Alliance Laundry Systems UM202 User Manual

Washer-Extractor

NOTA: El manual en

español aparece después

del manual en inglés.

Installation/Operation/Maintenance

Top Loading

UM202

Design 2 Models

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

CAR2C

CAR2C

Part No. F232212R1

January 2005

Table of

Contents

Introduction......................................................................................... 3

Model Identification ............................................................................. 3

Nameplate Location.............................................................................. 3

Replacement Parts ................................................................................ 3

Customer Service.................................................................................. 3

Safety Information.............................................................................. 5

Explanation of Safety Messages........................................................... 5

Important Safety Instructions ............................................................... 5

Specifications and Dimensions........................................................... 7

Installation........................................................................................... 11

Dimensional Clearances ....................................................................... 11

Machine Foundation............................................................................. 11

Machine Anchoring .............................................................................. 11

Electrical Installation............................................................................ 12

Input Voltage Requirements ............................................................ 12

Connection Specifications ............................................................... 12

Grounding ........................................................................................ 12

Phase Adder ..................................................................................... 12

Drain Connection.................................................................................. 14

Water Connection................................................................................. 15

Control Function Test........................................................................... 16

Operation............................................................................................. 17

Control Panel ........................................................................................ 17

Operating Instructions .......................................................................... 18

Maintenance ........................................................................................ 21

Daily ..................................................................................................... 21

Weekly.................................................................................................. 21

Monthly................................................................................................. 21

Care of Stainless Steel.......................................................................... 22

© Copyright 2005, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232212

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232212

Introduction

1

Model Identification

Information in this manual is applicable to this model:

UM202*

* This manual applies to models with U2 in the 9th and 10th

positions in the model number (e.g. UM202M1OU2

0001).

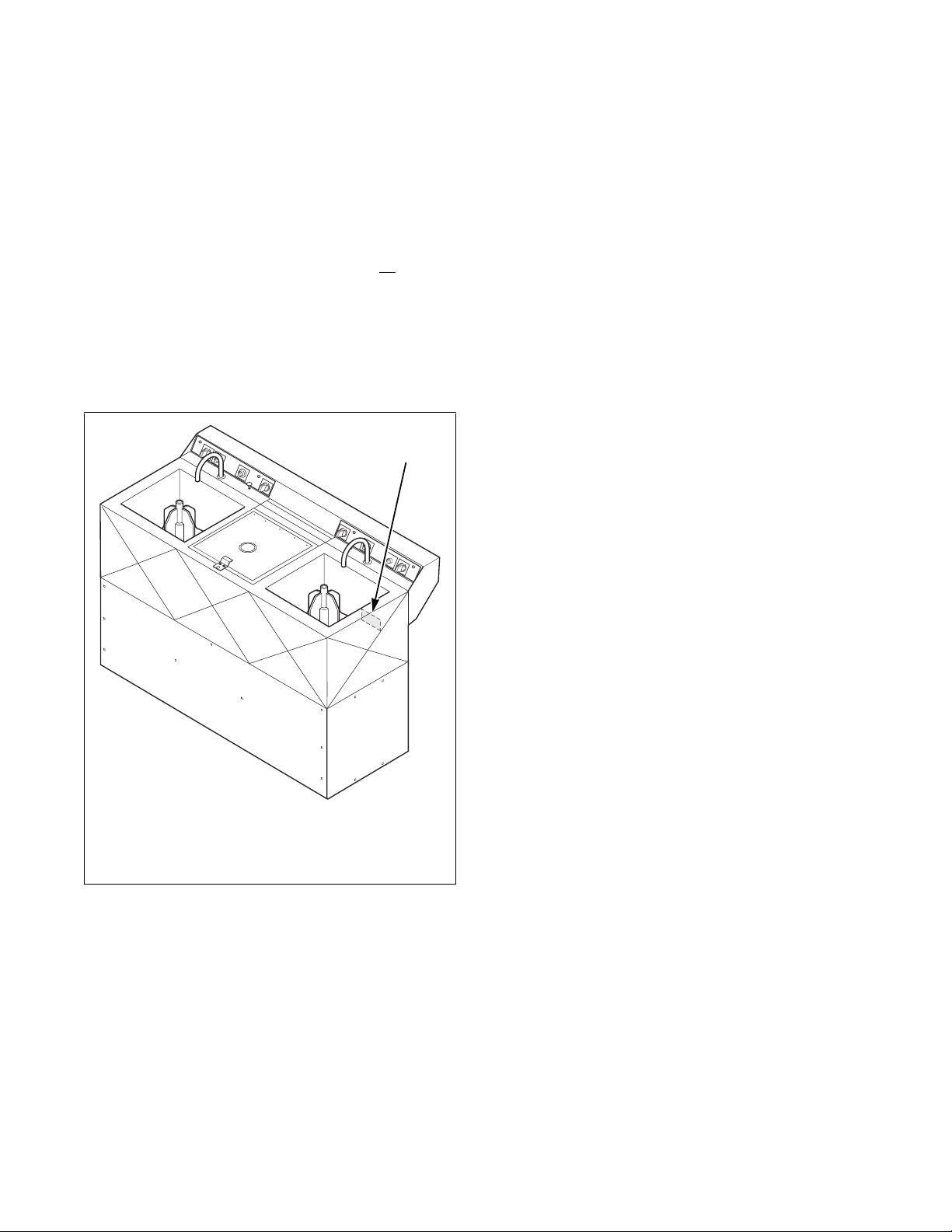

Nameplate Location

The nameplate decal is located at the rear of the

machine. Always provide the machine’s serial number

and model number when ordering parts or when

seeking technical assistance.

Replacement Parts

If literature or replacement parts are required, contact

the source from which the machine was purchased or

contact Alliance Laundry Systems LLC at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call (920) 748-3121.

1 Nameplate

F232212

CAR2C

CAR2C

Figure 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Introduction

Model Number Familiarization Guide

Sample Model Number: UM202M1OU20001

UM

202

M

1

O

U2

0001

Model Number Prefix

Washer-Extractor Capacity (pounds dry weight of laundry)

Type of Electrical Control

Washer-Extractor Speed Capability (1 = 1 speed)

Electrical Characteristics

Design Series

Option Identification (varies from machine to machine)

Model No:

Serial No:

Voltage:

Circuit Breaker:

Hz: Wire: Phase:

60 3 3

UM202M1OU20001

xxxxxxxxx

208 – 240

amps

15

Amps:

5

Max Load:

Electric Heat: Steam Pressure: psi bar

24 lbs 11 kg

N/A N/A

ETL Listed

Conforms To ANSI/UL Std. 1206, 4th Ed

Certified To CAN/CSA Std. C22.2 No. 53-1968

Certified for use in wet locations

EXAMPLE OF NAMEPLATE

Figure 2

Max Speed: rpm

1750

0.0

CAR17N

CAR17N

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232212

Safety Information

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

CAUTION

Explanation of Safety Messages

Throughout this manual and on machine decals, you

will find precautionary statements (“DANGER,”

“WARNING,” and “CAUTION”) followed by specific

instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and

those maintaining the machine.

Important Safety Instructions

Save These Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable, do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the extract

compartment.

F232212

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Safety Information

8. Do not reach into the washer if the extract drum

or the wash agitator is moving.

9. Do not tamper with the controls.

10. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

11. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

12. Use washer only for its intended purpose,

washing textiles.

13. ALWAYS disconnect the washer from electrical

supply before attempting any service.

14. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

15. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

16. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Replace worn power cords and/or loose plugs.

19. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

20. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

21. Always follow the fabric care instructions

supplied by the textile manufacturer.

22. Never operate the washer with any guards

and/or panels removed.

23. DO NOT operate the washer with missing or

broken parts.

24. DO NOT bypass any safety devices.

25. Failure to install, maintain, and/or operate this

washer according to the manufacturer's

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

17. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232212

Specifications and Dimensions

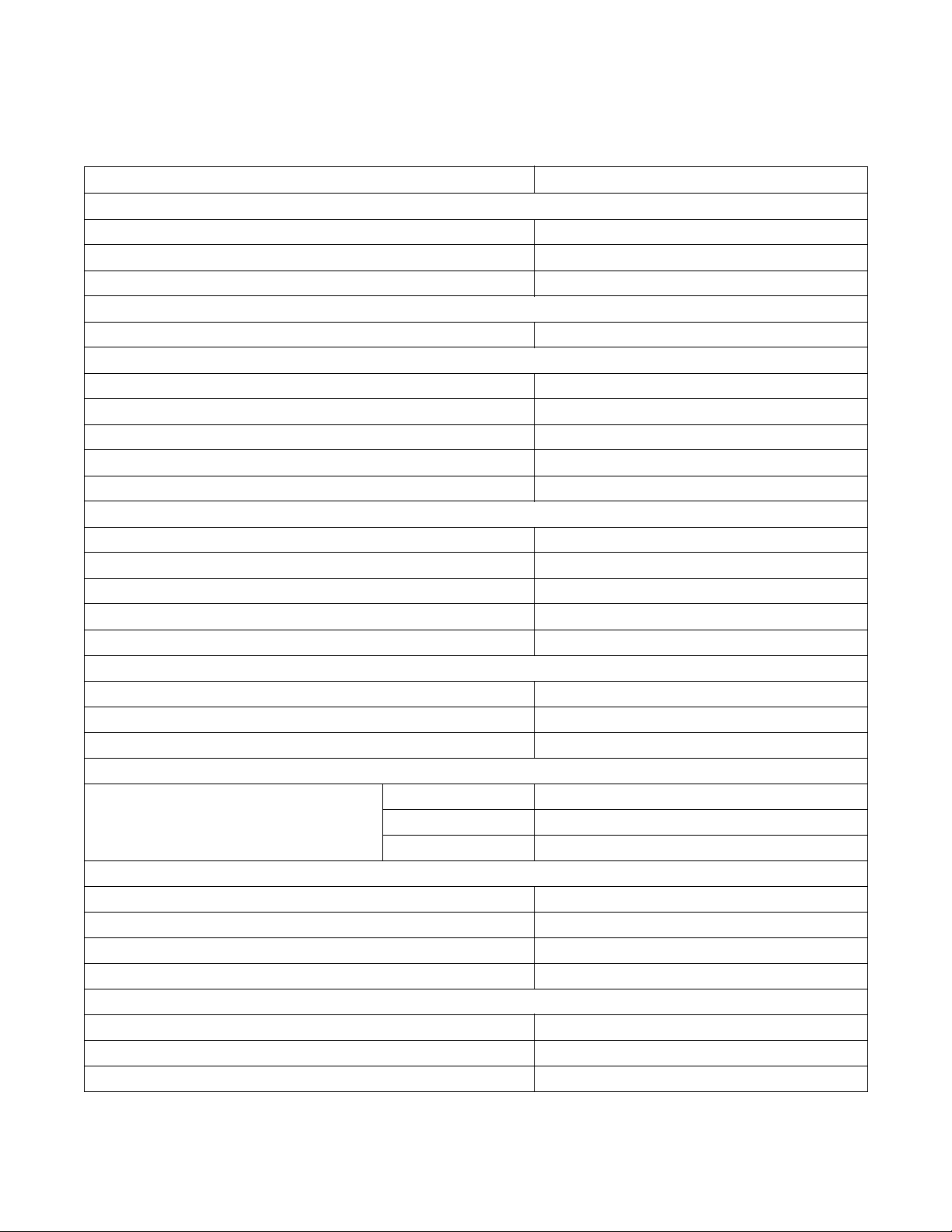

Specifications and Dimensions

Specification

Overall Dimensions

Overall width, in. (mm) 60 (1524)

Overall depth, in. (mm) 29-1/2 (749)

Overall height, in. (mm) 40 (1016)

Weight & Shipping Information

Net weight, lb. (kg) 510 (232)

Wash Compartment Information

Width, in. (mm) 20-1/4 (514)

Length, in. (mm) 22-1/4 (565)

Depth, in. (mm) 11-3/4 (298)

Volume, cu. ft. (liter) 2.74 (77.6)

Dry weight capacity, lb. (kg) 12 (5.45)

Extractor Basket Information

Basket volume, cu. ft. (liter) 1.09 (30.9)

Basket diameter, in. (mm) 16-1/16 (409)

Basket depth, in. (mm) 9-1/4 (235)

Basket dry weight capacity, lb. (kg) 12 (5.45)

Perforation open area, % 1.5

Drive Train Information

Number of motors in drive train 3

Wash motor power, hp (kW) 2 x 0.33 (0.25)

Extract motor power, hp (kW) 1 x 1.0 (0.75)

Water Consumption

Average water consumption

per agitation cycle, gallons (liters)

Drain Information

Drain connection size, in. (mm) 2 (50)

Number of drain outlets 1

Drain flow capacity, gallons (liters) per min. 27 (101)

Recommended drain pit size, cu. ft. (liters) 7.7 (219)

Water Supply Information

Water inlet connection size, in. (mm) 3/4NH (G3/4)

Number of water inlets (1 hot, 2 cold) 3

Inlet flow capacity, gallons (liters) per min. 21 (79)

Low 14 (53)

Medium 17 (64)

High 21 (80)

F232212

Table 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

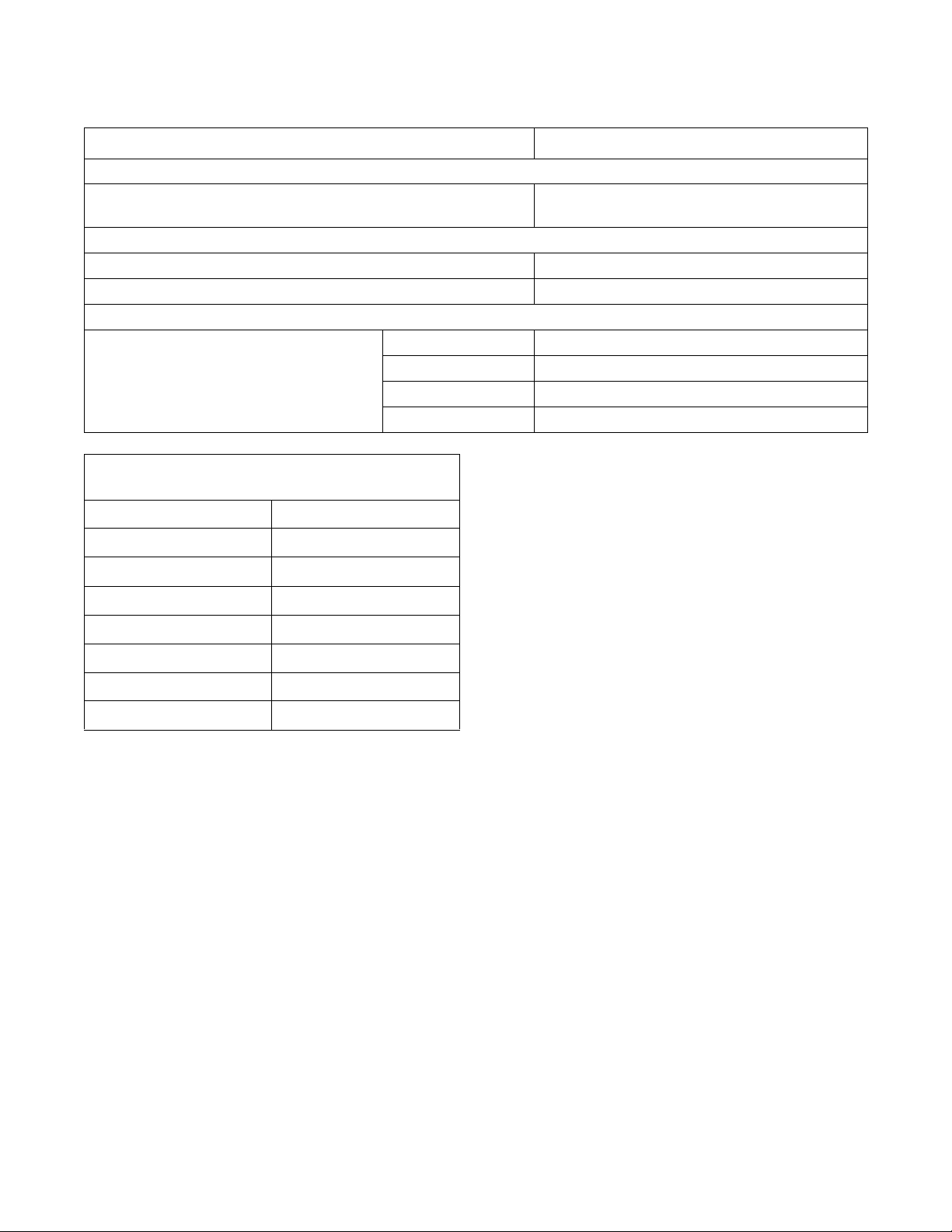

Specifications and Dimensions

Table 1 (Continued)

Specification

Operating Speeds

Wash agitator speed, reversals per minute

60/50

(Input frequency: 60 Hz/50 Hz)

Power Consumption

Average power consumption per cycle, kW-hr 0.25

Average HVAC load, Btu/hr (kcal/hr) 200 (51)

Centrifugal Force Data

Extract centrifugal force, G’s 208-240 V, 60 Hz 690

220-240 V, 50 Hz 496

380-415 V, 50 Hz 499

440-480 V, 60 Hz 698

Machine Capacity Dimensions

Refer to Figure 3

A

B

C

D

E

F

G

H

60 in. (1524 mm)

11-3/4 in. (298 mm)

18-3/8 in. (467 mm)

22-1/4 in. (565 mm)

16-1/ in. (419 mm)

29-1/2 in. (749 mm)

19-7/8 in. (505 mm)

40-1/2 in. (1029 mm)

Ta bl e 2

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232212

Specifications and Dimensions

A

1

2

B

D

E

3

C

4

A

F

H

G

1 Faucet 3 Extractor Basket

2 Agitator 4 Control Panel

Figure 3

F232212

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CAR2N

9

Specifications and Dimensions

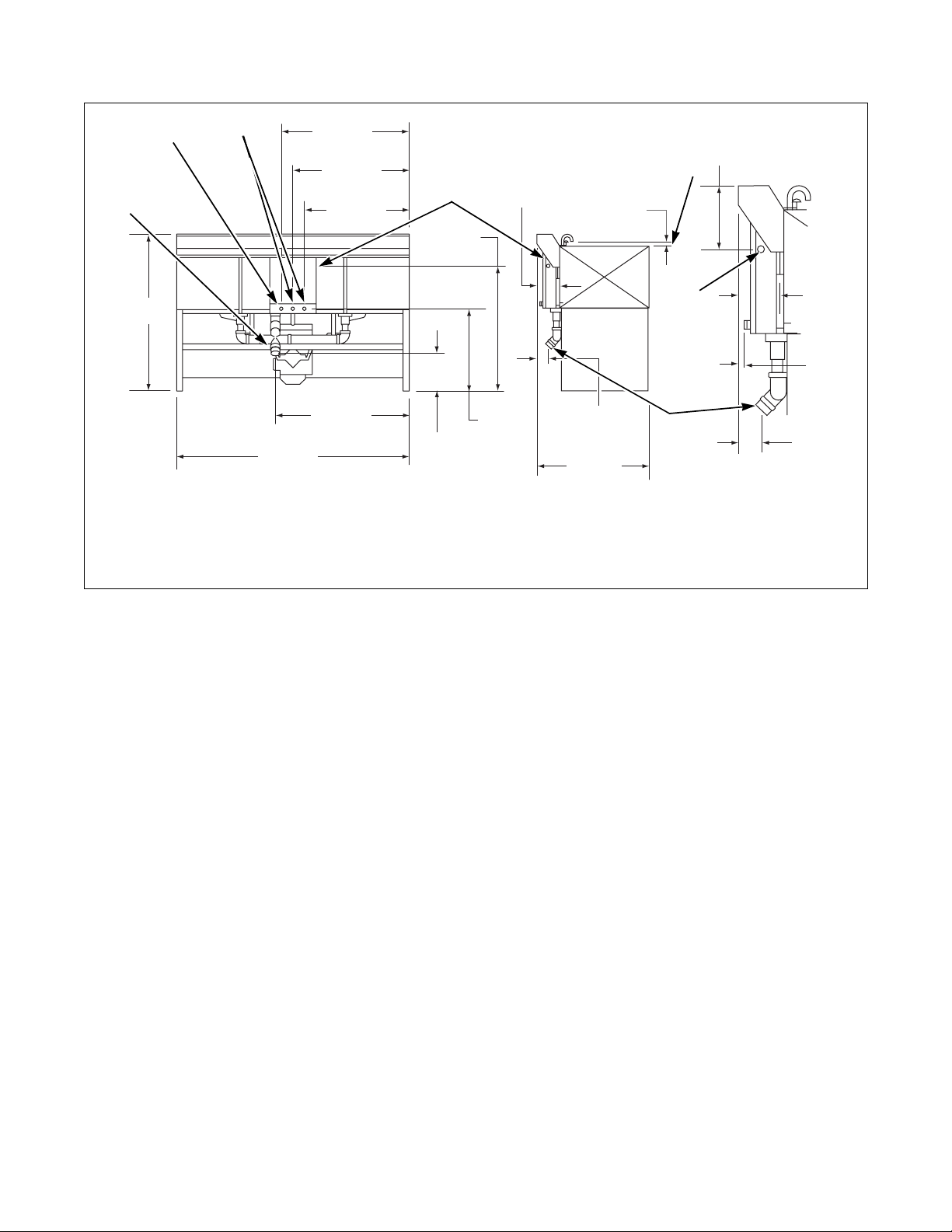

60 in.

33-9/16 in.

852 mm)

30-1/16 in.

(964 mm)

26-9/16 in.

(675 mm)

34-1/2 in.

(876 mm)

2

33-1/2 in.

(851 mm)

9-3/4 in.

(248 mm)

6-3/4 in.

(171 mm)

21 in.

(533 mm)

1-1/8 in.

(29 mm)

3-7/8 in.

(98 mm)

29-1/2 in.

(749 mm)

4

40 in.

(1016 mm)

5

1

(1524 mm)

1 Cold Water Inlets 4 Drain Outlet

2 Electrical Connection 5 Hot Water Inlet

3 Overflow Level

3

2

1-3/4 in.

(102 mm)

4

6-3/4 in.

(171 mm)

6-3/4 in.

(171 mm)

3-7/8 in.

(98 mm)

CAR3N

Figure 4

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232212

Installation

Dimensional Clearances

Refer to Figure 5 for recommended dimensional

clearances.

1/2 in.

(13 mm)

6 in.

(152 mm)

Machine Foundation

The machine may be placed on any level floor as long

as floor will hold the weight of the machine.

Position the machine and level with shims or grout

under the corners.

Refer to Ta bl e 3 for static loads on the floor.

Floor Load Data

Specification

Static floor load 840 lbs.

(3.7 kN)

Static pressure 68 lbs-ft

(3.3 kN-m2)

Table 3

2

Figure 5

Machine Anchoring

Bolting to floor is optional. To bolt down the machine,

use 3/8 inch bolt holes located on the frame at the

bottom of each corner. One quarter inch machine

anchors should be used.

6 in.

(152 mm)

CAR10N

CAR10N

F232212

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Installation

WARNING

Turn off power and water before attempting

any maintenance, repairs, or service, or

before opening any service panel or door.

W532

Electrical Installation

Input Voltage Requirements

Electrical Specifications

Voltage Cycle Phase Wire

208-240 60 Hz 3 3

220-240 50 Hz 3 3

380-415 50 Hz 3 4

440-480 60 Hz 3 3

NOTE: The control voltage is 220 V for all

systems.

Table 4

Grounding

For personal safety and proper operation, the machine

must be grounded in accordance with state and local

codes. If such codes are not available, grounding must

conform with the National Electric Code. The ground

connection must be to a proven earth ground at the

location service panel and/or to a grounded metal cold

water pipe.

Use wire size indicated in Electrical Specifications

table for runs up to 50 feet. Use next larger size for

runs of 50 – 100 feet. Use TWO

sizes larger for runs

greater than 100 feet. This protects against voltage

drop which would result in a reduction of starting

torque.

Phase Adder

If three-phase service is not available and a RotoPhase or other phase adder is used, the artificial leg

must be connected to the L3A lead.

If a delta supply system is used, the high leg must be

connected to the L3 lead at the J-box.

NOTE: Rotation of the extractor basket should be

clockwise as indicated by the arrow on the lid. To

change direction of extractor rotation, interchange

the L1 and L2 leads.

IMPORTANT: Improper connections will result in

equipment damage and will void the warranty.

Connection Specifications

IMPORTANT: Connection must be made by a

qualified electrician using wiring diagram provided

with machine. Use liquid tight conduit and

connectors.

NOTE: Machine has passed rain test and is

certified for use in wet locations.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232212

Electrical Specifications

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground

lug near the input power block on this

machine. Without proper grounding,

personal injury from electric shock could

occur and machine malfunctions may be

evident.

SW008

Voltage Designation Standard

Installation

Code Voltage Cycle Phase Wire

C 380-450 50 3 4 5 15 14 2.5

D 220-240 50 3 3 7 15 14 2.5

F 440-480 60 3 3 5 15 14 2.5

O 208-240 60 3 3 7 15 14 2.5

Full Load

Amps

Breaker AWG mm

NOTE: Wire sizes shown are for copper, THHN, 90° conductor per NEC 2001 edition.

Ta bl e 5

IMPORTANT: Installation shall conform with local

codes or, in absence of local codes, with the

National Electric Code ANSI/NFPA No. 70.

Overloaded or undersized lines, or any low voltage

condition will burn out motors and solenoid

windings.

2

F232212

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Loading...

Loading...