Alliance Laundry Systems UW35B2, UW60B2 User Manual

Washer-Extractors

UW Pocket Hardmount

B-Series Microcomputer

2 Speed

Models UW35B2 and UW60B2

NORMAL

NOTA: El manual en

español aparece después

del manual en inglés.

WASH

ADD

BLEACH

RINSE

SPIN

DOOR

START

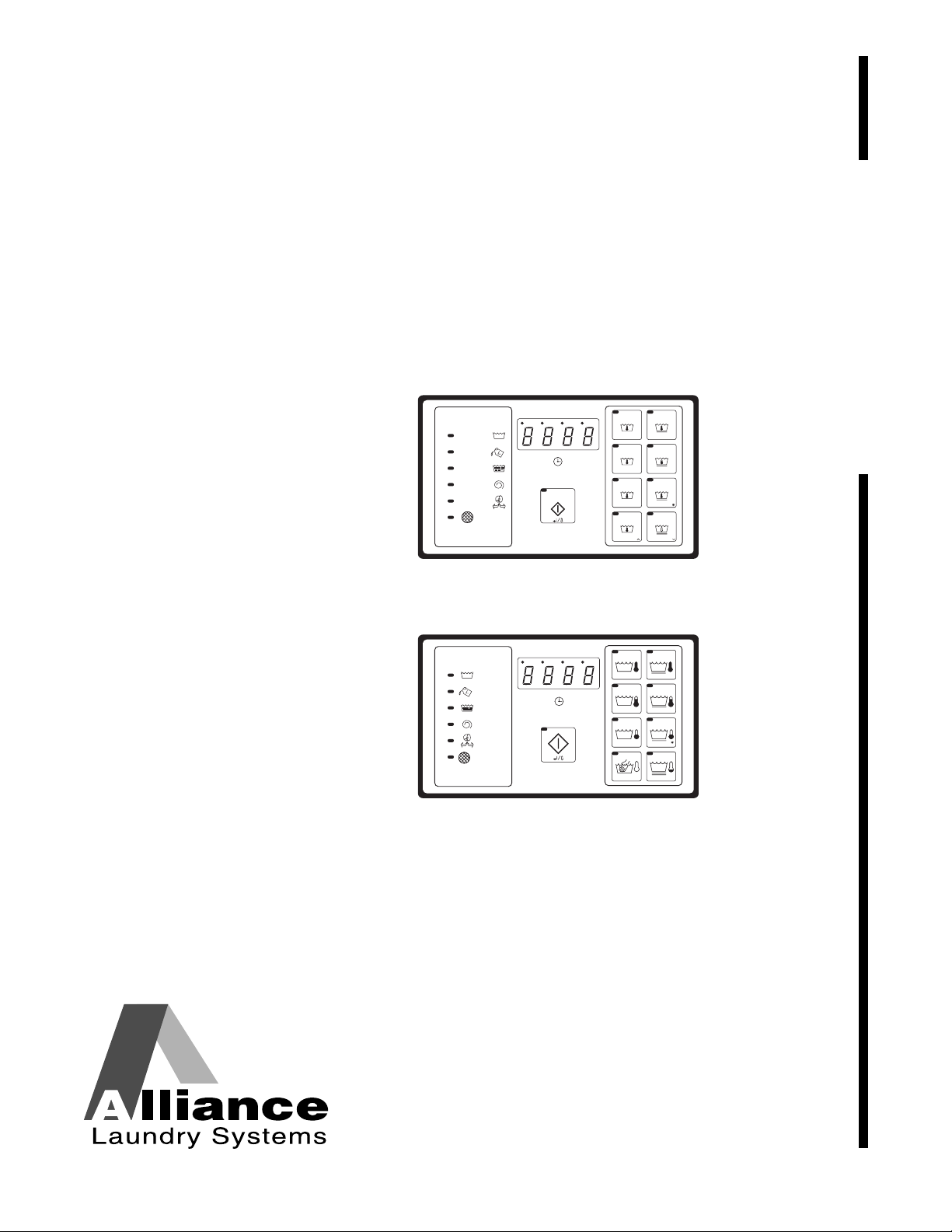

DOMESTIC MODELS

HOT

LIGHT SOIL

HOT

HEAVY SOIL

HOT HOT

STAINED

HOT

PERM PRESS

HOT

TM

VISA

WARM

UNIFORMS

DELICATE

COLD

Programming

95C 95C

60C 60C

40C 40C

<

INTERNATIONAL MODELS

30C

<

PHM1392C

PHM1

www.comlaundry.com

Part No. F232168R2

November 2005

Table of

Safety Information.............................................................................. 3

Important Safety Instructions ............................................................... 3

Contents

Programming ...................................................................................... 5

Entering Program Mode ....................................................................... 5

Determining Firmware ID Code........................................................... 5

Setup Mode (For Models With Firmware ID Code

“o2HC”, “o2UC”, “ouHC” and “ouUC”) ...................................... 6

Cycle and Error Count.......................................................................... 6

Setup Mode (For Earlier Models).................................................... 7

Cycle and Error Count.......................................................................... 7

Programming Cycle Segments......................................................... 8

Options for Each Segment.................................................................... 9

To Edit an Entire Wash Cycle Formula................................................ 13

Wash 1 – Wash 4 ............................................................................. 13

Rinse 1 – Rinse 4 ............................................................................. 14

Abnormal Conditions............................................................................ 16

Door Open During Operation .......................................................... 16

Excessive Fill Time.......................................................................... 16

Door Will Not Open......................................................................... 16

Excessive Drain Time...................................................................... 16

Drain Error (For Models With Firmware ID Code

“o2HC”, “o2UC”, “ouHC” and “ouUC”) ...................................... 16

Temperature Probe Sensor Problem ................................................ 16

Frame Limit Switch Trip ................................................................. 16

Rapid Advance (For Models With Firmware ID Code

“o2HC”, “o2UC”, “ouHC” and “ouUC”) ...................................... 17

How to Rapid Advance During All Steps (Except First Fill Step).. 17

How to Rapid Advance (During First Fill Step).............................. 17

Test Cycle ............................................................................................. 17

Permanent Diagnostic Test Cycle......................................................... 18

Cycle Charts for Domestic OPL Models Built After April 2005

(Displays P-F5) .................................................................................. 20

Cycle Charts for Domestic OPL Models Built Prior to April 2005

(Displays P-F1) .................................................................................. 23

Cycle Charts for International OPL...................................................... 26

© Copyright 2005, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232168

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232168

Safety Information

Precautionary statements (“DANGER,” “WARNING,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

DANGER

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

WARNING

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

CAUTION

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the grounding instructions in the

installation manual for the proper grounding of

the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils,

dry-cleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

IMPORTANT: The word “NOTE” is used to

communicate installation, operation, maintenance

or servicing information that is important but not

hazard related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232168

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the installation

instructions. All connections for water, drain,

electrical power and grounding must comply

with local codes and be made by licensed

personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards and/or

panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232168

Programming

NOTE: The machines are factory-programmed

with basic cycles to make the units operational

without programming at the installation.

Entering Program Mode

1. Open control compartment lid.

2. Locate Program/Run switch on the computer

board. (This is accessed through a cutout in the

metal control unit cover.) This switch protrudes

from the rear of the electronic control unit cover.

3. Flip switch to the left (as seen from the front of

machine) to enter Program Mode.

4. Display will show a temperature.

Determining Firmware ID Code

1. Turn on the main power source (circuit breaker or

cut-off switch on wall).

2. Display will show Firmware ID code (i.e.,

“o2UC” and “ouUC” etc...).

3. Record Firmware ID Code for future reference.

F232168

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Programming

Setup Mode (For Models With Firmware ID

Code “o2HC”, “o2UC”, “ouHC” and

“ouUC”)

NOTE: In Setup Mode, certain machine functions

can be configured. The settings in this mode are

related to how the machine is equipped from the

factory. Usually, these would not be changed in this

field.

NOTE: Enter Setup Mode through the Program Mode.

1. Press (*) key. Display will show “FAr” or “CEL”.

NOTE: This selects whether temperatures display

in degrees Fahrenheit (F) or Celsius (C), if control

is equipped with a temperature sensor. Press the

) or (∨) key to change.

(∧

NOTE: Changing degrees “FAr” or “CEL” only

has an effect if the control has a temperature probe

connected and/or heat capability.

2. Press START key.

3. Model will display “HEAt” or “noHt”. Change

the selection by pressing the (∧) or (∨) key.

4. Press START key to continue to the next step.

return to Program Mode. Refer to “Programming

Cycle Segments” section for additional information.

9. “Adv” or “noAd” will display. If “Adv” is set,

control will advance to the next step when up

arrow keypad is pressed during a regular cycle. If

“noAd” is set, control cannot advance during a

regular cycle, but can advance during the factory

test cycle when up arrow keypad is pressed.

10. Press START (enter) keypad to continue to next

step.

11. “PtIM” or “EtIM” will display. “PtIM” means

control will not display remaining time in a cycle.

“EtIM” means control will display an estimated

remaining time for a fill and drain. Press the up

or down keypad to change “PtIM”/ “EtIM”

selection.

12. Press START (enter) keypad to continue to the

next step.

Cycle and Error Count

1. To read, enter Program Mode. Refer to Entering

Program Mode.

2. Press START (enter) keypad. Display shows

“Erdn” (indicates Drain Error count).

NOTE: If set for “HEAt”, the control has heat

capability enabled. The washer-extractor MUST

have electric or steam heat, and a temperature

probe. If display shows “noHt”, or if the message

“HEAt” or “noHt” does NOT display, the control

does NOT have heat capability.

5. Certain models will display “EFIL” or “ESUP”.

For these models, the control provides a spare

output (for certain models). The spare output can

be set up to control an extra fill valve (“EFIL”),

with the ability to fill to a programmable water

level (just as for regular fills), OR the spare

output can be set up to control an extra chemical

supply signal (“ESUP”).

6. Press START keypad.

7. Certain models display “bEEP” (control sounds

beeper during Add Bleach [Supply 2]) or “nobP”

(control does NOT sound beeper during Add

Bleach [Supply 2]). Change selection by pressing

(∧) or (∨) keypad.

8. Press START keypad.

NOTE: If “EFIL” or “ESUP” does NOT display,

the extra fill capability is NOT present. If either

message does display, change the selection by

pressing the (∧) or (∨) key. Press START key to

3. Press START (enter) keypad. Display shows a

number (2 or 3 digits) showing how many drain

errors have occurred. This number can range

from ‘00’ to ‘255’, and cannot be set to zero.

4. Press START (enter) keypad. Display shows

“ErFL” (indicates Fill Error count).

5. Press START (enter) keypad. Display shows a

number (2 or 3 digits showing how many fill

errors have occurred. This number can range

from ‘00’ to 255’, and cannot be set to zero.

6. Press START (enter) keypad. Display shows

“CYC “ (indicates Cycle count).

7. Press START (enter) keypad. Displays show a

number (up to 4 digits) showing how many

complete cycles have been operated. This

excludes cycles stopped because of an error.

8. Press START (enter) keypad.

9. If display does not show “E Pr”, control will

revert to normal program mode.

10. If display shows “E Pr”, this is for factory

reference regarding power interruption. Press

START (enter) keypad. A number will display.

Press START (enter) keypad. After a brief pause,

the control will display normal program mode.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232168

Programming

Setup Mode (For Earlier Models)

NOTE: In Setup Mode, certain machine functions

can be configured. The settings in this mode are

related to how the machine is equipped from the

factory. Usually, these would not be changed in this

field.

NOTE: Enter Setup Mode through the Program

Mode.

1. Press (*) key. Display will show “FAr” or “CEL”.

NOTE: This selects whether temperatures display

in degrees Fahrenheit (F) or Celsius (C), if control

is equipped with a temperature sensor. Press the

) or (∨) key to change.

(∧

NOTE: Changing degrees “FAr” or “CEL” only

has an effect if the control has a temperature probe

connected and/or heat capability.

2. Press START key.

3. Model will display “HEAt” or “noHt”. Change

the selection by pressing the (∧) or (∨) key.

NOTE: If “EFIL” or “ESUP” does NOT display,

the extra fill capability is NOT present. If either

message does display, change the selection by

pressing the (∧

) or (∨) key. Press START key to

return to Program Mode. Refer to “Programming

Cycle Segments” section for additional information.

Cycle and Error Count

The control logs cycle count (total of all cycles

completed).

● To read, enter Program Mode.

● Press START (enter) key. Display will show the

cycle count.

● Press START (enter) key. Display will show

certain error conditions that may have been

recorded by the control.

● Read the information when consulting technical

assistance as needed.

● Step through the error log by pressing START

key repeatedly until display reverts to normal

Program Mode (showing a temperature).

4. Press START key to continue to the next step.

NOTE: If set for “HEAt”, the control has heat

capability enabled. The washer-extractor MUST

have electric or steam heat, and a temperature

probe. If display shows “noHt”, or if the message

“HEAt” or “noHt” does NOT display, the control

does NOT have heat capability.

5. Certain models will display “EFIL” or “ESUP”.

For these models, the control provides a spare

output (for certain models). The spare output can

be set up to control an extra fill valve (“EFIL”),

with the ability to fill to a programmable water

level (just as for regular fills), OR the spare

output can be set up to control an extra chemical

supply signal (“ESUP”).

6. Press START keypad.

7. Certain models display “bEEP” (control sounds

beeper during Add Bleach [Supply 2]) or “nobP”

(control does NOT sound beeper during Add

Bleach [Supply 2]). Change selection by pressing

(∧) or (∨) keypad.

8. Press START keypad.

F232168

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Loading...

Loading...