Page 1

Washer-Extractors

Pocket Hardmount

Va ri ab le -S pe ed

V-Series Microcomputer

Models UW100VV and UW125VV

For Designs 1-4

NOTA: El manual en

español aparece después

del manual en inglés.

Operation/Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

Part No. F232123R3

March 2006

Page 2

Page 3

Table of

Contents

Safety.................................................................................................... 3

Key to Symbols..................................................................................... 4

Safety Decals ........................................................................................ 5

Operator Safety..................................................................................... 6

Safe Operating Environment ................................................................ 6

Environmental Conditions............................................................... 6

Machine Location ............................................................................ 7

Input and Output Services................................................................ 7

AC Inverter Drive ............................................................................ 8

Misuse................................................................................................... 8

Operation............................................................................................. 9

Model Identification ............................................................................. 9

Customer Service.................................................................................. 9

Machine Familiarization Guide ............................................................ 11

Theory of Operation ............................................................................. 12

V-Computer ..................................................................................... 12

Keypad ............................................................................................. 13

Conditions Monitored by the Computer .......................................... 13

Start-Up................................................................................................. 15

Opening Door ....................................................................................... 15

Loading................................................................................................. 15

Cycle Selection..................................................................................... 15

Cycle Execution.................................................................................... 16

Fill.................................................................................................... 16

Wash ................................................................................................ 16

Drain ................................................................................................ 17

Spin .................................................................................................. 17

Stop Routine ......................................................................................... 17

Balance Detection................................................................................. 18

Overtravel Limit Switch Balance Detection.................................... 18

AC Inverter Drive Balance Detection.............................................. 18

Motor Thermal Overload Indicator ...................................................... 18

Programming ...................................................................................... 19

Key Functions in Program Mode.......................................................... 19

Setup Mode........................................................................................... 19

Degrees Displayed in Fahrenheit or Celsius.................................... 20

Procedure for Temperature Calibration ........................................... 20

Auxiliary Heat.................................................................................. 21

Supply 5 or Auxiliary Fill................................................................ 21

Temperature-Controlled Fill............................................................ 21

Automatic Cool-Down..................................................................... 21

Cycle Count .......................................................................................... 21

Cycle Programming.............................................................................. 21

Cycle Options................................................................................... 22

Segment Programming..................................................................... 22

© Copyright 2006, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Test Cycle............................................................................................. 25

Cycle Segment Charts........................................................................... 27

V-Computer Cycle Charts .................................................................... 31

Cycle Programming Worksheet....................................................... 37

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 5

Safety

Anyone operating or servicing this machine must

follow the safety rules in this manual. Particular

attention must be paid to the CAUTION, WARNING,

and DANGER blocks which appear throughout the

manual.

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

WARNING

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel

familiar with electrical test procedures,

test equipment, and safety precautions

should attempt adjustments and

troubleshooting. Disconnect power from

the machine before removing the control

box cover, and before attempting any

service procedures.

SW005

The following warnings are general examples that

apply to this machine. Warnings specific to a particular

operation will appear in the manual with the

discussion of that operation.

DANGER

Death or serious injury can result if

children become trapped in the machine.

Do not allow children to play on or around

this machine. Do not leave children

unattended while the machine door is

open.

SW001

CAUTION

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

SW020

WARNING

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety

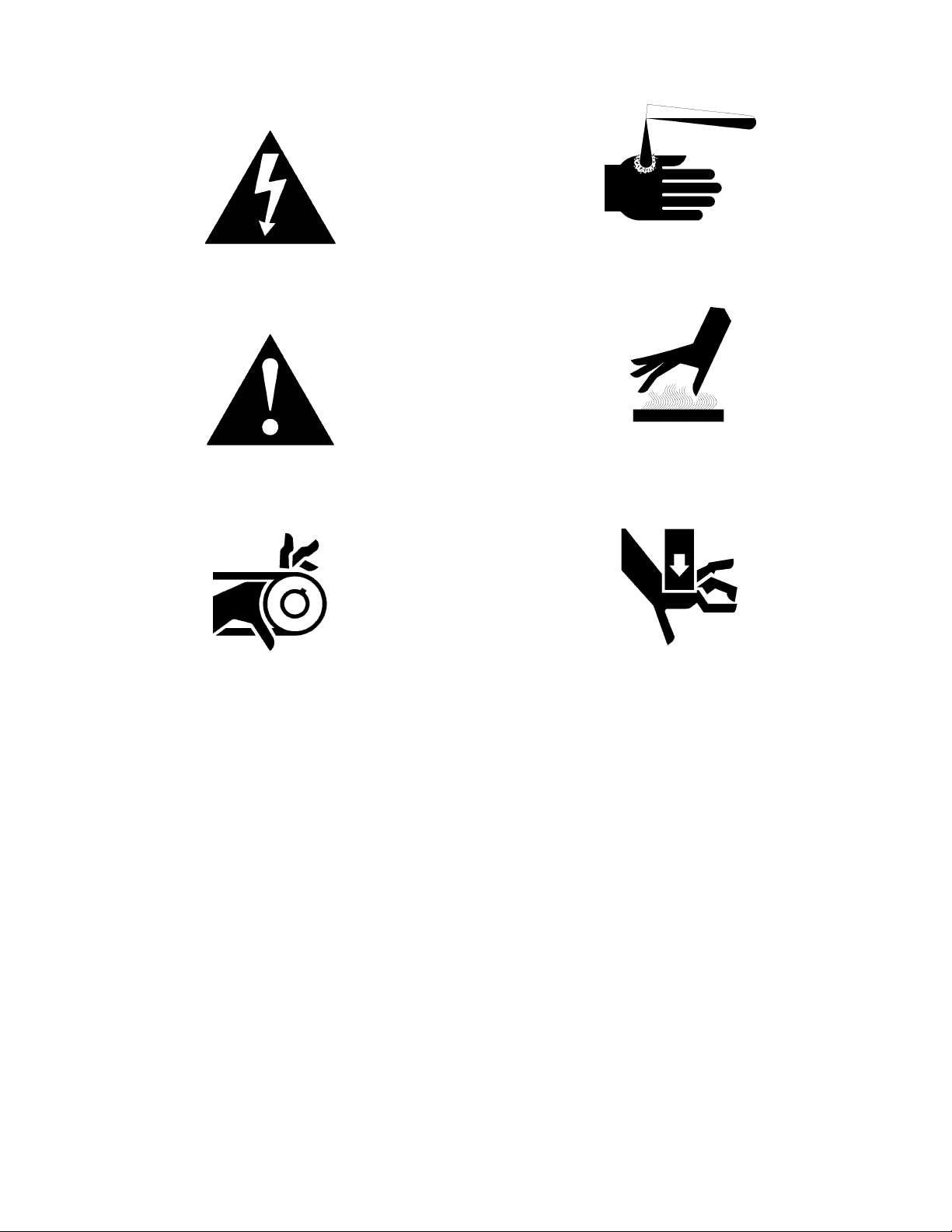

Key to Symbols

The lightning flash and arrowhead within the triangle

is a warning sign indicating the presence of dangerous

voltage.

The exclamation point within the triangle is a warning

sign indicating important instructions concerning the

machine and possibly dangerous conditions.

This warning symbol indicates the presence of possibly

dangerous chemicals. Proper precautions should be

taken when handling corrosive or caustic materials.

This warning symbol indicates the presence of hot

surfaces that could cause serious burns. Stainless steel

and steam lines can become extremely hot and should

not be touched.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms within the

machine. Guards should always be in place when the

machine is in operation.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving mechanical

parts can crush and/or sever body parts.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 7

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals could

result in injury to the operator or service technician.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If questions

regarding safety arise, contact the factory immediately.

Use factory-authorized spare parts to avoid safety

hazards.

Safety

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Safety

Operator Safety

WARNING

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

To ensure the safety of machine operators, the following

maintenance checks must be performed daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in the machine.

WARNING

Never operate the machine with a

bypassed or disconnected balance

system. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW039

Safe Operating Environment

Safe operation requires an appropriate operating

environment for both the operator and the machine. If

questions regarding safety arise, contact the factory

immediately.

Environmental Conditions

● Ambient Temperature. Water in the machine will

freeze at temperatures of 32°F (0°C) or below.

Temperatures above 120°F (50°C) will result in

more frequent motor overheating and, in some

cases, malfunction or premature damage to solid

state devices that are used in some models.

Special cooling devices may be necessary.

Water pressure switches are affected by increases

and decreases in temperature. Every 25°F

(10°C) change in temperature will have a 1%

effect on the water level.

● Humidity. Relative humidity above 90% may

cause the machine’s electronics or motors to

malfunction or may trip the ground fault

interrupter. Corrosion problems may occur on

some metal components in the machine.

If the relative humidity is below 30%, belts and

rubber hoses may eventually develop dry rot.

This condition can result in hose leaks, which

may cause safety hazards external to the machine

in conjunction with adjacent electrical

equipment.

● Ventilation. The need for make-up air openings

for such laundry room accessories as dryers,

ironers, or water heaters must be evaluated

periodically. Louvers, screens, or other

separating devices may reduce the available air

opening significantly.

● Radio Frequency Emissions. A filter is available

for machines in installations where floor space is

shared with equipment sensitive to radio

frequency emissions.

● Elevation. If the machine is to be operated at

elevations of over 3280 feet (1000 meters) above

sea level, pay special attention to water levels and

electronic settings (particularly temperature) or

desired results may not be achieved.

● Chemicals. Keep stainless steel surfaces

freeofchemical residues.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 9

DANGER

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel

reducers, carbon tetrachloride, gasoline,

benzene, naptha, etc. Doing so could

result in serious personal injury and/or

damage to the machine.

SW002

● Water Damage. Do not spray the machine with

water. Short circuiting and serious damage may

result.

Machine Location

● Foundation. The concrete floor must be of

sufficient strength and thickness to handle the

floor loads generated by the high extract speeds

of the machine.

● Service/Maintenance Space. Provide sufficient

space to allow comfortable performance of

service procedures and routine preventive

maintenance.

This is especially important in connection with

machines equipped with an AC inverter drive.

Consult installation instructions for specific details.

Safety

Input and Output Services

● Wate r Pressure. Best performance will be

realized if water is provided at a pressure of

30 – 85 psi (2.0 – 5.7 bar). Although the machine

will function properly at lower pressure,

increased fill times will occur. Water pressure

higher than 100 psi (6.7 bar) may result in

damage to machine plumbing. Component

failure(s) and personal injury could result.

● Steam Heat (Optional) Pressure. Best

performance will be realized if steam is provided

at a pressure of 30 – 80 psi (2.0 – 5.4 bar). Steam

pressure higher than 125 psi (8.5 bar) may result

in damage to steam components and may cause

personal injury.

For machines equipped with optional steam heat,

install piping in accordance with approved

commercial steam practices. Failure to install the

supplied steam filter may void the warranty.

● Compressed Air. For machines requiring

compressed air service, best performance will be

realized if air is provided at a pressure of

80 – 100 psi (5.4 – 6.7 bar).

● Drainage System. Provide drain lines or troughs

large enough to accommodate the total number of

gallons that could be dumped if all machines on

the site drained at the same time from the highest

attainable level. If troughs are used, they should

be covered to support light foot traffic.

CAUTION

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any safety

devices.

SW019

● Powe r. For personal safety and for proper

operation, the machine must be grounded in

accordance with state and local codes. The

ground connection must be to a proven earth

ground, not to conduit or water pipes. Do not use

fuses in place of the circuit breaker. An easyaccess cutoff switch should also be provided.

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground

lug near the input power block on this

machine. Without proper grounding,

personal injury from electric shock could

occur and machine malfunctions may be

evident.

SW008

Always disconnect power and water supplies before

a service technician performs any service procedure.

Where applicable, steam and/or compressed air

supplies should also be disconnected before service

is performed.

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Safety

AC Inverter Drive

Machines equipped with the AC inverter drive require

special attention with regard to the operating

environment.

● An especially dusty or linty environment will

require more frequent cleaning of the AC inverter

drive cooling fan filter and of the AC inverter

drive itself.

● Power line fluctuations from sources such as

uninterruptible power supplies (UPS) can

adversely affect machines equipped with the AC

inverter drive. Proper suppression devices should

be utilized on the incoming power to the machine

to avoid problems.

● A clean power supply free from voltage spikes

and surges is absolutely essential for machines

equipped with the AC inverter drive. Nonlinear

inconsistencies (peaks and valleys) in the power

supply can cause the AC inverter drive to

generate nuisance errors.

If voltage is above 240 Volt for 200 Volt

installations or above 480 Volt for 400 Volt

installations, a buckboost transformer is required.

Misuse

Never use this machine for any purpose other than

washing fabric with water.

● Never wash petroleum-soaked rags in the

machine. This could result in an explosion.

● Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

● Never allow children to play on or around this

machine. Death or serious injury can result if

children become trapped in the machine. Do not

leave children unattended while the machine door

is open. These cautions apply to animals as well.

● Sufficient space to perform service procedures

and routine preventive maintenance is especially

important for machines equipped with the AC

inverter drive.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 11

Operation

Model Identification

Information in this manual is applicable to these

models:

UW100VV*

UW125VV*

*This manual applies to models with U1, U2, U3 or

U4 in the 9

(e.g., UW100VVXU4

Familiarization Guide.

This manual is designed as a guide to operating

and programming the 100 pound and 125 pound

capacity pocket hardmount washer-extractor equipped

with the V-computer and AC inverter drive.

The manuals, installation instructions, and wiring

diagrams which accompany the machine have been

included with the machine at no charge. Additional

copies are available at a nominal charge.

NOTE: Read this manual thoroughly before

attempting to operate the machine or program the

microcomputer.

th

and 10th positions in the model number

0001). Refer to Model Number

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased

or contact Alliance Laundry Systems LLC at

(920) 748-3950 for the name and address of the

nearest authorized parts distributor.

For technical assistanc

A record of each machine is on file with the

manufacturer. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance.

e call:

(920) 748-3121

Ripon, Wisconsin

www.comlaundry.com

NOTE: Do not use this manual in conjunction with

earlier model computer-controlled machines. Do

not use technical literature intended for earlier

models when operating this machine.

NOTE: All information, illustrations, and

specifications contained in this manual are based

on the latest product information available at the

time of printing. We reserve the right to make

changes at any time without notice.

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Operation

Model Number Familiarization Guide

Sample Model Number: UW100VVXU40001

UW

100

V

V

X

4

0001

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control

Washer-Extractor Speed Capabilities

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

UW100VVXU40001

00000000000

200 – 240

14

20

50 – 60 2/3

1/3

Drawings:

60 27

N/A

ETL Listed

Conforms To ANSI/UL Std. 1206, 3rd Ed

Certified To CAN/CSA Std. C22.2 No.53-1968

EXAMPLE OF NAMEPLATE

Figure 1

N/A

813

0.0

PHM627N

PHM627N

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 13

Operation

Machine Familiarization Guide

The machine familiarization guide in Figure 2

provides front and rear views of the washer-extractor

14

13

12

11

Down

Up

WARNING

MACHINE MAY BE HOT

AND CAUSE BURNS

ATTEMPT NO ENTRY UNTIL

BASKET HAS STOPPED

SERIOUS INJURY MAY RESULT

and identifies the major operational features of the

machine.

1

2

p

o

t

S

y

c

n

e

rg

e

m

E

R

k

c

o

l

n

U

r

o

o

D

d

l

o

H

d

n

a

s

Stop

s

e

r

P

Start

3

4

5

6

10

9

P005I

1 Emergency Stop Button 8 Side Panel

2 Supply Valve Box 9 Front Panel

3 Supply Dispenser 10 Rub Rail

4 Door Handle 11 Shell Front

5 Door Box 12 Door Hinge

6 Door Latch Extension Arm 13 Door

7 Door Latch 14 Control Module

Figure 2

7

8

P005I

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Operation

Theory of Operation

The design of the machine emphasizes performance

reliability and long service life. The cylinder, shell,

and main body panels are fabricated of stainless steel.

The cylinder is driven by a V-drive system supported

via the shaft by two flange-mounted spherical roller

bearings bolted to the A-frame.

The machine uses one motor to drive the cylinder via a

V-belt drive in all speeds.

A door-lock system prevents opening of the stainless

steel door when water is in the machine. It also

prevents operation of the machine when the door is

open.

Electrically operated drain valves are used to retain the

water and wash solution in the machine during the

wash and fill steps. The drain valve closes when power

is applied and opens when power is removed, allowing

the machine to drain in the event of a power failure.

The cylinder is designed with lifters or ribs that lift the

garments from the wash solution when the cylinder

rotates at slow speed and allow the garments to tumble

back into the solution. The cylinder is perforated,

allowing the water to pass through and drain from

within during the wash process and extract.

Electrical controls for the machine are housed in a

separate enclosure located underneath the top cover of

the machine.

There are two possible load balance systems, the “AC

Inverter Drive Balance Detection” and the “Overtravel

Balance Detection.”

The balance detection system using the overtravel

limit switch does not rely on the AC inverter drive and

does not attempt to balance the load in a drain step. As

the cylinder is spinning at the programmed speed, if

the wash load becomes unbalanced, the overtravel

limit switch is “tripped” causing the cylinder to slow

to a stop until the end of the spin step.

The machine uses an AC inverter drive control which

provides five motor speeds using a single motor. The

solid state output board converts motor logic from the

V-computer to the correct signals for the AC inverter

drive.

The operator can select from among 30 cycles. A

special permanent test cycle can be selected to verify

proper operation of the machine.

Liquid supplies can be injected directly into the cups

by a customer-supplied external chemical supply

system. Five hose strain reliefs on top of the supply

dispenser facilitate connection to an external supply

system. A terminal strip inside a compartment

attached to the left side of the control module, viewed

from the rear of the washer-extractor, provides

connection points for external supply signals.

V-Computer

The V-computer control is a programmable solid-state

control capable of storing and running up to 30 cycles.

A detailed description of these cycles can be found in

the Programming section of this manual.

If this machine’s computer has been equipped with

special preprogrammed cycles, a separate insert listing

these cycles has been included in the resealable plastic

bag which contained this manual.

NOTE: Never turn the power off while the

computer mode switch is in the Program position.

Such action will disorder portions of the

programmed data, necessitating reprogramming of

some or all of the existing cycles. Always return the

mode switch to Run position before turning the

power off.

The balance detection system using the AC inverter

drive uses special balance detection software in

conjunction with the V-computer to prevent out-ofbalance conditions. When the AC drive detects an

unbalanced load at the end of a drain step, the

computer will make up to seven attempts to balance

the load. After the seventh try the machine spins at a

safe speed. As a fail-safe measure, an overtravel limit

switch is installed.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 15

Operation

Keypad

Operation of the V-computer control is performed with

a four-key touch keypad and LED display located on

the front of the machine. Refer to Figure 3.

1

1 Out-of-Balance Condition

2 High Water Level

3 Medium Water Level

4 Low Water Level

2

Figure 3

Table 1 describes the function of the individual keys

when the machine is in Run Mode.

Keypad

Key Description

Up

Down

Start

Stop

Used in cycle selection; pressing this key

moves among cycles from smaller to greater.

Used in cycle selection; pressing this key

moves among cycles from greater to smaller.

Used to start a cycle.

Used to stop a cycle.

3

4

PHM199R

Conditions Monitored by the Computer

● Door – The computer continuously monitors

the open/locked status of the door. If it detects

that the door is open during a wash cycle, it

immediately aborts the cycle and executes the

stop routine.

● Power – If power is interrupted long enough

for the computer to go off, after the power is

restored, the display flashes “Hold” briefly to

indicate the interruption. The door unlock will be

disabled to keep the door from being opened

while the basket is still turning.

● Balance – If the AC inverter balance detection

system is utilized, the computer monitors the

balance signal provided by the AC drive during

drain steps. The computer will attempt to

distribute the load seven times. The dot at the

top of the leftmost display digit will light

following the final unsuccessful attempt. If the

inverter balance detection is not utilized, this dot

will not light.

● Water level – The computer attempts to maintain

the water level programmed for the fill preceding

the agitation step. If the level falls below the

programmed level, the computer will stop the

time countdown and re-energize the fill valves

until the level is restored.

● Water level in a heat step – In order for the

computer to energize the heat output, there must

be at least a low water level in the machine. If this

minimum level is not detected, the heat output

will be turned off until the required level is

restored.

● Temperature probe problem – If the

temperature sensor fails when prompted for

degrees Fahrenheit, the computer flashes “tSFL”

in Program Mode rather than showing the

temperature. If the temperature sensor fails when

prompted for degrees Celsius, the display will

read “-17C” rather than showing the temperature.

F232123

Table 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Operation

Table 2 lists the various displays and what they mean.

The operator should become familiar with these

computer displays.

Display Indications

Display Meaning Display Meaning

FPC3, bP3

Hold Wait...power has just been turned on. HI High water level

CY Cycle (followed by two-digit number) SUP1 Supply 1

tESt/CYC* Test cycle selected. SUP2 Supply 2

FAr Degrees Fahrenheit SUP3 Supply 3

CEL Degrees Celsius SUP4 Supply 4

HEAt Auxiliary heat enabled. SUP5 Supply 5 (SETUP option)

noHt Auxiliary heat disabled. SUP6 Supply 6 (supply 1 and 5)

tFIL Temperature-controlled fill enabled. SUP7 Supply 7 (supply 3 and 4)

ntFL Temperature-controlled fill disabled. SLo/For** Gentle wash speed, forward direction

CooL Automatic cool-down enabled. SLo/rEv** Gentle wash speed, reverse direction

noCL Automatic cool-down disabled. norn/For Normal wash speed, forward direction

Ag 1 Agitation 1 selected (90% agitation). norn/rEv Normal wash speed, reverse direction

Ag 2 Agitation 2 selected (33% agitation). drAI Drain enabled.

Ag 3 Agitation 3 selected (10% agitation). nodr Drain disabled.

Ag 4 Agitation 4 selected (6.7% agitation). dISt Distribution (load balancing before extract)

AgSn Agitation speed normal

AgSL** Agitation speed low

nP Pump output enabled (future use only). SPn1 Lowest of three spins

PU

nPnP Pump output disabled (future use only). SPn2 Middle of three spins

PrE PreWash segment (1st of 11 segments) SPn3 Highest of three spins

UASH Wash segment (2nd of 11 segments) STOP Stop routine

FIL1 First fill (3rd of 11 segments) SdLY Spin coast delay

FIL2 Second fill (4th of 11 segments) donE Cycle and stop routine have ended.

FIL3 Third fill (5th of 11 segments) dFLt Drive fault detected.

FIL4 Fourth fill (6th of 11 segments) door Door not properly closed.

FIL5 Fifth fill (7th of 11 segments)

FIL6 Sixth fill (8th of 11 segments)

FIL7 Seventh fill (9th of 11 segments)

FIL8 Eighth fill (10th of 11 segments)

FIL9 Ninth fill (11th of 11 segments)

CFIL Cold fill

bFIL Warm fill (both hot and cold)

HFIL Hot fill

AFIL Auxiliary fill (SETUP option) tSFL Temperature sensor failure or temperature out of range.

SPC? Special test cycle function (if present, ignore) bAL? Special test cycle function (if present, ignore)

* Display indications separated by a slash represent a flashing display.

** For UW100VV and UW125VV models, the washer-extractor will operate at normal wash speed regardless of the speed settings.

† This occurs only in the TEST cycle and only if the AC inverter drive balance detection is used. If the AC inverter drive balance detection is not used, this

will NOT appear during the TEST cycle (note, there are two types of balance systems).

Program identification code (ROM)

These are examples only.

Lo Low water level

nEd Medium water level

SPIn/tInE*

bAL/FAIL*†

FILL/STOP*

FULL

rotA

Table 2

Reads “SPIn” for one second, then “tI

time for spin.

Balancing routine failed during test cycle after

7 attempts to balance load.

Programmed water level not reached after

30 minutes.

The computer detects low water level or higher when

none should be present.

Computer detects possible rotation of motor when there

should be none.

nE” followed by

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 17

Operation

Start-Up

Turn on the main power source (circuit breaker or cutoff switch on the wall).

An identification code will appear for approximately

five seconds. Then the display will flash “Hold”

briefly.

The display will then read “CY” followed by a twodigit cycle number (01 – 30) to indicate that a cycle

can be selected. This display will be shown at all times

when power is on between cycles, indicating that the

door-unlock solenoid will function if the door-unlock

button is pressed. The machine is then ready for

loading and unloading.

Opening Door

Press and hold the door-unlock button next to the door

handle and turn door handle upward.

Loading

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

Load the machine to full capacity whenever possible,

but do not exceed the rated dry-weight capacity of the

machine if the fabric to be washed is quite dense,

closely woven, and heavily soiled. Overloading can

result in an inferior wash. The operator may need to

experiment to determine load size based on fabric

content, soil content, and level of cleanliness required.

When loading is complete, ensure that all fabric is

inside the basket. Then close and lock the door by

rotating the door handle clockwise until the door

handle is horizontal. The machine should not start or

run unless the door is both closed and locked.

CAUTION

Check the door safety interlock daily

before the machine is placed in operation.

SW024

NOTE: When washing items which may

disintegrate, such as mop heads or sponges, use

laundry net bags to prevent drain blockage.

Cycle Selection

NOTE: Press keys at their centers just hard enough

to activate them.

Press the Up or Down key until the desired cycle

number is displayed. The computer will skip blank

(unprogrammed) cycles automatically. Press the Start

key to start the cycle. For a more detailed description

of the preprogrammed cycles, refer to the cycle charts

at the end of the Programming section.

If the computer detects that the door is not properly

closed when the Start key is pressed, the display will

read “door” until the door is closed and locked. Press

Start again to begin the desired cycle.

NOTE: Washing small loads can cause out-ofbalance conditions which shorten life of bearing,

seals, basket/shaft assembly, etc.

WARNING

Never operate the machine with a

bypassed or disconnected balance

system. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

SW039

15

Page 18

Operation

Cycle Execution

A cycle can be stopped at any time by pressing the

Stop key. The machine will go to the stop routine.

When the routine is complete, the display shows

“donE” until the door is unlocked.

To display the temperature of the water while a cycle

is running, press the Up key. To display the number of

the cycle in progress, press the Start key.

NOTE: The computer does not count down the

remaining cycle time during fills, drains, cooldown, or prior to first achieving the programmed

heat temperature when heating. The computer

resumes counting down cycle time once the

programmed fill level is reached, when the machine

has drained, and after a programmed heat

temperature is reached.

Each of the 30 cycles consists of 11 segments:

PreWash, Wash, and Fills 1 – 9. A description of the

various steps in a cycle segment follows:

Fill

After the Start key is pressed, the drain closes and the

machine begins filling to the programmed level. Each

programmed segment begins with a fill. The display

counts down the remaining cycle time in minutes and

seconds while the cycle is running.

Wash

As soon as water level is reached (and any

programmed temperature is reached), the displayed

time begins counting down at one-second intervals.

Agitation is active during this portion of the segment.

There are four different agitation actions available.

Refer to Table 3 for more information.

Agitation Action Options

Display Description Percentage

27 seconds forward,

Ag 1

Ag 2

Ag 3

Ag 4

3 seconds pause,

27 seconds reverse,

3 seconds pause

10 seconds forward,

20 seconds pause,

10 seconds reverse,

20 seconds pause

3 seconds forward,

27 seconds pause,

3 seconds reverse,

27 seconds pause

4 seconds forward,

56 seconds pause,

4 seconds reverse,

56 seconds pause

90%

33%

10%

6.7%

If a supply is programmed in a step, the supply

dispenser will flush during the fill of that segment.

If the machine is connected to an external chemical

supply system, the programmed supply will begin

10 seconds into the fill. The supply will remain on

until the programmed water level is reached, or until

60 seconds have elapsed, whichever happens first.

If agitation options 1 or 2 are selected for the cycle

program, the cylinder will rotate slowly during the fill

step. If agitation options 3 or 4 are selected for the

cycle program, the cylinder will not rotate during the

fill step. Refer to Table 3 for more information.

If the computer does not receive a signal that water

level has been attained within 30 minutes, it will

alternately flash “STOP” and “FILL” and sound the

on-board beeper for ten seconds. The computer will

then initiate the stop routine.

Table 3

If the segment contains a heat step, the machine begins

heating after the water has reached the programmed

level.

NOTE: If the water does not reach the

programmed temperature in 40 minutes, the

computer progresses to the wash step.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 19

Operation

Drain

If the cycle program segment calls for a drain, the

drain valves will open after the programmed segment

time has elapsed. If a spin step follows a drain step, the

cylinder will turn clockwise (forward) at wash speed

for several seconds at the beginning of the drain step.

This clockwise direction mirrors the spin rotation and

is, therefore, also considered forward.

The cylinder then accelerates to distribution speed to

help ensure that the load is evenly distributed. The

drains open several seconds later.

NOTE: The machine should drain in 30 seconds. If

the machine fails to drain, contact a qualified

service technician.

If the cycle program segment does not call for a drain,

the computer moves to the next segment of the cycle

program. If the segment is at the end of a cycle

program, the computer goes into the stop routine.

If the cycle program segment does not call for a spin,

the cylinder will continue to turn at wash speed

throughout the drain step. When the drain has

completed, the computer moves to the next segment of

the cycle program. If the segment is at the end of a

cycle program, the computer goes into the stop

routine.

NOTE: The drain step in the final segment (Fill 9)

cannot be skipped.

Stop Routine

When the computer concludes the wash cycle or when

the Stop key is pressed while a cycle is in progress, the

computer goes into the stop routine.

The stop routine sequence:

● All inputs are turned off

● A brief pause, allowing the cylinder to coast

down if in extract

● Brief rotation counterclockwise at wash speed

● A brief pause

● Brief rotation clockwise at wash speed

● A brief pause

● The display shows “donE”

● The door interlock is energized, allowing the

door to be opened

If the stop routine seems excessively long, check for

“FULL” or “rotA” messages. If this occurs, contact a

qualified service technician.

WARNING

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

Spin

After the drain sequence ends, the speed of the

cylinder increases to the extract speed if the

programmed spin time is not zero. The displayed time

resumes counting down at one-second intervals.

After the programmed spin time has elapsed, the

computer moves on to the fill step in the next segment

of the cycle. If the spin is at the end of the cycle, the

computer begins the stop routine.

Once “donE” is displayed, open the door by pressing

and holding the door-unlock button as described

earlier. Once the door is opened, the computer display

will show the most recent cycle number.

The machine is now ready to begin another wash

cycle.

NOTE: A test cycle is provided as a means of

verifying proper machine operation. Refer to the

Programming section for instructions on running

the test cycle.

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Balance Detection

Motor Thermal Overload Indicator

Each machine is equipped with either an AC inverter

drive balance detection system or an overtravel limit

switch balance detection system. To determine which

system the machine is equipped with, consult the

wiring diagram sent with the machine.

Overtravel Limit Switch Balance Detection

This system uses the overtravel limit switch only; the

AC drive balance detection system is not utilized. As

the cylinder is spinning at the programmed speed, if

the wash load becomes unbalanced, the overtravel

limit switch is “tripped” causing the cylinder to slow

to a stop until the end of the spin step.

AC Inverter Drive Balance Detection

Load balance is monitored by the AC inverter drive

during any drain step that immediately precedes a spin

step.

If a spin step follows a drain step, the cylinder

accelerates to distribution speed seven seconds into the

drain step.

The computer begins monitoring the balance signal

from the AC inverter drive eight seconds after the

water level drops below low level. If the balance signal

indicates that the wash load is evenly distributed, the

computer will start the spin step.

If the machine is equipped with a small indicator lamp

on the side of the control module, it will light to

indicate that a thermal overload switch in the motor

has shut off the AC power to the computer board,

thereby preventing damage to the motor caused by

overheating and/or an overload condition. This feature

protects and extends the life of the motor.

The thermal overload switch will automatically reset

itself after the excessive heat condition has subsided.

Before attempting to restart the washer-extractor,

determine the reason for the overload. The following is

a partial list of possible problems:

● Washer-extractor not fully drained before spin

● Out-of-balance condition

● Low voltage

● Loss of one phase on a three-phase motor

● Bad bearings

● Air circulation blocked to motor

Contact a service technician to correct serious

problems. Failure to take corrective action will

ultimately result in damage to the motor and/or the

inverter drive.

If the balance signal indicates that the wash load is

unbalanced, the computer will slow the cylinder down

to wash speed for seven seconds in an attempt to

redistribute the load. The computer will make as many

as seven attempts if needed.

If on the seventh attempt the load is not balanced, the

machine will light the out-of-balance LED indicator

located in the upper left corner of the display (to the

left of the first digit) until the drain step is complete.

The machine will then continue the spin speed at a

safe level.

If this occurs in the final segment, the machine will

skip the spin step and initiate the stop routine. The outof-balance LED indicator will remain lit until the door

is opened.

As a fail-safe measure, an overtravel limit switch will

“trip” during a spin if the wash load becomes severely

unbalanced, slowing the cylinder to a stop until the end

of the spin step.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 21

Programming

The V-computer board is inside the control module.

Near the center of the board is a small toggle switch:

this is the Run/Program Mode switch.

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel

familiar with electrical test procedures,

test equipment, and safety precautions

should attempt adjustments and

troubleshooting. Disconnect power from

the machine before removing the control

box cover, and before attempting any

service procedures.

SW005

The Run/Program switch is normally in the down (Run

Mode) position. To enter Program Mode, flip the

switch to the up position. The display will now show

the current temperature in the sump.

1

Key Functions in Program Mode

Up – The Up key is used to increase cycle numbers

(1 through 30) and other numerical values such as

times or temperatures (when creating wash formulas).

Down – The Down key is used to decrease cycle

numbers (1 through 30) and other numerical values

such as times or temperatures (when creating wash

formulas).

Start – The Start key acts as an enter key in Program

Mode. Use this key to enter data and move to the next

function in the cycle.

Stop – The Stop key saves all data and terminates the

programming procedure. If it is the first key pressed in

Program Mode, the computer enters Setup Mode. The

Stop key can be pressed again to exit Setup Mode and

return to Program Mode.

Setup Mode

Setup options are programmable options that are in

effect for all wash formulas. These options include:

● Degrees displayed in Fahrenheit or Celsius

● Auxiliary heat enabled or disabled

2

CHM474R

1 Run/Program Mode Switch

2 Temperature Calibration Screw

Figure 4

Since the keypad operates in a slightly different

fashion when in Program Mode, pay careful attention

to the programming instructions provided in this

manual.

● Supply 5 or Auxiliary fill

● Temperature-controlled fill enabled or disabled

● Automatic cool-down enabled or disabled

NOTE: These options can be read or changed only

in Setup Mode.

To enter Setup Mode, press the Stop key while the

display is showing the temperature in the sump. Once

in Setup Mode, use the Up or Down key to change the

selected option. Use the Start key to accept the

selected option and move on to the next one. Press the

Stop key to exit Setup Mode.

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Programming

Degrees Displayed in Fahrenheit or

Celsius

WARNING

This setup option affects the programming and display

of all temperatures. If “FAr” is selected, all

temperatures will display in Fahrenheit. If “CEL” is

selected, all temperatures will display in Celsius.

Acceptable ranges for programmable temperatures are

75° – 200°F or 25° – 93°C.

Procedure for Temperature Calibration

1. Ensure that the V-Computer has no input power

applied.

2. Mount an accurate temperature sensor probe

(part of temperature calibration equipment) in the

bottom of the machine basket. Make sure the

wires for the probe exit the top of the door to

ensure the door gasket does not leak.

3. Close door and ensure that the door is locked.

4. Open machine top cover and remove control

component cover(s), if necessary, to gain access

to the V-Computer and output control board.

NOTE: For more accurate calibration proceed with

steps 5-9. For a quick estimated calibration skip to

step 10.

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

6. Restore input power to the machine.

7. Wait until machine message displays “CY”

followed by a two-digit cycle number (01 – 30).

8. Program one of the unused cycles to Fill to High

Level using both of the water inlet valves. Select

a time limit that would be sufficient to complete

the calibration procedure.

9. When machine has completed the Fill to High

Level, press and hold the Up key to display the

machine temperature. Make sure that the

V-Computer is in the correct temperature unit

(deg F or C). Refer to Setup Mode section of

manual to change.

10. Using a flat bladed screwdriver, turn the machine

temperature calibration screw until the displayed

temperature of the machine and the temperature

of the temperature calibration equipment are

accurate to the nearest degree (refer to Figure 4).

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel

familiar with electrical test procedures,

test equipment, and safety precautions

should attempt adjustments and

troubleshooting. Disconnect power from

the machine before removing the control

box cover, and before attempting any

service procedures.

SW005

5. Note wire connections on the output control

board for the AC Drive control. Some machines

will have six wires connected to “STF,” “STR,”

“RH,” “RM,” “RL,” and “COM” individually or a

single connector labeled “J11-1.” Remove these

wires or connector to ensure the basket will not

rotate. Also remove the input power to the drive.

NOTE: If this step is not followed, damage can

occur to the calibration temperature probe.

11. When the temperatures match, calibration is

completed.

12. Remove power from the machine input.

13. Reconnect any wires/connectors/fuses that were

removed, making sure they are installed exactly

as they were removed.

14. Reinstall all machine protective covers.

15. Remove the temperature calibration probe from

the bottom of the machine basket.

16. Restore input power to machine.

17. Machine is now ready for use.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 23

Programming

Auxiliary Heat

Heat is a dedicated output of the V-computer, which

controls an optional heat source. If “noHt” is selected,

the heat output will never energize during a cycle

(except briefly in the test cycle to ensure that the

output functions properly), regardless of programmed

temperature settings. If “HEAt” is selected, the output

will energize during a cycle if the three following

conditions are true:

● A nonzero heat temperature is programmed.

● The computer senses that the present temperature

is below the programmed target temperature.

● There is at least a low water level in the machine.

NOTE: Do not enable the auxiliary heat setup

option and disable the temperature-controlled fill

option on machines not equipped with auxiliary

heat. The machine will pause for 40 minutes during

any cycle segment where the fill water temperature

does not equal or exceed the programmed value of

the heat step.

Supply 5 or Auxiliary Fill

Cycle Count

To display the current cycle count, press the Start key

while the display is showing the temperature in the

sump. The display will show a two-digit number

indicating how many cycles have been run to

completion (cycles which were stopped in progress are

not counted). Press the Start key to return to Program

Mode without resetting the count. Press the Up or

Down key to reset the count to zero and return to

Program Mode.

Cycle Programming

To edit an existing cycle or create a new cycle, press

the Up key while the display is showing the

temperature in the sump. The display will show

“CY01.” Press the Up or Down key until the desired

cycle number is displayed. Press the Start key to begin

editing the selected cycle.

If “SUP5” is selected, the output labeled AF on the

solid state output board can be used to control a fifth

supply signal. This setup option must be selected to

program an “SUP5” or an “SUP6” (supply 1 and

supply 5 combined) in a cycle step.

If “AFIL” is selected, the output labeled AF can be

used to control an auxiliary fill valve. Auxiliary fills

can be programmed to low, medium, or high water

level. This setup option must be selected to program an

“AFIL” in a cycle step.

Temperature-Controlled Fill

If “tFIL” is selected, a temperature-controlled fill can

be programmed for any segment. This setup option

must be selected to program a “tFIL” in a cycle step. If

“ntFL” is selected, this feature is disabled.

Automatic Cool-Down

If “CooL” is selected, the automatic cool-down feature

is enabled. If the wash solution is 140°F (60°C) or

higher when a cycle step calls for a drain, the washing

action will continue and the cold water valve will

begin flushing cold water into the wash solution. Once

the wash solution temperature drops below 140°F

(60°C), the drains open and the cycle continues as

programmed. If “noCL” is selected, this feature is

disabled.

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Programming

Cycle Options

Cycle options are programmable options that are in

effect for the duration of the selected wash cycle.

These options include:

● Agitation action

● Agitation speed (defaults to normal wash speed

regardless of setting)

● Recirculation pump enabled or disabled (for

possible future application)

NOTE: Cycle option settings are unique to the cycle

for which they are programmed.

Use the Up or Down key to change the selected option.

Use the Start key to accept the selected option and

move on to the next one.

Agitation Action

The programmer may choose among four agitation

actions. Refer to Table 4.

Agitation Action Options

Display Description Percentage

27 seconds forward,

Ag 1

Ag 2

3 seconds pause,

27 seconds reverse,

3 seconds pause

10 seconds forward,

20 seconds pause,

10 seconds reverse,

20 seconds pause

90%

33%

Agitation Speed

If “AgSn” or “AgSL” is selected, the machine will

default to normal wash speed regardless of the setting.

Recirculation Pump

This cycle option setting is intended to be used with

a possible future recirculation application. Selecting

either “nP

the wash cycle. However, the “nP

nP” or “PUnP” will have no bearing on

nP” setting is

recommended to prevent the corresponding output

on the output board from energizing.

Press the Start key after selecting this last cycle option

setting to begin editing the cycle segments.

Segment Programming

All cycle programs (“CY01” – “CY30”) can be

customized within a preset program structure. Each

cycle program consists of eleven program segments.

Refer to Table 5.

Cycle Program Segments

Segment Display

PreWash PrE

Wash UA SH

Fill 1 FIL1

Fill 2 FIL2

Fill 3 FIL3

Fill 4 FIL4

3 seconds forward,

Ag 3

Ag 4

27 seconds pause,

3 seconds reverse,

27 seconds pause

4 seconds forward,

56 seconds pause,

4 seconds reverse,

56 seconds pause

Table 4

10%

6.7%

The selected agitation applies to the entire cycle. It is

possible to progam a different agitation action for each

of the 30 cycles. When “Ag 3” or “Ag 4” is in effect,

there is no agitation during the fill.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Fill 5 FIL5

Fill 6 FIL6

Fill 7 FIL7

Fill 8 FIL8

Fill 9 FIL9

Table 5

F232123

Page 25

Programming

When modifying a cycle, a time must be entered for

each segment. To skip a segment or spin, set the time

to “00” and press the Start key. Table 6 gives the time

parameters for each segment and spin, as well as the

allowable temperature range.

Time and Temperature Parameters

Function Minimum Maximum

PreWash 2 minutes 30 minutes

Wash 2 minutes 20 minutes

Fill 1 2 minutes 15 minutes

Fill 2 2 minutes 15 minutes

Fill 3 2 minutes 15 minutes

Fill 4 2 minutes 15 minutes

Fill 5 2 minutes 15 minutes

Fill 6 2 minutes 15 minutes

NOTE: The computer does not count down the

remaining cycle time during fills, drains, cooldown, or prior to first achieving the programmed

heat temperature when heating. The computer

resumes counting down cycle time once the

programmed fill level is reached, when the machine

has drained, and after a programmed heat

temperature is reached.

3. If the temperature-controlled fill setup option is

enabled, the display will show “tFIL.” Press the

Start key.

4. Use the Up or Down key to select the desired fill

temperature. Refer to Table 7 for fill options.

Fill Temperature Options

Display Fill Type

CFIL Cold Fill

HFIL Hot Fill

bFIL Warm Fill

Fill 7 2 minutes 15 minutes

Fill 8 2 minutes 15 minutes

Fill 9 2 minutes 15 minutes

Intermediate Spin* 30 seconds 240 seconds

Final Spin** 1 minute 10 minutes

Temperature 75°F (25°C) 200°F (93°C)

* Programmed with wash segment through Fill 8.

** Programmed with Fill 9.

Table 6

NOTE: Spin times in cycle segments 1 – 10 are

entered in seconds (30 to 240), and time for final

spin in segment 11 is entered in minutes (1 to 10).

1. Press the Up key until the computer display

shows the segment to be edited. Press the Start

key.

2. Use the Up or Down key to select the desired

segment time. Set this value to zero to skip the

segment. Press the Start key.

AFIL Auxiliary Fill*

*This is available only if the “SUP5”/“AFIL” setup

option is set to “AFIL.”

Table 7

If the temperature-controlled fill setup option is

enabled and a target temperature is set, the

selected fill valve(s) will energize for the first

three seconds of the segment fill. The computer

will then begin operating the fill valves in an

attempt to reach the target temperature. Press the

Start key.

5. Use the Up or Down key to select the desired fill

level. Refer to Table 8.

Water Level Options

Display Fill Level

Lo Low Level

nEd Medium Level

HI High Level

F232123

Table 8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Programming

6. Press the Start key.

7. Use the Up or Down key to select the desired

supply option. Refer to Table 9.

Supply Options

Display Supply

SUP0 No Supply

SUP1 Supply 1

SUP2 Supply 2

SUP3 Supply 3

SUP4 Supply 4

SUP5 Supply 5*

SUP6 Supply 1 and 5*

SUP7 Supply 3 and 4

*This is available only if the “SUP5”/“AFIL” setup

option is set to “SUP5.”

Table 9

8. Press the Start key.

9. If the temperature-controlled fill or the auxiliary

heat setup option is enabled, use the Up or Down

key to select the desired segment temperature. To

disable auxiliary heat and temperature-controlled

fill for this segment, set this value to zero. Press

the Start key.

NOTE: If the temperature-controlled fill setup

option is enabled and an auxiliary fill has been

selected for the segment, the segment temperature

should be set to zero. Otherwise, the auxiliary fill

valve will enable for only three seconds at the

beginning of the fill before the computer begins

using the hot and cold fill valves to reach the

programmed temperature.

10. Use the Up or Down key to select the desired

drain option. If “drAI” is selected, the machine

will drain after the segment time has elapsed. If

“nodr” is selected, the machine will not drain and

the spin step will be skipped entirely. Press the

Start key.

NOTE: The drain step in the final segment (Fill 9)

cannot be skipped.

11. For final “FIL9” spin only, use the Up or

Down key to select the desired spin speed.

Refer Table 10.

Spin Options

Display Spin Speed

SPn1 Low Spin

SPn2 Medium Spin

SPn3 High Spin

Table 10

12. Press the Start key.

13. Use the Up or Down key to select the desired spin

time. Set this value to zero to skip the spin step.

Press the Start key. The display will now show

the identifier for the next program segment (or

return to the temperature display if the edited

segment is the Fill 9 segment).

NOTE: Every intermediate spin is followed by a

25 second coast-down period, which occurs during

the fill step for the following segment.

14. Press the Stop key at any time to complete the

cycle programming procedure.

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 27

Programming

Test Cycle

1. Verify that the Run/Program Mode toggle switch

is in the Run position.

2. Press the Up or Down key until the display

alternately flashes “tESt” and “CYC,” indicating

that the test cycle is selected.

3. Press the Start key to begin the test cycle.

NOTE: If “bAL?” or “SPC?” appear on display,

ignore it; computer will proceed automatically.

NOTE: Pressing the Start key while the test cycle is

in progress will immediately advance to the next

step in the test cycle. Drain and load balancing

steps may not be skipped.

The test cycle is as follows:

a. Once the Start key is pressed, the door

interlock is de-energized (preventing the door

from being opened), the drain valve closes,

the cylinder begins agitating at wash speed,

and both water inlet valves are energized. The

display alternately flashes “bFIL” and “Lo”

(both hot and cold fill valves on, filling to low

level).

b. When the water level switch indicates that low

water level has been reached, the water fill

valves shut off and the dot above and to the

immediate left of the fourth digit of the

display lights.

c. The cold water fill valve is energized. The

display alternately flashes “CFIL” and “

(cold fill valve on, filling to medium water

level).

d. When the water level switch indicates that

medium water level has been reached, the

cold water fill valve shuts off and the dot

above and to the immediate left of the third

digit of the display lights.

e. The hot water fill valve is energized. The

display alternately flashes “HFIL” and “HI”

(hot fill valve on, filling to high water level).

f. When the water level switch indicates that

high water level has been reached, the hot

water fill valve shuts off and the dot above

and to the immediate left of the second digit

of the display lights.

nEd”

g. The auxiliary heat output is energized,

provided that the water level switch indicates

that at least low water level is present. The

cold water fill valve is energized. The supply

1 output is energized for five seconds. The

display alternately flashes “SUP1” and

“HEAt” (supply 1 output on, auxiliary heat

output on).

h. The supply 2 output is energized for five

seconds. The display alternately flashes

“SUP2” and “HEAt” (supply 2 output on,

auxiliary heat output on).

i. The supply 3 output is energized for five

seconds. The display alternately flashes

“SUP3” and “HEAt” (supply 3 output on,

auxiliary heat output on).

j. The auxiliary heat output is turned off. The

supply 4 output is energized for five seconds.

The display shows “SUP4” (supply 4 output

on).

k. The supply 5/auxiliary fill output energizes

for five seconds. If the “SUP5”/“AFIL” setup

option is set to “SUP5,” the display shows

“SUP5” (supply 5/auxiliary fill output on).

If the “SUP5”/“AFIL” setup option is set

to “AFIL,” the display shows “AFIL”

(supply 5/auxiliary fill output on).

l. The cold water fill valve turns off. The

recirculation pump output is energized for

ten seconds, provided that the water level

switch indicates that at least low water level

is present. The display shows “PU

(recirculation pump output on).

m. The motor rotates counterclockwise

(in reverse) at normal wash speed for

60 seconds. The display alternately flashes

“SLo” and “rEv” (normal wash speed,

counterclockwise).

n. The motor rotates clockwise (forward) at

normal wash speed for 60 seconds. The

display alternately flashes “SLo” and “For”

(normal wash speed, clockwise).

o. The motor rotates counterclockwise (in

reverse) at normal wash speed for 60 seconds.

The display alternately flashes “nor

“rEv” (normal wash speed,

counterclockwise).

nP”

n” and

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Programming

p. The motor rotates clockwise (forward) at

normal wash speed for 60 seconds. The

display alternately flashes “nor

n” and “For”.

q. The display begins alternately flashing “drAI”

and “For” (drain step, cylinder rotating at

wash speed). The motor continues to rotate

clockwise (forward) at normal wash speed for

seven seconds.

r. The motor accelerates to distribution speed.

The display alternately flashes “drAI” and

“dISt” (drain step, cylinder rotating at

distribution speed).

s. The drain opens between 15 to 27 seconds

into the drain step. The water level indicator

lights on the display will begin to go out, one

by one, as the machine drains past each water

level.

t. The computer begins monitoring the balance

signal from the AC inverter drive several

seconds after the water level switch indicates

that water level has dropped below low level.

u. If the balance signal indicates that the wash

load is unbalanced, the cylinder will slow

down to wash speed for seven seconds in an

attempt to redistribute the load. The computer

will make as many as seven attempts, as

needed, in this cycle.

v. The cylinder accelerates to low spin speed.

The display shows “SPn1” (cylinder rotating

at low spin speed). The basket rotates at low

spin speed for 60 seconds.

w. The cylinder accelerates to medium spin

speed. The display shows “SPn2” (cylinder

rotating at medium spin speed). The basket

rotates at medium spin speed for 60 seconds.

x. The cylinder accelerates to high spin speed.

The display shows “SPn3” (cylinder rotating

at high spin speed). The basket rotates at high

spin speed for 60 seconds.

y. All outputs are turned off for roughly

20 seconds. The display shows “SdLY”

(spin coast delay).

z. The computer performs the normal stop

routine.

The door interlock is energized (allowing the

door to be opened), provided that the water

level switch indicates that water has fallen

below low level and that the AC drive

indicates that the motor has stopped.

NOTE: If the machine utilizes the overtravel limit

switch balance detection system, the computer will

proceed through the drain step and will time steps t

and u. The computer will then proceed to step v.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 29

Cycle Segment Charts

Segment 1 (PreWash)

Instructions

Display

Use Up or Down key to change. Press Start key to enter or advance.

PrE

00 or 02 to 30 Select segment time: 02 to 30 minutes (00 to skip segment).

tFIL Indicates temperature fill is enabled.*

Programming

HFIL, CFIL, bFIL,

or AFIL

Lo,

nEd, or HI Select fill level: “Lo” (low), “nEd” (medium), or “HI” (high) water level.

SUP0 – SUP7 Select supply 0 – 7 (0 for no supply).***

00°F, 75° – 200°F

00°C, 25° – 93°C

drAI or nodr Select drain option: “drAI” (drain), “nodr” (no drain).‡

SPIn (flashed for one second)

tI

nE (flashed for one second)

00 or 30 to 240 Select time for spin: 30 to 240 seconds (00 for no spin).

* This is displayed only if temperature-controlled fills are enabled in the setup options and if the heat temperature is set to

a value other than “00.”

** “AFIL” can be selected only if the “SUP5”/“AFIL” setup option is set to “AFIL.”

***“SUP5” and “SUP6” can be selected only if the “SUP5”/“AFIL” setup option is set to “SUP5.”

† This value is not available when temperature-controlled fill and auxiliary heat setup options are disabled.

‡ If “nodr” is selected, the computer skips the spin step and goes on to the next segment.

Select “HFIL” (hot fill), “CFIL” (cold fill), “bFIL” (warm fill), or “AFIL” (auxiliary fill).**

Select temperature: 75° to 200°F or 25° to 93°C (00 for no heat).†

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Programming

Segment 2 (Wash)

Instructions

Display

Use Up or Down key to change. Press Start key to enter or advance.

UASH

00 or 02 to 20 Select segment time: 02 to 20 minutes (00 to skip segment).

tFIL Indicates temperature fill is enabled.*

HFIL, CFIL, bFIL,

or AFIL

Lo,

nEd, or HI Select fill level: “Lo” (low), “nEd” (medium), or “HI” (high) water level.

SUP0 – SUP7 Select supply 0 – 7 (0 for no supply).***

00°F, 75° – 200°F

00°C, 25° – 93°C

drAI or nodr Select drain option: “drAI” (drain), “nodr” (no drain).‡

SPIn (flashed for one second)

tI

nE (flashed for one second)

00 or 30 to 240 Select time for spin: 30 to 240 seconds (00 for no spin).

* This is displayed only if temperature-controlled fills are enabled in the setup options and if the heat temperature is set to

a value other than “00.”

** “AFIL” can be selected only if the “SUP5”/“AFIL” setup option is set to “AFIL.”

***“SUP5” and “SUP6” can be selected only if the “SUP5”/“AFIL” setup option is set to “SUP5.”

† This value is not available when temperature-controlled fill and auxiliary heat setup options are disabled.

‡ If “nodr” is selected, the computer skips the spin step and goes on to the next segment.

Select “HFIL” (hot fill), “CFIL” (cold fill), “bFIL” (warm fill), or “AFIL” (auxiliary fill).**

Select temperature: 75° to 200°F or 25° to 93°C (00 for no heat).†

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232123

Page 31

Segments 3 – 10 (Fills 1 – 8)

Instructions

Display

Use Up or Down key to change. Press Start key to enter or advance.

FIL1, FIL2, FIL3, FIL4, FIL5, FIL6, FIL7, or FIL8

00 or 02 to 15 Select segment time: 02 to 15 minutes (00 to skip segment).

tFIL Indicates temperature fill is enabled.*

Programming

HFIL, CFIL, bFIL,

or AFIL

Lo,

nEd, or HI Select fill level: “Lo” (low), “nEd” (medium), or “HI” (high) water level.

SUP0 – SUP7 Select supply 0 – 7 (0 for no supply).***

00°F, 75° – 200°F

00°C, 25° – 93°C

drAI or nodr Select drain option: “drAI” (drain), “nodr” (no drain).‡

SPIn (flashed for one second)

tI

nE (flashed for one second)

00 or 30 to 240 Select time for spin: 30 to 240 seconds (00 for no spin).

* This is displayed only if temperature-controlled fills are enabled in the setup options and if the heat temperature is set to

a value other than “00.”

** “AFIL” can be selected only if the “SUP5”/“AFIL” setup option is set to “AFIL.”

*** “SUP5” and “SUP6” can be selected only if the “SUP5”/“AFIL” setup option is set to “SUP5.”

† This value is not available when temperature-controlled fill and auxiliary heat setup options are disabled.

‡ If “nodr” is selected, the computer skips the spin step and goes on to the next segment.

Select “HFIL” (hot fill), “CFIL” (cold fill), “bFIL” (warm fill), or “AFIL” (auxiliary fill).**

Select temperature: 75° to 200°F or 25° to 93°C (00 for no heat).†

F232123

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Programming

Segment 11 (Fill 9)

Instructions

Display

Use Up or Down key to change. Press Start key to enter or advance.

FIL9

00 or 02 to 15 Select segment time: 02 to 15 minutes (00 to skip segment).

tFIL Indicates temperature fill is enabled.*

HFIL, CFIL, bFIL,

or AFIL

Lo,

nEd, or HI Select fill level: “Lo” (low), “nEd” (medium), or “HI” (high) water level.

SUP0 – SUP7 Select supply 0 – 7 (0 for no supply).***

00°F, 75° – 200°F

00°C, 25° – 93°C

drAI or nodr Select drain option: “drAI” (drain), “nodr” (no drain).