Alliance Laundry Systems HC18SN2, UC40VN2, SC35VN2, UC20PN2, HC18VC2 Operation & Maintenance Manual

...Page 1

Washer-Extractors

Cabinet Hardmount

S, P, and V-Series Microcomputers Coin and

Non-Coin Models

Refer to Page 3 for Model Identification

NOTA: El manual en

español aparece después

del manual en inglés.

Operation/Maintenance

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

www.comlaundry.com

CHM166C

Part No. F232137R2

April 2002

Page 2

Page 3

Table of

Contents

Introduction......................................................................................... 3

Model Identification ............................................................................. 3

Nameplate Location.............................................................................. 4

Replacement Parts ................................................................................ 4

Customer Service.................................................................................. 4

Safety Information.............................................................................. 5

Important Safety Instructions ............................................................... 5

Operation............................................................................................. 7

Control Panel ........................................................................................ 7

Display Indications............................................................................... 8

Operating Instructions .......................................................................... 12

Maintenance ........................................................................................ 15

Daily ..................................................................................................... 15

Beginning of Day............................................................................. 15

End of Day ....................................................................................... 15

Weekly.................................................................................................. 16

Monthly................................................................................................. 16

Quarterly............................................................................................... 19

Care of Stainless Steel.......................................................................... 20

© Copyright 2002, Alliance Laundry Systems LLC

All rights reserved. No part of the contents of this book may be reproduced or transmitted in any form or by any

means without the expressed written consent of the publisher.

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

1

Page 4

Notes

2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 5

Introduction

Model Identification

Information in this manual is applicable to these models:

HC18SN2 HC27VX2 HC50SN2 SC35VN2 UC20PN2 UC40VN2

HC18VC2 HC30SN2 HC50VC2 SC35VNV UC20VN2 UC40VNV

HC18VX2 HC30VC2 HC50VX2 SC40VN2 UC27PN2 UC50PN2

HC20SN2 HC30VX2 HC80VCV SC40VNV UC27VN2 UC50VN2

HC20VC2 HC35SN2 HC80VNV SC50VN2 UC30PN2 UC50VNV

HC20VX2 HC35VC2 HC80VXV SC50VNV UC30VN2 UC80VNV

HC25VC2 HC35VX2 SC18VN2 SC80VNV UC35PN2 UC125VNV

HC25VX2 HC40SN2 SC20VN2 SC125VNV UC35VN2

HC27SN2 HC40VC2 SC27VN2 UC18PN2 UC35VNV

HC27VC2 HC40VX2 SC30VN2 UC18VN2 UC40PN2

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

3

Page 6

Introduction

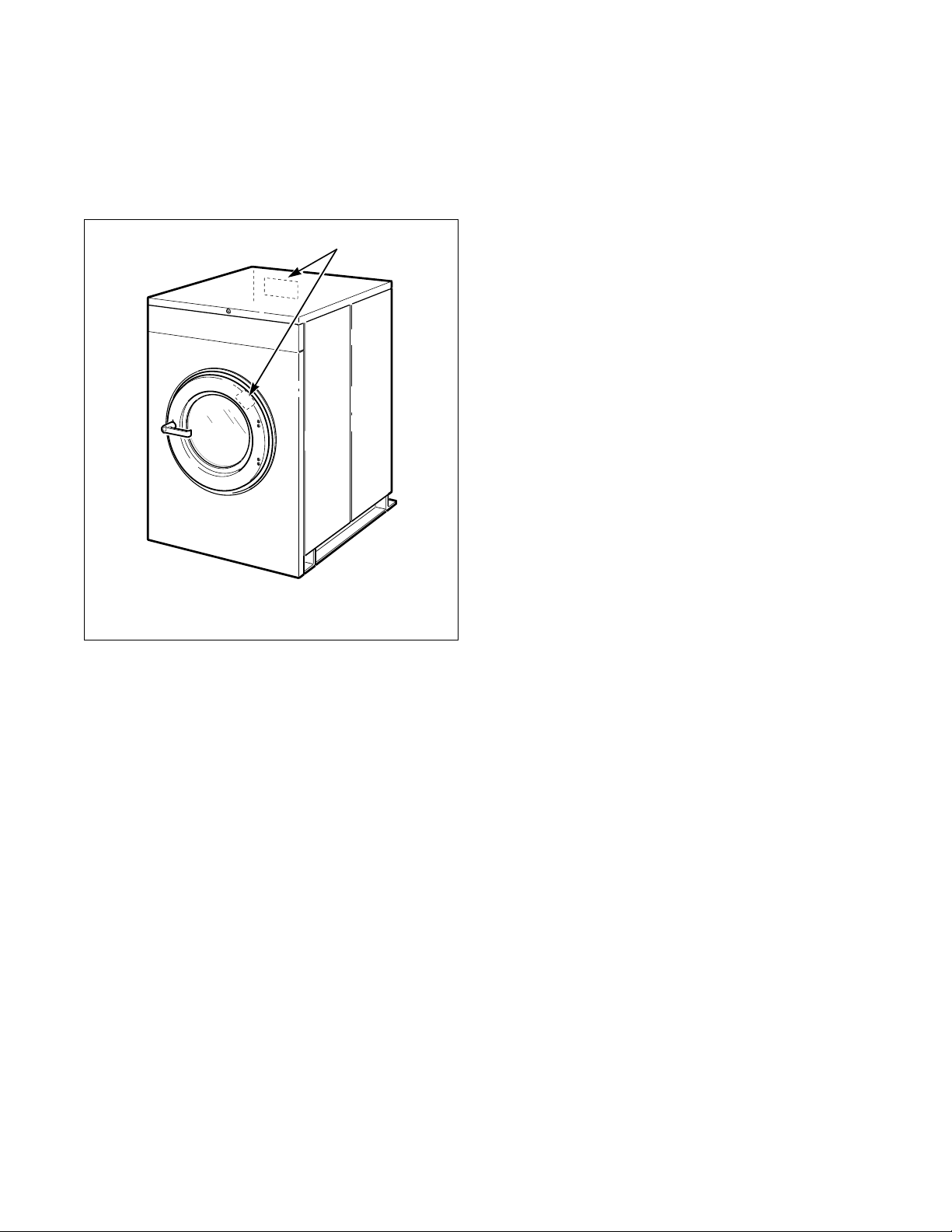

Nameplate Location

The nameplate is located at the rear of the machine and

inside door. Always provide the machine’s serial

number and model number when ordering parts or

when seeking technical assistance.

1

Replacement Parts

If literature or replacement parts are required, contact

the source from whom the machine was purchased or

contact Alliance Laundry Systems at (920) 748-3950

for the name and address of the nearest authorized

parts distributor.

Customer Service

For technical assistance, call any of the following

numbers:

(850) 718-1025

(850) 718-1026

Marianna, Florida U.S.A.

(920) 748-3121

Ripon, Wisconsin U.S.A.

1 Nameplate

CHM167R

Figure 1

4

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 7

Safety Information

DANGER indicates the presence of a

hazard that will cause severe personal

injury, death, or substantial property

damage if the danger is ignored.

DANGER

WARNING indicates the presence of a

hazard that can cause severe personal

injury, death, or substantial property

damage if the warning is ignored.

WARNING

CAUTION indicates the presence of a

hazard that will or can cause minor

personal injury or property damage if the

caution is ignored.

CAUTION

Precautionary statements (“DANGER”, “WA R N I N G ”

and “CAUTION”), followed by specific instructions,

are found in this manual and on machine decals. These

precautions are intended for the personal safety of the

operator, user, servicer and those maintaining the

machine.

Important Safety Instructions

WARNING

To reduce the risk of fire, electric shock,

serious injury or death to persons when

using your washer, follow these basic

precautions:

W023E

1. Read all instructions before using the washer.

2. Refer to the Grounding Instructions in the

Installation Manual for the proper grounding of

the washer.

3. Do not wash textiles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

4. Do not add gasoline, dry-cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

Additional precautionary statements (“IMPORTANT”

and “NOTE”) are followed by specific instructions.

IMPORTANT: The word “IMPORTANT” is used

to inform the reader of specific procedures where

minor machine damage will occur if the procedure

is not followed.

NOTE: The word “NOTE” is used to communicate

installation, operation, maintenance or servicing

information that is important but not hazard

related.

5. Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for two weeks or more. HYDROGEN GAS

IS EXPLOSIVE. If the hot water system has not

been used for such a period, before using a

washing machine or combination washer-dryer,

turn on all hot water faucets and let the water

flow from each for several minutes. This will

release any accumulated hydrogen gas. The gas is

flammable; do not smoke or use an open flame

during this time.

6. Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children. This is a safety

rule for all appliances.

7. Before the washer is removed from service or

discarded, remove the door to the washing

compartment.

8. Do not reach into the washer if the wash drum is

moving.

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

5

Page 8

Safety Information

9. Do not install or store the washer where it will be

exposed to water and/or weather.

10. Do not tamper with the controls.

11. Do not repair or replace any part of the washer, or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or in published user-repair

instructions that the user understands and has the

skills to carry out.

12. To reduce the risk of an electric shock or fire, DO

NOT use an extension cord or an adapter to

connect the washer to the electrical power source.

13. Use washer only for its intended purpose,

washing textiles.

14. ALWAYS disconnect the washer from electrical

supply before attempting any service. Disconnect

the power cord by grasping the plug, not the cord.

15. Install the washer according to the Installation

Instructions. All connections for water, drain,

electrical power and grounding must comply

with local codes and be made by licensed

personnel when required.

16. To reduce the risk of fire, textiles which have

traces of any flammable substances such as

vegetable oil, cooking oil, machine oil,

flammable chemicals, thinner, etc. or anything

containing wax or chemicals such as in mops and

cleaning cloths, must not be put into the washer.

These flammable substances may cause the

fabric to catch on fire by itself.

17. Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

18. Keep washer in good condition. Bumping or

dropping the washer can damage safety features.

If this occurs, have washer checked by a qualified

service person.

19. Replace worn power cords and/or loose plugs.

20. Be sure water connections have a shut-off valve

and that fill hose connections are tight. CLOSE

the shut-off valves at the end of each wash day.

21. Loading door MUST BE CLOSED any time the

washer is to fill, tumble or spin. DO NOT

bypass the loading door switch by permitting the

washer to operate with the loading door open.

22. Always read and follow manufacturer’s

instructions on packages of laundry and cleaning

aids. Heed all warnings or precautions. To reduce

the risk of poisoning or chemical burns, keep

them out of the reach of children at all times

(preferably in a locked cabinet).

23. Always follow the fabric care instructions

supplied by the textile manufacturer.

24. Never operate the washer with any guards

and/or panels removed.

25. DO NOT operate the washer with missing or

broken parts.

26. DO NOT bypass any safety devices.

27. Failure to install, maintain and/or operate this

washer according to the manufacturer’s

instructions may result in conditions which can

produce bodily injury and/or property damage.

NOTE: The WARNINGS and IMPORTANT

SAFETY INSTRUCTIONS appearing in this

manual are not meant to cover all possible

conditions and situations that may occur. Common

sense, caution and care must be exercised when

installing, maintaining or operating the washer.

Any problems or conditions not understood should be

reported to the dealer, distributor, service agent or the

manufacturer.

6

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 9

Operation

Up Down Start Stop

1

2

3

4

5

6

8 7

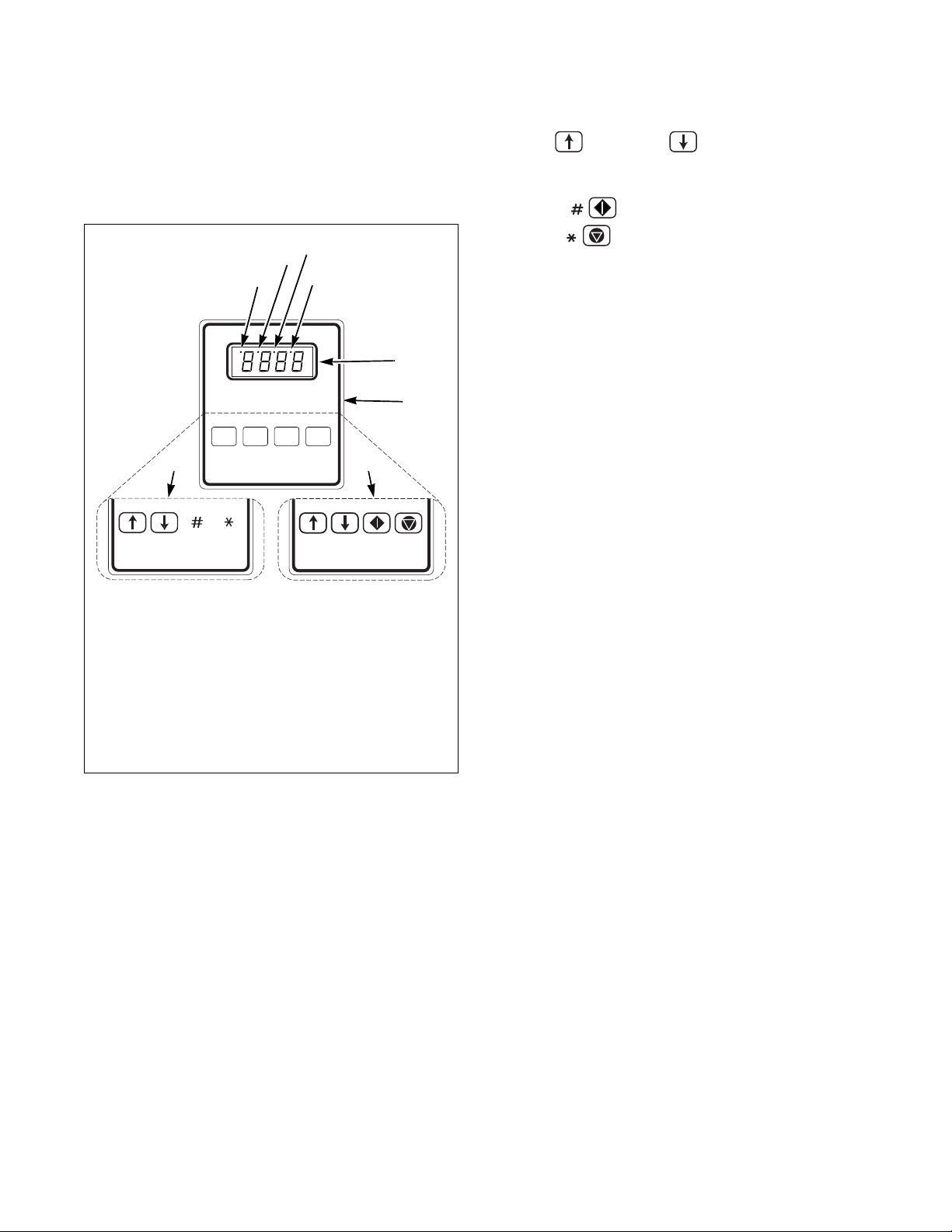

Control Panel

Figure 2 shows the control panel for S, P and

V-computer machines.

1 Out-of-Balance Condition for VCV, VXV

2 High Water Level

3 Medium Water Level for V-Series

4 Low Water Level

5 LED Display

6 Keys for Standard OPL

7 Keys for Icon OPL

8 Keys for VC2, VCV, VX2, VXV

The Up and Down keys are used in cycle

selection. Press these keys to move among cycles from

smaller to greater, or greater to smaller.

The Start key is used to start a cycle.

The Stop key is not active in normal Run

Mode. In Run Mode it is used only for stopping test

cycle.

The LED display informs operator of various

functions throughout operation of machine. Refer to

tables on the following pages for displays and their

meanings. Indicator lights in LED display indicate

out-of-balance conditions and water levels. Refer to

Figure 2.

B161R

Figure 2

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7

Page 10

Operation

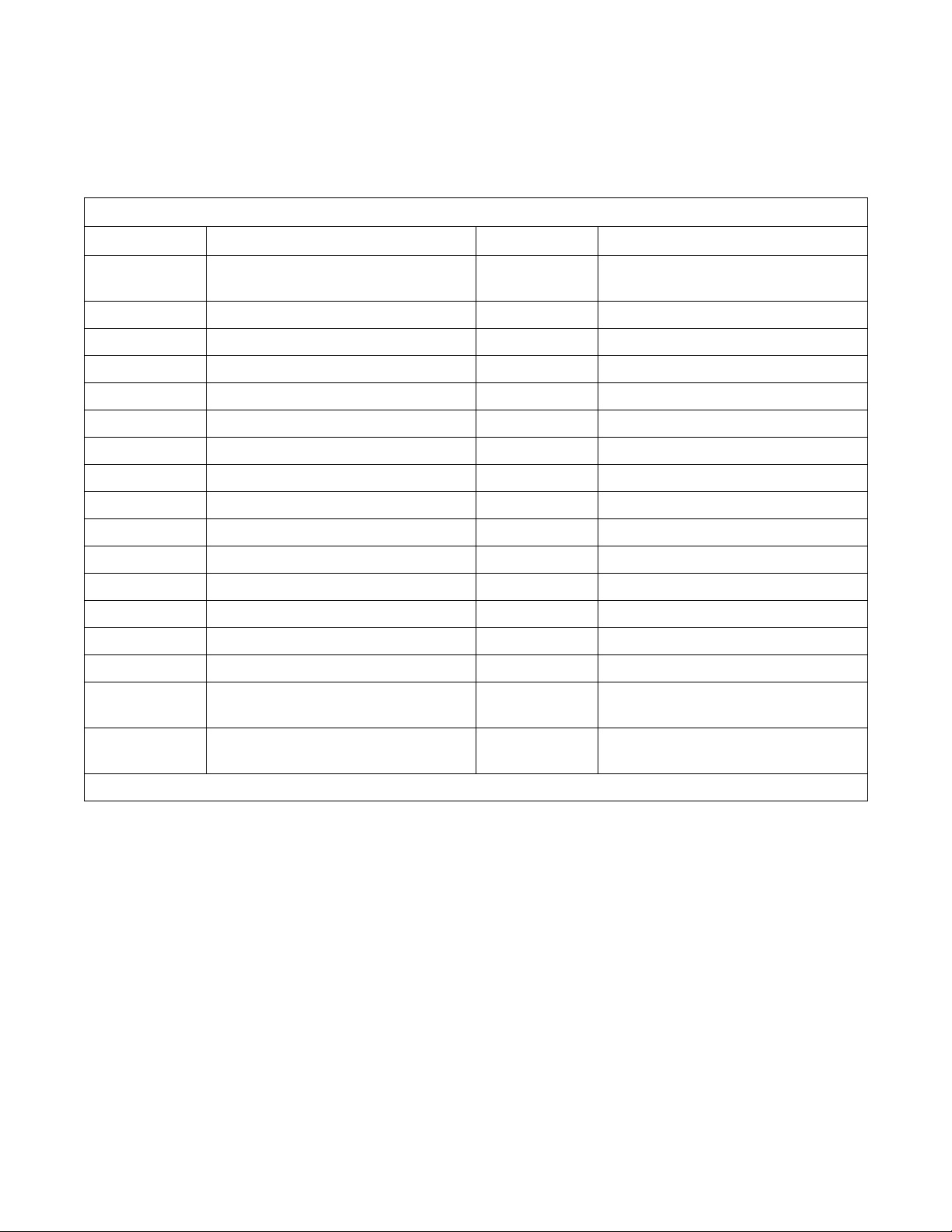

Display Indications

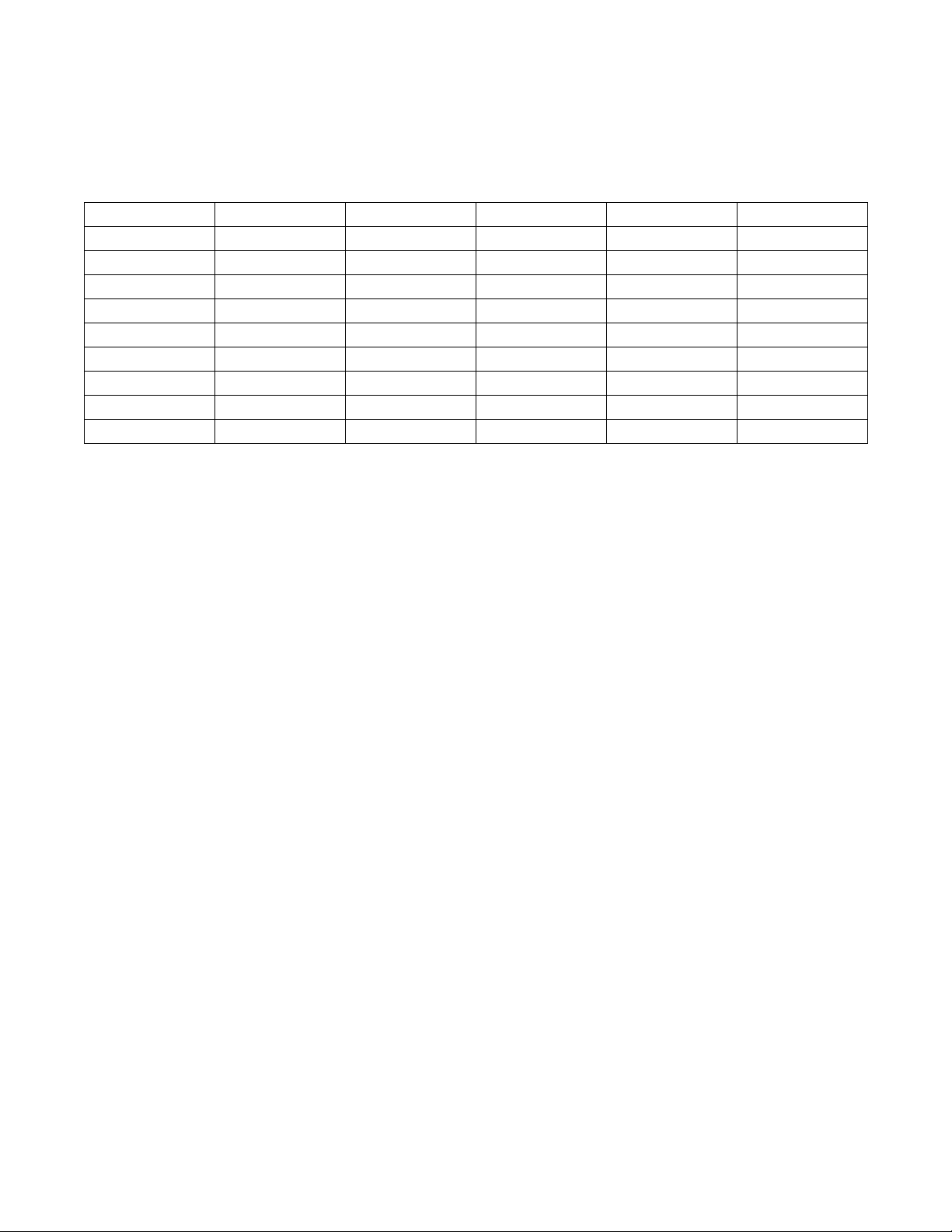

Table 1 through Ta b le 4 list the various displays and

what they mean. The operator should become familiar

with these computer displays.

Display Indications for S-Series – Non-Coin

Display Meaning Display Meaning

S-05 Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on HFIL Hot fill

CY Cycle (followed by two-digit number) LOLE Low water level

CHEC/CYC* Test cycle selected HILE High water level

FAr Degrees Fahrenheit SUP1 Supply 1

CEL Degrees Celsius SUP2 Supply 2

PrE Prewash segment (1st of 8 segments) SUP3 Supply 3

UASH Wash segment (2nd of 8 segments) SUP4 Supply 4

FIL1 First rinse (3rd of 8 segments) SUP5 Supply 5 (supply 1 and 2)

FIL2 Second rinse (4th of 8 segments) SUP6 Supply 6 (supply 2 and 3)

FIL3 Third rinse (5th of 8 segments) SUP7 Supply 7 (supply 3 and 4)

FIL4 Fourth rinse (6th of 8 segments) STOP Stop routine

FIL5 Fifth rinse (7th of 8 segments) SdLY Spin coast delay

FIL6 Sixth rinse (8th of 8 segments) donE Cycle and stop routine have ended

CFIL Cold fill door Door not properly closed

SPIn/tI

nE* Reads “SPIn” for one second, then

nE” followed by time for spin

“tI

bFIL Warm fill (both hot and cold)

FILL/STOP* Programmed water level not reached

after 30 minutes

tSFL Temperature sensor failure or

temperature out of range

*Display indications separated by a slash (/) represent an alternating display.

8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

FULL The computer detects low water level or

Table 1

higher when none should be present

F232137

Page 11

Operation

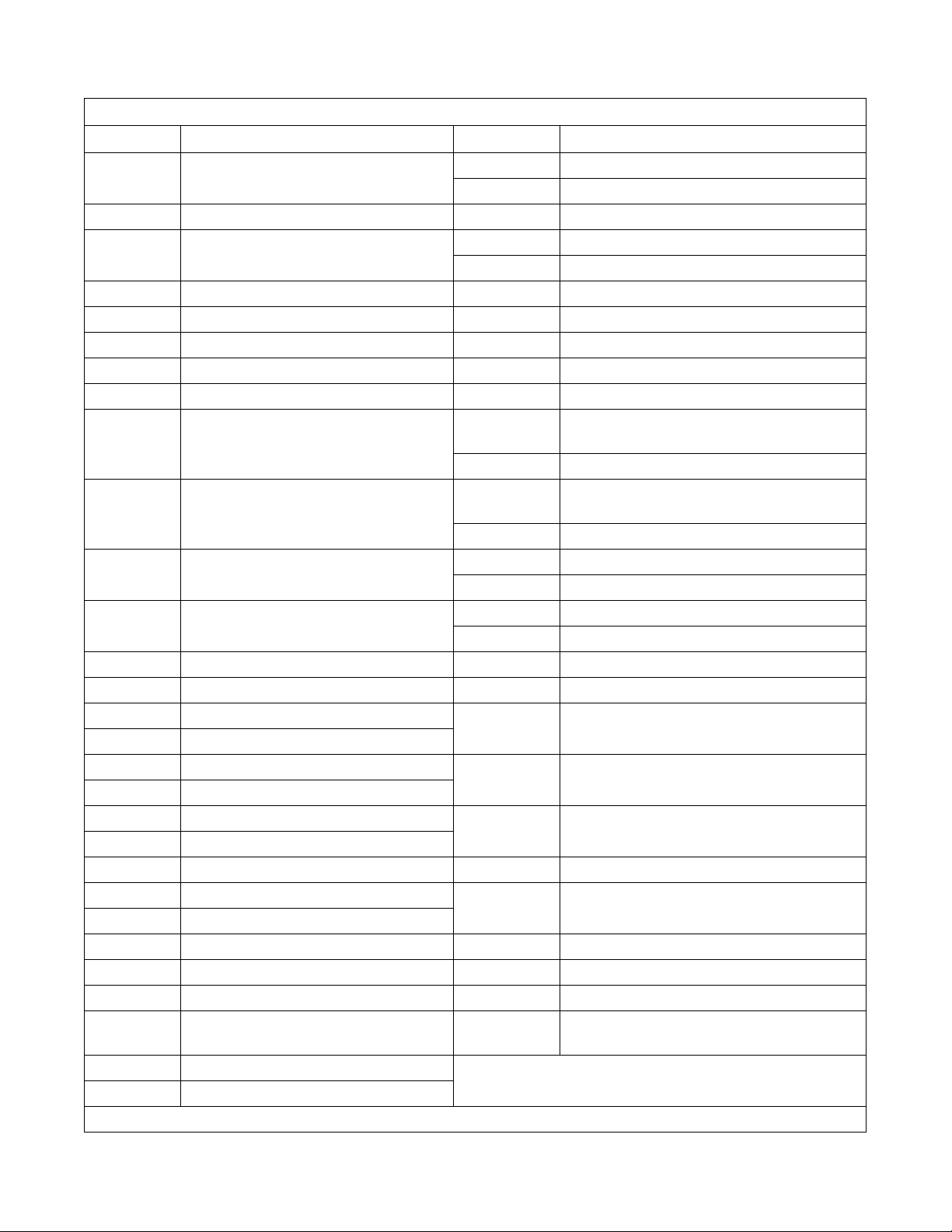

Display Indications for V-Series – Coin

Display Meaning Display Meaning

FC 5 Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on

PAY/(price)* Pay (flashes alternately with start price if

“FLSH” SETUP option is enabled)

CY Cycle (followed by two-digit number) SUP1 Supply 1

tESt/CYC* Test cycle selected SUP2 Supply 2

FAr Degrees Fahrenheit SUP3 Supply 3

CEL Degrees Celsius SUP5 Supply 5 (supply 1 and 2)

HEAt Auxiliary heat enabled SUP6 Supply 6 (supply 2 and 3)

noHt Auxiliary heat disabled drAI/dISt* Distribution (load balancing before extract)

Strt/A

nt* Start amount – flashes briefly before

showing vend price in Setup Mode

Con1/deno* Coin 1 value – flashes briefly before

showing value of coin 1 in Setup Mode

Con2/deno* Coin 2 value – flashes briefly before

showing value of coin 2 in Setup Mode

PrE Prewash segment (1st of 8 segments) bAL/FAIL* Balance routine failed during test cycle

UASH Wash segment (2nd of 8 segments) SHUT/door* Door not properly closed

FIL1 First fill (3rd of 8 segments) CANt/OPEN* Computer cannot unlock door after five

FIL2 Second fill (4th of 8 segments)

FIL3 Third fill (5th of 8 segments) FILL/STOP* Programmed water level not reached after

FIL4 Fourth fill (6th of 8 segments)

FIL5 Fifth fill (7th of 8 segments) FULL The computer detects low water level or higher

FIL6 Sixth fill (8th of 8 segments)

AFIL Auxiliary fill dFLt Drive fault detected (Variable-speed only)

bFIL Warm fill (both hot and cold) tSFL Temperature sensor failure or temperature out

CFIL Cold fill

bLCH Add bleach (for supply 2 only) bAL? Special factory balance setup mode

1Pr One vend price – all cycles SPC? Special factory valve flush mode

16Pr 16 vend prices – one per cycle SPIN Spin in test cycle (2 speed only)

CHEC/

CYC*

For Wash speed forward in test cycle

FrEE “Free” cycle option

*Display indications separated by a slash (/) represent an alternating display.

Test cycle selected (same as tESt/CYC) rEv Reverse wash speed in test cycle

HFIL Hot fill

Lo Low water level

nEd Medium water level

HI High water level

SUP0 No supplies

(Variable-speed only)

drAI/For* Drain step (low speed forward in test cycle)

SPIn/tInE* Reads “SPIn” for one second, then “tInE”

followed by time for spin

SdLY Spin coast delay

STOP Stop routine

donE Cycle and stop routine have ended

HI 1 Low spin in test cycle (Variable-speed only)

HI 2 High spin in test cycle (Variable-speed only)

attempts

30 minutes

when none should be present

of range

F232137

Table 2

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

9

Page 12

Operation

Display Indications for V-Series – Non-Coin

Display Meaning Display Meaning

FP 1 Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on SUP1 Supply 1

CY Cycle (followed by two-digit number) SUP2 Supply 2

tESt/CYC* Test cycle selected SUP3 Supply 3

FAr Degrees Fahrenheit SUP4 Supply 4

CEL Degrees Celsius SUP5 Supply 5 (Setup option)

HEAt Auxiliary heat enabled SUP6 Supply 6 (supply 1 and 5)

noHt Auxiliary heat disabled SUP7 Supply 7 (supply 3 and 4)

tFIL Temperature-controlled fill enabled SLo/For Gentle wash speed, forward direction

ntFL Temperature-controlled fill disabled SLo/rEv Gentle wash speed, reverse direction

CooL Automatic cool-down enabled nor

noCL Automatic cool-down disabled nor

Ag 1 Agitation 1 selected (90% agitation) drAI Drain enabled

Ag 2 Agitation 2 selected (33% agitation) nodr Drain disabled

Ag 3 Agitation 3 selected (10% agitation) dISt Distribution (load balancing before

Ag 4 Agitation 4 selected (6.7% agitation) SPIn/tI

AgSn Agitation speed normal

AgSL Agitation speed low SPn1 Lowest of three spins

PU

nP Pump output enabled (future use only) SPn2 Middle of three spins

nP

nP Pump output disabled (future use only) SPn3 Highest of three spins

PrE Prewash segment (1st of 11 segments) STOP Stop routine

UASH Wash segment (2nd of 11 segments) SdLY Spin coast delay

FIL1 First fill (3rd of 11 segments) donE Cycle and stop routine have ended

FIL2 Second fill (4th of 11 segments) dFLt Drive fault detected

FIL3 Third fill (5th of 11 segments) door Door not properly closed

FIL4 Fourth fill (6th of 11 segments) bAL/FAIL* Balancing routine failed during test cycle

FIL5 Fifth fill (7th of 11 segments)

FIL6 Sixth fill (8th of 11 segments) FILL/STOP* Programmed water level not reached

FIL7 Seventh fill (9th of 11 segments)

FIL8 Eighth fill (10th of 11 segments) FULL The computer detects low water level or

FIL9 Ninth fill (11th of 11 segments)

CFIL Cold fill rotA Computer detects possible rotation of

bFIL Warm fill (both hot and cold)

HFIL Hot fill tSFL Temperature sensor failure or

AFIL Auxiliary fill (Setup option)

Lo Low water level

*Display indications separated by a slash (/) represent a flashing display.

nEd Medium water level

HI High water level

n/For Normal wash speed, forward direction

n/rEv Normal wash speed, reverse direction

extract)

nE* Reads “SPIn” for one second, then

nE” followed by time for spin

“tI

after 10 attempts to balance load

after 30 minutes

higher when none should be present

motor when there should be none

temperature out of range

10

Table 3

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 13

Display Indications for V-Series Two Speed – Non-Coin

Display Meaning Display Meaning

Operation

F23n Program identification code (ROM)

(this is an example only)

HoLd Wait...power has just been turned on FIL8 Eighth fill (10th of 11 segments)

CY Cycle (followed by two-digit number) FIL9 Ninth fill (11th of 11 segments)

tESt/CYC* Test cycle selected CFIL Cold fill

FAr Degrees Fahrenheit bFIL Warm fill (both hot and cold)

CEL Degrees Celsius HFIL Hot fill

HEAt Auxiliary heat enabled AFIL Auxiliary fill (Setup option)

noHt Auxiliary heat disabled Lo Low water level

tFIL Temperature-controlled fill enabled

ntFL Temperature-controlled fill disabled HI High water level

CooL Automatic cool-down enabled SUP1 Supply 1

noCL Automatic cool-down disabled SUP2 Supply 2

Ag 1 Agitation 1 selected (90% agitation) SUP3 Supply 3

Ag 2 Agitation 2 selected (33% agitation) SUP4 Supply 4

Ag 3 Agitation 3 selected (10% agitation) SUP5 Supply 5 (or Setup option)

Ag 4 Agitation 4 selected (6.7% agitation) SUP6 Supply 6 (supply 1 and 5)

FIL6 Sixth fill (8th of 11 segments)

FIL7 Seventh fill (9th of 11 segments)

nEd Medium water level

PU

nP Pump output enabled (future use only) SUP7 Supply 7 (supply 3 and 4)

nP Pump output disabled (future use only) For Wash speed, forward direction

nP

PrE Prewash segment (1st of 11 segments) rEv Wash speed, reverse direction

UASH Wash segment (2nd of 11 segments) drAI Drain enabled

FIL1 First fill (3rd of 11 segments) nodr Drain disabled

FIL2 Second fill (4th of 11 segments) STOP Stop routine

FIL3 Third fill (5th of 11 segments) SdLY Spin coast delay

FIL4 Fourth fill (6th of 11 segments) donE Cycle and stop routine have ended

FIL5 Fifth fill (7th of 11 segments) door Door not properly closed

FULL The computer detects low water level or

higher when none should be present

tSFL Temperature sensor failure or

temperature out of range

*Display indications separated by a slash (/) represent a flashing display.

FILL/STOP* Programmed water level not reached

after 30 minutes

SPIn/tI

nE* Reads “SPIn” for one second, then

nE” followed by time for spin

“tI

Table 4

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

11

Page 14

Operation

Operating Instructions

1. Turn on main power source (circuit breaker).

For non-coin models: Turn on the On/Off switch

on the front panel to the On position.

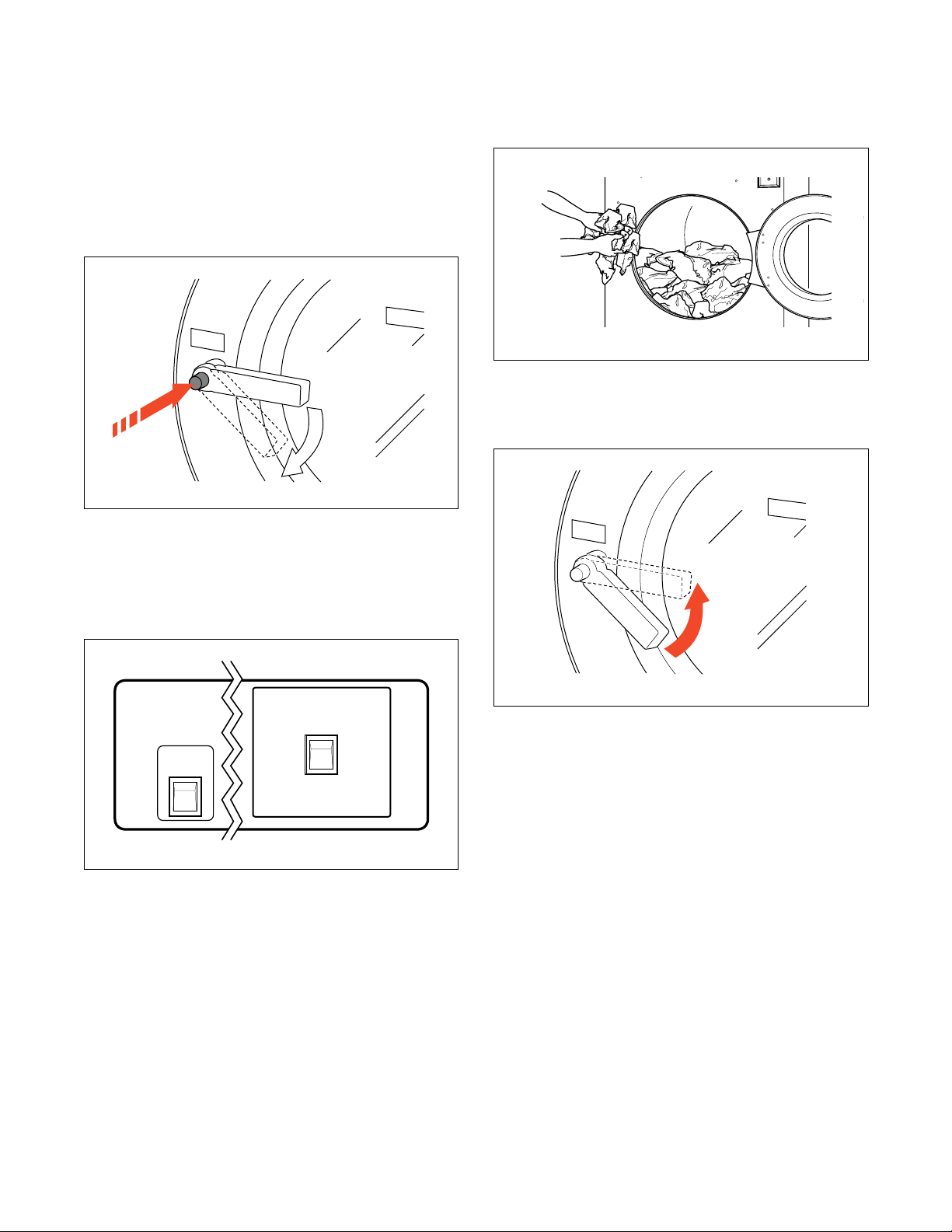

2. Push button and turn handle clockwise to open.

Refer to Figure 3.

U001I

Figure 3

For non-coin models: Press and hold the DOOR

UNLOCK button on the left side of the control

panel while performing the above step. Refer to

Figure 3 and Figure 4.

3. Load to capacity whenever possible. DO NOT

OVERLOAD. Refer to Figure 5.

U003I

Figure 5

4. Close door and turn handle counterclockwise

until button pops out. Refer to Figure 6.

U001I

DOOR UNLOCK

Figure 4

U005I

U005I

On

Off

U135R

U135R

Figure 6

12

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 15

Operation

5. Add liquid and/or powder supplies to supply

dispenser. Refer to Figure 7.

a. Add detergent to container 1.

b. Add softener to container 3.

For non-coin models: Liquid supplies may be

injected directly into the supply dispenser by an

external chemical supply dispenser. Refer to

Installation and Programming Manuals.

6. Press the Up or Down key to select wash cycle.

Press the Start key. Refer to Figure 8.

B157R

Figure 7

7. For coin models: Insert required number of coins

to start machines. Refer to Figure 7.

9. When applicable, add bleach to container 2

when the display reads “bLCH”. Refer to

Figure 9.

CYCLE SELECTION

Up Down Start Stop

U152R

Figure 9

NOTE: To stop a cycle at any time, press the Stop

(non-coin models only) key.

NOTE: To display the temperature of the water

while a cycle is running, press the Up key. To

display the number of the cycle in progress, press

the Start key.

8. For non-coin models: Press the Start key.

Refer to Figure 8.

CYCLE SELECTION

Up Down Start Stop

Figure 8

U137R

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

13

Page 16

Notes

14

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 17

Maintenance

Sharp Edges. Can cause personal injury.

Wear safety glasses and gloves, use

proper tools and provide lighting when

handling sheet metal parts.

W366

WARNING

4. Check door interlock before starting operation:

a. Attempt to start the machine with the door

open. The machine should not start with the

door open.

b. Close the door without locking it and attempt

to start the machine. The machine should not

start with the door unlocked.

IMPORTANT: Replace all panels that are removed

to perform service and maintenance procedures.

Do not operate the machine with missing guards or

with broken or missing parts. Do not bypass any

safety devices.

Daily

IMPORTANT: Door lock should be checked daily

to ensure proper operation. Also check that all

safety and instruction labels are on the machine.

Any missing or illegible safety instructions labels

should be replaced immediately.

Beginning of Day

1. Inspect water inlet valve hose connections on the

back of the machine for leaks.

2. Inspect steam hose connections for leaks (where

applicable).

3. Verify that insulation is intact on all external

wires and that all connections are secure. If

exposed wire is evident, call a service technician.

c. Close and lock the door, and start a cycle.

Attempt to open the door while the cycle is in

progress. The door should not open.

If the door lock and interlock are not functioning

properly, call a service technician.

End of Day

1. Clean the door gasket of residual detergent and

all foreign matter.

2. Clean automatic supply dispenser lid and general

area. Flush dispenser with clean water.

3. Clean the machine’s top, front and side panels

with mild detergent. Rinse with clean water.

4. Leave loading door open at the end of each day to

allow moisture to evaporate.

NOTE: Unload the machine promptly after each

completed cycle to prevent moisture buildup. Leave

loading door open after each completed cycle to

allow moisture to evaporate.

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

15

Page 18

Maintenance

Weekly

1. For variable-speed models only, clean the AC

drive box filter(s) weekly or more frequently as

needed:

NOTE: If fan filter service indicator light is on, fan

filter must be cleaned immediately to prevent

possible damage. Press thermostat button to reset

indicator light.

a. Open the top cover.

b. Grasp the filter handle and pull straight up to

remove filter.

c. Wash the filter with warm water and allow

filter to air-dry. As an alternative, the filter

may be vacuumed clean.

IMPORTANT: The control module cover and fan

filter must be in place for the fan to properly cool

the AC inverter drive. Failure to observe this

warning will void the warranty and could lead to

expensive AC inverter drive repair.

2. Check the machine for leaks.

a. Start an unloaded cycle to fill the machine.

b. Verify that door and door gasket do not leak.

Monthly

NOTE: Disconnect power to the machine at its

source before performing the monthly maintenance

procedures.

1. Use the following procedures to determine if

V-belt(s) require replacement or adjustment. Call

a qualified service technician in either case.

a. Check V-belt(s) for uneven wear and frayed

edges.

b. For groove-pulley drive systems, verify

alignment by placing a straightedge across

both pulley faces. The straightedge should

make contact with the pulleys in four places.

Refer to Figure 10.

1

4

2

3

c. Verify that the drain valve is operating and

that the drain system is free from obstruction.

If water does not leak out during the first wash

segment, the drain valve is closed and

functioning properly.

H040I

1 Motor

2 Motor Pulley

3 Straightedge

4 Basket Pulley

Figure 10

16

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 19

c. For flat-pulley drive systems, verify allowable

distance of belt from edge of pulley as shown

in Table 5 below:

Flat-Pulley Alignment

Maintenance

Model

Allowable

Distance from Edge

18 – 40 3/32 in. (2 mm)

50 3/8 in. (10 mm)

Table 5

d. For variable-speed models only, verify that

V-belts are properly tensioned by applying a

set force to the belt and measuring the

deflection to determine the belt tension. Refer

to Table 6 for the acceptable belt tension

1 Deflection

2 Span Length

ranges. Belt tension measurements should be

taken as close to the center of the belt span as

possible. Refer to Figure 11.

Belt Tension Testing for Variable-Speed Models

Model Belt Belt Span Deflection Range

1

2

H039I

Figure 11

Force

Min – Max

35, 40 Motor-Basket 16.9 in. (428 mm) 5/16 – 11/32 in. (7.9 – 8.7 mm) 6.1 – 7.4 lbs. (27 – 33 N)

50 Motor-Basket 16.8 in. (426 mm) 9/32 – 5/16 in. (7.1 – 7.9 mm) 6.1 – 7.4 lbs. (27 – 33 N)

80 Motor-Basket 22.1 in. (561 mm) 15/32 – 1/2 in. (11.9 – 12.7 mm) 4.9 – 7.3 lbs. (21.8 – 31.5 N)

Table 6

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

17

Page 20

Maintenance

1

2

1 Bearing Grease Fitting

2 Seal Grease Fitting

2. For 80 pound capacity models only, lubricate

bearings and seals each month OR after every

200 hours of operation. Refer to Figure 12.

a. Use a premium-grade lithium-based #2

grease. Never mix two types of grease, such

as petroleum and silicone.

H047I

Figure 12

b. Pump the grease gun slowly, permitting only

the following number of strokes:

● Bearing grease fitting, two strokes

● Seal grease fitting, one stroke

Do not pump the grease gun until grease

comes out of the bearing housing. This can

result in overlubrication, causing damage to

bearings and seals.

18

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 21

Maintenance

I

3. Remove back panel, and check overflow hose

and drain hose for leaks.

4. Unlock the hinged lid, and check the supply

dispenser hoses and hose connections.

5. Clean inlet hose filter screens:

a. Turn water off and allow valve to cool, if

necessary.

b. Unscrew inlet hose and remove filter screen.

c. Clean with soapy water and reinstall. Replace

if worn or damaged.

6. Tighten motor mounting bolt locknuts and

bearing bolt locknuts, if necessary.

7. Use compressed air to clean lint from motor.

8. Clean interior of machine, both basket and shell,

by wiping with a water-soaked sponge or cloth.

9. Use compressed air to ensure that all electrical

components are free of moisture and dust.

10. For variable-speed models only, clean AC drive

cooling fan blades monthly (more often if

required by the condition of the air).

4. Check all painted surfaces for exposed metal.

(Matching paint is available from the

manufacturer.)

● If exposed metal is showing, paint with primer

or solvent-based paint.

● If rust appears, remove it with sandpaper or by

chemical means. Then paint with primer or

solvent-based paint.

5. Clean customer-supplied steam filter, where

applicable. Refer to Figure 13.

a. Turn off steam supply and allow time for the

valve to cool.

b. Unscrew cap.

c. Remove filter element and clean.

d. Replace filter element and cap.

a. Open the top cover and remove the control

module cover.

b. Gently wipe the fan blades clean with a dry

cloth.

Quarterly

NOTE: Disconnect power to the machine before

performing the quarterly maintenance procedures.

1. Tighten door hinges and fasteners, if necessary.

2. Tighten anchor bolts, if necessary.

3. Verify that the drain motor shield is in place and

secure.

1

2

H042

H042I

1 Cap

2 Filter Element

Figure 13

F232137

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

19

Page 22

Maintenance

Care of Stainless Steel

● Remove dirt and grease with detergent and water.

Thoroughly rinse and dry after washing.

● Avoid contact with dissimilar metals to prevent

galvanic corrosion when salty or acidic solutions

are present.

● Do not allow salty or acidic solutions to

evaporate and dry on stainless steel. Wipe clean

of any residues.

● Rub in the direction of the polish lines or “grain”

of the stainless steel to avoid scratch marks when

using abrasive cleaners. Use stainless steel wool

or soft, non-metal bristle brushes. Do not use

ordinary steel wool or steel brushes.

● Remove discoloration or heat tint from

overheating by scouring with a powder or by

employing special chemical solutions.

● Do not leave sanitizers or sterilizing solutions on

stainless steel equipment for prolonged periods

of time.

● When an external chemical supply is used, ensure

no siphoning of chemicals occurs when the

washer-extractor is not in use. Highly

concentrated chemicals can cause severe damage

to stainless steel and other components with the

machine. Damage of this kind is not covered by

the manufacturer’s warranty. Locate the pump

below the washer-extractor’s injection point to

prevent siphoning of chemicals into the machine.

● If the stainless steel appears to be rusting, the

source of the rust may actually be an iron or steel

part not made of stainless steel, such as a nail or

screw. Tip: Paint all carbon steel parts with a

heavy protective coating. Stainless steel fasteners

should be used whenever possible.

20

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137

Page 23

Lavadoras

extractoras

de montaje permanente con

Micro-computadoras de las Series S, P, y V

modelos con tragamonedas y sin tragamonedas

Consulte la página 25 para la identificación de modelos

Operación/mantenimiento

Guarde estas instrucciones para referencia en el futuro.

(Si la unidad cambia de dueño, asegúrese de que este manual vaya con la misma).

www.comlaundry.com

CHM166C

Pieza No. F232137R2

Abril 2002

Page 24

Page 25

Contenido

Introducción ........................................................................................ 25

Identificación de modelos..................................................................... 25

Localización de la placa de identificación............................................ 26

Piezas de repuesto................................................................................. 26

Servicio al cliente ................................................................................. 26

Información de seguridad.................................................................. 27

Instrucciones de seguridad importantes................................................ 27

Operación ............................................................................................ 29

Tablero de control................................................................................. 29

Indicaciones en pantalla........................................................................ 30

Instrucciones de operación ................................................................... 37

Mantenimiento .................................................................................... 39

Diariamente........................................................................................... 39

Al comenzar la jornada diaria.......................................................... 39

Al terminar la jornada diaria............................................................ 39

Semanalmente....................................................................................... 40

Mensualmente....................................................................................... 40

Trimestralmente.................................................................................... 43

Cuidados al acero inoxidable................................................................ 44

© Copyright 2002, Alliance Laundry Systems LLC

Reservados todos los derechos. Ninguna sección del presente manual puede ser reproducida o transmitida en forma

alguna o a través de ningún medio sin el expreso consentimiento por escrito del editor.

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

23

Page 26

Notas

24

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 27

Introducción

Identificación de modelos

La información contenida en este manual es aplicable

a los siguientes modelos:

HC18SN2 HC27VX2 HC50SN2 SC35VN2 UC20PN2 UC40VN2

HC18VC2 HC30SN2 HC50VC2 SC35VNV UC20VN2 UC40VNV

HC18VX2 HC30VC2 HC50VX2 SC40VN2 UC27PN2 UC50PN2

HC20SN2 HC30VX2 HC80VCV SC40VNV UC27VN2 UC50VN2

HC20VC2 HC35SN2 HC80VNV SC50VN2 UC30PN2 UC50VNV

HC20VX2 HC35VC2 HC80VXV SC50VNV UC30VN2 UC80VNV

HC25VC2 HC35VX2 SC18VN2 SC80VNV UC35PN2 UC125VNV

HC25VX2 HC40SN2 SC20VN2 SC125VNV UC35VN2

HC27SN2 HC40VC2 SC27VN2 UC18PN2 UC35VNV

HC27VC2 HC40VX2 SC30VN2 UC18VN2 UC40PN2

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

25

Page 28

Introducción

Localización de la placa de

identificación

La placa de identificación está ubicada en la parte

posterior de la máquina y en el interior de la puerta.

Siempre proporcione el número de serie y el modelo

de la máquina al solicitar piezas o asistencia técnica.

1

Piezas de repuesto

Si necesita documentación o piezas de repuesto,

póngase en contacto con el lugar donde haya adquirido

la máquina o con Alliance Laundry Systems al

(920) 748-3950 para obtener el nombre y la dirección

de su distribuidor autorizado de piezas de repuesto

más cercano.

Servicio al cliente

Para obtener asistencia técnica, llame a cualquiera de

los siguientes números:

(850) 718-1025

(850) 718-1026

Marianna, Florida U.S.A.

(920) 748-3121

Ripon, Wisconsin U.S.A.

1 Placa de identificación

Figura 1

CHM167R

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 29

Información de seguridad

PELIGRO indica la presencia de un

peligro que, de ignorarse, ocasionará

lesiones graves, la muerte o daños

considerables a la propiedad.

PELIGRO

ADVERTENCIA indica la presencia de un

peligro que, de ignorarse, puede

ocasionar lesiones graves, la muerte o

daños considerables a la propiedad.

ADVERTENCIA

PRECAUCIÓN indica la presencia de un

peligro que, de ignorarse, puede

ocasionar lesiones menores o daños

considerables a la propiedad.

PRECAUCIÓN

En este manual, así como en las calcomanías adheridas

a la máquina, se incluyen avisos de precaución

(“PELIGRO”, “ADVERTENCIA” y

“PRECAUCIÓN”) seguidos de instrucciones

específicas. Estos avisos tienen como objetivo la

seguridad del operador, del usuario, del técnico de

servicio y de las personas encargadas del

mantenimiento de la máquina.

Instrucciones de seguridad

importantes

ADVERTENCIA

Para reducir el peligro de incendio,

descarga eléctrica, y lesiones personales

graves o incluso letales al utilizar la

lavadora, observe las siguientes medidas

de precaución básicas:

W023SB

1. Lea todas las instrucciones antes de utilizar la

lavadora.

2. Remítase a la sección de Instrucciones para la

conexión a tierra del Manual de instalación para

una correcta conexión a tierra de la lavadora.

3. No lave artículos textiles que se hayan limpiado,

lavado o sumergido en gasolina, solventes para

lavado al seco u otras sustancias inflamables o

explosivas, ya que las mismas despiden gases que

podrían encenderse o causar una explosión.

4. No agregue gasolina, solventes para lavar al seco

u otras sustancias explosivas o inflamables al

agua que utilizará para el lavado. Estas sustancias

despiden vapores que pueden encenderse o

explotar.

Existen otros avisos de precaución (“IMPORTANTE”

y “NOTA”) también seguidos de instrucciones

específicas.

IMPORTANTE: La palabra “IMPORTANTE” se

emplea para informar al lector acerca de

procedimientos específicos que, de no seguirse,

ocasionarán daño a la máquina.

NOTA: La palabra “NOTA” se usa para comunicar

información sobre instalación, operación,

mantenimiento y servicio que, aunque importante,

no representa peligro.

5. En ciertos casos, cuando no se utiliza el sistema

de agua caliente durante dos semanas o más,

puede producirse una acumulación de gas

hidrógeno en dicho sistema. EL GAS

HIDRÓGENO ES EXPLOSIVO. Si no ha

utilizado el sistema de agua caliente durante dos

semanas o más, antes de usar la lavadora o la

combinación de lavadora secadora, abra todos los

grifos del agua caliente y deje que el agua fluya

por ellos durante varios minutos. De esta manera,

se liberará todo el gas hidrógeno acumulado.

Dicho gas es inflamable. No fume ni utilice llama

abierta durante este lapso de tiempo.

6. No deje que los niños jueguen sobre la lavadora

ni dentro de la misma. Debe supervisarse

cuidadosamente a los niños cuando se utiliza la

lavadora cerca de ellos. Esta es una medida de

seguridad aplicable a todos los electrodomésticos.

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

27

Page 30

Información de seguridad

7. Antes de sacar de servicio la lavadora o desecharla,

saque la puerta del compartimiento de lavado.

8. No introduzca la mano en la lavadora si la tina

está en movimiento.

9. No instale ni coloque la lavadora en un lugar

donde esté expuesta al agua o a la intemperie.

10. No utilice inapropiadamente los controles.

11. No repare ni cambie ninguna pieza de la

lavadora, ni trate de hacerle mantenimiento, salvo

que las instrucciones de mantenimiento para el

usuario lo recomienden de manera expresa, o que

lo indiquen las instrucciones de mantenimiento

dirigidas al usuario, que esté en capacidad de

entender y llevar a cabo.

12. Para reducir el riesgo de choque eléctrico o

incendio, NO utilice extensiones ni adaptadores

para conectar la lavadora a la fuente de

suministro de energía eléctrica.

13. Utilice su lavadora sólo para la finalidad con la

que fue fabricada, es decir, para lavar artículos

textiles.

14. Desconecte SIEMPRE la lavadora del tomacorriente

antes de hacerle cualquier mantenimiento. Saque

el cable de suministro de electricidad sujetando el

tomacorriente, en lugar de tirar del cable.

15. Instale la lavadora según se indica en las

Instrucciones de instalación. Todas las

conexiones del suministro de agua, desagüe,

energía eléctrica y conexión a tierra deberán

satisfacer los reglamentos locales y ser realizadas

por personal que cuente con la debida licencia,

cuando el caso lo amerite.

16. Para reducir los riesgos de incendios, no deben

introducirse en la lavadora artículos textiles con

rastros de sustancias inflamables, como por

ejemplo, aceite vegetal, aceite de cocina, aceite

para lubricar máquinas, productos químicos

inflamables, diluyente de pinturas, etc., y prendas

que contengan ceras u otros productos químicos,

tales como mopas y paños de limpieza. Estas

sustancias inflamables pueden provocar que las

telas se prendan en fuego.

17. No utilice suavizadores de ropa o productos para

eliminar la estática, a menos que lo recomiende

el fabricante del suavizador o del producto.

18. Conserve su lavadora en buen estado. Golpear o

dejar caer la lavadora puede dañar los

dispositivos de seguridad. Si esto ocurre, haga

que un técnico de mantenimiento calificado

revise la lavadora.

19. Cambie los cables gastados y los enchufes flojos.

20. Asegúrese de que las conexiones de agua tengan

una válvula de corte y que las conexiones de las

mangueras de llenado estén bien apretadas.

CIERRE las válvulas de corte cuando termine la

jornada diaria.

21. La puerta de carga DEBERÁ ESTAR

CERRADA siempre que la lavadora vaya a

ejecutar un ciclo de llenado, de agitación o de

centrifugado. NO anule el seguro de la puerta de

carga, permitiendo que la lavadora funcione con

la puerta abierta.

22. Lea y siga siempre las instrucciones del fabricante

que aparecen en los paquetes de ayuda para el

lavado y secado. Observe todas las advertencias y

precauciones. Para reducir el riesgo de

envenenamiento o quemaduras con productos

químicos, mantenga en todo momento dichos

productos fuera del alcance de los niños (guárdelos

preferiblemente en un gabinete con llave).

23. Siga siempre las instrucciones para el cuidado de

los artículos textiles, suministradas por el

fabricante de los artículos textiles.

24. Nunca ponga a funcionar la lavadora sin los

protectores o paneles correspondientes.

25. NO utilice la lavadora si le faltan piezas o tiene

piezas dañadas.

26. NO anule ningún dispositivo de seguridad.

27. Si la instalación, mantenimiento u operación de

esta lavadora no se realiza de acuerdo con las

instrucciones del fabricante, es posible que se

originen situaciones peligrosas que podrían

ocasionar lesiones personales y/o daños a la

propiedad.

NOTA: Las INSTRUCCIONES DE SEGURIDAD

IMPORTANTES y ADVERTENCIAS que

aparecen en este manual no pretenden contemplar

todas las posibles condiciones y situaciones que

pueden presentarse. La instalación, mantenimiento

y operación de la lavadora deben hacerse con

sentido común, precaución y cuidado.

Comuníquese con el concesionario, distribuidor,

agente de servicios o fabricante, cuando tenga

problemas o se encuentre en una situación que no

comprenda.

28

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 31

Operación

Up Down Start Stop

5

6

8 7

1

2

3

4

Tablero de control

En la Figura 2 se muestra el tablero de control de las

máquinas equipadas con microcomputadoras serie S,

P y V.

Las teclas Up (Hacia arriba) y

Down (Hacia abajo) se usan para la selección

del ciclo. Presione cualquiera de estas teclas para

desplazarse a través de los ciclos, de menor a mayor,

o de mayor a menor.

La tecla de Start (Arranque) se usa para

iniciar un ciclo.

La tecla de Stop (Parada) no está activa en el

modalidad de funcionamiento normal. En el

modalidad de funcionamiento normal se emplea

únicamente para interrumpir el ciclo de prueba.

La pantalla de LED indica al operador las diferentes

operaciones que se suceden durante la operación de la

máquina. Consulte las tablas que aparecen en las

páginas siguientes, donde se presentan las

indicaciones en pantalla y sus significados. Las luces

indicadoras en la pantalla de LED indican las

condiciones de desbalance y los niveles de agua.

Consulte la Figura 2.

B161R

1 Condición desbalanceada para VCV, VXV

2 Nivel de agua alto

3 Nivel de agua intermedio para serie V

4 Nivel de agua bajo

5 Pantalla de LED

6 Teclas para lavanderías en instalaciones

estándar

7 Teclas para símbolos para lavanderías en

instalaciones

8 Teclas para VC2, VCV, VX2, VXV

Figura 2

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

29

Page 32

Operación

Indicaciones en pantalla

En las tablas siguientes se muestran los diferentes mensajes

que pueden aparecer en pantalla, y lo que significan.

El operador debe familiarizarse con estos mensajes.

Indicaciones en pantalla para máquinas serie S sin tragamonedas

Pantalla Significado Pantalla Significado

S-05 Código de identificación de programa

(ROM) (sólo como ejemplo)

HoLd Espere ... se acaba de encender la

máquina

CY Ciclo (seguido de un número de dos

dígitos)

CHEC/CYC* Ciclo de prueba seleccionado HILE Nivel de agua alto

FAr Grados Fahrenheit SUP1 Suministro 1

CEL Grados Celsius SUP2 Suministro 2

PrE Segmento de prelavado (1ro. de 8

segmentos)

UASH Segmento de lavado (2do. de 8

segmentos)

FIL1 Primer enjuague (3ro. de 8 segmentos) SUP5 Suministro 5 (suministros 1 y 2)

FIL2 Segundo enjuague (4to. de 8 segmentos) SUP6 Suministro 6 (suministros 2 y 3)

FIL3 Tercer enjuague (5to. de 8 segmentos) SUP7 Suministro 7 (suministros 3 y 4)

FIL4 Cuarto enjuague (6to. de 8 segmentos) STOP Rutina de parada

FIL5 Quinto enjuague (7mo. de 8 segmentos) SdLY Retardo de disminución gradual de

bFIL Llenado con agua tibia (ambas, caliente

y fría)

HFIL Llenado con agua caliente

LOLE Nivel de agua bajo

SUP3 Suministro 3

SUP4 Suministro 4

centrifugado

FIL6 Sexto enjuague (8vo. de 8 segmentos) donE Han terminado el ciclo y la rutina de

parada

CFIL Llenado con agua fría door La puerta no está cerrada debidamente.

SPIn/tI

nE* Aparece “SPIn” por un segundo y a

continuación “tI

de centrifugado

tSFL Falla del sensor de temperatura o

temperatura fuera de gama

*Las indicaciones de la pantalla separadas por un guión (/) representan un mensaje alternado.

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

nE” seguido del tiempo

FILL/STOP* No se alcanzó el nivel de agua

programado después de 30 minutos

FULL La computadora detecta nivel de agua

bajo o alto cuando no debería detectarse

ninguno

Tabla 1

F232137 (SP)

Page 33

Indicaciones en pantalla para máquinas serie V con tragamonedas

Pantalla Significado Pantalla Significado

Operación

FC 5 Código de identificación de programa

(ROM) (sólo como ejemplo)

HoLd Espere ... se acaba de encender la

máquina

PAY/(price)* Pague (se presenta alternadamente con el

precio de inicio, si está activada la

opción “FLSH” SETUP)

CY Ciclo (seguido de un número de dos

dígitos)

tESt/CYC* Ciclo de prueba seleccionado SUP2 Suministro 2

FAr Grados Fahrenheit SUP3 Suministro 3

CEL Grados Celsius SUP5 Suministro 5 (suministros 1 y 2)

HEAt Activado el calor auxiliar SUP6 Suministro 6 (suministros 2 y 3)

noHt Desactivado el calor auxiliar drAI/dISt* Distribución (balance de carga antes de

Strt/A

nt* Cantidad de inicio – destella

momentáneamente antes de presentar el

precio de la transacción en el modalidad

configuración

HFIL Llenado con agua caliente

Lo Nivel de agua bajo

nEd Nivel de agua intermedio

HI Nivel de agua alto

SUP0 Sin suministros

SUP1 Suministro 1

la extracción) (máquinas con velocidad

variable únicamente)

drAI/For* Paso de desagüe (baja velocidad hacia

adelante en ciclo de prueba)

nE* Aparece “SPIn” por un segundo y a

SPIn/tI

continuación “tI

de centrifugado

SdLY Retardo de disminución gradual de

centrifugado

nE” seguido del tiempo

Con1/deno* Valor de la moneda 1 – destella

momentáneamente antes de mostrar el

valor de la moneda 1 en el modalidad

configuración

Con2/deno* Valor de la moneda 2 – destella

momentáneamente antes de mostrar el

valor de la moneda 2 en el modalidad

configuración

PrE Segmento de prelavado (1ro. de

8 segmentos)

UASH Segmento de lavado (2do. de

8 segmentos)

FIL1 Primer llenado (3ro. de 8 segmentos) CANt/OPEN* La computadora no pudo desbloquear la

FIL2 Segundo llenado (4to. de 8 segmentos)

*Las indicaciones de la pantalla separadas por un guión (/) representan un mensaje alternado.

Tabla 2 (continuación)

STOP Rutina de parada

donE Han terminado el ciclo y la rutina de

parada

HI 1 Centrifugado lento en ciclo de prueba

(máquinas con velocidad variable

únicamente)

HI 2 Centrifugado alto en ciclo de prueba.

(máquinas con velocidad variable

únicamente)

bAL/FAIL* Falló la rutina de balanceo durante el

ciclo de prueba

SHUT/door* La puerta no está cerrada debidamente

puerta tras cinco intentos

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

31

Page 34

Operación

Tabla 2 (continuación)

Indicaciones en pantalla para máquinas serie V con tragamonedas

Pantalla Significado Pantalla Significado

FIL3 Tercer llenado (5to. de 8 segmentos) FILL/STOP* No se alcanzó el nivel de agua

FIL4 Cuarto llenado (6to. de 8 segmentos)

programado después de 30 minutos

FIL5 Quinto llenado (7mo. de 8 segmentos) FULL La computadora detecta nivel de agua

FIL6 Sexto llenado (8vo. de 8 segmentos)

bajo o alto cuando no debería detectarse

ninguno

AFIL Llenado auxiliar dFLt Se detectó falla en el mando (máquinas

con velocidad variable únicamente)

bFIL Llenado con agua tibia (ambas, caliente

y fría)

tSFL Falla del sensor de temperatura o

temperatura fuera de gama

CFIL Llenado con agua fría

bLCH Agregar blanqueador (sólo para

suministro 2)

1Pr Un precio de transacción – todos los

ciclos

bAL? Modalidad de configuración de balanceo

especial de fábrica

SPC? Modalidad de enjuague de válvula

especial de fábrica

16Pr 16 precios de transacción – uno por ciclo SPIN Centrifugado en ciclo de prueba

(máquinas de 2 velocidades únicamente)

CHEC/CYC* Ciclo de prueba seleccionado (igual que

tESt/CYC)

rEv Velocidad de lavado hacia atrás en ciclo

de prueba

For Velocidad de lavado hacia adelante en

ciclo de prueba

FrEE Opción de ciclo “libre”

*Las indicaciones de la pantalla separadas por un guión (/) representan un mensaje alternado.

32

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 35

Indicaciones en pantalla para máquinas serie V sin tragamonedas

Pantalla Significado Pantalla Significado

Operación

FP 1 Código de identificación de programa

(ROM) (sólo como ejemplo)

HoLd Espere ... se acaba de encender la máquina SUP1 Suministro 1

CY Ciclo (seguido de un número de dos dígitos) SUP2 Suministro 2

tESt/CYC* Ciclo de prueba seleccionado SUP3 Suministro 3

FAr Grados Fahrenheit SUP4 Suministro 4

CEL Grados Celsius SUP5 Suministro 5 (opción configuración)

HEAt Activado el calor auxiliar SUP6 Suministro 6 (suministros 1 y 5)

noHt Desactivado el calor auxiliar SUP7 Suministro 7 (suministros 3 y 4)

tFIL Activado el llenado controlado por

temperatura

ntFL Desactivado el llenado controlado por

temperatura

CooL Activado el enfriamiento automático nor

noCL Desactivado el enfriamiento automático nor

Ag 1 Seleccionada la agitación 1

(90% agitación)

nEd Nivel de agua intermedio

HI Nivel de agua alto

SLo/For Velocidad de lavado para prendas

delicadas, sentido hacia adelante

SLo/rEv Velocidad de lavado para prendas

delicadas, sentido hacia atrás

n/For Velocidad de lavado normal, sentido

hacia adelante

n/rEv Velocidad de lavado normal, sentido

hacia atrás

drAI Activado el desagüe

Ag 2 Seleccionada la agitación 2

(33% agitación)

Ag 3 Seleccionada la agitación 3

(10% agitación)

Ag 4 Seleccionada la agitación 4

(6,7% agitación)

AgSn Velocidad de agitación normal

AgSL Velocidad de agitación baja SPn1 Velocidad más baja de los tres

PU

nP Activada la salida de bombeo (sólo para

uso futuro)

nP

nP Desactivada la salida de bombeo (sólo

para uso futuro)

PrE Segmento de prelavado (1ro. de

11 segmentos)

UASH Segmento de lavado (2do. de

11 segmentos)

FIL1 Primer llenado (3ro. de 11 segmentos) donE Han terminado el ciclo y la rutina de parada

FIL2 Segundo llenado (4to. de 11 segmentos) dFLt Se detectó falla en el mando

*Las indicaciones de la pantalla separadas por un guión (/) representan un mensaje alternado.

nodr Desactivado el desagüe

dISt Distribución (balance de carga antes de

la extracción)

SPIn/tI

nE* Aparece “SPIn” por un segundo y a

continuación “TI

de centrifugado

centrifugados

SPn2 Velocidad intermedia de los tres

centrifugados

SPn3 Velocidad más alta de los tres

centrifugados

STOP Rutina de parada

SdLY Retardo de disminución gradual de

centrifugado

nE” seguido del tiempo

F232137 (SP)

Tabla 3 (continuación)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

33

Page 36

Operación

Tabla 3 (continuación)

Indicaciones en pantalla para máquinas serie V sin tragamonedas

Pantalla Significado Pantalla Significado

FIL3 Tercer llenado (5to. de 11 segmentos) door La puerta no está cerrada debidamente

FIL4 Cuarto llenado (6to. de 11 segmentos) bAL/FAIL* Falló la rutina de balanceo durante el

FIL5 Quinto llenado (7mo. de 11 segmentos)

ciclo de prueba tras 10 intentos de

balancear la carga

FIL6 Sexto llenado (8vo. de 11 segmentos) FILL/STOP* No se alcanzó el nivel de agua

FIL7 Séptimo llenado (9no. de 11 segmentos)

programado después de 30 minutos

FIL8 Octavo llenado (10mo. de 11 segmentos) FULL La computadora detecta nivel de agua

FIL9 Noveno llenado (11mo. de 11 segmentos)

bajo o alto cuando no debería detectarse

ninguno

CFIL Llenado con agua fría rotA La computadora detectó una posible

bFIL Llenado con agua tibia (ambas, caliente

y fría)

rotación del motor cuando éste debería

estar inmóvil

HFIL Llenado con agua caliente tSFL Falla del sensor de temperatura o

AFIL Llenado auxiliar (opción configuración)

temperatura fuera de gama

Lo Nivel de agua bajo

*Las indicaciones de la pantalla separadas por un guión (/) representan un mensaje alternado.

34

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 37

Indicaciones en pantalla para máquinas serie V de dos velocidades sin tragamonedas

Pantalla Significado Pantalla Significado

Operación

F23n Código de identificación de programa

(ROM) (sólo como ejemplo)

HoLd Espere ... se acaba de encender la

máquina

CY Ciclo (seguido de un número de dos

dígitos)

tESt/CYC* Ciclo de prueba seleccionado CFIL Llenado con agua fría

FAr Grados Fahrenheit bFIL Llenado con agua tibia (ambas, caliente

CEL Grados Celsius HFIL Llenado con agua caliente

HEAt Activado el calor auxiliar AFIL Llenado auxiliar (opción configuración)

noHt Desactivado el calor auxiliar Lo Nivel de agua bajo

tFIL Activado el llenado controlado por

temperatura

ntFL Desactivado el llenado controlado por

temperatura

CooL Activado el enfriamiento automático SUP1 Suministro 1

noCL Desactivado el enfriamiento automático SUP2 Suministro 2

Ag 1 Seleccionada la agitación 1

(90% agitación)

FIL6 Sexto llenado (8vo. de 11 segmentos)

FIL7 Séptimo llenado (9no. de 11 segmentos)

FIL8 Octavo llenado (10mo. de 11 segmentos)

FIL9 Noveno llenado (11mo. de

11 segmentos)

y fría)

nEd Nivel de agua intermedio

HI Nivel de agua alto

SUP3 Suministro 3

Ag 2 Seleccionada la agitación 2

(33% agitación)

Ag 3 Seleccionada la agitación 3

(10% agitación)

Ag 4 Seleccionada la agitación 4

(6,7% agitación)

PU

nP Activada la salida de bombeo

(sólo para uso futuro)

nP

nP Desactivada la salida de bombeo (sólo

para uso futuro)

PrE Segmento de prelavado

(1ro. de 11 segmentos)

UASH Segmento de lavado

(2do. de 11 segmentos)

FIL1 Primer llenado (3ro. de 11 segmentos) nodr Desactivado el desagüe

FIL2 Segundo llenado (4to. de 11 segmentos) STOP Rutina de parada

FIL3 Tercer llenado (5to. de 11 segmentos) SdLY Retardo de disminución gradual de

*Las indicaciones de la pantalla separadas por un guión (/) representan un mensaje alternado.

SUP4 Suministro 4

SUP5 Suministro 5 (u opción configuración)

SUP6 Suministro 6 (suministros 1 and 5)

SUP7 Suministro 7 (suministros 3 and 4)

For Velocidad de lavado, sentido hacia

adelante

rEv Velocidad de lavado, sentido hacia atrás

drAI Activado el desagüe

centrifugado

F232137 (SP)

Tabla 4 (continuación)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

35

Page 38

Operación

Tabla 4 (continuación)

Indicaciones en pantalla para máquinas serie V de dos velocidades sin tragamonedas

Pantalla Significado Pantalla Significado

FIL4 Cuarto llenado (6to. de 11 segmentos) donE Han terminado el ciclo y la rutina de

parada

FIL5 Quinto llenado (7mo. de 11 segmentos) door La puerta no está cerrada debidamente

FULL La computadora detecta nivel de agua

bajo o alto cuando no debería detectarse

ninguno

tSFL Falla del sensor de temperatura o

temperatura fuera de gama

*Las indicaciones de la pantalla separadas por un guión representan un mensaje alternado.

FILL/STOP* No se alcanzó el nivel de agua

programado después de 30 minutos

nE* Aparece “SPIn” por un segundo y a

SPIn/tI

continuación “tI

de centrifugado

nE” seguido del tiempo

36

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 39

Operación

Instrucciones de operación

1. Conecte la alimentación principal (cortacircuitos).

En los modelos sin tragamonedas: Coloque en

la posición On (Encendido) el conmutador de

encendido ubicado en el tablero frontal.

2. Para abrir, oprima el botón y gire la manija en

sentido de las agujas del reloj. Consulte la

Figura 3.

U001I

3. Cargue a máxima capacidad siempre que sea

posible. NO SOBRECARGUE LA MÁQUINA.

Consulte la Figura 5.

U003I

Figura 5

4. Cierre la puerta y gire la manija en sentido

contrario a las agujas del reloj hasta que salga el

botón. Consulte la Figura 6.

U001I

Figura 3

En los modelos sin tragamonedas: Oprima y

mantenga oprimido el botón de DOOR

UNLOCK (Desbloqueo de puerta) ubicado en el

lado izquierdo del panel de control mientras que

realiza el paso anterior. Consulte la Figura 3 y la

Figura 4.

On

DOOR UNLOCK

Off

U135R

U135R

Figura 4

U005I

U005I

Figura 6

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

37

Page 40

Operación

5. Agregue suministros líquidos o en polvo al

surtidor de suministros. Consulte la Figura 7.

a. Agregue detergente al contenedor 1.

b. Agregue suavizador al contenedor 3.

En los modelos sin tragamonedas: Los

suministros líquidos pueden inyectarse

directamente en el surtidor de suministros a través

de un surtidor de suministros externo de productos

químicos. Consulte los manuales de instalación y

programación.

6. Presione la tecla de desplazamiento Up (Hacia

arriba) o de desplazamiento Down (Hacia abajo)

para seleccionar el ciclo de lavado. Oprima el

botón de Start (Arranque). Consulte la Figura 8.

9. Si corresponde, agregue blanqueador al

contenedor 2 cuando aparezca en pantalla

“bLCH”. Consulte la Figura 9.

CYCLE SELECTION

Up Down Start Stop

U152R

Figura 9

NOTA: Para detener un ciclo en cualquier

momento, presione la tecla Stop (Parada) (modelos

sin tragamonedas solamente).

B157R

B157R

Figura 7

7. En modelos con tragamonedas: Inserte la

cantidad requerida de monedas para arrancar la

máquina. Consulte la Figura 7.

8. En modelos sin tragamonedas: Presione la tecla

de Start (Arranque). Consulte la Figura 8.

CYCLE SELECTION

Up Down Start Stop

NOTA: Para visualizar la temperatura del agua

mientras que se ejecuta el ciclo, presione la tecla de

desplazamiento Up (Hacia arriba). Para visualizar

el número del ciclo que se encuentra en ejecución,

presione la tecla de Start (Arranque).

38

U137R

Figura 8

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 41

Mantenimiento

Bordes filosos. Pueden causar lesiones.

Use lentes de seguridad y guantes; use

las herramientas adecuadas y disponga

de suficiente iluminación cuando

manipule piezas elaboradas con láminas

metálicas.

W366S

ADVERTENCIA

IMPORTANTE: Reinstale todos los paneles que se

hayan retirado para efectuar procedimientos de

servicio y mantenimiento. No opere la máquina si

no tiene instalados los protectores, o si faltan piezas

o están dañadas. No anule ningún dispositivo de

seguridad.

Diariamente

IMPORTANTE: Diariamente debe verificarse

que la puerta se bloquee debidamente a fin de

garantizar una operación adecuada. También

debe verificarse que las etiquetas de seguridad

y de instrucciones estén sobre la máquina. Toda

etiqueta de seguridad o de instrucciones que falte o

que sea ilegible deberá reemplazarse

inmediatamente.

Al comenzar la jornada diaria

1. Inspeccione las conexiones de la válvula de

entrada de agua ubicadas por la parte posterior de

la máquina en busca de fugas.

2. Inspeccione las conexiones de mangueras en

busca de fugas (cuando corresponda).

3. Verifique que el aislamiento está intacto en todos

los cables externos y que todas las conexiones

están firmemente aseguradas. De encontrar un

alambre con el aislamiento dañado, llame a un

técnico de servicio.

4. Compruebe el funcionamiento del interruptor de

seguridad de la puerta antes de iniciar la

operación:

a. Intente arrancar la máquina con la puerta

abierta. No deberá poder arrancar la máquina

con la puerta abierta.

b. Cierre la puerta sin bloquearla e intente

arrancar la máquina. No deberá poder

arrancar la máquina con la puerta

desbloqueada.

c. Cierre y bloquee la puerta, e inicie un ciclo.

Intente abrir la puerta en medio del ciclo. No

deberá poder abrir la puerta.

Si el bloqueador de la puerta o el interruptor de

seguridad no funcionan adecuadamente, llame al

técnico de servicio.

Al terminar la jornada diaria

1. Limpie el empaque de la puerta para quitar todos

los residuos de detergente y de partículas

extrañas.

2. Limpie la tapa del surtidor automático de

suministros y el área en general. Enjuague el

surtidor con agua limpia.

3. Limpie la parte de arriba y la parte frontal de la

máquina así como los paneles laterales con un

detergente suave. Enjuague con agua limpia.

4. Deje abierta la puerta de carga al final del la

jornada de trabajo para dejar que se evapore la

humedad.

NOTA: Saque la ropa de la máquina tan pronto

como sea posible después de que termine cada ciclo

de lavado para evitar que se acumule humedad.

Deje abierta la puerta de carga después de

completado el ciclo, para dejar que se evapore la

humedad.

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

39

Page 42

Mantenimiento

Semanalmente

1. En modelos de velocidad variable solamente,

limpie el filtro o los filtros de la caja de mando de

CA semanalmente o con más frecuencia, según

sea necesario:

NOTA: Si se enciende la luz indicadora de servicio

del filtro, hay que limpiar inmediatamente el filtro

del ventilador para evitar posibles daños. Oprima

el botón del termostato para reinicializar la luz

indicadora.

a. Abra la cubierta superior.

b. Agarre la manija del filtro y tire de ella hacia

arriba para sacar el filtro.

c. Lave el filtro con agua tibia y deje que se

seque al aire. Optativamente, el filtro puede

limpiarse usando una aspiradora.

IMPORTANTE: La cubierta del módulo de control

y el filtro del ventilador han de estar en su lugar

para que el ventilador pueda enfriar debidamente

el mando del inversor de CA. Hacer caso omiso a

esta advertencia anulará la garantía y podría traer

como consecuencia una costosa reparación del

mando del inversor de CA.

Mensualmente

NOTA: Desconecte la fuente de alimentación de la

máquina antes de realizar los procedimientos de

mantenimiento mensual.

1. Realice los siguientes procedimientos para

determinar si las correas en V deben ser

cambiadas o si necesitan ajustes. Llame a un

técnico de servicio calificado en cualquiera de

estos casos.

a. Revise si las correas en V se han desgastado

en forma desigual y si tienen orillas

deshilachadas.

b. En sistemas impulsados por polea de

garganta, verifique la alineación colocando

una regla entre ambas caras de la polea. La

regla deberá hacer contacto con las poleas en

cuatro lugares. Consulte la Figura 10.

1

4

2. Inspeccione la máquina en busca de fugas.

a. Inicie un ciclo sin carga para llegar la

máquina.

b. Verifique que la puerta y el empaque de la

misma no presenten fugas.

c. Verifique que la válvula de desagüe esté

funcionando y que el sistema de desagüe no

tenga ninguna obstrucción. Si no se fuga agua

durante el segmento de primer lavado,

significa que la válvula de desagüe está

cerrada y que funciona correctamente.

2

1 Motor

2 Polea del motor

3 Regla

4 Polea conducida

Figura 10

3

H040I

40

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 43

c. En sistemas de mando por polea lisa,

verifique la distancia permitida de la correa

desde el borde de la polea, según se muestra

en la Tabla 5 siguiente:

Alineación de poleas lisas

Modelo

Distancia permitida

desde el borde

Mantenimiento

1

18 – 40 2 mm (3/32 plg)

50 10 mm (3/8 plg)

Tabla 5

2

d. En modelos de velocidad variable

solamente, verifique que las correas en

V tengan la tensión correcta; aplique para ello

la fuerza especificada a la correa y mida la

1 Deflexión

2 Longitud de la distancia libre entre poleas

deflexión para determinar la tensión de la

correa. Consulte la Tabla 6 siguientes para

determinar las gamas de tensión aceptables

Figura 11

para las correas. Las mediciones de la tensión

de la correa deben tomarse lo más cerca

posible del centro de la distancia libre entre

las poleas de la correa. Consulte la Figura 11.

Prueba de tensión de correa en modelos de velocidad variable

Modelo Correa

35, 40 Motor-cesto 428 mm (16,9 plg) 7,9 – 8,7 mm (5/16 – 11/32 plg) 27 – 33 N (6,1 – 7,4 lb)

Distancia libre

entre poleas

Gama de

deflexión

Fuerza

Mín. – Máx.

H039I

50 Motor-cesto 426 mm (16,8 plg) 7,1 – 7,9 mm (9/32 – 5/16 plg) 27 – 33 N (6,1 – 7,4 lb)

80 Motor-cesto 561 mm (22,1 plg) 11,9 – 12,7 mm (15/32 – 1/2 plg) 21,8 – 31,5 N (4,9 – 7,3 lb)

Tabla 6

F232137 (SP)

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

41

Page 44

Mantenimiento

1

2

1 Grasera de rodamientos

2 Grasera de sellos

2. En modelos de 80 libras de capacidad

solamente, lubrique los rodamientos y sellos

cada mes o cada 200 horas de operación.

Consulte la Figura 12.

a. Use una grasa de alta calidad a base de litio de

grado 2. Nunca mezcle dos tipos de grasa,

como por ejemplo, de petróleo y de silicona.

H047I

Figura 12

b. Bombee la grasa lentamente, y no exceda la

cantidad de aplicaciones siguiente:

● Grasera de rodamiento: dos aplicaciones

● Grasera de sello: una aplicación

No bombee la pistola de aplicación de

grasa hasta que salga grasa de la caja del

rodamiento. De lo contrario, podría

ocasionar una sobrelubricación y dañaría

los rodamientos y los sellos.

42

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

F232137 (SP)

Page 45

Mantenimiento

3. Desmonte el panel posterior, y revise si la

manguera de derrame y la manguera de desagüe

tienen fugas.

4. Quite el seguro a la cubierta con bisagras, y

revise las mangueras del surtidor de suministro y

sus conexiones.

5. Limpie las mallas de filtro de las mangueras de

entrada:

a. Cierre el agua y, si fuera necesario, deje que

se enfríe la válvula.

b. Desenrosque las mangueras de entrada y

saque las mallas de filtro.

c. Límpielas con agua jabonosa y reinstálelas.

Sustitúyalos si están dañados o desgastados.

6. Apriete las contratuercas de los pernos de

montaje del motor y las contratuercas de los

pernos de los rodamientos, si fuera necesario.

7. Use aire comprimido para quitar la pelusa

acumulada en el motor.

8. Limpie el interior de la máquina, tanto el cesto

como la coraza, limpiándolas con una esponja o

con un trapo humedecido en agua.

4. Revise si hay metal a la vista en las superficies

pintadas. (A través del fabricante puede

adquirirse pintura igual a la original).

● Si puede ver el metal, pinte con una base o con

pintura con base de solvente.

● Si aparece oxidación, quítela con lija o con

algún método químico.

Seguidamente, pinte con una base o con

pintura con base de solvente.

5. Limpie el filtro de vapor del cliente, si

corresponde. Consulte la Figura 13.

a. Cierre el suministro de vapor y deje que se

enfríe la válvula.

b. Destornille la tapa.

c. Quite el elemento del filtro y límpielo.

d. Vuelva a colocar el elemento del filtro y la tapa.

9. Use aire comprimido para asegurarse de que

ninguno de los componentes eléctricos tenga

humedad y polvo.

10. En modelos de velocidad variable solamente,