Page 1

Automatic

TLW12C

Washers

Metered Commercial

Installation/Operation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

TLW12C

Part No. 202068R5

August 2011

Page 2

Page 3

IMPORTANT: Read the complete

For your safety and to reduce the risk of

fire or an explosion, do not store or use

gasoline or other flammable vapors and

liquids in the vicinity of this or any other

appliance.

W022

WARNING

INSTALLATION/OPERATION INSTRUCTIONS

before using the washer.

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Table of

Contents

Safety Information.............................................................................. 3

Explanation of Safety Messages........................................................... 3

Important Safety Instructions ............................................................... 3

Installation........................................................................................... 5

Dimensions and Specifications............................................................. 5

Before You Start ................................................................................... 6

Tools ................................................................................................ 6

Installing the Washer ............................................................................ 6

Step 1: Remove the Shipping Brace and Shipping Plug.................. 6

Step 2: Wipe Out Inside of Washtub ............................................... 7

Step 3: Connect Fill Hoses............................................................... 7

Step 4: Connect Drain Hose to Drain Receptacle ............................ 9

Step 5: Position and Level the Washer ............................................ 10

Step 6: Plug In the Washer............................................................... 11

Step 7: Add Water to the Washer .................................................... 12

Step 8: Check Lid Switch ................................................................ 12

Step 9: Check Installation ................................................................ 12

Vending................................................................................................. 13

Meter Case ....................................................................................... 13

Models Prepped for Card Reader..................................................... 13

Additional Washer Security............................................................. 14

Operation............................................................................................. 15

Operation Instruction ............................................................................ 15

Step 1: Add Detergent...................................................................... 15

Step 2: Load Laundry....................................................................... 15

Step 3: Close Lid.............................................................................. 15

Step 4: Set Fabric Selector............................................................... 16

Step 5: Set Wash Temperature......................................................... 16

Step 6: Select Cycle Type/ Soil Level ............................................. 16

Step 7: Insert Money or Card........................................................... 16

Step 8: Start Washer......................................................................... 17

Indicator Lights................................................................................ 17

Maintenance ........................................................................................ 18

User-Maintenance Instructions............................................................. 18

Cold Weather Care........................................................................... 18

Care of Your Washer ....................................................................... 18

Replacing Hoses............................................................................... 18

Filter Screens ................................................................................... 18

Reinstallation of Shipping Materials ............................................... 18

Motor Overload Protector..................................................................... 18

Troubleshooting .................................................................................. 19

Contact Information........................................................................... 21

Installer Checklist............................................................... Back Cover

© Copyright 2011, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 5

Safety Information

Indicates an imminently hazardous

situation that, if not avoided, will cause

severe personal injury or death.

DANGER

Indicates a hazardous situation that, if not

avoided, could cause severe personal

injury or death.

WARNING

Indicates a hazardous situation that, if not

avoided, may cause minor or moderate

personal injury or property damage.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Explanation of Safety Messages

Throughout this manual and on machine decals, you

will find precautionary statements (“DANGER,”

“WARNING,” and “CAUTION”) followed by specific

instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and

those maintaining the machine.

Important Safety Instructions

Save These Instructions

1. Read all instructions before using the washer.

2. Install the washer according to the

INSTALLATION INSTRUCTIONS. Refer to the

GROUNDING INSTRUCTIONS in the

INSTALLATION manual for the proper

grounding of the washer. All connections for

water, drain, electrical power and grounding must

comply with local codes and be made by licensed

personnel when required. Do not do it yourself

unless you know how!

3. Do not install or store the washer where it will be

exposed to water and/or weather.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

4. Do not add the following substances or textiles

containing traces of the following substances to

the wash water: gasoline, kerosene, waxes,

cooking oils, vegetable oils, machine oils, drycleaning solvents, flammable chemicals, thinners

or other flammable or explosive substances.

These substances give off vapors that could

ignite, explode or cause the fabric to catch on fire

by itself.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. THE

GAS IS FLAMMABLE, DO NOT SMOKE OR

USE AN OPEN FLAME DURING THIS TIME.

6. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Safety Information

7. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This appliance

is not intended for use by persons (including

children) with reduced physical, sensory or

mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning the use of

the appliance by a person responsible for their

safety. This is a safety rule for all appliances.

8. Do not reach into the washer if the washtub or

agitator, if applicable, is moving.

9. Never operate the washer with any guards, panels

and/or parts removed or broken. DO NOT tamper

with the controls or bypass any safety devices.

10. Use your washer only for its intended purpose,

washing clothes. Always follow the fabric care

instructions supplied by the garment

manufacturer.

11. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. To reduce the risk of poisoning or chemical

burns, keep them out of the reach of children at

all times (preferably in a locked cabinet). Heed

all warnings or precautions.

12. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

13. Lid MUST BE CLOSED any time the washer is

to agitate or spin. DO NOT bypass the lid switch

by permitting the washer to agitate or spin with

the lid open. A brake will stop the washtub

within seconds if the lid is opened during

spinning. If the washtub does not stop when the

lid is opened, remove the washer from use and

call the service person.

15. Keep your washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have your washer checked by a

qualified service person.

16. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have the

skills to carry out. ALWAYS disconnect the

washer from electrical supply before attempting

any service.

17. Disconnect the power cord by grasping the plug,

not the cord. If the supply cord is damaged, it

must be replaced by a special cord or assembly

available from the manufacturer or its service

agent.

18. Before the washer is removed from service or

discarded, remove the lid to the washing

compartment.

19. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

Always contact your dealer, distributor, service agent

or the manufacturer about any problems or conditions

you do not understand.

14. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 7

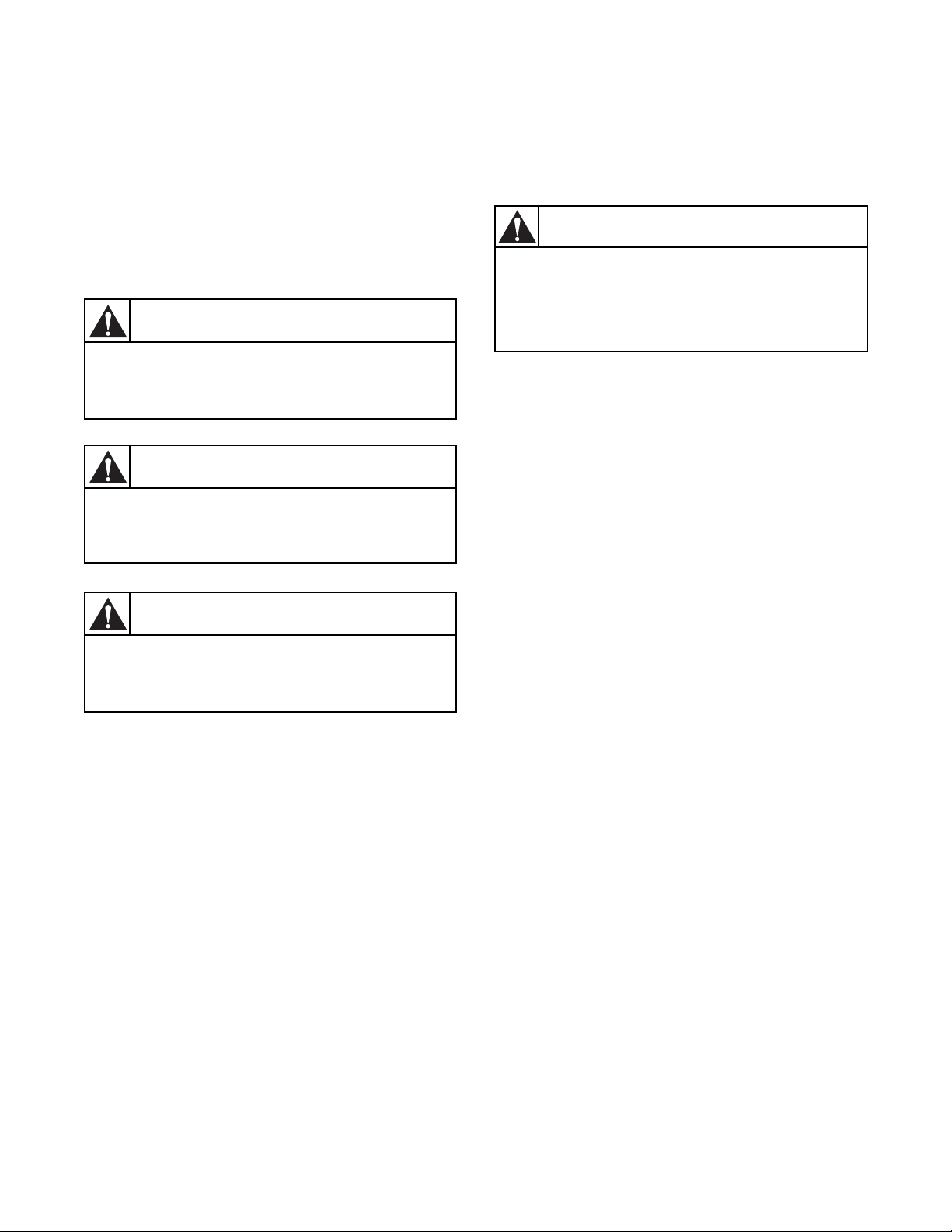

Installation

C

H

TLW2097N

25.625 in. (65.1 cm)

30.5 in. (74.47 cm)

Standard Capacity Meter Case

43 in. (109.2 cm)

0.44 in.

(1.12 cm)

26 in. (66.04 cm)

28.75 in. (73.02 cm)

41.25 in. (104.78 cm)

36 in. (91.44 cm)

51 in. (129.54 cm)

1

28 in. (71.1 cm)

38.19 in. (97 cm)

22.44 in. (57 cm)

High Capacity Meter Case

43.875 in. (111.44 cm)

Dimensions and Specifications

1 Pilot Hole

TLW2097N

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Installation

D074ID074I

1

2

4

3

TLW2

1

2

3

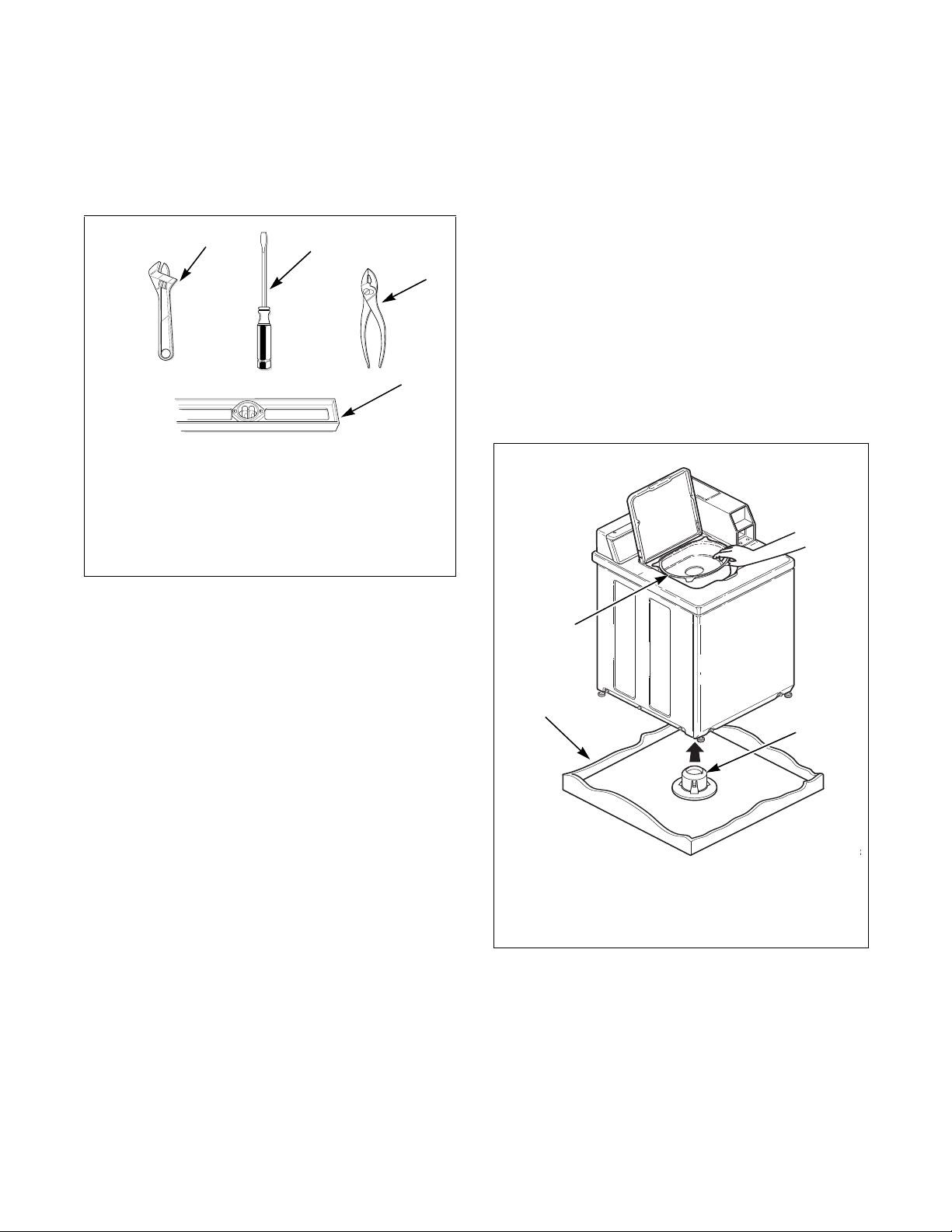

Before You Start

Tools

For most installations, the basic tools you will need

are:

D074I

1 Wrench

2 Screwdriver

3 Pliers

4 Level

Installing the Washer

Step 1: Remove the Shipping Brace and

Shipping Plug

Remove the shipping brace from under the lid.

The shipping plug will be released from the base of the

washer when removing the cardboard base from the

washer. Refer to Figure 2.

The shipping brace and plug should be saved and must

be reinstalled whenever washer is moved or

transported to a new location. This will prevent

damage to washer components.

Do not tilt washer to front or sides when moving.

Refer to User-Maintenance section for instructions on

reinstalling shipping brace and shipping plug.

Figure 1

NOTE: If the washer is delivered on a cold day

(below freezing), or is stored in an unheated room

or area during the cold months, do not attempt to

operate it until the washer has had a chance to

warm up.

IMPORTANT: Install dryer before washer. This

allows room for attaching exhaust duct.

TLW2098N

1 Shipping Brace

2 Shipping Plug

3 Cardboard Base

Figure 2

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 9

Installation

Under certain conditions, hydrogen gas

may be produced in a hot water system

that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If

the hot water system has not been used

for such a period and before using the

washer, turn on all hot water faucets and

let the water flow from each for several

minutes. This will release any

accumulated hydrogen gas. The gas is

flammable. Do not smoke or use an open

flame during this time.

W029

WARNING

To prevent personal injury, avoid contact

with inlet water temperatures higher than

125° Fahrenheit (51° Celsius) and hot

surfaces.

W748

WARNING

Step 2: Wipe Out Inside of Washtub

Prior to first wash, use an all purpose cleaner or a

detergent and water solution and a damp cloth to

remove shipping dust from inside of washtub.

TLW2099N

Figure 3

Step 3: Connect Fill Hoses

Water Supply Requirements

Water supply faucets must fit standard 3/4 inch

(19.1 mm) female garden hose couplings. DO NOT

USE SLIP-ON OR CLAMP-ON CONNECTIONS.

NOTE: Water supply faucets should be readily

accessible to permit turning them off when washer

is not being used.

Recommended cold water temperature is 50° to 75°

Fahrenheit (10° to 24° Celsius). Recommended

maximum hot water temperature is 125° Fahrenheit

(51° Celsius). Warm water is a mixture of hot and cold

water. Warm water temperature is dependent upon the

water temperature and the pressure of both the hot and

cold water supply lines.

Pressure must be a minimum of 20 to a maximum of

120 pounds per square inch (138 to 827 kPa) static

pressure measured at the faucet.

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

NOTE: Water pressure under 20 pounds per

square inch (138 kPa) will cause an extended fill

time in the washer.

Turn on the water supply faucets and flush the lines for

approximately two minutes to remove any foreign

materials that could clog the screens in the water

mixing valve. (This is especially important when

installing your washer in a newly constructed or

renovated building.)

7

Page 10

Installation

TLW1988N

HOT

COLD

C

H

2

1

3

4

5

6

7

2

1

Connecting Hoses

Insert rubber washers and filter screens (from

accessories bag) in water fill hose couplings (two

hoses supplied with washer). Connect fill hoses to

water supply faucets. Then connect the hoses to the

hot and cold valve connections at the rear of the

washer. Refer to Figure 4. Thread hose couplings onto

valve connections finger tight. Then turn 1/4 turn with

pliers.

IMPORTANT: DO NOT cross thread or

overtighten couplings.

IMPORTANT: Turn off water supply faucets after

check-out and demonstration. Owner should turn

off water supply whenever there will be an

extended period of non-use.

NOTE: Longer fill hoses are available (as optional

equipment at extra cost) if the hoses (supplied with

the washer) are not long enough for the

installation. Order hoses as follows:

No. 20617 Fill Hose (8 feet) (2.44 m)

No. 20618 Fill Hose (10 feet) (3.05 m)

Risers

Risers (or air cushions) may have to be installed if the

pipes knock or pound when flow of water stops. The

risers are more efficient when installed as close as

possible to the water supply faucets. Refer to Figure 5.

1 Filter Screen (Screen must be facing

outward)

2 Fill Hose

3 Rubber Washer (Plain)

4 Cold Water Connection

5 Hot Water Connection

6 Hose Coupling

7 Faucet

Figure 4

IMPORTANT: Hoses and other natural rubber

parts deteriorate after extended use. Hoses may

develop cracks, blisters or material wear from the

temperature and constant high pressure they are

subjected to.

All hoses should be checked on a monthly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately. All hoses should be replaced

every five years.

TLW1988N

W005I

1 Risers (Air cushions)

2 Water Supply Faucets

Figure 5

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 11

Installation

W294I

2

1

RECOMMENDED

STANDPIPE

HEIGHT

36 inches

MINIMUM

(91.44 cm)

{

3

1

MAXIMUM

STANDPIPE

HEIGHT NOT TO

EXCEED 5 feet

(1.5 m)

2

Step 4: Connect Drain Hose to Drain

Receptacle

Drain Facilities

IMPORTANT: The drain hose installation is a very

important factor in the washer installation. If care

is not taken when the drain hose is installed, a

siphoning action can be started which will cause

water to be siphoned from the washer during the

cycle.

End of drain hose should never be in water as

siphoning action can be started that will cause

water to be siphoned back into the washer.

The curved end of drain hose MUST be installed

even with or above the height of the cabinet top of

the washer to prevent siphoning. Refer to Figure 6.

If necessary, follow the instructions for your type of

drain receptacle (high standpipe or low standpipe) to

properly install the drain hose.

High Standpipe Installation

NOTE: No. 562P3 Siphon Break Kit and No. 25863

Hose Coupling are not required for this type of

installation.

The standpipe or drain receptacle must be capable of

handling a minimum of 1-1/2 inches (3.8 cm) outside

diameter drain hose. The drain hose should fit loose

within the standpipe (it should not be snug fit). Never

install the drain hose into a “sealed” drain system as

air cannot escape and will restrict the water from being

drained from the washer. A sealed drain system may

also allow water to be pumped back into the washer

during agitation. Both of these conditions may result

in flooding of the washer.

Remove the drain hose from its shipping position on

the rear of the washer by unhooking the hose from the

retainer clamp.

1 Drain Hose

2 Standpipe

Figure 6

W294I

W296I

1 Drain Hose

2 Cut Drain Hose off at This End to Fit the

Washer Installation

3 Standpipe

Figure 7

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 1-1/2 inch (3.8 cm) outside

diameter drain hose.

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Installation

{

2

1

5

4

3

1

3

2

5

4

6

Low Standpipe Installation

If the drain facility is lower than the cabinet top, a

siphon break kit, Part No. 562P3, must be installed in

the drain hose to prevent siphoning action and drain

hose MUST be cut to fit the washer installation. Refer

to Figure 8. Use one No. 25863 Hose Coupling to

splice hose. The No. 562P3 Siphon Break Kit and No.

25863 Hose Coupling are available as optional

equipment at extra cost through an authorized dealer

or parts distributor. Installation instructions are

supplied with the kit.

OPTIONAL: Raise the standpipe to the recommended

height of 36 inches (91.44 cm).

IMPORTANT: Drain receptacle must be capable of

handling a minimum of 1-1/2 inch (3.8 cm) outside

diameter drain hose.

If washer is not level, tilt washer back to access the

front leveling legs. Loosen the locknuts and adjust legs

by screwing into or out of washer base.

Once adjusted, tilt the washer forward on front legs

and lower back down into position to set the rear selfleveling legs.

Washer must not rock. After washer is at desired

height, tighten locknuts securely against bottom of

washer base. If these locknuts are not tight, washer

will not remain stationary during operation.

Improper installation or flexing of weak floor will

cause excessive vibration.

Do not slide washer across floor once the leveling legs

have been extended, as legs and base could become

damaged.

NOTE: For areas with uneven floors, a No. 566P3

Adjustable Rear Leg Extension Kit is available as

optional equipment at extra cost.

Verify that unit does not rock.

W295I

1 Drain Hose Elbow

2 562P3 Siphon Break Kit

3 Standpipe

4 Cut Hose in This Area and Install No. 25863

Hose Coupling

5 25863 Hose Coupling

Figure 8

Step 5: Position and Level the Washer

Position washer so it has sufficient clearance for

installation and servicing.

1 Washer Base

2 Locknut

3 Leveling Leg

4 Rubber Cup

5 1/2 inch (12.7 mm) Clearance Between

Washers

6 Level

Figure 9

TLW2100N

Place washer in position on a clean, dry, and

reasonably firm floor. Installing the washer on any

type of carpeting is not recommended.

Place rubber cups on all four leveling legs.

Place a level on the cabinet top and check if the

washer is level from side to side and front to back.

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 13

Step 6: Plug In the Washer

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA No. 70, and such local

regulations as might apply. It is the

customer’s responsibility to have the

wiring, fuses and circuit breakers

installed by a qualified electrician to make

sure adequate electrical power is

available to the washer.

W518

WARNING

1

2

3

4

5

Standard 120 Volt, 60 Hertz

3-Wire Effectively

Grounded Circuit

0 V.A.C.

120±12

V.A.C.

120±12

V.A .C .

To reduce the risk of an electric shock or

fire, DO NOT use an extension cord or an

adapter to connect the washer to the

electric power source.

W082

WARNING

Electrical Requirements

(120 Volt, 60 Hertz with 3-Prong Grounding Plug)

NOTE: The wiring diagram is located in the

control hood.

When plugging in the washer:

• DO NOT overload circuits.

Installation

DRY2022N

1 L1

2 Ground

3 Neutral Side

4 Round Grounding Prong

5 Neutral

• DO NOT use an extension cord.

• DO NOT use an adapter.

• DO NOT operate other appliances on the same

circuit. Use separately fused 15 Amp circuits.

The washer is designed to be operated on a separate

branch, polarized, three-wire, effectively grounded,

120 Volt, 60 Hertz, AC (alternating current), circuit

protected by a 15 ampere fuse, equivalent fusetron or

circuit breaker.

The three-prong grounding plug on the power cord

should be plugged directly into a polarized three-slot

effectively grounded receptacle rated 110/120 Volts

AC (alternating current) 15 Amps. Refer to Figure 10

to determine correct polarity of the wall receptacle.

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 10

11

Page 14

Installation

Improper connection of the equipmentgrounding conductor can result in a risk

of electric shock. Check with a qualified

electrician or service person if you are in

doubt as to whether the washer is

properly grounded.

W327

WARNING

Any disassembly requiring the use of

tools must be performed by a suitably

qualified service person.

W299

WARNING

TLW2056N

Grounding Instructions

The washer must be grounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing a path of least

resistance for electric current.

The washer is equipped with a cord having an

equipment-grounding conductor and a three-prong

grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

• DO NOT modify the plug provided with the

washer – if it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

NOTE: The agitator should not be removed except

for service. The washtub is designed to be selfcleaning.

TLW2056N

Figure 11

Step 8: Check Lid Switch

Washer should stop filling, agitating and spinning

when lid is opened.

• If the laundry room’s electrical supply does not

meet the above specifications and/or if you are

not sure the laundry room has an effective

ground, have a qualified electrician or your local

electrical utility company check it and correct

any problems.

Step 7: Add Water to the Washer

To prevent damage to pump, do not run washer before

adding at least one quart water to the tub. If the washer

is run before any water is added, the pump seal may

overheat, causing the pump to leak. Once installed, the

water retained in the drain system from the previous

cycle will provide sufficient cooling to prevent pump

seal damage.

TLW2101N

Figure 12

Step 9: Check Installation

Refer to Installer Checklist on the back cover of this

manual and make sure that washer is installed

correctly.

Run washer through one complete cycle to make sure

it is operating properly.

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 15

Installation

1

Vending

Meter Case

The factory mounted coin meter case does not include

the service door lock, coin drawer, coin drawer lock or

keys. These parts must be ordered (at extra cost)

according to the purchaser’s requirements direct from

the manufacturer of your choice.

NOTE: On models with standard capacity meter

case and high capacity meter case models starting

with Serial Nos. beginning 1010, you have the

option of using a screw type lock or a 1/4 turn lock

on the meter case service door. If you choose to use

a screw lock, then the special bracket (located

inside the meter case) must be used. DO NOT use

the special bracket if a 1/4 turn lock is used. High

capacity meter case models with Serial Nos.

beginning 0910 through 1010 use 1/4 turn lock only.

Coin Drawer Security (Models with Standard

Capacity Meter Case and high capacity meter case

models starting with Serial Nos. beginning 1010

Only) – For additional security, drill out the two pilot

holes on each side of the front of the meter case to 1/4

or 5/16 inch (6.4 or 7.9 mm) holes and install a bicycle

lock through these holes.

NOTE: An 8 in. (20.32 cm) coin drawer is required

for models with standard capacity meter case and

high capacity meter case models starting with

Serial Nos. beginning 1010. High capacity meter

case models with Serial Nos. beginning 0910

through 1010 require a 7.21 in. (18.31 cm) coin

drawer.

Models Prepped for Card Reader

The machine is shipped from the factory with the

Electronic Control Diagnostic Harness Assembly

unplugged. To avoid unauthorized manual

programming or vending, perform the following steps.

1. Open control panel. Refer to Figure 13.

2. Locate diagnostic harness on electronic control.

3. Plug connectors for “white/black” wire and “red/

blue” wire together.

FLW6R

1 Control Panel

Figure 13

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Installation

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the washer

before servicing.

• Never start the washer with any guards/

panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

washer is properly grounded.

W003

WARNING

Any disassembly requiring the use of tools

must be performed by a suitably qualified

service person.

W299

2

1

3

Additional Washer Security

(Coin Models Only)

Located on the service door of the washer is a flat

Phillips head screw. During shipment, this screw is

used to attach the service door to the meter case. For

additional security, this screw can be reinstalled inside

the control hood of your washer. Refer to instructions

below for installation.

Tamper-resistant screws also can be installed for

additional security. Tamper-resistant screws, bits and

bit holder are available as optional equipment at extra

cost. Part numbers are:

• Bit (No. 8 screws) Part No. 281P4

• Bit (No. 12 screws) Part No. 282P4

• Bit Holder (3/8 drive) Part No. 24161

• Control panel tamper-resistant screw

Part No. 35528

• Front panel tamper-resistant screw

Part No. 35527

The following list is the procedure required to install

the Phillips head screw and tamper-resistant screws:

4. Insert Phillips head screw down through double

“D” hole in left rear corner of cabinet top (inside

control hood) until it engages retainer nut located

on left rear corner gusset of cabinet.

5. Finger tighten screw.

IMPORTANT: Do not use a power driver to tighten

screw. Torque of a power driver could over-tighten

screw causing damage to cabinet assembly.

6. Secure control panel to control hood using two

No. 8 tamper-resistant screws, Part No. 35528.

7. Remove two screws holding front panel to base

of washer and install two No. 12 tamper-resistant

screws, Part No. 35527.

1. Remove the Phillips head screw from service

door (refer to Figure 14).

2. Remove two screws holding control panel to

control hood.

3. Tilt control panel forward and lay on a protective

pad to prevent scratching of cabinet top.

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TLW2102N

1 35528 No. 8 Screws

2 Double “D” Hole

3 35527 No. 12 Screws

Figure 14

202068

Page 17

Operation

Operation Instruction

IMPORTANT: Prior to first wash, use an allpurpose cleaner, or a detergent and water solution,

and a damp cloth to remove shipping dust from

inside of washer.

IMPORTANT: Remove all sharp objects from

laundry to avoid tears and rips to items during

normal machine operation.

Step 1: Add Detergent

Pour measured amount of detergent into washtub.

Refer to package directions.

NEVER POUR UNDILUTED BLEACH DIRECTLY

ON LAUNDRY. Follow package directions when

using dry bleach.

If desired, fabric softener may be added to rinse water

when RINSE light comes on.

Step 2: Load Laundry

Load dry clothes loosely into washtub – DO NOT

overload!

When washing large items such as shag rugs and

bedspreads, add several small items to balance wash

load.

W392I

Figure 16

Step 3: Close Lid

Figure 15

Washer will not operate with lid open.

W395I

H338I

Figure 17

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Operation

TLW2118N

Step 4: Set Fabric Selector

Push touchpad for NORMAL, PERM PRESS or

DELICATES. Light indicates selection.

TLW2138N

Figure 18

Step 5: Set Wash Temperature

Push touchpad for HOT, WARM or COLD. Light

indicates selection.

Step 6: Select Cycle Type/ Soil Level

Push CYCLE SELECT or SOIL LEVEL touchpad.

Light indicates selection.

TLW2118N

Figure 20

TLW12R

Step 7: Insert Money or Card

To Insert Money

Insert coin(s) in coin slot. Check pricing as seen on

digital display.

Figure 19

TLW2139N

W387I

Figure 21

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 19

Operation

To Insert Card

Insert card into opening.

DRY1927N

Figure 22

Step 8: Start Washer

After vend price has been satisfied, push the START

pad. LID MUST BE CLOSED TO START WASHER.

Indicator Lights

INSERT COINS/CARD

INSERT COINS/CARD is lit to prompt the user to

insert coins or a card to satisfy the vend price. When

INSERT COINS/CARD is lit, the digits show the vend

price remaining to be satisfied.

WA SH

WASH is lit at the beginning of the Wash portion of the

cycle and will remain lit until the Wash step is

complete.

RINSE

RINSE is lit at the beginning of the Rinse or Extra

Rinse portion of the cycle and will remain lit until the

Rinse step is complete.

SPIN

SPIN is lit during the Final Spin portion of the cycle.

SMALL LOAD

SMALL LOAD is lit if selected for the current cycle.

MEDIUM or LIGHT/MEDIUM

MEDIUM or LIGHT/MEDIUM is lit if selected for the

current cycle.

Figure 23

HEAVY

HEAVY is lit if selected for the current cycle.

START

START flashes one second on and one second off when

the full vend price has been satisfied.

TLW2140N

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Maintenance

2

1

3

4

User-Maintenance Instructions

Cold Weather Care

If the washer is delivered on a cold day (below

freezing), or is stored in an unheated room or area

during the cold months, do not attempt to operate the

washer until it has had a chance to warm up.

Care of Your Washer

Use only a damp or sudsy cloth for cleaning the

control panel. Some cleaning products may harm the

finish on the control panel. Wipe the panel dry after

cleaning.

Wipe the washer cabinet as needed. If detergent,

bleach or other washing products are spilled on the

cabinet, wipe immediately. Some products will cause

permanent damage if spilled on the cabinet.

Do not use scouring pads or abrasive cleansers.

The washtub will need no particular care though it

may need rinsing or wiping after some unusual loads

have been washed. This also may be necessary if too

little detergent has been used.

Reinstallation of Shipping Materials

Shipping Brace

The shipping brace in the lid opening should be saved

and reinstalled whenever the washer is moved. To

reinstall the brace, open the washer lid and place the

brace over the washer agitator, placing the back of the

brace into the lid opening first.

Shipping Plug

The plastic shipping plug should be saved and

reinstalled any time the washer is moved. The plug fits

into two openings: The base opening and the shipping

plug opening on the bottom of the movable pivot

dome. The plug MUST be inserted into both openings

to prevent damage to the washer. In order to

accomplish this, the shipping plug opening must be

directly lined up with the base opening. Refer to

Figure 24.

Leave the lid open to allow the inside of the washer to

dry out after use. This helps prevent musty odors from

developing.

The agitator should not be removed except for service.

The washtub is designed to be self cleaning.

Replacing Hoses

Hoses and other natural rubber parts deteriorate after

extended use. Hoses may develop cracks, blisters or

material wear from the temperature and constant high

pressure they are subjected to.

All hoses should be checked on a monthly basis for

any visible signs of deterioration. Any hose showing

the signs of deterioration listed above should be

replaced immediately. All hoses should be replaced

every five years.

Filter Screens

Check the filter screens in the fill hoses for debris or

damage annually. Clean or replace them if necessary.

If the washer is filling with water slower than normal,

check the filter screens. Clean or replace them if

necessary.

Order filter screen Part No. F270300 from the nearest

authorized parts distributor.

TLW2103N

1 Shipping Plug Opening

2 Base Opening

3 Shipping Plug

4 Shipping Brace

Figure 24

Motor Overload Protector

The internal overload protector will stop the motor

automatically in the event of an overload.

The overload protector will reset itself in two or three

minutes and the motor will restart automatically.

If the overload protector stops motor again, remove

the washer from use and call the service person to

correct the problem.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 21

Troubleshooting

Try these troubleshooting tips before making a service call. They may save you time and money.

Washer Symptom Possible Cause/Solution

Won’t Fill

Won’t Start

Won’t Agitate

• Make sure lid is closed.

• Make sure power cord is plugged all the way into the electrical outlet.

• Make sure hot and cold water faucets are turned on.

• Make sure that the fill hoses are not kinked or twisted.

• Place coin(s) in drop or card in reader.

• Make sure that the controls are properly set.

• Make sure that the last spin has been completed.

• Check the laundry room fuse or circuit breaker.

• Clean the screens in the water mixing valve and the filter screens located at the faucet end

of the fill hoses.

• Water is being siphoned from the washer during the cycle. Refer to the Installation

section to make sure that the drain hose has been properly installed.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

• Make sure lid is closed.

• Place coin(s) in drop or card in reader.

• Make sure power cord is plugged all the way into the electrical outlet.

• Make sure that the controls are properly set.

• Check the laundry room fuse or circuit breaker.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

• Make sure lid is closed.

• Place coin(s) in drop or card in reader.

• Make sure power cord is plugged all the way into the electrical outlet.

• Check the laundry room fuse or circuit breaker.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

• Broken drive belt. Call the service person.

• Have a qualified electrician check polarity and grounding. Refer to Electrical

Requirements section.

Won’t Spin

Stops/Pauses During

Cycle

202068

• Make sure lid is closed.

• Place coin(s) in drop or card in reader.

• Make sure power cord is plugged all the way into the electrical outlet.

• Check the laundry room fuse or circuit breaker.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

• Broken drive belt. Call the service person.

• Have a qualified electrician check polarity and grounding. Refer to Electrical

Requirements section.

• Pauses are part of the washer’s normal operation. The washer will stop (pause) shortly

before the wash and rinse spins.

• Check the laundry room fuse or circuit breaker.

• The motor overload protector may have stopped the cycle. It will reset itself in two or

three minutes and restart the washer automatically.

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Troubleshooting

Washer Symptom Possible Cause/Solution

Won’t Drain

Water Leaks

Is Noisy

Load is too Wet

Wrong Water

Tem p eratur e

• Make sure drain hose is not kinked or twisted.

• Make sure drain hose is not clogged.

• Make sure drain receptacle is not clogged.

• Refer to the Installation section to make sure that the drain hose has been properly

installed.

• Check that fill hoses are properly installed on the faucets and the washer’s water mixing

valve.

• Replace the fill hoses every five years.

• Make sure drain receptacle is not clogged.

• Check laundry room plumbing.

• Laundry load may be oversudsing or overloaded. Use less detergent (or low-sudsing

detergent) and proper load sizes.

• Wash load may be unbalanced. Open lid and redistribute the load.

• Make sure washer is level. Uneven leveling can cause vibration.

• A newly installed washer may make a knocking sound if the machine has been in storage.

The belt may have settled. Run washer through 4-5 cycles to loosen belt. Washer

operation will not be affected.

• Wash load may be unbalanced. Open lid and redistribute the load.

• Load is too small. Add items to make full load.

• Make sure that the controls are properly set.

• Check fill hoses. Make sure hot faucet hose is connected to hot mixing valve (indicated

with “H” on the valve bracket) and cold faucet is connected to cold mixing valve

(indicated with “C” on the valve bracket).

• Make sure laundry room water heater is adjusted properly.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

202068

Page 23

Contact Information

1

To reduce the risk of serious injury or death,

DO NOT repair or replace any part of the unit

or attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that you understand and have

the skills to carry out.

W329

WARNING

If service is required, contact the nearest Factory

Authorized Service Center.

If you are unable to locate an authorized service center

or are unsatisfied with the service performed on your

unit, contact:

Alliance Laundry Systems

Shepard Street

P.O. B ox 99 0

Ripon, WI 54971-0990

U.S.A.

www.comlaundry.com

Phone: (920) 748-3121

When calling or writing about your unit, PLEASE

GIVE THE MODEL AND SERIAL NUMBERS. The

model and serial numbers are located on the

nameplate. The nameplate will be in the location

shown in Figure 25.

Date Purchased_______________________________

Model Number_______________________________

Serial Number _______________________________

Please include a copy of your bill of sale and any

service receipts you have.

If replacement parts are required, contact the source

from where you purchased your washer or call (920)

748-3950 for the name and address of the nearest

authorized parts distributor.

1 Nameplate

Figure 25

202068

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

TLW12C

TLW12C

21

Page 24

Page 25

Page 26

Installer Checklist

TLW1988N

HOT

COLD

C

H

CHECK

• Remove the

Shipping Brace

and Shipping Plug.

• Wipe Out Inside

of Washtub.

• Add Water

to the Washer.

• Check

Lid Switch.

TLW2101N

• Connect

Fill

Hoses.

• Connect Drain

Hose to Drain

Receptacle.

W294IE0A

•Plug In the

Washer.

D254IE0A

W316IE0A

CHECK

CHECK

CHECK

CHECK

CHECK

CHECK

CHECK

TLW2056N

•Position

and Level

the Washer.

TLW1988N

TLW2056N

LEVEL

D255I

D255I

W316IE0A

TLW2098N

TLW2099N

TLW2101N

D254IE0A

W294IE0A

1

2

3

7

4

8

5

6

Fast Track for Installing the Washer

(Refer to the manual for more detailed information)

TLW2098N

TLW2099N

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Loading...

Loading...