiliary) Fill Inlet

(governed by the configuration settings)

10. Optional Heat

For standard models, the components for outputs

shown as “optional” will not be populated on the

output printed circuit board.

AC outputs are solid state outputs that operate either

120 Volt AC or 220 Volt AC (nominal voltage)

components, depending on the control voltage

configuration. Outputs are fused appropriately.

Replacement Parts

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call: (920) 748-3121 Ripon,

Wisconsin.

Inputs

1. Low Water Level

2. Medium Water Level

3. High Water Level

4. Door

5. Temperature Signal

Control Voltage

The control power supply is configured to operate on

220 Volt AC nominal RMS input voltage 50/60 Hertz.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 9

Model Number Familiarization Guide

Sample Model Number: UW60AVXU80001

Introduction

UW

60

A

V

X

U8

0001

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control A = A – Control

Washer-Extractor Speed Capabilities V = Variable Speed (Inverter)

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

UW60AVXU80001

00000000000

200 – 240

10

15

50 – 60 2/3

S 3

Drawings:

60 27

N/A

ETL Listed

Conforms To ANSI/UL Std. 1206, 3rd Ed

Certified To CAN/CSA Std. C22.2 No.53-1968

EXAMPLE OF NAMEPLATE

N/A

594

0.0

PHM625N

PHM625N

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Notes

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 11

Control Panel

14

Operation

15 16 17 18

2

1

5

12

13

12

11

34

56

10

<

39

1 Cycle Keypad “1” 11 Spin Cycle LED

2 Cycle Keypad “3” 12 Rinse Cycle LED

3 Cycle Keypad “5” 13 Add Bleach LED

4 Rapid Advance/Up Edit 14 Wash Cycle LED

5 Cycle Keypad “2” 15 Out-of-Balance Indicator Dot

6 Cycle Keypad “4” (Variable-speed only)

7 Cycle Keypad “6” 16 High Water Level Indicator Dot

8 Stop/Down Edit 17 Medium Water Level Indicator Dot

9 START Keypad 18 Low Water Level Indicator Dot

10 Door Open LED

4

<

CHM1766C

6

7

8

CHM1766C

F232227

Figure 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Operation

Summary of Major Features

LED for Machine Functions LED lights inform operator which machine function is active. DOOR LED lights to

inform operator that the door can be opened or should be closed. The circle LED

indicates that the filter needs cleaning.

Water Levels Three (3) – Contacts from pressure switch (test cycle)

Main LED display 4 digit LED display counts down cycle time. Lights in LED display indicate out-of-balance

conditions and, in test cycle, water level. Display shows “01” as the final spin time.

Cycle selection keypads Six (6) cycle select keypads. Thirty (30) cycles may be selected using these keys.

START keypad Press to start a cycle after cycle selection is made. LED light will flash to prompt user to

press keypad.

“Advance” keypad Advance rapidly through cycle by pressing the Advance keypad.

Fill Temperatures Cold, Hot, Warm

Supplies Five (5) or Four (4) with auxillary fill value option.

Agitation Types AG 1-4

Drain Options Normally open gravity drain

Cycle Count 0 to 9999 cannot be reset – Rolls over after 9999

Table 1

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 13

Display Indicators

Table 2 lists the various displays and what they

mean. The operator should become familiar with

these machine displays.

Display Meaning

Operation

tESt

SPIn

SUP1

SUP2

SUP3

SUP4

SUP5

SUP6

SUP7

SdLY

CFIL

HFIL

bFIL

bLCH

PASS

FAIL

Diagnostic test cycle selected or enabled

Spin (extract) step

Supply signal 1 (“S1” output), normally detergent

Supply signal 2 (“S2” output), normally bleach

Supply signal 3 (“S3” output), normally softener

Supply signal 4

Supply signal 5

Supply signal 6

Supply signal 7

Spin coast (motor coasts after high speed extract)

Cold Fill

Hot Fill

Warm Fill (cold + hot)

Control will also light “add bleach” indicator

Variable-speed ONLY – balance “PASS” condition; shows in “test” cycle only

Variable-speed ONLY – balance “FAIL” condition; shows in “test” cycle only

bAL?

CY__

SPn1

SPn2

SPn3

For

rEv

dISt

LO

nEd

HI

CEL

FAr

___C

Variable-speed ONLY – meaning: “Do you wish to enter balance detection test routine?”

Cycle number (followed by number 1 through 46)

Variable-speed ONLY – low spin speed (the lowest of 3 spin speeds)

Variable-speed ONLY – medium spin speed (the middle of 3 spin speeds)

Variable-speed ONLY – high spin speed (the highest of 3 spin speeds)

Wash speed forward (during test cycle)

Wash speed reverse (during test cycle)

Variable-speed ONLY – distribution speed (during test cycle)

Low water level

Medium water level

High water level

Display all temperatures in degrees Celsius

Display all temperatures in degrees Fahrenheit

The first 3 digits are reserved for temperature reading, C indicates “degrees Celsius”

Table 2

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Operation

Display Meaning

___F

FILL

door

SHUt/ door

CAnt/OPEn

USH1

USH2

USH3

USH4

USH5

rIn1

rIn2

rIn3

rIn4

rIn5

rIn6

The first 3 digits are reserved for temperature reading, F indicates “degrees Fahrenheit”

“Fill error” – machine did not fill to programmed water level within 10 minutes

“Door” opened during cycle

Machine user must “shut door” of the washer to allow the cycle to begin

Control cannot unlock the door

“Wash 1” segment

“Wash 2” segment

“Wash 3” segment

“Wash 4” segment

“Wash 5” segment

“Rinse 1” segment

“Rinse 2” segment

“Rinse 3” segment

“Rinse 4” segment

“Rinse 5” segment

“Rinse 6” segment (final rinse)

AG1

AG2

AG3

AG4

donE

drAI

----

Agitation 1, 18 seconds forward, 3 seconds off, 18 seconds reverse, 3 seconds off

Agitation 2, 3 seconds forward, 27 seconds off, 3 seconds reverse, 27 seconds off

Agitation 3, 10 seconds forward, 20 seconds off, 10 seconds reverse, 20 seconds off

Agitation 4, 4 seconds forward, 56 seconds off, 4 seconds reverse, 56 seconds off

Cycle has concluded

Drain selected for segment; also indicates in drain step during 2 speed version test cycle

Flashes for a period of time (for safety) after power up while keeping outputs OFF

Table 2 (Continued)

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 15

Operation

Operating Instructions

1. When display shows “Cyxx,” washer-extractor is

ready to be loaded with laundry.

2. Use left hand to press and hold the door unlock

button located on the lower right front of the

control panel. Refer to Figure 3.

12

4

3

6

5

<

<

PHM626N

4. Load the washer-extractor to full capacity

whenever possible, but do not exceed the rated

dry-weight capacity of the machine if the fabric

to be washed is quite dense, closely woven, and

heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine

load size based on fabric content, soil content,

and level of cleanliness required. Do not

underload the machine. Underloading can result

in premature bearing and sealing failure and outof-balance situations.

WARNING

MACHINE MAY B

E HOT

AND CAUSE BUR

N

S

ATTEMPT NO ENTRY UNTIL

BASKET HAS STOPPED

SERIOUS INJURY

MAY

RESULT

Figure 3

3. Use right hand to turn door handle clockwise and

swing the door left to open. Refer to Figure 4.

PHM593N

Figure 4

PHM590N

Figure 5

WARNING

Do not operate machine in a cycle with

program keymode switch in program

position. Program keymode switch must

be in run position at all times, except

when editing or programming cycle or

setup information.

W528

WARNING

Do not operate machine in a cycle or if

spinning with program keymode switch in

program position.

W529

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Operation

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

IMPORTANT: To prevent out-of-balance

conditions, premature wear or damage to machine

when using laundry nets, use several small nets in a

load.

5. When loading is complete, make sure that all

fabric is inside the basket.

6. Close and lock the door.

7. Dry supplies can be placed in the supply dispenser

compartment cups prior to the start of each cycle.

Liquid supplies can be injected directly into the supply

dispenser by an external chemical supply system.

NOTE: Supply dispenser compartment cups must

not be removed when an external chemical

injection supply system is attached to the washerextractor.

8. The default wash cycle will display. If desired,

select a different cycle at this point. Refer to

Table 3.

Cycle

Number

1 Permanent Press Light Soil

2 Cotton Terrycloth Light Soil

3 Permanent Press Medium Soil

4 Cotton Terrycloth Medium Soil

5 Permanent Press Heavy Soil

6 Cotton Terrycloth Heavy Soil

11 Table Napery Blends Colors

12 Table Napery Blends Whites

13 VISA Table Napery Colors

14 VISA Table Napery Whites

15 Rags Heavy Soil

16 Reclaim

21 Personals with Bleach

22 Personals No Bleach

23 Delicates Spreads Cold Water

24 Delicates Spreads Warm Water

25 Custom #1

26 Custom #2

31 Normal 90°C (Pre Wash)

32 Normal 90°C

33 Normal 60°C (Pre Wash)

34 Normal 60°C

Cycle Name

9. Press the Start keypad.

NOTE: The cycle number can be changed during

the FIRST FILL ONLY by pressing another cycle

select key.

At the conclusion of the cycle, the display will show

‘doNE’. The door can be unlocked. At this point the

washer-extractor may be unloaded.

When the door is opened, the display will revert to

showing “----” and the default cycle.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35 Normal 40°C (Pre Wash)

36 Custom #3

41 Permanent Press 90°C (Pre Wash)

42 Permanent Press 90°C

43 Permanent Press 60°C (Pre Wash)

44 Permanent Press 60°C

45 Fine 40°C

46 Custom #4

Table 3

F232227

Page 17

Maintenance

Routine maintenance maximizes operating efficiency

and minimizes downtime. The maintenance

procedures described below will prolong the life of the

machine and help prevent accidents.

WARNING

Be careful when handling sheet-metal

parts. Sharp edges can cause personal

injury. Wear safety glasses and gloves,

use the proper tools, and provide

adequate lighting.

SW035

CAUTION

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any safety

devices.

SW019

Daily, weekly, monthly, and quarterly checklists are

provided at the end of this section. Laminate the

checklists to preserve them for repeated copying.

Operators and technicians are encouraged to add

checks specific to their washer-extractor’s particular

application. Where possible, space is provided on the

checklists for this purpose.

Daily

Beginning of Day

1. Inspect water inlet valve hose connections on the

back of the washer-extractor for leaks.

2. Inspect steam hose connections for leaks (where

applicable).

3. Verify that insulation is intact on all external

wires and that all connections are secure. If bare

wire is evident, call a service technician.

4. Check door interlock before starting operation:

a. Attempt to start the washer-extractor with the

door open. The washer-extractor should not

start with the door open.

b. Close the door without locking it and attempt

to start the washer-extractor. The washerextractor should not start with the door

unlocked.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

The following maintenance procedures must be

performed regularly at the required intervals.

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Maintenance

End of Day

1. Clean the AC drive box filters:

a. Snap off the external plastic cover which

contains the filter.

b. Remove the foam filter from the cover.

c. Wash the filter with warm water and allow to

air dry. Filter can be vacuumed clean.

2. Clean the door gasket of residual detergent and

all foreign matter.

3. Clean automatic supply dispenser and lid inside

and out with mild detergent. Rinse with clean

water.

4. Clean powder dispenser and lid with mild

detergent. Rinse with clean water.

5. Clean washer-extractor’s top, front, and side

panels with mild detergent. Rinse with clean

water.

6. Leave loading door open at the end of each day to

allow moisture to evaporate.

Weekly

1. Check the washer-extractor for leaks.

a. Start an unloaded cycle to fill the washer-

extractor.

b. Verify that door and door gasket do not leak.

c. Verify that the drain valve is operating and

that the drain system is free from obstruction.

If water does not leak out during the prewash

segment, drain valve is closed and functioning

properly.

Monthly

NOTE: Disconnect power to the washer-extractor

at its source before performing the monthly

maintenance procedures.

1. Each month OR after every 200 hours of

operation, lubricate bearings. (Locate the bearing

lubrication decal at the rear of the left side of the

control module, as viewed from the front of the

washer-extractor.)

NOTE: Unload the washer-extractor promptly

after each completed cycle to prevent moisture

buildup. Leave loading door open at the end of each

completed cycle to allow moisture to evaporate.

The grease must have the following

characteristics:

● NLGI Grade 2

● Lithium-based

● Water-insolubl

● Anti-rusting

● Anti-oxidizing

● Mechanically stable

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 19

Maintenance

The grease must have adequate base oil viscosity

with one of the following ratings:

● ISO VG 150 (135–165 cSt at 40°C or

709–871 SUS at 100°F)

● ISO VG 220 (198–242 cSt at 40°C or

1047–1283 SUS at 100°F)

● An SAE 40 rating is also acceptable as long

as the cSt or SUS values are within the

specified ranges.

Pump the grease gun slowly, permitting only

two strokes.

2. Clean the AC drive cooling fins:

a. Remove the AC drive box cover.

b. Blow the fins clean using compressed air at a

pressure of 60 – 90 psi or canned compressed

air. Use care to avoid damaging cooling fan or

other components.

NOTE: No amount of visible foreign matter should

be allowed to accumulate on the fins or the finger

guard.

● Deflection. Refer to Figure 6. Loosen

motor mounting bolts and slide motor along

motor plate to change belt span length. Belt

tension measurements should be taken as

close to the center of the belt span as

possible. For every inch of belt span length,

the belt should deflect 1/64 of an inch, or

0.40 millimeter, with an exerted force of

5.25 pounds for a new belt or 3.5 pounds for

a used belt. A belt with a span length of 20

inches should deflect

20/64 of an inch, or 7.8 millimeters. The

belt(s) should be as loose as possible

without allowing slippage during peak load

condition. An initial (run-in) force of 7 lbs.

should be used to set the belt tension. An

operating (normal) force of 5 lbs. should be

used after the washer-extractor has been

operated for a few hours.

3. Use the following procedures to determine if

belts require replacement or adjustment. Call a

qualified service technician in either case.

a. Check belts for uneven wear and frayed

edges.

b. After disconnecting power to the washer-

extractor and removing all panels necessary

for access to the drive belt, use one of the

following methods to verify that belts are

properly tensioned:

● Tension Gauge. Belt tension

measurements should be taken as close to

the center of the belt span as possible.

Measurements can be performed with the

Belt Tension Checker. Make adjustments for

the motor pulley diameter and belt type on

the machine.

If belt tension adjustment is required,

loosen motor mounting bolts and slide

motor along motor plate to change the belt

tension. Retighten motor mounting bolts

before verifying belt tension.

1

2

PHM189N

1 Deflection

2 Span Length

Figure 6

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Maintenance

c. Verify that belts are properly aligned by

checking pulley alignment. Place a

straightedge across both pulley faces. The

straightedge should make contact with the

pulleys in four places. Refer to Figure 7.

1

4

5

PHM560N

2

1 Drive Motor

2 Drive Pulley

3 Belt

4 Straightedge

5 Driven Pulley

3

9. Clean interior of washer-extractor, both basket

and shell, by wiping with a water-soaked sponge

or cloth.

10. Use compressed air to ensure that all electrical

components are free of moisture and dust.

11. Remove chemical supply components and check

for residual chemicals. Clean as necessary and

replace.

Quarterly

NOTE: Disconnect power to the washer-extractor

before performing the quarterly maintenance

procedures.

1. Tighten door hinges and fasteners, if necessary.

2. Tighten anchor bolts, if necessary.

3. Verify that the drain motor shield is in place and

secure.

4. Check all painted surfaces for bare metal.

(Matching gray paint is available from the

manufacturer.)

Figure 7

4. Remove back panel and check overflow hose and

drain hose for leaks.

5. Unlock the hinged lid and check the supply

dispenser hoses and hose connections.

6. Clean inlet hose filter screens:

a. Turn water off and allow valve to cool, if

necessary.

b. Unscrew inlet hose and remove filter screen.

c. Clean with soapy water and reinstall. Replace

if worn or damaged.

7. Tighten motor mounting bolt locknuts and

bearing bolt locknuts, if necessary.

8. Use compressed air to clean lint from motor.

● If bare metal is showing, paint with primer or

solvent-based paint.

● If rust appears, remove it with sandpaper or by

chemical means. Then paint with primer or

solvent-based paint.

5. Clean steam filter, where applicable.

a. Turn off steam supply and allow time for the

valve to cool.

b. Unscrew nut.

c. Remove element and clean.

d. Replace element and nut.

6. Verify frame-mounted vibration safety switch

gap setting. Check for proper switch function.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 21

Maintenance

Care of Stainless Steel

Maintain the natural beauty of stainless steel and

prolong its service life by following these tips:

● Ordinary deposits of dirt and grease can be

removed with detergent and water. The metal

should be thoroughly rinsed and dried after

washing. Periodic cleaning will help to maintain

the bright surface appearance and prevent

corrosion.

● Contact with dissimilar metals should be avoided

whenever possible. This will help prevent

galvanic corrosion when salty or acidic solutions

are present.

● Salty or acidic solutions should not be allowed to

evaporate and dry on stainless steel. They may

cause corrosion. Ensure that the stainless steel is

wiped clean of acidic solution residues.

● Deposits that adhere to the stainless steel should

be removed, especially from crevices and

corners. When using abrasive cleaners, always

rub in the direction of the polish lines or “grain”

of the stainless steel to avoid scratch marks.

Never use ordinary steel wool or steel brushes on

the stainless steel. Use stainless steel wool or soft

non-metal bristle brushes.

● If the stainless steel appears to be rusting, the

source of the rust may actually be an iron or steel

part not made of stainless steel, such as a nail or

screw. One remedy is to paint all carbon steel

parts with a heavy protective coating. Stainless

steel fasteners should be used whenever possible.

● Discolorations or heat tint from overheating may

be removed by scouring with a powder or by

employing special chemical solutions.

● Sanitizers or sterilizing solutions should not be

left in stainless steel equipment for prolonged

periods of time. They often contain chlorine,

which may cause corrosion. The stainless steel

should be cleaned and rinsed thoroughly of any

solution containing chlorine.

● When an external chemical supply system is

used, make certain that no siphoning of

chemicals occurs when the washer-extractor is

not in use. Highly concentrated chemicals can

cause severe damage to stainless steel and other

components within the washer-extractor. Damage

of this kind is not covered by the manufacturer’s

warranty. Locate the pump below the washerextractor’s injection point to prevent siphoning of

chemicals into the washer-extractor. Refer to the

chemical injection supply system in the

Installation Manual.

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Maintenance

Daily Preventive Maintenance

Checklist

Machine ____________________________

Operator

___________________________

Checks 1234567

Observe All Safety Warnings!

Disconnect power to the washer-extractor before performing the

daily maintenance procedures.

Beginning of Day

1. Inspect water inlet valve hose connections on the back of the

washer-extractor for leaks.

2. Inspect steam hose connections for leaks (where applicable).

3. Verify that insulation is intact on all external wires and that all

connections are secure.

4. Check door lock and interlock before starting operation:

a. Attempt to start the washer-extractor with door open.

b. Close the door without locking it and attempt to start the

washer-extractor.

Week Of: ________________

Days

c. Close and lock the door, start a cycle, and attempt to open the

door while the cycle is in progress.

End of Day

1. Clean the AC drive box filters.

2. Clean the door gasket of all foreign matter.

3. Clean automatic supply dispenser and lid.

4. Clean the washer-extractor’s top, front, and side panels.

5. Leave loading door open at the end of each day to allow moisture

to evaporate.

NOTE: Unload the washer-extractor promptly

NOTE: Leave loading door open

after each completed cycle

after each completed cycle

to allow moisture to evaporate.

to prevent moisture buildup.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 23

Weekly Preventive Maintenance

Checklist

Maintenance

Machine ____________________________

Operator

___________________________

Checks /////

Observe All Safety Warnings!

Disconnect power to the washer-extractor before performing the

weekly maintenance procedures.

1. Check the washer-extractor for leaks:

a. Start an unloaded cycle to fill the washer-extractor.

b. Verify that door and door gasket do not leak.

c. Verify that the drain valve is operating.

2.

3.

4.

5.

6.

Month __________

Week Ending:

7.

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Maintenance

Monthly Preventive Maintenance

Checklist

Machine ____________________________

Operator

___________________________

Checks

Observe All Safety Warnings!

Disconnect power to the washer-extractor before performing the

monthly maintenance procedures.

1. Each month OR after every 200 hours of operation, lubricate bearings.

2. Clean the AC drive fins.

3. Determine if belts require replacement or adjustment:

a. Check belts for uneven wear and frayed edges.

b. Verify that belts are properly tensioned.

c. Verify that belts are properly aligned.

4. Remove back panel and check hoses for leaks.

5. Check supply dispenser hoses and connections.

Month

6. Clean inlet hose filter screens. Replace if worn or damaged.

7. Tighten motor mounting bolt locknuts and bearing bolt locknuts, if necessary.

8. Use compressed air to clean lint from motor.

9. Clean interior of washer-extractor, both basket and shell, by wiping with a

water-soaked sponge or cloth.

10. Use compressed air to clean moisture and dust from all electrical components.

11.

12.

13.

14.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 25

Quarterly Preventive Maintenance

Checklist

Maintenance

Machine ____________________________

Operator

___________________________

Checks

Observe All Safety Warnings!

Disconnect power to the washer-extractor before performing the

quarterly maintenance procedures.

1. Tighten door hinges and fasteners, if necessary.

2. Tighten anchor bolts, if necessary.

3. Verify that the drain motor shield is in place and secure.

4. Check all painted surfaces for bare metal. Repair, if necessary.

5. Clean steam filter, if applicable.

6. Check vibration safety switch gap setting to switch function.

7.

8.

Quarter

10.

11.

9.

F232227

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Notes

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232227

Page 27

Removal from Service

Decommissioning

In the event that the machine must be

decommissioned, follow these steps:

1. Remove the chemical injection supply system, if

applicable.

a. Have a qualified electrician disconnect power

to the chemical injection supply system at its

source.

b. Using the manufacturer’s instructions,

carefully remove the chemical injection

supply system from the machine. Make

certain that no chemical supplies come into

contact with skin or clothing.

2. Clean interior of machine, both basket and shell.

a. Flush supply dispenser (soap dish) with water.

b. Run a short rinse cycle to clean detergent and

chemical residues from the interior of the

machine.

3. Disconnect electrical power.

a. Shut off main power supply at the breaker box

or main control panel.

b. Do not attempt to disconnect power supply

wires from power supply. Have a qualified

electrician disconnect power to machine and

reuse unit, if applicable, at its source.

4. Disconnect hoses.

a. Disconnect drain hose from sump, gutter, or

drain.

b. Turn off water supply. Disconnect individual

hot and cold water inlet hoses from the

machine.

c. Allow time for residual water in the machine

to drain. Then disconnect drain hose from the

machine.

5. Disconnect steam hose, if applicable.

a. Turn off steam supply and allow time for the

valve to cool.

b. Disconnect steam hose from machine.

6. Remove the washer-extractor from its foundation

pad.

a. Keep all panels in place to provide stability

when moving the machine.

b. Verify that door is closed and secure.

c. Loosen and remove anchor bolts holding

machine base to floor.

d. Break the grout seal at each corner of the

machine, using a crowbar.

e. Use crowbars at the front corners to lift the

machine a few inches so that the forks of a

forklift truck can reach under the machine.

F232227

f. Bolting the base frame to a pallet will

facilitate removal to a transport vehicle.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Loading...

Loading...