Alliance Laundry Systems HF25VCV, SF18VCV, UF18PC, HF18VCV, UF25PCV User Manual

Washer-Extractor

Cabinet Freestanding

Variable-Speed

Instructions for Operating and

Programming the V-Series

Microcomputer

Model Numbers

HF18VCV SF18VCV UF18PCV

HF25VCV SF25VCV UF25PCV

Operation/Programming

NOTA: El manual en

español aparece

des pués del manu al en

inglés.

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

Part No. F232061

September 1999

R2

Table of Contents

Operation/Programming

Safety

Key to Symbols ................................................ 4

Operator Safety ................................................ 5

Safe Operating Environment ............................ 6

Environmental Conditions ............................ 6

Machine Location ......................................... 7

Input and Output Service s ..... ....................... 7

AC Inverter Driv e ..... .. ... .......... .. .. .......... ... .. .. 8

Misuse .............................................................. 8

Operation

Customer Service ............................................. 9

Machine Familiarizati o n G u id es.............. .. ....... 9

Theory of Operation ......................................... 12

V-Co mputer .. .......... ....... .......... ......... .......... .. 12

Keypa d ... .... ..... ... ..... .... ..... ..... ... .... ..... ..... ..... .. 1 3

Conditions Monitored by the Computer ....... 14

Display Indications ....................................... 15

Start-U p ......... ............. ............ ............ ............ .. 16

Openi ng D oo r ............... .. ... .......... .. .. .......... ... .. .. 16

Loadin g ..... ......... ... .. .......... .. .......... .. ... .......... .. .. 16

Supply Dispenser ............................................. 16

Cycle Selection ................................................ 17

Cycle Execution ............................................... 17

Programming

Key Functions in Programm ing Mode ............ 21

Setup Mode ...................................................... 21

Degrees Displayed in Fahrenheit or

Celsius ...................................................... 22

Auxiliary Heat .............................................. 22

Setting Display to Flash “PAY” and a

Start Amount............................................. 22

Programming Start Price............................... 22

Coin 1 Denomination .................................... 23

Coin 2 Denomination .................................... 23

Cycle Count ..................................................... 23

Cycle Programming ......................................... 23

Segment Programming ................................. 23

Test Cycle......................................................... 25

Cycle Segment Charts ..................................... 27

V-Computer Standard Coin Cycles .................. 30

Fill .. ... .. .......... .. .......... .. ... .......... .. .. .......... ... .. .. 17

Wash .................. .. ... ......... ... .. .......... .. .......... .. 1 8

Drain .......... ... .......... .. .. .......... ... .. .......... .. ... .... 18

Spin ........ ....... ....... ....... ..... ........ ....... ....... ....... 1 8

Stop Routine ................................................. 19

Balance Detection ............................................ 19

Over tr av e l Li mit Switch ........ .......... .. .......... .. 1 9

Test Cyc l e ...... .......... ... .. .......... .. ... ......... ... ......... 19

F232061

1

© Copyright 1999 Alli ance Laundry Syst em s LLC

All rights reser ved. No part of this book ma y be reproduced or transmitted in any form or by any means wit hout the written

permission of the publisher .

2

F232061

Section 1

Death or serious injury can resu lt if children

become trapped in the ma c hine. Do not

allow childre n t o play o n or around this

machine. Do not leave children unattended

while the machine door is open.

SW001

DANGE R

This mach ine must be installed, adjuste d,

and serviced by qualif ied electrica l

maintena nc e personnel familiar with the

construc t ion and operation of this type o f

machine ry. They mu s t al s o be familiar with

the potential hazards involved. Failure to

observe th is warning may resu lt in personal

injury and/or equipment dama ge, a nd may

void the warranty.

SW004

WARNING

Safety

Anyone operating or servicing this machine

must follow the safety rules in this manual.

Particular attention must be paid to the

DANGER, WARNING

, and

CAUTION

blocks which appear throughout the manual.

CAUTION

Be carefu l around the open door,

par ticularly wh en loading from a level

below the doo r. Impact wi th door edges

can cause personal injury.

SW025

WARNING

Dangerous voltages are p res ent in the

electrical control box(es ) and at the motor

termin als. Only qualifi ed personnel familia r

with electrical te st procedures, test

equipment, and safety precautions shou ld

attempt ad justments and troubleshoot ing.

Disconnec t pow er f rom the mach ine before

removing the c ontrol box cover, and before

attemptin g any servic e procedures.

SW005

The following warnings are general examples

that apply to this machine. Warnings specific

to a particular operation will appear in the

manual with the discussion of that oper ation.

F232061

3

Safety

CAUTION

Ensure th at th e m ac hine is installed on a

level floor of sufficient s t rength and that the

recommended clearances for inspection

and maint enance are prov ided. Never allow

the inspect ion and maint enance space to

be blocked.

SW020

Key To Symbols

The lightning flash and arrowhead within the

triangle is a warning sign indica ting the

presence of dangerous voltage.

WARNING

Never touch internal or exter nal steam

pipes, connections, or components. These

surfaces can be extremely hot and will

cause severe burn s. Th e s t eam must be

turned off and the pipe, co nnections, and

compone nt s allow ed to cool before the pipe

can be touched.

SW014

This warning symbol indicates the presence of

possibly dangerous chemicals. Proper

precautions should be taken when handling

corrosive or caustic materi als.

The exclamation point within the triangle is a

warning sign indicating important instructions

concerning the machine and possibly

dangerous conditions.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms

within the machine. Guards should always be

in place when the machine is in operation.

4

This warning symbol indicates the presence of

hot surfaces that could cause serious burns.

Stainless steel and steam lines can become

extremely hot and should not be touched.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving

mechanical parts can crush and/or sever

body parts.

F232061

Safety

Never operate the machine with a bypassed

or disconnected b alance system. Operating

the machine with severe out-of-balance

loads cou ld result in personal injury and

serious equipment da m age.

SW039

WARNING

To provide personal safety and keep the

machine in proper working or der, follow all

maintenance and safety procedures presented in

this manual. If questions reg arding sa fety ari se,

contact the factory immediately.

Use factory-authorized spare parts to avoid

safety hazards.

Operator Safety

WARNING

NEVER in s ert hands or objects into basket

until it has co m pletely stopp ed. Doing so

could resu lt in s erious injury.

SW012

To ensure the safety of machine operators, the

following maintenance checks must be

performed daily:

If the door lock and interlock are

not functioning properly, call a

service technician.

3. Do not attempt to ope rate the machine if

any of the following conditions are present:

a. The door does not remain securely

locked during the entire cycle.

b. E xcessively high water level

is evident.

c. Machine is not connected to a

properly grounded circuit.

Do not bypass any safety devices in

the machine.

1. Prior to operating the machine, verify that

all warning signs are present and legible.

Missing or illegible signs must be replaced

immediately. Make certain that spares

are available.

2. Check door interlock before starting

operation of the machine:

a. Attempt to start the machine

with the door open. The machine should

not start with the door open.

b. Cl ose the door without locking it and

attempt to start the machine. The

machine should not start with the

door unlocked.

c. Close and lock the door and start a

cycle. Attempt to open the door while

the cycle is in progress. The door

should not open.

F232061

5

Safety

Do not place volatile or flammable fluids

in any machine. D o not clean the m ac hine

with volatile or flammable fluids s uc h as

acetone, lacquer thinners, enamel reducers,

carbon tetrachloride, gasoline, benzene,

naptha, etc. Doing so could result in serious

personal injury and/or damage t o

the machine.

SW002

DANGER

Safe Operating Environment

Safe operation requires an appropriate

operating environment for both the operator

and the machine. If questions regarding safety

arise, contact the factory immediately.

V entilation

•

. The need for make-up air

openings for such laundry room

accessories as dryers, ironers, water

heaters, etc., must be evaluated

periodically. Louvers, screens, or other

separating devices may r educe the

available air opening significantly.

Environmental Conditions

Ambient Temperatur e

•

. Water in the

machine will freeze at temperatures

of 32° F or below.

Temperatures above 120° F (50° C) will

result in more frequent motor ove rhea ting

and, in some cases, malfunction or

premature damage to solid state devices

that are used in some models. Special

cooling devices may be necessary.

Water pressure switches are affected by

increases and decrease s in temperat ure .

Every 25° F (10° C) change in temperature

will have a 1% effect on the water level.

Humidity

•

. Relative humidity above 90%

may cause the machine’s electronics or

motors to malfunction or may trip the

ground fault interrupter. Corrosion

problems may occur on some metal

components in the machine.

Radio Frequency Emissions

•

. A filter is

availa ble for mac hines in installations

where floor space is shared with

equipment sensitive to radio

frequency emissions.

Elevation

•

. If the machine is to be operated

at elevations of over 3,280 feet (1,000

meters) above sea level, pay special

attention to water levels and electronic

settings (particularly temperature ) or

desired results may not be achieved.

Chemicals

•

. Ke ep stainless steel surfaces

free of chemical residues.

If the relative humidity is below 30%,

belts and rubber hoses may eventually

develop dry r ot. This condition can result

in hose leaks, which may cause safety

hazards external to the machine in

conjunction with adjacent electrical

equipment.

6

Water Dama ge

•

. Do not spray the machine

with water. Short circuiting and serious

damage may result. Repair immediately all

seepage due to faulty gaskets, etc.

F232061

Safety

Safe Operating Environment

(Continued)

Machine Location

Foundation

•

sufficient strength and thickness to handle

the floor loads generated by the high

extract speeds of the machine.

Ser v ic e/ M aintenanc e Space

•

sufficient space to allow comfortable

performance of service procedures and

routine preventive maintenance.

This is especially important in connection

with machines equipped with an AC

inverter drive.

Consult installation instructions for

specific details.

. The concrete floor must be of

. Provide

(6.7 bar) may result in damage to m achine

plumbing. Component failure(s) and

personal injury could result.

Steam Heat (Optiona l) Pressure

•

. Best

performance will be realized if steam is

provided at a pressure of 30–80 psi

(2.0–5.4 bar). Steam pressure higher than

125 psi (8.5 bar) may result in damage

to steam components and may cause

personal injury.

For machines equipped with optional

steam heat, install piping in accordance

with approved commerc ial steam

practices. Failure to install the s upplied

steam filter may void the war ranty.

Compressed Air

•

. For machines requiring

compressed air service, best performance

will be realized if air is provided at a

pressure of 80–100 psi (5.4–6.7 bar).

CAUTION

Replace a ll panels that are removed to

perform service an d m aintenance

procedures. Do not opera te th e m ac hine

with missing gua rds or with broken or

missing parts. Do not bypass any

safety devices.

SW019

Input and Output Services

Water Pressure

•

realized if water is provided at a pressure

of 30–85 psi (2.0–5.7 bar). Although the

machine will function properly at lower

pressure, increased fill times will occur.

Water pressure higher than 100 psi

. Best performance will be

Drainage System

•

. Provide drain lines or

troughs large enough to accommodate the

total number of gallons that could be

dumped if all machines on the site

drained at the same time fr om the highest

attainable level. If drain troughs are used,

they should be covered to support light

foot traffic.

Power

•

. For personal safety and for proper

operation, the machine must be grounded

in accordance with state and local codes.

The ground connection must be to a

proven earth ground, not to conduit or

water pipes. Do not use fuses in place of

the circuit breaker. An easy-access cutoff

switch should be provided.

F232061

7

Safety

WARNING

Ensure that a ground wire from a proven

earth ground is connected to the ground lug

near the input power block on this machine.

Without proper ground ing, personal injury

from electric shock could occur and machine

malfunctions may be evident.

SW008

Always disconnect power and water supplies

before a service technician performs any

service procedure. Where applicable, steam

and/or compressed air supplies should also be

disconnected before service is performed.

AC Inverter Drive

Machines equipped with the AC inverter driv e

require special attention with regard to the

operating environment.

• An especially dusty or linty environment

will require more frequent cleaning of the

AC inverter drive cooling fan f ilte r and of

the AC inverter drive itself.

• Power line fluctuations from sources such

as uninterruptible power supplies (UPS)

can adversely affect machines equipped

with the AC in verter drive. Proper

suppression devices should be utilized on

the incoming power to the machine to

avoid problems.

If voltage is above 230V for 200V

installations or above 440V f or 400V

installations, a buckboost transformer is

recommended. If voltage is above 240 or

480, a buckboost transformer is required.

• Sufficient space to perform service

procedures and routine preventive

maintenance is especially important for

machines equipped with the AC

inverter drive.

Misuse

Never use this machine for any purpose other

than washing fabric.

• Never wa sh petroleu m- soaked rags in the

machine. This could result in an explosion.

• Never wash machine parts or automotive

parts in the mac hine. This could result in

serious damage to the basket.

• Never allo w children to play on or around

this machine. Death or serious injury can

result if children become trapped in the

machine. Do not leave children unattended

while the machine door is open. Th es e

cautions apply to animals as well.

• A clean power supply free from voltage

spikes and surges is absolutely essential for

machines equipped with the AC inverter

drive. Nonlinear inconsistencies (peaks and

valleys) in the power supply can cause

the AC inverter drive to generate

nuisance errors.

8

F232061

Section 2

Operation

This manual is designed as a guide to

operating and programming the 18-pound

and 25-pound capacity cabinet freestanding

washer-extractors equipped with the

V-computer and AC inv erter driv e. The

models covered by this manual are designed

for use in coin laundries.

The manuals, installation instructions, and

wiring diagrams which accompany the

machine have been included with the machine

at no charge. Additional copies are available at

a nominal charge.

Note:

attempting to operate the machine or program

the microcomputer.

Note:

with earlier model computer-controlle d

machines. Do not use technical literature

intended for earlier models when operating

this machine.

Read this manual thoroughly before

Do not use this manual in conjunction

Customer Service

If literature or replacement parts are

required, contact the source from whom

the machine was pur chased or contac t Alliance

Laundry Systems LLC at (920) 748-3950 for

the name and address of the nearest authorized

parts distributor.

For technical assistance, call any of the

following numbers:

(850) 718-1035

(850) 718-1026

Marianna, Florida

(920) 748-3121

Ripon, Wisconsin

A record of each machine is on file with

the manufacturer. Always provide the

machine’s serial number and model

number when ordering parts or when seeking

technical assistance.

Note:

specifications contained in this manual are

based on the latest product information

availa ble at the time of printing. We reserve

the right to make changes at any time

without notice.

F232061

All information, illustrations, and

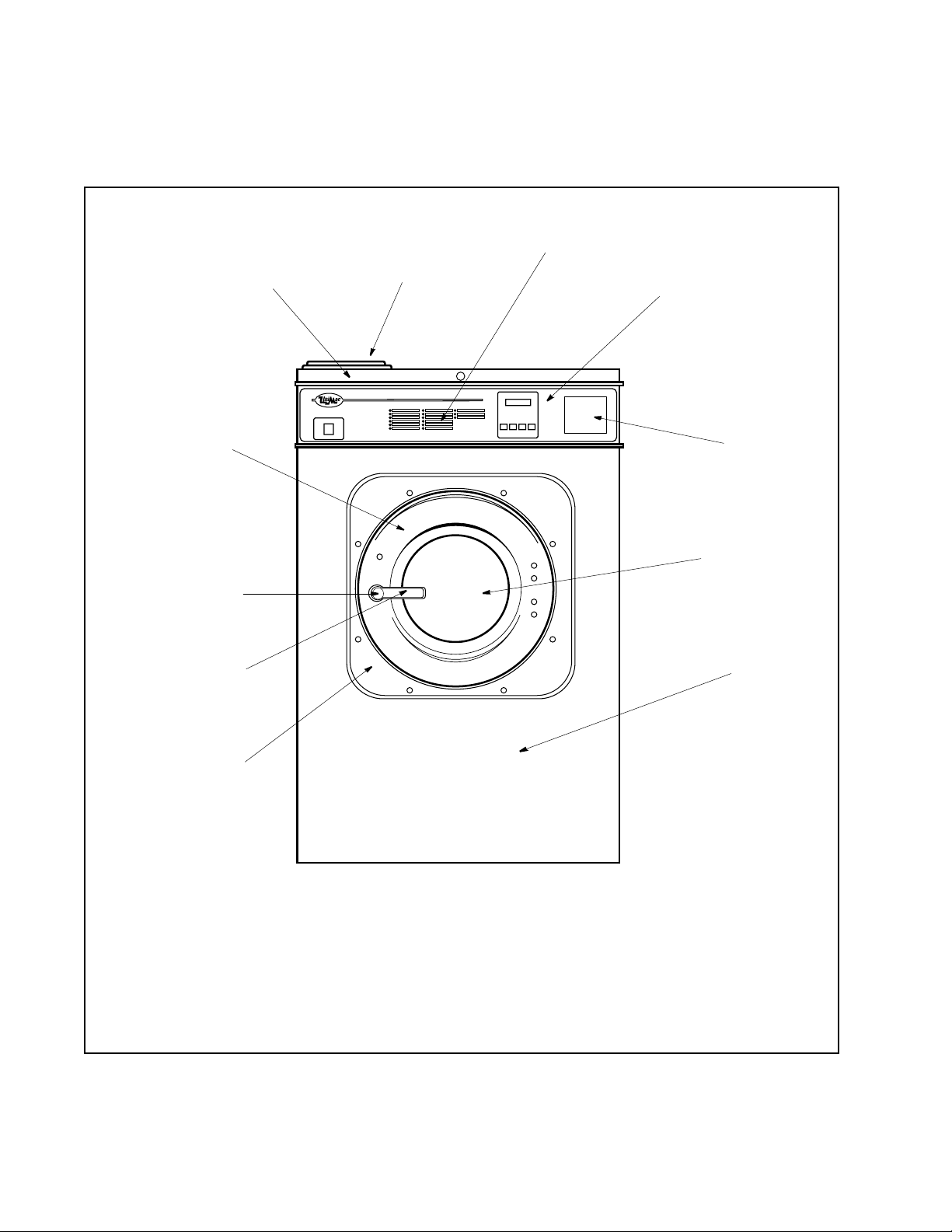

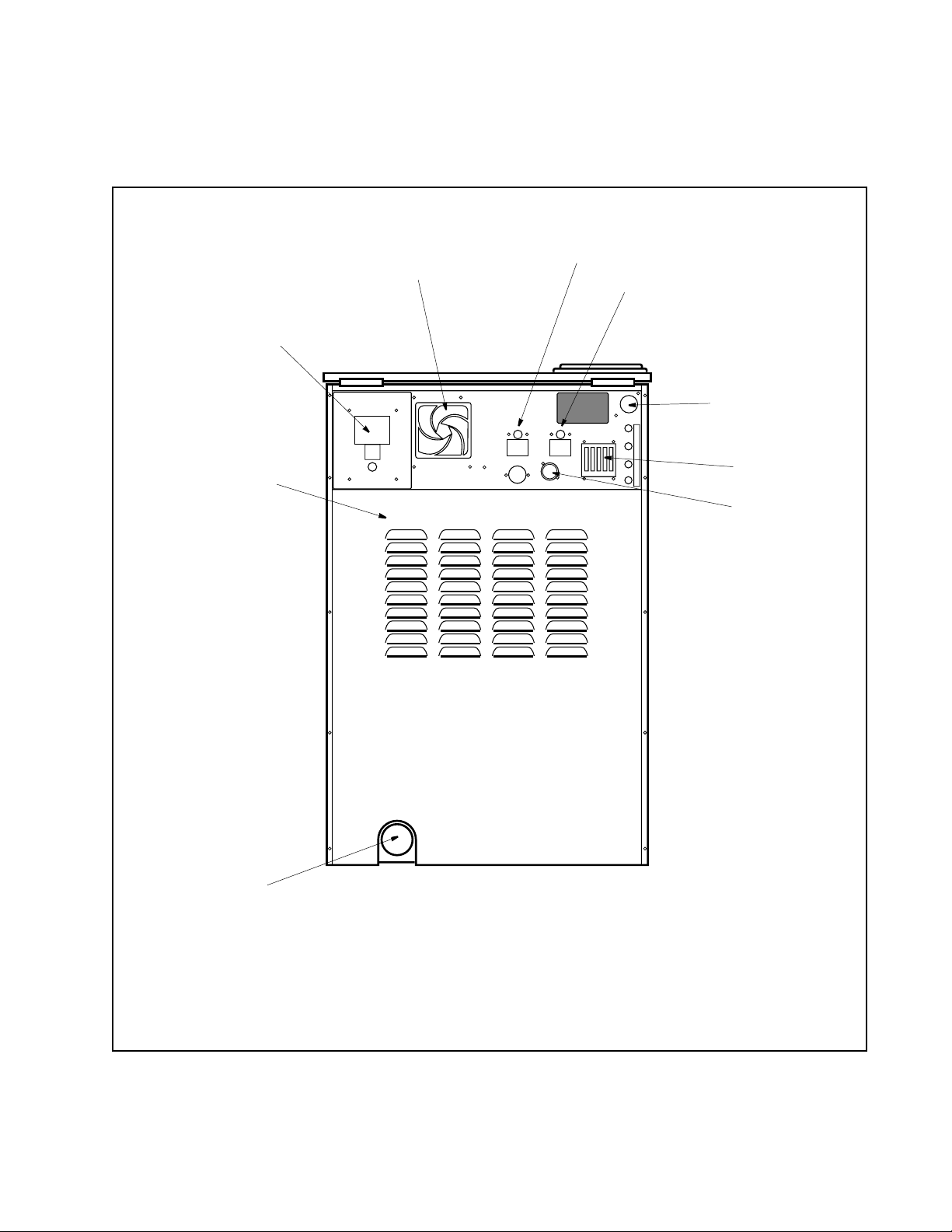

Machine Familiarization Guides

The machine familiarization guides in Figures

1 and 2 provide front and rea r views of the

washer-extractor and identify the major

operational features of the machine.

9

Operation

Top Cover

Supply Dispenser

®

Control Panel

V-Computer Keypad

Door

Door Unlock

Button

Door Handle

Inner Fro nt Panel

Coin Meter

Door Glass

Outer Front Panel

MA019K

Front View

10

MA019K

Figure 1

F232061

Power Connection

Rear Panel

Operation

Cold Water Inlet

AC Drive Cooling Fan Filter

Hot Water In let

Steam Inlet

(Optional)

Vacuum

Breaker

Vent

Rear View

F232061

MA018K

Drain Outlet

MA018K

Figure 2

11

Operation

Theory of Operation

The design of the machine emphasizes

performance reliability and long service life.

The cylinder, shell, and main body panels are

fabricated of stainless steel.

The machine uses one motor to drive the

cylinder via a V-belt drive in all speeds.

A door-lock system prevents opening of the

stainless steel door when water is in the

machine. It also prevents operation of the

machine when the door is open.

An electrically operated drain valve is used

to retain the water and wash solution in the

machine during the wash and fill steps.

The drain valve closes when power is applied

and opens when power is removed, allowing

the machine to drain in the event of a

power fail ure.

The cylinder is designed with lifters or ribs

that lift the garments from the wash solution

when the cylinder rotates at slow speed and

allow the garments to tumble back into the

solution. The cylinder is perforated, allowing

the water to pass through and drain from

within during the wash pr oces s and extract.

The AC inverter drive uses special balance

detection software in conjunction with the

V-computer to prevent out-of-balance

conditions. When the AC dri ve detects an

unbalanced load at the end of a drain step, the

computer will make up to seven attempts to

balance the load.

The operator can select from among 10

preprogrammed

cycles and program up to six for a total of 16

cycles available. A special permanent test

cycle can be selected to verify proper

operation of the machine.

V-Computer

The V-computer control is a programmable

solid-state control capable of storing and

running up to 16 cycles. A detailed

description of these cycles can be found in

the Programming section of this manual.

If this machine’s computer has been equipped

with special preprogrammed cycles, a separate

insert listing these cycles has been included in

the resealable plastic bag which contained

this manual.

Electrical controls for the machine are housed

in a separate enclosure located underneath the

top cover of the machine.

The machine uses an AC inverter drive control

which provides four motor speeds using a

single motor. The solid state output board

converts motor logic from the V-computer to

the correct signals for the AC inverter drive.

12

Note:

computer mode switch is in the PROGRAM

position. Such action will disorder portions of

the programmed data, necessitating

reprogramming of some or all of the existing

cycles. Always return the mode swit ch to R UN

position before turning the power off.

Never turn the power off while the

F232061

Operation

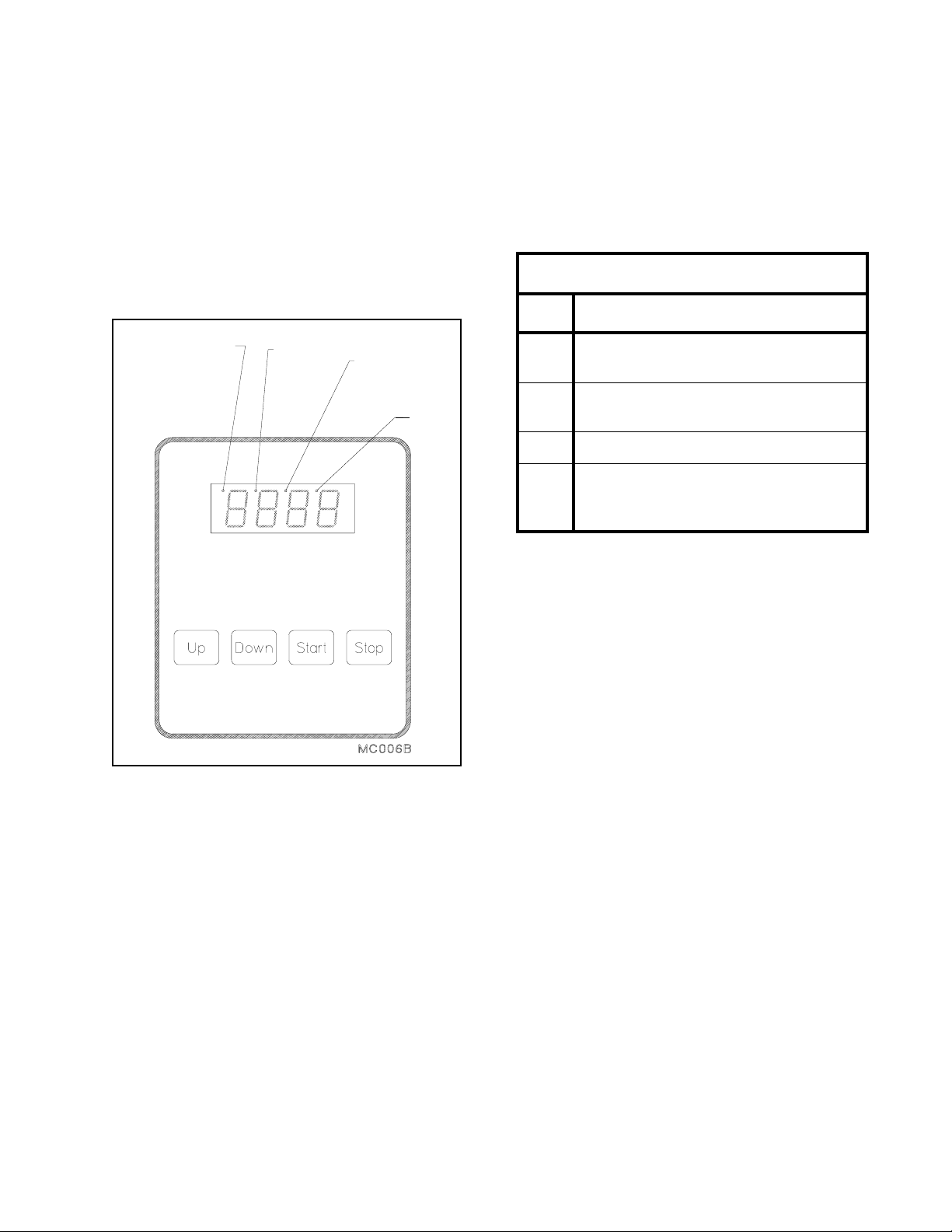

Keypad

Operation of the V-computer control is

performed with a 4-key touch keypad and LED

display located on the front of the machine.

See Figure 3.

Out-of-Balance

Condition

High Water

Level

Medium Water

Level

Low

Water

Level

The following table describes the function of

the individual keys when the machine is in

RUN mode.

Keypad

Key Description

Up

Down

Start

Stop

Used in cycle selection; pressing thi s k ey

moves among cycles from smaller to greater.

Used in cycle selection; pressing thi s k ey

moves among cycles from greater to s maller.

Used to s ta r t a cyc le .

This key is not active in normal RUN mode.

In RUN m ode, it is used only fo r s toppin g t he

test cycle.

F232061

Figure 3

13

Operation

Theory of Operation

Conditions Monitored

by the Computer

•

•

•

–The computer continuously

Door

monitors the open/locked status of the

door. If it detects that the door is open

during a wash cycle, it immediately aborts

the cycle and exe cutes the stop routine.

Power

enough for the computer to go off, after

the power is restored, the display briefly

flashes “Hold” to indicate the interruption.

The door unlock will be disabled to keep

the door from being opened while the

basket is still turning.

Balance

balance signal provided by the AC drive

during drain steps. It will attempt to

optimize the load seven times before

skipping the programmed spin for the

extract step. The dot at the top of the

leftmost display digit will light following

the final unsuccessful attempt.

–If power is interrupted long

–The computer monitors the

(Continu ed)

•

Tempe rature probe problem

temperature sensor fails when prompted

for degrees Fahrenheit, the computer

flashes “tSFL” in PROGRAM mode rather

than showing the temperature. If the

temperature sensor fails when prompted

for degrees Celsius, the display will re ad

“-17C” rather than showing the

temperature.

The following table, entitled “Display

Indications,” lists the various displays and

what they mean. The operator should become

familiar with these computer displays.

–If the

•

Water level

maintain the water level programmed for

the fill preceding the agitation step. If the

level f alls below the programmed le vel, the

computer will stop the time countdown

and re-energize the fill valves until the

level is restored.

•

Water level in a heat step

the computer to energize the heat output,

there must be at least a low water level in

the machine. If this minimum level is not

detected, the heat output will be turned off

until the required level is restored.

14

–The computer attempts to

–In order for

F232061

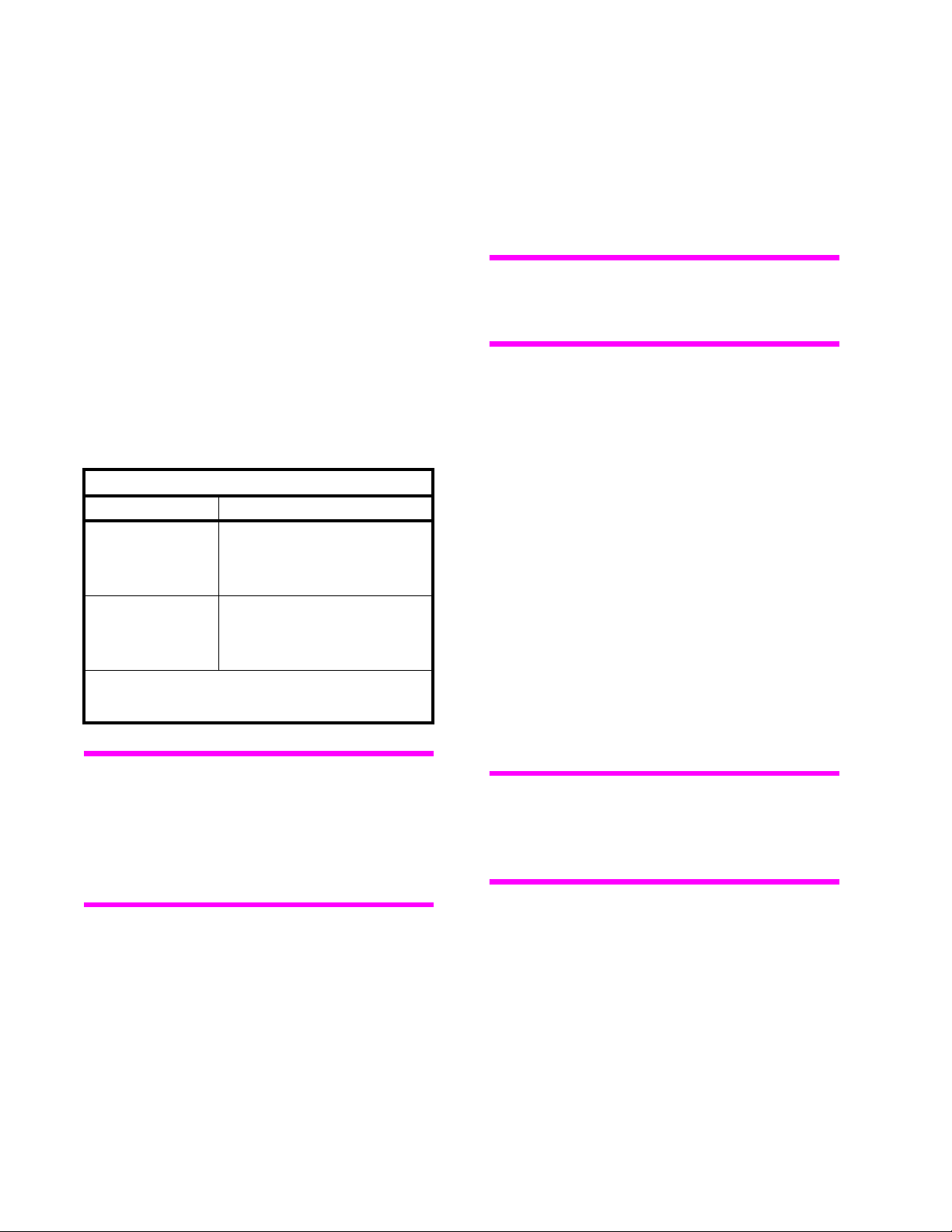

Display Indications

Display Meaning Display Meaning

FC 5

Program identification code (ROM). This

is an example onl y.

HFIL Hot fill

Lo Low water level

Operation

Hold Wait...power has just been turned on.

PAY/(pric e)*

CY Cycle (followed by two-digit number) SUP1 Supply 1

tESt/CYC* Test cycle selecte d. SUP2 Supply 2

FAr Degrees Fahrenheit SUP3 Supply 3

CEL Degrees Ce lsius SUP5 Supply 5 (Supply 1 and 2)

Heat Auxiliary hea t enabled. SUP6 Supply 6 (Supply 2 and 3)

noHt Auxiliar y hea t disabled. drAI/dISt* Distribution (load balancing before extract)

FLSH Flashing ve nd price enabled. drAI/For*

nFLS Flashing ve nd price disabled.

Strt/A

Con1/deno*

Con2/deno*

PrE Prewash segment (1st of 8 se gm ents) bAL/FAIL* Balance routine failed during test cycle.

UASH Wa sh segment (2nd of 8 segments) SHUT/door* Door not prope rly closed.

FIL1 First fill (3rd of 8 segments)

FIL2 Second f ill (4th of 8 segments)

FIL3 Third f ill (5th of 8 segments)

FIL4 Fourth fill (6th of 8 segments)

FIL5 Fifth fill (7th of 8 segments)

FIL6 Sixth fill (8th of 8 segments)

AFIL Auxiliary fill dFLt Drive f ault detected.

bFIL Warm fill (both hot and cold)

CFIL Cold fill

bLCH Add ble ach

*Display indications separated by a slash represent an alte rnating display.

t*

n

Pay (flashes alternately with start price if

“FLSH” SETUP option is enabl ed)

Start amount—flashe s bri efly before

showing vend price in SETUP mode

Coin 1 value—flashes briefly before

showi ng value of coin 1 in SE TUP mo de

Coin 2 value—flashes briefly before

showi ng value of coin 2 in SE TUP mo de

ed

n

HI High water level

SUP0 No supplies

SPIn/tI

SdLY Spin coast delay

STOP Stop routine

donE Cycle and stop routine have ended.

HI 1 Low spin in test cycle.

HI 2 High spin in test cycle.

CANt/OPEN*

FILL/STOP*

FULL

tSFL

E*

n

Medi um wate r leve l

Drain step (low speed forward in test

cycle)

Reads “SPIn” for one second, then

E” followed by time for spin.

“tI

n

Computer cannot unlock door after f ive

attempts.

Programmed wate r level not reached after

30 minutes.

The computer detects low water level or

higher when none should be present.

Temperature sensor fail ure or temperature

out of range.

F232061

15

Operation

Start-Up

Turn on th e main power source (circuit bre aker

or cut-off switch on the wall).

The display shows an identification code for

approximately fiv e seconds. The display then

flashes “hold” briefly.

The display then shows the vend price or

alternately flashes the vend price and “PAY,”

depending upon which setting was prompted

in the “FLSH”/“nFLS” setup option.

Opening Door

Press the round button on the door handle and

turn the door handle downward.

Loading

Partial loads are a waste of energy, water, and

chemicals, and cause greater machine wear

than full loads. Partial loads also increase the

possibility of a severe out-of-balance

condition.

WARNING

Never operate the machine with a bypassed

or disconnected b alance system. Operating

the machine with severe out-of-balance

loads cou ld result in personal injury and

serious equipment da m age.

SW039

When loading is complete, ensure that all

fabric is inside the basket. Then close and

lock the door by rotating the door handle

counterclockwise until the door handle

pushbutton pops out. The machine should not

start or run unless the door is both closed

and locked.

CAUTION

Be carefu l around the open door,

par ticularly wh en loading from a level

below the doo r. Impact wi th door edges

can cause personal injury.

SW025

Load the machine to full capacity whenever

possible, but do not exceed the rated dryweight capacity of the machine if the fabric to

be washed is quite dense, closely woven, and

heavily soiled. Overloading can result in an

inferior wash. The operator may need to

experiment to determine load size based on

fabric content, soil content, and level of

cleanliness required.

16

CAUTION

Check the door safety interlock daily before

the machine is placed in operation.

SW024

Note:

disintegrate, such as mop heads or sponges,

use laundry net bags to prevent drain blockage.

Supply Dispenser

Both liquid and powder supplies may be added

by raising the flexible cover of the dispenser.

When washing items which may

F232061

Cycle Selection

Note:

enough to activate them.

As coins are inserted in the coin meter slot, the

display shows the remaining amount to start. It

will continue to count down until the start

price is satisfie d.

Once the amount to start is satisfied, the

display will read “CYxx” where “xx”

represents a cycle number. Pr es s t he Up or

Down key until the desired cycle number is

displayed. Press the Start key to start the

cycle. For a more detailed description of the

preprogrammed cycles, see the cycle charts at

the end of the Programming section.

Note:

blocking coil, the machine must be loaded and

the door closed before coins can be added. The

meter will not accept coins until these two

conditions are met.

If the computer detects that the door is not

properly closed when the Start key is pressed,

the display will alternately read “SHUT” and

“door. ” Verify that the door is properly

closed, and press Start again to begin the

desired cycle.

Press keys at their centers just hard

If the coin meter is equipped with a coin

Operation

Note:

remaining cycle time during fills and drains or

prior to first achieving the programmed heat

temperature when heating. The computer

resumes counting down cycle time once the

programmed fill level is reached, when the

machine has drained, and after a programmed

heat temperature is reached.

Each of the 16 cycles consists of eight

segments: Prewash, Wash, and Fills 1–6. A

description of the various steps in a cycle

segment follows:

After the Start key is pressed, the door locks,

the drain closes, and the machine begins fi lling

to the programmed level. Each programmed

segment begins with a fill. The display counts

down the remaining cycle time in minutes and

seconds while the cycle is running, except as

noted above.

If a supply is programmed in a step, the

supply dispenser will flush during the fill of

that segment. If the programmed supply is

supply 2 (“sup 2”), the display will fla sh

“bLCH” alternately with the cycle time while

supply 2 is on. This signals the user to

manually add liquid bleach in the middle

supply dispenser compartment.

The computer does not count down the

Fill

Cycle Execution

To display the temperature of the w ater while a

cycle is running, press the Up key. To display

the number of the cycle in progress, press the

Start key.

F232061

Note:

programmed water leve l after attempting to fill

to that level for 30 minutes, the display will

flash “FILL”/“STOP” while sounding the

buzzer briefly. The computer will then abort

the cycle. This indicates a serious problem.

Contact a qualified service technician.

If the computer does not detect the

17

Operation

Cycle Execution (Continued)

Wash

As soon as water level is reached (and any

programmed temperature is reached), the

displayed time begins counting down at

one-second intervals.

The machine will agitate low speed forward,

pause, low speed reverse, pause, then repeat

this sequence for the programmed time. The

table below shows available agitation options.

Agitation Action Option s

Agitation Type Description

12 seconds forward,

Normal

Gentle*

* Gentle agitat ion information must be programmed

in cylces 15 and 16.

3 seconds pause,

12 sec o nds revers e,

3 seconds pause

3 seconds forward,

12 seconds pause,

3 seconds reverse,

12 sec o nds paus e

The cylinder accelerates to distribution speed

seven seconds into the drain step. About five

seconds later, the drain opens.

Note:

The machine should drain in

30 seconds. If the machine fails to drain,

contact a qualified service technician.

Spin

Spin steps for all segments except Fill 6 are

low-speed spins. These spin steps are cal le d

intermediate spins. For cycles 1–14, the spin

step for the Fill 6 segment is the final spin and

is thus a high-speed spin. For cycles 15 and 16

(gentle cycles), the final spin is always a

low-speed spin.

Intermediate spin steps can be 30 to 240

seconds in length. Final spin steps can be from

1 to 10 minutes in length. Any spin step can be

skipped by programming 0 for the spin time.

However, in order to have a high speed spin in

the Fill 6 segment, a nonzero time must be

programmed for that segment.

Note:

If the water does not reach the

programmed temperature in 30 minutes, the

computer will proceed with the cycle. (The

time countdown will resume as though

temperature had been reached, but the

computer will continue heating).

Drain

The drain v al ve w ill open afte r th e pro gramm ed

segment time has elapsed. The cylinder will

turn counterclockwise (forw ar d ) at w ash speed

while in th e drain step. This counterclockwise

direction mirrors the spin rotation and is,

therefor e, also considered for ward.

18

Note:

An automatic 25-second coastdown

follows all spins. This does not add to the cycle

time because the fill for next segment begins

during the coastdown.

If the cycle program se gment spin time is set to

zero, the computer moves to the next segment

of the cycle program. I f the segment is at the

end of a cycle program, the computer goes into

the stop routine.

F232061

Operation

Stop Routine

When the wash cycle concludes, the c omputer

goes into the stop routine. The stop routine

consists of a brief countdown and a brief

reversing sequence, after which the computer

will display “donE.”

WARNING

NEVER in s ert hands or objects into basket

until it has co m pletely stopp ed. Doing so

could resu lt in s erious injury.

SW012

If no water level is detected, and no rotation is

detected from the AC drive, the computer will

unlock the door and sound the buzzer for five

seconds. The computer will display “dONE”

for 25 seconds regardless of whether or not the

door is opened.

If the computer cannot unlock the door, it will

display “----” while attempting to unlock the

door fiv e additional ti mes. If it is still unable to

unlock the door after fiv e attempts, it will flash

“CANt”/“OPEN.” No further attempts will be

made to unlock the door.

If the balance signal indicates that the wash

load is unbalanced, the computer will slow

the cylinder down to wash speed for seven

seconds in an attempt to redistribute the load.

The computer will make as many as seven

attempts, if needed.

If on the seventh attempt the load is not

balanced, the machine will light the out-ofbalance LED indicator located in the upper left

corner of the display (to the left of the first

digit) until the next drain step. The machine

will then skip the programmed spin and

continue to the next programmed step.

If this occurs in the final segment, the machine

will begin the Stop routine.

Overtravel Limit Switch

As a fail-safe measure, an overtra vel limit

switch is installed. The limit switch serves to

trigger a rapid stop. This means that if the

machine balance “passes” the inverter drive

balance detection system at the drain step but

the balance switch detects an out-of-balance

load condition at the extract step, the basket

will brake to a rapid stop.

Balance Dete ct io n

All models come equipped with an inverter

drive balance detection system.

Load balance is detected by the invert er drive

during the drain step. The V-series computer

will make up to seven attempts to balance the

load during a drain step.

The computer begins monitoring the balance

signal from the AC in verter drive eight s econds

after the water level drops below low level. If

the balance signal indicates that the wash load

is evenly distributed, the computer will start

the spin step.

F232061

To reset the control, push the stop button and

open the door when the display shows “donE.”

Test Cycle

A test cycle is provided as a means of verifying

proper machine operation. Before the test

cycle is run, it must be enabled. Refer to the

Programming section of this ma nual for

instructions on enabling and running the

test cycle.

19

Operation

NOTES

20

F232061

Section 3

Programming

The V-computer board is inside the control

module. Near the center of the board is a s mall

toggle switch: this is the RUN/PROGRAM

mode switch.

WARNING

Dangerous voltages are p res ent in the

electrical control box(es ) and at the motor

termin als. Only qualifi ed personnel familia r

with electrical te st procedures, test

equipment, and safety precautions shou ld

attempt ad justments and troubleshoot ing.

Disconnec t pow er f rom the mach ine before

removing the c ontrol box cover, and before

attemptin g any servic e procedures.

SW005

The RUN/PROGRAM switch is normally in

the down (RUN mode) position. To enter

PROGR AM mode, flip the switch to the up

position. The display will now show the

current temperature in the sump.

Down–The Down key is used to decrease

cycle numbers (1 through 16) and other

numerical values such as times or temperatures

(when creating wash formulas).

Start–The Start key acts as an enter key in

program mode. Use this key to enter data and

move to the next function in the cycle.

Stop–The Stop key saves all data and

terminates the programming procedure.

If it is the first key pressed in program mode,

the computer enters setup mode. The Stop ke y

can be pressed again to exit setup mode and

return to program mode.

Setup Mode

Setup options are programmable options that

are in effect for all wash formulas. These

options include:

Since the keypad operates in a slightly

different fashion when in program mode, pay

careful attention to the programming

instructions provided in this manual.

Key Functions In Programming

Mode

Up–The Up key is used to increase cycle

numbers (1 through 16) and other numerical

values such as times or temperature s (when

creating wash formulas).

F232061

• Degrees displayed in Fahrenheit or Celsius

• Auxiliary heat enabled or disabled

• Set the display to flash or not flash

• Program coin denominations and start

price

Note:

only in setup mode.

These options can be read or changed

21

Loading...

Loading...