Page 1

Washer-Extractor

Pocket Hardmount

Instructions for Operating the

WE-4 and WE-5 Microcomputers

UW50P4

Operation

COLD / HOT / WARM /

LOW HIGH OVER

WASH / HEAT / SUPPLY

FLUSH RINSE

SOAK MEDIUM HIGH

PAUSE SPEED SPEED

CLEAR

STOP

DRAIN

BUZZER

REVERSE

NO

DISPLAY

TEMP. /

CYCLE

ADD

CYCLE

NUMBER /

ADVANCE

ERASE

CYCLE

NUMBER

ENTER

START

PHM542N

www.comlaundry.com

Part No. F232161

September 2002

Page 2

Page 3

Table of

Contents

Introduction......................................................................................... 3

Nameplate Location.............................................................................. 3

Replacement Parts ................................................................................ 3

Customer Service.................................................................................. 3

Safety Information .............................................................................. 5

Important Safety Instructions ............................................................... 5

Operation............................................................................................. 7

General Information.............................................................................. 7

Theory of Operation ............................................................................. 7

Start-Up................................................................................................. 8

Loading ................................................................................................. 8

Select Cycle .......................................................................................... 8

Start Cycle ............................................................................................ 8

Test Cycle ............................................................................................. 9

End of Cycle ......................................................................................... 9

LED Display ......................................................................................... 9

Test Procedure ...................................................................................... 11

Motor Thermal Overload Indicator ...................................................... 13

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232161

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232161

Page 5

Introduction

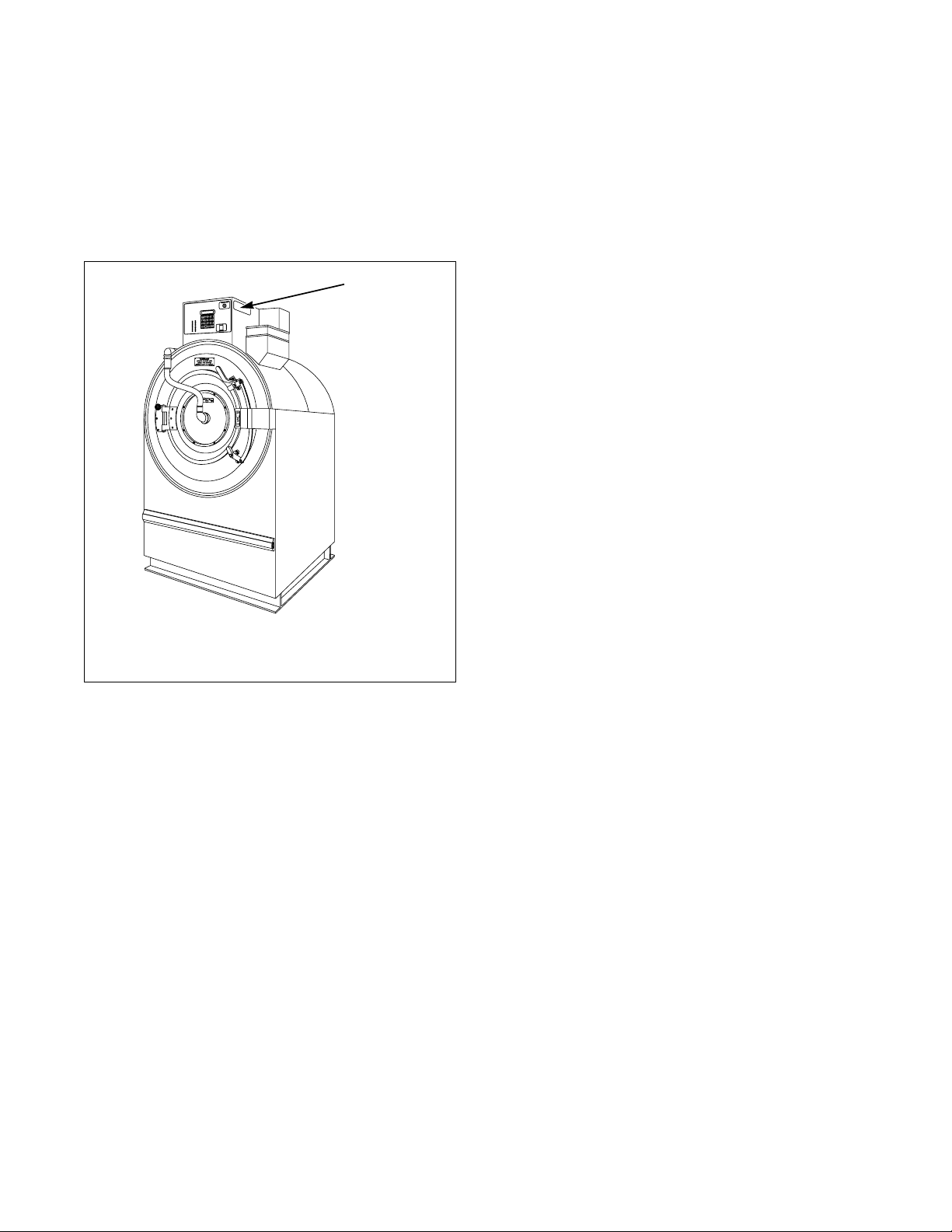

Nameplate Location

The nameplate is located at the top of the machine.

Always provide the machine’s serial number and

model number when ordering parts or when seeking

technical assistance.

1

Replacement Parts

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call any of the following

numbers:

(850) 718-1025

(850) 718-1026

Marianna, Florida U.S.A.

(920) 748-3121

Ripon, Wisconsin U.S.A.

1 Nameplate

PHM516N

PHM516N

F232161

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Notes

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232161

Page 7

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

Precautionary statements (“DANGER,” “WA R N I N G ”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023E

1. Read all instructions before using the washer.

2. Refer to the Grounding Instructions in the

installation manual for the proper grounding of

the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232161

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the Installation

Instructions. All connections for water, drain,

electrical power and grounding must comply

with local codes and be made by licensed

personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards and/or

panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232161

Page 9

Operation

General Information

This manual is designed as a guide to operating and

maintaining your washer-extractor. It also serves as an

aid to troubleshooting.

Read and be sure you understand this manual and any

other literature included with your machine before

attempting to start the machine. For warranty

purposes, keep this manual, along with any other

literature and the wiring diagrams which accompany

the machine, in a safe place for ready reference. The

first copy is included with your machine. Additional

copies are available at a nominal charge.

3

2

1

Theory of Operation

NOTE: When power has been turned off from the

machine and then reapplied, the display will read

“WA I T ” for approximately 30 seconds before the

display changes to “NEXT 00”.

4

5

6

COLD / HOT / WARM /

LOW HIGH OVER

WASH / HEAT / SUPPLY

FLUSH RINSE

SOAK MEDIUM HIGH

PAUSE SPEED SPEED

CLEAR

STOP

DRAIN

BUZZER

REVERSE

NO

DISPLAY

TEMP. /

CYCLE

ADD

CYCLE

NUMBER /

ADVANCE

ERASE

CYCLE

NUMBER

ENTER

START

PHM543N

1 Hot Spray Valve On 4 Cold Fill Valve On

2 Cold Spray Valve On 5 Low Level Fill Indicator

3 Hot Fill Valve On 6 High Level Fill Indicator

U152R

F232161

Figure 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Operation

Start-Up

Turn on the main power source (breaker panel or cutoff switch on the wall). The front panel display should

light up and show “WAI T 0 0” for 30 seconds followed

by “NEXT 00” which means Select Cycle. This

display will be on at all times that power is on

indicating the machine is ready for loading and

unloading.

NOTE: Throughout this manual, when display

indications are referred to, these indications will

pertain to the first four digits of the display reading

left to right. The last two digits on the right side of

the display will indicate either the last cycle used or

the current cycle in process.

Loading

To load the washer, use left hand to press the door

unlock button located on the lower right front of the

control panel. Use right hand to turn door handle to the

right. The door can then be opened.

Load linen until the machine is full. Partial loads are a

waste of energy, water and chemicals and cause

greater machine wear than full loads. If you do not

have enough to fill the basket, wait until you do.

Partial loads, if necessary, should only occur at the end

of the day. Even then, they can usually be held until

the next day when more linen is received.

IMPORTANT: If stringy items such as mop heads

are to be washed, laundry nets should be used in

order to prevent fouling of seals and drains.

Once loading is complete (you cannot overload the

machine as far as harm to the machine is concerned;

however, overloading can cause improper mechanical

action and an inferior quality wash), close and lock the

door making sure that all fabric is inside the basket.

The machine should not start or run if the door is not

both closed and locked.

Select Cycle

Find the cycle number (cycle numbers must be twodigit numbers) of the desired wash cycle from the

cycle code list provided. Press (do not punch) with

your finger the numbers desired on the keypad and

note that this number is displayed instead of “NEXT”.

When keys are pressed on the keypad, a beep will be

heard. If an error is made, simply press the CLEAR

key and then press the numbers again. As numbers are

entered, they move from right to left on the display.

Display will show “CY12” if cycle 12 is pressed.

NOTE: In order to Clear or Enter data, the display

must be filled – i.e., no blank spaces.

Start Cycle

To start the cycle that has been selected, simply press

the START key. If the cycle number selected is not in

the computer memory, the display will show

“NOGO”. If this happens, select another cycle.

Otherwise, the display will now show the first step.

(Example: “HL01”.) This number indicates the step

number in the cycle as listed in the Selection List. As

the cycle proceeds, the display will show the step

being run and the cycle number selected.

If the door is not locked, the display will indicate

“DOOR”. If this occurs, be sure the door is closed and

locked and again press the START key. If the computer

starts but the machine does nothing, this indicates the

door hinge microswitch cam may need adjusting. The

door hinge microswitch interlocks all 120 volt power

to the controls with the exception of the computer

itself.

As the cycle progresses, the display will show the step

in the cycle that is being run as well as the cycle

number. In addition, as water is being turned on to fill

the machine, one or more of the four indicator lights

above the first four digits (left to right) in the display

will come on and stay on until the required water level

is reached. Indicator lights above the last two digits on

the right will indicate the water level(s) reached. When

the indicator light in the next to last digit is

illuminated, the low water level has been reached.

Likewise, when the light in the last digit to the right

illuminates, high water level has been reached. The

cycle will continue until its completion and, at this

time, the display will show “NEXT”.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232161

Page 11

Operation

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Test Cycle

Cycle number 01 is a test cycle to check out all

machine functions. The program for the cycle is shown

following the copy of the Program Worksheet.

The first step is a cold fill to low level and is designed

to give not quite enough time to complete a fill and

cause the display to read “FILL”. When the START

key is pressed again, it should continue to fill and

proceed with the test cycle.

The steps in the test cycle are relatively short with the

exception of step 3, step 15, and step 17. These can be

shortened by pressing the ADVANCE key to go on to

the next step.

End of Cycle

When the cycle is completed, the display will show

“NEXT” plus the cycle number just run. To unload the

machine, press the door unlock button and again open

the door to remove contents and place them in the

dryer.

LED Display

When display shows letters and/or numbers with or

without the beeper, refer to Tab l e 1 . The computer

control in this machine is continuously on the alert for

problems both within the machine and with the total

installation. As the computer sees a problem, it

immediately flashes a letter or number or both on the

display and may activate the beeper as well. Tab l e 1

shows the various displays and what they mean. The

operator should become familiar with these computer

displays.

To display temperature, press the DISPLAY TEMP.

key. Display will read “---F” as long as the key is

pressed and will update display automatically.

It is possible to skip to the next step in the cycle except

a drain step. To do so, press the ADVANCE key. Drain

procedures must be allowed to complete.

F232161

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Operation

Display Interpretations

Display Meaning Display Meaning

DOOR Door not locked problem SK Soak

EMTY Empty problem S1 Supply #1 (Soap/Break)

FILL Fill problem S2 Supply #2 (Bleach)

SDLY Spin coast delay S3 Supply #3 (Softener/Sour)

NEXT Select cycle or open door or program S4 Supply #4 (as needed)

NOGO

STOP Stop key has been pressed or end of cycle TH Controlled Temperature Fill to High Level

01/4 One quarter hour (soak intervals) TL Controlled Temperature Fill to Low Level

A1 Buzzer or Auxiliary Output TO Controlled Temperature Overflow

CF

CH Cold Fill to High Level W1 Wash #1 (Regular Reversing)

CL Cold Fill to Low Level W2 Wash #2 (Gentle Reversing)

Cycle not available

Cold flush

S5 Supply #5 (as needed)

NO FILL Indicates machine cannot add heat due to low

level fill not being reached

CO Cold Fill to Overflow W3 Wash #3 (No Agitation)

CR Cold Rinse WF Warm Flush

CY Cycle Number WH Warm Fill to High Level

DR Drain WL Warm Fill to Low Level

F Heat select temperature (F--) in degrees F WO Warm Fill to Overflow

OH Auxiliary heat in minutes (no hours) WR Warm Rinse

HF Hot Flush

HH Hot Fill to High Level

HL Hot Fill to Low Level

HO Hot Fill to Overflow

HR Hot Rinse

HS High Speed Spin

HT Heat (steam or electric)

M Minutes (used when programming time) PAUSE 5 Paused during Cycle (see explanation in this

MS Medium Speed Spin

• • • • • •

•

•

•

•

Dots indicate water valves turned on

Left dot – hot spray valve

2nd dot from left – cold spray valve

3rd dot from left – hot fill valve

4th dot from left – cold fill valve

5th dot from left – low level fill reached

•

6th dot from left – high level fill reached

•

manual)

NOTE: For further explanation of problem

indication displays, consult Test Procedure section

of this manual.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Table 1

F232161

Page 13

Operation

Serious shock may occur. Open primary

disconnect switch before attempting any

repairs.

W447

WARNING

Test Procedure

1. The WE-4 and WE-5 Programmable Computer,

with its display/fuse board should be easier to

maintain than other type controls. The following

procedure should help to eliminate problems and

determine if components are defective.

2. Test equipment required:

a. 20K OHM/Volt AC-DC voltmeter

b. Programmable computer diagram, WE-4

page 43, WE-5 page 44.

c. Display board diagram, drawing #2091

3. Power Up

a. When AC power is turned on, after

30 seconds the computer should read

“NEXT”.

b. Door unlock solenoid should work if Door

Unlock button is depressed.

c. If these are correct, go to step 5.

4. If computer does not read “NEXT” or does not

light:

a. Examine display board; the door light (DR)

should be on and all others off.

b. If not, check 2 AMP fuse on side of module.

c. Check for 115 volts AC between AC HOT

(ACH) and AC NEUTRAL (ACN) at top

center of display board. (Ref. Drawing #2091)

d. Be certain that all plugs are correctly installed

on the computer board.

e. If all above check OK, remove the 6 pin plug

(J-1) just above the transformer on the

computer board. Carefully check for 115 volt

AC between pins 1 and 6; if correct voltage is

there, replace computer board.

5. If computer reads “NEXT”:

a. Test the keypad, first with the keyed mode

switch in the Run position. A beep tone

should sound as each key is pressed.

NOTE: Keys should be pressed at their centers and

only hard enough to activate them. With the

computer showing “NEXT”, press each of the

15 keys not including the START key and listen for

each beep. After pressing all 15 keys (except

START), press 0 twice then press the START key.

Display should read “NOGO00”.

b. When the DISPLAY TEMP. key is pressed,

the computer display should change to show

the temperature inside the sump. When key is

released, the display should return to previous

read-out.

c. Turn the keyed mode switch to Program and

press “Display/Cycle”. Read-out should show

“CY--”. Then press 0 twice.

d. Press the CLEAR/STOP key. Display should

return to “NEXT”.

e. Return Mode switch to the Run position.

6. If keypad does not function as above:

a. Check the plug at the bottom center of

computer board for proper installation. (P-1)

b. If the plug is correct, proceed to “Replacing

Keypad” section.

7. Test Cycle

a. Cycle 01 is a preprogrammed test cycle. If it

has not been erased, it may be used to check

all functions of the machine.

b. Start this cycle by pressing 0, then 1, then the

START key.

c. Display should show “CL01” with two dots

indicating water valves turned on. (Refer to

Table 1.)

d. On the display/fuse board inside the control

module, these lights should be lit: Cold Fill

(CF), Cold Spray (CS), Drain (DN), plus

Forward (FW) and Reverse (RV) should

alternate on and off. (Ref. Drawing No. 2091)

e. Printed program will indicate which lights to

expect for each step. (Ref. Cycle 01 as shown

in this manual)

8. If read-out is OK but no lights are lit on display/

fuse board:

a. Check 2 AMP fuse and door hinge

microswitch.

b. Check thermal overload indicator light on side

of control module. If lit, thermal overload

circuit is open.

F232161

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Operation

9. If only one light on display/fuse board not lit:

a. Check the fuse on the fuse board associated

with that light.

b. If fuse is OK, check jumpers between

computer and display board, J4 and J5,

making sure J4 on display board is connected

to J4 plug on computer board, etc.

c. If the fuse is blown, check the related valve or

relay for shorted condition before replacing

the fuse with one of the same size.

d. Use similar procedure for any individual

function which does not work.

10. “DOOR” Alarm

a. Computer has not been told that door is

locked.

b. Check switch activator tab on extension arm.

c. Check door lock switch.

d. Check input plug, J3, on computer board.

11. “FILL” Alarm

a. Computer has not been told that water level

was reached in the allotted time.

b. Check for leaks in air system between level

switches and water level air chamber.

c. Check for obstruction in water level air

chamber or tubing.

d. Check for obstructions or low pressure in

water supply system.

e. Check for failed drain solenoid.

12. “EMTY” Empty Alarm

a. Computer has not been told that level reached

empty in the allotted time.

b. Check for obstructions in air system to level

switches.

c. Check for slow drain.

NOTE: Sufficient time for filling and draining must

be allowed when a program is written into the

computer. If a “FILL” or “EMTY” alarm occurs

only in one program, edit that program and reenter it into the computer making sure enough time

has been allowed for fill and/or drain.

13. No Spin, Rest of Program OK:

a. When a spin is called for (medium or high

speed) the computer looks for an

out-of-balance condition and an empty

condition.

NOTE: Computer will look for out-of-balance

three (3) times. If balance condition is not

corrected, computer will advance to next step

without completing spin cycle.

b. Check input plug, J3, on computer.

c. Check balance switch inside “A” Frame.

d. Check water level and drain line.

14. “NO FILL” Alarm

a. The computer has not received a low level fill

signal prior to an auxiliary “HEAT” step.

b. Check as for “FILL” Alarm as in step 11.

15. Spins too soon after “SOAK” step:

a. Check for leaks in pressure system to water

level switches.

16. Temperature indication inconsistent:

a. Temperature probe is short circuited.

b. If reading is 53

°

F and does not change,

temperature probe circuit is open.

c. Check input plug, J3, on computer.

d. Replace temperature probe in sump.

17. If the above procedures and troubleshooting have

failed to determine the problem, call the factory.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232161

Page 15

Motor Thermal Overload Indicator

MOTOR THERMAL INDICATOR

AUTOMATIC RESET

PHM521N

Figure 2

Operation

WARNING

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

Located on the side of the control module is a small

indicator lamp with the above descriptive decal.

When this lamp is lit, it indicates that there is an open

thermal overload switch on the motor(s) which shuts

off the A.C. power to the computer board thereby

preventing damage to the motor(s) caused by

overheating and/or an overload condition.

This feature is provided to protect the motor and

extend the life of the motor. The thermal overload

switch will automatically reset itself after the

excessive heat condition has subsided; however, before

attempting to restart the machine, always check to find

out the reason for the overload (e.g., machine not fully

drained before spin, defective motor, continual out of

balance condition, low voltage, loss of one phase on

three phase motor, failed bearings, air circulation

blocked to motor fan). The thermal overload switch

should not open under normal operating conditions.

Failure to take corrective action when the indicator

lamp is lit will ultimately result in damage to the

motor(s).

If you have difficulty in locating the problem, do not

hesitate to call the factory.

F232161

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Notes

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232161

Loading...

Loading...