Page 1

Washer-Extractors

Cabinet Freestanding

Instructions for Operating and Programming

the WE-6 Microcomputer

Models SF35PV, SF50PV, SF85PV,

UF35PV, UF50PV and UF85PV

NOTA: El manual en

español aparece después

del manual en inglés.

Operation/Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

R077R

Part No. F232059R7

January 2002

Page 2

Page 3

Table of

Contents

Safety.................................................................................................... 3

Key to Symbols..................................................................................... 4

Operator Safety..................................................................................... 5

Safe Operating Environment ................................................................ 6

Environmental Conditions............................................................... 6

Machine Location ............................................................................ 7

Input and Output Services................................................................ 7

AC Inverter Drive ............................................................................ 8

Misuse................................................................................................... 8

Operation............................................................................................. 9

Customer Service............................................................................. 9

Machine Familiarization Guides...................................................... 10

Theory of Operation ............................................................................. 12

Emergency Stop Button................................................................... 12

Wet Clean Features.......................................................................... 12

Wet Clean Capabilities......................................................................... 13

Wet Clean Functions........................................................................ 13

WE-6 Microcomputer ...................................................................... 15

LED Display .................................................................................... 15

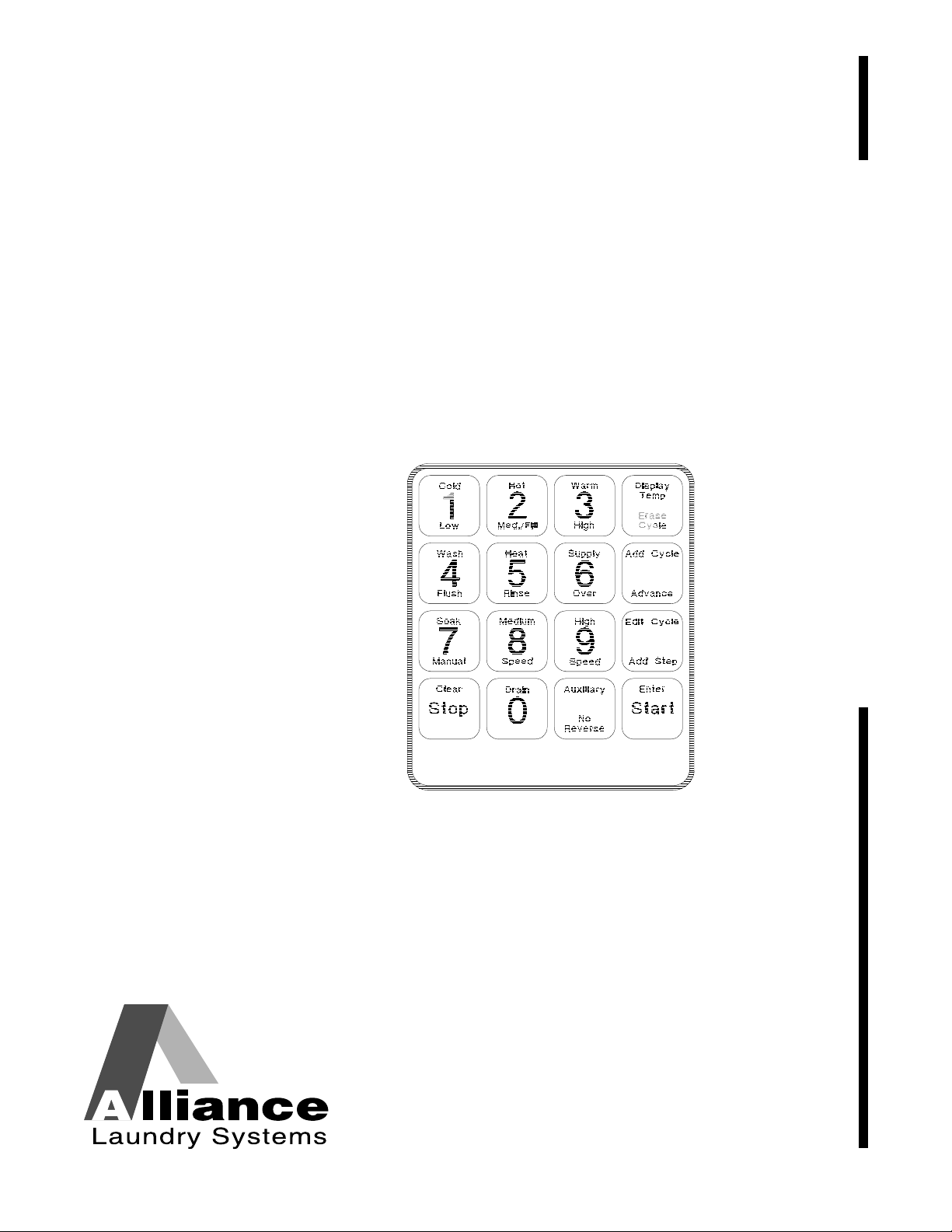

Operational Keypad ......................................................................... 18

Start-Up................................................................................................. 20

Opening Door ....................................................................................... 20

Loading................................................................................................. 20

Supply Dispenser.................................................................................. 21

Cycle Selection..................................................................................... 21

Cycle Execution.................................................................................... 21

Test Cycle............................................................................................. 22

Wet Clean Testing............................................................................ 22

Stop Routine ......................................................................................... 23

Balance Detection................................................................................. 24

Balance Sensor Detection ................................................................ 24

Inverter Drive Balance Detection .................................................... 24

Temperature Display ............................................................................ 25

Calibrating the WE-6 Temperature Circuit...................................... 25

Error Recovery Routine........................................................................ 27

Thermal Overload Indicator ................................................................. 28

Resetting Thermal Overload Switch................................................ 28

Manual Mode Control Feature.............................................................. 29

Programming ...................................................................................... 31

Programming Keypad........................................................................... 31

Programming Tutorial .......................................................................... 33

Programming Hints............................................................................... 36

System Programming............................................................................ 37

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Cycle Programming.............................................................................. 39

Displaying a Cycle in Memory........................................................ 39

Displaying Individual Cycle Usage ................................................. 39

Editing a Cycle................................................................................. 40

Erasing a Cycle in Memory ............................................................. 41

Programming a Wet Clean Cycle .................................................... 41

Step Programming ................................................................................ 42

Programming a Fill Temperature..................................................... 42

Programming a Supply Step – Models with 5 Supplies .................. 43

Programming a Supply Step – Models with 8 Supplies .................. 44

Programming Heat........................................................................... 47

Programming a Wash Step............................................................... 47

Programming a Wash 5 Thermal Cool-Down ................................. 48

Programming No Reversing ............................................................ 49

Programming a Soak Step................................................................ 49

Programming a Drain Step............................................................... 50

Programming a Spin Step ................................................................ 50

Programming an Auxiliary Step ...................................................... 50

Simulator Operation and Program Transfer ......................................... 52

Simulator Operation......................................................................... 52

Transferring All Cycles from Computer to Simulator..................... 54

Transferring One Cycle from Computer to Simulator..................... 54

Transferring All Cycles from Simulator to Computer..................... 55

Transferring One Cycle from Simulator to Computer..................... 55

Preprogrammed Cycles......................................................................... 56

Cycle Categories.............................................................................. 56

Standard Supply Legend.................................................................. 57

Standard Cycle Charts...................................................................... 58

Sample Cycle for Wet Clean ................................................................ 78

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 5

Safety

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel

familiar with electrical test procedures,

test equipment, and safety precautions

should attempt adjustments and

troubleshooting. Disconnect power from

the machine before removing the control

box cover, and before attempting any

service procedures.

SW005

WARNING

Death or serious injury can result if

children become trapped in the machine.

Do not allow children to play on or around

this machine. Do not leave children

unattended while the machine door is

open.

SW001

DANGER

Anyone operating or servicing this machine must

follow the safety rules in this manual. Particular

attention must be paid to the CAUTION, WARNING,

and DANGER blocks which appear throughout the

manual.

The following warnings are general examples that

apply to this machine. Warnings specific to a particular

operation will appear in the manual with the

discussion of that operation.

WARNING

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

CAUTION

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

SW020

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

3

Page 6

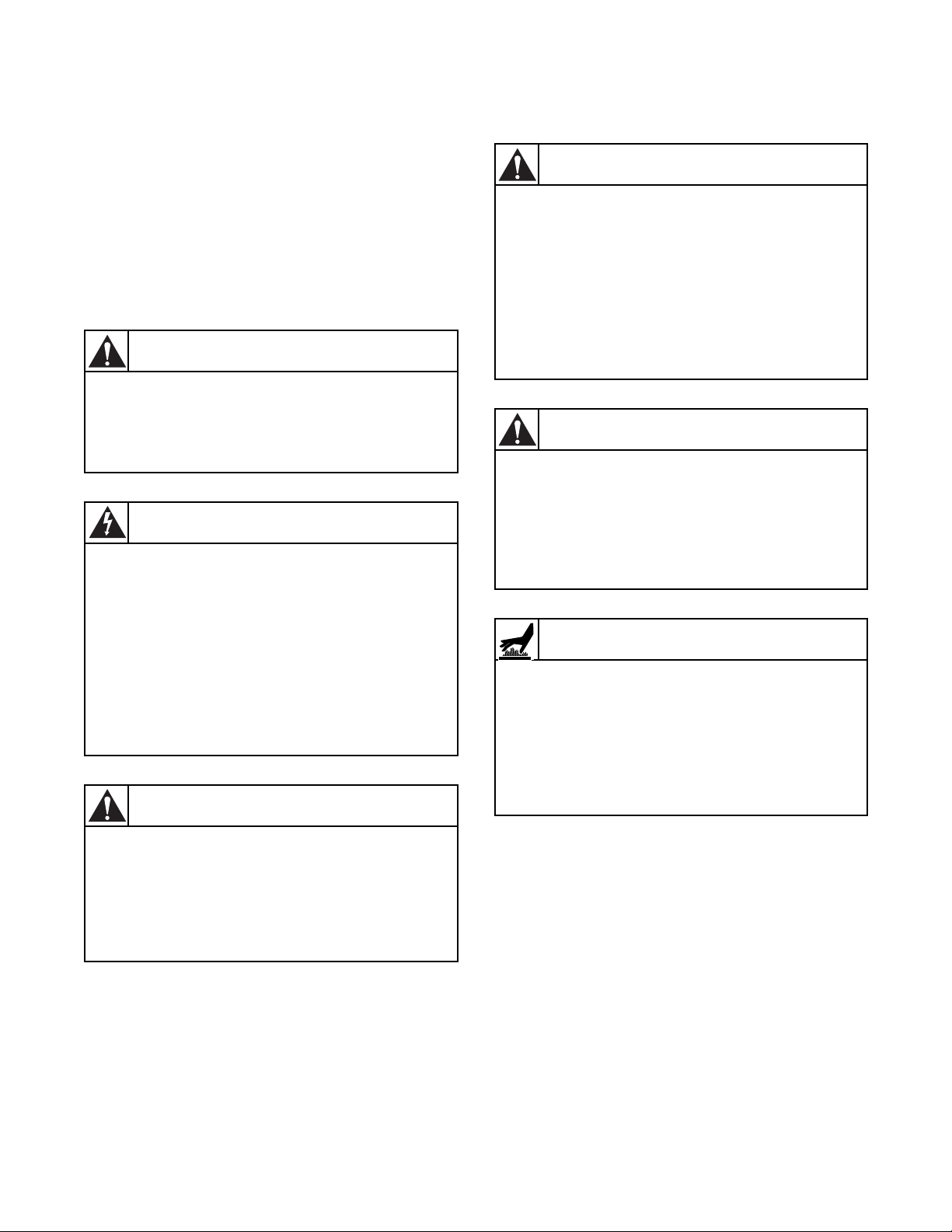

Safety

Key to Symbols

The lightning flash and arrowhead within the triangle

is a warning sign indicating the presence of dangerous

voltage.

This warning symbol indicates the presence of

possibly dangerous chemicals. Proper precautions

should be taken when handling corrosive or caustic

materials.

The exclamation point within the triangle is a warning

sign indicating important instructions concerning the

machine and possibly dangerous conditions.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms within the

machine. Guards should always be in place when the

machine is in operation.

This warning symbol indicates the presence of hot

surfaces that could cause serious burns. Stainless steel

and steam lines can become extremely hot and should

not be touched.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving mechanical

parts can crush and/or sever body parts.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the factory

immediately.

Use factory-authorized spare parts to avoid safety

hazards.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 7

Safety

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open. Although the WE-6 display shows

cycle steps, the machine should not operate.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in the machine.

WARNING

Never operate the machine with a

bypassed or disconnected out-of-balance

switch. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW033

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Safety

Safe Operating Environment

Safe operation requires an appropriate operating

environment for both the operator and the machine. If

questions regarding safety arise, contact the factory

immediately.

Environmental Conditions

● Ambient Temperature. Water in the machine will

freeze at temperatures of 32°F (0°C) or below.

Temperatures above 120°F (50°C) will result in

more frequent motor overheating and, in some

cases, malfunction or premature damage to solid

state devices that are used in some models.

Special cooling devices may be necessary.

Water pressure switches are affected by increases

and decreases in temperature. Every 25°F (10°C)

change in temperature will have a 1% effect on

the water level.

● Humidity. Relative humidity above 90% may

cause the machine’s electronics or motors to

malfunction or may trip the ground fault

interrupter. Corrosion problems may occur on

some metal components in the machine.

If the relative humidity is below 30%, belts and

rubber hoses may eventually develop dry rot.

This condition can result in hose leaks, which

may cause safety hazards external to the machine

in conjunction with adjacent electrical

equipment.

● Radio Frequency Emissions. A filter is available

for machines in installations where floor space is

shared with equipment sensitive to radio

frequency emissions.

● Elevation. If the machine is to be operated at

elevations of over 3280 ft. (1000 m) above sea

level, pay special attention to water levels and

electronic settings (particularly temperature) or

desired results may not be achieved.

● Chemicals. Keep stainless steel surfaces free of

chemical residues.

DANGER

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel

reducers, carbon tetrachloride, gasoline,

benzene, naptha, etc. Doing so could

result in serious personal injury and/or

damage to the machine.

SW002

● Water Damage. Do not spray the machine with

water. Short circuiting and serious damage may

result. Repair immediately all seepage due to

worn or damaged gaskets, etc.

● Ventilation. The need for make-up air openings

for laundry room accessories such as dryers,

ironers, and water heaters must be evaluated

periodically. Louvers, screens, or other

separating devices may reduce the available air

opening significantly.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 9

Safety

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any safety

devices.

SW019

CAUTION

Machine Location

● Foundation. The concrete floor must be of

sufficient strength and thickness to handle the

floor loads generated by the high extract speeds

of the machine.

● Service/Maintenance Space. Provide sufficient

space to allow comfortable performance of

service procedures and routine preventive

maintenance.

This is especially important in connection with

machines equipped with an AC inverter drive.

Consult installation instructions for specific details.

Input and Output Services

● Water Pressure. Best performance will be

realized if water is provided at a pressure of

30-85 psi (2.0-5.7 bar). Although the machine

will function properly at lower pressure,

increased fill times will occur. Water pressure

higher than 100 psi (6.7 bar) may result in

damage to machine plumbing. Component

failure(s) and personal injury could result.

● Steam Heat (Optional) Pressure. Best

performance will be realized if steam is provided

at a pressure of 30-80 psi (2.0-5.4 bar). Steam

pressure higher than 125 psi (8.5 bar) may result

in damage to steam components and may cause

personal injury.

● Compressed Air. For machines requiring

compressed air service, best performance will

be realized if air is provided at a pressure of

80-100 psi (5.4-6.7 bar).

● Drainage System. Provide drain lines or troughs

large enough to accommodate the total number of

gallons that could be dumped if all machines on

the site drained at the same time from the highest

attainable level. If troughs are used, they should

be covered to support light foot traffic.

● Pow er. For personal safety and for proper

operation, the machine must be grounded in

accordance with state and local codes. The

ground connection must be to a proven earth

ground, not to conduit or water pipes. Do not use

fuses in place of the circuit breaker. An easyaccess cutoff switch should also be provided.

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground

lug near the input power block on this

machine. Without proper grounding,

personal injury from electric shock could

occur and machine malfunctions may be

evident.

SW008

Always disconnect power and water supplies before a

service technician performs any service procedure.

Where applicable, steam and/or compressed air

supplies should also be disconnected before service is

performed.

For machines equipped with optional steam heat,

install piping in accordance with approved

commercial steam practices. Failure to install the

supplied steam filter may void the warranty.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Safety

AC Inverter Drive

Machines equipped with the AC inverter drive require

special attention with regard to the operating

environment.

● An especially dusty or linty environment will

require more frequent cleaning of the AC inverter

drive cooling fan filter(s) and of the AC inverter

drive itself.

● Power line fluctuations from sources such as

uninterruptible power supplies (UPS) can

adversely affect machines equipped with the AC

inverter drive. Proper suppression devices should

be utilized on the incoming power to the machine

to avoid problems.

● A clean power supply free from voltage spikes

and surges is absolutely essential for machines

equipped with the AC inverter drive. Nonlinear

inconsistencies (peaks and valleys) in the power

supply can cause the AC inverter drive to

generate nuisance errors.

● If voltage is above 240 Volt for 200 Volt

installation, ask the power company to correct.

As an alternative, a step-down transformer kit is

available from the distributor. If voltage is above

480 Volt for 400 Volt installation, a buckboost

transformer is required.

Misuse

Never use this machine for any purpose other than

washing fabric.

● Never wash petroleum-soaked rags in the

machine. This could result in an explosion.

● Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

● Never allow children to play on or around this

machine. Death or serious injury can result if

children become trapped in the machine. Do not

leave children unattended while the machine door

is open. These cautions apply to animals as well.

● Sufficient space to perform service procedures

and routine preventive maintenance is especially

important for machines equipped with the AC

inverter drive.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 11

Operation

This manual is designed as a guide for operating and

programming the 35, 50 and 85 pound capacity

freestanding washer-extractors equipped with the

WE-6 microcomputer and an AC inverter drive. These

washer-extractors feature programmable custom

cycles and high extract force. Wet cleaning capability

and water reuse capability offer the operator versatility

and economy.

The manuals, installation instructions, and wiring

diagrams which accompany the washer-extractor have

been included at no charge. Additional copies are

available at a nominal charge.

NOTE: Read this manual thoroughly before

attempting to operate the washer-extractor or

program the microcomputer.

NOTE: Do not use this manual in conjunction with

earlier model microcomputer-controlled

freestanding washer-extractors. Do not use

technical literature intended for earlier models

when operating this machine.

NOTE: All information, illustrations, and

specifications contained in this manual are based

on the latest product information available at the

time of printing. We reserve the right to make

changes at any time without notice.

Customer Service

If literature or replacement parts are required, contact

the source from whom the washer-extractor was

purchased or contact Alliance Laundry Systems LLC

at (920) 748-3950 for the name and address of the

nearest authorized parts distributor.

For technical service, call any of the following

numbers:

(920) 748-3121

Ripon, Wisconsin

(850) 718-1025

(850) 718-1026

Marianna, Florida

A record of each washer-extractor is on file with the

manufacturer. Always provide the washer-extractor’s

serial number and model number when ordering parts

or when seeking technical assistance.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Operation

Machine Familiarization Guides

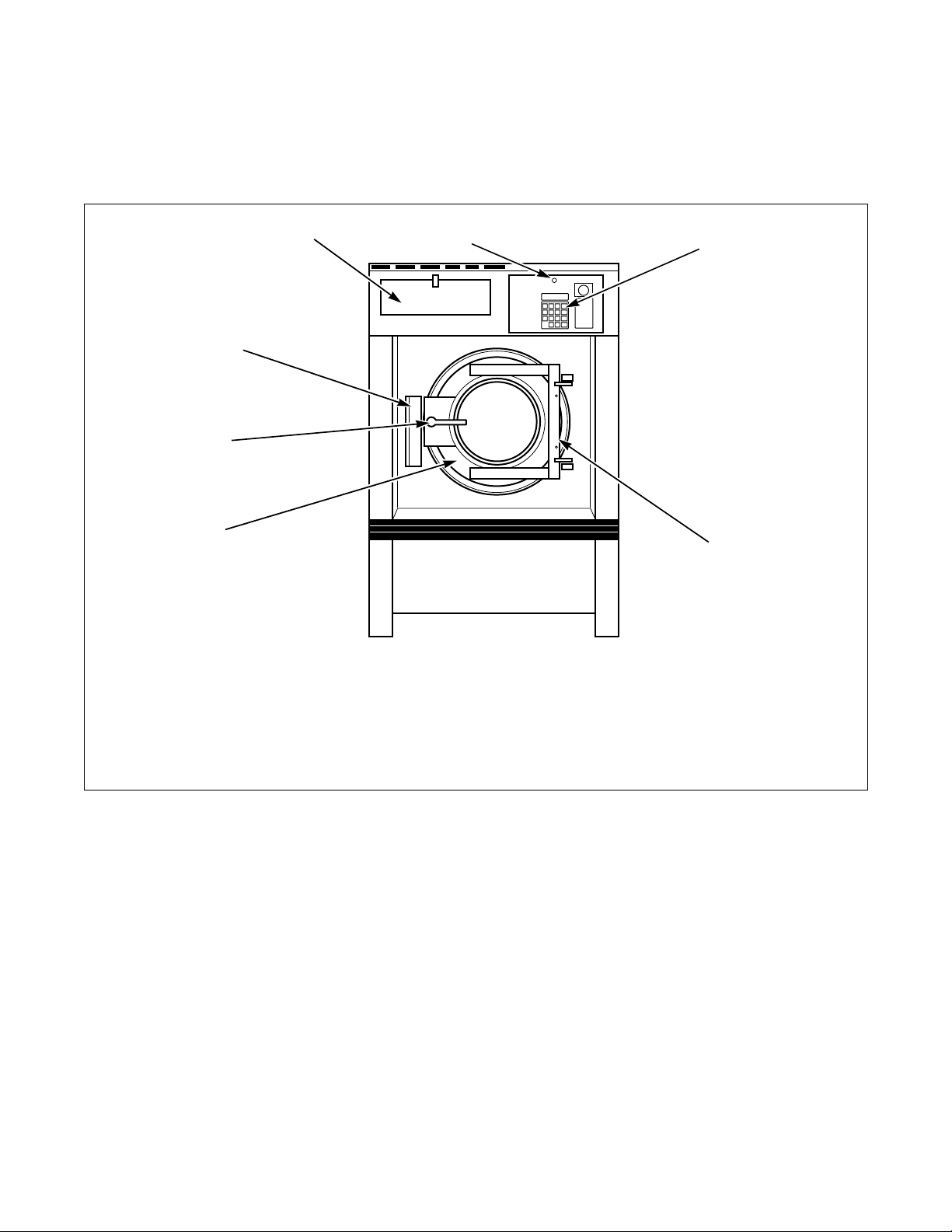

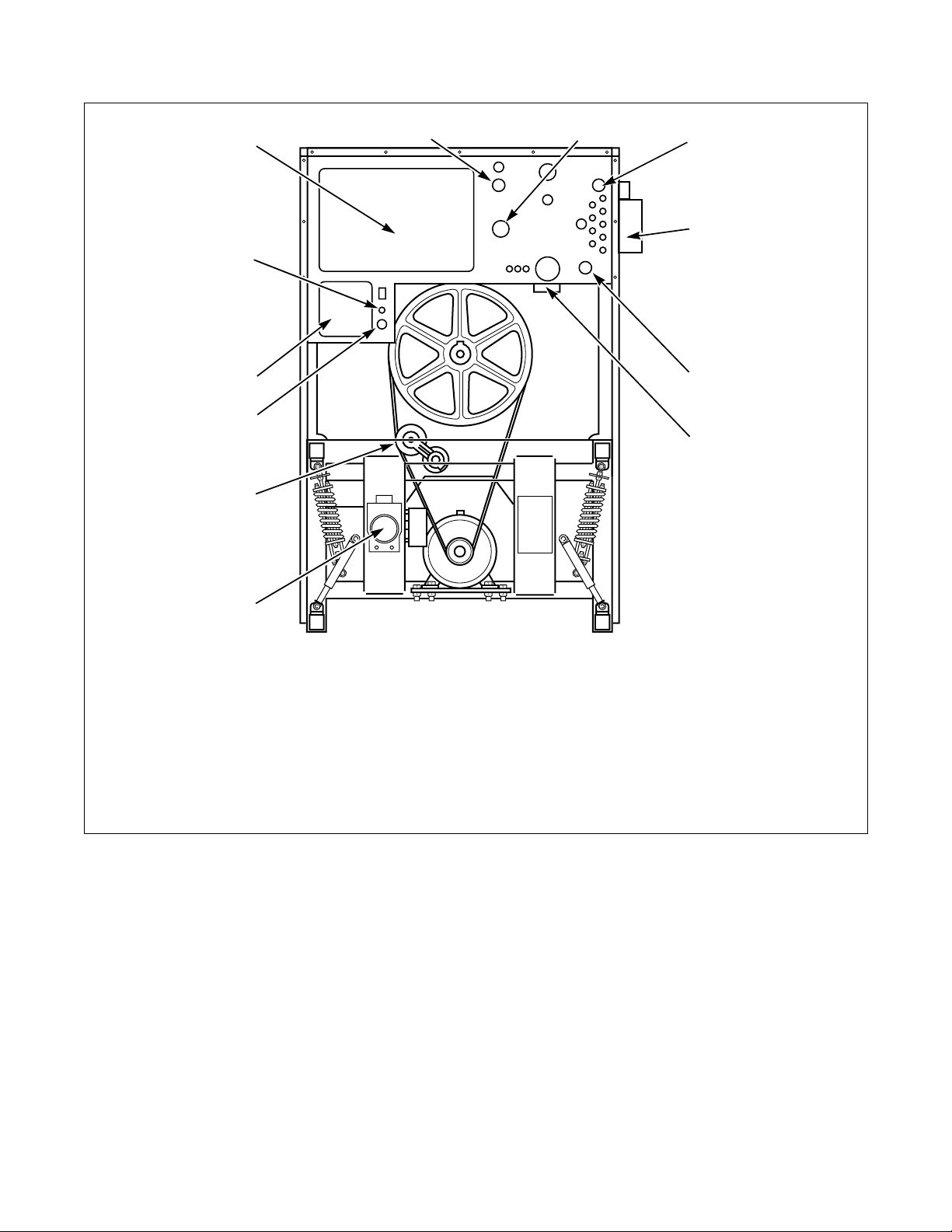

The machine familiarization guides in Figure 1 and

Figure 2 identify major operational features of each

washer-extractor.

7

6

5

4

1 Front Control Module Lock 5 Door Handle

2 Computer Keypad 6 Door Lock Box

3 Door Hinge 7 Supply Dispenser

4 Door

1

CFS227R

2

3

FS227R

10

Figure 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 13

Operation

12

11

10

1

2

3

4

5

9

6

8

7

CFS228R

1 Cold Water 7 Drain Valve

2 Vent 8 Idler Pulley

3 Hot Water 9 Power Cable Connection

4 Liquid Supply Connections 10 Terminal Block

5 Steam Connection 11 Liquid Supply Control

6 Vacuum Breaker 12 AC Drive Box Enclosure

Figure 2

CFS228R

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Operation

Theory of Operation

The design of the washer-extractor emphasizes

performance reliability and long service life. The

cylinder, shell, and main body panels are fabricated of

stainless steel.

Electrical controls for the washer-extractor are housed

in separate enclosures. The front control module

houses the WE-6 microcomputer, the fuse/relay board

together with its interface board, water level switches,

a motor thermal overload reset switch, and other

control components. The rear control module houses

the AC inverter drive and its components.

All variable-speed freestanding machines use the AC

inverter drive control, which provides programmable

motor speeds using a single motor. The AC drive

interface board converts motor logic from the WE-6

microcomputer to the correct signals for the AC

inverter drive. In addition, all logic inputs to the

computer are routed through this board.

The cylinder is supported by roller bearings housed

inside a trunnion.

The cylinder is constructed with four lifters or ribs that

lift the laundry from the bath solution when the

cylinder rotates at slow speed and then allow the

laundry to tumble back into the bath. This mechanical

action accomplishes the washing function. The

cylinder is perforated, allowing the water to drain from

within during the wash and extract steps.

Water enters the machine through electromechanical

water valves controlled by the microcomputer. The

microcomputer also controls the drain and door lock.

In addition, it selects the water levels according to the

programmed cycle. Vacuum breakers are installed in

the water-inlet plumbing to prevent backflow of water.

A door-lock system prevents opening of the stainless

steel door when a cycle is in progress. It also prevents

operation of the washer-extractor when the door is

open.

The doorbox contains the Hall-effect door-locked and

door-closed sensors and the door-unlock solenoid.

The supply dispenser is located on the left side of the

front of the washer-extractor. The dispenser has five

supply compartments, numbered 1 to 5 from left to

right. The compartments hold supply cups that are

used for either liquid or dry supplies. A nozzle flushes

supplies from the cups with water for the time

programmed in the cycle.

Liquid supplies can be injected directly into the cups

by a customer-supplied external chemical supply

system. Five hose barbs on the rear of the washerextractor facilitate connection to an external supply

system.

Emergency Stop Button

A red emergency stop button is located on the upper

right-hand corner of the control panel. Push the button

in to stop the washer-extractor. Turn button to the left

and pull out to reset.

Wet Clean Features

The washer-extractor is equipped with the following

wet clean capable features: One-half wash speed

allows gentle mechanical action during wash. Eight

supply signals provide not only normal laundering

signals to dispense detergents, bleaches, softeners,

sours, etc., but also chemicals unique to wet clean

processing.

Motorized drain valves hold water in the machine

during the wash, soak, and rinse steps. The drain valve

is normally open, which means that it closes only

when power is applied, thus allowing the machine to

drain in the event of a power failure.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 15

Operation

Wet Clean Capabilities

Differences in WE-6 prompt (setup) options

The WE-6 software provides the usual setup options:

● Degrees F or C

● One or Two drain

● Advance or No Advance

● Manual or No Manual

● Balance setting

In addition, the software provides a new selection: Wet

Clean/No Wet Clean. The wet clean/no wet clean

option enables or disables wet clean functions. In

summary then, the prompt (setup) options are now as

follows:

● CEN/FAR

● 1DRAIN/2DRAIN

● ADV/NO ADV

● MANUAL/NO MAN

● WET CL/NO WCL

● BAL SW, BAL 1, BAL 2, BAL 3

Wet Clean Functions

Wet clean functions include a reduced wash speed

capability and a recirculation pump capability. These

functions are enabled by the WET CL/NO WCL

prompt selection. Other wet clean features are

permanently enabled, and can be used for other

applications as well. In particular, extra supply

capability (up to eight supplies, in two banks of four

supplies), and additional agitation actions as outlined

below.

Agitations:

● Wash 1 – normal: 18 seconds forward / three

seconds off / 18 seconds reverse / three seconds

off; repeat

● Wash 2 – gentle: three seconds forward /

27 seconds off / three seconds reverse / 27

seconds off; repeat

● Wash 3 – no rotation

● Wash 4 – ten seconds forward / 20 seconds off /

ten seconds reverse / 20 seconds off; repeat

● Wash 5 – uses most recent agitation; defaults to

Wash 1 agitation

● Wash 6 – super gentle: four seconds forward /

56 seconds off / four seconds reverse / 56 seconds

off; repeat

● Wash 7 – no rotation; drain 1 (sewer drain) open;

no attempt to refill to level

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Operation

Using the auxiliary 1 (A1) and auxiliary 2 (A2)

outputs for wet cleaning

The A1 and A2 outputs (so labeled on the solid state

WE-6 output PC board) can be made to operate as

timed outputs, or to remain on until a drain step.

Reduced wash speed

Normally, the A1 output would govern optional

reduced wash speed. This means that if the WE-6 is

prompted for “WET CL”, and then an auxiliary 1 “A1”

step is programmed for any amount of time (one

second is a good choice for time in the event of

controlling reduced wash speed), the A1 output will

remain on until a drain step, or until Stop routine.

Thereby the reduced wash speed remains in effect as

long as A1 remains on.

For example, with “WET CL” prompt selected, a

Wash 1 agitation is wanted, but at reduced wash speed.

Program auxiliary 1 step for one second, then program

a Wash 1 step. The A1 output will remain on during

the Wash 1 step, selecting reduced wash speed during

the Wash 1 step. Upon reaching a drain step, or upon

entering the Stop routine, the WE-6 will operate the

machine at reduced wash speed (PROVIDED the

machine is equipped with the necessary hardware for

controlling reduced wash speed).

Control of an optional recirculation pump

The A2 output will also remain on until a drain or the

Stop routine if the WE-6 prompt is “WET CL” and if

“1DRAIN” is selected. This would allow control of an

optional recirculation pump by permitting the pump to

continue operating during a wash step. For this

control, program an auxiliary 2 “A2” step for one

second or other suitable time, and the output would

remain on until a drain step or until the Stop routine.

The auxiliary 2 step would also go off upon entering a

Wash 7 step.

Note that “2DRAIN” prompt will OVERRIDE wet

clean control of auxiliary 2 output. If “2DRAIN” is

selected that means that the auxiliary 2 output is

reserved for controlling a second independent drain

(not for integrated reuse – you should select

“1DRAIN” for integrated reuse). Also, if “2DRAIN”

is selected. the WE-6 will not permit programming an

auxiliary 2 step.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 17

Operation

WE-6 Microcomputer

The WE-6 microcomputer control is a fieldprogrammable solid-state control capable of storing

and running up to 39 preprogrammed ready-to-use

cycles.

Cycle 01 is a test cycle used to verify proper operation

of the machine. With the exception of Cycle 39, the

remaining cycles are complete wash cycles or

specialty cycles designed to handle various fabrics at

specific water temperatures and levels. Cycle 39 is

designed to test an external chemical injection supply

system.

A detailed description of the cycles can be found in the

Programming section of this manual under

Preprogrammed Cycles. (If this washer-extractor’s

computer has been equipped with special

preprogrammed cycles, a separate insert listing these

cycles has been included in the resealable plastic bag

which contained this manual.)

Never turn the power off while the computer mode

switch is in the PROGRAM position. Such action will

disorder portions of the programmed data,

necessitating reprogramming of some or all of the

existing cycles. Always return the mode switch to

RUN position before turning the power off.

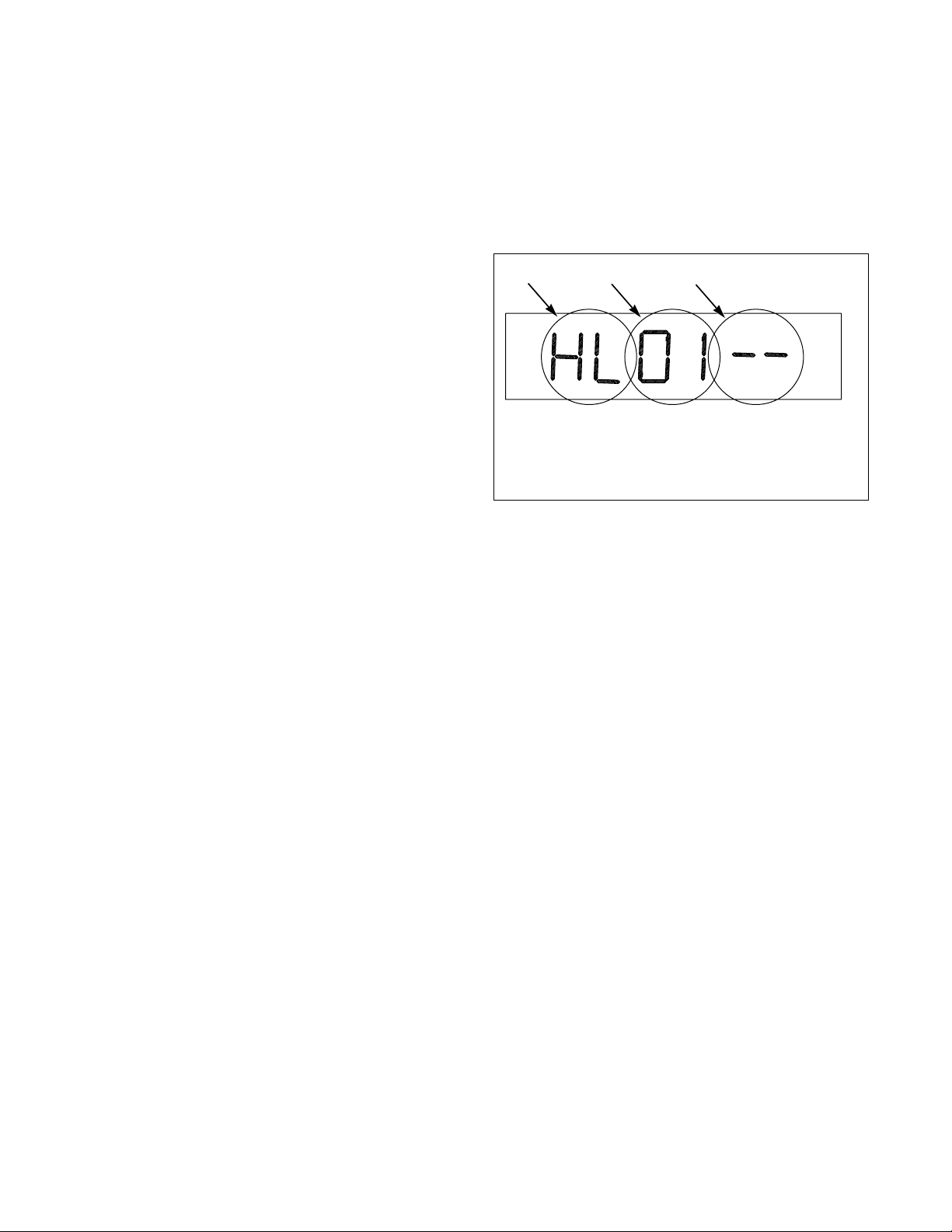

LED Display

The WE-6 microcomputer has a six-digit LED display.

References to display indications pertain to the first

four digits of the display, reading left to right. The last

two digits on the right side of the display will indicate

either the last cycle used or the current cycle in

progress. Refer to Figure 3.

1

1 Function Being Executed

2 Step Number

3 Cycle Number

2

3

U151R

Figure 3

Never leave the mode switch key inserted in the switch

lock where it may be accessible to unauthorized

personnel not familiar with programming procedures.

The computer control in this washer-extractor is

continuously on the alert for problems within the

machine. When the computer detects a problem, it

immediately flashes a letter or number or both on the

display. It may activate the signal buzzer as well.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Operation

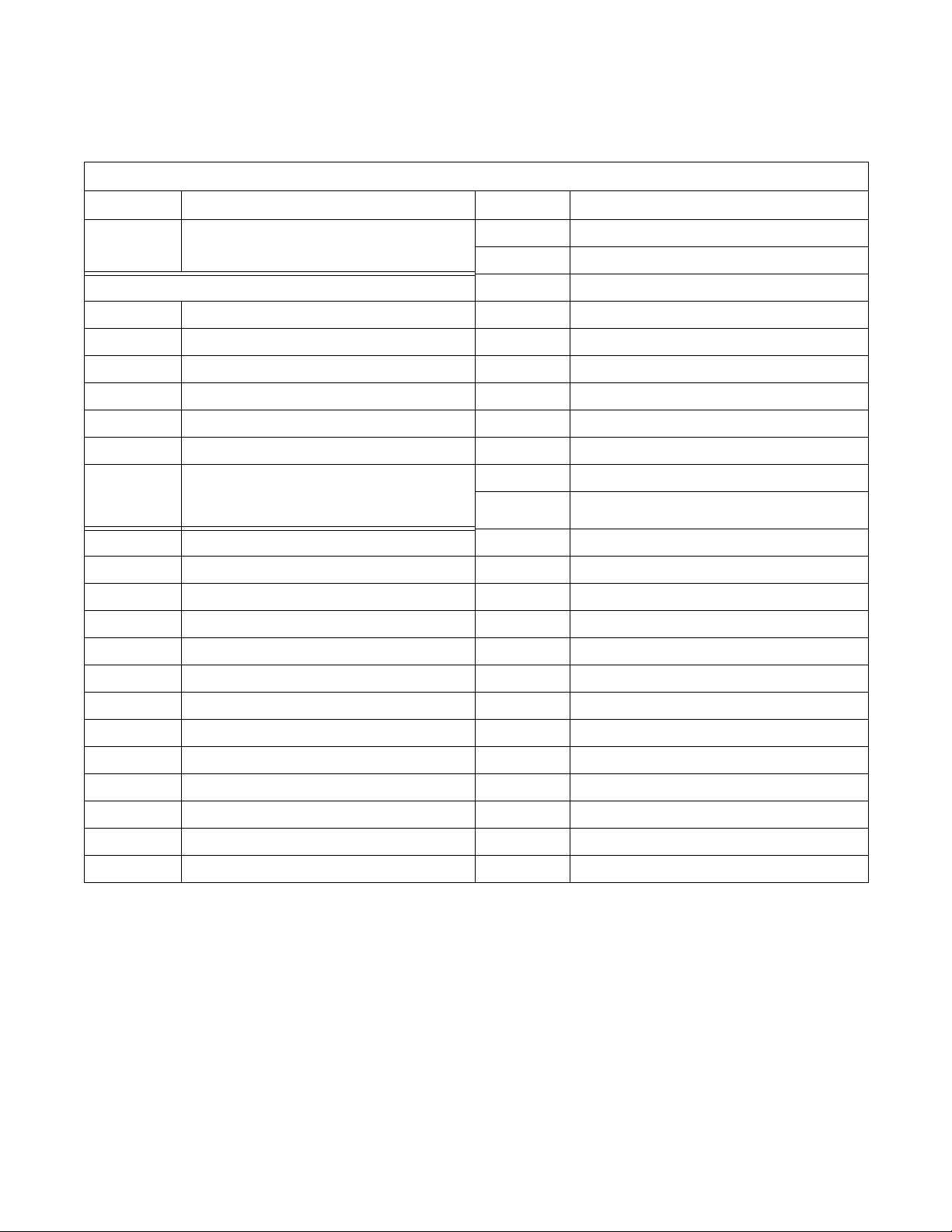

Table 1 lists the various displays and what they mean.

The last digit represents version number.

The operator should become familiar with these

computer displays.

Display Interpretations

Display Meaning Display Meaning

FRWC00 Program identification code (ROM). CY Cycle number

D1 Drain #1

Error Messages Da Drain to optional reuse tank A

FILL Fill problem Db Drain to optional reuse tank B

EMTY Empty problem DONE End of cycle

TEMP Over-temperature-limit condition EXISTS Cycle already in memory

ME Cycle information problem EDIT? Do you want to edit the cycle?

WATER Water in washer-extractor at end of cycle F Heat select temperature in ° Fahrenheit

DOOR Door not locked problem C Heat select temperature in ° Centigrade

OVERHT Open or shorted temperature input circuit or

temperature out of computer’s allowable

limits

aL Fill from reuse tank A to low level HM Hot fill to medium level

HH Hot fill to high level

HL Hot fill to low level

aM Fill from reuse tank A to medium level HO Hot fill to overflow

aH Fill from reuse tank A to high level HT Heat (steam or electric)

bL Fill from reuse tank B to low level H1 High speed #1

bM Fill from reuse tank B to medium level H2 High speed #2

bH Fill from reuse tank B to high level H3 High speed #3

A1 Auxiliary output #1 MS Medium speed spin

A2 Auxiliary output #2 --M Minutes (used when programming time)

A3 Signal --S Seconds (used when programming time)

CH Cold fill to high level NCYC Cycle not available

CM Cold fill to medium level NEXT Select cycle or open door or select program

CL Cold fill to low level SDLY Spin coast delay

CO Cold fill to overflow SK Soak

Table 1

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

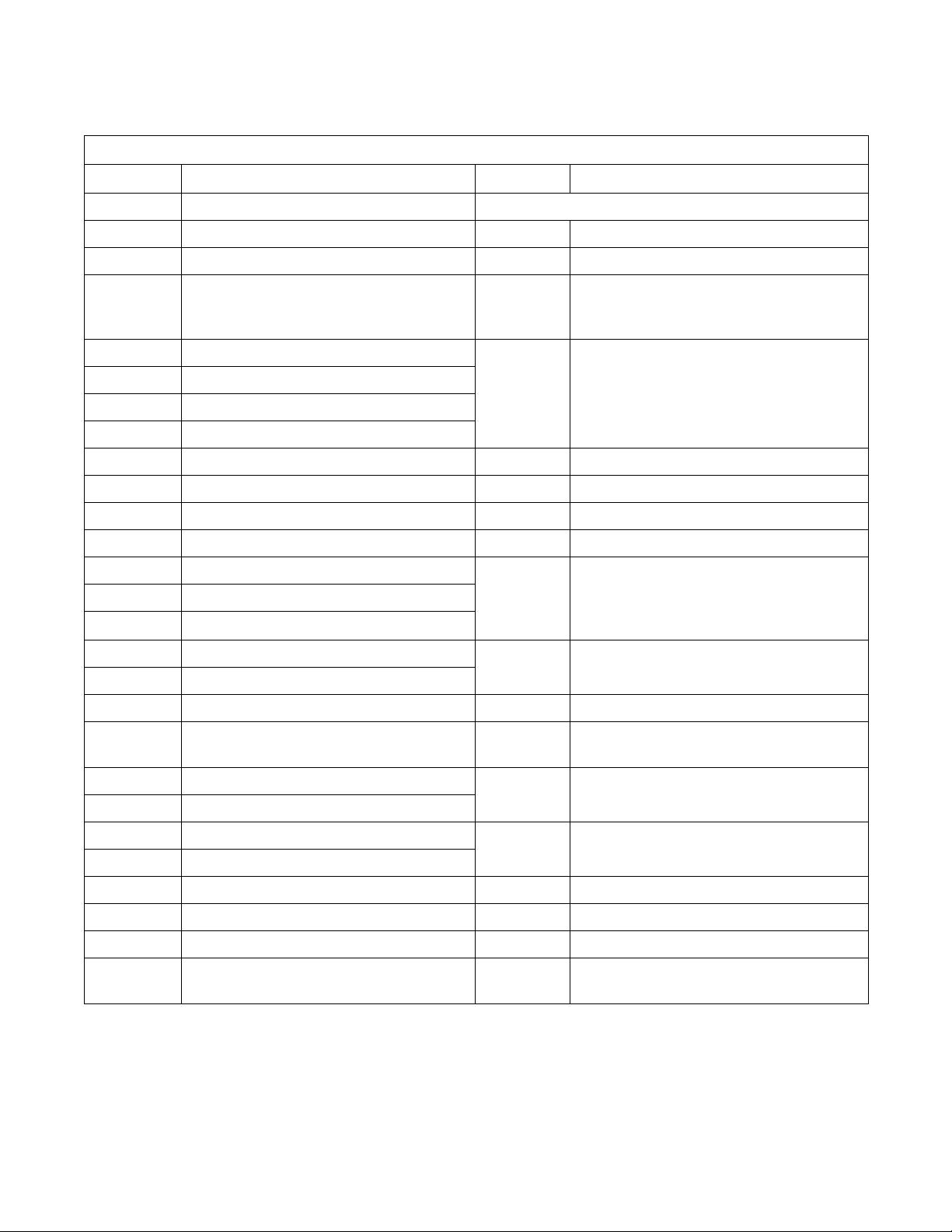

Page 19

Operation

Table 1 (Continued)

Display Interpretations

Display Meaning Display Meaning

STOP Stop button pressed or cycle ended WE-6 Prompts

S1 Supply #1 (Detergent) °FAR Temperature in degrees Fahrenheit

S2 Supply #2 (Bleach) °CEN Temperature in degrees Centigrade

S3 Supply #3 (Sour) 1DRAIN One drain capability selected. (This means

that a second independent drain controlled by

Auxiliary 2 output is disabled.)

S4 Supply #4 (Softener) 2DRAIN Second independent drain enabled (via

S5 Supply #5 (Starch/Sizing)

TH Controlled temperature fill to high level

TM Controlled temperature fill to medium level

Auxiliary 2 output – precludes control of

recirculation pump via Auxiliary 2, if

selected). This should not be confused with

the “dual drain” option.

TL Controlled temperature fill to low level ADV Advance (skip steps) feature enabled

TO Controlled temperature overflow NO ADV Advance feature disabled

WH Warm fill to high level MANUAL Manual Mode enabled

WM Warm fill to medium level NO MAN Manual Mode disabled

WL Warm fill to low level

WO Warm fill to overflow level

W1 Wash 1 (regular reversing)

WET CL

Wet clean function for Auxiliary 1 output

(1/2 wash speed) and Auxiliary 2 output

(recirculation pump) enabled. (Refer to

“2DRAIN”.)

W2 Wash 2 (gentle reversing) NO WCL Wet clean function for Auxiliary 1 and 2

W3 Wash 3 (no agitation)

disabled (Auxiliary 1 and 2 are timed outputs.

W4 Wash 4 (medium reversing action) BAL SW Balance sensor

W5 Wash 5 (temp.-controlled cool-down) BAL 1 Balance routine for 35 pound and 50 pound

capacity

W6 Wash 6 (extra low agitation) BAL 2 Balance routine for 85 pound and 135 pound

W7 Wash 7 (no agitation, drain 1 open, no refill)

capacity

• Left dot – poor balance condition BAL 3 Balance routine for 250 pound capacity

• Second dot from left – door lock switch

• Third dot from left – Program Mode RL Fill from optional extra fill inlet to low level.

• Fourth dot from left – high level reached RM Fill from extra fill inlet to medium fill.

• Fifth dot from left – medium level reached RH Fill from extra fill inlet to high level.

F232059

• Right dot – low level reached DRTEMP Temperature is above 160°F in drain to reuse

tank A or B step.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Operation

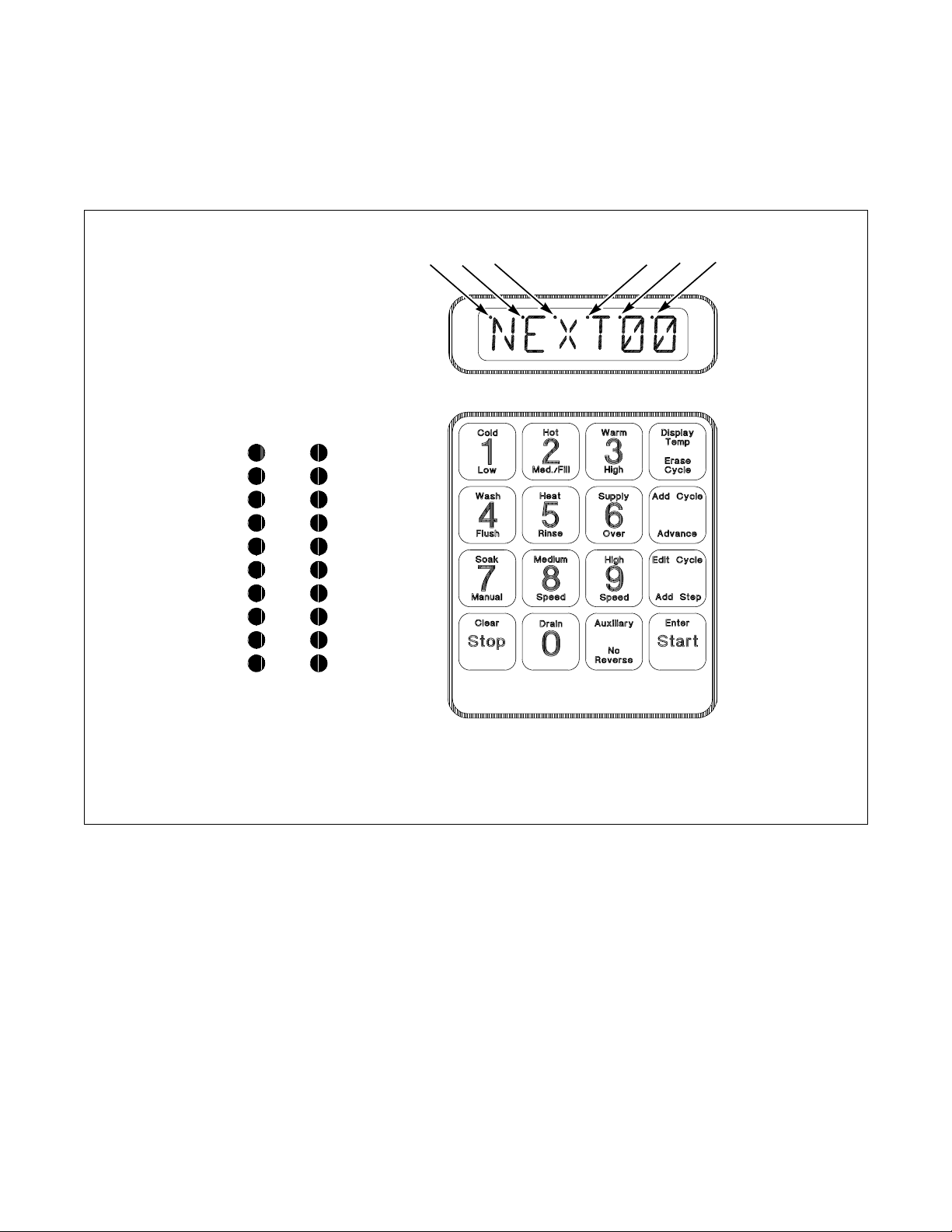

Operational Keypad

These functions are available to the operator and are

intended to control operation of the washer-extractor.

The computer’s control keypad includes sixteen keys.

Refer to Ta b le 2.

Refer to Figure 4. Fourteen of these keys list functions

printed in black lettering on a silver background.

Operational Keypad

Key Description

Numbers 0-9 Press to select cycle number

Display Temp Press and hold. Display will show and update sump temperature in degrees Fahrenheit or Centigrade.

Advance Press to cause computer to skip to the next step in the cycle. The computer will not advance past drain

step. (The Advance key is enabled at the factory and can be disabled at the laundry site.)

Stop Press to immediately abort the cycle and initiate the Stop routine

Start Press to start selected cycle or to restart a step following a “FILL” or “EMTY” alarm. Refer to Error

Recovery Routine.

Manual Refer to Manual Mode Control Feature.

Table 2

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 21

Located to the left of the computer keypad

are 20 LED indicator lights for the computer outputs.

During the time that a cycle is running, one or more of

these lights will be on to indicate the outputs activated

for a particular step. Refer to Figure 4.

Operation

Output Indicators

Supply 1

Supply 2

Supply 3

Supply 4

Supply 5

Cold Fill

Hot Fill

Spare

Spare

Signal

Heat

Forward

Reverse

Dist. Speed

Med. Speed

High Speed

Unlock Door

Drain Closed

Auxiliary 1

Auxiliary 2

3

2

1

4

6

5

1 Balance Sensing Indicator 4 High Level Fill Indicator

2 Door Lock Switch 5 Medium Level Fill Indicator

3 Program Mode 6 Low Level Fill Indicator

Figure 4

U152R

U152R

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Operation

Start-Up

Turn on the main power source (circuit breaker or cutoff switch on the wall).

When AC power is turned on, the front panel display

will show the program (ROM) identification code.

This identification code will appear for approximately

five seconds. Then the computer display will flash

“POWER” and “WA I T ” alternately for two minutes.

The display will then show “NEXT00” to indicate that

a cycle can be selected. This display will be shown at

all times that power is on between cycles, indicating

that the door-unlock solenoid will function if the doorunlock button is pressed. The washer-extractor is then

ready for loading and unloading.

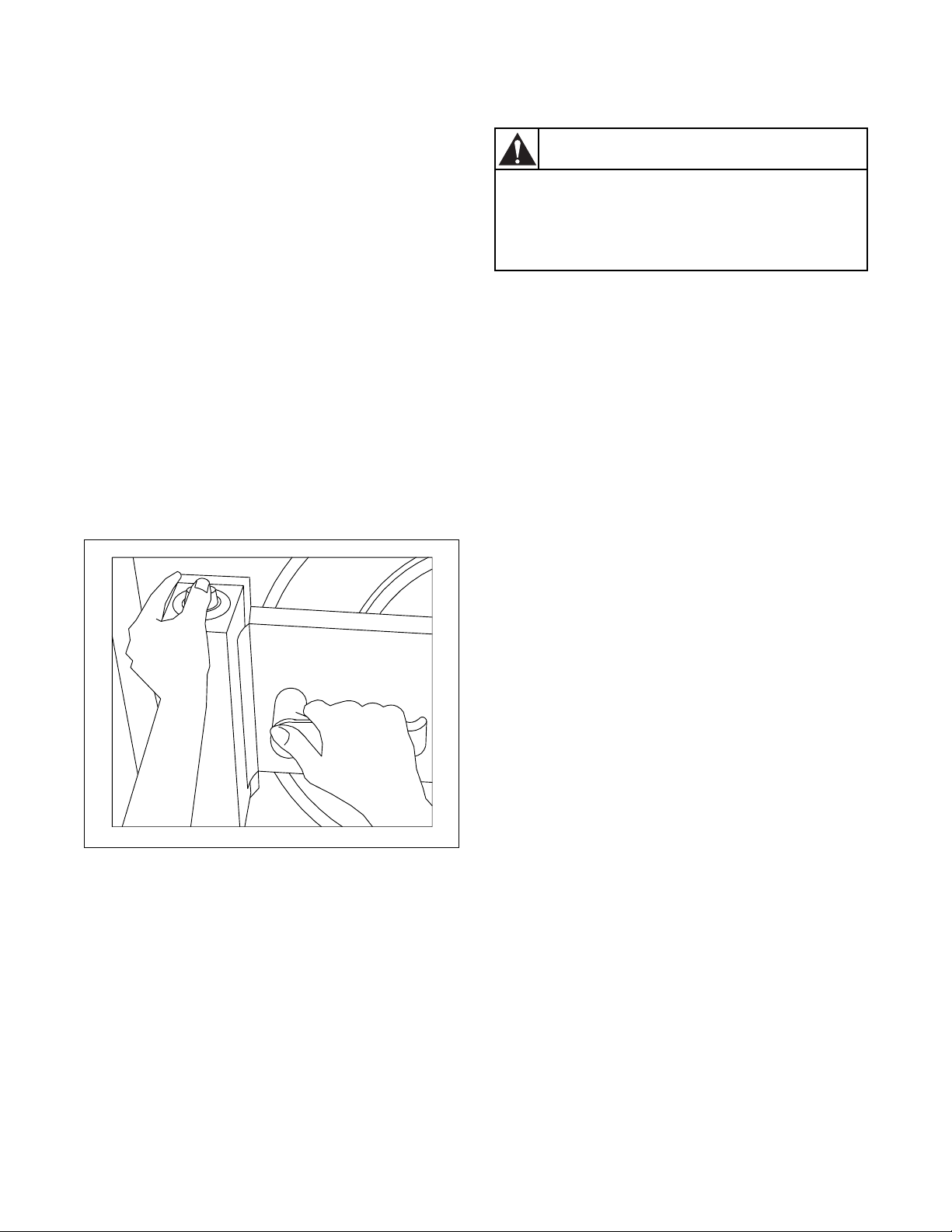

Opening Door

Use left hand to press and hold the door-unlock button

located on the top of the doorbox cover. Use right hand

to turn door handle upward and swing the door right to

open. Refer to Figure 5.

Loading

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

Load the washer-extractor to full capacity whenever

possible, but do not exceed the rated dry-weight

capacity of the machine if the fabric to be washed is

quite dense, closely woven, and heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine load

size based on fabric content, soil content, and level of

cleanliness required.

Partial loads can cause greater machine wear than full

loads. Partial loads, if necessary, should only occur at

the end of the day.

When loading is complete, ensure that all fabric is

inside the basket. Then close and lock the door.

Figure 5

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

U153R

U153R

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 23

Operation

Supply Dispenser

Dry supplies are placed in the supply dispenser

compartment cups prior to the start of each cycle.

Liquid supplies can be injected directly into the supply

dispenser by an external chemical supply system.

Supply dispenser compartment cups must not be

removed when an external chemical injection supply

system is attached to the washer-extractor.

Cycle Selection

NOTE: Press keys at their centers just hard enough

to activate them.

Find the cycle number of the desired wash cycle from

the Standard Cycle Charts in the Programming

section of this manual. Cycle numbers must be twodigit numbers from 01 to 39.

Press the numbers desired on the keyboard and note

that these numbers are displayed after “NEXT”.

When keys are pressed on the keyboard, a beep will be

heard. If an error is made, press the numbers again. As

numbers are entered, they move from right to left on

the display.

To begin the cycle at any step other than the first step,

press the Advance key to advance through the cycle to

the desired starting point. (The Advance key is enabled

at the factory and can be disabled at the laundry site.)

Then press the Start key.

It is possible to skip to the next step in a cycle, with the

exception of a drain step; drain steps must be allowed

time to complete.

When the display shows the step desired to begin the

cycle, press the Start key.

If the door is not locked, the display will indicate

“CLOSE” and “DOOR”. If this occurs, be sure the

door is closed and locked and press the Start key again.

If the LED indicator lights for the computer outputs

indicate that one or more outputs are activated but the

washer-extractor is not functioning according to the

output or outputs indicated, contact a service

technician.

As water fills the washer-extractor, one or more of the

indicator lights located to the left of the keyboard will

come on and stay on until the required water level is

reached. LED dots located in the upper left corner of

the last three digits on the right of the display will

illuminate to indicate the water level(s) reached:

NOTE: If the washer-extractor is equipped with

both steam and electric heat, the selector switch on

the valve panel must be in the correct position for

the desired heat source, down for steam heat, up for

electric heat.

Cycle Execution

To start the selected cycle, press the Start key. If the

selected cycle number is not in the computer memory,

the display will show “NCYC”. If this happens, select

another cycle. Otherwise, the display will now show

the first step. For example, if the display reads

“HL01”, “HL” represents a hot fill to low level, and

“01” indicates that this is the first step of the cycle.

As the cycle proceeds, the display will show the

function being executed, the step number, and the

cycle number selected. Pressing the Edit Cycle key

while the cycle is running will cause the display to

show the remaining cycle time in minutes. Pressing

this key again will return the display to normal.

● When the indicator dot in the last digit on the

right is lit, the low water level has been reached.

● When the dot in the next-to-the-last digit is lit,

medium water level (optional) has been reached.

● When the dot over the third digit from the right

has been lit, high level has been reached.

The cycle will continue until its completion. Then the

display will show “DONE”.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Operation

Test Cycle

Cycle number 01 is a test cycle used to analyze

washer-extractor functions. Refer to the Programming

section of this manual.

Step 01 in cycle number 01 is a cold fill to low level.

This step is designed to give not quite enough time to

complete a fill, causing the display to read “FILL”.

Press the Start key to continue the fill, and the test

cycle will proceed.

Step 02 in the test cycle is a drain step. Again, the time

allotted is shorter than it would be in a normal cycle.

The display will read “EMTY”. To proceed, press the

Start key.

The steps in the test cycle are relatively short, with the

exception of steps 03, 20, 22, 24, 25, 26, and 29. These

can be shortened by pressing the Advance key to go on

to the next step.

The operator may skip to any next step in the cycle

with the exception of a drain step: Drain steps must be

allowed to complete. To skip forward in the test cycle,

press the Advance key.

Wet Clean Testing

Wet clean processing outputs are tested through the

energizing of the Auxiliary 1 output in step 17 and

Auxiliary 2 output in step 18. Steps after step 28 are

designed to test water reuse processing, if this option

is installed. If it is not, press the Stop key to abort the

cycle.

NOTE: Prompts for “1DRAIN” and “WET CL”

must be selected when prompting the WE-6

microcomputer in order for steps 17 and 18 to

work properly for wet clean processing.

NOTE: The Advance feature may be disabled.

Refer to System Programming in the Programming

section of the manual.

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 25

Operation

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Stop Routine

The operator can select the agitation which will be in

effect for the entire Stop routine. This will help

prevent tangling of the load and provide maximum

control. Three agitations are available for the Stop

routine. They are as follows:

Wash 1

● 18 seconds forward

● 3 seconds pause

● 18 seconds reverse

● 3 seconds pause

● sequence repeated

Wash 2

● 3 seconds forward

● 27 seconds pause

NOTE: The forward and reverse times differ

slightly for the Wash 1 selection. These times give

the best results during the Stop routine when no

water is in the washer-extractor.

To select the agitation in the Stop routine, program a

Wash 1, 2, or 3 step for 1 second. The washer-

extractor will begin refilling to the most recent water

level if the time is more than 1 second. If the most

recent wash type was Wash 4, 6, or 7, the WE-6 will

default to no agitation (Wash 3) during the Stop

routine.

NOTE: If the desired action is not programmed in

the final cycle step, the computer will default to the

most recent action in the cycle. If the cycle stops

prematurely, the most recent action at the time the

cycle is interrupted will be in effect during the Stop

routine.

The display will read “W1-cc”, “W2-cc”, or “W3-cc”

for Wash 1, Wash 2, or Wash 3 action during the entire

Stop routine until the final 10 seconds. (The “cc” here

stands for the current cycle number and will be

represented by numbers in the actual display.) During

the final ten seconds, the display reads “STOPcc”. The

display will then read “DONEcc”. At that point, the

door can be opened.

● 3 seconds reverse

● 27 seconds pause

● sequence repeated

Wash 3

● no agitation

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Operation

Balance Detection

The washer-extractor may be equipped with either of

two balance detection systems: (1) a balance sensor

detection system or (2) an inverter drive balance

detection system.

Balance Sensor Detection

If the washer-extractor is equipped with the balance

sensor detection system, the optical sensor installed on

a bracket on a shock absorber signals the computer to

slow the washer-extractor when an out-of-balance load

occurs during extract.

If the balance sensor is tripped, the out-of-balance

LED indicator located in the upper left corner of the

first digit of the display will light and will remain

lighted until the end of the extract step. This indicator

tells the operator that an out-of-balance condition

existed during an extract step. The washer-extractor

will attempt to balance three times during an extract

step.

If on the third attempt the out-of-balance condition

continues, the washer-extractor will advance to the

next step. (If the next step is another spin step, it will

be skipped also.)

Inverter Drive Balance Detection

If the washer-extractor is equipped with the inverter

drive balance detection system, balance is detected by

the inverter drive during a drain step as opposed to an

extract step. The WE-6 microcomputer will make up

to seven attempts to balance the load during a drain

step. During the final balance attempt, the out-ofbalance LED indicator located in the upper left corner

of the first digit of the display will light. The indicator

will remain lighted until the drain step is complete.

If on the seventh attempt the load is not balanced, the

washer-extractor will continue to the next step in the

cycle following the drain step that is not a spin step.

Therefore, if one spin step or two or more consecutive

spin steps follow, all will be skipped if seven attempts

to balance the load in the drain step fail. High speed

steps include medium, H1, H2, and H3 spin steps.

NOTE: The computer cannot advance through a

drain step, nor will the computer allow starting a

cycle in a spin step.

NOTE: A drain step must be programmed prior to

a high speed step to allow for inverter drive balance

detection. Otherwise, spin steps will be skipped by

the computer.

If the washer-extractor is equipped with the inverter

drive balance detection system, a special balance

switch serves to remove power to the machine. This

means that if the washer-extractor balance “passes” the

inverter drive balance detection system at the drain

step but the balance switch detects an out-of-balance

load condition at the extract step, power will be

removed from the washer-extractor.

At this point, the LED display goes blank on the WE-6

microcomputer, and the washer-extractor coasts to a

stop. Such a condition indicates a serious problem.

Contact a service technician before attempting to

restore power to the washer-extractor.

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 27

Operation

Temperature Display

The temperature display can be prompted to display in

Fahrenheit or Centigrade. Refer to System

Programming in the Programming section of this

manual.

To display temperature, press the Display Temp key.

The display will read “F” or “C” and the temperature

as long as the key is pressed. The computer will update

the display automatically.

Calibrating the WE-6 Temperature Circuit

1. Open the control compartment to gain access to

the WE-6 computer board.

2. Viewing the WE-6 computer board from the rear,

locate the blue rectangular plastic component

with a white plastic screw head in the center. This

is the temperature calibration potentiometer.

Turning this screw head adjusts the temperature

reading.

3. Fill the machine sump with water and place an

accurate temperature sensor in the water to

provide a measurement of the actual water

temperature. The WE-6 temperature readout is

then adjusted to match this to the nearest unit. It

is easiest to program a Wash 3 (no agitation) for

10 seconds (to prevent rotation and subsequent

damage to the temperature sensor), then a cold

fill to high level, followed by a Wash 3 for

9 minutes and 99 seconds. Do not press STOP.

Calibration must be completed before the last

wash step finishes. Remove power to machine

after calibration until computer goes off to

prevent rotation when the cycle ends.

4. Start the cycle. When the water level is reached

(and the external temperature sensor is

submerged), press the DISPLAY TEMP key on

the WE-6 keypad. The display will show a

reading in either degrees F or degrees C, or the

conversion will have to be made by calculation as

follows:

Degrees F = (Degree C x 9/5) + 32

Degrees C = (Degrees F - 32) x 5/9

5. While pressing the DISPLAY TEMP key, use the

screwdriver to turn the temperature calibration

screw until the WE-6 displays the same

temperature as the external sensor, which should

be accurate at least to the nearest degree. Turning

the screw clockwise increases the displayed

temperature.

6. When the temperatures match, calibration is

completed. Close the control compartment and

remove the external temperature sensor. To

prevent rotation, DO NOT PRESS STOP; instead

remove power to the machine until the computer

goes off.

*As an alternative, if an external sensor is not

available, measure the temperature of the inflowing

water, and follow step 5.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Operation

BEEPER

ROM

1

J2

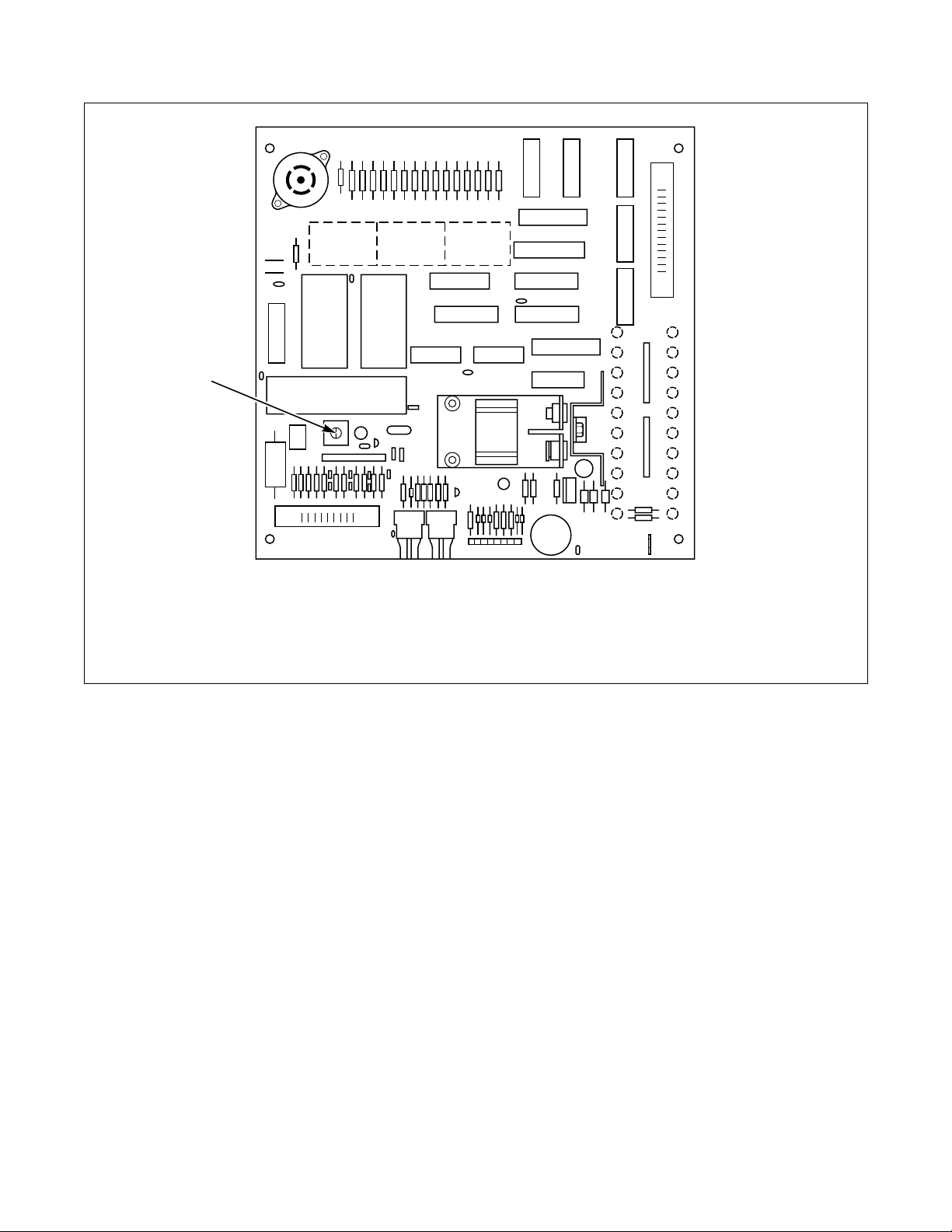

1 Temperature Calibration Adjustment

EE ROM

BATTERY

BACKUP

J3

WE-6 CONTROL BOARD

J1

J5

CFS442N

NOTE: Control board shown is WE-6 washer unit. Board for simulator does not have battery backup. Washer and

simulator boards are not interchangeable.

Figure 6

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 29

Operation

Error Recovery Routine

When the computer detects an error, it will stop

running the current step and display a message to

indicate what type of error was found:

● “FILL” indicates that the washer-extractor did

not fill within the allotted time.

● “EMTY” indicates that the washer-extractor did

not drain in the allotted time.

● “TEMP” indicates that the temperature sensor

has recognized an over-temperature-limit

condition.

● “ME” indicates that the computer has detected a

problem with the cycle information. The cycle

must be edited.

● “WATER” indicates that the WE-6

microcomputer senses low, medium, or high

water level at the end of the Stop routine.

● “DRTEMP” indicates that the WE-6 has detected

water temperature over 160°F (71°C) in a “drain

to reuse” step. Instead of draining to a tank, the

computer gives this error message. The cycle

must be edited so the temperature is below 160° F

(71°C) upon entering a reuse drain step (“Da” or

“Db”).

All outputs remain off while the message

displays, and the door cannot be unlocked.

NOTE: The WE-6 microcomputer will not allow

the door to be opened while there is water in the

washer-extractor.

Each of these errors is considered to be recoverable.

The operator has two minutes to respond to the error

condition (except in the case of “WATER”). During

this time, the computer will turn the signal (buzzer)

relay on and off at the rate of one second on and one

second off to alert the operator to the error condition.

The washer-extractor may be restarted by pressing the

Enter key. Pressing the Enter key will restart the cycle

step for the originally programmed time period. The

cycle may be aborted by pressing the Clear key. After

aborting the cycle, the computer will go to the normal

stop routine. If the operator does not respond to the

error condition within the allocated two minutes, the

computer will automatically abort the cycle.

NOTE: The “TEMP” alarm can be recovered only

after the temperature falls below the alarm level.

Certain error conditions are considered to be nonrecoverable:

● If the door opens during a cycle, the computer

will display “DOOR”. The operator must close

the door.

Then, after the computer has detected that the

door is closed, it will automatically abort the

cycle and go to the normal Stop routine.

● “OVERHT” will be displayed when the computer

detects an open or shorted temperature input

circuit or temperatures are outside of the washerextractor’s allowable limits. Contact a service

technician.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Operation

Thermal Overload Indicator

To protect the AC drive from damage due to excessive

temperature, a thermal limit switch is embedded in the

drive box.

If the thermal limit switch is tripped due to damaging

conditions, the “Drive Thermal Indicator” light located

in the WE-6 control module will light and power will

be removed from the drive. The AC drive thermal limit

switch MUST be manually reset. Refer to the

following for location and instructions.

Before resetting the thermal overload switch,

determine the reason for the overload. The following is

a partial list of possible problems:

● Bad motor bearings.

● Motor cooling fan blocked or not operating.

● Excessively dirty motor (lint build-up, for

example).

● Room temperature higher than 104°F (40°C).

● Dirty fan filter.

● Fan not operating properly.

Resetting Thermal Overload Switch

1. Remove the main power from the machine.

2. Locate the AC drive box and remove the cover.

The AC drive box enclosure is located at the rear

in the upper, left-hand corner of the machine as

seen from the rear.

3. Locate the thermal limit switch in the AC drive box

and press the red reset button located on the switch.

The thermal limit switch is mounted in the center

of the left side wall of the AC drive box.

4. Replace the cover and return power to the

machine.

● Fan not installed properly.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 31

Operation

Manual Mode Control Feature

With the exception of a spin or drain step, manual

control is available only while a preprogrammed cycle

is in progress, and if Manual Mode is prompted in the

WE-6 programming. Except for the motor outputs and

door unlock output, the WE-6 microcomputer outputs

can be operated manually from the keypad. (In order to

ensure proper sequencing, motor speeds are always

controlled by the computer.)

In normal operation, when the Program Mode switch

is in the RUN position, only the operations printed in

black on the keys are accessible to the operator.

NOTE: When the Manual Mode control feature is

activated, the operator must supply on/off

commands for the controllable outputs. If an

output is on, it will remain on until turned off by

the operator or until the assigned time for the

Manual Mode expires. This can be as long as

9 minutes and 99 seconds.

During the Manual Mode, normal cycle timing is

suspended. When the Manual Mode is entered, the

operations printed in red on the keys and mentioned in

the following discussion are activated.

Entering the Manual Mode during a fill operation is

not recommended. This bypasses the water-level

switch inputs, and the water must be turned off

manually by the operator.

When the computer receives all these inputs within the

three-second time limit, it will enter the Manual Mode

for the time assigned.

The computer display will flash between “MAN230”

(reflecting the time chosen in step 2 of the above

procedure) and the current cycle step display for four

seconds.

After four seconds, the display will flash between

“MANUAL” and the current cycle step display for the

remainder of the assigned time.

Manual Mode operation will automatically end when

the assigned time elapses. Normal program timing will

then resume from the same point in the cycle where

the Manual Mode was entered. To exit the Manual

Mode and return to normal program timing before the

assigned time elapses, press the Start key.

All water fill valves, supplies, heat (if the machine has

reached low water level), main drain valve (Drain 1)

and auxiliary outputs (excluding water reuse control

outputs) can be manually controlled. The heat and

drain outputs require that only one key be pressed

(Heat and Drain respectively). All other outputs

require that two keys be pressed. For example, to turn

on the cold fill valve, press the keys Cold and Fill.

When an output is on, pressing the same key or keys

which caused it to energize will turn it off. Thus, to

turn off the cold fill valve, press the keys Cold and Fill

once again.

The following procedure must be accomplished within

three seconds in order to enter the Manual Mode:

1. Press the Manual key.

2. Then press three number keys to assign a time in

minutes and seconds to the Manual Mode. For

example, press key 2, key 3, and key 0 to enter

the Manual Mode for 2 minutes and 30 seconds.

3. Then press the Add Step key.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Notes

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232059

Page 33

Programming

Programming Keypad

function keys in the Program Mode. In each instance

(with the exception of the Warm/High key), when a

All sixteen keys are used in the Programming Mode.

Specific functions are printed in red on the keys. The

Programming Mode is active only when the Program

Mode switch is in the PROGRAM position. (When

programming is complete, remember to return the

key is first pressed in a programming step, the word

printed at the top of the key applies. In most instances,

the next time the same key is pressed – or if another

key has been pressed in the interim – the word printed

on the bottom of the key applies.

mode switch to the RUN position and remove the key.)

Keys 1-6 and the Auxiliary/No Reverse key are dual

Programming Keypad

Red Keys Description

Cold

Low

Hot

Med./Fill

Warm

High

Erase Cycle Erase Cycle and a two-digit cycle code number are pressed to erase a cycle from memory.

Wash Wash is pressed when the step is a wash or dilution rinse. Then key 1, 2, 3, 4, 6, or 7 is pressed to

Cold is pressed when the step requires cold water.

Low is pressed for low-level fill.

Hot is pressed when the step requires hot water.

Med./Fill is pressed to select medium water level.

Fill is pressed in the Manual Mode to operate fill valves.

Warm is pressed when the step requires warm water.

High is pressed for high-level fill.

choose the type of agitation.

Heat Heat is pressed when auxiliary heat is needed. This must be followed by a specific temperature

selection, such as 165°F. The temperature must be entered; then a time assigned to reach that

temperature must be entered.

Supply

Over

Add Cycle Add Cycle is pressed to begin the process of programming a new cycle into memory.

Soak Soak is used when no agitation is desired. This follows a fill and/or supply step. The time must be

Medium Speed Medium Speed is pressed when a medium spin only is desired for washing delicate items not suited

High Speed High Speed is pressed when a fast spin is desired. Pressing the High Speed key once will activate the

Edit Cycle

Add Step

Clear (black on

red background)

Supply is pressed when soap, bleach, or other chemicals are desired. Key 1, 2, 3, 4, or 5 must then be

pressed to indicate the specific supply dispenser being used. Combinations of these supplies can be

programmed. Refer to Programming a Supply Step.

Over is pressed when an overflow of water is desired. The drain is closed and water is added without

regard to level. Water flows out the overflow connection for the time assigned to the step.

assigned in hours and minutes. (Wash 3 also provides no agitation.)

for high-speed spin or when an intermediate spin is desired.

H1 spin; twice, the H2 spin; and three times, the H3 spin.

Edit Cycle is pressed followed by a two-digit cycle code number to display the steps of a

preprogrammed cycle. The cycle may be altered during the edit cycle procedure by deleting, changing,

or adding steps.

Add Step is pressed to add a step to an existing cycle during the edit cycle procedure.

Clear is pressed when an error has been made in programming a step. Instead of pressing Enter as the

step is completed, press Clear to eliminate the incorrect information. (Clear should never be pressed

when displaying a cycle unless a particular step is to be eliminated or changed. Refer to Displaying a

Cycle in Memory.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Programming

Programming Keypad (Continued)

Red Keys Description

Drain Drain is pressed after a wash, dilution rinse, or soak step is programmed in order to remove water from

the machine. A time must be assigned that will allow the machine to reach empty. There are always

three possible selections for the drain step. These are selected after you press the Drain key by pressing

key 1 for drain 1 (main drain), key 2 for a drain to reuse tank A, and key 3 for a drain to reuse tank B.

For special applications utilizing “2DRAIN”, contact the factory. Refer to System Programming.

Auxiliary

Auxiliary is pressed to activate the buzzer or other auxiliary output. NOTE: Auxiliary 4 is used to

activate a special fill to water level using a special output. Contact the manufacturer for details. (For

special applications only).

No Reverse

No Reverse is used to rotate the basket in one direction only during a step and should be pressed just

before pressing the Enter key.

Enter Enter is pressed to enter programming information into the computer’s memory.

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232059

Page 35

Programming

Programming Tutorial

The following procedure guides the programmer

through a complete cycle and allows hands-on

experience for programming cycles. The complete

cycle is listed in Table 3.

1. Locate the key-operated programming switch

behind the access door directly below the

emergency stop button (top right on the front

panel of the washer-extractor).

Insert the key and turn the switch to PROGRAM

position. The display will read “CYC00”.

2. Press the Add Cycle key. The display will read

“ACYC00”.

3. A two-digit number from 01 to 39 must be

entered. Cycle number 39 is recommended

because standard program versions use this short

cycle for performing a chemical supply setup.

4. Press key 3, then key 9, then the Enter key. The

display will read “CYC39”.

a. If the display alternately flashes “EXISTS”

and “EDIT?”, press the Clear/Stop key. The

display will return to “CYC39”.

b. Erase the existing cycle: Press the Erase Cycle

key. The display will show “ECYC39”. Press

key 3, then key 9, then the Enter key. The

display will read “WA I T ” briefly and then

“CYC39”.

c. Press the Add Cycle key. The display will

read “ACYC39”. Press key 3, then key 9, then

the Enter key. The display will show “0139”.

5. Enter the desired function for step 1. A natural

choice might be hot fill to low level.

a. Press the Hot key and then the Low key. The

display will read “HL0139”.

b. Press the Enter key. The display will read

“M---S”.

c. Now enter the desired fill time. The

recommended number of minutes is four.

Press key 4. The display will read “4M-00S”.

6. Now press the Enter key. The display will read

“0239”, indicating that the computer is ready for

step 2 of cycle 39.

7. A natural choice for step 2 is the addition of a

supply.

a. To add supply No. 1, press the Supply key and

then key 1. The display will read “S10239”.

b. Press the Enter key and the display will read

“M---S”.

c. Now enter the desired time in minutes and

seconds for the supply valve to be turned on.

Thirty seconds is the recommended time.

Press key 0 for minutes, and the display will

read “0M-00S”.

Now press key 3 and then key 0. The display

will read “0M-30S”, indicating a supply time

of thirty seconds.

8. Now press the Enter key. The display will change

to read “0339”, indicating that the computer is

ready for step 3.

9. If no other supply is required, the next step is to

choose the type of wash desired and assign it a

time. For example, one might choose a wash with

standard reversing action (Wash 1) and a time of

six minutes.

a. Press the Wash key and then key 1. The

display will read “W10339”.

b. Press the Enter key. The display will read

“M---S”.

c. Press key 6. The display will read “6M-00S”,

indicating a wash step of six minutes.

10. Press the Enter key. The display will read“0439”,

indicating that the computer is ready for step 4.

11. A drain step usually comes next.

a. Press the Drain key. The display will read

“D-0439”. This program allows a choice

among drains 1, a, or b. For this application,

press key 1. The display will read “D10439”.

b. Then press the Enter key. The display will

read “M---S”.

c. Enter the maximum time desired for the

computer to allow the machine to drain to

empty. The recommended time is one minute.

Press key 1, and the display will change to

“1M-00S”, indicating a drain step of one

minute.

F232059

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Programming

NOTE: The manufacturer does not recommend

more than one minute for a drain step. If the

machine does not drain in the amount of time

programmed, the “EMTY” alarm will be

displayed.

12. Press the Enter key. The display will now read

“0539”, indicating that the computer is ready for

step 5.

13. A natural next step in the cycle might be a

dilution rinse.

a. Press the Cold and High keys to program a

cold fill to high level. The display will read

“CH0539”.

b. Press the Enter key. The display will read

“M---S”.

c. Enter the desired time for the computer to

allow the machine to fill to high level. Five

minutes is acceptable. Press key 5. The

display will read “5M-00S”.

NOTE: If the machine does not fill in the amount of

time programmed, the “FILL” alarm will be

displayed.

14. Press the Enter key. The display will read

“0639”, indicating that the computer is ready for

step 6.

15. Next, program another wash step:

a. Press the Wash key and key 1 to program an

action with normal reversing. The display will

read “W10639”.

b. Press the Enter key. The display will read

“M---S”.

c. Now enter the step duration. Three minutes is

acceptable. Press key 3. The display will read

“3M-00S”.

16. Press the Enter key. The display will read

“0739”, indicating that the computer is ready for

step 7.

17. Now program a drain step:

a. Press the Drain key. The display will read

“D-0739”. Then press key 1. The display will

read “D10739”.

b. Press the Enter key. The display will now read

“M---S”.

c. Enter the length of time the computer will

allow the machine to drain (one minute).

Press key 1. The display will read “1M-00S”,

indicating that a one-minute step has been

programmed.

18. Press the Enter key. The display will read

“0839”.

19. Program a cold fill to high level:

a. Press the Cold key and the High key. The

display will read “CH0839”.

b. Press the Enter key. The display will read

“M---S”.

c. Enter the maximum time to allow for the fill.

In this case, five minutes is sufficient. Press

key 5. The display will read “5M-00S”.

20. Press the Enter key as always after programming

a time duration. The display will read “0939”,

indicating that the computer is ready for step 9.