Alliance Laundry Systems SF25VNV, UF25VNV, UF18VNV, SF25VCV, UF25PNV User Manual

...

Washer-Extractor

Cabinet Freestanding

Model Numbers

SF18VNV SF25VCV UF18VNV

SF25VNV UF25PNV UF25VNV

NOTA: El manual en

español aparece después

del manual en inglés.

Installation/Maintenance

www.comlaundry.com

Part No. F232060R4

July 2002

Table of Contents

Installation/Maintenance

Safety

Key to Symbols................................................. 4

Operator Safety ................................................ 5

Safe Operating Environment ............................ 6

Environmental Conditions............................. 6

Machine Location.......................................... 7

Input and Output Services ............................. 7

AC Inverter Drive.......................................... 8

Misuse .............................................................. 8

Installation

Machine Overview............................................ 9

Delivery Inspection .......................................... 10

Customer Service ............................................. 10

Model Number Familiarization Guide.............. 11

General Specifications ...................................... 12

Dimensional Clearances.................................... 14

Machine Foundation ......................................... 18

Mechanical Installation..................................... 19

Maintenance

Daily ................................................................. 33

Beginning of Day...................................... 33

End of Day ................................................ 34

Weekly.............................................................. 34

Monthly ............................................................ 34

Quarterly........................................................... 36

Care of Stainless Steel ...................................... 36

Maintenance Checklists.................................... 38

Removal from Service

Decommissioning ............................................. 43

Mounting Bolt Installation ............................ 20

Drain Connection .............................................. 21

Water Connection ............................................. 23

Electrical Installation ........................................ 24

Steam Requirements ......................................... 27

Chemical Injection Supply System................... 28

Control Function Test ....................................... 31

F232060

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

© Copyright 2002 Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form

or by any means without the expressed written consent of the publisher.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232060

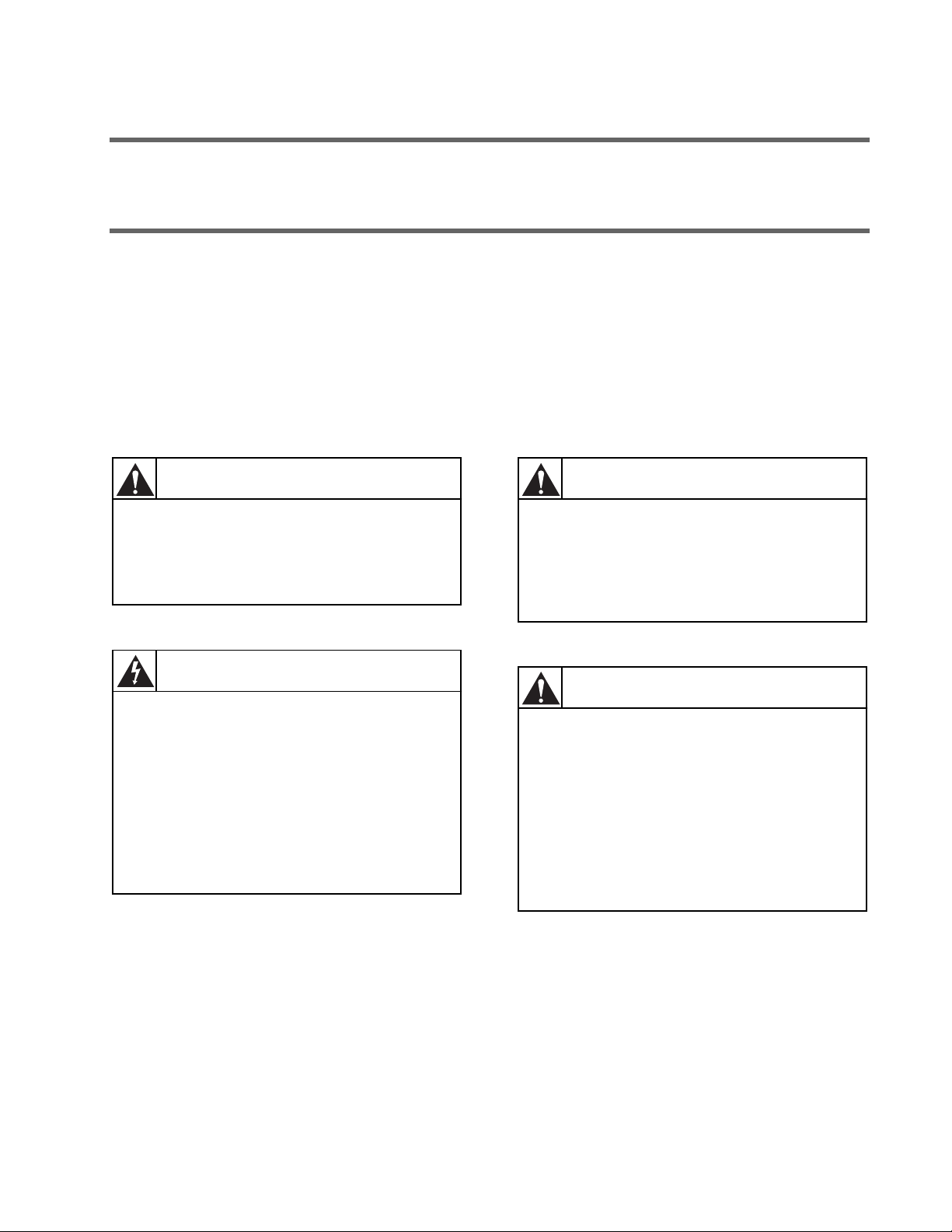

Section 1

Safety

Anyone operating or servicing this machine

must follow the safety rules in this manual.

Particular attention must be paid to the

DANGER, WARNING, and CAUTION

blocks which appear throughout the manual.

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel familiar

with electrical test procedures, test

equipment, and safety precautions should

attempt adjustments and troubleshooting.

Disconnect power from the machine before

removing the control box cover, and before

attempting any service procedures.

SW005

The following warnings are general examples

that apply to this machine. Warnings specific

to a particular installation or maintenance

procedure will appear in the manual with the

discussion of that procedure.

DANGER

Death or serious injury can result if children

become trapped in the machine. Do not

allow children to play on or around this

machine. Do not leave children unattended

while the machine door is open.

SW001

WARNING

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar with

the potential hazards involved. Failure to

observe this warning may result in personal

injury and/or equipment damage, and may

void the warranty.

SW004

F232060

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Safety

Ensure that the machine is installed on a

level floor of sufficient strength and that the

recommended clearances for inspection

and maintenance are provided. Never allow

the inspection and maintenance space to

be blocked.

SW020

CAUTION

WARNING

Never touch internal or external steam

pipes, connections, or components. These

surfaces can be extremely hot and will

cause severe burns. The steam must be

turned off and the pipe, connections, and

components allowed to cool before the pipe

can be touched.

SW014

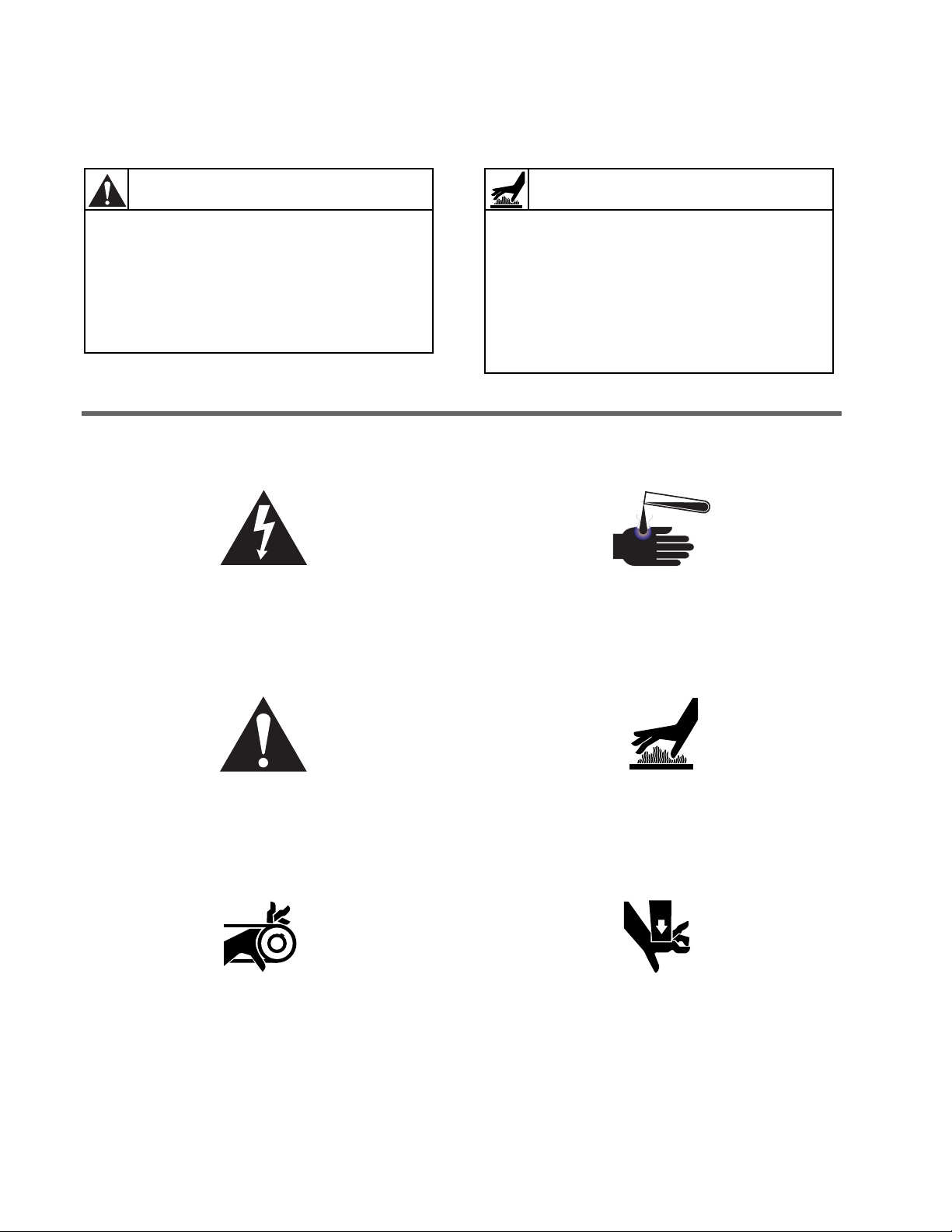

Key to Symbols

The lightning flash and arrowhead within the

triangle is a warning sign indicating the

presence of dangerous voltage.

The exclamation point within the triangle is a

warning sign indicating important instructions

concerning the machine and possibly

dangerous conditions.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms within

the machine. Guards should always be

in place when the machine is in operation.

This warning symbol indicates the presence of

possibly dangerous chemicals. Proper

precautions should be taken when handling

corrosive or caustic materials.

This warning symbol indicates the presence of

hot surfaces that could cause serious burns.

Stainless steel and steam lines can become

extremely hot and should not be touched.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving

mechanical parts can crush and/or sever

body parts.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232060

Safety

To provide personal safety and keep the

machine in proper working order, follow all

maintenance and safety procedures presented in

this manual. If questions regarding safety arise,

contact the factory immediately.

Use factory-authorized spare parts to avoid

safety hazards.

Operator Safety

WARNING

NEVER insert hands or objects into basket

until it has completely stopped. Doing so

could result in serious injury.

SW012

To ensure the safety of machine operators,

the following maintenance checks must be

performed daily:

1. Prior to operating the machine, verify that

all warning signs are present and legible.

Missing or illegible signs must be replaced

immediately. Make certain that spares

are available.

If the door lock and interlock are

not functioning properly, call a

service technician.

3. Do not attempt to operate the machine if

any of the following conditions are present:

a. The door does not remain securely

locked during the entire cycle.

b. Excessively high water level

is evident.

c. Machine is not connected to a

properly grounded circuit.

Do not bypass any safety devices in

the machine.

WARNING

Never operate the machine with a bypassed

or disconnected balance system. Operating

the machine with severe out-of-balance

loads could result in personal injury and

serious equipment damage.

SW039

2. Check door interlock before starting

operation of the machine:

a. Attempt to start the machine

with the door open. The machine should

not start with the door open.

b. Close the door without locking it and

attempt to start the machine. The

machine should not start with the

door unlocked.

c. Close and lock the door and start a

cycle. Attempt to open the door while

the cycle is in progress. The door

should not open.

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Safety

Safe Operating Environment

Safe operation requires an appropriate

operating environment for both the operator

and the machine. If questions regarding safety

arise, contact the factory immediately.

Environmental Conditions

• Ambient Temperature. Water in the

machine will freeze at temperatures

of 32°F (0°C) or below.

Temperatures above 120°F (50°C) will

result in more frequent motor overheating

and, in some cases, malfunction or

premature damage to solid state devices

that are used in some models. Special

cooling devices may be necessary.

Water pressure switches are affected by

increases and decreases in temperature.

Every 25°F (10°C) change in temperature

will have a 1% effect on the water level.

• Humidity. Relative humidity above 90%

may cause the machine’s electronics or

motors to malfunction or may trip the

ground fault interrupter. Corrosion

problems may occur on some metal

components in the machine.

be evaluated periodically. Louvers, screens,

or other separating devices may reduce the

available air opening significantly.

•

Radio Frequency Emissions. A filter is

available for machines in installations

where floor space is shared with equipment

sensitive to radio

frequency emissions.

• Elevation. If the machine is to be operated

at elevations of over 3,280 feet

(1,000 meters) above sea level, pay special

attention to water levels and electronic

settings (particularly temperature) or

desired results may not be achieved.

Chemicals. Keep stainless steel surfaces

•

free of chemical residues.

DANGER

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel reducers,

carbon tetrachloride, gasoline, benzene,

naptha, etc. Doing so could result in serious

personal injury and/or damage to

the machine.

SW002

If the relative humidity is below 30%,

belts and rubber hoses may eventually

develop dry rot. This condition can result in

hose leaks, which may cause safety hazards

external to the machine in conjunction with

adjacent electrical equipment.

Ventilation. The need for make-up air

•

openings for such laundry room accessories

as dryers, ironers, water heaters, etc., must

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

• Water Damage. Do not spray the machine

with water. Short circuiting and serious

damage may result. Repair immediately all

seepage due to faulty gaskets, etc.

F232060

Safety

Machine Location

•

Foundation. The concrete floor must be of

sufficient strength and thickness to handle

the floor loads generated by the high

extract speeds of the machine.

Service/Maintenance Space. Provide

•

sufficient space to allow comfortable

performance of service procedures and

routine preventive maintenance.

This is especially important in connection

with machines equipped with an AC

inverter drive.

Consult installation instructions for

specific details.

CAUTION

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any

safety devices.

• Steam Heat (Optional) Pressure. Best

performance will be realized if steam is

provided at a pressure of 30 – 80 psi

(2.0 – 5.4 bar). Steam pressure higher than

125 psi (8.5 bar) may result in damage

to steam components and may cause

personal injury.

For machines equipped with optional steam

heat, install piping in accordance with

approved commercial steam practices.

Failure to install the supplied steam filter

may void the warranty.

• Compressed Air. For machines requiring

compressed air service, best performance

will be realized if air is provided at a

pressure of 80 – 100 psi (5.4 – 6.7 bar).

• Drainage System. Provide drain lines or

troughs large enough to accommodate the

total number of gallons that could be

dumped if all machines on the site

drained at the same time from the highest

attainable level. If drain troughs are used,

they should be covered to support light foot

traffic.

SW019

•

Power. For personal safety and for proper

operation, the machine must be grounded

Input and Output Services

in accordance with state and local codes.

The ground connection must be to a proven

• Water Pressure. Best performance will be

realized if water is provided at a pressure of

30 – 85 psi (2.0 – 5.7 bar). Although the

machine will function properly at lower

earth ground, not to conduit or

water pipes. Do not use fuses in place of

the circuit breaker. An easy-access cutoff

switch should be provided.

pressure, increased fill times will occur.

Water pressure higher than 100 psi

(6.7 bar) may result in damage to machine

plumbing. Component failure(s) and

personal injury could result.

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Safety

Ensure that a ground wire from a proven

earth ground is connected to the ground lug

near the input power block on this machine.

Without proper grounding, personal injury

from electric shock could occur and machine

malfunctions may be evident.

SW008

WARNING

Safe Operating Environment

(Continued)

Always disconnect power and water supplies

before a service technician performs any

service procedure. Where applicable, steam

and/or compressed air supplies should also be

disconnected before service is performed.

AC Inverter Drive

Machines equipped with the AC inverter drive

require special attention with regard to the

operating environment.

• An especially dusty or linty environment

will require more frequent cleaning of the

AC inverter drive cooling fan filter and of

the AC inverter drive itself.

• Power line fluctuations from sources such

as uninterruptible power supplies (UPS)

can adversely affect machines equipped

with the AC inverter drive. Proper

suppression devices should be utilized on

the incoming power to the machine to

avoid problems.

valleys) in the power supply can cause

the AC inverter drive to generate

nuisance errors.

If voltage is above 230V for 200V

installations or above 440V for 400V

installations, a buckboost transformer is

recommended. If voltage is above 240 or

480, a buckboost transformer is required.

• Sufficient space to perform service

procedures and routine preventive

maintenance is especially important for

machines equipped with the AC

inverter drive.

Misuse

Never use this machine for any purpose other

than washing fabric.

• Never wash petroleum-soaked rags in the

machine. This could result in an explosion.

• Never wash machine parts or automotive

parts in the machine. This could result in

serious damage to the basket.

• Never allow children to play on or around

this machine. Death or serious injury can

result if children become trapped in the

machine. Do not leave children unattended

while the machine door is open. These

cautions apply to animals as well.

• A clean power supply free from voltage

spikes and surges is absolutely essential for

machines equipped with the AC inverter

drive. Nonlinear inconsistencies (peaks and

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232060

Section 2

Installation

This manual is designed as a guide to the

installation and maintenance of the 18-pound

and 25-pound capacity freestanding

washer-extractors.

Note: All information, illustrations, and

specifications contained in this manual are

based on the latest product information

available at the time of printing. We

reserve the right to make changes at

any time without notice.

Machine Overview

The design of these machines emphasizes

performance and long service life. The

cylinder, shell, and main body panels are

fabricated of stainless steel.

These machines feature the V-Series

microcomputer which offers preprogrammed

cycles and programming versatility in

the field.

to tumble back into the bath. This mechanical

action accomplishes the cleaning function.

The cylinder is perforated, allowing the water

to drain from within during the wash and

extract steps.

Water enters the machine through

electromechanical water valves, which

are controlled by the V-computer. The

computer also controls the supply dispenser,

drain, and door lock, and selects water levels

according to the programmed cycle.

Electrical controls for the machine are housed

in a separate enclosure located underneath the

top cover of the machine.

The supply dispenser is located on top of the

machine. The supply dispenser compartments

are accessed by lifting the rubber cover.

These compartments accept powder or liquid

supplies. Each compartment is controlled

independently by the V-computer, and is

energized independently of other

compartments.

The AC inverter drive control provides

programmable motor speeds, using a single

motor. This makes it possible to achieve

ultra-high extract speeds.

The cylinder is supported by two deep groove,

sealed, permanently lubricated bearings. The

cylinder is constructed with lifters or ribs that

lift the laundry from the bath solution when the

cylinder rotates at slow speed and then allow it

F232060

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

A door-lock system prevents opening of the

door when water is in the machine. It also

prevents operation of the machine when

the door is open. The door lock system

contains the door-lock microswitch, output

voltage interlock magnetic switch, and the

door unlock solenoid.

9

Installation

Delivery Inspection

Upon delivery, visually inspect crate,

protective cover, and unit for any visible

shipping damage. If the crate, protective

cover, or unit are damaged or signs of possible

damage are evident, have the carrier note the

condition on the shipping papers before the

shipping receipt is signed, or advise the carrier

of the condition as soon as it is discovered.

Remove the crate and protective cover as soon

after delivery as possible. If any damage is

discovered upon removal of the crate and/or

protective cover, advise the carrier and file a

written claim immediately.

Customer Service

If literature or replacement parts are required,

contact the source from whom the machine

was purchased or contact Alliance Laundry

Systems LLC at (920) 748-3950 for the name

of the nearest authorized parts distributor.

For technical assistance, call any of the

following numbers:

(850) 718-1025

(850) 718-1026

Marianna, Florida

(920) 748-3121

Ripon, Wisconsin

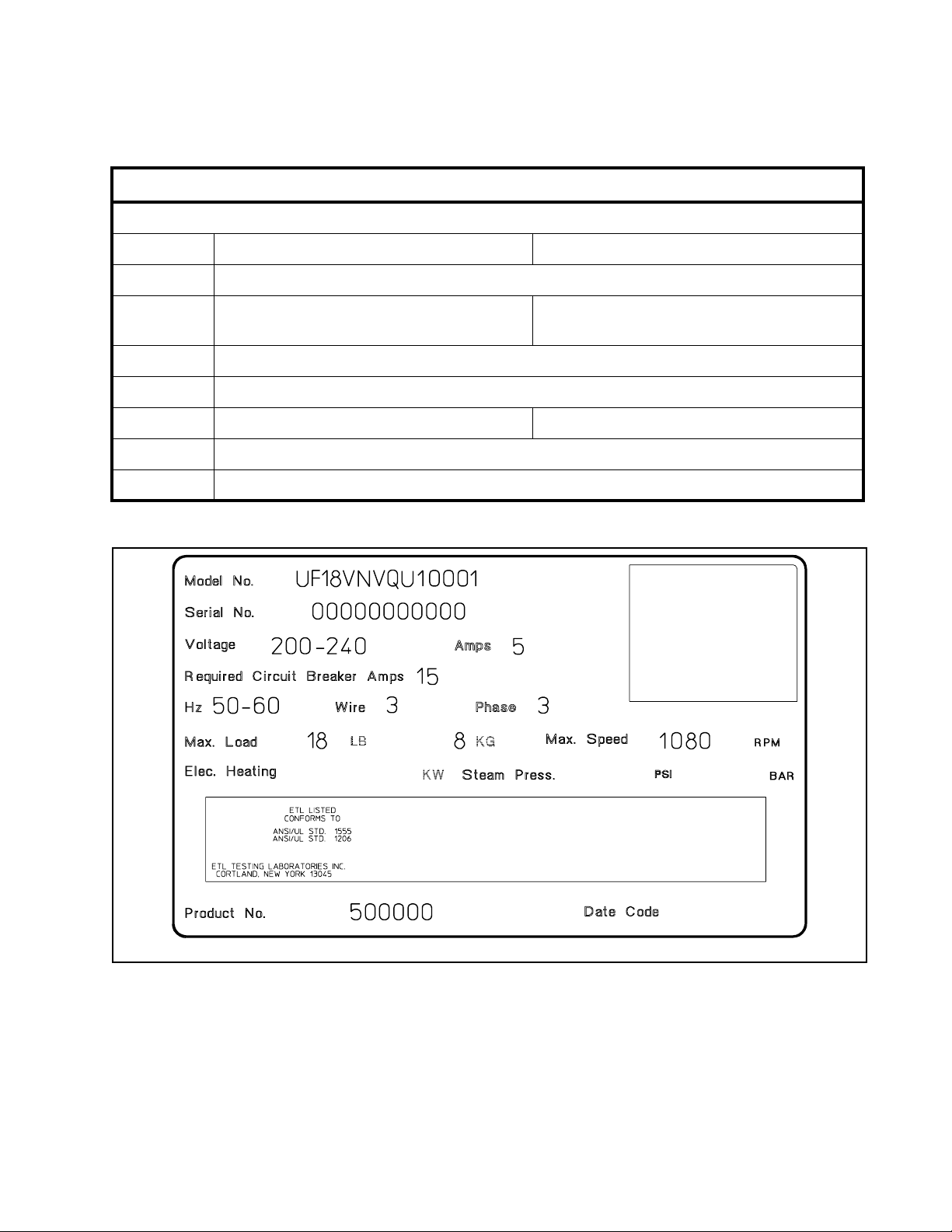

A record of each machine is on file with

the manufacturer. The serial number decal is

located at the rear of the machine. Figure 1

shows the location of the serial number on the

decal. Always provide the machine’s serial

number and model number when ordering

parts or when seeking technical assistance.

10

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

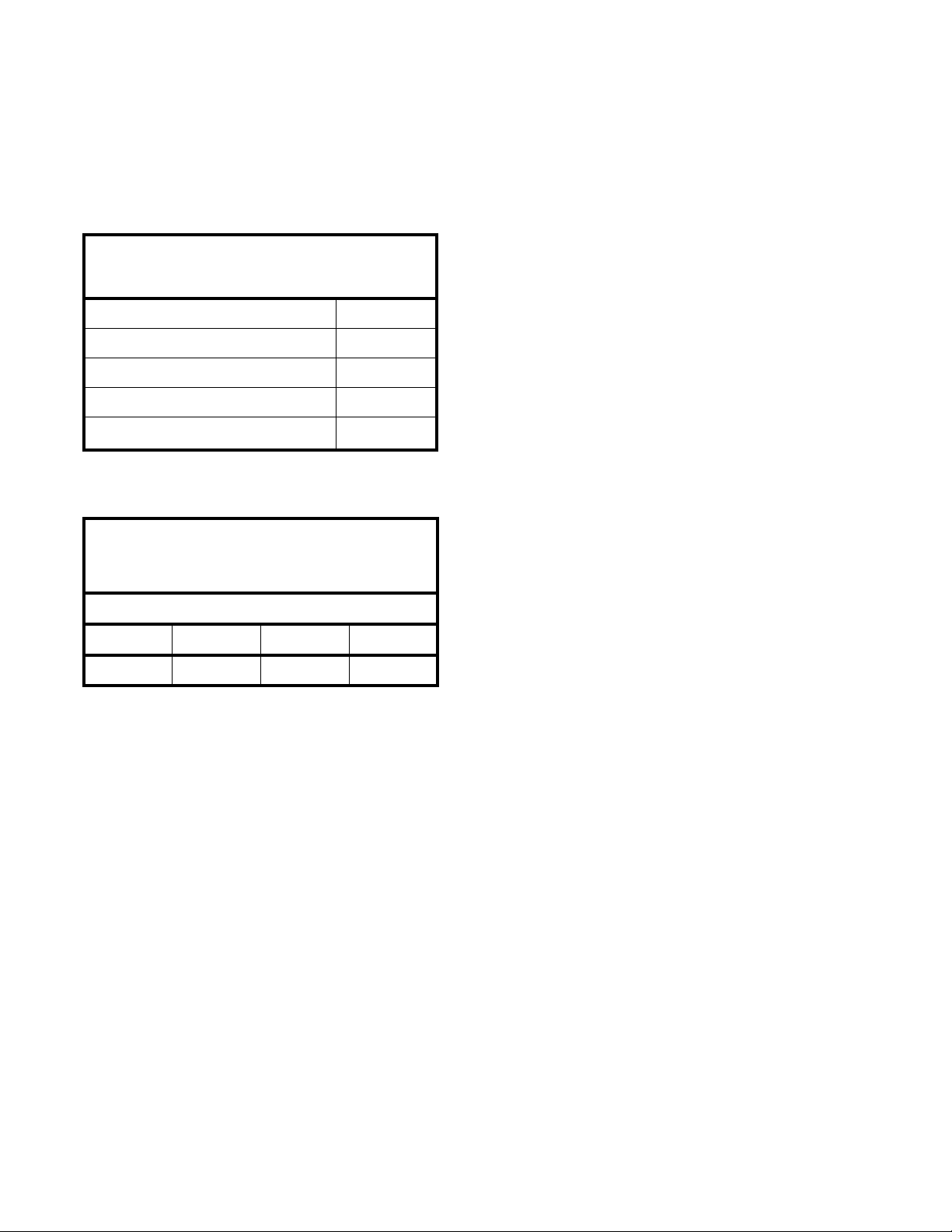

Model Number Familiarization Guide

Sample Model Number: UF18VNVQU10001

SF, UF Machine Type F = Freestanding

18, 25 Machine Capacity

Installation

P

(V)

N Non-coin

V Variable Speed

Q Electrical Characteristics See Voltage Designation Chart in this section.

U1 Design Series

0001 Option Identification (varies from machine to machine)

Type of Electrical Control

P = WE-6 Computer

V = V-computer

Figure 1

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

R08IE3A

11

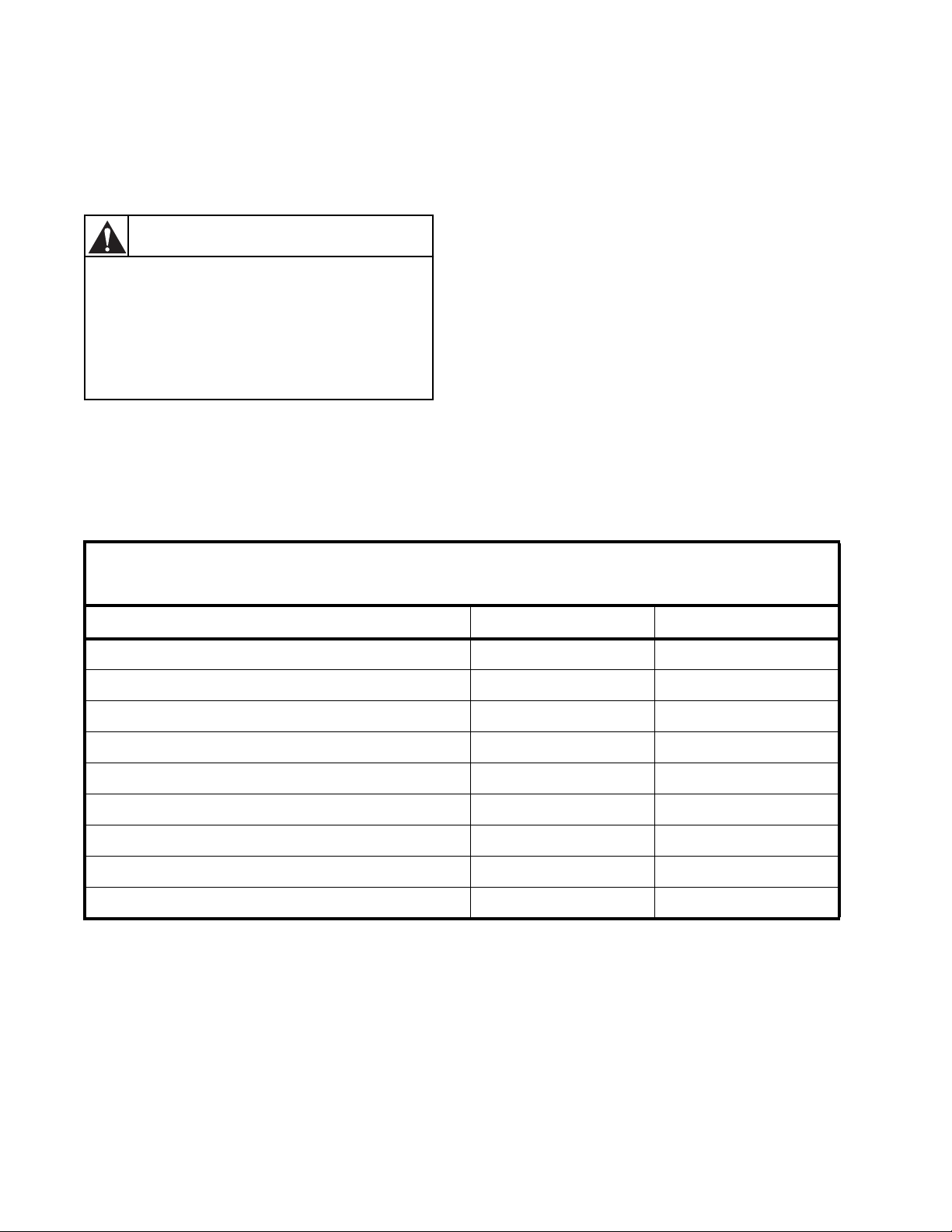

Installation

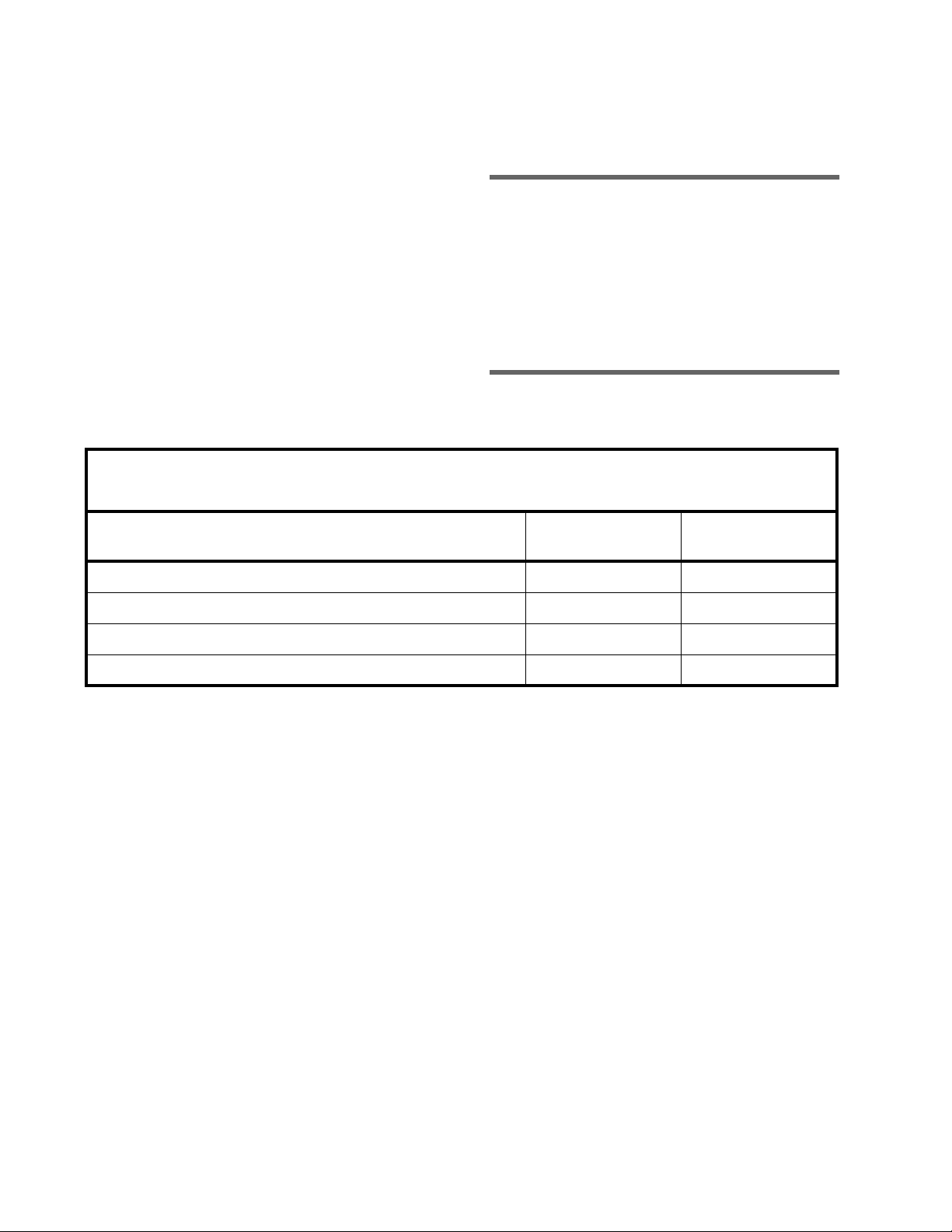

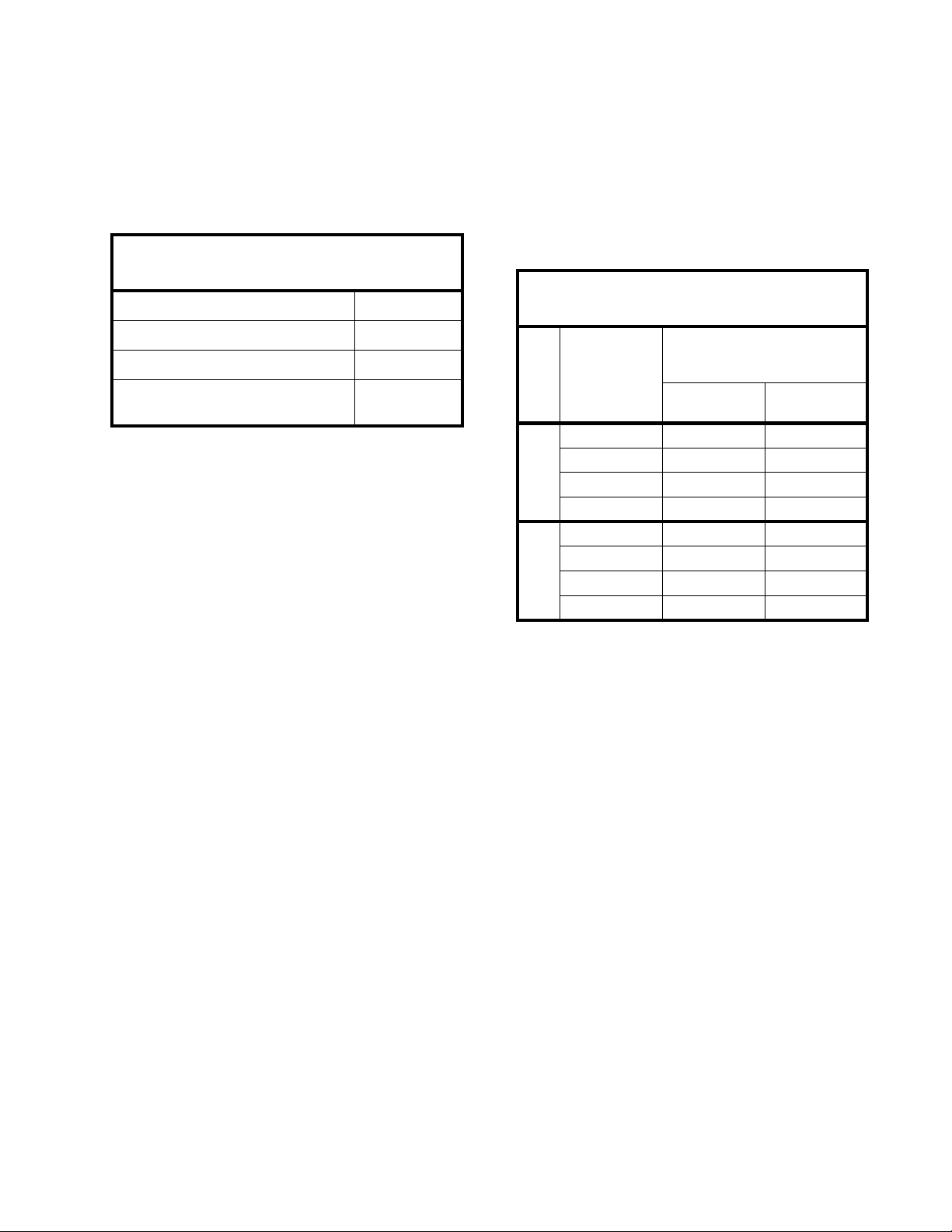

Cabinet Freestanding

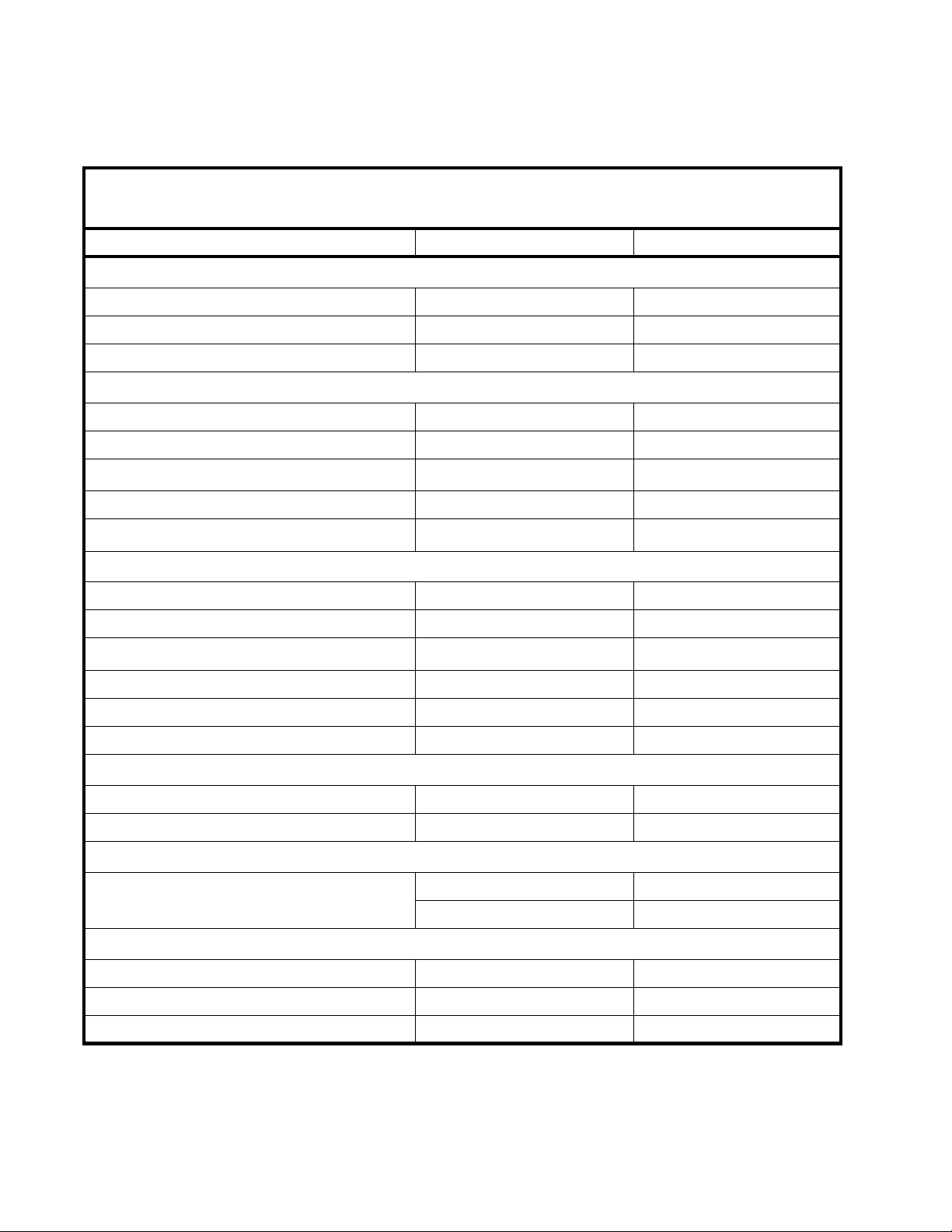

General Specifications

18 25

Overall Dimensions

Overall width, in (mm) 29.0 (737) 32.0 (813)

Overall height, in (mm) 46.0 (1168) 48.5 (1232)

Overall depth, in (mm) 32.8 (833) 37.0 (940)

Weight and Shipping Information

Net weight, lb (kg) 550 (250) 700 (318)

Domestic shipping weight, lb (kg) 550 (250) 750 (341)

3

(m3)

3

(m3)

Domestic shipping volume, ft

Export shipping weight, lb (kg) 600 (272) 800 (363)

Export shipping volume, ft

34.6 (0.98) N/A

41.44 (1.17) N/A

Wash Cylinder Information

Cylinder diameter, in (mm) 21.0 (533) 24.0 (610)

Cylinder depth, in (mm) 13.75 (349) 16.0 (406)

Cylinder volume, ft

Perforation size, in (mm) 0.188 (4.77) 0.188 (4.77)

Perforation open area, % 23 23

Load capacity (dry cloth weight), lb (kg) 18 (18.6) 25 (11.34)

3

(l)

2.76 (78) 4.19 (119)

Door Opening Information

Door opening size, in (mm) 12.0 (305) 14.345 (364)

Height of door bottom above floor, in (mm) 20.4 (518) 20.1 (511)

Water Consumption

Average water consumption HOT

per cycle, gal (l) COLD

23 (87) 28 (106)

11 (42) 13 (49)

Power Consumption

Average power used per cycle, kW/hr 0.2* 0.3*

Nominal sound emission, dBA 58 Data not available

Average HVAC load, BTU/hr 400 (101) 450 (113)

*These figures are approximate values only.

12

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

Cabinet Freestanding

General Specifications (Continued)

18 25

Drive Train Information

Number of motors in drive train 1 1

Drive motor power, hp (kW) 1.0 (0.75) 2.25 (1.7)

Cylinder Speeds

Low wash/reverse speed, rpm 29 27

Normal wash/reverse speed, rpm 52 49

Distribution speed, rpm 86 73

Extract l, rpm 534 500

Extract 2, rpm 685 641

Extract 3, rpm 1080 1011

Centrifugal Force Data

Low wash/reverse centrifugal force, Gs 0.25 0.80

Normal wash/reverse centrifugal force, Gs 0.80 0.80

Distribution centrifugal force, Gs 2.20 1.80

Extract 1 centrifugal force, Gs 85 85

Extract 2 centrifugal force, Gs 140 140

Extract 3 centrifugal force, Gs 348 348

Load Balancing

Balance detection system AC drive AC drive

Direct Steam Heating (Optional)

Steam inlet connection size, in (mm) 1/2 NPT (DN15) 1/2 NPT (DN15)

Number of steam inlets 1 1

Steam required to LOW 1.13 (0.81) 1.46 (1.05)

raise bath temperature 10

Average steam use per cycle, BHP (kg) 0.75 (11.7) 0.96 (15)

°F, lb (1 0°C, kg) MED 1.25 (0.90) 1.61 (1.16)

HIGH 1.45 (1.04) 1.85 (1.33)

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

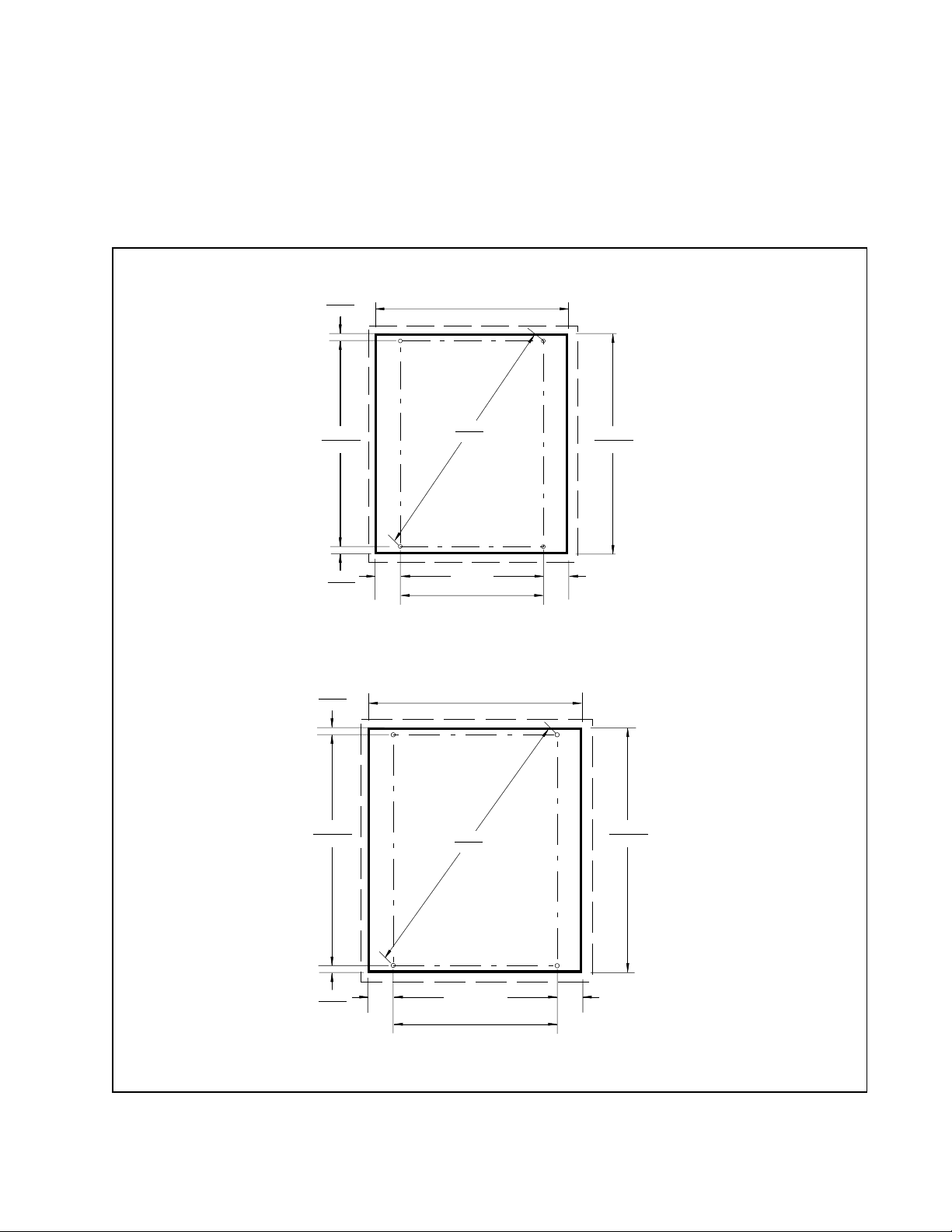

Installation

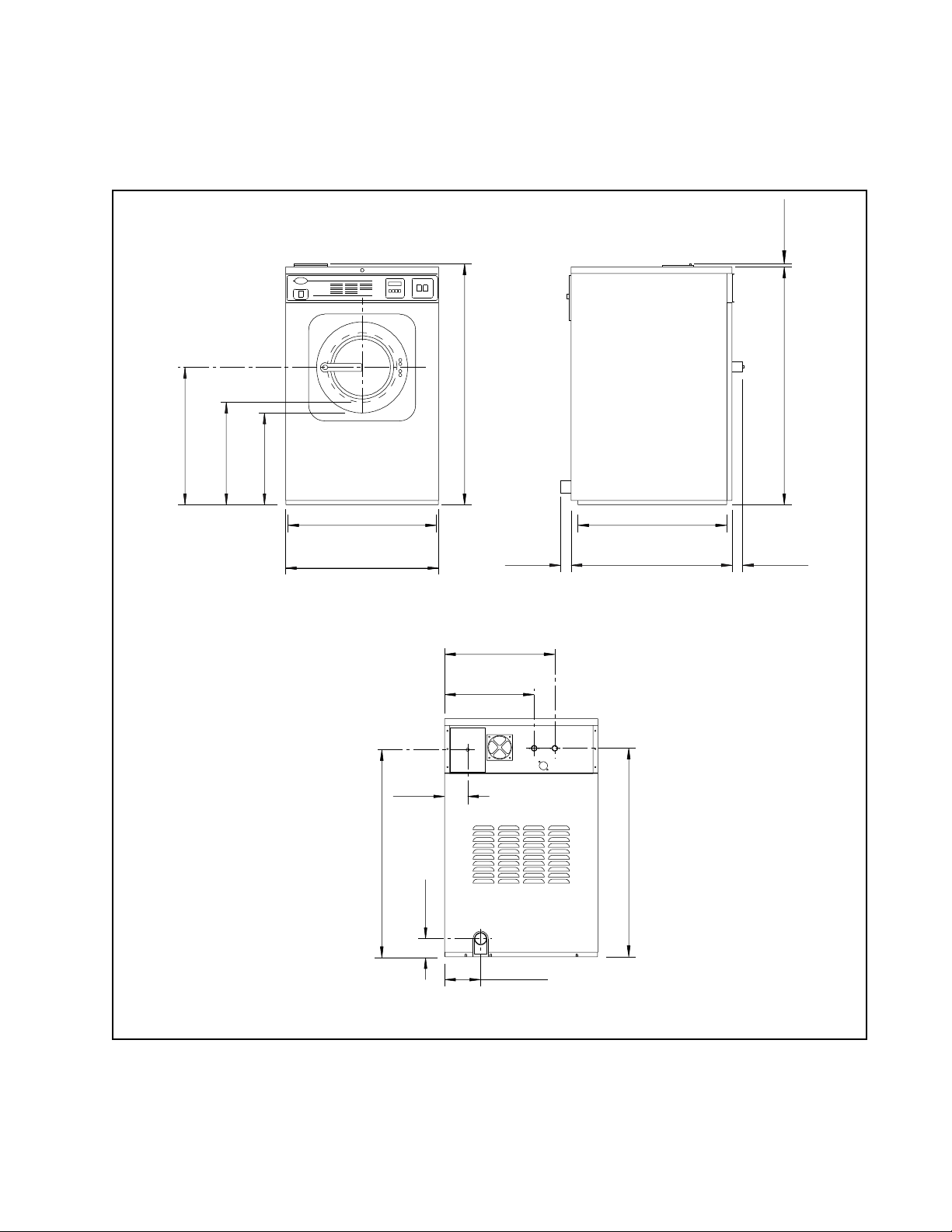

Dimensional Clearances

Both single and multiple machine installations

require specified minimum clearances on all

sides of each machine. The table below shows

these clearances.

See Figures 2 and 3 for dimensions of

18-pound and 25-pound capacity models.

Figure 4 provides installation guidelines for

sites with multiple installations.

Cabinet Freestanding

Recommended Minimum Clearances

Note: The dimensions shown here are for

planning purposes only. They are approximate

and subject to normal manufacturing

tolerances. If exact dimensions are required

for construction purposes, contact the

distributor or manufacturer. We reserve

the right to make changes at any time

without notice.

18

[in (mm)]

Minimum rear clearance 12 (305) 12 (305)

Minimum clearance between machine and wall 2 (50) 2 (50)

Minimum clearance between machines (side) 1 (25) 1 (25)

Minimum front clearance 16 (406) 17.5 (445)

25

[in (mm)]

14

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

26"

659 mm

492 mm

19 13/32"

17 5/16"

440 mm

1161 mm

45 23/32"

Installation

23/32"

18 mm

45"

1143 mm

27"

686 mm

29"

737 mm

Front

4 1/2"

114 mm

40 1/2"

1029 mm

86 mm

3 13/32"

1 5/16"

33 mm

20 29/32"

530 mm

16 29/32"

430 mm

27 15/16"

709 mm

30 1/2"

774 mm

Left Side

42 5/16"

1074 mm

1"

25 mm

6 13/16"

173 mm

18-Pound Capacity Models

Rear

Figure 2

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Z005IE3A

15

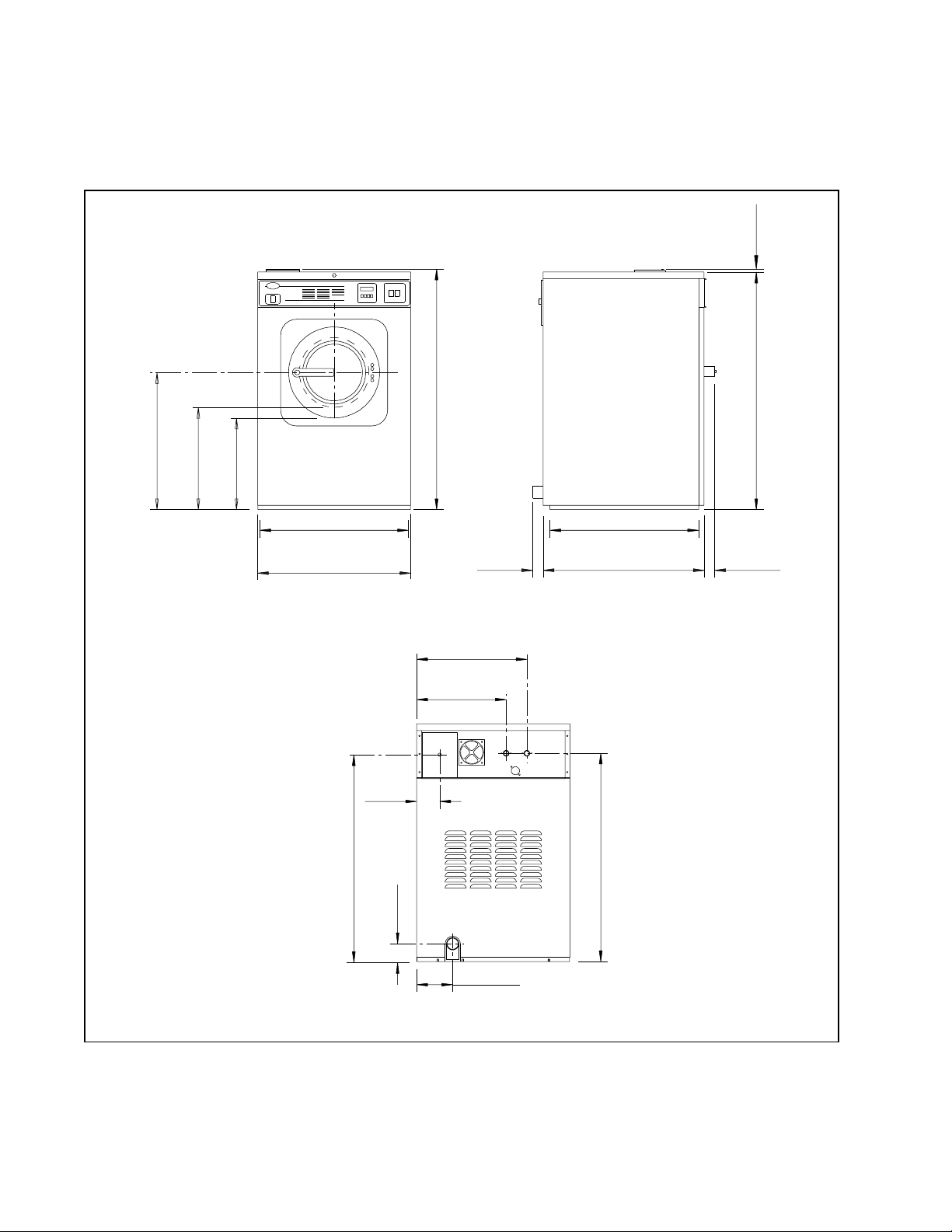

Installation

27"

20"

686 mm

17"

508 mm

432 mm

48 1/2"

1232 mm

23/32"

18 mm

1214 mm

47 13/16"

30"

762 mm

32"

813 mm

Front

4 13/16"

122 mm

42"

1067 mm

86 mm

3 13/32"

38 mm

23 1/2"

597 mm

19 1/2"

495 mm

1 1/2"

32 1/8"

816 mm

34 1/2"

876 mm

Left Side

42 5/16"

1074 mm

1"

25 mm

25-Pound Capacity Models

16

8 5/16"

211 mm

Figure 3

Rear

Z006IE3A

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

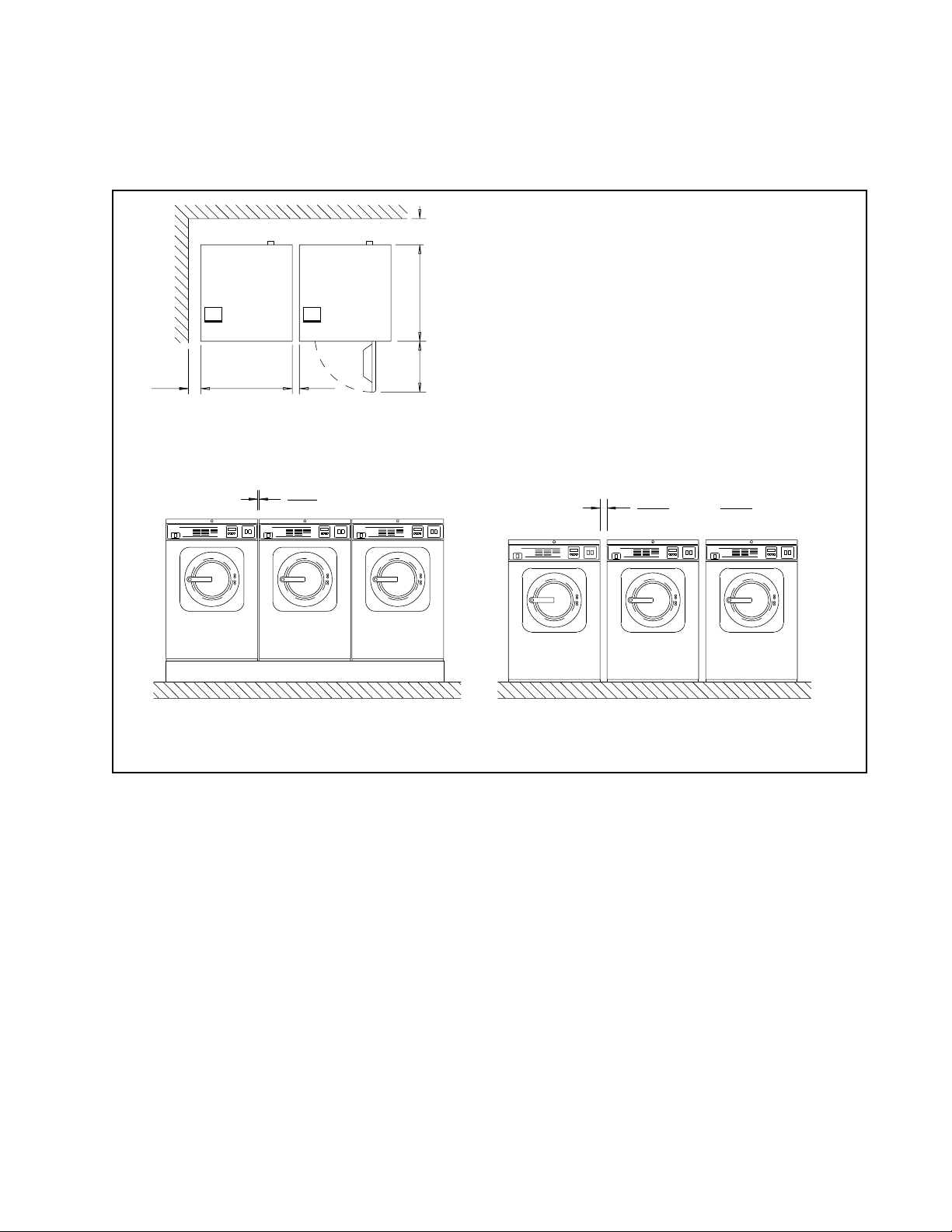

2"

50 mm

29"

737 mm

1"

25 mm

12"

305 mm

30 1/2"

16"

Installation

774 mm

406 mm

3/8"

10 mm

Specifications for Multiple Installations

Figure 4

For most installations, a 1-inch (25 mm)

clearance between machines is sufficient. When

an elevated base frame is used, a

3/8-inch (10 mm) clearance is provided by

the base. A clearance of at least 12 inches

(305 mm) should be provided behind the

washer-extractors, and water inlets should be

accessible. See Figure 4.

recommended

Mounting on FloorElevated Base Frame

1"

25 mm

(1/2")

(13 mm)

(allowable)

CFS461N

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Installation

Ensure that the machine is installed on a

level floor of sufficient strength and that the

recommended clearances for inspection

and maintenance are provided. Never allow

the inspection and maintenance space to

be blocked.

SW020

CAUTION

Machine Foundation

Thoroughness of detail must be stressed with

all foundation work to ensure a stable unit

installation, eliminating possibilities of

excessive vibration during extract.

Cabinet Freestanding

Floor Load Data

The machine must be installed on a smooth,

level surface so that the entire base of the

machine is supported and rests on the

mounting surface. (Do not support the machine

on only four points.)

Static and dynamic loads on the floor or

foundation are shown in the table below.

This table can be used as a reference when

designing floors and foundations.

18 25

Static floor load, lbs (kN) 682 (3.03)* 760 (3.40)*

Static pressure, lbs/sq ft (kN/sq m) 130 (6.22)* 115 (5.51)*

Dynamic floor load, lbs (kN) 100 (0.44)* 139 (0.62)*

Maximum dynamic load, lbs (kN) 100 (0.44)* 139 (0.62)*

Dynamic pressure, lbs/sq ft (kN/sq m) 19.1 (0.91) 21.1 (1.01)

Maximum vertical load, lbs (kN) 682 (3.03) 869 (3.87)

Minimum vertical load, lbs (kN) 468 (2.08) 586 (2.61)

Maximum moment about base, lb-ft (kN-m) 72 (0.09) 103 (0.14)

Dynamic load frequency, Hz 18 16.9

*These figures are approximate values only.

18

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Mechanical Installation

Installation

1"

25 mm

25 15/16"

659 mm

1"

25 mm

1"

25 mm

27"

686 mm

32 3/4"

832 mm

FRONT

3 1/2"

89 mm

20"

508 mm

18 - Pound

30"

762 mm

3 1/2"

89 mm

27 15/16"

709 mm

OUTSIDE OF MACHINE

OUTLINE OF MACHINE BASE

R025IE3A

29 15/16"

760 mm

1"

25 mm

37 5/8"

956 mm

FRONT

3 9/16"

91 mm

22 13/16"

579 mm

25 - Pound

3 9/16"

91 mm

31 15/16"

811 mm

OUTSIDE OF MACHINE

OUTLINE OF MACHINE BASE

R026IE3A

Figure 5

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Installation

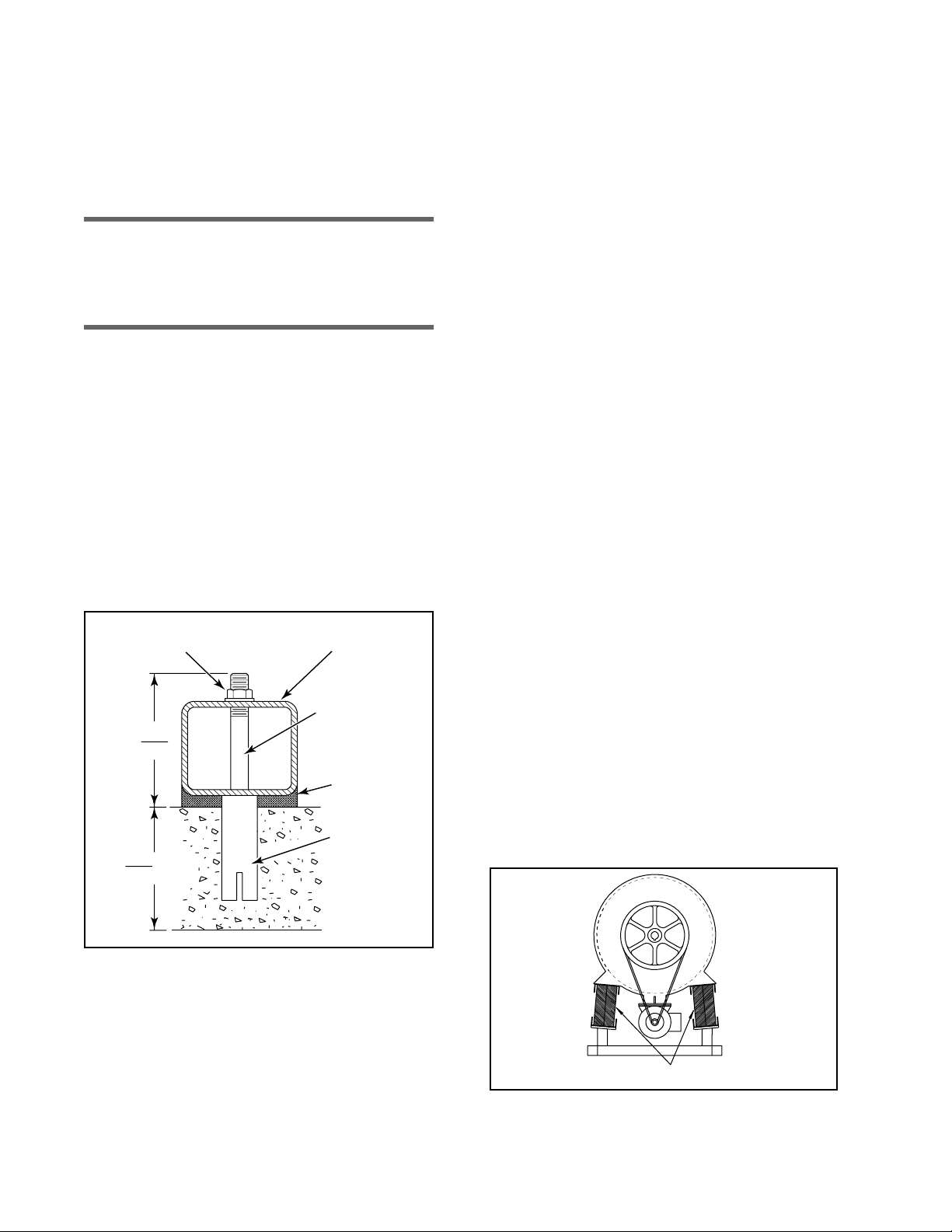

Mechanical Installation (Continued)

Note: The 18-pound and 25-pound capacity

freestanding washer-extractors do not require

anchoring unless mandated by state or

local codes.

Mounting Bolt Installation

The 18-pound and 25-pound capacity

freestanding washer-extractors use 3/4-11 x

8 inch anchor bolts. The bolts should be

embedded in a 3500 psi minimum reinforced

concrete floor that is a minimum of 6 inches

thick. Use the mounting bolt layouts in

Figure 5. (The front of the washer-extractor is

the bottom of each diagram.) See Figure 6 for

detailed mounting bolt information.

Base

Frame

3/4 - 11 x 8 Inch

Dia. Bolt

Grout

Anchor

Bolt

6"

152 mm

6"

152 mm

Lock Nut

Min

2. Remove the wood skid by unscrewing

the carriage bolts holding it to the bottom

frame of the machine.

3. Carefully place the machine over the

anchor bolts. Raise and level it 1/2 inch

above the floor on three points, using

spacers such as nut fasteners.

4. Fill the spaces between the machine

base and floor with machinery grout.

Grout completely under all frame

members. Remove front and rear panels

to gain access to all frame members.

Force grout under the machine base until

all voids are filled.

5. Remove the spacers carefully, allowing the

machine to settle into the wet grout.

6. Position washers and locknuts on

machinery anchor bolts and fingertighten

to machine base.

7. After the grout is completely dry, tighten

the locknuts by even increments – one

after the other – until all are tightened

evenly and the machine is fastened

securely to the floor.

8. Remove the four red transport brackets

which secure the moving components of

the machine during shipping. See Figure 7

for typical transport bracket locations on

18-pound and 25-pound capacity

freestanding models.

Figure 6

After the concrete has cured, proceed

as follows:

1. Place the machine adjacent to the

foundation. Do not attempt to move

it by pushing on the sides.

20

U094ME3B

Transport Brackets

Figure 7

U133IE3A

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

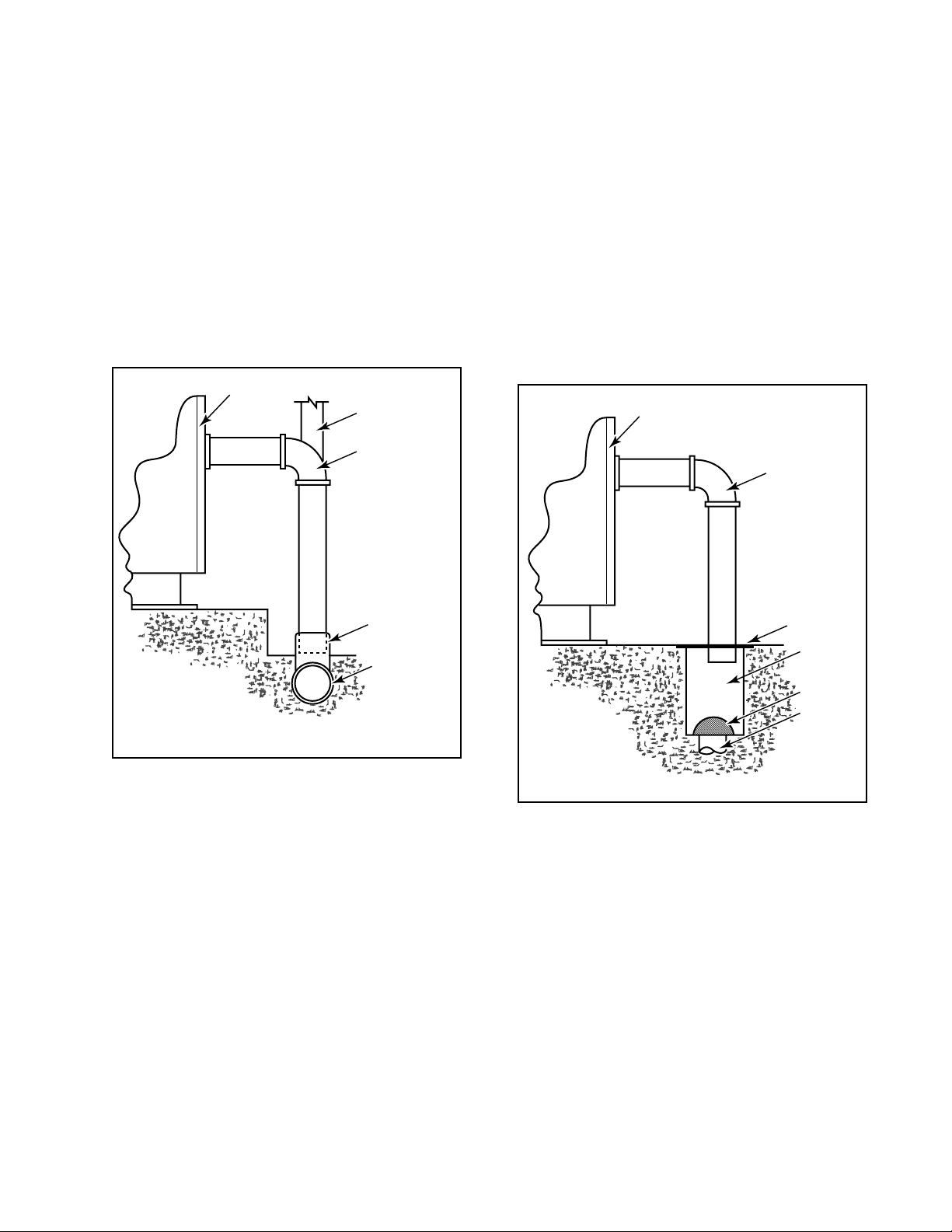

Drain Connection

A drain system of adequate capacity is

essential to washer-extractor performance.

Ideally, the water should empty through a

vented pipe directly into a sump or floor drain.

Figures 8 and 9 show drain line and drain

trough configurations.

Rear of Machine

Vent

Drain Pipe

Waste Line

Before any deviation from specified

installation procedures is attempted,

the customer or installer should contact

the distributor.

Increasing the drain hose length, installing

elbows, or causing bends will decrease drain

flow rate and increase drain times, impairing

washer-extractor performance.

Rear of Machine

Drain Pipe

Steel Grate

Waste Line

Tee

P013IE3A

Figure 8

A flexible connection must be made to a

vented drain system to prevent an air lock and

to prevent siphoning. If proper drain size is not

available or practical, a surge tank is required.

A surge tank in conjunction with a sump pump

should be used when gravity drainage is not

possible, such as in below-ground-level

installations.

Drain

Trough

Strainer

Waste

Line

P014IE3A

Figure 9

See the Cabinet Freestanding Drain

Information table in this subsection for

capacity-specific drain information.

Installation of additional washer-extractors

will require proportionately larger drain

connections. See the Cabinet Freestanding

Drain Line Sizing table in this subsection.

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Installation

Drain Connection (Continued)

Cabinet Freestanding

Drain Information

Overflow size, in (mm) 1.5 (3.8)

Drain connection size, I.D., in (mm) 2 (51)

Number of drain outlets 1

Drain flow capacity, gal-min (l-min) 20 (76)*

3

Recommended drain pit size, ft

*These figures are approximate values only.

(l)

1.80 (51)

Cabinet Freestanding

Drain Line Sizing

Minimum Drain I.D. [in (mm)]

Number of Machines

1234

3 (76.2) 3 (76.2) 3-1/2 (88.9) 4 (102)

22

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

Water Connection

Cabinet Freestanding

Water Supply Information

Water inlet connection size, in (mm) 3/4 NH (G 3/4)

Number of water inlets (standard) 2

Recommended pressure psi (bar) 30 – 85 (2 – 5.7)

Inlet flow capacity, gal-min (l-min)

(80 psi)

Connections should be supplied by a hot and a

cold water line of at least the sizes shown in

the Water Supply Line Sizing table.

Installation of additional machines will require

proportionately larger water lines. See table.

To connect water service to machine with

rubber hoses, use the following procedure:

12 (45)

Suitable air cushions should be installed in

supply lines to prevent “hammering.” If the

water pressure is above 60 psi, flexible copper

tubing should be used in place of rubber hoses.

Cabinet Freestanding

Water Supply Line Sizing

Model

18

25

Number

of

Machines

1 0.75 (19) 0.75 (19)

2 1.0 (25) 1.0 (25)

3 1.25 (32) 1.0 (25)

4 1.5 (38) 1.0 (25)

1 0.75 (19) 0.75 (19)

2 1.0 (25) 1.0 (25)

3 1.25 (32) 1.0 (25)

4 1.5 (38) 1.0 (25)

Supply Line Size

[in (mm)]

Main Hot/Cold

1. Before installing hoses, flush the water

system for at least two minutes.

2. Check filters in the washer-extractor’s

inlet hoses for proper fit and cleanliness

before connecting.

3. Hang the hoses in a large loop; do not

allow them to kink.

If additional hose lengths are needed, use

flexible hoses with screen filters. Each hose

should have a screen filter installed to keep

rust and other foreign particles out of the water

inlet valves.

Pressure of 30 – 85 psi (2 – 5.7 bar) provides

best performance. Although the washerextractor will function properly at lower

pressures, increased fill times will occur.

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Installation

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar with

the potential hazards involved. Failure to

observe this warning may result in personal

injury and/or equipment damage, and may

void the warranty.

SW004

WARNING

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel familiar

with electrical test procedures, test

equipment, and safety precautions should

attempt adjustments and troubleshooting.

Disconnect power from the machine before

removing the control box cover, and before

attempting any service procedures.

SW005

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground lug

near the input power block on this machine.

Without proper grounding, personal injury

from electric shock could occur and machine

malfunctions may be evident.

SW008

WARNING

Electrical Installation

The AC inverter drive requires a clean power

supply free from voltage spikes and surges.

A voltage monitor should be used to check

incoming power. The customer’s local power

company may provide such a monitor.

If input voltage measures above 230V for a

200V drive or above 440V for a 400V drive,

ask the power company to lower the voltage.

As an alternative, a step-down transformer kit

is available from the distributor. Voltages

above 250V and 490V require additional

measures. Contact the distributor or the

manufacturer for assistance.

WARNING

Never touch terminals or components of

the AC inverter drive unless power is

disconnected and the “READY” indicator

LED is off. The AC inverter drive retains

potentially deadly voltage for some time

after the power is disconnected. There are

no user-serviceable parts inside the

AC inverter drive. Tampering with the drive

will void the warranty.

SW009

24

DANGER

When controlling the AC inverter drive with

a parameter unit, the machine’s computer

and its safety features are bypassed. This

would allow the basket to rotate at high

speeds with the door open. When using a

parameter unit to control the AC inverter

drive, a large sign should be placed on the

front of the machine warning people of the

imminent danger.

SW003

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Installation

The AC drive provides overload protection for

the drive motor. However, a separate threephase circuit breaker or single-phase circuit

breaker (if machine is a single-phase model)

must be installed for complete electrical

overload protection. This circuit breaker must

disconnect all poles when in the open position.

This prevents damage to the motor by

disconnecting all legs if one should be lost

accidentally. Check the data plate on the back

of the washer-extractor or consult the

Electrical Specifications chart in this

subsection for circuit breaker requirements.

Note: Do NOT use fuses in place of a circuit

breaker.

CAUTION

Do not use a phase adder on any variablespeed machine.

SW037

Use wire sizes indicated in the Electrical

Specifications chart for runs up to 50 feet.

Use next larger size for runs of 50 to 100 feet.

Use 2 sizes larger for runs greater than

100 feet.

For personal safety and for proper operation,

the washer-extractor must be grounded in

accordance with state and local codes. If such

codes are not available, grounding must

conform with the National Electric Code,

article 250-95. The ground connection must be

made to a proven earth ground, not to conduit

or water pipes.

If a delta supply system is used, the high

leg may be connected to L3 on the cabinet

freestanding models as all machines are

equipped with control transformers.

Note: Timers or similar devices that could

switch off the machine automatically are not to

be installed, whether in the machine’s supply

circuit or elsewhere.

The washer-extractor should be connected to

an individual branch circuit not shared with

lighting or other equipment.

The connection should be shielded in a liquidtight or approved flexible conduit with proper

conductors of correct size installed in

accordance with the National Electric Code or

other applicable codes. The connection must

be made by a qualified electrician using the

wiring diagram provided with the washerextractor, or according to accepted European

standards for CE-approved equipment.

F232060 © Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

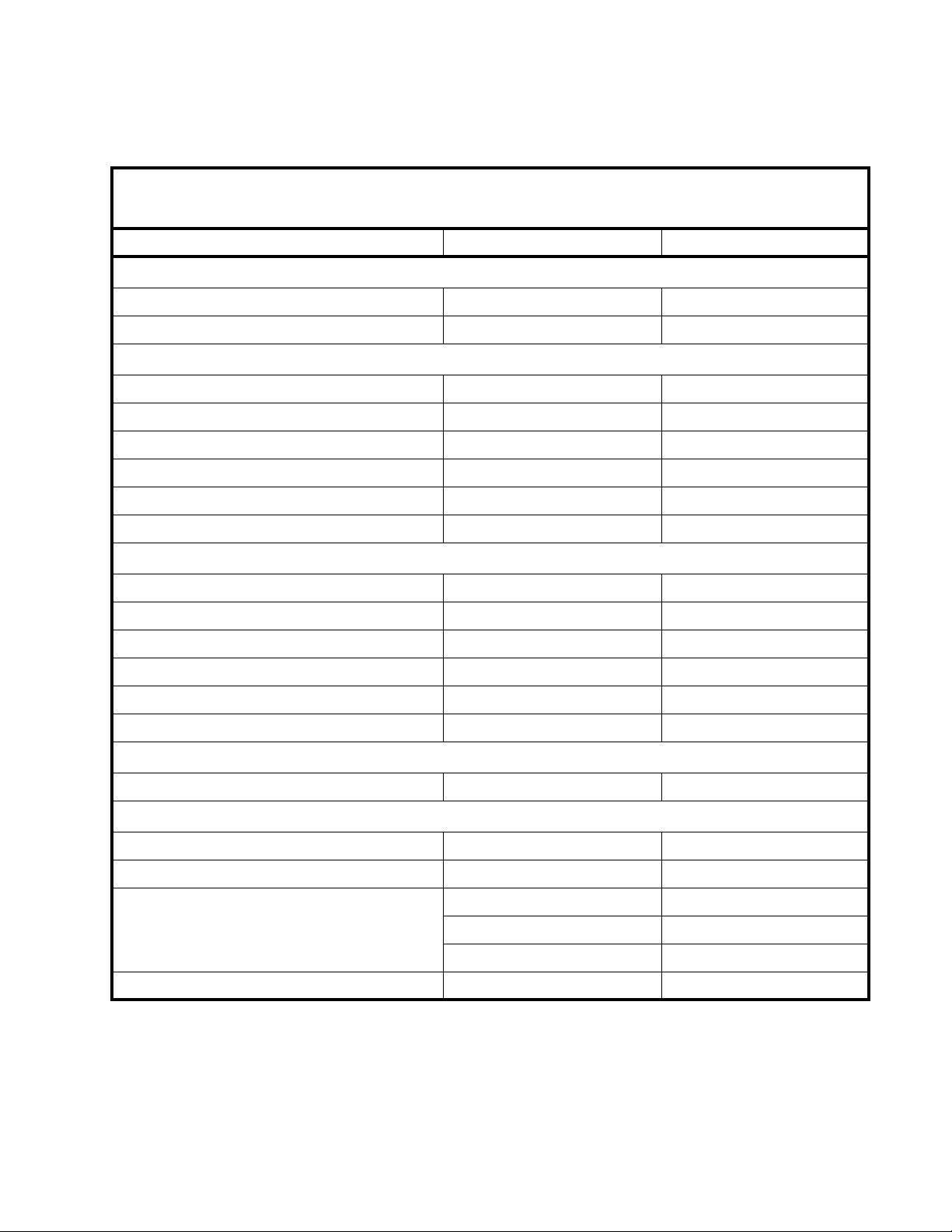

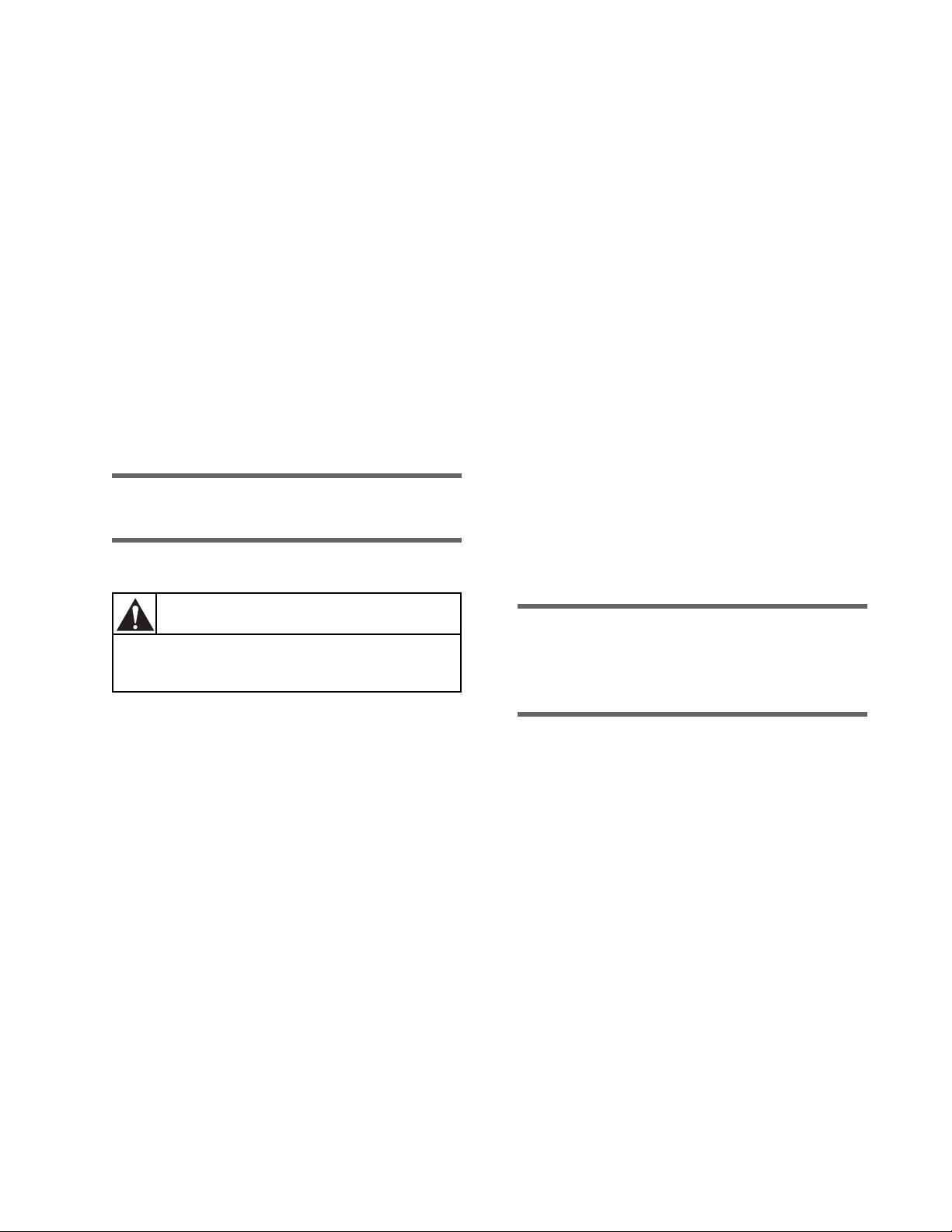

Installation

.

Voltage Designation Standard Electric Heat

Model

Code

Volt age

Cabinet Freestanding

Electrical Specifications

Cycle

Phase

Wire

Full Load

Amps

Breaker

AWG

mm

Full Load

Amps

Breaker

AWG

mm

2

X 200-240 50-60 1 or 32 or 36/4 15 14 2x2.5

3x2.5

P* 380-415 50-60 3 3 3 15 -- 3x2.5 12 15 -- 3x2.5

18

Q 200-240 50-60 3 3 5 15 14 -- 18 20 12 --

T* 200-240 50-60 1 2 8 15 14 -- 31 35 8 --

X 200-240 50-60 1 or 32 or 311/6 15 14 2x2.5

3x2.5

P* 380-415 50-60 3 3 3 15 -- 3x2.5 12 15 -- 3x2.5

25

Q 200-240 50-60 3 3 7 15 14 -- 18 20 12 --

T 200-240 50-60 1 2 12 15 14 -- 31 35 8 --

Note: Wire sizes shown are for copper, THHN, 90° conductor per NEC article 310.

Note: The X voltage is not compatible with

CE and/or electric heat models.

IMPORTANT: For machines with X

voltage: If input power is single-phase,

connect L1 to L1 of terminal block and L2

to L2 of terminal block. Leave L3

unconnected on the input terminal block. If

input power is three-phase, connect L1, L2

and L3 to L1, L2 and L3 of the terminal

block.

2

-- -- -- --

-- -- -- --

26

F232060© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Loading...

Loading...