Page 1

Washer-Extractor

Cabinet Hardmount

Instructions for

Operating and Programming

the S-Series Microcomputer

Model Numbers

HC25SN SC18SN UC25PN

HC80SN SC25SN UC80PN

SC27SN

SC35SN

Operation/Programming

NOTA: El manual en

español aparece después

del manual en inglés.

SC50SN

SC80SN

www.comlaundry.com

Part No. F232073R4

March 2001

Page 2

Page 3

Table of Contents

Operation/Programming

Safety

Safety

Key to Symbols . . . . . . . . . . . . . . . . . . . . . . . . 4

Safety Decal Location . . . . . . . . . . . . . . . . . . . 5

Operator Safety . . . . . . . . . . . . . . . . . . . . . . . . 6

Safe Operating Environment . . . . . . . . . . . . . . 7

Environmental Conditions . . . . . . . . . . . . . 7

Machine Location . . . . . . . . . . . . . . . . . . . . 8

Input and Output Services . . . . . . . . . . . . . 8

Misuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Operation

Customer Service . . . . . . . . . . . . . . . . . . . . . . . 11

Machine Familiarization Guide . . . . . . . . . . . . 11

Theory of Operation . . . . . . . . . . . . . . . . . . . . . 13

S-Computer . . . . . . . . . . . . . . . . . . . . . . . . . 14

Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Display Indications . . . . . . . . . . . . . . . . . . . 15

Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Programming

Key Functions in Programming Mode . . . . . . 21

Setup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Cycle Count . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Cycle Programming . . . . . . . . . . . . . . . . . . . . 22

Chemical Injection Supply System . . . . . . . . . 24

Cycle Segment Charts . . . . . . . . . . . . . . . . . . . 25

Cycle Programming Worksheet . . . . . . . . . . . 29

S-Computer Cycle Charts . . . . . . . . . . . . . . . . 30

Opening Door . . . . . . . . . . . . . . . . . . . . . . . . . 16

Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Supply Dispenser . . . . . . . . . . . . . . . . . . . . . . . 17

Cycle Selection . . . . . . . . . . . . . . . . . . . . . . . . 17

Cycle Execution . . . . . . . . . . . . . . . . . . . . . . . . 17

Fill . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Spin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Stop Routine . . . . . . . . . . . . . . . . . . . . . . . . 19

F232073 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 4

© Copyright 2001, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

2 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Section 1

Safety

Anyone operating or servicing this machine must

follow the safety rules in this manual. Particular

attention must be paid to the DANGER,

WARNING, and CAUTION blocks which appear

throughout the manual.

&$87,21

Be careful around the open door, particularly

when loading from a level below the door.

Impact with door edges can cause personal

injury.

SW025

The following warnings are general examples that

apply to this machine. Warnings specific to a

particular installation or maintenance procedure

will appear in the manual with the discussion of that

procedure.

F232073 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 6

Safety

&$87,21

Ensure that the machine is installed on a level

floor of sufficient strength and that the

recommended clearances for inspection and

maintenance are provided. Never allow the

inspection and maintenance space to be

blocked.

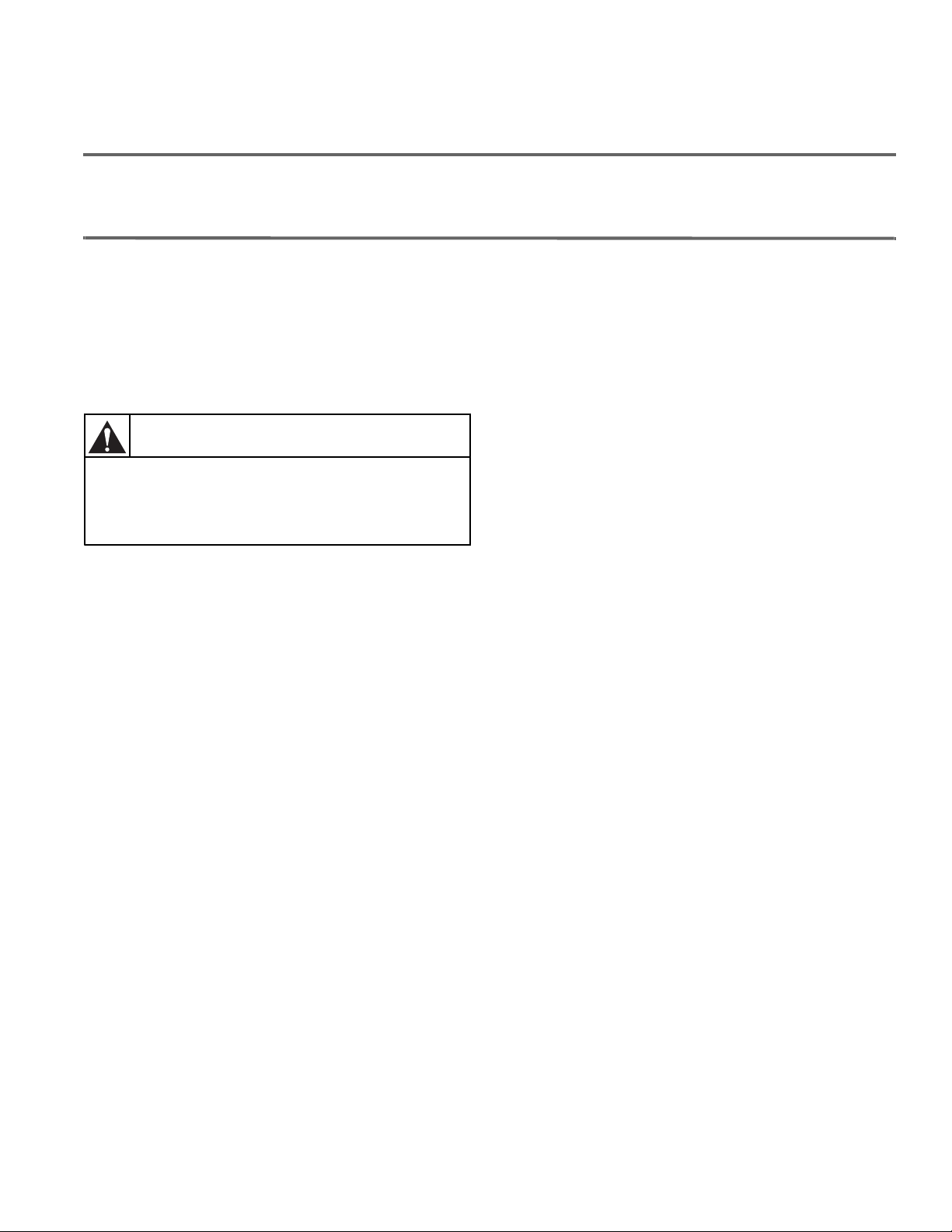

Key To Symbols

The lightning flash and arrowhead within the

triangle is a warning sign indicating the presence of

dangerous voltage.

SW020

:$51,1*

Never touch internal or external steam pipes,

connections, or components. These surfaces

can be extremely hot and will cause severe

burns. The steam must be turned off and the

pipe, connections, and components allowed to

cool before the pipe can be touched.

This warning symbol indicates the presence of

possibly dangerous chemicals. Proper precautions

should be taken when handling corrosive or caustic

materials.

SW014

The exclamation point within the triangle is a

warning sign indicating important instructions

concerning the machine and possibly dangerous

conditions.

This warning symbol indicates the presence of

potentially dangerous drive mechanisms within the

machine. Guards should always be in place when

This warning symbol indicates the presence of hot

surfaces that could cause serious burns. Stainless

steel and steam lines can become extremely hot and

should not be touched.

This warning symbol indicates the presence of

possibly dangerous pinch-points. Moving

mechanical parts can crush and/or sever body parts.

the machine is in operation.

4 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 7

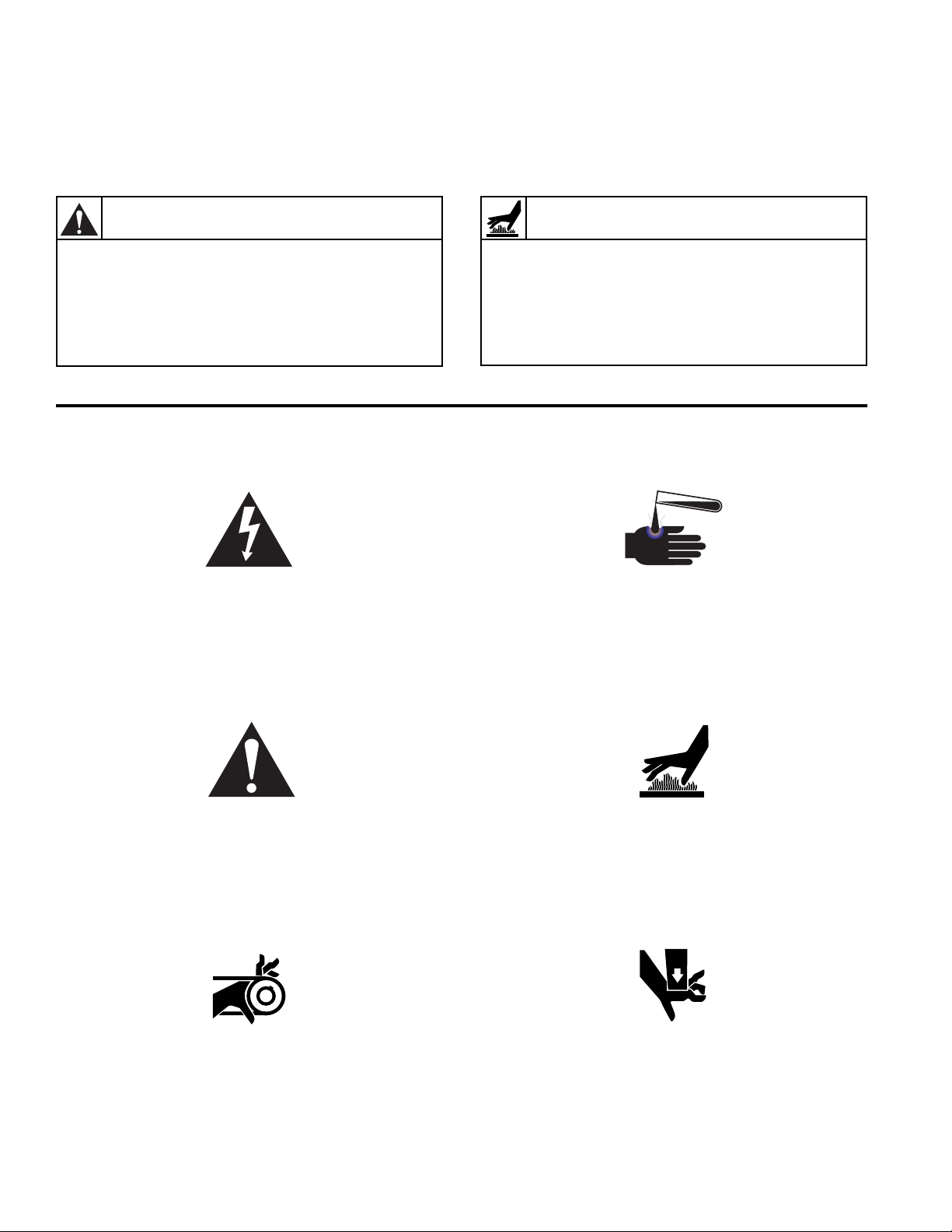

Safety

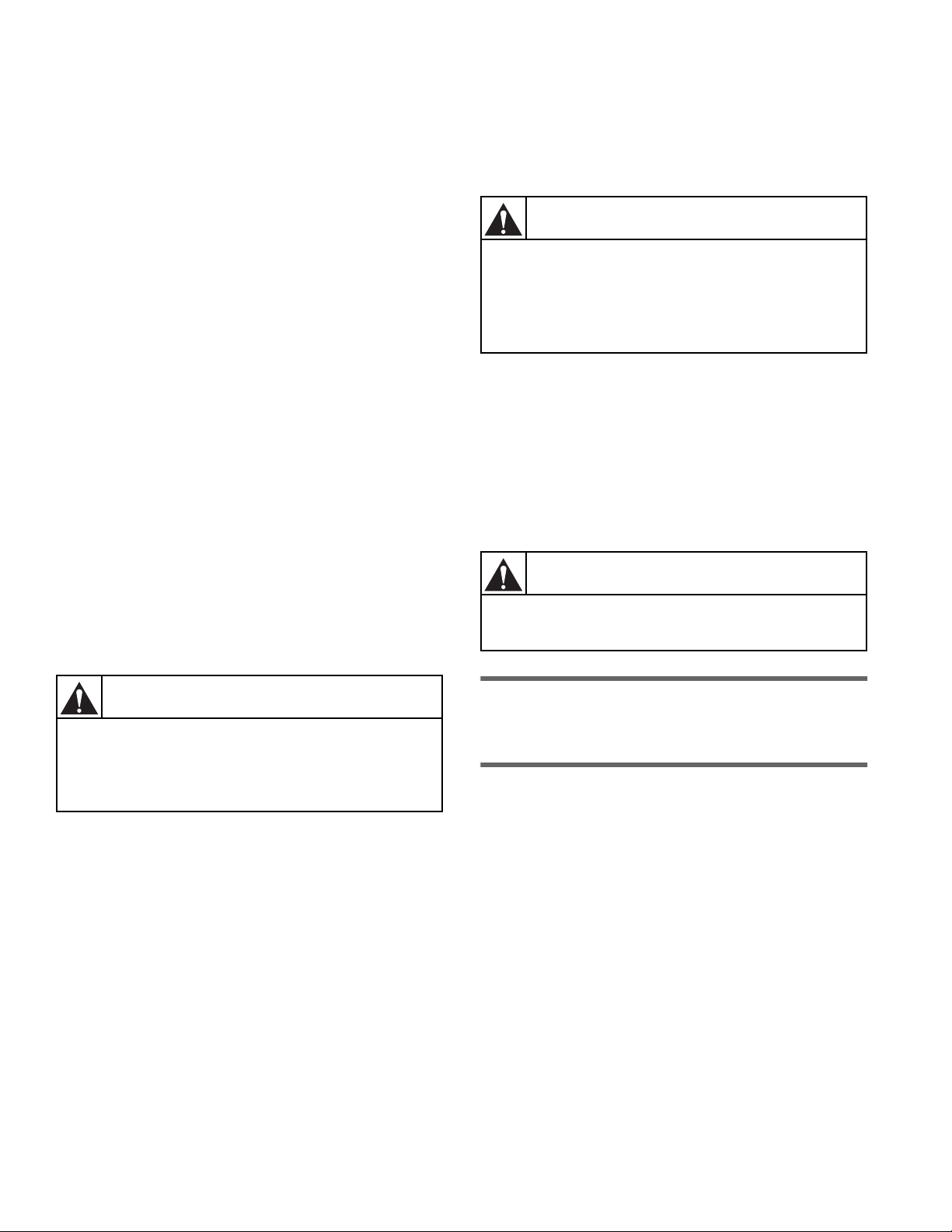

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

81968R1

81

9

68

R

1

B005RE3A

Figure 1

F232073 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 8

Safety

To provide personal safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the factory

immediately.

Use factory-authorized spare parts to avoid safety

hazards.

Operator Safety

:$51,1*

NEVER insert hands or objects into basket

until it has completely stopped. Doing so could

result in serious injury.

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing

or illegible signs must be replaced immediately.

Make certain that spares are available.

SW012

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locked

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

Do not bypass any safety devices in the machine.

2. Check door interlock before starting operation

of the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and

attempt to start the machine. The machine

should not start with the door unlocked.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is

in progress. The door should not open.

If the door lock and interlock are not

functioning properly, call a service technician.

6 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 9

Safe Operating Environment

Safe operation requires an appropriate operating

environment for both the operator and the machine.

If questions regarding safety arise, contact the

factory immediately.

Environmental Conditions

l

Ambient Temperature. Water in the machine

will freeze at temperatures of 32° F (0° C) or

below.

Temperatures above 120° F (50° C) will result

in more frequent motor overheating and, in

some cases, malfunction or premature damage

to solid state devices that are used in some

models. Special cooling devices may be

necessary.

Water pressure switches are affected by

increases and decreases in temperature. Every

25° F (10° C) change in temperature will have a

1% effect on the water level.

l

Humidity. Relative humidity above 90% may

cause the machine’s electronics or motors to

malfunction or may trip the ground fault

interrupter. Corrosion problems may occur on

some metal components in the machine.

If the relative humidity is below 30%, belts and

rubber hoses may eventually develop dry rot.

This condition can result in hose leaks, which

may cause safety hazards external to the

machine in conjunction with adjacent electrical

equipment.

l

Ventilation. The need for make-up air openings

for such laundry room accessories as dryers,

ironers, water heaters, etc., must be evaluated

periodically. Louvers, screens, or other

separating devices may reduce the available air

opening significantly.

Safety

l

Radio Frequency Emissions. A filter is

available for machines in installations where

floor space is shared with equipment sensitive

to radio frequency emissions.

l

Elevation. If the machine is to be operated at

elevations of over 3,280 feet (1,000 meters)

above sea level, pay special attention to water

levels and electronic settings (particularly

temperature) or desired results may not be

achieved.

l

Chemicals. Keep stainless steel surfaces free of

chemical residues.

'$1*(5

Do not place volatile or flammable fluids in any

machine. Do not clean the machine with

volatile or flammable fluids such as acetone,

lacquer thinners, enamel reducers, carbon

tetrachloride, gasoline, benzene, naptha, etc.

Doing so could result in serious personal injury

and/or damage to the machine.

l

Water Damage. Do not spray the machine with

water. Short circuiting and serious damage may

result. Repair immediately all seepage due to

worn or damaged gaskets, etc.

SW002

F232073 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 10

Safety

Safe Operating Environment

(Continued)

Machine Location

l

Foundation. The concrete floor must be of

sufficient strength and thickness to handle the

floor loads generated by the high extract speeds

of the machine.

l

Service/Maintenance Space. Provide sufficient

space to allow comfortable performance of

service procedures and routine preventive

maintenance.

This is especially important in connection with

machines equipped with an AC inverter drive.

Consult installation instructions for specific details.

&$87,21

Replace all panels that are removed to perform

service and maintenance procedures. Do not

operate the machine with missing guards or

with broken or missing parts. Do not bypass

any safety devices.

Input and Output Services

l

Water Pressure. Best performance will be

realized if water is provided at a pressure of

30 – 85 psi (2.0 – 5.7 bar). Although the

machine will function properly at lower

pressure, increased fill times will occur. Water

pressure higher than 100 psi (6.7 bar) may

result in damage to machine plumbing.

Component failure(s) and personal injury could

result.

l

Steam Heat (Optional) Pressure. Best

performance will be realized if steam is

provided at a pressure of 30 – 80 psi (2.0 – 5.4

bar). Steam pressure higher than 125 psi (8.5

bar) may result in damage to steam components

and may cause personal injury.

SW019

For machines equipped with optional steam

heat, install piping in accordance with approved

commercial steam practices. Failure to install

the supplied steam filter may void the warranty.

l

Drainage System. Provide drain lines or

troughs large enough to accommodate the total

number of gallons that could be dumped if all

machines on the site drained at the same time

from the highest attainable level. If troughs are

used, they should be covered to support light

foot traffic.

l

Power. For personal safety and for proper

operation, the machine must be grounded in

accordance with state and local codes. The

ground connection must be to a proven earth

ground, not to conduit or water pipes. Do not

use fuses in place of the circuit breaker. An

easy-access cutoff switch should also be

provided.

:$51,1*

Ensure that a ground wire from a proven earth

ground is connected to the ground lug near the

input power block on this machine. Without

proper grounding, personal injury from electric

shock could occur and machine malfunctions

may be evident.

Always disconnect power and water supplies before

a service technician performs any service

procedure. Where applicable, steam and/or

compressed air supplies should also be

disconnected before service is performed.

SW008

8 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 11

Misuse

Never use this machine for any purpose other than

washing fabric.

l

Never wash petroleum-soaked rags in the

machine. This could result in an explosion.

l

Never wash machine parts or automotive parts

in the machine. This could result in serious

damage to the basket.

l

Never allow children to play on or around this

machine. Death or serious injury can result if

children become trapped in the machine. Do not

leave children unattended while the machine

door is open. These cautions apply to animals

as well.

Safety

F232073 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 12

Safety

Notes

10 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 13

Section 2

Operation

This manual is designed as a guide to operating and

programming the cabinet hardmount washerextractor equipped with the S-Series

microcomputer control.

Keep the manuals, installation instructions, and the

wiring diagrams which accompany the machine in a

safe place for ready reference. They have been

included with the machine at no charge. Additional

copies are available at a nominal charge.

Note: Read this manual thoroughly before

attempting to operate the machine or program the

microcomputer.

Note: Do not use this manual in conjunction with

earlier model computer-controlled machines. Do

not use technical literature intended for earlier

models when operating this machine.

Customer Service

If literature or replacement parts are required,

contact the source from whom the machine was

purchased or contact Alliance Laundry Systems

LLC at (920) 748-3950 for the name and address of

the nearest authorized parts distributor.

For technical assistance, call any of the following

numbers:

(850) 718-1025

(850) 718-1026

Marianna, Florida

(920) 748-3121

Ripon, Wisconsin

A record of each machine is on file with the

manufacturer. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance.

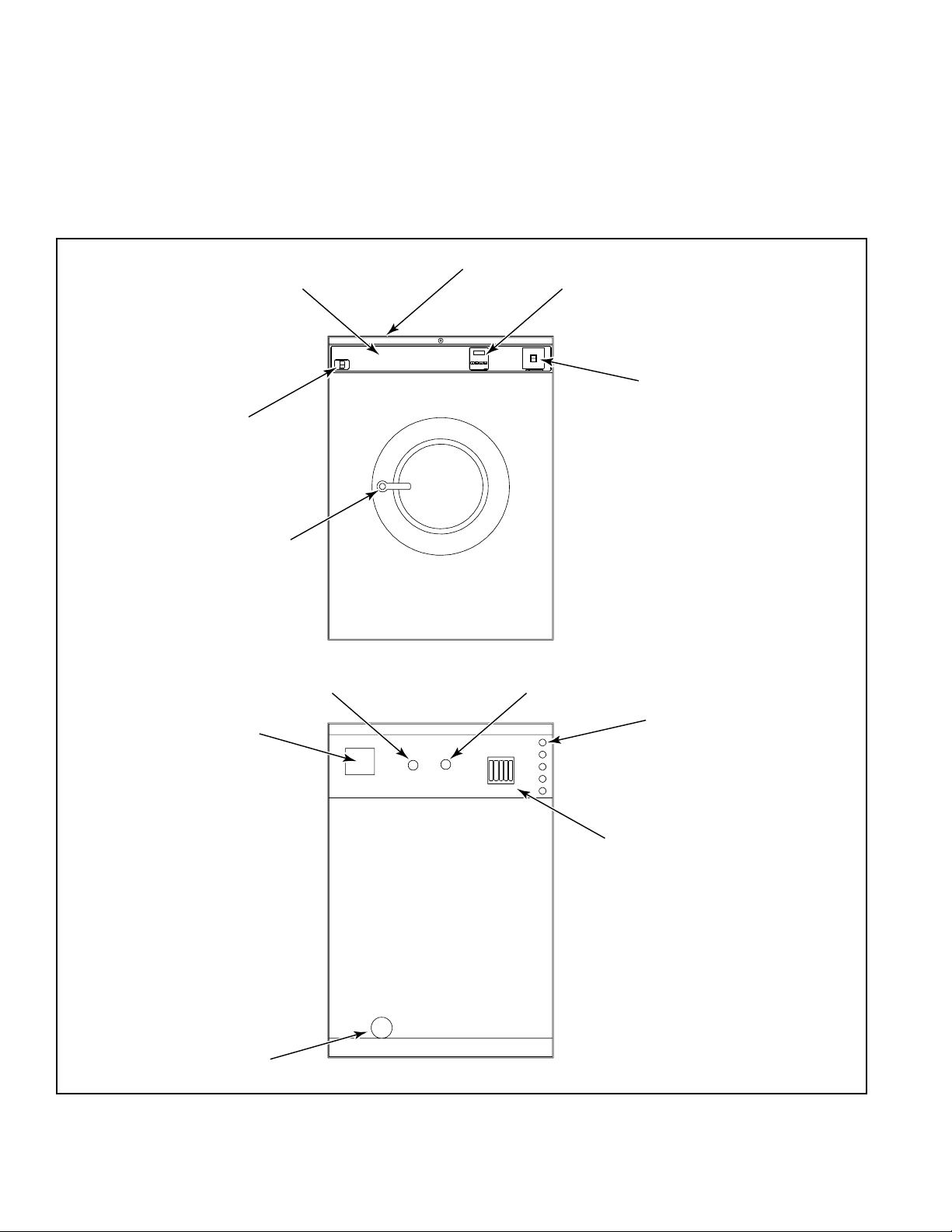

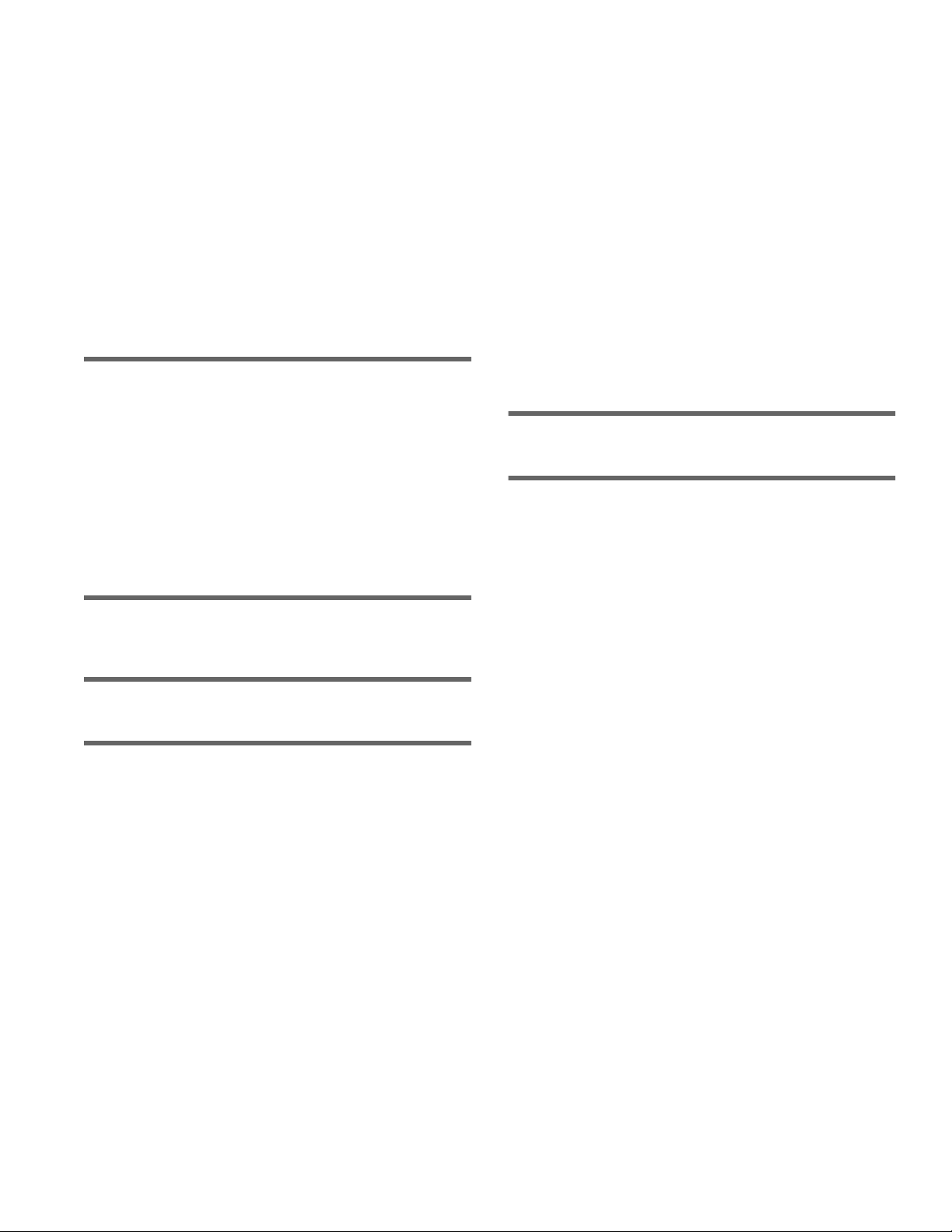

Machine Familiarization Guide

The machine familiarization guide in Figure 2

provides front and rear views of the washer-

Note: All information, illustrations, and

specifications contained in this manual are based on

the latest product information available at the time

of printing. We reserve the right to make changes at

any time without notice.

F232073 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

extractor and identify the major operational features

of the machine.

Page 14

Safety

Machine Familiarization

Operating Instructions

Door Unlock Button

Door Handle Button

Supply Dispenser

S-Series Microcomputer Control

On/Off Switch

Cold Water Inlet Hot Water Inlet

Input Power

Junction Box

Drain

Figure 2

External Chemical

Supply System Inlets

Vacuum Breaker

B011RE3A

12 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 15

Safety

Theory of Operation

The design of the machine emphasizes performance

reliability and long service life. The cylinder, shell,

and main body panels are fabricated of stainless

steel.

The cylinder on 50-pound capacity machines and

smaller is supported with two sealed bearings

mounted in a machined cast iron trunnion bolted to

a heavy gamma frame.

On 80-pound capacity machines, the cylinder and

shaft assembly is supported by two flange roller

bearing assemblies. The bearing housings are bolted

to the frame.

The 2-speed machines use one dual-speed motor to

drive the cylinder via a V-belt drive in wash speed

and extract speed.

The 3-speed 18-pound capacity models use one

triple-speed motor, while all other 3-speed models

use one single-speed and one dual-speed motor to

drive the cylinder at wash speed, medium extract

speed, and high extract speed.

A door-lock system prevents opening of the

stainless steel door when water is in the machine. It

also prevents operation of the machine when the

door is open.

An electrically operated drain valve is used to retain

the water and wash solution in the machine during

the wash and rinse steps. The drain valve closes

when power is applied and opens when power is

removed, allowing the machine to drain in the event

of a power failure.

The cylinder is designed with lifters or ribs that lift

the garments from the wash solution when the

cylinder rotates at slow speed and allow the

garments to tumble back into the solution. The

cylinder is perforated, allowing the water to pass

through and drain from within during the wash

process and extract.

Electrical controls for the machine are housed in a

separate enclosure located underneath the top cover

of the machine.

The operator can select from among 30 cycles, 12

of which are preprogrammed at the factory. A

special permanent test cycle can be selected to

verify proper operation of the machine.

The polypropylene supply dispenser is located

under a flexible cover on the left side of the

machine, viewed from the front. The compartments

are numbered 1 – 3, starting from the left side of the

machine. A nozzle flushes dry supplies from the

compartment with water at the appropriate time in

the cycle.

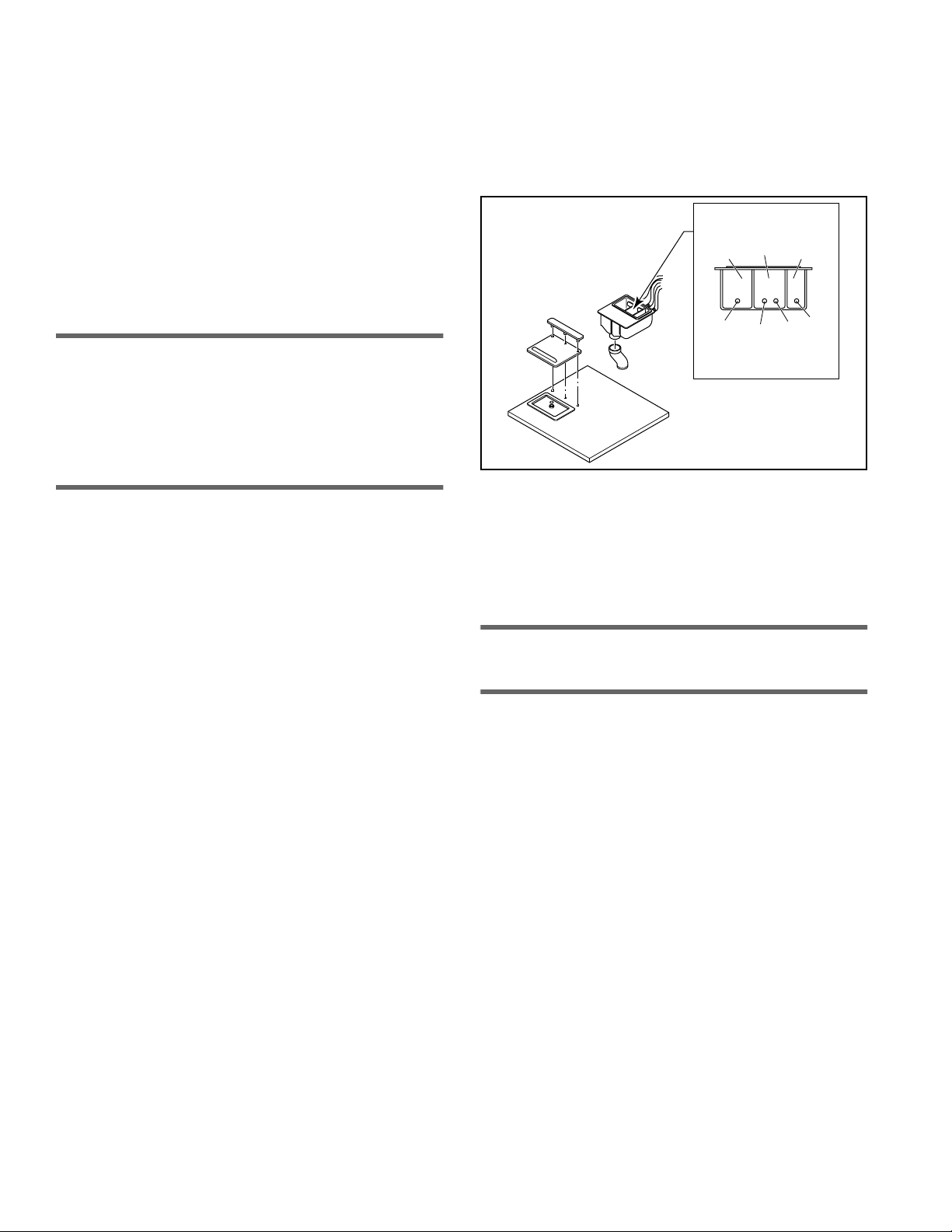

Liquid supplies can be injected directly into the

dispenser compartments by a customer-supplied

external chemical supply system. Four hose barbs

on the rear of the machine facilitate connection to

an external chemical supply system. A terminal

strip in the input power junction box provides

control signals.

F232073 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 16

Safety

Theory Of Operation (Continued)

S-Computer

The S-computer control is a programmable solidstate control capable of storing and running up to 30

cycles. A detailed description of these cycles can be

found in the Programming section of this manual

under S-computer Standard OPL Cycles.

If this machine’s computer has been equipped with

special preprogrammed cycles, a separate insert

listing these cycles has been included in the

resealable plastic bag which contained this manual.

Note: Never turn the power off while the computer

mode switch is in the PROGRAM position. Such

action will disorder portions of the programmed

data, necessitating reprogramming of some or all of

the existing cycles. Always return the mode switch

to RUN position before turning the power off.

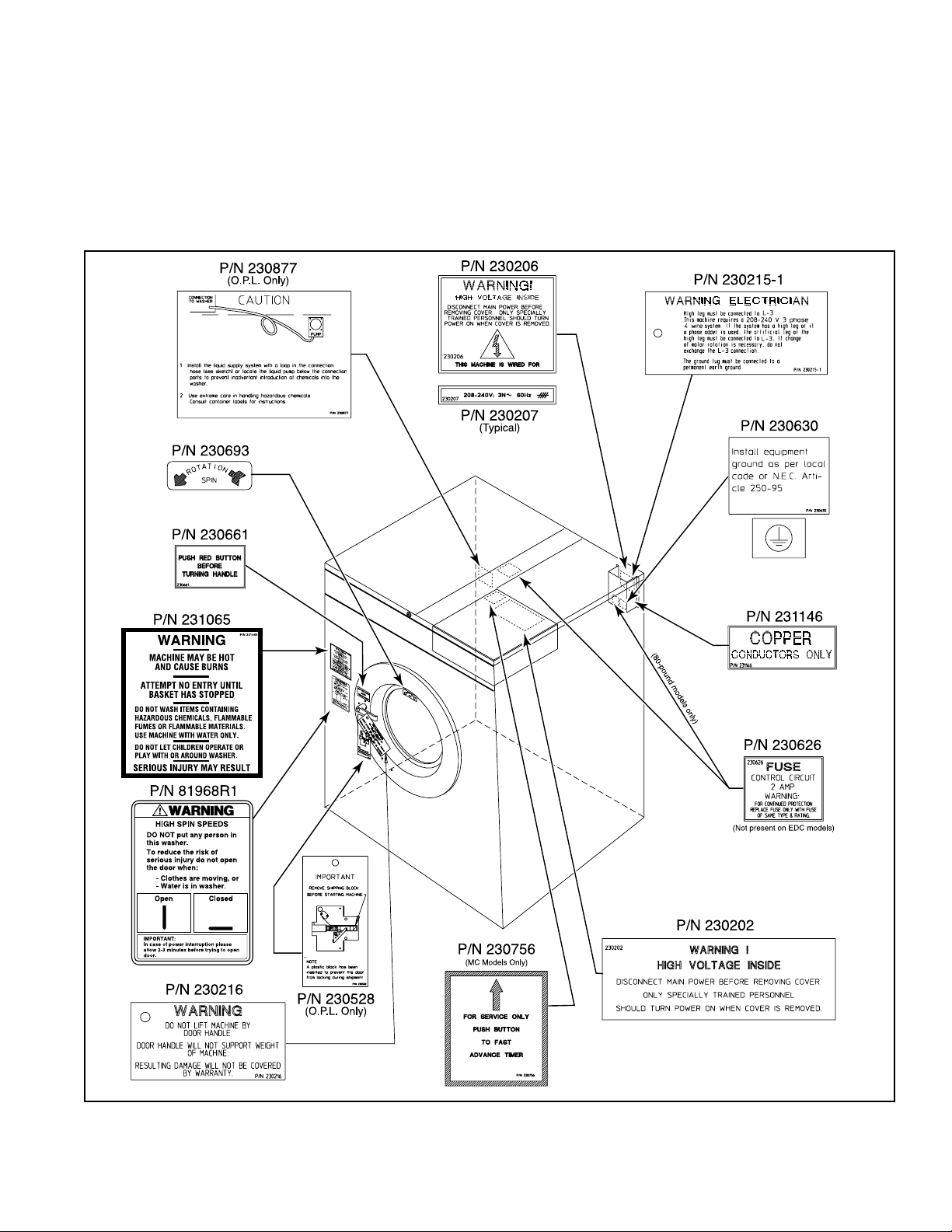

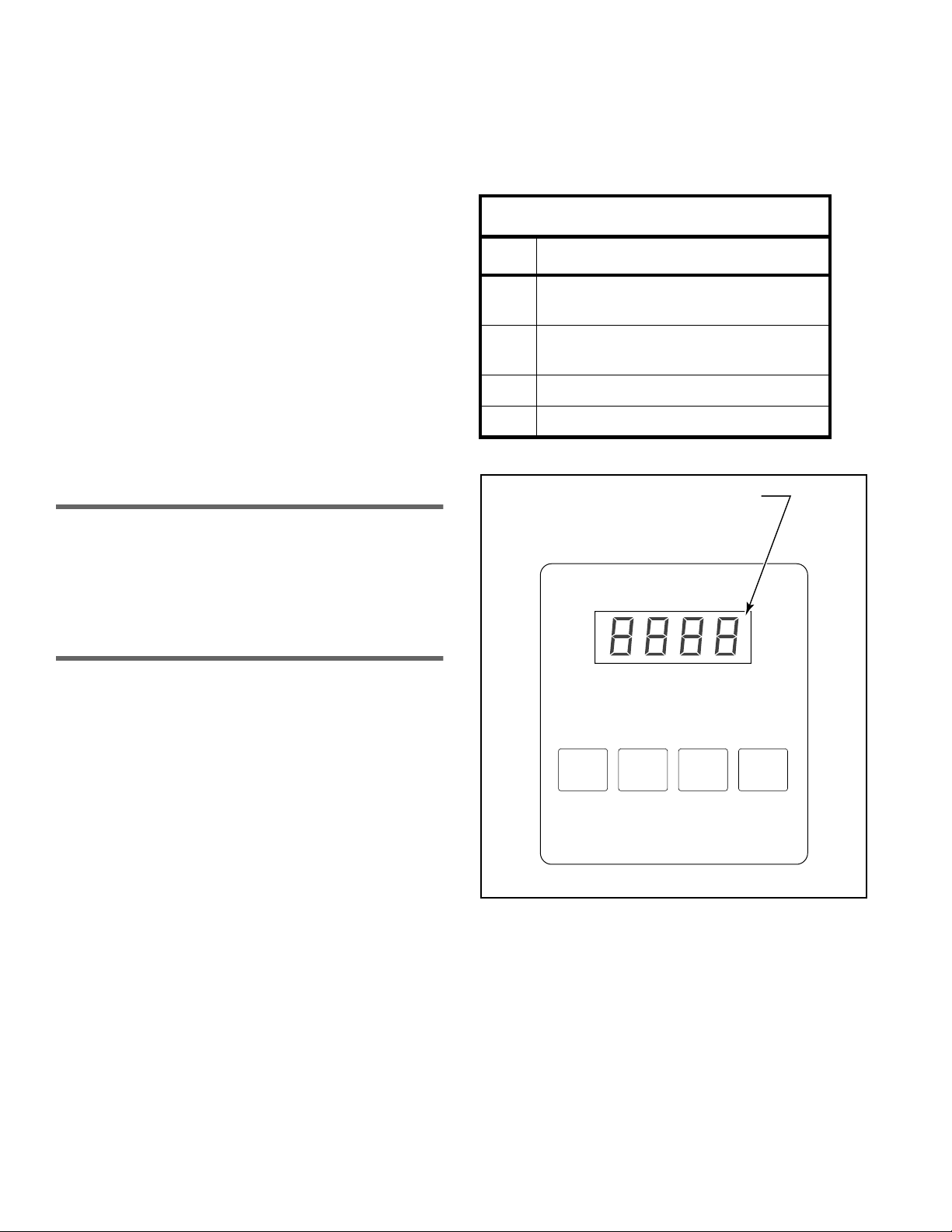

Keypad

Key Description

Up

Down

Start Used to start a cycle.

Stop Used to stop a cycle.

Used in cycle selection; pressing this key

moves among cycles from smaller to greater.

Used in cycle selection; pressing this key

moves among cycles from greater to smaller.

LED Display

Keypad

Operation of the S-computer control is performed

with a 4-key touch keypad and LED display located

on the front of the machine. See Figure 3. The

following table describes the function of the

individual keys when the machine is in RUN mode.

Up Down Start Stop

B008RE3A

Figure 3

14 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 17

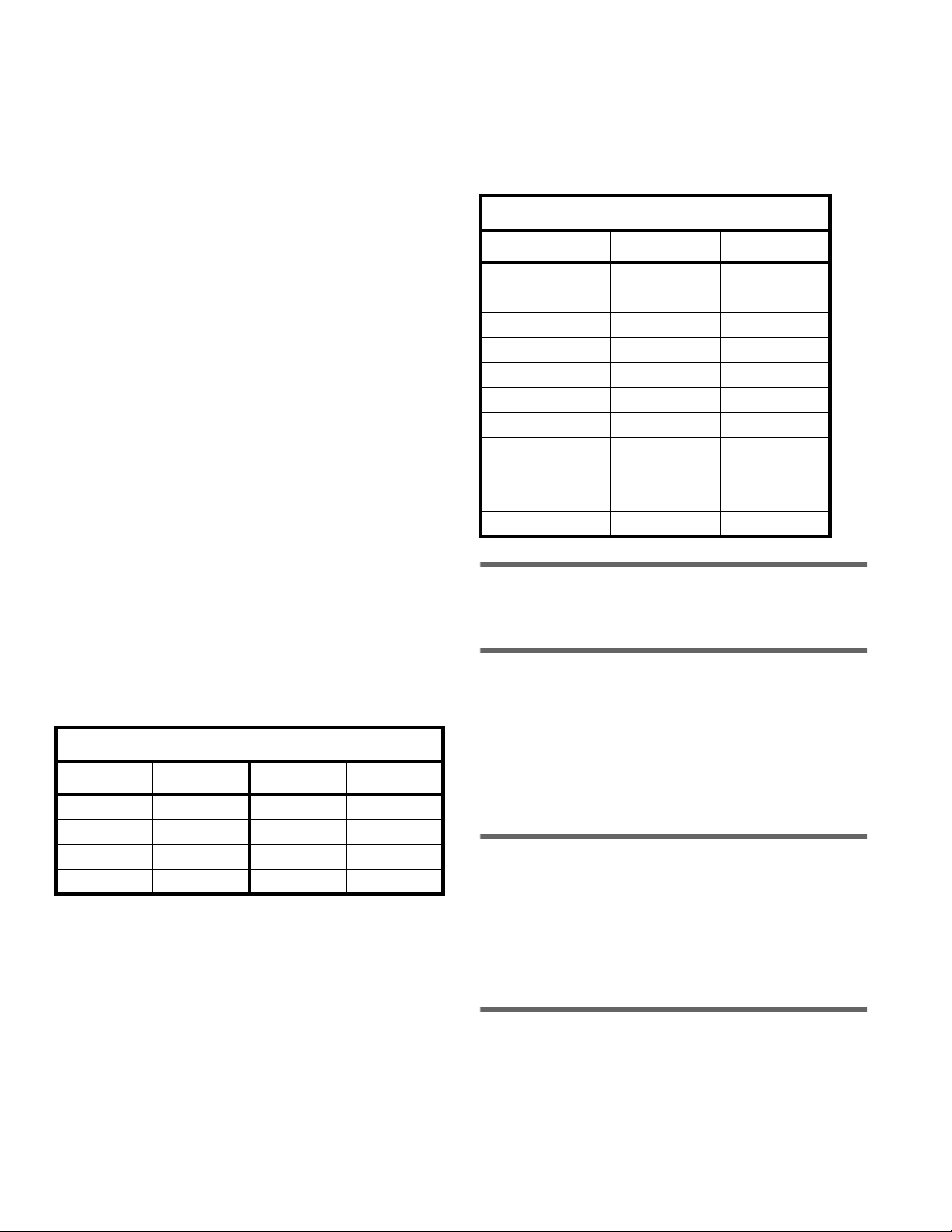

The following table lists the various displays and

what they mean. The operator should become

familiar with these computer displays.

Display Indications

Display Meaning Display Meaning

S-05

Hold Wait...power has just been turned on. HFIL Hot fill

CY Cycle (followed by two-digit number) LOLE Low water level

CHEC/CYC* Test cycle selected. HILE High water level

FAr Degrees Fahrenheit SUP1 Supply 1

CEL Degrees Celsius SUP2 Supply 2

PrE Prewash segment (1st of 8 segments) SUP3 Supply 3

UASH Wash segment (2nd of 8 segments) SUP4 Supply 4

FIL1 First rinse (3rd of 8 segments) SUP5 Supply 5 (supply 1 and 2)

FIL2 Second rinse (4th of 8 segments) SUP6 Supply 6 (supply 2 and 3)

FIL3 Third rinse (5th of 8 segments) SUP7 Supply 7 (supply 3 and 4)

FIL4 Fourth rinse (6th of 8 segments) STOP Stop routine

FIL5 Fifth rinse (7th of 8 segments) SdLY Spin coast delay

FIL6 Sixth rinse (8th of 8 segments) donE Cycle and stop routine have ended.

CFIL Cold fill door Door not properly closed.

SPIn/tIME*

tSFL

*Display indications separated by a slash represent an alternating display.

Program identification code (ROM)

This is an example only.

Reads “SPIn” for one second, then

“tIME” followed by time for spin.

Temperature sensor failure or temperature

out of range.

bFIL Warm fill (both hot and cold)

FILL/STOP*

FULL

Programmed water level not reached after 30

minutes.

The computer detects low water level or higher

when none should be present.

Safety

F232073 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 18

Safety

Start-Up

Turn on the main power source (circuit breaker or

cut-off switch on the wall).

An identification code will appear for

approximately five seconds. Then the display will

flash “hold” for thirty seconds.

The display will then read “CY” followed by a twodigit cycle number (01 – 30) to indicate that a cycle

can be selected. This display will be shown at all

times that power is on between cycles, indicating

that the door-unlock solenoid will function if the

door-unlock button is pressed. The machine is then

ready for loading and unloading.

Opening Door

:$51,1*

Never operate the machine with a bypassed or

disconnected out-of-balance switch. Operating

the machine with severe out-of-balance loads

could result in personal injury and serious

equipment damage.

SW010

When loading is complete, ensure that all fabric is

inside the basket. Then close and lock the door by

rotating the door handle counterclockwise until the

door handle pushbutton pops out. The machine

should not start or run unless the door is both closed

and locked.

Press and hold the door-unlock button on the left

side of the control panel. Press the round button on

the door handle and turn the door handle downward.

Loading

&$87,21

Be careful around the open door, particularly

when loading from a level below the door.

Impact with door edges can cause personal

injury.

Load the machine to full capacity whenever

possible, but do not exceed the rated dry-weight

capacity of the machine if the fabric to be washed is

quite dense, closely woven, and heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine load

size based on fabric content, soil content, and level

of cleanliness required.

SW025

&$87,21

Check the door safety interlock daily before the

machine is placed in operation.

Note: When washing items which may disintegrate,

such as mop heads or sponges, use laundry net bags

to prevent drain blockage.

SW024

Partial loads are a waste of energy, water, and

chemicals, and cause greater machine wear than full

loads. Partial loads also increase the possibility of a

severe out-of-balance condition.

16 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 19

Safety

Supply Dispenser

Both liquid and powder supplies may be added by

raising the flexible cover of the dispenser. Liquid

supplies may also be injected directly into the

supply dispenser by an external chemical supply

system.

Note: When a liquid supply is manually added to

the machine through supply compartments 1 or 2,

that liquid is immediately dispensed to the laundry

load. Therefore, when adding supplies such as

liquid detergent and bleach to the machine,

coordinate the addition of the supply with the

appropriate cycle segment. Add softener to

compartment 3 at the beginning of the cycle. The

machine automatically dispenses softener at the

appropriate time.

Cycle Selection

Note: Press keys at their centers just hard enough to

activate them.

Press the Up or Down key until the desired cycle

number is displayed. Press the Start key to start the

cycle. For a more detailed description of the

preprogrammed cycles, see the cycle charts at the

end of the Programming section.

Cycle Execution

A cycle can be stopped at any time by pressing the

Stop key. The machine will go to the stop routine.

When the routine is complete, the door may be

unlocked.

To display the temperature of the water while a

cycle is running, press the Up key. To display the

number of the cycle in progress, press the Start key.

Note: The display pauses the cycle time countdown

during the fill, heat, and drain steps.

Each of the 30 cycles consists of 8 segments:

Prewash, Wash, and Fills 1 – 6. A description of the

various steps in a cycle segment follows:

Fill

After the Start key is pressed, the door locks, the

drain closes, and the machine begins filling to the

programmed level; each programmed segment

begins with a fill. The display counts down the

remaining cycle time in minutes and seconds while

the cycle is running.

If a supply is programmed in a step, the supply

dispenser will flush during the fill of that segment.

If the computer detects that the door is not properly

closed when the Start key is pressed, the display

will read “door” until the door is closed and locked.

Press the Start key again to begin the desired cycle.

F232073 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 20

Safety

Cycle Execution (Continued)

If the machine is connected to an external chemical

supply system, the programmed supply will begin

10 seconds into the fill. The supply will remain on

until the programmed water level is reached, or

until 60 seconds have elapsed, whichever happens

first.

If the computer does not receive a signal that water

level has been attained within 30 minutes, it will

alternately flash “STOP” and “FILL” and sound the

on-board beeper for ten seconds; it will then initiate

the stop routine.

Wash

Standard Wash

As soon as water level is reached (and any

programmed temperature is reached), the displayed

time begins counting down at one-second intervals.

All but three cycles use the standard wash agitation.

This agitation repeats for the first programmed time

duration in the prewash, wash, and fill segments.

Gentle Wash

Cycles 8, 16, and 24 use a gentle wash agitation in

place of the standard wash agitation. This agitation

repeats for the programmed segment time duration

in the prewash, wash, and fill segments.

The gentle wash agitation sequence:

l

3 seconds counterclockwise at wash speed

l

A 12-second pause

l

3 seconds clockwise at wash speed

l

A 12-second pause

Heat

If the segment contains a heat step, the machine

begins heating after the water has reached the

programmed level.

Note: If the water does not reach the programmed

temperature in 30 minutes, the computer progresses

to the wash step.

The standard wash agitation sequence:

l

12 seconds counterclockwise at wash speed

l

A 3-second pause

l

12 seconds clockwise at wash speed

l

A 3-second pause

Note: While a cycle is in progress, pressing and

holding the Start key will cause the current cycle

number to be displayed. Pressing and holding the

Up key while a cycle is running will display the

temperature inside the sump.

18 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 21

Safety

Drain

At the conclusion of a spin, the drain valve opens,

and the cylinder turns counterclockwise (forward)

at wash speed. This counterclockwise direction

mirrors the spin rotation direction and is, therefore,

considered forward.

Note: The machine should drain in 30 seconds. If

the machine fails to drain, contact a qualified

service technician.

When the water level falls below the low level, there

is a 15-second delay, during which the computer

continues to monitor water level. If a water level

input is sensed, the computer waits until both high

and low level inputs indicate the machine is empty.

Assuming the computer detects no water level

during the 15-second period, the drain sequence

concludes.

Stop Routine

When the programmed duration for the machine’s

final spin expires, the computer begins the stop

routine.

The stop routine sequence:

l

All inputs are turned off.

l

A 40-second coast-down (if stop routine is

preceded by a spin)

l

12 seconds counterclockwise at wash speed (if

stop routine is not preceded by a spin)

l

A 3-second pause (if stop routine is not

preceded by a spin)

l

12 seconds clockwise at wash speed

l

A 5-second pause

l

The display shows “donE.”

l

The door interlock is energized, allowing the

door to be opened

.

Spin

After the drain sequence ends, the speed of the

cylinder increases to the extract speed if the

programmed spin time is not zero. The displayed

time resumes counting down at one-second

intervals.

After the programmed spin time has elapsed, the

computer moves on to the fill step in the next

segment of the cycle. If the spin is at the end of the

cycle, the computer begins the stop routine.

:$51,1*

NEVER insert hands or objects into basket

until it has completely stopped. Doing so could

result in serious injury.

Once “donE” is displayed, open the door by

pressing and holding the door unlock button as

described earlier. Once the door is opened, the

computer display will show the most recent cycle

number.

The machine is now ready to begin another wash

cycle.

F232073 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 22

Safety

Notes

20 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 23

Section 3

Programming

The computer board is inside the control module.

Near the center of the board is a small toggle

switch: this is the RUN/PROGRAM mode switch.

:$51,1*

Dangerous voltages are present in the

electrical control box(es) and at the motor

terminals. Only qualified personnel familiar with

electrical test procedures, test equipment, and

safety precautions should attempt adjustments

and troubleshooting. Disconnect power from

the machine before removing the control box

cover, and before attempting any service

procedures.

The RUN/PROGRAM switch is normally in the up

(RUN mode) position. To enter PROGRAM mode,

flip the switch to the down position. The display

will now show the current temperature in the sump.

Since the keypad operates in a slightly different

fashion when in PROGRAM mode, pay careful

attention to the programming instructions provided

in this manual.

SW005

Start – The Start key acts as an enter key in

program mode. Use this key to enter data and move

to the next function in the cycle.

Stop – The Stop key saves all data and terminates

the programming procedure. If it is the first key

pressed in PROGRAM mode, the computer enters

SETUP mode. The Stop key can be pressed again to

exit SETUP mode and return to PROGRAM mode.

Setup Mode

SETUP mode allows the selection of degrees

Fahrenheit or degrees Celsius for the temperature

display.

To enter SETUP mode, press the Stop key while the

display is showing the temperature in the sump.

Once in SETUP mode, use the Up or Down key to

change the selected option. Use the Start key to

accept the selected option, either “FAr” or “CEL.”

Press the Stop key to exit SETUP mode.

Key Functions In Programming Mode

Up – The Up key is used to increase cycle numbers

(1 through 30) and other numerical values such as

times or temperatures (when creating wash

formulas).

Down – The Down key is used to decrease cycle

numbers (1 through 30) and other numerical values

such as times or temperatures (when creating wash

formulas).

F232073 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 24

Safety

Cycle Count

To display the current cycle count, press the Start

key while the display is showing the temperature in

the sump. The display will show a 2-digit number

indicating how many cycles have been run to

completion (cycles which were stopped in progress

are not counted). Press the Start key to return to

PROGRAM mode without resetting the count.

Press the Up or Down key to reset the count to zero

and return to PROGRAM mode.

Cycle Programming

To edit an existing cycle or create a new cycle, press

the Up key while the display is showing the

temperature in the sump. The display will show

“CY01.” Press the Up or Down key until the

desired cycle number is displayed. Press the Start

key to begin editing the selected cycle.

All cycle programs (“CY01” – “CY30”) can be

customized within a preset program structure. Each

cycle program consists of eight program segments.

See the table below.

Cycle Program Segments

Segment Display Segment Display

Prewash PrE Fill 3 FIL3

Wash UASH Fill 4 FIL4

Fill 1FIL1Fill 5FIL5

Fill 2FIL2Fill 6FIL6

When modifying a cycle, a time must be entered for

each segment. To skip a segment or spin, set the

time to “00” and press the Start key. The following

table gives the time parameters for each segment

and spin, as well as the allowable temperature

range.

Time And Temperature Parameters

Function Minimum Maximum

Prewash 2 minutes 30 minutes

Wash 2 minutes 20 minutes

Fill 1 2 minutes 15 minutes

Fill 2 2 minutes 15 minutes

Fill 3 2 minutes 15 minutes

Fill 4 2 minutes 15 minutes

Fill 5 2 minutes 15 minutes

Fill 6 2 minutes 15 minutes

Intermediate Spin 30 seconds 120 seconds

Final Spin 1 minute 10 minutes

Temperature 75°F (25°C) 200°F (93°C)

Note: Spin times in cycle segments 1 – 8 are

entered in seconds (30 to 120), and time for final

spin in segment 11 is entered in minutes (1 to 10).

1. Press the Up key until the computer display

shows the segment to be edited. Press the Start

key.

2. Use the Up or Down key to select the desired

segment time. Set this value to zero to skip the

segment. Press the Start key.

Note: The computer does not count down the

remaining cycle time during fills, drains, or prior to

first achieving the programmed heat temperature

when heating. The computer resumes counting

down cycle time once the programmed fill level is

reached, when the machine has drained, and after a

programmed heat temperature is reached.

22 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 25

Safety

3. Use the Up or Down key to select the desired

fill temperature. See the following table for fill

options.

Fill Temperature Options

Display Fill Type

CFIL Cold fill

HFIL Hot fill

bFIL Warm fill

4. Press the Start key.

5. Use the Up or Down key to select the desired

fill level. See the following table.

Water Level Options

Display Fill Level

8. Press the Start key.

9. If the machine is equipped with an auxiliary

heating system, use the Up or Down key to

select the desired segment temperature. To

disable auxiliary heat for this segment, set this

value to zero.

Note: Do not program heat steps for machines not

equipped with auxiliary heat. The machine will

pause for 30 minutes during any step in which the

fill water temperature does not already equal or

exceed the programmed value of the heat step.

10. Press the Start key.

LOLE Low Level

HILE High Level

6. Press the Start key.

7. Use the Up or Down key to select the desired

supply option. See the table below.

Supply Options

Display Supply

SUP0 No Supply

SUP1 Supply 1

SUP2 Supply 2

SUP3 Supply 3

SUP4 Supply 4

SUP5 Supply 1 and 2

SUP6 Supply 2 and 3

SUP7 Supply 3 and 4

F232073 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 26

Safety

Cycle Programming (Continued)

11. Use the Up or Down key to select the desired

spin time. Set this value to zero to skip the spin

step. Press the Start key. The display will now

show the identifier for next program segment.

Note: An automatic 40-second coast-down follows

every high-speed spin. For all spins except the final

spin, this coast-down occurs during the fill for the

following segment. Therefore, cycle time is not

increased for coast-downs following all but the final

spin.

12. Press the Stop key at any time to complete the

cycle programming procedure.

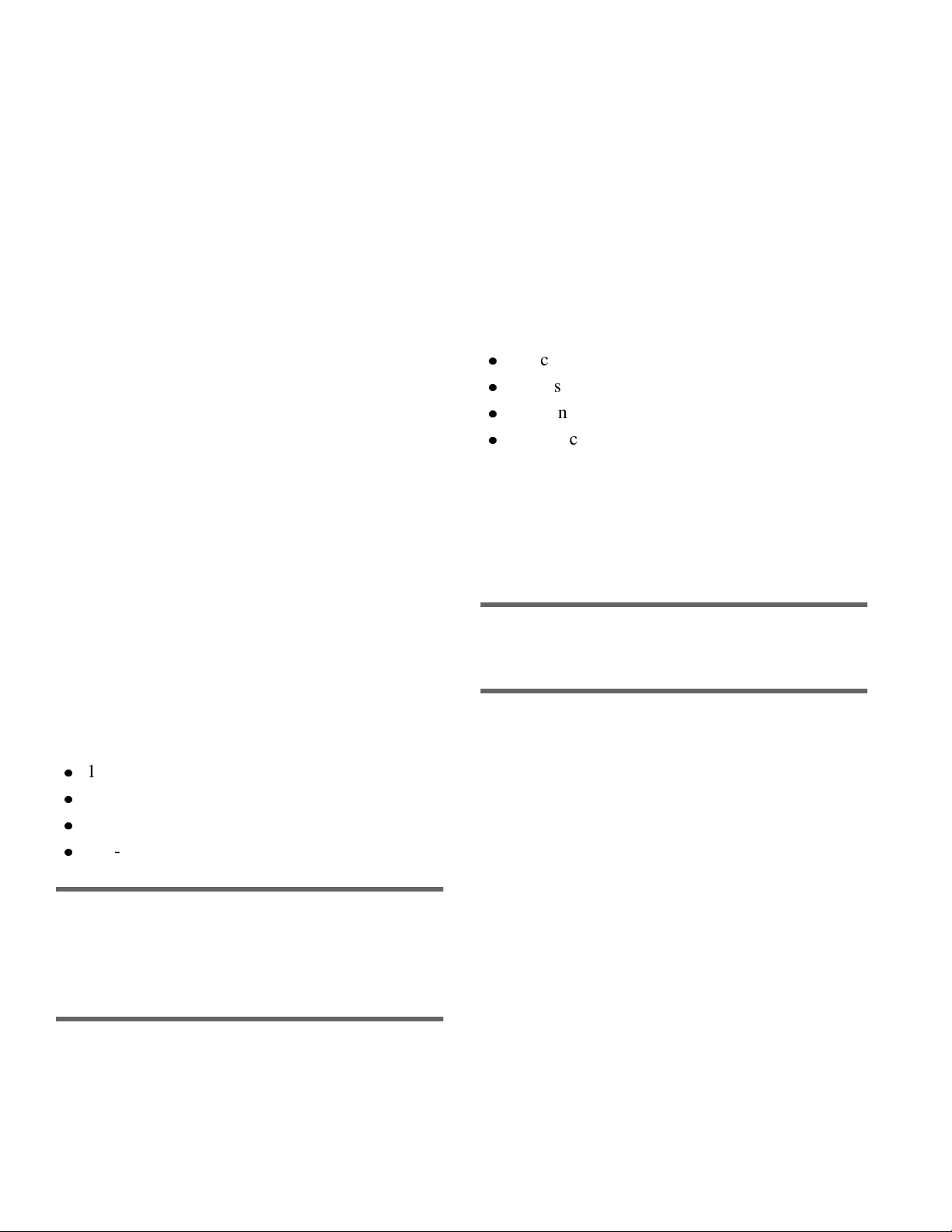

Chemical Injection Supply System

The external supply connection ports are designated

1, 2, 3, and 4, in that order, viewed from the rear of

the machine, top to bottom. The supply dispenser

compartments are designated 1, 2, and 3, in that

order, viewed from the front of the machine, left to

right.

Supply Dispenser

Compartments

2

1

1

Chemical Injection

Supply Nozzles

3

3

4

2

B009RE3A

Figure 4

Compartment 1 flushes with each fill. Compartment

2 flushes when the program calls for supply 2

during a fill. Compartment 3 flushes when the

program calls for supply 3 during a fill.

Note: Compartment 2 does not flush when supply 4

is called for in a program.

The chemical injection supply nozzles located in

their respective supply compartments function as

follows: supply nozzle 1 empties into compartment

1, supply nozzles 2 and 4 empty into compartment

2, and supply nozzle 3 empties into compartment 3.

See Figure 4.

24 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 27

Cycle Segment Charts

Safety

Segment 1 (Prewash)

Display

PrE

00 or 02 to 30 Select segment time: 02 to 30 minutes (00 to skip segment)

HFIL, CFIL, or bFIL Select “HFIL” (hot fill), “CFIL” (cold fill), or “bFIL” (warm fill)

LOLE or HILE Select fill level: “LOLE” (low), or “HILE” (high) water level

SUP0–SUP7 Select supply 0 – 7 (0 for no supply)

00°F, 75°F–200°F

00°C, 25°C–93°C

SPIn (flashed for one second)

tIME (flashed for one second)

00 or 30 to 120 Select time for spin: 30 to 120 seconds (00 for no spin)

Use the Up or Down key to change. Press the Start key to enter or advance.

Select temperature: 75 to 200°F or 25 to 93°C (00 for no heat)

Instructions

F232073 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 28

Safety

Cycle Segment Charts (Continued)

Segment 2 (Wash)

Display

UASH

00 or 02 to 20 Select segment time: 02 to 20 minutes (00 to skip segment)

HFIL, CFIL, or bFIL Select “HFIL” (hot fill), “CFIL” (cold fill), or “bFIL” (warm fill)

LOLE or HILE Select fill level: “LOLE” (low), or “HILE” (high) water level

SUP0–SUP7 Select supply 0–7 (0 for no supply)

00°F, 75°F–200°F

00°C, 25°C–93°C

SPIn (flashed for one second)

tIME (flashed for one second)

00 or 30 to 120 Select time for spin: 30 to 120 seconds (00 for no spin)

Use the Up or Down key to change. Press the Start key to enter or advance.

Select temperature: 75 to 200°F or 25 to 93°C (00 for no heat)

Instructions

26 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 29

Segments 3 – 7 (Fills 1 – 5)

Safety

Display

FIL1, FIL2, FIL3, FIL4, or FIL5

00 or 02 to 15 Select segment time: 02 to 15 minutes (00 to skip segment)

HFIL, CFIL, or bFIL Select “HFIL” (hot fill), “CFIL” (cold fill), or “bFIL” (warm fill)

LOLE or HILE Select fill level: “LOLE” (low), or “HILE” (high) water level

SUP0–SUP7 Select supply 0 – 7 (0 for no supply)

00°F, 75°F–200°F

00°C, 25°C–93°C

SPIn (flashed for one second)

tIME (flashed for one second)

00 or 30 to 120 Select time for spin: 30 to 120 seconds (00 for no spin)

Use the Up or Down key to change. Press the Start key to enter or advance.

Select temperature: 75 to 200°F or 25 to 93°C (00 for no heat)

Instructions

F232073 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 30

Safety

Cycle Segment Charts (Continued)

Segment 8 (Fill 6)

Display

FIL6

00 or 02 to 15 Select segment time: 02 to 15 minutes (00 to skip segment)

HFIL, CFIL, or bFIL Select “HFIL” (hot fill), “CFIL” (cold fill), or “bFIL” (warm fill)

LOLE or HILE Select fill level: “LOLE” (low), or “HILE” (high) water level

SUP0–SUP7 Select supply 0 – 7 (0 for no supply)

00°F, 75°F–200°F

00°C, 25°C–93°C

SPIn (flashed for one second)

tIME (flashed for one second)

00 or 01 to 10 Select time for spin: 1 to 10 minutes (00 for no spin)

Use the Up or Down key to change. Press the Start key to enter or advance.

Select temperature: 75 to 200°F or 25 to 93°C (00 for no heat)

Instructions

28 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 31

Cycle Programming Worksheet

Cycle Programming Worksheet

Program Prewash Wash

Cycle Time (Min) Time (Min)

Title Water Water

Level Level

Supply Supply

Temp Temp

Spin (Sec) Spin (Sec)

Fill 1 Fill 2 Fill 3

Time (Min) Time (Min) Time (Min)

Water Water Water

Level Level Level

Safety

Supply Supply Supply

Temp Temp Temp

Spin (Sec) Spin (Sec) Spin (Sec)

Fill 4 Fill 5 Fill 6

Time (Min) Time (Min) Time (Min)

Water Water Water

Level Level Level

Supply Supply Supply

Temp Temp Temp

Spin (Sec) Spin (Sec) Spin (Min)

F232073 29

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 32

Safety

S-Computer Cycle Charts

S-Computer Standard Cycles

1

Program

Prewash

Time (Min)000222

Water --- --- --- Cold Hot Cold

Level --- --- --- High High High

Supply --- --- --- 0 0 0

Temp (F) --- --- --- 0 0 0

Spin (Sec) --- --- --- 0 0 0

Wash

Time (Min)667755

Water Hot Warm H ot Warm Ho t Wa rm

Level Low Low Low Low Low Low

Supply511111

Temp (F)000000

Spin (Sec) 40 40 60 60 60 60

Fill 1

Time (Min)005255

Water --- --- Hot Warm Hot Warm

Level --- --- Low High Low Low

Supply --- --- 2 0 1 1

Temp (F) --- --- 0 0 0 0

Spin (Sec) --- --- 60 40 0 60

Fill 2

Time (Min)002063

Water --- --- Warm --- Hot Warm

Level --- --- High --- Low High

Supply --- --- 0 --- 2 0

Temp (F) --- --- 0 --- 0 0

Spin (Sec) --- --- 40 --- 60 0

Light

Soil

Whites

2

Light

Soil

Colors

3

Medium

Soil

Whites

4

Medium

Soil

Colors

5

Heavy

Soil

Whites

6

Heavy

Soil

Colors

30 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 33

S-Computer Standard Cycles (Continued)

Safety

1

Program

Fill 3

Time (Min)000020

Water --- --- --- --- Hot ---

Level --- --- --- --- High ---

Supply --- --- --- --- 0 ---

Temp (F) --- --- --- --- 0 ---

Spin (Sec) --- --- --- --- 60 ---

Fill 4

Time (Min)000020

Water --- --- --- --- Hot ---

Level --- --- --- --- High ---

Supply --- --- --- --- 0 ---

Temp (F) --- --- --- --- 0 ---

Spin (Sec) --- --- --- --- 0 ---

Fill 5

Time (Min)332233

Water Warm Warm Warm Warm Warm Warm

Level High High High High High High

Supply000000

Temp (F)000000

Spin (Sec)000000

Fill 6

Time (Min)333333

Water Warm Warm Warm Warm Warm Warm

Level Low High High High High High

Supply533333

Temp (F)000000

Spin (Min) 5 4 5 4 5 4

Light

Soil

Whites

2

Light

Soil

Colors

3

Medium

Soil

Whites

4

Medium

Soil

Colors

5

Heavy

Soil

Whites

6

Heavy

Soil

Colors

F232073 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 34

Safety

S-Computer Cycle Charts (Continued)

S-Computer Standard Cycles

7

Program

Prewash

Time (Min)223306

Water Cold Cold Warm Warm --- Warm

Level High High High High --- Low

Supply 0 0 1 0 --- 1

Temp (F) 0 0 0 0 --- 0

Spin (Sec) 0 0 0 0 --- 0

Wash

Time (Min)268605

Water Warm Cold Hot Hot --- Hot

Level High Low Low Low --- Low

Supply 0 1 5 1 --- 1

Temp (F) 0 0 0 0 --- 0

Spin (Sec)060060---60

Fill 1

Time (Min)626503

Water Warm Cold Hot Hot --- Hot

Level Low High High Low --- High

Supply 1 0 2 1 --- 0

Temp (F) 0 0 0 0 --- 0

Spin (Sec) 30 0 60 60 --- 60

Fill 2

Time (Min)303600

Water Warm --- Warm Hot --- ---

Level High --- High Low --- ---

Supply 0 --- 0 2 --- ---

Temp (F) 0 --- 0 0 --- ---

Spin (Sec) 0 --- 60 60 --- ---

Permanent

Press

Visa

8

Gentle

Delicate

Wool

9

Rewash

Destaining

(Continued)

10

Heavy

Soil

11

Rinse

Spin

12

Personals

Starch

32 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 35

S-Computer Standard Cycles (Continued)

Safety

7

Program

Fill 3

Time (Min)200300

Water Warm --- --- Hot --- ---

Level High --- --- High --- ---

Supply 0 --- --- 0 --- ---

Temp (F) 0 --- --- 0 --- ---

Spin (Sec) 0 --- --- 0 --- ---

Fill 4

Time (Min)000000

Water --- --- --- --- --- ---

Level --- --- --- --- --- ---

Supply --- --- --- --- --- ---

Temp (F) --- --- --- --- --- ---

Spin (Sec) --- --- --- --- --- ---

Fill 5

Time (Min)303302

Water Col d - -- Wa rm Warm --- Wa rm

Level High --- High High --- High

Supply 3 --- 0 0 --- 0

Temp (F) 0 --- 0 0 --- 0

Spin (Sec) 40 --- 0 0 --- 0

Fill 6

Time (Min)033324

Water --- Co ld Wa rm Wa rm Wa rm Wa rm

Level --- High High High Low High

Supply---33304

Temp (F) --- 0 0 0 0 0

Spin (Min) --- 3 5 5 2 4

Permanent

Press

Visa

8

Gentle

Delicate

Wool

9

Rewash

Destaining

10

Heavy

Soil

11

Rinse

Spin

12

Personals

Starch

F232073 33

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 36

Safety

S-Computer Cycle Charts (Continued)

S-Computer Blank Cycle Charts

Program 13 14 15 16 17 18

Prewash

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Wash

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 1

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 2

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

34 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 37

Safety

S-Computer Blank Cycle Charts (Continued)

Program 13 14 15 16 17 18

Fill 3

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 4

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 5

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 6

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Min)

F232073 35

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 38

Safety

S-Computer Cycle Charts (Continued)

S-Computer Blank Cycle Charts

Program 19 20 21 22 23 24

Prewash

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Wash

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 1

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 2

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

(Continued)

36 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 39

Safety

S-Computer Blank Cycle Charts (Continued)

Program 19 20 21 22 23 24

Fill 3

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 4

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 5

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 6

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Min)

F232073 37

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 40

Safety

S-Computer Cycle Charts (Continued)

S-Computer Blank Cycle Charts

Program 25 26 27 28 29 30

Prewash

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Wash

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 1

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 2

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

(Continued)

38 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 41

Safety

S-Computer Blank Cycle Charts (Continued)

Program 25 26 27 28 29 30

Fill 3

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 4

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 5

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Sec)

Fill 6

Time (Min)

Water

Level

Supply

Temp ( F )

Spin (Min)

F232073 39

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 42

Safety

Notes

40 F232073

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 43

/DYDGRUDH[WUDFWRUD

de gabinete de montaje permanente

Instrucciones de

operación y programación

de la microcomputadora serie S

Números de modelo

HC25SN SC18SN UC25PN

HC80SN SC25SN UC80PN

SC27SN

SC35SN

SC50SN

2SHUD

ción/Programación

SC80SN

www.comlaundry.com

Pieza No. F232073R4

Marzo 2001

Page 44

Page 45

Contenido

Operación/Programación

Seguridad

Descripción de los símbolos . . . . . . . . . . . . . . . 46

Ubicación de las calcomanías de seguridad . . . 47

Seguridad del operador . . . . . . . . . . . . . . . . . . . 48

Medio ambiente donde usar la máquina sin

peligro . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Condiciones ambientales . . . . . . . . . . . . . . . 49

Ubicación de la máquina . . . . . . . . . . . . . . 50

Servicios de entrada y salida . . . . . . . . . . . . 50

Uso incorrecto. . . . . . . . . . . . . . . . . . . . . . . . . . 51

Operación

Servicio a los clientes . . . . . . . . . . . . . . . . . . . . 53

Guía de familiarización con la máquina . . . . . . 53

Teoría de funcionamiento . . . . . . . . . . . . . . . . . 55

Computadora serie S . . . . . . . . . . . . . . . . . . 56

Teclado. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Mensajes del indicado . . . . . . . . . . . . . . . . . 57

Arranque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Para abrir la puerta . . . . . . . . . . . . . . . . . . . . . . 58

Para cargar la ropa. . . . . . . . . . . . . . . . . . . . . . . 58

Surtidor de suministros . . . . . . . . . . . . . . . . . . 59

Selección de ciclos. . . . . . . . . . . . . . . . . . . . . . 59

Ejecución de un ciclo. . . . . . . . . . . . . . . . . . . . 59

Llenado . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Lavado . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Desagüe . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Centrifugado . . . . . . . . . . . . . . . . . . . . . . . 60

Rutina de paro. . . . . . . . . . . . . . . . . . . . . . . 60

Programación

Funciones clave en la modalidad de

programación . . . . . . . . . . . . . . . . . . . . . . . . 63

Modalidad de preparación . . . . . . . . . . . . . . . . 63

Cuenta de ciclos . . . . . . . . . . . . . . . . . . . . . . . . 64

Programación de ciclos . . . . . . . . . . . . . . . . . . 64

Sistema de suministro por inyección de

productos químicos. . . . . . . . . . . . . . . . . . . . 66

Tablas de segmentos de ciclos . . . . . . . . . . . . . 67

Hoja de trabajo de programación

de ciclos . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Tablas de ciclos de la

computadora serie S . . . . . . . . . . . . . . . . . . . 72

F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

43

Page 46

© Copyright 2001, Alliance Laundry Systems LLC

Reservados todos los derechos. Ninguna sección del presente manual puede ser reproducida o transmitida en forma

alguna o a través de ningún medio sin el expreso constimiento por escrito del editor.

44 F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 47

Sección 1

Seguridad

Cualquier persona que use o que dé servicio a esta

máquina debe cumplir con las reglas de seguridad

que incluimos en este manual. Se debe prestar

atención especial a los avisos de PELIGRO,

ADVERTENCIA y PRECAUCIÓN que aparecen en

todo el manual.

PRECAUCIÓN

Tenga cuidado cuando esté cerca de la puerta

abierta, especialmente cuando cargue la ropa

desde un nivel más bajo de la puerta. Si se

llegara a golpear contra la orilla de la puerta

podría sufrir lesiones personales.

SW025

ADVERTENCIA

Hay voltajes peligrosos en las cajas de control

eléctrico y en las conexiones del motor. Sólo el

personal capacitado para realizar

procedimientos de pruebas eléctricas y

conocedor del equipo de pruebas y de las

precauciones de seguridad debe intentar hacer

ajustes y reparar averías. Desconecte la

corriente eléctrica de la máquina antes de

quitar la cubierta de la caja de control eléctrico

y de intentar realizar los procedimientos de

servicio.

SW005

Los siguientes avisos de seguridad son ejemplos

generales que se aplican a esta máquina. Las

advertencias específicas a una instalación o a algún

procedimiento de mantenimiento en particular

aparecen en el manual con la explicación de tal

procedimiento.

PELIGRO

Si algún niño se queda atrapado dentro de la

máquina puede sufrir lesiones graves o hasta

la muerte. No permita que los niños jueguen

en o cerca de esta máquina. No deje de

prestar atención a los niños mientras la puerta

de esta máquina esté abierta.

SW001

ADVERTENCIA

Sólo personal capacitado de mantenimiento

eléctrico debe instalar, ajustar y dar

mantenimiento a esta máquina. Este personal

debe estar familiarizado con la construcción y

el funcionamiento de este tipo de maquinaria y

con los peligros potenciales que presenta. Si

no se cumple con esta advertencia, pueden

ocasionarse lesiones personales y/o daños al

equipo y podría anularse la garantía.

SW004

F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

45

Page 48

Seguridad

PRECAUCIÓN

Asegúrese de que esta máquina sea instalada

sobre un piso nivelado con la suficiente

resistencia y de que se mantengan los

espacios libres necesarios para la inspección y

el mantenimiento. Nunca permita que el

espacio para inspección y mantenimiento

quede bloqueado.

Descripción de los símbolos

El rayo con punta de flecha dentro del triángulo es

un signo de advertencia que indica la presencia de

voltaje peligroso.

SW020

ADVERTENCIA

Nunca toque tuberías, conexiones o

componentes internos o externos de vapor.

Estas superficies pueden estar demasiado

calientes y pueden causar quemaduras graves.

Es necesario cerrar el vapor y dejar enfriar las

tuberías, las conexiones y los componentes

antes de tocarlos.

Este símbolo de advertencia indica la presencia de

productos químicos posiblemente peligrosos.

Deben tomarse precauciones adecuadas al manejar

materiales corrosivos o cáusticos.

SW014

El signo de admiración dentro del triángulo es un

símbolo de advertencia que indica que existen

importantes instrucciones acerca de la máquina y

condiciones potencialmente peligrosas

Este símbolo de advertencia indica que existen

superficies calientes que podrían causar graves

quemaduras. El acero inoxidable y las líneas de

vapor pueden ponerse demasiado calientes y no

deben ser tocadas.

Este símbolo de advertencia indica que hay

mecanismos de transmisión (mando)

potencialmente peligrosos dentro de la máquina.

Los protectores siempre deben estar en su lugar

cuando la máquina esté funcionando.

46 F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Este símbolo de advertencia indica que hay puntos

de agarre potencialmente peligrosos. Las piezas

mecánicas móviles pueden aplastar y/o cortar partes

del cuerpo.

Page 49

Seguridad

Hay calcomanías de seguridad en lugares

importantes de la máquina. Si las calcomanías no se

mantienen de tal forma que se puedan leer, los

P/N 230877

T

A

T

O

SPIN

BEFORE

I

O

N

(Sólo OPL)

CAUTION

P/N 231065

PUMP

P/N 230877

IMPORTANT

REMOVE SHIPPING BLOCK

BEFORE STARTING MACHINE.

DISCONNECT MAIN POWER BEFORE

REMOVING COVER. ONLY SPECIALLY

TRAINED PERSONNEL SHOULD TURN

POWER ON WHEN COVER IS REMOVED.

230206

230207

CONNECTION

TO WASHER

1 Install the liquid supply system with a loop in the connection

hose. (see sketch) or locate the liquid pump below the connection

parts to prevent inadvertant introduction of chemicals into the

washer.

2 Use extreme care in handling hazardous chemicals

Consult container labels for instructions.

P/N 230693

R

P/N 230661

PUSH RED BUTTON

TURNING HANDLE

230661

P/N 231065

WARNING

MACHINE MAY BE HOT

AND CAUSE BURNS

ATTEMPT NO ENTRY UNTIL

BASKET HAS STOPPED

DO NOT WASH ITEMS CONTAINING

HAZARDOUS CHEMICALS, FLAMMABLE

FUMES OR FLAMMABLE MATERIALS.

USE MACHINE WITH WATER ONLY.

DO NOT LET CHILDREN OPERATE OR

PLAY WITH OR AROUND WASHER.

SERIOUS INJURY MAY RESULT

P/N 81968R1

WARNING

HIGH SPIN SPEEDS

DO NOT put any person in

this washer.

To reduce the risk of

serious injury do not open

the door when:

- Clothes are moving, or

- Water in in washer.

operadores o técnicos de servicio pueden sufrir

lesiones.

P/N 230206

WARNING!

HIGH VOLTAGE INSIDE

THIS MACHINE IS WIRED FOR

208_240V; 3N~ 60Hz

P/N 230207

(Típico)

P/N 230215-1

WARNING ELECTRICIAN

High leg must be connected to L-3.

This machine requires a 208-240 V 3 phase

4 wire system. If the system has a high leg or if

a phase adder is used, the artificial leg or the

high leg must be connected to L-3. If change

of motor rotation is necessary., do not

exchange the L-3 connection.

The ground lug must be connected to a

permanent earth ground.

P/N 230630

Install equipment

ground as per local

code or N.E.C. Artcle 250-95

P/N 231146

(Sólo modelos de 80 libras)

COPPER

CONDUCTORS ONLY

P/N 231146

P/N 230626

230626

FUSE

CONTROL CIRCUIT

WARNING:

FOR CONTINUED PROTECTION

REPLACE FUSE ONLY WITH FUSE

(No está presente en modelos EDC)

OF SAME TYPE & RATING

P/N 230215-1

P/N 230630

2 AMP

IMPORTANT:

In case of power interruption please

allow 2-3 minutes before trying to open

door.

DOOR HANDLE WILL NOT SUPPORT WEIGHT

RESULTING DAMAGE WILL NOT BE COVERED

F232073 (SP)

81968R1

P/N 230216

WARNING

DO NOT LIFT MACHINE BY

DOOR HANDLE

OF MACHINE.

BY WARRANTY.

P/N 230202

NOTE

A plastic block has been

inserted to prevent the door

from locking durning shipment

P/N 230528

(Sólo OPL)

230216

P/N 230528

P/N 230756

(Sólo modelos MC)

FOR SERVICE ONLY

PUSH BUTTON

TO FAST

ADVANCE TIMER

P/N 230756

HIGH VOLTAGE INSIDE

DISCONNECT MAIN POWER BEFORE REMOVING COVER.

ONLY SPECIALLY TRAINED PERSONNEL

SHOULD TURN POWER ON WHEN COVER IS REMOVED.

Figura 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

WARNING!

B005RS3A

47

Page 50

Seguridad

Para ofrecer seguridad personal y mantener la

máquina funcionando correctamente, cumpla con

todos los procedimientos de mantenimiento y

seguridad que aparecen en este manual. Si tiene

alguna pregunta concerniente a la seguridad, de

inmediato póngase en contacto con el fabricante.

Use piezas de repuesto autorizadas por el fabricante

de esta máquina para evitar situaciones peligrosas.

Seguridad del operador

ADVERTENCIA

NUNCA meta las manos ni objetos dentro de la

unidad de la canasta hasta que ésta se haya

detenido por completo. Hacerlo podría

ocasionar graves lesione.

Por la seguridad de los operadores de la máquina,

cumpla con los puntos de revisión diaria de

mantenimiento:

SW012

3. No intente usar la máquina si se presenta

cualquiera de las siguientes situaciones:

a. La puerta no permanece asegurada durante

todo el ciclo.

b. Es evidente que el nivel de agua es

demasiado alto.

c. La máquina no está conectada a un circuito

correctamente conectado a tierra.

No evite ninguno de los dispositivos de seguridad

de la máquina.

1. Antes de usar la máquina, verifique que todos

los avisos de seguridad estén visibles y en su

lugar. Los avisos que falten o que no se puedan

leer deben ser reemplazados de inmediato.

Asegúrese de contar con avisos de repuesto.

2. Revise el sistema de enclavamiento de la puerta

antes de usar la máquina:

a. Trate de arrancar la máquina con la puerta

abierta. La máquina no debe arrancar si la

puerta está abierta.

b. Cierre la puerta sin ponerle el seguro e

intente arrancar la máquina. La máquina no

debe arrancar si la puerta no está asegurada.

c. Cierre y ponga el seguro a la puerta y

comience el ciclo. Intente abrir la puerta

mientras el ciclo está funcionando. No debe

ser posible abrir la puerta.

Si el seguro y el sistema de enclavamiento de la

puerta no funcionan correctamente, llame a un

técnico de servicio.

48 F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 51

Medio ambiente donde usar la

máquina sin peligro

Para que la máquina funcione sin peligro es

necesario que el medio ambiente sea adecuado tanto

para el operador como para la máquina. Si tiene

alguna pregunta concerniente a la seguridad, de

inmediato póngase en contacto con el fabricante.

Condiciones ambientales

l

Temperatura ambiente. El agua en la máquina se

congela a temperaturas inferiores a 0° C (32° F).

A temperaturas superiores a 50° C (120° F) el

motor se sobrecalienta más frecuentemente y,

en algunos casos, los dispositivos de estado

sólido que se usan en algunos modelos pueden

fallar o dañarse prematuramente. Es posible que

sea necesario instalar dispositivos especiales de

enfriamiento.

Los interruptores de presión de agua pueden

resultar afectados por los aumentos y las

disminuciones en la temperatura. Cada cambio

de 10° C (25° F) en temperatura tendrá un

efecto de 1% en el nivel de agua.

l

Humedad. La humedad relativa superior al 90%

puede hacer que el sistema electrónico o que los

motores fallen y puede accionar el interruptor

de falla en la conexión a tierra. También pueden

presentarse problemas de corrosión en algunos

componentes metálicos de la máquina.

Si la humedad relativa es menor al 30%, las

correas y las mangueras de goma (caucho)

pueden secarse. Esta condición puede ocasionar

fugas en las mangueras, lo que puede presentar

peligros externos a la máquina y al equipo

eléctrico adyacente.

l

Ventilación. Es necesario evaluar

periódicamente la necesidad de contar con aire

de reemplazo en la lavandería para los equipos

como secadoras, planchadoras, calentadores de

agua, etc. Los reguladores de tiro (persianas),

las mallas y otros dispositivos pueden reducir

significativamente el aire disponible que entra

por las aberturas.

Seguridad

l

Emisiones de frecuencia de radio. Existe un

filtro disponible para máquinas instaladas en

lugares donde éstas comparten el área con

equipo sensitivo a emisiones de frecuencia de

radio.

l

Elevación. Si la máquina va a ser usada a

elevaciones sobre los 1.000 metros (3.280 pies)

sobre el nivel del mar, ponga especial atención

a los niveles de agua y a los ajustes electrónicos

(particularmente la temperatura), ya que de lo

contrario es posible que no obtenga buenos

resultados.

l

Productos químicos. No permita que queden

residuos de productos químicos sobre las

superficies de acero inoxidable.

PELIGRO

No coloque fluidos volátiles ni inflamables en

ninguna máquina. No limpie la máquina con

fluidos volátiles ni inflamables tales como

acetona, adelgazadores de lacas, reductores

de esmaltes, tetracloruro de carbono, gasolina,

benceno, naftaleno, etc. Si lo hace puede

causar graves lesiones personales y/o daños a

la máquina.

l

Daños causados por agua. No rocíe la

máquina con agua. Pueden ocasionarse cortos

circuitos y daños considerables. Repare de

inmediato las fugas debidas a empaques

desgastados o dañados.

SW002

F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

49

Page 52

Seguridad

Medio ambiente donde usar la

máquina sin peligro

Ubicación de la máquina

l

Cimentación. El piso de concreto debe tener la

resistencia y el espesor necesarios para soportar

cargas generadas por las altas velocidades de

extracción de la máquina.

l

Espacio para servicio y mantenimiento. Deje

suficiente espacio para realizar procedimientos

de servicio y mantenimiento de rutina.

Esto es especialmente importante en relación

con máquinas equipadas con un mando inversor

de CA.

Consulte las instrucciones de instalación para

obtener detalles específicos.

(continuación)

PRECAUCIÓN

Vuelva a colocar todos los paneles que haya

quitado al realizar los procedimientos de servicio

y mantenimiento. No use la máquina si no tiene

instalados todos los protectores ni si tiene piezas

descompuestas o si le faltan piezas. No evite

ningún dispositivo de seguridad.

Servicios de entrada y salida

l

Presión de agua. Se obtiene el mejor

rendimiento si el agua se suministra a una

presión entre 2,0 y 5,7 Barias (30 y 85 PSI).

Aunque la máquina funciona correctamente a

presiones menores, se tarda más en llenar. A

presiones mayores de 6,7 Barias (100 PSI) las

tuberías de la máquina pueden sufrir daños,

ciertos componentes pueden fallar y pueden

ocasionarse graves lesiones personales.

l

Presión de vapor (opcional). Se obtiene el

mejor rendimiento si el vapor se suministra a

una presión entre 2,0 y 5,4 Barias (30 y 80 PSI).

A presiones mayores de 8,5 Barias (125 PSI)

los componentes de vapor pueden sufrir daños y

pueden ocasionarse graves lesiones personales.

SW019

En el caso de máquinas equipadas con calor de

vapor opcional, instale tubería que cumpla con

las normas comerciales para vapor. Si no se

instala el filtro para línea de vapor que

adjuntamos se anula la garantía.

l

Sistema de desagüe. Instale líneas de desagüe

o canaletas lo suficientemente grandes para el

número total de galones que podrían desaguar

si todas las máquinas instaladas en ese lugar se

desaguaran al mismo tiempo desde el nivel más

alto de agua posible. Si usa canaletas, éstas

deben estar cubiertas de tal forma que soporten

tráfico ligero a pie.

l

Corriente eléctrica. Por su seguridad personal y

para obtener un funcionamiento correcto, la

máquina debe estar conectada a tierra de

acuerdo a las normas estatales y locales. La

conexión a tierra debe ser hecha a una conexión

real a tierra, no a un conducto ni a tuberías de

agua. No use fusibles para reemplazar el

interruptor de circuito. También debe instalarse

un interruptor de corte de corriente en algún

lugar accesible.

ADVERTENCIA

Asegúrese de conectar a tierra a partir de una

conexión tierra adecuada a la orejeta terminal

de conexión a tierra cerca del bloque de

suministro de corriente de esta máquina. Si no

se conecta a tierraa correctamente, se pueden

ocasionar lesiones personales debidas a

descargas eléctricas y la máquina puede fallar.

SW008

Siempre desconecte el suministro de corriente

eléctrica y de agua antes de que un técnico de

servicio lleve a cabo cualquier procedimiento de

servicio. Cuando corresponda, el suministro de

vapor y/o de aire comprimido también deben ser

desconectados antes de realizar el servicio.

50 F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 53

Uso incorrecto

Nunca use esta máquina con otro propósito que no

sea lavar tela.

l

Nunca lave trapos remojados en petróleo en la

máquina. Esto puede ocasionar una explosión.

l

Nunca lave piezas de maquinaria o de

automóviles en la máquina. Esto puede dañar

seriamente la canasta.

l

Nunca permita que los niños jueguen en o cerca

de esta máquina. Si algún niño queda atrapado

dentro de la máquina pueden sufrir lesiones de

gravedad o morir. No deje de prestar atención a

los niños mientras la puerta de esta máquina

esté abierta. Estas precauciones también se

aplican a los animales.

Seguridad

F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

51

Page 54

Seguridad

Notas

52 F232073 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 55

Sección 2

Operación

Este manual está diseñado como guía de

funcionamiento y programación de la lavadora

extractora de gabinete de montaje permanente

equipada con el control de una microcomputadora

de la serie S.

Los manuales, las instrucciones de instalación y los

diagramas de cableado que acompañan a esta

máquina han sido incluidos con la máquina sin

costo para usted. Puede obtener copias adicionales a

un costo nominal.

Nota: Lea este manual por completo antes de

intentar usar la máquina o de programar la

microcomputadora.

Nota: No use este manual con los modelos

anteriores de máquinas controladas por