Alliance Laundry Systems SCA020VC, SCL060VL, SCT020VY, SCL030VE, SCU080VY Original Instruction

...

Washer-Extractor

Cabinet Hardmount

Quantum Touch Vend Control

Refer to Page 13 for Model Identification

Programming

Original Instructions

Keep These Instructions for Future Reference.

CAUTION: Read the instructions before using the machine.

(If this machine changes ownership, this manual must accompany machine.)

www.alliancelaundry.com

Part No. F8669401ENR4

September 2019

WARNING

Machine installations must comply with minimum

specifications and requirements stated in the applicable Installation Manual, any applicable municipal

building codes, water supply requirements, electrical

wiring regulations and any other relevant statutory

regulations. Due to varied requirements and applicable local codes, this machine must be installed, adjusted, and serviced by qualified maintenance personnel familiar with applicable local codes and the

construction and operation of this type of machinery.

They must also be familiar with the potential hazards

involved. Failure to observe this warning may result

in personal injury, property damage, and/or equipment damage, and will void the warranty.

W820

NOTE: The WARNINGS and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not meant

to cover all possible conditions and situations that may

occur. Common sense, caution, and care must be exercised when installing, maintaining, or operating the

machine.

Any problems or conditions not understood should be reported to

the dealer, distributor, service agent or the manufacturer.

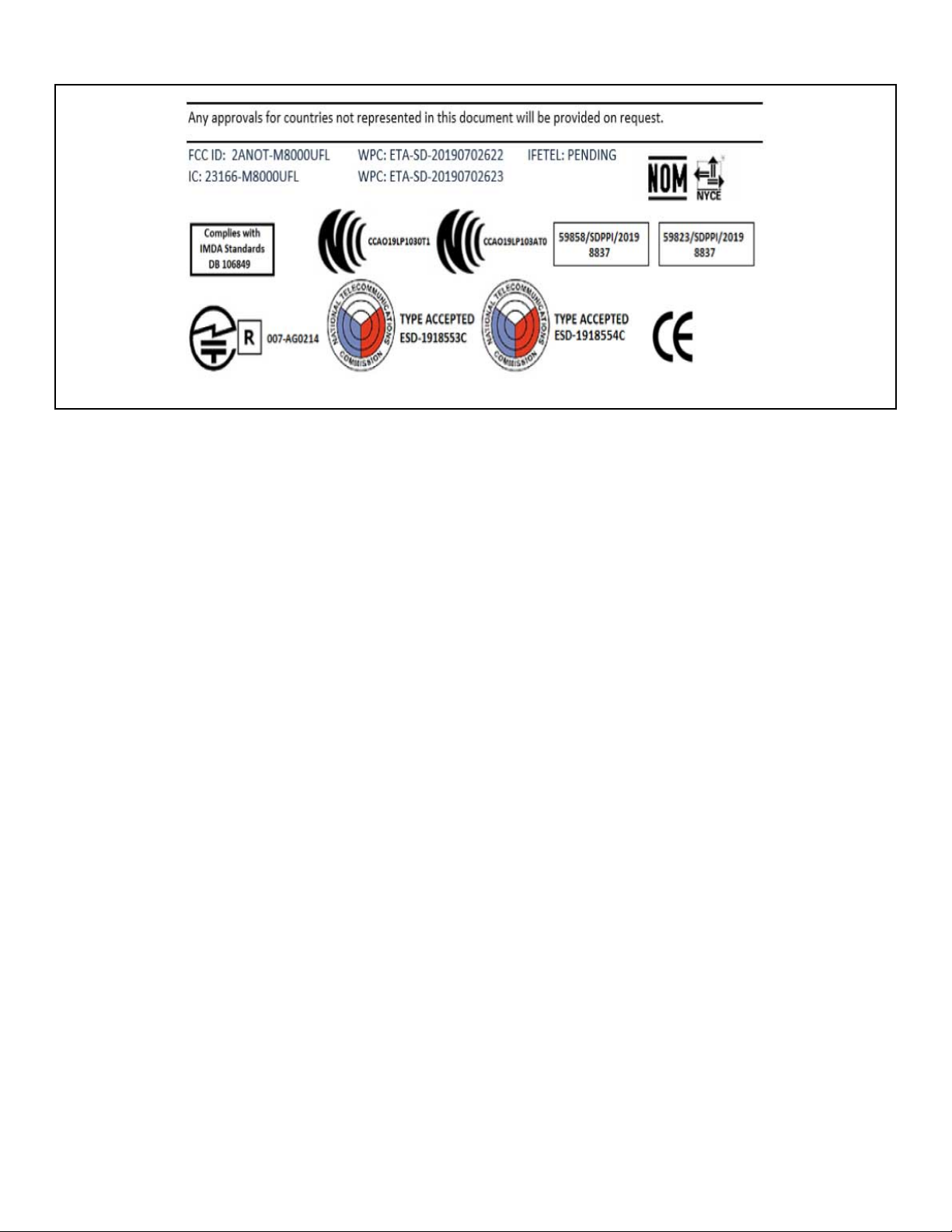

Regulatory Statements

PRODUCT COMPLIANCE

Users of this product are cautioned not to make modifications or

changes that are not approved by Alliance Laundry Systems,

LLC. Doing so may void the compliance of this product with applicable laws and regulatory requirements and may result in the

loss of the user’s authority to operate the equipment.

UNITED STATES

This device complies with Part 15 of the FCC Rules. Operation is

subject to the following two conditions; (1) This device may not

cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

This equipment has been tested and found to comply with the

limits for a Class B digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference in a residential installation. This

equipment generates uses and can radiate radio frequency energy

and, if not installed and used in accordance with the instructions,

may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful inter-

ference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try

to correct the interference by one or more of the following measures:

• Reorient or relocate the radio or television receiving antenna.

• Increase the separation between the computer equipment or

receiver.

• Connect the equipment into an outlet on a circuit different

from that to which the radio or television receiver is connected.

• Consult the dealer or experienced radio television technician

for help.

CAUTION

To comply with the limits of the Class B device, pursuant to Part 15 of the FCC Rules, this device is to

comply with Class B limits. All peripherals must be

shielded and grounded. Operation with non-certified

peripherals or non-shielded cables is likely to result

in interference and reception of the device.

W1004

Radiation Exposure Statement: This equipment complies with

FCC radiation exposure limits set forth for an uncontrolled environment. The radio installed in this equipment and is intended to

operate with minimum distance 20cm between the radiator and

your body.

Limited Channels Fixed For Use In USA: IEEE 802.11b or

802.11g or 802.11n(HT20) operation of this product in the U.S. is

firmware-limited to Channel 1 through 11.

CANADA - CAN ICES-3(B)/NMB-3(B)

This device contains license-exempt transmitter(s)/receiver(s)

that comply with Innovation, Science and Economic Development Canada’s license-exempt RSS(s) standards. Operation is

subject to the following two conditions:

• This device may not cause interference.

• This device must accept any interference, including interference that may cause undesired operation of the device.

Radiation Exposure Statement: This equipment complies with

Innovation, Science and Economic Development Canada’s radiation exposure limits set forth for in RSS-102. The radio installed

in this equipment is installed and is intended to operate with minimum distance 20cm between the radiator and your body.

EUROPE

Products bearing the CE mark comply with the following EU directives:

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

3 Part No. F8669401ENR4

• EMC Directive 2014/30/EU

• Low Voltage Directive 2014/35/EU

• Ecodesign Directive 2009/125/EC

• RoHS Directive 2011/65/EU

If the product has telecommunications functionality, it also complies with the requirements of the following EU directive:

• Radio Equipment Directive 2014/53/EU

Compliance with these Directives implies conformity to harmonized European standards that are noted in the EU Declaration of

Conformity which is available upon request.

Alliance Laundry Systems products comply with the requirement

of Article 10(2) as it can be operated in at least one Member State

as examined and the product is compliant with Article 10(10) as

it has no restrictions on putting into service in all EU member

states.

This device contains a 2.4GHz transceiver, intended for indoor

use only in all EU member states, EFTA states, and Switzerland.

Attention has been given to allowed operational frequencies. For

detailed information concerning installations in France, the user

should contact the national spectrum authority in France (http://

www.arcep.fr/ )

Be aware that outdoor installations require special attention and

will only be handled by trained and qualified installation personnel. No one from the general-public is permitted to install wireless products outdoors when external antennas, power and

grounding must be installed for use.

AUSTRALIA/NEW ZEALAND

The radio in this equipment complies with and is certified to the

Australian and New Zealand regulatory requirements.

BRAZIL ANATEL

This equipment operates in secondary status, that is, it is not entitled to protection against harmful interference, even for type stations, and cannout cause interference to systems operating in primary status.

CHINA SRRC

This product is equipped with a certified wireless device pursuant

to Article 2-1-19 of the Certification Ordinance. No changes are

authorized to the radio or the antenna of the approved device.

MEXICO IFETEL

“The operation of this equipment is subject to the following two

conditions: (1) it is possible that this equipment or device does

not cause harmful interference and (2) this equipment or device

must accept any interference, including that which may cause its

unwanted operation.”

SOUTH KOREA (KC)

The radio device has received certification of conformance in accordance with the Radio Waves Act. Integration of this radio into

a final product does not require additional radio certification provided installation instructions are followed. No changes are authorized to the radio or the antenna of the approved device.

TAIWAN

The information in this section applies to products bearing the

Taiwan National Communications Commission mark:

This telecom equipment has complied with NCC regulations.

According to “Administrative Regulations of Low Power Radio

Waves Radiated Devices:

Article 12 The low-power radio-frequency devices must not be

altered by changing the frequency, enhancing emission power,

adding external antenna, and modification of original design

characteristic as well as function.

Article 14 The operation of the low-power radio-frequency devices is subject to the conditions that no harmful interference is

caused. The user must stop operating the device immediately

should harmful interference is caused and shall not resume until

the condition causing the harmful interference has been corrected.

Moreover, the interference must be accepted that may be caused

by the operation of an authorized communications, or ISM equipment. (1) Precautions (marked in the product manual and on outer packaging)

The radio device has recieved certification of conformance in accordance with the People's Republic of China State Radio Regulation Committee (SRRC) certification scheme. Integrations of

this radio into a final product does not require additional radio

certification provided installation instructions are followed. No

changes are authorized to the radio or the antenna of the approved device.

JAPAN

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

THAILAND

The information in this section applies to products approved by

the Thailand National Communications Commission:

These telecommunication and device are compliance with the requirements of National Broadcasting and Telecommunication

Commission.

4 Part No. F8669401ENR4

MIX4N_SVG

Figure 1

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

5 Part No. F8669401ENR4

Table of Contents

Safety Information..................................................................................9

Explanation of Safety Messages....................................................................... 9

Important Safety Instructions........................................................................... 9

Safety Decals................................................................................................10

Operator Safety.............................................................................................10

Introduction..........................................................................................12

Model Identification......................................................................................12

Serial Plate Location..................................................................................... 17

Replacement Parts ........................................................................................18

Customer Service..........................................................................................18

Preliminary Information.......................................................................19

About the Control......................................................................................... 19

IR Communications...................................................................................... 19

IR Communications Menu..........................................................................19

Wi-Fi Communications..................................................................................19

Audit Information......................................................................................... 19

Special Features....................................................................................20

Break-In Alarm.............................................................................................20

Cycle Time Display.......................................................................................20

Cycle Completed Timer.................................................................................20

Passcode Security......................................................................................... 20

Language Selection.......................................................................................20

Lucky Cycle.................................................................................................20

Speed Cycle................................................................................................. 20

Special Vend.................................................................................................20

Increased Water Levels..................................................................................20

Increased Spin Speed.................................................................................... 20

Dispense Soap.............................................................................................. 20

Control Identification........................................................................... 21

Operational Touch Display.............................................................................21

Operation Modes.......................................................................................... 22

Ready Mode............................................................................................. 22

Lockout Mode...........................................................................................22

Drop Off Mode......................................................................................... 22

Auto-Flush Mode...................................................................................... 23

Overflow Mode.........................................................................................23

©

Copyright 2019, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without the expressed

written consent of the publisher.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

6 Part No. F8669401ENR4

Machine Error Mode..................................................................................23

Internal Control Failure..............................................................................23

Coast Down Mode.....................................................................................24

Shutdown Mode........................................................................................ 24

Out of Order Mode.................................................................................... 24

Menu Navigation.................................................................................. 26

Opening the Service Door..................................................................... 29

Stacked Washer-Extractor/Tumble Dryer.........................................................29

Machine Cycle Definition and Operation.............................................. 31

Machine Cycle Operation.............................................................................. 31

Approach Screen...........................................................................................31

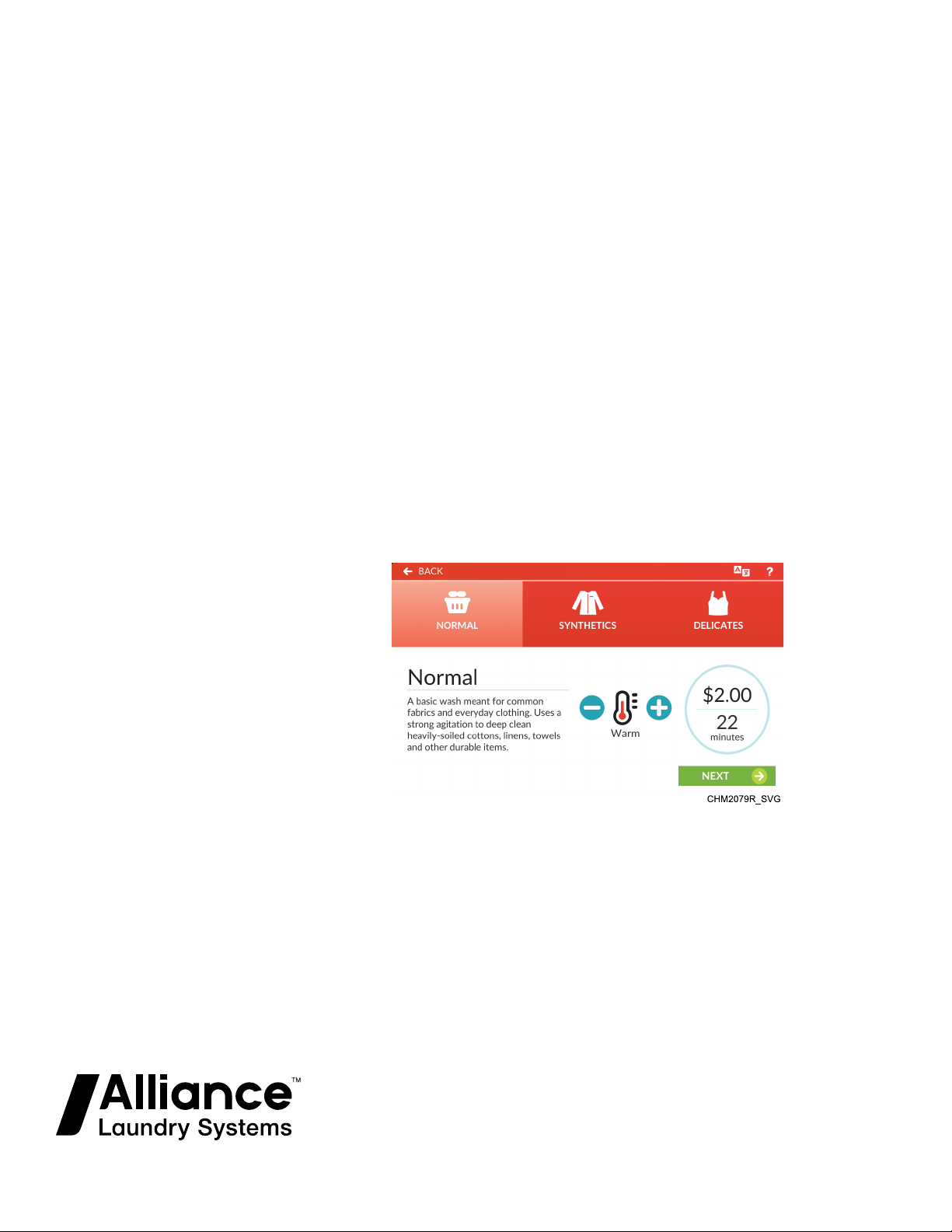

Cycle Preset ................................................................................................ 32

Speed Cycle................................................................................................. 33

Pre-Clean (If Available).................................................................................33

Help Menu .................................................................................................. 34

Language Selection Panel ............................................................................. 34

Start a Cycle.................................................................................................34

Close Door Menu..........................................................................................35

Run Menu ................................................................................................... 35

Cycle Pause Menu ........................................................................................37

Cycle Complete Menu...................................................................................37

Lucky Cycle Mode........................................................................................37

Manual Programming...........................................................................38

System Menu................................................................................................38

Passcode Menu......................................................................................... 38

Save Changes Menu.................................................................................. 38

Rapid Advance Activation..........................................................................39

Cancel Cycle.............................................................................................39

Clear Active Error .................................................................................... 39

Clear Partial Vend .....................................................................................40

Change Vend Price ................................................................................... 40

Settings Menu.......................................................................................41

Vend Settings ...............................................................................................41

Basic Settings .............................................................................................. 53

Machine Settings ......................................................................................... 57

Cycle Settings...............................................................................................61

Audit Data Menu.................................................................................. 84

Diagnostics Menu..................................................................................85

Machine ID Menu.........................................................................................85

Alarms Menu................................................................................................85

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

7 Part No. F8669401ENR4

Inputs/Outputs Menu.....................................................................................86

Factory Test Menu........................................................................................ 86

Individual Tests Menu................................................................................... 90

Machine Errors......................................................................................... 92

Service Schedule Menu......................................................................... 99

Reset Menu.........................................................................................100

Default Cycles.....................................................................................101

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

8 Part No. F8669401ENR4

Safety Information

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “WARNING,” and

“CAUTION”), followed by specific instructions, are found in this

manual and on machine decals. These precautions are intended

for the personal safety of the operator, user, servicer, and those

maintaining the machine.

DANGER

Indicates an imminently hazardous situation that, if

not avoided, will cause severe personal injury or

death.

WARNING

Indicates a hazardous situation that, if not avoided,

could cause severe personal injury or death.

CAUTION

Indicates a hazardous situation that, if not avoided,

may cause minor or moderate personal injury or

property damage.

Additional precautionary statements (“IMPORTANT” and

“NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of specific procedures where minor

machine damage will occur if the procedure is not followed.

NOTE: The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is important but not hazard related.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using your washer,

follow these basic precautions:

W023

• Read all instructions before using the washer.

• Install the washer according the INSTALLATION instructions. Refer to the EARTH/GROUND instructions in the IN-

STALLATION manual for the proper earth/ground connection

of the washer. All connections for water, drain, electrical

power and earth/ground must comply with local codes and be

made by licensed personnel when required. It is recommended that the machine be installed by qualified technicians.

• Do not install or store the washer where it will be exposed to

water and/or weather.

• To prevent fire and explosion, keep the area around machine

free from flammable and combustible products. Do not add

the following substances or textiles containing traces of the

following substances to the wash water: gasoline, kerosene,

waxes, cooking oils, vegetable oils, machine oils, dry-cleaning solvents, flammable chemicals, thinners, or other flammable or explosive substances. These substances give off vapors

that could ignite, explode or cause the fabric to catch fire by

itself.

• Under certain conditions, hydrogen gas may be produced in a

hot water system that has not been used for two weeks or

more. HYDROGEN GAS IS EXPLOSIVE. If the hot water

system has not been used for such a period, before using a

washing machine or combination washer-dryer, turn on all hot

water faucets and let the water flow from each for several minutes. This will release any accumulated hydrogen gas. The

gas is flammable, do not smoke or use an open flame during

this time.

• To reduce the risk of an electric shock or fire, DO NOT use an

extension cord or an adapter to connect the washer to the electrical power source.

• Do not allow children to play on or in the washer. Close supervision of children is necessary when the washer is used

near children. This appliance is not intended for use by young

children or infirm persons without supervision. Young children should be supervised to ensure that they do not play with

the appliance. This is a safety rule for all appliances.

• DO NOT reach and/or climb into the tub or onto the washer,

ESPECIALLY if the wash drum is moving. This is an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

• Never operate the washer with any guards, panels and/or parts

removed or broken. DO NOT bypass any safety devices or

tamper with the controls.

• Use washer only for its intended purpose, washing textiles.

Never wash machine parts or automotive parts in the machine. This could result in serious damage to the basket or

tub.

• Use only low-sudsing, no-foaming types of commercial detergent. Be aware that hazardous chemicals may be present.

Wear hand and eye protection when adding detergents and

chemicals. Always read and follow manufacturer’s instructions on packages of laundry and cleaning aids. Heed all

warnings or precautions. To reduce the risk of poisoning or

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

9 Part No. F8669401ENR4

Safety Information

chemical burns, keep them out of the reach of children at all

times [preferably in a locked cabinet].

• Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of the fabric softener

or product.

• Always follow the fabric care instructions supplied by the textile manufacturer.

• Loading door MUST BE CLOSED any time the washer is to

fill, tumble or spin. DO NOT bypass the loading door switch

by permitting the washer to operate with the loading door

open. Do not attempt to open the door until the washer has

drained and all moving parts have stopped.

• Be aware that hot water is used to flush the supply dispenser.

Avoid opening the dispenser lid while the machine is running.

• Do not attach anything to the supply dispenser’s nozzles, if

applicable. The air gap must be maintained.

• Do not operate the machine without the water reuse plug or

water reuse system in place, if applicable.

• Be sure water connections have a shut-off valve and that fill

hose connections are tight. CLOSE the shut-off valves at the

end of each wash day.

• Keep washer in good condition. Bumping or dropping the

washer can damage safety features. If this occurs, have washer checked by a qualified service person.

• DANGER: Before inspecting or servicing machine, power

supply must be turned OFF. The servicer needs to wait for at

least 5 minutes after turning the power OFF and needs to

check for residual voltage with a voltage meter. The inverter

capacitor or EMC filter remains charged with high voltage for

some time after powering OFF. This is an imminently hazardous situation that, if not avoided, will cause severe personal

injury or death.

• Do not repair or replace any part of the washer, or attempt any

servicing unless specifically recommended in the user-maintenance instructions or in published user-repair instructions that

the user understands and has the skills to carry out. ALWAYS

disconnect the washer from electrical, power and water supplies before attempting any service.

• Disconnect the power by turning off the circuit breaker or by

unplugging the machine. Replace worn power cords.

• Before the washer is removed from service or discarded, remove the door to the washing compartment.

• Failure to install, maintain, and/or operate this washer according to the manufacturer’s instructions may result in conditions

which can produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not meant

to cover all possible conditions and situations that may

occur. Common sense, caution and care must be exercised when installing, maintaining, or operating the

washer.

WARNING

Machine installations must comply with minimum

specifications and requirements stated in the applicable Installation Manual, any applicable municipal

building codes, water supply requirements, electrical

wiring regulations and any other relevant statutory

regulations. Due to varied requirements and applicable local codes, this machine must be installed, adjusted, and serviced by qualified maintenance personnel familiar with applicable local codes and the

construction and operation of this type of machinery.

They must also be familiar with the potential hazards

involved. Failure to observe this warning may result

in personal injury, property damage, and/or equipment damage, and will void the warranty.

W820

IMPORTANT: Ensure that the machine is installed on a

level floor of sufficient strength. Ensure that the recommended clearances for inspection and maintenance are

provided. Never allow the inspection and maintenance

space to be blocked.

WARNING

Never touch internal or external steam pipes, connections, or components. These surfaces can be extremely hot and will cause severe burns. The steam

must be turned off and the pipe, connections, and

components allowed to cool before the pipe can be

touched.

SW014

NOTE: All appliances are produced according the EMCdirective (Electro-Magnetic-Compatibility). They can be

used in restricted surroundings only (comply minimally

with class A requirements). For safety reasons there

must be kept the necessary precaution distances with

sensitive electrical or electronic device(s). These machines are not intended for domestic use by private

consumers in the home environment.

Safety Decals

Safety decals appear at crucial locations on the machine. Failure

to maintain legible safety decals could result in injury to the operator or service technician.

Use manufacturer-authorized spare parts to avoid safety hazards.

Any problems or conditions not understood should be reported to

the dealer, distributor, service agent or the manufacturer.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

10 Part No. F8669401ENR4

Operator Safety

WARNING

NEVER insert hands or objects into basket until it

has completely stopped. Doing so could result in serious injury.

SW012

Machines referred to by model in this manual are intended to be

used by the general public in applications such as:

• staff areas in shops, offices, kitchens and other working environments

• by clients in hotels, motels and other residential type environments

• areas for communal use in blocks of flats or in launderettes

• any other similar applications

Installation of these machines must fully conform to the instructions contained in this manual.

The following maintenance checks must be performed daily:

1. Verify that all warning labels are present and legible, replace

as necessary.

2. Check door interlock before starting operation of the machine:

a. Attempt to start the machine with the door open. The ma-

chine should not start.

b. Close the door without locking it and start the machine.

The machine should not start.

c. Attempt to open the door while a cycle is in progress. The

door should not open.

If the door lock and interlock are not functioning properly, disconnect power and call a service technician.

3. Do not attempt to operate the machine if any of the following

conditions are present:

a. The door does not remain securely locked during the en-

tire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly grounded circuit.

Safety Information

Do not bypass any safety devices in the machine.

WARNING

Operating the machine with severe out-of-balance

loads could result in personal injury and serious

equipment damage.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

W728

11 Part No. F8669401ENR4

Introduction

Model Identification

Information in this manual is applicable to these models:

Introduction

20 Models

SCA020VC

SCA020VD

SCA020VE

SCA020VF

SCA020VH

SCA020VL

SCA020VT

SCA020VQ

SCA020VV

SCA020VX

SCA020VY

SCD020VC

SCD020VD

SCD020VE

SCD020VF

SCD020VH

SCD020VL

SCD020VT

SCD020VQ

SCD020VV

SCD020VX

SCD020VY

SCE020VC

SCE020VD

SCE020VE

SCE020VF

SCE020VH

SCE020VL

SCE020VT

SCE020VQ

SCE020VV

SCE020VX

SCE020VY

SCG020VC

SCG020VD

SCG020VE

SCG020VF

SCG020VH

SCG020VL

SCG020VT

SCG020VQ

SCG020VV

SCG020VX

SCG020VY

SCH020VC

SCH020VD

SCH020VE

SCH020VF

SCH020VH

SCH020VL

SCH020VQ

SCH020VT

SCH020VV

SCH020VX

SCH020VY

SCJ020VV

SCK020VC

SCK020VD

SCK020VE

SCK020VF

SCK020VH

SCK020VL

SCK020VQ

SCK020VT

SCK020VV

SCK020VX

SCK020VY

SCL020VC

SCL020VD

SCL020VE

SCL020VF

SCL020VH

SCL020VL

SCL020VQ

SCL020VT

SCL020VV

SCL020VX

SCL020VY

SCT020VC

SCT020VD

SCT020VE

SCT020VF

SCT020VH

SCT020VL

SCT020VT

SCT020VQ

SCT020VV

SCT020VX

SCT020VY

SCU020VC

SCU020VD

SCU020VE

SCU020VF

SCU020VH

SCU020VL

SCU020VT

SCU020VQ

SCU020VV

SCU020VX

SCU020VY

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

12 Part No. F8669401ENR4

30 Models

Introduction

SCA030VC

SCA030VD

SCA030VE

SCA030VF

SCA030VH

SCA030VL

SCA030VT

SCA030VQ

SCA030VV

SCA030VX

SCA030VY

SCD030VC

SCD030VD

SCD030VE

SCD030VF

SCD030VH

SCD030VL

SCD030VT

SCD030VQ

SCD030VV

SCD030VX

SCD030VY

SCE030VC

SCE030VD

SCE030VE

SCE030VF

SCE030VH

SCE030VL

SCE030VT

SCE030VQ

SCE030VV

SCE030VX

SCE030VY

SCG030VC

SCG030VD

SCG030VE

SCG030VF

SCG030VH

SCG030VL

SCG030VT

SCG030VQ

SCG030VV

SCG030VX

SCG030VY

SCH030VC

SCH030VD

SCH030VE

SCH030VF

SCH030VH

SCH030VL

SCH030VQ

SCH030VT

SCH030VV

SCH030VX

SCH030VY

SCJ030VD

SCJ030VV

SCK030VC

SCK030VD

SCK030VE

SCK030VF

SCK030VH

SCK030VL

SCK030VQ

SCK030VT

SCK030VV

SCK030VX

SCK030VY

SCL030VC

SCL030VD

SCL030VE

SCL030VF

SCL030VH

SCL030VL

SCL030VQ

SCL030VT

SCL030VV

SCL030VX

SCL030VY

SCT030VC

SCT030VD

SCT030VE

SCT030VF

SCT030VH

SCT030VL

SCT030VT

SCT030VQ

SCT030VV

SCT030VX

SCT030VY

SCU030VC

SCU030VD

SCU030VE

SCU030VF

SCU030VH

SCU030VL

SCU030VT

SCU030VQ

SCU030VV

SCU030VX

SCU030VY

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

13 Part No. F8669401ENR4

Introduction

40 Models

SCA040VC

SCA040VD

SCA040VE

SCA040VF

SCA040VH

SCA040VL

SCA040VT

SCA040VQ

SCA040VV

SCA040VX

SCA040VY

SCE040VC

SCE040VD

SCE040VE

SCE040VF

SCE040VH

SCE040VL

SCE040VT

SCE040VQ

SCE040VV

SCE040VX

SCE040VY

SCG040VC

SCG040VD

SCG040VE

SCG040VF

SCG040VH

SCG040VL

SCG040VT

SCG040VQ

SCG040VV

SCG040VX

SCG040VY

SCH040VC

SCH040VD

SCH040VE

SCH040VF

SCH040VH

SCH040VL

SCH040VQ

SCH040VT

SCH040VV

SCH040VX

SCH040VY

SCJ040VV

SCK040VC

SCK040VD

SCK040VE

SCK040VF

SCK040VH

SCK040VL

SCK040VQ

SCK040VT

SCK040VV

SCK040VX

SCK040VY

SCL040VC

SCL040VD

SCL040VE

SCL040VF

SCL040VH

SCL040VL

SCL040VQ

SCL040VT

SCL040VV

SCL040VX

SCL040VY

SCT040VC

SCT040VD

SCT040VE

SCT040VF

SCT040VH

SCT040VL

SCT040VT

SCT040VQ

SCT040VV

SCT040VX

SCT040VY

SCU040VC

SCU040VD

SCU040VE

SCU040VF

SCU040VH

SCU040VL

SCU040VT

SCU040VQ

SCU040VV

SCU040VX

SCU040VY

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

14 Part No. F8669401ENR4

60 Models

Introduction

SCA060VC

SCA060VD

SCA060VE

SCA060VF

SCA060VH

SCA060VL

SCA060VT

SCA060VQ

SCA060VV

SCA060VX

SCA060VY

SCE060VC

SCE060VD

SCE060VE

SCE060VF

SCE060VH

SCE060VL

SCE060VT

SCE060VQ

SCE060VV

SCE060VX

SCE060VY

SCG060VC

SCG060VX

SCG060VD

SCG060VE

SCG060VF

SCG060VH

SCG060VL

SCG060VT

SCG060VQ

SCG060VV

SCG060VX

SCG060VY

SCH060VC

SCH060VD

SCH060VE

SCH060VF

SCH060VH

SCH060VL

SCH060VV

SCH060VQ

SCH060VT

SCH060VX

SCH060VY

SCJ060VV

SCK060VC

SCK060VD

SCK060VE

SCK060VF

SCK060VH

SCK060VL

SCK060VQ

SCK060VT

SCK060VV

SCK060VX

SCK060VY

SCL060VC

SCL060VD

SCL060VE

SCL060VF

SCL060VH

SCL060VL

SCL060VQ

SCL060VT

SCL060VV

SCL060VX

SCL060VY

SCT060VC

SCT060VD

SCT060VE

SCT060VF

SCT060VH

SCT060VL

SCT060VT

SCT060VQ

SCT060VV

SCT060VX

SCT060VY

SCU060VC

SCU060VD

SCU060VE

SCU060VF

SCU060VH

SCU060VL

SCU060VT

SCU060VQ

SCU060VV

SCU060VX

SCU060VY

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

15 Part No. F8669401ENR4

Introduction

80 Models

SCA080VC

SCA080VD

SCA080VE

SCA080VF

SCA080VH

SCA080VL

SCA080VQ

SCA080VT

SCA080VV

SCA080VX

SCA080VY

SCG080VH

SCG080VL

SCG080VT

SCG080VQ

SCG080VC

SCG080VD

SCG080VE

SCG080VF

SCG080VV

SCG080VX

SCG080VY

SCH080VC

SCH080VD

SCH080VE

SCH080VF

SCH080VH

SCH080VL

SCH080VQ

SCH080VT

SCH080VV

SCH080VX

SCH080VY

SCJ080VV

SCK080VC

SCK080VD

SCK080VE

SCK080VF

SCK080VH

SCK080VL

SCK080VQ

SCK080VT

SCK080VV

SCK080VX

SCK080VY

SCT080VC

SCT080VD

SCT080VE

SCT080VF

SCT080VH

SCT080VL

SCT080VT

SCT080VQ

SCT080VV

SCT080VX

SCT080VY

SCU080VC

SCU080VD

SCU080VE

SCU080VF

SCU080VH

SCU080VL

SCU080VT

SCU080VQ

SCU080VV

SCU080VX

SCU080VY

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

16 Part No. F8669401ENR4

100 Models

TMB1880R_SVG

Introduction

SCA100VC

SCA100VD

SCA100VE

SCA100VF

SCA100VH

SCA100VL

SCA100VT

SCA100VQ

SCA100VV

SCA100VX

SCA100VY

SCG100VC

SCG100VD

SCG100VE

SCG100VF

SCG100VH

SCG100VL

SCG100VT

SCG100VQ

SCG100VV

SCG100VX

SCG100VY

SCH100VC

SCH100VD

SCH100VE

SCH100VF

SCH100VH

SCH100VL

SCH100VQ

SCH100VT

SCH100VV

SCH100VX

SCH100VY

SCJ100VV

SCK100VC

SCK100VD

SCK100VE

SCK100VF

SCK100VH

SCK100VL

S30 (13/13 Kg) Stacked Washer-Extractor/Tumble Dryer

SSG030E SST030E

SSG030L SST030L

SSG030N SST030N

S50 (23/23 Kg) Stacked Washer-Extractor/Tumble Dryer

SSG050L SST050L

SCK100VQ

SCK100VT

SCK100VV

SCK100VX

SCK100VY

SCT100VC

SCT100VD

SCT100VE

SCT100VF

SCT100VH

SCT100VL

SCT100VT

SCT100VQ

SCT100VV

SCT100VX

SCT100VY

SCU100VC

SCU100VD

SCU100VE

SCU100VF

SCU100VH

SCU100VL

SCU100VT

SCU100VQ

SCU100VV

SCU100VX

SCU100VY

SSG050N SST050N

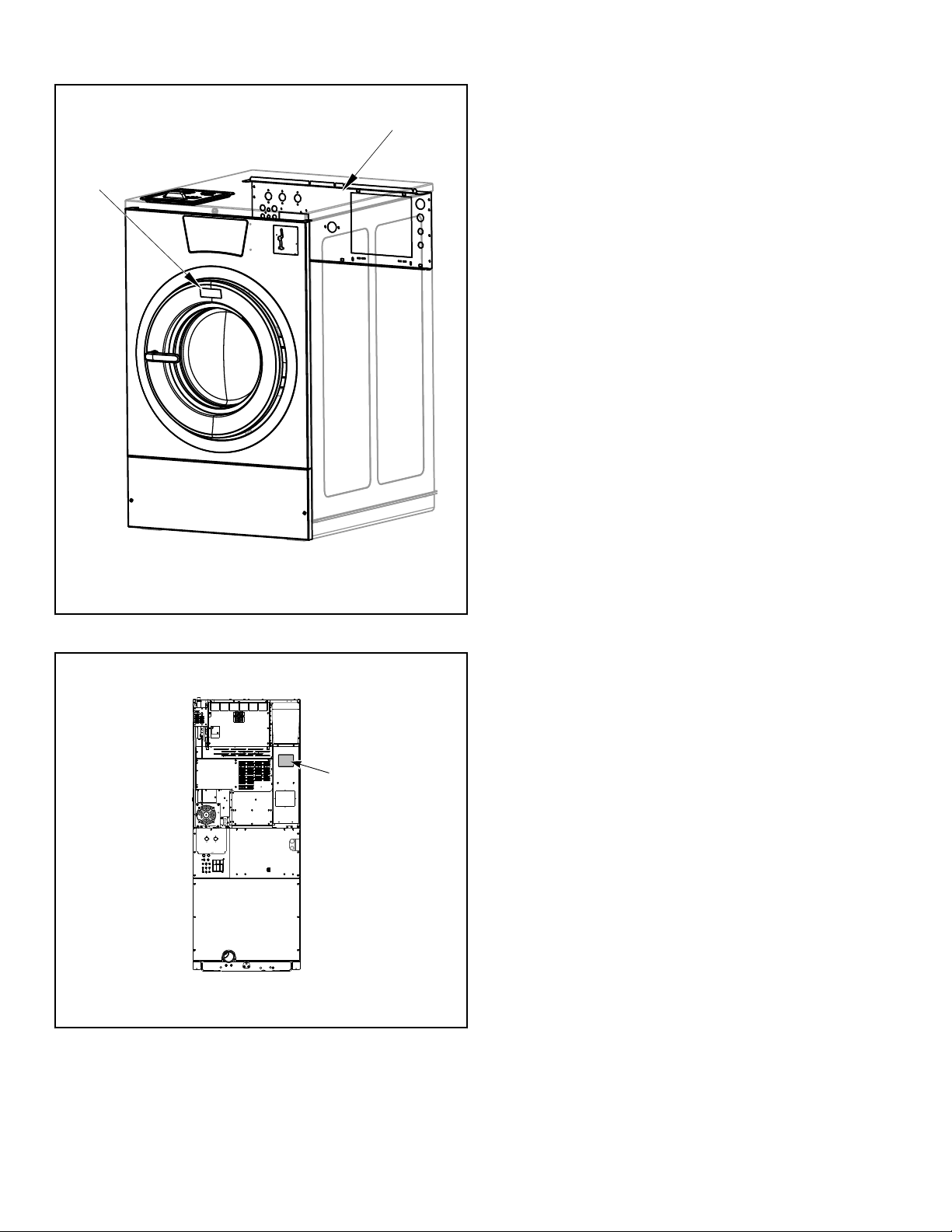

Serial Plate Location

1. From the System Menu, select DIAGNOSTICS to enter the

Diagnostics Menu.

2. From the Diagnostics Menu, select MACHINE ID. The MACHINE ID display includes the machine's model and serial

number.

Figure 2

Always provide the machine’s serial number and model number

when ordering parts or when seeking technical assistance. Refer

to Figure 3 or Figure 4 .

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

17 Part No. F8669401ENR4

2

1

C-CHM11P12

STX5N_SVG

1

Introduction

Model Example of Serial Plate Location

Replacement Parts

If literature or replacement parts are required, contact the source

from which the machine was purchased or contact Alliance Laundry Systems at +1 (920) 748-3950 for the name and address of

the nearest authorized parts distributor.

Customer Service

For technical assistance, contact your local distributor or contact:

Alliance Laundry Systems

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

U.S.A.

www.alliancelaundry.com

Phone: +1 (920) 748-3121 Ripon, Wisconsin

1. Serial Plate on Panel

2. Serial Plate on Door Frame

Figure 3

Stacked Washer-Extractor/Tumble Dryer Serial Plate

Location

1. Serial Plate

Figure 4

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

18 Part No. F8669401ENR4

Preliminary Information

CHM2043R_SVG

Preliminary Information

About the Control

The control on the machine is an advanced, graphical, programmable computer that lets the owner control most machine features by interacting with the control.

This control allows the owner to program custom cycles, run diagnostic tests and retrieve audit and error information. Limited

programmable options can be programmed manually via the Set-

tings Menu. Full programmable options can be programmed via

IR Communications and Wi-Fi Communications.

Machines shipped from the factory have default cycles and wash

temperature settings built in. The owner can change the default

cycles or any cycle.

IMPORTANT: It is extremely important that the machine

has a positive ground and that all mechanical and electrical connections are made before applying power to

or operating the machine.

IR Communications

The control has the ability to communicate with a PC with an IrDA device running the control software. Devices such as PCs

that are IrDA capable (able to transmit information to machine)

that have been tested and approved for use with the control software can be used as a tool for managing the machine.

face device. Connection with the ALS Wi-Fi Network allows the

user to program, collect data, and run diagnostics remotely.

Audit Information

The control collects and stores audit information which can be

accessed through the touch display, IR communication or Wi-Fi

communication. Refer to the Audit Data Menu for a list of available audit information.

Using IR communication or Wi-Fi communication, the user can

receive audit and program data from the control and send programming data and diagnostic commands to the control.

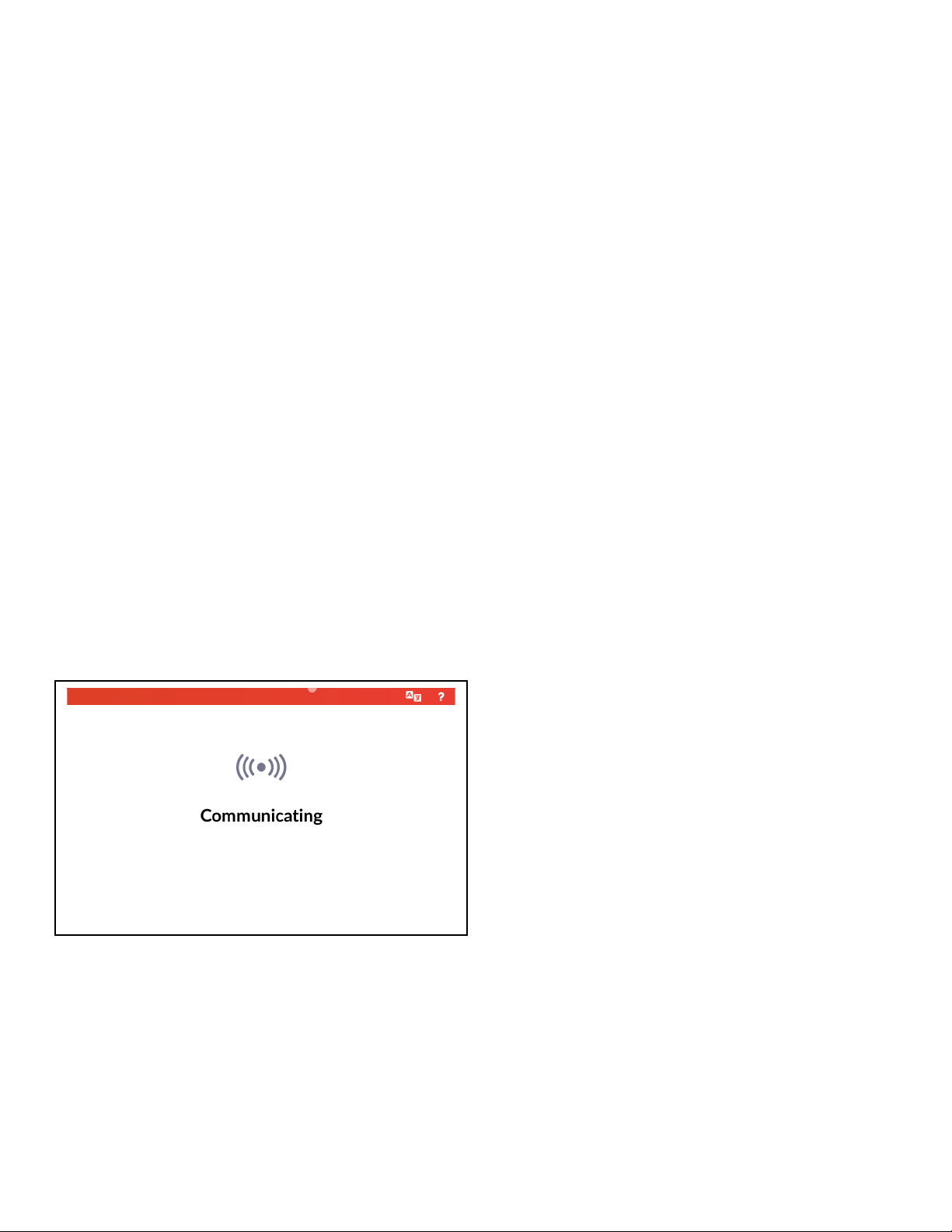

IR Communications Menu

Figure 5

The IR Communications Menu displays while the control is communicating with a PC. The control will return to the previous

page when the communication is complete.

Wi-Fi Communications

The control has the ability to connect with the ALS Wi-Fi Network via an internet connection using the network gateway inter-

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

19 Part No. F8669401ENR4

Special Features

Special Features

Break-In Alarm

The Break-In Alarm allows the owner to program the machine to

set a Break-In Alarm Error if the Service Door or Coin Vault is

opened without first disabling the alarm.

Cycle Time Display

The Run Menu shows the time remaining in the currently running

cycle for user convenience.

Cycle Completed Timer

If enabled in programming, a timer begins counting up in the Cycle Complete Menu since the cycle ended.

Passcode Security

If enabled in programming, this option allows the owner to require a passcode to gain access to Rapid Advance Activation, Di-

agnostics Menu, Drop Off Mode, Lockout Mode, Settings Menu,

Audit Data Menu, Reset Menu and various sub-menus.

To disable passcode protection to the System Menu, programming

through PC communication is required.

Language Selection

The control contains 34 languages. Once a language is selected,

all menus and displays will be shown in the chosen language.

Special Vend

The Special Vend option allows the owner to set a special vend

price or free vend between specific times of day, days of week,

dates, months and years. The owner can program the control for

up to eight (8) Special Vends periods. The owner can manually

program Special Vend 1 and can only enable or disable Special

Vends 2-8. Full programming of all Special Vends requires the

use of a PC. Refer to the System Menu for manual programming.

Increased Water Levels

Increased water levels is a modifier option that can be enabled/

disabled for the Cycle Modifier 1 and 2 options. Refer to Globals

Menu. If enabled, a cycle containing Prewash, Wash, or Rinse

Fill or Reuse Fill steps would ignore that programmed water level

and instead use the Increased Water Level for Prewash, Wash, or

Rinse steps.

Increased Spin Speed

Increased Spin Speed is a modifier option that can be enabled/

disabled for the Cycle Modifier 1 and 2 options. Refer to System

Menu. If enabled, a cycle containing extract steps with the spin

step label would ignore the cycle programmed spin speed and instead attempt the Increased Spin Speed parameter’s globally programmed value.

Dispense Soap

Lucky Cycle

The Lucky Cycle option allows the owner to program the machine to provide a free or reduced vend cycle to users after a programmed number of machine cycles have occurred or on certain

dates and times. Refer to Lucky Cycle Mode for more information.

Speed Cycle

Speed Cycle allows the owner to program special cycles with a

shorter total wash time to save the user time. The owner can program the Speed Cycle with distinct vend prices and functions.

Refer to Speed Cycle for more information.

This option can be programmed for machines that are equipped

with supply injection.

When the Supply Injection prompt parameter is enabled, refer to

Settings Menu, the user will be prompted to accept and pay for

external supplies with the start of a cycle. A cycle programmed

with external supply signals that would normally trigger during

cycle operation would be restricted from activating if the prompt

is enabled, unless the feature was accepted and paid for during

the prompt at the beginning of the cycle. Cycle execution should

halt during this prompt since it is dependent upon water to flush

the paid-for chemical into the basket.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

20 Part No. F8669401ENR4

Control Identification

Control Identification

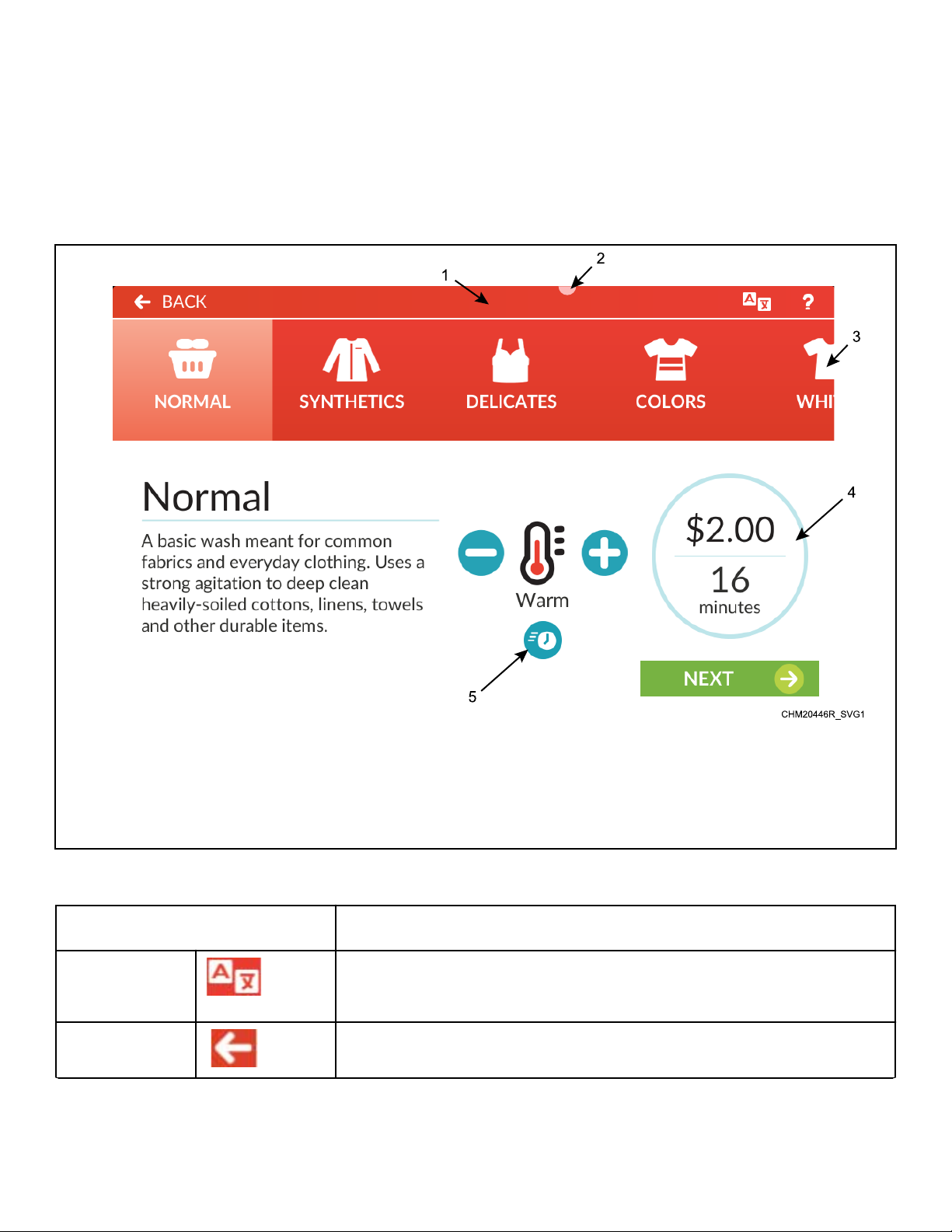

Operational Touch Display

The control includes a capacitive touch display with text and

icons that are available for the operator to control and manage the

machine's operation. The primary icons used for general naviga-

tion that are available on most menus and displays are shown in

Table 1 . Additional icons and descriptions are described throughout this manual as needed. Sections of certain menu displays can

be swiped to scroll through options.

1. System Menu Access (touch and hold for 5 seconds)

2. Non-Fatal Error Indicator

3. Preset Ribbon

4. Cycle Properties/Cycle Status Ring

5. Speed Cycle Indicator

Figure 6

Icon* Description

Translate Touch to open the Language Select Panel showing the list of available languages. The

default language is at the top of the list. Selecting a different language changes all displays to that language.

Back Touch to navigate to the previously-displayed menu.

Table 1 continues...

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

21 Part No. F8669401ENR4

CHM2045R_SVG

CHM2046R_SVG

Control Identification

Icon* Description

Help Touch to display the Help Menu showing (if programmed in the Settings Menu) staff

contact phone number, machine operating instructions, soap dispenser icon key and

common questions.

Wi-Fi Signal

Strength

Shows the connectivity status and signal strength of the Wi-Fi connection. This icon is

only shown in the System Menu. Touch to access Wi-Fi Settings.

Directional Arrow Indicates there is more information than what is visible on the screen.

*Not all icons are shown on every menu or display.

Table 1

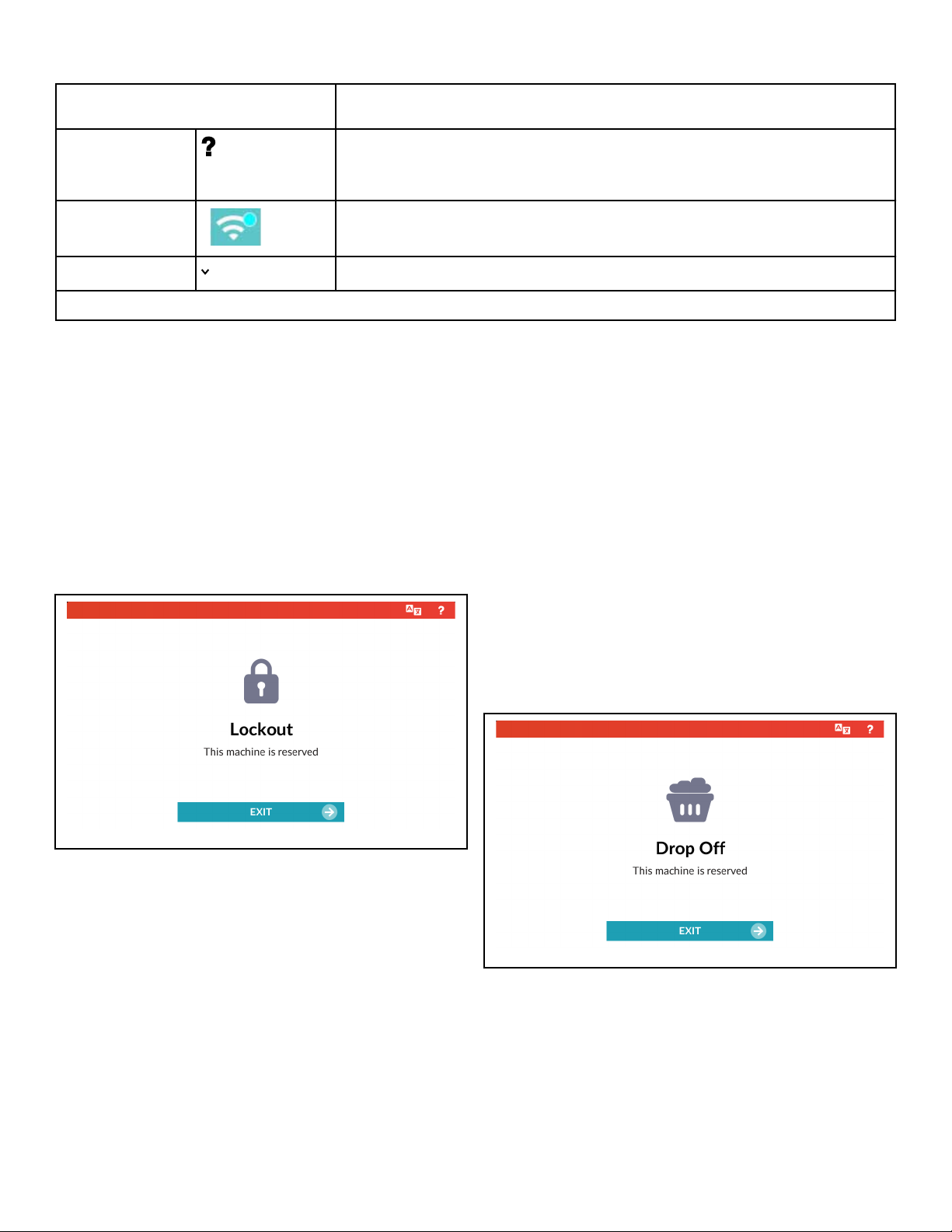

Operation Modes

ters and the machine has either not received any vend or is configured for free vend. If the lockout time occurs during a cycle,

In each mode of operation, the user may touch the screen or communicate with the control to change the displayed menu.

the machine waits until the cycle ends, then enters Lockout Mode

if the time is still within the programmed time period. The control

automatically exits Lockout Mode when the Lockout Duration

Ready Mode

The control is ready for operation in Ready Mode. The control

displays the Approach Page, if enabled. If there is no user input

for 4.25 minutes, the display dims.

Lockout Mode

time has elapsed.

To exit Lockout, send a command via PC connection, program

the Lockout Duration to 0, or enter the Lockout Unlock Passcode.

The control limits access to certain features while in Lockout

Mode. Audit counters (refer to Audit Data Menu), manual programming (refer to Settings Menu) and communication via an external device (IR, network, payment system, etc) are available.

The control will also display errors as usual. The Diagnostics

Menu and Rapid Advance Activation are not available during

Lockout Mode.

Figure 7

This feature prevents the machine from being used except by a

particular user who has reserved the machine in advance. If a user

pays or reserves a machine from a kiosk or central pay system,

the machine enters Lockout Mode and the user is given a passcode to unlock the reserved machine. This guarantees that the

user does not need to wait for an available machine or risk that

the selected machine is taken after vend is added.

To access the reserved machine, touch EXIT and enter the passcode. If the passcode is entered correctly, the control displays the

Cycle Preset Page.

If programmed, the machine enters Lockout Mode when the current time falls within the time period set in the Lockout parame-

Drop Off Mode

Figure 8

This feature allows the owner to limit machine use to an attendant without requiring vend. The attendant accesses the machine

by entering the programmed Drop Off Passcode.

To access the machine in Drop Off Mode, touch EXIT and enter

the passcode. If the passcode is entered correctly, the control displays the Cycle Preset .

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

22 Part No. F8669401ENR4

Control Identification

The machine enters Drop Off Mode when enabled in programming. To exit, disable Drop Off Mode in programming.

The Diagnostics Menu and Rapid Advance Activation are not

available during Drop Off Mode.

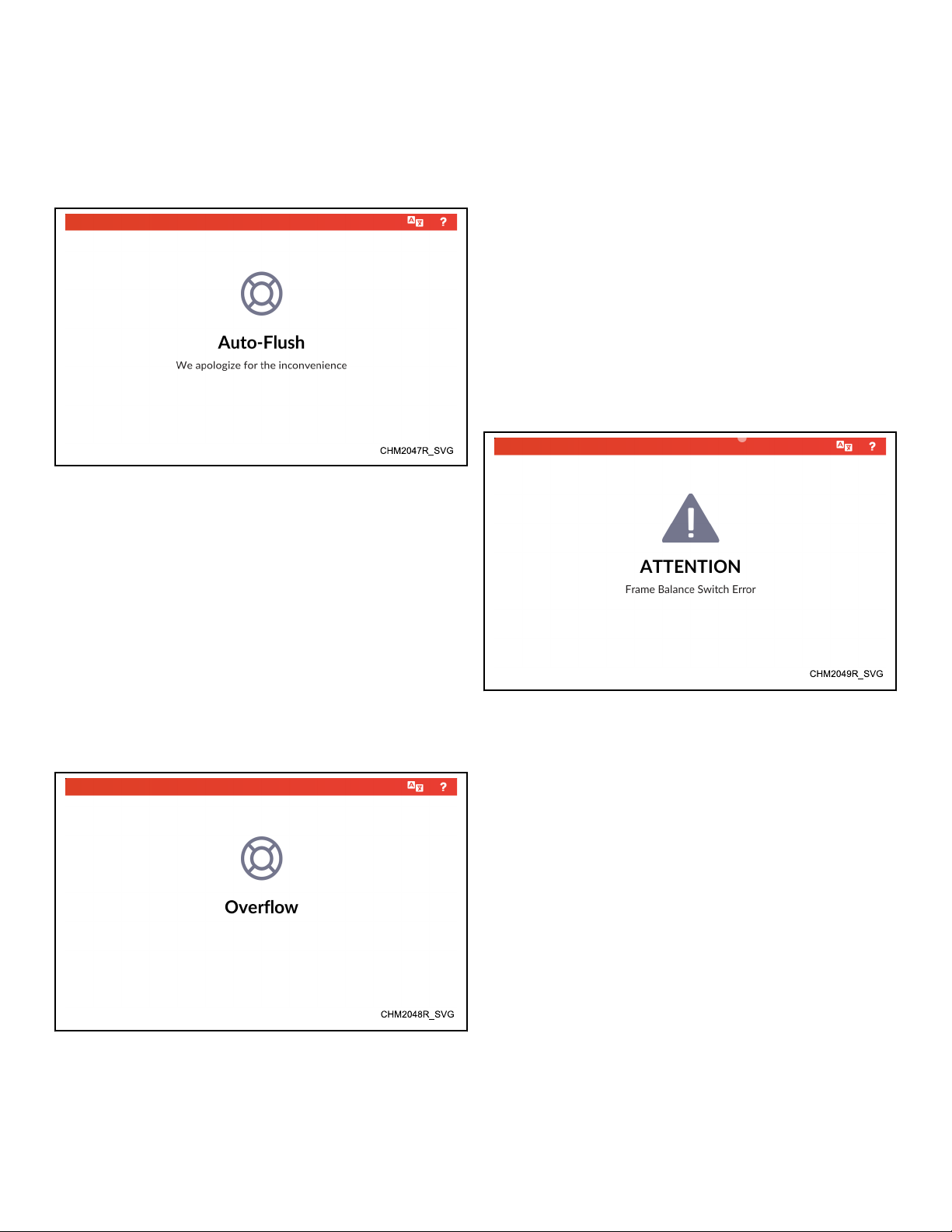

Auto-Flush Mode

Figure 9

This feature is used to periodically clean out the basket and dispenser compartments. This option is programmable through a PC

connection.

"Overflow". If disabled, the control does not display the overflow

condition.

If overflow occurs during a cycle, the cycle time pauses, water

valves and heater outputs turn off and the machine drains until

the water level is below the highest programmable water level. If

the water level drops below the overflow level within five (5) minutes of first detection and the door is locked, the cycle continues

as normal. If the control continues to see an overflow level after

five (5) minutes with the door locked, the control enters Machine

Error Mode with an Overflow Error (Fatal).

If not in a cycle, the machine drains until empty. If the door is

open or is unable to lock and the water level does not drop below

the overflow level after one (1) minute, the control enters Ma-

chine Error Mode with an Overflow Error (Fatal).

All vending inputs are ignored during this mode.

Machine Error Mode

The control enters Auto-Flush Mode on the programmed day and

time after the programmed number of cycles have occurred. The

door must be closed with no cycle running or vend added. During

Auto-Flush Mode, the control locks the door, turns of the pump

or opens the gravity drain, turns on the hot water to flush each

compartment and ignores all user inputs.

When Auto-Flush is complete, the control unlocks the door and

returns to the previous display.

Overflow Mode

Figure 11

The control enters this mode when an error is set. The control

displays the error and error information. The owner can enable

and disable certain errors and error displays as well as access to

clear errors in programming.

A notch appears in the header bar when a non-fatal error is set.

Figure 10

The control enters this mode when the control detects the water

level is too high. If enabled in programming, the display shows

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

23 Part No. F8669401ENR4

CHM2051R_SVG

CHM2052R_SVG

Control Identification

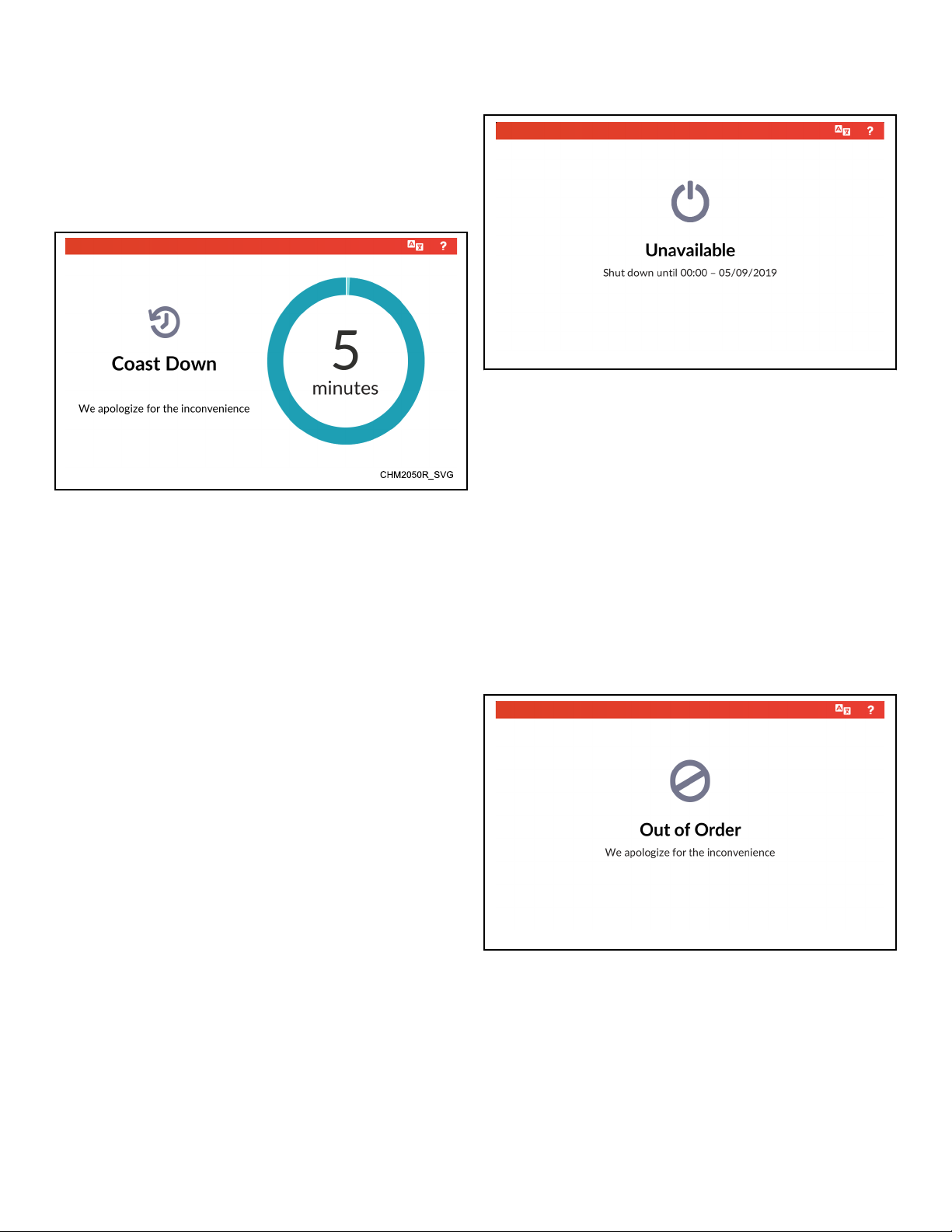

Internal Control Failure

If the control detects an error in its software or hardware, all outputs are turned off and the control displays the failure. If this condition persists after an attempt to restart, then the control must be

replaced.

Coast Down Mode

Figure 13

The machine enters Coast Down Mode when an error or power

failure occurs during an extract cycle step. This mode allows for

adequate time to stop any spinning motion of the basket.

Shutdown Mode

Figure 14

The shutdown option allows the owner to program the machine to

enter Shutdown Mode for a certain time and date range. The control displays "Unavailable" and ignores all screen touches and

vend additions. The Language Selection Panel , Settings Menu

and Help Menu are accessible while in Shutdown Mode.

The control enters Shutdown Mode at the start date and time set

in programming and takes priority over other modes of operation.

The control remains in Shutdown Mode until the end date and

time set in programming.

The control shows the Coast Down display with a coast down

timer for five (5) minutes. If the control enters Coast Down Mode

upon power-up, the length of the power fail is subtracted from the

timer. Multiple power cycles will not reset the timer. The control

exits Coast Down Mode before the timer expires once the basket

stops spinning.

While in Coast Down Mode, the Settings Menu, Language Selec-

tion Panel and Help Menu are accessible.

If the control enters Coast Down Mode because of a power failure, the control returns to Approach Screen (if enabled) or the Cy-

cle Preset . If Coast Down Mode occurred from an error, the control enters Out of Order Mode.

The control cannot enter Shutdown Mode if running a cycle, in

Lockout Mode or if vend has been added. The control will enter

Shutdown Mode once those conditions are cleared.

Out of Order Mode

Figure 15

The owner can activate and deactivate Out of Order Mode

through the Settings Menu from the Approach Page and the Cycle

Preset Page.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

The display shows "Out of Order" and "We apologize for the inconvenience" to show the the machine is unavailable. The machine will accept coins, but the vend does not count toward a cycle. The control does not allow cycles to run in this mode.

24 Part No. F8669401ENR4

While in Out of Order Mode, the Settings Menu, Language Selection Panel and Help Menu are accessible.

Control Identification

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

25 Part No. F8669401ENR4

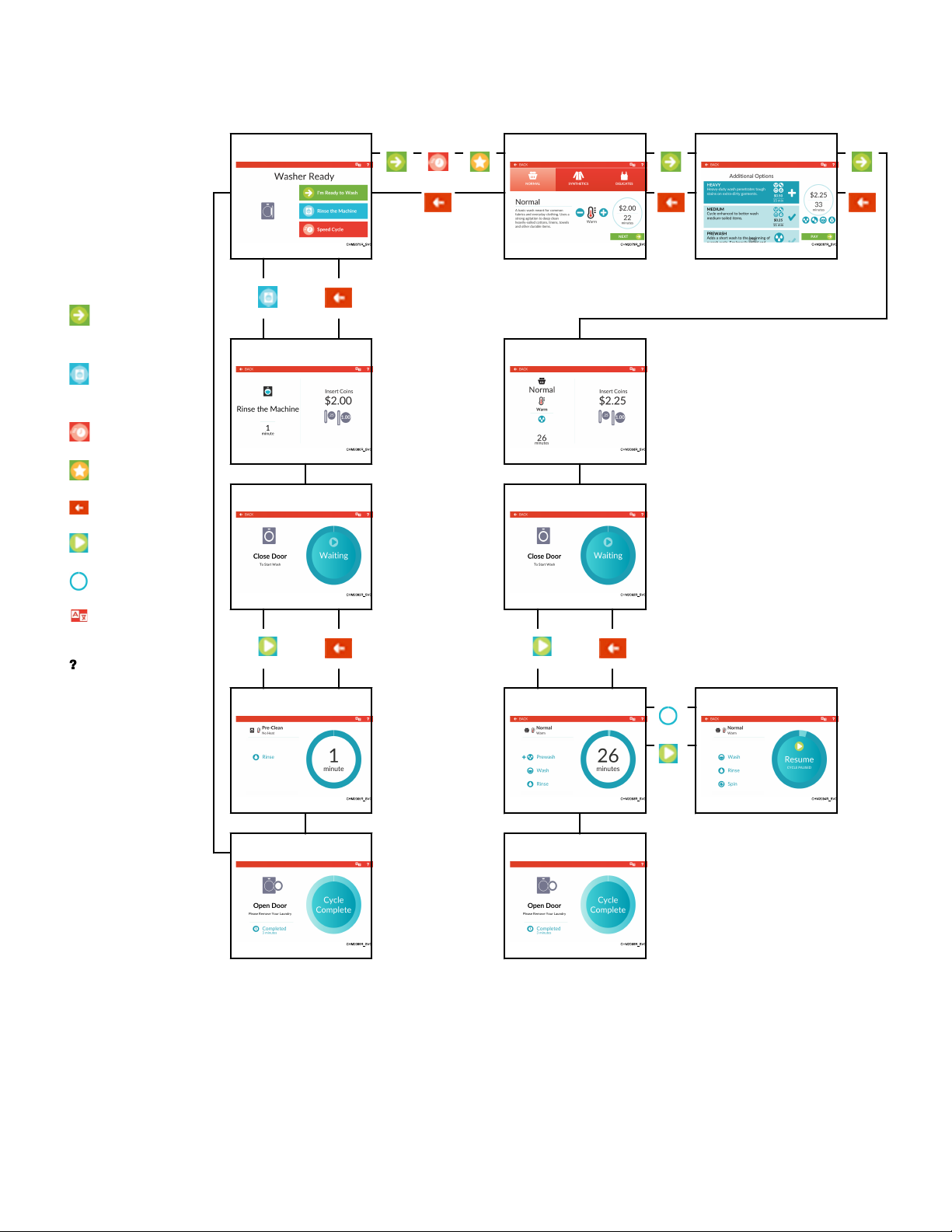

Menu Navigation

Refer to the following charts for maps of the display menus.

Menu Navigation

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

26 Part No. F8669401ENR4

System Menu Navigation

NOTE: Refer to a specific menu section for sub-menus and additional information.

Menu Navigation

SYSTEM MENU

Rapid Advance*

Cancel Cycle

Error Presentation

Partial Vend Presentation

Settings*

Audit Data

Diagnostics*

Service Schedule

Reset*

* PASSCODE

(bypassed if disabled)

RAPID ADVANCE

Activate

CANCEL CYCLE

Cancel

ERROR PRESENT

Clear

PARTIAL VEND

PRESENT

Clear

AUDIT DATA

Machine Totals

Resettable Counters

Other Metrics

Individual Cycle

Counts

SERVICE SCHED-

ULE

Daily

Monthly

Yearly

RESET

Global Settings

Cycle Resets

SETTINGS

Vend Settings

Basic Settings

Machine Settings

Cycle Settings

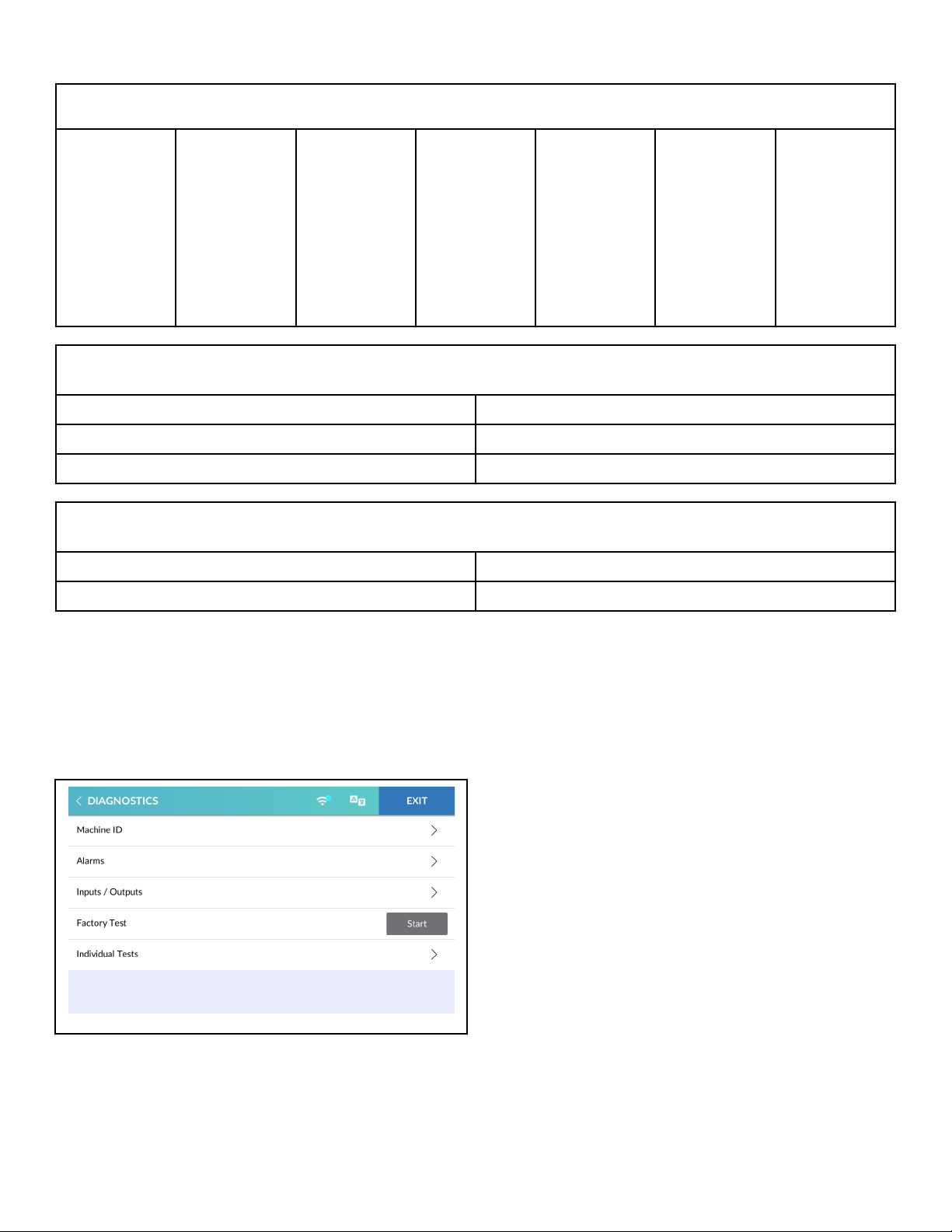

DIAGNOSTICS

Machine ID

Alarms

Inputs/Outputs

Factory Test

Individual Tests

MACHINE SET-

TINGS

Machine Configuration

Approach Screen

Custom Approach

Message

Errors

Suds Removal Routine

Pocket Indicator

Heating Indicator

Temperature Display

Target Temperature

Valve Limits

Connection Settings

Modes

Output Signals

BASIC SETTINGS

Language Settings

Time and Date

Temperature Units

Speed Units

Display Settings

Audio Signal

Time Display

Cycle Complete

Timer

CYCLE SET-

TINGS

Default Cycle

Cycle Programming

Cycle Options

Global Water Temperatures

Global Water Levels

Hold Step Custom

Messages

Other Settings

Cycle Temperature

Overrides

VEND SETTINGS

Currency

Payment Settings

Vend Price Display

Override

Vend Prices

Vend Price Modifiers

Cycle Modifier Settings

Lucky Cycle

Special Vend

Pre-Clean Cycle Interval

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

27 Part No. F8669401ENR4

Menu Navigation

Cycle Menus Navigation (Vend Mode)

Approach Screen Cycle Preset Additional Options Menu

Navigation Key

I'm Ready to Wash/

NEXT/PAY

Rinse the Machine (if

availible)

Speed Cycle

Lucky Cycle

BACK

Payment Menu Payment Menu

Close Door Menu Close Door Menu

START/Resume

Pause

Language Selection

Panel

Help Menu

Pre-Clean Run Menu Cycle Pause Menu

Cycle Complete Menu Cycle Complete Menu

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

28 Part No. F8669401ENR4

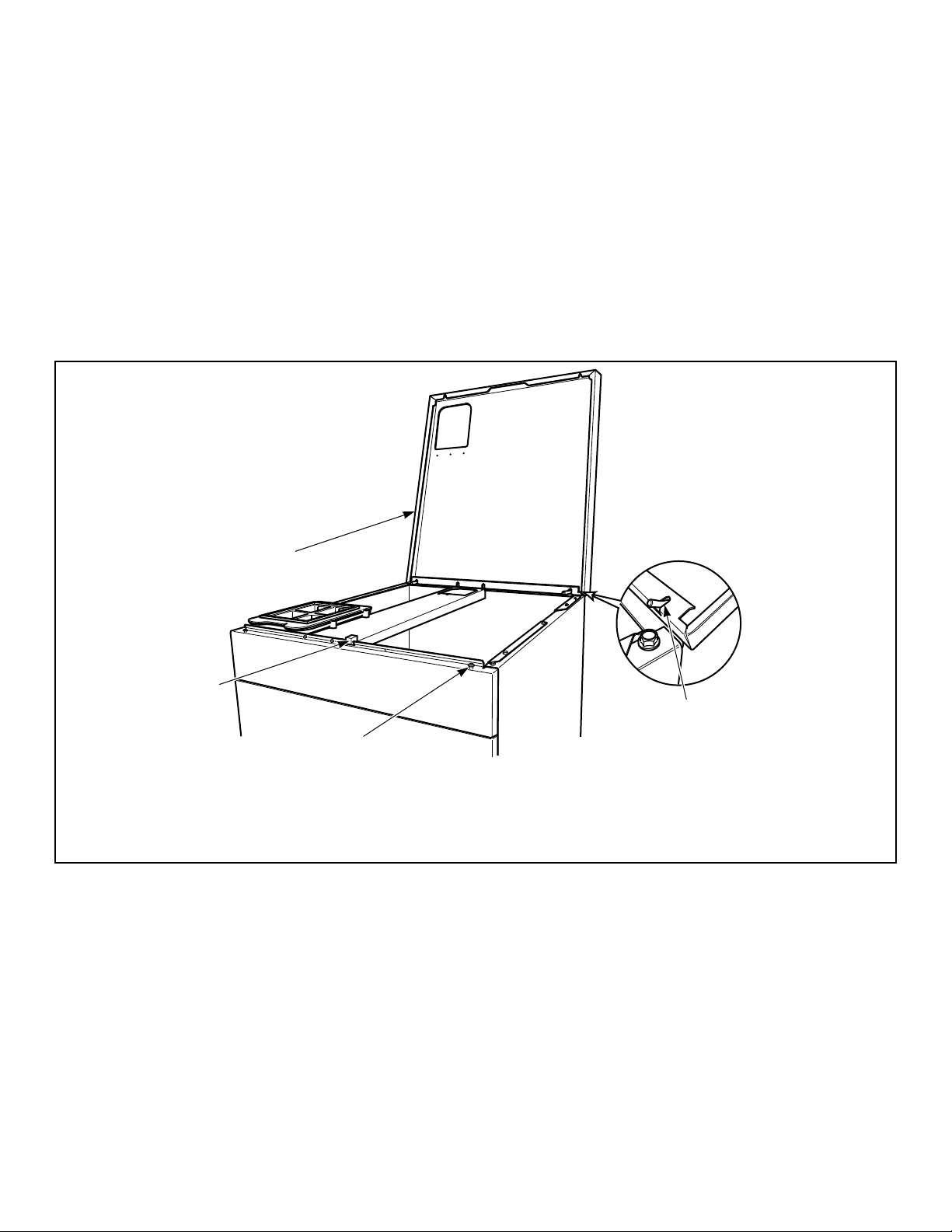

Opening the Service Door

CHM1357R_SVG

4

3

2

1

Opening the Service Door

The service door, or top cover, must be opened to manually program the control. Opening the top cover 3 inches and closing it

trips a switch which allows access to various programming options.

NOTE: If the Break-In Alarm is enabled in programming,

it must be disabled before opening the top cover. For

more information on using the Break-In Alarm, refer to

the instructions included with the external device.

The top cover is located on the top of the machine.

1. Unlock the top cover.

2. Slide the top cover forward slightly to move the notches away

from the pegs on the front of the cabinet.

3. Lift the top cover up. Refer to Figure 16 .

After opening and closing the top cover, the operator has 4 minutes and 15 seconds to begin programming. If the correct passcode is not entered in that time, the control will not accept operator programming. Should this happen, open and close the top

cover again to trip the switch and allows access to the programming options.

1. Top Cover Lock

2. Top Cover

3. Top Cover Hinge

4. Peg

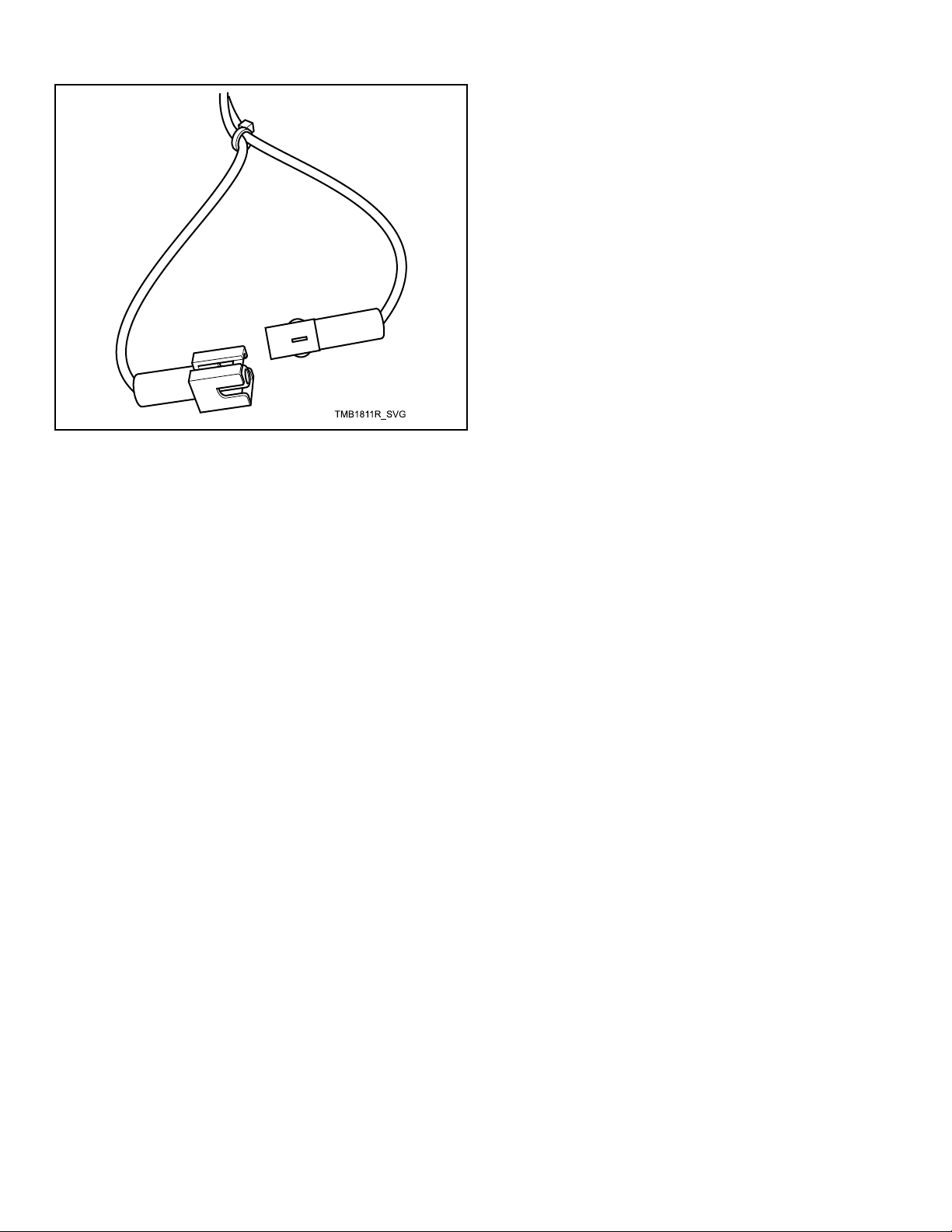

Stacked Washer-Extractor/Tumble Dryer

Open service door and disconnect bullet connector located between the "white/black" and "red/blue" wires for one second,

then reconnect.

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

Figure 16

29 Part No. F8669401ENR4

Opening the Service Door

Figure 17

©

Copyright, Alliance Laundry Systems LLC -

DO NOT COPY or TRANSMIT

30 Part No. F8669401ENR4

Loading...

Loading...