Alliance Laundry Systems HF304, HF234, HF150, HF185 User Manual

Washer Extractors

HF150, HF185, HF234, HF304

for corresponding “CHF” and “IHF” models,

see page 5 for complete model list

Technical specications

Installation instructions

Maintenance

Instruction manual

Part No. D0289R8

Code: 249/00390/10

May 2011

Contents

1

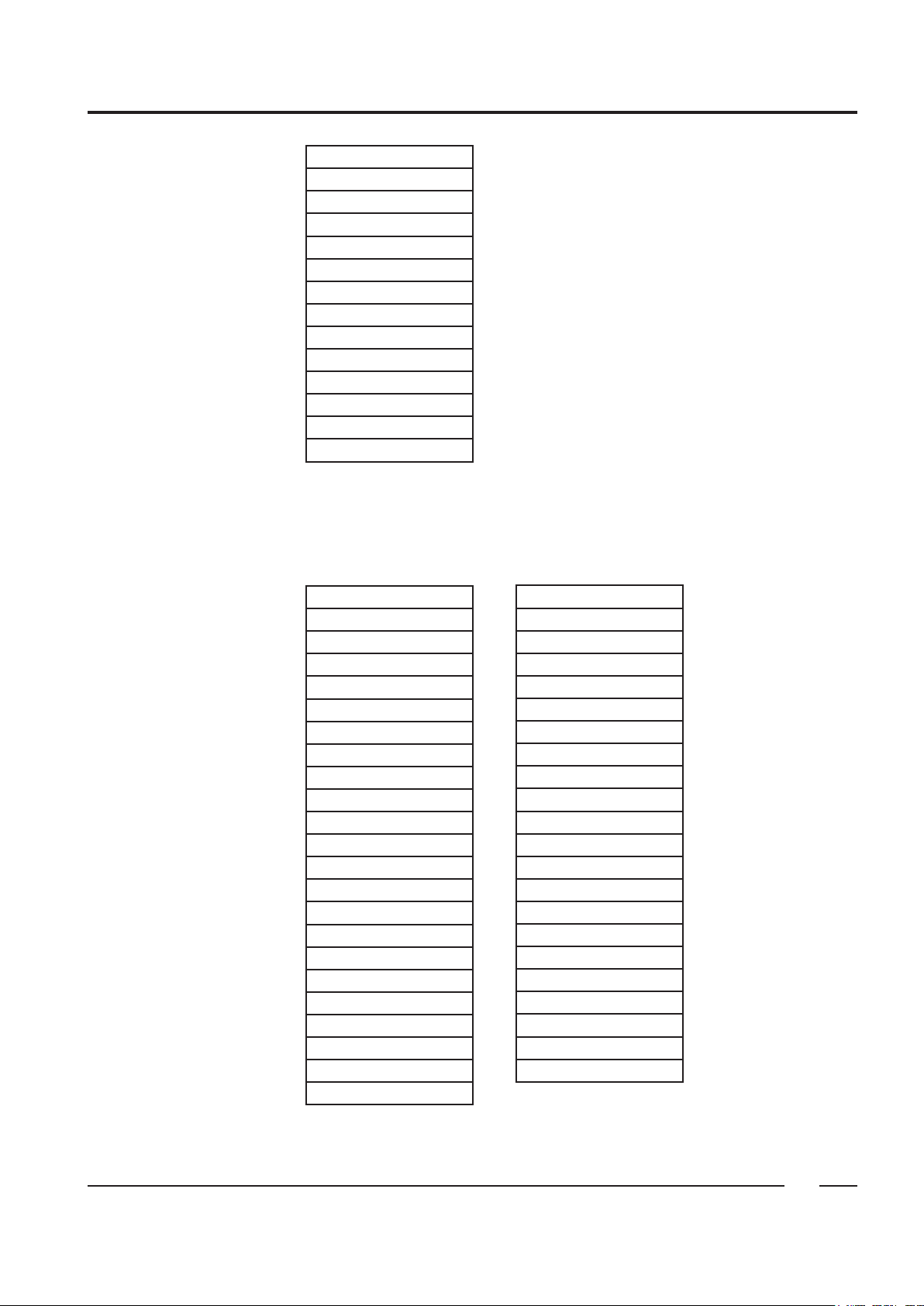

Model Numbers .............................................................................................. 5

2

Safety and Environmental Informations ...................................................... 6

Safety .......................................................................................................... 6

Environmental .............................................................................................. 7

Explanation of Safety Messages .................................................................8

Important Safety Instructions ....................................................................... 9

Operator Safety ......................................................................................... 11

3

Technical data and dimensions ................................................................. 12

Technical data HF150, IHF150, IHF033, CHF150, CHF033 ..................... 12

Dimensions HF150, IHF150, IHF033, CHF150, CHF033 .......................... 13

Technical data HF185, IHF185, IHF045, CHF185, CHF045 ..................... 14

Dimensions HF185, IHF185, IHF045, CHF185, CHF045 .......................... 15

Technical data HF234, IHF234, IHF055, CHF234, CHF055 ..................... 16

Dimensions HF234, IHF234, IHF055, CHF234, CHF055 .......................... 17

Technical data HF304, IHF304, IHF075, CHF304, CHF075 ..................... 18

Dimensions HF304, IHF304, IHF075, CHF304, CHF075 .......................... 19

4

Installation and Connection Instructions .................................................. 20

Surface ...................................................................................................... 20

Out of balance switch ................................................................................20

Removal of the transport safety ................................................................. 21

Mounting Bolt Hole Locations for machines, HF150, IHF150, IHF033,

CHF150, CHF033 ...................................................................................... 22

Mounting Bolt Hole Locations for machines, HF185, IHF185, IHF045,

CHF185, CHF045 ...................................................................................... 23

Mounting Bolt Hole Locations for machines, HF234, IHF234, IHF055,

CHF234, CHF055 ...................................................................................... 24

Mounting Bolt Hole Locations for machines, HF304, IHF304, IHF075,

CHF304, CHF075 ...................................................................................... 25

Water connection ....................................................................................... 26

Water drain ................................................................................................ 26

Electrical installation .................................................................................. 27

Main power connection .............................................................................. 29

Electrical Specifications HF150, IHF150, IHF033, CHF150, CHF033 ......31

Electrical Specifications HF185, IHF185, IHF045, CHF185, CHF045 .......32

Electrical Specifications HF234, IHF234, IHF055, CHF234, CHF055 .......33

Electrical Specifications HF304, IHF304, IHF075, CHF304, CHF075 .......34

Liquid soap connection (option) ................................................................. 35

Connection of a central operating panel for coin machines (option) .........37

3

Contents

5

Steam connection ........................................................................................ 38

6

Technical remarks ....................................................................................... 39

Internal connections of the electrical heating ............................................39

7

Maintenance instruction of the machine ................................................... 40

End of day .................................................................................................. 40

General maintenance ................................................................................40

Periodical maintenance .............................................................................40

Annual maintenance .................................................................................. 41

8

Contact Information .....................................................................................42

Nameplate ................................................................................................. 42

9

Repair and after-sales service .................................................................... 44

4

Model Numbers

1

Build-up

Model numbers

HF150

HF185

HF234

HF304

HX55

HX75

xHF150yyHyyyyyy

xHF185yyHyyyyyy

xHF234yyHyyyyyy

xHF304yyHyyyyyy

xHF033yyHyyyyyy

xHF045yyHyyyyyy

xHF055yyHyyyyyy

xHF075yyHyyyyyy

CHF033

CHF045

CHF055

CHF055ANHX1

CHF055MNHX1

CHF075

CHF075ANHP1

CHF075ANHQ1

CHF150

CHF185

CHF234

CHF304

IHF033

IHF033ANHX1

IHF045

IHF045ANHX1

IHF055

IHF055ANHX1

IHF055ZNHX1

IHF075

IHF075ANHN1

IHF075ANHQ1

IHF150

IHF150MNHX1

IHF150ZNHP1

IHF185

IHF185ANHN1

IHF185ANHP1

IHF185ANHX1

IHF185YNHP1

IHF185ZNHP1

IHF185ZNHX1

IHF234

IHF234ANHN1

IHF234ANHP1

IHF234ANHQ1

IHF234MNHP1

IHF234MNHX1

IHF234ZNHP1

IHF234ZNHX1

IHF234ANHX1

IHF304

IHF304ANHP1

IHF304MNHP1

IHF304ZNHP1

5

Safety and Environmental Informations

Safety

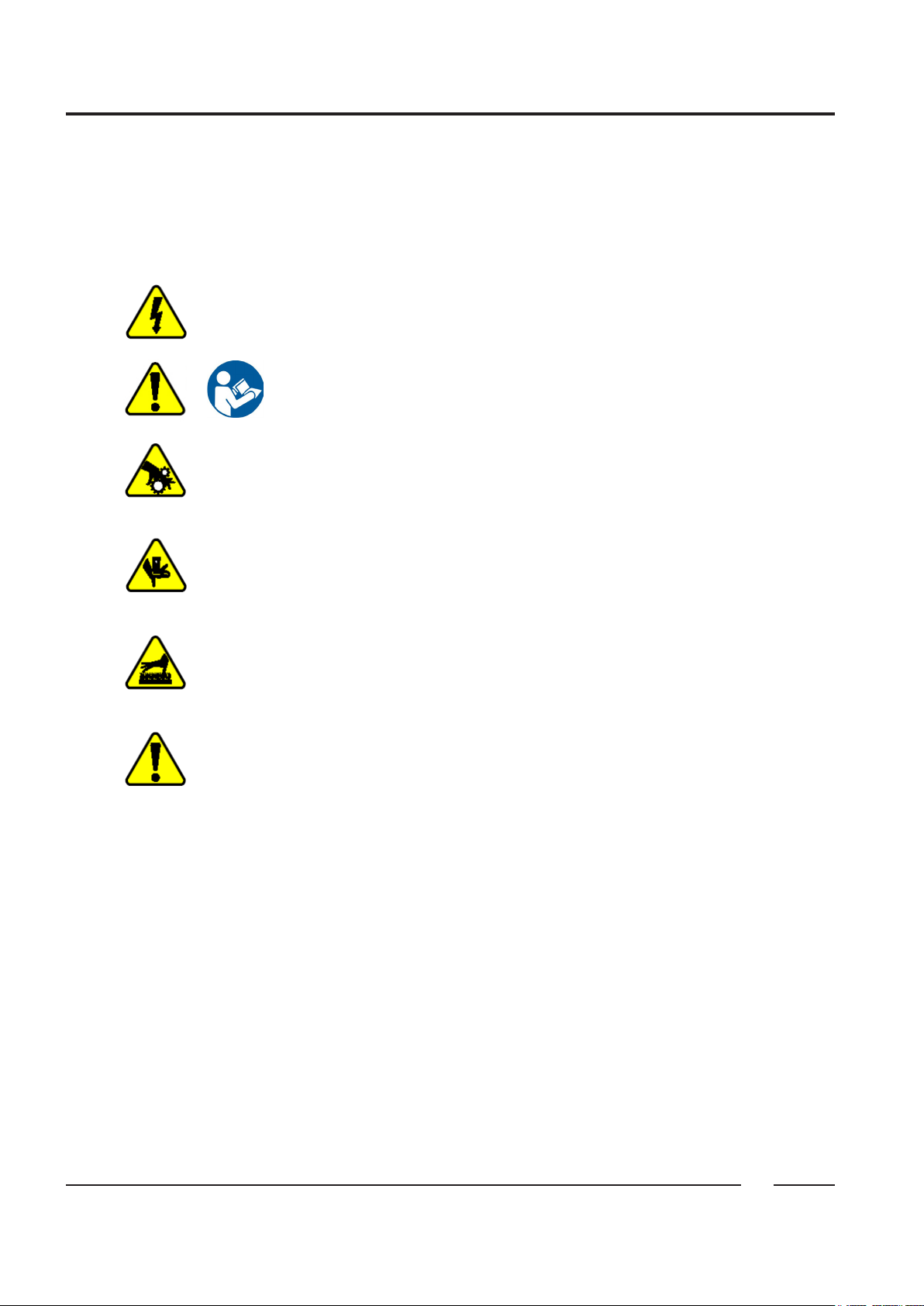

CAUTION LABELS

Please familiarize yourself with the following standard warning symbols. They are

used throughout this manual and on the equipment to alert you to possible hazards.

Anyone operating or servicing this equipment must understand these symbols and

must follow all safety rules in this manual.

ELECTRICAL HAZARD

This symbol alerts you to the presence of a dangerous voltage, which could cause a

serious shock resulting in personal injury or death.

CONSULT MANUAL

This symbol warns you to consult the manual for important instructions concerning

the machine and possible hazards.

MOVING PARTS HAZARD

This symbol alerts you to the presence of possible dangerous moving parts within

the machine. Guards should always be in place when the machine is in operation. Be

very careful when servicing the drive system.

2

PINCHING HAZARD

This warning symbol indicates the presence of a pinch point on the machine. This is

a place where your hand might be pinched or crushed, resulting in a severe injury.

Make sure you understand these hazards and keep all body parts clear of them.

HOT SURFACE HAZARD

This symbol indicates the presence of a potentially hot surface. Some machine

surfaces and parts may become extremely hot during normal operation and should

not be touched.

ATTENTION

This symbol identies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss.

6

Environmental

Disposal of Unit

This appliance is marked according to the European directive

2002/96/EC on Waste Electrical and Electronic Equipment (WEEE).

This symbol on the product or on its packaging indicates that this

product shall not be treated as household waste. Instead it shall be

handed over to the applicable collection point for the recycling of

electrical and electronic equipment. Ensuring this product is disposed

of correctly, you will help prevent potential negative consequences

for the environment and human health, which could otherwise be

caused by inappropriate waste handling of this product. The recycling

of materials will help to conserve natural resources. For more detailed

information about recycling of this product, please contact your local

distributor resources.

2

7

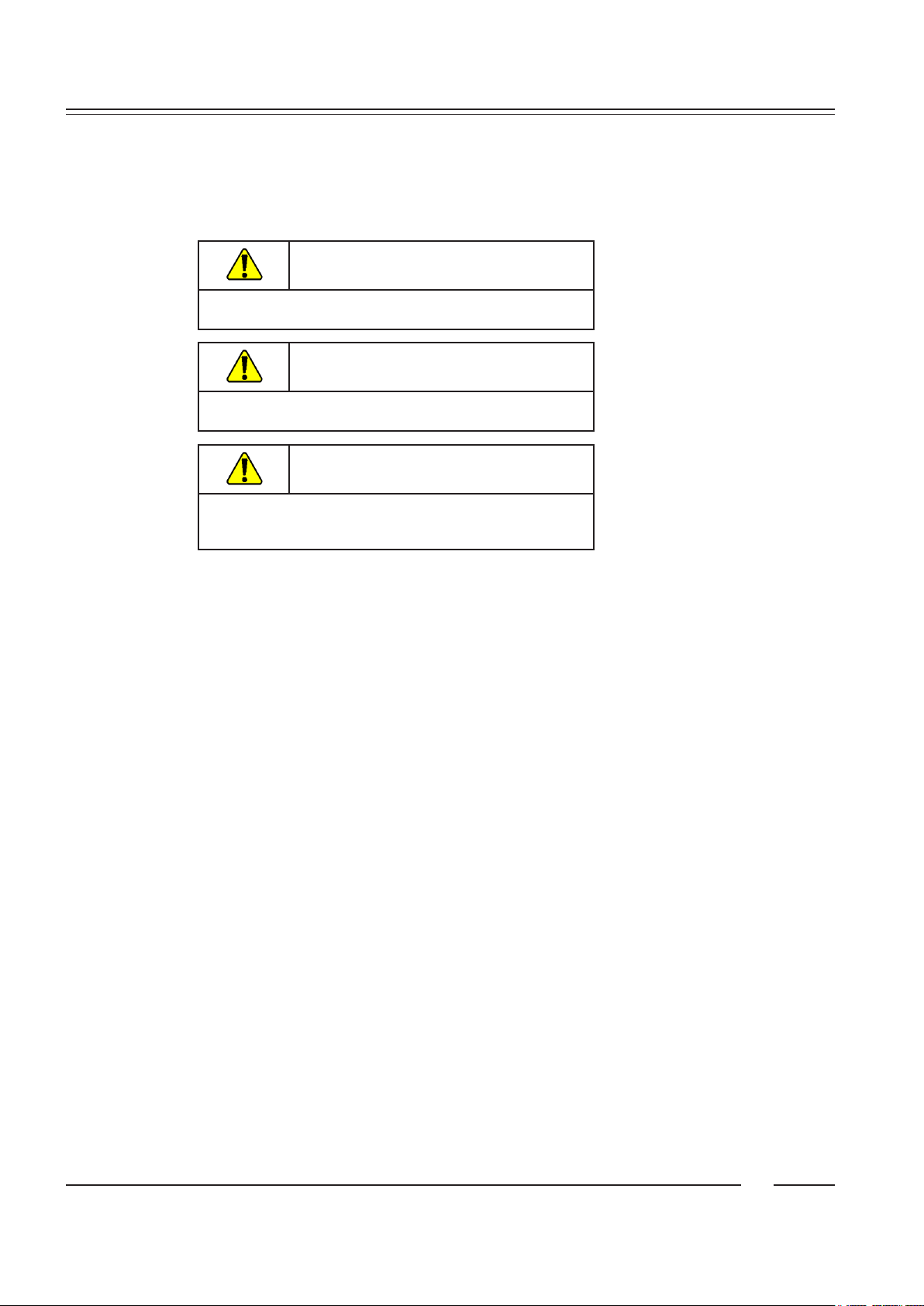

Explanation of Safety Messages

Throughout this manual and on machine decals, you will nd precautionary statements (“DANGER”,

“WARNING” and “CAUTION”) followed by specic instructions. These precautions are intended for the

personal safety of the operator, user, servicer, and those maintaining the machine.

DANGER

Indicates an imminently hazardous situation that, if not

avoided, will cause severe personal injury or death.

WARNING

Indicates a hazardous situation that, if not avoided, could

cause severe personal injury or death.

CAUTION

Indicates a hazardous situation that, if not avoided, may

cause minor or moderate personal injury or property

damage.

2

Safety Decals

Safety decals appear at crucial locations on the machine. Failure to maintain legible safety decals could

result in injury to the operator or service technician.

To provide personal safety and keep the machine in proper working order, follow all maintenance and

safety procedures presented in this manual. If questions regarding safety arise, contact the manufacturer

immediately.

Use manufacturer-authorized spare parts to avoid safety hazards.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specic instructions.

IMPORTANT: The word “IMPORTANT” is used to inform the reader of specic procedures where

minor machine damage will occur if the procedure is not followed.

NOTE: The word “NOTE” is used to communicate installation, operation, maintenance or servicing

information that is important but not hazard related.

8

2

Important Safety Instructions

WARNING

To reduce the risk of re, electric shock, serious injury or

death to persons when using your washer, follow these

basic precautions:

1. Read all instructions before using the washer.

2. Refer to the GROUNDING INSTRUCTIONS in the installation Manual for the proper grounding of the

washer.

3. Do not wash textiles that have been previously cleaned, washed, soaked, or spotted with gasoline,

dry-cleaning solvents, or other ammable or explosive substances as they give off vapors that could

ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or other ammable or explosive substances to the wash

water. These substances give off vapors that could ignite or explode.

5. Under certain conditions, hydrogen gas may be produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS IS EXPLOSIVE. If the hot water system has not been

used for such a period, before using a washing machine or combination washer-dryer, turn on all hot

water faucets and let the water ow from each for several minutes. This will release any accumulated

hydrogen gas. The gas is ammable, do not smoke or use an open ame during this time.

6. Do not allow children to play on or in the washer. This appliance is not intended for use by young

children or inrm persons without supervision. Young children should be supervised to ensure that

they do not play with the appliance.

7. Before the washer is removed from service or discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is moving. This is an imminently hazardous situation

that, if not avoided, will cause severe personal injury or death.

9. Do not install or store the washer where it will be exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or attempt any servicing unless specically

recommended in the user-maintenance instructions or in published user-repair instructions that the

user understands and has the skills to carry out.

12. To reduce the risk of an electric shock or re, DO NOT use an extension cord or an adapter to connect

the washer to an electrical power source.

13. Use a washer only for its intended purpose, washing textiles.

14. ALWAYS disconnect the washer from the electrical supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the INSTALLATION INSTRUCTIONS. All connections for water, drain,

electrical power and grounding must comply with local codes and be made by licensed personnel

when required.

16. To reduce the risk of re, textiles which have traces of any ammable substances such as vegetable

oil, cooking oil, machine oil, ammable chemicals, thinner, etc., or anything containing wax or

chemicals such as in mops and cleaning cloths, must not be put into the washer. These ammable

substances may cause the fabric to catch on re.

17. Do not use fabric softeners or products to eliminate static unless recommended by the manufacturer of

the fabric softener or product.

18. Keep washer in good condition. Bumping or dropping the washer can damage safety features. If this

occurs, have washer checked by a qualied service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve and that ll hose connections are tight. CLOSE the

shut-off valves at the end of each wash day.

9

22

21. Loading door MUST BE CLOSED any time the washer is to ll, tumble, or spin. DO NOT bypass the

loading door switch by permitting the washer to operate with the loading door open.

22. Always read and follow manufacturer’s instructions on packages of laundry and cleaning aids. Heed all

warnings or precautions. To reduce the risk of poisoning or chemical burns, keep them out of the reach

of children at all times (preferably in a locked cabinet).

23. Always follow the fabric care instructions supplied by the textile manufacturer.

24. Never operate the washer with any guards and/or panels removed.

25. DO NOT operate the washer with missing or broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain, and/or operate this washer according to the manufacturer’s instructions

may result in conditions which can produce bodily injury and/or property damage.

28. It is recommended that the machine be installed by qualied technicians.

29. Before starting repairs or maintenance, shut off all power and water supplies.

30. To prevent re and explosion:

Keep the area around the machine free from inammable or combustible products.

NOTE: The WARNINGS and IMPORTANT SAFETY INSTRUCTIONS appearing in this manual are not

meant to cover all possible conditions and situations that may occur. Common sense, caution, and

care must be exercised when installing, maintaining, or operating the washer.

Any problems or conditions not understood should be reported to the dealer, distributor, service agent, or

the manufacturer.

SAVE THESE INSTRUCTIONS

10

2

Operator Safety

WARNING

NEVER insert hands or objects into basket until it has

completely stopped. Doing so could result in serious

injury.

To ensure the safety of machine operators, the following maintenance checks must be performed daily:

1. Prior to operating the machine, verify that all warning signs are present and legible. Missing or illegible

signs must be replaced immediately. Make certain that spares are available.

2. Check door interlock before starting operation of the machine:

a. Attempt to start the machine with the door open. The machine should not start with the door open.

b. Close the door without locking it and attempt to start the machine. The machine should not start with

the door unlocked.

c. Close and lock the door and start a cycle. Attempt to open the door while the cycle is in progress.

The door should not open.

If the door lock and interlock are not functioning properly, call a service technician.

3. Do not attempt to operate the machine if any of the following conditions are present:

a. The door does not remain securely locked during the entire cycle.

b. Excessively high water level is evident.

c. Machine is not connected to a properly grounded circuit.

Do not bypass any safety devices in the machine.

WARNING

Never operate the machine with a bypassed or

disconnected balance system. Operating the machine

with severe out-of-balance loads could result in personal

injury and serious equipment damage.

SAVE THESE INSTRUCTIONS

11

Technical data and dimensions

Technical data HF150, IHF150, IHF033, CHF150, CHF033

Capacity (dry weight) Ratio [kg/Lit]

1:11 13,2 kg 29.10 lb.

1:10 14,5 kg 31.97 lb.

1:9 16,1 kg 35.49 lb.

Cylinder

Diameter 680 mm 26.77 inch

Depth 400 mm 15.75 inch

Volume 145 Lit 5.12 ft³

Cabinet

Height 1376 mm 54.15 inch

Width 780 mm 30.71 inch

Depth 840 mm 33.07 inch

Front loading

Diameter door opening 400 mm 15.75 inch

Height under door 472 mm 18.58 inch

To center 745 mm 29.33 inch

Speed

Wash 10 - 50 tr/min - RPM

Distribution 85 tr/min - RPM

Spin 250 - 1000 tr/min - RPM

G-factor

High spin 380

Dynamic bottom load (N/Hz)

Motor (3-phase)

4p. 1470 tr/min 2,2 kW / 2,95 HP

Drain valve

Water supply

Hard, soft, warm water 3/4"

Steam connection

Steam connection 3/8"

Heating

Electrical 230/400 V 12 kW - 15 kW - 18 kW

Electrical 400V 21 kW - 24 kW

Steam 6 bar

Warm water (without additional heating) X

Warm water (with additional heating) X

Packing dimensions

(H x W x D) mm - inch 1500x850x950 mm - 59.06x33.46x37.40 inch

Weight

Net 368 kg 811.30 lb.

Gross 383 kg 844.37 Ib.

METRIC US

1010/16

2"

3

3

12

170 [6.69]

K

185 [7.29]

35 [1.38]

L

E

D

C

B

A

I

G

F

109 [4.3]

1015 [39.96]

1066 [41.95]

1108 [43.6]

1141 [44.9]

105 [4.13]

704 [27.7]

332 [13.05]

267 [10.49]

202 [7.93]

1376 [54.15]

1348 [53.07]

780 [30.71]

680 [26.77]50 [1.97] 50 [1.97]

472 [18.58]

34 [1.34]

220 [8.66]

86.5 [3.41]

34 [1.34]

88 [3.47]

665 [26.18]

733 [28.86]

753 [29.65]

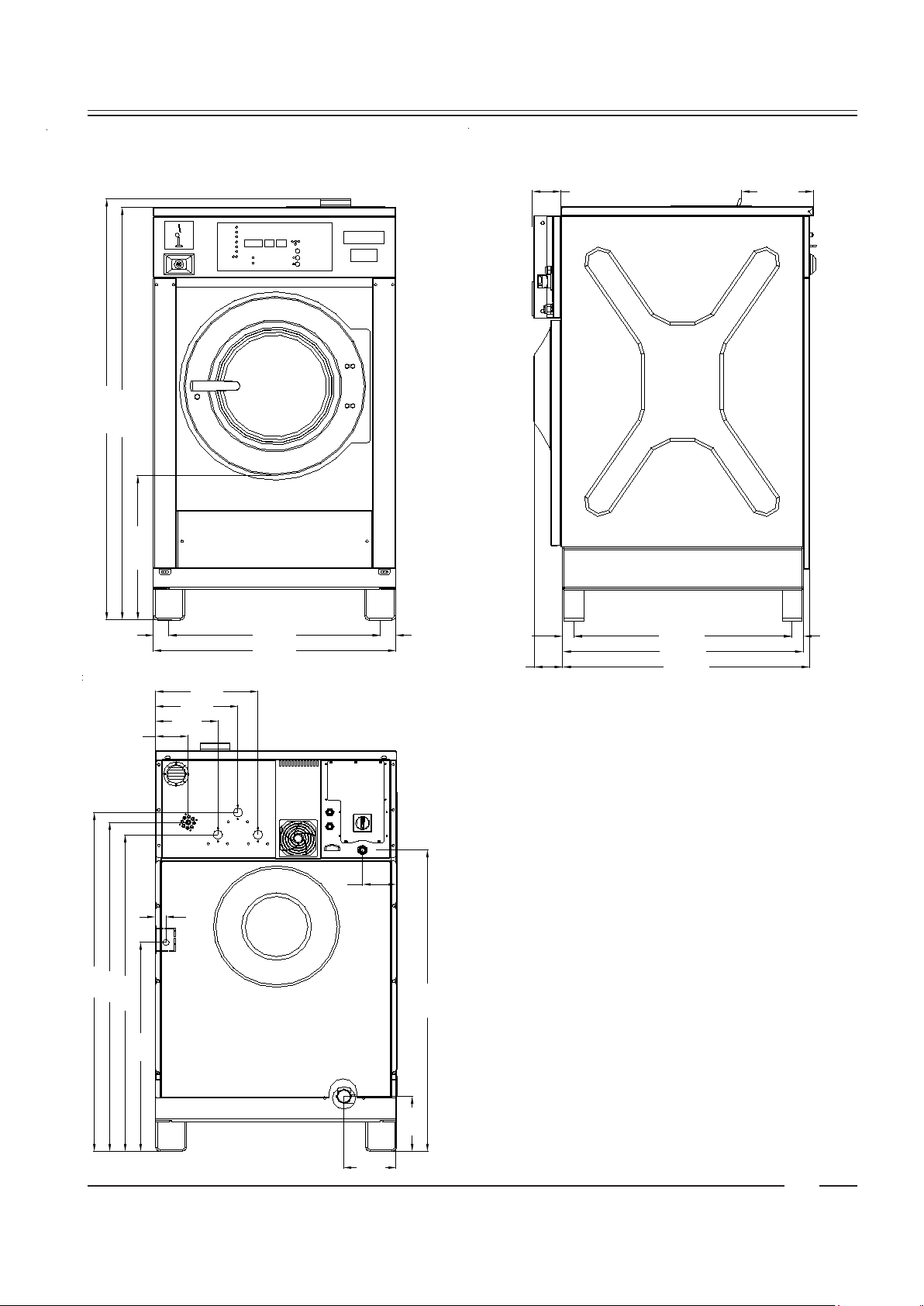

Dimensions HF150, IHF150, IHF033, CHF150, CHF033

Legend: metric mm [inches]

3

A. Ventilation soap dispenser

B. Liquid soap connections

C. Hard water connections 3/4"

D. Warm water connections 3/4"

E. Soft water connections 3/4"

F. Connection clamps

G. Electrical connections

I. Ventilation tub

K. Drain valve

L. Steam connections

13

Technical data HF185, IHF185, IHF045, CHF185, CHF045

Capacity (dry weight) Ratio [kg/Lit]

1:11 16,5 kg 36.38 lb.

1:10 18,1 kg 39.90 lb.

1:9 20,1 kg 44.31 lb.

Cylinder

Diameter 680 mm 26.77 inch

Depth 500 mm 19.69 inch

Volume 181 Lit 6.39 ft³

Cabinet

Height 1376 mm 54.15 inch

Width 780 mm 30.71 inch

Depth 940 mm 37.01 inch

Front loading

Diameter door opening 400 mm 15.75 inch

Height under door 472 mm 18.58 inch

To center 745 mm 29.33 inch

Speed

Wash 10 - 50 tr/min - RPM

Distribution 85 tr/min - RPM

Spin 250 - 1000 tr/min - RPM

G-factor

High spin 380

Dynamic bottom load (N/Hz)

Motor (3-phase)

4p. 1470 tr/min 2,2 kW / 2,95 HP

Drain valve

Water supply

Hard, soft, warm water 3/4"

Steam connection

Steam connection 3/8"

Heating

Electrical 230/400 V 12 kW - 15 kW - 18 kW

Electrical 400V 21 - 24 kW

Steam 6 bar

Warm water (without additional heating) X

Warm water (with additional heating) X

Packing dimensions

(H x W x D) mm - inch 1500x850x1020 mm - 59.06x33.46x40.16 inch

Weight

Net 391 kg 862.01 lb.

Gross 418 kg 921.53 Ib.

3

METRIC US

1090/16

2"

14

Loading...

Loading...