Alliance Laundry Systems HC18PC2, HC20VC2, HC18VC2, HC20SN2, HC25PC2 Troubleshooting Manual

...Page 1

Washer-Extractor

Cabinet Hardmount

P, S and V Computer

Refer to Page 8 for Model Numbers

Troubleshooting

www.comlaundry.com

CHM1323C

Part No. F232203R2

December 2006

Page 2

Page 3

Table of

Contents

Safety Information...................................................................................3

General Safety Precautions....................................................................3

Important Safety Instructions ................................................................4

Locating an Authorized Servicer...........................................................5

Introduction..............................................................................................7

Customer Service...................................................................................7

Nameplate Location...............................................................................7

Model Identification..............................................................................8

Troubleshooting.......................................................................................9

1. No Hot Fill Analysis (OPL)........................................................10

2. No Hot Fill Analysis (Coin)........................................................14

3. No Cold Fill Analysis (OPL)......................................................18

4. No Cold Fill Analysis (Coin)......................................................22

5. No Supply Fill Analysis (OPL)...................................................26

6. No Supply Fill Analysis (Coin) ..................................................30

7. No Motor Function (FWD or REV)............................................34

8. No Motor Function (SP) .............................................................38

9. Drain Valve Malfunction ............................................................42

10. Overflow Analysis ......................................................................46

11. Contactor Analysis (FWD and REV)..........................................50

12. Contactor Analysis (SP)..............................................................54

13. Coins Ignored When Entered......................................................58

14. Control Has No Display (OPL)...................................................62

15. Control Has No Display (Coin) ..................................................66

16. The Machine Does Not Hold Water ...........................................70

17. Compartment 2 of Supply Dispenser Not Flushing Completely 74

18. The Door Leaks...........................................................................75

19. No Keypad Function...................................................................76

20. Excessive Vibration and/or Noise During Spin..........................77

21. The Water Level is Too High or Too Low.................................78

22. Excessive Cycle Time.................................................................79

23. Water Running Continuously with Machine Power Off.............80

24. Door Unlocking Malfunction (OPL)...........................................82

25. Door Unlocking Malfunction (Coin)..........................................86

26. Pump Drain Analysis ..................................................................90

27. Machine Won't Start (OPL) ........................................................94

28. Machine Won't Start (Coin)........................................................98

29. Motor Runs Continuously in One Direction.............................102

30. Machine Stops in Mid-Cycle ....................................................103

31. Overload Relay Tripping Repeatedly .......................................104

32. Compartment 2 of Supply Dispenser Not Flushing

Completely................................................................................105

33. Troubleshooting and Cleaning the Coin Drop..........................106

© Copyright 2006, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any means without

the expressed written consent of the publisher.

F232203 1

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 4

Notes

2 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 5

Section 1

Safety Information

Throughout this manual and on machine decals, you will find precautionary statements (“CAUTION,”

“WARNING,” and “DANGER”) followed by specific instructions. These precautions are intended for the personal

safety of the operator, user, servicer and those maintaining the machine.

a DANGER

Danger indicates the presence of a hazard that will cause severe personal injury, death or substantial property

damage if the danger is ignored.

a WARNING

Warning indicates the presence of a hazard that can cause severe personal injury, death or substantial property

damage if the warning is ignored.

a CAUTION

Caution indicates the presence of a hazard that will or can cause minor personal injury or property damage if the

caution is ignored.

Additional precautionary statements (“IMPORTANT” and “NOTE”) are followed by specific instructions.

IMPORTANT

The word “IMPORTANT” is used to inform the reader of specific procedures where minor machine damage will

occur if the procedure is not followed.

NOTE

The word “NOTE” is used to communicate installation, operation, maintenance or servicing information that is

important but not hazard related.

General Safety Precautions

In the interest of safety, some general precautions relating to the operation of this machine follow.

WARNING

• Failure to install, maintain and/or operate this product according to the manufacturer’s

instructions may result in conditions which can produce serious injury, death and/or property

damage.

• Do not repair or replace any part of the product or attempt any servicing unless specifically

recommended or published in this Service Manual and unless you understand and have the

skills to carry out the servicing.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the product is properly grounded and to reduce the risk of fire,

electric shock, serious injury or death.

W006R2

F232203 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 6

Safety Information

WARNING

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the washer-extractor before servicing.

• Never start the washer-extractor with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer-extractor is properly grounded.

WARNING

Repairs that are made to your products by unqualified persons can result in hazards due to

improper assembly or adjustments subjecting you or the inexperienced person making such

repairs to the risk of serious injury, electrical shock or death.

WARNING

If you or an unqualified person perform service on your product, you must assume the

responsibility for any personal injury or property damage which may result. The manufacturer

will not be responsible for any injury or property damage arising from improper service and/or

service procedures.

W460

W007

W008

Always contact your dealer, distributor, service agent or the manufacturer about any problems or conditions you do

not understand.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock, serious injury or death to persons when using your

washer, follow these basic precautions:

1. Read all instructions before using the washerextractor.

2. Refer to the GROUNDING INSTRUCTIONS in

the INSTALLATION manual (supplied with your

washer-extractor) for the proper grounding of the

washer-extractor.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in or spotted with

gasoline, dry-cleaning solvents or other

flammable or explosive substances. They give off

vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washer-extractor, turn on all hot water faucets and

let the water flow from each for several minutes.

This will release any accumulated hydrogen gas.

The gas is flammable. Do not smoke or use an

open flame during this time.

W023E

4 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 7

Safety Information

6. Do not allow children to play on or in a washerextractor. Close supervision of children is

necessary when the washer-extractor is used near

children.

7. Before the washer-extractor is removed from

service or discarded, remove the door to the

washing compartment.

8. Do not reach into the washer-extractor if the wash

basket is moving.

9. Do not install or store the washer-extractor where

it will be exposed to water and/or weather.

10. Do not tamper with the washer-extractor’s

controls.

11. Do not repair or replace any part of the washerextractor or attempt any servicing unless

specifically recommended in the usermaintenance instructions or in published userrepair instructions that the user understands and

has the skills to carry out.

12. To reduce the risk of an electrical shock or fire,

DO NOT use an extension cord or an adapter to

connect the washer-extractor to an electrical

power source.

13. Use the washer-extractor only for its intended

purpose, washing clothes.

14. ALWAYS disconnect the washer-extractor from

its electrical supply before attempting any

service.

15. Install the washer-extractor according to the

INSTALLATION INSTRUCTIONS. All

connections for water, drain, electrical power and

grounding must comply with local codes and,

when required, be made by licensed personnel.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops or

cleaning cloths, must not be put into the washerextractor. These flammable substances may cause

the fabric to ignite.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep the washer-extractor in good condition.

Bumping or dropping the washer-extractor can

damage its safety features. If this occurs, have the

washer-extractor checked by a qualified service

person.

19. Replace worn power cords and/or loose plugs.

20. Be sure that water connections have a shut-off

valve and that fill hose connections are tight.

CLOSE the shut-off valves at the end of each

wash day.

21. The loading door MUST BE CLOSED any time

the washer-extractor is to fill, tumble or spin. DO

NOT by-pass the loading door switch and permit

the washer-extractor to operate with the loading

door open.

22. Always read and follow the manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings and precautions. To

reduce the risk of poisoning or chemical burns,

keep them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer-extractor with any

guards and/or panels removed.

25. DO NOT operate the washer-extractor with

missing or broken parts.

26. DO NOT by-pass any safety devices.

27. Failure to install, maintain and/or operate this

washer-extractor according to the manufacturer's

instructions may result in conditions that can

produce bodily injury and/or property damage.

NOTE: The WARNING and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining and operating the washerextractor.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

Locating an Authorized Servicer

Alliance Laundry Systems is not responsible for

personal injury or property damage resulting from

improper service. Review all service information

before beginning repairs.

Warranty service must be performed by an authorized

technician, using authorized factory parts. If service is

required after the warranty expires, Alliance Laundry

Systems also recommends contacting an authorized

technician and using authorized factory parts.

F232203 5

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 8

Notes

6 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 9

Section 2

Introduction

Customer Service

Alliance Laundry Systems is not responsible for

personal injury or property damage resulting from

improper service. Review all service information

before beginning repairs.

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name of the nearest authorized parts distributor.

For technical assistance, call the following number:

(920) 748-3121

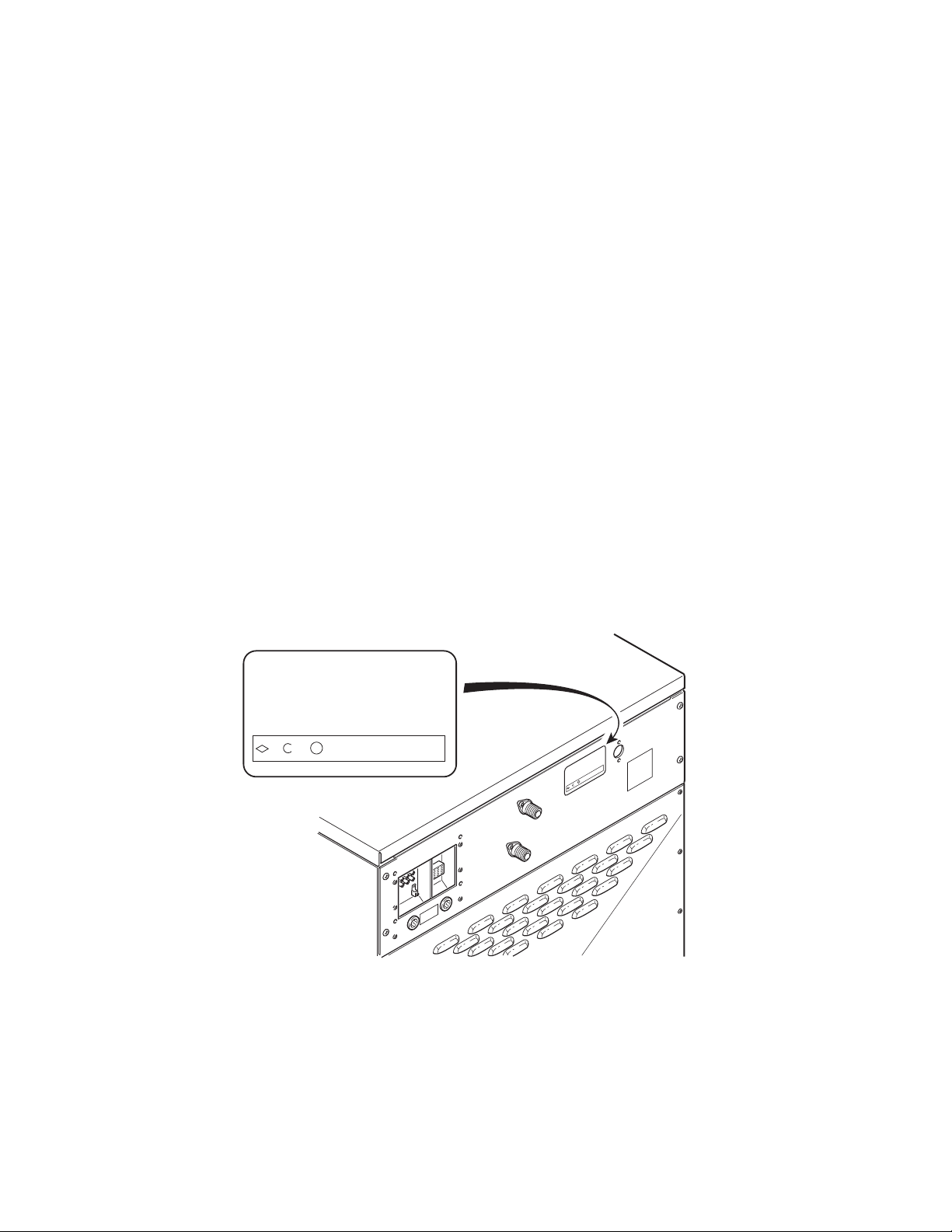

Nameplate Location

When calling or writing about your product, be sure to

mention model and serial numbers. Model and serial

numbers are located on nameplate(s) as shown.

Model No.

Serial No.

Voltage Amps

Required Circuit Breaker Amps.

Hz Wire Phase

Max. Load KG Max. Speed RPMLB

Elec. Heating

Product No. Date Code

KW Steam Press PSI

BAR

M

P

R

R

A

B

ps

m

A

d

e

.

e

s

o.

I

p

p

S

S

se

l N

a

x.

Am

h

de

r

.

P

o

Ma

o

ke

M

a

e

ss P

r

G

e

rial N

B

K

r

e

t

i

P

S

e

e

cu

ir

m

g

a

a

W

Cir

e

t

olt

S

V

ed

e

B

L

W

od

K

quir

C

e

e

R

t

Da

d

a

Hz

o

L

g

n

i

x.

t

a

a

M

lec. He

E

o.

N

t

c

odu

r

P

CHM2411P

F232203 7

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 10

Introduction

Model Identification

Information in this manual is applicable to these washer-extractors.

HC18PC2

HC18SN2

HC18VC2

HC20SN2

HC20VC2

HC20VX2

HC25PC2

HC25SN2

HC25VC2

HC25VX2

HC27PC2

HC27SN2

HC27VC2

HC30SN2

HC30VC2

HC30VX2

HC35PC2

HC35SN2

HC35VC2

HC40SN2

HC40VC2

HC40VX2

HC50PC2

HC50SN2

HC50VC2

HC50VX2

HC60SN2

HC60VC2

HC60VX2

HC80PC3

HC80SN3

HC80VCV

HC80VNV

HC80VXV

SC125VNV

SC18PC3

SC18SN2

SC18SN3

SC18VN2

SC18VNV

SC20VN2

SC25SN2

SC25VN2

SC27SN2

SC27VN2

SC27VNV

SC30VN2

SC35PC3

SC35SN2

SC35SN3

SC35VN2

SC35VNV

SC40VN2

SC40VNV

SC50PC3

SC50SN2

SC50SN3

SC50VN2

SC50VNV

SC60VN2

SC60VNF

SC60VNV

SC80SN3

SC80VNV

UC125VNV

UC18PC2

UC18PC3

UC18PN2

UC18PN3

UC18VN2

UC18VNV

UC20PN2

UC20VN2

UC25PC2

UC25PN2

UC25VN2

UC27PC2

UC27PN2

UC27VN2

UC27VNV

UC30PN2

UC30VN2

UC35PC2

UC35PC3

UC35PN2

UC35PN3

UC35VN2

UC35VNV

UC40PN2

UC40VN2

UC40VNV

UC50PC2

UC50PC3

UC50PN2

UC50PN3

UC50VN2

UC50VNV

UC60PN2

UC60VN2

UC60VNF

UC60VNV

UC80PC3

UC80PN3

UC80VNV

8 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 11

Section 3

Troubleshooting

WARNING

To reduce the risk of electrical shock, fire, explosion, serious injury or death:

• Disconnect electrical power to the washer-extractor before servicing it.

• Close the gas shut-off valve to the washer-extractor (when applicable) before servicing it.

• Never start the washer-extractor with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be

reconnected to ensure that the washer-extractor is properly grounded.

W461R1

F232203 9

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 12

Troubleshooting

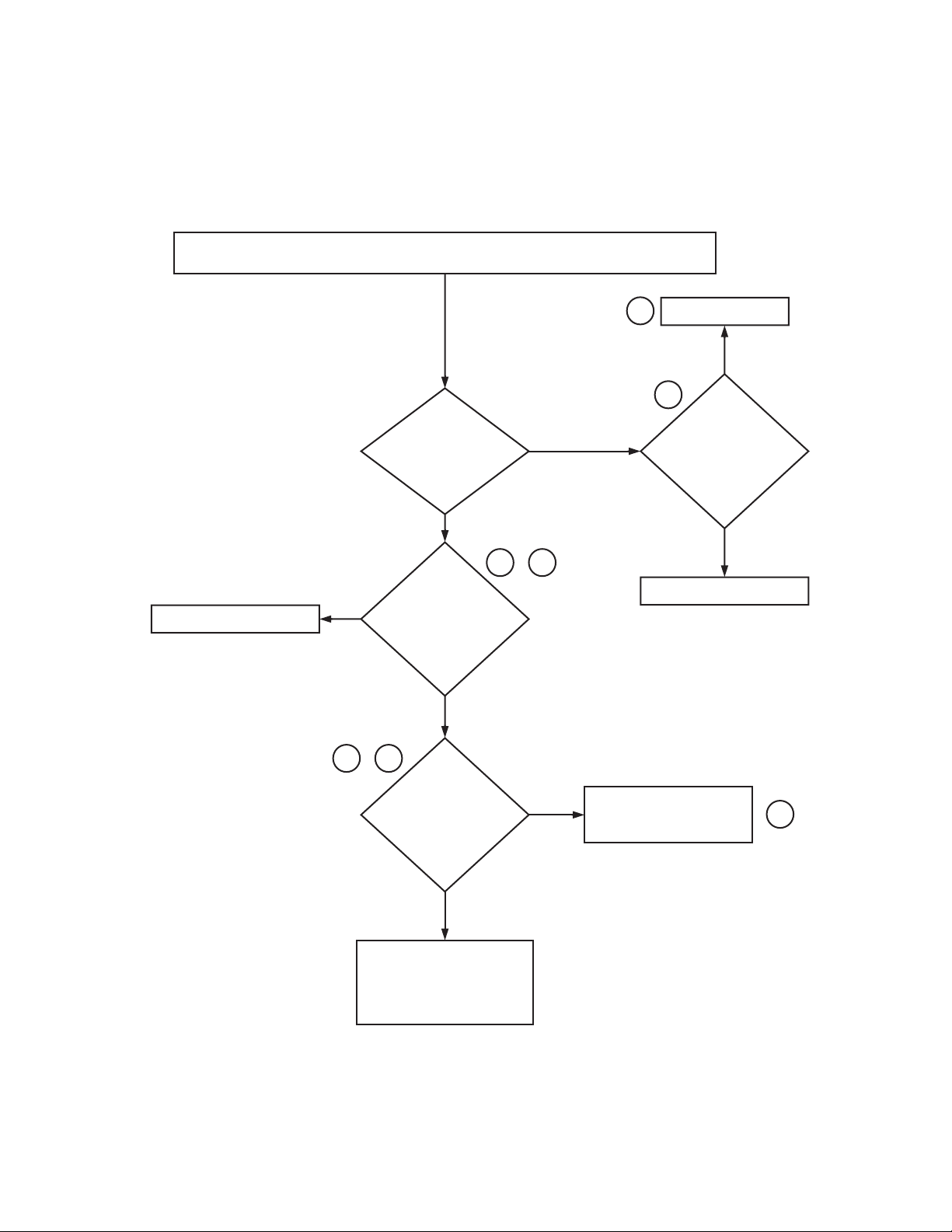

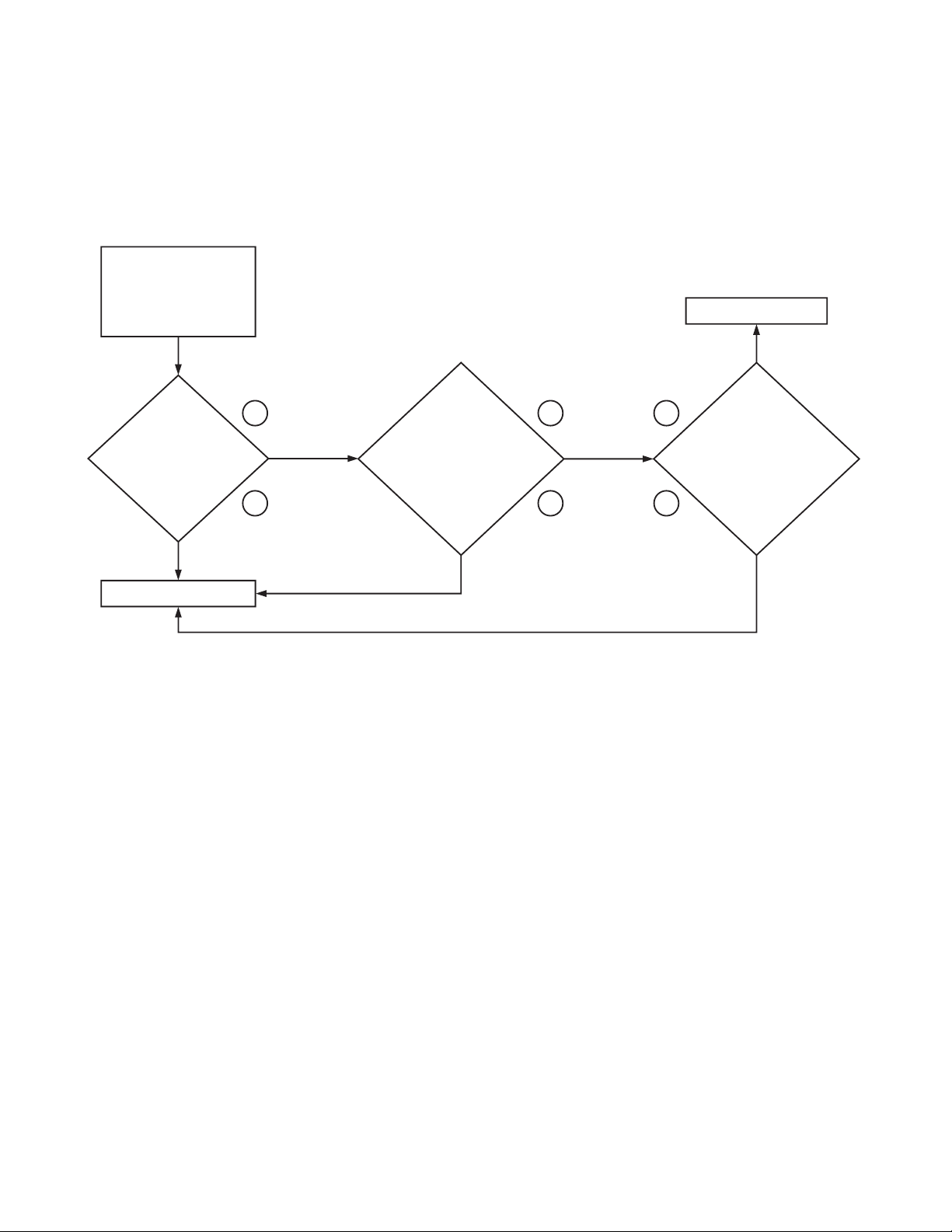

1. No Hot Fill Analysis (OPL)

No Hot Fill Analysis (OPL)

With the water turned on to the machine, during a cycle that has been programmed for a hot fill,

no hot water is filling the machine.

Replace the HF fuse.1A

YES

1A

Replace the output board.

NO

4A 3A

Is the HF light

on the output board

turned on?

YES

Is there voltage

(120 Volts AC)

between the HF

terminal and the

ACN?

YES

Is there voltage

(120 Volts AC)

between the V1

terminal and the

ACN?

NO

2A 3A

NO

Test the HF

fuse with an ohm

meter. Is the HF

fuse blown?

Replace the output board.

Inspect wire HF TS16 and

repair or replace the wire as

needed.

NO

5A

YES

Inspect the water inlet valve

and hoses. Repair or replace

the water inlet valve as

needed.

CHM388S

10 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 13

Troubleshooting

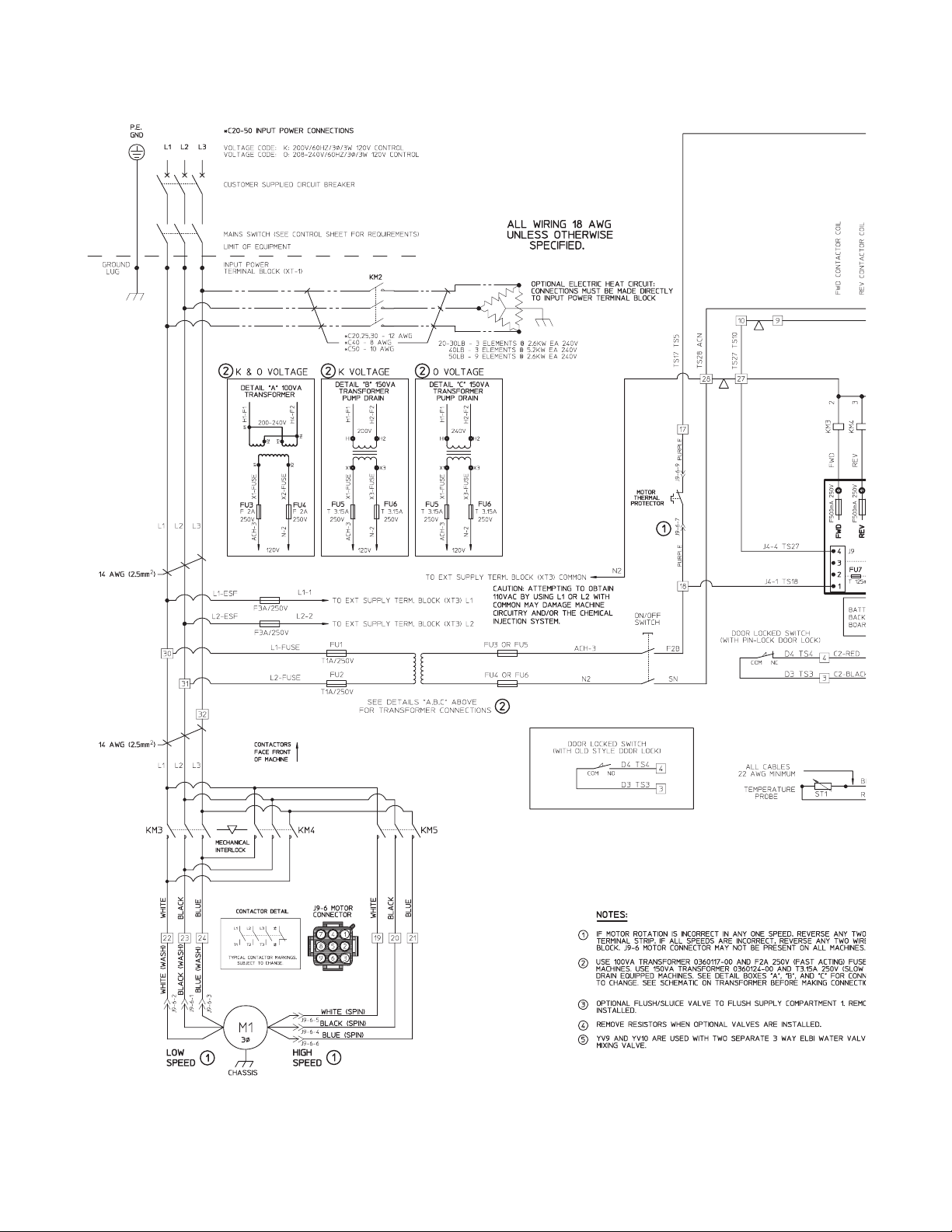

Please refer to the following 2 pages for wiring diagram information.

F232203 11

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 14

Troubleshooting

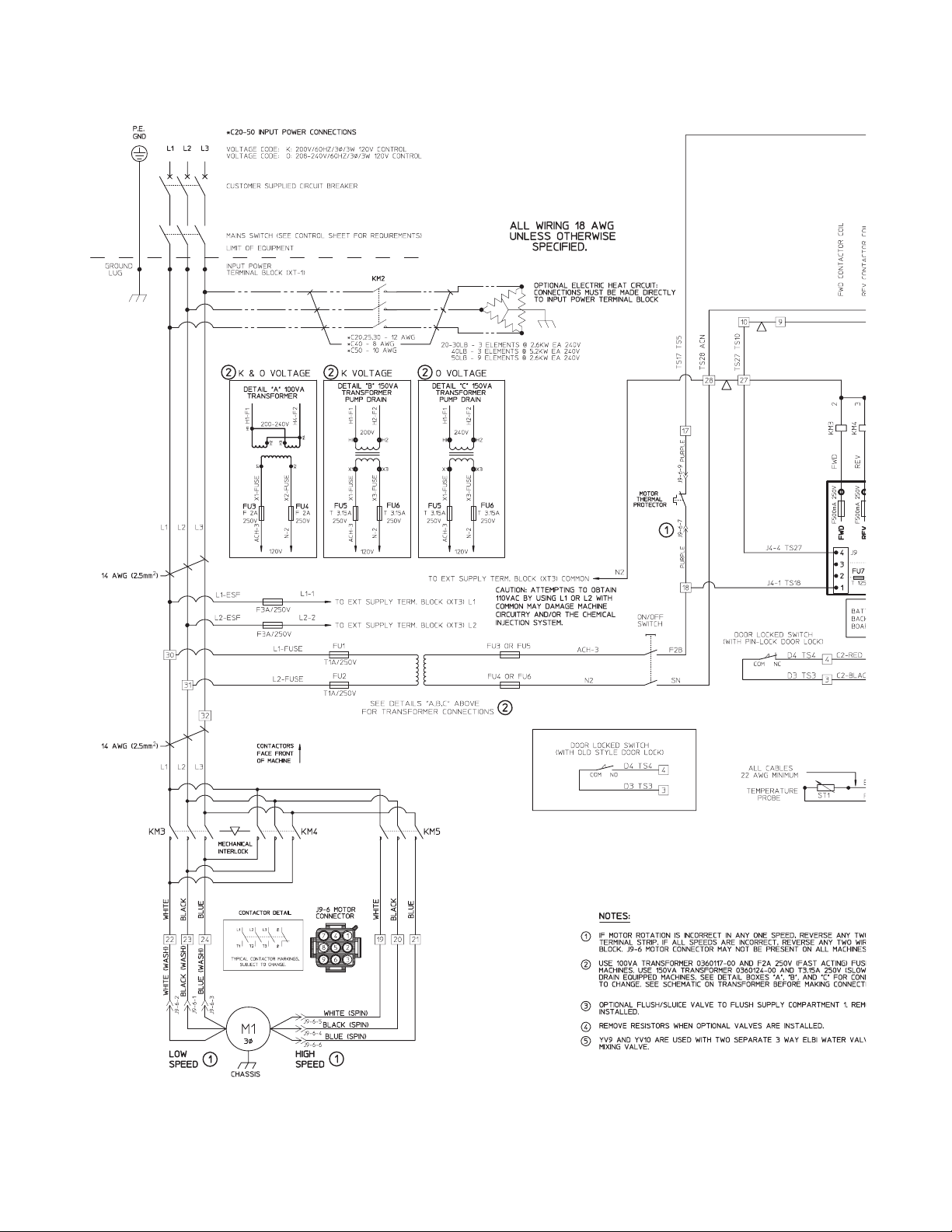

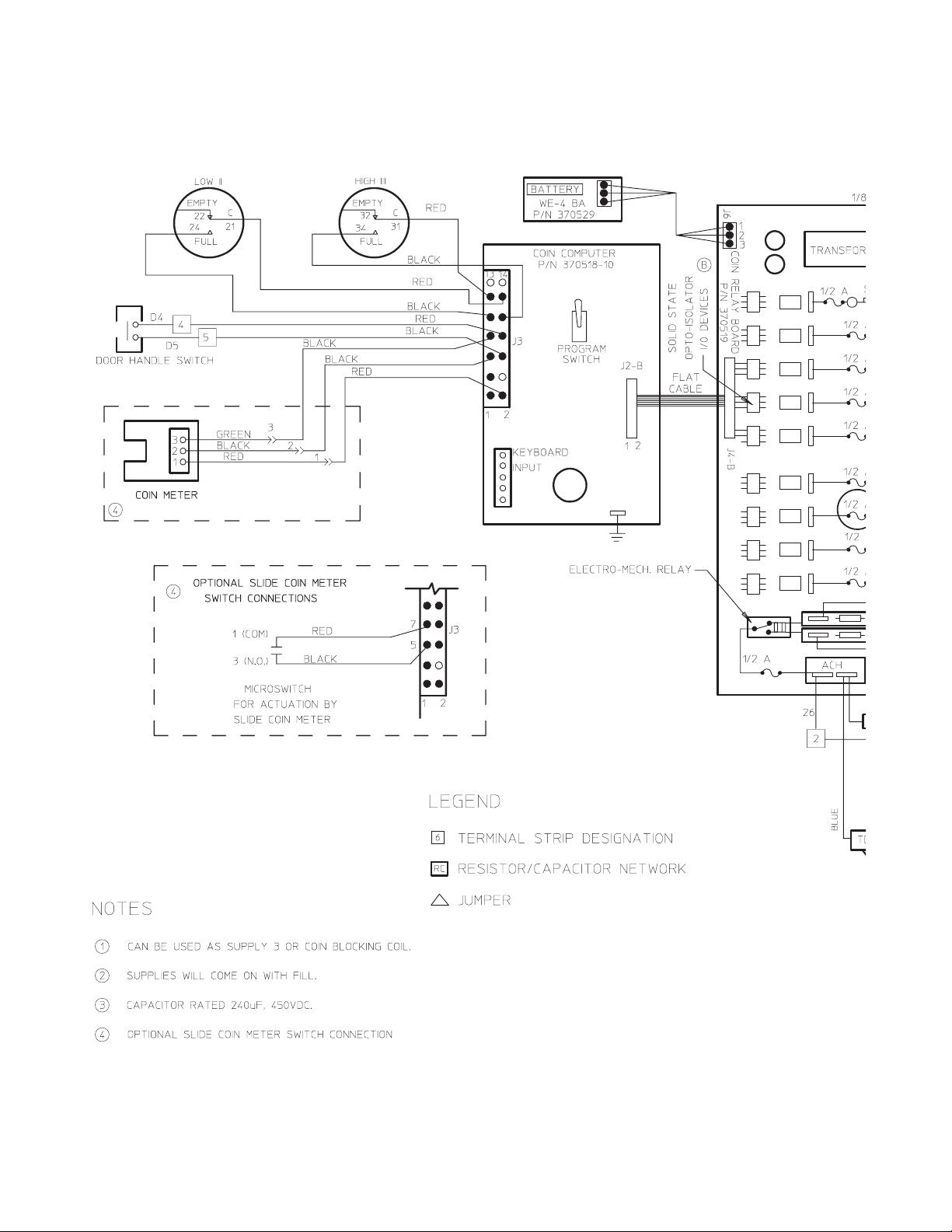

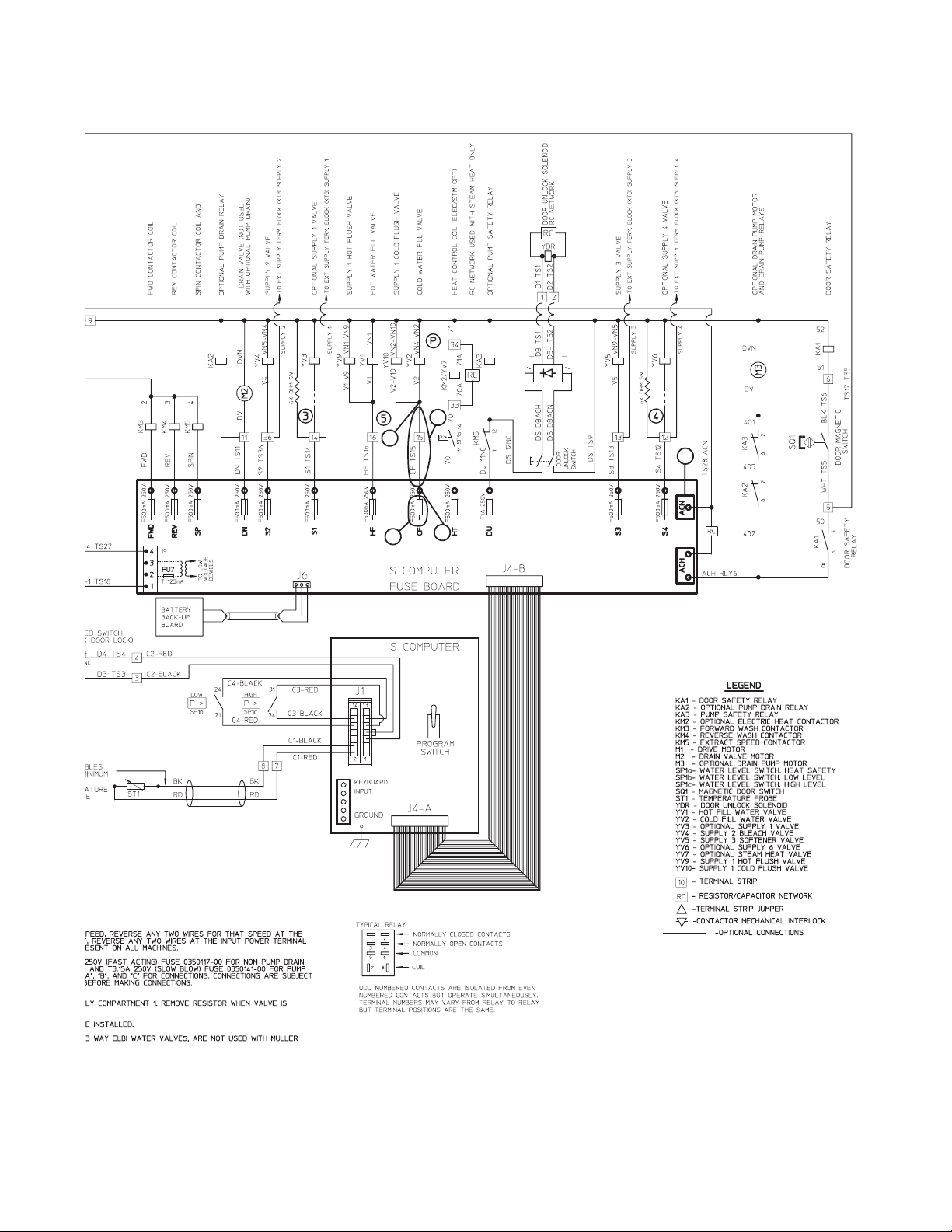

No Hot Fill Analysis (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

12 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 15

No Hot Fill Analysis (Sheet 2 of 2)

Troubleshooting

4A

1A

5A

3A

2A

CHM389S

607072(P)

F232203 13

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 16

Troubleshooting

2. No Hot Fill Analysis (Coin)

No Hot Fill Analysis (Coin)

With the water turned on to the machine, during a cycle that has been programmed for a hot fill,

no hot water is filling the machine.

Replace the HF fuse.1A

YES

1A

Replace the output board.

NO

4A 3A

Is the HF light

on the output board

turned on?

YES

Is there voltage

(120 Volts AC)

between the HF

terminal and the

ACN?

YES

Is there voltage

(120 Volts AC)

between the V1

terminal and the

ACN?

NO

2A 3A

NO

Test the HF

fuse with an ohm

meter. Is the HF

fuse blown?

Replace the output board.

Inspect wire 16 and repair or

replace the wire as needed.

NO

5A

YES

Inspect the water inlet valve

and hoses. Repair or replace

the water inlet valve as

needed.

14 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CHM390S

Page 17

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 15

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 18

Troubleshooting

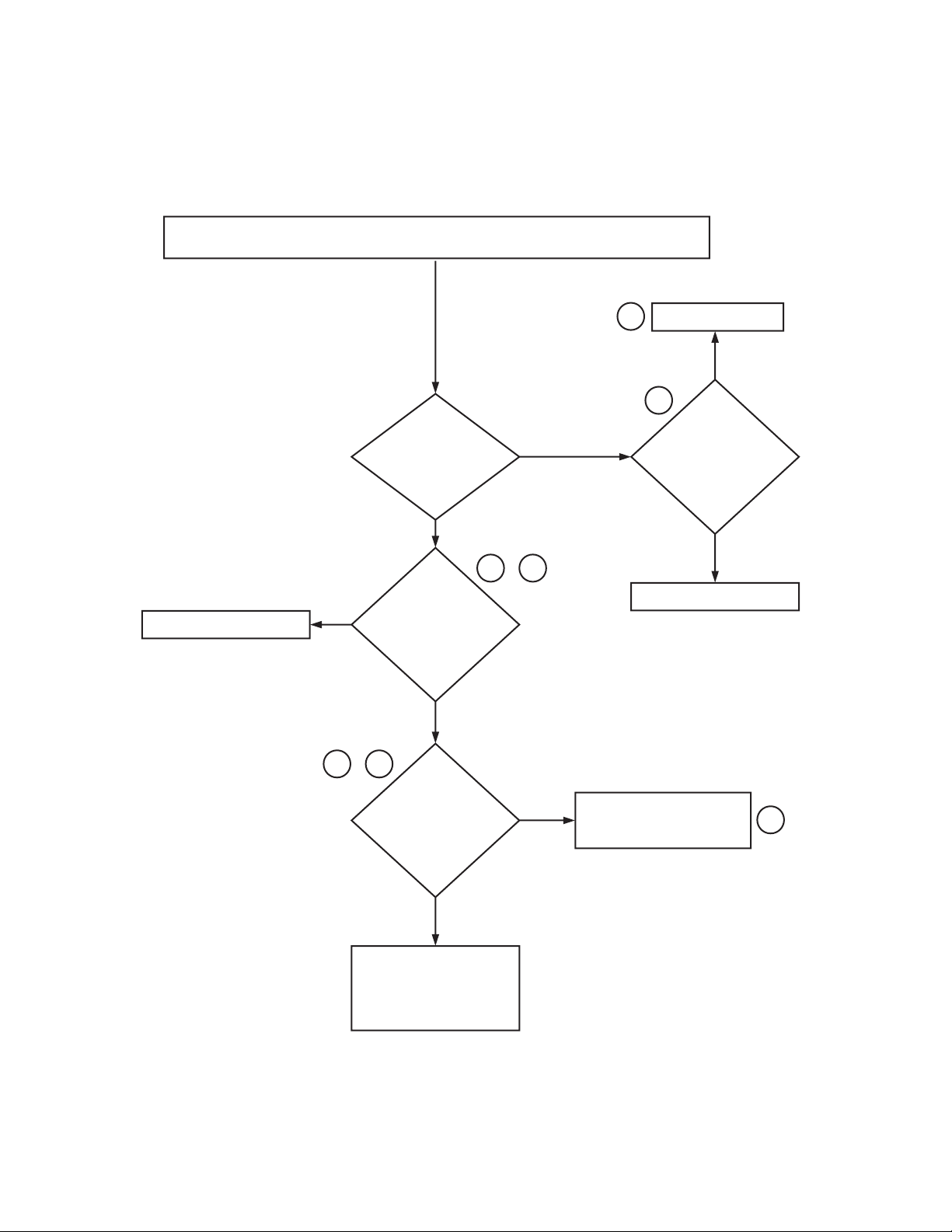

No Hot Fill Analysis (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

16 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 19

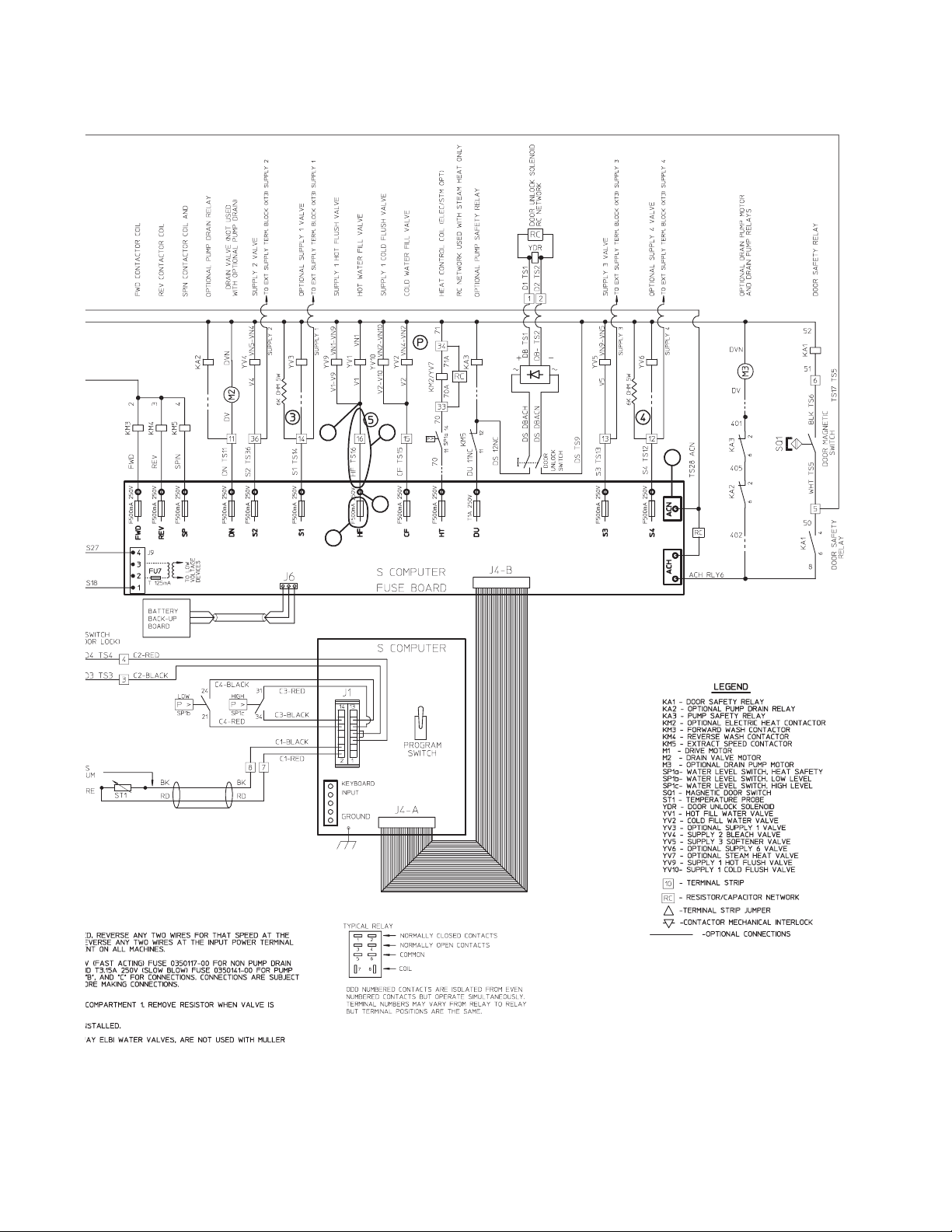

Troubleshooting

No Hot Fill Analysis (Sheet 2 of 2)

5A

2A

1A

3A

4A

CHM391S

606909(F)

F232203 17

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 20

Troubleshooting

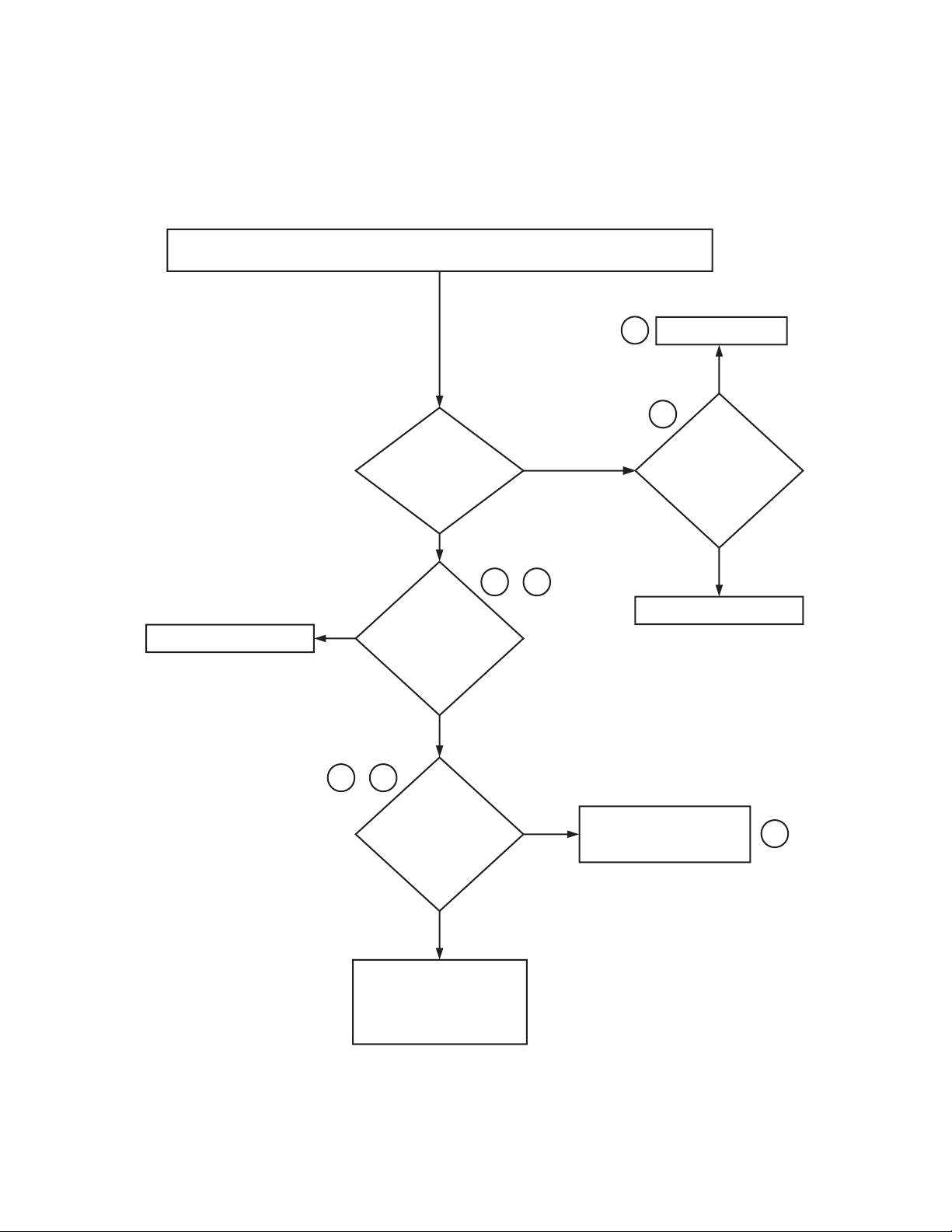

3. No Cold Fill Analysis (OPL)

No Cold Fill Analysis (OPL)

With the water turned on to the machine, during a cycle that has been programmed for a cold fill,

no cold water is filling the machine.

Replace the CF fuse.1A

YES

1A

Replace the output board.

NO

4A 3A

Is the CF light

on the output board

turned on?

YES

Is there voltage

(120 Volts AC)

between the CF

terminal and the

ACN?

YES

Is there voltage

(120 Volts AC)

between the V2

terminal and the

ACN?

NO

2A 3A

NO

Test the CF

fuse with an ohm

meter. Is the CF

fuse blown?

Replace the output board.

Inspect wire CF TS15 and

repair or replace the wire

as needed.

NO

5A

YES

Inspect the water inlet valve

and hoses. Repair or replace

the water inlet valve as

needed.

CHM392S

18 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 21

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 19

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 22

Troubleshooting

No Cold Fill Analysis (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

20 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 23

No Cold Fill Analysis (Sheet 2 of 2)

5A

4A

Troubleshooting

3A

1A

2A

CHM393S

607072(P)

F232203 21

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 24

Troubleshooting

4. No Cold Fill Analysis (Coin)

No Cold Fill Analysis (Coin)

With the water turned on to the machine, during a cycle that has been programmed for a cold fill,

no cold water is filling the machine.

Replace the CF fuse.

1A

1A

YES

Replace the output board.

NO

4A 3A

Is the CF light

on the output board

turned on?

YES

Is there voltage

(120 Volts AC)

between the CF

terminal and the

ACN?

YES

Is there voltage

(120 Volts AC)

between the V2

terminal and the

ACN?

NO

2A 3A

NO

Test the CF

fuse with an ohm

meter. Is the CF

fuse blown?

Replace the output board.

Inspect wire 15 and repair or

replace the wire as needed.

NO

5A

YES

Inspect the water inlet valve

and hoses. Repair or replace

the water inlet valve as

needed.

CHM394S

22 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 25

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 23

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 26

Troubleshooting

No Cold Fill Analysis (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

24 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 27

No Cold Fill Analysis (Sheet 2 of 2)

Troubleshooting

2A

1A

3A

4A

5A

CHM395S

606909(F)

F232203 25

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 28

Troubleshooting

5. No Supply Fill Analysis (OPL)

No Supply Fill Analysis (OPL)

With the machine beginning

a wash step that has been

programmed with a supply,

no water is coming into a

supply compartment.

Replace the supply fuse.

YES

Is there voltage

(120 Volts AC) between

the supply terminal

(i.e., S1, S2 or S3)

and the ACN?

NO

Replace the output board.

1A

2A

YES

Is there voltage

(120 Volts AC) between

the output side of the supply

fuse (i.e., S1, S2 or S3)

and the ACN?

NO

3A

2A

YES

2A

Is there voltage

(120 Volts AC) between

the input side of the supply

fuse (i.e., S1, S2 or S3)

and the ACN?

3A

NO

CHM396S

26 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 29

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 27

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 30

Troubleshooting

No Supply Fill Analysis (OPL) (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

28 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 31

No Hot Supply 1 Fill Analysis (OPL) (Sheet 2 of 2)

Troubleshooting

1A 1A

3A

1A

3A

2A

CHM397S

607072(P)

F232203 29

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 32

Troubleshooting

6. No Supply Fill Analysis (Coin)

No Supply Fill Analysis (Coin)

With the machine beginning

a wash step that has been

programmed with a supply,

no water is coming into a

supply compartment.

Replace the supply fuse.

YES

Is there

voltage (120 Volts AC)

between the supply terminal

(i.e., S1 or S2) and

the ACN?

NO

Replace the output board.

1A

2A

YES

Is there

voltage (120 Volts AC)

between the output side

of the supply fuse (i.e.,

S1 or S2) and the

ACN?

NO

3A

2A

YES

2A

voltage (120 Volts AC)

between the input side of

the supply fuse (i.e.,

S1 or S2) and the

3A

Is there

ACN?

NO

CHM398S

30 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 33

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 31

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 34

Troubleshooting

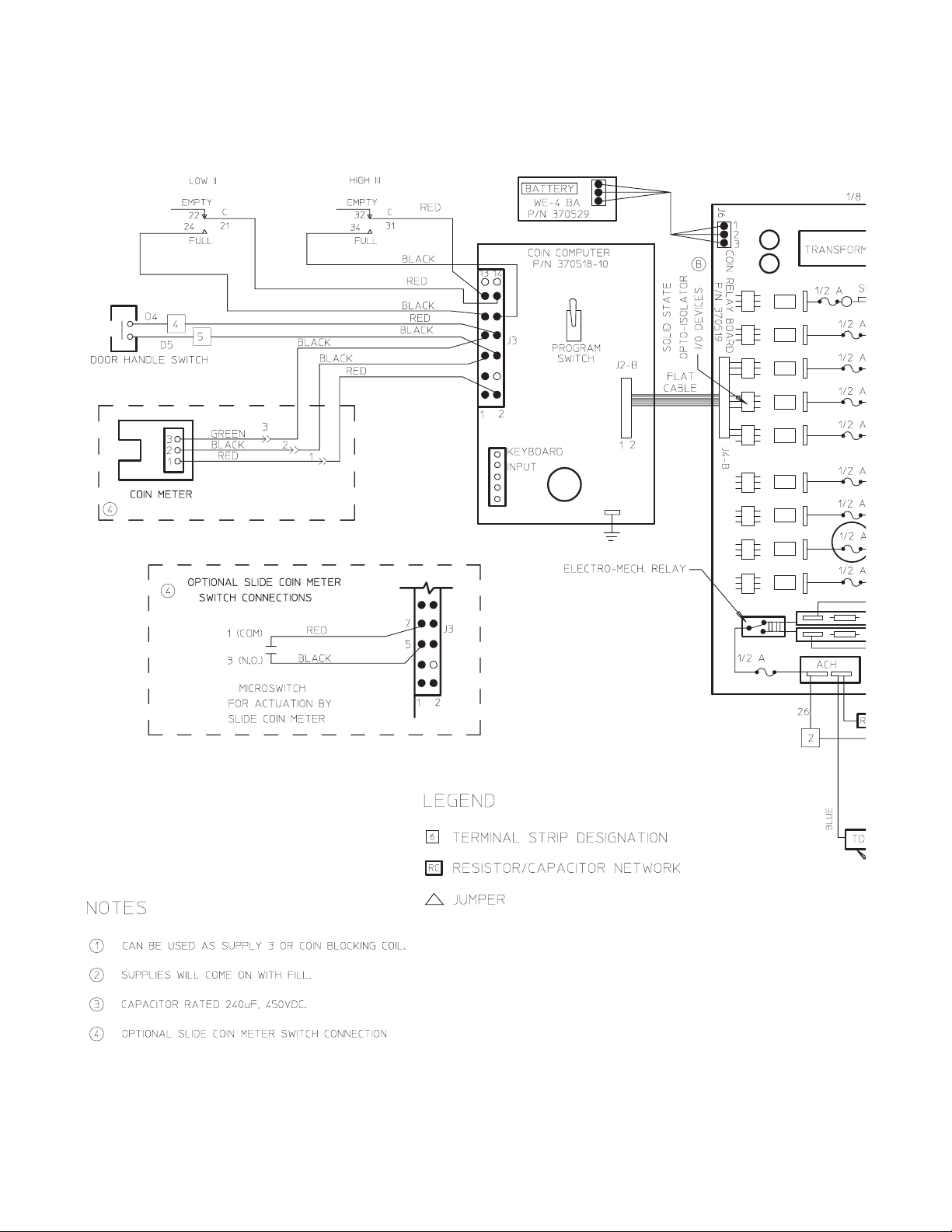

No Supply Fill Analysis (Coin) (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

32 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 35

No Hot Supply 1 Fill Analysis (Coin) (Sheet 2 of 2)

Troubleshooting

3A

1A

2A

CHM399S

606909(F)

F232203 33

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 36

Troubleshooting

7. No Motor Function (FWD or REV)

No Motor Function (FWD or REV)

With the machine running, the water

valves on and the machine holding

water (i.e., filling up), the basket has

no wash function (i.e., FWD or REV).

YES

Is there voltage

(120 Volts AC)

between wire FWD on the

output board and the ACN?

Is there voltage (120 Volts AC)

between wire REV on the

output board and

the ACN?

Inspect the motor.

Repair/replace the motor

as needed.

YES

4A

Is there voltage

(120 Volts AC) across

the coil of the KM3 and

the KM4 contactors?

1A

2A

NO

YES

2A

Is there voltage

(120 Volts AC)

between the input side of

the FWD fuse and the ACN?

Is there voltage (120 Volts AC)

between the input side

of the REV fuse and

the ACN?

YES

2A

Is there voltage

(120 Volts AC) between the

output side of the FWD fuse and

the ACN?

Is there voltage (120 Volts AC)

between the output side

of the REV fuse and

the ACN?

3A

3A

NO

Replace the output board.

NO

Replace the FWD and/or

the REV fuse as needed.

NO

Inspect the contactors'

wiring connections.

34 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CHM400S

Page 37

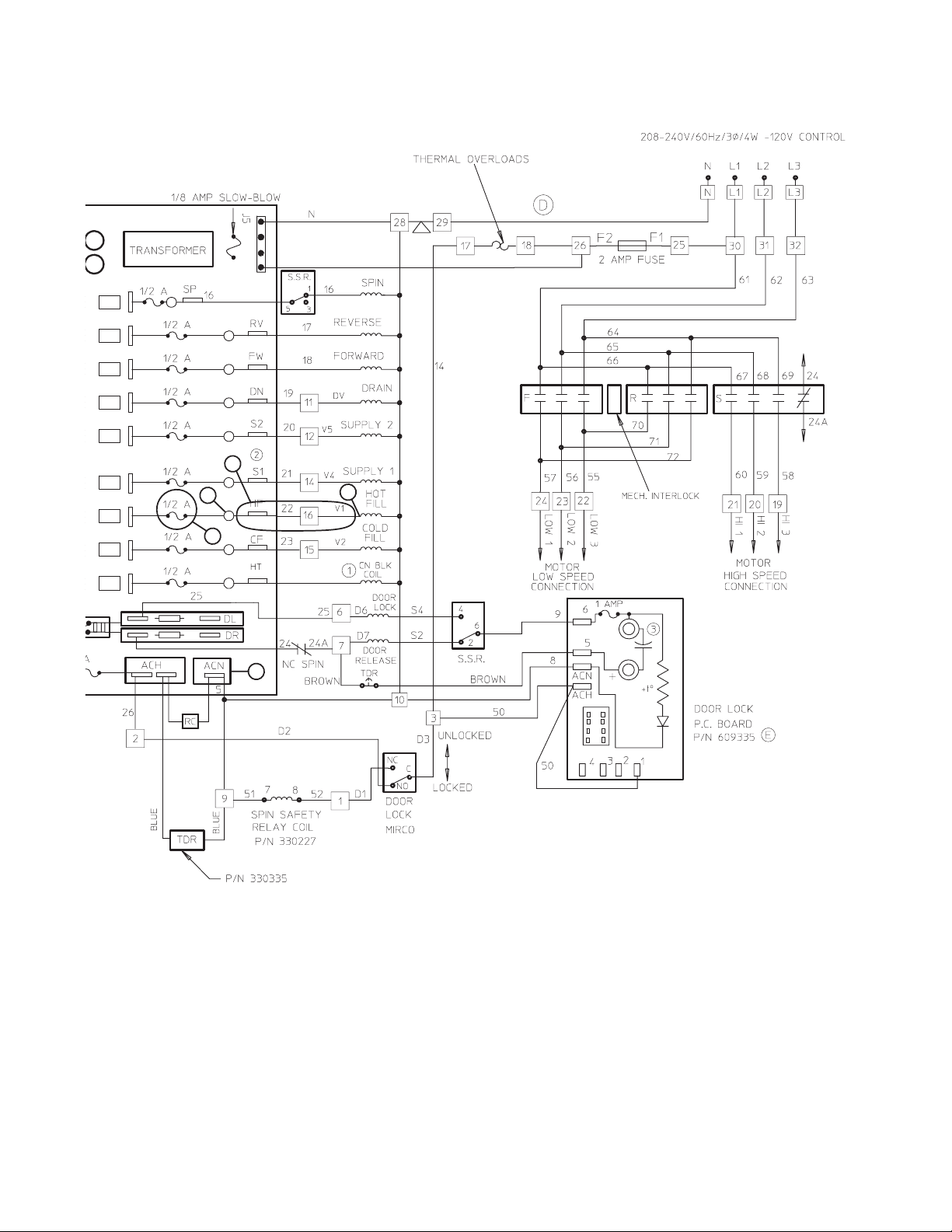

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 35

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 38

Troubleshooting

No Motor Function (FWD or REV) (Sheet 1 of 2)

4A

1A

NOTE: Refer to the wiring diagram supplied with your machine.

36 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 39

Troubleshooting

No Motor Function (FWD or REV) (Sheet 2 of 2)

4A

1A

3A

2A

CHM401S

607072(P)

F232203 37

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 40

Troubleshooting

8. No Motor Function (SP)

With the machine running, the water

valves on and the machine holding

water (i.e., filling up), the basket has

no extract function (i.e., SP).

1A

1A

YES

Is there voltage

(120 Volts AC) between

wire SPIN on the output

board and the ACN?

No Motor Function (SP)

2A

NO

Is there voltage

(120 Volts AC) between the

input side of the SP fuse

and the ACN?

2A

2A

3A

NO

Replace the output board.

Inspect the motor.

Repair/replace the motor

as needed.

YES

Is there voltage

(120 Volts AC) across

the coil of the KM5 and

the KM4 contactors?

NO

Inspect the contactors'

wiring connections.

4A

4A

YES

YES

Is there voltage

(120 Volts AC) between the

output side of the SP fuse

and the ACN?

2A

2A

3A

3A

NO

Replace the SP fuse.

CHM402S

38 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 41

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 39

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 42

Troubleshooting

No Motor Function (SP) (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

40 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 43

Troubleshooting

No Motor Function (SP) (Sheet 2 of 2)

4A

2A

1A

3A

CHM403S

607072(P)

F232203 41

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 44

Troubleshooting

9. Drain Valve Malfunction

Drain Valve Malfunction

With the machine running, the basket moving and the water valves on, the machine does not

hold water (i.e., the machine does not fill).

Replace the DN fuse.

YES

Replace the output board.

NO

Is the

DN light on

the output board

turned on?

YES

Is there voltage

(120 Volts AC)

between the DN

terminal and

the ACN?

YES

4A

Is there voltage

(120 Volts AC)

between the TS11

terminal and

the ACN?

1A

3A

3A

NO

NO

2A

Test the

DN fuse with an

ohm meter. Is the

DN fuse blown?

NO

Replace the output board.

Inspect wire DN TS11 and

repair or replace the wire

as needed.

YES

6A

Inspect the drain valve.

Repair/replace the drain

valve as needed.

42 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

YES

Is there voltage

(120 Volts AC)

Across the drain

valve motor?

NO

Inspect wiring between the drain

valve and the output board and

repair or replace the wiring as

needed.

CHM404S

Page 45

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 43

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 46

Troubleshooting

Drain Valve Malfunction (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

44 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 47

Troubleshooting

Drain Valve Malfunction (Sheet 2 of 2)

6A

4A

5A

1A

2A

3A

CHM405S

607072(P)

F232203 45

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 48

Troubleshooting

y

10. Overflow Analysis

Water is running continuously into the machine.

Disconnect

power to the

machine. Does the

machine continue

to fill with

water?

NO

YES

Repair/replace the water inlet valve that is

allowing water to enter the machine when

power is disconnected.

Replace the output board.

YES

Is there voltage

from the terminal for the

water inlet valve that is allowing

water to fill the machine (i.e., CF,

HF, S1, S2 and S3) and

the ACN?

2A

3A

Reconnect

power to the machine.

Is the drain valve

closed tightly?

YES

Make sure that the

water level switch is open.

Perform an ohms test

across terminals 21 and 24 on the

water level switch.

Is it opened or closed?

Perform an ohms test

across terminals 31 and 34

on the water level switch.

Is it opened or

closed?

NO

NO

Refer to the "Drain Valve

Malfunction" flowchart.

1A

YES

NO

YES

Examine the water inlet valve

wiring. Repair/replace the wiring

as needed.

46 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Examine the water

level switch and the air

trap hose. Repair or replace

either as needed.

Does the machine continue

to fill with water?

CHM406S

Page 49

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 47

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 50

Troubleshooting

Overflow Analysis (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

48 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 51

Overflow Analysis (Sheet 2 of 2)

Troubleshooting

3A

2A

1A

1A

2A 2A

2A 2A

CHM407S

607072(P)

F232203 49

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 52

Troubleshooting

11. Contactor Analysis (FWD and REV)

Contactor Analysis (FWD and REV)

Inspect the motor wiring and repair

or replace it as needed.

Inspect the motor and replace it

as needed.

YES

The contactor is not energizing.

1A

Is there voltage

(120 Volts AC) between the

FWD wire and the ACN?

Is there voltage (120 Volts AC)

between the REV wire and

the ACN?

YES

2A

Disconnect

power to the machine.

Using an ohm meter, is there continuity

between the coils on the KM3

contactor and the coils on

the KM4 contactor?

3A

Examine the wiring to terminal

strip 27. Repair and/or replace

the wiring as needed.

Replace the KM3 and/or the KM4

contactor(s) as needed.

NO

YES

Manually operate

the KM3 and/or the KM4

contactor(s). Does the

motor function?

NO

NO

Replace the KM3 and/or the KM4

contactor(s) as needed.

CHM408S

50 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 53

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 51

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 54

Troubleshooting

Contactor Analysis (FWD and REV) (Sheet 1 of 2)

3A

2A

1A

NOTE: Refer to the wiring diagram supplied with your machine.

52 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 55

Troubleshooting

Contactor Analysis (FWD and REV) (Sheet 2 of 2)

3A

2A

1A

1A

CHM409S

607072(P)

F232203 53

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 56

Troubleshooting

12. Contactor Analysis (SP)

Contactor Analysis (SP)

The contactor is not energizing.

Is there voltage (120 Volts

AC) between the SPIN wire

and

the ACN

?

1A

3A

Examine the wiring to terminal

strip 27. Repair and/or replace

the wiring as needed.

Replace the KM5 contactor.

NO

YES

Inspect the motor wiring and repair

or replace it as needed.

Inspect the motor and replace it as

needed.

YES

YES

Disconnect

power to the machine.

Using an ohm meter, is there

continuity between the coils

on the KM5 contactor?

NO

Replace the KM5 contactor.

Manually operate the

KM5 contactor. Does

the motor function?

2A

NO

CHM410S

54 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 57

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 55

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 58

Troubleshooting

Contactor Analysis (SP) (Sheet 1 of 2)

3A

NOTE: Refer to the wiring diagram supplied with your machine.

56 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 59

Troubleshooting

Contactor Analysis (SP) (Sheet 2 of 2)

3A

2A

1A

1A

CHM411S

607072(P)

F232203 57

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 60

Troubleshooting

13. Coins Ignored When Entered

Coins Ignored When Entered

When coins are deposited in the machine, the machine does not recognize them.

Run the coin meter diagnostic

test outlined in the programming

manual supplied with the

machine.

Examine the

coin meter's wiring

connections on the J3 plug that

is located on the computer board.

Are the connections

secure?

YES

Examine the

computer board's

wiring connections on the 3-pin

connector located on the coin meter.

Are the connections

secure?

YES

1A

2A

NO

NO

Secure the coin meter wiring

connections.

Run the coin meter test

procedure to test the coin

meter's operation.

Secure the computer board's

wiring connections.

Run the coin meter test

procedure to test the coin

meter's operation.

3A

Examine the coin

meter's optic sensor wiring.

Is the optic sensor's

wiring damaged?

58 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

YESNO

Replace the coin meter.Replace the optic sensor.

CHM412S

Page 61

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 59

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 62

Troubleshooting

3A

Coins Ignored When Entered (Sheet 1 of 2)

1A

2A

NOTE: Refer to the wiring diagram supplied with your machine.

60 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 63

Coins Ignored When Entered (Sheet 2 of 2)

Troubleshooting

2A

CHM413S

606909(F)

F232203 61

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 64

Troubleshooting

y

14. Control Has No Display (OPL)

The machine's control doesn't show a display.

Replace the FU7 fuse.

YES

2A

Test the

FU7 fuse with an

ohm meter. Is the

FU7 fuse blown?

NO

3A

YES

Is there

voltage (120 Volts

AC) between pins

1 and 4 of the

J9 plug?

1A

NO

Is there

voltage (120 Volts AC)

from terminal 30 to

terminal 31?

YES

Test the

FU1 and FU2 fuses

with an ohm meter. Is the

FU1 and/or the FU2

fuse blown?

NO

Test the

FU3 or the FU5

fuse and the FU4 or the

FU6 fuse with an ohm

meter. Are any of the

fuses blown?

5A

6A

NO

YES

YES

Is there voltage (200-240

Volts AC) at input power

connections L1 and L2?

Replace the FU1 and/or

the FU2 fuse.

Is there voltage

(120 Volts AC)

from terminal 18

to terminal 27?

7A

4A

Inspect the main

transformer and replace it

as needed.

8A

YES

Replace the FU3 or the

FU5 fuse and/or the FU4

or the FU6 fuse .

62 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Inspect the J9 plug wiring

connections.

YES

CHM414S

Page 65

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 63

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 66

Troubleshooting

4A

Control Has No Display (OPL) (Sheet 1 of 2)

7A

7A

1A

6A

3A

5A

8A

NOTE: Refer to the wiring diagram supplied with your machine.

64 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 67

Control Has No Display (OPL) (Sheet 2 of 2)

Troubleshooting

2A

1A

CHM415S

607072(P)

F232203 65

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 68

Troubleshooting

15. Control Has No Display (Coin)

The machine's control doesn't show a display.

Is there

NO

voltage (120 Volts

AC) between pins 1

and 4 of the

J9 plug?

YES

Test the

1/8 Amp fuse on

the fuse board with an

ohm meter. Is the

1/8 Amp fuse

blown?

1A

2A

YES

Replace the 1/8 Amp fuse.

NO

Is there voltage

(120 Volts AC)

from terminal 28

to terminal 25?

YES

Test the

F1 and F2 fuses

with an ohm meter.

Is the F1 and/or

the F2 fuse

blown?

NO

3A

5A

NO

YES

Is there voltage (200-240 Volts

AC) between input power

connections L1 and the ACN?

Replace the F1 and/or the

F2 fuse.

4A

Is there voltage (120 Volts AC)

from terminal 28 to terminal 26?

66 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

6A

CHM416S

Page 69

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 67

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 70

Troubleshooting

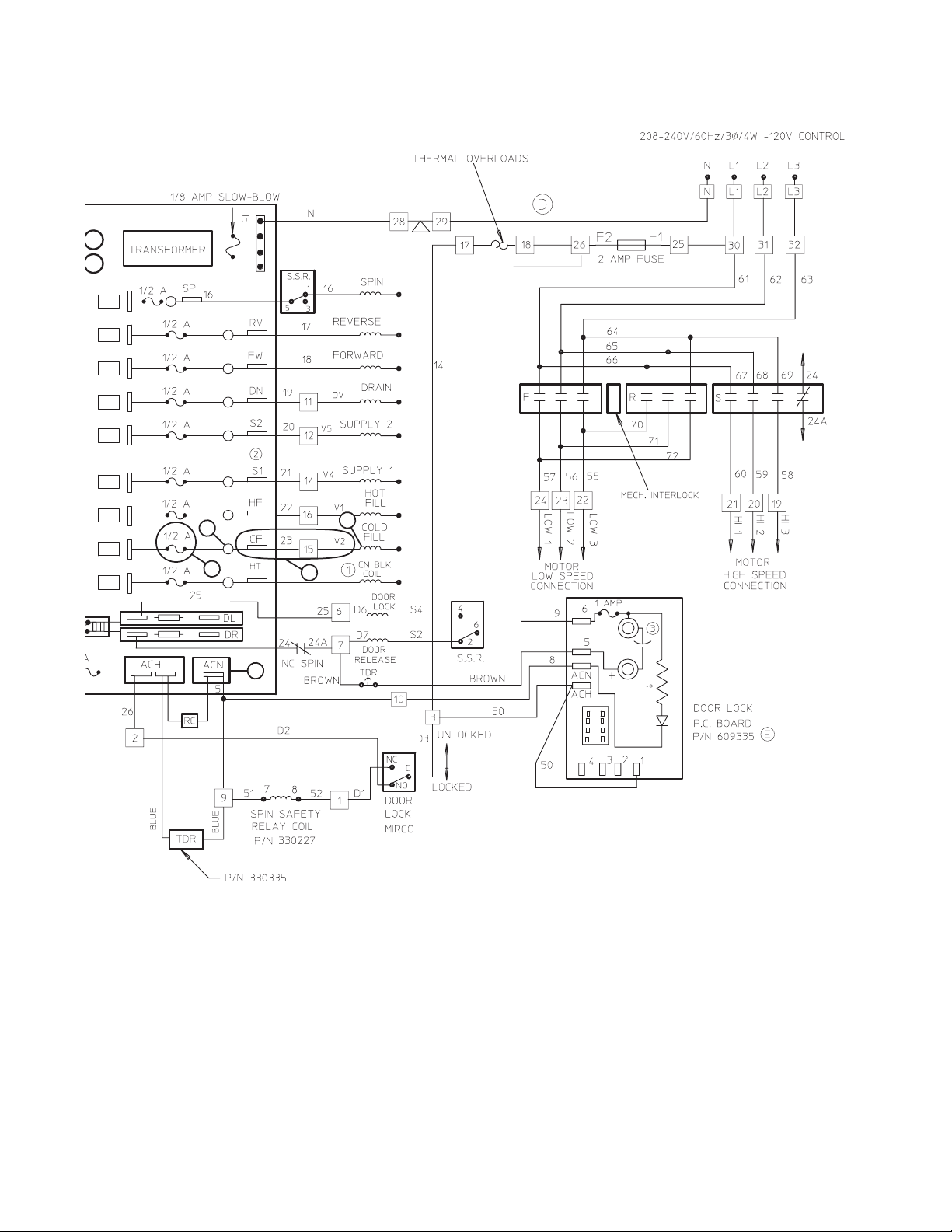

Control Has No Display (Coin) (Sheet 1 of 2)

2A

NOTE: Refer to the wiring diagram supplied with your machine.

68 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 71

Troubleshooting

Control Has No Display (Coin) (Sheet 2 of 2)

4A

6A

3A

2A

1A

6A

5A

3A

4A

CHM417S

606909(F)

F232203 69

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 72

Troubleshooting

16. The Machine Does Not Hold Water

The Machine Does Not Hold Water

Water drains from the machine when the machine has not been programmed to

do so.

1A

Test the

DN fuse with an

ohm meter. Is the DN

fuse blown?

NO

Is there voltage

(120 Volts AC) at

the drain valve

motor?

YES

Is there

foreign material

inside of the drain

valve that is preventing

it from closing?

2A

YES

NO

YES

Replace the DN fuse.

Replace the drain valve motor.

Remove the foreign material

from the drain valve motor.

NO

Inspect the drain valve wiring

connections.

CHM418S

70 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 73

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 71

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 74

Troubleshooting

The Machine Does Not Hold Water (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

72 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 75

The Machine Does Not Hold Water (Sheet 2 of 2)

2A

Troubleshooting

1A

CHM419S

607072(P)

F232203 73

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 76

Troubleshooting

17. Compartment 2 of Supply Dispenser Not Flushing Completely

Compartment 2 of the

supply dispenser is not

flushing completely.

Cut a 3/4-inch by 1/2 inch notch out of the bottom of the

water deflector in compartment 2 of the supply dispenser.

Is there low

water pressure

(i.e., less than 30

psi) to the supply

dispenser?

Yes

Refer to the

NOTE: If the water pressure is corrected to factory

specifications, the notch must be plugged to avoid

splashing.

As an alternative, install a hose clamp onto one of the hoses

connecting to the top of the vacuum breaker and tighten the

hose clamp slightly. Refer to the Vacuum Breaker

Illustration.

NOTE: If the water pressure is corrected to factory

specifications, the hose clamp must be removed.

Dispenser Illustration

.

Dispenser Illustration

CHM433S

Notch

CHM366S

74 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 77

18. The Door Leaks

The door leaks.

Troubleshooting

Is the door

leaking between

the door and the

door gasket?

No

Is the door

leaking between

the door glass

and the door

gasket?

Yes

Yes

Add or remove shims behind the

door hinge and/or the door lock to

reduce or increase the pressure

that is applied to the door gasket

when the door is closed.

Remove the door gasket. Inspect it

for damage and remove all foreign

matter from it. Do not clean the

door gasket with oil or with

petroleum-based products. Replace

the door gasket if needed.

CHM434S

F232203 75

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 78

Troubleshooting

19. No Keypad Function

The keypad does

not function.

Does the

keypad

show a

display?

No

Yes

Press each of

the keypad's

keys. Does a

beep tone sound

as each key is

pressed?

No

Inspect the ribbon cable from

the keypad to the computer

board.

Is the ribbon cable connected

to the computer board?

Is the ribbon cable damaged?

Yes

Replace the

keypad.

CHM435S

76 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 79

20. Excessive Vibration and/or Noise During Spin

There is excessive

vibration and/or

noise during a spin

cycle.

Always make sure that full loads are used. Never wash partial

Has the

machine been

loaded

improperly?

No

Yes

loads.

Do not mix various laundry items together in the same wash

(e.g., do not wash towels and sheets together).

Avoid using laundry bags.

Troubleshooting

Has the machine

been installed

improperly?

Yes

Do the

bearings

require

replacement?

No

Yes

Make sure that the washer-extractor is anchored to a flat, level

surface with the proper depth of concrete.

Tighten all anchor bolts and nuts. Make sure that they are of

the correct size and grade.

Make sure that the washer-extractor is grouted properly.

Refer the installation manual that was supplied with the machine

for exact installation specifications.

Check the bearings' noise factor.

Lift up on the basket at the front of the tub. Check for any up

and down play that would indicate bearing wear.

Replace the bearings as needed.

CHM431S

F232203 77

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 80

Troubleshooting

21. The Water Level is Too High or Too Low

The water level

is too high or

too low.

Is the machine

equipped with an

adjustable water

level switch?

Yes

Adjust the water level

switch to raise or lower the

machine's water level.

After adjusting the water

level, is the machine's

water level still too high or

too low?

No

Replace the

water level

switch.

Yes

CHM436S

78 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 81

22. Excessive Cycle Time

One or more cycles

is excessively long.

Are any of the cycles' fill

times excessively long?

NOTE: All fill times should

not exceed 4-5 minutes.

Any fill times should easily

complete during this time.

Yes

Troubleshooting

Refer to the

"No Fill

Analysis"

flowchart.

No

Are any of the

drain times

excessively long?

NOTE: Any drain

time should not

exceed 30-40

seconds.

Yes

Check all internal and

external plumbing

entering and exiting the

machine.

CHM432S

F232203 79

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 82

Troubleshooting

23. Water Running Continuously with Machine Power Off

Water Running Continuously With Machine Power Off

With electrical power removed

from the machine, water is

running continuously into

compartment 1 of the supply

dispenser.

Using the “Water Running

Continuously” schematic, follow

the hose from compartment 1 of

the supply dispenser back

through the vacuum breaker and

the Y-connector to the hot water

valve at V9 and the cold water

valve at V10.

To determine which of the

valves is leaking, turn off the

water supply to each of the

valves, one valve at a time.

When the water supply is

removed from the leaking valve,

the water running into

compartment 1 of the supply

dispenser will stop.

For example, if water is running

into compartment 1 of the supply

dispenser continuously, when

the water supply is removed

from the hot water valve, the

water continues to run into

compartment 1. However,

when the water supply is

removed from the cold water

valve, the water running into

compartment 1 stops.

Therefore, the cold water valve

is the leaking valve.

With electrical power removed

from the machine, water is

running continuously into

compartment 2 of the supply

dispenser.

Using the “Water Running

Continuously” schematic, follow

the hose from compartment 2 of

the supply dispenser back

through the vacuum breaker to

the cold water valve at V4.

Install a valve repair kit onto the

cold water valve or replace the

valve. Refer to the Parts manual

for your washer-extractor for

valve and valve repair kit part

numbers.

With electrical power removed

from the machine, water is

running continuously into

compartment 3 of the supply

dispenser.

Using the “Water Running

Continuously” schematic, follow

the hose from compartment 3 of

the supply dispenser back

through the vacuum breaker to

the cold water valve at V5.

Install a valve repair kit onto the

hot water valve or replace the

valve. Refer to the Parts manual

for your washer-extractor for

valve and valve repair kit part

numbers.

With electrical power removed

from the machine, water is

running continuously into the

bottom of the washer-extractor.

To determine which of the

valves is leaking, turn off the

water supply to each of the

valves, one valve at a time.

When the water supply is

removed from the leaking valve,

the water running into the

bottom of the washer-extractor

will stop.

For example, when the water

supply is removed from the hot

water valve at V1, the water

continues to run into the bottom

of the washer-extractor.

However, when the water supply

is removed from the cold water

valve at V2, the water running

into the bottom of the washerextractor stops. Therefore, the

cold water valve at V2 is the

leaking valve.

Once the leaking valve(s) has

been determined, install a valve

repair kit onto the leaking valve

or replace the leaking valve.

Refer to the Parts manual for

your washer-extractor for valve

and valve repair kit part numbers.

Once the leaking valve(s) has

been determined, install a valve

repair kit onto the leaking valve

port or replace the entire leaking

valve. Refer to the Parts manual

for your washer-extractor for

valve and valve repair kit part

numbers.

CHM263S

80 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 83

Water Running Continuously Illustration

Troubleshooting

Y – CONNECTOR

HOT WATER VALVE COLD WATER VALVE

VACUUM BREAKER

SUPPLY DISPENSER

CHM264S

0635860(G)

F232203 81

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 84

Troubleshooting

24. Door Unlocking Malfunction (OPL)

The machine runs a complete cycle and all functions act normally, but the machine will not

unlock at the end of the cycle.

there voltage

(120 Volts AC)

between the DU

Check to make sure

that the magnetic switch

is in place.

NO

6A

Is there voltage

(120 Volts AC)

between terminal

5 and the ACN?

2A

YES

YES

terminal and the

there voltage

(120 Volts AC)

between the ACN

Is

ACN?

Is

and the

ACH?

YES

1A

2A

4A

NO

NO

Test the DU fuse with an

ohm meter and replace it as

needed.

Inspect the KA1 door safety

relay coil.

Test the on/off switch.

3A

5A

YES

Test the door locking arm to

make sure that it is moving

freely. Adjust it as needed.

Is

there voltage

(120 Volts AC)

at the KM5

extract speed

contactor?

NO

Inspect the nc wiring

connections.

Te st

the door

solenoid with an

ohm meter.

Is there

continuity?

NO

Replace the door

solenoid.

7A

11A

YES

Inspect the door unlock

switch wiring connections.

YES

Replace the door bridge

rectifier.

Is

there voltage

(120 Volts AC) at

the input side of

the door unlock

switch?

NO

Is

there DC

voltage at outputs

+ and - on the

door bridge

rectifier?

NO

8A

10A

YES

Is

there voltage

(120 Volts AC) at

the output side of

the door unlock

switch?

Test the door unlock switch

with an ohm meter and

replace it as needed.

Is

YES

there voltage

(120 Volts AC) at

the input side of

the door bridge

rectifier?

Press the door unlock

switch.

If there is not voltage on the

output side of the door bridge

rectifier when the door unlock

switch is pressed, replace

the door bridge rectifier.

8A

YES

NO

9A

NO

CHM420S

82 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 85

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 83

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 86

Troubleshooting

Door Unlocking Malfunction (OPL) (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

84 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 87

Door Unlocking Malfunction (OPL) (Sheet 2 of 2)

11A

10A

9A

7A

8A

2A

Troubleshooting

1A

3A

4A

6A

5A

CHM421S

607072(P)

F232203 85

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 88

Troubleshooting

25. Door Unlocking Malfunction (Coin)

When coins are placed into the coin slot, do they fall into the coin vault and does the

Figure 1

coin drop sensor register that coins have been entered? Refer to

path that coins follow when the drop is working properly.

No

1. Disconnect electrical power to the machine and the coin drop.

2. Remove the coin drop from the machine.

Refer to the wiring

diagram supplied

with the machine

for connection

information.

Refer to the

installation manual

supplied with the

machine for

instructions on

leveling the

machine.

No

No

Is proper

electrical

power

supplied to

the coin

drop?

Yes

Is the

machine

level?

Yes

3. If lint is preventing coins from rolling through the coin drop, blow compressed air

through the coin entry and along the side of the coin drop. Refer to

4. Insert a coin into the coin drop. If the coin does not fall through the drop, continue

to step 5.

5. Remove the cotter pin from the top of the drop. Refer to

reinstallation when the cleaning of the coin drop is complete.

6. Move the metal clip closer to the sensor so that it comes off of the frame. Refer to

Figure 2

.

7. Remove the coin return from the coin drop frame. Refer to

8. Check the path in the coin drop for lint and residue. If lint or light residue is present,

use a cotton swab to remove it. If heavy residue is present, it may be necessary to

first scrape off the excessive residue and then to use a cotton swab dipped in water

or isopropyl alcohol to remove the remainder of the residue. Refer to

for the

Figure 2

Figure 3

Figure 2

.

. Save the pin for

.

Figure 4

.

Is the coin

drop clean?

No

9. Check the return pendulum to verify it swings freely. If the pendulum does not

swing freely, spray the pendulum pivot point with Teflon-based lubricant and move

the pendulum back and forth 3 times. An additional application of Teflon-based

Figure 5

lubricant may be necessary to ensure the pendulum swings freely. Refer to

10. Check the coin drop sensor for dust or dirt on the eyes. Wipe the eyes with a dry

Figure 6

cotton swab. Refer to

the electronic sensor or eyes.

11. Reinstall the coin return onto the coin drop frame.

12. Reinstall the metal clip and slide toward the coin insert slot. All cotter pin holes

must line up.

13. Reinstall the cotter pin.

14. Place the coin drop on a level surface to verify that coins follow the correct path to

the coin drop. It may be necessary to lift the coin drop to allow the coin to follow

through the sensor.

15. Reinstall the coin drop into the machine.

16. Reconnect electrical power to the machine and coin drop.

17. Insert a coin into the coin drop to verify that the coin drop is operating properly.

If the coin drop does not operate properly after the above steps have been

completed, corrosion of the metal or vandalized components within the coin drop may

be preventing it from functioning properly. Replace the coin drop.

. IMPORTANT: Do not use isopropyl alcohol to clean

.

CHM442S

86 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 89

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 87

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 90

Troubleshooting

Door Unlocking Malfunction (Coin) (Sheet 1 of 2)

NOTE: Refer to the wiring diagram supplied with your machine.

88 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 91

Door Unlocking Malfunction (Coin) (Sheet 2 of 2)

2A

2A

Troubleshooting

2A

3A

4A

5A

7A

1A

6A

CHM423S

606909(F)

F232203 89

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 92

Troubleshooting

26. Pump Drain Analysis

Is

there voltage (120

Volts AC) between

the input side of the

DN terminal and the

ACN?

YES

Is

there voltage (120

Volts AC) between

the output side of the

DN terminal and the

ACN?

1A

NO

Replace the output board.

1A

NO

Replace the DN fuse.

YES

Is

there voltage (120

Volts AC) across the

coil of the KM2

relay?

YES

Is

there voltage (120

Volts AC) across the

drain pump

motor?

2A

3A

NO

NO

Inspect the wiring to the KM2 relay

and repair/replace it as needed.

Inspect the wiring to the drain

pump motor and repair/replace it

as needed.

YES

Inspect the mechanical operation

of the drain pump and replace it as

needed.

CHM428S

90 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 93

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 91

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 94

Troubleshooting

Pump Drain Analysis (Sheet 1 of 2)

2A

NOTE: Refer to the wiring diagram supplied with your machine.

92 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 95

Troubleshooting

Pump Drain Analysis (Sheet 2 of 2)

2A

3A

1A

1A

CHM429S

607072(P)

F232203 93

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 96

Troubleshooting

27. Machine Won't Start (OPL)

The machine

won't start.

1A

Is there

input

voltage to

the

machine?

No

Connect power

to the machine.

Refer to the

Door Unlocking

Malfunction

flowchart.

Yes

Test the contol

circuit fuses with

an ohm meter.

Are any of the

fuses blown?

No

Is any of the

machine's

wiring loose

or damaged?

2A

Yes

Yes

Replace the

control circuit

fuse(s) as

needed.

Repair/replace

the wiring as

needed.

Yes

Does the door

handle switch

lever completely

depress the

switch?

Yes

5A

Is the

on/off

switch

intact?

No

No

Replace the

on/off switch

Adjust the door

handle switch

lever.

No

3A

Is there voltage

(120 Volts AC)

between ACH

and ACN on the

fuse board?

Yes

94 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

No

Replace the

fuse board.

Test the FU3,

FU4, FU5 and

FU6 fuses with

an ohm meter.

Are any of the

fuses blown?

No

4A

Yes

Replace the

FU3, FU4, FU5

and FU6 fuses

as needed.

CHM437S

Page 97

Troubleshooting

Please refer to the following 2 pages for wiring diagram information.

F232203 95

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 98

Troubleshooting

Machine Won’t Start (OPL) (Sheet 1 of 2)

1A

4A

2A

NOTE: Refer to the wiring diagram supplied with your machine.

5A

96 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 99

Machine Won’t Start (OPL) (Sheet 2 of 2)

Troubleshooting

3A

CHM425S

607072(P)

F232203 97

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Page 100

Troubleshooting

28. Machine Won't Start (Coin)

The machine

won't start.

1A

Is there

input

voltage to

the

machine?

Yes

Test the contol

circuit fuses with

an ohm meter.

Are any of the

fuses blown?

No

Connect power

to the machine.

2A

Yes

Replace the

control circuit

fuse(s) as

needed.

No

Is any of the

machine's

wiring loose

or damaged?

No

Is there voltage

(120 Volts AC)

between ACH

and ACN on the

fuse board?

3A

Yes

No

Repair/replace

the wiring as

needed.

Replace the

fuse board.

Refer to the

Door Unlocking

Malfunction

flowchart.

Does the door

handle switch

lever completely

depress the

switch?

Yes

No

Adjust the door

handle switch

lever.

Yes

98 F232203

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

CHM438S

Loading...

Loading...