Page 1

Washer-Extractors

Pocket Hardmount

Basic Installation/Operation

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

P005I

Part No. F232156R9

June 2010

Page 2

Page 3

Basic Installation/Operation

Table of

Content s

Safety Information.............................................................................. 2

Explanation of Safety Messages........................................................... 2

Important Safety Instructions ............................................................... 2

Safety Decals........................................................................................ 4

Operator Safety....................................................................... ..... ......... 5

Installation........................................................................................... 6

General Specifications.......................................................................... 6

UW UniLinc and M30 Control Models........................................... 6

UW A-Control, Variable-Speed Models.......................................... 9

UW P-Control, Variable-Speed Models .......................................... 11

UW 2 Speed Models with P-Control, S-Control,

Mechanical Timer or B-Control..................................................... 13

UW 3 Speed Models with P-Control or S-Control.......................... 15

UniLinc and M30 Control Models................................................... 17

UWAV Models................................................................................ 20

UWPV Models................................................................................. 22

UW 2 Speed Models with P-Control, S-Control,

Mechanical Timer or B-Control..................................................... 25

UW 3 Speed Models with P-Control or S-Control.......................... 27

Operation............................................................................................. 29

UW Models With UniLinc Control...................................................... 29

UW Models With M30 Control............................................................ 31

Models Equipped with Both Steam and Electric Heating

(UniLinc and M30 Controls).............................................................. 33

UW Models with S-Control.................................................................. 34

UW Models with P-Control.................................................................. 36

Pre-Operating Instructions............................................................... 36

Operating Instructions...................................................................... 36

UW Models with A-Control................................................................. 39

UW Models with B-Control ................................................................. 41

Disposal of Unit................................................................................... 43

© Copyright 2010, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Basic Installation/Operation

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023

WARNING

Safety Information

Explanation of Safety Messages

Precautionary statements (“DANGER,” “W ARNING ,”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer, and those maintaining the

machine.

Important Safety Instructions

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual for the proper

grounding of the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, kerosene, waxes, cooking oils, drycleaning solvents, or other flammable or

explosive substances as they give off vapors that

could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORT ANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas

is flammable, do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer .

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232156

Page 5

Basic Installation/Operation

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer , or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. T o reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power

source.

13. Use washer only for its intended purpose,

washing textiles.

14. Never wash machine parts or automotive parts in

the machine. This could result in serious damage

to the basket.

15. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

16. Install the washer according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and be

made by licensed personnel when required.

17. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc., or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

20. If the supply cord is damaged, it must be replaced

by a special cord or assembly available from the

manufacturer or its service agent.

21. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

22. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT bypass

the loading door switch by permitting the washer

to operate with the loading door open.

23. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. T o reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

24. Always follow the fabric care instructions

supplied by the textile manufacturer.

25. Never operate the washer with any guards and/or

panels removed.

26. DO NOT operate the washer with missing or

broken parts.

27. DO NOT bypass any safety devices.

28. Failure to install, maintain, and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining, or operating the washer.

18. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

19. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a

qualified service person.

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

3

Page 6

Basic Installation/Operation

This machine must be installed, adjusted,

and serviced by qualified electrical

maintenance personnel familiar with the

construction and operation of this type of

machinery. They must also be familiar

with the potential hazards involved.

Failure to observe this warning may result

in personal injury and/or equipment

damage, and may void the warranty.

SW004

WARNING

Install the machine on a level floor of

sufficient strength. Failure to do so may

result in conditions which can produce

serious injury, death and/or property

damage.

W703

WARNING

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

Never touch internal or external steam

pipes, connections, or components.

These surfaces can be extremely hot and

will cause severe burns. The steam must

be turned off and the pipe, connections,

and components allowed to cool before

the pipe can be touched.

SW014

WARNING

IMPORTANT: Ensure that the recommended

clearances for inspection and maintenance

are provided. Never allow the inspection and

maintenance space to be blocked.

Safety Decals

Safety decals appear at crucial locations on the

machine. Failure to maintain legible safety decals

could result in injury to the operator or service

technician.

To provide person al safety and keep the machine in

proper working order, follow all maintenance and

safety procedures presented in this manual. If

questions regarding safety arise, contact the

manufacturer immediately.

Use manufacturer-authorized spare parts to avoid

safety hazards.

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 7

Basic Installation/Operation

NEVER insert hands or objects into

basket until it has completely stopped.

Doing so could result in serious injury.

SW012

WARNING

Never operate the machine with a

bypassed or disconnected balance

system. Operating the machine with

severe out-of-balance loads could result

in personal injury and serious equipment

damage.

SW039

WARNING

Operator Safety

To ensure the safety of machine operators, the

following maintenance checks must be performed

daily:

1. Prior to operating the machine, verify that all

warning signs are present and legible. Missing or

illegible signs must be replaced immediately.

Make certain that spares are available.

2. Check door interlock before starting operation of

the machine:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

Do not bypass any safety devices in the machine.

c. Close and lock the door and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

3. Do not attempt to operate the machine if any of

the following conditions are present:

a. The door does not remain securely locke d

during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly

grounded circuit.

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Basic Installation/Operation

Installation

General Specifications

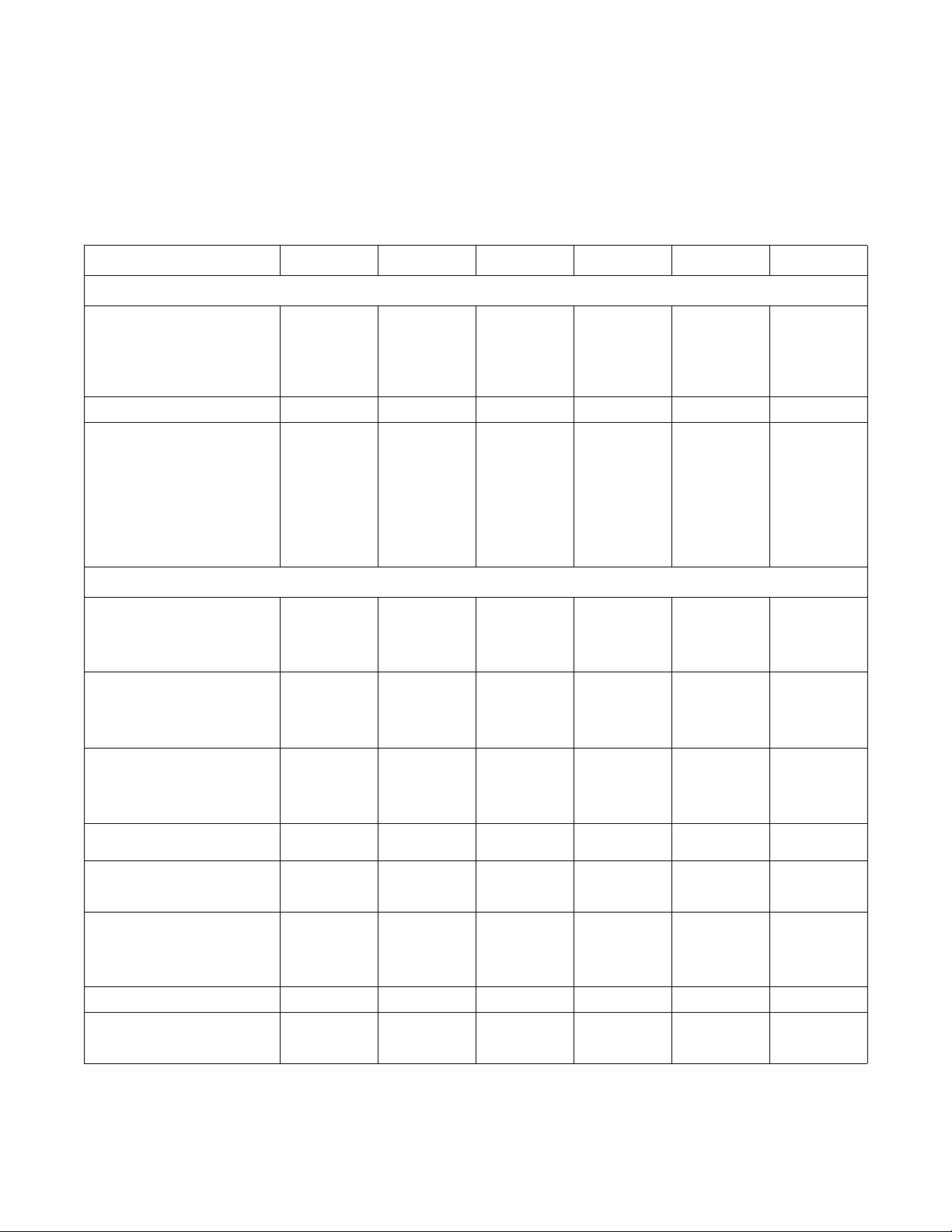

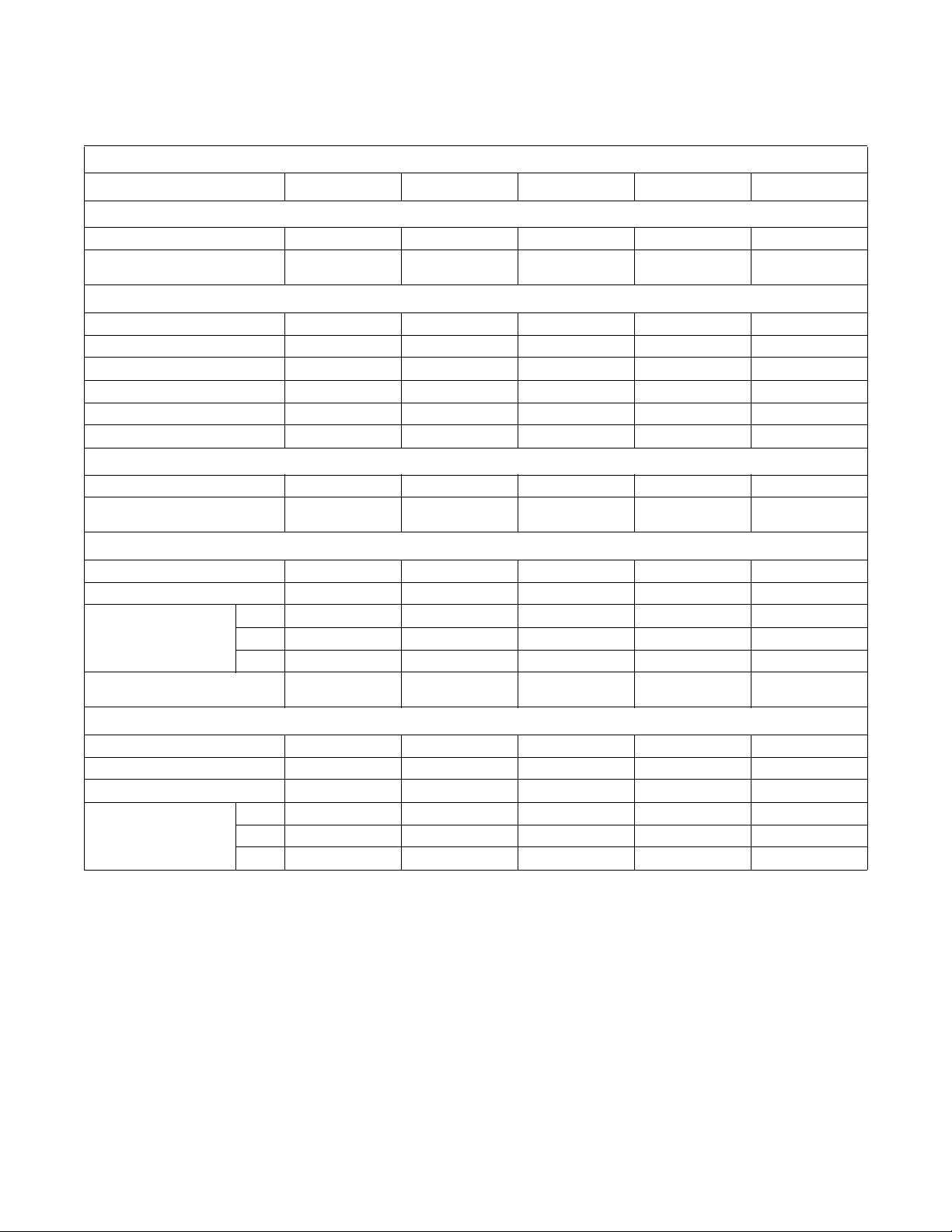

UW UniLinc and M30 Control Models

Refer to Table 1.

.

Specifications 35 60 80 100 125 150

Overall Dimensions

Overall width, in (mm) 33.375 (848)

Overall height, in (mm) 55.5 (1410) 64.5 (1638) 68.5 (1740) 68.5 (1740) 72 (1829) 79 (2007)

Overall depth, in (mm) 43.625 (1108)

(Models through

5/31/09)

32.5 (826)

(Models starting

6/1/09)

(Variable-speed

models through

5/31/09)

38.25 (972)

(2-speed models

through 5/31/09)

44 (1118)

(All models

starting 6/1/09)

36.625 (930) 41.5 (1054) 41.5 (1054) 48 (1219) 50.25 (1277)

45 (1143) 51.5 (1308) 54.5 (1384) 58 (1473) 63 (1600)

Weight And Shipping Information

Net weight, lb (kg) 1030 (468)

Basket Weight, lb (kg) 150 (68)

Domestic shipping weight, lb (kg) 1085 (493)

Domestic shipping volume,

3

(m3)

ft

Domestic shipping dimensions,

WxDxH, in (mm)

Export shipping weight, lb (kg) 1150 (522)

3

Export shipping volume, ft

Export shipping dimensions,

WxDxH, in (mm)

* Basket Only

(m3) 78 (2.2) 96 (2.7) 134 (3.8) 134 (3.8) 184 (5.3) 220 (6.3)

(Variable-speed

models)

750 (341)

(2-speed models)

(Variable-speed

models)

74 (34)

(2-speed models)

(Variable-speed

models)

810 (367)

(2-speed models)

66 (1.9) 84 (2.4) 119 (3.4) 119 (3.4) 166 (4.7) 172 (4.87)

38x47x64

(970x1200x

1630)

(Variable-speed

models)

910 (413)

(2-speed models)

41x50x65.5

(1050x1280x

1670)

1300 (590)

(Variable-speed

models)

1136 (515)

(2-speed models)

200 (92) 330 (150) 360 (163) 550 (250) 572 (260)*

1340 (608)

(Variable-speed

models)

1175 (533)

(2-speed models)

40x49x74.5

(1016x1245x

1892)

1464 (664)

(Variable-speed

models)

1300 (590)

(2-speed models)

43x52.125x74.5

(1092x1324x

1892)

1730 (785) 1770 (805) 2420 (1100) 2970 (1347)

1795 (814) 18 35 (832) 252 5 (1148) 3022 (1371)

44x60.5 x77.25

(1118x1537x

1962)

1990 (903) 2030 (921) 2800 (1270) 3350 (1520)

47x63.5x77.25

(1194x1613x

1962)

44x60.5x77.25

(1118x1537x

1962)

47x63.5x77.25

(1194x1613x

1962)

61.5x60x77.75

(1560x1520x

1980)

63.5x63x80

(1620x1610x

2030)

54.5x69x79

61.5x71x87

(1562x1804x

(139x176x

201)

2210)

Table 1 (continued)

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT F232156

Page 9

Basic Installation/Operation

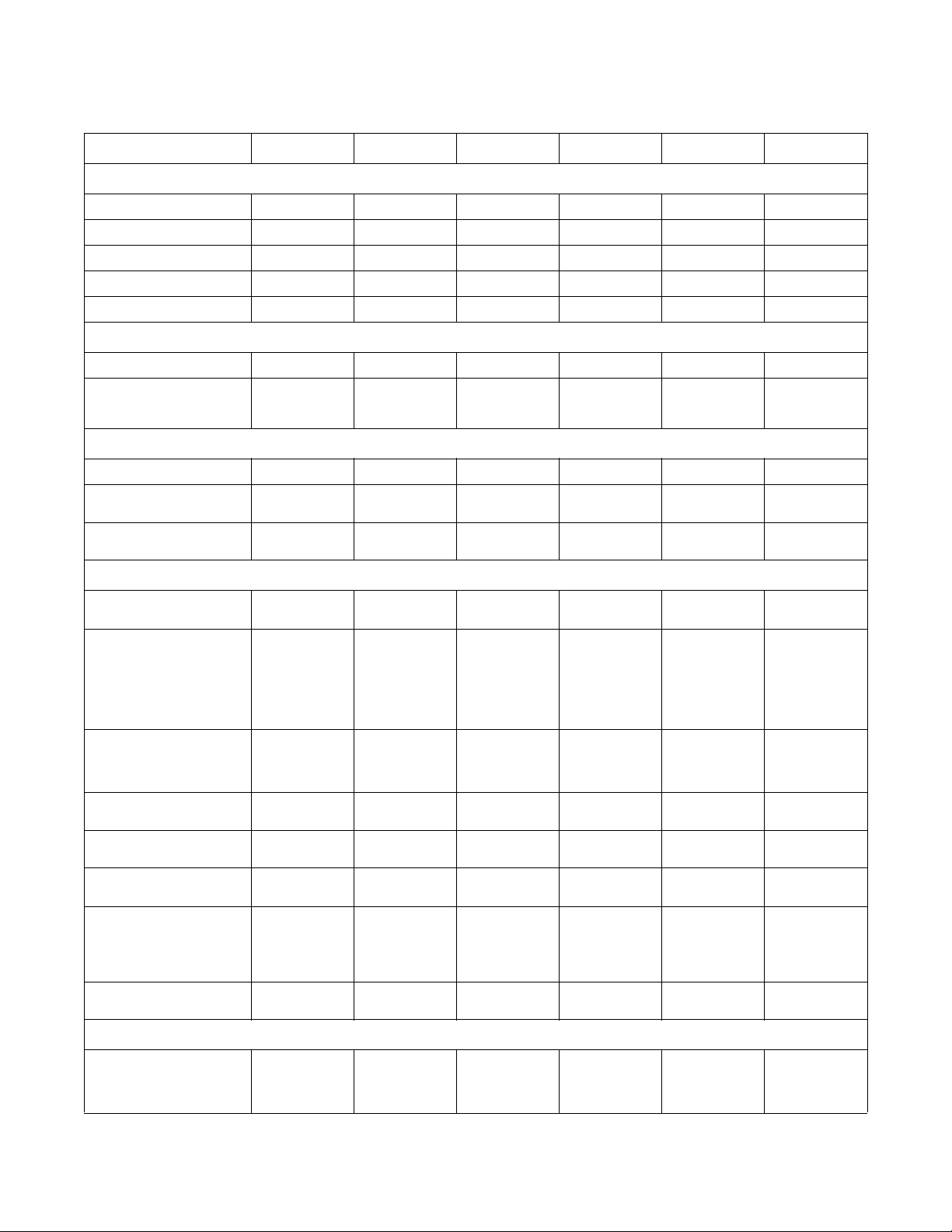

Table 1 (continued)

Specifications 35 60 80 100 125 150

Wash Cylinder Information

Cylinder diameter, in (mm) 26.25 (667) 32 (813) 36 (914) 36 (914) 42 (1067) 43 (1093)

Cylinder depth, in (mm) 18.375 (467) 20 (508) 21 (533) 27 (686) 24 (610) 27.8125 (706)

3

Cylinder volume, ft

Perforation size, in (mm) 0.1875 (4.8) 0.1875 (4.8) 0.1875 (4.8) 0.1875 (4.8) 0.1875 (4.8) 0.1875 (4.8)

Perforation open area, % 18 22 23 23 24 21.5

(l) 5.76 (163) 9.31 (264) 12.4 (350) 15.9 (450) 19.2 (544) 23.4 (662)

Door Opening Information

Door opening size, in (mm) 14.375 (365) 17.5 (445) 17.5 (445) 17.5 (445) 20 (508) 24.75 (629)

Height of door bottom above

floor,

in (mm)

23.75 (603) 28.25 (718) 29 (737) 29 (737) 29 (737) 32 (813)

Drive Train Information

Number of motors in drive train111111

Drive motor power, hp (kW)

(variable-speed models)

Drive motor power, hp (kW)

(2-speed models)

5.0 (3.7) 5.0 (3.7) 7.5 (5.6) 7.5 (5.6) 10 (7.5) 10 (7.5)

2.0 (1.3) 3.0 (2.2) N/A N/A N/A N/A

Cylinder Speeds / Centrifugal Force Data

1/2 Wash/reverse, rpm (g)

(Variable-speed models only)

Wash/reverse, rpm (g) 42 (.66)

Distribution, rpm (g)

(Variable-speed models only)

Very Low extract, rpm (g)

(Variable-speed models only)

Low extract rpm (g)

(Variable-speed models only)

Medium extract, rpm (g)

(Variable-speed models only)

High extract, rpm (g) 803 (240)

Very High extract, rpm (g)

(Variable-speed models only)

26 (.25) 26 (.31) 26 (.35) 26 (.35) 26 (.40) 23 (.32)

(UniLinc Models)

44 (.73)

(M30 Variable-

speed models)

50 (.95)

(2-speed models)

83 (2.57) 71 (2.3) 73 (2.57)

401 (60) 364 (60) 343 (60) 343 (60) 317 (60) 314 (60)

568 (120) 51 4 (120) 485 (120) 485 (120) 449 (120) 444 (120)

695 (180) 63 0 (180) 594 (180) 594 (180) 550 (180) 543 (180)

(Variable-speed

models)

504 (95)

(2-speed models)

898 (300) 813 (300) 766 (300) 766 (300) 579 (200) 701 (300)

40 (.73) (Variable-

speed models)

(2-speed models)

(Variable-speed

(2-speed models)

44 (.88)

727 (240)

models)

465 (98)

40 (0.8) 40 (0.8) 37 (0.8) 36 (0.8)

(UniLinc Models)

70 (2.5)

(M30 Models)

686 (240) 686 (240) 565 (190) 627 (240)

70 (2.50) 62 (2.29) 61 (2.29)

Balance Detection

Vibration switch installed STD (Variable-

F232156

speed models)

N/A (2-speed

models)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

STD (Variable-

speed models)

N/A (2-speed

models)

Table 1 (continued)

STD STD STD STD

7

Page 10

Basic Installation/Operation

Table 1 (continued)

Specifications 35 60 80 100 125 150

Direct Steam Heating (Optional)

Steam inlet connection size,

in (mm)

Number of steam inlets111111

Steam required to

raise bath temperature

10°F, lb (10°C, kg)

Average consumption per

cycle, BHP (kg)

LOW 2.1 (1.5) 3.3 (2.4) 4.6 (3.3) 5.7 (4.1) 6.7 (4.9) 8.3 (6.0)

MED 2.3 (1.7) 3.7 (2.6) 5.2 (3.8) 6.5 (4.7) 7.8 (5.6) 9.5 (6.9)

HIGH 2.7 (1.9) 4.1 (2.9) 6.1 (4.4) 7.6 (5.5) 9.1 (6.6) 11.1 (8.0)

0.5 (13) 0.5 (13) 0.5 (13) 0.5 (13) 0.75 (19) 0.75 (19)

1.4 (21.4) 2.1 (33.4) 3.1 (48.4) 3.8 (60.4) 4.6 (72.0) 5.8 (91.0)

Electrical Heating (Optional)

Total electrical heating

capacity, kW (N/A for 2-speed

models)

Number of electrical heating

elements

Electrical heating element size,

kW

Time required to

raise bath temperature

10°F, min (5°C, min)

LOW 2.4 (3.6) 2.4 (3.7) 2.2 (3.4) 2.8 (4.2) N/A N/A

MED 2.7 (4.1) 2.7 (4.1) 2.5 (3.9) 3.2 (4.8) N/A N/A

HIGH 3.1 (4.7) 3.0 (4.6) 3.0 (4.5) 3.7 (5.6) N/A N/A

15.6 27.4 41.2 (Q-Volt)

6699N/AN/A

2.6 4.2 4.2 4.2 N/A N/A

27.4 (N-Volt)

41.2 (Q-Volt)

27.4 (N-Volt)

N/A N/A

Table 1

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 11

Basic Installation/Operation

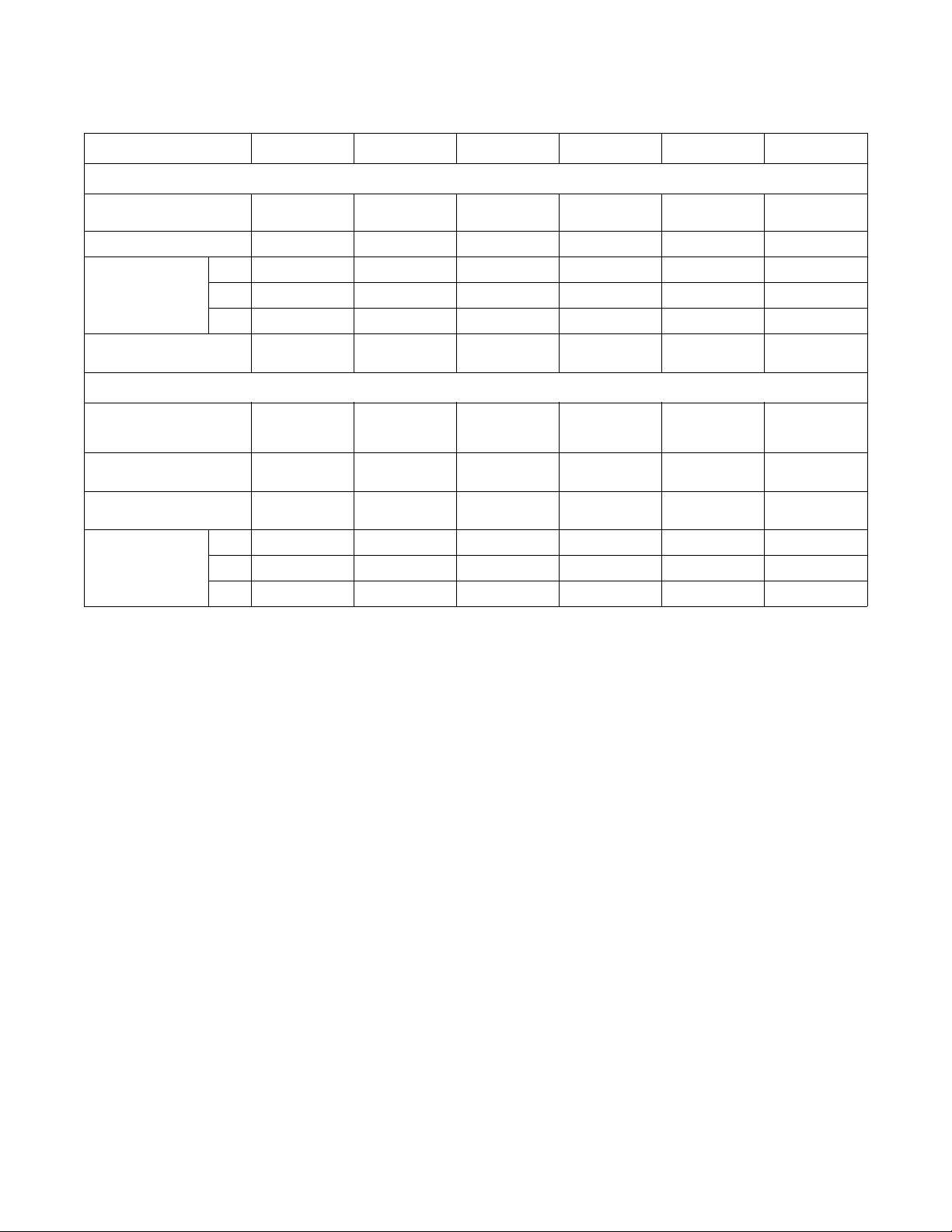

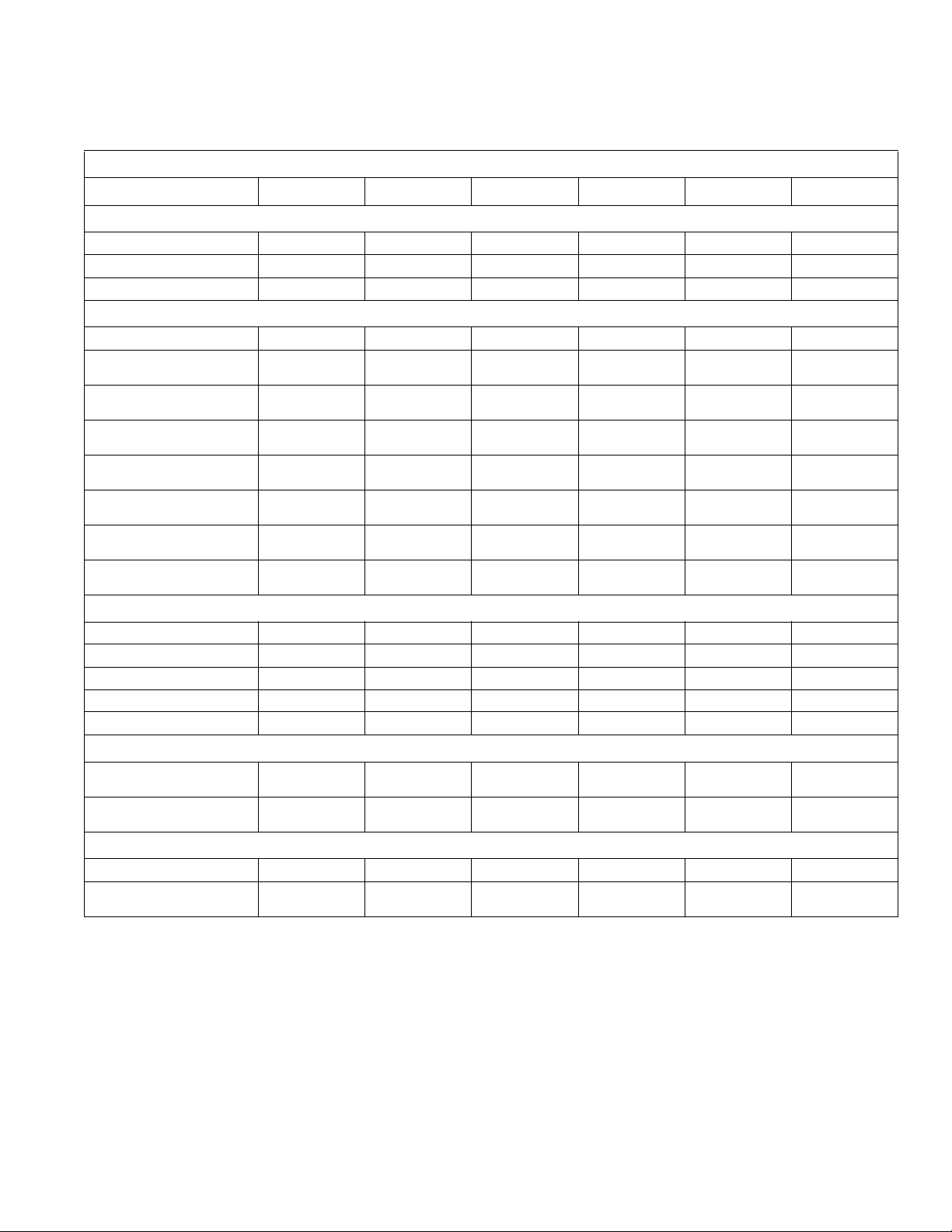

UW A-Control, Variable-Speed Models

.

Refer to Table 2.

UWAV Pocket Hardmount General Specifications

Specifications 35 60 80 100 125

Overall Dimensions

Overall width, in. (mm) 32.5 (826) 36.625 (930) 41.5 (1054) 41.5 (1054) 48 (1219)

Overall height, in. (mm) 55.5 (1410) 64.5 (1638) 65.5 (1740) 68.5 (1740) 72 (1829)

Overall depth, in. (mm) 43.625 (1108) 45 (1143) 51.5 (1308) 54.5 (1384) 58 (1473)

Weight and Shipping Information

Net weight, lb. (kg) 750 (341) 1229 (559) 1640 (744) 1680 (762) 2211 (1005)

Domestic shipping weight, lb. (kg) 800 (361) 1268 (575) 1705 (773) 1745 (792) 2525 (1148)

Domestic shipping volume, ft.

3

(m

)

Domestic shipping dimensions,

WxDxH, in. (mm)

Export shipping weight, lb. (kg) 910 (413) 1392 (631) 1900 (863) 1940 (881) 2591 (1178)

Export shipping volume, ft.

Export shipping dimensions,

WxDxH, in. (mm)

Wash Cylinder Information

Cylinder diameter, in. (mm) 26.25 (667) 32 (813) 36 (914) 36 (914) 42 (1067)

Cylinder depth, in. (mm) 18.375 (467) 20 (508) 21 (533) 27 (686) 24 (610)

Cylinder volume, ft.

Perforation size, in. (mm) .1875 (4.8) .1875 (4.8) .1875 (4.8) .1875 (4.8) .1875 (4.8)

Perforation open area, % 18 22 23 23 24

3

Door Opening Information

Door opening size, in. (mm) 14.375 (365) 17.5 (445) 17.5 (445) 17.5 (445) 20 (50 8)

Height of door bottom above floor ,

in. (mm)

Water Consumption

Average water

consumption per

cycle, gal. (l)

Average hot water used per hour,

gal. (l)

Power Consumption

Average power used per cycle, kW/

hr

Average HVAC load, Btu/hr (kcal/

hr)

3

3

(m3) 78 (2.2) 96 (2.7) 134 (3.8) 134 (3.8) 184 (5.3)

(l) 5.76 (163) 9.31 (264) 12.4 (350) 15.9 (450) 19.2 (544)

HOT 45 (170) 61 (231) 90 (341) 106 (401) 114 (431)

COLD

1.9 (66) 2.4 (84) 3.4 (119) 3.4 (119) 4.7 (166)

38x47x64

(970x1200x1630)

41x50x65.5

(1050x1280x1670)

23.75 (603) 28.25 (718) 29 (737) 29 (737) 29 (737)

24 (91) 29 (110) 41 (155) 47 (178) 52 (197)

78 (295) 102 (386) 139 (526) 161 (609) 168 (636)

0.18 0.28 0.40 0.40 0.48

800 (202) 950 (240) 1050 (265) 1150 (290) 1200 (302)

40x49x74.5

(1016x1245x1892)

43x52x72.5

(1092x1324x1892)

44x60.5x77.25

(1118x1537x1962)

47x63.5x76

(1194x1613x1962)

44x60.5x77.25

(1118x1537x1962)

47x63.5x76

(1194x1613x1962)

61.5x60x77.75

(1560x1520x1980)

(1620x1610x2030)

59x63x80

F232156

Table 2 (continued)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Basic Installation/Operation

Table 2 (continued)

UWAV Pocket Hardmount General Specifications

Specifications 35 60 80 100 125

Drive Train Information

Number of motors in drive train11111

Drive motor power, hp (kW) 2.3 (1.7) 2.9 (2.2) 5.0 (3.7) 5.0 (3.7) 7.5 (5.6)

Cylinder Speeds / Centrifugal Force Data

1/2 Wash/reverse, RPM / g 26 / .25 26 / .31 26 / .35 26 / .35 26 / .40

Wash/reverse, RPM / g 42 / .66 40 / .73 40 / .82 40 / .82 37 / .82

Distribution, RPM / g 83 / 2.57 71 / 2.29 73 / 2.57 70 / 2.50 62 / 2.29

High extract 1, RPM / g 329 / 40 297 / 40 280 / 40 280 / 40 260 / 40

High extract 2, RPM / g 534 / 106 483 / 106 456 / 106 456 / 106 422 / 106

High extract 3, RPM / g 656 / 160 594 / 160 560 / 160 560 / 160 518/ 160

Balance Detection

Vibration safety switch installed N/A STD STD STD STD

Safety switch gap setting, in. (mm)*

N/A

.25 (.010) NO-GO

.20 (.008) GO

.25 (.010) NO-GO

.20 (.008) GO

.25 (.010) NO-GO

.20 (.008) GO

.20 (.008) NO-GO

.15 (.006) GO

Direct Steam Heating (Optional)

Steam inlet connection size, in. (mm) .5 (13) .5 (13) .5 (13) .5 (13) .75 (19)

Number of steam inlets 11111

Steam required to raise bath

temperature,

10°F, lb. (10°C, kg)

Average consumption per cycle, bhp

(kg)

LOW 2.1 (1.5) 3.3 (2.4) 4.6 (3.3) 5.7 (4.1) 6.7 (4.9)

MED 2.3 (1.7) 3.7 (2.6) 5.2 (3.8) 6.5 (4.7) 7.8 (5.6)

HIGH 2.7 (1.9) 4.1 (2.9) 6.1 (4.4) 7.6 (5.5) 9.1 (6.6)

1.4 (21.4) 2.1 (33.4) 3.1 (48.4) 3.8 (60.4) 4.6 (72.0)

Electrical Heating (Optional)

Total electrical heating capacity, kW 15.6 25.2 37.8 37.8 50.4

Number of electrical heating elements669912

Electrical heating element size, kW 2.6 4.2 4.2 4.2 4.2

Time required to raise bath

temperature,

10°F, min. (10°C, min.)

* Gap setting should be made with “GO/NO-GO” type feeler gauge.

LOW 2.4 (3.6) 2.4 (3.7) 2.2 (3.4) 2.8 (4.2) 2.5 (3.8)

MED 2.7 (4.1) 2.7 (4.1) 2.5 (3.9) 3.2 (4.8) 2.9 (4.4)

HIGH 3.1 (4.7) 3.0 (4.6) 3.0 (4.5) 3.7 (5.6) 3.4 (5.1)

Table 2

10

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 13

Basic Installation/Operation

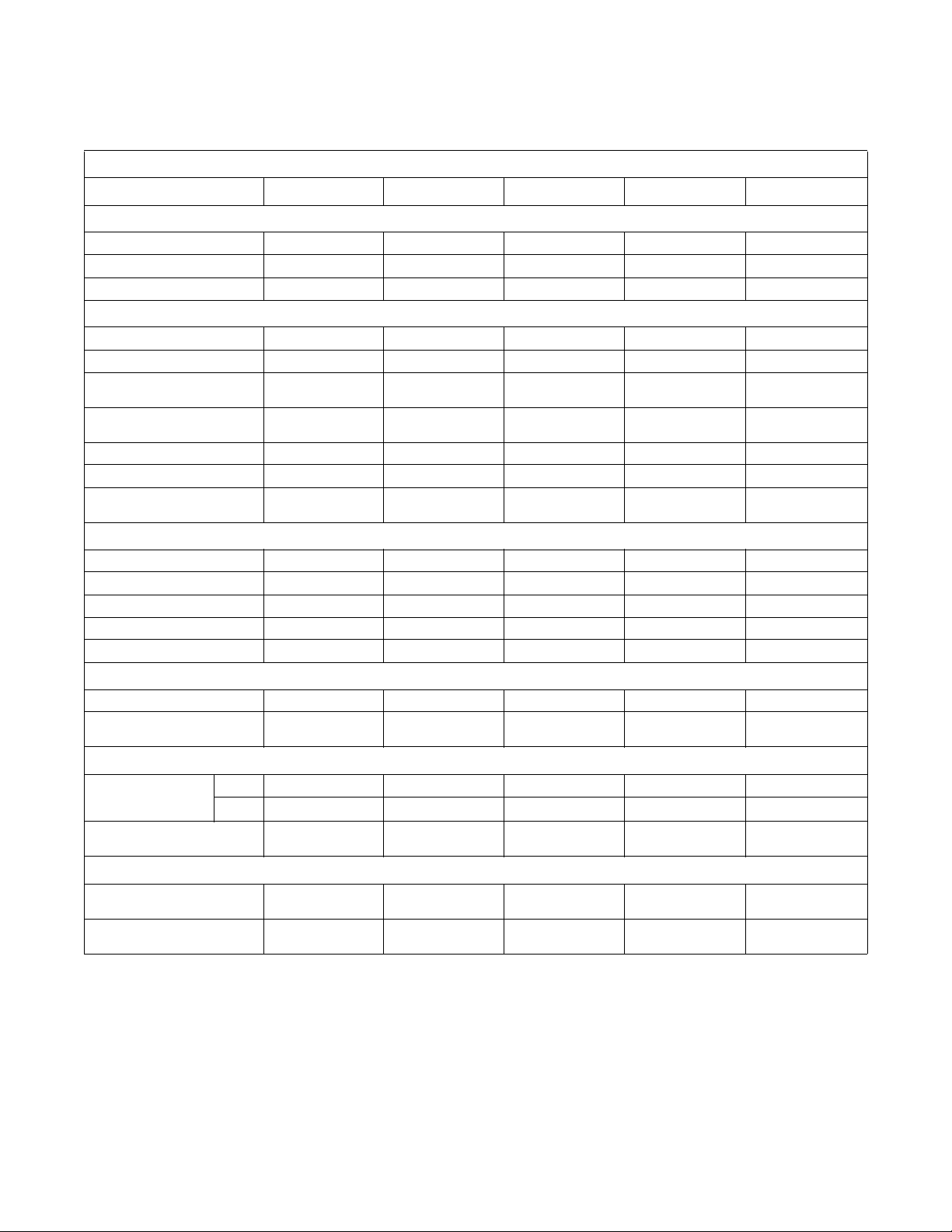

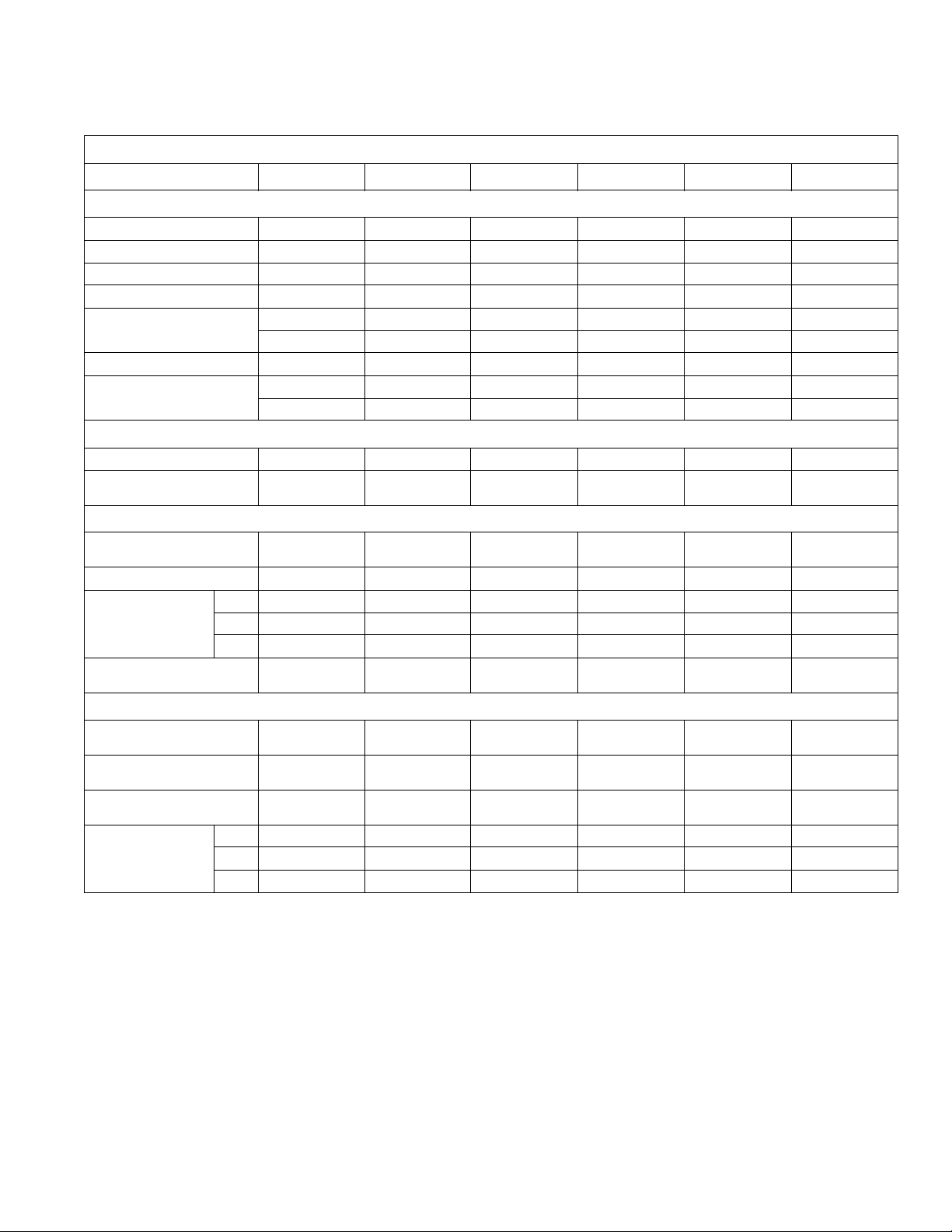

UW P-Control, Variable-Speed Models

.

Refer to Table 3.

UWPV Models

Specifications 35 60 80 100 125 150

Overall Dimensions

Overall width, in. (mm) 32.5 (826) 36.63 (930) 41.5 (1054) 41.5 (1054) 48 (1219) 50.25 (1277)

Overall height, in. (mm) 55.5 (1410) 64.5 (1638) 68.5 (1740) 68.5 (1740) 72 (1829) 79 (2007)

Overall depth, in. (mm) 43.63 (11 08) 45 (1143) 51.5 (1308) 54.5 (1384) 58 (1473) 63 (1600)

Weight And Shipping Information

Net weight, lb. (kg) 1030 (468) 1300 (590) 1730 (785) 1770 (805) 2420 (1100) 2970 (1347)

Basket/shaft weight,

lb. (kg)

Domestic shipping weight,

lb. (kg)

Domestic shipping volume,

3

ft.

(m3)

Domestic shipping dimensions,

WxDxH, in. (mm)

Export shipping weight,

lb. (kg)

Export shipping volume,

3

ft.

(m3)

Export shipping dimensions,

WxDxH, in. (mm)

Wash Cylinder Information

Cylinder diameter, in. (mm) 26.25 (667) 32 (813) 36 (914) 36 (914) 42 (1067) 43 (1093)

Cylinder depth, in. (mm) 18.38 (467) 20 (508) 21 (533) 27 (686) 24 (610) 27.81 (706)

Cylinder volume, ft.

Perforation size, in. (mm) 0.19 (4.8) 0.19 (4.8) 0.19 (4.8) 0.19 (4.8) 0.19 (4.8) 0.19 (4.8)

Perforation open area, % 18 22 23 23 24 21.5

3

(l) 5.76 (163) 9.31 (264) 12.4 (350) 15.9 (450) 19.2 (544) 23.38 (662)

Door Opening Information

Door opening size,

in. (mm)

Height of door bottom above

floor, in. (mm)

Drive Train Information

Number of motors in drive train111111

Drive motor power,

hp (kW)

150 (68) 200 (92) 330 (150) 360 (163) 550 (250) 260 (572)

1085 (493) 1340 (608) 1795 (814) 1835 (832) 2525 (1148) 3022 (1371)

66 (1.9) 84 (2.4) 119 (3.4) 119 (3.4) 166 (4.7) 172 (4.87)

38x47x64

(970x1200x1630)

1150 (522) 1464 (664) 1990 (903) 2030 (921) 2800 (1270) 3350 (1520)

78 (2.2) 96 (2.7) 134 (3.8) 134 (3.8) 184 (5.3) 220 (6.3)

41x50x65.5

(1050x1280x1670)

14.34 (364) 17.5 (445) 17.5 (445) 17.5 (445) 20 (508) 24.75 (629)

23.75 (603) 28.25 (718) 29 (737) 29 (737) 29 (737) 32 (813)

3.0 (2.2) 5.0 (3.7) 7.5 (5.6) 7.5 (5.6) 10 (7.5) 10 (7.5)

40x49x74.5

(1016x1245x1892)

43x52.12x74.5

(1092x1324x1892)

44x60.5x77.25

(1118x1537x1962)

47x63.5x77.25

(1194x1613x1962)

44x60.5x77.25

(1118x1537x1962)

47x63.5x77.25

(1194x1613x1962)

61.5x60x77.75

(1560x1520x1980)

63.5x63x80

(1620x1610x2030)

54.5x69x79

(139x176x201)

61.5x71x87

(1562x1804x2210)

F232156

Table 3 (continued)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Basic Installation/Operation

Table 3 (continued)

UWPV Models

Specifications 35 60 80 100 125 150

Cylinder Speeds / Centrifugal Force Data

1/2 Wash/reverse, RPM / g 26 / .25 26 / .31 26 / .35 26 / .35 26 / .40 23 / .31

Wash/reverse, RPM / g 42 / .66 40 / .73 40 / .82 40 / .82 37 / .82 36 / 0.8

Distribution, RPM / g 83 / 2.57 71 / 2.29 73 / 2.57 70 / 2.50 62 / 2.29 61 / 2.29

Medium extract, RPM / g 325 / 39 305 / 42 325 / 54 325 / 54 260 / 40 262 / 42

High extract l, RPM / g

*Design U6 models

High extract 2, RPM / g 610 / 139 555 / 140 523 / 140 523 / 140 485 / 140 512 / 160

High extract 3, RPM / g

*Design U6 models

474 / 84 435 / 86 408 / 85 408 / 85 380 / 86 417 / 106

533 / 106 483 / 106 456 / 106 456 / 106 N/A 417 / 106

795 / 235 720 / 235 671 / 230 601 / 184 534 / 170 573 / 200

897 / 308 813 / 300 767 / 300 767 / 300 580 / 200 701 / 300

Balance Detection

Vibration switch installed STD STD STD STD STD STD

Switch gap setting, in. (mm)** .20 (.008) NO-GO

.15 (.006) GO

.25 (.010) NO-GO

.20 (.008) GO

.25 (.010) NO-GO

.20 (.008) GO

.25 (.010) NO-GO

.20 (.008) GO

.20 (.008) NO-GO

.15 (.006) GO

.30 (.014) NO-GO

.33 (.013) GO

Direct Steam Heating (Optional)

Steam inlet connection size,

in. (mm)

Number of steam inlets 1 1 1 1 1 1

Steam required to

raise bath temperature,

10°F, lb. (10°C, kg)

Average consumption per cycle,

bhp (kg)

LOW 2.1 (1.5) 3.3 (2.4) 4.6 (3.3) 5.7 (4.1) 6.7 (4.9) 8.3 (6.0)

MED 2.3 (1.7) 3.7 (2.6) 5.2 (3.8) 6.5 (4.7) 7.8 (5.6) 9.5 (6.9)

HIGH 2.7 (1.9) 4.1 (2.9) 6.1 (4.4) 7.6 (5.5) 9.1 (6.6) 11.1 (8.0)

1/2 (13) 1/2 (13) 1/2 (13) 1/2 (13) 3/4 (19) 3/4 (19)

1.4 (21.4) 2.1 (33.4) 3.1 (48.4) 3.8 (60.4) 4.6 (72.0) 5.8 (91.0)

Electrical Heating (Optional)

Total electrical heating capacity,

kW

Number of electrical heating

elements

Electrical heating element size,

kW

Time required to

raise bath temperature,

10°F, min. (5°C, min.)

*Refer to Figure 4 and Figure 5, and serial number decal on machine to determine design series.

** Gap setting should be made with “GO–NO-GO” type feeler gauge.

N/A = Not Applicable

LOW 2.4 (3.6) 2.4 (3.7) 2.2 (3.4) 2.8 (4.2) 2.5 (3.8) N/A

MED 2.7 (4.1) 2.7 (4.1) 2.5 (3.9) 3.2 (4.8) 2.9 (4.4) N/A

HIGH 3.1 (4.7) 3.0 (4.6) 3.0 (4.5) 3.7 (5.6) 3.4 (5.1) N/A

15.6 25.2 37.8 37.8 50.4 N/A

669912N/A

2.6 4.2 4.2 4.2 4.2 N/A

12

Table 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 15

Basic Installation/Operation

UW 2 Speed Models with P-Control,

.

S-Control, Mechanical Timer or B-Control

Refer to Table 4.

UW 2 Speed Models

UW35 UW60

Overall Dimensions

Overall width, in. (mm) 32-1/2 (826) 36-5/8 (930)

Overall height, in. (mm) 55-1/2 (1410) 64-1/2 (1638)

Overall depth, in. (mm) 38-1/4 (972) 45 (1143)

Weight and Shipping Information

Net weight, lb. (kg) 750 (341) 1136 (515)

Basket/shaft weight, lb. (kg) 74 (34) 200 (92)

Domestic shipping weight, lb. (kg) 810 (367) 1175 (533)

Domestic shipping volume, ft.

Domestic shipping dimensions W x D x H, mm (in.) 38 x 47 x 64

Export shipping weight, lb. (kg) 910 (413) 1300 (590)

Export shipping volume, ft.

Export shipping dimensions W x D x H, in. (mm) 41 x 50 x 65-1/2

Wash Cylinder Information

Cylinder diameter, in. (mm) 26-1/4 667 32 (813)

Cylinder depth, in. (mm) 18-3/8 (467) 20 (508)

Cylinder volume, ft.

Perforation size, in. (mm) 3/16 (4.8) 3/16 (4.8)

Perforation open area, % 18 22

3

Door Opening Information

Door opening size, in. (mm) 14-11/32 (364) 17-1/2 (445)

Height of door bottom above floor, in. (mm) 23-3/4 (603) 28-1/4 (718)

Water Consumption*

Averag e water consumption per cycle, gal. (l) HOT 45 (170) 61 (231)

Averag e hot water used per hour, gal. (l) 78 (295) 102 (386)

Power Consumption

Average power used per cycle, kWh 0.3 0.47

Max. nominal sound emission, dBA 72 81

Average HVAC load, Btu/hr (kcal/hr) 600 (151) 875 (220)

*

For P and S controls only. M control has no spray rinse.

3

(m3) 66 (1.9) 84 (2.4)

(970 x 1200 x 1630)

3

(m3) 78 (2.2) 96 (2.7)

(1050 x 1280 x 1670)

(l) 5.76 (163) 9.31 (264)

COLD 24 (91) 29 (110)

40 x 49 x 74-1/2

(1016 x 1245 x 1892)

43 x 52-1/8 x 74-1/2

(1092 x 1324 x 1892)

F232156

Table 4 (continued)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Basic Installation/Operation

Table 4 (continued)

UW 2 Speed Models

UW35 UW60

Drive Train Information

Number of motors in drive train 1 1

Wash/reverse motor power, HP (kW) 0.4 (0.3) 0.6 (0.5)

High extract motor power, HP (kW) 1.8 (1.3) 3.0 (2.2)

Cylinder Speeds/Centrifugal Force Data

Wa sh/reverse speed, RPM / g 50 / 0.95 44 / 0.88

Distribution speed, RPM / g – –

High extract speed, RPM / g 504 / 95 465 / 98

Balance Detection

Vibration safety switch installed N/A STD

Safety switch gap setting, in. (mm) N/A 0.008-0.010 (0.20-0.25)

Direct Steam Heating (Optional)

Steam inlet connection size, in. (mm) 1/2 (13) 1/2 (13)

Number of steam inlets 1 1

Steam required to raise bath temperature,

10°F, lb. (10°C, kg)

Average consumption per cycle, bhp (kg/hr) 1.4 (21.4) 2.1 (33.4)

LOW 2.1 (1.5) 3.3 (2.4)

MED 2.3 (1.7) 3.7 (2.6)

HIGH 2.7 (1.9) 4.1 (2.9)

Electrical Heating (Optional)

Total electrical heating capacity, kW 15.6 25.2

Number of electrical heating elements 6 6

Electrical heating element size, kW 2.6 4.2

Time required to raise bath temperature,

10°F, min. (10°C, min.)

LOW 2.4 (3.6) 2.4 (3.7)

MED 2.7 (4.1) 2.7 (4.1)

HIGH 3.1 (4.7) 3.0 (4.6)

14

Table 4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 17

Basic Installation/Operation

UW 3 Speed Models with P-Control or

S-Control

Refer to Table 5.

UW 3 Speed Models

UW35 UW60

Overall Dimensions

Overall width, in. (mm) 32-1/2 (826) 36-5/8 (930)

Overall height, in. (mm) 55-1/2 (1410) 64-1/2 (1638)

Overall depth, in. (mm) 36-3/4 (933) 45 (1143)

Weight and Shipping Information

Net weight, lb. (kg) 750 (341) 557 (1229)

Basket/shaft weight, lb. (kg) 90 (41) 200 (92)

Domestic shipping weight, lb. (kg) 810 (367) 1268 (575)

Domestic shipping volume, ft.

Domestic shipping dimensions, WxDxH, in. (mm) 38 x 47 x 64

Export shipping weight, lb. (kg) 413 (910) 631 (1392)

Export shipping volume, ft.

Export shipping dimensions, WxDxH, in. (mm) 41 x 50 x 65-1/2

Wash Cylinder Information

Cylinder diameter, in. (mm) 26-1/4 (667) 32 (813)

Cylinder depth, in. (mm) 18-3/8 (467) 20 (508)

Cylinder volume, ft.

Perforation size, in. (mm) 3/16 (4.8) 3/16 (4.8)

Perforation open area, % 18 22

3

Door Opening Information

Door opening size, in. (mm) 14-11/32 (364) 17-1/2 (445)

Height of door bottom above floor, in. (mm) 23-3/4 (603) 28-1/4 (718)

Water Consumption

Average water consumption per cycle, gal. (l) HOT 45 (170) 61 (231)

Average ho t water used pe r hour, gal. (l) 78 (295) 102 (386)

3

(m3) 66 (1.9) 2.4 (84)

(970 x 1200 x 1630)

3

(m3) 2.2 (78) 2.7 (96)

(1050 x 1280 x 1670)

(l) 5.76 (163) 9.31 (264)

COLD 24 (91) 29 (110)

40 x 49 x 74-1/2

(1016 x 1245 x 1892)

43 x 52-1/8 x 74-1/2

(1092 x 1324 x 1892)

Table 5 (continued)

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Basic Installation/Operation

Table 5 (continued)

UW 3 Speed Models

UW35 UW60

Power Consumption

Average power used per cycle, kWh 0.24 0.47

Max nominal sound emission, dBA 72 81

Average HVAC load, Btu/hr (kcal/hr) 625 (157) 875 (220)

Drive Train Information

Number of motors in drive train 2 2

Wash/reverse motor power, hp (kW) 0.4 (0.3) 0.9 (0.7)

Distribution motor power, hp (kW) 0.45 (0.34) 1.0 (0.8)

High extract motor power, hp (kW) 3 (2.2) 3.5 (2.6)

Cylinder Speeds/Centrifugal Force Data

Wash/reverse speed, RPM / g 45 / 0.76 42 / 0.80

Distribution speed, RPM / g 75 / 2.10 67 / 2.04

High extract speed, RPM / g 597 / 133 561 / 139

Balance Detection

Vibration safety switch installed N/A STD

Safety switch gap setting, in. (mm) N/A 0.006 (0.15)

Direct Steam Heating (Optional)

Steam inlet connection size, in. (mm) 1/2 (13) 1/2 (13)

Number of steam inlets 1 1

Steam required to raise bath temperature,

10°F, lb. (10°C, kg)

Average consumption per cycle, bhp (kg) 1.4 (21.4) 2.1 (33.4)

LOW 2.1 (1.5) 3.3 (2.4)

MED 2.3 (1.7) 3.7 (2.6)

HIGH 2.7 (1.9) 4 .1 (2. 9)

Electrical Heating (Optional)

Total electrical heating capacity, kW 15.6 25.2

Number of electrical heating elements 6 6

Electrical heating element size, kW 2.6 4.2

Time required to raise bath temperature,

10°F, min. (10°C, min.)

LOW 2.4 (3.6) 2.4 (3.7)

MED 2.7 (4.1) 2.7 (4.1)

HIGH 3.1 (4.7) 3 .0 (4. 6)

16

Table 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 19

Basic Installation/Operation

Crush hazard.

To avoid personal injury and/or property

damage, do not tip the UW150 machine

more than 25 degrees in any direction.

W642

WARNING

UniLinc and M30 Control Models

Dimensional Clearances

Allow a minimum of 24 inches (60 cm) a t the rea r and

6 inches (45 cm) at the sides for maintenance,

inspection, and adjustment. Allow at least 6 inches

(45 cm) between machines in multiple installations.

Machine dimensions are indicated in Table 6 and

specified in Figure 1 and Figure 2.

NOTE: The dimensions shown here are for

planning purposes only . They ar e approximate and

subject to normal manufacturing tolerances. If

exact dimensions are required for construction

purposes, contact the distributor or the

manufacturer. We reserve the right to make

changes at any time without notice.

UniLinc and M30 Control Pocket Hardmount Machine Dimensions (Refer to Figure 1 and Figure 2)

Dimension

35 60 80 100 125 150

in mm in mm in mm in mm in mm in mm

A

33.375 (Models through 5/31/09)

1

B

32.5 (Models starting 6/1/09)

C

43.625 (Variable speed models

D

44 (All models starting 6/1/09)

2

E

F

2

G

H

J

K

L

M

N

O

P

Q

1

Overhang dimensions for the optional starch dispenser are as follows: 35, 3.8 8 inches (9.86 cm); 60, 1.75 inches (4.45 cm); 80 and 100, 0.33 inches

(0.83 cm). (The starch dispenser does not overhang the 125. ) (No longer available.)

2

The overhang dimension for the premium wet clean module option (compatible with wet-clean-capable washer-extractors only) adds 24 inches

(60.96 cm) to combined machine dimensions E and G.

30.125 765 35.625 905 41.125 1045 41.125 1045 48 1219 50.25 1277

23.75 603 28.25 718 29 737 29 737 29 737 32 813

through 5/31/09)

38.25 (2-speed models

through 5/31/09)

.5 131253763761.5382.973

55.5 1410 64.5 1638 68.5 1740 68.5 1740 72 1829 79 2007

36 914 36 914 43.75 1111 43.75 1111 48 1219 56 1422

8 203 15.5 394 16.875 429 16.875 429 11.375 289 15.75 400

43.14 1096 49.8 1265 53.54 1360 53.54 1360 56.4 1433 62.85 1596

46.64 1185 53.3 1354 57.04 1449 57.04 1449 59.9 1521 66.35 1685

5.12 130 5.12 130.05 7.12 181 7.12 181 7.12 181 7.12 181

2.62 66 2.62 66 3.62 92 3.62 92 3.62 92 3.62 92

1.37 35 1.37 35 2.25 57 2.25 57 2.25 57 2.25 57

3.87 98 3.87 98 5 127 5 127 5 127 5 127

2.5 64 2.5 64 2.75 70 2.75 70 2.75 70 2.75 70

2.5 64 2.5 64 3.5 89 3.5 89 3.5 89 3.5 89

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

848 36.625 930 41.5 1054 41.5 1054 48 1219 50.25 1277

1108 45 1143 51.5 1308 54.5 1384 58 1473 63 1600

Table 6

17

Page 20

Basic Installation/Operation

3

5

2

9

13

C

A (BASE)

B (OVERALL)

G (BASE)

D (OVERALL)

35 - 125

F

J

H

7

15

6

14

4

8

E

10

3

11

12

16

K

M

N

L

O

P

Q

1

PHM770N

1 External Supply Control Mounting Bracket 9 Water Inlet V a lves

(Models through 6/30/08) 10 Steam Connection (Optional)

2 Door Unlock Button 11 Shell Vent

3 Supply Valve Box 12 Power Input (Electric Heat Models)

4 Emergency Stop Button 13 Power Input (Non-Electric Heat Models)

5 Supply Dispenser (optional) 14 Drain (80, 100 and 125 models only)

6 Door Handle 15 Drain

7 Spray Rinse Nozzle (optional) 16 Overflow Vent

8 Recirculation Inlet

Figure 1

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 21

Basic Installation/Operation

TMB736N

4

5

7

9

11

C

A (BASE)

B (OVERALL)

E

G (BASE)

D (OVERALL)

UW150TV

F

J

H

6

13

14

3

8

2

11

15

M

N

L

O

P

Q

J

K

10

12

10

1

1 External Supply Control Mounting Bracket 8 Basket Jog Buttons

(Models through 6/30/08) 9 Recirculation Inlet

2 Door Unlock Button 10 Shell Vent

3 Emergency Stop Button 11 Water Inlet V alves

PHM736N

4 Supply Valve Box 12 Steam Connection (Optional)

5 Supply Dispenser 13 Power Input

6 Spray Rinse Nozzle 14 Drain

7 Door Handle 15 Overflow Vent

F232156

Figure 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Basic Installation/Operation

UWAV Models

Dimensional Clearances

Allow a minimum of 24 inches (60 cm) a t the rea r and

18 inches (45 cm) at the sides for maintenance,

inspection, and adjustment. Allow at least 18 inches

(45 cm) between machines in multiple installations.

Machine dimensions are indicated in Figure 3 and

specified in Table 7.

UWAV Pocket Hardmount Machine Dimensions (Refer to Figure 3)

35 60 80 100 125

Dimension

in.mmin.mmin.mmin.mmin.mm

A

B

C

D

E

30.125 765 35.625 905 41.125 1045 41.125 1045 48 1219

32.5 826 36.625 930 41.5 1054 41.5 1054 48 1219

23.75 603 28.25 718 29 737 29 737 29 737

43.625 972 45 1143 51.5 1308 54.5 1384 58 1473

1251253763761.538

NOTE: The dimensions shown here are for

planning purposes only. They ar e approximate and

subject to normal manufacturing tolerances. If

exact dimensions are required for construction

purposes, contact the distributor or the

manufacturer. We reserve the right to make

changes at any time without notice.

F

G

H

I

55.5 1410 64.5 1638 68.5 1740 68.5 1740 72 1829

30.5 775 36 914 43.75 1111 43.75 1111 48 1219

7.625 194 15.5 394 16.875 429 16.875 429 11.375 289

43.875 1114 55 1397 58.5 1486 58.5 1486 63.375 1610

Table 7

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 23

Basic Installation/Operation

<

<

12

34

56

H

7

4

5

6

1

2

3

G (BASE)

E

C

F

D (OVERALL)

B (OVERALL)

A (BASE)

I

Models UW 35 – 125

PHM623N

1 Supply Valve Box 5 Power Input Area (Inside)

2 Supply Dispenser 6 Steam Connector (Optional)

3 Door Handle 7 Drain

4 Water I nlet Valve

F232156

Figure 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

21

Page 24

Basic Installation/Operation

UWPV Models

NOTE: The dimensions shown here are for

planning purposes only. They ar e approximate and

Dimensional Clearances

Allow a minimum of 24 inches (60 cm) a t the rea r and

18 inches (45 cm) at the sides for maintenance,

inspection and adjustment. Allow at least 18 inches

(45 cm) between machines in multiple installations.

subject to normal manufacturing tolerances. If

exact dimensions are required for construction

purposes, contact the distributor or the

manufacturer. We reserve the right to make

changes at any time without notice.

Machine dimensions are indicated in Figure 4 and

specified in Table 8.

Dimension

30.12 765 35.63 905 41.12 1045 41.12 1045 48 1219 50.25 1277

A

1

33.39 847 36.63 930 41.5 1054 41.5 1054 48 1219 50.25 1277

B

23.75 603 28.25 718 29 737 29 737 29 737 32 813

C

43.63 1108 45 1143 51.5 1308 54.5 1384 58 1473 63 100

D

2

E

F

2

G

H

43.88 1114 55 1397 58.5 1486 58.5 1486 63.38 1610 70.25 1778

I

1

Overhang dimensions for the optional starch dispenser are as follows: UW35PV, 3.88 inches (9.86 cm); UW60PV, 1.75 inches

(4.45 cm); UW80PV and UW100PV, 0.33 inches (0.83 cm). (The starch dispenser does not overhang the UW125PV.) (No longer

available.)

2

The overhang dimension for the premium wet clean module option (compatible with wet-clean-capable washer-extractors only) adds 24

inches (60.96 cm) to combined machine dimensions E and G.

UWPV Pocket Hardmount Machine Dimensions (Refer to Figure 4 and Figure 5)

35 60 80 100 125 150

in mm in mm in mm in mm in mm in mm

.5 13 1 25 3 76 3 76 1.5 38 2.9 4.6

55.5 1410 64.5 1638 68.5 1740 68.5 1740 72 1829 79 2007

36 914 36 914 43.75 1111 43.75 1111 48 1219 56 1422

8 203 15.52 394 16.88 429 16.88 429 11.38 289 15.75 400

22

Table 8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 25

Basic Installation/Operation

PHM387N

C

1

2

3

F

A (BASE)

B (OVERALL)

5

G (BASE)

D (OVERALL)

6

E

7

11

8

9

10

H

I

4

UW35PV – UW125PV

1 Supply Valve Box 7 Power Input Area (Inside)

2 Supply Dispenser 8 Steam Connection (Optional)

3 Door Handle 9 Premium Wet Clean Module (Optional)

4 Spray Rinse Nozzle 10 Drain

5 Recirculation Inlet 11 Water Inlet Valves

6 Premium Wet Clean Module (Optional)

Figure 4

PHM387N

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Basic Installation/Operation

543 21

1

2

3

4

5

6

7

8

9

1

0

1

2

4

5

6

C

A (BASE)

B (OVERALL)

E

G (BASE)

D (OVERALL)

UW150PV

F

I

H

3

7

8

9

1 Supply Valve Box 6 W a ter Inlet Valves

PHM603N

2 Supply Dispenser 7 Power Input Area (Inside)

3 Spray Rinse Nozzle 8 Steam Connection (Optional)

4 Door Handle 9 Drain

5 Recirculation Inlet

Figure 5

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 27

Basic Installation/Operation

UW 2 Speed Models with P-Control,

S-Control, Mechanical Timer or B-Control

Dimensional Clearances

Allow a minimum of 24 inches (60 cm) at the rear, and

18 inches (45 cm) at the sides for maintenance,

inspection and adjustment. Allow at least 18 inches

(45 cm) between machines in multiple installations.

Machine dimensions are indicated in Figure 6 and

specified in Table 9.

NOTE: The dimensions shown here are for

planning purposes only . They ar e approximate and

subject to normal manufacturing tolerances. If

exact dimensions are required for construction

purposes, contact the distributor or the

manufacturer. We reserve the right to make

changes at any time without notice.

UW 2 Speed Machine Dimensions

(Refer to Figure 6)

Dimensions

35 60

in. mm in. mm

A

*

B

C

D

E

F

G

H

I

*

Overhang dimensions for the optional starch dispenser are as follows:

UW35, 3.88 inches (9.86 cm); UW60, 1.75 inches (4.45 cm).

30.13 765 35.63 905

32.5 826 36.63 930

23.75 603 28.25 718

38.25 972 45 1143

0.5 13 1 25

55.5 1410 64.5 1638

30.5 775 36 914

8 203 15.5 394

43.88 1114 55 1397

Table 9

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Basic Installation/Operation

PHM388N

E

C

1

2

3

F

A (BASE)

B (OVERALL)

G (BASE)

D (OVERALL)

E

6

5

7

8

H

I

4

UW 2 Speed Models

1 Supply Valve Box 5 W a ter Inlet Valves

2 Supply Dispenser 6 Power Input Area (Inside)

3 Door Handle 7 Steam Connection (Optional)

4 S pray Rinse Nozzle (2 Speed, P-Control Models

Only)

8 Drain

Figure 6

P032I

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 29

Basic Installation/Operation

UW 3 Speed Models with P-Control or

S-Control

Dimensional Clearances

Allow a minimum of 24 inches (60 cm) a t the rea r and

18 inches (45 cm) at the sides for maintenance,

inspection, and adjustment. Allow at least 18 inches

(45 cm) between machines in multiple installations.

Machine dimensions are indicated in Figure 7 and

specified in Table 10.

NOTE: The dimensions shown here are for

planning purposes only . They ar e approximate and

subject to normal manufacturing tolerances. If

exact dimensions are required for construction

purposes, contact the distributor or the

manufacturer. We reserve the right to make

changes at any time without notice.

UW 3 Speed Machine Dimensions

(Refer to Figure 7)

Dimensions

35 60

in. mm in. mm

A

*

B

C

D

E

F

G

H

I

*

Overhang dimensions for the optional starch dispenser are as follows:

UW35, 3.88 inches (9.86 cm); UW60, 1.75 inches (4.45 cm).

30.13 765 35.63 905

32.5 825 36.63 930

23.75 604 28.25 718

36.75 934 45 1143

125125

55.5 1409 64.5 1638

30.5 775 36 914

7.63 194 15.5 394

43.63 1108 55 1397

Table 10

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Basic Installation/Operation

P032I

C

1

2

3

F

D (OVERALL)

E

7

6

5

8

I

4

B (OVERALL)

A (BASE)

H

UW 3 Speed Models

G (BASE)

1 Supply Valve Box 5 Steam Connection (Optional)

2 Supply Dispenser 6 W a ter Inlet Valves

3 Door Handle 7 Power Input Area (Inside)

4 Spray Rinse Nozzle 8 Drain

Figure 7

P032I

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 31

Operation

PHM705N

UW35 – UW150 MODELS

UW35 – UW125 MODELS

150 MODELS

W

A

R

N

IN

G

MACHINE M

AY B

E HOT

AND CAUSE BUR

NS

ATTEMPT NO

ENT

RY UNTIL

BASKET HAS STOPPED

SER

IOUS INJURY

MAY

RESULT

Basic Installation/Operation

UW Models With UniLinc Control

1. When display shows the Cycle Menu Screen

washer-extractor is ready to be loaded with

laundry.

2. On UW35-UW150 models. Press the door

unlock button located on the lower left front on

the control. Refer to Figure 8.

3. Open door within five seconds of pressing the

door unlock keypad.

PHM705N

Figure 8

4. On 35 – 125 models, turn door handle clockwise

and swing the door left to open. Door must be

opened within 5 seconds of pressing the door

unlock button. Refer to Figure 9.

unlock button. Refer to

Figure 10.

PHM717N

Figure 10

6. Load the washer-extractor to full capacity

whenever possible, but do not exceed the rated

dry-weight capacity of the machine if the fabric

to be washed is quite dense, closely woven, and

heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine

load size based on fabric content, soil content,

and level of cleanliness required. Do not

underload the machine. Underloading can result

in premature bearing and sealing failure and outof-balance situations.

5. On 150 models, turn handle counterclockwise

Figure 9

and swing the door right to open. Door must be

opened within 5 seconds of pressing the door

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

MD004J

PHM590N

Figure 11

29

Page 32

Basic Installation/Operation

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

For Technical Service

Distributor ABC

1-800-555-5555

Cycle41:

Supply Set

Up

Cycle02:

Towels White

Cycle01:

Towels

White

Bleach

Cycle Menu

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

IMPORTANT: To prevent out-of-balance

conditions, premature wear or damage to machine

when using laundry nets, use several small nets in a

load.

7. When loading is complete, ensure that all fabric

is inside the basket. Then close and lock the door.

Add dry supplies are placed in the supply dispenser

compartment cups prior to the start of each cycle.

Liquid supplies can be injected directly into the

supply dispenser by an external chemical supply

system.

NOTE: Supply dispenser compartment cups must

not be removed when an external chemical

injection supply system is attached to the washerextractor.

As the cycle proceeds, the display will show a

summary of the cycle occurring. Refer to Figure 8

To begin the cycle at any step other than the first step,

press the keypad to advance through the cycle

to the desired starting point. (The Rapid Advance

feature keypad is enabled at the factory and can be

disabled.) Refer to Programming Manual for

information to disable Rapid Advance.

If the door is not closed and locked, the display will

indicate that the door needs to closed and locked.

Refer to Figure 13.

PHM706N

Figure 13

Close door to start cycle or press keypad to

return to Cycle Menu.

8. Press and keypads to select desired

wash cycle.

9. Press to start the selected cycle.

Figure 12

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

10. The cycle will continue until its completion.

Then the display will show the door is ready to be

unlocked and opened.

NOTE: The Drain Step that occurs before an

Extract Step or a Spray Rinse Extract Step cannot

be skipped using Rapid Advance. The machine

MUST drain and balance during the Drain Step

before it can extract.

PHM702N

F232156

Page 33

Basic Installation/Operation

W

A

R

N

IN

G

M

A

C

H

I

N

E

M

A

Y

BE

H

O

T

A

N

D

C

A

U

S

E

B

U

R

N

S

A

T

T

E

M

P

T

N

O

E

N

T

R

Y

U

N

T

I

L

B

A

S

K

E

T

H

A

S

S

T

O

P

P

E

D

S

E

R

IO

U

S

IN

J

U

R

Y

M

A

Y R

E

S

U

L

T

UW Models With M30 Control

1. When display shows a cycle number, the washerextractor is ready to be loaded with laundry.

2. Press the STOP/UNLOCK button located on the

control. Refer to Figure 14.

PHM758N

Figure 14

3. Open door within five seconds of pressing the

door unlock keypad.

4. Turn the door handle clockwise and swing the

door left to open it. The door must be opened

within 5 seconds of pressing the door unlock

button. Refer to Figure 15.

5. Load the washer-extractor to full capacity

whenever possible, but do not exceed the rated

dry-weight capacity of the machine if the fabric

to be washed is quite dense, closely woven, and

heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine

load size based on fabric content, soil content and

level of cleanliness required. Do not underload

the machine. Underloading can result in

premature bearing and sealing failure and out-ofbalance situations.

PHM590N

Figure 16

PHM593N

Figure 15

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Basic Installation/Operation

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

IMPORTANT: To prevent out-of-balance

conditions, premature wear or damage to machine

when using laundry nets, use several small nets in a

load.

6. When loading is complete, ensure that all fabric

is inside the basket. Then close and lock the door.

7. Where applicable, add dry supplies into the supply

dispenser compartment cups prior to the start of

each cycle.

Liquid supplies can be injected directly into the

washer-extractor by an external chemical supply

system.

NOTE: Supply dispenser compartment cups must

not be removed when an external chemical

injection supply system is attached to the washerextractor.

8. Press the numeric keypads to select the desired

wash cycle. Refer to Table 11.

Cycle Number Cycle Name

1 Permanent Press Light Soil

2 Light Soil

3 Permanent Press Medium Soil

4 Medium Soil

5 Permanent Press Heavy Soil

6Heavy Soil

7Rags

8 Reclaim

9 Delicates

10 95°C

11 60°C

12 40°C

13 95°C Permanent Press

14 60°C Permanent Press

15 40°C Permanent Press

16 70°C Permanent Press

17 50°C Gentle

18 30°C Gentle

19 Custom #1

20 Custom #2

21 Custom #3

22 Custom #4

23 Custom #5

24 Custom #6

25 Custom #7

26 Custom #8

27 Custom #9

28 Custom #10

29 Custom #11

30 Custom #12

Table 11

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 35

Models Equipped with Both Steam

PHM784N

and Electric Heating (UniLinc and

M30 Controls)

1. To switch between the heating type, locate the

switch on the left side of control module. Refer to

Figure 17.

2. To select steam heat, make sure the switch is in

the down position.

OR

T o select electric heat, make sure the switch is in

the up position.

Basic Installation/Operation

Figure 17

PHM784N

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Basic Installation/Operation

W

A

R

N

IN

G

M

A

C

H

I

N

E

M

A

Y

BE

H

O

T

A

N

D

C

A

U

S

E

B

U

RN

S

A

T

T

E

M

P

T

N

O

E

N

T

R

Y

U

N

T

I

L

B

A

S

K

E

T

H

A

S

S

T

O

P

P

E

D

S

E

R

I

O

U

S

I

N

J

U

R

Y

M

A

Y

R

E

S

U

L

T

Be careful around the open door,

particularly when loading from a level below

the door . Imp act with door edges can cause

personal injury.

SW025

CAUTION

Check the door safety interlock daily before

the machine is placed in operation.

SW024

CAUTION

UW Models with S-Control

1. Turn on the main power source (circuit breaker or

cut-off switch on the wall).

2. Use left hand to press and hold the Door Unlock

button located on the lower right front of the

control panel. Refer to Figure 18.

MD003J

Figure 18

4. Load the machine to full capacity whenever

possible. DO NOT OVERLOAD.

PHM590N

Figure 20

3. Use right hand to turn door handle clockwise,

and swing the door left to open. Refer to

Figure 19.

MD004J

Figure 19

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

5. Close door and turn handle counterclockwise.

Door will lock automatically.

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 37

Basic Installation/Operation

6. Add dry supplies to the supply dispenser

compartment cups prior to the start of each cycle.

Liquid supplies can be injected directly into the

supply dispenser by an external chemical supply

system.

NOTE: Supply dispenser compartment cups must

not be removed when an external chemical

injection supply system is attached to the washerextractor.

7. Press the Up or Down keypad until the desired

cycle number is displayed. Press the Start keypad

to start the cycle.

To display the temperature of the water while

cycle is running, press the Up keypad. T o display

the number of the cycle in progress, press the

Start keypad.

NOTE: Press keypads at their centers just hard

enough to activate them.

8. Cycle is complete when display reads “

donE”.

NOTE: A cycle can be stopped at any time by

pressing the Stop keypad.

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

Basic Installation/Operation

UW35 – UW125 MODELS

Do not operate machine in a cycle with

program keymode switch in program

position. Program keymode switch must

be in run position at all times, except

when editing or programming cycle or

setup information.

W528

WARNING

UW35 – UW125 MODELS

UW Models with P-Control

Pre-Operating Instructions

1. Turn on the main power source (circuit breaker or

cut-off switch on wall). Models with the rotation

sensor will display WE-6 Firmware ID Code

HRWC18” and later (i.e., “HRWC19”) after

“

power up. For models without rotation sensor,

proceed to step 1 of Operating Instructions.

2. Display shows size of machine and will flash

“TEST?” and “SPEED” for 15 seconds.

3. Push Start keypad during the 15 seconds.

Machine will test rotation sensing for 15 seconds.

4. Display will flash “POWER” and “WAIT” one

time and will display “NEXT00.”

NOTE: If START keypad is not pushed while

display flashes “TEST?” and “SPEED” or if

rotation sensing fails, then display flashes

“POWER” and “WAIT” before showing

“NEXT00” for approximately 2 minutes.

Operating Instructions

1. When display shows “NEXT00,” washerextractor is ready to be loaded with laundry.

2. On UW35 – UW125 models, use left hand to

press and hold the door unlock button located on

the lower right front of the control panel. Refer to

Figure 21.

3. On UW35 – UW125 models, use right hand to

turn door handle clockwise and swing the door

left to open. Refer to Figure 22.

Figure 21

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

MD004J

Figure 22

MD003J

F232156

Page 39

Basic Installation/Operation

UW150 MODELS

W

A

R

N

IN

G

M

A

C

H

I

N

E

M

A

Y

BE

H

O

T

A

N

D

C

A

U

S

E

B

U

R

N

S

A

T

T

E

M

P

T

N

O

E

N

T

R

Y

U

N

T

I

L

B

A

S

K

E

T

H

A

S

S

T

O

P

P

E

D

S

E

R

IO

U

S

IN

J

U

R

Y

M

A

Y R

E

S

U

L

T

4. On UW150 models, use left hand to press and

hold the door unlock button located on the door

box. Refer to Figure 23.

6. Load the washer-extractor to full capacity

whenever possible, but do not exceed the rated

dry-weight capacity of the machine if the fabric

to be washed is quite dense, closely woven, and

heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine

load size based on fabric content, soil content,

and level of cleanliness required. Do not

underload the machine. Underloading can result

in premature bearing and sealing failure and

out-of-balance situations.

PHM597N

Figure 23

5. On UW150 models, use right hand to turn door

handle counterclockwise and swing the door

right to open. Refer to Figure 23.

PHM590N

Figure 24

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Basic Installation/Operation

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

IMPORTANT: To prevent out-of-balance

conditions, premature wear or damage to machine

when using laundry nets, use several small nets in a

load.

As the cycle proceeds, the display will show the

function being executed, the step number, and the

cycle number selected. Pressing the Edit Cycle keypad

while the cycle is running will cause the display to

show the remaining cycle time in minutes. Pressing

this keypad again will return the display to normal.

To begin the cycle at any step other than the first step,

press the Advance keypad to advance through the

cycle to the desired starting point. (The Advance

keypad is enabled at the factory and can be disabled at

the laundry site.) Then press the Start keypad.

It is possible to skip to the next step in a cycle, with the

exception of a drain step: drain steps must be allowed

time to complete.

When the display shows the step desired to begin the

cycle, press the Start keypad.

7. When loading is complete, ensure that all fabric

is inside the basket. Then close and lock the door.

8. Add dry supplies in the supply dispenser

compartment cups prior to the start of each cycle.

Liquid supplies can be injected directly into the supply

dispenser by an external chemical supply system.

NOTE: Supply dispenser compartment cups must

not be removed when an external chemical

injection supply system is attached to the washerextractor.

9. Find the cycle number of the desired wash cycle.

Cycle numbers must be two-digit numbers from

01 to 39.

NOTE: Press keypads at their centers just hard

enough to activate them.

Press the numbers desired on the keyboard and note

that these numbers are displayed after “NEXT.”

When keypads are pressed on the keyboard, a signal

will be heard. If an error is made, press the numbers

again. As numbers are entered, they move from right

to left on the display.

10. T o start the selected cycle, press the Start keypad.

If the selected cycle number is not in the control

memory, the display will show “

NCYC.” If this

happens, select another cycle. Otherwise, the

display will now show the first step. For

example, if the display reads “

represents a hot fill to low level, and “

HL01,” “HL”

01”

indicates that this is the first step of the cycle.

If the door is not locked, the display will indicate

“CLOSE” and “DOOR.” If this occurs, be sure the door

is closed and locked and press the Start keypad again.

If the LED indicator lights for the control outputs

indicate that one or more outputs are activated but the

washer-extractor is not functioning according to the

output or outputs indicated, contact a service

technician.

As water fills the washer-extractor, one or more of the

indicator lights located to the left of the keyboard will

come on and stay on until the required water level is

reached. LED dots located immediately above the last

three digits on the right of the control display will

illuminate to indicate the water level(s) reached:

• When the indicator dot above the last digit on the

right is lit, the low water level has been reached.

• When the dot above the next-to-the-last digit is

lit, medium water level (optional) has been

reached.

• When the dot over the third digit from the right

has been lit, high level has been reached.

11. The cycle will continue until its completion.

Then the display will read “DONE.”

38

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232156

Page 41

Basic Installation/Operation

<

<

12

3

4

5

6

W

A

R

N

IN

G

M

A

C

H

I

N

E

M

A

Y

BE

H

O

T

A

N

D

C

A

U

S

E

B

U

R

N

S

A

T

T

E

M

P

T

N

O

E

N

T

R

Y

U

N

T

I

L

B

A

S

K

E

T

H

A

S

S

T

O

P

P

E

D

S

E

R

IO

U

S

IN

J

U

R

Y

M

A

Y R

E

S

U

L

T

Do not operate machine in a cycle with

program keymode switch in program

position. Program keymode switch must

be in run position at all times, except

when editing or programming cycle or

setup information.

W528

WARNING

Do not operate machine in a cycle or if

spinning with program keymode switch in

program position.

W529

WARNING

UW Models with A-Control

1. When display shows “Cyxx,” washer-extractor is

ready to be loaded with laundry.

2. Use left hand to press and hold the door unlock

button located on the lower right front of the

control panel. Refer to Figure 25.

PHM626N

4. Load the washer-extractor to full capacity

whenever possible, but do not exceed the rated

dry-weight capacity of the machine if the fabric

to be washed is quite dense, closely woven, and

heavily soiled.

Overloading can result in an inferior wash. The

operator may need to experiment to determine

load size based on fabric content, soil content,

and level of cleanliness required. Do not

underload the machine. Underloading can result

in premature bearing and sealing failure and outof-balance situations.

Figure 25

3. Use right hand to turn door handle clockwise and

swing the door left to open. Refer to Figure 26.

PHM593N

Figure 26

PHM590N

Figure 27

F232156

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

Basic Installation/Operation

Be careful around the open door,

particularly when loading from a level

below the door. Impact with door edges

can cause personal injury.

SW025

CAUTION

NOTE: When washing items which may

disintegrate or fragment, such as mop heads or

sponges, use laundry nets to prevent drain

blockage.

IMPORTANT: To prevent out-of-balance

conditions, premature wear or damage to machine

when using laundry nets, use several small nets in a

load.

5. When loading is complete, make sure that all

fabric is inside the basket.

6. Close and lock the door.

Liquid supplies can be injected directly into the supply

dispenser by an external chemical supply sy s t em .

NOTE: Supply dispenser compartment cups must

not be removed when an external chemical

injection supply system is attached to the washerextractor.

8. The default wash cycle will display. If desired,

select a different cycle at this point.

9. Press the Start keypad.

NOTE: The cycle number can be changed during

the FIRST FILL ONLY by pressing another cycle

select key.

At the conclusion of the cycle, the display will show

doNE’. The door can be unlocked. At this point the

‘