Alliance Laundry Systems LGS19A, LES37A, LES33A User Manual

Installation Instructions

Home Laundry Automatic Dryers

(Electric and Gas Models)

D311IE3A

NOTA: El manual en español aparece

después del manual en inglés.

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE. (If the dryer changes ownership,

be sure this manual accompanies the dryer.)

Part No. 504607R2

August 1998

WARNING

FOR YOUR SAFETY, the information in this manual must be followed to minimize the risk of

fire or explosion or to prevent property damage, personal injury or death.

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or

any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

– Do not try to light any appliance.

– Do not touch any electrical switch; do not use any phone in your building.

– Clear the room, building or area of all occupants.

– Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

– If you cannot reach your gas supplier, call the fire department.

• Installation and service must be performed by a qualified installer, service agency or the gas

supplier.

W033

W052

© Copyright 1998, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

504607

1

Table of

Contents

Replacement Parts ............................................................................... 2

Roughing In Dimensions .....................................................................3

Before You Start

Tools ................................................................................................ 4

Exhaust .............................................................................................4

Electrical........................................................................................... 4

Gas....................................................................................................4

Location............................................................................................4

Installing the Dryer

STEP 1 (Position and Level the Dryer) ...........................................5

STEP 2 (Connect Dryer Exhaust System)........................................5

STEP 3 (Connect Gas Supply Pipe).................................................6

STEP 4 (Connect Electrical Plug) ....................................................7

STEP 5 (Wipe Out Inside of Dryer) ................................................. 8

STEP 6 (Plug in the Dryer) ..............................................................8

STEP 7 (Check Installation).............................................................8

Heat Source Check ............................................................................... 9

Reversing Door Procedure ................................................................10

Manufactured (Mobile) Home Installation ......................................11

Electrical Requirements (Electric Dryers) .......................................12

Electrical Plug Connection ................................................................13

Electrical Requirements (Gas Dryers) .............................................15

Gas Requirements .............................................................................16

Location Requirements .....................................................................17

Dryer Exhaust Requirements

Exhaust System Materials ..............................................................18

Make Up Air Requirements............................................................18

Exhaust System .............................................................................. 19

Exhaust Direction...........................................................................19

Exhaust System Maintenance.........................................................20

Dryer Airflow .................................................................................20

Reduced Clearance Elbow.............................................................. 20

User-Maintenance Instructions

Lubrication ..................................................................................... 21

Care of Your Dryer .........................................................................21

Exhaust System .............................................................................. 21

Information for Handy Reference ....................................................22

Installer Check .................................................................... Back Cover

Replacement Parts . . .

If replacement parts are required, contact the source

where you purchased your dryer, or contact

2

Alliance Laundry Systems LLC

Shepard Street

P.O. Box 990

Ripon, WI 54971-0990

Phone:

(920) 748-3950

for the name and address of the nearest authorized parts

distributor.

504607

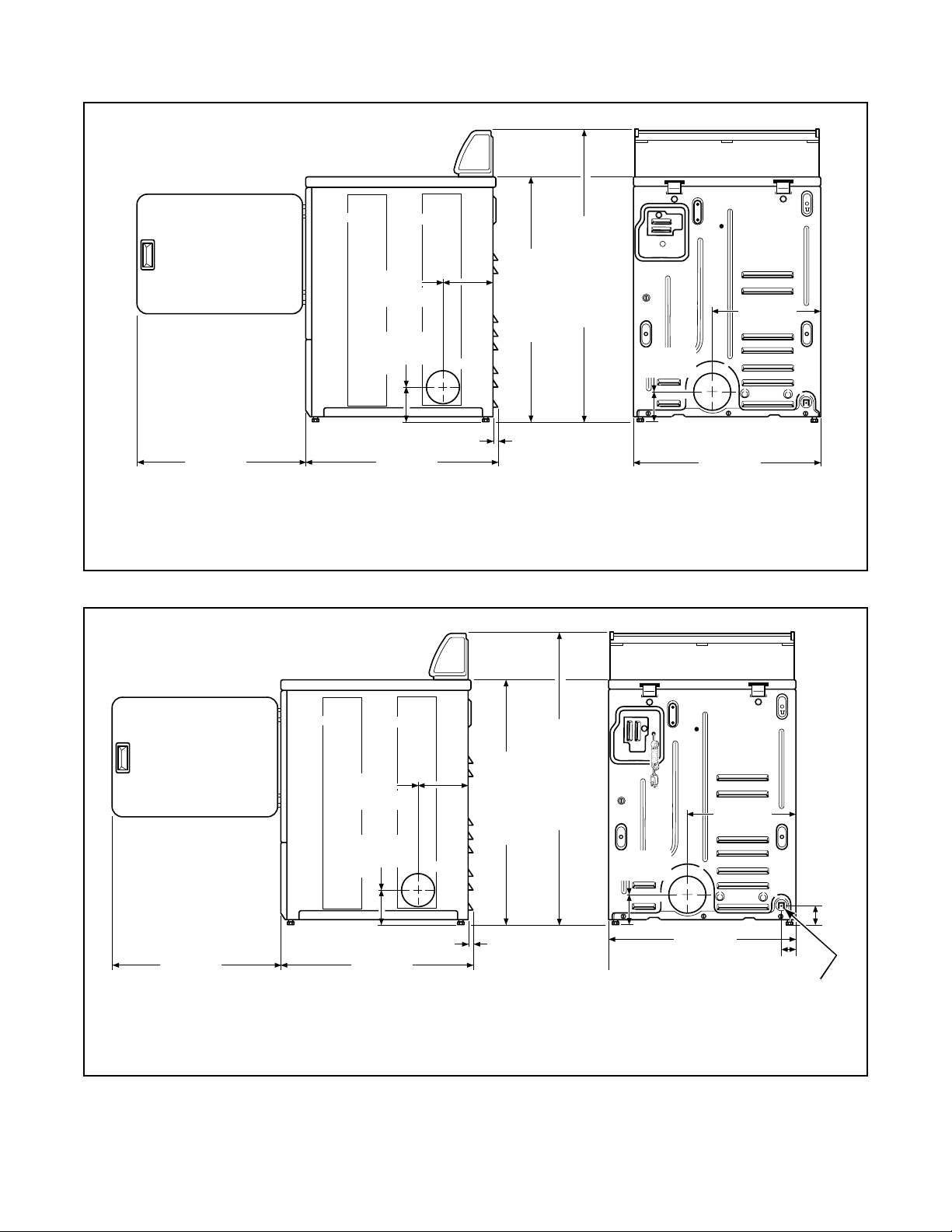

Roughing In Dimensions . . .

7.7"

23.5"

(59.7 cm)

(19.6 cm)

4.0"

(10.2 cm)

28"

(71.1 cm)

*36" (91.4 cm)

.4"

(1.1 cm)

*43" (109.2 cm)

4.0"

(10.2 cm)

(39.1 cm)

26.9"

(68.3 cm)

15.4"

* WITH LEVELING LEGS TURNED INTO BASE

(19.6 cm)

4.0"

(10.2 cm)

23.5"

(59.7 cm)

* WITH LEVELING LEGS TURNED INTO BASE

(71.1 cm)

ELECTRIC DRYERS

7.7"

*36" (91.4 cm)

.4"

28"

(1.1 cm)

*43" (109.2 cm)

4.0"

(10.2 cm)

(39.1 cm)

26.9"

(68.3 cm)

D312IE3A

15.4"

2.8"

(7 cm)

2.3" (6 cm)

3/8"NPT

GAS CONNECTION

D313IE3A

504607

GAS DRYERS

3

Before You Start . . .

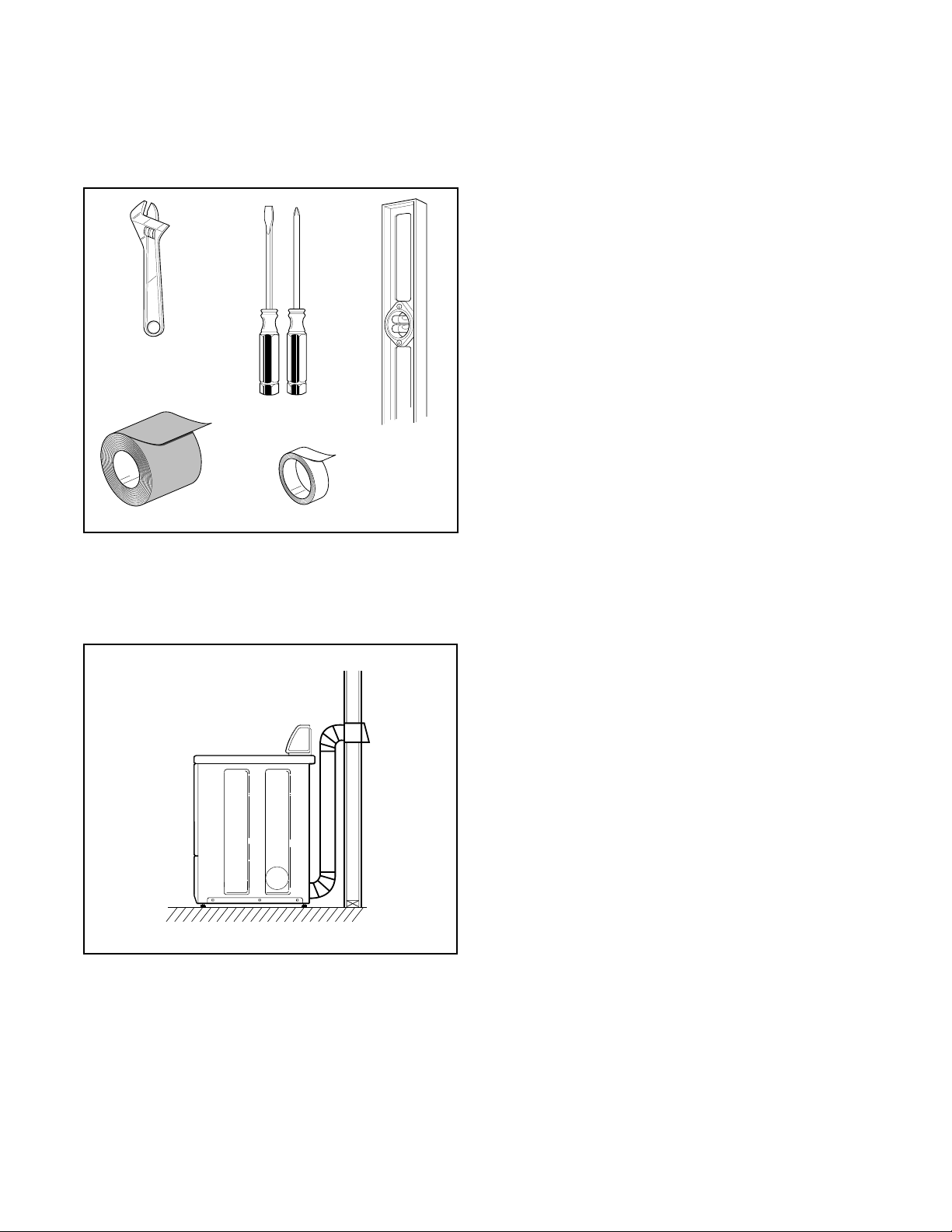

Tools

For most installations, the basic tools you will need are:

WRENCH

SCREWDRIVERS

LEVEL

DUCT TAPE

TEFLON TAPE

D074IE1F

Exhaust

Electrical

• ELECTRIC DRYER

Dryer needs a 3 or 4 wire 120/240 Volt, 30 Amp, 60

Hertz, 1 Phase electrical supply.

• GAS DRYER

Dryer needs a 120 Volt, 15 Amp, 60 Hertz, polarized

3-slot effectively grounded receptacle.

NOTE: For more detailed information, refer to

Section on Electrical Requirements.

Gas

Dryer is equipped for Natural Gas with a 3/8" NPT gas

supply connection. For more detailed information,

refer to Section on Gas Requirements.

Location

Place the dryer on a solid floor with an adequate air

supply. For more detailed information, refer to Section

on Location Requirements.

Use rigid metal duct and exhaust the dryer to the

outside by the shortest route possible.

D314IE0A

NOTE: For more detailed information, refer to

Section on Dryer Exhaust Requirements.

4

504607

Installing the Dryer . . .

D298IE1A

DRYER

BASE

LEVELING

LEG

LEVEL

D259I

DO

D314IE0C

DON'T

D315IE0C

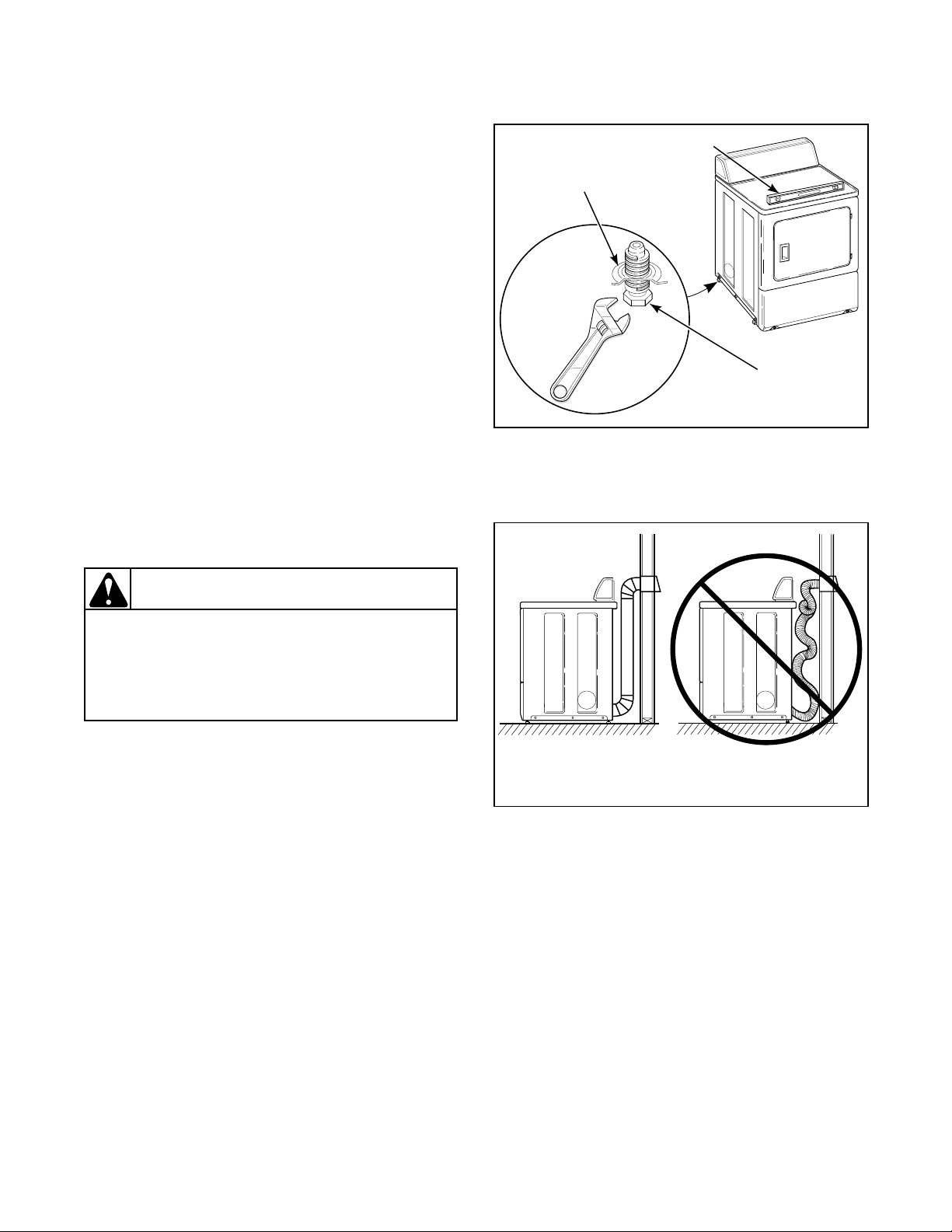

Step 1:

Position and Level

the Dryer

For further assistance refer to Section on Location

Requirements.

Install dryer before washer. This allows room for

attaching exhaust duct.

Place the dryer in position, and adjust the legs until the

dryer is level.

Step 2:

Connect Dryer Exhaust System

For further assistance refer to Sections on Location

Requirements and Dryer Exhaust Requirements.

WARNING

A clothes dryer produces combustible lint.

To reduce the risk of fire and combustion

gas accumulation the dryer MUST be

exhausted to the outdoors.

• DO NOT use plastic or thin foil flexible ducting.

• Locate dryer so exhaust duct is as short as possible.

• Be certain old ducts are cleaned before installing

your new dryer.

• Use 4" (10.2 cm) diameter rigid or flexible metal

duct.

• Use as few elbows as possible.

• Use duct tape on all joints.

• Failure to exhaust dryer properly will void

W116

NOTE: Venting materials are not supplied with the

dryer (obtain locally).

504607

5

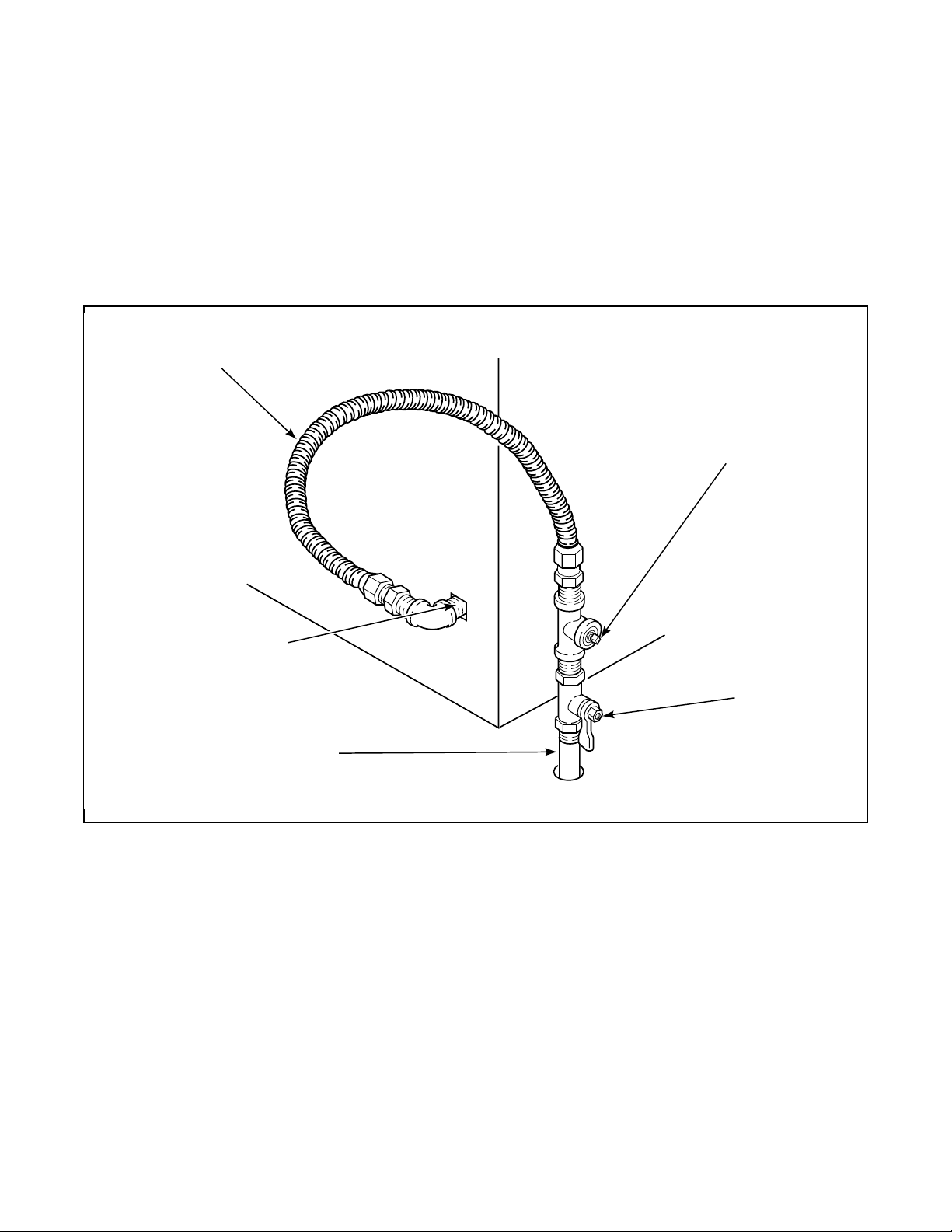

Step 3: (Gas Dryer ONLY)

Connect Gas Supply Pipe

For further assistance, refer to Section on Gas Requirements.

1. Make certain your dryer is equipped for use with

the type of gas in your laundry room. Dryer is

equipped at the factory for Natural Gas with a 3/8"

NPT gas connection.

2. Remove the shipping cap from the gas connection

at the rear of the dryer. Make sure you do not

damage the pipe threads when removing the cap.

NEW

STAINLESS STEEL

FLEXIBLE

CONNECTOR

USE ONLY

IF ALLOWED

BY LOCAL

CODES

(Use

Design A.G.A.

Certified

Connector)

3. Connect to gas supply pipe.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal & external) for

gas leaks with a non-corrosive leak detection fluid.

5. For L.P. (propane) gas connection, refer to Section

on Gas Requirements.

1/8" NPT

PIPE PLUG

(For checking

inlet gas pressure)

3/8" NPT

GAS CONNECTION

BLACK IRON PIPE

Shorter than 20' (6.1 m) - use 3/8" pipe

Longer than 20' (6.1 m) - use 1/2" pipe

EQUIPMENT

SHUT-OFF

VALVE

Install within

6' (1.8 m) of dryer

D233IE3D

6

504607

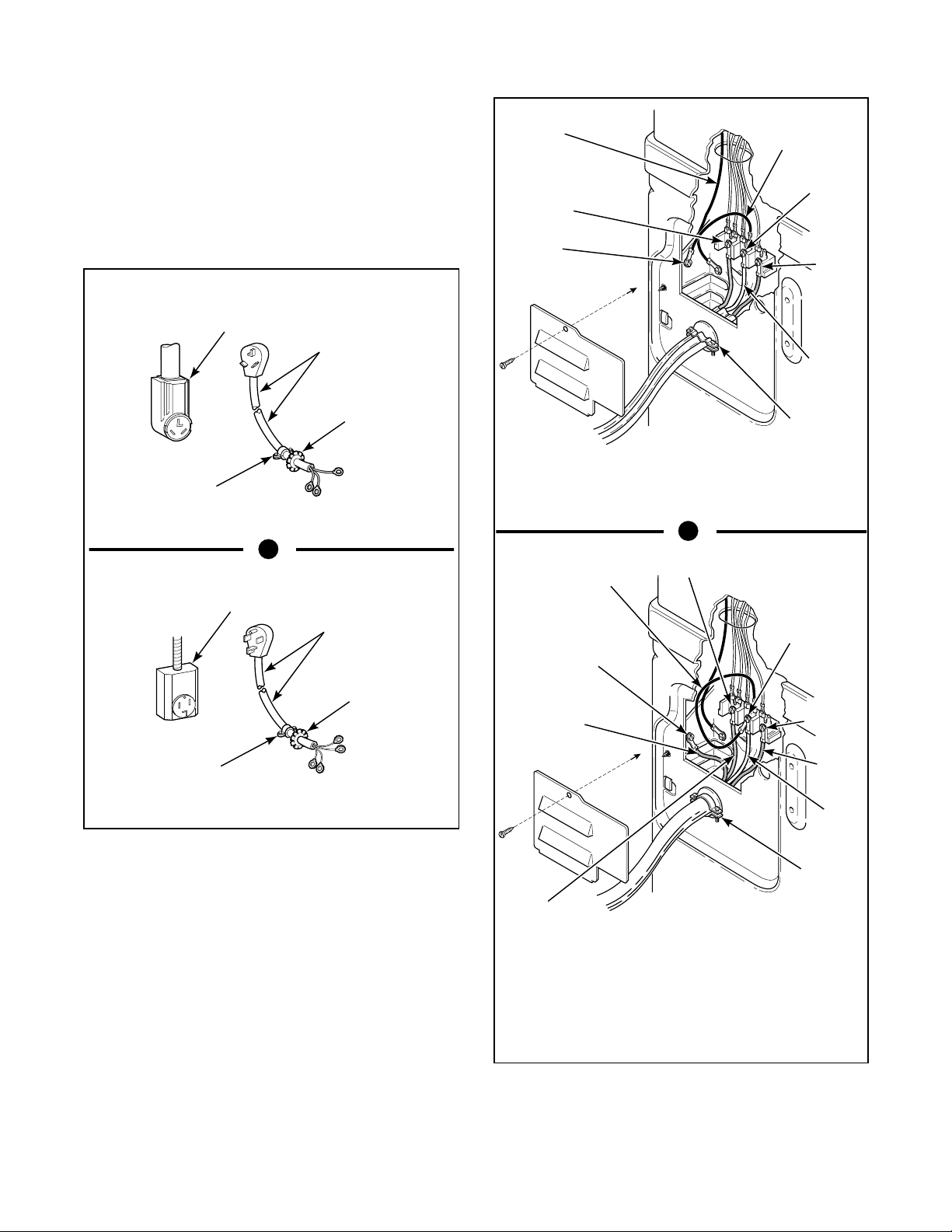

Step 4: (ELECTRIC DRYER ONLY)

D276IE1A

CENTER

WIRE

(NEUTRAL)

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

NEUTRAL

TERMINAL

GROUND

WIRE

"L2"

TERMINAL

"L1"

TERMINAL

GROUND

SCREW

GROUND

TO NEUTRAL

WIRE

Three-Wire Connection

D171IE1A

WHITE

WIRE

(NEUTRAL)

GROUND

SCREW

NEUTRAL

TERMINAL

"L1"

TERMINAL

BLACK

WIRE

GROUND

WIRE

STRAIN

RELIEF

(NOT SUPPLIED

WITH DRYER)

GROUND

WIRE

"L2"

TERMINAL

RED

WIRE

Four-Wire Connection

NOTE: Dryer is shown with access cover removed

for illustration purposes only. NEVER operate

dryer with access cover removed.

Connect Electrical Plug

For further assistance, refer to Section on Electrical

Requirements.

IMPORTANT: Use only a new U.L. listed No. 10

(copper wire only) three conductor power supply

cord kit rated 240 Volts (minimum) 30 Amperes

and labeled as suitable for use in a clothes dryer.

TYPICAL

THREE-WIRE

RECEPTACLE

POWER CORD

(Three-Wire)

STRAIN

RELIEF

NUT

STRAIN

RELIEF

D275IE0D

Three Wire

Three Wire

TYPICAL

FOUR-WIRE

RECEPTACLE

STRAIN

RELIEF

Four Wire

NOTE: For more detailed information on

connecting three-wire or four-wire plugs, refer to

Section on Electrical Plug Connection.

NOTE: Four-wire cord is required for mobile

homes or where codes do not permit grounding

through neutral.

POWER CORD

(Four-Wire)

STRAIN

RELIEF

NUT

D006IE0A

504607

7

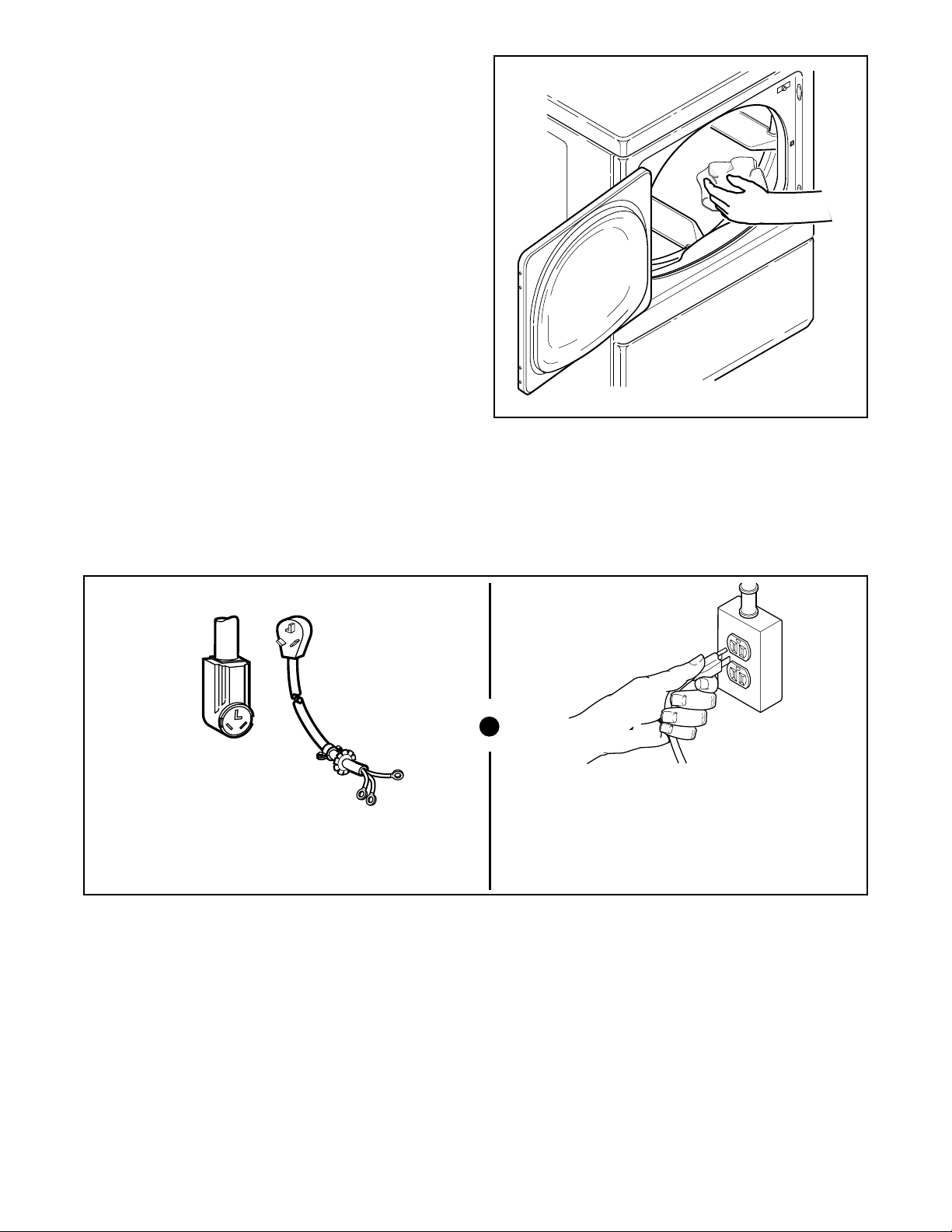

Step 5:

D327IE2A

Wipe Out Inside Of Dryer

Before using dryer for the first time, use an all-purpose

cleaner, or a detergent and water solution, and a damp

cloth to remove shipping dust from inside dryer drum.

Step 6:

Plug in the Dryer

Refer to Section on Electrical Requirements, and

connect the dryer to an electrical power source.

ELECTRIC

Connect to 30 Amp circuit.

D275IE0C

Step 7:

Check Installation

D254IE0B

GAS

Plug cord into separately fused

15 Amp circuit.

Refer to Installer Check on the back cover of this

manual and make sure that dryer is installed correctly.

8

504607

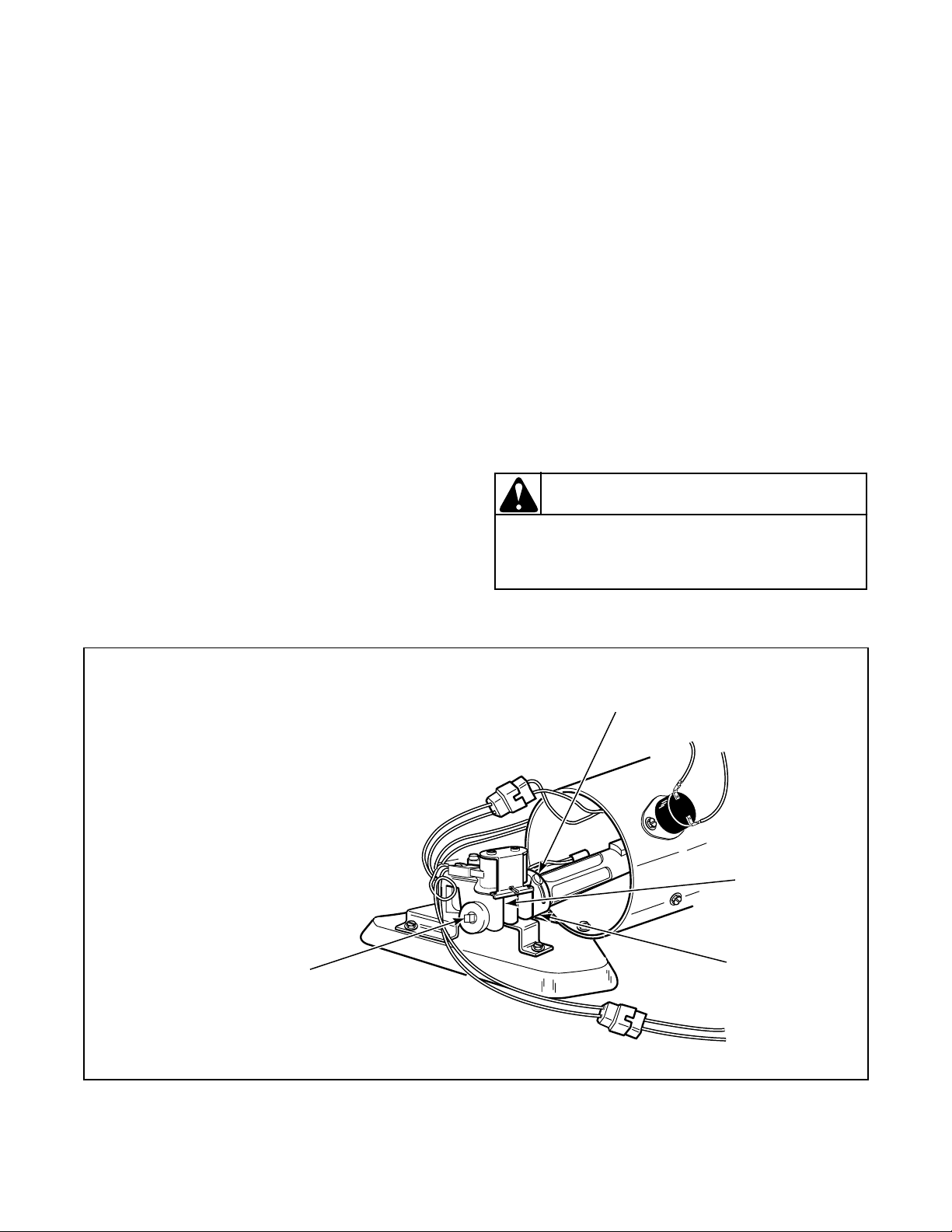

Heat Source Check . . .

For personal safety, lower front panel must

be in place during normal operation.

W046

WARNING

Electric Dryers

Close the loading door and start the dryer in a heat

setting (refer to the Operating Instructions supplied

with the dryer). After the dryer has operated for three

Gas Dryers

To view the burner flame, remove the lower front panel

of the dryer.

Close the loading door, start the dryer in a heat setting

(refer to the Operating Instructions supplied with the

dryer); the dryer will start, the igniter will glow red and

the main burner will ignite.

IMPORTANT: If all air is not purged out of gas

line, gas igniter may go off before gas is ignited. If

this happens, after approximately two minutes

igniter will again attempt gas ignition.

After the dryer has operated for approximately five

minutes, observe burner flame through lower front

panel. Adjust the air shutter to obtain a soft, uniform

blue flame. (A lazy, yellow tipped flame indicates lack

of air. A harsh, roaring, very blue flame indicates too

much air.) Adjust the air shutter as follows:

minutes, the exhaust air or exhaust pipe should be

warm.

a. Loosen the air shutter lockscrew.

b. Turn the air shutter to the left to get a luminous

yellow-tipped flame, then turn it back slowly to the

right to obtain a steady, soft blue flame.

c. After the air shutter is adjusted for proper flame,

tighten the air shutter lockscrew securely.

d. Reinstall the lower front panel.

After the dryer has operated for approximately three

minutes, exhaust air or exhaust pipe should be warm.

1/8" (3.1 mm) PIPE PLUG

(For checking

manifold pressure)

AIR SHUTTER

LOCKSCREW

APPLIANCE

MAIN GAS

VALVE

AIR

SHUTTER

D316IE3A

504607

9

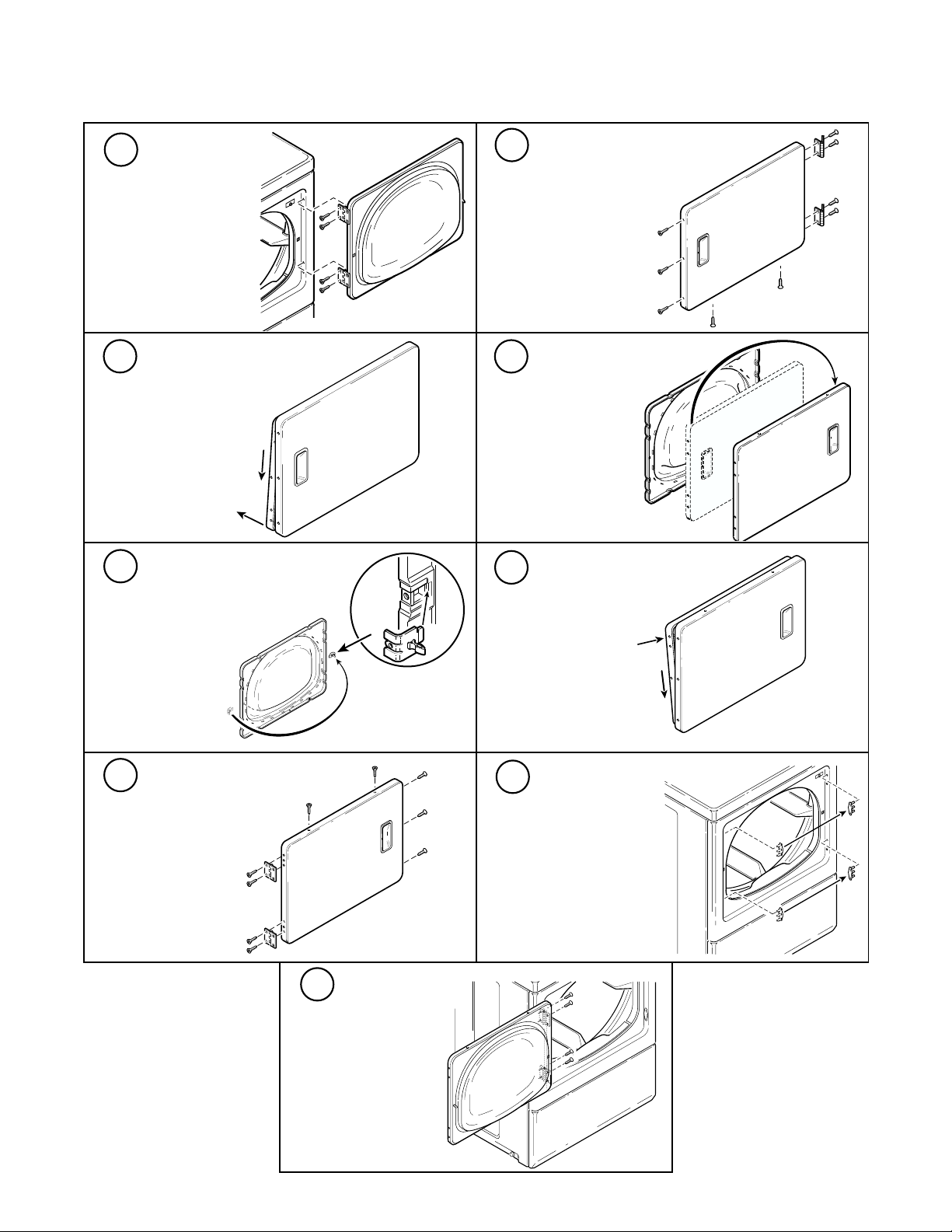

Reversing Door Procedure . . .

The door on this dryer is completely reversible. To reverse door proceed as follows:

1

Remove four

hinge attaching

screws.

3

Pull bottom of

door liner out,

then pull down,

removing door

liner from door

panel.

5

2

Remove all nine screws.

D271PE1B

D272PE1A

4

Rotate door panel

180 degrees

as shown.

B

A

D268PE1A

D273PE1C

6

Remove door strike

from door liner

and reinstall on

opposite side.

7

Reinstall nine screws

removed in Step 2.

D276PE1B

D270PE1B

9

Reinstall four hinge

attaching screws

removed in Step 1.

Insert liner under

flange on bottom of

door, then push

B

top of door

liner into place.

8

Using a screwdriver,

remove two door plugs,

and reinstall on

opposite side of

door opening.

A

D269PE1C

D274PE1A

10

D275PE1A

504607

Manufactured (Mobile) Home

To reduce the risk of fire, the exhaust duct

and weather hood MUST be fabricated of a

material that will not support combustion.

Rigid or flexible metal pipe is recommended

for a clothes dryer.

W048

WARNING

Installation . . .

IMPORTANT: Installation must conform to

the Manufactured Home Construction and

Safety Standards, Title 24 CFR, Part 32-80 or

Standard CAN/CSA-Z240 MH.

The dryer can be installed in a manufactured (mobile)

home by following these instructions:

1. IMPORTANT: Gas dryers MUST be

permanently attached to the floor at the time of

installation. Order No. 526P3 Dryer Installation

Kit for a manufactured (mobile) home

installation. Follow the instructions supplied

with the kit.

2. Electrical Connections (Electric Dryer Only) must

be a 4-wire connection, refer to page 13.

3. Venting—Dryer MUST be exhausted to the

outdoors.

WARNING

To reduce the risk of fire and combustion

gas accumulation, the dryer MUST BE

EXHAUSTED TO THE OUTDOORS. Refer to

Section on Dryer Exhaust Requirements.

W047

• The dryer can be exhausted to the outdoors through

the back, left, right or bottom panel. Gas dryers

cannot be exhausted out the left side because of the

burner housing.

• Dryer exhaust duct MUST NOT terminate under the

mobile home.

• For proper operation, it is important that the dryer

has an ample amount of outside make-up air. The

free area of any opening for the introduction of

outside air must be at least 25 in

• When exhausting the dryer to the outdoors, the dryer

can be installed with “0” inch clearance at the sides

and rear. Clearance of the duct from combustible

construction must be a minimum of 2 inches (5.08

cm).

• Venting materials are not supplied with the dryer

(obtain locally).

2

(163 cm2).

• The dryer exhaust duct must be secured to the

mobile home structure.

• Exhaust ducts MUST NOT be connected with sheet

metal screws or fasteners which extend into the duct.

• Exhaust duct must not be connected to any other

duct, vent or chimney.

504607

11

Electrical Requirements . . .

(Electric Dryers)

NOTE: The wiring diagram is located inside the

control hood.

WARNING

To reduce the risk of fire, electric shock,

serious injury or death, all wiring and

grounding MUST conform with the latest

edition of the National Electrical Code,

ANSI/NFPA 70, or the Canadian Electrical

Code, CSA C22.1, and such local

regulations as might apply. It is the

customer’s responsibility to have the wiring

and fuses checked by a qualified electrician

to make sure your home has adequate

electrical power to operate the dryer.

W113

NOTE: The power cord (pigtail) is NOT supplied with the

electric dryer. Type of pigtail and gauge of wire must conform

to local codes and instructions.

The method of wiring the dryer is optional and subject to local

code requirements.

NOTE: Connect the dryer to the power supply with the

MAXIMUM RATED VOLTAGE listed on the nameplate.

Grounding Instructions

This dryer must be connected to a grounded metal,

permanent wiring system; or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on the dryer.

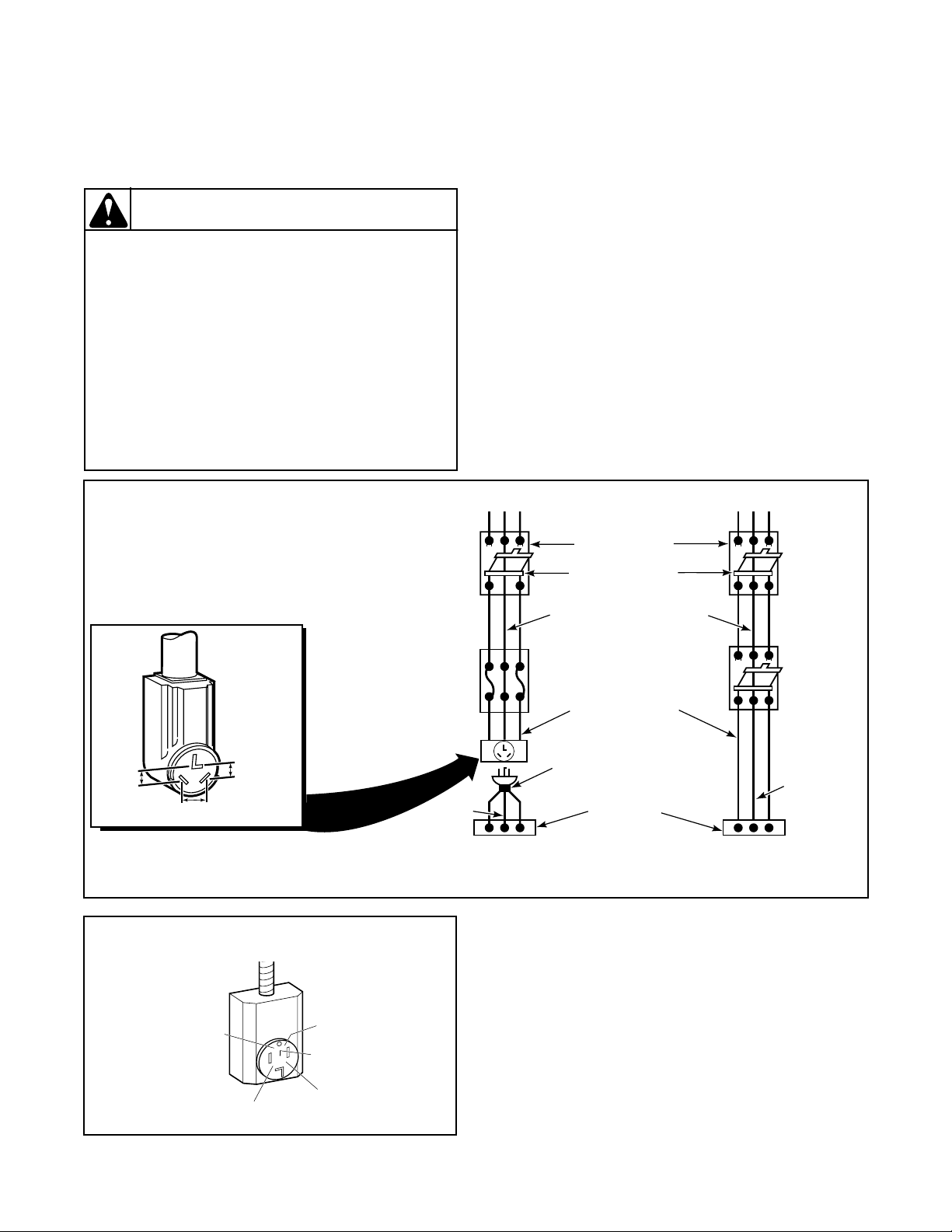

POWER SUPPLY POWER SUPPLY

3-WIRE GROUNDED NEUTRAL

120/240 VOLT, 60 HERTZ AC 1 PHASE

SERVICE ENTRANCE SWITCH BOX

(SEE NOTE BELOW)

30 AMPERE FUSES OR

CIRCUIT BREAKER

NEUTRAL WIRE NEUTRAL WIRE

A typical

30-Amp

Three-wire

Receptacle

NEMA Type

10-30R

120 ± 12

120 ± 12

VAC

240 ± 12

VAC

VAC

NOTE: Use COPPER WIRE only.

Shorter than 15' (4.5 m) use 10 A.W.G.

Longer than 15' (4.5 m) use 8 A.W.G.

A typical 30-Amp

Four-wire Receptacle

120 ± 12

120 ± 12

VAC

VAC

240 ± 12

VAC

INTERMEDIATE

FUSE BOX

(MAY BE

OMITTED IF

SERVICE

ENTRANCE

BOX IS FUSED)

WALL

RECEPTACLE

NEUTRAL

L1 L2

PIGTAIL CONNECTION

METALLIC OR

NON-METALLIC

SHEATHED CABLE

(COPPER WIRE

ONLY)

PIGTAIL

TO DRYER

(SEE NOTE BELOW)

TERMINAL BLOCK

IN DRYER

INTERMEDIATE

SHUT-OFF BOX

(MAY OR MAY

NOT BE FUSED)

NEUTRAL

L1 L2

DIRECT CONNECTION

D003IE3A

12

120 ± 12

VAC

120 ± 12

VAC

D006IE1F

504607

Electrical Plug Connection . . .

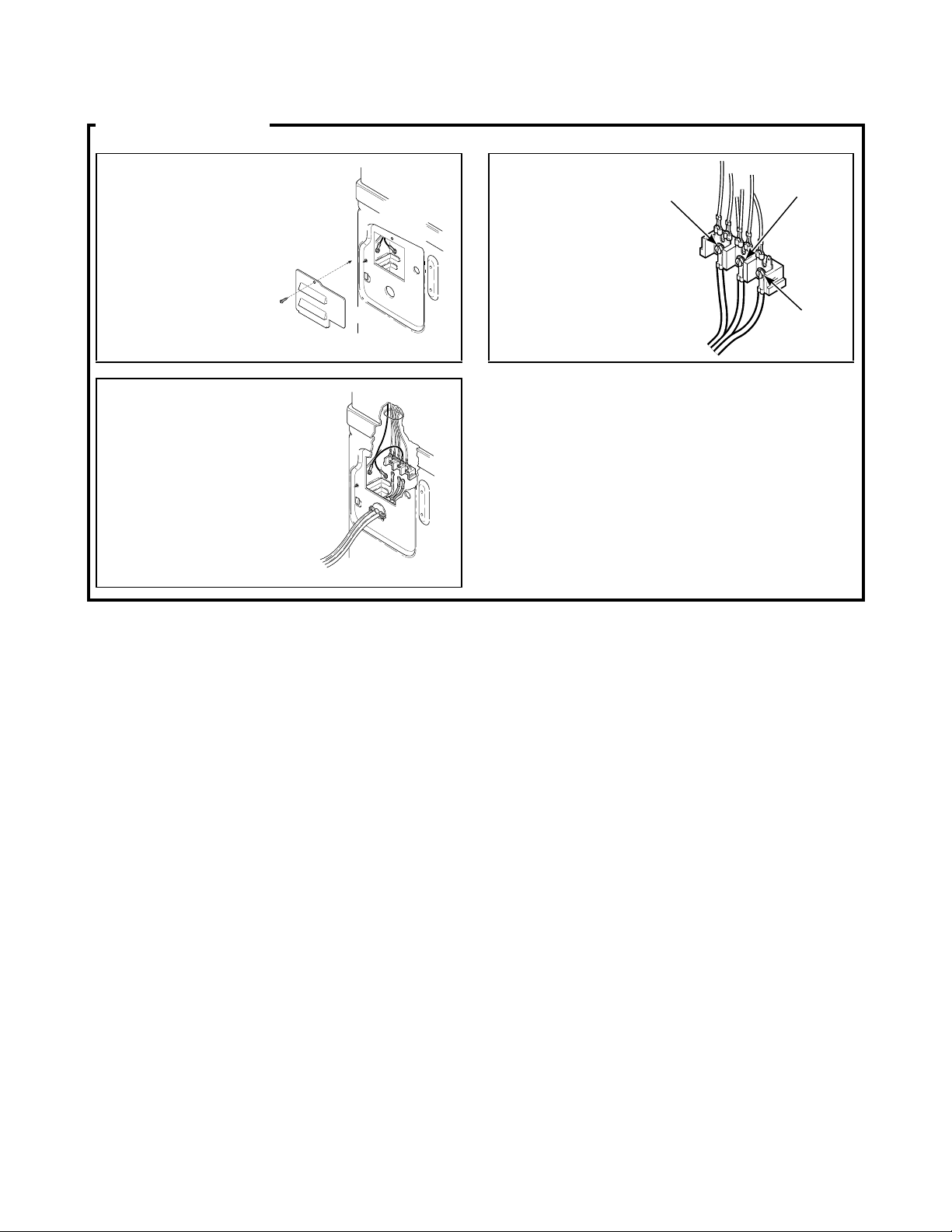

Three-Wire Plug

1. Remove access

cover from rear of

dryer.

2. Use a strain relief and insert

end of power cord through

power supply hole.

D284IE0C

D285IE0D

3. Use the three

screws from

"L1"

TERMINAL

NEUTRAL

TERMINAL

the envelope

located in the

cylinder to attach

the power cord

wires to the

terminal block.

"L2"

TERMINAL

D286IE0B

4. Tighten all screws and reinstall access cover

removed in Step 1.

504607

13

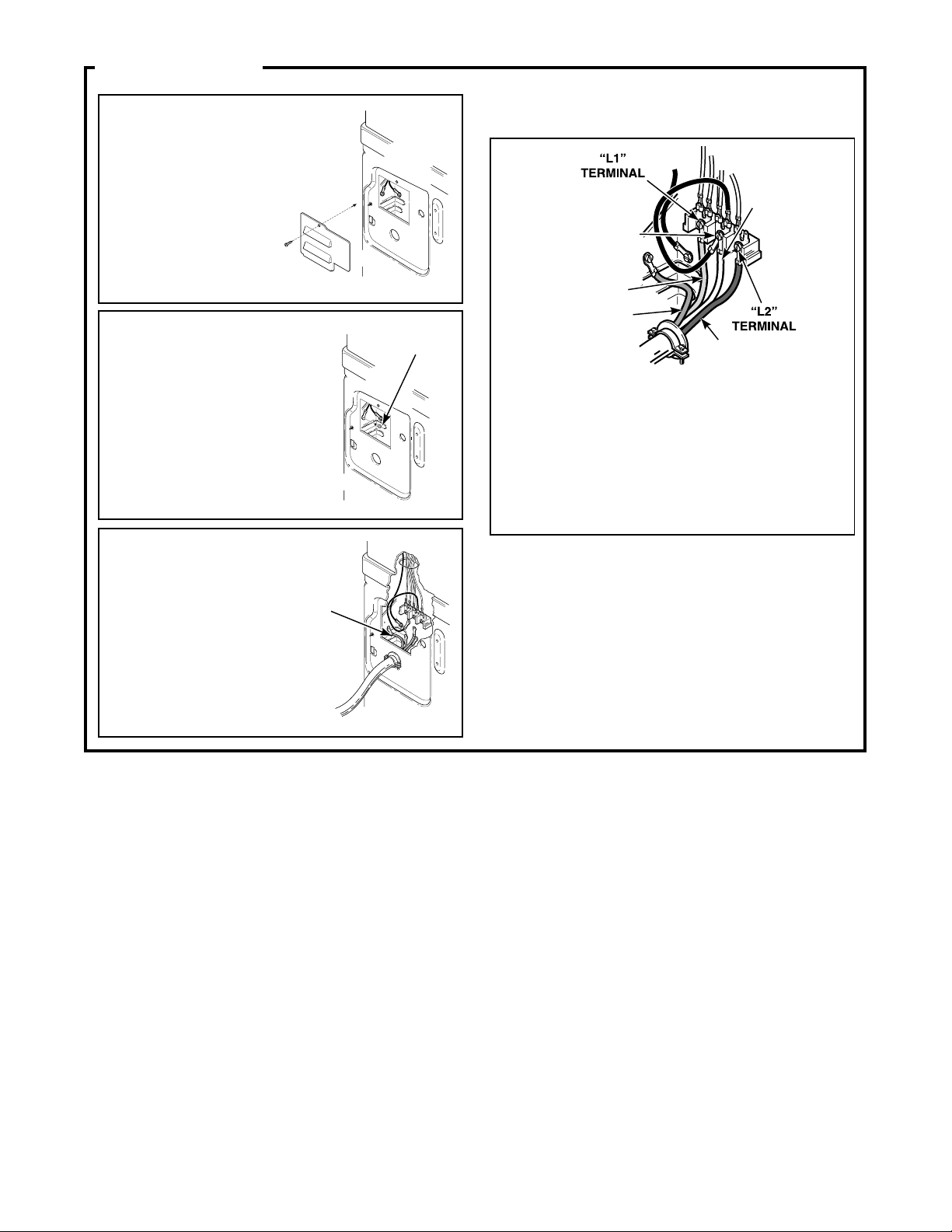

Four-Wire Plug

1. Remove access cover

from rear of dryer.

4. Attach power cord ground (green) wire to rear

bulkhead using ground screw removed in Step 2.

WHITE

NEUTRAL

TERMINAL

2. Remove ground screw and

save for use in Step 4.

Remove wire and use in

Step 5.

3. Use a strain relief

and insert end of

power cord

through power

supply hole.

POWER

CORD

GROUND

WIRE

D284IE0C

GROUND

SCREW

D287IE0E

D288IE0D

RED

GREEN

BLACK

D289IE0C

5. Use the three screws from the envelope located

in the cylinder to attach the remaining power

cord wires to the terminal block as follows:

a. Red wire to “L1” terminal.

b. Black wire to “L2” terminal.

c. White wire to Neutral terminal.

NOTE: When installing the white wire, loop the

free eyelet end of the ground wire (removed in Step

2) and attach along with the white wire to the

neutral (center) terminal on the terminal block.

6. Tighten all screws and reinstall access cover

removed in Step 1.

14

504607

Loading...

Loading...