Alliance Laundry Systems BDGLLFGS301EW01, BD3LLFGS401UW01, SDGLCRGS111TW02, BDGLXFSS301EN01, HDELEFGS151CW01 Troubleshooting Manual

...Page 1

DRY716C

Single and

Stacked Dryers

Refer to Page 6 for Model Numbers

Troubleshooting

www.comlaundry.com

Part No. 513447

April 2010

Page 2

Page 3

Table of

Section 1 – Safety Information ...............................................................3

Locating an Authorized Servicer...........................................................4

Contents

Section 2 – Introduction..........................................................................5

Customer Service...................................................................................5

Nameplate Location...............................................................................5

Model Identification..............................................................................6

How Your Dryer Works ........................................................................9

Section 3 – Dryer Troubleshooting ......................................................10

1. Dryer Motor Does Not Run ........................................................10

2. Dryer Stops In Cycle; Quits After The First Few Loads;

Has A Burning Smell; Cycles On Motor Thermal Protector......12

3. Dryer Motor Runs But Cylinder Does Not Turn ........................13

4. Dryer Motor Does Not Stop........................................................14

5. Dryer Runs Only When Door is Open........................................15

6. Dryer Heating Assembly Does Not Heat or

Burner Does Not Ignite...............................................................16

7. Igniter Does Not Glow (Gas Supply Sufficient) –

Gas Dryer Models.......................................................................18

8. Burner Ignites and Goes Out Repeatedly –

Gas Dryer Models.......................................................................19

9. Igniter Glows But Burner Does Not Ignite –

Gas Dryer Models.......................................................................20

10. Dryer Heater Assembly Or Burner Shuts Off Prematurely ........21

11. Dryer Heater Assembly or Burner Repeatedly

Cycles Off On Limit Thermostat................................................22

12. Dryer Heater Assembly or Burner Does Not Shut Off...............24

13. Clothes Do Not Dry in Dryer......................................................25

14. Clothes Are Too Hot When Removed From Dryer ....................26

15. Excessive Chattering Or Vibrating Noise in Dryer ....................27

16. Excessive Humming Or Whistling Noise in Dryer.....................28

Section 4 – Electronic Control Troubleshooting.................................29

17. Error Codes .................................................................................29

18. Coins Ignored When Entered......................................................30

19. No IR Communication................................................................31

20. No Display ..................................................................................32

21. Door Open...................................................................................34

22. Motor Will Not Start...................................................................36

23. No Heat (Electric).......................................................................38

24. No Heat (Gas) .............................................................................40

Section 5 – Coin Drop Troubleshooting...............................................42

25. Troubleshooting Coin Drop........................................................42

Section 6 – Adjustments........................................................................47

26. Leveling Legs..............................................................................47

27. Burner Flame (Gas Models)........................................................48

28. Cleaning Non-Electronic Coin Drop...........................................50

29. Cleaning Electronic Coin Drop...................................................52

© Copyright 2010, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

513447 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 4

Section 7 – Test Procedures..................................................................55

30. Timer Contacts............................................................................55

31. Fabric Selector Switch ................................................................56

32. Drive Motor.................................................................................57

33. Accumulator (Metered Models)..................................................60

34. Motor Switch...............................................................................61

35. Burner System Operation (Gas Models).....................................63

36. Electrical Circuit To Ignition System (Gas Models) ..................65

37. Gas Valve Coils Check (Gas Models) ........................................65

38. Sensor Check (Gas Models)........................................................66

39. Igniter Check (Gas Models)........................................................66

40. Ignition Control Grounding Check (Silicon Nitride Ignition)....66

41. Thermal Fuse (Electric Models) .................................................66

42. Heater Assembly (Electric Models)............................................67

43. Cycling or Limit Thermostat.......................................................67

44. Door Switch ................................................................................67

45. Thermistor...................................................................................68

Section 8 – Internal Wiring of Dryer Motor Switch...........................69

2 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Section 1

• Failure to install, maintain, and/or operate this machine according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or property

damage.

• Do not repair or replace any part of the machine or attempt any servicing unless specifically

recommended or published in this Service Manual and that you understand and have the

skills to carry out.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the machine is properly grounded and to reduce the risk of fire,

electric shock, serious injury, or death.

W284

WARNING

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer, and those maintaining the machine.

a DANGER

Danger indicates an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

WARNING

Warning indicates a hazardous situation that, if not avoided, could cause severe personal injury or death.

CAUTION

Caution indicates a hazardous situation that, if not avoided, may cause minor or moderate personal injury or

property damage.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

513447 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 6

Safety Information

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

W007

WARNING

If you or an unqualified person perform service on your machine, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W286

WARNING

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the machine.

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized

technician and using authorized factory parts.

4 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 7

Section 2

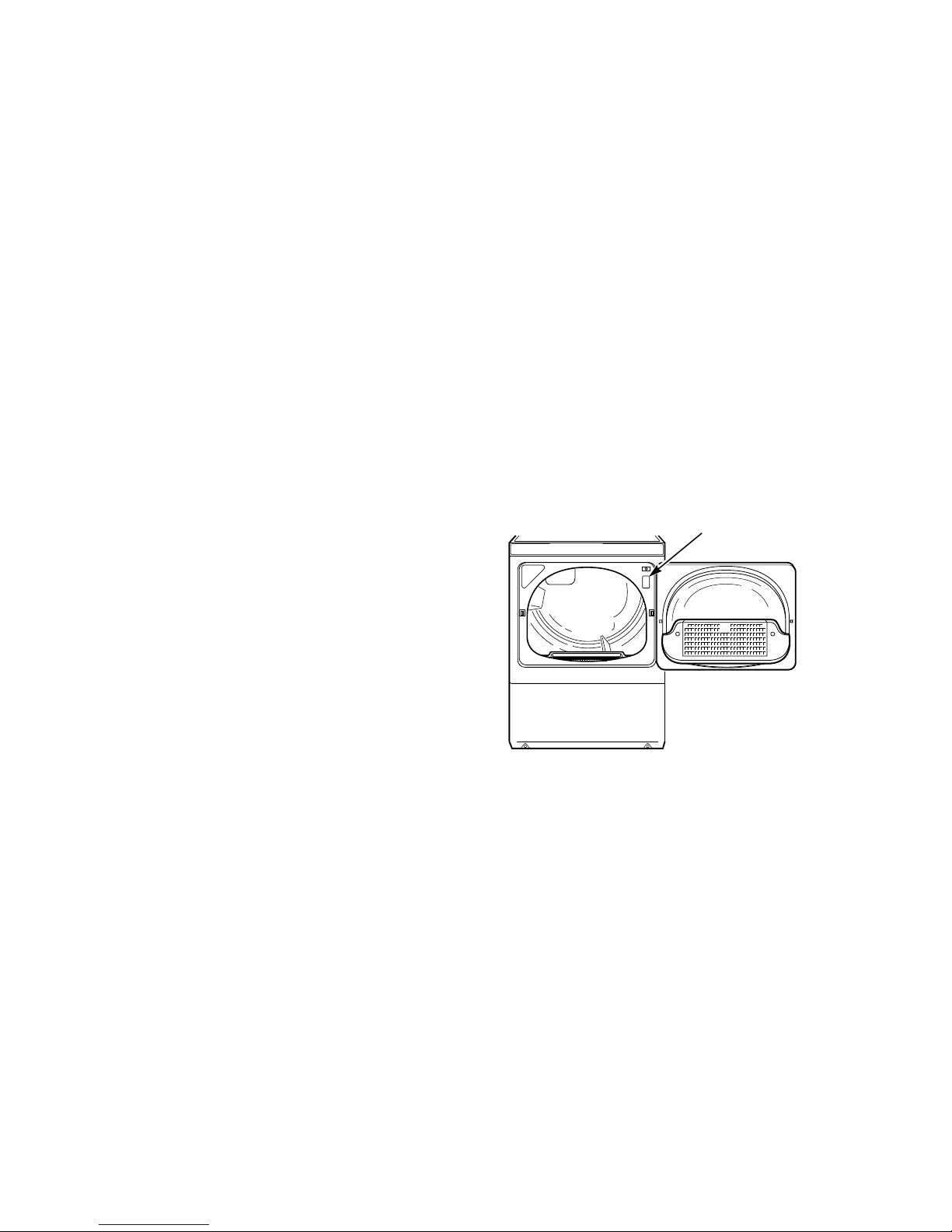

D412P

Nameplate

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized parts

distributor.

For technical assistance, call (920) 748-3121.

Nameplate Location

When calling or writing about your dryer, be sure to

mention model and serial numbers. Model and serial

numbers are located on the nameplate. The nameplate

is in one of the four corners of the door well. The door

well is the shaded area shown.

513447 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 8

Introduction

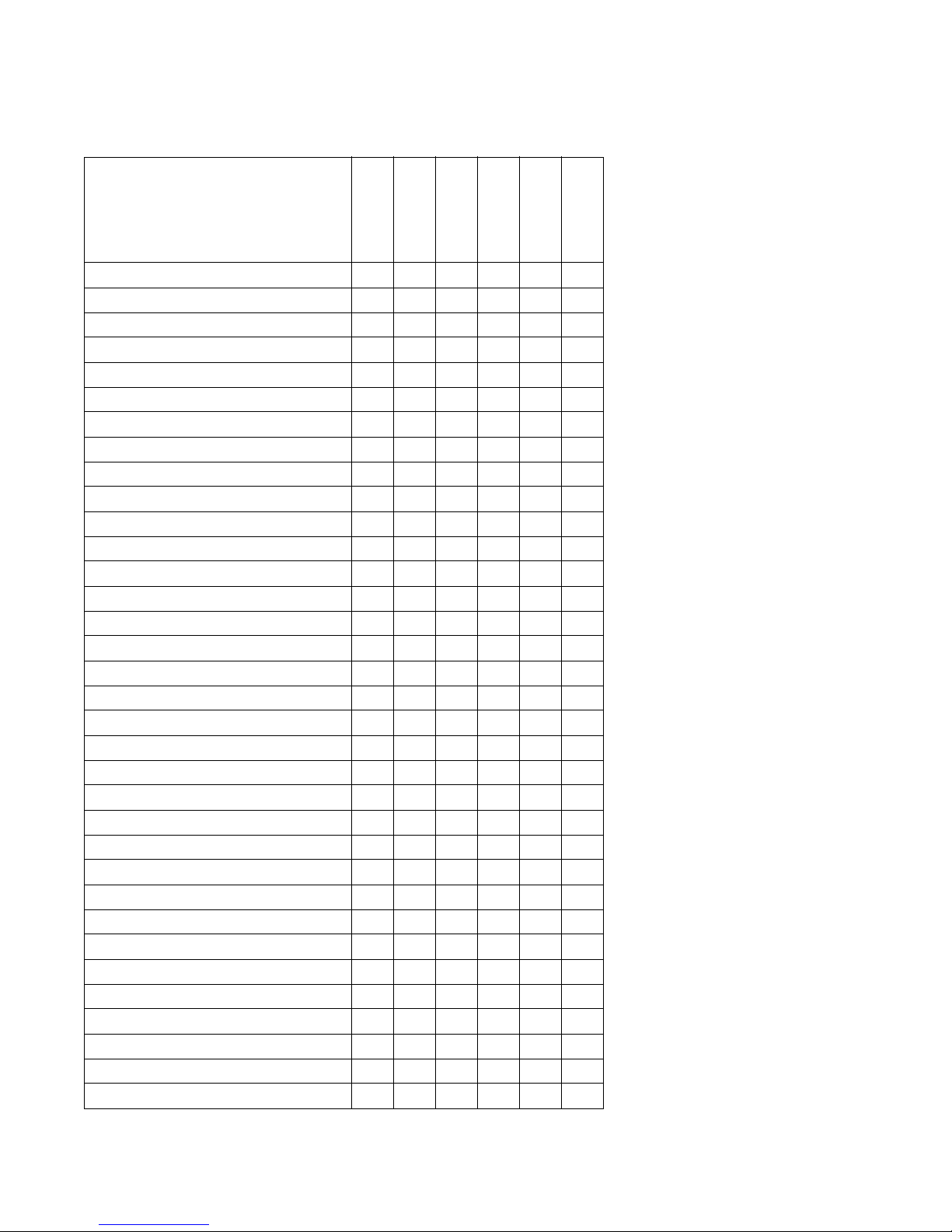

Model Identification

Information in this manual is applicable to these dryers.

Model

Number

BD3LLFGS401UW01

BD3LLFSS401UN01

BD3LXFGS401UW01

BD3LXFSS401UN01

BDGLLFGS301EW01

BDGLLFSS301EN01

BDGLXFGS301EW01

BDGLXFSS301EN01

HDELEFGS151CW01

HDELEFGS151CWNA

HDELEFGS171CQ01

HDELEFGS171CW01

HDELERGS151CW01

HDELERGS151CWNA

HDELERGS171CW01

HDELXFGS151CW01

HDELXFGS171CW01

HDELXRGS151CW01

HDELXRGS171CW01

HDELYFGS151CW01

HDELYFGS171CW01

HDELYRGS151CW01

HDELYRGS151CWNA

HDELYRGS171CW01

HDGLEFGS111CW01

HDGLERGS111CW01

HDGLERGS111CWNA

HDGLXFGS111CW01

HDGLXFGS111CWNA

HDGLXRGS111CW01

HDGLYFGS111CW01

HDGLYFGS111CWNA

HDGLYRGS111CW01

HSELXFGW281CW01

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Coin Drop

Ready

Coin Drop

Installed

Card Reader

Ready

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

Central Pay

Electric Heat

X X

X X

X X

X X

Gas Heat

6 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 9

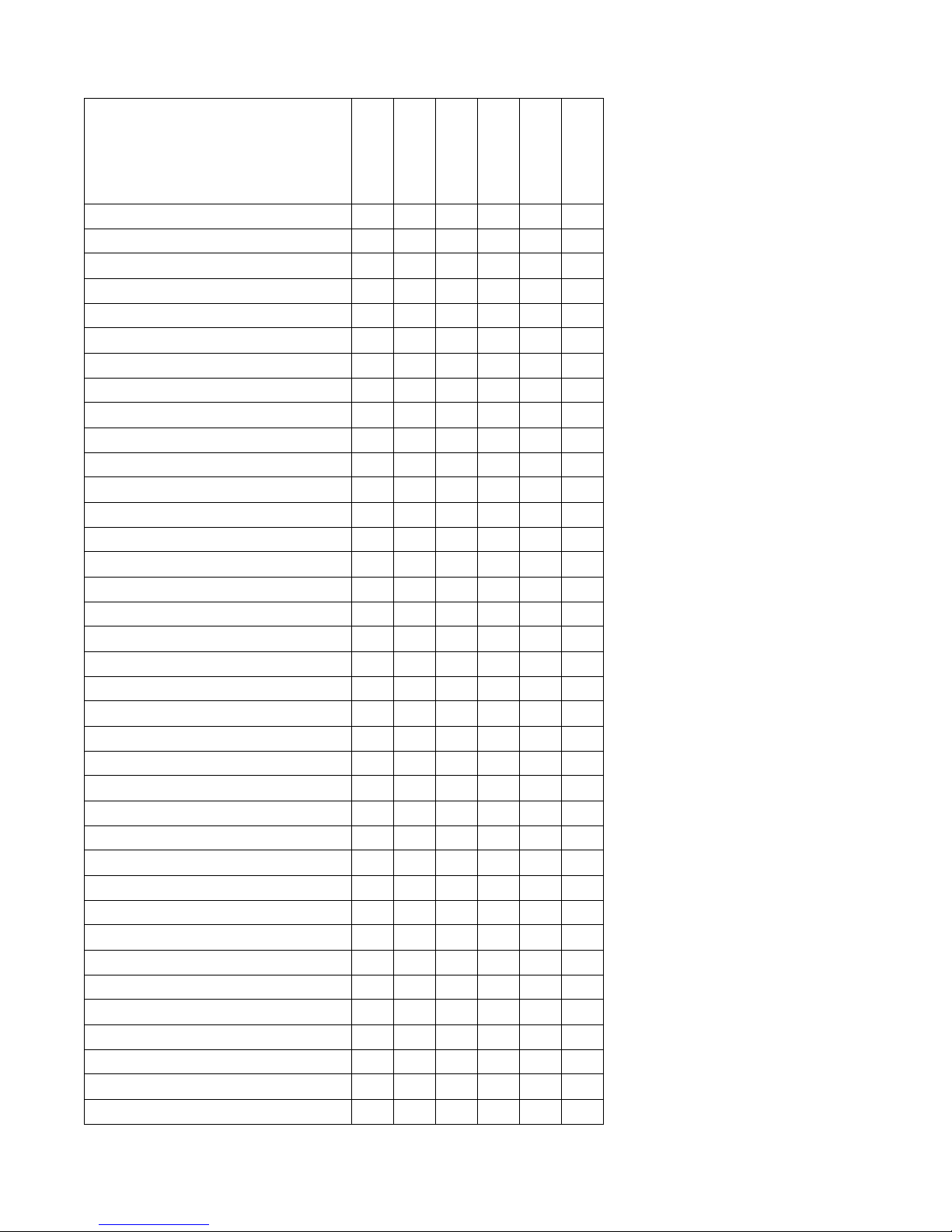

Model

Number

HSELXFGW291CW01

HSELYFGW281CW01

HSELYFGW291CW01

HSGLXFGW091CW01

HSGLYFGW091CW01

NDELXFGS301UW01

NDGLXFGS301EW01

RDELYFGS151CW01

RDELYFGS171CW01

RDGLYFGS111CW01

SDELCFGS171TW01

SDELCFSW171TN01

SDELCRGS151TW01

SDELCRGS171TW01

SDELCRGS171TW02

SDELCRGS171TWNA

SDELXRGS171TW01

SDELXRGS171TW02

SDELYFGS171TW01

SDELYFSW171TN01

SDELYRGS151TW01

SDELYRGS171TW01

SDGLCFGS111TW01

SDGLCFSW111TN01

SDGLCRGS111TW01

SDGLCRGS111TW02

SDGLCRGS111TWNA

SDGLXRGS111TW01

SDGLXRGS111TW02

SDGLYFGS111TW01

SDGLYFGS111TWNA

SDGLYFSW111TN01

SDGLYRGS111TW01

SDGLYRGS111TWNA

SSELCFGS151TW01

SSELCFGS171TW01

SSELCFGW151TW01

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Coin Drop

Ready

Coin Drop

Installed

Card Reader

Ready

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

Introduction

Central Pay

Electric Heat

Gas Heat

513447 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 10

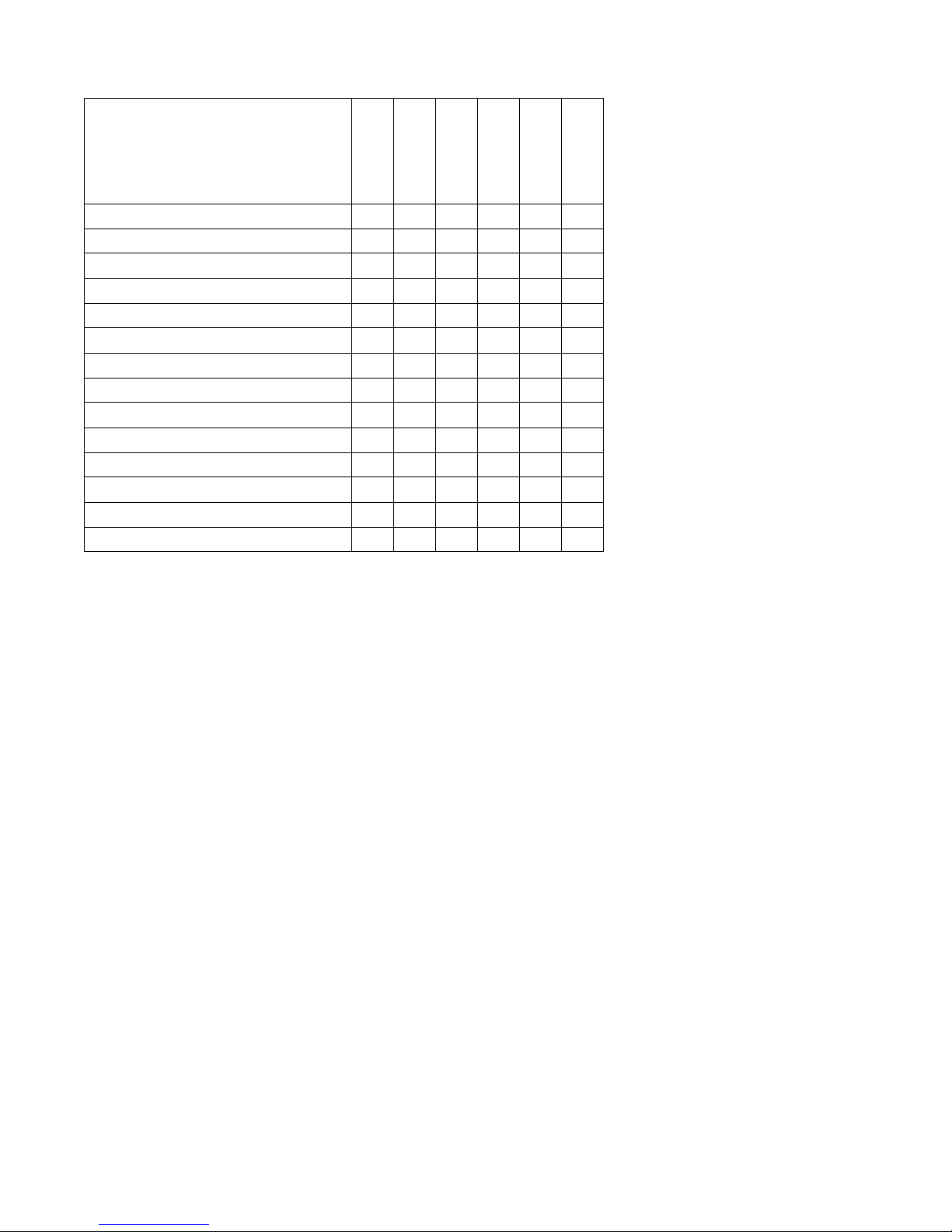

Introduction

Model

Number

SSELCFGW171TW01

SSELXFGW171TW01

SSELYFGS171TW01

SSELYFGW171TW01

SSELYFGW171TWNA

SSGLCFGS111TW01

SSGLCFGS111TWNA

SSGLCFGW111TW01

SSGLCFGW111TWNA

SSGLXFGW111TW01

SSGLYFGS111TW01

SSGLYFGS111TWNA

SSGLYFGW111TW01

SSGLYFGW111TWNA

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Coin Drop

Ready

Coin Drop

Installed

Card Reader

Ready

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

X X

Central Pay

Electric Heat

Gas Heat

8 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 11

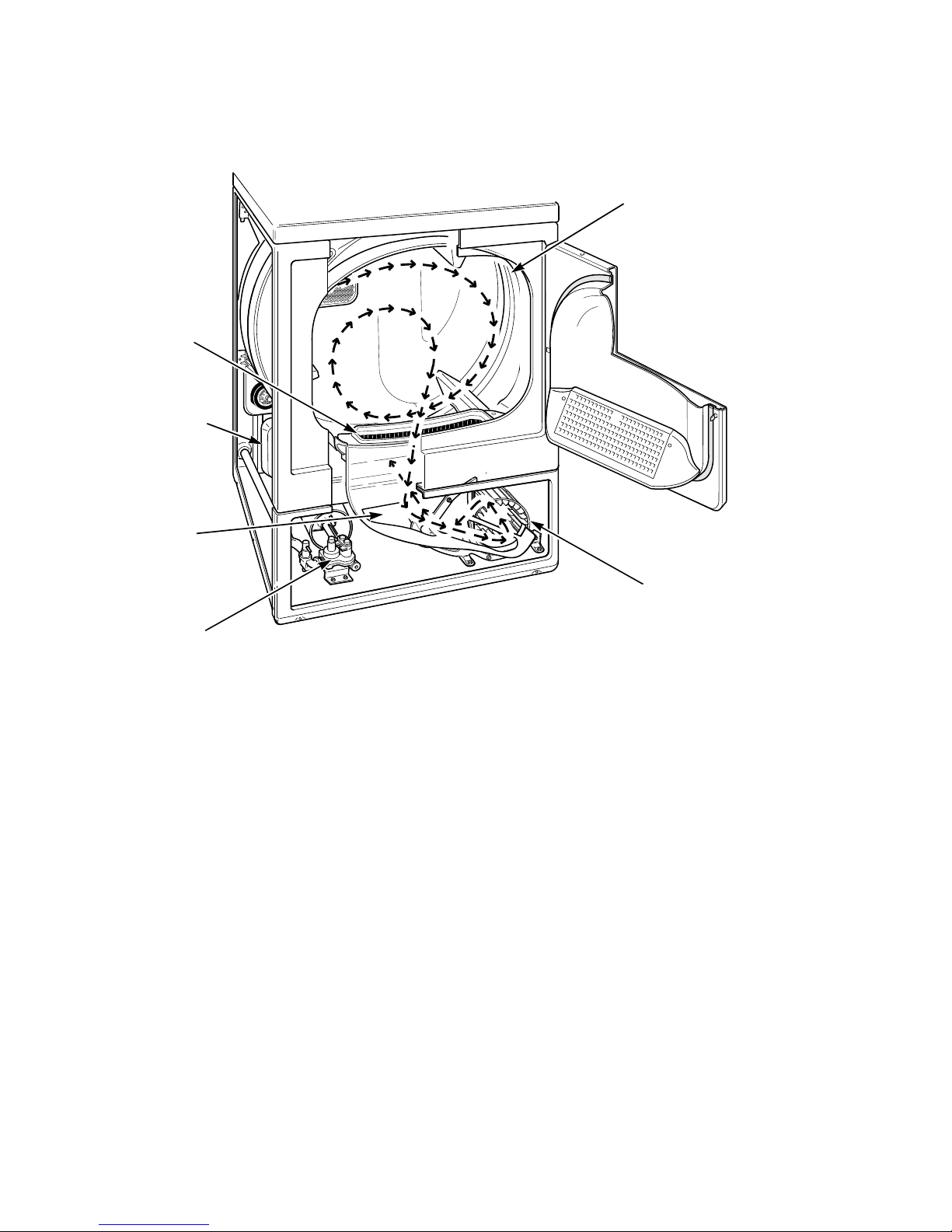

How Your Dryer Works

DRY1819S

Cylinder

Exhaust Fan

Gas Valve

Air Duct

Lint Filter

Heater Duct

Introduction

The dryer uses heated air to dry loads of laundry. When the motor is started, the exhaust fan pulls room temperature

air in through louvers at the rear of the dryer and over the heat source (burner flame for gas and heating element for

electric). The heated air moves through the heater duct and into the cylinder, where it circulates through the wet load.

The air then passes through the lint filter, air duct, and exhaust fan, where it is vented to the outdoors.

513447 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 12

Section 3

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

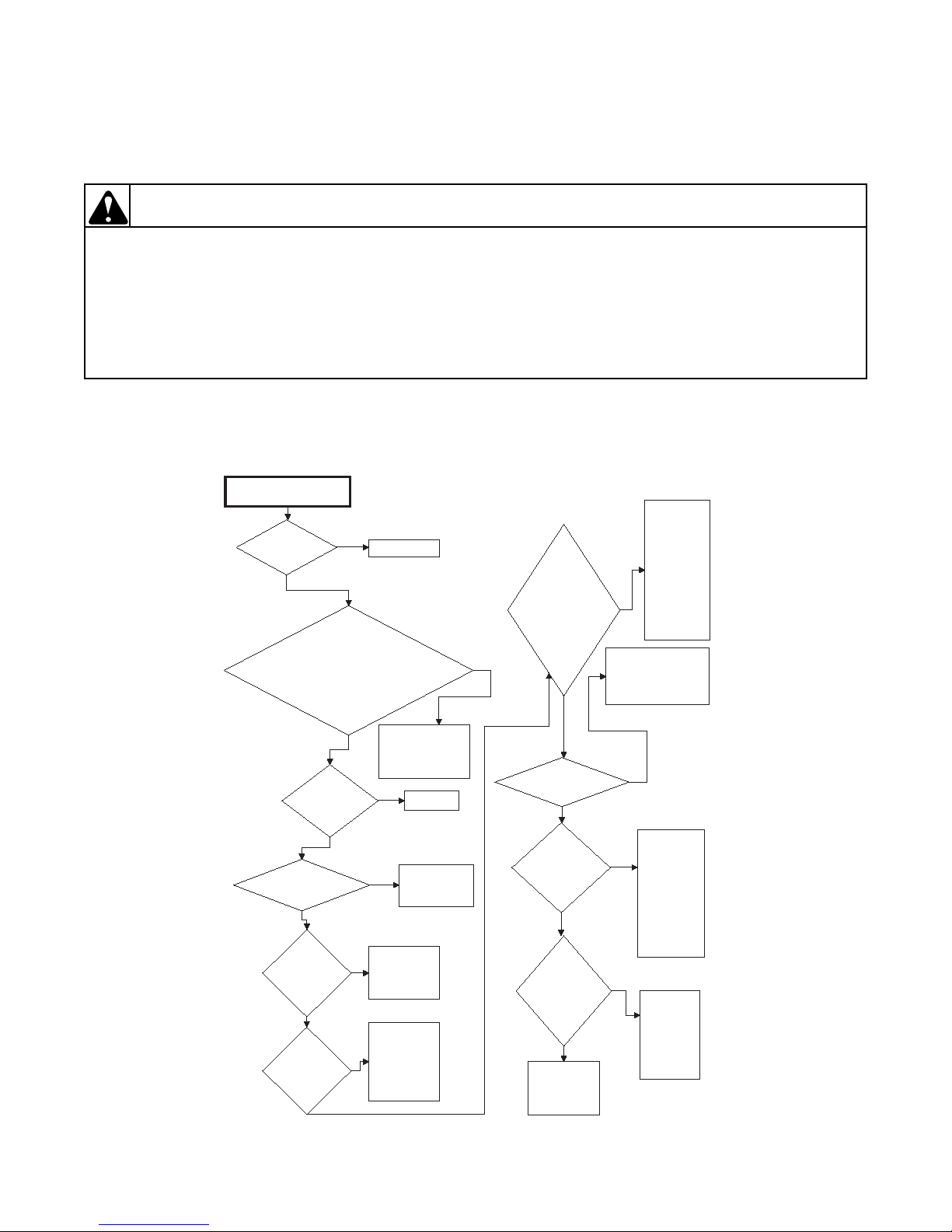

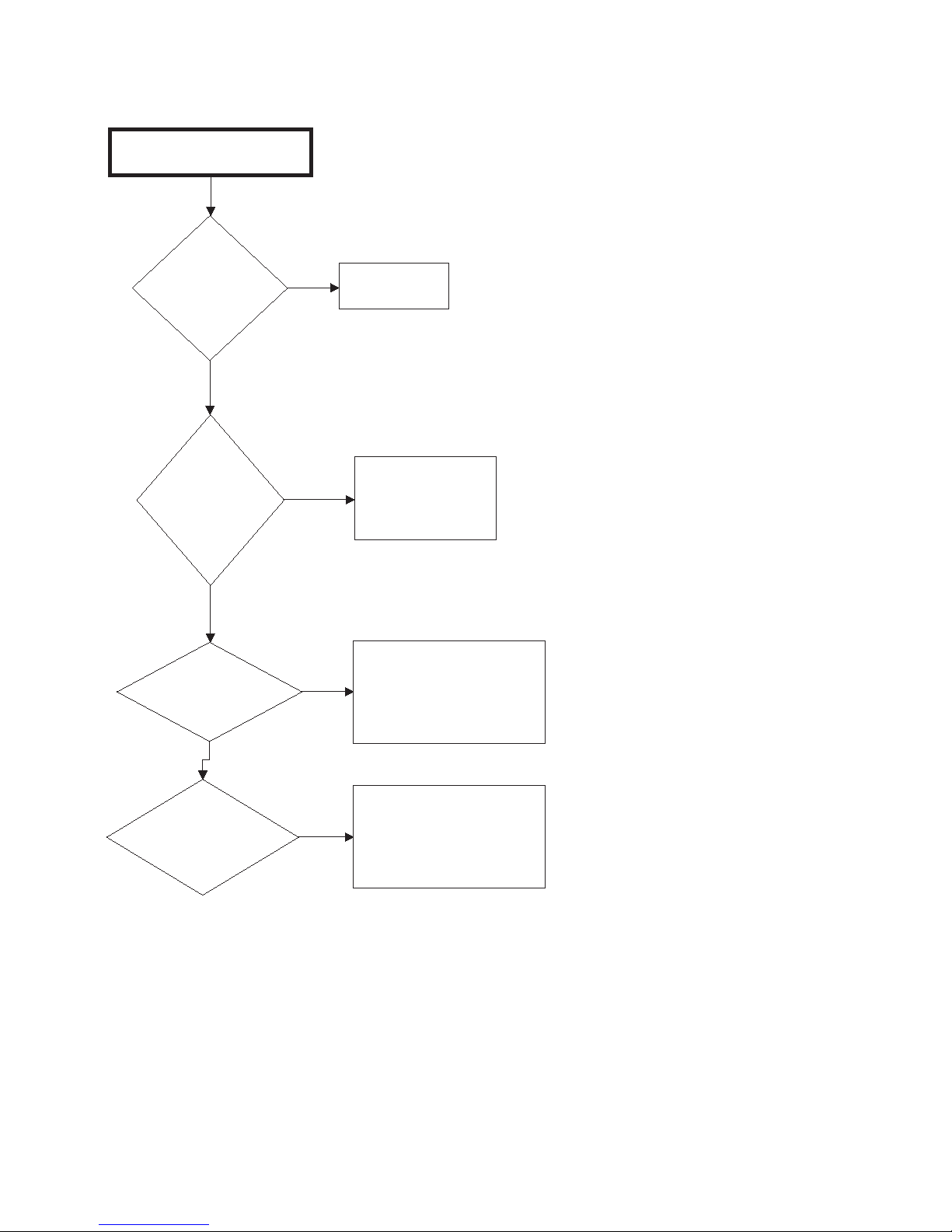

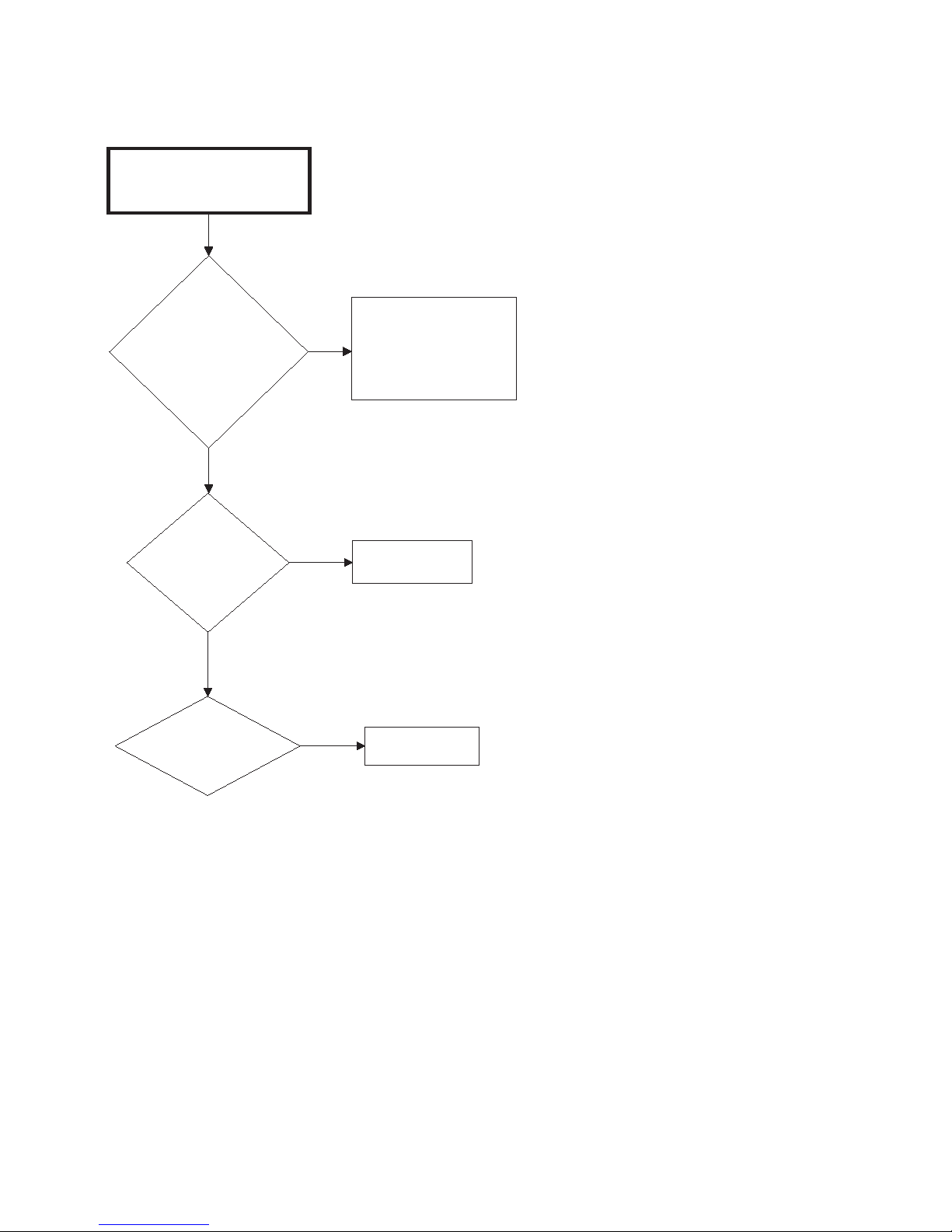

Dryer motor does not run.

Is power cord

plugged in?

Plug in cord.

Is electrical power off or fuse

blown? Check laundry room for

blown or loose fuse(s), or open

circuit breaker(s). The dryer itself

doesn't have an electrical fuse.

Yes

Turn power on or

replace fuse. Check

both fuses for

electric models.

Yes

Is loading

door closed?

Close door.

No

Is door switch

inoperative?

Yes

Test switch and

replace if

inoperative.

DRY1845Sa

Yes

No

No

Yes

Refer to

Adjustments

section to

check start

switch and

start windings.

Check for

foreign

objects

jammed in

blower fan.

Are motor

starting

functions

inoperative,

does motor

not start, or

motor just

hum?

No

Is motor dead,

won't run?

Yes

Refer to

Adjustments

section to check start

switch, start windings

and main windings.

Is timer

properly

set?

No

Reset timer or

try another

cycle.

No

Is timer

inoperative?

Test timer and

replace if

inoperative.

Refer to

Test

Procedures

section.

Yes

Yes

No

Has motor

overload

protector

cycled?

Wait two or

three minutes

for overload

protector to

reset. If

protector

cycles

repeatedly,

refer to next

flowchart.

No

Yes

Is motor

centrifugal

switch sticky

or plugged

with lint?

No

Remove

dust or lint

and spray

with a

cleaner and

lubricant.

Yes

Continued on

next page.

No

Dryer Troubleshooting

IMPORTANT: Refer to wiring diagram for aid in testing dryer components.

1. Dryer Motor Does Not Run

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

10 513447

Page 13

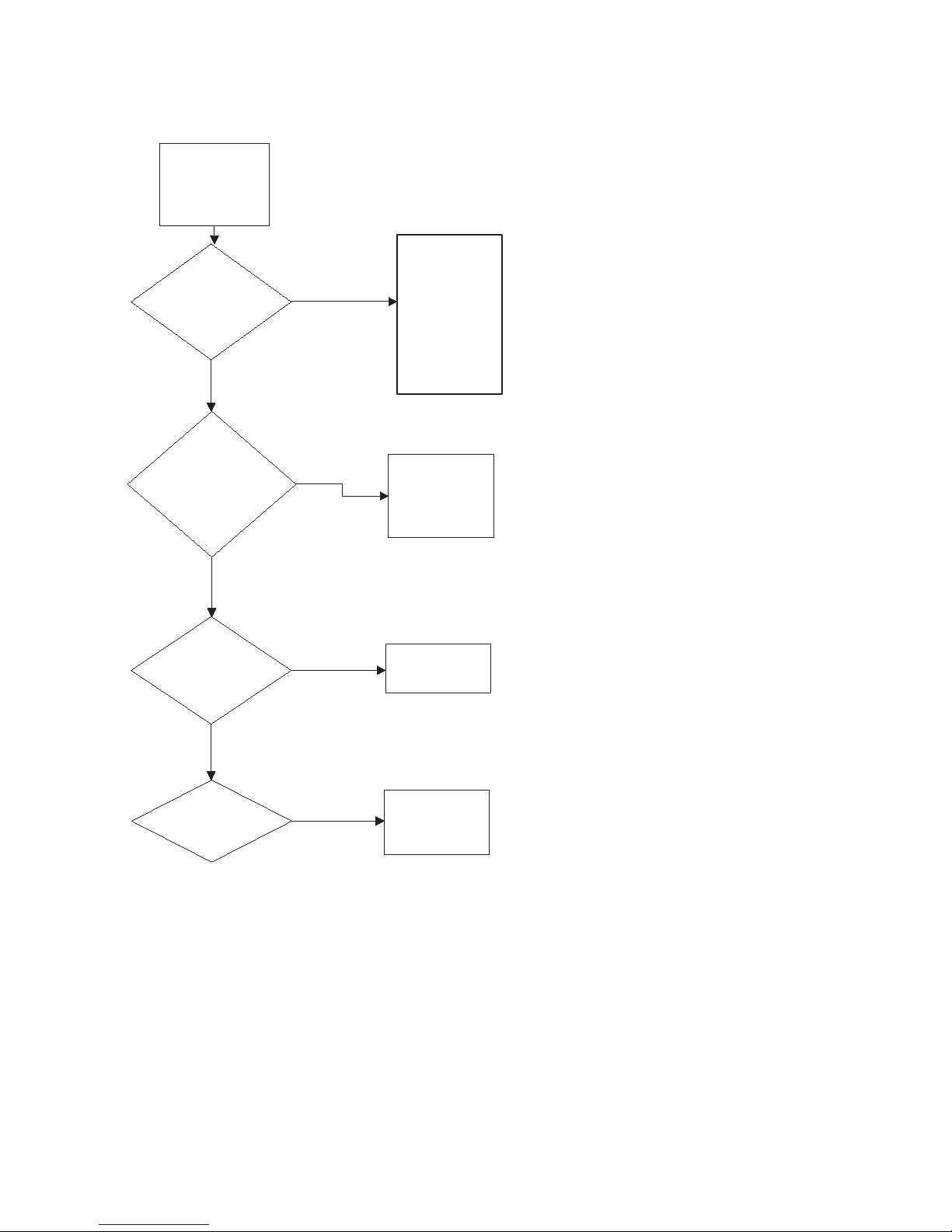

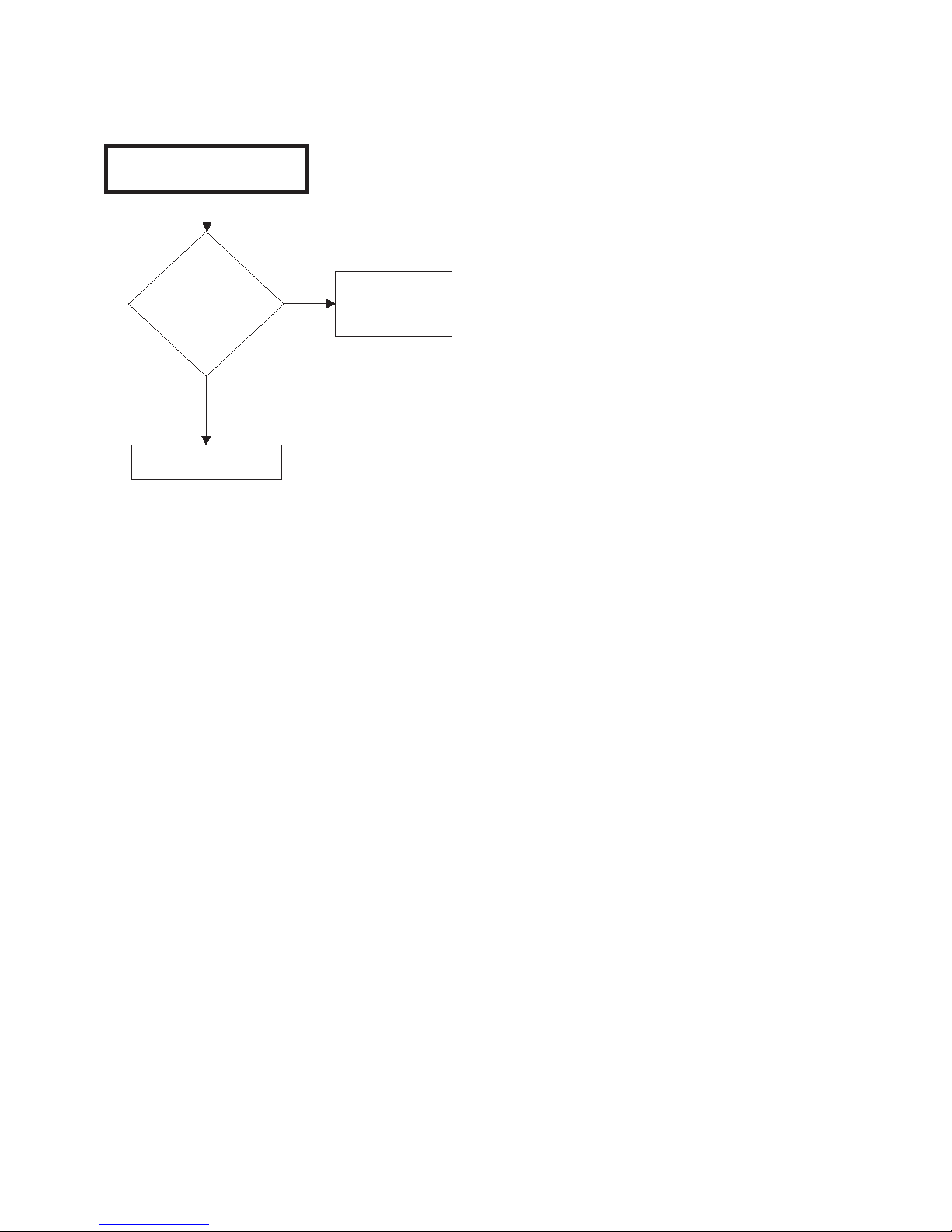

1. Dryer Motor Does Not Run (continued)

Remove belt

and

determine if

motor shaft

will spin.

Replace motor

if shaft is

locked up.

Is there a bind

in motor

bearing?

Is motor wire

harness

connection

block loose?

Firmly press

connection

block onto

motor switch.

Is wiring

broken, loose

or incorrect?

Yes

Refer to wiring

diagram.

Is power cord

miswired?

Refer to wiring

diagram for

correct wiring.

Continued from

previous page.

No

Yes

No

No

Yes

DRY1845Sb

Yes

Dryer Troubleshooting

513447 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 14

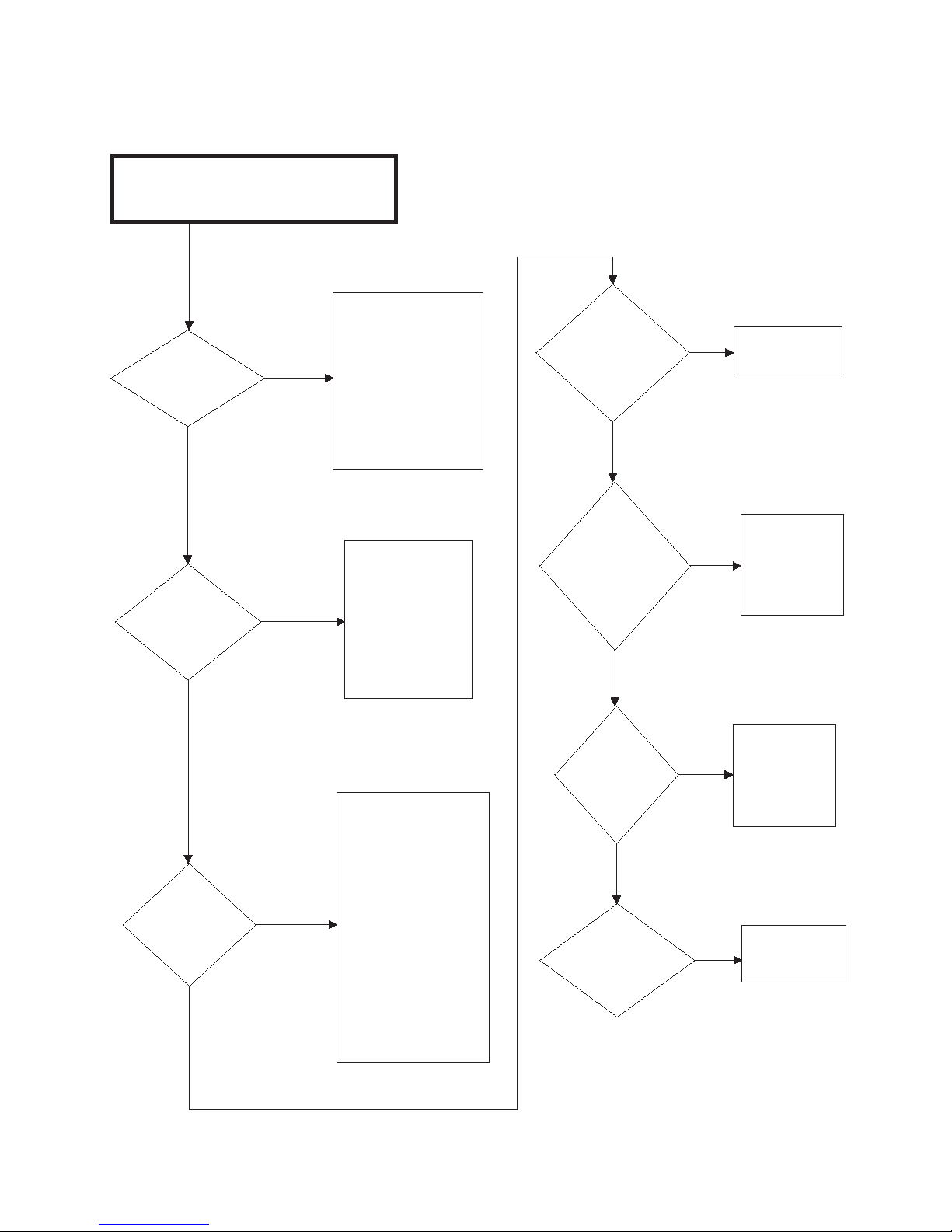

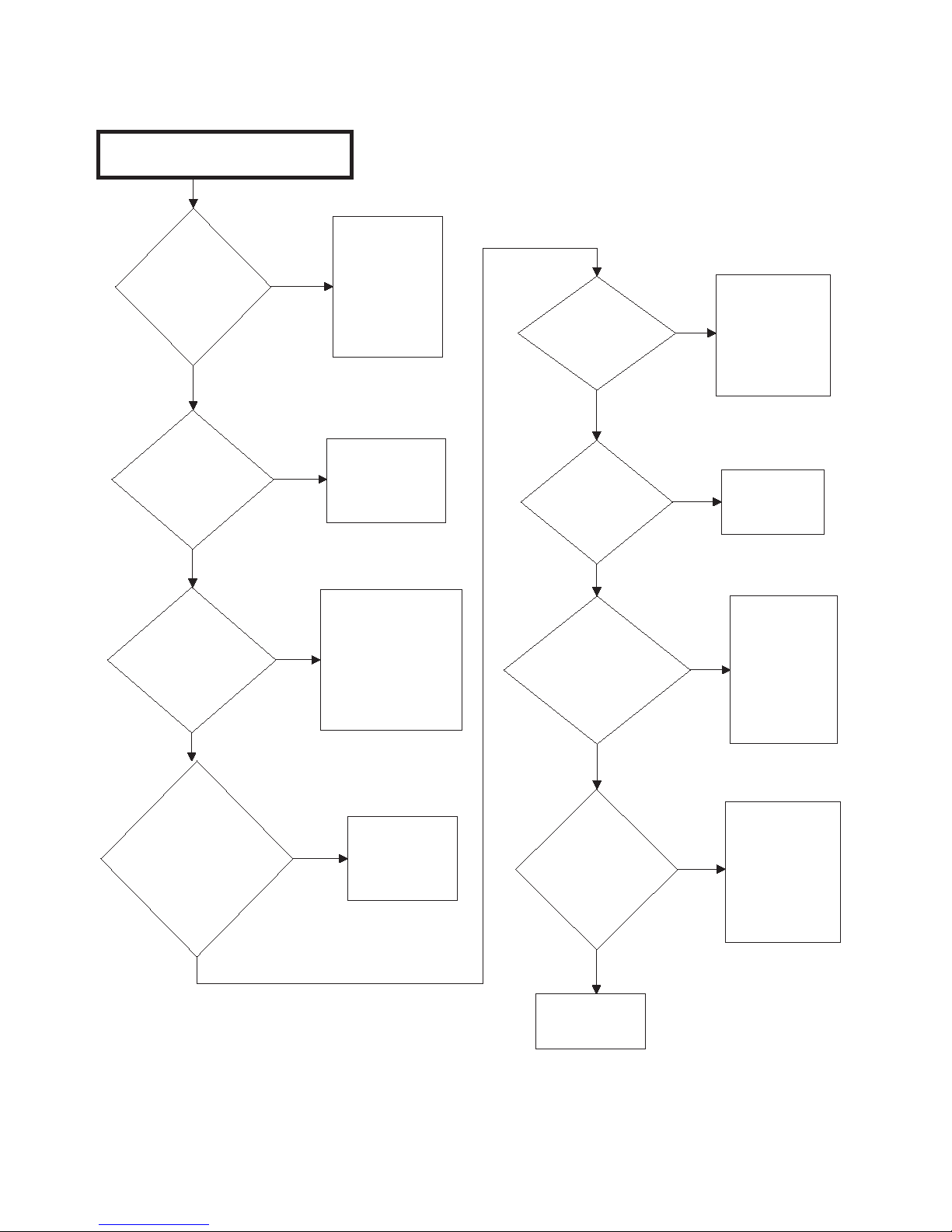

Dryer Troubleshooting

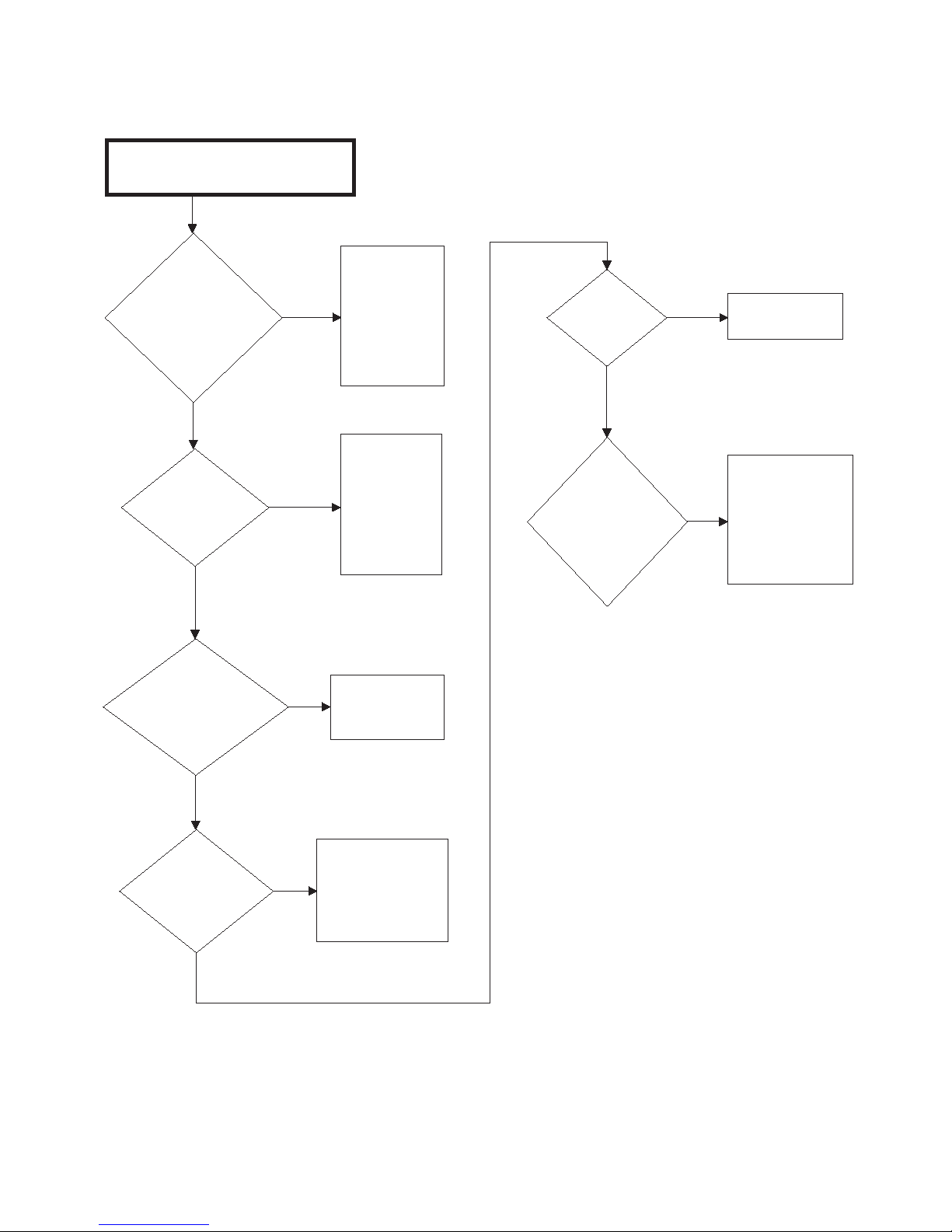

Dryer stops in cycle, quits after first few

loads, has burning smell or cycles on

motor thermal protector.

Is voltage

incorrect?

Refer to nameplate in

door well for correct

voltage. Refer to

Installation

Instructions

(supplied

with unit) for

electrical

requirements.

Yes

Is clothes

load too

large?

No

Remove part of

load. A normal

washer load is a

normal dryer load.

Maximum load:

dryer cylinder one

half full of wet

clothes.

Yes

Is clothes

cylinder

binding?

Check cylinder for

binding and "out of

round" condition.

Check front and rear

bulkheads for

warping. Check

support rollers for

binding. Check

cylinder seals and

glides for wear or

damage. Check for

clothes lodged

between cylinder

baffle and bulkhead.

No

Yes

Is there

broken, loose

or incorrect

wiring?

Refer to wiring

diagram.

Yes

Are motor

switch

functions

inoperative?

Refer to

Adjustments

section to

check switch

and windings.

Yes

Is there a

short in

motor

winding?

No

Is a clothes

item caught in

fan?

Check fan for

obstruction.

Yes

No

SWD1690S

Refer to

Adjustments

section to

check switch

and windings.

No

Yes

No

2. Dryer Stops In Cycle; Quits After The First Few Loads; Has A Burning

Smell; Cycles On Motor Thermal Protector

12 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 15

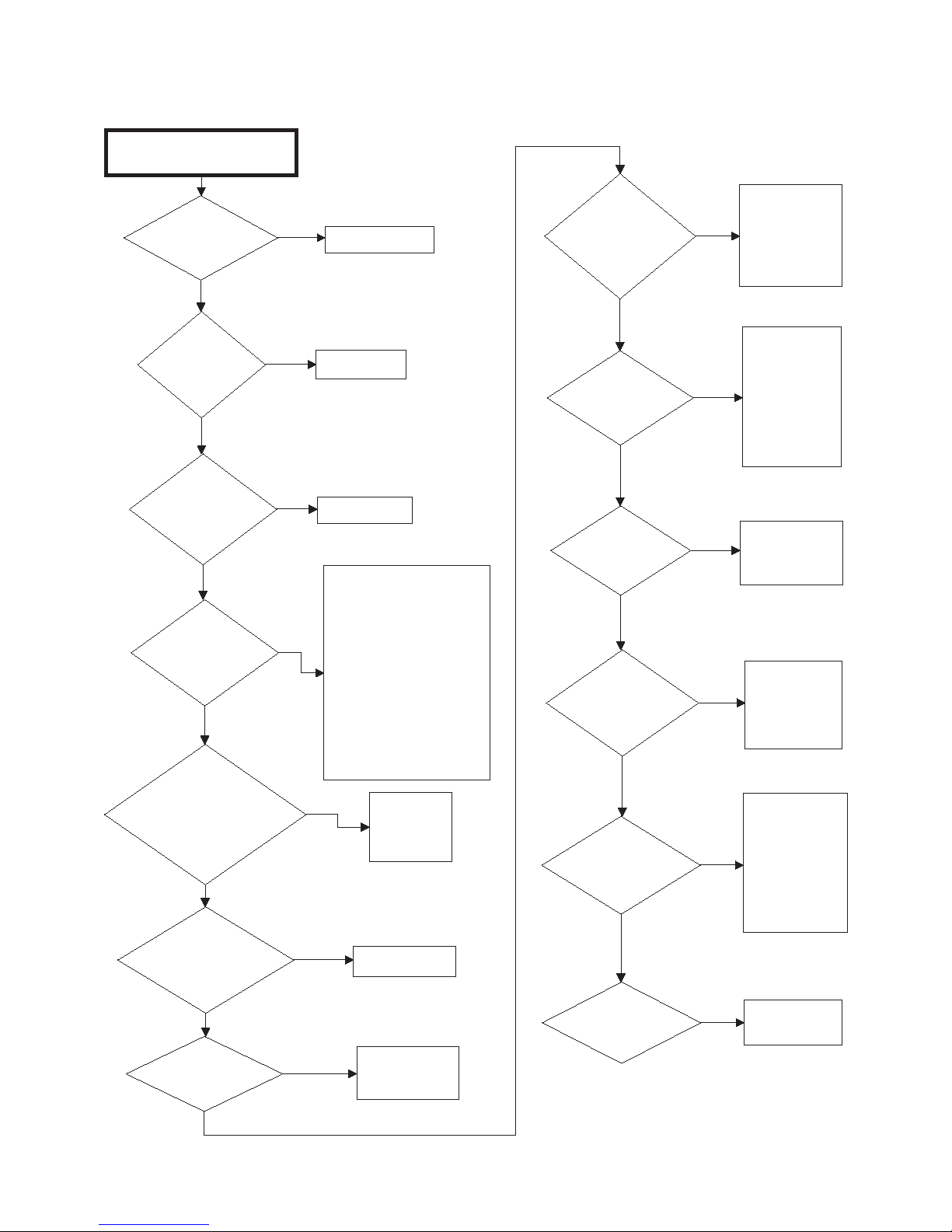

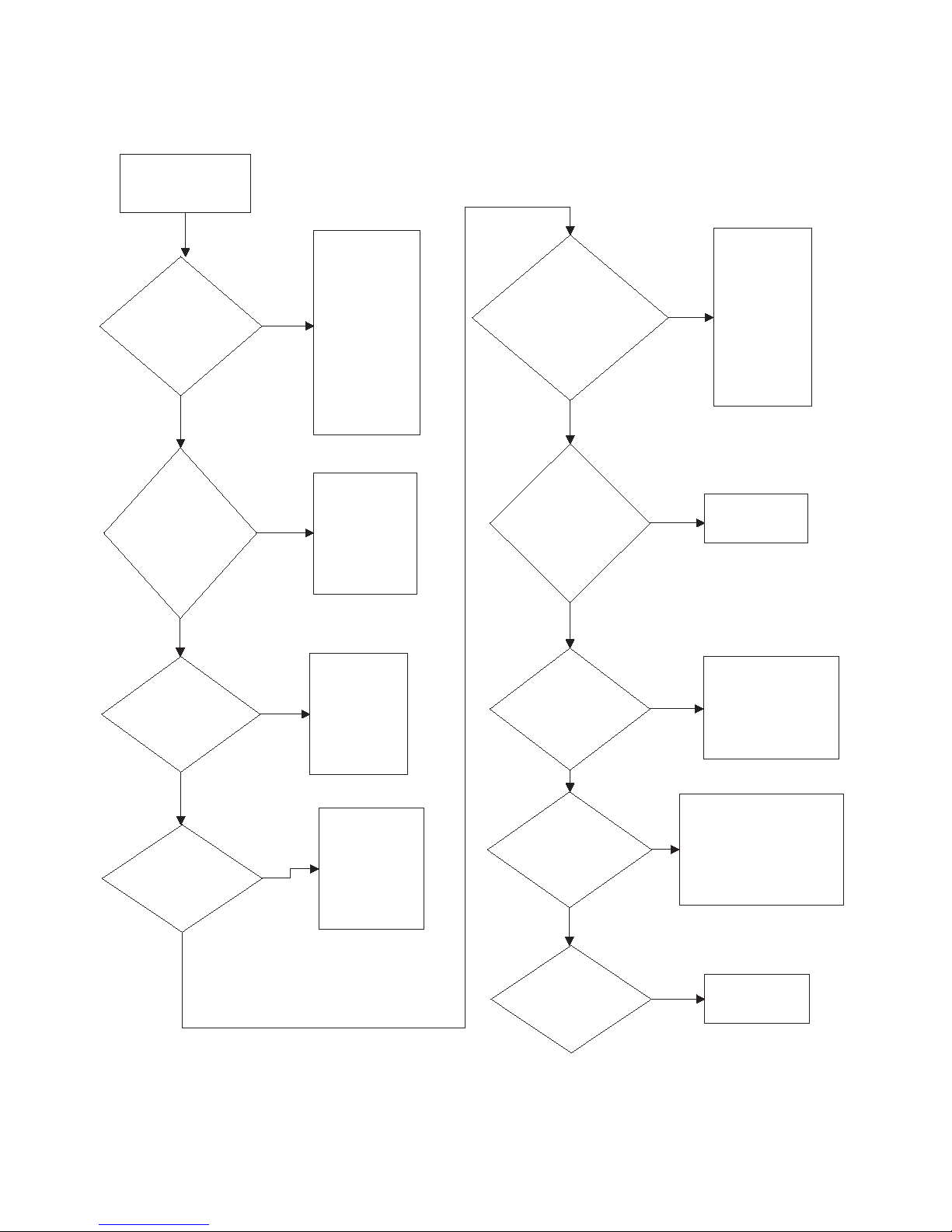

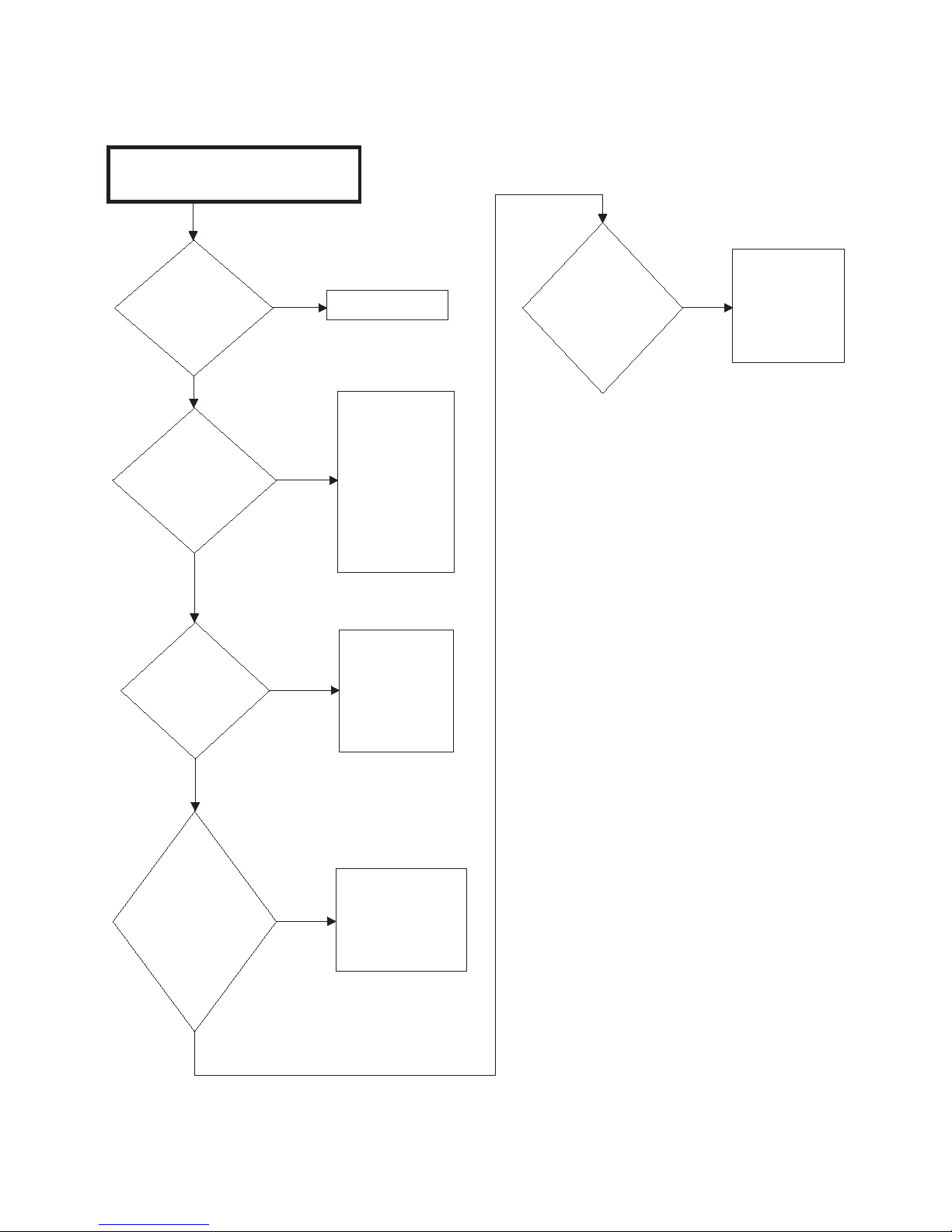

3. Dryer Motor Runs But Cylinder Does Not Turn

Dryer motor runs but

cylinder does not turn.

Is motor drive

pulley loose?

Tighten pulley.

Is belt

installed on

pulley?

No

Install belt.

No

Is cylinder

belt broken?

Replace belt.

Yes

Is clothes

cylinder

binding?

No

Check cylinder for

binding and "out of

round" condition. Check

front and rear

bulkheads for warping.

Check cylinder rollers

for binding. Check

cylinder seals and

glides for wear or

damage. Check leveling

of unit.

Is idler lever

spring broken,

weak or

disconnected?

Replace or

reconnect

spring.

Yes

Is there oil on

cylinder?

Wipe oil from

cylinder.

Yes

Is belt "inside

out" ?

Reinstall belt

with ribbed

surface

against

cylinder.

Yes

Is idler arm

binding?

Add grease

between idler

arm and

motor mount.

Replace idler

arm and bolt

if needed.

Yes

No

Is dryer

overloaded?

Remove some

laundry from

dryer.

Yes

No

DRY1846S

Yes

Yes

Yes

No

Is the wrong

motor

installed?

Refer to parts

manual for

correct motor

part number.

Is the wrong

belt installed?

Check belt

part number

against correct

part number in

parts manual

and replace

belt if needed.

Is idler arm

bent?

Replace idler

arm.

No

No

No

Yes

Yes

Yes

Is belt routed

on wrong side

of idler lever?

Reroute belt.

No

No

No

Yes

Dryer Troubleshooting

513447 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 16

Dryer Troubleshooting

Dryer motor does not stop.

Is wiring to

motor switch

incorrect?

Refer to wiring

diagram.

Yes

Is motor

centrifugal

switch sticky

or plugged

with lint?

No

Remove dust or lint

and spray with a

cleaner and

lubricant.

Yes

Is door switch

inoperative?

Test switch and replace if

inoperative. Refer to

Test

Procedures

section.

No

Yes

DRY1847S

Is accumulator

inoperative?

Test timer and replace if

inoperative. Refer to

Test

Procedures

section.

No

Yes

4. Dryer Motor Does Not Stop

14 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 17

5. Dryer Runs Only When Door is Open

Dryer runs when door is

open.

Is door switch

miswired?

Rewire door

switch. Refer to

wiring diagram.

Yes

DRY1856S

Replace door switch.

No

Dryer Troubleshooting

513447 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 18

Dryer Troubleshooting

Dryer heating assembly does not

heat or burner does not ignite.

Is exhaust

system

improper or

inadequate?

Refer to

Installation

Instructions

(supplied with

unit) for

exhaust

requirements.

Is exhaust

duct made of

plastic or thin

foil?

No

Replace with

rigid or semirigid metal

exhaust duct.

Yes

Is house fuse

blown or

circuit breaker

tripped?

Check fuses or

circuit breakers. A

240 Volt electric

heat dryer uses two

fuses. Make sure

both fuses are

good.

Yes

Electric

Models: Is

heater assembly

inoperative?

Test heater

assembly and

replace if cold

Ohms do not

read between

9 and 10.5

Ohms.

Yes

Electric

Models: Is

thermal fuse

inoperative?

Test thermal

fuse and

replace if

inoperative.

Refer to

Test

Procedures

section.

Yes

DRY1848Sa

Yes

No

Continued on

next page.

No

Is limit

thermostat

inoperative?

Test thermostat

and replace if

inoperative.

Refer to

Test

Procedures

section.

Is drive

motor switch

inoperative?

Test switch

and replace if

inoperative.

Is termperature

selector switch

set at FLUFF/NO

HEAT or

inoperative?

No

No

Reset or test

switch and

replace if

inoperative.

Yes

No

Yes

No

Yes

No

6. Dryer Heating Assembly Does Not Heat or Burner Does Not Ignite

16 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 19

6. Dryer Heating Assembly Does Not Heat or Burner Does Not Ignite

DRY1848Sb

Gas Models: Is

harness properly

connected to gas

controls?

Check

harness

connections

to gas valve

coils, sensor

and main

harness.

Reconnect as

required.

Test igniter

and replace if

inoperative.

Refer to

Test

Procedures

section.

Gas Models:

Is igniter

inoperative?

Gas Models:

Is sensor

inoperative?

Test sensor

and replace if

inoperative.

Refer to

Test

Procedures

section.

Continued from

previous page.

Yes

No

Yes

No

No

Gas Models:

Is gas flow

restricted in

gas orifice?

Clean out gas

orifice.

Yes

Yes

Is cycling

thermostat

inoperative?

Test thermostat

and replace if

inoperative. Refer

to

Test Procedures

section.

Yes

No

Is wiring

broken, loose

or incorrect?

Refer to wiring

diagram.

Yes

Gas Models:

Is gas supply

insufficient?

Check gas

shut-off valve

in dryer and

main gas line

valve. Open

partially closed

gas shut-off

valve or

correct low

gas pressure.

Gas Models:

Are gas valve

coils

inoperative?

Test coils and

replace if

inoperative.

Refer to

Test

Procedures

section.

Yes

No

Yes

No

Is

accumulator

inoperative?

Test and replace

accumulator

if inoperative. Refer to

Test Procedures

section.

No

Yes

No

(continued)

Dryer Troubleshooting

513447 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 20

Dryer Troubleshooting

Gas dryer models: Igniter

does not glow (gas supply

sufficient).

Is there power to

power leads on

valve (pink and

blue wires)?

Check selector switch,

thermostats, motor

switch and wiring.

No

Has flame

sensor failed

with contacts

open?

Yes

Replace sensor.

Yes

Is igniter broken

or open?

Replace igniter.

No

Yes

DRY1850S

7. Igniter Does Not Glow (Gas Supply Sufficient) – Gas Dryer Models

18 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 21

8. Burner Ignites and Goes Out Repeatedly – Gas Dryer Models

Gas dryer models: Burner ignites

and goes out repeatedly.

Is exhaust

system

improper or

inadequate?

Refer to

Installation

Instructions

(supplied with

unit) for

exhaust

requirements.

Ye s

Is weather

hood flapper

restricted?

No

Is burner heat

holding sensor

contacts open?

Replace sensor

or correct gas

supply problem.

No

No

DRY1851S

Refer to

Installation

Instructions

(supplied with

unit) for

exhaust

requirements.

Ye s

Is gas supply

insufficient?

Check gas supply

and pressure.

Make sure gas

shut-off valve is

turned on.

Is igniter

cracked?

Replace igniter

and bracket.

Are gas valve

coils

inoperative or

intermittent?

Check coils and

replace

appropriate coils.

Refer to Te st

Procedures

section.

No

Ye s

No

Ye s

Ye s

Ye s

Dryer Troubleshooting

513447 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 22

Dryer Troubleshooting

Gas dryer models: Igniter glows but

burner does not ignite.

Did sensor

fail in closed

position?

Replace sensor.

Yes

Is secondary

coil or holding

coil open?

No

Is gas supply

insufficient?

Check gas

supply and

pressure. Make

sure gas shutoff valve is

turned on.

No

Yes

DRY1852S

Replace gas

valve (in

warranty) or

replace coils

(out of

warranty). Refer

to

Test

Procedures

section.

Yes

Are igniter

and bracket

improperly

installed on

burner tube

assembly?

Loosen screw and

properly position

igniter and bracket

on burner tube

assembly.

Is sensor

improperly

installed on

burner

housing?

Loosen screw

and properly

position the

sensor on the

burner housing.

No

Yes

Yes

No

9. Igniter Glows But Burner Does Not Ignite – Gas Dryer Models

20 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 23

10. Dryer Heater Assembly Or Burner Shuts Off Prematurely

Dryer heater assembly or burner

shuts off prematurely.

Is exhaust

system

improper or

inadequate?

Refer to

Installation

Instructions

(supplied with

unit) for

exhaust

requirements.

Yes

Is weather

hood flapper

restricted?

No

Gas Models: Is

gas supply

insufficient?

Check main gas

line shut-off

valve. Open

partially closed

gas shut-off

valve or correct

low pressure.

No

Yes

DRY1853S

Refer to

Installation

Instructions

(supplied with

unit) for

exhaust

requirements.

Yes

Gas Models: Is

dryer properly

equipped for type

of gas used?

Refer to "Gas

Burner Conversion

Procedures"

supplied in gas

burner conversion

kit.

Gas Models:

Is burner flame

improperly

adjusted?

Adjust flame.

Refer to

Adjustments

section.

Cycling off on

limit

thermostat?

Momentarily

connect a

jumper wire

across

thermostat

terminals. If

heater element

heats or burner

ignites when

jumper wire is

connected, refer

to next flowchart.

No

Yes

Yes

No

Gas Models: Is

sensor contact

closing?

Replace sensor

or adjust burner

flame (refer to

Adjustments

section).

Yes

Is cycling

thermostat

inoperative?

Test thermostat

and replace if

inoperative.

Is wiring

broken, loose

or incorrect?

Refer to wiring

diagram.

No

No

Yes

Yes

Yes

Is

accumulator

inoperative?

Test and replace

accumulator if

inoperative. Refer

to

Test Procedures

section.

No

Yes

No

Dryer Troubleshooting

513447 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 24

Dryer Troubleshooting

Dryer heater assembly or burner repeatedly

cycles off on limit thermostat.

Is external exhaust

system longer or

providing greater

restriction than

recommended?

Refer to

Installation

Instructions

(supplied with

unit) for

exhaust system

requirements.

Is exhaust duct

made of plastic

or thin foil?

No

Replace with rigid

or semi-rigid metal

exhaust duct.

Yes

Is lint filter

clogged?

Clean lint

filter.

Yes

Is there lint in

internal dryer

ductwork?

No

Disassemble

dryer ductwork

and clean.

Is there lint

or other

obstruction in

external

exhaust

system?

Disassemble

and clean

exhaust

system.

Yes

Is hinged

damper on

exhaust system

weather hood

not free to

open?

Free hinged

damper or

replace

weather

hood.

Yes

Is limit

thermostat

cycling at too

low a

temperature?

Replace

thermostat.

Yes

SWD1699S-a

Yes

Yes

No

Continued on

next page.

No

No

No

No

11. Dryer Heater Assembly or Burner Repeatedly Cycles Off On Limit

Thermostat

22 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 25

Dryer Troubleshooting

DRY1857S

Continued from

previous page.

Is there an air

leak at front

panel seal?

Check and

replace seal if

necessary.

Check and

replace seal(s)

if necessary.

Is there an air

leak at cylinder

seal(s)?

Is there an air

leak at blower

seal?

Check and

replace seal if

necessary.

Test

thermistor

and replace if

inoperative.

Refer to

Test

Procedures

section.

Is thermistor

inoperative?

Is there an air leak

around loading door?

(Door not sealing due

to damaged seal or

inoperative door

catch)?

Replace seal

or catch.

Yes

No

No

No

No

Yes

Yes

Yes

Yes

11. Dryer Heater Assembly or Burner Repeatedly Cycles Off On Limit

Thermostat (continued)

513447 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 26

Dryer Troubleshooting

Dryer heater assembly or

burner does not shut off.

Is motor switch

inoperative?

(Must be in a

heat setting.)

Test switch and

replace if

inoperative.

Yes

Motor does

not stop?

No

Refer to

Dryer

Motor Does Not

Stop

paragraph.

Yes

Is wiring

incorrect?

Refer to wiring

diagram.

No

Yes

SWD1700S

Has heater

assembly

shorted?

Remove heater

assembly and

check for short.

No

Yes

12. Dryer Heater Assembly or Burner Does Not Shut Off

24 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 27

13. Clothes Do Not Dry in Dryer

Clothes do not dry in dryer.

Does heater

assembly not

heat or

burner not

ignite?

Refer to

Dryer

Heating

Assembly Does

Not Heat or

Burner Does

Not Ignite

paragraph.

Yes

Is there too

much water

in articles

being dried?

No

Is laundry

load too

large?

Remove part of

load. A normal

washer load is a

normal dryer

load. Maximum

load: Dryer

cylinder one half

full of wet

clothes.

No

Yes

DRY1854S

Remove

excess water.

Yes

Is laundry

load too

small?

Add one or two

bath towels to

load.

Is there

excessive

lint on lint

filter?

Clean lint

filter.

Is exhaust

system

improper or

inadequate?

Refer to

Installation

Instructions

(supplied with

unit) for exhaust

requirements.

No

Yes

Yes

Yes

Does heater

assembly or

burner shut off

prematurely?

Refer to

Dryer

Heater

Assembly or

Burner Shuts

Off Prematurely

paragraph.

Yes

Gas Models: Is

gas line

pressure too

high or too low?

If Natural Gas

line pressure to

dryer exceeds 8

inch water

column pressure,

or is lower than

6.5 + 1.5 inch

water column,

ask Gas

Company to

correct.

Is belt installed

improperly (low

RPM - correct

RPM is 52 ± 1)?

Check for

proper

installation.

No

No

No

Yes

Yes

No

Is heat selector

switch set on

FLUFF/NO HEAT

or inoperative?

Reset switch or

test and

replace switch

if inoperative.

Refer to

Test

Procedures

section.

No

Yes

No

Dryer Troubleshooting

513447 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 28

Dryer Troubleshooting

Clothes are too hot when

removed from dryer.

Is exhaust

system

improper or

inadequate?

Refer to

Installation

Instructions

(supplied with unit)

for exhaust

requirements.

Yes

Were clothes

removed from

dryer before

cycle has

completed?

No

Allow the dryer to

complete the

cycle through the

cool-down to the

OFF position.

Yes

Is cycling

thermostat

inoperative?

Test cycling

thermostat and

replace if

inoperative.

No

Yes

DRY1855S

Are seals

inoperative

(air leaks)?

Check and replace any inoperative

seals in the following areas:

1. Seal between loading door and

front panel.

2. Seal between front panel and front

bulkhead.

3. Seal between blower cover and air

duct.

4. Seal between cylinder and front or

rear bulkhead.

5. Gap between air duct and filter

mounting.

Add additional

cool-down time.

Is

accumulator

inoperative

(not allowing

cool-down)?

Test and replace

accumulator if

inoperative. Refer

to

Test Procedures

section.

No

Yes

No

No

Yes

14. Clothes Are Too Hot When Removed From Dryer

26 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 29

15. Excessive Chattering Or Vibrating Noise in Dryer

Excessive chattering or

vibrating noise in dryer.

Is idler spring

inoperative?

Remove lower access panel. Set

dryer to normal cycle and allow it

to heat to operating temperature.

If the belt vibrates as it rotates

around the cylinder, the idler

arm is making the noise. Replace

the idler spring.

Yes

DRY1858S

Check blower fan

for missing or

cracked fan blades.

Are idler

pulley and

shaft worn?

Are rollers

worn?

Replace idler

pulley and

shaft.

Replace

rollers.

No

Yes

No

Yes

No

Dryer Troubleshooting

513447 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 30

Dryer Troubleshooting

Excessive humming or

whistling noise in dryer.

Is blower

housing

inoperative?

If the abnormal operating noise is

loudest at the vent exit, the

problem is originating from the

blower housing. Replace the

current housing and cover.

Yes

SWD1704S

Check blower fan

for missing or

cracked fan blades.

No

16. Excessive Humming Or Whistling Noise in Dryer

28 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 31

Electronic Control Troubleshooting

17. Error Codes

Following is a list of possible error codes.

Section 4

Display

Information

Right most DP

(decimal point)

Lit

Alrm Break-in Alarm Error Service the door or coin vault switches.

OFF Break-in Alarm Shutdown Error Service the door or coin vault switches.

E:OP Open Temperature Sensor Error Open temperature sensor circuit wiring. Replace sensor.

E:SH Shorted Temperature Sensor Error Short in temperature sensor circuit wiring. Replace sensor.

Err Coin Error

OP Open Thermistor Physical open in the thermistor circuit. Replace thermistor.

SH Shorted Thermistor Dead short in the thermistor circuit. Replace thermistor.

Description

Network Communication Error

Cause/

Corrective Action

Communication problem. Wait for 1.5 minutes for error to

clear. If error doesn’t clear, power-down and power-up the

machine. If error persists, replace control or network board.

Invalid coin pulse or inoperative coin sensor. Check coin

drop area and remove obstructions. If error persists,

tampering may have occurred. Evaluate security

procedures.

513447 29

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 32

Electronic Control Troubleshooting

18. Coins Ignored When Entered

Coins Ignored When Entered

Start coin drop

diagnostic test.

Dwg. 2

Does the

display on the

electronic control

increment properly?

NO

Is connector H5 on the

control firmly seated in

its receptacle?

YES

Is the

3 pin connector

between the coin drop

and the control

connected

correctly?

YES

YES

testing and reset

diagnostic test

Exit diagnostic

control.

NO

Reconnect

and run

again.

NO

Are wires exiting coin

drop optical sensor

cracked or broken?

YES

Replace coin drop.

If problem still exists

replace the control.

30 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

NO

Replace

electronic

control.

DRY353S

Page 33

19. No IR Communication

Attempt to communicate with

control using PDA.

Is there a

response of

any kind from

the control?

Check PDA

manual for

correct use of IR.

No

DRY1859S

Check PDA. Set up

comport, baud rate

and consumer IR bit.

Does the

control display

"EIOF" or "-C-"?

If PDA displays

control mismatch,

select proper

control type.

Communication

sequence

checks out.

Yes

Yes

No

Does the

control

respond?

Make sure that

SDIO IrDA card

is installed if

required on PDA.

No

Yes

"-C-"

"EIOF"

Has IR

communication

been turned off?

Turn IR communication on.

Refer to

Programming Manual

.

Change

control.

No

Yes

Electronic Control Troubleshooting

513447 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 34

Electronic Control Troubleshooting

20. No Display

(1)

No Display

Dwg. 1

1

Are there 24 volts AC

across terminals H1-3

and H1-1 on the

control?

NO

2

(2)

Are there 24 Volts AC

across the secondary

of the transformer?

NO

NOTE: Refer to wiring

3

diagram for primary

(3)

voltage.

Are there 120 or 240

volts AC to the primary

of the transformer?

YES

YES

YES

NO

Replace

the control.

Correct wiring

between the

transformer and

the control.

Correct wiring to the

primary of the

transformer. Make

sure the machine is

plugged in and

power is on.

32 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Replace the

transformer.

DRY351S

Page 35

No Display

DRY1863S

1

2

3

Electronic Control Troubleshooting

513447 33

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 36

Electronic Control Troubleshooting

Replace electronic

control.

Correct wiring

between door switch

and control. Also

check neutral

supply to control.

Correct wiring to

door switch.

Check operation of

the door switch.

Replace if necessary.

Is there voltage across

terminals H3-1 and

H3-6?

Is there

voltage on the

N.O. terminal of the

door switch to a

neutral wire?

Is there

voltage on the

COM terminal of the

door switch to a

neutral wire?

(2)

(3)

(4)

YES

NO

Replace

resistor.

Does

resistor or jumper at

proper ohms?

(1)

NO

YES

NOTE: Conduct all tests

with the door closed.

YES

NO

YES

NO

DRY1860S

1

2

3

4

H3-2 and H3-5 read

21. Door Open

34 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 37

Electronic Control Troubleshooting

1

2

3

4

Door Open

513447 35

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

DRY1863S

Page 38

Electronic Control Troubleshooting

Is there voltage across

terminals 5 and 4 of

the motor?

Is there voltage across

H3-4 and H3-6 on the

control?

Is there voltage across

H3-1 and H3-6 on the

control?

Replace the

motor.

Correct the

wiring to

the motor.

Replace the

electronic

control.

Refer to

door open

troubleshooting.

NOTE: Checks to be made only if

motor does not start and “door”

is not diplayed on control. If “door”

is displayed please refer to door

open troubleshooting.

YES

(1)

(2)

(3)

NO

YES

NO

YES

NO

DR

Y1861S

1

2

3

22. Motor Will Not Start

36 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 39

Motor Will Not Start

1

2

3

Electronic Control Troubleshooting

513447 37

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

DRY1863S

Page 40

Electronic Control Troubleshooting

Is there voltage across

the leads to the heating

element?

Is there

voltage from the

output side of the

limit thermostat

to L2?

Is there

voltage to the

input side of the limit

thermostat to L2?

Is there

voltage to the

output side of the

thermo fuse on the

element?

Is there voltage to the

input side of the

thermal fuse?

Is there voltage on

FS-1 on the control to

L2?

Is there voltage on

FS-2 on the control

board to L2?

Check for

proper operation

of centrifugal switch on

motor. Does it operate

properly?

Replace heating

element.

Check and

replace wiring

between

components.

Replace element.

Check for proper

air flow and

operation of

limit thermostat.

Replace thermo

fuse.

Correct wiring

between control

and thermo fuse

on the

element.

Replace motor.

Correct wiring

between motor

and element &

motor and L2.

Make sure unit is

calling for heat.

Check operation

of thermistor.

Replace the

control.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

YES

NO

YES

NO

YES

NO

YES

YES

NO

NO

YES

NO

YES

NO

YES

NO

No Heat Electric

Dwg. 6

DRY359S

1

7

8

2

3

4

5

6

23. No Heat (Electric)

38 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 41

No Heat (Electric)

1

2

3

4

5

6

7

8

Electronic Control Troubleshooting

FLW1864S

513447 39

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 42

Electronic Control Troubleshooting

Refer to

NOTE.

(1)

(2)

(3)

(4)

(5)

(6)

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Refer to Door Open troubleshooting.

Replace either

the gas valve,

coils of gas valve

or the sensor.

DRY1862S

Is there

voltage across

the pink wire of the gas

valve to terminal 2 on

the motor?

Is there

voltage at the

output of the limit

thermostat referenced

to neutral?

Correct wiring

between

limit thermostat

and gas valve.

Is there

voltage to the

input of the limit

thermostat referenced

to neutral?

Check for proper

air flow making

sure venting is

not blocked and

lint screen is clean.

Reset or replace

limit thermostat.

Is there

voltage across

FS-1 and H2-3

(neutral) on the

control?

Correct wiring

between FS-1 and

limit thermostat.

Is

there

voltage across

FS-2 and H2-3

(neutral) on the

control?

Make sure unit

is calling for heat.

Check operation

of thermistor.

Replace control.

Is there voltage across

terminal 1 of the motor

and L1?

Check for proper

operation of

centrifugal on the

motor. Replace

motor if necessary.

Correct wiring

to the motor.

NOTE:

When calling for heat the holding coil, the booster coil

and the igniter will be energized. Once the sensor

senses that the igniter is hot enough for ignition, it will

open. At this time the holding coil and the secondary

coil will be energized allowing gas to flow. If the flame

cycles on and off check for proper operation of sensor.

If gas never ignites, check for problems with the coil

and check to see if the sensor opens. If coils are good

and the sensor opens with the glow bar operational

and there is no ignition/gas flow, replace the gas valve.

1

2

3

4

5

6

24. No Heat (Gas)

40 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 43

No Heat (Gas)

1

6

2

3

5

4

Electronic Control Troubleshooting

DRY1863S

513447 41

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 44

Coin Drop Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

Additional coins

following path to

sensor

Coin Drop

Sensor

Coin in

Coin Slot

25. Troubleshooting Coin Drop

a. Non-Electronic Coin Drops:

When coin is placed into coin slot, the coin

should roll down drop and be heard dropping into

coin vault. If coin does not fall into coin vault or

if coin drop sensor does not register that coin has

been entered, follow troubleshooting instructions

on following page. Refer to

coin follows when working properly.

Figure 1 for path that

Section 5

IMPORTANT: Never use oil to correct coin drop

problems. Oil residue will prevent coins from

rolling properly.

IMPORTANT: Do not bend or damage mechanical

parts within coin drop.

DRY2B

Figure 1

42 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 45

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

25. Troubleshooting Coin Drop (continued)

Is proper

electrical power

supplied to coin drop?

(Incorrect electrical connection

may prevent coins from

registering in

coin drop.)

Yes

No

Refer to wiring

diagram for

proper connections.

Coin Drop Troubleshooting

Is

machine level?

(Machines that aren't

level may prevent coins from

following through required

check stages

of drop.)

Yes

Is coin drop

clean? (Residue or

lint build-up may prevent

coins from following through

required check stages

of drop.)

Yes

Do coins

fall freely

through drop?

Yes

No

No

No

Installation Instructions

for instructions

on leveling machine.

Adjustments section

for instructions on cleaning

Replace

coin drop.

Refer to

Refer to

drop.

Replace

coin drop sensor.

SWD1714S

513447 43

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 46

Coin Drop Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

Coin Drop

Cover

Coin Return

Button

Tension Spring

MIX6B

Coin Drop

Cover

Cover Catch

Tension Spring

b. Electronic Coin Drops:

If coin drop is not accepting coins, perform the

following:

(1) Clean coin drop. Refer to Paragraph 29.

(2) On electronic coin drops with an old-style

tension spring (shown in

Figure 2 and

Figure 4), test and replace tension spring

using the following instructions.

Remove Coin Drop From Machine

(1) Disconnect electrical power to machine and

drop.

(2) Remove coin drop from machine.

Test Tension Spring

(1) Push coin return button to open and close

coin drop cover to clear possible coin jams.

Refer to Figure 2.

(3) If coin drop now operates properly, replace

tension spring using instructions on

following pages.

Replace Tension Spring

(1) Move tension spring downward until cover

catch is free. Refer to Figure 4.

DRY2088N

Figure 4

(2) Open cover for coin drop.

MIX7B

Figure 2

(2) Manually hold down coin drop cover and

insert coin. Refer to

Figure 3

Figure 3.

44 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 47

Coin Drop Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

Small Flathead

Screwdriver

Right Side of

Tension Spring

Left Tab

MIX3B

Tabs

Center Tab

MIX4B

Clip

MIX8B

Slot

(3) Place a small flathead screwdriver under

right side of tension spring and lift up.

Refer to

Figure 5.

MIX2B

Figure 5

(4) Use screwdriver to move spring

approximately 3 mm to left.

(5) Lift spring over left tab. Refer to Figure 5.

(6) Rotate spring clockwise, 40 to 60 degrees,

until it is free from right tabs. Refer to

Figure 6.

(9) Remove clip from spring. Refer to

Figure 7.

Figure 7

(10) Attach clip to new tension spring, Part No.

209/00598/02.

(11) Place clip, installed on spring, in slot on

coin drop. Refer to

Figure 8.

Figure 8

Figure 6

(7) Use screwdriver to remove spring from

center tab. Refer to

(8) Lift spring, with attached clip, off drop.

Figure 6.

513447 45

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 48

Coin Drop Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

MIX5B

Small Flat

Screwdriver

Center

Tab

Left Tab

(12) Use a small flathead screwdriver to push

spring under center tab. Refer to

Figure 9

Figure 9.

(13) Lift spring gently to place in position under

left tab.

(14) Push spring to right until it snaps into

position. Refer to

Figure 5.

(15) Close coin drop cover.

(16) Move tension spring over cover catch.

Refer to

Figure 4.

Reinstall Coin Drop Into Machine

(1) Reinstall coin drop into machine.

(2) Reconnect electrical power to machine and

drop.

(3) Add a coin to drop to verify that coin drop

is operating properly and that electrical

connection is working properly.

46 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 49

Section 6

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

To reduce the risk of serious injury or death

by carbon monoxide and other gases in gas

dryers, carefully read and follow all

instructions given in this section.

W005

WARNING

D351S

Dryer

Base

Leveling

Leg

Adjustments

IMPORTANT: When reference is made to

directions (right or left) in this manual, it is from

operator’s position facing front of washer.

26. Leveling Legs

Refer to Figure 10.

NOTE: Dryer should be installed on a solid and

level floor.

a. Place dryer in position, adjusting the legs until

dryer is level.

NOTE: Legs can be adjusted outside the dryer by

using a 1-1/4 inch size wrench, or from inside the

dryer (with lower front access panel removed) by

using a 1/4 inch drive ratchet with extension.

b. Keep dryer as close to the floor as possible. All

four legs must rest firmly on the floor so weight

of the dryer is evenly distributed. The dryer

MUST NOT rock.

IMPORTANT: DO NOT move the dryer at any

time unless the dryer is completely assembled. DO

NOT slide the dryer across the floor once the

leveling legs have been extended as the legs and

base could become damaged.

513447 47

Figure 10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 50

Adjustments

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

To reduce the risk of fire or serious injury,

the access panel must be in place during

normal operation.

W262

WARNING

27. Burner Flame (Gas Models)

a. While supporting the access panel, remove two

screws from bottom edge of access panel.

b. Gently lower the access panel to disengage

locators from bottom edge of front panel.

c. Set timer to 60 minutes.

d. Close the loading door. Start the dryer in a heat

setting (refer to Operating Instructions supplied

with the dryer). The dryer will start, the igniter

will glow red, and the main burner will ignite.

e. Allow the dryer to operate for approximately

five minutes, then loosen the air shutter

lockscrew. Refer to

f. Turn the air shutter to the left to get a luminous

yellow tipped flame, then turn it back slowly to

the right to obtain a steady blue flame.

g. After proper flame is obtained, tighten air

shutter lockscrew firmly. Refer to

h. Reinstall access panel and screws.

Figure 11.

Figure 11.

NOTE: After the dryer has operated for

approximately three minutes, exhaust air or

exhaust pipe should be warm.

48 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 51

Silicon Carbide Ignition System

Air Shutter

Lockscrew

Air

Shutter

Shut-Off Valve

Handle

1/8 Inch Pipe Plug

(For checking manifold pressure)

D265SE3A

WR

Air Shutter

Lockscrew

Air

Shutter

Shut-Off Valve

Handle

(Shown in Open Position)

1/8" Pipe Plug

(For checking manifold pressure)

D363SE3A

Adjustments

513447 49

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Silicon Nitride Ignition System

Figure 11

Page 52

Adjustments

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

DRY3B

Compressed

Air

Cotter

Pin

Metal

Clip

DRY4B

Coin Drop

Frame

Coin

Return

DRY5B

Cotton

Swab

28. Cleaning Non-Electronic

Coin Drop

a. Disconnect electrical power to machine and

drop.

b. Remove coin drop from machine.

c. If lint is preventing coins from rolling through

coin drop, blow compressed air though coin

entry and along the side of the coin drop. Refer

to

Figure 12.

g. Remove coin return from coin drop frame.

Refer to

Figure 13.

Figure 13

h. Check coin path in coin drop for lint and

residue. If lint or light residues are present, use

a cotton swab to remove. If heavy residue is

present, it may be necessary to first scrape off

excessive residue and then use a cotton swab

dipped in water or isopropyl alcohol (rubbing

alcohol) to remove remainder of residue. Refer

to

Figure 14.

Figure 12

d. Insert a coin through the coin drop. If coin does

not roll through drop, continue with the

following.

e. Remove cotter pin from top of drop. Refer to

Figure 12. Save pin for reinstallation when

cleaning is complete.

f. Move metal clip closer to sensor so that it

comes off frame. Refer to

Figure 12.

50 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Figure 14

Page 53

Adjustments

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

DRY6B

Pivot

Point

Pendulum

DRY7B

Eyes

Dry

Cotton

Swab

i. Check coin return pendulum to verify it swings

freely. If pendulum does not swing freely, spray

pendulum pivot point with Teflon based

lubricant and move pendulum back and forth

two to three times. An additional application of

Teflon based lubricant may be necessary to

ensure that pendulum swings freely. Refer to

Figure 15.

Figure 15

j. Check coin drop sensor for dust or dirt on eyes.

Wipe eyes with dry cotton swab. Refer to

Figure 16.

IMPORTANT: DO NOT use isopropyl alcohol to

clean electronic sensor or eyes.

Figure 16

k. Reinstall coin return on to coin drop frame.

l. Reinstall metal clip and slide towards coin

insert slot. All cotter pin holes must line up.

m. Reinstall cotter pin.

n. Place drop on level surface to verify that coins

follow correct path in drop. It may be necessary

to lift drop to allow coin to follow through

sensor.

o. Reinstall coin drop into machine.

p. Reconnect electrical power to machine and

drop.

q. Add a coin to drop to verify that coin drop is

operating properly and that electrical

connection is working properly.

NOTE: If coin drop does not operate properly after

above steps have been completed, corrosion of

metal or vandalized components within coin drop

may be preventing the coin drop from functioning

correctly. Replace coin drop.

513447 51

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 54

Adjustments

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

Catch

Spring

Cover

Spring

29. Cleaning Electronic Coin Drop

NOTE: The electronic coin drop should be cleaned

once a year. Clean the drop more often if it is

exposed to high levels of residue or lint build-up.

a. Disconnect electrical power to machine and

drop.

b. Remove coin drop from machine.

c. Check the spring style of coin drop.

Coin Drops with Old-Style Spring (refer to

Figure 17):

(1) Move spring downward until cover catch is

free. Refer to

NOTE: Do not lift or overbend the spring in any

direction.

Figure 17.

(2) Open cover for coin drop. Refer to

Figure 18.

Figure 18

Coin Drops with New-Style Spring (refer

to

Figure 19):

DRY2089N

DRY2088N

Figure 17

Figure 19

52 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

(3) Open cover of coin drop. Refer to

Figure 20.

DRY2404N

DRY2404N

Page 55

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

NOTE: Do not overbend the spring by opening

DRY2408N

Spring

DRY2090N

Old-Style Spring Coin Drop

New-Style Spring Coin

Alcohol

Moistened

Cloth

cover too far.

Adjustments

DRY2408N

Figure 20

d. Clean the coin path with a soft brush and wipe

exposed surfaces with an alcohol moistened

cloth. Refer to

Figure 21 or Figure 22.

DRY2405N

DRY2405N

Figure 22

e. Clean residue from coin rail with an alcohol

moistened cloth. Refer to

Figure 23

Figure 23.

DRY2406N

DRY2090N

Figure 21

513447 53

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 56

Adjustments

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

Light

Sensors

f. Clean light sensors with a soft brush or air

spray duster. Refer to

Figure 24.

DRY2407N

DRY2407N

Figure 24

g. Close cover for coin drop.

h. Coin Drops with OLD-Style Spring - Move

spring back over cover catch.

i. Reinstall coin drop into machine.

j. Reconnect electrical power to machine and

drop.

k. Add a coin to drop to verify that coin drop is

operating properly and that electrical

connection is working properly.

54 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 57

Section 7

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

DRY1836S

Timer

Motor

Wires

“M”

“L1”

“H”

“N”

Test Procedures

IMPORTANT: Electrical test procedures in this

service manual are performed by using a Volt-Ohm

meter. Tests can also be performed using a multimeter or any other electrical testing equipment

with which the service person is familiar.

30. Timer Contacts

Refer to Figure 25.

a. Disconnect wires from timer, except timer

motor wires.

NOTE: Refer to wiring diagram when rewiring

timer.

b. While supporting timer, remove screws holding

timer to control cabinet.

c. Pull timer out through control panel opening as

far as wires will permit.

d. Manually rotate timer out of “OFF” position

and into cycle.

e. Set test meter to read Ohms. The following

readings should be found:

(1) Motor circuit test – L1 and M = “zero”

Ohms (closed)

(2) Heat circuit test – L2 and H = “zero” Ohms

(closed)

(3) Timer motor test – T and M (1702 and1709

suffix models) or T and N (all other

models) = approximately 2460-3100 Ohms

or apply live power to timer motor

terminals and motor should run.

513447 55

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

NOTE: Timer Motor Resistance:

120 Volt, 60 Hz2,460 – 3,100 Ohms

240 Volt10,900 – 13,000 Ohms

24 Volt80 – 130 Ohms

(4) Rotate timer to “cooldown” (5 minutes

before “OFF”). “Infinite” (open) reading

should be found between L2 and H.

(5) Rotate timer to “OFF” position. “Infinite”

(open) reading should be found between L1

and M and between L2 and H.

NOTE: Timer motor power is supplied through M

(1702 and1709 models) or N (all other models)

terminal.

Figure 25

Page 58

Test Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.

• Never start the dryer(s) with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the dryer is properly grounded.

W001R1

WARNING

31. Fabric Selector Switch

NOTE: Refer to proper model wiring diagram

when rewiring switch.

a. Set test meter to read Ohms and apply meter

probes to switch terminals.

NOTE: Refer to proper model wiring diagram

when reconnecting wires.

FABRIC SELECTOR SWITCH – 4 Position

L1-1 L1-2

Fluff (No Heat) – –

Delicate X X

Perm. Press – X

Normal (Regular) – X

X indicates closed

FABRIC SELECTOR SWITCH – 3 Position

L1-2 L1-3 L1-1

Fluff (No Heat) – X –

Delicate X – X

Regular/Perm.

Press

X – –

X indicates closed

56 513447

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 59

Test Procedures

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the dryer(s) before servicing.

• Close gas shut-off valve to gas dryer(s) before servicing.