Alliance Laundry Systems BWT820WN1102, BWT820QN1102, BWT820LN1102, BWT920WN1102, BWTT20WN Troubleshooting Manual

...

Commercial

H002C

Automatic

Washer

Metered and Nonmetered

Refer to Page 6 for Model Numbers

Troubleshooting

www.comlaundry.com

Part No. 39201R8

December 2009

Table of

Section 1 – Safety Information ...............................................................3

Locating an Authorized Servicer...........................................................4

Contents

Section 2 – Introduction..........................................................................5

Customer Service...................................................................................5

Nameplate Location...............................................................................5

Model Identification..............................................................................6

Theory of Operation ............................................................................15

Section 3 – General Troubleshooting...................................................17

1. Clicking Noise During Operation on NEWLY Installed Units ..17

2. No Hot Water..............................................................................18

3. No Cold Water ............................................................................19

4. No Warm Water..........................................................................20

5. Water Fill Does Not Stop At Proper Level.................................21

6. Timer Does Not Advance (Models with Timer Only)................22

7. Motor Does Not Run...................................................................23

8. No Agitation................................................................................24

9. Constant Agitation ......................................................................25

10. Washer Overheats, Cycles On Motor Thermal Protector, Switch

Actuator Kicks In and Out..........................................................26

11. Slow Spin Or No Spin.................................................................27

12. Constant Spin..............................................................................28

13. Washer Stops In Cycle; Quits After A Couple Loads; Is

Intermittent..................................................................................29

14. Washer Is Locked Up Or Binding...............................................30

15. Outer Tub Does Not Empty ........................................................31

16. Excessive Vibration ....................................................................32

17. Water Leaking From Outer Tub..................................................33

18. Troubleshooting Coin Drop........................................................34

Coin Slide Operated and Non-Metered Models with the Number

“8” or “9” in the 4th Character of the Model Number ...............39

19. Error Mode..................................................................................39

20. Coin Slide Can Not Fully Insert..................................................40

21. Coin Slide Fully Inserts, Switch Does Not Activate...................41

22. Switch Is Activated Too Soon ....................................................42

23. Coin Slide Does Not Return Freely............................................43

24. No Cycle Start When the Coin Slide is Activated ......................44

25. Washer Will Not Fill (Pressure Switch Diagnostic)...................46

26. Washer Will Not Fill (Mixing Valve Diagnostic) ......................48

27. Washer Over Fills (Pressure Switch Open) ................................50

28. No Agitation – Low and High Speed..........................................52

29. Washer Will Not Spin – Low Speed...........................................54

30. Washer Will Not Spin – High Speed..........................................56

EDC Models.....................................................................................59

31. EDC Error Code Listing .............................................................59

© Copyright 2009, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

39201 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

32. Cannot Perform Infrared Communication ..................................60

33. Coins Ignored When Entered......................................................61

34. Electronic Control Has No Visible Display................................62

35. No Fill Analysis ..........................................................................64

36. No Motor Run — Agitate Analysis ............................................66

37. No Motor Run — Spin Analysis.................................................68

38. Overflow Analysis ......................................................................70

39. Audit Switch Function Analysis.................................................72

MDC Models....................................................................................73

40. MDC Error Code Listing ............................................................73

41. No Visible Display on Control....................................................74

42. Coins Ignored When Entered......................................................76

43. Washer Will Not Fill (Pressure Switch Diagnostic)...................78

44. Washer Will Not Fill (Mixing Valve Diagnostic) ......................80

45. Washer Over Fills (Pressure Switch Open) ................................82

46. No Agitation – Low and High Speed..........................................84

47. Washer Will Not Spin – High Speed..........................................86

48. Washer Will Not Spin – Low Speed...........................................88

NetMaster Models...........................................................................91

49. NetMaster Error Code Listing.....................................................91

50. Microwand Does Not Communicate With Control ....................95

51. No Visible Display on Control....................................................96

52. Coins Ignored When Entered......................................................98

53. Washer Will Not Fill (Pressure Switch Diagnostic).................100

54. Washer Will Not Fill (Mixing Valve Diagnostic) ....................102

55. Washer Over Fills .....................................................................104

56. No Agitation – Low and High Speed........................................106

57. Washer Will Not Spin – High Speed........................................108

58. Washer Will Not Spin – Low Speed.........................................110

Section 4 – Adjustments......................................................................113

59. Leveling Legs............................................................................113

60. Pressure Switch.........................................................................114

61. Belt (Agitate and Spin) .............................................................114

62. Cleaning Non-Electronic Coin Drop.........................................114

63. Cleaning Electronic Coin Drop.................................................116

Section 5 – Motor Test Procedure......................................................119

Section 6 – Cycle Sequence Charts.....................................................121

Timer No. 28716P and 28719 Cycle Sequence ..............................121

Timer No. 31111P, 31504P and 35368P Cycle Sequence..............122

Timer No. 36986 Cycle Sequence ..................................................123

Timer No. 34601P, 34603P, 34604 and 36987 Cycle Sequence....124

Timer No. 34602P Cycle Sequence................................................125

Timer No. 200914 Cycle Sequence ................................................126

Timer No. 201066 Cycle Sequence ................................................127

Cycle Sequence For Coin Slide Operated/Non-Metered Models ...128

2 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 1

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or property

damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

WARNING

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING,” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer and those maintaining the machine.

a DANGER

Danger indicates an imminently hazardous situation that, if not avoided, will cause severe personal injury or death.

a WARNING

Warning indicates a hazardous situation that, if not avoided, could cause severe personal injury or death.

a CAUTION

Caution indicates a hazardous situation that, if not avoided, may cause minor or moderate personal injury or property

damage.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

In the interest of safety, some general precautions relating to the operation of this machine follow.

39201 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Safety Information

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

W007

WARNING

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W008

WARNING

NOTE: The WARNINGS and IMPORTANT INSTRUCTIONS appearing in this manual are not meant to

cover all possible conditions and situations that may occur. Common sense, caution and care must be

exercised when installing, maintaining or operating the washer.

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do

not understand.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for personal injury or property damage resulting from improper

service. Review all service information before beginning repairs.

Warranty service must be performed by an authorized technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry Systems also recommends contacting an authorized technician

and using authorized factory parts.

4 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 2

W363PE3A

Nameplate

Introduction

Customer Service

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

For technical assistance, call either of the numbers

listed below:

(920) 748-3121 Ripon, Wisconsin

+32 56 41 20 54 Wevelgem, Belgium

Nameplate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

39201 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

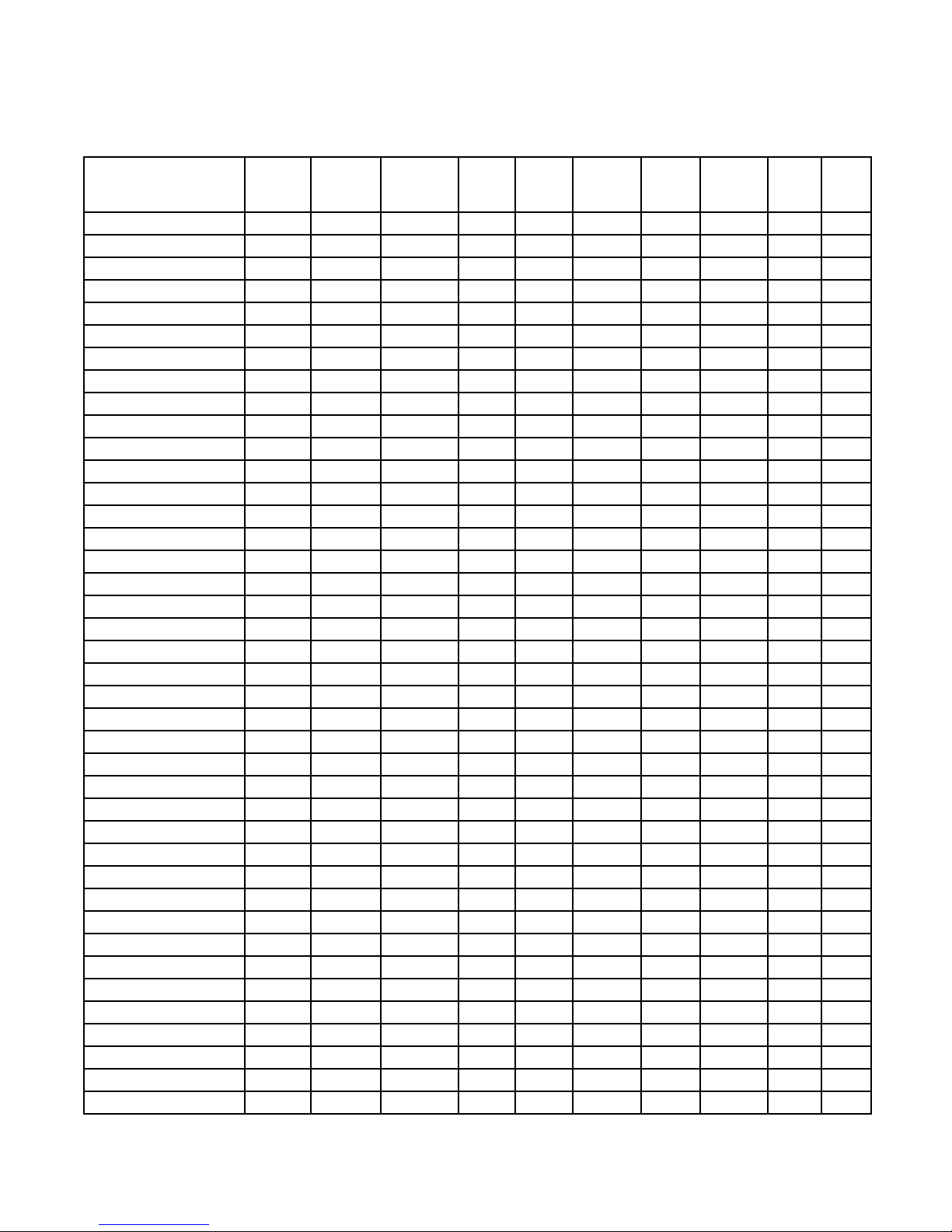

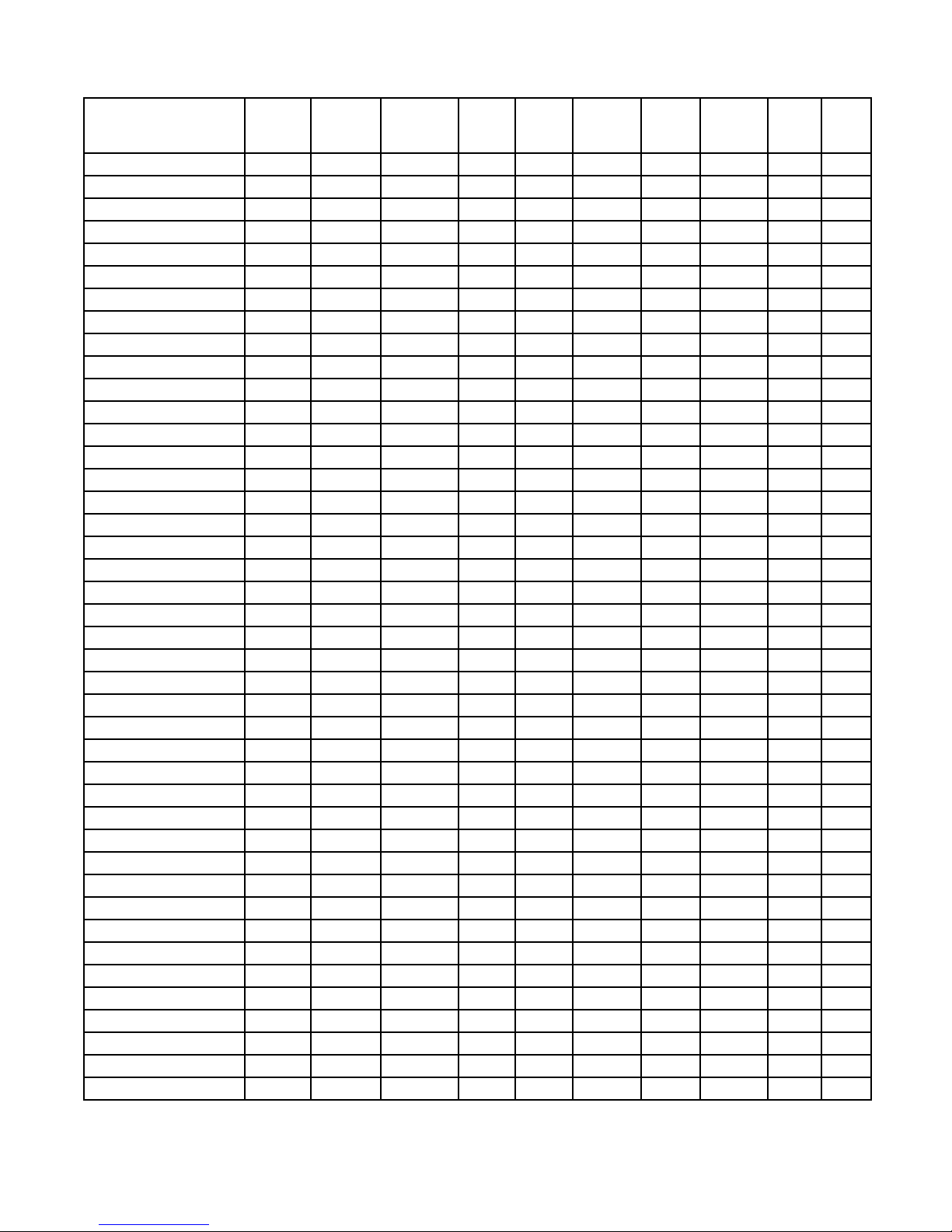

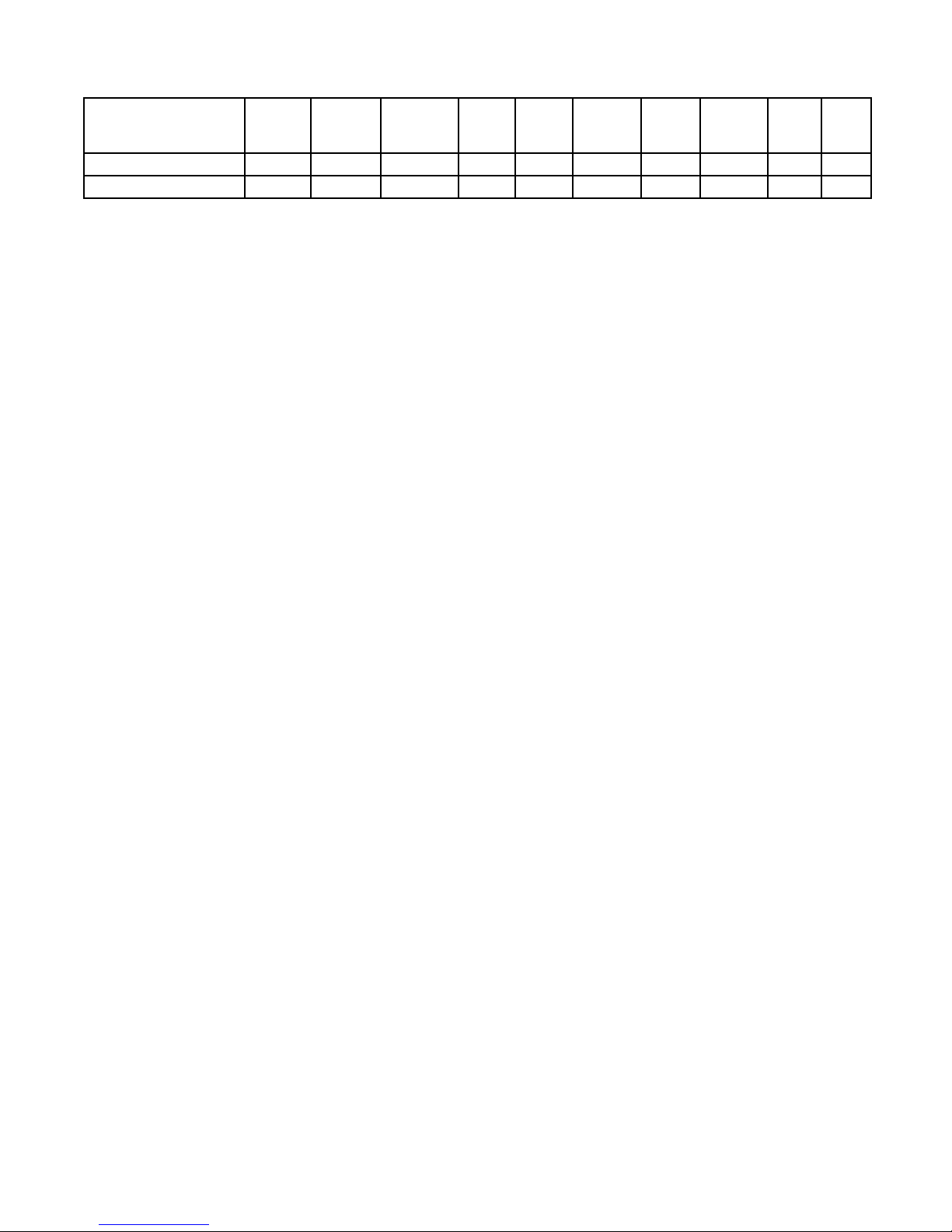

Model Identification

Information in this manual is applicable to these washers.

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

BWT820*N1102 X 2 P

BWT920*N1102 X X 2 P

BWTT20*N X X X 2 P

HWLX21*N1102 X X X 2 S

HWT011*B3073 X 1 S

HWT020*A X 2 P

HWT020*C X 2 P

HWT020*M X 2 P

HWT020*N X 2 P

HWT021*A1102 X 2 S

HWT021*C1102 X 2 S

HWT021*M1102 X 2 S

HWT021*N1102 X 2 S

HWT110*A X X 1 P

HWT110*C X X 1 P

HWT110*M X X 1 P

HWT110*N X X 1 P

HWT111*A1102 X X 1 S

HWT111*A3000 X X 1 S

HWT111*B3069 X X 1 S

HWT111*C1102 X X 1 S

HWT111*C3000 X X 1 S

HWT111*M1102 X X 1 S

HWT111*M3000 X X 1 S

HWT111*N1102 X X 1 S

HWT120*A X X 2 P

HWT120*C X X 2 P

HWT120*M X X 2 P

HWT120*N X X 2 P

HWT121*A1102 X X 2 S

HWT121*C1102 X X 2 S

HWT121*C1123 X X 2 S

HWT121*M1102 X X 2 S

HWT121*M1123 X X 2 S

HWT121*N1102 X X 2 S

HWT1A0*N X X 2 P

HWT210*A1102 X X 1 P

HWT210*C1102 X X 1 P

HWT210*M1102 X X 1 P

HWT210*N1102 X X 1 P

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

6 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

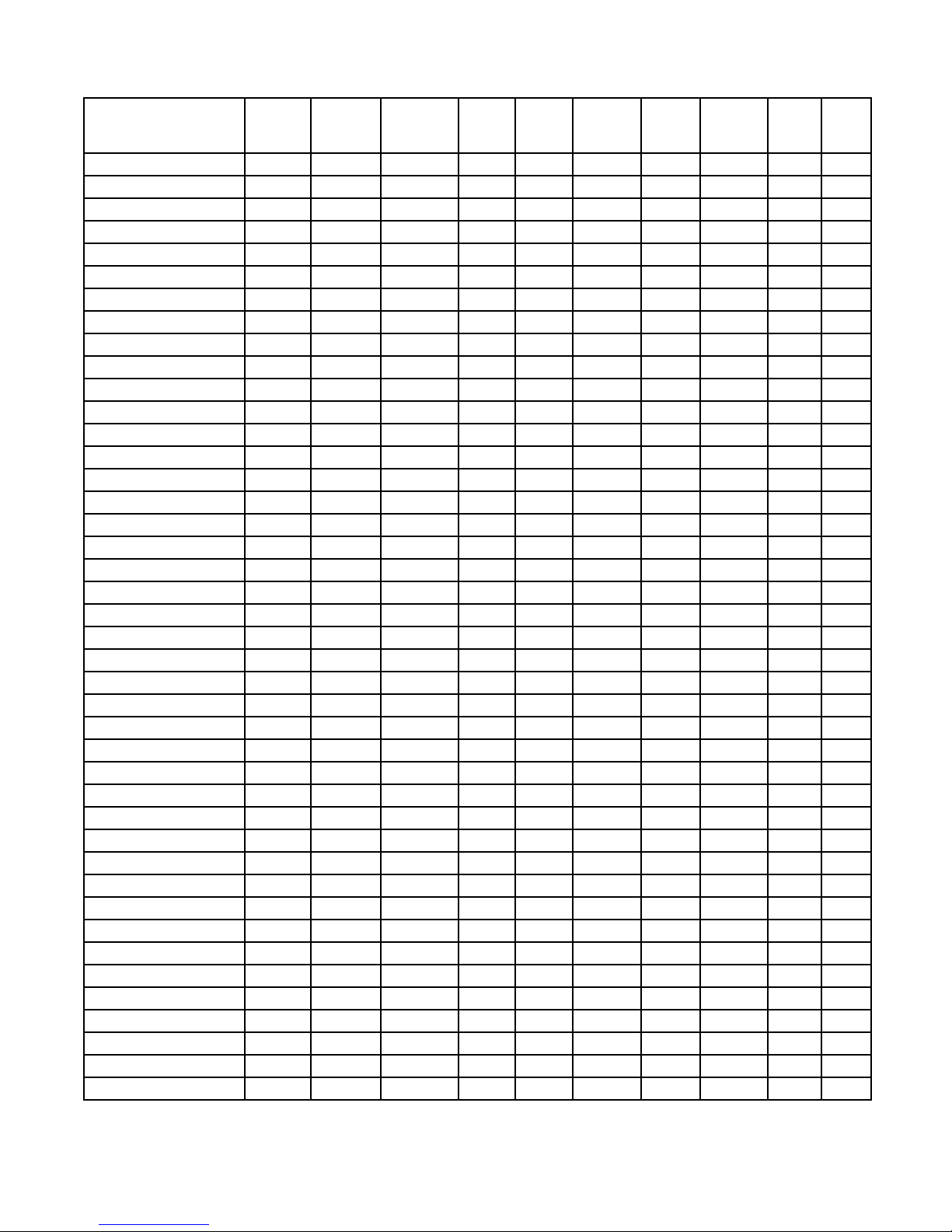

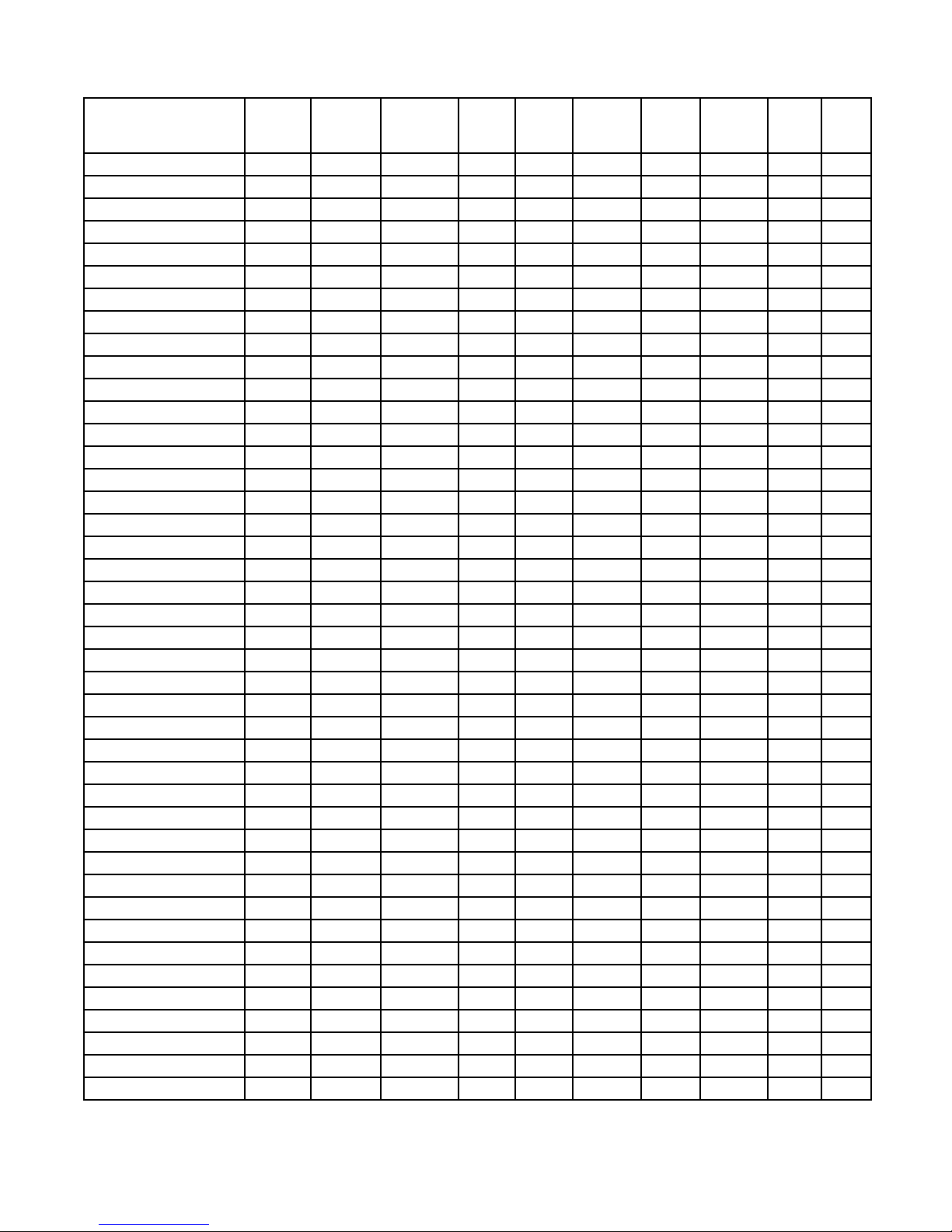

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

HWT211*A3000 X X 1 S

HWT211*B3020 X X 1 S

HWT211*C1102 X X 1 S

HWT211*C3000 X X 1 S

HWT211*M3000 X X 1 S

HWT211*M3020 X X 1 S

HWT211*N3020 X X 1 S

HWT220*A1102 X X 2 P

HWT220*C1102 X X 2 P

HWT220*M1102 X X 2 P

HWT220*M3000 X X 2 P

HWT220*M3020 X X 2 P

HWT221*A1102 X X 2 S

HWT221*C1102 X X 2 S

HWT221*M1102 X X 2 S

HWT221*N1102 X X 2 S

HWT221*N1127 X X 2 S

HWT521*A1102 X X X 2 S

HWT521*C1102 X X X 2 S

HWT621*A1102 X X X 2 S

HWT621*C1102 X X X 2 S

HWT721*A1102 X X X 2 S

HWT721*C1102 X X X 2 S

HWT820*N X 2 P

HWT821*N1102 X 2 S

HWT910*N X X 1 P

HWT911*N1102 X X 1 S

HWT911*N3020 X X 1 S

HWT920*N X X 2 P

HWT921*N1102 X X 2 S

HWT921*N1127 X X 2 S

HWTB21*M1102 X X X 2 S

HWTB21*N1102 X X X 2 S

HWTF21*M1102 X X X 2 S

HWTF21*N1102 X X X 2 S

HWTR21*N1102 X X X 2 S

HWTT20*N X X X 2 P

HWTT21*N1102 X X X 2 S

HWTV20*N X X 2 P

HWTX21*M3020 X X X 2 S

HWTX21*M3022 X X X 2 S

HWTX21*N1102 X X X 2 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

39201 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

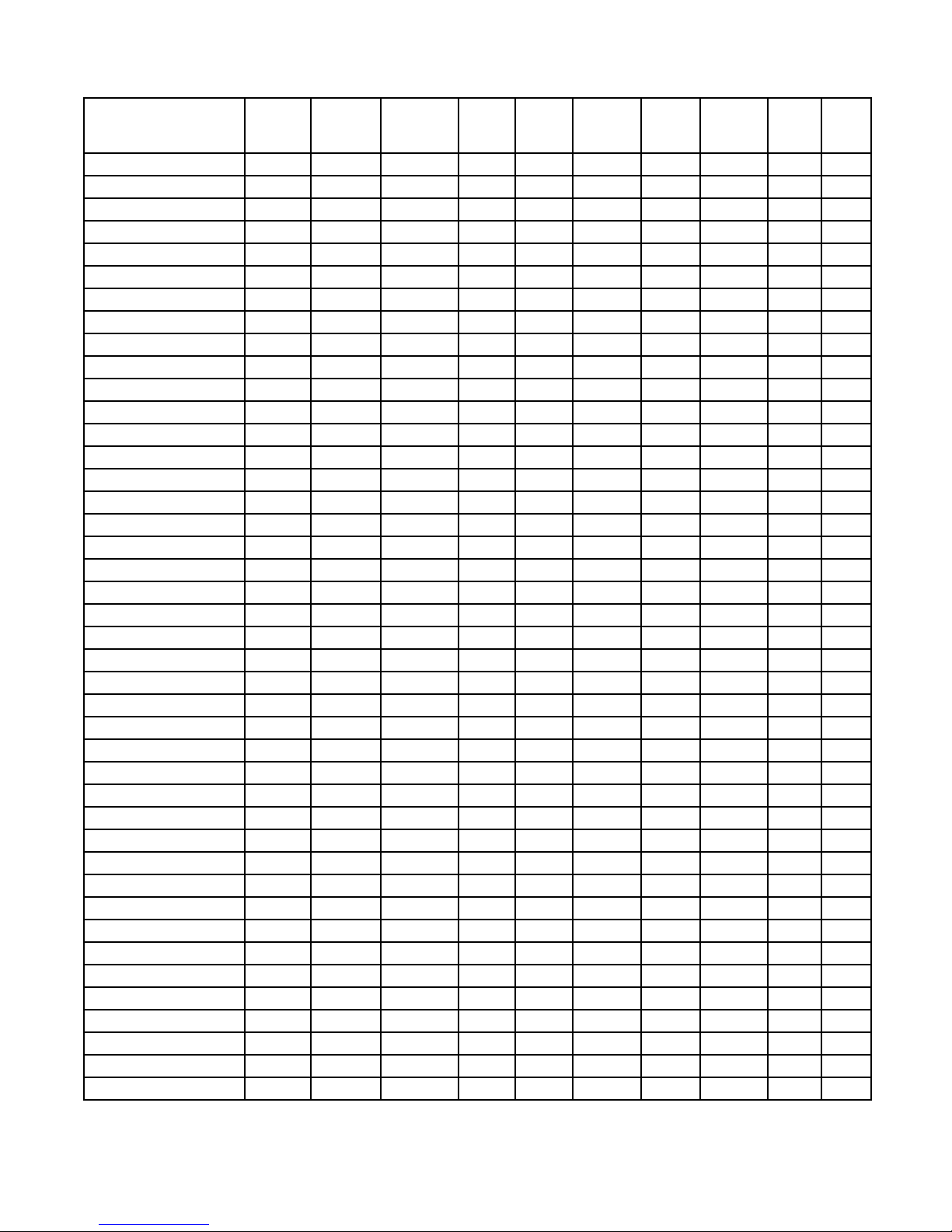

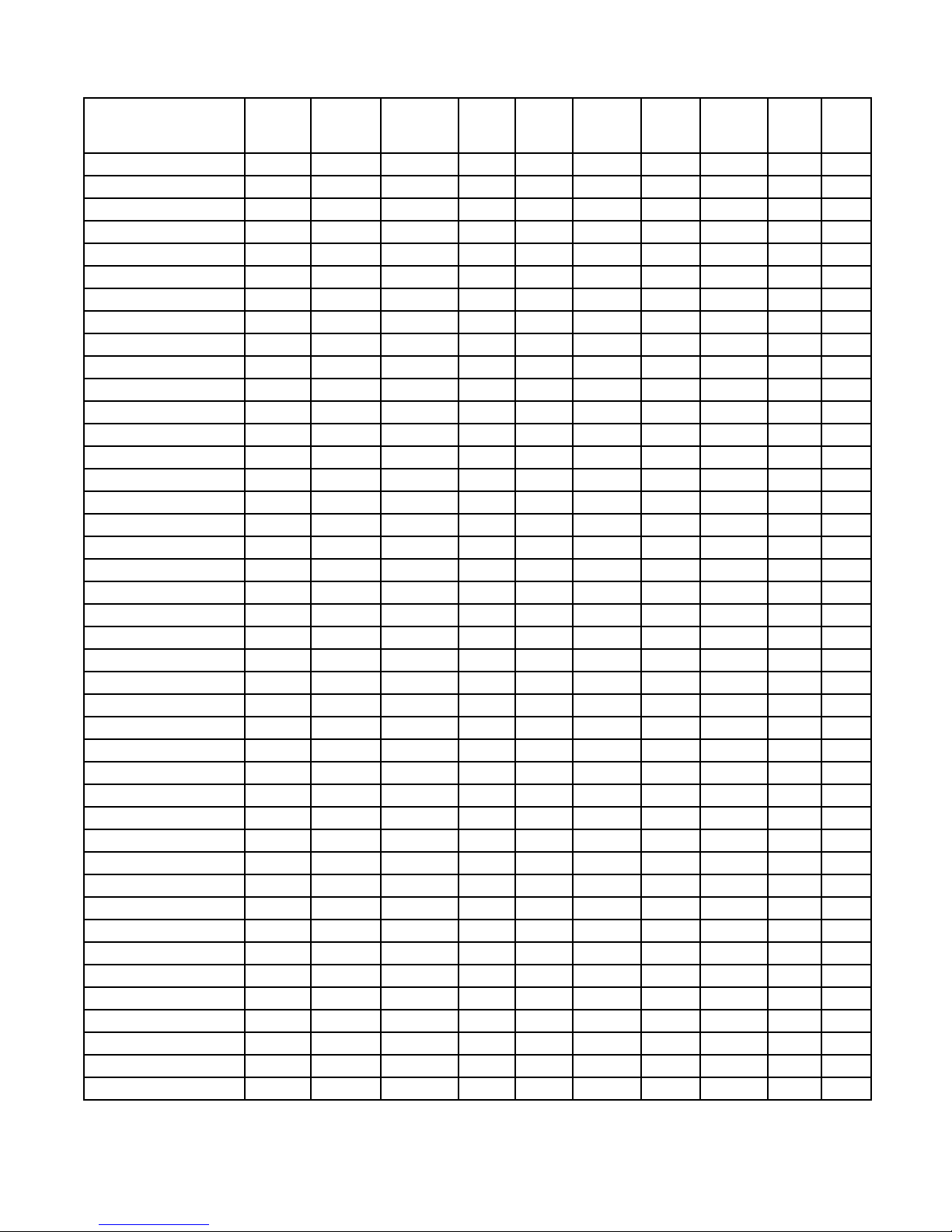

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

HWTX21*N3020 X X X 2 S

HWTX21*N3022 X X X 2 S

HWTY20*M X X X 2 P

HWTY20*N X X X 2 P

HWTY21*M1102 X X X 2 S

HWTY21*N1102 X X X 2 S

HWTZ20*M X X X 2 P

HWTZ20*N X X X 2 P

HWTZ21*M1102 X X X 2 S

HWTZ21*N1102 X X X 2 S

JWT110*A X X 1 P

JWT110*M X X 1 P

JWT110*N X X 1 P

JWT810*N3020 X 1 P

JWT810*N3050 X 1 P

JWT810*N5400 X 1 P

JWT820*N X 2 P

JWT820*N3050 X 2 P

JWT910*N X X 1 P

JWT910*N3020 X X 1 P

JWT910*N3050 X X 1 P

JWT910*N3069 X X 1 P

JWT920*N X X 2 P

JWT920*N3050 X X 2 P

NWNBX2SP301NW22 X X X 2 S

NWT721*A1126 X X X 2 S

NWT811*N5422 X 1 S

NWT821*N3022 X 2 S

NWT911*N5422 X X 1 S

NWT921*N3022 X X 2 S

NWTF21*M1126 X X X 2 S

NWTF21*N1126 X X X 2 S

SWL520*N X X X 2 P

SWL521*N X X X 2 S

SWLB20*N X X X 2 P

SWLB21*N X X X 2 S

SWLF20*N X X X 2 P

SWLF21*N X X X 2 S

SWLT20*N X X X 2 P

SWLT21*N X X X 2 S

SWLY20*N X X X 2 P

SWLY21*N X X X 2 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

8 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

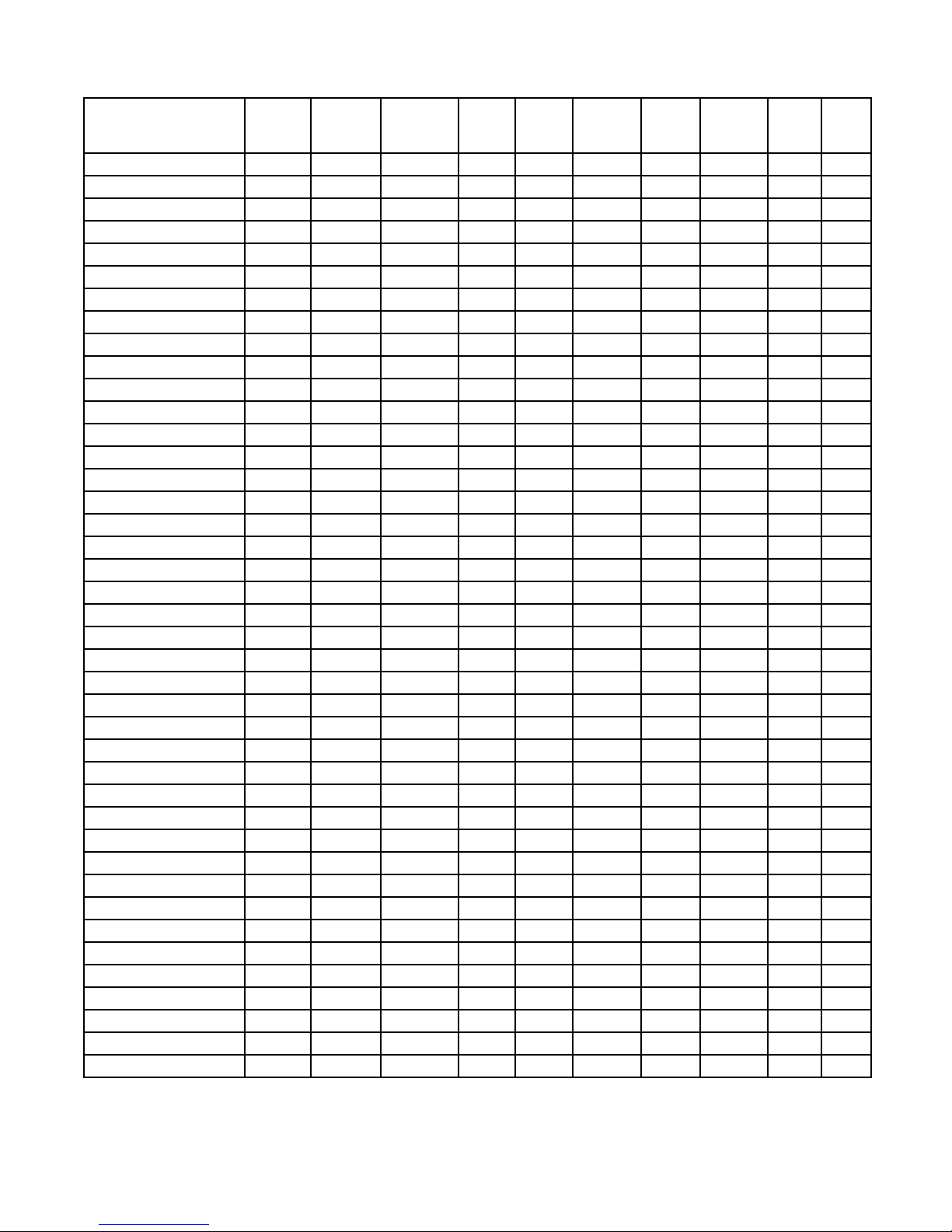

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

SWNBC2PP111TW02 X X X 2 P

SWNSX2PP111TW02 X X 2 P

SWT011*A3000 X 1 S

SWT011*A3022 X 1 S

SWT011*A3028 X 1 S

SWT011*A3050 X 1 S

SWT011*A3062 X 1 S

SWT011*M3000 X 1 S

SWT011*M3022 X 1 S

SWT011*M3050 X 1 S

SWT011*N3000 X 1 S

SWT011*N3022 X 1 S

SWT011*N3028 X 1 S

SWT011*N3050 X 1 S

SWT011*N3062 X 1 S

SWT020*A X 2 P

SWT020*M X 2 P

SWT020*N X 2 P

SWT021*A X 2 S

SWT021*M X 2 S

SWT021*N X 2 S

SWT110*A X X 1 P

SWT110*M X X 1 P

SWT110*N X X 1 P

SWT111*A X X 1 S

SWT111*A1200 X X 1 S

SWT111*A1300 X X 1 S

SWT111*A3000 X X 1 S

SWT111*A3022 X X 1 S

SWT111*A3028 X X 1 S

SWT111*A3050 X X 1 S

SWT111*A5412 X X 1 S

SWT111*B3069 X X 1 S

SWT111*M X X 1 S

SWT111*M1200 X X 1 S

SWT111*M1300 X X 1 S

SWT111*M3000 X X 1 S

SWT111*M3022 X X 1 S

SWT111*M3050 X X 1 S

SWT111*M3069 X X 1 S

SWT111*M5412 X X 1 S

SWT111*N X X 1 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

39201 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

SWT111*N3000 X X 1 S

SWT111*N3022 X X 1 S

SWT111*N3028 X X 1 S

SWT111*N3050 X X 1 S

SWT111*N3069 X X 1 S

SWT111*N5412 X X 1 S

SWT111*N5417 X X 1 S

SWT120*A X X 1 P

SWT120*M X X 1 P

SWT120*N X X 1 P

SWT121*A X X 2 S

SWT121*A3000 X X 2 S

SWT121*M X X 2 S

SWT121*M3000 X X 2 S

SWT121*N X X 2 S

SWT210*A X X 1 P

SWT210*A1124 X X 1 P

SWT210*M X X 1 P

SWT210*M1124 X X 1 P

SWT210*N X X 1 P

SWT210*N1124 X X 1 P

SWT211*A1200 X X 1 S

SWT211*A1300 X X 1 S

SWT211*A3000 X X 1 S

SWT211*A3020 X X 1 S

SWT211*A3022 X X 1 S

SWT211*A3062 X X 1 S

SWT211*B3020 X X 1 S

SWT211*M3000 X X 1 S

SWT211*M3020 X X 1 S

SWT211*M3022 X X 1 S

SWT211*N3000 X X 1 S

SWT211*N3020 X X 1 S

SWT211*N3022 X X 1 S

SWT211*N3050 X X 1 S

SWT211*N3062 X X 1 S

SWT220*A X X 2 P

SWT220*M X X 2 P

SWT220*M1124 X X 2 P

SWT220*N X X 2 P

SWT220*N1124 X X 2 P

SWT221*A X X 2 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

10 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

SWT221*M X X 2 S

SWT221*N X X 2 S

SWT2A0*N X X 2 P

SWT2A0*N1124 X X 2 P

SWT2B0*N1124 X X 1 P

SWT320*A X X 2 P

SWT320*M X X 2 P

SWT321*A X X 2 S

SWT321*M X X 2 S

SWT420*A X X X 2 P

SWT420*D X X X 2 P

SWT420*M X X X 2 P

SWT421*A X X X 2 S

SWT421*A3000 X X X 2 S

SWT421*A3022 X X X 2 S

SWT421*A3028 X X X 2 S

SWT421*A3050 X X X 2 S

SWT421*D X X X 2 S

SWT421*M X X X 2 S

SWT421*M3000 X X X 2 S

SWT421*M3022 X X X 2 S

SWT421*M3050 X X X 2 S

SWT520*A X X X 2 P

SWT520*M X X X 2 P

SWT520*N X X X 2 P

SWT521*A X X X 2 S

SWT521*A1119 X X X 2 S

SWT521*M X X X 2 S

SWT521*N X X X 2 S

SWT620*A X X X 2 P

SWT620*C X X X 2 P

SWT620*D X X X 2 P

SWT620*M X X X 2 P

SWT621*C X X X 2 S

SWT621*D X X X 2 S

SWT621*D1121 X X X 2 S

SWT621*M X X X 2 S

SWT621*M1121 X X X 2 S

SWT720*A X X X 2 P

SWT720*M X X X 2 P

SWT721*A X X X 2 S

SWT721*M X X X 2 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

39201 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

SWT811*N3000 X 1 S

SWT811*N3022 X 1 S

SWT811*N3050 X 1 S

SWT811*N3062 X 1 S

SWT820*N X 2 P

SWT821*N X 2 S

SWT910*N X X 1 P

SWT910*N1124 X X 1 P

SWT910*N3050 X X 1 P

SWT911*N X X 1 S

SWT911*N3000 X X 1 S

SWT911*N3020 X X 1 S

SWT911*N3022 X X 1 S

SWT911*N3028 X X 1 S

SWT911*N3050 X X 1 S

SWT911*N3062 X X 1 S

SWT911*N3069 X X 1 S

SWT911*N5412 X X 1 S

SWT920*N X X 2 P

SWT920*N1124 X X 2 P

SWT921*N X X 2 S

SWTA21*M X X X 2 S

SWTA21*M3022 X X X 2 S

SWTA21*M3050 X X X 2 S

SWTA21*N X X X 2 S

SWTA21*N3050 X X X 2 S

SWTB20*M X X X 2 P

SWTB20*N X X X 2 P

SWTB21*M X X X 2 S

SWTB21*N X X X 2 S

SWTBA0*N X X X 2 P

SWTBA1*N X X X 2 S

SWTC20*M X X X 2 P

SWTC20*N X X X 2 P

SWTC21*M X X X 2 S

SWTC21*N X X X 2 S

SWTF20*M X X X 2 P

SWTF20*N X X X 2 P

SWTF21*M X X X 2 S

SWTF21*M3050 X X X 2 S

SWTF21*N X X X 2 S

SWTF21*N3050 X X X 2 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

12 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

SWTH20*M X X X 2 P

SWTH20*N X X X 2 P

SWTH21*M X X X 2 S

SWTH21*N X X X 2 S

SWTJ21*M X X X 2 S

SWTJ21*N X X X 2 S

SWTT20*M X X X 2 P

SWTT20*N X X X 2 P

SWTT20*N99M6 X X X 2 P

SWTT21*M X X X 2 S

SWTT21*N X X X 2 S

SWTV20*N X X 2 P

SWTW20*N X X 2 P

SWTW21*N X X 2 S

SWTX21*M X X X 2 S

SWTX21*M3000 X X X 2 S

SWTX21*M3020 X X X 2 S

SWTX21*M3022 X X X 2 S

SWTX21*M3050 X X X 2 S

SWTX21*M3069 X X X 2 S

SWTX21*N X X X 2 S

SWTX21*N1127 X X X 2 S

SWTX21*N3000 X X X 2 S

SWTX21*N3020 X X X 2 S

SWTX21*N3022 X X X 2 S

SWTX21*N3050 X X X 2 S

SWTX21*N3069 X X X 2 S

SWTY20*M X X X 2 P

SWTY20*N X X X 2 P

SWTY21*M X X X 2 S

SWTY21*N X X X 2 S

SWTZ20*M X X X 2 P

SWTZ20*N X X X 2 P

SWTZ21*M X X X 2 S

SWTZ21*N X X X 2 S

UWT011*A3022 X 1 S

UWT011*A3025 X 1 S

UWT011*M3022 X 1 S

UWT021*A X 2 S

UWT021*M X 2 S

UWT021*N X 2 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

39201 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Introduction

Washer

Model

Non-

metered

Metered

Electronic

Control

Coin

Slide

Ready

Coin

Drop

Ready

Coin

Drop

Installed

Card

Reader

Ready

Card

Reader

Installed

Motor

Speed

Wash-

tub

UWT821*N X 2 S

UWT821*N1102 X 2 S

* Add Letter To Designate Color. L – Almond W – White Q – Bisque

Key: 1 = 1 Speed Motor, 2 = 2 Speed Motor, P = Porcelain Washtub, S = Stainless Steel Washtub

14 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

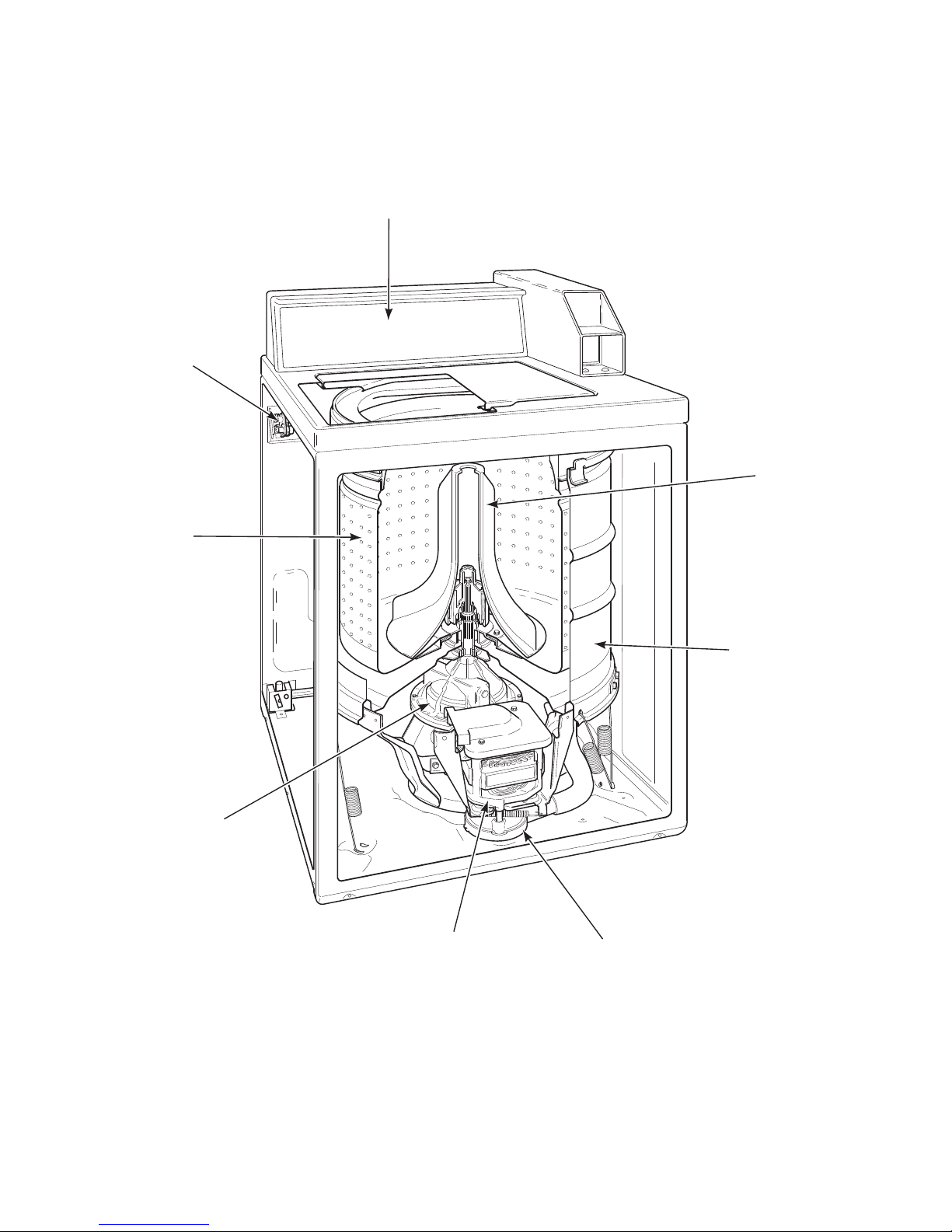

Theory of Operation

Mixing

Valve

Introduction

Pressure Switch

(Located

inside control

hood)

Agitator

Washtub

Transmission

Motor

Pump

Outer

Tub

W488SE3B

The cycle begins with a wash fill. The water

temperature is determined by the temperature selected.

While water fills the washtub, a column of air is

trapped in a pressure bulb and hose. The air pressure

continues to increase as the washtub fills with water

until it is great enough to activate the pressure switch.

The pressure switch then causes the wash fill to stop

39201 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

and wash agitation to begin. However, the lid must be

closed for the washer to agitate or spin.

The washer uses a reversing type motor, a special drive

belt and an idler assembly. The idler assembly applies

tension to the outside of the drive belt.

During agitation, the motor runs in the

counterclockwise direction. The spring tension on the

idler pulley applies the tension required to reduce the

slack on the drive belt and maintain maximum belt to

motor pulley contact. This eliminates belt slippage and

ensures an efficient wash action, even with extra large

loads.

The belt drives the transmission drive pulley in the

counterclockwise direction. The pulley drives the helix

which is splined to the input shaft of the transmission.

This causes the input shaft to turn inside of a roller

clutch which is pressed into the transmission cover.

This roller clutch acts as a bearing in the

counterclockwise direction allowing the transmission

gears to operate. The transmission’s rack and pinion

gear design produces a 210 degree agitation stroke at

the output shaft of the transmission which drives the

agitator. The brake assembly remains locked during the

agitation mode since no pressure is applied to it by the

transmission drive pulley.

After the wash agitation is completed, the timer

advances into the first spin. During spin, the motor

reverses turning in the clockwise direction to spin the

water out of the washtub. The combination of water,

washtub and load weight cause the drive belt tension on

the idler side of the belt to overtake the idler spring

pressure allowing the belt to become slack on the

opposite side. This reduces the belt to pulley contact

and allows slipping between the belt and pulley.

As water is removed by the pump and the momentum

of the washtub increases, the idler spring tension

gradually overcomes the belt tension removing the belt

slack. This eventually increases the belt to pulley

contact until maximum spin speed is achieved.

The drive pulley turns clockwise riding up the ramps of

the helix, exerting pressure on the brake and forcing it

to release from brake pads. The helix drives the input

shaft of the transmission, and when the input shaft turns

in the clockwise direction the roller clutch locks onto

the shaft causing the entire transmission assembly to

turn. None of the gears in the transmission are

operating at this time. The hub of the washtub is splined

to the transmission tube and rotates with the

transmission assembly. The centrifugal force created

by the spinning washtub causes water to be extracted

from the clothes.

Water is introduced during the first spin to “SPRAY”

the garments and remove suds from them. The initial

spin is followed by rinse agitation to rinse away any

detergent residue. The washer fills and then agitates

like the wash portion of the cycle. Following rinse

agitation, a final spin extracts the rinse water from the

clothes preparing them for the dryer.

16 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Section 3

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

General Troubleshooting

IMPORTANT: Refer to appropriate model wiring diagram for aid in testing washer components.

1. Clicking Noise During Operation on NEWLY Installed Units

If a clicking noise is heard when first starting up a new

topload washer, the noise is related to the belt taking a

temporary “set” around the idler pulley. The set causes

a slight bump in the belt which in turn causes the idler

lever to tap the motor bracket making the clicking

noise. THE BELT DOES NOT NEED TO BE

REPLACED.

To correct this condition please perform the following

break-in procedure:

1. After installing the unit start a fill cycle to

make sure the seals have been lubricated.

2. Stop the fill cycle and place the unit into a

spin cycle.

3. Run the cycle for several minutes until the

belt has warmed up. This will remove the

“set.”

4. Normal use will keep the belt from

resetting.

5. For extended periods of non-use (three to

four weeks), this procedure might need to

be repeated.

39201 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

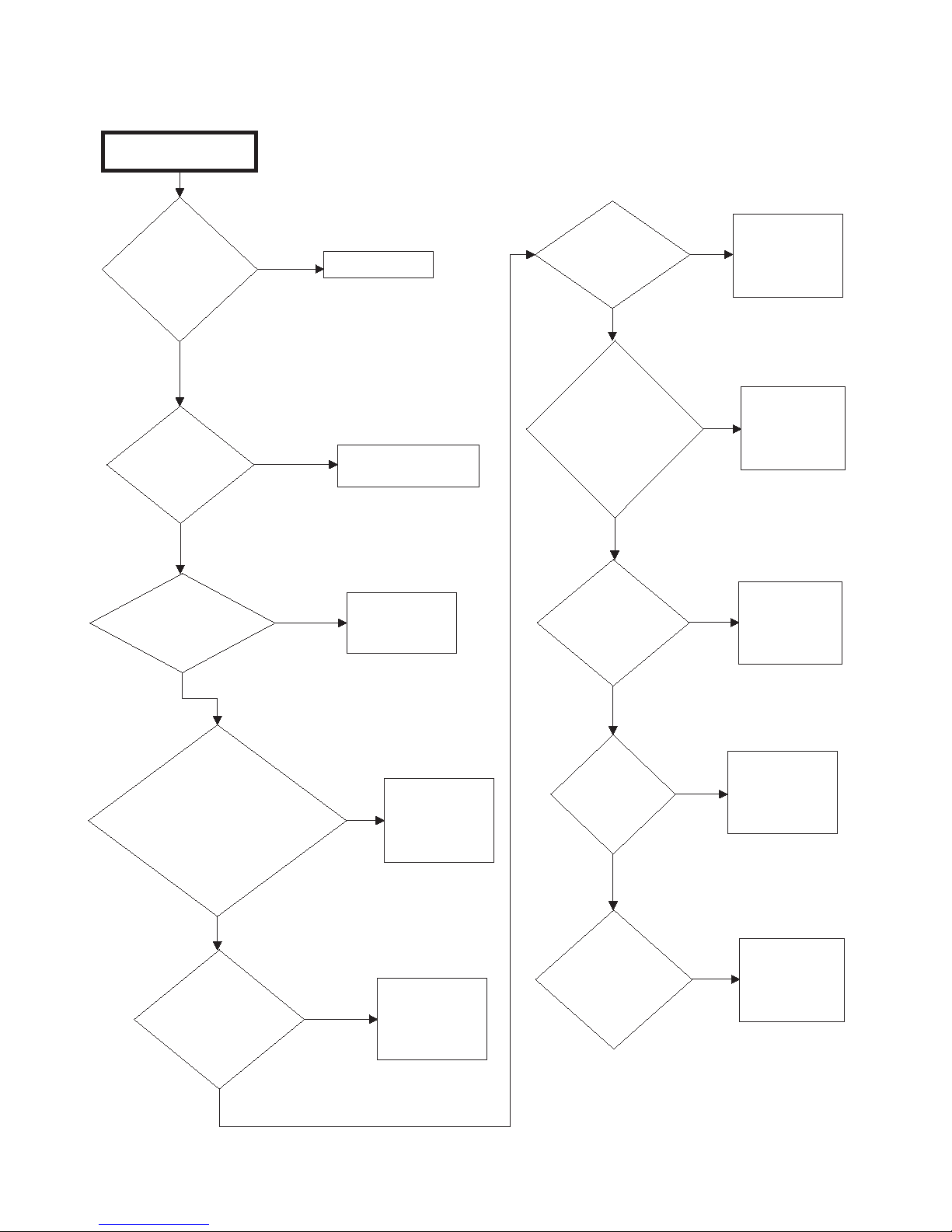

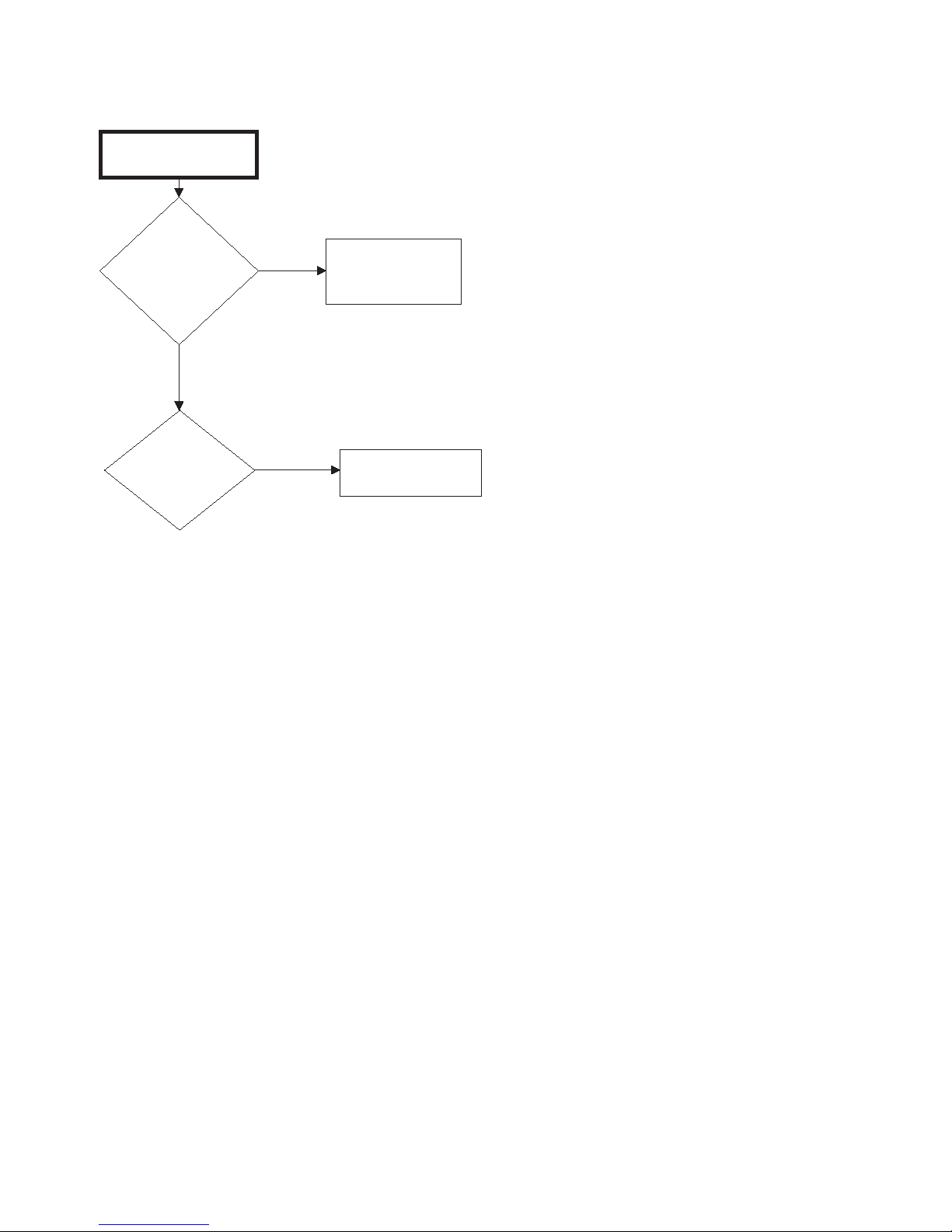

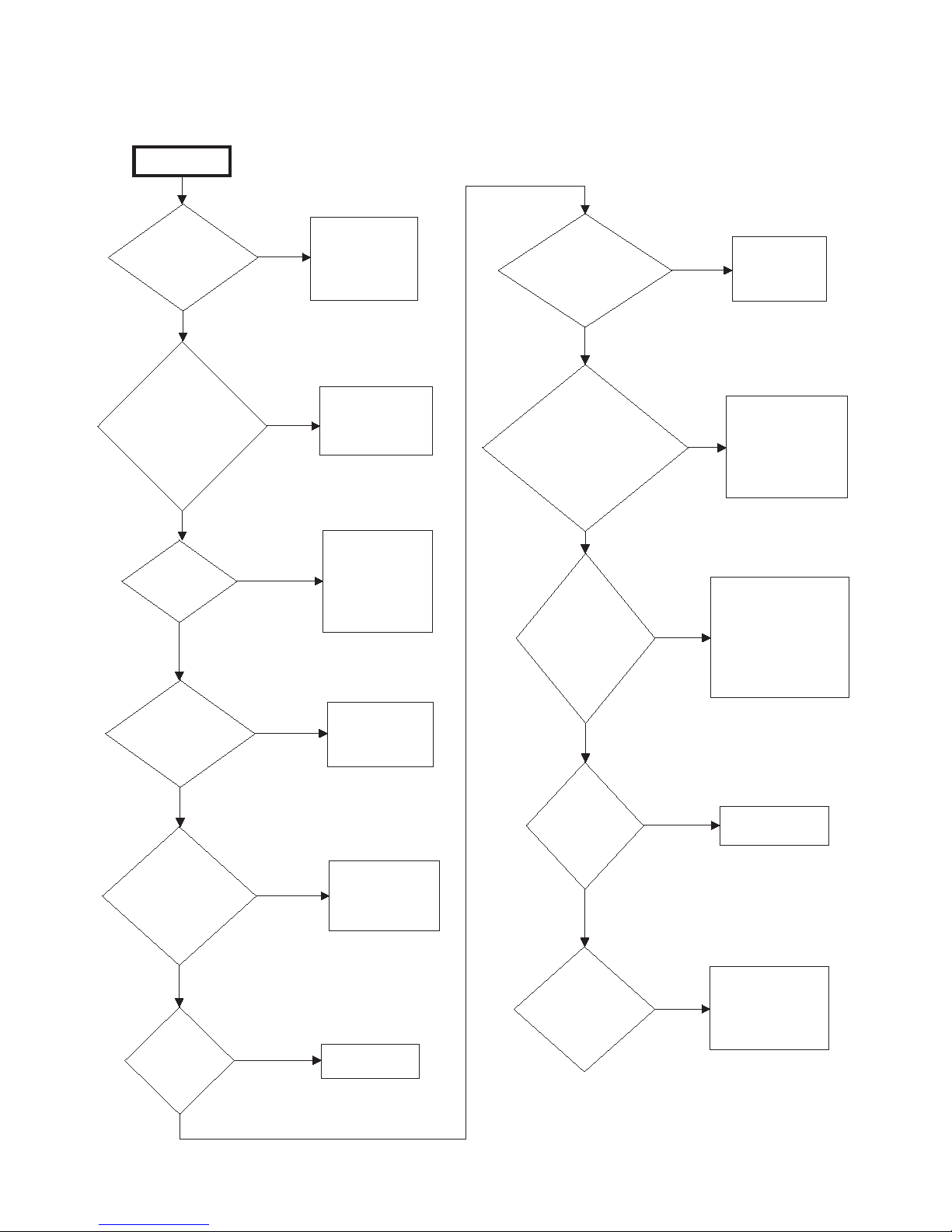

There is no hot water.

Is the water

supply faucet

closed?

Open faucet.

Yes

Is the water

supply cold?

No

Check water heater.

Yes

Is the hot water

fill hose kinked?

Straighten or

replace hose.

No

Yes

Is the mixing valve

screen or screen in

outer end of fill hose

nearest water supply

faucet clogged?

No

Disconnect hot

fill hose and

clean or

replace screen.

Yes

Is hot water

mixing valve

solenoid

inoperative?

No

Test solenoid

and replace if

necessary.

Is

timer/control

inoperative?

Test

timer/control

and replace if

inoperative.

Yes

No

Is temperature

switch (if

present)

inoperative?

Test switch (if

present) and

replace if

inoperative.

Yes

No

Is pressure

switch

inoperative?

Test switch

and replace if

inoperative.

Yes

No

Is pressure

hose

clogged?

Remove and

clean or

replace hose.

Yes

No

Is there

broken, loose

or incorrect

wiring?

Refer to

appropriate

wiring

diagram.

Yes

No

TLW326S

Yes

2. No Hot Water

18 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

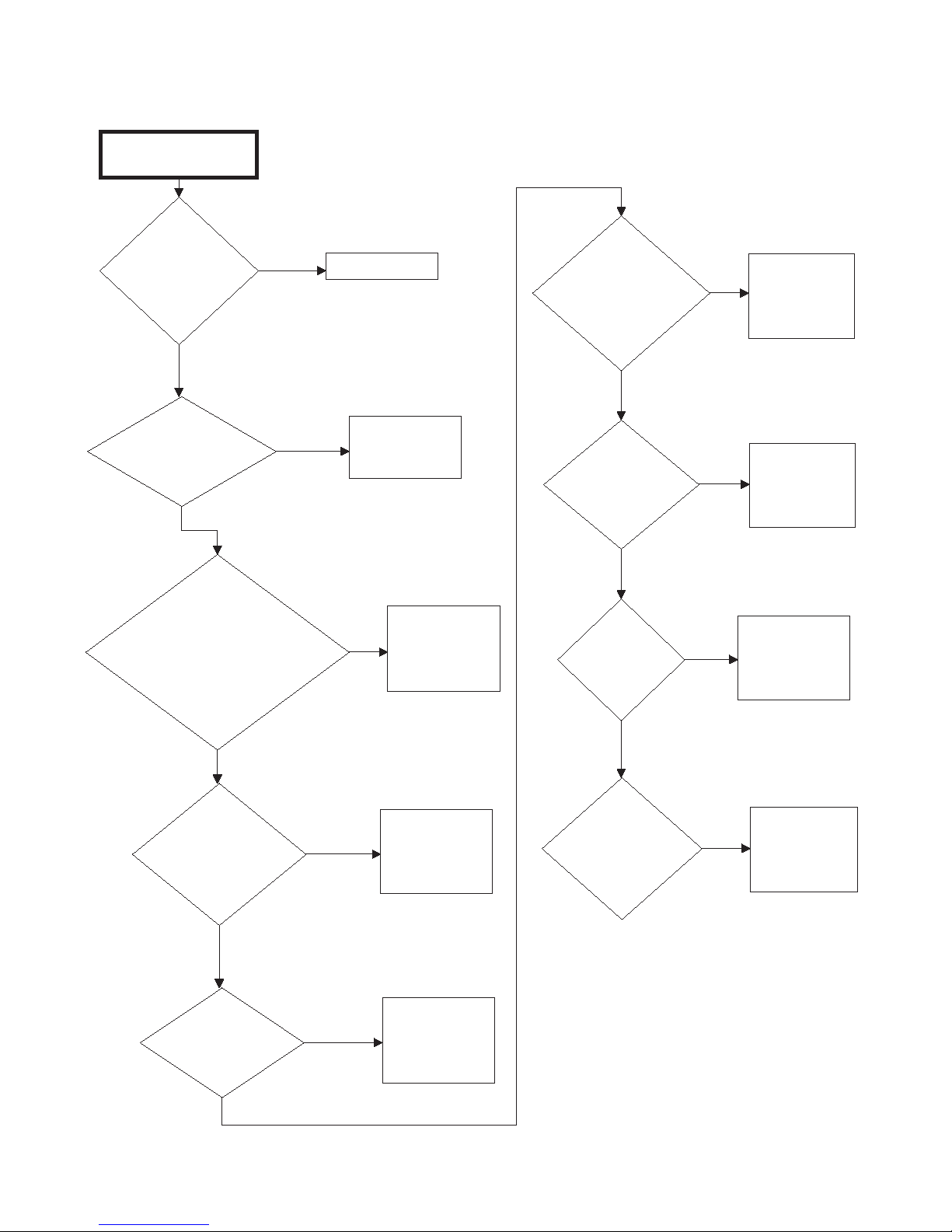

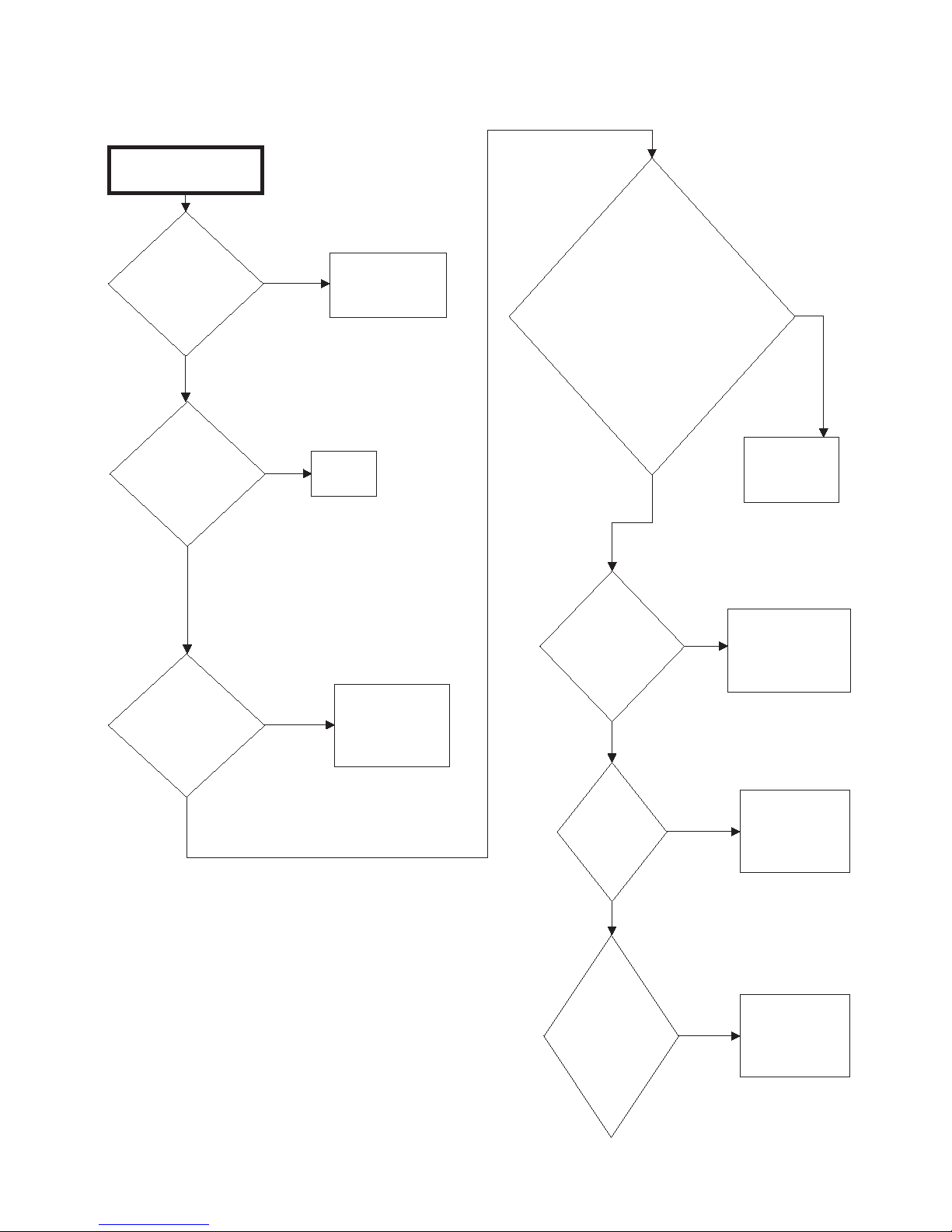

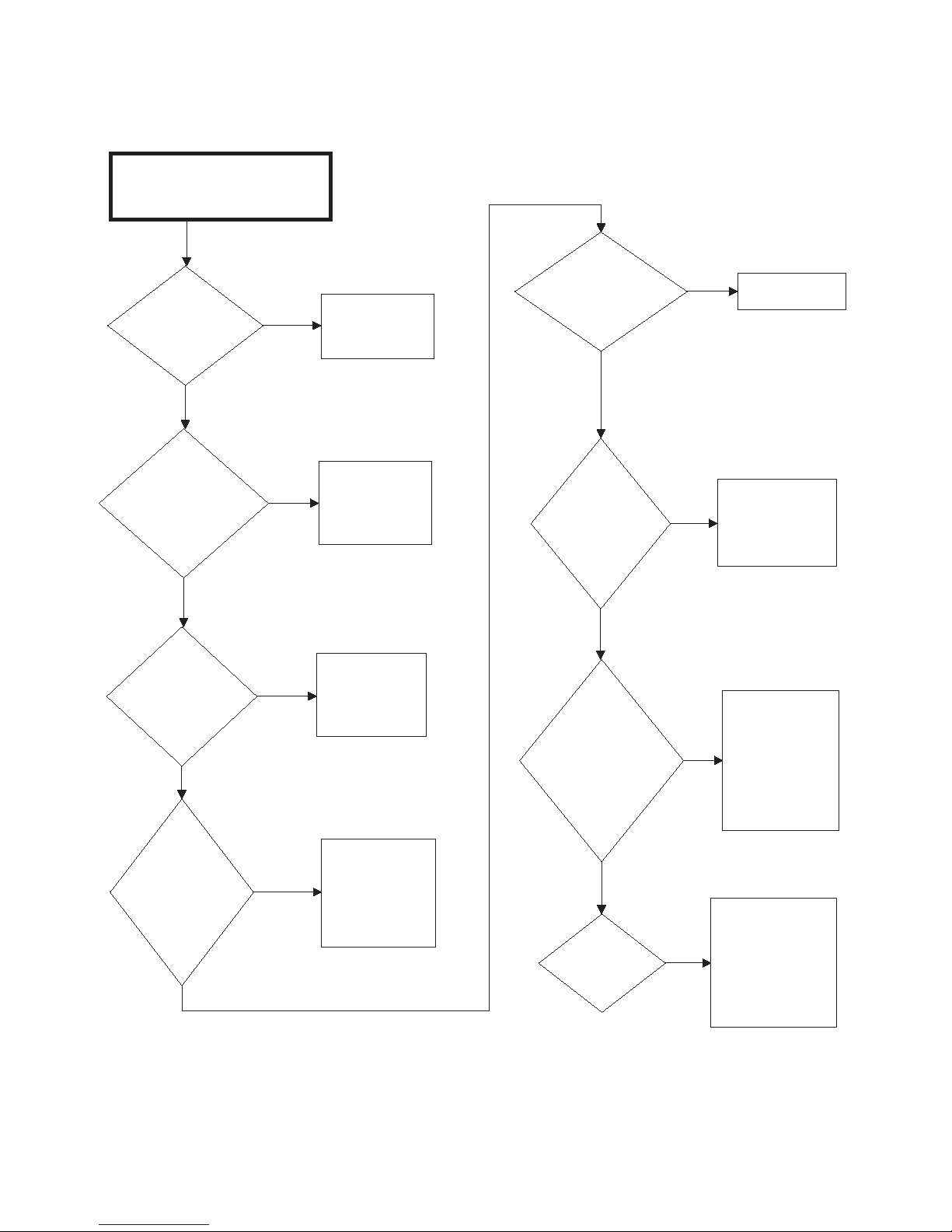

3. No Cold Water

There is no cold

water.

Is the water

supply faucet

closed?

Open faucet.

Yes

Is the cold

water fill hose

kinked?

Straighten or

replace hose.

Yes

Is the mixing valve

screen or screen in

outer end of fill hose

nearest water supply

faucet clogged?

No

Disconnect

cold fill hose

and clean or

replace screen.

Yes

Is cold water

mixing valve

solenoid

inoperative?

No

Test solenoid

and replace if

necessary.

Yes

Is

timer/control

inoperative?

Test

timer/control

and replace if

inoperative.

Yes

Is temperature

switch (if

present)

inoperative?

Test switch (if

present) and

replace if

inoperative.

Yes

No

Is pressure

switch

inoperative?

Test switch

and replace if

inoperative.

Yes

No

Is pressure

hose

clogged?

Remove and

clean or

replace hose.

Yes

No

Is there

broken, loose

or incorrect

wiring?

Refer to

appropriate

wiring

diagram.

Yes

No

TLW373S

No

No

General Troubleshooting

39201 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

There is no warm

water.

Is there no

hot water?

Refer to

No Hot

Water paragraph

.

Yes

Is there no

cold water?

No

Refer to

No Cold

Water paragraph

.

Yes

TLW362S

4. No Warm Water

20 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

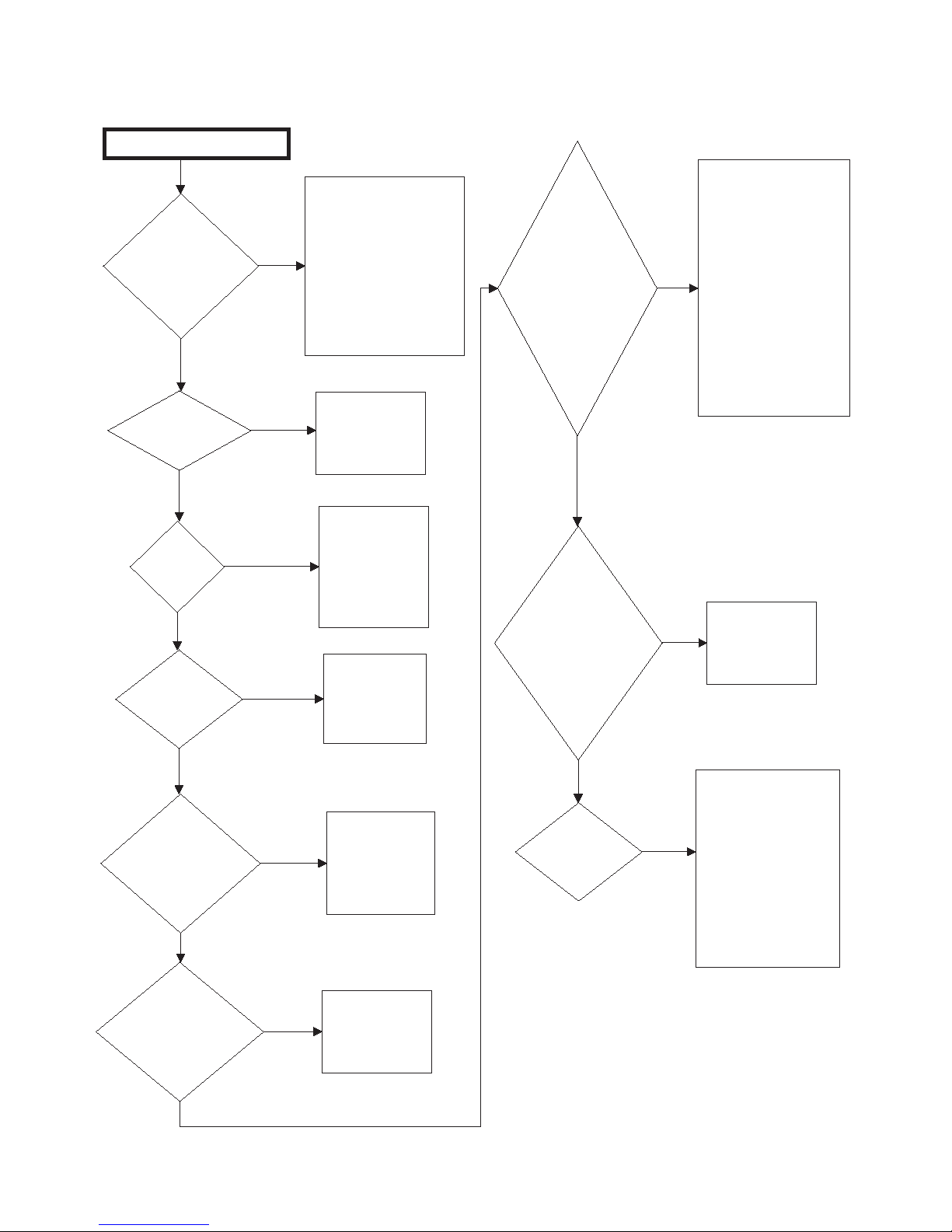

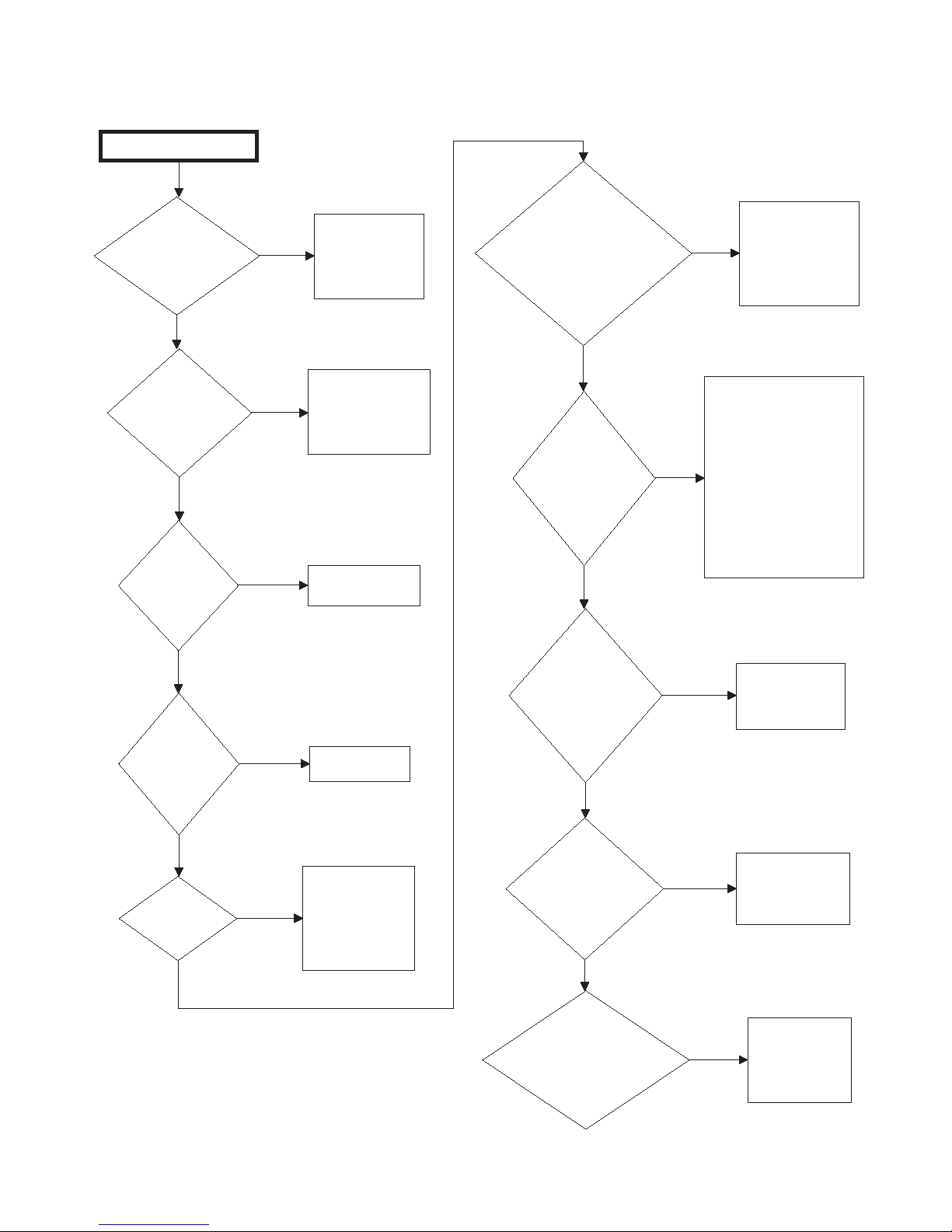

5. Water Fill Does Not Stop At Proper Level

Water fill does not

stop at proper level.

Is pressure

switch

inoperative?

Test switch and

replace if

inoperative.

Yes

Is mixing

valve

inoperative?

Test valve and

replace if

inoperative.

Yes

Was there a siphoning

action started in washer

causing water to be

siphoned from washer

during cycle due to end

of drain hose being

lower than cabinet top of

washer?

Install 562P3

Siphon

Break Kit.

TLW329S

Yes

Is there

water in

pressure

hose?

Blow air

through hose to

remove water.

Yes

Is there

broken,

loose,

shorted or

incorrect

wiring?

Refer to

appropriate

wiring diagram.

No

Yes

Is there an

air leak in

pressure

hose?

Replace

hose.

Yes

No

Does drain

hose fit tight

in standpipe

or drain?

Provide an air

gap around

drain hose and

drain receptacle.

No

No

No

Yes

No

General Troubleshooting

39201 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

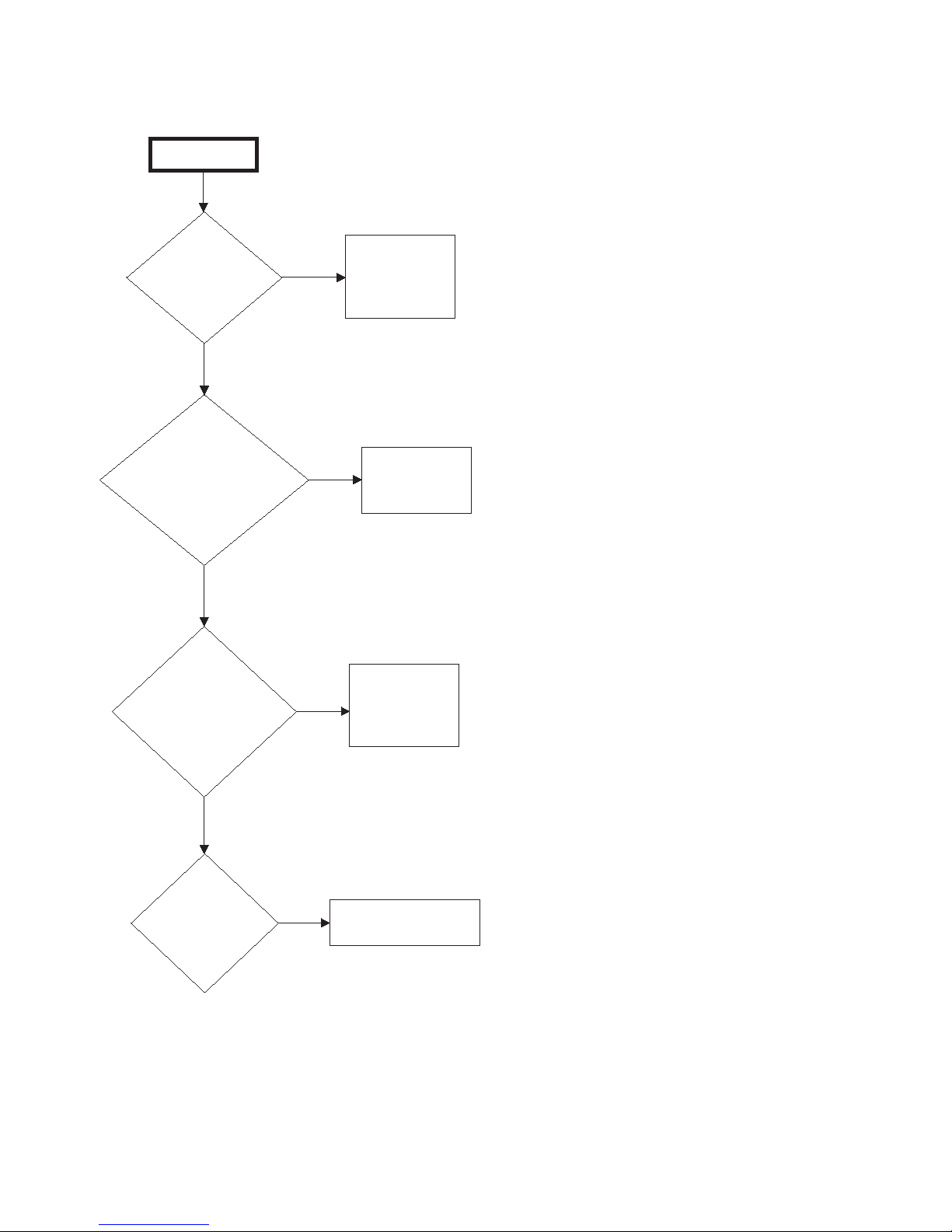

General Troubleshooting

Timer does not advance.

Is pause part

of normal

operation?

Timer is designed to

pause during fill

periods and when

going from agitate to

spin. Allow completion

of those steps. Refer

to diagram for

information on time

required.

Yes

Is timer

inoperative?

Test timer and

replace if

inoperative.

Yes

Is lid

open?

No

Close lid. Lid

MUST be

closed any time

the washer is

set to fill,

agitate or spin.

Yes

Washer

will not fill?

Timer pauses

until pressure

switch is

satisfied.

TLW330S

No

Has washer

drive motor

over loaded

and motor

thermal

overload

been tripped?

Timer is designed to

stop under these

conditions. Motor

thermal proctor reset

time may vary

depending upon the

reason for the washer

overload, however, it

should reset within 15

minutes. Check to

ensure that washer

was not overloaded

with clothes.

Yes

Is circuit

breaker to

washer

tripped,

disconnecting

power to

washer?

Reset circuit

breaker.

No

Yes

Timer is designed to

pause when going

from spin into rinse

to allow the washtub

to stop spinning

before filling. Make

sure timer has

advanced into fill

portion of rinse

cycle.

No

Yes

Is timer

motor lead

wire off timer

terminal?

Refer to

appropriate

wiring diagram

and reattach

wire.

No

Yes

Is there

broken, loose

or incorrect

wiring?

No

Refer to

appropriate

wiring diagram.

Yes

No

Washer

will not fill?

No

Yes

6. Timer Does Not Advance (Models with Timer Only)

22 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

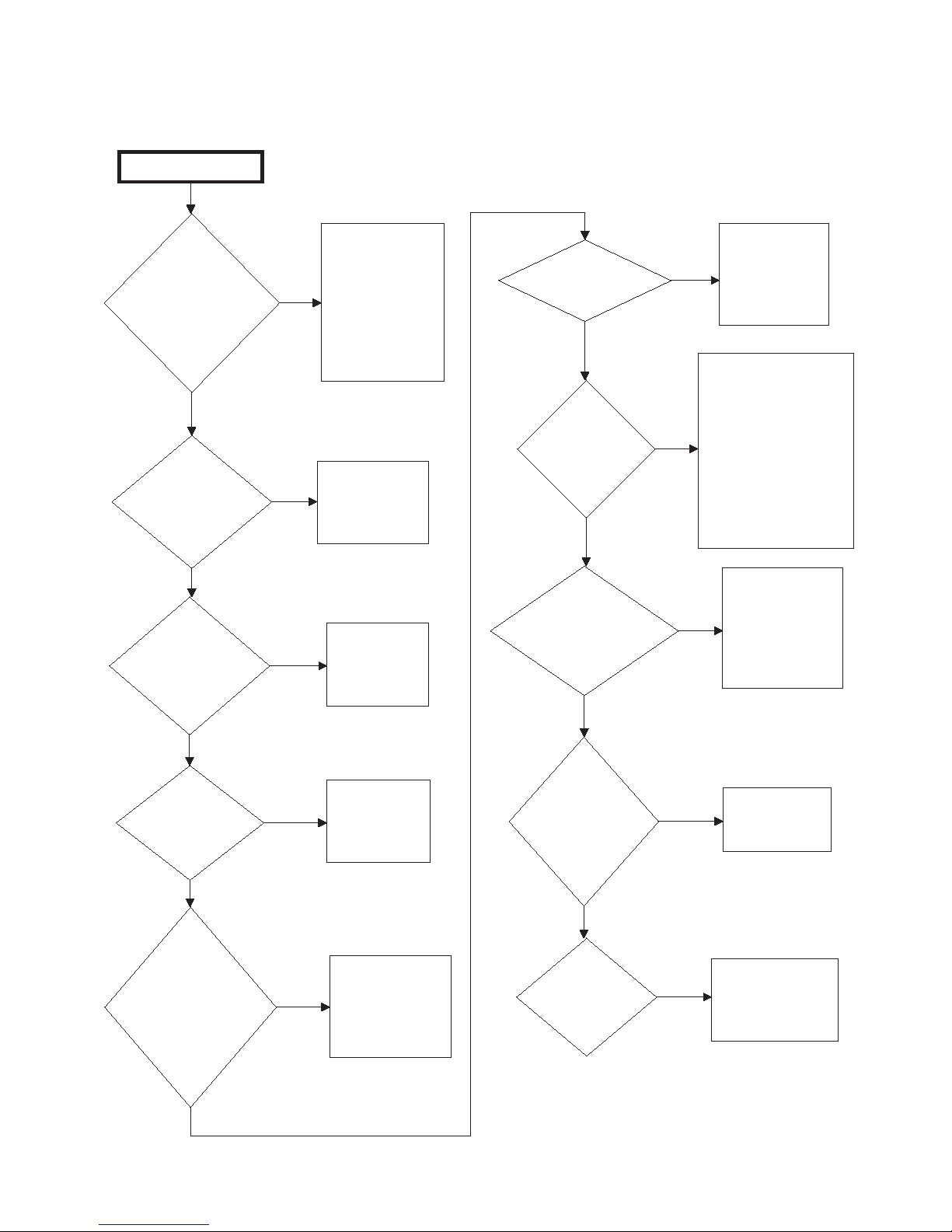

7. Motor Does Not Run

Motor does not run.

Is electrical

power off, fuse

blown or power

cord not

plugged in?

Check laundry

room for blown or

loose fuse(s) or

open circuit

breakers.

(Washer itself

does not have an

electrical fuse.)

Yes

Is lid open or

lid switch

inoperative?

Close lid or

test switch and

replace if

inoperative.

Yes

Is

timer/control

improperly

set?

No

Reset

timer/control

or try another

cycle.

Yes

Are motor

starting

functions

inoperative; no

start or motor

hums only?

Refer to

Motor

Test Procedure

section to check

start switch and

start windings.

TLW398S

No

Is

timer/control

inoperative?

Test

timer/control

and replace if

inoperative.

Yes

Is there

broken,

loose or

incorrect

wiring?

Refer to

appropriate

wiring diagram.

Yes

Refer to

appropriate wiring

diagram for

correct wiring.

Yes

Is motor dead,

won't run?

Refer to

Motor

Test Procedure

section to

check switch

and windings.

Yes

Is there a bind in

upper or lower

motor bearing?

Remove belt and

determine if

motor shaft will

spin. Replace

motor if shaft is

locked up.

Yes

Is power

cord

miswired?

No

Yes

Has motor

overload

protector

cycled?

Wait two or three

minutes for overload

protector to reset. If

protector cycles

repeatedly, refer to

Washer Overheats,

Cycles On Motor

Thermal Protector,

Switch Actuator Kicks

In and Out

paragraph.

No

Yes

No

No

No

No

No

General Troubleshooting

39201 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

No agitation.

Is

timer/control

inoperative?

Test

timer/control

and replace if

inoperative.

Yes

Is action

switch (fabric

selector), if

present,

inoperative?

Test switch and

replace if

inoperative.

Yes

Motor

won't run?

No

Refer to

Motor

Test Procedure

section to

check switch

and windings.

Yes

Is pressure

switch

inoperative?

Test switch

and replace if

inoperative.

TLW399S

No

Has drive

motor

overload

protector

cycled?

Refer to

Washer

Overheats, Cycles

On Motor Thermal

Protector, Switch

Actuator Kicks In

and Out

paragraph.

Yes

Is there a

bind in

pump?

Replace pump.

No

Yes

Close lid or test

switch and

replace if

inoperative.

No

Yes

Is there

broken, loose

or incorrect

wiring?

Refer to

appropriate

wiring diagram.

No

Yes

Is motor pulley

roll pin sheared

(through Serial

No. 001113645)?

Remove drive

motor and

replace roll pin

and any other

damaged parts.

Yes

Is lid open

or lid switch

inoperative?

No

Yes

Is transmission

assembly

inoperative?

Replace

transmission

assembly.

No

Yes

No

Is drive

belt

broken?

Replace belt.

No

Yes

No

8. No Agitation

24 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9. Constant Agitation

Constant agitation.

Is

timer/control

inoperative?

Test

timer/control

and replace if

inoperative.

Yes

Is there

shorted or

incorrect

wiring?

No

Refer to appropriate

wiring diagram.

Yes

TLW333S

Is transmission

assembly

inoperative?

Repair or

replace

transmission

assembly.

No

Yes

General Troubleshooting

39201 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

Washer overheats, cycles on

motor thermal protector, switch

actuator kicks in and out.

Is belt tacky,

not allowing

proper slip?

Check belt and

replace if

defective.

Yes

Is belt tension

too great, not

allowing

proper slip?

Make sure idler

spring is

properly

connected.

Yes

Is

timer/control

inoperative?

No

Test

timer/control

and replace if

inoperative.

Yes

Are motor

switch

functions

inoperative?

Refer to

Motor

Test Procedure

section to check

switch

functions.

TLW334S

No

Are brake

pads or

brake

assembly

binding?

Free binding

pads, or replace

pads and brake

assembly.

Yes

Have

bearings,

transmission

or motor

locked up and

will not turn?

Check that all

these

components are

able to move

freely. Correct

binding

component.

No

Yes

Contact local

utility company,

or have a

qualified

electrician check

power supply.

No

Yes

Is there a bind

in water pump?

Replace pump.

Yes

Is voltage

incorrect?

No

Yes

No

No

10. Washer Overheats, Cycles On Motor Thermal Protector, Switch Actuator

Kicks In and Out

26 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11.Slow Spin Or No Spin

Slow spin or no spin.

Is

timer/control

inoperative?

Test

timer/control

and replace if

inoperative.

Yes

Motor

won't run?

Refer to

Motor

Test Procedure

section to

check switch

and windings.

Yes

Is there no

clearance

between

brake pads

and discs?

Replace pads

and brake

assembly.

TLW400S

Has drive

motor

overload

protector

cycled?

Wait two or three

minutes for overload

protector to reset. If

protector cycles

repeatedly, refer to

Washer Overheats,

Cycles On Motor

Thermal Protector,

Switch Actuator Kicks

In and Out

paragraph.

Yes

Is there a

bind in

pump?

Replace pump.

Yes

Close lid or test

switch and

replace if

inoperative.

Yes

Is there

broken, loose

or incorrect

wiring?

Refer to

appropriate

wiring diagram.

Yes

Is lid open

or lid switch

inoperative?

Yes

Is transmission

assembly

inoperative?

Repair or

replace

transmission

assembly.

Yes

Is drive

belt

broken or

worn?

Replace belt.

Yes

No

No

No

No

No

No

No

Is motor pulley

roll pin sheared

(through Serial

No. 001113645)?

Remove drive

motor and

replace roll pin

and any other

damaged parts.

No

Yes

No

General Troubleshooting

39201 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

Constant spin.

Is

timer/control

inoperative?

Test

timer/control

and replace if

inoperative.

Yes

Is there

shorted or

incorrect

wiring?

Refer to appropriate

wiring diagram.

Yes

TLW336S

Is there

excessive wear

on brake pads

or missing

brake pads?

Replace brake

pads and brake

assembly.

Yes

Washtub does

not stop spinning

within seven

seconds after lid

is opened.

Replace brake

pads and brake

assembly.

No

No

No

Yes

12. Constant Spin

28 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13. Washer Stops In Cycle; Quits After A Couple Loads; Is Intermittent

Washer stops in cycle, quits

after a couple loads or is

intermittent.

Is belt tacky,

not allowing

proper slip?

Check belt and

replace if

defective.

Yes

Is belt tension

too great, not

allowing

proper slip?

Make sure idler

spring is

properly

connected.

Yes

Is

timer/control

inoperative?

No

Test

timer/control

and replace if

inoperative.

Yes

Are motor

switch

functions

inoperative?

Refer to

Motor

Test Procedure

section to check

switch

functions.

TLW401S

No

Has motor

overload

protector

cycled?

Wait two or three

minutes for

overload protector

to reset. If protector

cycles repeatedly,

refer to

Washer

Overheats, Cycles

On Motor Thermal

Protector, Switch

Actuator Kicks In

and Out

paragraph.

Yes

Has brake,

transmission

or motor

locked up and

will not turn?

Check that all

these

components

are able to

move freely.

Yes

Refer to

appropriate wiring

diagram.

Yes

Is there

broken, loose

or incorrect

wiring?

Yes

No

No

No

No

General Troubleshooting

39201 29

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

Washer is locked up or binding.

Is there

excessive

belt tension?

Replace belt

and/or idler

spring.

Yes

Is there a bind

in upper or

lower bearing?

Replace bearing.

Yes

Is there a

bind in water

pump?

No

Replace pump.

Yes

Is voltage

incorrect?

Contact local

utility company

or have a

qualified

electrician

check power

supply.

TLW338S

No

Are brake

pads

binding?

Free binding

pads or

replace pads.

Yes

Repair or replace

transmission.

Yes

Is there a

bind in

transmission?

Yes

No

No

No

14. Washer Is Locked Up Or Binding

30 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15. Outer Tub Does Not Empty

Outer tub does

not empty.

Is drain hose

kinked?

Straighten hose.

Yes

Is there an

obstruction

in outer tub

outlet hose?

Remove obstruction.

Yes

TLW339S

Is water pump

inoperative?

Replace pump.

Yes

Is drain hose out

of hose retainer

clip in back of

cabinet.

Remove washer

front panel and

install drain hose

into hose retainer

clip in back of

cabinet.

No

No

No

Yes

General Troubleshooting

39201 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

Excessive vibration.

Is there an

unbalanced

load in tub?

Stop washer,

redistribute

load, then

restart washer.

Yes

Is there a

broken or

disconnected

module

spring(s)?

Connect or

replace module

spring(s).

Yes

Is washer

unleveled?

No

Adjust leveling

legs.

Yes

Is base

damaged

(washer was

dropped)?

Replace base

assembly.

TLW340S

No

Are cabinet

screws

incorrect or

loose?

Replace with

correct screws

or tighten.

Yes

Is friction

ring

broken?

Replace

friction ring.

Yes

Relocate washer or

support floor to

eliminate weak or

"spongy" condition.

Yes

Is washer

installed on

weak, "spongy",

carpeted or

built-up floor?

Yes

No

No

No

No

16.Excessive Vibration

32 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17. Water Leaking From Outer Tub

Water leaking from

outer tub.

Is water seal

in outer tub

leaking?

Replace hub

and seal kit

assembly.

Yes

Is there a

hole in outer

tub?

Replace outer

tub.

Yes

Is pressure

hose or

accumulator

leaking?

No

Replace

pressure hose

and/or

accumulator.

Yes

Is tub-to-

pump hose

leaking at

clamp?

Tighten clamp.

TLW341S

No

Is there an

obstruction in

drain causing

water to come

over top of outer

tub cover?

Remove

obstruction.

Yes

Replace gasket.

Yes

Is outer tub

cover

gasket

leaking?

Yes

No

No

No

General Troubleshooting

39201 33

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

DRY2B

Additional coins following

path to sensor

Coin Drop

Sensor

Coin in

Coin Slot

18. Troubleshooting Coin Drop

a. Non-Electronic Coin Drops:

When coin is placed into coin slot, the coin should roll down drop and be heard dropping into coin vault. If coin

does not fall into coin vault or if coin drop sensor does not register that coin has been entered, follow

troubleshooting instructions on the following page. Refer to Figure 1 for path that coin follows when working

properly.

IMPORTANT: Never use oil to correct coin drop problems. Oil residue will prevent coins from rolling

properly.

IMPORTANT: Do not bend or damage mechanical parts within coin drop.

Figure 1

34 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting Coin Drop

Is

machine level?

(Machines that aren't

level may prevent coins from

following through required

check stages

of drop.)

No

Yes

No

Refer to wiring

diagram for

proper connections.

Yes

No

Yes

SWD1714S

Is proper

electrical power

supplied to coin drop?

(Incorrect electrical connection

may prevent coins from

registering in

coin drop.)

Is coin drop

clean? (Residue or

lint build-up may prevent

coins from following through

required check stages

of drop.)

Refer to

Adjustments section

for instructions on cleaning

drop.

Replace

coin drop sensor.

Refer to

Installation Instructions

for instructions

on leveling machine.

Do coins

fall freely

through drop?

No

Replace

coin drop.

Yes

General Troubleshooting

39201 35

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

MIX7B

Coin Drop

Cover

Coin Return

Button

Coin Drop

Cover

Cover Catch

Small Flathead

Screwdriver

Right Side of

Tension Spring

Left Tab

b. Electronic Coin Drops:

If coin drop is not accepting coins, perform the

following:

(1) Clean coin drop. Refer to Paragraph 62.

(2) Test and replace tension spring using the

following instructions.

Remove Coin Drop From Machine

(1) Disconnect electrical power to machine and

drop.

(2) Remove coin drop from machine.

Test Tension Spring

(1) Push coin return button to open and close

coin drop cover to clear possible coin jams.

Refer to Figure 2.

(3) If coin drop now operates properly, replace

tension spring using instructions on

following pages.

Replace Tension Spring

(1) Move tension spring downward until cover

catch is free. Refer to Figure 4.

DRY2088N

Figure 4

Figure 2

(2) Manually hold down coin drop cover and

insert coin. Refer to Figure 3.

MIX6B

(2) Open cover for coin drop.

(3) Place a small flathead screwdriver under

right side of tension spring and lift up.

Refer to Figure 5.

MIX2B

Figure 5

(4) Use screwdriver to move spring

approximately 3 mm to left.

(5) Lift spring over left tab. Refer to Figure 5.

Figure 3

36 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

General Troubleshooting

MIX3B

Tabs

Center Tab

MIX4B

Clip

MIX8B

Slot

MIX5B

Small Flat

Screwdriver

Center

Tab

Left Tab

(6) Rotate spring clockwise, 40 to 60 degrees,

until it is free from right tabs. Refer to

Figure 6.

Figure 6

(7) Use screwdriver to remove spring from

center tab. Refer to Figure 6.

(8) Lift spring, with attached clip, off drop.

(9) Remove clip from spring. Refer to

Figure 7.

(12) Use a small flathead screwdriver to push

spring under center tab. Refer to Figure 9.

Figure 9

(13) Lift spring gently to place in position under

left tab.

(14) Push spring to right until it snaps into

position. Refer to Figure 5.

(15) Close coin drop cover.

(16) Move tension spring over cover catch.

Refer to Figure 4.

Figure 7

(10) Attach clip to new tension spring, Part No.

209/00598/02.

(11) Place clip, installed on spring, in slot on

coin drop. Refer to Figure 8.

Figure 8

39201 37

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

(1) Reinstall coin drop into machine.

(2) Reconnect electrical power to machine and

drop.

(3) Add a coin to drop to verify that coin drop

is operating properly and that electrical

connection is working properly.

Reinstall Coin Drop Into Machine

General Troubleshooting

Notes

38 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer before servicing.

• Never start the washer with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer is properly grounded.

W003

WARNING

Coin Slide Operated and Non-Metered Models with the Number “8” or “9” in

the 4th Character of the Model Number

19. Error Mode

In Error Mode, the IN USE LED flashes to display fill and drain errors (refer to paragraphs below). Error Mode

can only be exited by powering down washer.

Fill Error

A Fill Error will occur if the tub does not fill within 62 minutes of the start of the cycle. A Fill Error is indicated

by the control repeatedly flashing the IN USE LED twice separated by a one and a half second pause until the

control is powered down. If Error Mode is turned off, the fill error will not occur and the control will continue

to wait for the fill level to be reached.

Drain Error

A Drain Error will occur if the tub is not empty after a spin cycle. A Drain Error is indicated by the control

repeatedly flashing the IN USE LED three times separated by a one and a half second pause until the control is

powered down. If Error Mode is turned off, the drain error will not occur and the machine cycle will advance

to the next cycle step as though the water had been pumped out.

39201 39

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Coin slide can't be

fully inserted.

Make sure switch

activation lever is off

switch when installing

coin slide.

Is coin slide

installed

correctly?

Refer to

Installation

manual. Make sure

all four mount screws

are engaged into

meter case opening.

Tighten extension rod

correctly.

No

TLW1836B

Are wires

and/or shield

from control

board interfering

with coin slide

movement?

Reposition wires

and/or shield.

Yes

No

20. Coin Slide Can Not Fully Insert

40 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Switch isn't activated when coin

slide is fully inserted.

Was the wrong

extension lever

setup used?

Are coin slide

extension lever

and flat washers

(shims) installed

correctly?

Refer to

Installation

manual. Extension

lever should rotate

freely after assembly.

Extension lever

shouldn't have

excess play.

No

TLW1837B

Is the switch

activation lever

bent or out of

position?

Correct lever or

replace switch

mount assembly.

Yes

No

Make sure one or two

stars, depending on

type of coin slide,

face down. Refer to

Installation

manual.

Yes

Switch activation

lever doesn't rotate

under the force of

the coin slide

extension lever?

Friction wave

washer in switch

mount assembly

is too tight.

Compress wave

washer slightly

and retest, or

replace switch

mount assembly.

Yes

Is wiring

connected

correctly?

Examine wiring

and terminals

for proper

connections.

Refer to wiring

diagram.

No

No

Yes

No

21. Coin Slide Fully Inserts, Switch Does Not Activate

39201 41

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Switch is activated

too soon.

Is the switch

activation lever

bent or out of

position?

TLW1838B

Does the switch

activation lever

rotate freely?

Replace

switch mount

assembly.

Yes

Correct lever

or replace

switch mount

assembly.

Yes

No

Was the wrong

extension lever

setup used?

Make sure one or two

stars, depending on

type of coin slide,

face down. Refer to

Installation

manual.

No

Yes

22. Switch Is Activated Too Soon

42 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Coin slide doesn't freely return.

Was the

wrong

extension

lever setup

used?

Are coin slide

switch and

extension

assemblies

equipped with

updated parts?

Replace with

assemblies that

have

nitrocarburized

(black-coated)

brackets and

lighter spring with

open hooks.

No

TLW376S

Consult coin slide

manufacturer

instructions, clean and

lubricate coin slide,

double check that return

springs are present.

Make sure one

or two stars,

depending on

type of coin

slide, face

down. Refer to

Installation

manual.

Yes

Review

extension lever

for proper free

rotation.

Is there a

burr present

on extension

lever or

switch

bracket?

Remove burr,

lubricate and

retest.

Yes

Yes

No

23. Coin Slide Does Not Return Freely

39201 43

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Cycle won't start after the

coin slide is activated.

Is the "In Use"

light lit?

Refer to

Washer Will

Not Fill

paragraph.

Yes

Is the H8

connection

properly seated

on the control

board?

Properly seat

connector and

try again.

No

Is coin slide

switch

activated when

slide is pushed

in?

Replace or

repair slide

extension

assembly.

No

Replace control

harness.

TLW342S

Is there

continuity

through switch

when

activated?

Replace

switch.

Replace

control.

Is there continuity

through switch and

switch wires when

activated?

Yes

No

1

Yes

2

No

3

Yes

Yes

No

24. No Cycle Start When the Coin Slide is Activated

44 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

1

2

3

No Cycle Start When the Coin Slide is Activated

39201 45

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Is the lid closed?

Is there 120 volts AC

between terminal

"H3-5" on the control

and neutral?

Is there 120 volts AC

between pressure

switch terminal 2 and

neutral?

Is there 120 volts AC

between pressure

switch terminal 1 and

neutral?

Close lid and

check switch for

continuity.

Refer to Washer

will not fill (mixing

valve diagnostics).

Check wiring

between control

board and

pressure switch.

Check for proper

function of

pressure switch,

pressure hose and

accumulator.

Replace if

necessary.

Check wiring

between pressure

switch and lid

switch.

Yes

No

Yes

Yes

No

Yes

No

No

TLW343S

(1)

(2)

(3)

(4)

Note: Assuming water is turned on.

25. Washer Will Not Fill (Pressure Switch Diagnostic)

46 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

2

3

4

1

Washer Will Not Fill (Pressure Switch Diagnostic)

39201 47

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Is there voltage from

either "H3-4" or "H3-1" (based

to the Neutral wire?

Is there 120 volts AC

between either the

hot or cold coil to

terminal 8 on the

motor?

Is there 120 volts AC

between either the

hot or cold coil to

terminal 4 on the

motor?

Is there 120 volts AC

across the coil of

either the hot or cold

valve?

Is there voltage

across either the hot

or cold coil to

neutral?

Replace control.

Correct wiring

between mixing

valve and control.

Replace mixing

valve.

Correct wiring

between motor

and neutral wire.

Thermal protector

in motor open.

Replace motor.

Correct wiring

between terminal 8

of the motor and

neutral side of the

hot/cold coil.

No

Yes

Yes

Yes

Yes

Yes

No

No

No

No

(1)

(2)

(3)

(4)

(5)

Does water flow

through the mixing

valve?

No

Unit operates

properly.

Yes

TLW344S

on temperature selection)

Note: Assuming No Fill (pressure

switch diagnostics) checks out okay, and

cycle is started and "In Use" light is lit.

26. Washer Will Not Fill (Mixing Valve Diagnostic)

48 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

1

2

3

4

5

Washer Will Not Fill (Mixing Valve Diagnostic)

39201 49

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

With power

disconnected, does

the unit still over

flow?

Washer Over Fills.

Is there voltage

on either the orange

wire of the hot valve

or gray wire of the cold

valve to neutral?

Replace mixing

valve.

Check for

incorrect or

damaged wiring

between water

valve and L1

Yes

No

Yes

No

Reconnect

power.

(1)

Unit works

properly.

TLW287S

27. Washer Over Fills (Pressure Switch Open)

50 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

1

Washer Over Fills (Pressure Switch Open)

39201 51

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Is there voltage

between "H6-1" on

control to terminal 4

on the motor?

Is there voltage

between "H6-3" on

control to terminal 1

on the motor?

Is there voltage

between terminal 1

of the motor and

"H6-2" on the control?

Is there voltage

across terminal 1 & 8

of the motor?

Is there voltage at

"H6-4" on the control

to terminal 8 on the

motor?

Is there voltage

across terminals 3 &

8 on the motor?

Is there voltage

across terminals 3 &

4 on the motor?

Is there voltage

between "H6-6" and

terminal 4 on the

motor?

Check operation of

lid switch, check

wiring to control.

Replace control

Correct wiring

between control

and motor.

Check operation of

thermal protector

in the motor.

Replace motor if

necessary.

Replace control.

Correct wiring

between control

and motor. Check

capacitor, replace

if necessary.

Correct wiring

between motor

terminal 8 and

control.

Replace control.

Replace motor.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

Yes

No

Low speed

Is there voltage

between "H6-5" and

terminal 4 on the

motor?

(2a)

No

Yes

High speed

Is there voltage

across terminals 7 &

4 on the motor?

(3a)

No

Yes

Low speed

Is there voltage

across terminals 8 &

7 on the motor?

(4a)

No

Yes

High speed

Low speed

TLW345S

High speed

28. No Agitation – Low and High Speed

52 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

1

3a

3

7

8

6

5

4

2

4a

2a

No Agitation – Low and High Speed

39201 53

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29. Washer Will Not Spin – Low Speed

Is there voltage

across "H6-1" on the

control and terminal

4 on the motor?

Is there voltage

across terminals 3 &

8 of the motor?

Is there voltage

across terminals 3 &

4 on the motor?

Is there voltage

across "H6-6" on the

control and terminal

4 on the motor?

Check lid switch

for proper

operation. Check

wiring from control

to lid switch to

supply.

Replace control.

Correct wiring

between motor

and control.

Check operation of

motor

thermal protector.

Replace motor if

necessary.

Yes

No

Yes

No

Yes

No

Yes

No

Is there voltage

across "H6-3" on

control to terminal 8

of the motor?

Is there voltage from

"H6-4" on control to

terminal 1 of the

motor?

Is there voltage from

"H6-2" on control to

terminal 6 of the

motor?

Is there voltage

across terminals 6 &

8 of the motor?

Replace the

control.

Correct wiring to

the motor.

Replace control.

Yes

No

Yes

No

Yes

No

Yes

No

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Unit should

operate properly.

TLW293S

54 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

1

2

3

8

6

4

5

7

Washer Will Not Spin – Low Speed

39201 55

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Is there voltage

across "H6-1" on the

control and terminal

4 on the motor?

Is there voltage

across terminals 7 &

8 of the motor?

Is there voltage

across terminals 7 &

4 on the motor?

Is there voltage

across "H6-5" on the

control and terminal

4 on the motor?

Check lid switch

for proper

operation. Check

wiring from control

to lid switch to

supply.

Replace control.

Correct wiring

between motor

and control.

Check operation of

motor

thermal protector.

Replace motor if

necessary.

Yes

No

Yes

No

Yes

No

Yes

No

Is there voltage

across "H6-3" on

control to terminal 8

of the motor?

Is there voltage from

"H6-4" on control to

terminal 1 of the

motor?

Is there voltage from

"H6-2" on control to

terminal 6 of the

motor?

Is there voltage

across terminals 6 &

8 of the motor?

Replace the

control.

Correct wiring to

the motor.

Replace control.

Yes

No

Yes

No

Yes

No

Yes

No

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

Unit should

operate properly.

TLW291S

30. Washer Will Not Spin – High Speed

56 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

1

2

3

7

8

6

4

5

Washer Will Not Spin – High Speed

39201 57

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting (Coin Slide Operated/Non-Metered Models with “8” or “9” in 4th Character of Model No.)

Notes

58 39201

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Troubleshooting