Alliance Laundry Systems SF250PV, SF135PV, UF135PV, UF250PV User Manual

Washer-Extractors

Cabinet Freestanding

Instructions for Operating and Programming

the WE-6 Microcomputer

Models SF135PV, SF250PV, SF250PV Tilt,

UF135PV, UF250PV and UF250PV Tilt

NOTA: El manual en

español aparece después

del manual en inglés.

Operation/Programming

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

R077R

Part No. F232101R3

January 2002

Table of

Contents

Safety.................................................................................................... 3

Key to Symbols..................................................................................... 4

Operator Safety..................................................................................... 6

Safe Operating Environment ................................................................ 7

Environmental Conditions............................................................... 7

Machine Location ............................................................................ 8

Input and Output Services................................................................ 8

AC Inverter Drive ............................................................................ 9

Misuse................................................................................................... 9

Operation............................................................................................. 11

Customer Service............................................................................. 11

Machine Familiarization Guides...................................................... 11

Theory of Operation ............................................................................. 16

Emergency Stop Button................................................................... 17

Wet Clean Features.......................................................................... 17

Wet Clean Capabilities .................................................................... 17

WE-6 Microcomputer ...................................................................... 19

LED Display .................................................................................... 19

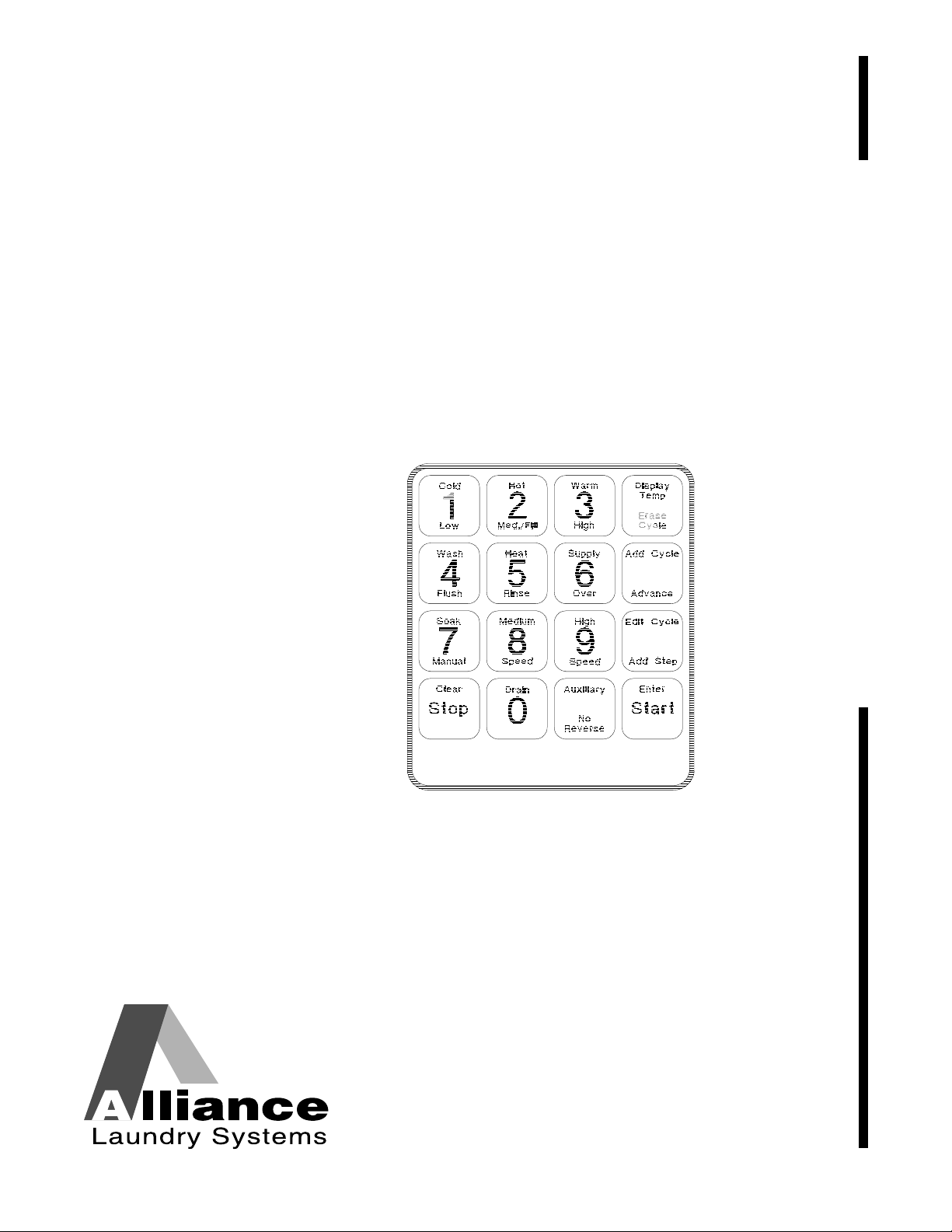

Operational Keypad ......................................................................... 22

Start-Up................................................................................................. 24

Opening Door ....................................................................................... 24

Loading and Unloading ........................................................................ 24

Tilt Option........................................................................................ 24

Forward Tilt Option......................................................................... 25

Two-Way Tilt Option ...................................................................... 26

Two-Way Tilt Inductive Proximity Sensor Adjustment.................. 26

Supply Dispenser.................................................................................. 27

Cycle Selection..................................................................................... 27

Cycle Execution.................................................................................... 27

Test Cycle............................................................................................. 28

Wet Clean Testing............................................................................ 28

Stop Routine ......................................................................................... 29

Balance Detection................................................................................. 30

Balance Sensor Detection ................................................................ 30

Inverter Drive Balance Detection .................................................... 30

Temperature Display ............................................................................ 30

Calibrating the WE-6 Temperature Circuit...................................... 31

Error Recovery Routine........................................................................ 33

Motor Thermal Overload Indicator ...................................................... 33

135-Pound Capacity Models............................................................ 33

250-Pound Capacity Models............................................................ 33

Manual Mode Control Feature.............................................................. 34

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Programming ...................................................................................... 35

Programming Keypad........................................................................... 35

Programming Tutorial .......................................................................... 37

Programming Hints............................................................................... 41

System Programming............................................................................ 42

Cycle Programming.............................................................................. 44

Displaying a Cycle in Memory........................................................ 44

Displaying Individual Cycle Usage ................................................. 44

Editing a Cycle................................................................................. 45

Erasing a Cycle in Memory ............................................................. 46

Programming a Wet Clean Cycle .................................................... 46

Step Programming ................................................................................ 47

Programming a Fill Temperature..................................................... 47

Programming a Supply Step – Models with 5 Supplies .................. 48

Programming a Supply Step – Models with 8 Supplies .................. 49

Programming Heat........................................................................... 52

Programming a Wash Step............................................................... 52

Programming a Wash 5 Thermal Cool-Down ................................. 53

Programming No Reversing ............................................................ 54

Programming a Soak Step................................................................ 54

Programming a Drain Step............................................................... 55

Programming a Spin Step ................................................................ 55

Programming an Auxiliary Step ...................................................... 55

Simulator Operation and Program Transfer ......................................... 57

Simulator Operation......................................................................... 57

Transferring All Cycles from Computer to Simulator..................... 59

Transferring One Cycle from Computer to Simulator..................... 59

Transferring All Cycles from Simulator to Computer..................... 60

Transferring One Cycle from Simulator to Computer..................... 60

Preprogrammed Cycles......................................................................... 61

Cycle Categories.............................................................................. 61

Standard Supply Legend.................................................................. 61

Standard Cycle Charts...................................................................... 62

Sample Cycle for Wet Clean ................................................................ 82

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Safety

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel

familiar with electrical test procedures,

test equipment, and safety precautions

should attempt adjustments and

troubleshooting. Disconnect power from

the machine before removing the control

box cover, and before attempting any

service procedures.

SW005

WARNING

Death or serious injury can result if

children become trapped in the machine.

Do not allow children to play on or around

this machine. Do not leave children

unattended while the machine door is

open.

SW001

DANGER

Anyone operating or servicing this machine must

follow the safety rules in this manual. Particular

attention must be paid to the CAUTION, WARNING,

and DANGER blocks which appear throughout the

manual.

The following warnings are general examples that

apply to this machine. Warnings specific to a particular

operation will appear in the manual with the

discussion of that operation.

WARNING

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

CAUTION

Ensure that the machine is installed on a

level floor of sufficient strength and that

the recommended clearances for

inspection and maintenance are provided.

Never allow the inspection and

maintenance space to be blocked.

SW020

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

3

Safety

Key to Symbols

The lightning flash and arrowhead within the triangle

is a warning sign indicating the presence of dangerous

voltage.

This warning symbol indicates the presence of

possibly dangerous chemicals. Proper precautions

should be taken when handling corrosive or caustic

materials.

The exclamation point within the triangle is a warning

sign indicating important instructions concerning the

machine and possibly dangerous conditions.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms within the

machine. Guards should always be in place when the

machine is in operation.

This warning symbol indicates the presence of hot

surfaces that could cause serious burns. Stainless steel

and steam lines can become extremely hot and should

not be touched.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving mechanical

parts can crush and/or sever body parts.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

DO NOT EXCEED

Safety

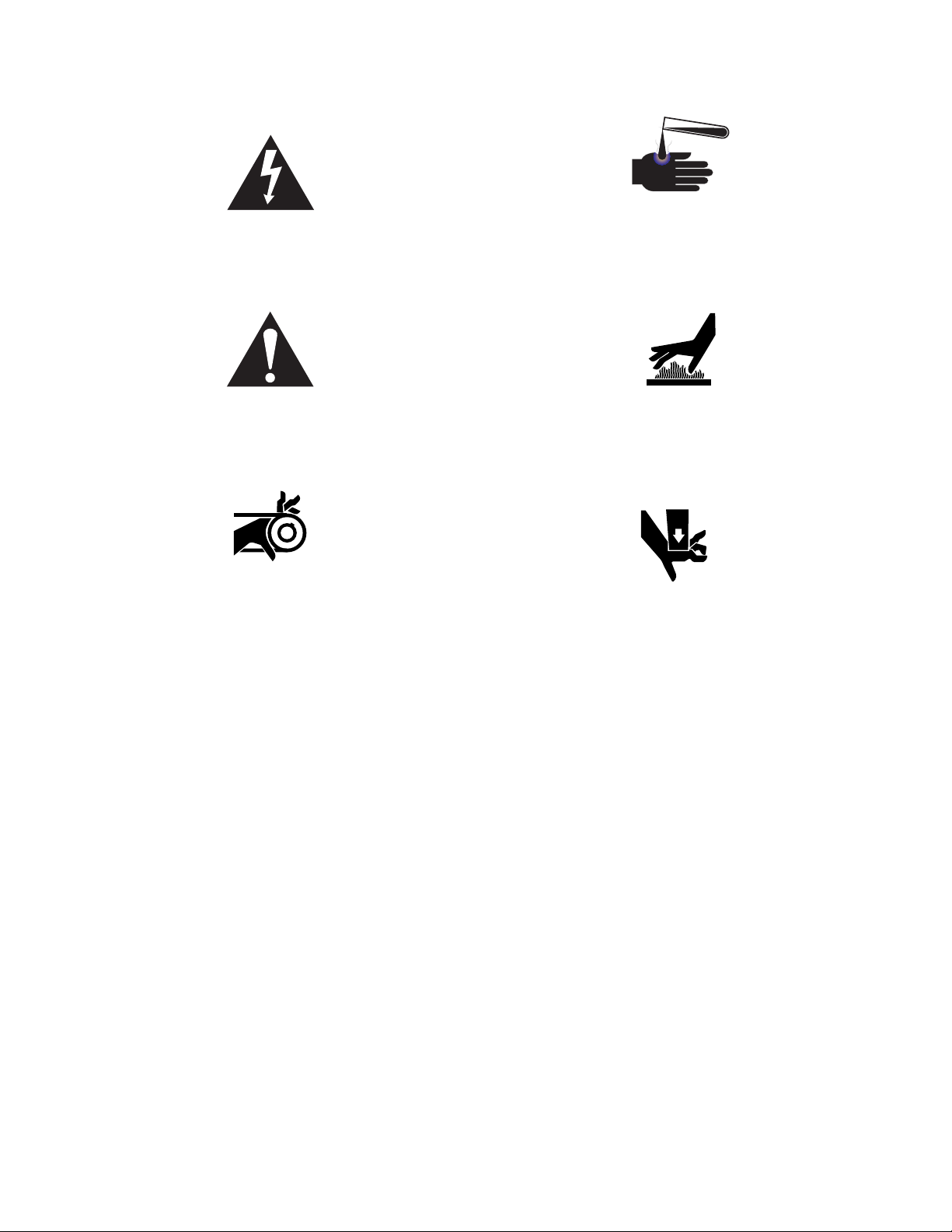

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the factory

immediately.

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

R066I

R066I

Figure 1

Use factory-authorized spare parts to avoid safety

hazards.

5

Safety

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open. Although the WE-6 display shows

cycle steps, the machine should not operate.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in the machine.

WARNING

Never operate the machine with a

bypassed or disconnected out-of-balance

switch. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW033

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Safety

Safe Operating Environment

Safe operation requires an appropriate operating

environment for both the operator and the machine. If

questions regarding safety arise, contact the factory

immediately.

Environmental Conditions

● Ambient Temperature. Water in the machine will

freeze at temperatures of 32°F (0°C) or below.

Temperatures above 120°F (50°C) will result in

more frequent motor overheating and, in some

cases, malfunction or premature damage to solid

state devices that are used in some models.

Special cooling devices may be necessary.

Water pressure switches are affected by increases

and decreases in temperature. Every 25°F (10°C)

change in temperature will have a 1% effect on

the water level.

● Humidity. Relative humidity above 90% may

cause the machine’s electronics or motors to

malfunction or may trip the ground fault

interrupter. Corrosion problems may occur on

some metal components in the machine.

If the relative humidity is below 30%, belts and

rubber hoses may eventually develop dry rot. This

condition can result in hose leaks, which may

cause safety hazards external to the machine in

conjunction with adjacent electrical equipment.

● Radio Frequency Emissions. A filter is available

for machines in installations where floor space is

shared with equipment sensitive to radio

frequency emissions.

● Elevation. If the machine is to be operated at

elevations of over 3280 ft. (1000 m) above sea

level, pay special attention to water levels and

electronic settings (particularly temperature) or

desired results may not be achieved.

● Chemicals. Keep stainless steel surfaces free of

chemical residues.

DANGER

Do not place volatile or flammable fluids

in any machine. Do not clean the machine

with volatile or flammable fluids such as

acetone, lacquer thinners, enamel

reducers, carbon tetrachloride, gasoline,

benzene, naptha, etc. Doing so could

result in serious personal injury and/or

damage to the machine.

SW002

● Water Damage. Do not spray the machine with

water. Short circuiting and serious damage may

result. Repair immediately all seepage due to

worn or damaged gaskets, etc.

● Ventilation. The need for make-up air openings

for such laundry room accessories as dryers,

ironers, water heaters, etc., must be evaluated

periodically. Louvers, screens, or other

separating devices may reduce the available air

opening significantly.

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Safety

Replace all panels that are removed to

perform service and maintenance

procedures. Do not operate the machine

with missing guards or with broken or

missing parts. Do not bypass any safety

devices.

SW019

CAUTION

Machine Location

● Foundation. The concrete floor must be of

sufficient strength and thickness to handle the

floor loads generated by the high extract speeds

of the machine.

● Service/Maintenance Space. Provide sufficient

space to allow comfortable performance of

service procedures and routine preventive

maintenance.

This is especially important in connection with

machines equipped with an AC inverter drive.

Consult installation instructions for specific details.

Input and Output Services

● Water Pressure. Best performance will be

realized if water is provided at a pressure of

30 – 85 psi (2.0 – 5.7 bar). Although the machine

will function properly at lower pressure,

increased fill times will occur. Water pressure

higher than 100 psi (6.7 bar) may result in

damage to machine plumbing. Component

failure(s) and personal injury could result.

● Steam Heat (Optional) Pressure. Best

performance will be realized if steam is provided

at a pressure of 30 – 80 psi (2.0 – 5.4 bar). Steam

pressure higher than 125 psi (8.5 bar) may result

in damage to steam components and may cause

personal injury.

● Compressed Air. For machines requiring

compressed air service, best performance will

be realized if air is provided at a pressure of

80 – 100 psi (5.4 – 6.7 bar).

● Drainage System. Provide drain lines or troughs

large enough to accommodate the total number of

gallons that could be dumped if all machines on

the site drained at the same time from the highest

attainable level. If troughs are used, they should

be covered to support light foot traffic.

● Pow er. For personal safety and for proper

operation, the machine must be grounded in

accordance with state and local codes. The

ground connection must be to a proven earth

ground, not to conduit or water pipes. Do not use

fuses in place of the circuit breaker. An easyaccess cutoff switch should also be provided.

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground

lug near the input power block on this

machine. Without proper grounding,

personal injury from electric shock could

occur and machine malfunctions may be

evident.

SW008

Always disconnect power and water supplies before a

service technician performs any service procedure.

Where applicable, steam and/or compressed air

supplies should also be disconnected before service is

performed.

For machines equipped with optional steam heat,

install piping in accordance with approved

commercial steam practices. Failure to install the

supplied steam filter may void the warranty.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Safety

AC Inverter Drive

Machines equipped with the AC inverter drive require

special attention with regard to the operating

environment.

● An especially dusty or linty environment will

require more frequent cleaning of the AC inverter

drive cooling fan filter(s) and of the AC inverter

drive itself.

● Power line fluctuations from sources such as

uninterruptible power supplies (UPS) can

adversely affect machines equipped with the AC

inverter drive. Proper suppression devices should

be utilized on the incoming power to the machine

to avoid problems.

● A clean power supply free from voltage spikes

and surges is absolutely essential for machines

equipped with the AC inverter drive. Nonlinear

inconsistencies (peaks and valleys) in the power

supply can cause the AC inverter drive to

generate nuisance errors.

● If voltage is above 230 Volt for 200 Volt

installations or above 440 Volt for 400 Volt

installations, a buckboost transformer is

recommended. If voltage is above 240 or 480, a

buckboost transformer is required.

Misuse

Never use this machine for any purpose other than

washing fabric.

● Never wash petroleum-soaked rags in the

machine. This could result in an explosion.

● Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

● Never allow children to play on or around this

machine. Death or serious injury can result if

children become trapped in the machine. Do not

leave children unattended while the machine door

is open. These cautions apply to animals as well.

● Sufficient space to perform service procedures

and routine preventive maintenance is especially

important for machines equipped with the AC

inverter drive.

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Notes

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232101

Operation

This manual is designed as a guide for operating and

programming the 135-pound and 250-pound capacity

freestanding washer-extractors equipped with the

WE-6 microcomputer and an AC inverter drive. These

washer-extractors feature programmable custom

cycles and high extract force. Wet cleaning capability

and water reuse capability offer the operator versatility

and economy.

The manuals, installation instructions, and wiring

diagrams which accompany the washer-extractor have

been included at no charge. Additional copies are

available at a nominal charge.

NOTE: Read this manual thoroughly before

attempting to operate the washer-extractor or

program the microcomputer.

NOTE: Do not use this manual in conjunction with

earlier model microcomputer-controlled

freestanding washer-extractors. Do not use

technical literature intended for earlier models

when operating this machine.

NOTE: All information, illustrations, and

specifications contained in this manual are based

on the latest product information available at the

time of printing. We reserve the right to make

changes at any time without notice.

Customer Service

If literature or replacement parts are required, contact

the source from whom the washer-extractor was

purchased or contact Alliance Laundry Systems LLC

at (920) 748-3950 for the name and address of the

nearest authorized parts distributor.

For technical service, call any of the following

numbers:

(920) 748-3121

Ripon, Wisconsin

(850) 718-1025

(850) 718-1026

Marianna, Florida

A record of each washer-extractor is on file with the

manufacturer. Always provide the washer-extractor’s

serial number and model number when ordering parts

or when seeking technical assistance.

Machine Familiarization Guides

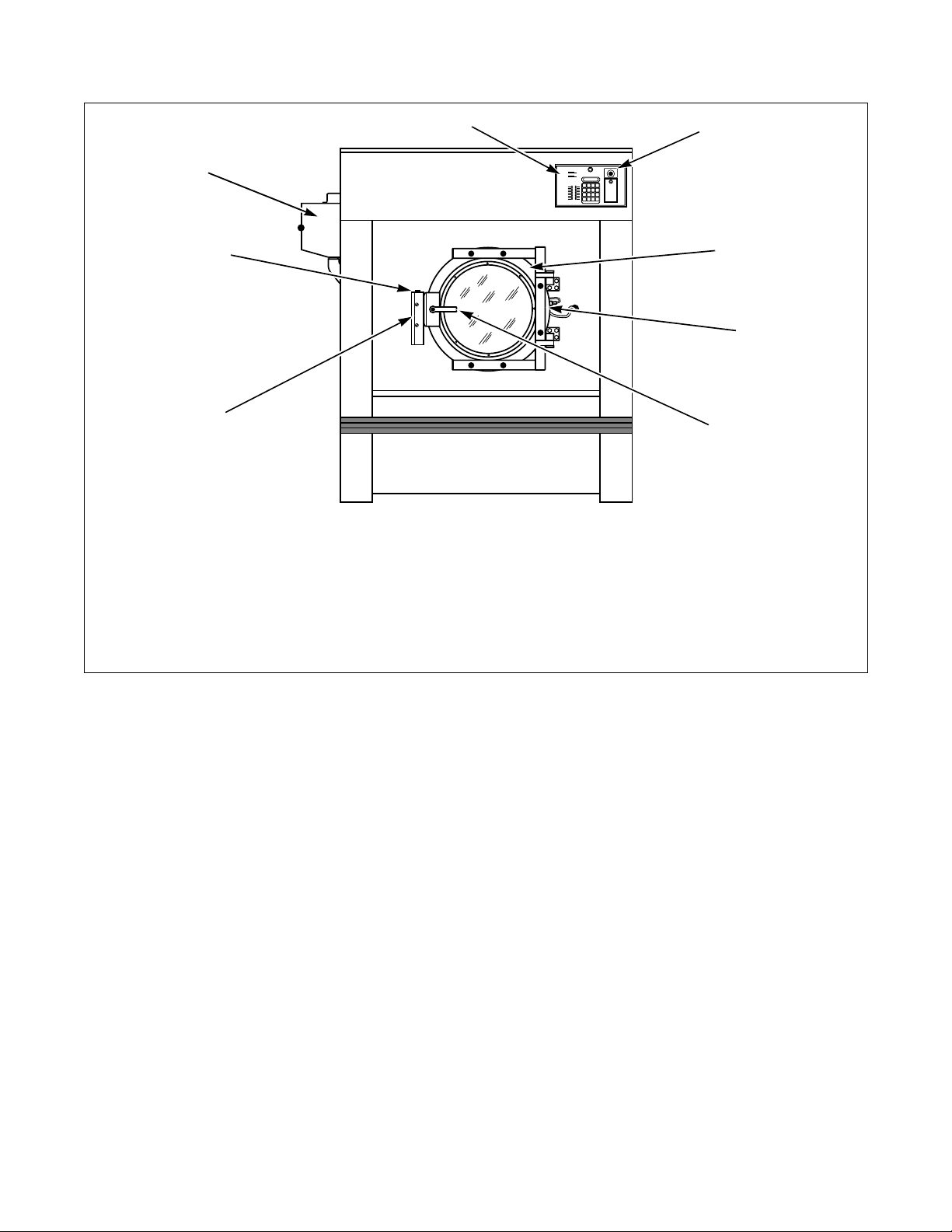

The machine familiarization guides in Figure 2

through Figure 5 identify major operational features of

each washer-extractor.

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Operation

1

Emergency Stop

Operating Instructions

1. Open Door

8

2. Load Articles

3. Close Door

4. Enter 2 Digit Wash Cycle

5. Press Start

Output Indicators

7

6

R017I

135-POUND CAPACITY FRONT FAMILIARIZATION

1 Computer Keypad 5 Door Handle

2 Emergency Stop Button 6 Door Lock Box

3 Door 7 Door Lock Pushbutton

4 Door Hinge 8 Supply Dispenser

2

3

4

5

R017I

Figure 2

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Operation

10

11

12

13

14

1

2

3

4

5

6

7

8

R078R

9

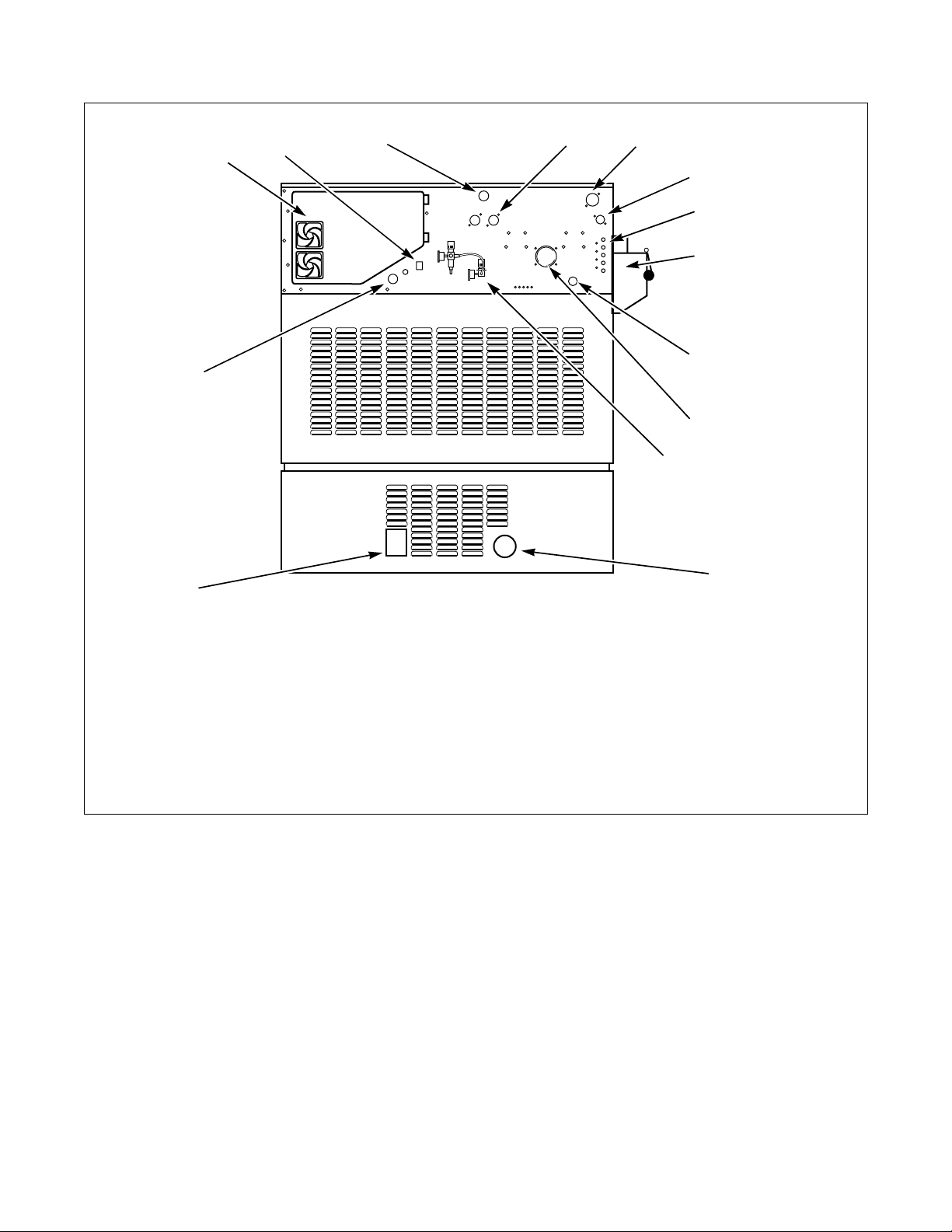

135-POUND CAPACITY REAR FAMILIARIZATION

1 Cold Water Inlet 8 Air Inlet and Regulator

2 Vent 9 Standard Drain

3 Hot Water Inlet 10 Cover Plate for Optional Drain

4 Liquid Supply Connections 11 Power In put Cable Port

5 Supply Dispenser 12 Inverter Drive Cooling Fans

6 Steam Connection 13 Electric Heat/Steam Heat Switch

7 Vacuum Breaker 14 Wet Clean Recirculation Port

Figure 3

R078R

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Operation

1

2

8

¨

Output Indicators

7

Emergency Stop

Operating Instructions

1. Open Door

2. Load Articles

3. Close Door

4. Enter 2 Digit Wash Cycle

5. Press Start

3

4

6

5

R018I

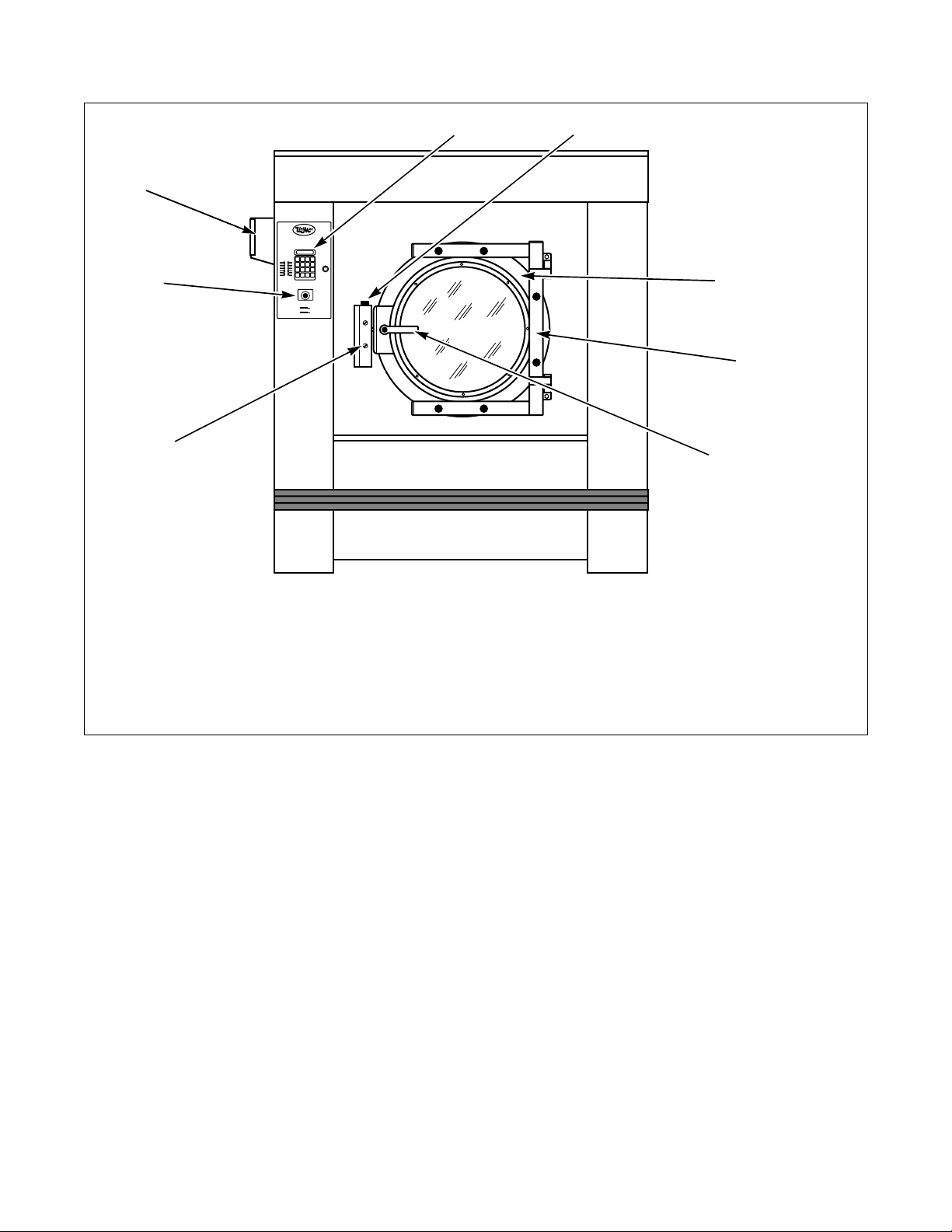

250-POUND CAPACITY FRONT FAMILIARIZATION

1 Computer Keypad 5 Door Handle

2 Door Lock Pushbutton 6 Door Lock Box

3 Door 7 Emergency Stop Button

4 Door Hinge 8 Supply Dispenser

Figure 4

R018I

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Operation

11

10

1

2

3

4

5

9

6

7

8

R079R

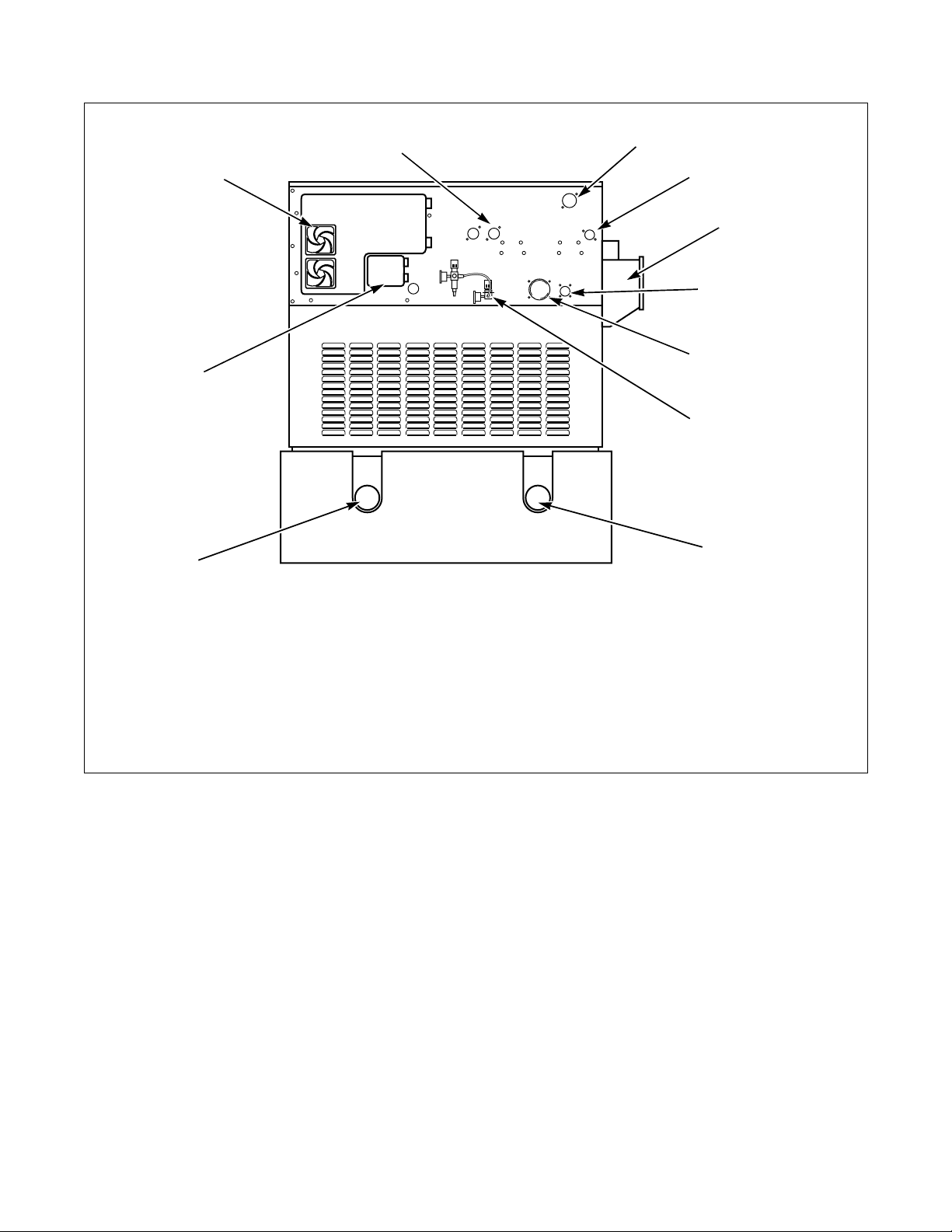

250-POUND CAPACITY REAR FAMILIARIZATION

1 Vent 7 Standard Drain

2 Hot Water Inlet 8 Optional Drain

3 Supply Dispenser 9 Power Connection

4 Steam Connection 10 Inverter Drive Cooling Fans

5 Vacuum Breaker 11 Cold Water Inlet

6 Air Inlet and Regulator

Figure 5

R079R

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Operation

Theory of Operation

The design of the washer-extractor emphasizes

performance reliability and long service life. The

cylinder, shell, and main body panels are fabricated of

stainless steel.

Electrical controls for the washer-extractor are housed

in separate enclosures. The front control module

houses the WE-6 computer, the fuse/relay board

together with its interface board, water level switches,

a circuit breaker which interrupts control voltage, and

other control components. The rear control module

houses the AC inverter drive and its components.

All variable-speed freestanding machines use the AC

inverter drive control, which provides programmable

motor speeds using a single motor. The AC drive

interface board converts motor logic from the WE-6

computer to the correct signals for the AC inverter

drive. In addition, all logic inputs to the computer are

routed through this board.

Two separate bearings support the cylinder on

135-pound and 250-pound models.

The cylinder is constructed with four lifters or ribs that

lift the laundry from the bath solution when the

cylinder rotates at slow speed and then allow the

laundry to tumble back into the bath. This mechanical

action accomplishes the washing function. The

cylinder is perforated, allowing the water to drain from

within during the wash and extract steps.

On 135-pound capacity models, water enters the

machine through electromechanical water valves. On

250-pound capacity models, water enters the machine

through pneumatic water valves on the rear of the

machine. (Pneumatic water valves are an option on

135-pound capacity models.)

Water valves on both washer-extractors are controlled

by the microcomputer. The microcomputer also

controls the drain and door lock. In addition, it selects

the water levels according to the programmed cycle.

Vacuum breakers are installed in the water-inlet

plumbing to prevent backflow of water.

Air-operated drain valves hold water in the machine

during the wash, soak, and rinse steps. The drain valve

is normally open, which means that it closes only

when air is applied, thus allowing the machine to drain

in the event of a power failure.

A door-lock system prevents opening of the stainless

steel door when a cycle is in progress. It also prevents

operation of the washer-extractor when the door is

open.

The doorbox contains the Hall-effect door-locked and

door-closed sensors and the door unlock solenoid.

The stainless steel supply dispenser is located on the

left side panel of the washer-extractor, viewed from

the front. The dispenser has five supply compartments,

numbered 1 – 5, starting from the rear of the machine.

The compartments hold supply cups that are used for

either liquid or dry supplies. A nozzle flushes supplies

from the cups with water for the time programmed in

the cycle.

Liquid supplies can be injected directly into the cups

by a customer-supplied external chemical supply

system. On 135-pound capacity models, five hose

barbs on the rear of the washer-extractor facilitate

connection to an external supply system. On

250-pound capacity models, five strain reliefs on top

of the supply dispenser provide the same connection

capability.

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Operation

Emergency Stop Button

On 135-pound capacity models, a red emergency stop

button is located on the upper right-hand corner of the

control panel. On 250-pound capacity models, the

emergency stop button is on the left side of the washerextractor front. Push the button in to stop the washerextractor. Pull out to reset.

Wet Clean Features

The washer-extractor is equipped with the following

wet clean capable features: One-half wash speed

allows gentle mechanical action during wash. Eight

supply signals provide not only normal laundering

signals to dispense detergents, bleaches, softeners,

sours, etc., but also chemicals unique to wet clean

processing.

Wet Clean Capabilities

Differences in WE6 prompt (setup) options

The WE6FRWC software provides the usual setup

options:

● Degrees F / C

● One or Two drain

● Advance / No Advance

● Manual / No Manual

● Balance setting

In addition, the software provides Wet Clean / No Wet

Clean. The Wet Clean / No Wet Clean option enables

or disables wet clean functions. The prompt (setup)

options are now as follows:

● CEN / FAR

● 1DRAIN / 2DRAIN

● ADV / NO ADV

● MANUAL / NO MAN

● WET CL / NO WCL

● BAL SW, BAL 1, BAL 2, BAL 3

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Operation

Wet Clean Functions

Wet clean functions include a reduced wash speed

capability and a recirculation pump capability. These

functions are enabled by the WET CL / NO WCL

prompt selection. Other wet clean features are

permanently enabled, and can be used for other

applications as well. In particular, extra supply

capability (up to eight supplies, in two banks of four

supplies), and additional agitation actions as outlined

below.

Agitations:

● wash 1 - normal: 18 seconds forward / three

seconds off / 18 seconds reverse / three seconds

off; repeat

● wash 2 - gentle: three seconds forward / 27

seconds off / three seconds reverse / 27 seconds

off; repeat

● wash 3 - no rotation

● wash 4 - ten seconds forward / 20 seconds off /

ten seconds reverse / 20 seconds off; repeat

● wash 5 - uses most recent agitation; defaults to

wash 1 agitation

● wash 6 - super gentle: four seconds forward / 56

seconds off / four seconds reverse / 56 seconds

off; repeat

● wash 7 - no rotation; drain 1 (sewer drain) open;

no attempt to refill to level

Using the auxiliary 1 (A1) and auxiliary 2 (A2)

outputs for wet cleaning

The A1 and A2 outputs (so labeled on the solid state

WE6 output PC board) can be made to operate as

timed outputs, or to remain on until a drain step.

Reduced wash speed

Normally, the A1 output would govern optional

reduced wash speed. This means that if the WE6 is

prompted for “WET CL”, and then an auxiliary 1 “A1”

step is programmed for any amount of time (one

second is a good choice for time in the event of

controlling reduced wash speed), the A1 output will

remain on until a drain step, or until stop routine.

Thereby the reduced wash speed remains in effect as

long as A1 remains on.

For example, with “WET CL” prompt selected, a wash

1 agitation is wanted, but at reduced wash speed.

Program auxiliary 1 step for one second, then program

a wash 1 step. The A1 output will remain on during the

wash 1 step, selecting reduced wash speed during the

wash 1 step. Upon reaching a drain step, or upon

entering the STOP routine, the WE6 will operate the

machine at reduced wash speed (PROVIDED the

machine is equipped with the necessary hardware for

controlling reduced wash speed).

Control of an optional recirculation pump

The A2 output will also remain on until a drain or the

STOP routine if the WE6 prompt is “WET CL” and if

“1DRAIN” is selected. This would allow control of an

optional recirculation pump by permitting the pump to

continue operating during a wash step. For this

control, program an auxiliary 2 “A2” step for one

second or other suitable time, and the output would

remain on until a drain step or until the STOP routine.

The auxiliary 2 step would also go off upon entering a

Wash 7 step.

Note that “2DRAIN” prompt will OVERRIDE wet

clean control of auxiliary 2 output. If “2DRAIN” is

selected that means that the auxillary2 output is

reserved for controlling a second independent drain

(not for integrated reuse - you should select

“1DRAIN” for integrated reuse). Also, if “2DRAIN”

is selected. the WE6 will not permit programming and

auxiliary 2 step.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Operation

WE-6 Microcomputer

The WE-6 microcomputer control is a fieldprogrammable solid-state control capable of storing

and running up to 39 preprogrammed ready-to-use

cycles.

Cycle 01 is a test cycle used to verify proper operation

of the machine. With the exception of Cycle 39, the

remaining cycles are complete wash cycles or

specialty cycles designed to handle various fabrics at

specific water temperatures and levels. Cycle 39 is

designed to test an external chemical injection supply

system.

A detailed description of the cycles can be found in the

Programming section of this manual under

Preprogrammed Cycles. (If this washer-extractor’s

computer has been equipped with special

preprogrammed cycles, a separate insert listing these

cycles has been included in the resealable plastic bag

which contained this manual.)

Never turn the power off while the Program Mode

switch is in the PROGRAM position. Such action will

disorder portions of the programmed data,

necessitating reprogramming of some or all of the

existing cycles. Always return the switch to RUN

position before turning the power off.

Never leave the mode switch key inserted in the switch

lock where it may be accessible to unauthorized

personnel not familiar with programming procedures.

The computer control in this washer-extractor is

continuously on the alert for problems within the

machine. When the computer detects a problem, it

immediately flashes a letter or number or both on the

display. It may activate the signal buzzer as well.

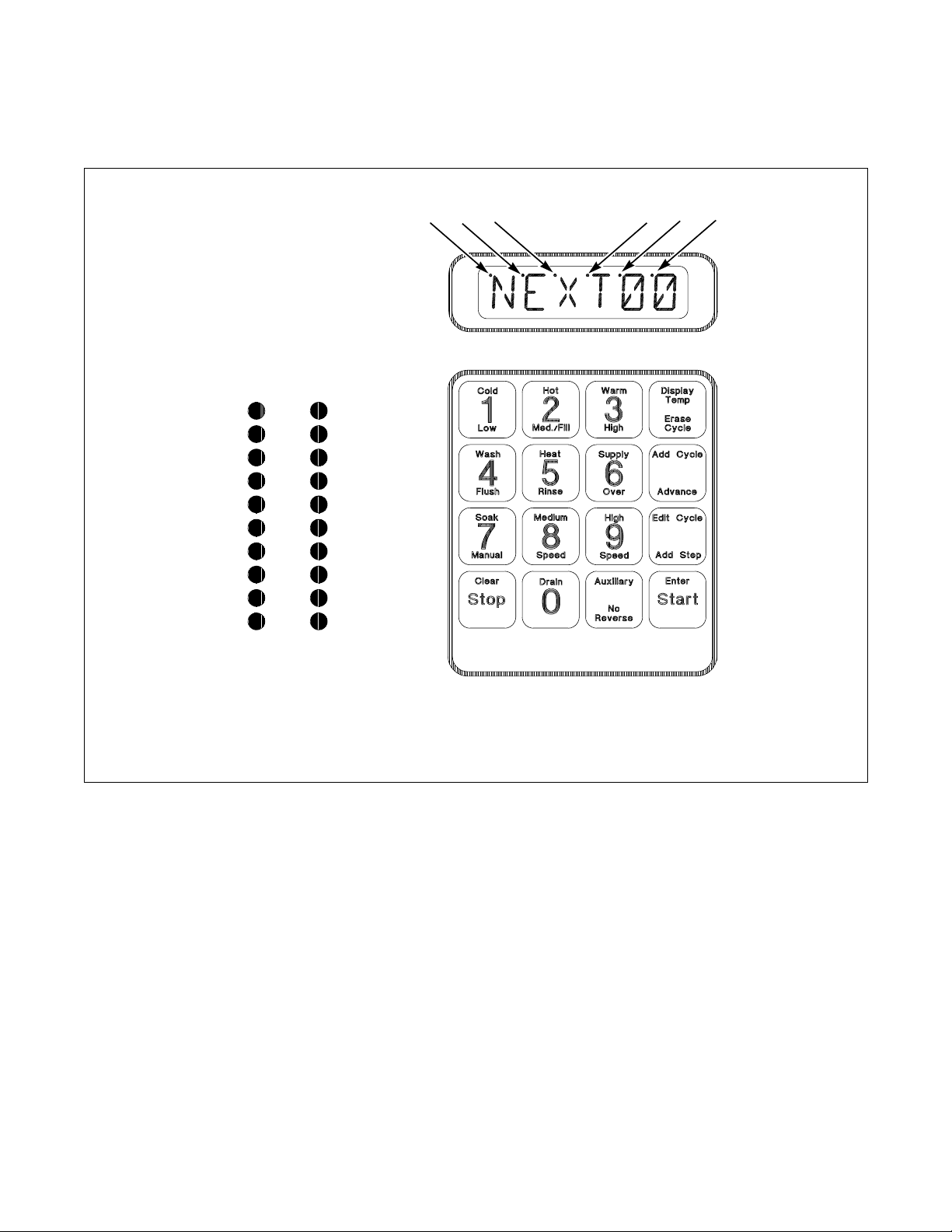

LED Display

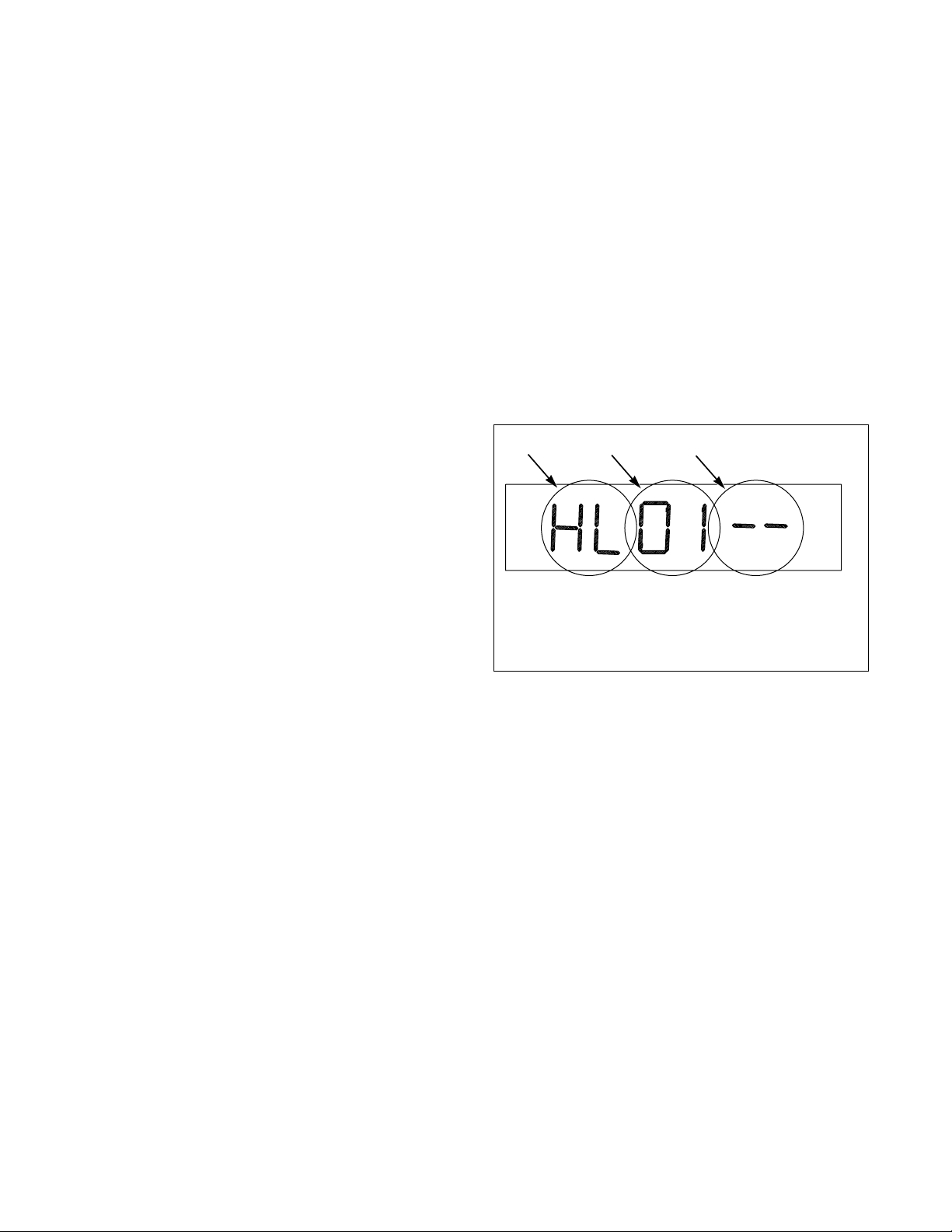

The WE-6 microcomputer has a six-digit LED display.

References to display indications pertain to the first

four digits of the display, reading left to right. The last

two digits on the right side of the display will indicate

either the last cycle used or the current cycle in

progress. Refer to Figure 6.

1

1 Function Being Executed

2 Step Number

3 Cycle Number

2

3

U151R

Figure 6

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Operation

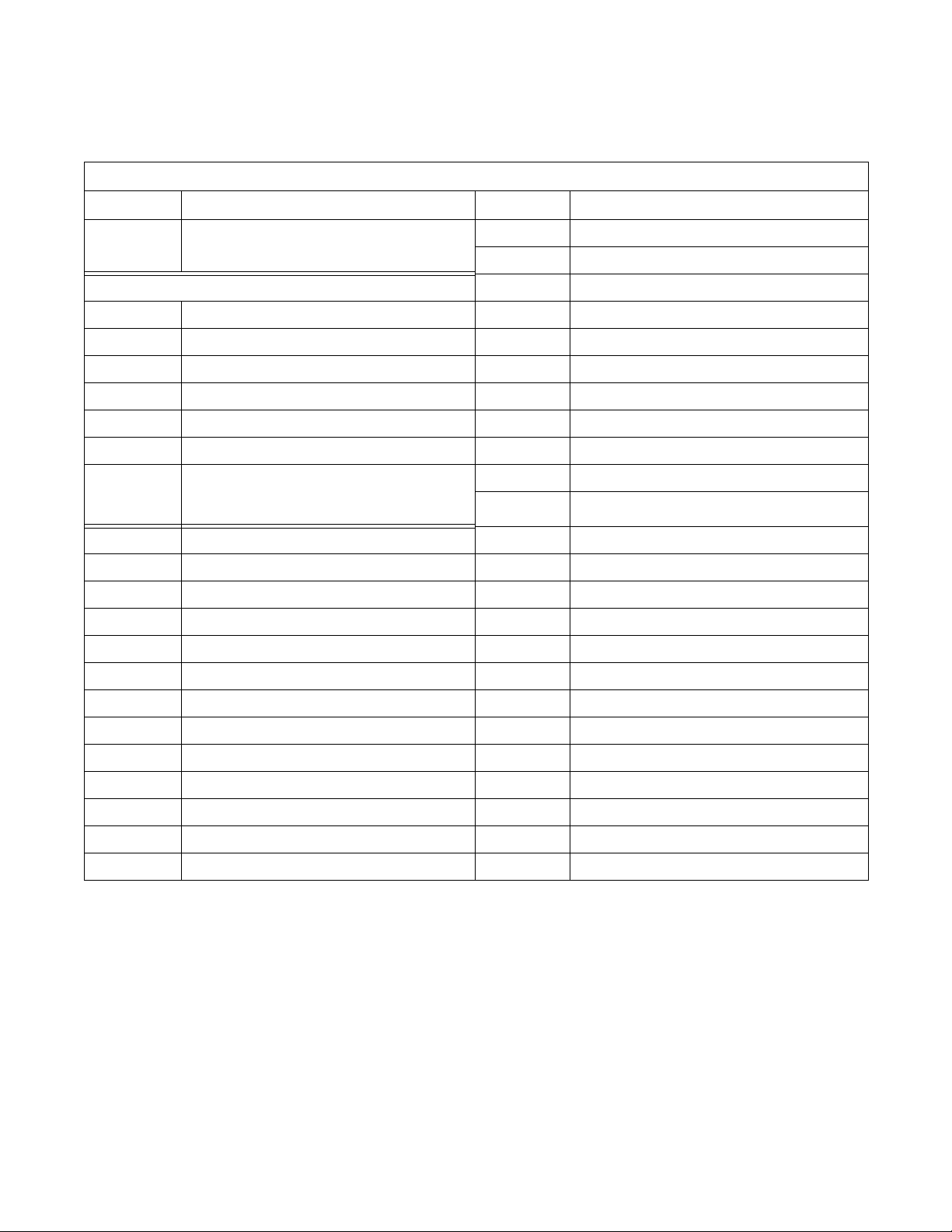

Table 1 lists the various displays and what they mean.

The operator should become familiar with these

computer displays.

Display Interpretations

Display Meaning Display Meaning

FRWC00 Program identification code (ROM).

The last digit represents version number.

CY Cycle number

D1 Drain #1

Error Messages Da Drain to optional reuse tank A

FILL Fill problem Db Drain to optional reuse tank B

EMTY Empty problem DONE End of cycle

TEMP

Over-temperature-limit condition

EXISTS Cycle already in memory

ME Cycle information problem EDIT? Do you want to edit the cycle?

WATER Water in washer-extractor at end of cycle F Heat select temperature in ° Fahrenheit

DOOR Door not locked problem C Heat select temperature in ° Centigrade

OVERHT

Open or shorted temperature input circuit or

temperature out of computer’s allowable

limits

HH Hot fill to high level

HL Hot fill to low level

aL Fill from reuse tank A to low level HM Hot fill to medium level

aM Fill from reuse tank A to medium level HO Hot fill to overflow

aH

Fill from reuse tank A to high level

HT Heat (steam or electric)

bL Fill from reuse tank B to low level H1 High speed #1

bM Fill from reuse tank B to medium level H2 High speed #2

bH Fill from reuse tank B to high level H3 High speed #3

A1 Auxiliary output #1 MS Medium speed spin

A2 Auxiliary output #2 --M Minutes (used when programming time)

A3 Signal --S Seconds (used when programming time)

CH Cold fill to high level NCYC Cycle not available

CM Cold fill to medium level NEXT Select cycle or open door or select program

CL Cold fill to low level SDLY Spin coast delay

CO Cold fill to overflow SK Soak

Table 1

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Operation

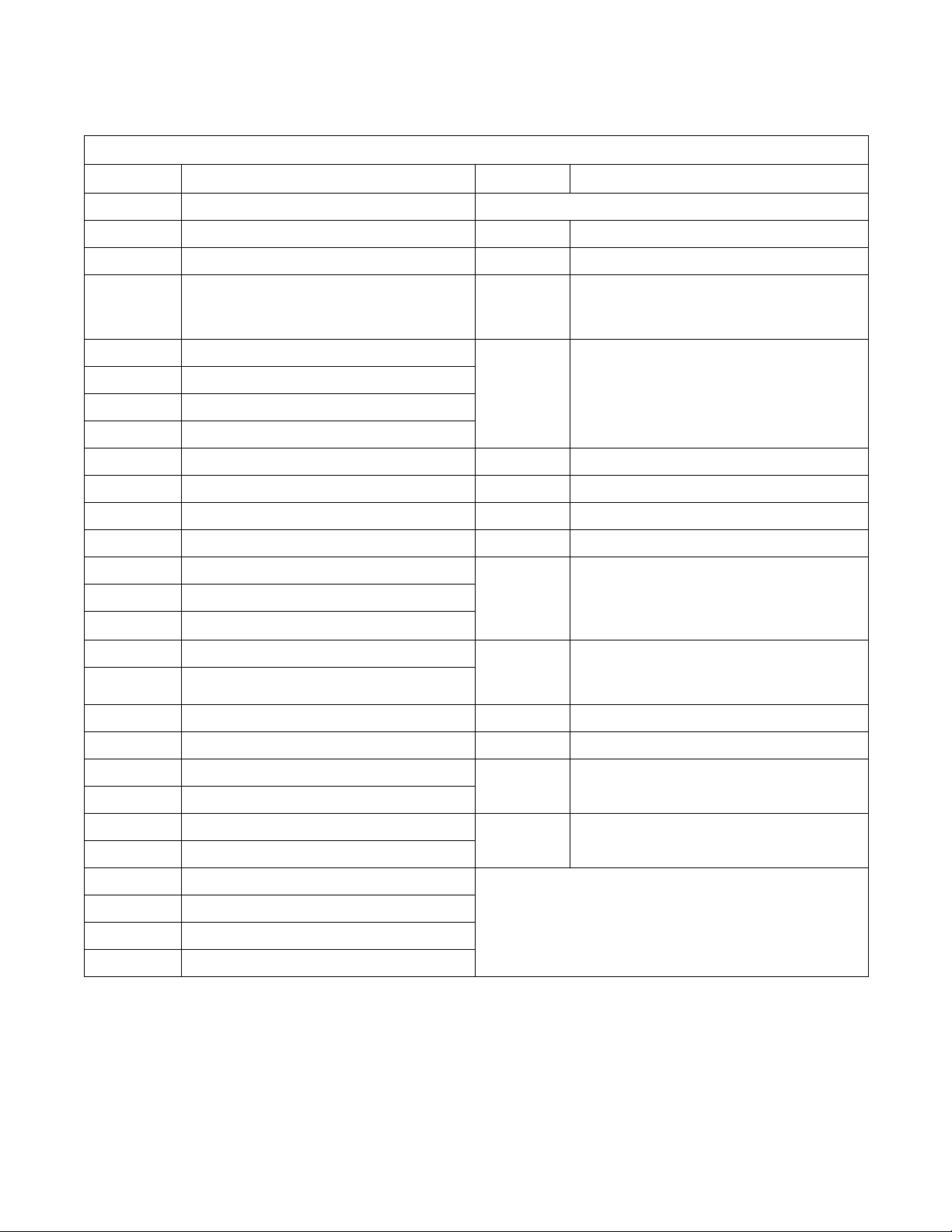

Table 1 (Continued)

Display Interpretations

Display Meaning Display Meaning

STOP Stop button pressed or cycle ended WE-6 Prompts

S1 Supply #1 (Detergent) °FAR Temperature in degrees Fahrenheit

S2 Supply #2 (Bleach) °CEN Temperature in degrees Centigrade

S3 Supply #3 (Sour) 1DRAIN One drain capability selected. (This means

that a second independent drain controlled by

Auxiliarry 2 output is disabled.)

S4 Supply #4 (Softener) 2DRAIN Second independent drain enabled (via

S5 Supply #5 (Starch/Sizing)

TH Controlled temperature fill to high level

TM Controlled temperature fill to medium level

Auxiliary 2 output – precludes control of

recirculation pump via Auxiliary 2, if

selected). This should not be confused with

the “dual drain” option.

TL Controlled temperature fill to low level ADV Advance (skip steps) feature enabled

TO Controlled temperature overflow NO ADV Advance feature disabled

WH Warm fill to high level MANUAL Manual Mode enabled

WM Warm fill to medium level NO MAN Manual Mode disabled

WL Warm fill to low level

WO Warm fill to overflow level

W1 Wash 1 (regular reversing)

WET CL

Wet clean function for Auxiliary 1 output

(1/2 wash speed) and Auxiliary 2 output

(recirculation pump) enabled. (Refer to

“2DRAIN”.)

W2 Wash 2 (gentle reversing) NO WCL Wet clean function for Auxiliary 1 and 2

W3 Wash 3 (no agitation)

disabled (Auxiliary 1 and 2 are timed

outputs).

W4 Wash 4 (medium reversing action) BAL SW Balance sensor

W5 Wash 5 (temp.-controlled cool-down) BAL 1 Balance routine for 1305 inverter drive

W6 Wash 6 (extra low agitation) BAL 2 Balance routine for 1336 inverter drive for

W7 Wash 7 (no agitation, drain 1 open, no refill)

135-pound capacity

• Left dot – poor balance condition BAL 3 Balance routine for 1336 inverter drive for

• Second dot from left – door lock switch

250-pound capacity

• Third dot from left – Program Mode

• Fourth dot from left – high level reached

• Fifth dot from left – medium level reached

• Right dot – low level reached

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Operation

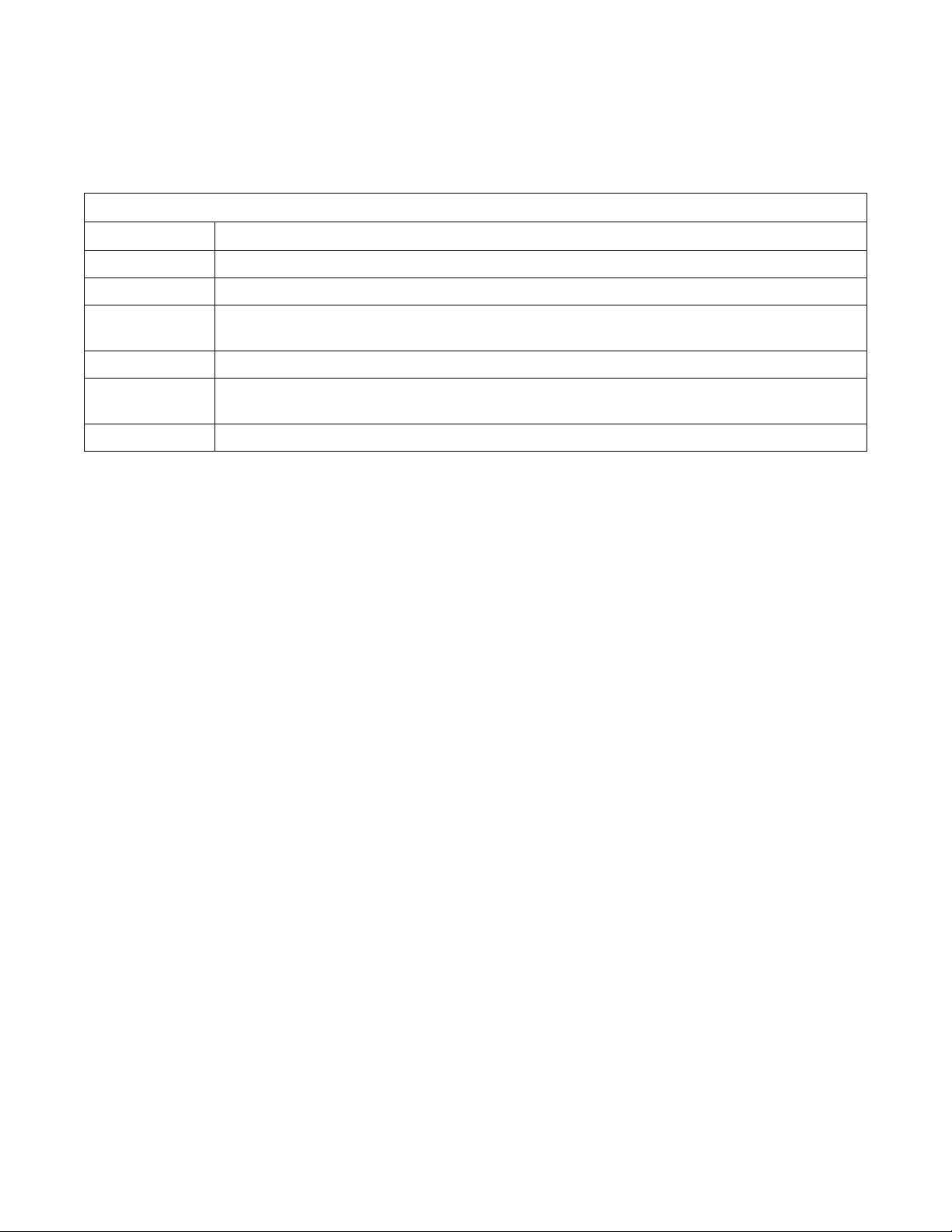

Operational Keypad

These functions are available to the operator and are

intended to control operation of the washer-extractor.

The computer’s control keypad includes sixteen keys.

Refer to Ta b le 2.

Refer to Figure 7. Fourteen of these keys list functions

printed in black lettering on a silver background.

Operational Keypad

Key Description

Numbers 0 – 9 Press to select cycle number

Display Temp Press and hold. Display will show and update sump temperature in degrees Fahrenheit or Centigrade.

Advance Press to cause computer to skip to the next step in the cycle. The computer will not advance past drain

step. (The Advance key is enabled at the factory and can be disabled at the laundry site.)

Stop Press to immediately abort the cycle and initiate the Stop routine

Start Press to start selected cycle or to re-start a step following a “FILL” or “EMTY” alarm. Refer to Error

Recovery Routine in this section of the manual.

Manual Refer to Manual Mode Control Feature at the end of this section.

Tab l e 2

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Operation

Located to the left of the computer keypad are 20 LED

indicator lights for the computer outputs. During the

time that a cycle is running, one or more of these lights

1

Output Indicators

Supply 1

Supply 2

Supply 3

Supply 4

Supply 5

Cold Fill

Hot Fill

Spare

Spare

Signal

Heat

Forward

Reverse

Dist. Speed

Med. Speed

High Speed

Unlock Door

Drain Closed

Auxiliary 1

Auxiliary 2

will be on to indicate the outputs activated for a

particular step. Refer to Figure 7.

3

2

4

6

5

1 Balance Sensing Indicator 4 High Level Fill Indicator

2 Door Lock Switch 5 Medium Level Fill Indicator

3 Program Mode 6 Low Level Fill Indicator

Figure 7

U152R

U152R

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Operation

Start-Up

Turn on the main power source (circuit breaker or cutoff switch on the wall).

When AC power is turned on, the front panel display

will show the program (ROM) identification code.

This identification code will appear for approximately

five seconds. Then the computer display will flash

“POWER” and “WA I T ” alternately for two minutes.

The display will then show “NEXT00” to indicate that

a cycle can be selected. This display will be shown at

all times that power is on between cycles, indicating

that the door-unlock solenoid will function if the doorunlock button is pressed. The washer-extractor is then

ready for loading and unloading.

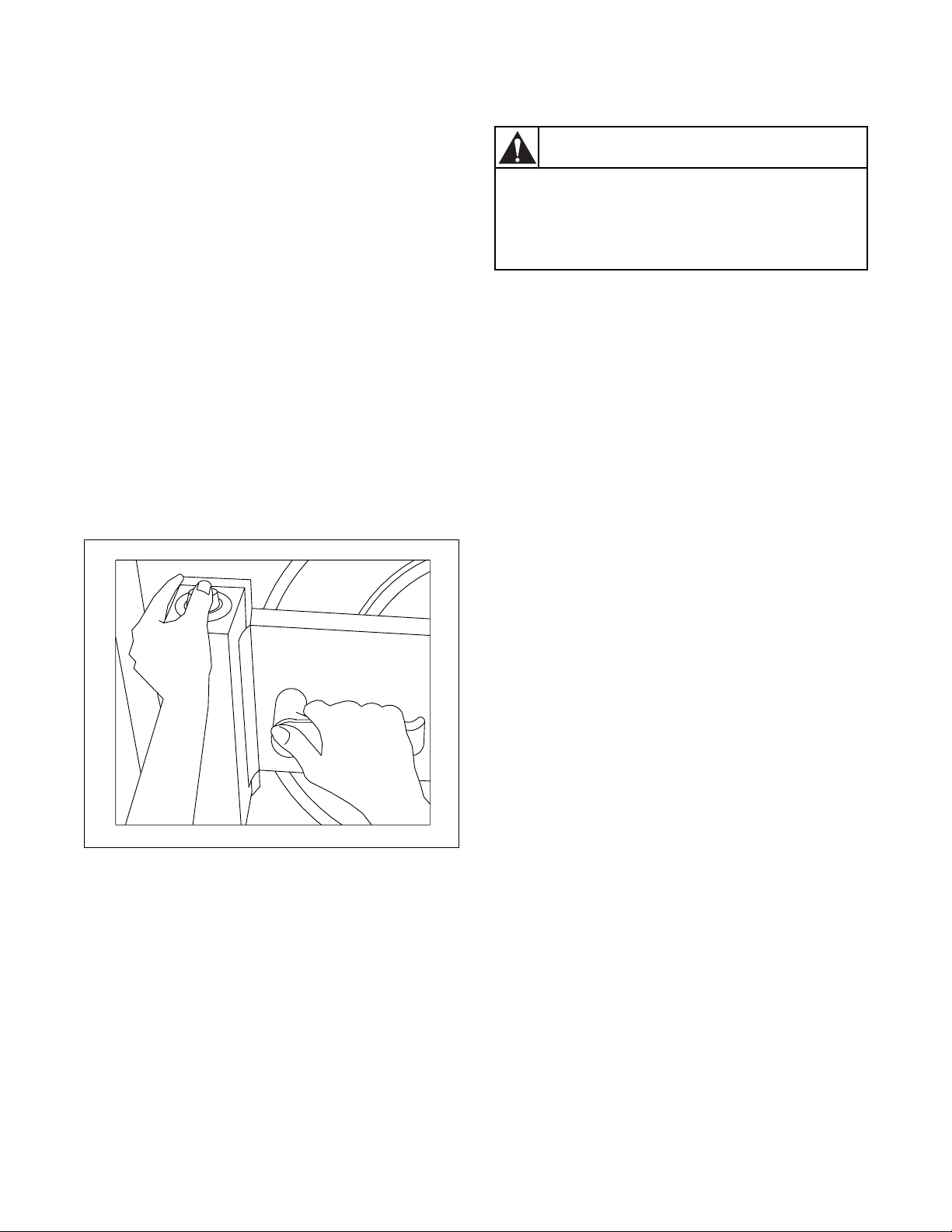

Opening Door

Use left hand to press and hold the door unlock button

located on the top of the doorbox cover. Use right hand

to turn door handle upward and swing the door right to

open. Refer to Figure 8.

Loading and Unloading

CAUTION

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

Load the washer-extractor to full capacity whenever

possible, but do not exceed the rated dry-weight

capacity of the machine if the fabric to be washed is

quite dense, closely woven, and heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine load

size based on fabric content, soil content, and level of

cleanliness required.

When loading is complete, ensure that all fabric is

inside the basket. Then close and lock the door.

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

Figure 8

U153R

Tilt Option

Cabinet freestanding 250-pound capacity washerextractors equipped with the tilt option offer the

operator more convenient loading and unloading.

Forward tilt and two-way tilt are available on

250-pound capacity models.

The tilt mechanism operates independently of the

WE-6 microcomputer. Mechanical interlocks are in

place, however, which do not permit operation of the

washer-extractor while the tilt mechanism is raised,

and vice versa.

U153R

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Operation

ENABLE

FORWARD

REVERSE

U150R3

2

3

1

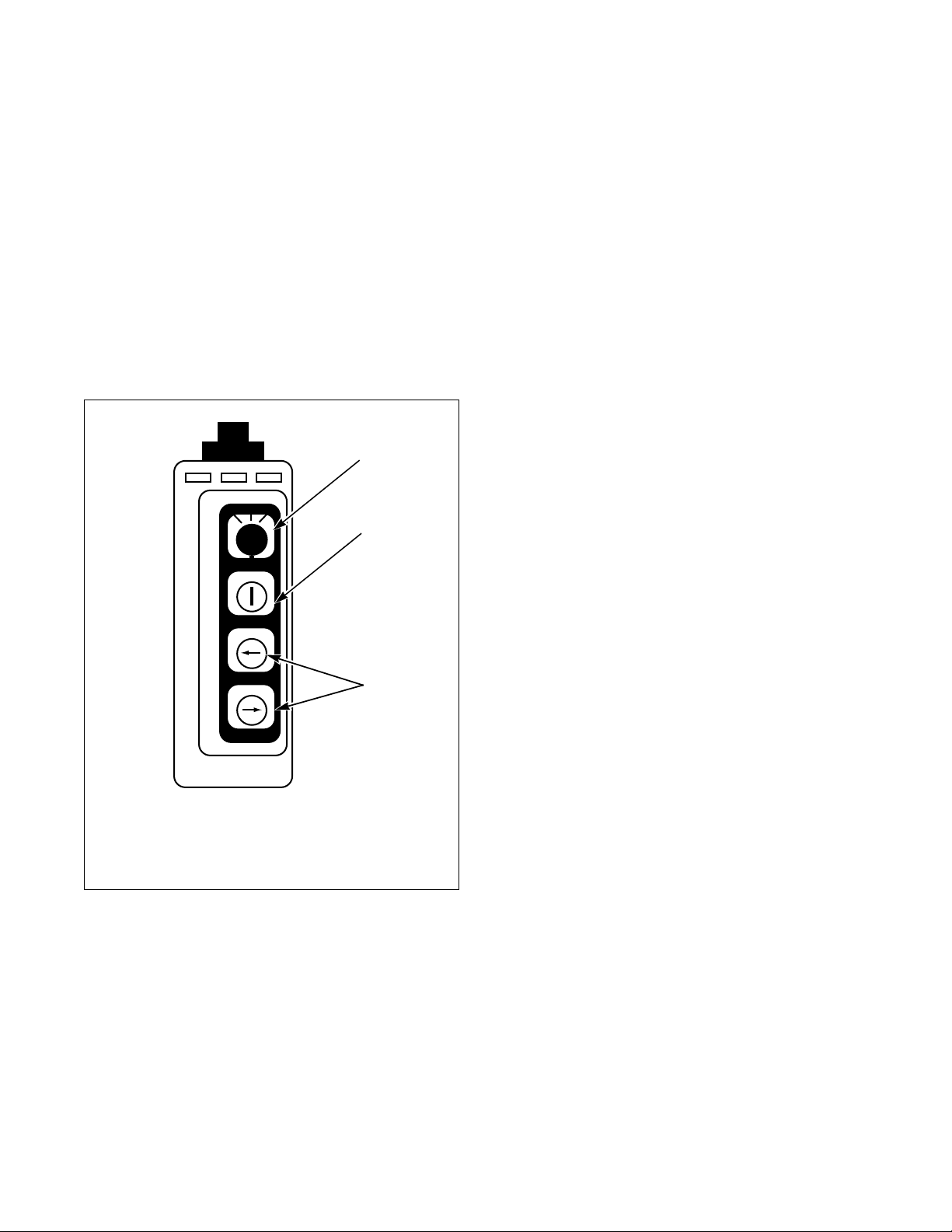

The mechanism is controlled via a pendant switch

(refer to Figure 9), which is suspended from a point

just above the electrical panel on the left side of the

washer-extractor. Access height has been determined

based upon an average-sized person.

The tilt mechanism is pneumatically operated. Airstroke actuators raise and lower the machine when the

tilt is selected. On two-way tilt mechanisms,

pneumatic pins positioned at strategic points along the

mechanism frame allow it to achieve both forward and

reverse tilt. When reverse tilt is selected, pins in the

rear of the mechanism engage and prevent the rear of

the machine from being raised. When forward tilt is

selected, pins in the front of the mechanism prevent

the front of the machine from being raised.

NOTE: When the washer-extractor/tilt mechanism

assembly is lowered, it must properly seat itself in

order to be operable. Improper seating will result

in total inoperability of the WE-6 microcomputer,

in which case it will be necessary to raise and lower

the assembly again. Further, once the assembly is

raised, it must be lowered and properly seated

before it can be raised again.

Forward Tilt Option

Washer-extractors equipped with the forward tilt

option are capable of tilting as much as 13° forward.

Upon completion of a cycle, the basket can be

unloaded as follows:

1. Open the loading door and secure it to the door

latch on the right side of the washer-extractor.

2. Turn the selector dial on the pendant switch right

to the forward tilt position. Refer to Figure 9.

3. While holding down the green ENABLE button,

press the black FORWARD button. Refer to

Figure 9. The washer-extractor will slowly tilt

forward, and the basket will rotate clockwise.

4. Unload the washer-extractor.

5. To lower the washer-extractor, turn the selector

dial back to the center position. Refer to Figure 9.

6. Unlatch and close loading door.

U150R

1 Selector Dial

2 Green Button

3 Black Buttons

Figure 9

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Operation

On cabinet freestanding models with tilt

option, the loading door must be securely

latched in the open position before the

machine is tilted. A freely swinging door

could cause personal injury.

SW040

CAUTION

Two-Way Tilt Option

Washer-extractors equipped with the two-way tilt

option are capable of tilting as much as 13° forward or

backward.

The forward tilt is used primarily for unloading. The

reverse tilt is used for loading the washer-extractor.

To load the washer-extractor, follow this procedure:

1. Open the loading door and secure it to the door

latch on the right side of the washer-extractor.

2. Turn the selector dial on the pendant switch left

to the reverse tilt position. Refer to Figure 9.

3. While holding down the green ENABLE button,

press the black REVERSE button. Refer to

Figure 9. The washer-extractor will slowly tilt

backward and the basket will rotate

counterclockwise.

4. Load the washer-extractor.

5. To lower the washer-extractor, turn the selector

back to the center position. Refer to Figure 9.

6. Unlatch and close loading door.

Upon completion of a cycle, the basket can be

unloaded as follows:

1. Open the loading door and secure it to the door

latch on the right side of the washer-extractor.

Two-Way Tilt Inductive Proximity Sensor

Adjustment

The Programmable Logic Controller (PLC) uses four

inductive proximity sensors on the two-way tilt

platform to detect the position of the frame and

prevent unsafe operation. These sensors MUST be in

place and operational.

Front Down and Rear Down Sensor

Adjustment

The front down sensor is located next to the front left

lock cylinder mounted on the lower (floor) frame. The

rear down sensor is located next to the rear left lock

cylinder mounted on the lower (floor) frame. Adjust

these two sensors so that the plastic face is 4 to 6 mm

from the edge of the upper channel when fully seated

on the lower frame. The sensor LED should be on

when the frame is fully seated and should turn off

before the machine has lifted more than 3/4 in. out of

the associated pivot point.

Seated Sensor Adjustment

Adjust the seated sensor so that the plastic face is 4 to

6 mm from the edge of the upper channel when the

frame is fully seated. The sensor LED should be on

when the frame is fully seated and should turn off

before the upper channel edge has lifted more than

1/2 in. at the sensor face.

Up Sensor Adjustment

2. Turn the selector dial on the pendant switch right

to the forward tilt position. Refer to Figure 9.

3. While holding down the green ENABLE button,

press the black FORWARD button. Refer to

Figure 9. The washer-extractor will slowly tilt

forward, and the basket will rotate clockwise.

4. Unload the washer-extractor.

5. To lower the washer-extractor, turn the selector

dial back to the center position. Refer to Figure 9.

6. Unlatch and close loading door.

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Adjust this sensor so that it is on when the washerextractor is fully tilted in either direction and off when

the washer-extractor is seated or in transition from one

position to another. This adjustment will vary

somewhat from machine to machine because it is

impossible to seat the washer-extractor on the tilt

frame in exactly the same relative position every time.

F232101

Operation

Supply Dispenser

Dry supplies are placed in the supply dispenser

compartment cups prior to the start of each cycle.

Liquid supplies can be injected directly into the supply

dispenser by an external chemical supply system.

NOTE: Supply dispenser compartment cups must

not be removed when an external chemical

injection supply system is attached to the washerextractor.

Cycle Selection

NOTE: Press keys at their centers just hard enough

to activate them.

Find the cycle number of the desired wash cycle from

the Stardard Cycle Charts in the Programming

section of this manual. Cycle numbers must be twodigit numbers from 01 to 39.

Press the numbers desired on the keyboard and note

that these numbers are displayed after “NEXT”.

When keys are pressed on the keyboard, a beep will be

heard. If an error is made, press the numbers again. As

numbers are entered, they move from right to left on

the display.

NOTE: If the 135-pound capacity washer-extractor

is equipped with both steam and electric heat, the

selector switch on the valve panel must be in the

correct position for the desired heat source, down

for steam heat, up for electric heat. (Electric heat is

not available on the 250-pound capacity model.)

Cycle Execution

To start the selected cycle, press the Start key. If the

selected cycle number is not in the computer memory,

the display will show “NCYC”. If this happens, select

another cycle. Otherwise, the display will now show

the first step. For example, if the display reads

“HL01”, “HL” represents a hot fill to low level, and

“01” indicates that this is the first step of the cycle.

To begin the cycle at any step other than the first step,

press the Advance key to advance through the cycle to

the desired starting point. (The Advance key is enabled

at the factory and can be disabled at the laundry site.)

Then press the Start key.

NOTE: Computer will not start in a spin step. It

should be started in the drain step just prior to the

spin.

It is possible to skip to the next step in a cycle, with the

exception of a drain step: Drain steps must be allowed

time to complete.

When the display shows the step desired to begin the

cycle, press the Start key.

If the door is not locked, the display will indicate

“CLOSE” and “DOOR”. If this occurs, be sure the

door is closed and locked and press the Start key again.

If the LED indicator lights for the computer outputs

indicate that one or more outputs are activated but the

washer-extractor is not functioning according to the

output or outputs indicated, contact a service

technician.

As water fills the washer-extractor, one or more of the

indicator lights located to the left of the keyboard will

come on and stay on until the required water level is

reached. LED dots located in the upper left corner of

the last three digits on the right of the display will

illuminate to indicate the water level(s) reached:

● When the indicator dot in the last digit on the

right is lit, the low water level has been reached.

● When the dot in the next-to-the-last digit is lit,

medium water level (optional) has been reached.

● When the dot over the third digit from the right

has been lit, high level has been reached.

The cycle will continue until its completion. Then the

display will show “DONE”.

As the cycle proceeds, the display will show the

function being executed, the step number, and the

cycle number selected. Pressing the Edit Cycle key

while the cycle is running will cause the display to

show the remaining cycle time in minutes. Pressing

this key again will return the display to normal.

F232101

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Operation

Test Cycle

Cycle number 01 is a test cycle used to analyze

washer-extractor functions. Refer to the Programming

section of this manual.

Step 01 in cycle number 01 is a cold fill to low level.

This step is designed to give not quite enough time to

complete a fill, causing the display to read “FILL”.

Press the Start key to continue the fill, and the test

cycle will proceed.

Step 02 in the test cycle is a drain step. Again, the time

allotted is shorter than it would be in a normal cycle.

The display will read “EMTY”. To proceed, press the

Start key.

The steps in the test cycle are relatively short, with the

exception of steps 03, 21, 25, 27, 28, and 29. These

can be shortened by pressing the Advance key to go on

to the next step.

The operator may skip to any next step in the cycle

with the exception of a drain step; drain steps must be

allowed to complete. To skip forward in the test cycle,

press the Advance key.

Wet Clean Testing

Wet clean processing outputs are tested through the

energizing of the Auxiliary 1 output in step 18 and

Auxiliary 2 output in step 19. Steps 30 through 33 are

designed to test water reuse processing, if this option

is installed. If it is not, the outputs associated with

each step will be energized, and the cycle will

conclude normally.

NOTE: Prompts for “1DRAIN” and “WET CL”

must be selected when prompting the WE-6

microcomputer in order for steps 18 and 19 to

work properly for wet clean processing.

NOTE: The Advance feature may be disabled.

Refer to Prompting the WE-6 in the Programming

section of the manual.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232101

Loading...

Loading...